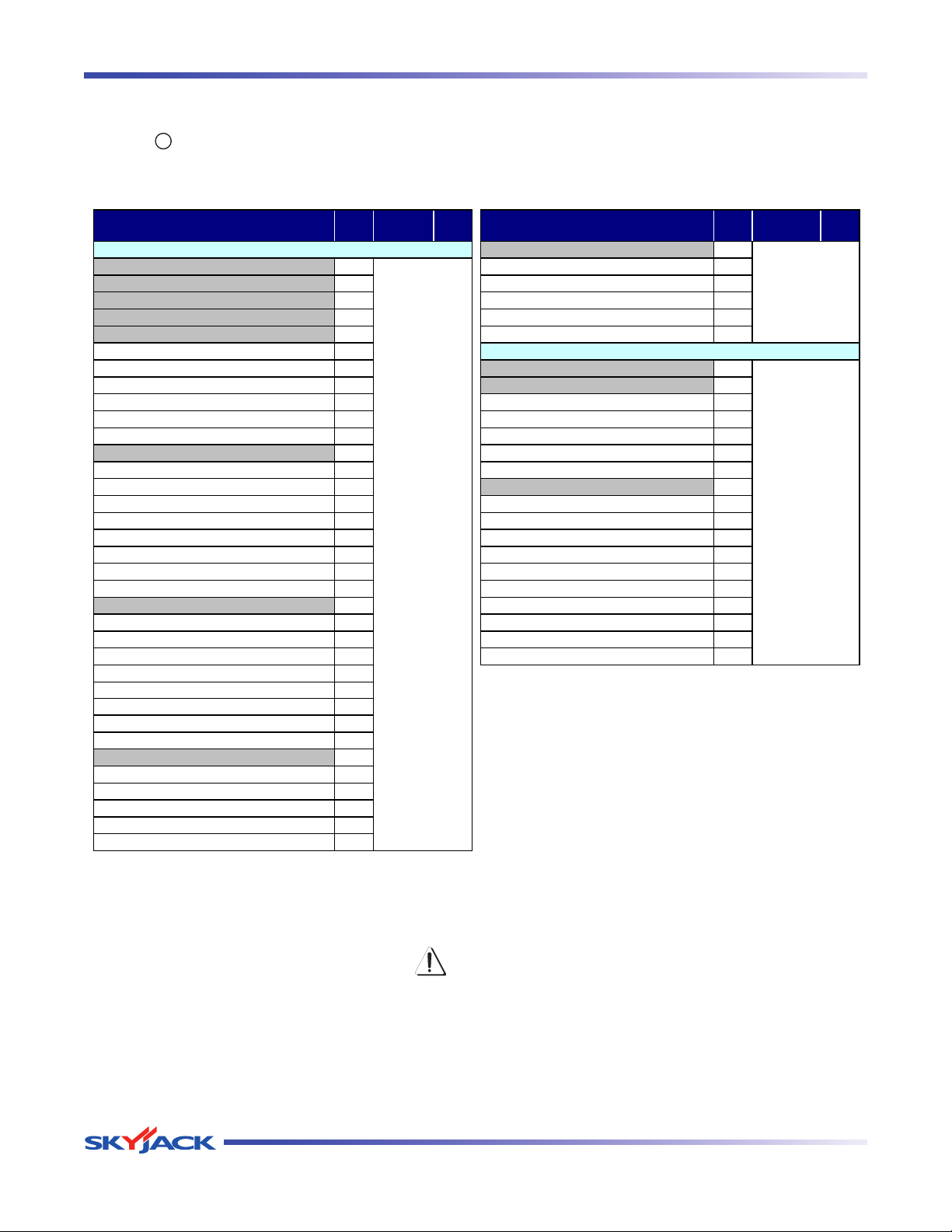

MODELS SJ 3215 SJ 3219 SJ 3220 SJ 3226 SJ 4620 SJ 4626 SJ 4632

Operating Manual

Compact & Conventional Series (CE)

155150AB-A September 2010

NOTE

143856AC 143881AD 155150AB

February 2008 October 2009 September 2010

3215

10 000 001 to 10 000 329 10 000 330 to 10 000 573 10 000 574 & Above

3219 22 000 001 to 22 013 837 22 013 838 to 22 019 596 22 019 597 & Above

3220 60 000 001 to 60 001 522 60 001 523 to 60 002 031 60 002 032 & Above

4620

4626

4632

145AB

27 005 501 & Above27 000 001 to 27 004 499

70 000 001 to 70 004 719

USE THE SERIAL NUMBER OF YOUR MACHINE TO DETERMINE THE CORRECT OPERATING MANUAL TO USE

70 004 720 to 70 006 052

27 004 500 to 27 005 500

Manual Part #

70 006 053 & Above

Release Date

M

O

D

E

L

3226

If your machine’s serial number is not listed above, please refer to www.skyjack.com for

a complete list of older machine models/operating manuals.

Skyjack Service Center 3451 Swenson Ave. St. Charles, Illinois, 60174 USA

Phone: 630-262-0005

Toll Free: 1-800-275-9522

Fax: 630-262-0006

Email: service@skyjack.com

Parts (North America)

Toll Free: 1-800-965-4626

Toll Free Fax: 1-888-782-4825

Email: parts@skyjack.com

Parts & Service (Europe) Unit 1 Maes Y Clawdd, Maesbury Road Industrial Estate

Oswestry, Shropshire SY10 8NN UK

Phone: +44-1691-676-235

Fax: +44-1691-676-238

Email: info@skyjackeurope.co.uk

Skyjack Asia Pacific

Singapore

Phone: +65-6449-3710

Fax: +65-6449-7690

Email: skyjack@singnet.com.sg

TM

The Safety Alert Symbol identifies important

safety messages on aerial platform, safety signs

in manuals or elsewhere. When you see this

symbol, be alert to the possibility of personal

injury or death. Follow the instructions in the

safety message.

DANGER indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

WARNING indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided,

may result in minor or moderate injury. It may also be used to alert against

This Safety Alert Symbol means attention!

Become alert! Your safety is involved.

DANGER

WARNING

CAUTION

unsafe practices.

IMPORTANT

IMPORTANT indicates a procedure essential for safe operation and which,

if not followed, may result in a malfunction or damage to the aerial platform.

SJIII Compacts & Conventionals

December 2007 Page 3

TM

Table of Contents

Section 1 - About Your Aerial Platform

Read and Heed

Aerial Platform Definition .............................................................................................................................................7

Purpose of Equipment .................................................................................................................................................7

Use of Equipment ........................................................................................................................................................7

Manual ..........................................................................................................................................................................7

Operator .......................................................................................................................................................................7

Service Policy and Warranty ........................................................................................................................................7

Optional Accessories ...................................................................................................................................................7

Scope of this Manual ...................................................................................................................................................7

Safety Rules

Operator Safety Reminders .........................................................................................................................................8

Electrocution Hazard ...................................................................................................................................................8

Safety Precautions .......................................................................................................................................................9

Section 2 - Operation

2.1 General ............................................................................................................................................................13

2.1-1 Operator Qualifications .....................................................................................................................13

2.1-2 Operator’s Responsibility for Maintenance ......................................................................................13

2.1-3 Maintenance and Inspection Schedule ............................................................................................13

2.1-4 Owner’s Inspections .........................................................................................................................13

2.2 Major Components .........................................................................................................................................14

2.3 Major Assemblies ...........................................................................................................................................15

2.3-1 Base .................................................................................................................................................15

2.3-2 Lifting Mechanism .............................................................................................................................15

2.3-3 Platform .............................................................................................................................................15

2.4 Serial Number Nameplate ..............................................................................................................................15

2.5 Component Identification ...............................................................................................................................16

2.5-1 Main Power Disconnect Switch .......................................................................................................16

2.5-2 Tilt Alarm ...........................................................................................................................................16

2.5-3 Load Sensing System .......................................................................................................................16

2.5-4 Base Control Console .......................................................................................................................17

2.5-5 Electrical Panel ..................................................................................................................................17

2.5-6 Brake System ....................................................................................................................................17

2.5-7 Free-wheeling Valve ..........................................................................................................................18

2.5-8 Battery Charger .................................................................................................................................18

2.5-9 Pothole Protection Device.................................................................................................................18

2.5-10 Emergency Lowering System ...........................................................................................................19

2.5-11 Lowering Warning System ................................................................................................................19

2.5-12 Maintenance Support .......................................................................................................................19

2.5-13 Platform Control Console .................................................................................................................20

2.5-14 Manual Storage Box .........................................................................................................................20

2.5-15 Folding Guardrail System .................................................................................................................20

2.5-16 Lanyard Attachment Anchorage .......................................................................................................21

Page 4 December 2007

SJIII Compacts & Conventionals

TM

Table of Contents

Section 2 - Operation (Continued)

2.6 Component Identification (Special Options) ...................................................................................................22

2.6-1 Powered Extension Control Console (If Equipped) ........................................................................22

2.6-2 1500W AC Inverter (If Equipped) ......................................................................................................22

2.6-3 Motion Alarm (If Equipped) ...............................................................................................................22

2.7 Operator’ Responsibility ..................................................................................................................................23

2.8 Visual and Daily Maintenance Inspections .....................................................................................................24

2.9 Function Tests..................................................................................................................................................31

2.10 Start Operation ................................................................................................................................................38

2.10-1 To Activate Base Control Console ....................................................................................................38

2.10-2 To Raise or Lower Platform Using Base Control Console ................................................................38

2.10-3 To Activate Platform Control Console ...............................................................................................39

2.10-4 To Raise or Lower Platform Using Platform Control Console ..........................................................39

2.10-5 To Drive Forward or Backward .........................................................................................................40

2.10-6 To Steer .............................................................................................................................................40

2.10-7 To Select Level Drive or Inclined Drive Mode ...................................................................................41

2.10-8 To Extend/Retract Manual Extension Platform .................................................................................41

2.10-9 To Extend/Retract Powered Extension Platform (If Equipped) .........................................................42

2.10-10 Electrical Inverter (If Equipped) ........................................................................................................42

2.10-11 Shutdown Procedure ........................................................................................................................42

2.11 Guardrail Folding Procedure ...........................................................................................................................43

2.12 Loading/Unloading ..........................................................................................................................................44

2.12-1 Lifting .................................................................................................................................................44

2.12-2 Driving ...............................................................................................................................................45

2.13 Moving the Aerial Platform Through a Doorway .............................................................................................46

2.14 Winching and Towing Procedures ..................................................................................................................48

2.14-1 To Release Free-wheeling Valve .......................................................................................................48

2.14-2 To Release Brakes Manually .............................................................................................................49

2.15 Emergency Lowering Procedure ....................................................................................................................50

2.16 Maintenance Support Procedure ....................................................................................................................51

2.17 Battery Maintenance .......................................................................................................................................52

2.17-1 Battery Service Procedures ..............................................................................................................52

2.17-2 Battery Charging Operation ..............................................................................................................52

2.18 Tables...............................................................................................................................................................56

2.19 Labels ..............................................................................................................................................................66

List of Tables

Table 2.1 Standard and Optional Features .............................................................................................................56

Table 2.2 Owner’s Annual Inspection Record .........................................................................................................57

Table 2.3 Specifications and Features.....................................................................................................................58

Table 2.4 Floor Loading Pressure ............................................................................................................................60

Table 2.5 Maximum Platform Capacities (Evenly Distributed) ................................................................................62

Table 2.6 EC Declaration of Conformity .................................................................................................................63

Table 2.7 Maintenance and Inspection Schedule ...................................................................................................64

Table 2.8 Operator’s Checklist ................................................................................................................................65

SJIII Compacts & Conventionals

December 2007 Page 5

TM

Section 1 - About Your Aerial Platform Read and Heed

SKYJACK is continuously improving and expanding product features on its equipment, therefore, specifications and

dimensions are subject to change without notice.

Aerial Platform and Mobile Elevating Work Platform Definition

A mobile device that has a positionable platform supported from ground level by a structure.

Purpose of Equipment

The SKYJACK SJIII Compact and Conventional series aerial platforms are designed to transport and raise personnel,

tools and materials to overhead work areas.

Use of Equipment

The aerial platform is a highly maneuverable, mobile work station. Lifting and driving must be on a flat, level,

compacted surface.

Manual

The operating manual is considered a fundamental part of the aerial platform. It is a very important way to communicate

necessary safety information to users and operators. A complete and legible copy of this manual must be kept in

the provided weather-resistant storage compartment on the aerial platform at all times.

Operator

The operator must read and completely understand both this operating manual and the safety panel label located on

the platform and all other warnings in this manual and on the aerial platform. Compare the labels on the aerial platform

with the labels found within this manual. If any labels are damaged or missing, replace them immediately.

1

Service Policy and Warranty

SKYJACK warrants each new SJIII Series work platform to be free of defective parts and workmanship for the first

24 months. Any defective part will be replaced or repaired by your local SKYJACK dealer at no charge for parts or

labor. Contact the SKYJACK Service Department for warranty statement extensions or exclusions.

Optional Accessories

The SKYJACK aerial platform is designed to accept a variety of optional accessories. These are listed under “Standard

and Optional Features” in Table 2.1.

Operating instructions for these options (if equipped) are located in Section 2 of this manual.

For options not listed under “Standard and Optional Features,” contact the SKYJACK Service Department at

( : 44-1691-676-235

7 : 44-1691-676-238

Include the model and serial number for each applicable aerial platform.

Scope of this Manual

a. This manual applies to the CE version of the SJIII Series aerial platform models listed on Table 2.1.

Equipment identified with “CE” meets the requirements for the European countries, i.e., Machinery Directive

2006/42/EC and Directive 2004/108/EC and the corresponding EN standards.

b. Operators are required to conform to national, state or territorial/provincial and local health and safety regulations

applicable to the operation of this aerial platform.

SJIII Compacts & Conventionals

December 2007 Page 7

TM

Safety Rules Section 1 - About Your Aerial Platform

60023AE-CE

DANGER

Adhere strictly to the governmental rulings and regulations applicable in your country.

FAILURE TO AVOID THIS HAZARD WILL RESULT IN DEATH OR SERIOUS INJURY!

Avoid Power Lines

Minimum Safe Approach Distance

CE Guidance Note

“Avoidance of danger from overhead lines”

WARNING

Failure to comply with your required responsibilities in the use and operation of the aerial platform

could result in death or serious injury!

Operator Safety Reminders

A study conducted by St. Paul Travelers showed that most accidents are caused by the failure of the operator to

follow simple and fundamental safety rules and precautions.

You, as a careful operator, are the best insurance against an accident. Therefore, proper usage of this aerial

platform is mandatory. The following pages of this manual should be read and understood completely before

operating the aerial platform.

Common sense dictates the use of protective clothing when working on or near machinery. Use appropriate safety

devices to protect your eyes, ears, hands, feet and body.

Any modifications from the original design are strictly forbidden without written permission from SKYJACK.

Electrocution Hazard

This aerial platform is not electrically insulated. Maintain a Minimum Safe Approach Distance (MSAD) from

energized power lines and parts as listed below. The operator must allow for the platform to sway, rock or sag.

This aerial platform does not provide protection from contact with or proximity to an electrically charged

conductor.

DO NOT USE THE AERIAL PLATFORM AS A GROUND FOR WELDING.

DO NOT OPERATE THE AERIAL PLATFORM DURING LIGHTNING OR STORMS.

Page 8 December 2007

SJIII Compacts & Conventionals

TM

Section 1 - About Your Aerial Platform Safety Rules

Safety Precautions

Know and understand the safety precautions before going on to next section.

WARNING

Failure to heed the following safety

precautions could result in tip over,

falling, crushing, or other hazards leading

to death or serious injury.

• KNOW all national, state or territorial/provincial

and local rules which apply to your aerial platform

and jobsite.

• TURN main power disconnect switch “ ” off when

leaving the aerial platform unattended. Remove

the key to prevent unauthorized use of the aerial

platform.

• WEAR all the protective clothing and personal

safety devices issued to you or called for by job

conditions.

• DO NOT wear loose clothing,

dangling neckties, scarves,

rings, wristwatches or other

jewelry while operating this

lift.

• AVOID entanglement with

ropes, cords or hoses.

• DO NOT increase the lateral

surface area of the platform.

Increasing the area exposed

to the wind will decrease aerial

platform stability.

• DO NOT drive or elevate the

aerial platform if it is not on a

firm level surface. Do not drive

elevated near depressions

or holes of any type, loading

docks, debris, drop-offs and

surfaces that may affect the

stability of the aerial platform.

• If operation in areas

with holes or drop-offs

is absolutely necessary,

elevated driving shall not be

allowed. Position the aerial

platform horizontally only with

the platform fully lowered. After

ensuring that all 4 wheels or

outriggers (if equipped) have

contact with level firm surface,

the aerial platform can be

elevated. After elevation, the

drive function must not be

activated.

• AVOID falling. Stay within the

boundaries of the guardrails.

• DO NOT raise the aerial

platform in windy or gusty

conditions.

SJIII Compacts & Conventionals

• Elevated driving must

only be done on a firm level

surface.

• DO NOT ascend or descend

a grade when elevated.

When fully lowered, ascend

or descend grades up to

maximum rated inclines listed

in Table 2-3a and Table 2-3b.

December 2007 Page 9

TM

Safety Rules Section 1 - About Your Aerial Platform

Safety Precautions (Continued)

Know and understand the safety precautions before going on to next section.

• DO NOT operate on surfaces not capable of

holding the weight of the aerial platform including

the rated load, e.g. covers, drains, and trenches.

• DO NOT operate an aerial

platform that has ladders,

scaffolding or other devices

mounted on it to increase its size

or work height. It is prohibited.

• DO NOT exert side forces on

aerial platform while elevated.

• DO NOT use the aerial platform

as a crane. It is prohibited.

• DO NOT raise the aerial platform

while the aerial platform is on a

truck, fork lift or other device or

vehicle.

• BE AWARE of crushing

hazards. Keep all body parts

inside platform guardrail.

• DO NOT lower the platform

unless the area below is

clear of personnel and

obstructions.

• ENSURE that there are no personnel or

obstructions in the path of travel, including blind

spots.

• DO NOT sit, stand or climb on

the guardrails. It is prohibited.

• BE AWARE of blind spots when operating the

• DO NOT climb on scissor arm

assembly. It is prohibited.

• STUNT driving and horseplay are prohibited.

• ENSURE ALL tires are in good condition and lug

• DO NOT alter or disable limit switches or other

• BE AWARE of overhead

obstructions or other possible

hazards around the aerial

• DO NOT use the aerial platform without guardrails,

platform when driving or lifting.

Page 10 December 2007

aerial platform.

nuts are properly tightened.

safety devices.

locking pins and the entry gate in place.

SJIII Compacts & Conventionals

TM

Section 1 - About Your Aerial Platform Safety Rules

Safety Precautions (Continued)

Know and understand the safety precautions before going on to next section.

• DO NOT exceed the rated capacity of the

aerial platform. Do make sure the load is evenly

distributed on the platform.

• DO NOT attempt to free a snagged platform with

lower controls until personnel are removed from

the platform.

• DO NOT position the aerial platform against

another object to steady the platform.

• DO NOT place materials on the guardrails

or materials that exceed the confines of the

guardrails unless approved by Skyjack.

WARNING

Entering and exiting the aerial platform

should only be done using the three

points of contact.

• Useonlyequippedaccessopenings.

• Enter and exit only when the aerial

platform is in the fully retracted position.

• Do use three points of contact to enter and exit

the platform. Enter and exit the platform from

the ground only. Face the aerial platform when

entering or exiting the platform.

WARNING

An operator should not use any aerial

platform that:

does not appear to be working properly.•

has been damaged or appears to have worn or •

missing parts.

has alterations or modifications not approved by •

the manufacturer.

has safety devices which have been altered or •

disabled.

has been tagged or locked out for non-use or •

repair.

Failure to avoid these hazards could

result in death or serious injury.

Jobsite Inspection

Do not use in hazardous locations.•

Perform a thorough jobsite inspection prior to •

operating the aerial platform, to identify potential

hazards in your work area.

Be aware of moving equipment in the area. Take •

appropriate actions to avoid collision.

• Three points of contact means that two hands

and one foot or one hand and two feet are in

contact with the aerial platform or the ground at

all times during entering and exiting.

SJIII Compacts & Conventionals

December 2007 Page 11

TM

Section 2 - Operation General

2.0 Operation

This section provides the necessary information needed

to operate the aerial platform. It is important that the user

reads and understands this section before operating

the aerial platform.

2.1 General

In order for this aerial platform to be in good working

condition, it is important that the operator meets the

necessary qualifications and follow the maintenance

and inspection schedule referred to in this section.

2.1-1 Operator Qualifications

Only trained and authorized personnel shall• be

permitted to operate an aerial platform.

Safe use of this aerial platform requires the •

operator to understand the limitations and

warnings, operating procedures and operator’s

responsibility for maintenance. Accordingly, the

operator must understand and be familiar with this

operating manual, its warnings and instructions,

and all warnings and instructions on the aerial

platform.

The operator must be familiar with employer’s work •

rules and related government regulations and be

able to demonstrate the ability to understand and

operate this make and model of aerial platform in

the presence of a qualified person.

2.1-2 Operator’s Responsibility for

Maintenance

The operator must be sure that the aerial platform •

has been properly maintained and inspected

before using it.

The operator must perform all the daily inspections •

and function tests found in Table 2.7, even if

the operator is not directly responsible for the

maintenance of this aerial platform.

2.1-3 Maintenance and Inspection Schedule

The inspection points covered in • Table 2.7 indicate

the areas of the aerial platform to be maintained or

inspected and at what intervals the maintenance

and inspections are to be performed.

The actual operating environment of the aerial •

platform may affect the maintenance schedule.

WARNING

Use original or manufacturer-approved

parts and components for the aerial

platform.

2.1-4 Owner’s Inspections

It is the responsibility of the owner to arrange daily,

quarterly (or 150 hours) and annual inspections of the

aerial platform. Refer to Table 2.7 for recommended

maintenance and inspection areas and intervals. A

record of annual inspection is kept on a label located

on the scissor assembly. Refer to Table 2.2 in this

manual.

2

WARNING

Maintenance must be performed by

trained and competent personnel who are

familiar with mechanical procedures.

Death or serious injury could result from

the use of an aerial platform that is not

properly maintained or kept in good

working condition.

SJIII Compacts & Conventionals

December 2007 Page 13

TM

Major Components Section 2 - Operation

2.2 Major Components

Platform Control

Console

Manual Storage

Box

Main Platform

Battery Tray

Extension

Platform

Lifting

Mechanism

Maintenance

Support

Hydraulic/Electric

Tray

Pothole

Protection Device

SKYJACK SJIII Series Aerial Platform

Page 14 December 2007

Base

SJIII Compacts & Conventionals

TM

Section 2 - Operation Major Assemblies

2.3 Major Assemblies

The aerial platform consists of three major assemblies:

base, lifting mechanism and platform.

2.3-1 Base

The base is a rigid, one-piece weldment which supports

two swing out trays.

On Models 3215 and 3219 (Compacts):

One tray contains the hydraulic and electrical

components. The other tray contains four (4) 6 volt

batteries. The charger is located at the rear of the

aerial platform. The front axle has two hydraulic

motor-driven wheels, steerable by a hydraulic

cylinder. The rear axle is fixed and has non-driven,

spring-applied, hydraulically released brake.

On Models 3220, 3226, 4620, 4626 and

4632 (Conventionals):

One tray contains the hydraulic and electrical

components. The other tray contains battery

charger and four (4) 6 volt batteries. The front axle

has two non-driven wheels, steerable by a hydraulic

cylinder. The rear axle has two hydraulic motordriven wheels with spring-applied, hydraulically

released brakes.

2.4 Serial Number Nameplate

The serial number nameplate, located at the rear of the

aerial platform, lists the following:

Model number•

Serial number•

Capacity and maximum number of persons •

permissible on the platform

Maximum wind speed•

Maximum manual force•

Machine weight•

Drive height•

Platform height•

System pressure•

Lift pressure•

Wheel load•

Voltage•

Maximum incline•

Year of manufacture•

2.3-2 Lifting Mechanism

The lifting mechanism is constructed of formed steel or

tube sections making up a scissor-type assembly. The

scissor assembly is raised and lowered by single-acting

hydraulic lift cylinders with holding valves. A pump,

driven by an electric motor, provides hydraulic power

to the lift cylinders.

2.3-3 Platform

The platform is constructed of a tubular support frame,

a skid-resistant “diamond plate” deck surface and 1.1 m

hinged guardrails with 0.15 m toe boards and mid-rails.

The platform can be entered from the rear through a

spring-returned gate with latch. The platform is also

equipped with a manual extension platform. An AC

outlet is also located on the platform.

SJIII Compacts & Conventionals

December 2007 Page 15

TM

Component Identification Section 2 - Operation

2.5 Component Identification

The following descriptions are for identification,

explanation and locating purposes only.

2.5-1 Main Power Disconnect Switch

This switch is located at the rear of the base.

1

Figure 2-1. Main Power Disconnect Switch

1. Main Power Disconnect Switch - This switch,

when in “

all circuits. Switch must be in “ ” on position to

operate any circuit. Turn switch “ ” off when

transporting aerial platform.

2.5-2 Tilt Alarm

The aerial platform is equipped with a device which

senses when the aerial platform is out of level in any

direction. When activated, it disables drive and lift

functions of the aerial platform and an alarm produces

an audible sound accompanied by the amber light

(if equipped).

If the tilt alarm sounds and the platform

does no t, or on l y partia l l y ra ises ,

immediately lower the platform completely

and ensure that the aerial platform is on

” off position, disconnects power to

WARNING

a firm level surface.

2.5-3 Load Sensing System

This system is a safety device that will prevent any

normal movement of the aerial platform from a stationary

working position after the rated load is reached and

exceeded. Refer to Table 2.5 for maximum platform

capacities.

When 90% of the rated load is reached:•

The red power indicator light on the platform

control console flashes.

When the rated load is reached:•

An audible alarm sounds for approximately

2 seconds, 5 times per minute.

When the rated load is exceeded:•

The flashing light and audible alarm continue and

all electrically controlled aerial platform movement

functions stop. To resume normal operation,

remove the overload from the platform.

If the aerial platform comes in contact with an •

overhead obstruction:

The platform could become overloaded and all

functions would stop. Release of the platform

from this situation can only be effected by use

of the emergency lowering system. Refer to

Section 2.15.

NOTE

After reaching full extension and upon

lowering, the aerial platform could stop

and take an overload reading. Return the

controller to the neutral center position,

and release the enable trigger switch. If the

aerial platform is overloaded, the flashing

light and audible alarm continue and

all electrically controlled aerial platform

movement functions stop. To resume

normal operation, remove the overload

from the platform.

Page 16 December 2007

SJIII Compacts & Conventionals

TM

Section 2 - Operation Component Identification

2.5-4 Base Control Console

This control console is located at the rear of the base.

It contains the following controls:

1

2

3

Figure 2-2. Base Control Console

1. Lower/Neutral/Raise Switch - This switch controls

” raising or “ ” lowering of platform.

“

2. Off/Platform/Base Key Switch - This three-way

switch allows the operator to turn “ ” off power

to aerial platform or to activate either “

or “

” base controls.

” platform

2.5-5 Electrical Panel

This panel is located in the hydraulic/electric tray. It

contains the following controls:

21

Figure 2-3. Electrical Panel

1. Circuit Breaker Resets - In the event of power

overload or positive circuit grounding, the circuit

breaker pops out. Push the breaker back in to

reset.

2. Hourmeter - This gauge records accumulated

operating time of the aerial platform.

2.5-6 Disc Brake System

The brake system is located at the rear of the base.

The brakes must be manually disengaged before

pushing, winching or towing. Refer to Section 2.14-2

for procedure on how to release brakes manually. The

system contains the following controls:

21

3. Emergency Stop Button - This button “

when depressed, disconnects power to the control

circuit.

SJIII Compacts & Conventionals

”,

Figure 2-4. Disc Brake System

1. Brake auto reset valve plunger

2. Brake hand pump

December 2007 Page 17

TM

Component Identification Section 2 - Operation

2.5-7 Free-wheeling Valve

1

Models 3220, 3226, and 46xx

1

Models 3215 and 3219

Figure 2-5. Free-wheeling Valve

1. Free-wheeling Valve - The free-wheeling valve

is located at the front and/or rear of the aerial

platform (depending on the model). Refer to

Section 2.14-1 for procedure on how to release

the free-wheeling valve.

2.5-8 Battery Charger

The charger is located at the rear of the base or inside

the battery tray. Refer to Section 2.17-2 for battery

charging operation.

Figure 2-6. Battery Charger

2.5-9 Pothole Protection Device

1

Figure 2-7. Pothole Protection Device

1. Pothole Protection Device - This device consists

of a set of mechanically actuated steel weldments

located under the hydraulic/electric tray and battery

tray. These weldments will automatically rotate for

reduced ground clearance when elevating the

aerial platform. If the pothole protection device

has not fully lowered, the drive function will be

disabled.

WARNING

Crushing Hazard - Personnel on ground

must stay clear of pothole protection

device.

WARNING

Do not drive elevated in areas where

electrical cords or debris are in the path

of travel.

Maintenance of the Pothole

Protection Device

As with all safety devices, periodic inspection and

maintenance is required to ensure the proper

operation of the pothole protection device.

This mechanism is designed to reduce ground

clearance and assist in the stability of an elevated

aerial platform in the event the aerial platform

encounters a “drop-off” or “pothole.” The nature

of this safety feature relies on maintaining a

consistent ground clearance, therefore, if the aerial

platform ever does come to rest on the pothole

device, the platform should be immediately

lowered and “locked out” to prevent further use

until a complete inspection of the mechanism is

performed by a qualified technician.

Page 18 December 2007

SJIII Compacts & Conventionals

TM

Section 2 - Operation Component Identification

2.5-10 Emergency Lowering System

This emergency lowering system allows platform

lowering in the event of an emergency or an electrical

system failure. Refer to Section 2.15 for the emergency

lowering procedure. The system contains the following

controls:

1

2

3

Figure 2-8. Emergency Lowering System

1. Holding Valve Manual Override Knob - Located

on the holding valve at the bottom of each lift

cylinder.

2. Emergency Lowering Valve - Located at the rear

of the hydraulic/electric tray.

2.5-12 Maintenance Support

1

Figure 2-9. Maintenance Support

1. Maintenance Support - The maintenance support

is a safety mechanism designed to support the

scissor assembly. When properly positioned it

can support the scissor assembly and empty

platform. The maintenance support must be used

when inspection and/or maintenance is to be

performed within the lifting mechanism. Refer to

Section 2.16 for procedure on how use and store

the maintenance support.

WARNING

The maintenance support must be used

when inspection and/or maintenance or

repairs are to be performed within the

lifting mechanism. Failure to use this

safety mechanism could result in death

or serious injury.

3. Access Rod (3226, 4626 & 4632) - Located at the

left side of the base.

2.5-11 Lowering Warning System

A lowering warning system automatically stops the

lowering function before reaching the fully retracted

position and sounds an alarm.

SJIII Compacts & Conventionals

December 2007 Page 19

WARNING

Do not reach through the scissor assembly

when the platform is raised without the

maintenance support properly positioned.

Failure to avoid this hazard could result

in death or serious injury.

TM

Component Identification Section 2 - Operation

2.5-13 Platform Control Console

This removable control console is mounted at the right

front of the platform. It contains the following controls:

2

1

3

5

4

6

Figure 2-10. Platform Control Console

with Toggle Switch

2

1

3. Emergency Stop Button/Operation Light - This

button “

”, when depressed, disconnects

power to the control circuit. The operation light

indicates upper control availability and overload

status. When the light is continuously illuminated,

upper controls are available. When the light is

flashing, it signals an overload function. Refer to

Section 2.5-3.

4. Horn Pushbutton - This “

” pushbutton sounds

an automotive-type horn.

5. Inclined Drive/Level Drive Switch (If Equipped)

- This switch selects “

speed/high torque) or “

” inclined drive (low

” level drive (high

speed/low torque).

NOTE

Inclined drive (low speed/high torque) is

not available on models 3215 and 3219.

6. Lift/Off/Drive Switch - Selecting “

” off position

disconnects power from both lift and drive circuits.

3

7

4

Figure 2-11. Platform Control Console

with Rotary Switch

1. Lift/Drive/Steer Enable Trigger Switch - This

momentary “

” switch energizes the controller.

It must be held depressed continuously while

engaging either the lift/drive or steer functions.

2. Lift/Drive/Steer Controller - This one-hand lever

controls lift/drive and steer motions. Internal

springs return it to neutral when controller is

released.

Selecting “

Selecting “

” lift position energizes the lift circuit.

” drive position energizes the drive

circuit.

7. Lift/Inclined Drive/Level Drive Switch - This

switch selects “

speed/high torque) or “

” lift, “ ” inclined drive (low

” level drive (high

speed/low torque).

NOTE

Inclined drive (low speed/high torque) is

not available on 3215 and 3219 models.

Page 20 December 2007

SJIII Compacts & Conventionals

TM

Section 2 - Operation Component Identification

2.5-14 Manual Storage Box

This weather-resistant box is mounted on the platform

railings. It contains the operating manual,

EC declaration and other important

documents. The operating manual for

this make and model of aerial platform

must be stored in this box.

2.5-15 Folding Guardrail System

This system, when folded down, reduces the height

of the retracted aerial platform for transporting and

traveling through doorways only. Refer to Section 2.11

for guardrail folding procedure.

Entrance

Left

1

Right

Extension

2.5-16 Lanyard Attachment Anchorage

1

Figure 2-13. Lanyard Attachment Anchorage

1. Lanyard Attachment Anchorage - Use this as an

attachment point for safety belt/harness tethers.

Do not attach belts/harnesses to any other point

on the platform. Do not use this point to lift,

anchor, secure or support the platform or any

other apparatus or material.

WARNING

The la n y a r d attachment anchorage

is used for travel restraint, within the

limits of the platform only. It is not a fall

arresting device! Use as such could result

in death or serious injury.

Figure 2-12. Folding Guardrail System

1. Guardrail Locking Pin with Lanyard - This pin is

used to lock the guardrail in place.

WARNING

The scissor assembly must be fully

lowered before raising or lowering the

guardrails.

SJIII Compacts & Conventionals

December 2007 Page 21

TM

Component Identification (Special Options) Section 2 - Operation

2.6 Component Identification

(Special Options)

This section describes the components that are optional

to aerial platforms.

2.6-1 Powered Extension Control Console

(If Equipped)

This control console is mounted on one of the extension

platform guardrails. It contains the following controls:

2

1

Figure 2-14. Powered Extension Control Console

2.6-2 1500W AC Inverter (If Equipped)

The inverter is located on the base of the aerial platform.

It has the following controls:

1

4

2

3

Figure 2-15. 1500W AC Inverter

NOTE

The inverter operation is automatic. These

controls do not need to be manipulated for

normal operation.

1. Status LEDs - These LEDs indicate the operating

or fault status of the inverter.

1. Enable Switch - This switch, when activated and

held, allows the extension platform extend/retract

switch functions to operate.

2. Extend/Retract Switch - This switch, when

activated, “ ” extends or “ ” retracts

the powered extension platform. Refer to

Section 2.10-9 on how to extend/retract the powered

extension platform.

2. On/Off Switch - This diagnostic slide switch

activates or terminates inverter operation. It should

remain in on position.

3. GFCI Outlet - During inverter operation, this outlet

provides AC power.

4. 15 Amp Circuit Breaker - In the event of a power

overload or circuit grounding, the circuit breaker

pops out. Press the breaker back in to reset.

2.6-3 Motion Alarm (If Equipped)

The alarm produces an audible sound when any

control function is selected. On aerial platforms with

certain options, a flashing amber light will accompany

this alarm.

Page 22 December 2007

SJIII Compacts & Conventionals

TM

Section 2 - Operation Operator’s Responsibility

2.7 Operator’s Responsibility

It is the responsibility of the operator, prior to each work

shift, to perform the following:

1. Visual and Daily Maintenance Inspections

are designed to discover any damage of •

components before the aerial platform is put

into service.

are done before the operator performs the •

function tests.

WARNING

Failure to locate and repair damage, and

discover loose or missing parts may

result in an unsafe operating condition.

2. Function Tests

are designed to discover any malfunctions •

before the aerial platform is put into service.

IMPORTANT

The operator must understand and

follow the step-by-step instructions

to test all aerial platform functions.

Repairs to the aerial platform may only be made by a

qualified service technician. After repairs are completed,

the operator must perform visual and daily maintenance

inspections & function tests again.

Sc h eduled main t enance insp e ctions shal l only

be performed by qualified service technician (see

Table 2.7).

The operator should make a copy of the Operator’s

Checklist (see Table 2.8) and fill out the visual and

daily maintenance inspections and the function

tests sections while performing the items outlined in

Section 2.8 and Section 2.9.

IMPORTANT

If aerial platform is damaged or any

unauthorized variation from factorydelivered condition is discovered, aerial

platform must be tagged and removed

from service.

SJIII Compacts & Conventionals

December 2007 Page 23

TM

Visual and Daily Maintenance Inspections Section 2 - Operations

High Speed

Limit Switch

High Speed

Limit Switch

Pothole Protection

Limit Switch

2.8 Visual & Daily Maintenance

Inspections

Begin the visual and daily maintenance inspections

by checking each item in sequence for the conditions

listed in this section.

WARNING

To avoid injury, do not operate an aerial

platform until all malfunctions have been

corrected.

WARNING

To avoid possible injury, ensure aerial

platform power is off during your visual

and daily maintenance inspections.

NOTE

While performing visual and daily

inspections in different areas, be aware to

also inspect limit switches, electrical and

hydraulic components.

2.8-1 Labels

Refer to the labels section in this manual and determine

that all labels are in place and are legible.

2.8-2 Electrical

Maintaining the electrical components is essential

to good performance and service life of the aerial

platform.

Inspect the following areas for chafed, corroded and

loose wires:

• basetoplatformcablesandwiringharness

• batterytraywiringharnesses

• hydraulic/electricalwiringharnesses

2.8-3 Limit Switches

Ensure limit switches are properly secured with no signs

of visible damage and movement is not obstructed.

2.8-4 Hydraulic

Maintaining the hydraulic components is essential

to good performance and service life of the aerial

platform.

Perform a visual inspection around the following

areas:

hoses and fittings•

all hydraulic cylinders•

all hydraulic manifolds•

the underside of the base•

ground area under the aerial platform•

Page 24 December 2007

SJIII Compacts & Conventionals

TM

Section 2 - Operation Visual and Daily Maintenance Inspections

CAUTION

A106515AC

Compact

2.8-5 Entrance Side

Main Power Disconnect Switch •

Turn main power disconnect switch to -

“ ” off position.

Ensure all cables are secure and switch

-

is in proper working condition.

220V Outlet

Receptacle

Base Control

Console

Free-wheeling

Valve

Free-wheeling

Valve

Conventional

(Back View)

Main Power

Ladder

Disconnect

Switch

Compact

(Back View)

220V Outlet Receptacle•

Ensure receptacle is free from dirt and

-

obstructions.

Ladder•

-

Ensure there are no loose or missing

parts and there is no visible damage.

Base Control Switches•

-

Ensure there are no signs of visible

damage and all switches are in their

neutral positions.

Free-wheeling Valve Knob•

(Compacts - Front Side)

Ensure there are no loose or missing -

parts and there is no visible damage.

Brakes•

Ensure there are no loose or missing -

parts and there is no visible damage.

SJIII Compacts & Conventionals

December 2007 Page 25

TM

Visual and Daily Maintenance Inspections Section 2 - Operations

Conventional Compact

Battery

Charger

Battery Tray

Battery Fuse Box

2.8-6 Battery Tray Side

Pothole Protection Device•

Ensure mechanisms have no sign of -

visible damage and are free from dirt and

obstructions.

Battery Tray•

Ensure tray latch is secure and in proper -

working order.

Battery Charger•

(Compacts - Entrance Side)

Ensure charger is secure and shows no -

visible damage.

Battery•

Proper battery condition is essential to

good performance and operational safety.

Improper fluid levels or damaged cables and

connections can result in component damage

and hazardous conditions.

WARNING

Explosion hazard. Keep flames

and sparks away. Do not smoke

near batteries.

Hydraulic/Electric

Tray

Battery

Charger

Pothole Protection Device

Battery Tray

Battery

WARNING

Battery acid is extremely corrosive Wear proper eye and facial protection as

well as appropriate protective clothing.

If contact occurs, immediately flush with

cold water and seek medical attention.

1. Check battery case for damage.

2. Clean battery terminals and cable ends

thoroughly with a terminal cleaning tool or

wire brush.

3. Ensure all battery connections are tight.

4. If applicable, check battery fluid level. If plates

are not covered by at least 13 mm of solution,

add distilled or demineralized water.

5. Replace battery if damaged or incapable of

holding a lasting charge.

WARNING

Use original or manufacturer-approved

parts and components for the aerial

platform.

Page 26 December 2007

SJIII Compacts & Conventionals

TM

Section 2 - Operation Visual and Daily Maintenance Inspections

Conventional

Steer Cylinder

Wheel/Tire

Battery Tray

Tie Rod

Steer Cylinder Assembly•

Ensure steer cylinder assemb l y is -

properly secured and there are no loose

or missing parts.

Wheel/Tire Assembly•

The aerial platform is either equipped with

solid rubber tires or foam-filled tires. Tire

and/or wheel failure could result in an aerial

platform tip-over. Component damage may

also result if problems are not discovered and

repaired in a timely fashion.

Check all tire treads and sidewalls for -

cuts, cracks, punctures and unusual

wear.

Check each wheel for damage and -

cracked welds.

Check each lug nut for proper torque to -

ensure none are loose.

Check wheel motor assembly for loose -

or missing parts and signs of visible

damage.

Tie Rod (Conventionals)•

Ensure there are no loose or missing -

parts, tie rod end studs are locked and

there is no visible damage.

Greasing Points•

Ensure greasing points have no sign of -

visible damage and are free from dirt and

obstructions.

Ensure wheels are aligned and true -

vertically and horizontally.

SJIII Compacts & Conventionals

December 2007 Page 27

TM

Visual and Daily Maintenance Inspections Section 2 - Operations

Compact

Emergency Lowering

Access Rod

Load/Tilt

Sensor

Greasing Point

2.8-7 Hydraulic/Electric Tray Side

Ensure tray latch is secure and in proper -

working order.

Pothole Protection Device•

Ensure mechanisms have no sign of -

visible damage and are free from dirt and

obstructions.

Hydraulic Tank •

Ensure hydraulic filler cap is secure. -

Main Manifold

Hydraulic Pump and

Motor

Proportional and Main Manifolds•

Ensure all fittings and hoses are properly -

tightened and there is no evidence of

hydraulic leakage.

Ensure there are no loose wires or -

missing fasteners.

Load/Tilt Sensor •

Ensure load/tilt sensor is properly secure -

and there is no visible damage.

Greasing Point

Electrical Panel

Hydraulic/Electric

Tray

Hydraulic Tank

Ensure tank shows no visible damage -

and no evidence of hydraulic leakage.

Hydraulic Oil•

Ensure platform is fully lowered, and then -

visually inspect the sight gauge located

on the side of the hydraulic oil tank.

The hydraulic oil level should be at or -

slightly above the top mark of the sight

glass.

Hydraulic Pump and Motor •

Ensure there are no loose or missing -

parts and there is no visible damage.

Electrical Panel •

Ensure panel is properly secured and -

there is no visible damage.

Ensure there are no loose wires or -

missing fasteners.

Page 28 December 2007

Emer g en c y Lowe r in g A c ce s s Rod •

(If Equipped)

Ensure rod is properly secured and there -

is no visible damage.

SJIII Compacts & Conventionals

TM

Section 2 - Operation Visual and Daily Maintenance Inspections

Platform Control Console

Platform

Railing

Manual Storage

Box

Platform

Assembly

2.8-8 Platform Assembly

WARNING

Ensure that you maintain three points of

contact to mount/dismount platform.

1. Use the ladder of aerial platform to access

platform.

2. Close the gate.

Ensure there are no loose or missing -

parts and there is no visible damage.

Ensure all fasteners are securely in -

place.

Ensure all railings are properly positioned -

and secured.

Ensure gate is in good working order. -

Lanyard Attachment Anchors•

Ensure attachment rings are secure and -

no visible damage.

Platform Control Console•

Ensure all switches and controller are -

returned to neutral and are properly

secured.

Ensure there are no loose or missing -

parts and there is no visible damage.

Manuals•

En s ure a copy of operatin g manual is

enclosed in manual storage box.

Check to be sure manual storage box is -

present and in good condition.

Ensure manuals are legible and in good -

condition.

Always return manuals to the manual -

storage box after use.

AC Outlet on Platform•

Ensure outlet has no visible damage and -

free from dirt or obstructions.

SJIII Compacts & Conventionals

December 2007 Page 29

TM

Visual and Daily Maintenance Inspections Section 2 - Operations

Powered Extension Control

Console

Maintenance

Support

Lift Cylinder

Scissor Assembly

Powered Extension Control Console •

(If Equipped)

Ensure all switches are returned to -

neutral and are properly secured.

Ensure there are no loose or missing -

parts and there is no visible damage.

WARNING

Ensure that you maintain three points of

contact to mount/dismount platform.

3. Use the ladder to dismount from platform.

2.8-9 Lifting Mechanism

1. Raise the platform (refer to Section 2.10-2)

until there is adequate clearance to swing

down the maintenance support (refer to

Section 2.16).

Maintenance Support•

Ensure maintenance support is properly -

secured and shows no visible damage.

Scissor Assembly•

Ensure scissor assembly shows no visible -

damage and no signs of deformation in

weldments.

Scissor Bumper

Roller

Ensure cables and wires are properly -

routed and shows no signs of wear and/

or physical damage.

Scissor Bumpers•

Ensure bumpers are secure and shows -

no sign of visible damage.

Rollers•

Ensure rollers are secure and there is no -

visible damage.

Ensure rollers’ path of travel are free from -

dirt and obstructions.

Lift Cylinder(s)•

Ensure each lift cylinder is properly -

secured, there are no loose or missing

parts and there is no evidence of

damage.

Ensure all fittings and hoses are properly -

tightened and there is no evidence of

hydraulic leakage.

2. Raise the platform until there is adequate

clearance to swing up the maintenance

support.

3. Swing up maintenance support into storage

bracket.

Ensure all pins are properly secured. -

Page 30 December 2007

4. Fully lower the platform.

SJIII Compacts & Conventionals

TM

Section 2 - Operation Function Tests

CAUTION

A106515AC

Conventional

(Back View)

Free-wheeling

Valve

Lower/

Neutral/Raise

Switch

Emergency Stop

Button

Off/Platform/Base Switch

2.9 Function Tests

Function tests are designed to discover any malfunctions

before aerial platform is put into service. The operator

must understand and follow step-by-step instructions

to test all aerial platform functions.

WARNING

Never us e a malfu n c tion i n g ae r ial

platform. If malfunctions are discovered,

aerial platform must be tagged and

placed out of service. Repairs to aerial

platform may only be made by a qualified

service technician.

After repairs are completed, operator must perform a

pre-operation inspection and a series of function tests

again before putting aerial platform into service.

Prior to performing function tests, be sure to read and

understand Section 2.10 - Start Operation.

Lower/

Neutral/Raise

Switch

2.9-2 Base Control Console

Ensure that you maintain three points of

contact when using the ladder to mount/

dismount platform.

1. Use the ladder of aerial platform to access

platform.

2. Close the gate.

3. On platform control console, pull out “

emergency stop button.

4. Use the ladder to dismount from platform.

5. Turn main power disconnect switch to “ ” on

position.

Compact

(Back View)

Emergency Stop

Button

WARNING

”

2.9-1 Test Main Power Disconnect Switch

1. At rear of the base, turn main power disconnect

switch to “ ” off position.

Result: Aerial platform functions should not

operate.

SJIII Compacts & Conventionals

December 2007 Page 31

TM

Function Tests Section 2 - Operation

CAUTION

A106515AC

Conventional

(Back View)

Lower/

Neutral/Raise

Switch

Test Base Emergency Stop•

1. Push in base “

button and attempt to raise or lower the

platform.

Result: Platform raising and lowering

functions should not operate.

2. Pull out base “

button.

Test Off/Platform/Base Switch•

Emergency Stop

Button

Free-wheeling

Valve

Off/Platform/Base Switch

” emergency stop

” emergency stop

Lower/

Neutral/Raise

Switch

Compact

(Back View)

Emergency Stop

Button

2. Select off/platform/base key switch to “

platform position. Attempt to raise or lower

the platform.

Result: Platform raising and lowering

functions should not operate.

3. Select and hold off/platform/base key

switch to “

” base position. Attempt

to raise or lower the platform.

Result: Platform raising and lowering

functions should operate.

”

WARNING

Be aware of overhead obstructions

or other possible hazards around the

aerial platform when lifting.

1. Se lect off/p latform/ba se key swit ch

“ ” off position. Attempt to raise or lower

the platform.

Result: Platform raising and lowering

functions should not operate.

Page 32 December 2007

Test Lower/Neutral/Raise Switch•

1. Select and hold off/platform/base key

switch to “

” raise the platform with lower/neutral/

“

” base position an d

raise switch.

Result: Platform should rise.

2. Select and hold off/platform/base key

switch to “

“

” lower the platform with lower/

” base position an d

neutral/raise switch.

Result: Platform should lower.

SJIII Compacts & Conventionals

TM

Section 2 - Operation Function Tests

CAUTION

A106515AC

Conventional

(Back View)

Lower/

Neutral/Raise

Switch

Test Emergency Lowering•

1. Raise the platform.

Emergency Stop

Button

Free-wheeling

Valve

Lower/

Neutral/Raise

Switch

Off/Platform/Base Switch

Test Free-wheeling•

1. Ensure path of intended motion is clear.

Compact

(Back View)

Emergency Stop

Button

2. Locate holding valve manual override

knob at the base of each lift cylinder.

Depress and turn counterclockwise. If

necessary, use access rod that is located

on the base of the aerial platform.

3. On hydraulic/electric tray, pull out and

hold emergency lowering valve to fully

lower the platform.

Result: The platform should lower.

4. To restore normal operation, depress and

turn holding valve manual override knobs

clockwise.

2. Release the brake manually (refer to

Section 2.14-2).

3. Tu r n f r e e -w h e e li n g v a l v e k n ob

co untercloc kwise to a fully open ed

position and attempt to push/pull the aerial

platform.

Result: Platform should move

4. Turn free-wheeling valve knob clockwise

to a fully closed position for normal

operation.

5. R ee n ga g e t h e b ra k e ( r e f e r t o

Section 2.14-2).

SJIII Compacts & Conventionals

December 2007 Page 33

TM

Function Tests Section 2 - Operation

Lift/Drive/Steer Enable

Trigger Switch

Inclined Drive/Level Drive

Switch

Rocker Switch

Controller

Emergency Stop Button/

Operation Light

Lift/Drive/Steer Enable

Trigger Switch

Rocker Switch

Emergency Stop Button/

Operation Light

Horn Pushbutton

Horn Pushbutton

Lift/Off/Drive Switch

Lift/Inclined Drive/Level Drive Switch

Platform Control Console with Toggle Switch Platform Control Console with Rotary Switch

2.9-3 Platform Control Console

1. Ensure base “

” emergency stop button is

Test Enable Trigger Switch•

1. Pull out “

” emergency stop button.

pulled out.

2. Select off/platform/base key switch to “

platform position.

3. Ensure main power disconnect switch is in “ ”

on position.

WARNING

Ensure that you maintain three points of

contact when using the ladder to mount/

dismount platform.

4. Use the ladder of aerial platform to access

platform.

5. Close the gate.

6. On platform control console, pull out “

emergency stop button.

Test Platform Emergency Stop•

1. Push in “

” emergency stop button

and attempt to activate any platform

function.

Result: All selected platform functions

should not operate.

2. Without activating “

”

switch, attempt to activate any platform

” enable trigger

function.

Result: All platform functions should not

operate.

Test Steering•

1. For platform control console with toggle

switch:

Select lift/off/drive switch to “

” drive

position.

For platform control console with rotary

switch:

Select lift/inclined drive/level drive switch

to either “

”

high torque) or “

” inclined drive (low speed/

” level drive (high

speed/low torque) position.

2. Activate and hold “

” enable trigger

switch.

Page 34 December 2007

SJIII Compacts & Conventionals

TM

Section 2 - Operation Function Tests

Lift/Drive/Steer Enable

Trigger Switch

Inclined Drive/Level Drive

Switch

Rocker Switch

Controller

Emergency Stop Button/

Operation Light

Lift/Drive/Steer Enable

Trigger Switch

Rocker Switch

Emergency Stop Button/

Operation Light

Horn Pushbutton

Horn Pushbutton

Lift/Off/Drive Switch

Lift/Inclined Drive/Level Drive Switch

Platform Control Console with Toggle Switch Platform Control Console with Rotary Switch

3. Press rocker switch on top of controller

Test Brakes•

handle to “ ” left and “ ”

right.

Result: Steer wheels should turn left and

right.

Brakes will engage instantly when you

release the controller handle, causing

WARNING

aerial platform to stop immediately.

Test Driving•

1. Ensure path of intended motion is clear.

1. Ensure path of intended motion is clear.

2. Activate and hold “

” enable trigger

switch.

2. Activate and hold “

switch.

”enable trigger

3. Drive aerial platform “

” forward and then

3. Slo w ly mo ve co nt ro ll er ha nd l e in

“

” forward direction until aerial platform

begins to move, and then return handle to

center position.

Result: Aerial platform should move in

forward direction, and then come to a

stop.

4. Slowly move controller handle in “

reverse direction until aerial platform begins

to move, and then return handle to center

position.

Result: Aerial platform should move in

reverse direction, and then come to a

stop.

SJIII Compacts & Conventionals

” backward. Test brake by releasing

“

controller handle.

Result: Aerial platform should come to

a stop. If aerial platform pulls to one side

while stopping, do not operate aerial

platform until brake adjustments have

been checked.

4. Drive aerial platform “

”

then “

by releasing “

” backward. Test brake again

” enable trigger switch

” forward and

only.

Result: Aerial platform should come to an

instant and abrupt stop. If aerial platform

does not stop immediately, or if aerial

platform pulls to one side while stopping,

do not operate aerial platform until brake

adjustments have been checked.

December 2007 Page 35

TM

Function Tests Section 2 - Operation

Lift/Drive/Steer Enable

Trigger Switch

Inclined Drive/Level Drive

Switch

Rocker Switch

Controller

Emergency Stop Button/

Operation Light

Lift/Drive/Steer Enable

Trigger Switch

Rocker Switch

Emergency Stop Button/

Operation Light

Horn Pushbutton

Horn Pushbutton

Lift/Off/Drive Switch

Lift/Inclined Drive/Level Drive Switch

Platform Control Console with Toggle Switch Platform Control Console with Rotary Switch

Test Platform Raising/Lowering•

WARNING

Test Lowering Warning•

1. Raise the platform until approximately a

height of 3 to 4 meters is reached then

Be aware of overhead obstructions

or other possible hazards around the

aerial platform when lifting.

attempt to fully lower the platform.

Result: Platform should stop lowering at

a height of 2.5 meters high and an alarm

should sound.

1. For platform control console with toggle

switch:

Select lift/off/drive switch to “

position.

” lift

2. Release controller handle.

Test Horn•

For platform control console with rotary

switch:

Select lift/inclined drive/level drive switch

” lift position.

to “

2. Activate and hold “

” enable trigger

switch.

3. Push controller handle and raise the

platform to an approximate height of

0.5 meter.

Result: Platform should rise.

4. Pull controller handle and lower the

platform fully.

Result: Platform should lower.

Page 36 December 2007

1. Push “

” horn pushbutton.

Result: Horn should sound.

SJIII Compacts & Conventionals

TM

Section 2 - Operation Function Tests

Compact

Pothole Protection

Device

Test Pothole Sensor •

WARNING

Ensure that you maintain three points of

contact to mount/dismount platform.

1. Use the ladder to dismount from platform

and place a block, approximately 3.75 cm,

under the hydraulic/electric tray.

2. Use the ladder of aerial platform to access

platform.

3. Close the gate.

4. Raise the platform until approximately a

height of 2 meters is reached and attempt

to drive forward or reverse.

Result: Aerial platform should not move

forward or backward.

5. Repeat the steps above with block placed

under battery tray.

Result: Aerial platform should not move

forward or backward.

Test Elevated Drive Speed•

WARNING

Be aware of overhead obstructions

or other possible hazards around the

aerial platform when lifting.

1. Ensure path of intended motion is clear.

2. Raise the platform until approximately a

height of 2 meters is reached and attempt

to drive forward or reverse.

Result: Aerial platform should move slower

than when it was in stowed position.

SJIII Compacts & Conventionals

December 2007 Page 37

TM

Start Operation Section 2 - Operation

2.10 Start Operation

Carefully read and completely understand the operating

manual and all warnings and instruction labels (refer to

labels section) on the aerial platform.

WARNING

Do not operate this aerial platform without

proper authorization and training. Failure

to avoid this hazard could result in death

or serious injury.

Before operating this aerial platform, perform the

following steps:

1. Visual and daily maintenance inspections (see

Section 2.8)

2. Function tests (see Section 2.9)

3. Jobsite inspection

It is the responsibility of the operator to perform

a jobsite inspection and avoid the following

hazardous situations:

holes or drop-offs•

ditches or soft fills•

floor obstructions, bumps or debris•

overhead obstructions•

electrical cords, hoses and high voltage •

conductors

hazardous locations•

inadequate surface support to withstand all •

load forces imposed by the aerial platform

wind and weather conditions•

the presence of unauthorized personnel•

other possible unsafe conditions•

WARNING

An operator should not use any aerial

platform that:

2.10-1 To Activate Base Control Console

WARNING

Ensure that you maintain three points of

contact when using the ladder to mount/

dismount platform.

1. Use the ladder of aerial platform to access

platform.

2. Close the gate.

3. On platform control console, pull out “

emergency stop button.

4. Use the ladder to dismount from platform.

5. Turn main power disconnect switch to “ ” on

position.

6. On base control console, pull out “

” emergency

stop button.

2.10-2 To Raise or Lower Platform Using Base

Control Console

WARNING

Be aware of overhead obstructions or

other possible hazards around the aerial

platform when lifting.

WARNING

Do not lower the platform unless the area

is clear of personnel and obstructions.

1. A ct iv at e ba se con t rol co n so le ( re fe r to

Section 2.10-1).

”

does not appear to be working properly.•

has been damaged or appears to have worn or •

2. Select and hold off/platform/base key switch to

missing parts.

has alterations or modifications not approved by •

the manufacturer.

3. Select and hold lower/neutral/raise switch to either

has safety devices which have been altered or •

disabled.

Failure to avoid these hazards could

result in death or serious injury.

Page 38 December 2007

“

” base position.

” raise or “ ” lower position. Release switch

“

to stop.

SJIII Compacts & Conventionals

TM

Section 2 - Operation Start Operation

Lowering Warning System - A lowering warning

system automatically stops lowering function

before reaching fully retracted position and

sounds the alarm. After the operator has released

down controls and taken time to check that no

person is near the scissors, the lowering function

can be reactivated.

2.10-3 To Activate Platform Control Console

1. Turn main power disconnect switch to “ ” on

position.

2. On base control console, pull out “

” emergency

stop button.

3. Select off/platform/base key switch to “

platform position.

WARNING

Ensure that you maintain three points of

contact when using the ladder to mount/

dismount platform.

2. For platform control console with toggle switch:

Select lift/off/drive switch to “

” lift position.