MicroGuard 534

Operator’s Manual

NOTICE

SkyAzúl makes no warranty of any

kind with regard to this material, including, but not limited to, the

implied warranties of merchantability and/or its fitness for a particular purpose.

SkyAzúl will not be liable for errors contained in this manual or for incidental or consequential

damages in connection with the furnishing, performance, or use of this manual. This document

contains proprietary information, which is protected by copyright, and all rights are reserved.

No part of this document may be photocopied, reproduced, or translated to another language without

the prior written consent of SkyAzúl.

SkyAzúl reserves proprietary rights to all drawings, photos and the data contained therein. The

drawings, photos and data are confidential and cannot be used or reproduced without the written

consent of SkyAzúl. The drawings and/or photos are subject to technical modification without prior

notice.

All information in this document is subject to change without notice.

SkyAzúl, Equipment Solutions www.skyazul.com 301-371-6126

SkyAzúl, Inc.

16 Walnut Street

Middletown, MD 21769

Fax 301-371-0029

info@skyazul.com

MicroGuard 534 Operator’s Manual

TABLE OF CONTENTS

CONSOLE LAYOUT AND DESCRIPTION ............................................................................................ 1

SYSTEM DESCRIPTION ....................................................................................................................... 2

DISPLAY UNIT ...................................................................................................................................... 2

SYSTEM OPERATION .......................................................................................................................... 4

SYSTEM SELF-TEST ............................................................................................................................ 4

SYSTEM BYPASS ................................................................................................................................ 4

CONFIGURATION SELECTION ............................................................................................................ 5

NORMAL WORKING SCREEN EXAMPLES ......................................................................................... 9

SELECTION OF RIGGING/TRAVEL MODE ........................................................................................ 11

CANCEL AUDIBLE ALARM AND RESET FUNCTION LIMITERS ...................................................... 11

OPERATOR SETTABLE ALARMS ..................................................................................................... 11

ANGLE, LENGTH, AND HEIGHT OPERATOR SERRABLE ALARMS ............................................... 12

SWING OPERATOR SETTABLE ALARM ........................................................................................... 13

OPERATOR DEFINED AREA ALARM ................................................................................................ 13

SETTING OPERATOR DEFINED AREA ALARM ................................................................................ 14

SYSTEM FAULT CODES .................................................................................................................... 16

CALIBRATION ..................................................................................................................................... 16

SkyAzúl, Equipment Solutions www.skyazul.com 301-371-6126

1

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

1

301-371-6126

32

4

5

17

16

15

14

13

12

36.5’

2_

9.7 X 1000 LBS MAX

0.5

61.0

60.0ft

90.0ft

!! TWO BLOCK !!

12000

6

1

7

1. Bar-Graph

2. Pre-Alarm Indicator

3. Overload Indicator

4. Maximum Rated Capacity Display

5. Actual Load Display

6. Parts-of-Line Display

Figure 1−68

Microguard 534 Rated Capacity Limiter

11 10 9 8

7. Configuration Selection Buttons

8. Cancel Alarm Button

9. Operator Alarms Button

10. Crane Setup Button

11. Display/Select Button

12. Warning Message Area

13. Boom Length Display

14. Brightness Buttons

15. Load Radius Display

16. Boom Angle Display

17. Erected Attachment Display

MicroGuard 534 Rated Capacity

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

2

301-371-6126

Limiter

The following describes the function and operation of

the Microguard 534 Rated Capacity Limiter. The system is intended to aid the operator in the efficient operation of the crane by continually monitoring the load

and warning of an approach to an overload or unsafe

condition.

WARNING

Although the system will alert the operator of

an approaching overload or unsafe condition,

it remains the responsibility of the operator to

operate the crane safely at all times.

This system must never be substituted for the

good judgment of the crane operator using safe

operating procedures. The operator is solely

responsible for safe operation of the crane.

!!THIS SYSTEM IS AN OPERATOR’S AID −

NOT A SAFETY DEVICE!!

3

2

1

1. Green Lights − Percentage of Rated Load

231

2. Amber Lights − Approaching Overload

3. Red Lights − Overload

System Description

The system monitors crane functions by means of high

accuracy sensors and continuously compares the load

with a copy of the crane capacity chart which is stored

in the computer memory. If an overload is approached,

the system warns by means of audible and visual

alarms and is configured to cause function limitation.

The MicroGuard 534 Rated Capacity Limiter provides

the operator with a continuous display of:

Rated Capacity

Actual Load

Percentage of Rated Capacity

Radius of the Load

Angle of the Main Boom

Crane Configuration

Length of the Main Boom

An additional feature of the system is the provision of

operator settable alarms. These alarms, when properly set, provide a method of obstacle avoidance. This is

achieved by means of maximum boom angle, maximum load radius, maximum boom head height, left

and right swing, and defined area alarms. These

alarms can be programmed for each job site and set

rapidly for the prevailing site conditions thereby aiding

the operator in safe operation of the crane.

Figure 1−69

Overhead Bar Graph And External Light Bar

(If Equipped)

Display Unit

The following is a description of the control buttons, indicators, and windows on the display unit. Use them

along with Figure 1−68.

1. Bar-Graph

The Bar-Graph is a series of twelve colored lights which

gives a visual indication of how much of the crane’s capacity is being used and the rate at which an overload

is being approached. Each green light represents 10%

of the crane’s rated capacity is being used. Yellow indicates 90−99.9%, and the red lights indicate an overload.

Note: System may be equipped with an overhead

bar graph or an external light bar which operates

similar to the bar graph on the display. Refer to

Figure 1−69.

2. Pre-Alarm indicator

The Pre-Alarm (yellow) Indicator illuminates at a preset value of 90% of Maximum Rated Capacity and provides a visual indication of an approach to an overload.

3. Overload Indicator

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

3

301-371-6126

10. Crane Setup Button

The Overload Indicator (red) illuminates at a pre-set

value of 100% of Maximum Rated Capacity and provides a visual indication of Maximum Allowed Load. It

will also illuminate whenever a wire rope limit is exceeded. Function limiters will occur simultaneously for an

Overload, Wire Rope Limit, or a Two Block condition

but function limiters will not occur when exceeding an

operator settable alarm. An audible alarm will sound

and a message will appear in the warning message

area for all 4 conditions.

4. Maximum Rated Capacity Display

The Maximum Rated Capacity is a digital display of the

maximum permitted capacity. It is derived from a copy

of the crane’s capacity chart which is stored in the computer memory and is the reference capacity for any lifting operation. It is dependent on the configuration currently selected, which is shown in the crane setup

screen, and which determines the section of the capacity chart to be used as the rated capacity reference.

5. Actual Load Display

The Actual Load Display is a digital display which

shows total load suspended below the boom or fly

head. It includes the load, any slings, pins, or tackle

used to secure the load and the hook block or ball.

6. Parts-of-Line Display

Parts-of-Line displays the parts of line currently selected for the winch in use.

7. Configuration Selection Buttons

These buttons are used during the crane configuration

selection routine. Refer to Configuration Selection"

found later in this Section of the Operator’s Manual.

8. Cancel Alarm Button

This button is used to silence the audible alarm when

the alarm has occurred as a result of either an Overload, Wire Rope Limit, a Two Block, or an Operator Settable alarm. It is also used to reset the function limit

relay when it is necessary to by-pass function limit

which has occurred as a result of either an Overload,

Wire Rope Limit, or a Two Block alarm.

This button is used to start the configuration selection

routine. Refer to Configuration Selection" found later

in this Section of the Operator’s Manual.

11. Display/Select Button

This button is used to access the Calibration And Diagnostic Screen. Refer to System Fault Codes" and

Calibration" found later in this Section of the Operator’s Manual.

12.Warning Message Area

The Warning Message Area displays text messages of

various alarms which may occur during normal operation of the system. When an alarm occurs, the rectangular area fills in red.

13. Boom Length Display

The Boom Length Display gives a continuous indication of the boom length in feet (m). It is the distance

from the centerline of the boom foot pin to the center

line of the boom head machinery.

14. Brightness Buttons

These buttons are used to adjust the display brightness.

15.Load Radius Display

The Load Radius Display gives a continuous indication

of the radius of the load in feet (m). It is the horizontal

distance from the centerline of rotation to the centerline

of the hook.

16. Boom Angle Display

The Boom Angle Display gives a continuous indication

of the angle of the main boom relative to horizontal.

17. Erected Attachment Display

The Erected Attachment Display gives a continuous

display of the erected attachment with the top number

indicating the actual fly length and the bottom number

indicating the offset angle if applicable.

9. Operator Alarms Button

This button is used to start the operator settable alarms

routines. Refer to Operator Settable Alarms" found

later in this section of the Operator’s Manual.

System Operation

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

4

301-371-6126

The following is a list of procedures which are used to

operate the multiple features of the Rated Capacity

Limiter. Use these procedures in conjunction with the

previous display unit control descriptions.

System Self-Test

At start-up the system automatically performs a self test

after which all lamps, audible alarms, and digital displays will be functionally tested and all memory areas

checked for accuracy. If faults in the system are detected during a test, the warning message area will

show the words SYSTEM FAULT. If the words SYSTEM

FAULT occur, press the Display/Select button to display the Calibration And Diagnostic screen. Through

the Calibration And Diagnostic screen, information can

be accessed about the fault condition by means of an

error code. Contact your local distributor for details of

the fault codes.

Note: If the batteries have been disconnected interrupting power to the computer, the start-up time for

on-board computer systems will be longer than

normal.

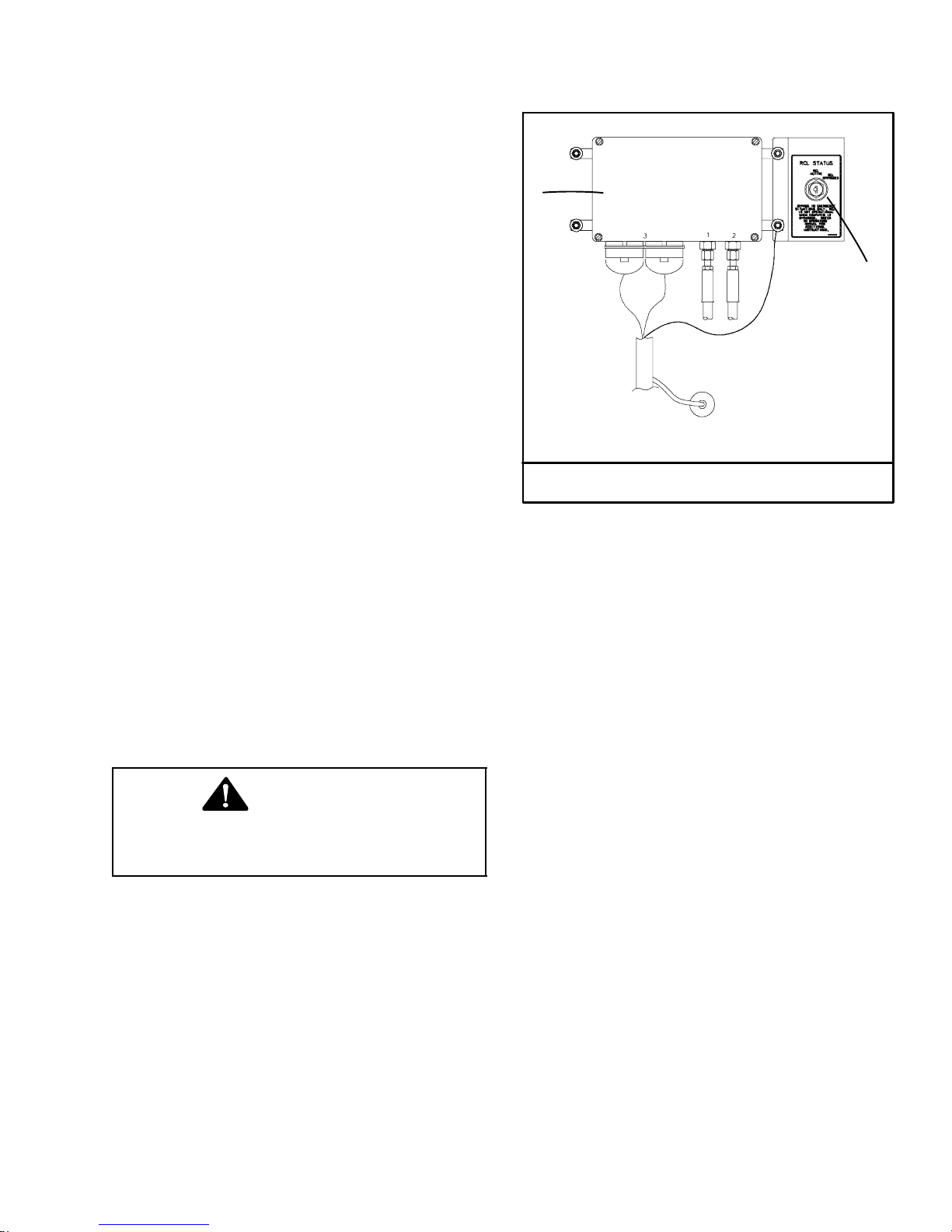

System Bypass

In emergency situations, the Rated Capacity Limiter

computer can be bypassed. The computer is located

on the back of the operator’s cab. Refer to

Figure 1−70. There is a RCL Status keyswitch adjacent to the computer to bypass the system. Move the

key to the Bypass" position to bypass the system. For

emergency use while the system is bypassed, refer to

System Inoperative or Malfunctioning" that follows.

WARNING

The Microguard 534 is not operational when

the computer is bypassed. Bypass the

system in emergency situations only.

System Inoperative Or Malfunctioning

When operational aids are inoperative or malfunctioning, the following recommendations for continued use

of the crane should be followed or the crane should be

shutdown.

1. Steps shall be taken to schedule repairs and recalibration immediately. The operational aids shall be

put back into service as soon as replacement

parts, if required, are available and the repairs and

recalibration can be carried out. Every reasonable

effort must be made to expedite the repairs and recalibration.

1

2

1. RCL Status Keyswitch 2. Computer

Figure 1−70

Rated Capacity Limiter Computer

2. When the rated capacity limiter is inoperative or

malfunctioning, the designated person responsible for supervising the lifting operations shall establish procedures for determining load weights

and shall ascertain that the weight of the load does

not exceed the crane ratings at the radius where

the load is to be handled.

3. When a boom angle or radius indicator is inoperative or malfunctioning, the radius or boom angle

shall be determined by measurement.

4. When the anti-two block warning device is inoperative or malfunctioning, the designated person responsible for supervising the lifting operations

shall establish procedures, such as assigning an

additional signal person, to furnish equivalent

protection. This does not apply when lifting personnel in load line supported baskets. Personnel

shall not be lifted in load line supported baskets

when the anti-two block devices are not functioning properly.

5. When a boom length indicator is inoperative or

malfunctioning, the designated person responsible for supervising the lifting operations shall establish the boom length at which the lift will be

made by actual measurement or markings on the

boom.

6. When a level indicator is inoperative or malfunctioning, other means shall be used to level the

crane.

7. In situations where inconsistency exists, verified

weights, measured radii, boom lengths, and authorized crane capacities must always take precedence over indicator readings.

Configuration Selection

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

5

301-371-6126

In the normal operational mode the system is programmed to remember the last configuration selected. Each time

the system is powered up it will automatically default to that configuration. Only when the crane is rigged differently

must a new configuration be selected. Use the following procedure to select the crane configuration.

Note: When selecting configurations allowed on outriggers, all beams must be equally extended; all fully

retracted, intermediate extended, or fully extended.

Depending on how the crane is equipped or which selections have been made, some screens shown may not

appear or may not appear as illustrated. The system cannot be programmed for configurations not allowed

by the capacity charts listed in the Crane Rating Manual.

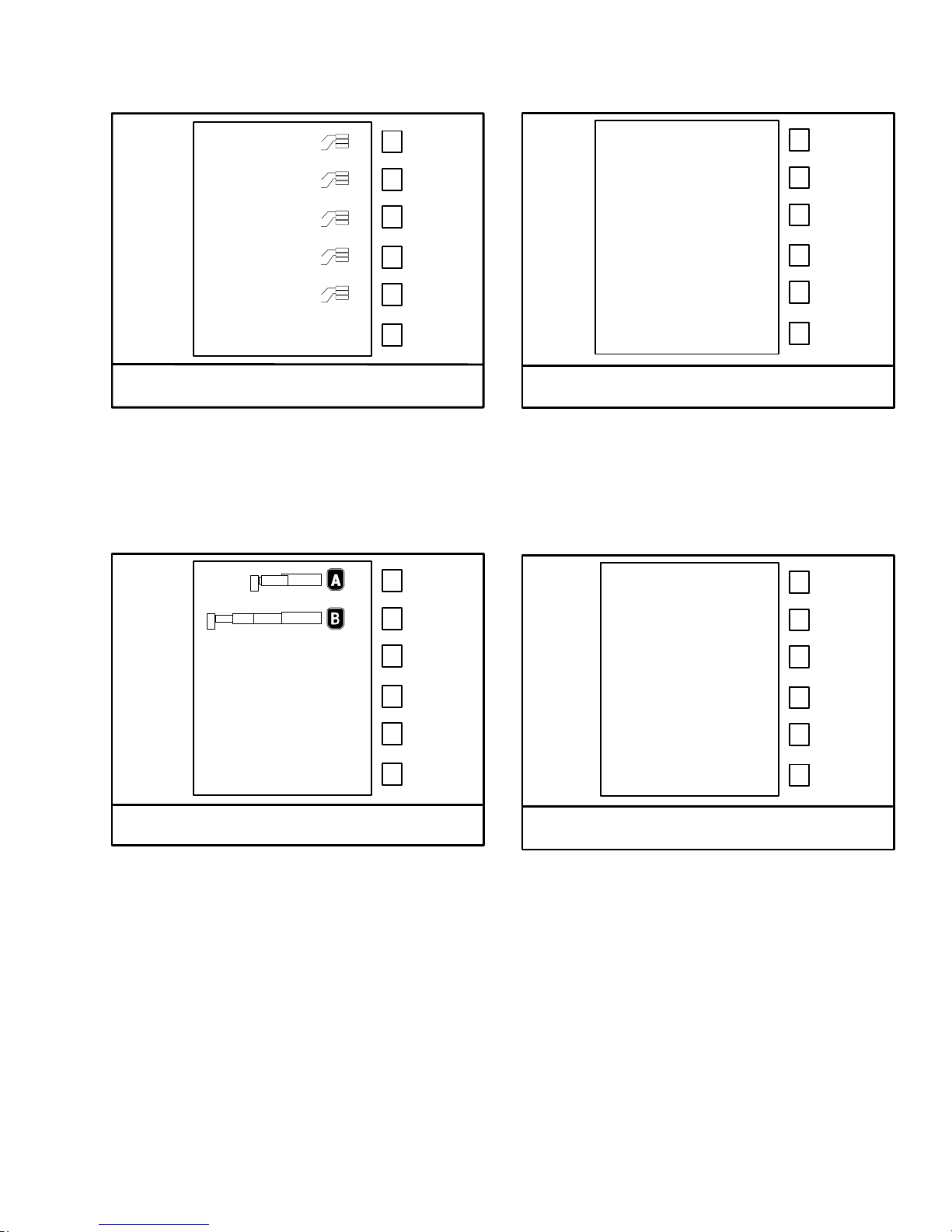

Figure 1−71

Carrier Selection

1. From the normal working screen press the CRANE SETUP button. The normal working screen will change and

graphically display the carrier options. Press the corresponding configuration selection button to select the

desired carrier configuration. If rigging is desired, refer to To Select Rigging/Travel Mode" found later in this

Section of the Operator’s Manual.

WARNING

The Microguard 534 is not operational when in the RIGGING/TRAVEL Mode. Return the Microguard 534

to normal operation before operating the crane.

0

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

6

301-371-6126

4 000

8 000

12000

16000

Figure 1−72

Counterweight Selection

2. The carrier selection screen will change and

graphically display the counterweight options.

Press the corresponding configuration selection

button to select the installed counterweight.

Figure 1−73

Boom Extend Mode Selection

Figure 1−74

Auxiliary Head Selection

4. The boom mode selection screen will change and

graphically display the auxiliary lifting sheave fitted

or not fitted. Press the corresponding configuration selection button to select the acual auxiliary lifting sheave configuration.

36.5’ Fly

61’ Fly

Figure 1−75

Erected Attachment Selection

3. The counterweight selection screen will change

and graphically display the boom mode options.

Press the corresponding configuration selection

button to select the desired boom mode.

Note: Consult the Crane Rating Manual to determine the best boom mode to maximize lift capacity at working radius. Boom mode options

will only be displayed when the boom is fully retracted.

5. If the crane is equipped with a fly, the auxiliary

sheave selection screen will change and graphically display an erected attachment. Press the corresponding configuration selection button to select the installed erected attachment if required.

20

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

7

301-371-6126

40

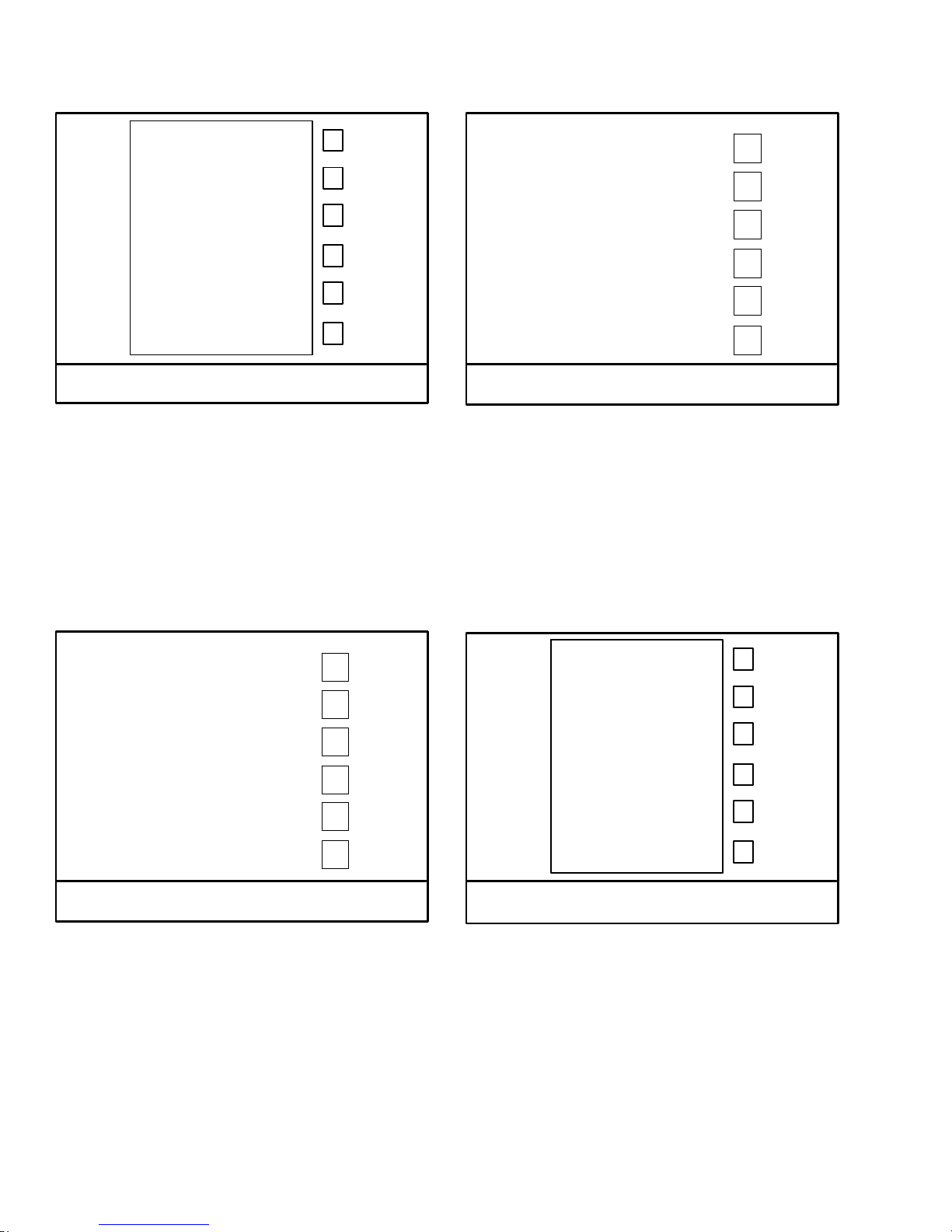

Figure 1−76

Erected Attachment Offset Selection

6. If an offset fly was previously selected, the erected

attachment selection screen will change and

graphically display the available offset angles.

Press the corresponding configuration selection

button to select the installed offset angle if required.

Figure 1−78

Front Winch Lifting Point Selection

8. If the crane is equipped with a front winch, the rear

winch lifting point screen will change and graphically display the front winch lifting point. Press the corresponding configuration selection button to select

the actual front winch lifting point. Or press the corresponding configuration selection button to select

the front winch not in use.

24.5’

36.5’

61’

Figure 1−77

Rear Winch Lifting Point Selection

7. The erected attachment or erected attachment offset selection screen will change and graphically

display the rear winch lifting point. Press the corresponding configuration selection button to select

the actual rear winch lifting point. Or press the corresponding configuration selection button to select the rear winch not in use.

Figure 1−79

Stowed Attachment Selection

9. If the crane is equipped with a fly and was not selected as an erected attachment, the winch lifting

point screen will change and graphically display

the stowed attachment. Press the corresponding

configuration selection button to select the actual

stowed attachment if required.

Figure 1−80

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

8

301-371-6126

Rear Winch Parts Of Line Selection

Figure 1−81

Front Winch Parts Of Line Selection

10. The crane setup screen will change to the normal

working screen and graphically display the crane

configuration as previously selected. Press the

corresponding configuration selection button to

select the actual parts of line for the rear winch.

11. If the crane is equipped with a front winch and it

was selected, press the corresponding configuration selection button to select the front winch.

Press the corresponding configuration selection

button to select the actual parts of line for the front

winch.

Note: From the normal working screen, after

crane setup has been established, only two

selection buttons are active; the winch select

button and the parts of line button.

To change winches, push the winch select button to toggle between winches. The winch lifting points cannot be changed without going

through the crane setup routine.

The parts of line can be changed for the selected winch by pressing the parts of line button

to scroll through the available options for that

winch.

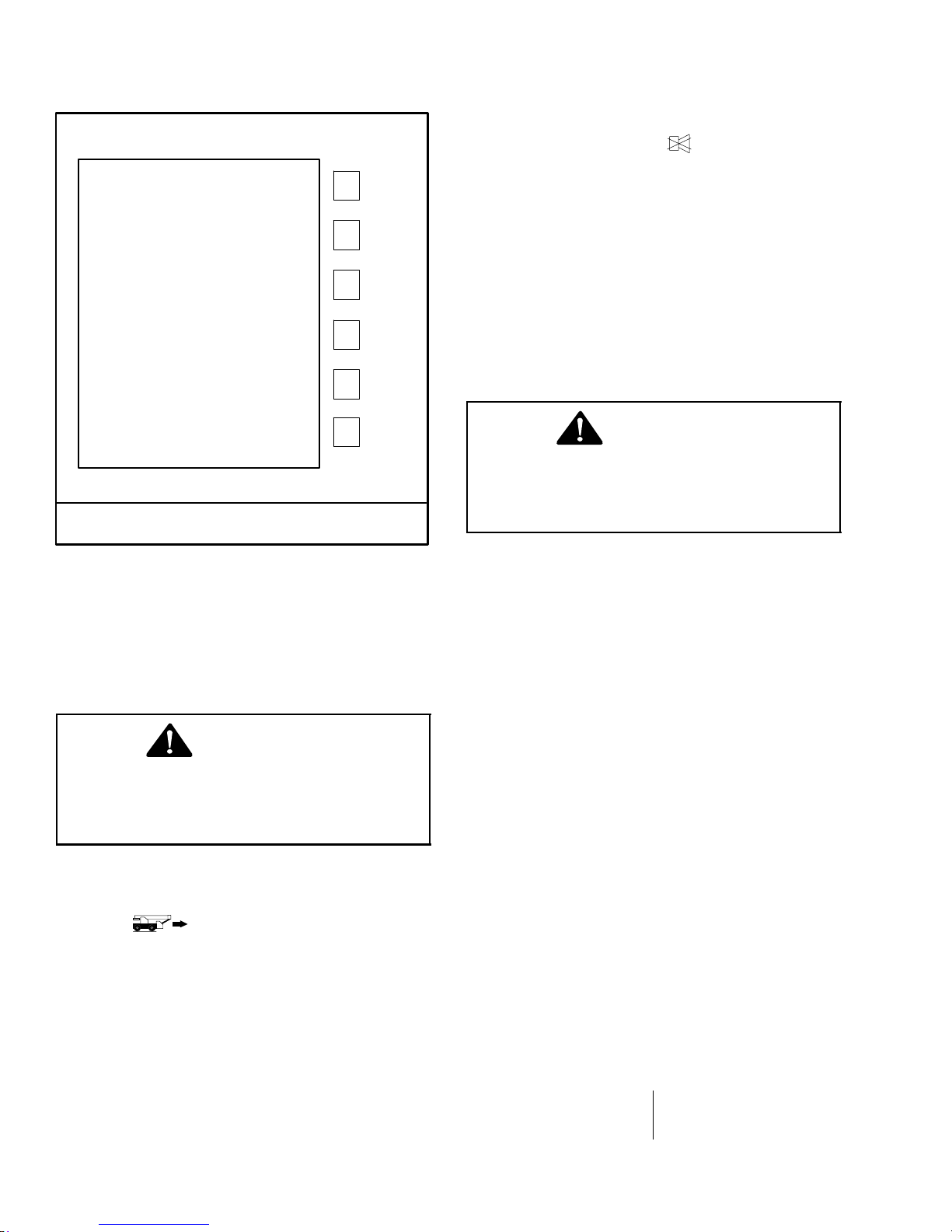

Refer to Figure 1−82 and Figure 1−83 for examples of some normal working screens.

4

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

9

301-371-6126

8

7

6

9

2

5

1

3

In this example the crane is setup on fully extended outriggers (1), boom mode B (2), 12,000 lb

counterweight (3), 36.5’ fly base erected at 2 degree offset (4), fly tip stowed (5), the rear winch

available with the main boom head and the front winch selected (6), with the winch rope reeved

over the fly base (7), with one part of line (8), and an operator settable alarm enabled (9).

7

6

5

2

4

3

1

In this example the crane is setup on intermediate extended outriggers (1), boom mode B (2), 12,000 lb counterweight (3) 61’ fly

stowed (4), the front winch available with the auxiliary head and

the rear winch selected (5), with the winch rope reeved over the

main boom head (6) with three parts of line (7).

Figure 1−82

Normal Working Screen Examples

6

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

10

301-371-6126

5

4

2

7

3

1

In this example the crane is setup for stationary on tires (1), boom mode

B (2), 12,000 lb of counterweight (3), front winch not in use and the rear

winch selected (4), winch rope reeved over the main boom (5), with

three parts of line (6), and the 61’ fly stowed (7).

7

4

6

2

5

1

3

In this example the crane is setup on fully retracted outriggers (1),

boom mode B (2), 12,000 lb of counterweight (3), winch rope

reeved over the main boom (4), 61’ fly stowed (5), rear winch not

in use and the front winch selected (6), with three parts of line (7).

Figure 1−83

Normal Working Screen Examples

Cancel Audible Alarm And Reset Function Limiters

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

11

301-371-6126

The CANCEL ALARM button is used to cancel the

audible alarm when the alarm has occurred as a result

of either an Overload, a Two Block alarm, or an Operator settable alarm. The audible alarm may be canceled

by pressing and releasing the CANCEL ALARM button.

The audible alarm remains canceled until the condition

which caused the alarm has been removed. For example, if the audible alarm was canceled because of an

overload condition, it will remain canceled until the

overload condition is removed. However, if a different

alarm, e.g. two block condition, was to occur when the

audible alarm was still canceled for an earlier overload

condition, the new alarm condition would cause the audible alarm to be re-started.

Figure 1−84

Rigging/Travel Mode Screen

To Select Rigging/Travel Mode

The CRANE SETUP push button is also used to select

RIGGING/TRAVEL MODE. This mode is used to facilitate rigging and travel of the crane by inhibiting function limiters and the audible alarm while selected. To

resume crane operation, select proper outrigger or tire

configuration per the proper procedure.

WARNING

The Microguard 534 is not operational when in

the RIGGING/TRAVEL Mode. Return the Microguard 534 to normal operation before operating the crane.

1. From the normal working screen press the CRANE

SETUP button. The crane setup screen will

change and graphically display the carrier options.

2. Select for stationary rigging or when traveling the crane. Refer to Figure 1−84.

Note: Boom must be fully retracted to enter

travel mode.

WARNING

Once the function limiters have been

by-passed, the crane is no longer protected

against the condition that initially caused the

function limiters to occur.

Note: The CANCEL ALARM feature is a temporary

function. The audible alarm or function limit is automatically reset when the condition which caused

the alarm is no longer present.

The CANCEL ALARM is also used to reset the function

limiters when it is necessary to by-pass the function limiters which has occurred as a result of either an overload, a two block alarm, or a rope limit. Function limiters are reset by first canceling the audible alarm (as described above) and then pressing and holding the

CANCEL ALARM button for about 3 seconds, after

which the function limiters will be reset to allow normal

operation. However, should another different alarm

condition occur when the function limiters had previously been over-ridden, then the newly occurring

alarm condition would cause the function limiters to activate again.

Operator Settable Alarms

Some alarms occur automatically as a result of limitations imposed by the capacity chart. The operator has

control over additional alarms which can be set to operate within the normal chart limitations and which are, in

addition to, those already set by the chart.

Operator settable alarms will be stored in the computer

memory, even if the crane is shutdown, until they are

cleared. Refer to Figure 1−85.

Alarms available for operator use are:

Minimum Boom Angle Maximum Boom Length

Maximum Boom Angle Left and Right Swing

Maximum Tip Height Operator Defined Area

EXIT

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

12

301-371-6126

SETTABLE ALARMS

BOOM LIMITS

SWING LIMITS

AREA LIMITS

Figure 1−85

Boom Limit Alarms

WARNING

The operator settable alarms are a warning

device. All functions remain operational when

entering the operator defined bad area. For

safe operation, adequate distance must be

maintained to allow for operator reaction time

to avoid entering the bad area. It is the

responsibility of the operator to set points

which ensure that the crane’s boom,

attachment, load, rigging, etc. maintains a

safe working distance and complies with local

safety regulations.

Angle, Length, And Height Operator Settable Alarms

1. From the normal working screen press OPERATOR ALARM button to access the Settable

Alarms screen.

2. Press the corresponding button for Boom Limits

.

WARNING

Avoid positioning the boom, attachment, load,

rigging, etc. into the bad area when setting the

alarm values.

When selecting the alarm values, ensure that

the load will maintain a safe distance from the

obstacle.

EXIT

4. Press the corresponding selection button to set the

desired alarm value as defined below. Press the

button again to turn alarm off.

5. When all alarm values are set, press the EXIT button to return to the alarm screen. At the Settable

Alarm screen, press the EXIT button again to return

to the normal working screen.

6. Test the alarm, with no load, to ensure the alarm

points have been properly set. When approaching

the alarm set point, the audible will sound intermittently and a warning message will appear in the

warning message area. When exceeding the

alarm set point, the audible alarm will sound continuously and a warning message will appear in

warning message area.

Note: An alarm icon will appear on the normal working screen to alert the operator that an

operator alarm has been set.

75.0

HEIGHTLENGTH ANGLE

75.0 75.0 60.0

75.0

60.0

30.0

Maximum Boom Length

Maximum Tip Height

Maximum Boom Angle

Minimum Boom Angle

3. Position the boom in the desired position depending upon the alarm to be set. The numerical value

displayed will be the current position of the boom.

WARNING

If crane or obstacle is moved or if a different

size load is lifted, the alarm(s) must be reset.

265.0

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

13

301-371-6126

SET

SETTABLE ALARMS

BOOM LIMITS

SWING LIMITS

AREA LIMITS

Figure 1−86

Swing Alarm

Swing Operator Settable Alarm

To have an alarm whenever the left swing and right

swing exceed pre-determined alarm points, use the following procedure:

1. From the normal working screen press OPERATOR ALARM button to access the Settable

Alarms screen.

2. Press the corresponding button for Swing Limits

.

3. Swing the boom to the left alarm point .

4. Press the corresponding button for Left Swing

to enter the left alarm point. The displayed value

will be the left alarm setting.

5. Swing the boom to the right alarm point.

6. Press the corresponding button for Right Swing

to enter the right alarm point. The displayed

value will be the right alarm setting.

7. Press the EXIT button to return to the settable

alarm screen. Press the EXIT button on the settable alarms screen to return to the normal working

screen.

8. Test the alarm, with no load, to ensure the alarm

points have been properly set. When approaching

the set alarm point, the audible alarm will sound intermittently and Swing Alarm" will appear in the

warning message area. The audible alarm will activate whenever the swing exceeds the alarm points

and Swing Alarm" will appear in warning message

area.

EXIT

SWING ANGLE

95.0

EXIT

95.0

SET

Operator Defined Area Alarm

The operator defined area alarm, when set, will define

an imaginary vertical plane between two set points to

optimize the working area. When approaching the

plane, the audible alarm will sound intermittently, and

the message Bad Working Area" will appear in the

warning message area. When passing the plane, the

audible alarm will sound continuously and the message Bad Working Area" will appear on the warning

message area. Use the following procedure,

Figure 1−87, and Figure 1−88 to set the operator defined area alarm.

WARNING

The operator defined area alarm is a warning

device. All functions remain operational when

entering the operator defined bad area. For

safe operation, adequate distance must be

maintained to allow for operator reaction time

to avoid entering the bad area. It is the

responsibility of the operator to set points

which ensure that the crane’s boom,

attachment, load, rigging, etc. maintains a

safe working distance and complies with local

safety regulations.

Note: Both the left and right swing alarms must

be set for the system to determine the operator

set working area.

Note: An alarm icon will appear on the normal working screen to alert the operator that an

operator alarm has been set.

EXIT

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

14

301-371-6126

SETTABLE ALARMS

BOOM LIMITS

SWING LIMITS

AREA LIMITS

Figure 1−87

Operator Defined Area Alarm

Setting Operator Defined Area Alarm

1. From the normal working screen press OPERATOR ALARM button to access the Settable

Alarms screen.

2. Disable any previously set left and right swing

alarms if required.

Note: The left and right swing alarms must be

cleared prior to setting the defined area alarm.

3. Press the corresponding button for Area Limit .

WARNING

Avoid positioning the boom, attachment, load,

rigging, etc. into the bad area when setting the

left or right alarm points.

When selecting the left and right alarm points,

ensure that the load will maintain a safe

distance from the obstacle. Also ensure that

the two points are set so that the tailswing of

the crane will not enter the bad area.

4. Position the boom, attachment, load, rigging, etc.

to the right alarm point and press the corresponding button to enter the right alarm point. The

displayed value will be the right alarm setting.

5. Position the boom, attachment, load, rigging, etc.

to the left alarm point and press the corresponding

EXIT

SWING ANGLE

97.2

button to enter the left alarm point. The displayed value will be the left alarm setting.

Note: For best results, the two points should be

separated by a minimum of 10 ft (3m) or 30 de-

grees.

6. When both alarm points are set, press the EXIT

button to return to the settable alarms screen.

Press the EXIT button on the settable alarms to return to the normal working screen.

7. Test the alarm, with no load, to ensure the alarm

points have been properly set. When approaching

the plane, the audible alarm will sound intermittently and the message Bad Working Area" will appear on the warning message area. When passing

the plane, the audible alarm will sound continuously and the message Bad Working Area" will appear on the warning message area.

WARNING

If crane or obstacle is moved or if a different

size load is lifted, the area alarm must be

reset.

Note: An alarm icon will appear on the normal working screen to alert the operator that an

operator alarm has been set.

IlIIIIIIlnary

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

15

301-371-6126

Vertlclll Plane

RlahtAiann

Polnt

Figure 1−88

Operator Defined Area Alarm

Working Area

Figure 1−89

MicroGuard 534

Operator's Manual

SkyAzúl, Equipment Solutions

www.skyazul.com

16

301-371-6126

Calibration And Diagnostic Screen

CALIBRATION AND DIAGNOSTICS

A00 B0 C00 D00

ERROR CODES

ENTER CALIBRATION

Message Data Count

System Fault Codes

If faults in the system are detected during a test, the

warning message area will show the words SYSTEM

FAULT. If the words SYSTEM FAULT occur, press the

Display/Select button to display the Calibration And

Diagnostic screen. On the Calibration And Diagnostic

screen, press the Error Code button to display error

codes in the box at the top of the screen. This information can then be used to assist the service technician in

determining the fault. Contact your distributor for assistance with the fault codes.

Calibration

If the system requires calibration, contact you distributor for assistance. Calibration must be done by a qualified technician. Press the Display/Select button to display the Calibration And Diagnostic screen. On the

Calibration And Diagnostic screen, press the Enter

Calibration button. The calibration screen will be displayed and prompt a calibration key sequence to begin

the calibration routine.

SkyAzúl, Equipment Solutions www.skyazul.com 301-371-6126

www.skyazul.com

SkyAzúl, Inc.

16 Walnut Street

Middletown, MD 21769

Phone 301-371-6126

Fax 301-371-0029

info@skyazul.com

Loading...

Loading...