Page 1

TC 9-56

DEPARTMENT OF THE ARMY TRAINING CIRCULAR

SKS RIFLE

SIMONOV TYPE 56

iEADQUARTERS,

DEPARTMENT OF THE ARMY

OCTOBER 1969

Page 2

THE 7.62~MM SIMONOV SEMIAUTOMATIC

CARBINE (SKS)

General

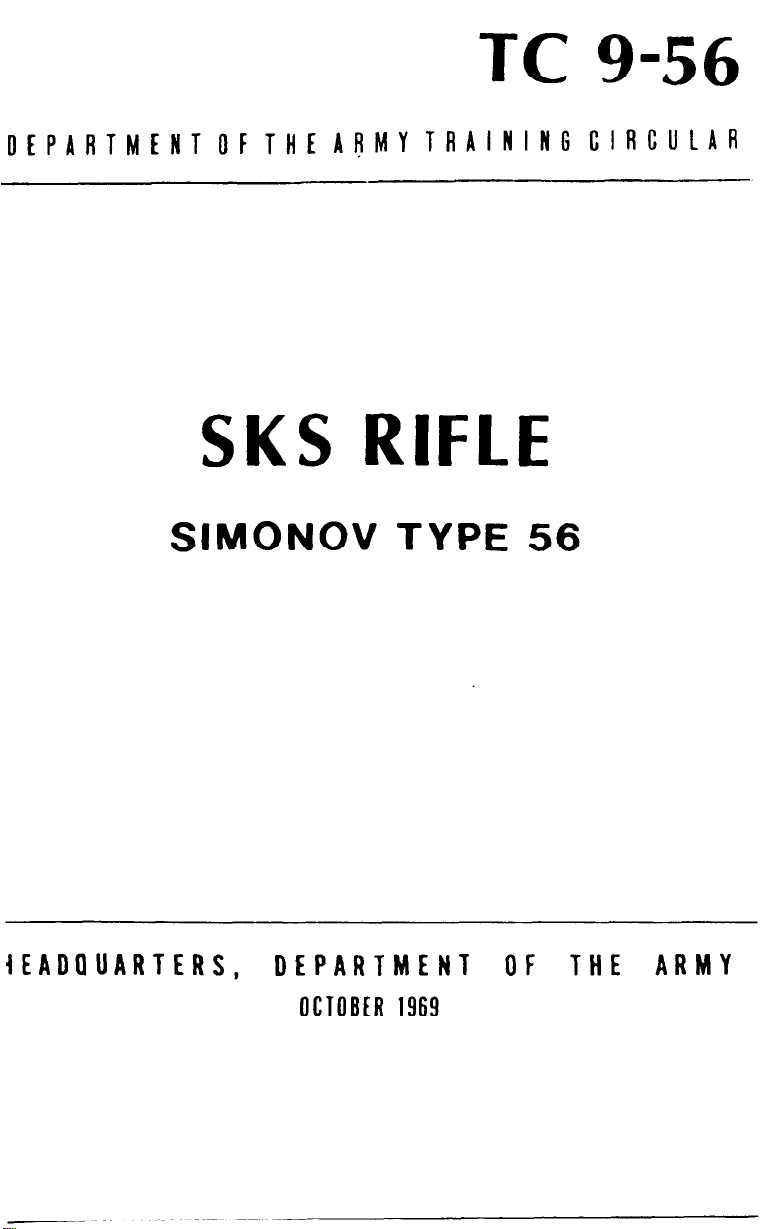

The Soviet-designed Simonov semiautomatic carbine (fig1 ), a

gas-operated, integral box magazine-fed weapon equipped with a

folding blade bayonet, is now obsolete in the Soviet Army, but is

used by most of the other Eurasian Communist countries. This

weapon has been manufactured in East Germany as the

Karabiner-S (fig 2 ),

56 semiautomatic carbine, in North Korea as the Type 63 carbine,

and in Yugoslavia as the M59/66 rifle. The country of origin can

be determined by the markings. The Soviet and East German

weapons usually carry the year of manufacture and the serial

number on the front left of the receiver; the PRC weapons have

the symbol XhA

PRC Type 56 has a spike bayonet. The North Korean weapons

have “63” stamped into the receiver cover. The East German

version has a hole through the stock for attaching the lower end of

the sling; the others all have sling swivels. The Yugoslav M59/66

(fig 3 ! has a prominent spigot-type grenade launcher permanently

attached to the muzzle and a folding grenade launching sight (fig

4 ) at the rear of the launcher.

in the People’s Republic of China as the Type

(Type 56) located there, and the late

OPERATING HANDLE

I

Wu.9. 511396

SAFtlY

Figure 1 . Soviet Simonov semiautomatic carbine (SKS).

Page 3

Figure 2 . East German Karabiner-S.

Figure3 .

Figure 4 .

Technical Data

Technical data concerning the SKS carbine will be found in table

II.

Yugoslav M59/66 rifle.

M59/66 gas cutoff.

Page 4

Operation

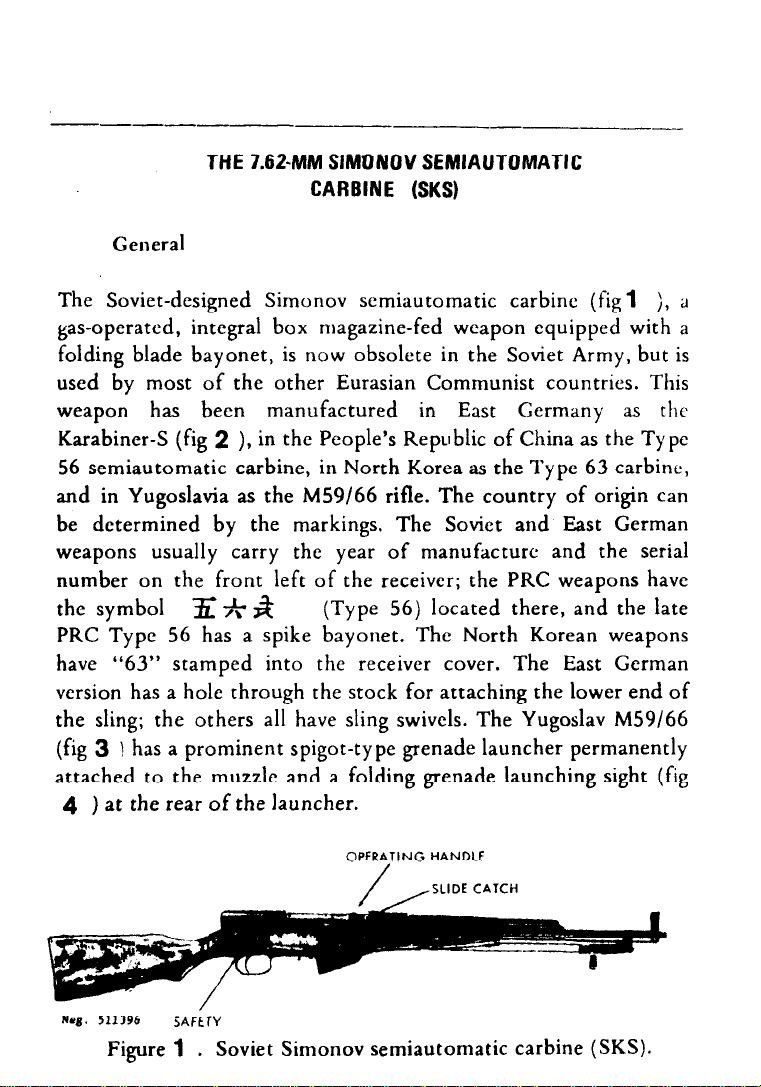

a. Grasp the operating handle (fig 1 ), pull it fully to the

rear, and release it. If the magazine is empty, the bolt will remain

open. Insert a stripper clip into the clip guides at the top front of

the bolt carrier, and with the thumb as close as possible to the

base of the top cartridge, press the cartridges off the clip and into

the magazine (fig 5 ). Remove the empty clip. If clipped

Figure 5 . Loading the SKS.

ammunition is not available, individual cartridges can be placed on

top of the magazine follower and pressed down into the magazine

until it is full. Pull operating handle rearward and release it; the

bolt will run forward and chamber a cartridge.

CAUTION: The rifle is now ready to fire!

3

Page 5

b. If the rifle is not to be fired immediately, apply the

safety (fig 1 ) by rotating it forward and upward.

C.

Set the rear sight for the desired range by depressing the

slide catch (fq 1 )

and moving the sight bar along the leaf until

the front edge of the bar is aligned with the line below the number

that corresponds to the range in hundreds of meters. The first

character on the sight leaf is a battle sight setting that is used in

combat, for shooting at ranges up to 300 meters. The Yugoslav

M59/66 has folddown luminous sights (fii 3 ) for use when firing

under poor light conditions; flip these up for use.

d. The front sight is adjustable for zero.

e. To fire the weapon, rotate the safety rearward until it is

parallel to the trigger; then aim, using a normal sight picture, and

press the trigger. The SKS will fire one shot and reload itself; when

the last round has been fued, the bolt will remain open. (The gas

cutoff of the Yugoslav M59/66 must be turned to the right for the

rifle to function. Press the gas cutoff button (fig 4

) down and

swing to the right).

*

f. To unload or clear the SKS, apply the safety, then pull

back the magazine catch (fig 3 )

and allow the magazine to swing

open. Remove all cartridges and close the magazine. Grasp the

operating handle, pull it fully rearward to eject any cartridge that

might have been in the chamber, and release the handle; the bolt

will remain open. Inspect to insure that no cartridges remain in the

magazine, barrel, or receiver.

Close the bolt, either by opening the

magazine again and pulling rearward on the operating handle and

releasing it, or by pressing the magazine platform down slightly

and pulling the operating handle rearward and releasing it. Move

the safety to the ready position, press the trigger and apply the

safety.

4

Page 6

The SKS bayonet is affixed by forcing the hilt to the

g-

rear (against spring pressure) ‘and swinging the bayonet forward

until it locks to the muzzle. This action is reversed to fold the

bayonet in its stowed position.

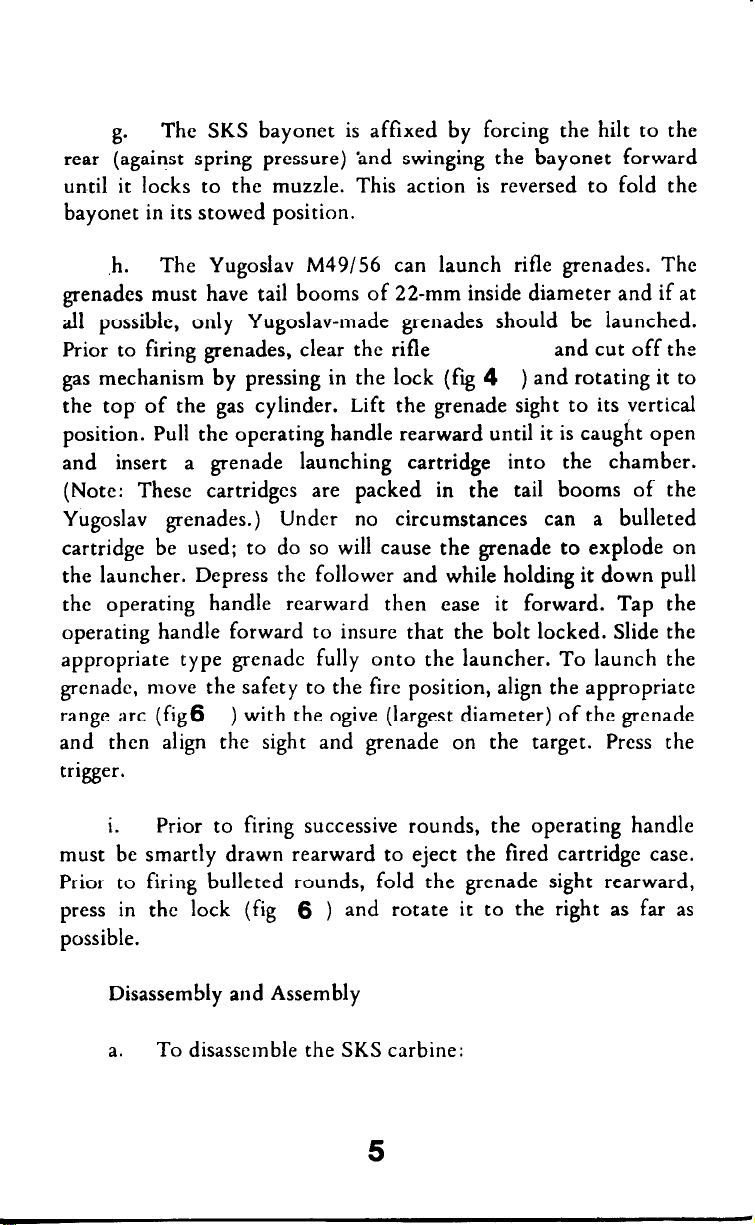

The Yugoslav M49/56 can launch rifle grenades. The

.h.

grenades must have tail booms of 22-mm inside diameter and if at

all possible, only Yugoslav-made grenades should be launched.

Prior to firing grenades, clear the rifle and cut off the

gas mechanism by pressing in the lock (fig 4

) and rotating it to

the top of the gas cylinder. Lift the grenade sight to its vertical

position. Pull the operating handle rearward until it is caught open

and insert a grenade launching cartridge into the chamber.

(Note: These cartridges are packed in the tail booms of the

Yugoslav grenades.) Under no circumstances can a bulleted

cartridge be used; to do so will cause the grenade to explode on

the launcher. Depress the follower and while holding it down pull

the operating handle rearward then ease it forward. Tap the

operating handle forward to insure that the bolt locked. Slide the

appropriate type grenade fully onto the launcher. To launch the

grenade, move the safety to the fire position, align the appropriate

range arc (fig6 ) with the ogive (largest diameter) of the grenade

and then align the sight and grenade on the target. Press the

trigger.

1. Prior to firing successive rounds, the operating handle

must be smartly drawn rearward to eject the fired cartridge case.

Prior to firing bulleted rounds, fold the grenade sight rearward,

press in the lock (fig 6 ) and rotate it to the right as far as

possible.

Disassembly and Assembly

a. To disassemble the SKS carbine:

5

Page 7

Figure 6

(1) Clear the weapon

(2) Press in on the cover in the butt plate until the

combination tool case is ejected. Unlock the bayonet, let it hang

vertically, and after disengaging the head of the cleaning rod from

the front sight base, pull the cleaning rod out of the rifle.

Note: The East German Karabiner-S does not have a combination tool case

in the butt, nor does it have a cleaning rod; these are carried separately.

(3)

Rotate the receiver cover pin (fig 2 J to a vertical

position and pull it out as far as possible.

M59/66 grenade sight erected.

6

Page 8

Note: It may be necessary to pry the receiver cover pin handle away 1;onl

the receiver before it can be rotated.

Remove the rcceivcr cover to the rear and pull the driving spring

assembly out of the bolt carrier.

(4) Open the magazine by pulling the magazine catch

(fig 3 ) to the rear. Pull the operating handle fully rearward, and

lift the bolt carrier and bolt out of the receiver. Separate the bolt

from the bolt carrier.

(5) Rotate the gas cylinder tube lock (fig 2 ) to its

uppermost position and lift the rear of the handguard to remove

the gas cylinder tube and the gas piston. The tube can be upended

and the piston will slide out.

Figure 7 .

(6) If necessary,

dcprcssing the catch located behind the loop of the trigger guard

and pulling the trigger group down and out of the rifle. The safety

must be in the safe position before the catch can be depressed.

(7) No further disassembly is necessary or desirable.

SKS field stripped.

the trigger group can be removed by

7

Page 9

To rcasscmblc the wc;~pon, follow the proccdurc listed

b.

below:

(1) Invert the rifle and engage the pins at the front of

the trigger group with the notches behind the magazine box.

Swing the trigger group into position in the stock and seat it by a

blow of the hand on the loop of the trigger guard. Move the safety

to the fire position to insure that the catch is fully engaged.

(2) Slide the gas piston,

cylinder tube; fit the large end of the tube over the gas cylinder

(fig 2 ). Swing the rear end of the gas cylinder tube into the rear

sight base and turn the gas cylinder lock downward.

(3) Place the bolt into the receiver, with the extractor

to the right front,

three-eights of an inch from the inner rear wall of the receiver. Lay

the bolt carrier on the bolt and while pressing down on the carrier,

move it slightly back and forth until it mates with the bolt. Slide

the bolt and bolt carrier fully forward in the receiver. Insert the

driving spring assembly, stepped end first, into the bolt carrier.

(4) Insure that the receiver cover pin is pulled fully out

to the right, then slide the receiver cover into place from the rear.

Secure it with the receiver cover pin and rotate the pin down to

the locked position. Close the magazine, and replace the cleaning

rod and the combination tool case.

Functioning

and position the rear of the bolt about

small end first, into the gas

1

The SKS semiautomatic carbine is gas operated (fq

a.

8 ). After the SKS has been loaded, pressure on the trigger

releases the hammer, which impacts against the firing pin, firing

the rifle. The propellant gases drive the bullet through the barrel,

8

Page 10

and after the bullet passes the gas port, some of the gases are

tapped off and directed against t’he piston head.

b. The propellant gases drive the piston and operating rod

rearward against the bolt carrier.

This forces the carrier and the

hammer rearward and compresses the driving and hammer springs.

After the bolt carrier moves rearward about one-fourth inch, a

cam on the inner top of the bolt carrier (6, fig 8 ) contacts a

projection on the top rear of the bolt and lifts the rear of the bolt

up and out of its seat in the receiver. The disconnector, which has

been held down by the bolt, now rises. The bolt and bolt carrier

now travel rearward as a unit, while the piston is returned forward

by the spring. The extractor withdraws the fired cartridge case

from the chamber and holds it to the bolt until the case strikes the

ejector and is expelled. The rear end of the bolt carrier

fixed

strikes the inner wall of the receiver, and all rearward movement

then terminates.

The driving spring expands and forces the bolt and bolt

C.

carrier forward; the bolt drives the top round out of the magazine

and into the chamber. When the cartridge is fully seated in the

chamber, the extractor snaps into the groove of the cartridge, and

forward movement of the bolt ceases. The bolt carrier still has a

short distance to travel, and as it does, cams the rear of the bolt

down into its seat in the receiver; the bolt, as it scats, forces the

disconnector down. All forward movement terminates when the

bolt carrier strikes the receiver.

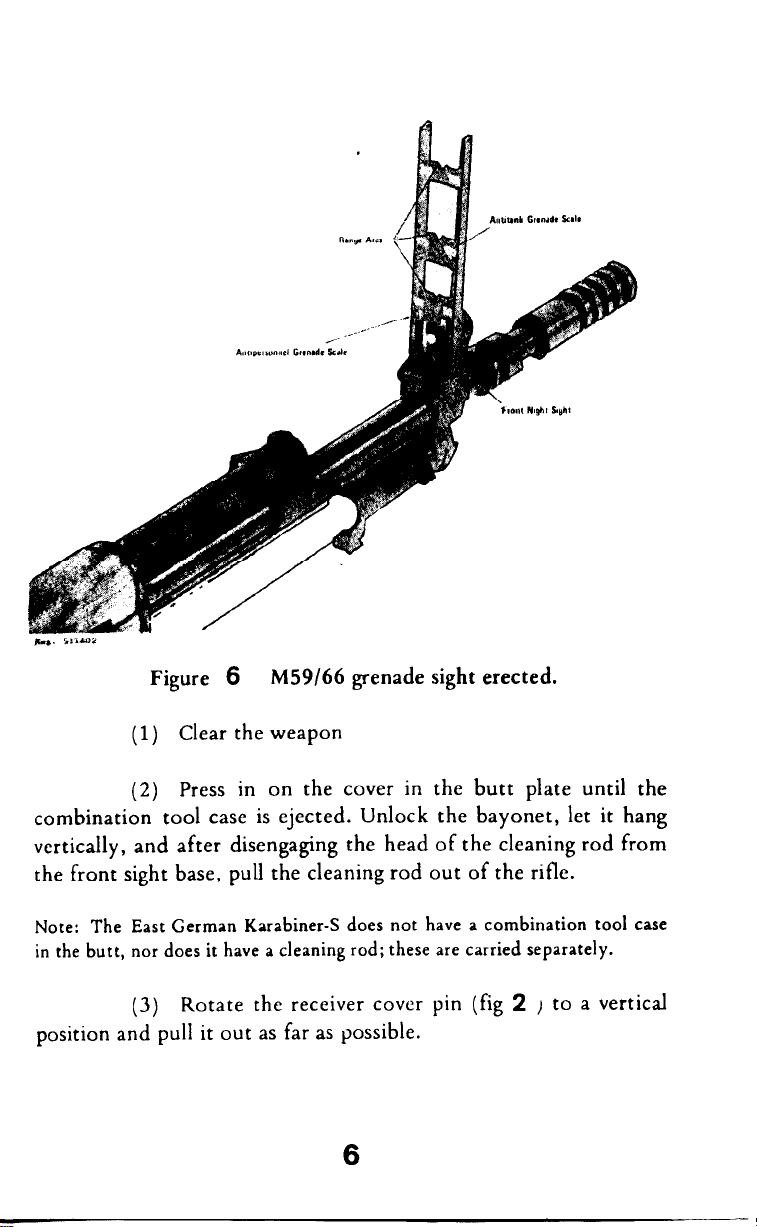

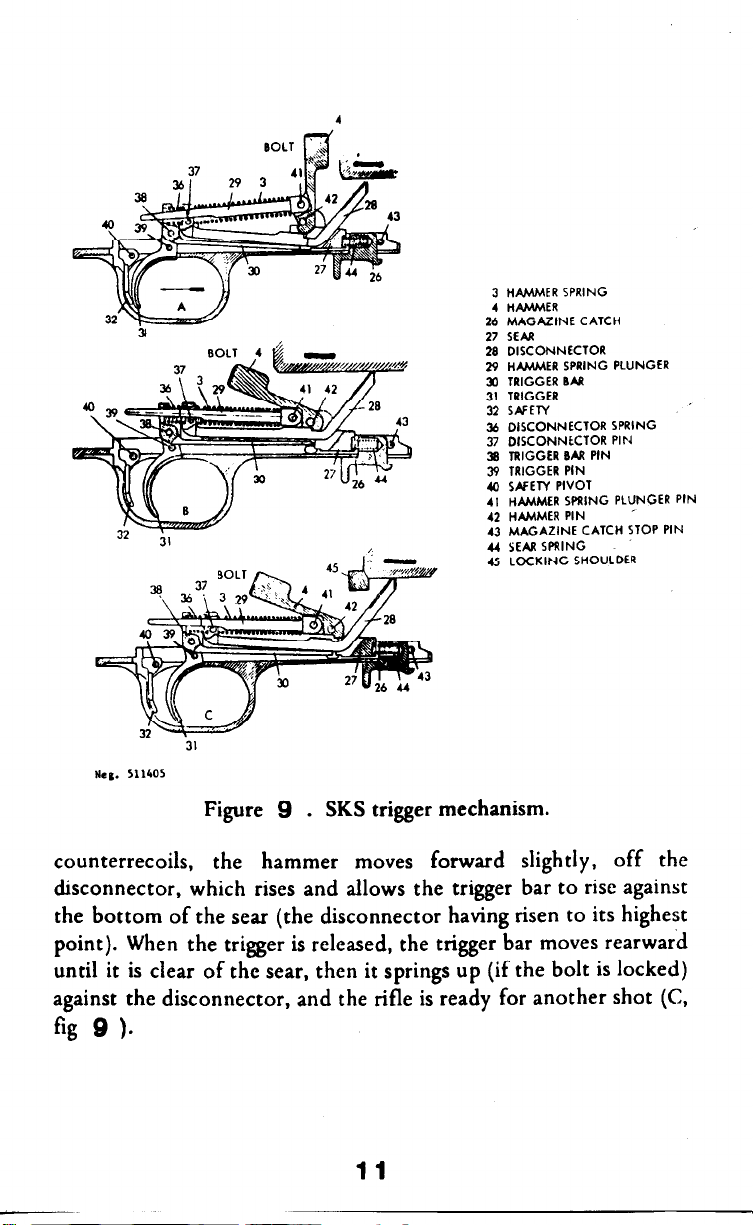

d. The SKS has a complicated trigger mechanism (fig 9 ).

The hammer is cocked by the recoiling bolt and is held cocked by

a sliding sear.

The sear is disengaged from the hammer by a

spring-loaded trigger bar pivoted to the top of the trigger. The

vertical alignment of the trigger bar is controlled by the

disconnector; this, when depressed by the locking of the bolt,

9

Page 11

1

BOLT COVER

2

DRIVING SPRING

3 HAMMER SPRING 26

4 HAMMER

5

BOLT CARRIER

6

LOCKING CAM

7

LAST ROUND STOP

8

BOLT

9 TAPPET

10 TAPPET RETURN SPRING

11

HANDGUARD

23 FOLLOWER SPRING

24

FOLLOWER ARM

25

FOLLOWER

MAGAZINE CATCH

27

SEAR

28

DISCONNECTOR

29

HAMMER SPRING PLUNGER

30

TRIGGER BAR

31

TRIGGER

32

SAFETY

33

LATCH

34

STOCK

36

DISCONNECTOR SPRING

Neg. 511404

Figure 8 . SKS section.

presses down on the trigger bar and thus aligns the trigger bar and

scar. Prcssurc on the trigger will force the trigger bar to move

forward and disengage the scar from the hammer. The hammer

swings forward to fire the rifle (A, f’ig 9 ), and as it does, a cam

on the bottom of the hammer dcprcsscs the disconnector, which

in turn dcprcsses the trigger bar below the scar. The scar spring

forces the sear back against the harnnrer.

C.

When the hammer is rocked back by the bolt, it strikes

the disconnector and depresses it.

The disconnector insures that

the contact bctwecn the trigger bar and the sear is broken by

depressing the trigger bar

(B, fig 9 ). When the bolt

10

Page 12

3 HAMMER SPRING

4 HAMMER

26 MAGAZINE CATCH

27 SEAR

28 DISCONNECTOR

29 HAMMER SPRING PLUNGER

30 TRIGGER BAR

31 TRIGGER

32 SAFETY

36 DISCONNECTOR SPRING

37 DISCONNECTOR PIN

38 TRIGGER 8M PIN

39 TRIGGER PIN

40 SAfEW PIVOT

4, HAMMER SPRING PLUNGER PIN

42 HAMMER PIN _

43 MAGAZINE CATCH STOP PIN

U SEARSPRING

45 LOCKING SHOULDER

SKS trigger mechanism.

counterrecoils,

Figure 9 .

the hammer moves forward slightly, off the

disconnector, which rises and allows the trigger bar to rise against

the bottom of the sear (the disconnector having risen to its highest

point). When the trigger is released, the trigger bar moves rearward

until it is clear of the sear, then it springs up (if the bolt is locked)

against the disconnector, and the rifle is ready for another shot (C,

fig 9 1.

11

Page 13

f. The disconnector (B, fig 9 ) prevents the rifle from

firing if the bolt is not fully lockcc!. It does this in two ways: by

its control of the position of the trigger bar; and by a notch in the

disconnector, which intercepts the scar notch of the hammer if the

disconnector is not fully dcprcsscd, such as when the bolt is not

fully lock&

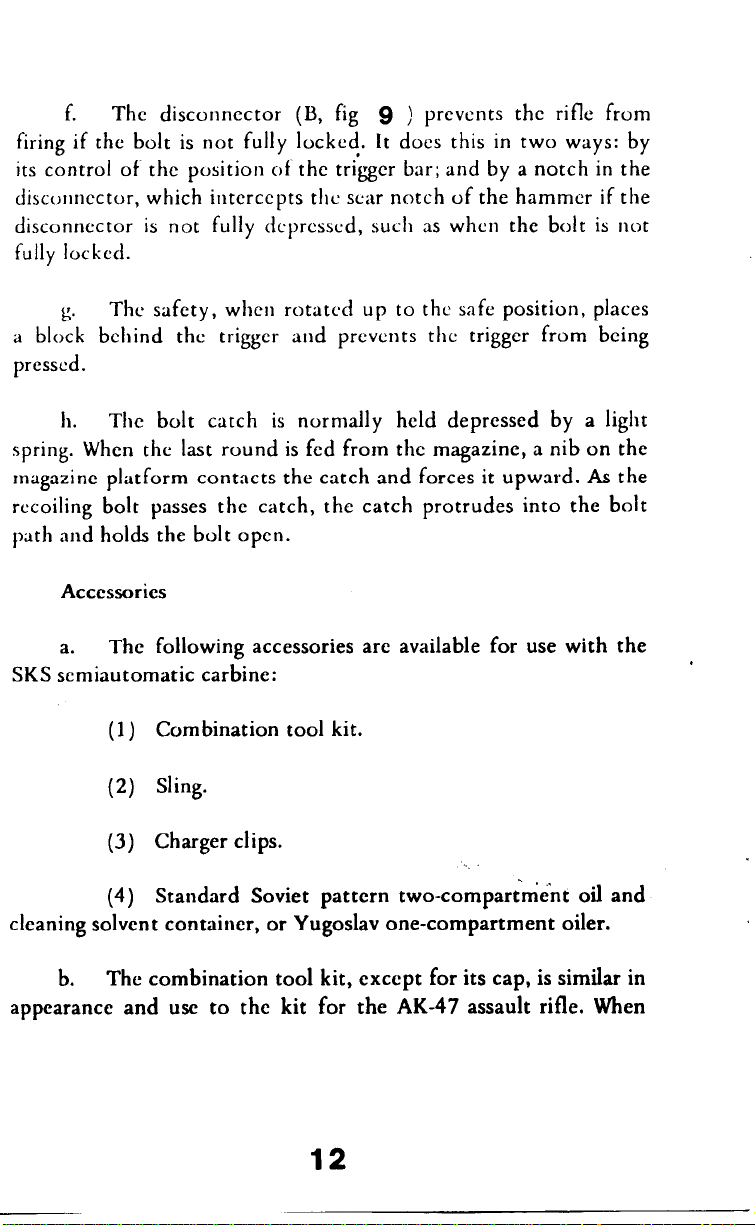

The safety, when rotated up to the safe position, places

6.

a block behind the trigger and prevents the trigger from being

pressed.

h. The bolt catch is normally held depressed by a light

spring. When the last round is fed from the magazine, a nib on the

magazine platform contacts the catch and forces it upward. As the

recoiling bolt passes the catch, the catch protrudes into the bolt

path and holds the bolt open.

Accessories

The following accessories arc available for use with the

a.

SKS semiautomatic carbine:

(1) Combination tool kit.

(2) Sling.

(3) Charger clips.

‘..,

(4) Standard Soviet pattern two-compar;;n’&t oil and

cleaning solvent container, or Yugoslav one-compartment oiler.

The combination tool kit, except for its cap, is similar in

b.

appearance and use to the kit for the AK-47 assault rifle. When

12

Page 14

used as a cleaning rod guide, the cap is twisted into engagement

with

the front sight base.

C.

The stripper clips are used to charge the rifle’s magazine.

Each holds 10 cartridges.

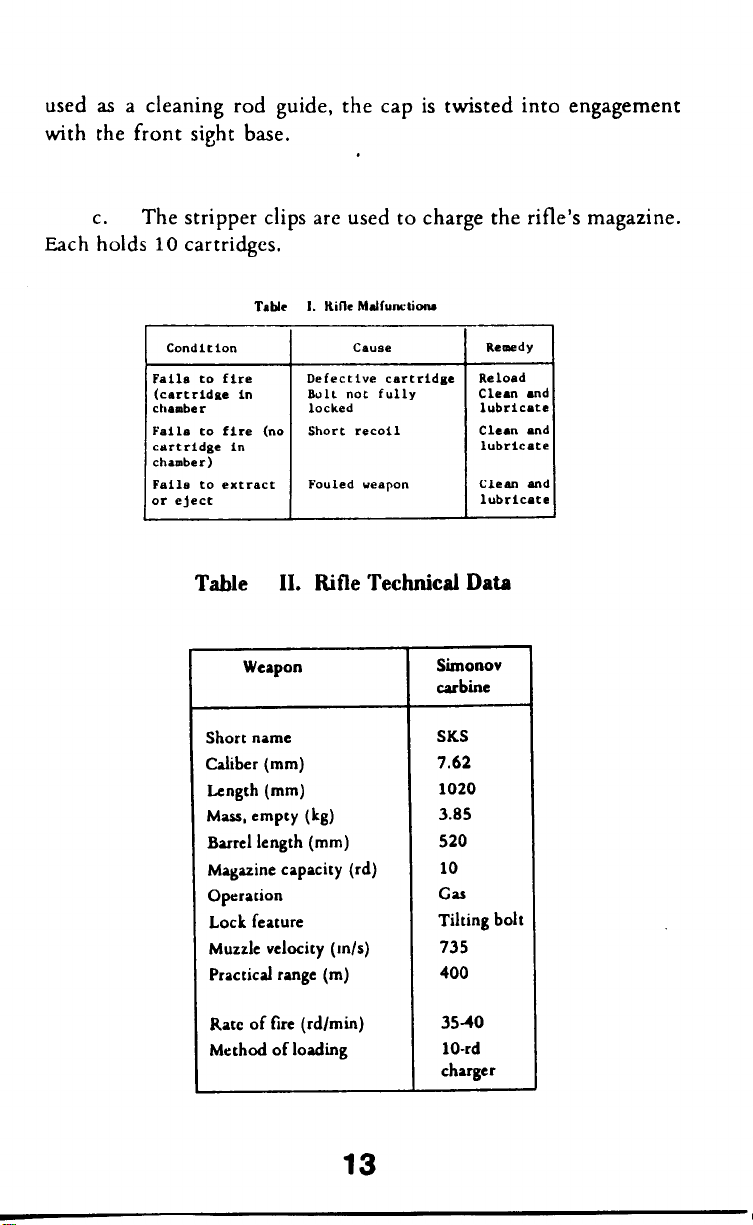

Condition

Defective cartridlc

BolL not fully

locked

Fails to fire (no

cart ridge in

Short recoil

Feile to extract

Fouled weepon

Table II. Rifle Technical Data

Weapon

Short name

Caliber (mm)

Length (mm)

~w, empty (kg)

Barrel length (mm)

Magazine capacity (rd)

Operation

Lock feature

Muzzle velocity (m/s)

I Practical range (m)

Rate of fire (rdlmin)

Method of loading

Simonov

carbine

SKS

7.62

1020

3.85

520

10

Gas

Tilting bolt

735

400

35-40

lo-rd

charger

13

Page 15

FURFQSEANDSCOPE

I.

This manual will provide information to the user which will

allow proficiency training in the use and care of the Simonov

Type 45, or the PRC Type 56 rifles. The information contained

within this report will apply to either type rifle and where

differences occur you will find notation to that effect.

CONDITIONS OF PERFOF!M?WCE

II.

You will be given a Simonov type rifle, ten rounds of 7.62X39MM

ammunition,

an inert round, a striper clip, and a combination

tool kit.

Within the limitations given in performance standards below,

adjust, load, fire, reduce a stoppage, unload, and clear the

weapon.

IV. PB

Adjust, load and fire the weapon.

A.

____________________-____--------___--____---______----------_-

(See fig. 1.)

FIGURE 1

-----------------------====------==============================

1.

Adjust:

Adjust rear sight:

a.

Depress slide catch.

1.

(See fig. 2.)

2. Slide sight carrier along the leaf until

front edge of bar aligns with line below

the number that corresponds to specified

range in hundreds of meters (100-10000.

14

Page 16

FIGURE 2

Is.

Adjust rear sight:

1.

Slip combination wrench over the front sight

post.

strike of the bullet;

to lower the strike of bullet.

(See fig. 2.)

Turn ,post clockwise to raise the

turn conterclockwise

2.

Remove tool from sight post.

2.

Loac' within 20 seconds:

a. Rotate safety for$?ard

this will be p'arallcl

Pull operatin:! handle

b.

into the "safe" position

with the stock.

back and release it.

If the magazine is empty, the bolt will

remain open.

Insert a stripper clip into the clip guides at

C.

the front of the bolt carrier.

d. Press cartridges off the clip and into the

magazine, (the thumb should be as close to the

face of the clip as possible).

e.

Remove empty clip.

NOTE:

IF CLIPPED AM!40 IS YoT AVAILABLE, INDIVIDUAL ROUNDS XAY

BE PLACED ON TOP OF THE XAGAZTPJE FOLLOWER AND PRESSED DoW?'J INTO

THE YAGAZILJE UNTIL IT IS FUJA.

15

Page 17

Pull operating handle back and release it.

f.

(Dolt will go forward and chamber a round).

3. Fire within 5 seconds: ,

a. Rotate the safety selector to the rear until

it is pointed full down and is against the

rear of the trigger guard. ("FIRE" position).

b.

Aim and fire.

The bolt will remain closed

between rounds and open after the last round.

4. IMMEDIATE ACTION TO: Reduce stoppage.

a. When rifle fails to fire, pull the operating

handle back to eject bad round, watch for

ejection, release handle to chamber new round.

Aim and atempt to fire.

b.

If immediate action fails to reduce stoppage,

C.

unload, clear, disassemble, and inspect.

Repair or replace defect and reasemble.

5. UNLOAD AND CLEAR WEAPON:

Place weapon on "SAFE".

a.

Pull back magazine catch and allow magazine to

b.

swing open.

C.

Remove all cartridges

d.

Close the magazine.

e.

Pull operating handle

to the rear to eject any

remaining rounds.

Release the handle (bolt will remain open).

f.

Inspect to insure no cartridges remain in the

g.

magazine, chamber, or receiver.

Close bolt:

h.

Open magazine again and pull operating

1.

handle to rear and release.

2. Pull operating handle to the rear, press

down on the magazine follower slightly,

then ease bolt carrier forward.

16

Page 18

1.

'

Move safety td "FIRE" position.

Press trigger.

j.

-~------~~---~~~-----~~---~-~~------_----~~---~~~-----~----~---

____-----------------------------------------------------------

---__-----_-----___---~------~__---___----_---_~~---~~~-----~~-

--~__--------~--__---~~----__-------------_---~_~--____~---_~~-

k. Place weapon on "SAFE".

17

Page 19

You will learn disassembly, cleaning, reassembly of the weapon

within 35 minutes.

You will also learn ammunition maintainence

and to perform a function check.

CONDITION OF PERFORTUNCJZ

VI.

You will be given an SKS rifle,

a cleaning rod and combination

tool kit, 10 rounds of 7.62 X 3MM ammunition, a wire bore

brush, chamber brush, and toothbrush, rifle bore cleaner, lube

solvent, cleaning patches, and clean rags.

oil,

VII. PERFOEMANCE

Disassemble weapon within 2 minutes.

---------_------------__-___----____---------~~~~~~~~~-_____-~~~

____-________________------__-------_--____--

A.

-., 1

I I

\-

Rifle SKS Soviet

Gas cylinder

1.

Bolt carrier

2.

Gas piston

Gas piston extension & sp-ing

Z:

Bolt

5.

===================================___--------_-_--------

;:

8. stock

9.

10.

----___-------_______------~

18

Receiver cover

Barrel & receiver

Magazine

Trigger group

__----

Page 20

Insure weapon is clear and on "SAFE".

1.

Remove recoil spring assembly:

2.

a. Rotate the receiver cover retaining pin

to the vertical position and pull to the

right.

b.

Remove the receiver cover by sliding it

to the rear and lifting off.

c. Pull the recoil spring assembly from the

bolt carrier.

3. Remove the bolt and carrier.

a.

Pull operating handle to the rear.

b.

Lift the bolt and bolt carrier out of

the receiver.

4.

Separate the bolt from the carrier.

5.

Remove the gas cylinder and piston:

a.

Rotate the gas cylinder tube lock until

the handle is at a 45 degree angle to

the rear.

~_ ~__ ~

b.

Lift the rear of the handguard to remove

the gas cylinder tube and gas piston.

c. Lower front end of tube and allow piston

to slide out.

6. Remove gas piston extension and spring:

a.

Place thumb in front of rear sight base.

b. Rotate gas cylinder tube lock slowly

forward.

C. Remove and separate piston extension and

spring.

7.

Remove trigger group:

a. Insure weapon is on "SAFE".

b.

Push in on trigger group retaining lock.

c. Pull trigger group up and out.

19

-

Page 21

Remove magazine by pulling up and out.

a.

e. Unlock bayonet and separate barrel from

the stock.

Identify weapon parts.

B.

Cleaning and maintainance.

C.

Reassemble weapon within 4 minutes:

D.

Attach barrel to stock, and

1.

(See fig 2).

into closed position.

Replace magazine into stock

2.

open.

Replace trigger group:

3.

a. Invert rifle and engage

front of the trigger group (notches

must be behind the magazine box).

b. Swing trigger group into position in

the stock (seat it by a hand blow on

the loop of the trigger guard).

c. Move safety to "FIRE" position to

insure catch is fully engaged.

Replace gas piston extension and spring:

4.

a. Place gas piston extension and spring:

(See page 22).

lock bayonet

leaving it

pins at the

Hold gas tube lock in vertical position.

b.

C. Insert gas piston extension with spring

back into it's recess in front of the

rear sight.

d. Push back into recess until it can be

locked into place.

e. Dock by rotating gas tube lock 45 degree

angle to the rear.

Replace gas cylinder tubs and piston:

5.

a. Slide gas piston, small end first, into

the front of the gas tube.

20

Page 22

b.

Fit large end of gas tube over the gas

cylinder block on barrel.

C. Swing rear end of gas cylinder tube into

rear sight base.

d.

Turn gas cylinder lock down into the

detent.

6.

Replace bolt and carrier:

a. Connect bolt and carrier together and

place bolt and carrier into the receiver.

b.

Push down and forward all the way to seat.

7.

Replace recoil spring assembly:

a.

Insert recoil spring assembly, curled end

first, into bolt carrier.

b. Pull receiver cover pin fully to the right.

Slide receiver cover into place from the

C.

rear.

d. Secure cover with receiver cover pin.

e. Rotate pin down to locked position.

8.

Close magazine.

VII. P-~IONCHlXKWI'lWIN20SECONDS.

Pull operating handle to the rear and hold it.

1.

2.

Press down on magazine follower.

3.

Allow bolt to go forward.

4.

Place safety lever on "SAFE".

5.

Press trigger (harmwar should not go forward).

6. Place safety lever on "FIRE".

7.

Press trigger (hamner should go forward).

21

Page 23

Ix. CL-THE-.

Use rifle bore cleaner (RRC) to clean the

1.

face of the slide.

2. Clean the bore and chamber by:

Wetting a patch with Rl3C and running it

a.

back and forth through the bore several

times.

b. Attach a bore brush to the cleaning rod

and run

several

it through the bore and chamber

times.

c. Run dry patches through the bore and

chamber until they come out clean.

d. Inspect

bore for fouling and residue.

If it is not clean, repeat the above

cleaning process.

Clean the other parts with RBC or a cleaning

3.

solvent to remove all grease, dirt, or

powder fouling.

Soak small parts in cleaning

solution.

Dry the parts using clean, dry rags.

4.

Cover all parts with a light coat of oil.

5.

22

Loading...

Loading...