Page 1

TMEF Series

User Manual

MAN10132 Rev. 1.0 Oct. 2010

SKOPE Vertical Freezer

Page 2

TMEF Series

SKOPE Vertical Freezer

Type: (CAREL ir32 Controller)

User Manual

MAN10132

Rev. 1.0 Oct. 2010

© 2010 SKOPE Industries Limited. All rights reserved.

SKOPE Industries Limited reserve the right to alter specifications without notice.

is a registered trademark of SKOPE Industries Limited.

SKOPE INDUSTRIES LIMITED

Head Office

PO Box 1091, Christchurch

New Zealand

Freephone: 0800 947 5673

Fax: (03) 983 3896

E-mail: enquiry@skope.co.nz

Website: www.skope.co.nz

Trademark Infringement

The SKOPE trademark on this product is infringed if the owner, for the time

being, does any of the following:

• Applies the trade mark to the product after their state, condition, get-up or

packaging has been altered in any manner

• Alters, removes (including part removal) or obliterates (including part

obliteration) the trade mark on the product

• Applies any other trade mark to the product

• Adds to the product any written material that is likely to damage the

reputation of the trade mark

Notice of the above contractual obligations passes to:

• Successors or assignees of the buyer

• Future owners of the product

Page 3

SKOPE TMEF Series

User Manual

iii

CONTENTS

1 Installation

Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Positioning the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Before Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Cabinet Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2 Operation

Automatic Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Loading Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

CAREL Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controller Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Alarms and Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Manual Defrost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Continuous Refrigeration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Display Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Buzzer Off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Parameter Modification (if keypad is enabled) . . . . . . . . . . . . . . .12

3 Servicing

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Interior Side Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Centre Pillar Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 4

4

Installation

User Manual

SKOPE TMEF Series

1 Installation

Safety First Always observe safety precautions when using any electrical appliance.

Read these instructions carefully and retain them for future reference.

When the appliance is used by or near young children or infirm persons,

close supervision is necessary, especially to ensure children do not play

with it.

Do not use this appliance for other than its intended use.

Do not cover the grilles or block the entry or exhaust of airflow by

placing objects up against the refrigeration freezer unit.

Do not probe any opening.

Only use this appliance with the voltage specified on the cabinet rating

label affixed to the refrigeration unit.

Ensure the freezer has adequate ventilation as this is essential to

economical, high performance.

Be careful not to touch moving parts and hot surfaces.

For your own safety and that of others, ensure that all electrical work is

done by authorised personnel.

If the power supply flexible cord becomes damaged, it must be replaced

by an authorised service agent or similarly qualified person in order to

avoid a hazard.

Ensure all necessary safety precautions are observed during installation

or removal of the refrigeration unit.

The freezer is not designed to be stable while in motion. Use extreme

caution when moving or transporting the freezer.

WARNING

The TMEF1500 (3 door) freezer has two seperate power

supplies.

CAUTION

Always isolate the cabinet from the power supply before

attempting any maintenance.

CAUTION

Never overload the power supply, which could damage the

chiller and product. See the rating label inside the cabinet for

the safe power supply and current draw.

Page 5

5

SKOPE TMEF Series

Installation

User Manual

Positioning the Cabinet

Before

Operating

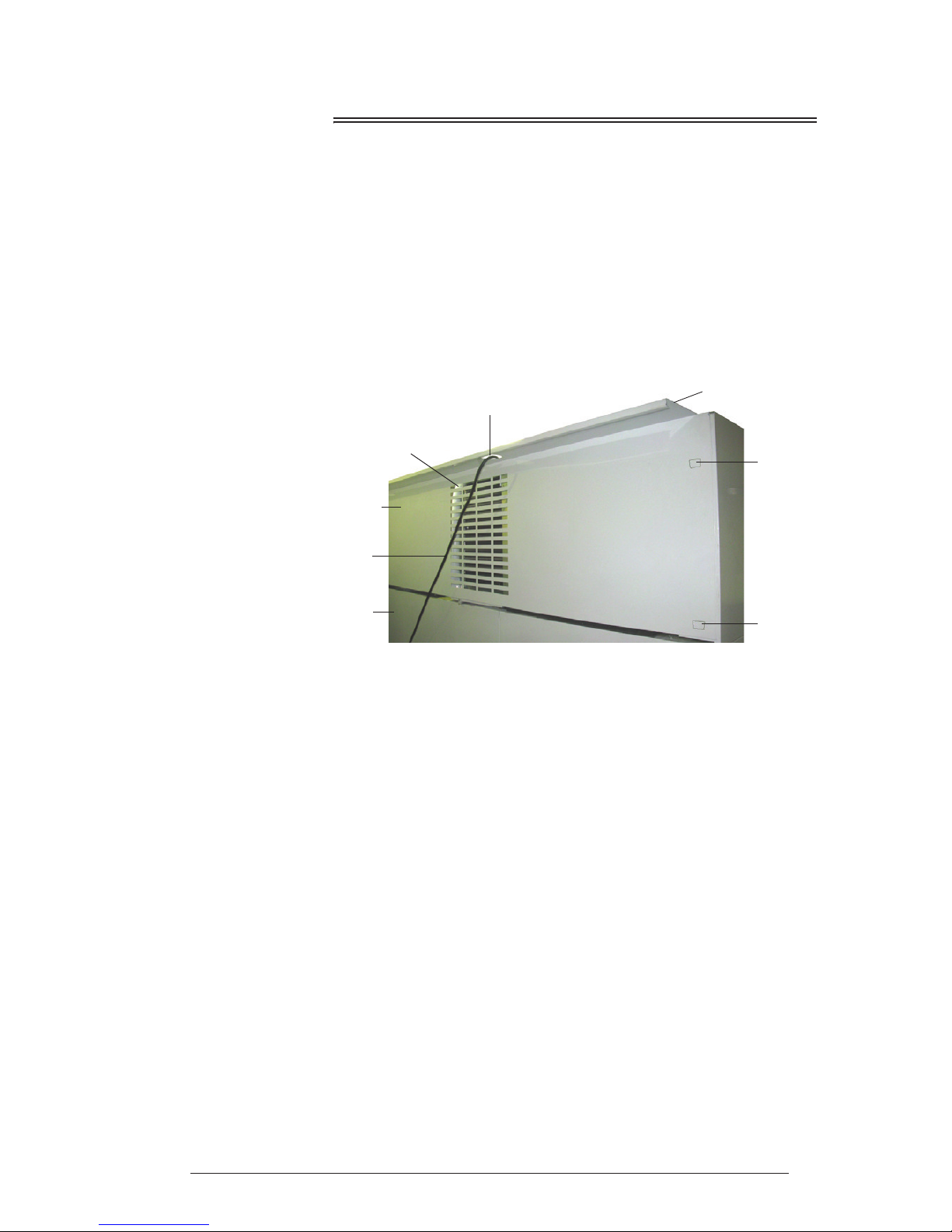

Follow the below steps to ensure the back sign panel is reversed and the

rear spacer is protruding from the back of the cabinet (TMEF1500 3 door

cabinet only). This will provide the necessary air gap at the rear of the

cabinet for correct operation.

1. Cut the cable ties securing the sign back panel to the sign side panels.

2. Reverse the sign back panel so that the rear spacer protrudes from the

rear of the cabinet, and attach the sign back panel to the cabinet by

hooking into the slots on the sign side panel ends.

3. Retrieve and unravel the power cords and fit through the exit holes on

top of the rear spacer.

Power Cord The freezer has a flexible power cord fitted with a 3-pin plug, which exits

from the top rear of the cabinet. Pull the power cord around so that it’s not

trapped before you position the cabinet.

Note: The TMEF1500 (3 door) freezer has two power cords, one for each

refrigeration unit.

Cabinet

Location

The location of the freezer may be the single most important decision that

will extend its life and ensure economical, high performance. We

recommend that you put the freezer in the coolest place possible because it

will use less power and last longer.

Avoid direct sunlight, warm draughts etc. Allow adequate space for doors to

open and close properly. Self-closing doors have internal torsion bars

pretensioned at the factory, and must be unobstructed. Ensure the cabinet

sits on a level surface so that the doors shut and correctly seal. Level footing

also prevents the condensate tray from overflowing.

Power Cord

Rear Spacer

Power Cord Exit Hole

Sign Back Panel

Back of Cabinet

Hanging

Hook/Slot

Hanging

Hook/Slot

Ventilation Slots

Page 6

6

Installation

User Manual

SKOPE TMEF Series

Ventilation Adequate ventilation is essential:

Ensure the is a minimum of 200mm of space above the cabinet and

100mm behind the cabinet.

Air onto the refrigeration unit should not exceed 25°C.

Do not cover any ventilation holes on the front and back of the freezer.

Ensure there is always at least a 200mm gap above the cabinet, and when

installing a TMEF1500 (3 door) cabinet a 100mm gap behind the cabinet

(see below). Keep the ventilation slots at the top of the cabinet clear at all

times, never store cardboard cartons or other objects on top of the freezer.

Shelves

Shelves may be positioned at different heights to suit various products.

Always ensure that the shelf clips are securely engaged in each of the shelf

support strips. Support strips are marked ‘+’ for easy location of shelf clips.

TMEF650/1000

TMEF1500

200mm min

200mm min 100mm min

Page 7

7

SKOPE TMEF Series

Operation

User Manual

2 Operation

Automatic Start-Up

After the cabinet has been positioned in a suitable place, plug it in and check

the following activity.

Loading Product

Let the freezer run 30 minutes before loading it with product the first

time.

Allow adequate air space around each item to ensure even cooling and

efficient operation of the chiller.

Do not exceed a maximum load of 20kg per shelf.

Leave airspace of at least 75mm (3”) above the product on the top shelf.

Do not cover air outlet at the bottom of the cabinet with product as this

may cause spot freezing of products and other products to be warm.

Remove some product if the shelves are flexing.

Do not let anything overhang the shelves because this might stop the

doors from shutting or even break something.

Item Activity

Condenser Fan

The condenser fan runs continuously throughout all

operations of the machine.

Lighting

The sign and interior lights turn on and stabilise after a few

flickers.

Electronic

Controller

An electronic controller runs the chiller and is visible

behind the front panel. The display panel first shows - - before stabilising on the cabinet temperature.

Compressor

The compressor starts about one minute after the lights go

on. The compressor should switch off when the cabinet

internal air reaches the preset ‘set point’ temperature.

Evaporator Fan

The evaporator fan which circulates the cabinet air will not

operate until the defrost probe senses a temperature of

-8°C. On initial start up the fan should come on after a

delay of approximately four minutes (verified by air blowing

out of the bottom duct and the green LED.

Page 8

8

Operation

User Manual

SKOPE TMEF Series

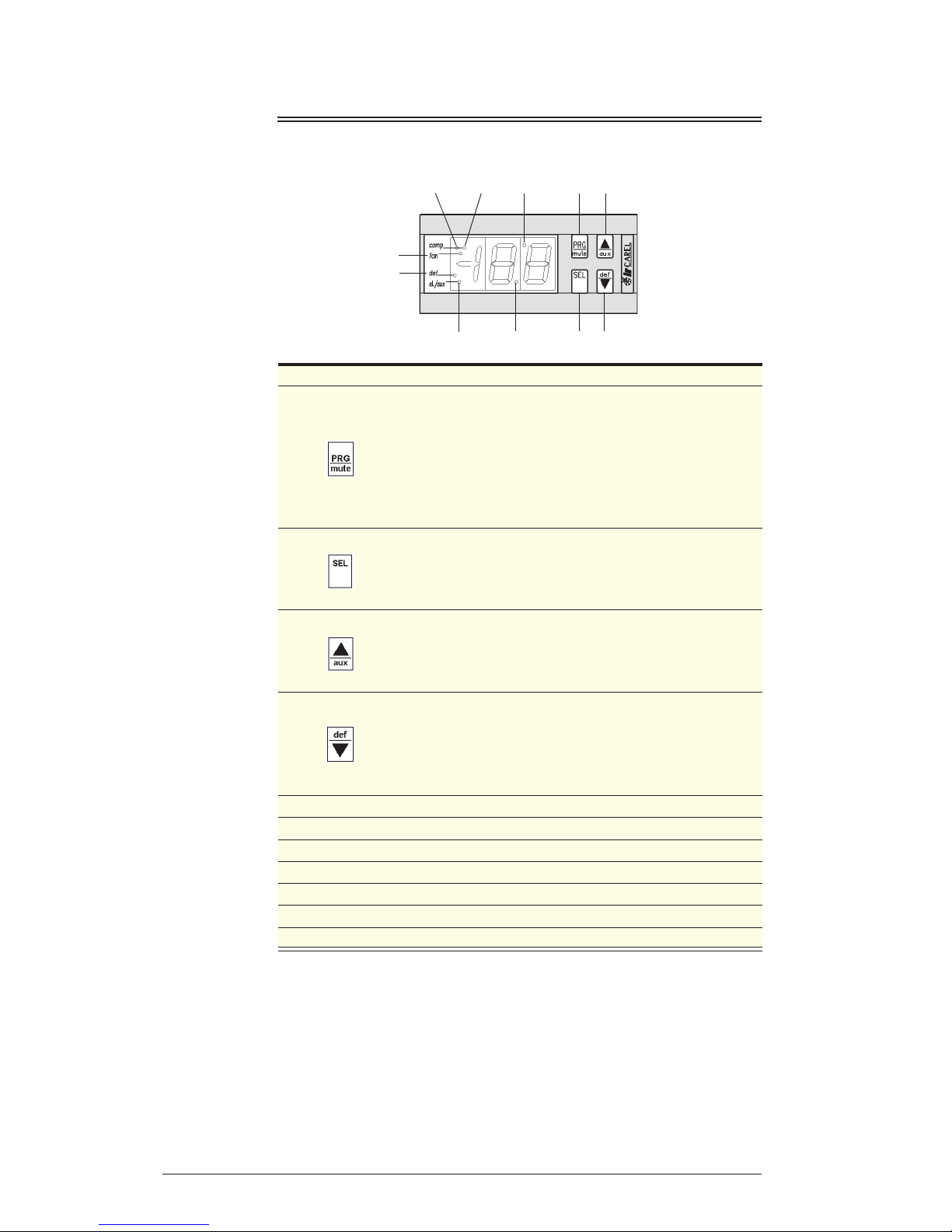

CAREL Electronic Controller

Faceplate

8

7

9

10

11

1 3

6

5 2

4

No. Item Description

1

Silences alarm buzzer.

Allows entry to frequent parameters section, if pressed for 5

seconds.

Allows entry to configuration parameters section, if pressed

simultaneously with ‘SEL’ for 5 seconds.

Locks in new parameters, and exits parameter sections.

Activates reset procedure.

2

Displays setpoint in run mode.

Displays selected parameter in parameter mode.

Allows entry to configuration parameters section if pressed

simultaneously with ‘PRG’ for 5 seconds.

3

Adjustment locked out

Alters parameters in parameter mode.

Activates and deactivates continuous refrigeration mode with ‘def’

key.

4

Adjustment locked out

Activates manual defrost cycle.

Alters parameters in parameter mode.

Activates and deactivates continuous refrigeration mode with ‘aux’

key.

5 Decimal point indicator.

6 Unused.

7 Defrost cycle on indicator

8 Evaporator fan on indicator.

9 Continuous refrigeration mode on indicator (fast freeze).

10 Compressor on indicator.

11 Remote controller indicator.

Page 9

9

SKOPE TMEF Series

Operation

User Manual

Operation The operation of this cabinet is controlled by a pre-programmed

microprocessor. The Microprocessor display indicates the temperature of

the cabinet ambient probe, except during a defrost where the temperature

of the cabinet probe is locked in, and during an alarm condition.

The display also has LED indicators showing the activation of the

compressor, the fan and the defrost. At alarm activation, the display

indicates the type of alarm signal; and an audible alarm sounds. The alarm

can be muted at the controller.

Controller

Components

A controlling probe located in a thermal mass inside the evaporator box,

called a ‘Cabinet Ambient Probe’.

An evaporator probe located within the evaporator coil, referred to as a

‘Defrost Probe’.

Defrost The first defrost will occur in 6 hours. During a defrost cycle (indicated by the

green defrost LED on the control panel) the compressor and the evaporator

fan will switch off. Four elements inside the evaporator box will then melt

away any ice build up. The duration of a defrost cycle depends on the

quantity of ice build up (usually about 10 minutes). A maximum of 22

minutes is preset. Defrost cycles are pre-programmed at 6 hour intervals.

During and after each defrost, the display will read the temperature detected

before the defrost cycle. The display will then show the return air

temperatures as the machine cycles during normal operation.

Defrosts should occur during off-peak periods to maximise the efficiency of

the machine. This can be achieved by switching the power off, then on

again, so that the subsequent 6 hourly cycle defrosts will not coincide with

peak periods.

Note:

A power cut would reset the defrost cycles.

This freezer has an over temperature cut-out inside the refrigeration unit

evaporator box. This is to safe guard the possibility of the defrost

elements remaining on under fault conditions (set at 55°C).

The light which illuminates the cabinet interior is permanently on, where

applicable.

Ensure the door gaskets form a good seal with the cabinet.

Component Description

Microprocessor: Located behind ventilated unit front cover.

Controller Relay Module: Located in control box. Performs processor

switching.

Module Connector Cable: Flat black cable connecting module to

microprocessor.

Probes: 2 x NTC probes are used.

Page 10

10

Operation

User Manual

SKOPE TMEF Series

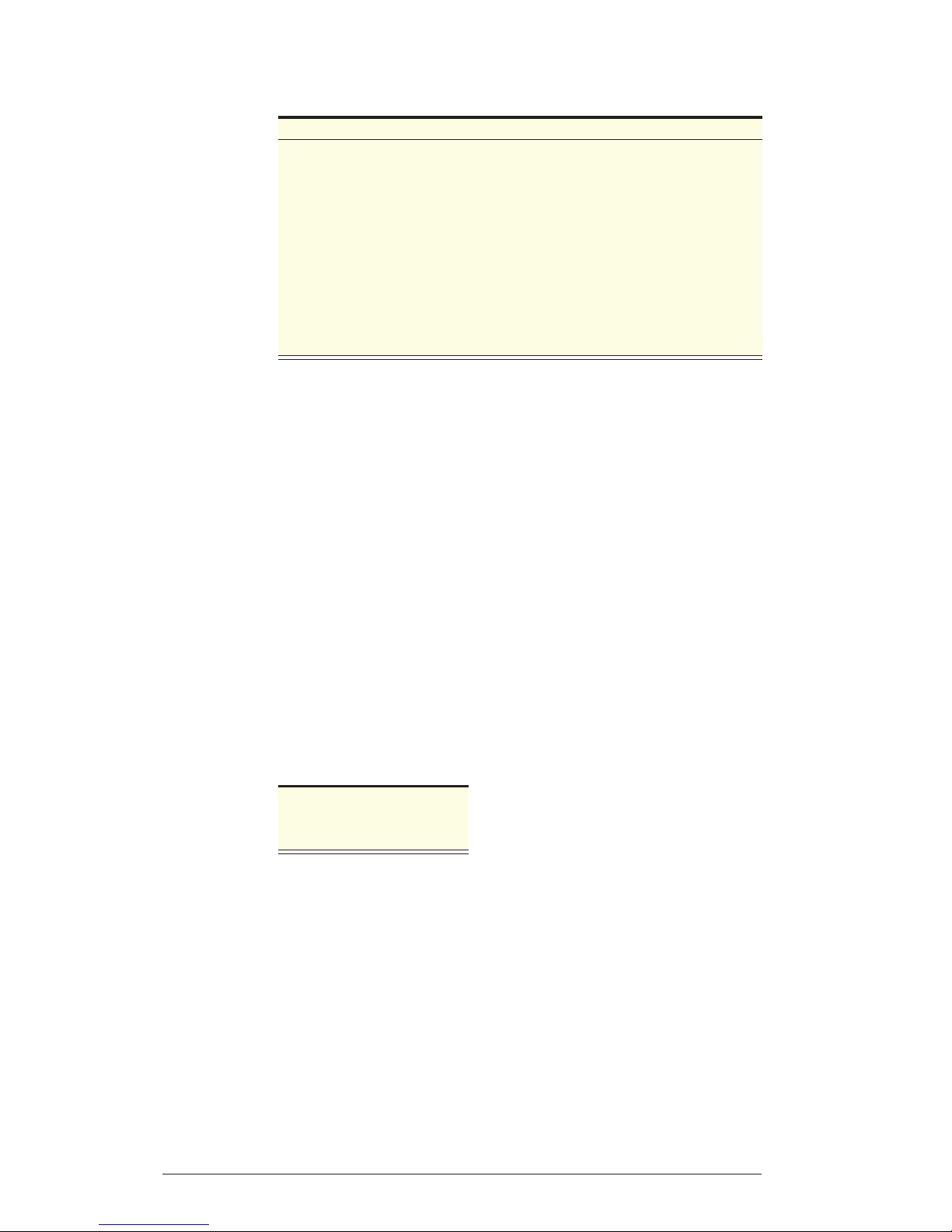

Alarms and

Signals

Note: Alarm HI may activate during cabinets initial pull down cycle, after being first powered

up. Alarm may be muted; and will automatically reset when cabinet passes alarm setpoint.

Programming To access the controller

1. Press and hold PRG and SEL simultaneously for more than 5 seconds

until 00 is displayed.

2. Press aux (up) until 22 is displayed.

3. Press SEL to confirm selection. The first parameter /C is displayed.

To turn the controller keypad on

1. Follow Access / Entry above, until the first parameter /C is displayed.

2. Press def (down) two times, until H2 is displayed.

3. Press SEL to display the ‘value’ of the parameter.

4. Press aux (up) to increase or def (down) to decrease, until 01 is displayed.

5. Press SEL to accept the ‘value’.

6. Press PRG to lock in new value and to exit program.

Setpoint Press SEL key for 1 second and the ‘Setpoint’ will be displayed. On

releasing the key, the display will flash. To alter the ‘Setpoint’, press aux (up)

or def (down). Press SEL to lock in the value and return to cabinet

temperature.

Manual

Defrost

Follow steps above to access the controller, and press def (down) key for

more than 5 seconds to manually initiate a defrost.

Continuous

Refrigeration

Press aux (up) and def (down) together, (down key first) to initiate a

‘Continuous Refrigeration’ mode. The compressor will run without

interruption to the parameter ‘cc’ (6 hours: SKOPE programme). Its purpose

is to achieve a fast product pull-down.

Display

Function

During run mode, the display shows the value measured by the ‘Cabinet

Ambient Probe’. In alarm status, the display indicates the relative alarm

code.

Buzzer Off Press mute key to silence the buzzer. The alarm display remains while the

alarm condition exists.

Signal Description

EO on Indicates faulty ambient probe.

El blinking Indicates faulty defrost probe.

IA blinking

Indicates unit has high pressure fault.

Note: At alarm initiation, check condenser radiator for

blockage, and clean if necessary. To reset alarm, cabinet

must be replugged into power supply.

LO blinking Indicates low temperature alarm.

HI blinking Indicates high temperature alarm.

EA, EB or EE

blinking

Indicates data acquisition failure.

The controller requires re-programming.

Ed blinking Indicates defrost timed out.

Factory setting: -21°C

Maximum: -18°C

Minimum: -21°C

Page 11

11

SKOPE TMEF Series

Operation

User Manual

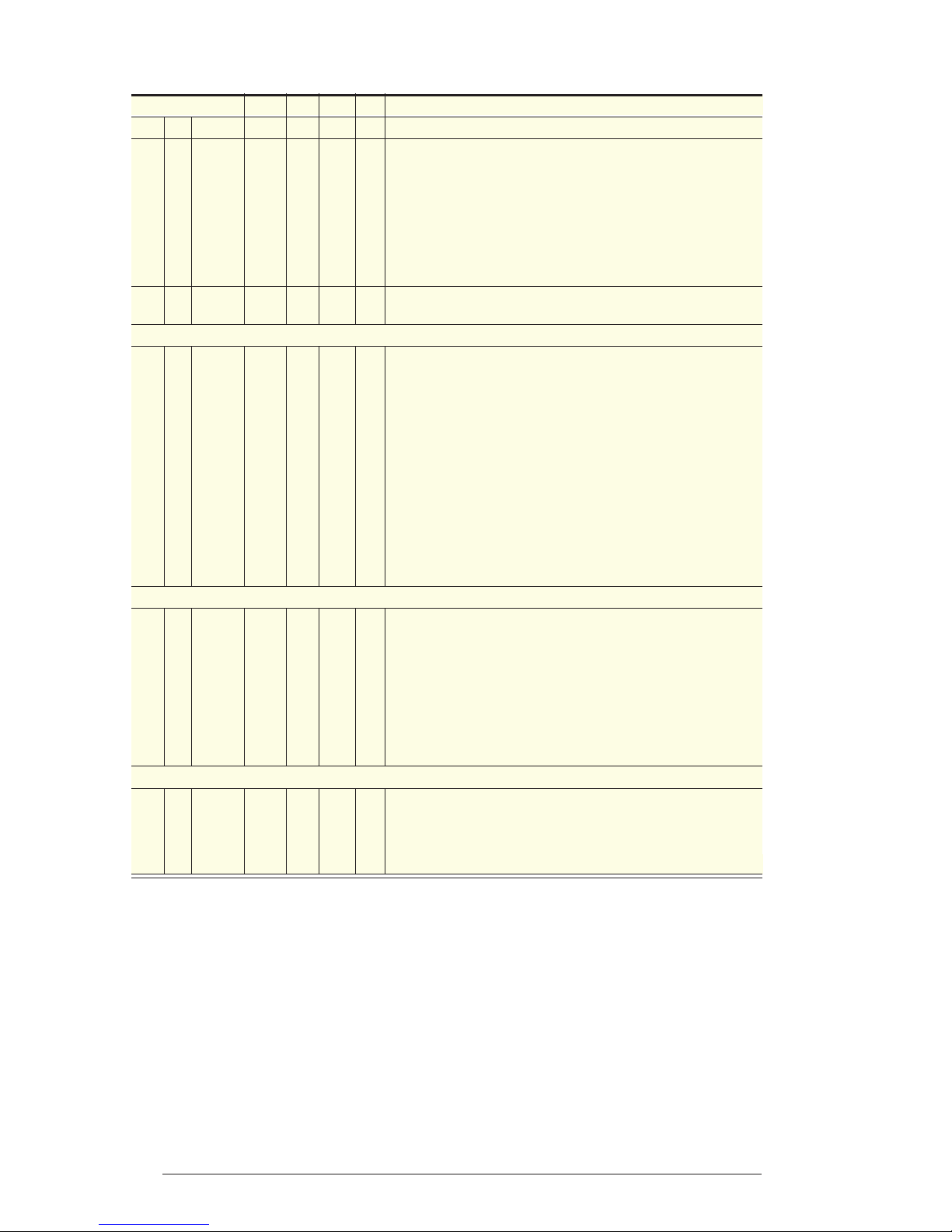

Parameters The following table describes SKOPE settings for CAREL controller

IR32POLBRO.

WARNING

The following parameters (Table 1: pp.10,11) are set exclusively for the SKOPE freezer

program, with its dedicated CAREL controller.

Any alteration from this program may adversely effect the operation of the freezer.

For full specifications, a detailed CAREL controller manual is available.

SKOPE Settings Type Min Max Def Parameter

PA 22 C 00 199 22 Password

Probe Parameters

/0 0

NTC

probe

n.a. 0 1 0

Type of probe used (NTC or PTC). Available after ‘Reset

Procedure’

/C 2.0 2°C F -20 20 0 Calibration offset for cabinet temperature display

/2 04 - C 1 15 4 Probe reading stability (lower the number, faster the response)

/3 08 - C 1 15 8 Probe reading speed (lower the number, slower the response)

/4 00 probe C 0 100 0 Designation as controlling probe

/5 00 °C C 0 1 0 Units of temperature measurement

/6 00 Yes C 0 1 0 Decimal point display

Cycle Parameters

rd 3.0 3°C F 0.1 20 2 Refrigeration differential

r1 -26 -26°C C -40 r2 -40 Minimum allowable setpoint

r2 -16 -16°C C r1 199 90 Maximum allowable setpoint

r3 01 Yes C 0 1 0

Enabling of ED alarm (defrost interrupted because maximum

duration has been reached, parameter dP) 0=No, 1=Yes

r4 3.0 3 C 0 20 3 Not used. Must be 3

r5 01 Yes C 0 1 0 Enabling of minimum / maximum temperature monitoring

rt - - F 0 199 - Actual interval in maximum / minimum temperature reading

rH - - F -50 +90 - Maximum temperature reading in the ‘rt’ interval

rL - - F -50 +90 - Minimum temperature reading in the ‘rt’ interval

Compressor Parameters

c0 01

1

minute

C 0 15 0 Compressor and evaporator fan start delay at power on

c1 03

3

minutes

C 0 15 0 Minimum time between compressor starts

c2 03

3

minutes

C 0 15 0 Minimum compressor OFF time

c3 00 0 C 0 15 0 Minimum compressor ON time

c4 99

99

minutes

C 0 100 0

Compressor backup for ‘Ambient’ probe failure (On for c4, off for

15 min)

cc 04 4 hours C 0 15 4 Duration of ‘Continuous Refrigeration Mode’

c6 02 2 hours C 0 15 2 Duration of alarm override after ‘Continuous Refrigeration Mode’

Defrost Parameters

d0 00 Electric C 0 1 0 Type of defrost

dl 06 6 hours F 0 199 8 Time interval between defrosts

dt 6 12°C F -40 199 4 Defrost termination temperature

dP 22

22

minutes

F 1 199 30 Maximum defrost time

Continued over page

Page 12

12

Operation

User Manual

SKOPE TMEF Series

* High Pressure trip is maintained as alarm status by latching relay. To reset, the freezer must be unplugged and then

replugged into the power supply.

Parameter Modification (if keypad is enabled)

1. Press aux (up) or def (down) to show the code of the parameter that has to be changed.

2. Press SEL to display the selected parameter value.

3. Press aux (up) or def (down) to increase or decrease the value.

4. Press SEL to temporarily confirm the new value, and display its code.

5. Repeat above procedures to alter further parameters.

Press PRG to lock in the new parameters and exit parameter modification procedure.

SKOPE Settings Type Min Max Def Parameter

d4 00 No C 0 1 0 Defrost at cabinet plug in

d5 00 No C 0 199 0 Defrost delay at cabinet plug in

d6 01 Yes C 0 1 1 Lock in temperature display during defrost

dd 03

3

minutes

F 0 15 2 Defrost drip time, before compressor and evaporator fan start

d8 01 1 hour F 0 15 1 Continuation of d6 at defrost end (until setpoint or d8 elapses)

d9 00 No C 0 1 0 Compressor protection times observed at defrost (c1, c2, c3)

d/ - - F n.a n.a n.a Evaporator temperature (via defrost probe) is displayed

dC 00

hrs /

mins

C 0 1 0 Time basis for parameter ‘dl’ and ‘dp’

Alarm Parameters

AO 1.0 1.0°C C 0.1 20 0.2 Alarm and fan differential

AL 10

-32°C /31°C

F 0 199 10 Low temp alarm (On=Setpoint -AL-A0) (Off=Setpoint -AL)

AH 09

-11°C /12°C

F 0 199 10 High temp alarm (On=Setpoint +AH+A0) (Off=Setpoint +AH)

Ad 60

60

minutes

C 0 199 120 Alarm delay time

A4 01 On C 0 5 0 Immediate external alarm i.e. High pressure switch trip*

A5 00 - C 0 5 0 Not used. must be 0

A6 99

99

minutes

C 0 100 0

Compressor run lock time due to A4 function. Compressor will

still cycle with HP switch

A7 00 - C 0 199 0 Not used. must be 0

Fan Parameters

F0 02 On C 0 1 0

Evaporator fan control type (controlled by Evaporator Defrost

Probe). Must be 2

F1

14.0-8°C /7°C

F 0 20 5

Evaporator fan start temperature (On=Setpoint +F1 -A0)

(Off=Setpoint +F1)

F2 00 No C 0 1 1 Evaporator fan off while compressor is off

F3 01 Yes C 0 1 1 Evaporator fan off during defrost

Fd 01

1

minute

F 0 15 1 Evaporator Fan delay after defrost

Other Selections

H0 00 - C 0 15 0 Serial address

H1 00 - C 0 1 1 Not used. Must be 0

H2 00 No C 0 3 1 Enable keypad & remote control (must be ‘01’ to enable)

H3 00 00 C 0 199 0 Password for remote control

Page 13

13

SKOPE TMEF Series

Servicing

User Manual

3 Servicing

Cleaning

Cabinet Periodically wipe the inside and outside of the cabinet with a damp cloth,

taking care to keep moisture away from electrical parts. As with any

maintenance, ensure the cabinet is disconnected from the power supply

before cleaning.

Condenser

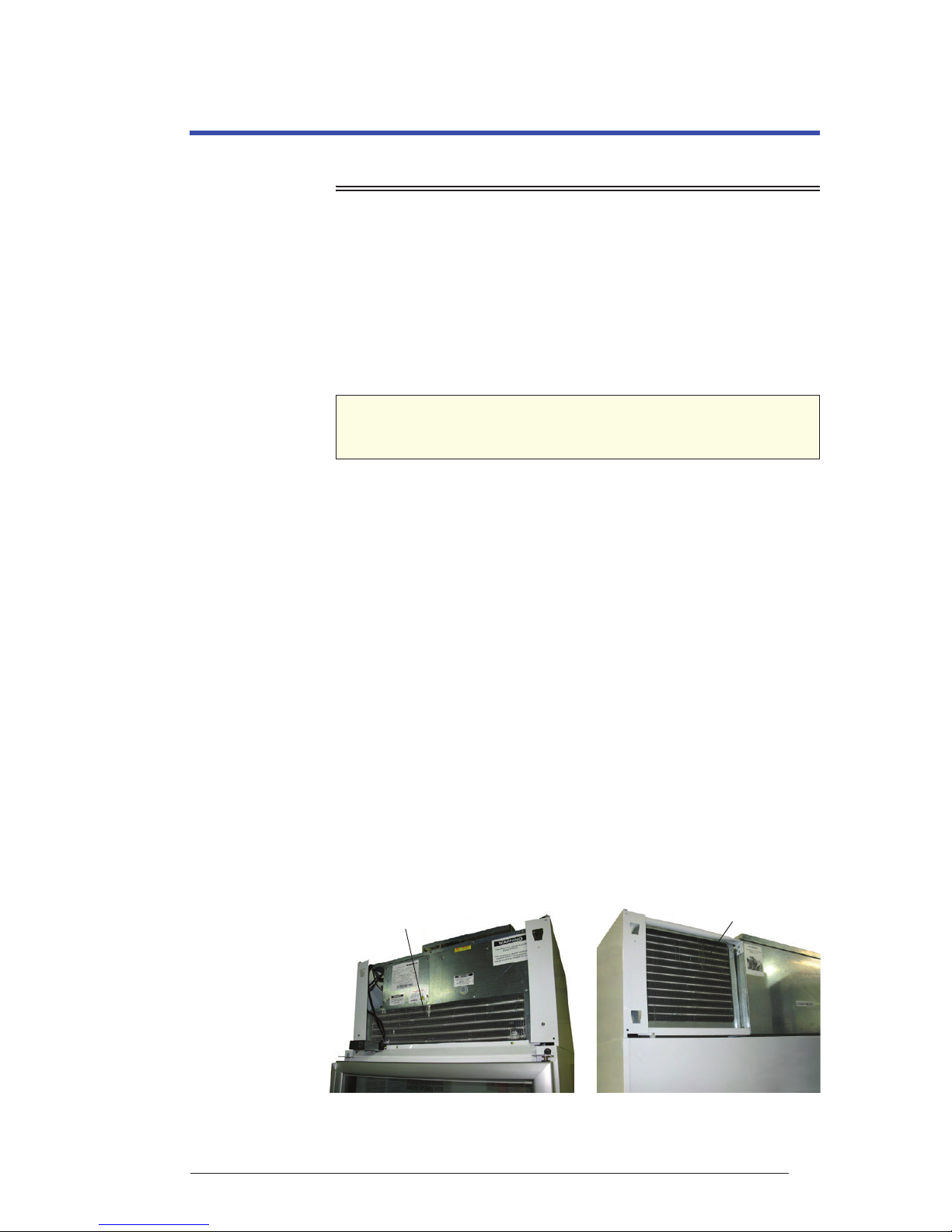

Coil

To ensure trouble-free performance, we strongly urge monthly cleaning with

a soft brush to remove dust and fluff. A more thorough cleaning is

recommended every six months by qualified service personnel. The

condenser coil must be kept clean for efficient and reliable operation.

To clean the condenser coil

(TMEF650 single door & TMEF1000 2 door cabinets)

1. Disconnect the cabinet from the mains power supply.

2. Remove the top panel (above the doors) by releasing the sign clips

above the panel and unscrewing the 2 fixing screws. Lift up and out

from the cabinet.

3. Clean the condenser coil with a soft brush (see image below).

4. Carefully place the top panel back into position by hooking into the slots

on the sign side ends, repositioning the sign clips and fix in place with

the fixing screws.

To clean the condenser coil

(TMEF1500 3 door cabinet)

1. Disconnect both power cords from the mains power supply.

2. Remove the sign back panel lifting up and out from the cabinet.

3. Clean the condenser coil with a soft brush (see image below).

Note: The TMEF1500 (3 door) cabinet is fitted with two refrigeration

units, each with a condenser coil.

4. Carefully place the top panel back into position by hooking into the slots

on the sign side ends.

CAUTION

Disconnect the cabinet from the power supply before cleaning

the condenser coil.

TMEF650

TMEF150

Condenser Coil

Condenser Coil

Page 14

14

Servicing

User Manual

SKOPE TMEF Series

Lighting

Interior Side

Light

TMEF650 (single door) cabinet.

The cabinet interior is lit by one 58 Watt T8 fluorescent tubes (Ø26mm x

1150mm), which can be replaced without moving shelves or removing

product.

To replace the interior side light

1. Disconnect the cabinet from the power supply.

2. Remove the diffuser by squeezing it until it is released from the

aluminium housing, and then push the diffuser out of the way.

3. Rotate the fluorescent tube until the pins on the ends of the tube align

with the slots, then slide it out.

4. Fit a new fluorescent tube taking care that the printing on the tube is at

the bottom (tube orientation is important).

5. Refit the diffuser by slipping the back section into the housing, then

squeezing and snapping the front section of the diffuser into place as

you work down the length of the light.

Centre Pillar

Light

TMEF1000 (2 door) and TMEF1500 (3 door) cabinets.

The cabinet interior is lit by one or two 58 Watt T8 fluorescent tubes (Ø26mm

x 1150mm), which can be replaced without removing shelves or removing

product.

To replace the sign light

1. Disconnect the cabinet from the mains power supply.

2. Remove the top panel (above the doors) by unscrewing the fixing

screw/s and lifting up and out from the cabinet. Keeping all wires

attached, carefully place on top of the cabinet.

3. Unscrew the bottom fixing screw from the centre pillar cover and unclip

from the centre pillar.

4. Rotate the tube until the pins on the ends of the tube align with the slots,

then slide the tube out.

5. Fit the new fluorescent tube taking care that the printing on the tube is at

the bottom (tube orientation is important).

6. Refit the centre pillar cover by clipping back onto the centre pillar and

reattach the bottom fixing screw.

7. Carefully place the top panel back into position by hooking into the slots

on the sign side ends and reattach the fixing screw.

Flourescent Tube

Centre Pillar Cover

Centre Pillar

Page 15

15

SKOPE TMEF Series

Servicing

User Manual

New Zealand Contact

SKOPE INDUSTRIES LIMITED

Head Office

PO Box 1091, Christchurch

New Zealand

Freephone: 0800 947 5673

Fax: (03) 983 3896

E-mail: enquiry@skope.co.nz

Website: www.skope.co.nz

Australian Contact

SKOPE AUSTRALIA PTY LTD

A.C.N. 000 384 270

PO Box 7543, Baulkham Hills B.C.

NSW 2153, Australia

Freephone: 1800 121 535

Fax: 1800 121 533

E-mail: enquiry@skope.com.au

Website: www.skope.com.au

SKOPE Contacts

Loading...

Loading...