Skope BB380i-2SL,BB580i-3SL,BB780i-4SL,BB380i-2SW,BB580i-2SW,BB780i-4SW,BB380r-2SL,BB580r-3SL,BB780r-4SL,BB380r-2SW,BB580r-3SW,BB780r-4SW,CL400i-2SL,CL800i-4SL,CL400i-2SW,CL800i-4SW,CL400r-2SL,CL600r-3SL,CL800r-4SL,CL400r-2SW,CL600r-3SW,CL800r-4SW,CC300i-2SL,CC700i-4SL,CC300i-2SW,CC700i-4SW,CC300r-2SL,CC500r-3SL,CC700r-4SL,CC300r-2SW,CC500r-3SW,CC700r-4SW User Manual

Page 1

SKOPE Backbar, Counterline & Slimline

BB, CL & CC Series

1, 2 & 3 Door Horizontal Chillers

CL400

User Manual

MAN11015 Rev. 2.1 Mar. 2019

BB580

CL800

Page 2

SKOPE Warranty Protection

Register now for peace of mind

It’s quick and simple. Take a few minutes to register

your SKOPE product and enjoy more efficient

support plus other warranty benefits. When

registering, make sure you have your cabinet serial

number at hand.

To register online:

Visit our website at www.skope.com/warrantyprotection

then complete and submit the online registration form.

Or freephone:

1800 121 535 (Australia)

0800 947 5673 (New Zealand)

SKOPE 1-year Extended Warranty

Extend your Warranty Protection by 1 year during registration. Please

check you have not already organised an extended warranty through

your dealer at time of purchase. For pricing information on an extended

warranty visit www.skope.com/warrantyprotection

Service & Support

We know you will get years of satisfaction from your new SKOPE

product when you follow a few simple preventative maintenance

guidelines.

Helpful information is available on our website

www.skope.com/serviceandsupport

Thank you for purchasing a SKOPE refrigeration product.

Page 3

CONTENTS

1 Models

Backbar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Counterline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Slimline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 Installation

Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Locating the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Positioning the Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Legs and Castors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Shelving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Fitting the Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Loading Product . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Remote Cabinet Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Pipe Locations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

3 Operation

Automatic Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Refrigeration Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Cabinet Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controller Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Controller Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4 Servicing

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cabinet Interior Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Page 4

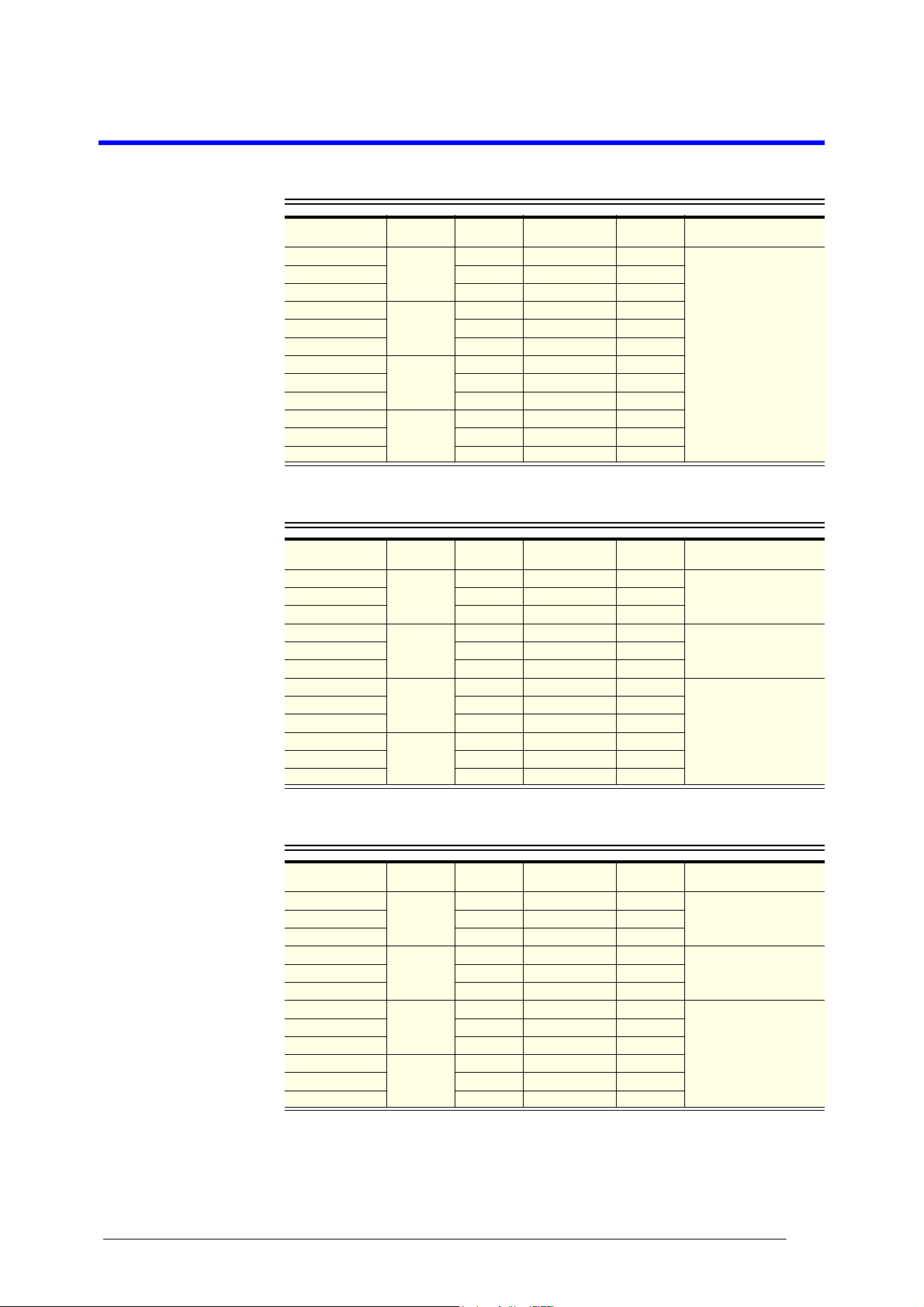

1 Models

Backbar

Model Config. Doors

BB380i-2SL

BB580i-3SL 3 Integral 3.9A

BB780i-4SL 4 Integral 4.0A

BB380i-2SW

BB580i-2SW 3 Integral 3.6A

BB780i-4SW 4 Integral 3.8A

BB380r-2SL

BB580r-3SL 3 Remote 1.5A

BB780r-4SL 4 Remote 1.6A

BB380r-2SW

BB580r-3SW 3 Remote 0.9A

BB780r-4SW 4 Remote 1.4A

Sliding

doors

Swing

doors

Sliding

doors

Swing

doors

2 Integral 3.6A

2 Integral 3.4A

2 Remote 0.9A

2 Remote 0.7A

Refrigeration

unit

Current

draw

Counterline

Model Config. Doors

CL400i-2SL

CL600i-3SL 3 Integral 3.4A

CL800i-4SL 4 Integral 4.0A

CL400i-2SW

CL600i-3SW 3 Integral 3.2A

CL800i-4SW 4 Integral 3.8A

CL400r-2SL

CL600r-3SL 3 Remote 0.9A

CL800r-4SL 4 Remote 1.3A

CL400r-2SW

CL600r-3SW 3 Remote 0.7A

CL800r-4SW 4 Remote 1.0A

Sliding

doors

Swing

doors

Sliding

doors

Swing

doors

2 Integral 2.5A

2 Integral 2.3A

2 Remote 0.5A

2 Remote 0.3A

Refrigeration

unit

Current

draw

Operating temperature

range

+1°C to +4°C up to 32°C

ambient

Operating temperature

range

+1°C to +4°C up to 32°C

ambient

+1°C to +4°C up to 40°C

ambient

+1°C to +4°C up to 32°C

ambient

Slimline

Model Config. Doors

CC300i-2SL

CC500i-3SL 3 Integral 3.4A

CC700i-4SL 4 Integral 4.0A

CC300i-2SW

CC500i-3SW 3 Integral 3.2A

CC700i-4SW 4 Integral 3.8A

CC300r-2SL

CC500r-3SL 3 Remote 0.9A

CC700r-4SL 4 Remote 1.3A

CC300r-2SW

CC500r-3SW 3 Remote 0.7A

CC700r-4SW 4 Remote 1.0A

SKOPE Backbar, Counterline & Slimline

User Manual

Sliding

doors

Swing

doors

Sliding

doors

Swing

doors

Refrigeration

unit

2 Integral 2.5A

2 Integral 2.3A

2 Remote 0.5A

2 Remote 0.3A

Current

draw

Operating temperature

range

+1°C to +4°C up to 32°C

ambient

+1°C to +4°C up to 40°C

ambient

+1°C to +4°C up to 32°C

ambient

4

Page 5

SKOPE Backbar, Counterline & Slimline

2 Installation

Safety First Always observe safety precautions when using any electrical appliance.

Read these instructions carefully and retain them for future reference.

When the appliance is used by or near young children or infirm persons,

close supervision is necessary, especially to ensure children do not play

with it.

Do not use this appliance for other than its intended use.

Do not cover the grilles or block the entry or exhaust of airflow by

placing objects up against the refrigeration unit.

Do not probe any opening.

Only use this appliance with the voltage specified on the rating label.

Ensure the appliance has adequate ventilation as this is essential to

economical, high performance.

Be careful not to touch moving parts and hot surfaces.

For your own safety and that of others, ensure that all electrical work is

done by authorised personnel.

If the power supply flexible cord becomes damaged, it must be replaced

by an authorised service agent or similarly qualified person in order to

avoid a hazard.

Ensure all necessary safety precautions are observed during installation

or removal of the refrigeration unit.

The appliance is not designed to be stable while in motion. Use extreme

caution when moving or transporting it.

Do not store explosive substances such as aerosol cans with a

flammable propellant in this appliance.

Please contact SKOPE customer services for advice regarding disposal

of this appliance.

CAUTION

Never overload the power supply, which could damage the

chiller and product. See the rating label inside the cabinet for

the safe power supply and current draw.

WARNING

Always disconnect the chiller from the mains power supply

before cleaning or maintenance.

WARNING

If retrofitting door locks, ensure retrofit is done by a SKOPE

approved service technician following SKOPE guidelines on

instruction sheet PRN8503.

Installation

User Manual

5

Page 6

SKOPE Backbar, Counterline & Slimline

Locating the Cabinet

Location When positioning the cabinet, avoid direct sunlight and warm draughts etc.

The cabinet must NOT be situated where it is affected by warm or hot air

from adjacent equipment, as this will compromise the airflow and

performance of the chiller.

The cabinet must be positioned on a level surface for the doors to shut and

seal correctly, and to prevent the condensate tray from overflowing.

Adequate allowance should be made for door opening.

Always ensure that the top of the cabinet is shielded from impact and

moisture, with either a SKOPE provided bench top, or with a custom or

existing bench top.

When installing the cabinet

Avoid direct sunlight and warm draughts etc.

Allow adequate space for the doors to open fully.

Ensure the cabinet is positioned on a level surface so the doors shut

and seal correctly and to prevent the condensate tray from overflowing.

Ventilation For efficient operation of the chiller, it is essential that adequate ventilation

be provided around the front of the refrigeration unit. Normal operating

conditions should not exceed the operating temperature range (see page 4).

It is critical that the hot refrigeration exhaust air is not restricted and that it

can easily flow out and away from the front of the cabinet. Never store

cardboard cartons or other items in front of the refrigeration unit. The

ventilation slots on the unit front cover must be kept clear at all times.

Power Supply The chiller is supplied with a flexible power cord and plug, which is located

at the rear of the cabinet.

Before final positioning of the cabinet, pull the power cord out from the

cabinet and connect to the power supply.

WARNING:

Do NOT overload the power supply. See the rating label inside

the cabinet for power supply and current draw.

6

Installation

User Manual

Page 7

SKOPE Backbar, Counterline & Slimline

Castor

mounting plate

Adjustable leg

Plastic foot

Lock nut

Positioning the Cabinet

Legs and

Castors

The chiller is packed with a set of adjustable height legs and a set of

adjustable height castors. Either of these sets can be fitted to the cabinet

depending on specific height and manoeuvrability requirements. The legs or

castors should be fitted to the base of the cabinet before final positioning.

The adjustable legs screw into the castor mounting plates attached to the

bottom of the cabinet. The adjustable legs can adjust the cabinet height up

to 30mm.

To adjust leg height

1. Turn the black plastic foot

at the bottom of the leg

counter-clockwise to raise

the height or clockwise to

lower.

The adjustable castors screw into the castor mounting plates attached to the

bottom of the cabinet. The two lockable castors should be fitted to the front

of the cabinet and the non-locking castors fitted to the rear. The adjustable

castors can adjust the cabinet height up to 15mm.

To adjust castor height

1. Loosen the lock nut.

2. Turn the castor counterclockwise to raise the

height or clockwise to

lower (see image below).

Re-tighten each lock nut

after final adjustment has

been made.

Installation

User Manual

7

Page 8

SKOPE Backbar, Counterline & Slimline

Shelving

Fitting the

Shelves

Loading Product

Remove all packaging material from the shelves. Clip the shelf support

brackets into the shelf support strips, at the desired heights, and fit the

shelves. The shelves may be positioned at different heights to suit various

products. Always ensure that the shelf clips are securely engaged in each

of the shelf support strips. The shelf support strips are marked ‘+’ for easy

location of shelf clips and can be lifted up and removed for cleaning

purposes.

The chiller should be left running for 30 minutes before loading with product.

When loading product

Allow air space around all the product to ensure even cooling and

efficient operation of the chiller.

Do not allow products to overhang the front of the shelf as this could

prevent the doors from shutting. Leave an airspace of at least 75mm

above product loaded on the top shelf.

Do not exceed a maximum loading of 20kg per shelf.

Remove some product if the shelves are flexing or bending.

8

Installation

User Manual

Page 9

SKOPE Backbar, Counterline & Slimline

Unit Pipework Cover

Refrigeration Unit Compartment

Drain Tube

Suction Line

Liquid Line

Rear of Cabinet

Remote Cabinet Installation

SKOPE horizontal remote cabinets are supplied with a seperate instruction

sheet: Guidelines for SKOPE remote Refrigeration (PRN2362), and

specification sheet: SKOPE Gen 2 Horizontal Remote Cooler -

Specifications (PRN1647). Refer to these sheets for SKOPE remote

refrigeration installation guidelines and specifications.

Electronic Controller

When the cabinet is connected to the power supply, the electronic controller

will display the current cabinet temperature. On the controller display, the

symbol will indicate the compressor output signal has been initiated and the

symbol will indicate the evaporator fan is on.

Pipe Locations Refer to the images below (remote chiller unit pictured) for component

locations and unit access points.

Installation

User Manual

9

Page 10

SKOPE Backbar, Counterline & Slimline

3 Operation

Automatic Start-Up

Connect the cabinet to the mains power supply and check operation of the

refrigeration unit and electronic controller. If the cabinet has been on its

back, leave for 30 minutes before running.

If the cabinet has been on its back, leave for 30 minutes

IMPORTANT

before running.

Refrigeration

Unit

Cabinet

Lighting

Electronic Controller

The compressor, and the condenser and evaporator fans should all operate

within two minutes from the time the cabinet is plugged in. This may be

verified by listening for compressor switch-on and checking for air

movement out of the top ventilation slots in the refrigeration unit front cover.

The compressor and condenser fan should switch on and off depending on

the cabinet temperature.

The light switch, located next to the electronic controller on the refrigeration

unit front cover, activates the cabinet interior lighting and can be switched on

or off as required.

When the cabinet is connected to the power supply, the electronic controller

will display the current cabinet temperature. The compressor LED will

indicate the compressor is operating and the evaporator fan LED will

normally come on within two minutes (see “Electronic Controller” on page 11

for controller display).

To ensure efficient operation, the electronic controller forces regular

defrosts. During the defrost cycle, the compressor and condenser fan switch

off and the evaporator fan stays on.

10

Operation

User Manual

Page 11

Electronic Controller

910

11

12

43

15

14

1312

8

7

6

5

Item Icon Function

Mute / program: Mutes the audible alarm (buzzer) and

1

deactivates the alarm relay. To initiate program sets, press for 5

seconds.

SKOPE Backbar, Counterline & Slimline

2 Up: To scroll settings up (in program mode).

3

4

5

6 Fan: Shows when the fan is operational.

7

8 Aux: n.a.

9 Alarm: Flashes in the event of alarms.

10 Clock: n.a.

11 Light: n.a.

12 Service: Flashes in the event of malfunctions.

Set point: If pressed for more than 2 seconds displays and / or

enables changing the temperature setpoint.

Manual defrost / down: Press for more than 5 seconds to initiate

manual defrost. To scroll settings down (in program mode).

Compressor: ON when the compressor and condenser fan

starts. Flashes when activation of the compressor is temporarily

delayed.

Defrost: ON when the defrost is activated. Flashes when the

activation of the defrost is temporarily delayed due to procedures

in progress.

13

14

15

DISPLAY: Shows the cabinet temperature. Flashes when the

door is open.

HACCP: n.a.

CONTINUOUS CYCLE: On when freezer is running in continuous

run mode.

Operation

User Manual

11

Page 12

SKOPE Backbar, Counterline & Slimline

Controller

Overview

Temperature

Setpoint

The CAREL ir33 electronic controller controls and displays the internal

cabinet temperature. The preset temperature setting keeps the product

temperature within the operating temperature range (see page 4). The

electronic controller also signals temperature alarms (see next page).

For general operation, the electronic controller requires no initial setup or

additional programming.

When the cabinet is connected to the power supply, the electronic controller

will display the current cabinet temperature. The compressor LED will

indicate the compressor is operating and the evaporator fan LED will

normally come on within 2 minutes.

The chiller temperature setpoint is factory set (see table below) and can be

adjusted if necessary. SKOPE do not recommend that the setpoint be

changed unless it is absolutely necessary, and then only by small

increments at a time.

Factory setpoints

Model series Factory setpoint

Backbar 1.5°C

Counterline & Slimline

1.0°C

To view and adjust the temperature setpoint

1. To view the setpoint:

Press and hold the key for 2 seconds, until the

setpoint value flashes.

2. To adjust the setpoint:

Press either the or keys to display the required

setpoint value.

3. Press the key again to memorise the new setpoint

value. If this is not done within 60 seconds changes will

be lost and you will need to repeat the above

procedure.

12

Operation

User Manual

Page 13

SKOPE Backbar, Counterline & Slimline

Controller

Alarms

The following table explains messages that the electronic controller displays

and related alarms. Alarms signal unexpected operational changes in the

freezer and stop when action is taken to resolve the problem.

Code Display Alarm Action

1. Check the cabinet product loading to ensure

ventilation slots are not blocked, and that

product does not overhang the shelves.

Ensure the doors are closed.

2. Ensure the cabinet is installed with good

refrigeration unit ventilation.

3. Check and clean the condenser coil (see

page 14).

4. If immediate alarm recovery is required unplug the cabinet from the power supply for

1 minute, then reconnect to power supply. If

alarm persists, contact SKOPE.

NOTE: The ‘HI’ and ‘LO’ alarms deactivate the

cabinet lighting and trim heaters.

1. Clean the condenser coil (see page 14).

2. Check refrigeration ventilation. Ensure clear

airpath in front of the cabinet.

3. Ensure the cabinet is installed in a suitable

environment.

4. To reset the ‘CHt’ alarm - unplug the cabinet

from the power supply for 1 minute, then

reconnect to power supply. If alarm persists,

contact SKOPE.

Flashing

Flashing

Flashing

Flashing

Product HIGH

temperature alarm

(auto reset)

Product LOW

temperature alarm

(auto reset)

Refrigeration

system high

temperature

pre-warning (auto

reset)

Refrigeration

system and

cabinet high

temperature

shutdown (manual

reset)

Flashing

Flashing

Flashing

None

Flashing

Flashing

Flashing

None

None

Control probe fault

Evaporator probe

fault

Condenser probe

fault

Defrost over-time

limit

Real-time clock

fault

Controller E prom

error

Controller E prom

error

Start defrost

request

End defrost

request

To reset alarm - unplug the cabinet from the

power supply for 1 minute, then reconnect to

power supply.

1. If alarm persists, contact SKOPE.

None

Operation

User Manual

Flashing

Door open alarm

Check that a door or drawer has not been left

open. Note: The audible alarm buzzer cannot

be turned off manually.

13

Page 14

SKOPE Backbar, Counterline & Slimline

Condenser coil

4 Servicing

Cleaning

Cabinet When necessary, wipe both the interior and exterior of the cabinet with a

damp cloth. Ensure the cabinet is disconnected from the mains power

supply before cleaning the cabinet.

Disconnect the cabinet from the mains power supply before

cleaning the condenser coil or washing the cabinet with water.

CAUTION

Condenser

Coil

Integral cabinets only. The condenser coil should be brushed clean once a

month and blown clean by qualified service personnel every six months.

Over time, dust may accumulate within the condenser that cannot be

removed with a brush. If this occurs, contact SKOPE to arrange for a

SKOPE authorised service agent to clean the condenser with compressed

air. The condenser coil is located inside the refrigeration unit compartment

and is accessed by opening the unit front cover. Disconnect the cabinet from

the power supply before cleaning the condenser coil.

14

IMPORTANT

If the electronic controller display flashes ‘cht’ the condenser

coil must be cleaned immediately.

Servicing

User Manual

Page 15

Lighting

SKOPE Backbar, Counterline & Slimline

Cabinet

Interior Lights

The cabinet is fitted with cabinet interior light/s mounted above the doors on

the ceiling of the cabinet. Backbar pass-through cabinets are fitted with

lights above the front and back doors. Refer to the table below for light tube

specifications.

Interior light specifications

Type LED Tube Specification

Two door cabinet 20 Watt T8 Frosted LED tube (Ø26 x 900mm, 5500K)

Three door cabinet 24 Watt T8 Frosted LED tube (Ø26 x 1500mm, 5500K)

Four door cabinet Counterline & Slimline

Four door cabinet Backbar

20 Watt T8 Frosted LED tube (×2) (Ø26 x 900mm, 5500K)

24 Watt T8 Frosted LED tube (Ø26 x 1500mm, 5500K)

To replace the interior LED light tube

1. Disconnect the cabinet from the power supply (see page 14).

2. Remove the top light

diffuser by squeezing it

until it is released from the

housing.

3. Rotate the LED tube until

the pins on the ends of the

tube align with the slots,

then slide it out.

4. Fit a new LED tube and

clip the diffuser back into

place. When fitting

vertically mounted LED

tubes, ensure the tube is

fitted with the ‘Power’ end

at the top.

Servicing

User Manual

15

Page 16

SKOPE Backbar, Counterline & Slimline

Troubleshooting

Complaint Possible Cause Repair

1. Cabinet not

operating and

no controller

display:

2. Power

consumption

is higher than

expected:

3. Product is too

warm and

spoiling:

4. Warm cabinet

temperatures

and/or

compressor

operating for

long periods

(more than 1

hour):

• Loss of power supply. • Check mains power supply.

• Unit operating too hot. • Clean condenser (see

• Cabinet doors are opened

excessively.

• Restricted cabinet airflow. • Ensure product is not

• Temperature setpoint is too

warm.

• Blocked condenser. • Clean condenser (see

• Poor refrigeration unit

ventilation.

page 14).

• Ensure the chiller is installed

with good ventilation around

the refrigeration unit.

• Keep door/s open for

minimum time.

blocking airflow slots.

• Adjust setpoint (see

page 12).

page 14).

• Ensure the cabinet is

installed with good

ventilation around the

refrigeration unit.

16

Servicing

User Manual

Page 17

SKOPE Industries Limited

NEW ZEALAND CONTACT

Head Office

PO Box 1091, Christchurch

New Zealand

Freephone: 0800 947 5673

Fax: (03) 983 3896

E-mail: enquiry@skope.co.nz

Website: www.skope.co.nz

AUSTRALIAN CONTACT

A.B.N. 73 374 418 306

PO Box 7543, Baulkham Hills B.C.

NSW 2153, Australia

Freephone: 1800 121 535

Fax: 1800 121 533

E-mail: enquiry@skope.com.au

Website: www.skope.com.au

SKOPE Contacts

Trademark Infringement

The SKOPE trademark on this product is infringed if the owner, for the time being, does

any of the following:

• Applies the trade mark to the product after their state, condition, get-up or packaging

has been altered in any manner

• Alters, removes (including part removal) or obliterates (including part obliteration) the

trade mark on the product

• Applies any other trade mark to the product

• Adds to the product any written material that is likely to damage the reputation of the

trade mark

Notice of the above contractual obligations passes to:

• Successors or assignees of the buyer

• Future owners of the product

SKOPE Backbar, Counterline & Slimline

BB, CL & CC Series

User Manual

MAN11015

Rev. 2.1 Mar. 2019

© 2013 SKOPE Industries Limited. All rights reserved.

SKOPE Industries Limited reserve the right to alter specifications without notice.

is a registered trademark of SKOPE Industries Limited.

Loading...

Loading...