Page 1

Operating and Service Manual

MAN0515 Rev. 4.0 Jan. 2006 edition

B550/660-2

BME550-2

SKOPE Gen2: Single Door Chiller

Vertical Display and Storage

Page 2

Page 3

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Designed and Manufactured by

New Zealand

SKOPE INDUSTRIES LIMITED

PO Box 1091, Christchurch

New Zealand

Freephone: 0800 947 5673

Fax: (03) 983 3896

E-mail: enquiry@skope.co.nz

Website: www.skope.co.nz

Australia

SKOPE AUSTRALIA PTY LTD

A.C.N. 000 384 270

PO Box 7543, Baulkham Hills B.C.

NSW 2153, Australia

Freephone: 1800 121 535

Fax: 1800 121 533

E-mail: enquiry@skope.com.au

Website: www.skope.com.au

CONTACT ADDRESSES

i

Page 4

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Operating and Service Manual

MAN0515

Rev. 4.0 Jan. 2006 edition.

Copyright © 2005

SKOPE Industries Limited.

All rights reserved.

SKOPE Industries Limited reserve the

right to alter specifications without

notice.

is a registered trade

mark of SKOPE Industries Limited.

ii

TRADE MARK INFRINGEMENT

The SKOPE trade mark on this product is infringed if the owner, for the time

being, does any of the following:

•Applies the trade mark to the product after their state, condition, get-up

or packaging has been altered in any manner

•Alters, removes (including part removal) or obliterates (including part

obliteration) the trade mark on the product

•Applies any other trade mark to the product

•Adds to the product any written material that is likely to damage the

reputation of the trade mark

Notice of the above contractual obligations passes to:

•Successors or assigns of the buyer

•Future owners of the product

Page 5

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

1SPECIFICATIONS

1.1Cabinet and Refrigeration Unit . . . . . . . . . . . . . . . . . . . . . . .7

2OPERATION

2.1Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

2.2Operation of Machine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Refrigeration Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Electronic Controller. . . . . . . . . . . . . . . . . . . . . . . . . . .9

Cabinet Lighting. . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Mains Isolating Switch . . . . . . . . . . . . . . . . . . . . . . . .10

2.3Shelving. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Loading Product. . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

2.4Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

3ELECTRONIC CONTROLLER

3.1Controller Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Meaning of LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.2Controller Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

3.3Programming Controller . . . . . . . . . . . . . . . . . . . . . . . . . . .15

3.4Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

3.5Alarm Displays. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Alarm Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

3.6Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Controller NTC Probe Resistance . . . . . . . . . . . . . . .20

Controller Removal . . . . . . . . . . . . . . . . . . . . . . . . . .21

Replacement Controller. . . . . . . . . . . . . . . . . . . . . . .22

Dixell Controller Wiring. . . . . . . . . . . . . . . . . . . . . . . .23

4SERVICE INSTRUCTIONS

4.1Interior Side Light . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

4.2Door. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

4.3Sign Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

TABLE OF CONTENTS

iii

Page 6

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.4Refrigeration Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

To Remove the Refrigeration Unit . . . . . . . . . . . . . . 34

To Re-Install the Refrigeration Unit. . . . . . . . . . . . . . 36

Refrigeration Unit Junction Box . . . . . . . . . . . . . . . . 37

Evaporator Fan Motor Assembly . . . . . . . . . . . . . . . 38

Condenser Fan Motor Assembly . . . . . . . . . . . . . . . 39

Cleaning the Condenser Coil . . . . . . . . . . . . . . . . . . 40

Recommended Service Procedures. . . . . . . . . . . . . 41

For a Suspected Refrigerant Problem . . . . . . . . . . . 41

Short of Refrigerant. . . . . . . . . . . . . . . . . . . . . . . . . . 41

Compressor Not Pumping Efficiently . . . . . . . . . . . . 42

Capillary Restriction . . . . . . . . . . . . . . . . . . . . . . . . . 42

Refrigerant R134a Handling Precautions. . . . . . . . . 43

4.5Cabinet Wiring Junction Box . . . . . . . . . . . . . . . . . . . . . . . 44

4.6Mains Isolating Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.7Pressure Temperature Chart . . . . . . . . . . . . . . . . . . . . . . . 47

4.8Troubleshooting Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

5WIRING DIAGRAM

5.1Model: B550/660-2, BME550-2 . . . . . . . . . . . . . . . . . . . . . 52

6SPARES

6.1Cabinet Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

6.2Interior Side Light. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.3Cabinet Wiring Junction Box . . . . . . . . . . . . . . . . . . . . . . . 56

6.4Mains Isolating Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

6.5Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

6.6Sign Unit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

6.7Refrigeration Unit: UB40AAC. . . . . . . . . . . . . . . . . . . . . . . 60

6.8Refrigeration Unit: UB30AAC. . . . . . . . . . . . . . . . . . . . . . . 61

TABLE OF CONTENTS

iv

Page 7

7

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

1.1Cabinet and Refrigeration Unit

Table 1: Specifications

Cabinet Construction

Exterior / Interior: White powdercoat on galvanised steel

Insulation:

50mm thick, polyurethane foam

Cyclo-iso Pentane blowing agent: C5H10/C5H

12

Dimensions

Model: B550-2 B660-2 BME550-2

Height: 2195mm 2195mm 1995mm

Width: 740mm 800mm 740mm

Depth: 750mm 800mm 750mm

Floor area:

0.56m

2

0.6m

2

0.56m

2

Internal volume: 558 litres 658 litres 558 litres

Refrigeration

Electronic controlled, bottom mounted SKOPE refrigeration unit

Model: UB40AAC UB30AAC

Nominal capacity: 581 Watts 581 Watts

Compressor: Electrolux GLY90RA Electrolux GLY90RA

Refrigerant: R134a / 465 grams R134A / 465 grams

Electrical

230-240 Volts a.c. 50 Hz, single phase power supply

Run Amps: 2.15 A 2.36 A 1.96 A

Interior Lighting

Either 1 or 2 vertical 28 Watt T5 fluorescent tubes (Ø16mm x 1150mm)

Illuminated Sign

1 x 14 W T5 fluorescent tube (Ø16mm x 550mm) No sign fitted

Door

Self-closing, aluminium framed, double glazed, toughened safety glass

Shelves

5 adjustable shelves 4 adjustable shelves

SPECIFICATIONS

1

Page 8

8

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

2.1Safety Information

When using any electrical appliance, safety precautions should

always be observed. Read these instructions carefully, and retain for

future reference.

•When used by, or near, young children or infirm persons, close

supervision is necessary. Young children should be supervised

to ensure that they do not play with the appliance.

•Do NOT use this appliance for other than its intended use.

•Do NOT cover the grilles or block the entry or exhaust of airflow

by placing objects up against the refrigeration units.

•Do NOT probe any opening.

•Only use this appliance with voltage specified on the rating label.

•Ensure adequate ventilation of the SKOPE refrigeration units.

•Be careful not to touch moving parts and hot surfaces.

•Regulations require that all electrical work be carried out by

authorised persons. For your own safety, and that of others,

ensure this is done.

•If the supply cord becomes damaged, it must be replaced by a

SKOPE authorised service agent, or similarly qualified person,

in order to avoid a hazard.

•If the refrigeration units are required to be installed or removed

from the cabinet, ensure all necessary safety precautions are

observed.

Warning: Do NOT overload the power supply.

Caution:

Disconnect the cabinet from the mains power supply before

attempting any electrical servicing, cleaning or maintenance.

OPERATION

2

Page 9

9

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

2.2Operation of Machine

Plug in the machine and check operation of the refrigeration unit,

electronic controller and cabinet lighting.

Refrigeration Unit

On initial startup the evaporator and condenser fans and the

compressor will operate. This may be verified by listening for

compressor switch on and checking air movement out of the slots in

the front kick panel. The internal cabinet air will continue to circulate

at all times, as the evaporator fans operate continuously.

The compressor should switch off when the cabinet internal

temperature reaches approximately +2°C. and switch on again at

approximately +4°C.

A fan reversing device reverses the condenser fan motor for a

period of time during the compressor ‘off-cycle’. This rotation

change is to assist with self-cleaning of the condenser coil.

Otherwise, the condenser fan operates continuously in a clockwise

(LE) direction.

The two evaporator fans, located inside the evaporator box, operate

continuously. Both evaporator fans operate in contra rotation, hence

there are dedicated left and right hand blades and different wiring for

the fan motors. Correct airflow, as viewed from the rear, of the unit

left hand fan is clockwise and the right hand fan is anti-clockwise.

Electronic Controller

On initial startup, the electronic controller will either display the

internal cabinet temperature or the controller set point. The

compressor ‘on’ LED will indicate when the compressor is operating.

The controller is located in the front kick panel (see page 14 for

further controller operation).

OPERATION

2

Page 10

10

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Cabinet Lighting

On initial startup, the lights which illuminate the cabinet interior and

top sign (when fitted) will come on and stay on permanently. The

lights will require a period of time to stabilise following initial start up.

Mains Isolating Switch

This cabinet is fitted with a mains isolating switch and IEC

(appliance) socket, located in the refrigeration unit compartment

(see Figure 1 below). The isolating switch and socket can be used

to isolate all cabinet and unit electrics, without unplugging the

cabinet from the wall. Ensure the mains isolating switch is turned

back on after servicing.

Figure 1: Isolating Switch

Isolating Switch

IEC Socket

Refrigeration Unit

Mains Flex

OPERATION

2

Page 11

11

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

2.3Shelving

The chiller is supplied with either four or five cabinet shelves, which

may be positioned at different heights to suit various products. Each

shelf is held in place with four shelf clips, which engage in each of

the four shelf support strips. The support strips are marked with a ‘+’

for easy location of shelf clips (see Figure 2 below).

Loading Product

When loading the cabinet shelves with product:

•For even cooling and efficient operation, allow air space around

packages etc.

•Do not allow products to overhang the front of the shelf as this

could prevent the door from shutting or cause glass breakage.

• Leave an airspace of at least 75mm (3") above packages etc.

on the top shelf.

Figure 2: Shelf Clip

Shelf Support Strip

Shelf Clip

‘+’ Mark

Shelf

OPERATION

2

Page 12

12

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

2.4Cleaning

When necessary, wipe both the interior and exterior of the cabinet

with a damp cloth. The exterior of the cabinet may be also be waxed

with automobile polish for extra protection. Ensure the cabinet is

disconnected from the mains power supply before cleaning.

Periodic cleaning of the condenser coil is also recommended (see

page 40 for cleaning instructions).

Caution:

Disconnect the cabinet from the mains power supply before

cleaning.

OPERATION

2

Page 13

13

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

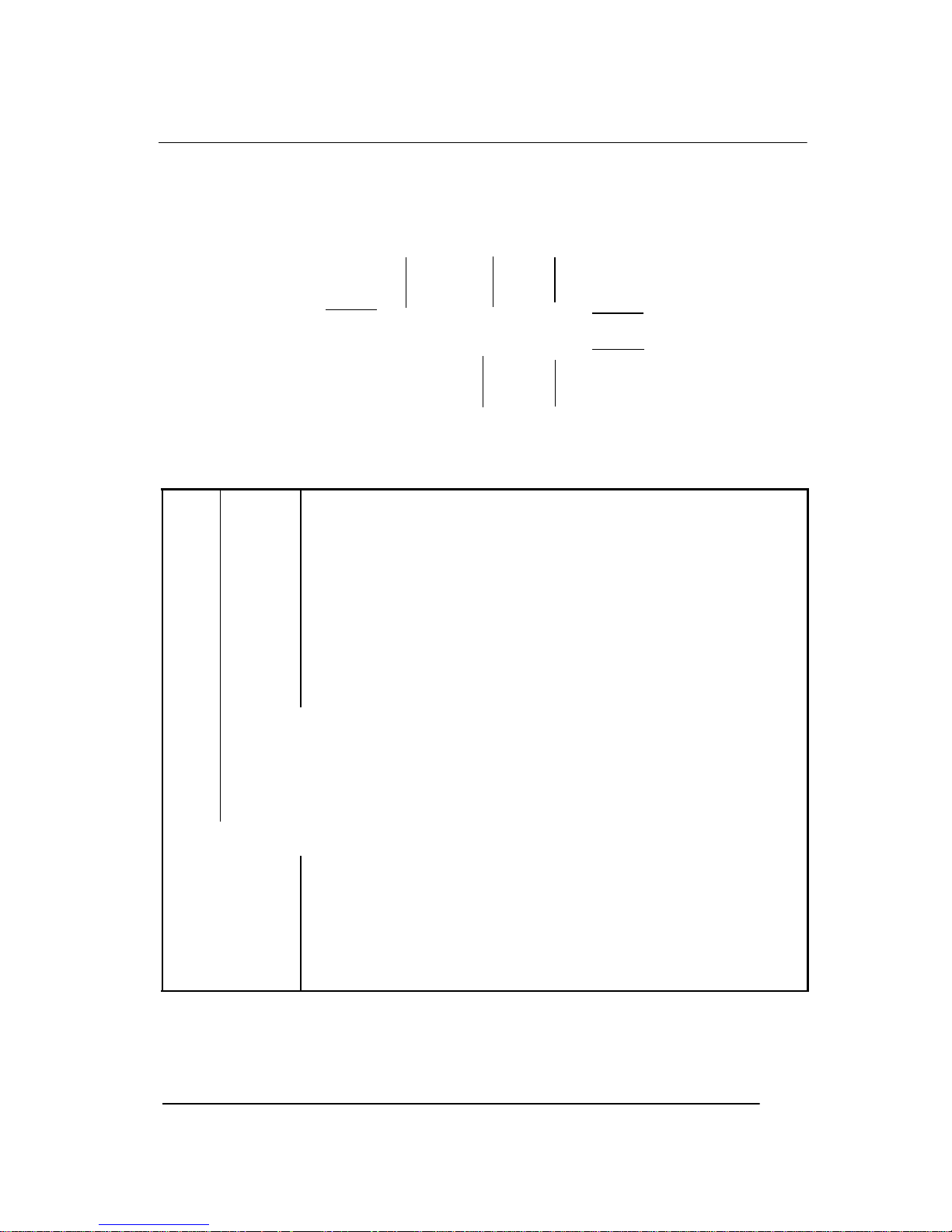

3.1Controller Display

Table 2: Controller Operation

Item KeyFunction

1

SET: Press to display target set point. In programming mode it selects

a parameter or confirms an operation

2

DEFROST: Press to start a manual defrost

3

UP: Press to see maximum stored temperature. In programming mode

it browses the parameter codes, or increases the displayed value

4

DOWN: Press to see the minimum stored temp. In programming mode

it browses the parameter codes, or decreases displayed value

5

Compressor on LED indicator

6

Defrost cycle on LED indicator

7

Set Point displayed LED indicator

8

Decimal point LED indicator

Key Combinations:

Press both keys simultaneously, to lock and unlock the keypad

Press both keys simultaneously, to enter the programming mode

Press both keys simultaneously, to return to room temperature display

1

35

2

4

6

7

8

Figure 3: Controller Display

+

+

+

ELECTRONIC CONTROLLER

3

Page 14

14

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

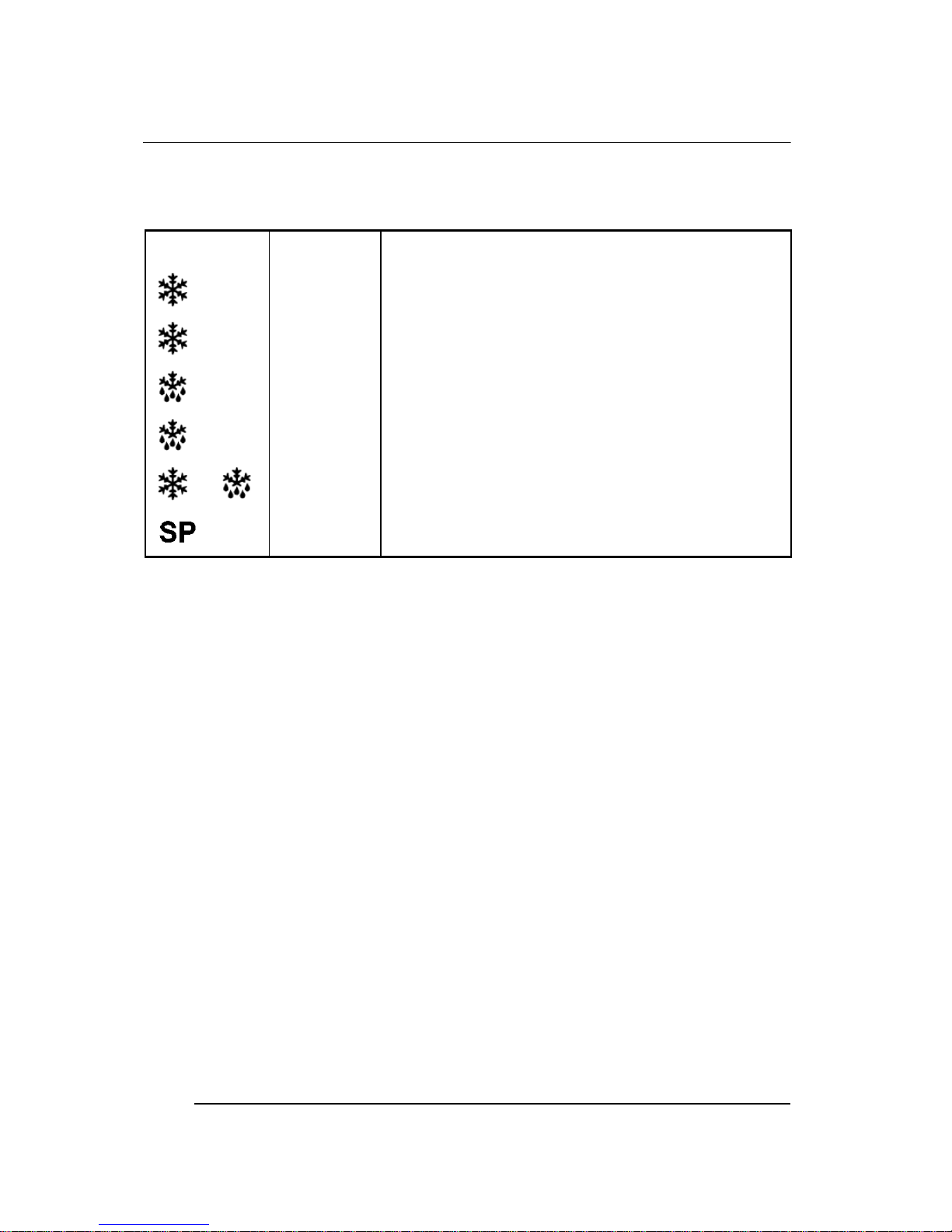

Meaning of LEDs

Table 3: LED Functions

3.2Controller Operation

The SKOPE electronic controller controls and displays the cabinet

temperature. The preset temperature setting controls the product

temperature between 2°C and 4°C.

The electronic controller also signals system and temperature

alarms (see Table 5 on page 19).

To ensure efficient operation, the electronic controller has a built in

minimum off cycle time of 3 minutes and features regular timed

defrost cycles. During the defrost cycle, the compressor switches off

and the evaporator fan stays on.

The controller has two temperature probes; one is used for the

cabinet temperature control and display, while the other probe is

used for the condenser over-temperature alarms.

LEDModeFunction

ONCompressor enabled

FlashingAnti-short cycle delay enabled

ONDefrost enabled

FlashingDrip time in progress

FlashingProgramming mode (see page 16)

ONTemperature alarm (see page 19)

+

ELECTRONIC CONTROLLER

3

Page 15

15

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

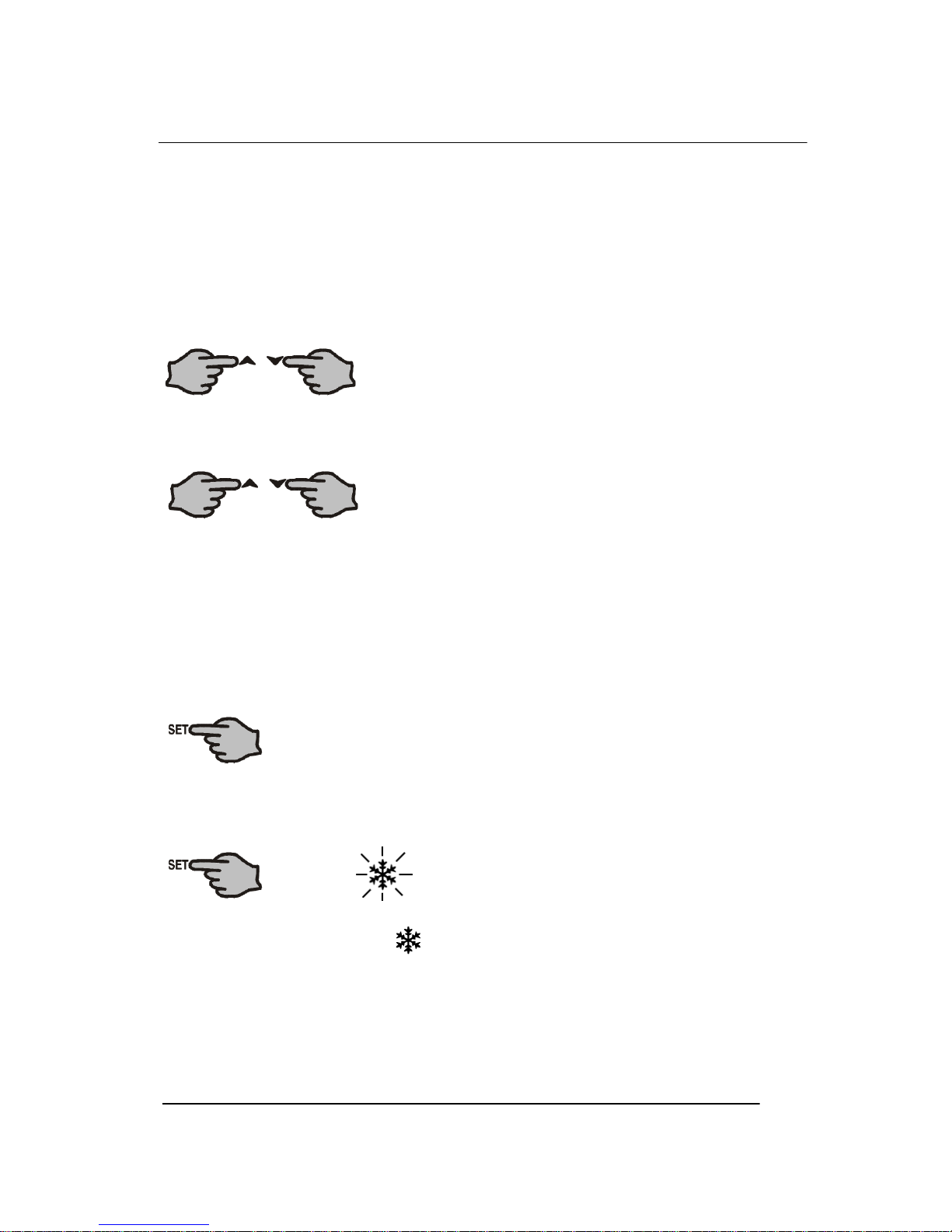

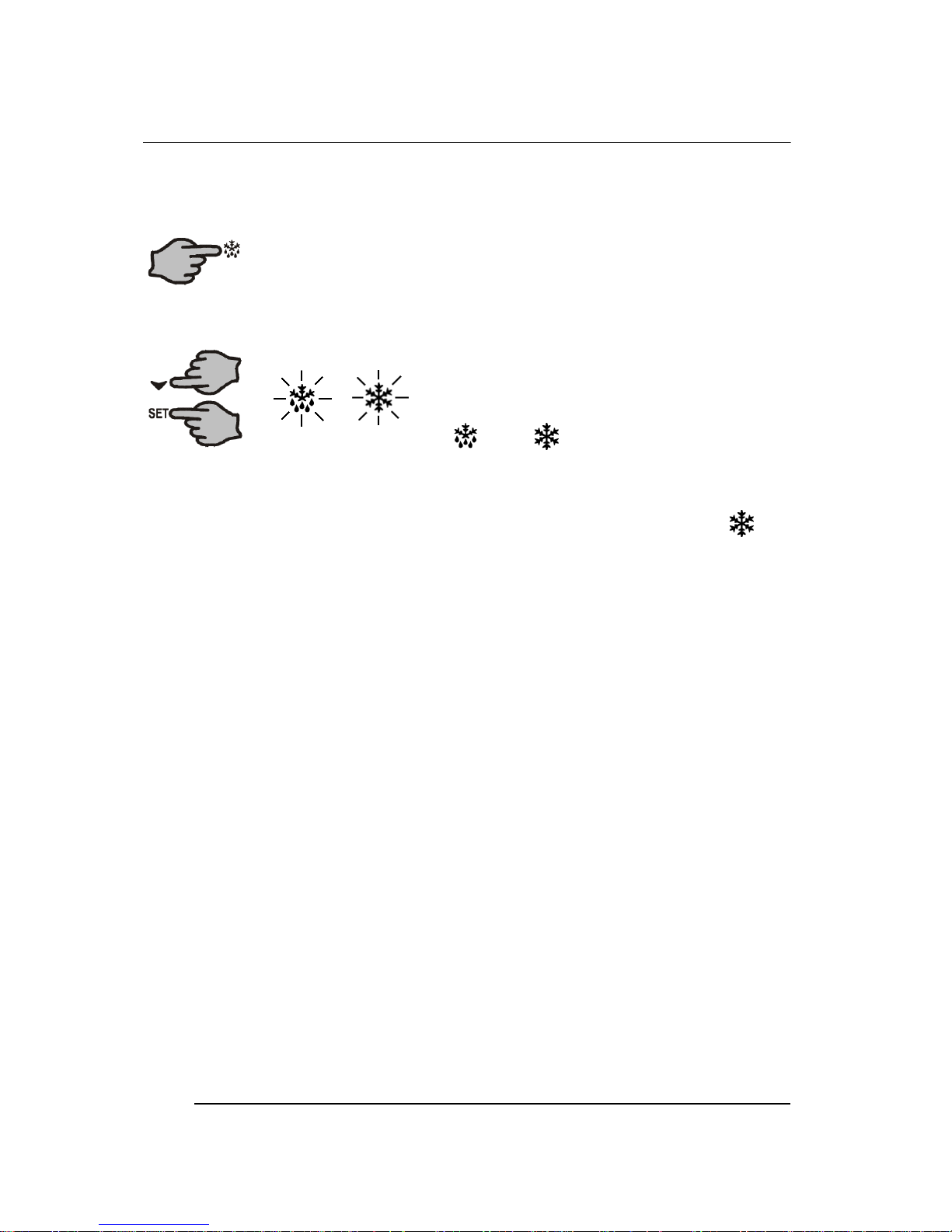

3.3Programming Controller

The controller keypad must always be locked, to prevent

unauthorised modification.

To Unlock the Keypad (to modify parameters)

Press both the UP and DOWN keys

simultaneously until ‘Pon’ is displayed.

To Lock the Keypad

1.Press and hold both the UP and DOWN

keys together for more than 3 seconds.

2. The ‘PoF’ message will be displayed and

the keypad will be locked. At this point it will be possible only to

see the Set Point or maximum or minimum temperature stored.

3.If a key is pressed for more than 3 seconds, the ‘PoF’ message

will be displayed.

To Display the Set Point

Press and immediately release the SET key. The

display will show the Set Point value and the Set Point

LED will be highlighted.

To Change the Set Point

1. Push and hold the SET key for

more than 2 seconds.

2. The value of the Set Point will be

displayed, and the LED will start blinking.

3.To change the Set value, push the UP or DOWN keys.

4.To memorise the new Set Point value, push the SET key again

or wait 15 seconds.

ELECTRONIC CONTROLLER

3

Page 16

16

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

To Start a Manual Defrost

Push and hold the DEFROST key for more than 2

seconds.

To Change a Parameter Value

1. Enter the programming mode by

pressing and holding both the

SET and DOWN keys for 3 sec.

(and start flashing).

2.Select the required parameter.

3.Press the SET key to display the Set value (now only the

LED is flashing).

4.Press the UP or DOWN keys to change the Set value.

5.Press the SET key to store the new value and move to the

following parameter.

6.To exit: Press both the SET and UP keys, or wait 15 seconds

without pressing any keys.

7.To lock in new parameter value: after one minute operation,

disconnect and reconnect cabinet into the mains power supply.

Notes:

1.The Set value is stored even when the procedure is exited, by

waiting for the time-out to expire.

2.Dependent on customer requirements, the SKOPE electronic

controller may have different parameter configurations (see

‘Controller Parameters’ in Table 4 on pages 18). To ensure the

controller is programmed with the correct SKOPE program,

check the program number printed on the controller box

(parameter configuration 160 = Beverage, and 170 = Food).

ELECTRONIC CONTROLLER

3

Page 17

17

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

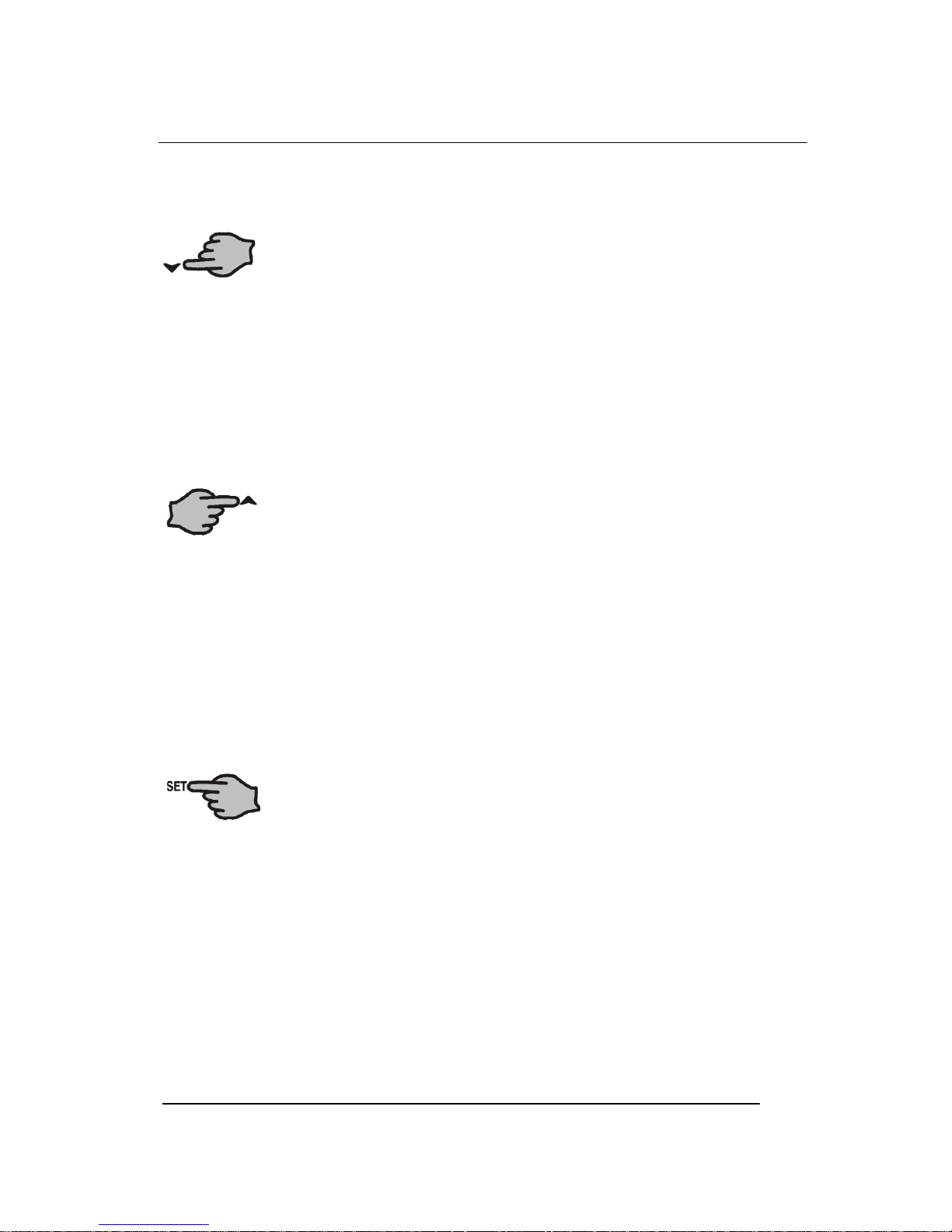

To See the Minimum Temperature

1.Press and release the DOWN key.

2.The ‘Lt’ message will be displayed, followed by the minimum

temperature.

3.Press the DOWN key again, or wait 5 seconds, to restore the

normal display.

To See the Maximum Temperature

1.Press and release the UP key.

2.The ‘Ht’ message will be displayed, followed by the maximum

temperature recorded.

3.Press the UP key again, or wait 5 seconds, to restore the

normal display.

To Reset the Maximum and Minimum

Temperature

1.Press and hold the SET key for more than 3 seconds, while the

maximum or minimum temperature is displayed. The ‘rSt’

message will be displayed.

2.To confirm the operation, the ‘rSt’ message starts flashing and

the normal temperature will be displayed.

ELECTRONIC CONTROLLER

3

Page 18

18

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

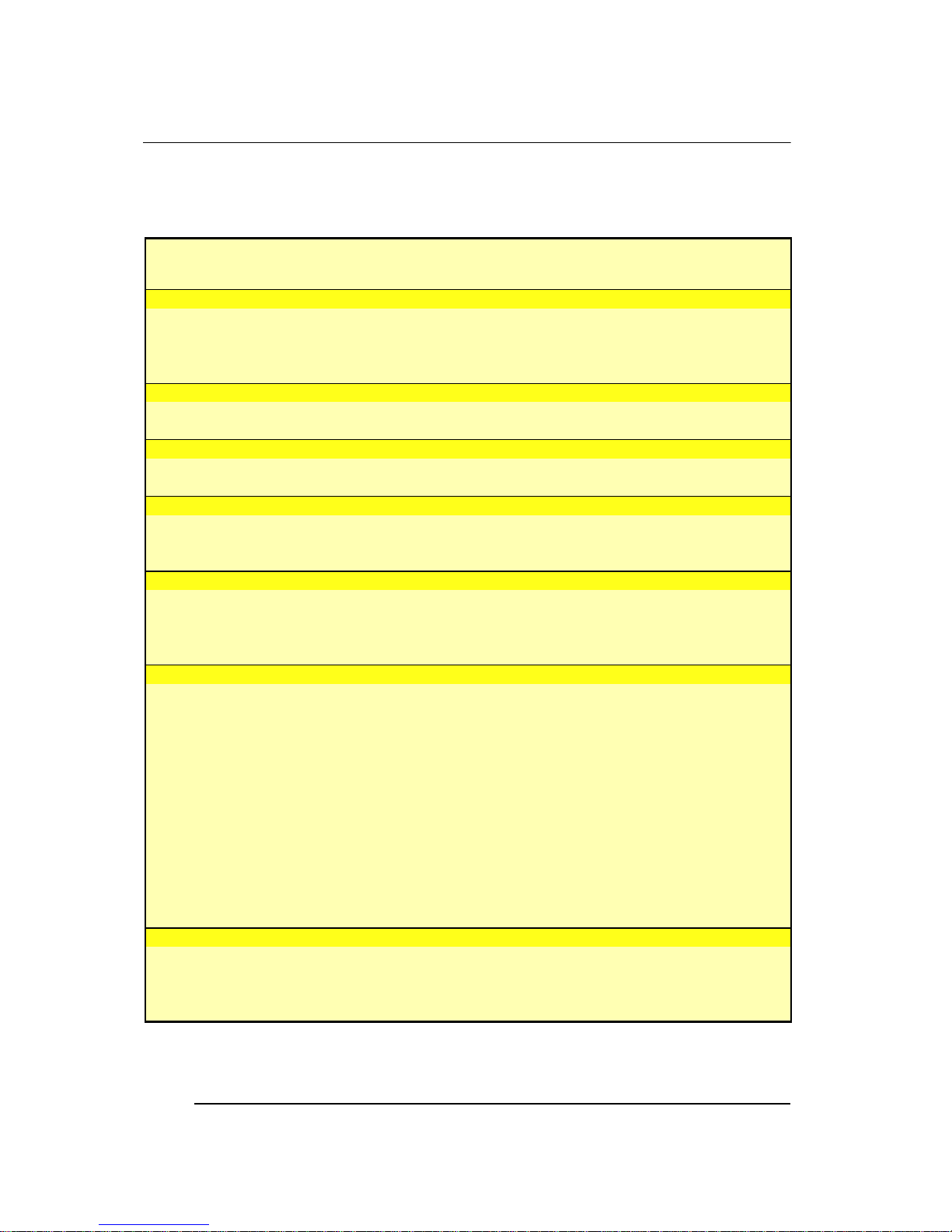

3.4Parameters

Table 4: Controller Parameters

Parameters

Display Beverage

160

Food

170

Range Description of Parameter

SET POINT PARAMETERS

Set 2 1 LS to US Set Point

Hy 2 2 0.1°C to 25.5°C Differential

LS 1 -1 -50°C to Set Minimum Set Point

US 15 5 Set to 150°C Maximum Set Point

PROBE PARAMETERS

Ot -0.7 0 -12°C to 12°C Thermostat probe calibration

OE 0 0 -12°C to 12°C Condenser probe calibration

CONTROL PARAMETERS

OdS 0 0 0 to 255 minutes Outputs delay at start up

AC 3 3 0 to 50 minutes Anti-short cycle delay

DISPLAY PARAMETERS

CF °C °C °C / °F Temperature measurement unit

rES dE in in / dE Resolution

LoD P1 P1 P1 / P2 or SP Local display

DEFROST PARAMETERS

IdF 6 6 1 to 120 hours Interval between defrost cycles

MdF 12 12 0 to 255 minutes Maximum length for defrost

dFd dEF dEF rt / it / Set / DEF Displaying during defrost

dAd 20 20 0 to 255 minutes Maximum display delay after defrost

ALARM PARAMETERS

ALc Ab Ab rE / Ab Temperature alarms configuration

ALU 12 7 up to 150°C Maximum temperature alarm

ALL -2 -2 -50°C to ALU Minimum temperature alarm

AtH 1 1 0.1°C to 25.5°C Differential for temperature alarm in cabinet

ALd 240 120 0 to 255 minutes Temperature alarm delay

dAO 24 24 0 to 23.5 hours Delay of temperature alarm at start up

tbA n n n = no / y = yes Alarm relay silencing

PA2 58 58 -40°C to AU2 Condenser over temperature

AU2 65 65 -40°C to 110°C AUE Condenser alarm temperature

ACH 5 5 0.1°C to 25.5°C Differential for condenser alarm temp recovery

dL2 2 2 0 to 255 minutes Condenser alarm delay

dA2 0 0 0 to 23.5 hours Condenser alarm temperature delay at start up

AOP CL CL OP / CL Alarm relay polarity

OTHER PARAMETERS

dP1 - - - Thermostat probe read out

dP2 - - - Condenser probe read out

rEL - - - Software release

Ptb - - - Map code

ELECTRONIC CONTROLLER

3

Page 19

19

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

ELECTRONIC CONTROLLER

3

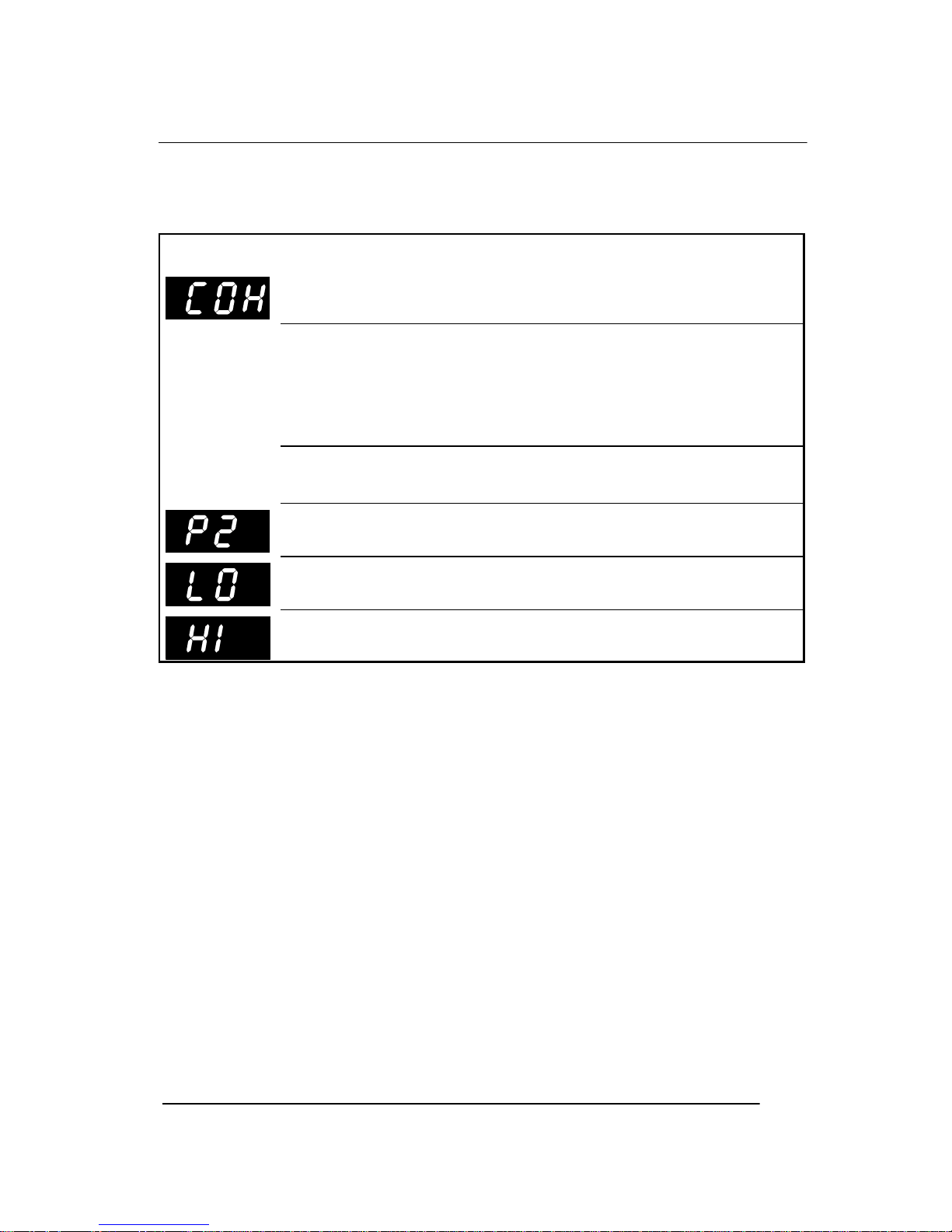

3.5Alarm Displays

Table 5: Controller Alarm Displays

Note: The refrigeration system and cabinet lighting shut down with

‘P1, P2 and CSd’ alarms.

Alarm Recovery

•Condenser Stage ONE over-temperature alarm (COH) recovers

when the condenser is either cleaned or cools down.

•Condenser Stage TWO over-temperature alarm (CSd) recovers

by disconnecting and reconnecting the cabinet mains power

supply (or isolation switch), which will reset all the alarms.

•Cabinet temperature alarms (LO and HI) automactically stop at

temperature recovery.

AlarmDescription

Stage ONE - Maintenance required:

Immediately attend condenser (for auto alarm reset).

Stage TWO - Refrigeration Shut-Down:

Condenser over-temperature has shut-down system and

cabinet lighting. Attend condenser. To reset alarm, cabinet

must be replugged into power supply. For repeat alarms,

contact an authorised service agent.

Faulty Ambient probe (internal cabinet - return air).

Refrigeration system and cabinet lighting shut down.

Faulty High Temperature probe (condenser).

Refrigeration system and cabinet lighting shut down.

Internal cabinet - LOW temperature alarm.

Alarm will stop at temperature recovery.

Internal cabinet - HIGH temperature alarm.

Alarm will stop at temperature recovery.

Page 20

20

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

3.6Replacement

If the SKOPE electronic controller has a suspected fault, care must

be taken to ensure accurate diagnosis. The controller has various

programmable parameters that effect operation such as time delay

and defost modes (see Table 4 on page 18).

•Any suspected failure must be double checked.

•Confirm all wiring and terminations are correct.

•Check probe resistance is correct (see Table 6 below).

•Replace any faulty components.

Controller NTC Probe Resistance

* Tolerance ± 2.4%

Table 6: NTC Probe Resistance

Temperature

Resistance*

(K Ohms)

-10°C 42.5

-5°C 34.0

0°C 27.3

5°C 22.1

10°C 18.0

20°C 12.1

30°C 8.3

40°C 5.8

50°C 4.2

ELECTRONIC CONTROLLER

3

Page 21

21

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Controller Removal

1.Disconnect the cabinet from the mains power supply.

Alternatively, the cabinet can be switched off and unplugged

from the mains isolating box, located on the left hand side of

the refrigeration unit compartment. The cabinet kick panel will

need to be removed to access the mains isolating box.

2.Remove the cabinet kick panel, by loosening the two top

keyhole fixing screws and lifting the panel up and forward.

3.Loosen off the two top keyhole fixing screws that hold the

controller box assembly to the kick panel.

4.Unscrew and remove the controller box cover.

5.Release the controller fixing clips, each side of the controller.

6.Disconnect the push-on terminals from the back of controller.

7.Fitting the controller is a reversal of these instructions.

Figure 4:

Removing the Controller Box

Controller

Fixing Clip

Controller Box

Controller

Controller

Keyhole Fixing

Screws

Figure 5:

Removing the Controller

Push-on Terminals

Cabinet Kick

Panel

ELECTRONIC CONTROLLER

3

Page 22

22

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Replacement Controller

The Dixell XR30C, ELZ0471, controller has been replaced by the

Dixell XR30C, ELZ0471B (Rev B) electronic controller.

The Dixell XR30C ELZ0471B Rev B controller provides identical

functionality in an essentially identical housing. The only difference

in the two models is the connection terminals at the rear of the

controller. The Dixell XR30C Rev A controller (see Figure 7) uses a

low insertion force right-angled socket. The XR30C Rev B controller

(see Figure 6) uses five standard right-angled 6.3mm Q.C. PCB

mount terminals, providing a more reliable connection.

This change is effective from February 2005, cabinet serial no.

A050212714.

Figure 7:

Dixell XR30C ELZ0471

Rev A Controller

Figure 6:

Dixell XR30C ELZ0471B

Rev B Controller

ELECTRONIC CONTROLLER

3

Page 23

23

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Dixell Controller Wiring

The wiring configuration has also been simplified to eliminate one of

the two external loop wires (see Figures 8 and 9 below).

Note: The arrangement of the order of the connections and position

of the external loop wire differs between the two variations.

However, the connections at the refrigeration system electrical

junction box remain the same.

Figure 9:

Dixell XR30C ELZ0471

Rev A Controller

Figure 8:

Dixell XR30C ELZ0471B

Rev B Controller

ELECTRONIC CONTROLLER

3

Page 24

24

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.1Interior Side Light

The cabinet can have one or two interior side lights. Each side light

houses one 28 Watt T5 fluorescent tube, which may be replaced

without removing shelves or product from the cabinet. To replace

the fluorescent tube:

1.Disconnect the cabinet from the mains power supply.

2.Remove the side light diffuser, by compressing the back

section of the diffuser until it disengages from the aluminium

housing and then push the diffuser back (see Figure 10 below).

3.The fluorescent tube can now be removed. Revolve the tube

until the pin position allows withdrawal.

4.When refitting the new fluorescent tube ensure the printing on

the tube is at the bottom, as the tube orientation is important.

5.When refitting the diffuser, engage the back section into the

housing, and then compress and snap the front section of

diffuser back into place working down the full length of the light.

Fluorescent Tube

Diffuser

Figure 10: Replacing the Fluorescent Tube

SERVICE INSTRUCTIONS

4

Page 25

25

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.2Door

Alignment

Door alignment can be achieved by removing the kick panel and

releasing the bottom hinge fixing bracket. The brackets are provided

with slots allowing alignment adjustment.

Gasket Replacement

The door gasket clips into the door frame extrusion and may be

removed for repair or replacement simply by peeling from the frame,

starting at a corner (see Figure 11 below).

Should the gasket be out of shape when in place, use hot air (i.e.

from hair drier) to realign.

Figure 11: Door Gasket Removal

Door Gasket

Gasket Retainer

Door Frame

SERVICE INSTRUCTIONS

4

Page 26

26

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Door Tension

The glass door has an internal torsion bar, pretensioned at the

factory, which enables the door to self-close. If necessary, door

tension can be further adjusted by rotating the capstan mounted in

the bottom hinge bracket. To adjust the door tension:

1.Slowly release tension on the capstan, by turning the capstan

with a Ø2.5mm steel rod and removing the split pin.

2.With the aid of another Ø2.5mm steel rod, increase the tension

by turning the capstan in the direction the door closes.

3.Once adequate tension has been achieved, re-insert the split

pin through the hole in the hinge bracket to lock in position.

4.To check door tension; hold the door open approximately

100mm and let go of the door. The door should gently close

with the door gasket forming an air tight seal with the cabinet.

In the event the door tension can no longer be adjusted, the torsion

bar may need replacing (see ‘Torsion Bar Replacement’, page 27).

Figure 12: Door Tension

Capstan

Split Pin

Bottom Hinge Bracket

Door

SERVICE INSTRUCTIONS

4

Page 27

27

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Torsion Bar Replacement

The torsion bar assembly is located inside the door frame and can

be replaced if necessary. To replace the door torsion bar assembly:

1.Remove the door from cabinet (see ‘Door Removal’, page 28).

2.Carefully lever out the bottom bush from the door frame and

pull old torsion bar out from the door frame. The end of the

torsion bar will need manoeuvring, to allow the ‘flat hook’ end to

clear the hinge hole.

3.Remove the existing capstan and bush from the old torsion bar.

4.Thread the capstan, complete with the bush, over the ‘round

hook’ end of the new torsion bar (see Figure 13 below). Ensure

the aluminium tube moves freely up and down the torsion bar.

5.Fit the new torsion bar assembly into the door frame. When the

torsion bar is correctly installed, the capstan should not turn.

6.Lightly tap the bottom of the capstan into the hinge hole, until

the bush is flush with the door frame.

7.Refit the door to the cabinet and adjust the tension (see ‘Door

Tension’ on page 26).

Figure 13: Door Torsion Bar Assembly

Torsion Bar

‘round hook end’

Door Bush

Capstan

Door Frame

SERVICE INSTRUCTIONS

4

Page 28

28

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Door Removal

For ease of servicing and reversing hinging, the door can be

removed from the cabinet. To remove the door:

1.Disconnect the cabinet from the mains power supply.

2.Slowly release tension on the door capstan, by turning the

capstan with a Ø2.5mm steel rod and removing the split pin

from the bottom hinge bracket.

3.Unscrew the bottom hinge. Important: ensure the weight of the

door is fully supported, before removing the bottom hinge.

4.The door and hinge can now be removed from the cabinet.

To refit the door:

1.Lift the door onto the top hinge pin. The weight of the door will

need supporting, until the bottom hinge is fitted.

2.Locate bottom hinge onto door capstan and attach to cabinet.

3.Check alignment with other doors and adjust as necessary.

4.Re-tension the door (see ‘Door Tension’ on page 26).

Hinge Reversal

The glass door can be hinged on either the left or right hand side. To

reverse the door hinging opposite hand top and bottom hinges are

required.

1.Remove the door (see ‘Door Removal’ above).

2.Remove the existing top and bottom hinges and replace with

the opposite hand hinges (see page 58 for part numbers).

3.Remove the torsion bar assembly from the door.

4.Refit torsion bar assembly into the opposite end of the door.

5.Refit top door bush.

6.Refit the door to the cabinet (see ‘Door Removal’, above).

7.Re-tension the door (see ‘Door Tension’ on page 26).

SERVICE INSTRUCTIONS

4

Page 29

29

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.3Sign Unit

The illuminated sign unit, located on top of the cabinet houses a

fluorescent tube and electronic ballast. Internal access to the sign

unit may be gained with the sign unit still attached to the cabinet.

To Replace the Fluorescent Tube

To access the fluorescent tube, the curved sign panel must first be

removed from the sign unit. No tools are required for this procedure.

To remove the sign panel:

1.Disconnect the cabinet from the mains power supply.

2.Start at one of the top corners of the sign unit and pull the sign

panel out from under the sign top cover (see Figure 14 below).

3.Work along the length of the sign unit, pulling the sign panel out

as you go.

4.Carefully remove the sign panel away from the sign unit.

5.The fluorescent tube can now be accessed for replacement

(see figure 16 on page 30).

Figure 15: Sign Corner Detail

Sign Top Cover

Corner Notch

Sign Panel

End Strip

Sign Panel

Figure 14: Removing Sign Panel

Sign Top Cover

Corner

Notch

SERVICE INSTRUCTIONS

4

Page 30

30

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

To refit the curved sign panel:

1.Ensure both sign end strips are fitted to the sign panel.

2.Carefully fit the sign panel into the bottom sign cover, ensuring

the sign end strips are correctly positioned in both of the bottom

corner notches.

3.Locate one top corner of the sign panel into the corner notch of

the top cover. Ensure the end strip fits neatly into the corner

notch (see Figure 15 on page 29).

4.Use your thumbs to push the sign panel under the top cover,

working progressively along the full length of the panel. Ensure

the sign panel engages into the sign top along the full length of

the sign unit.

5.Ensure both the sign end strips fit neatly into the top and

bottom corner notches.

Figure 16: Sign Unit (with sign panel removed)

Fluorescent Tube

Sign Top Cover

Sign Panel

Sign Bottom Cover

Sign Panel

End Strip

Sign Wiring Cover

SERVICE INSTRUCTIONS

4

Page 31

31

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

To Replace the Electronic Ballast

The electronic ballast is located inside the sign unit, mounted on the

back of the sign wiring cover. To access the electronic ballast:

1.Disconnect the cabinet from the mains power supply.

2.Remove the sign unit from the top of cabinet (see ‘To Remove

the Sign Unit’ on page 32).

3.Remove the curved sign panel (see ‘To Replace the

Fluorescent Tube’ on page 29).

4.Remove the fluorescent tube, to avoid it being damaged.

5.Remove the sign wiring cover, by undoing the four screws from

the rear of the sign unit.

6.The electronic ballast, mounted on the back of the sign wiring

cover, can now be accessed for replacement (see Figure 17

below).

Figure 17: Electronic Ballast

Electronic Ballast

Sign Wiring Cover

Connector Block

SERVICE INSTRUCTIONS

4

Page 32

32

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

To Remove the Sign Unit

For ease of servicing, the sign unit can be removed from the cabinet:

1.Unplug the sign unit from the cabinet roof top power supply

socket.

2.Loosen and turn the sign retaining clip on the top of each side

panel (see Figure 18 below).

3.Loosen the two screws on the back of the sign unit bracket.

4.Lift the sign unit up to separate the sign from the sign sides.

5.The sign unit can now be removed from the cabinet.

To Remove the Sign Side Panels

For ease of servicing, the sign side panels can be removed from the

cabinet. To remove the side panels:

1.Remove the sign back panel, by lifting up to disengage from

the side panels (see Figure 19 below).

2.Loosen the keyhole screws, holding side panels to cabinet top.

3.Slide the side panels forward to disengage the keyholes.

Figure 18: Sign Retaining Clip

Figure 19: Sign Back Panel

Sign Retaining Clip

Sign Side Panel

Sign Back

Panel

SERVICE INSTRUCTIONS

4

Page 33

33

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.4Refrigeration Unit

The SKOPE Cyclone® unit is a self-contained refrigeration module,

which aligns with port holes in the floor of the cabinet. Air is drawn

through the evaporator and blown up the back duct. Air returns to

the evaporator through the floor port hole.

The refrigeration unit can be isolated from the mains power, by

switching off the mains isolating switch and disconnecting the

appliance connector (unit to mains isolating box flex).

All electrical connections for the refrigeration unit are contained

inside the unit junction box, mounted on front of the refrigeration unit

(see page 37).

Figure 20: Refrigeration Unit

Unit Junction Box

Unit Side Baffle

Electronic Controller (in transit position)

Evaporator Coil

Condenser Coil

Compressor

SERVICE INSTRUCTIONS

4

Page 34

34

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

To Remove the Refrigeration Unit

For servicing, the refrigeration unit can be removed from the cabinet.

1.Disconnect the cabinet from the mains power supply.

2.Remove the cabinet kick panel, by loosening the screws along

the top back flange of the kick panel. Raise the kick panel

vertically to clear keyholes off the screw heads, then tilt panel

forward and lift up and off the bottom fixing brackets. Access to

top screws can be made easier by opening the cabinet door.

3.Unplug the cabinet sidelight 5-pole plug from underneath the

right hand side of the cabinet wiring junction box.

4.Unplug the cabinet roof top supply 3-pole plug from underneath

the centre of the cabinet wiring junction box.

5.Unplug the cabinet wiring junction box 3-pole plug from the

front of the refrigeration unit junction box.

Figure 21: Cabinet Wiring Junction Box

Refrigeration Unit Junction Box

3-Pole Socket

Cabinet Wiring

Junction Box

Cabinet Sidelight

5-Pole Plug

Cabinet Roof Top 3-Pole Plug

Electronic Controller

Unit Side Baffle

SERVICE INSTRUCTIONS

4

Page 35

35

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.Loosen the two keyhole screws holding the cabinet wiring

junction box to the guide rails.

7.The wiring junction box can now be lifted off the keyhole

screws and removed clear of the cabinet.

8.Switch off the isolating switch and unplug the refrigeration unit

from the mains isolating box.

9.Remove the unit bottom baffle by loosening both screws on the

bottom baffle and lifting up and off the screw heads.

10.Remove the top screws from both guide rails and pull both

guide rails down level with the unit base (this will lower the

entire refrigeration unit away from the base of the cabinet).

11.The refrigeration unit can now be pulled straight out from the

cabinet, using the diagonal white handles on either side.

12.Important: ensure the cabinet sidelight and roof top supply

flexes are drawn safely clear of the unit.

Figure 22: Isolating Switch

Isolating Switch

IEC Socket

Refrigeration Unit

Mains Flex

SERVICE INSTRUCTIONS

4

Page 36

36

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

To Re-Install the Refrigeration Unit

Refitting the refrigeration unit is a reversal of the removal procedure.

1.Ensure all cables, capillaries etc. are secured away from sharp,

hot or moving objects before replacing the refrigeration unit.

2.Ensure the refrigeration unit is plugged into the isolating box

and that the mains isolating switch is turned on.

3.Ensure the refrigeration unit is pushed fully home before raising

both the guide rails and locking into position.

4.Plug the cabinet wiring junction box into the refrigeration unit

junction box.

5.Important: ensure the unit bottom baffle is refitted (see Figure

21 on page 34).

6.Refit the cabinet wiring junction box and cabinet kick panel.

7.Reconnect the cabinet to the mains power supply.

Figure 23: Removing Refrigeration Unit

Refrigeration Unit

Junction Box

3-Pole Socket

Unit Side

Baffle

SERVICE INSTRUCTIONS

4

Page 37

37

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Refrigeration Unit Junction Box

Electrical connections for the refrigeration unit are contained inside

the refrigeration unit junction box, mounted on the front of the refrigeration unit. Evaporator fan connections and capacitors are located

inside the evaporator motor junction boxes. To access the fan motor

connections, fan motor capacitor and fan reversing timer:

1.Disconnect the cabinet from the mains power supply.

2.Remove the kick panel, electronic controller and refrigeration

unit from the cabinet (see page 34 for removal instructions).

3.Unplug the cabinet wiring junction box plug from the cabinet

supply socket, on the front of the unit junction box.

4.Undo the two screws from front and rear of the unit junction box

and remove the cover, leaving the Earth wire attached.

5.All electrical connections can now be accessed.

6.Ensure the unit junction box cover is replaced after servicing.

Figure 24: Refrigeration Unit Junction Box

Condenser

Fan Motor

Fan Reversing Timer

Cabinet Supply Socket

Refrigeration Unit Junction Box

Fan Motor

Capacitor

Resistor

Condenser Fan

Shroud

SERVICE INSTRUCTIONS

4

Page 38

38

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Evaporator Fan Motor Assembly

The evaporator fan motors can be removed from the evaporator box

as a complete assembly. To replace an evaporator fan motor:

1.Remove the refrigeration unit (see page 34).

2.Remove the cover from the refrigeration unit junction box.

3.Trace the evaporator fan motor flex to the push-on connections

inside the unit junction box and disconnect the terminals.

4.Undo the two top screws from the mounting bracket and lift out

complete evaporator fan motor ass’y (see Figure 25 below).

5.Undo two screws from motor junction box and disconnect flex.

6.Remove the fan blade and undo four screws holding fan motor.

7.Replace the fan motor capacitor inside the motor junction box.

8.Fit the new fan motor and re-assemble.

9.When refitting the evaporator fan motor assembly, reseal the

flex hole in the evaporator box.

Figure 25:

Evaporator Fan Motor Assembly

Figure 26:

Evaporator Motor Junction Box

Evaporator Fan

Motor Assembly

Evaporator Motor Junction Box

Evaporator Motor Flex

Evaporator Motor

Fan Blade

Refrigeration Unit

Junction Box

Fan Motor Capacitor

SERVICE INSTRUCTIONS

4

Page 39

39

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Condenser Fan Motor Assembly

The condenser fan motor, fan blade and mounting bracket can be

removed from the refrigeration unit as a complete assembly. To

replace the condenser fan motor assembly:

1.Remove the refrigeration unit (see page 34).

2.Remove the cover from the refrigeration unit junction box (see

page 37).

3.Trace the condenser fan motor flex to the push-on connections

inside the unit junction box and disconnect the terminals.

4.Withdraw condenser fan motor flex out of the unit junction box.

5.Undo the two top fixing screws from the mounting bracket.

6.Remove the complete condenser fan motor assembly.

7.Remove the fan blade and undo four screws holding fan motor.

8.Replace the fan motor capacitor inside the unit junction box.

9.Fit new fan motor and re-assemble.

Figure 27: Condenser Fan Motor Assembly

Condenser Fan

Motor Assembly

Condenser Coil

Fixing Screws (2)

Fan Blade

Condenser Fan Motor Flex (disconnected from unit junction box)

Mounting Bracket

SERVICE INSTRUCTIONS

4

Page 40

40

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Cleaning the Condenser Coil

The condenser coil MUST be kept clean for efficient and reliable

operation. Clean the condenser coil with a brush and vacuum

cleaner regularly. The condenser coil is located behind a side baffle,

on the right hand side of the refrigeration unit (see Figure 21 on p34).

To access the condenser coil:

1.Disconnect the cabinet from the mains power supply.

2.Remove the cabinet kick panel and cabinet wiring junction box

(see instructions on page 34).

3.Remove the two screws holding the side baffle to the

condenser coil and carefully pull the baffle out from the unit.

4.The condenser coil can now be accessed for cleaning. Clean

the condenser coil with a brush and vacuum cleaner.

5.Refit the side baffle and cabinet wiring junction box.

6.Refit the cabinet kick panel, and reconnect to the power supply.

Caution:

The cabinet MUST be disconnected from the mains power

supply before cleaning the condenser coil.

Figure 28: Condenser Coil

Cabinet

Kick Panel

Cabinet Wiring

Junction Box

Keyhole Fixing Screw

Cabinet Door

(open)

Condenser Coil

Kick Panel Keyhole

Fixing Screw

SERVICE INSTRUCTIONS

4

Page 41

41

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Recommended Service Procedures

SKOPE recommend the SKOPE Cyclone® demountability and

exchangeability philosophy, which in essence means: The customer

must not be inconvenienced during system maintenance.

In the unlikely event of Refrigeration failure, an exchange unit is

simply swapped in a matter of minutes. There is no cabinet down

time or unloading product. In one 5 minute visit, the customer's

inconvenience ends. The faulty Cyclone® is then removed to the

workshop for repair as time allows.

For a Suspected Refrigerant Problem

Disconnect the evaporator fan motor and with the system running, a

‘frost line’ will become obvious (after approximately 8 minutes):

Entire evaporator and accumulator must be frosting. Compressor at

suction inlet will be cold and sweating.

If these conditions are not met, the system is faulty, either short of

refrigerant, compressor not pumping efficiently, or capillary

restriction. The system must then be opened (see Refrigerant

R134a Handling Precautions section) and gauges temporarily fitted

(i.e. either temporarily fit line piercing valves, or braze in service

lines).

Short of Refrigerant

Where the frosting effect is shorter than required (unless all

refrigerant is lost, where there is no frosting effect). Only a small

amount of refrigerant will exit the system. A leak test (refrigerant /

dry nitrogen mix, up to 250 psig) should be performed to locate the

leak. If no leak is found, a pressure test should be performed (dry

nitrogen only, up to 250 psig) if there is no pressure drop over 24

hours, the fault should be treated as a capillary restriction.

SERVICE INSTRUCTIONS

4

Page 42

42

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Compressor Not Pumping Efficiently

Where the frosting effect is not as cold as it should be. Symptoms

include: compressor body hotter than normal, condenser cooler

than normal, and the compressor may make an unusual hissing

sound. All of these symptoms depend on the severity of the problem.

The only way to prove a pumping problem is to perform a

compressor pump-down test: braze closed compressor suction line,

Open discharge line; then run the compressor to pull a vacuum on a

vacuum gauge. The compressor should pull down to approximately

30" (inches) vacuum then turn the compressor off and this vacuum

must be held without any loss for 5 minutes. If the Compressor does

not pass these tests; it is not pumping efficiently and must be

replaced.

There are different methods to proving pumping efficiency. If the test

is performed with a system charged with refrigerant, a deep vacuum

will not be achieved.

Capillary Restriction

With a totally blocked capillary, there will be no refrigeration effect.

A partially blocked capillary may have similar symptoms to a system

being short of refrigerant. Flush a restricted capillary with dry

nitrogen. If the capillary will not clear, it must be replaced.

After the repair, the drier must be replaced (every time the

refrigeration system is opened, the drier must be replaced). The

Cyclone® must be fully evacuated and charged to the volume of

refrigerant indicated on the Cyclone® serial/rating label. All service

lines must be purged.

Finally, pinch-off the gauge process lines (or remove line piercing

valves) and braze the system closed. SKOPE recommend against

leaving service valves in the system as these are prone to leak (and

are open to abuse). Perform a final system leak test.

SERVICE INSTRUCTIONS

4

Page 43

43

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Refrigerant R134a Handling Precautions

It is important to maintain dedicated HFC service equipment and

parts:

•Refrigeration gauges

•Service lines / Fittings

•Vacuum Pump

•Charging equipment

•Driers

•Compressors

•Temperature / Pressure chart

HFC (R134a) refrigeration systems require special service

procedures because of the highly hygroscopic (moisture sensitive)

polyolester (POE) compressor oil:

•The system (especially compressor) must only be open for the

very minimum time (to prevent moisture ingression). All parts

required for servicing must be at hand - before the system is

opened, and there should be no interruption until the system is

on the vacuum pump (or hermetically sealed).

•The system must not be open for longer than 20 minutes max.

•The drier must be replaced every time the system is opened.

•Clean work practices are essential.

•SKOPE recommend brazing the system closed after service - as

valves are prone to leak due to the nature of R134a.

Important:

Every time the refrigeration system is opened, the drier MUST be

replaced.

SERVICE INSTRUCTIONS

4

Page 44

44

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.5Cabinet Wiring Junction Box

The cabinet wiring junction box houses the electronic ballast,

cabinet fuse and electrical supply wiring for the cabinet. The cabinet

wiring junction box is located behind the kick panel, in front of the

refrigeration unit. The cabinet sidelight and cabinet roof top supply

plug into the cabinet wiring junction box, which in turn plugs into the

refrigeration unit junction box. For servicing, the cabinet wiring

junction box can be removed from the cabinet.

To access the Cabinet Wiring Junction Box

1.Disconnect the cabinet from the mains power supply.

2.Remove the cabinet kick panel, by loosening the screws along

the the top back flange of the kick panel. Raise the kick panel

vertically to clear keyholes off the screw heads, then tilt panel

forward and lift up and off the bottom fixing brackets. Access to

top screws can be made easier by opening the cabinet door.

3.Unplug the cabinet sidelight 5-pole plug from underneath the

right hand side of the wiring junction box.

4.Unplug the cabinet roof top supply 3-pole plug from underneath

the centre of the wiring junction box.

5.Unplug the cabinet wiring junction box 3-pole plug from the

junction box on the refrigeration unit.

6.Loosen keyhole screws from either end of wiring junction box.

7.The cabinet wiring junction box can now be lifted off keyhole

screws and removed from the cabinet.

8.Remove the three bottom screws and slide the junction box lid

down and off.

9.When refitting the cabinet wiring junction box to the cabinet,

ensure the cabinet roof top supply and sidelight flexes are both

plugged in and the cabinet wiring junction box is plugged into

the refrigeration unit junction box.

SERVICE INSTRUCTIONS

4

Page 45

45

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

Cabinet Junction Box Lid

3 Amp Ceramic Fuse

Electronic Ballast

ENSTO 3-Pole Socket

Cabinet Junction Box to Unit Junction Box Flex

ENSTO 5-Pole Socket

Screw Keyhole

Figure 29: Cabinet Wiring Junction Box

SERVICE INSTRUCTIONS

4

Page 46

46

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.6Mains Isolating Box

The mains isolating box houses a 2-pole isolating switch and IEC

style appliance socket, providing mains connection to the

refrigeration unit and cabinet. The mains isolating box is located in

the refrigeration unit compartment, recessed into the left hand

cabinet side. The refrigeration unit plugs directly into the mains

isolating box.

To access the mains isolating box, for servicing:

1.Disconnect the cabinet from the mains power supply.

2.Remove the cabinet kick panel and cabinet wiring junction box

(see instructions on page 34).

3.Remove the two screws from the mains isolating box and pull

out from the cabinet wall.

4.The isolating switch, IEC socket and mains supply flex can now

be replaced if necessary. See Spares section for component

part numbers.

IEC Socket

Refrigeration Unit

Mains Flex

Figure 30: Mains Isolating Box

SERVICE INSTRUCTIONS

4

Page 47

47

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.7Pressure Temperature Chart

Table 7: Pressure Temperature Chart

TEMPERATURE R134a R404A

°F °C KPa psig KPa psig

-29.2 -34 -32 9.4 71 10

-27.4 -33 -28 8.4 79 11

-25.6 -32 -25 7.3 86 13

-23.8 -31 -21 6.2 94 14

-22.0 -30 -17 5.0 103 15

-20.0 -29 -13 3.8 111 16

-18.4 -28 -9 2.6 120 17

-16.6 -27 -4 1.3 129 19

-14.8 -26 0 0.0 138 20

-13.0 -25 5 0.7 148 21

-11.2 -24 10 1.4 158 23

-9.4 -23 15 2.2 168 24

-7.6 -22 20 2.9 179 26

-5.8 -21 26 3.7 189 27

-4.0 -20 31 4.5 200 29

-2.2 -19 37 5.4 212 31

-0.4 -18 43 6.3 224 32

1.4 -17 49 7.2 236 34

3.2 -16 56 8.1 248 36

5.0 -15 63 9.1 261 38

6.8 -14 69 10.0 274 40

8.6 -13 77 11.0 288 42

10.4 -12 84 12.0 302 44

12.2 -11 91 13.0 316 46

14.0 -10 99 14.0 331 48

15.8 -9 107 16.0 346 50

17.6 -8 116 17.0 361 52

19.4 -7 124 18.0 377 55

21.2 -6 133 19.0 393 57

23.0 -5 142 21.0 410 59

24.8 -4 151 22.0 427 62

26.6 -3 161 23.0 445 65

28.4 -2 171 25.0 463 67

30.2 -1 181 26.0 481 70

32.0 0 192 28.0 500 73

33.8 1 202 29.0 519 75

35.6 2 213 31.0 539 78

37.4 3 225 33.0 559 81

39.2 4 237 34.0 580 84

41.0 5 249 36.0 601 87

42.8 6 261 38.0 623 90

44.6 7 274 40.0 645 94

46.8 8 287 42.0 668 97

48.2 9 300 44.0 691 100

50.0 10 314 46.0 715 104

SERVICE INSTRUCTIONS

4

Page 48

48

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.8Troubleshooting

Table 8: Troubleshooting - continued on next page

Complaint Possible Cause Repair

1. Cabinet not

operating

- lights etc not

going.

Loss of power supply. Check power supply.

Refrigeration shut-down. Condenser

over-temperature has shut-down

system and cabinet lighting.

Attend condenser. To reset

alarm, cabinet must be replugged into power supply.

2. Compressor

will not start

- no hum.

Fuse removed or blown. No power. Replace fuse. Check reason.

Overload protector tripped. Refer to electrical section.

Thermostat stuck in open position. Repair or replace control.

Thermostat off, due to cold location. Relocate control.

Wiring improper, or loose. Check wiring against diagram.

3. Compressor

will not start

- hums but trips

on overload

protector.

Improperly wired. Check wiring against diagram.

Low voltage to unit. Determine reason and correct.

Start capacitor defective on CSIR or

CSR motor.

Determine reason and replace.

Run capacitor defective on PSC

motor.

Determine reason and replace.

Relay failing to close. Determine reason and correct.

Replace if necessary.

Compressor motor has a winding

open or shorted.

Check resistance values.

Replace compressor if necessary.

Internal mechanical trouble in compressor.

Replace compressor.

SERVICE INSTRUCTIONS

4

Page 49

49

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.8Troubleshooting

Table 8: Troubleshooting - continued on next page

Complaint Possible Cause Repair

9. Compressor

starts, but

does not

switch off

- start

winding.

Improperly wired. Check wiring against diagram.

Low voltage to unit. Determine reason and correct.

Relay failing to open, due to welded

contacts or relay incorrectly

mounted.

Determine reason and correct.

Replace if necessary.

Run capacitor defective on CSR

motor.

Determine reason and replace.

Excessively high discharge pressure.

Clean condenser. Check power

input. Possible overcharge,

insufficient condenser cooling,

or non-condensible gasses.

Compressor motor has winding open

or shorted. Check continuity and

resistance.

Replace compressor if faulty.

Internal mechanical trouble in compressor (tight). May be lubrication.

Replace compressor.

10. Compressor

starts and

runs, but

short cycles

on overload

protector

(relay may

chatter on

RSIR, CSIR

and CSR

motors).

Additional current passing through

overload protector.

Check wiring diagram. Check

for added fan motors etc.,

connected to wrong side of

protector.

Low voltage to unit. Determine reason and correct.

Overload protector defective. Check current, replace

protector.

Run capacitor defective on CSR

motor.

Determine reason and replace.

Excessive discharge pressure. Check condenser, check

ventilation, check for restrictions

in refrigeration system.

Suction pressure too high. Check for possibility of

misapplication.

Compressor too hot - insufficient

suction gas cooling.

Check refrigerant charge (fix

leak), add if necessary. Check

return vapour temperature and

suction superheat.

Comp’r motor has a winding shorted. Replace compressor.

SERVICE INSTRUCTIONS

4

Page 50

50

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.8Troubleshooting

Table 8: Troubleshooting - continued on next page

Complaint Possible Cause Repair

9. Unit runs OK,

but short

cycles.

Overload protector. See wiring on page 52.

Thermostat: requires adjustment or

incorrectly positioned.

Adjust or relocate thermostat

probe.

10. Unit operates

long or continuously.

Unsatisfactory

cabinet temperature.

Short of refrigerant. Fix leak, and add charge.

Overcharge of refrigerant. Remove refrigerant to correct

charge.

Thermostat not reading

temperature correctly.

Check air temperature with

thermometer. Adjust offset if

required.

Evaporator has excessive load. Establish load within limits.

Evaporator coil iced. Defrost evaporator, check

refrigeration. Check

thermostat. Check door

closing, seals etc. Check

defrost.

Restriction in refrigeration system. Determine location and clear

restriction. Flush with dry

nitrogen. Replace component

if blockage will not clear.

Dirty condenser. Clean condenser. Advise

client how to regularly clean

condenser.

Inadequate air circulation. Internal: Improve air

movement, alloe airflow around

stock.

External: Remove any

restrictions to condensing

ventilation.

Compressor not pumping

efficiently.

Replace compressor.

Filter dirty (if applicable). Clean or replace.

Faulty fan motor. Check rotation. Replace if

necessary.

SERVICE INSTRUCTIONS

4

Page 51

51

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

4.8Troubleshooting

Table 8: Troubleshooting

Complaint Possible Cause Repair

9. Start capacitor

open, shorted

or blown.

Relay contact not opening

properly.

Clean contacts, or replace

relay if necessary.

Prolonged operation on start cycle

due to:

(a) Low voltage to unit.

(b) Improper relay.

(a) Determine reason and

correct.

(b) Replace relay.

Excessive short cycling. Determine reason for short

cycling, and correct.

Improper capacitor. Determine correct size and

replace.

10. Relay

defective or

burned out.

Incorrect relay. Check and replace.

Line voltage too high or too low. Determine reason and correct.

Excessive short cycling. Determine reason, and correct.

Relay being influenced by loose

vibrating mount.

Remount rigidly.

11. Suction line

frosted.

Evaporator fan not running. Determine reason and correct.

Overcharge of refrigerant capillary

systems.

Correct charge.

12. Unit noisy. Loose parts or mountings. Find and tighten.

Tubing rattle. Reform to be free of contact.

Bent fan blade causing vibration. Replace blade.

Fan motor bearing worn. Replace motor.

SERVICE INSTRUCTIONS

4

Page 52

52

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

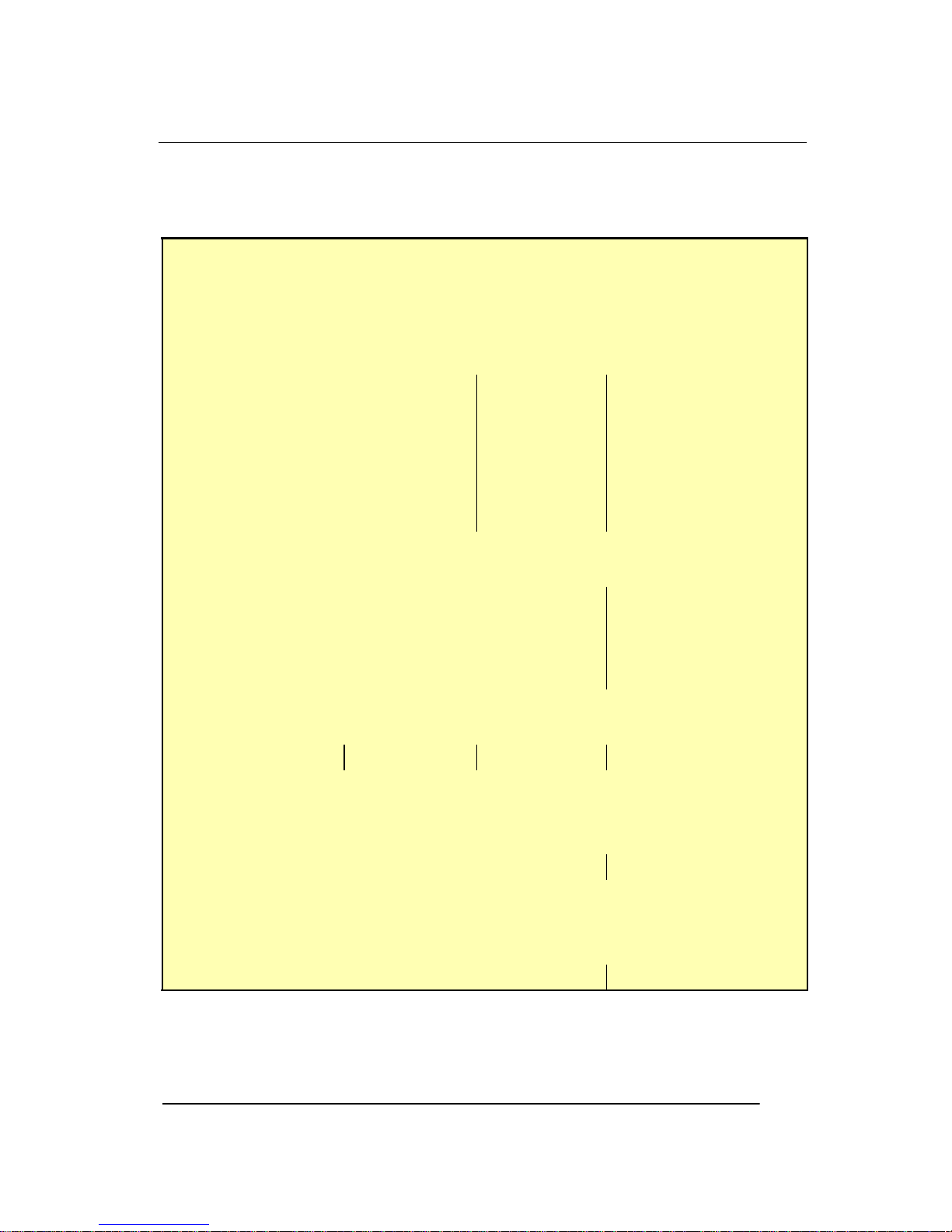

5.1Model: B550/660-2, BME550-2

Dixell XR30C

Rev. B Controller

30

WIRING DIAGRAM

5

Page 53

53

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

5.1Model: B550/660-2, BME550-2

* LE denotes fan motor orientation as viewed from the lead end.

** The wiring diagram opposite shows the Rev A electronic

controller, with an insert showing the Rev B controller (see page 22

for more information on the two variations).

Item Part Description Item Part Description

1

Sign Unit

(when applicable)

21 Capacitor

2 Lamp Holder 22

Evaporator Fan Motor

(clockwise - LE) *

3

14 Watt Fluorescent Tube

OSRAM FH 14W/860

23

Evaporator Fan Motor

(anti-clockwise - LE) *

4

Single Electronic Ballast

14-35 Watt

24

Condenser Fan Motor

(clockwise - LE) *

5 3-Way ENSTO Connector 25 Mains Terminal Block

6 Foamed Cabinet 26 RFI Capacitor

7 Sidelight Assembly 27 Resistor

8 28 Watt Fluorescent Tube 28 Relay

9 Mains Flex and Plug 29 Controller Housing

10 Mains Isolating Box 30 Electronic Controller **

11 2-Pole Isolating Switch 31 Cabinet Temp Probe

12 IEC Socket Outlet 32 Condenser Temp Probe

13 5-Way ENSTO Connector 33 Start Capacitor

14 Cabinet Junction Box 34 NTC Probe

15 5-Way ENSTO Socket 35 Run Capacitor

16 3-Way ENSTO Socket 36 Start Relay

17 3-Way Connector Block 37 Electrolux Compressor

18 3 Amp Ceramic Fuse 38 Compressor Overload

19 Refrigeration Unit 39 Unit Junction Box

20 Evap Motor Bracket Ass’y

WIRING DIAGRAM

5

Page 54

54

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.1Cabinet Assembly

Part Description SKOPE P/No. Customer P/N.

Kick Panel

(B550-2, BME550-2)

V48BA/131

Kick Panel (B660-2) D66BA/131

Kick Panel Bracket V48BA/R84

SKOPE Label - black LAB7562B

SKOPE Label - white LAB7562W

Sign Side V48BA/S20

Sign Back Panel

(B550-2)

V4800/C53

Sign Back Panel

(B660-2)

D66BA/C53

Shelf (B550-2) WRKV6000/J70

Shelf (BME550-2) V6000/J70-32

Shelf (B660-2) WRKC7200/J70

Shelf Bracket V0973-99

Light Junction Box - R/H V48BA/170

Condenser Baffle UB40AA/A62-GT

Bottom Baffle UB40AA/C93-GT

Swivel Castor SXX4339

Swivel Castor - lockable SXX4539

SPARES

6

Page 55

55

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.2Interior Side Light

Part Description SKOPE P/No. Customer P/No.

T5 Side Light Assembly - R/H V48BA/L85-32

T5 Side Light Assembly - L/H V48BB/L85-32

28 Watt T5 Fluorescent Tube ELL0603

T5 Lampholder ELZ0600

Light Cover V48BA/E71

SPARES

6

Page 56

56

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.3Cabinet Wiring Junction Box

Part Description SKOPE P/No. Customer P/No.

Cabinet Junction Box Ass’y V48BA/G29

Cabinet Junction Box Base V48BA/G30-GT

Cabinet Junction Box Cover V48BA/G31-GT

ENSTO Socket - 3 Pole ELZ0499-3

ENSTO Socket - 5 Pole ELZ0499-5

ENSTO Adaptor - 3 Pole PLM0497-3

ENSTO Adaptor - 3 Pole PLM0497-5

Single Electronic Ballast ELZ0605

3 Amp Ceramic Fuse ELZ9654

Fused Terminal Block ELZ9655

Cabinet Supply Flex V48BA/X03

SPARES

6

Page 57

57

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.4Mains Isolation Box

Part Description SKOPE P/No. Customer P/No.

Mains Isolation Box Ass’y V48BA/E80

Mains Isolation Box Base V48BA/E81-GT

Mains Isolation Box Cover V48BA/E82-GT

IEC Socket Outlet ELK8880

2-Pole Isolating Switch ELS0495

Mains Flex V4800/E53

SPARES

6

Page 58

58

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.5Door

Part Description SKOPE P/No. Customer P/No.

Glass Door Assembly - R/H

(B550-2, BME550-2)

V48BA/Z04R

Glass Door Assembly - R/H

(B660-2)

D66BA/Z04R

Door Gasket

(B550-2, BME550-2)

GKT0482N

Door Gasket (B660-2) GKT0427N

Gasket Retainer - Horizontal

(B550-2, BME550-2)

V6000/766

Gasket Retainer - Horizontal

(B660-2)

Y1100/766

Gasket Retainer - Vertical D6660/765

Torsion Bar Assembly REF5014

Bush PLM5075

Capstan TUR5100

Cotter Pin FAS5076

Top Hinge Assembly - R/H V4750/388

Bottom Hinge - R/H V48BA/393

Bottom Hinge - L/H V48BA/394

SPARES

6

Page 59

59

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.6Sign Unit

Part Description SKOPE P/No. Customer P/No.

Sign Unit Assembly (packed)

(B550-2)

V48BA/S11

Sign Unit Assembly (packed)

(B660-2)

D66BA/S11

Sign End - R/H D66BA/S13

Sign End - L/H D66BA/S14

Sign Reflector (B550-2) V48BA/S15-32

Sign Reflector (B660-2) D66BA/S15-32

Curved Sign Panel (B550-2) V4800/S17V

Curved Sign Panel (B660-2)

Wiring Cover Assembly

(B550-2)

V48BA/S18

Wiring Cover Assembly

(B660-2)

D66BA/S18

Wiring Cover (B550-2) V48BA/S19-32

Wiring Cover (B660-2) D66BA/S19-32

Sign Top / Bottom Panel V48BA/S06

Sign Panel Edge Strip RUE3704RE

14 Watt T5 Fluorescent Tube ELL0601

T5 Lamp Holder ELZ0600

Single Electronic Ballast ELZ0605

Sign Flex V60BA/934

ENSTO 3-Pole Plug ELZ0500-3

SPARES

6

Page 60

60

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.7Refrigeration Unit: UB40AAC

Part Description SKOPE P/No. Customer P/No.

Refrigeration Unit Assembly UB40AAC-160ZX

Unit Base UB40AA/210-32

Foamed Evaporator Box UB40AA/376

Compressor: Electrolux CPR0464P

Condenser Coil CLS9929

Evaporator Coil CLS9930

Drier DRY8783

Run Capacitor ELC9941NC

Start Capacitor ELC9942NC

Electrolux Relay ELR9943NC

DIXELL Electronic Contoller ELZ0471SP

DIXELL NTC Probe ELZ0472

Fan Motor - Reversible ELM9917

Fan Blade - R/H (clockwise) FAN4100

Evaporator Motor Bracket UT40AA/231

Suction Line Assembly UT40AA/378

Junction Box Assembly UB40AA/R86

Junction Box Base UB40AA/R87-GT

Junction Box Cover UB40AA/R88-GT

RFI Suppression Capacitor ELC8068

Motor Capacitor ELC9142NC

HONGFA Relay ELR0494

OMRON Relay ELR6183

ENSTO Socket ELZ0499-3

Resisistor ELZ7157

Controller Flex Assembly UB40AA/E19

Mains Flex (with IEC plug) UB40AA/E53

SPARES

6

Page 61

61

B550/660-2, BME550-2

SKOPE Gen2: Single Door Chiller

6.8Refrigeration Unit: UB30AAC

Part Description SKOPE P/No. Customer P/No.

Refrigeration Unit Assembly UB30AAC-160IX

Unit Base UB40AA/210-32

Foamed Evaporator Box UB40AA/376

Compressor: Electrolux CPR0464P

Condenser Coil CLS9967

Evaporator Coil CLS0752

Drier DRY8783

Run Capacitor ELC9941NC

Start Capacitor ELC9942NC

Electrolux Relay ELR9943NC

DIXELL Electronic Contoller ELZ0471SP

DIXELL NTC Probe ELZ0472

Fan Motor - Reversible ELM9917

Fan Blade - R/H (clockwise) FAN4100

Suction Line Assembly UT40AA/378

Junction Box Assembly UB40AA/R86

Junction Box Base UB40AA/R87-GT

Junction Box Cover UB40AA/R88-GT

RFI Suppression Capacitor ELC8068

Motor Capacitor ELC9142NC

HONGFA Relay ELR0494

OMRON Relay ELR6183

ENSTO Socket ELZ0499-3

Resisistor ELZ7157

Controller Flex Assembly UB40AA/E19

Mains Flex (with IEC plug) UB40AA/E53

SPARES

6

Loading...

Loading...