SKODA Citigo 2012, Fabia 2000, Fabia II 2007, Fabia II 2009, Fabia II 2011 Workshop Manual

...Page 1

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Service

GETtheMANUALS.orgGETtheMANUALS.org

Workshop Manual

Citigo 2012 ➤ , Fabia 2000 ➤ ,

Fab

ia II 2007 ➤ , Fabia II 2009 ➤ ,

Fabia II 2011 ➤ , Fabia III 2015 ➤ ,

Karoq 2018 ➤ , Kodiaq 2017 ➤ ,

Octavia 1997 ➤ , Octavia II 2004 ➤ ,

Octavia II 2010 ➤ , Octavia III 2013 ➤ ,

Octavia III 2014 ➤ , Rapid 2011 ➤ ,

Rapid NH 2013 ➤ , Rapid NH 2014 ➤ ,

Roomster 2006 ➤ , Superb 2002 ➤ ,

Superb II 2008 ➤ , Superb III 2015 ➤ ,

Yeti 2010 ➤ , Yeti 2011 ➤

Paint - general information

Edition 10.2017

Service Department. Technical Information

Page 2

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

List of Workshop Manual Repair Groups

GETtheMANUALS.orgGETtheMANUALS.org

Re

pai r G r o up

00 - Technical data

Service

Technical information should always be available to the foremen and mechanics, because their

careful

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

All rights reserved.

No reproduction without prior agreement from publisher.

Copyright © 2017 ŠKODA AUTO a. s. D4B8064A3AF

constant adherence to the instructions is essential to ensure vehicle road-worthiness and

and

Page 3

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Contents

00 - Technical data .

1 Safety instructions .

1.1 Safety measures when painting vehicles that use natural gas . . . . . . . . . . . . . . . . . . . . . . 1

2 General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 Structure of original paintwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.2 Structure of customer service paintwork . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Different paintwork structure for engine compartment and inside of front flap . . . . . . . . . . 5

2.4 Photo documentation of the reported paint damage according to the ŠKODA standard to

create the DISS paint report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.5 Work instructions for underseal and anti-chip coating . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.6 Instructions for repairing fold corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.7 Painting the parking aid transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.8 Adaptive cruise control (ACC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3 Original products . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.1 Paint products for customer service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.2 Filler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3.3 Corrosion prevention . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.4 Preservation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3.5 Underseal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

3.6 Protection against stone chipping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.7 Underbody sealing wax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

3.8 Sealant materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.9 Cleaning agent . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

3.10 SprayMax system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

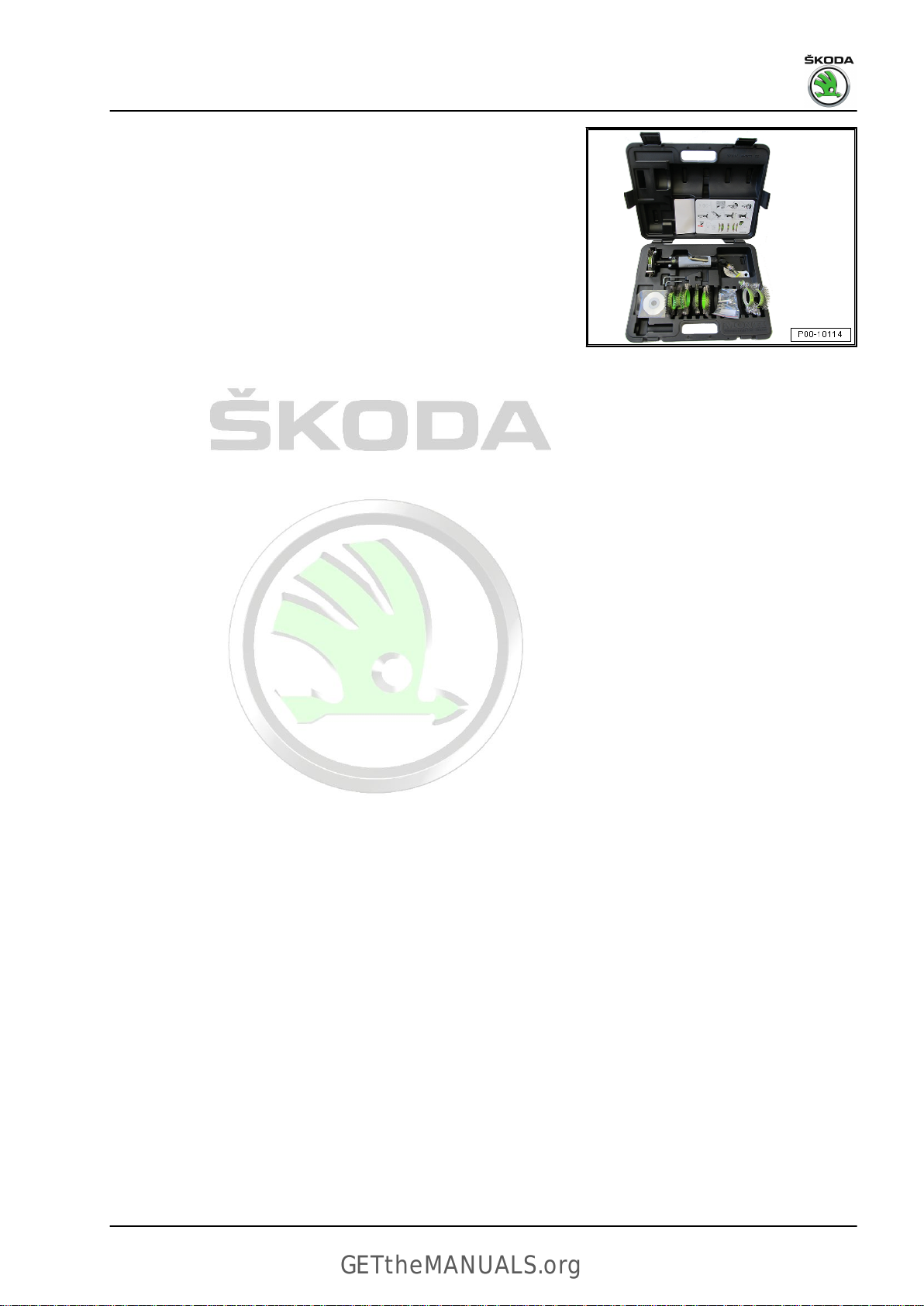

4 Workshop equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.1 Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

4.2 Dust-retention cloths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

5 Repairing rims . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

5.1 Colors approved for repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Contents i

Page 4

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

ii Contents

Page 5

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

00 – Technical data

1 Safety instructions

(SRL001128; Edition 10.2017)

⇒ “1.1 Safety measures when painting vehicles that use natural

gas”, page 1

1.1 Safety measures when painting vehicles that use natural gas

DANGER!

Danger of death if drying temperatures are too high! High tem‐

peratures increase the pressure in the natural gas or LPG fuel

tank. If the pressure is too high, a natural gas or LPG tank may

explode and cause death or serious injuries.

High temperatures trigger the thermal fuse of the shut-off valve

on natural gas fuel tanks. A pressure increase as a result of

high temperature triggers the pressure relief valve in LPG fuel

tanks. Gas escapes from the natural gas or LPG fuel tank and

may ignite, in particular in the presence of sparks, and cause

explosive flames. This can cause death or serious injuries.

♦ Parts that convey gas should never be exposed to tem‐

peratures above +60°C.

♦ For drying above +60°C in the drying furnace, all natural

gas or LPG fuel tanks must be removed and all gas lines

must be flushed.

♦ For infrared drying, parts that convey gas in the high pres‐

sure reservoir system should never be exposed to tem‐

peratures above +60°C.

The safety instructions for working on vehicles with an LPG or

natural gas system must be followed.

⇒ Engine; 00 technical data; safety instructions

⇒ Engine; 00 Specifications; CNG - General information

Removing and installing the fuel tank.

⇒ Engine; Rep. gr. 20 ; fuel supply, operation

1. Safety instructions 1

Page 6

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

2 General Instructions

⇒ “2.1 Structure of original paintwork”, page 2

⇒ “2.2 Structure of customer service paintwork”, page 3

⇒ “2.3 Different paintwork structure for engine compartment and

inside of front flap”, page 5

⇒ “2.4 Photo documentation of the reported paint damage ac‐

cording to the ŠKODA standard to create the DISS paint report”,

page 5

⇒ “2.5 Work instructions for underseal and anti-chip coating”,

page 7

⇒ “2.6 Instructions for repairing fold corrosion”, page 9

⇒ “2.7 Painting the parking aid transmitter”, page 11

⇒ “2.8 Adaptive cruise control (ACC)”, page 12

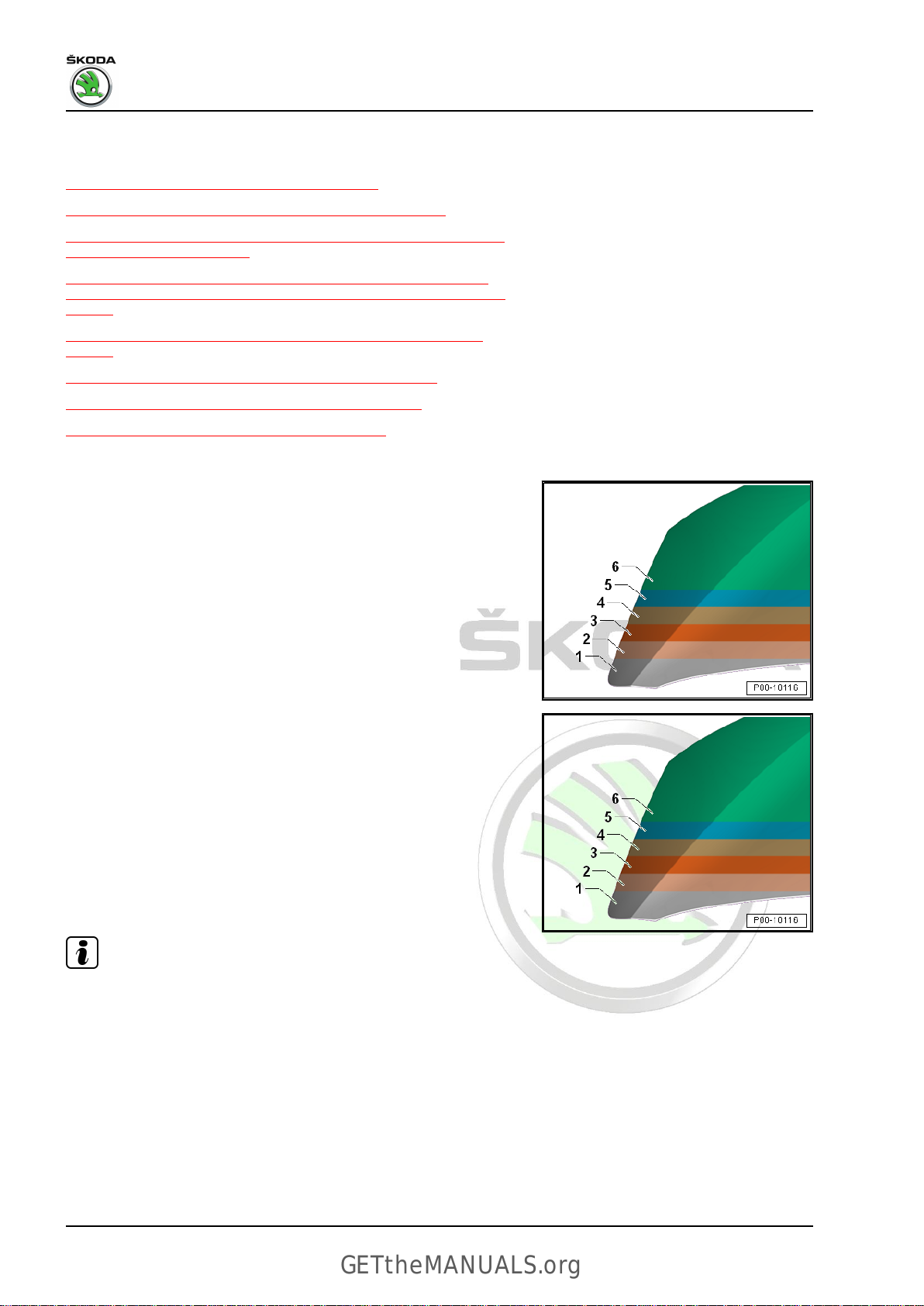

2.1 Structure of original paintwork

Structure of solid paint, water-based

Layer thickness: approx. 80-130 µm

1 - Steel sheet

2 - Zinc phosphating

3 - Electrophoretic coating

4 - Water-based filler

5 - Water-based paint

6 - 1K clear coat (Citigo - 2K clear coat)

Structure of metallic and pearl colour paint, water-based

Layer thickness: approx. 80-130 µm

1 - Steel sheet

2 - Zinc phosphating

3 - Electrophoretic coating

4 - Water-based filler

5 - Water-based metallic/pearl colour

6 - 1K clear coat (Citigo - 2K clear coat)

Note

♦

The approximate layer thickness may vary depending on tone

and indicates differences depending on position, as well as

vertical and horizontal surfaces.

♦

The values may be exceeded for some vehicles in two or more

coats are applied. However, this does not need to be commu‐

nicated.

2 Rep. gr.00 - Technical data

Page 7

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

2.2 Structure of customer service paintwork

Galvanized sheets on both sides

Note

♦

Ensure that:

♦

all sheets edges are adequately deburred for body repairs.

♦

inner surfaces not to be painted have a complete zinc CDP

layer.

♦

internal weld flanges and sanded-through areas are touched

up with e.g. InoxSpray - D 007 600 A1- .

Applying filler

Filler compounds are now essential for bodywork and in the paint

shop to restore contour. When applying filler, the different sub‐

strate requirements must be observed.

Product information

♦

⇒ “3.2 Filler”, page 13

Primer

The primer is the most important part of the anti-corrosion system,

because is prevents water and oxygen reaching the metal sur‐

face. Original spare parts are normally coated with a black or

yellow CDP.

Note

♦

Sanded-through areas and weld seams must be re-coated

with corrosion protection as soon as possible.

♦

The CDP primer is not resistant to UV or acid. Spare parts

must therefore also be painted from the inside.

♦

After repairing corrosion and in general for any bare metallic

substrate, you must insulate with e.g. 2K wash primer - LHV

043 000 A2- or -LLS MAX 230 M1- , then fill with 2K HS per‐

formance filler .

Product information

⇒ “3.3 Corrosion prevention”, page 18

♦

Filler

♦ The filler makes sure that the entire coating system adheres

well to the body part to be painted.

♦ The filler serves as the substrate for the top coat, levels out

unevenness in areas that have already been worked and de‐

termines the

against chipping and also acts as a barrier/substrate insula‐

tion, which is essential for corrosion protection.

quality of the top coat. The filler protects the body

2. General Instructions 3

Page 8

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

PVC seam sealing and underseal

Note

♦

For repair, the joint seal must be restored to its original thick‐

ness.

♦

To avoid damage and failures, the seal welds in the area of

the assembly-specific add-on parts must be coated smoothly.

♦

Water drain holes must be left clear.

♦

All threaded bolts and weld nuts with M-thread and all other

bolts and contact surfaces for assembly must be fully func‐

tional all along the seal.

♦

The sealant material must not be applied to bare sheet metal,

but only on to filled substrates.

♦

To prevent water ingress into the flanges, the sheet fold is

sealed with pasty, solvent-free PVC at critical points of the

body. A layer of PVC with varying thickness is also sprayed

onto accurately defined areas of the underbody and in the

wheelhousings as protection against chipping and for sound

absorption.

♦

Before sealing/applying underseal, the surface must always

be thoroughly primed and filled.

♦

After repairing corrosion and in general for any bare metallic

substrate, you must insulate with e.g. 2K wash primer - LHV

043 000 A2- or -LLS MAX 230 M1- , then fill with 2K HS per‐

formance filler .

♦

The specific layer thicknesses for the underseal must be ob‐

served.

Product information

♦

⇒ “3.5 Underseal”, page 26

♦ ⇒ “3.6 Protection against stone chipping”, page 37

♦ ⇒ “3.8 Sealant materials”, page 49

Base coat

The base coat is primarily decorative.

The paints provide different coverage depending on pigment con‐

tent. The manufacturer's instructions must be followed.

Clear coat

The clear coat is primarily decorative. The clear coat protects the

top coat/base

pollution, such as acid in bird droppings.

Wax preservation/cavity preservation

Wax preservation/cavity preservation plays an essential role in

corrosion protection. Depending on application, there are various

materials available for customer service. These materials provide

excellent protection because they have the following properties:

♦ They are hydrophobic (water-repellent).

♦ They have good adhesion.

♦ No corrosion creep.

♦ Water vapour permeates through them at a rate approx. 1500

times lower than a layer of paint of the same thickness.

coat against ultraviolet radiation and environmental

4 Rep. gr.00 - Technical data

Page 9

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Product information

♦ ⇒ “3.4 Preservation”, page 22

♦ ⇒ “3.7 Underbody sealing wax”, page 44

2.3 Different paintwork structure for engine compartment and inside of front flap

The paint in the “engine compartment and the inside of front flap”

may be

external paint, depending on model. The difference is productionrelated and is not a defect. The state as produced must be

restored.

different in terms of paintwork structure and tone from the

2.4 Photo documentation of the reported

paint damage according to the ŠKODA

standard to

Basic requirements for photo documentation of reported paint

damage

Note

create the DISS paint report

♦

Proper photo documentation is a basic requirement for the

DISS paint report to be approved, reimbursement and pro‐

cessing of the complaint.

♦

The photo documentation must also be created if an analysis

is required by the ŠKODA AUTO - TSC specialist on location

by the dealer.

– This group of mandatory photos must always be prepared, so

that the photo documentation that is prepared is clear and al‐

ways transparent for dealer and the manufacturer.

Vehicle identification number

Mileage

2. General Instructions 5

Page 10

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

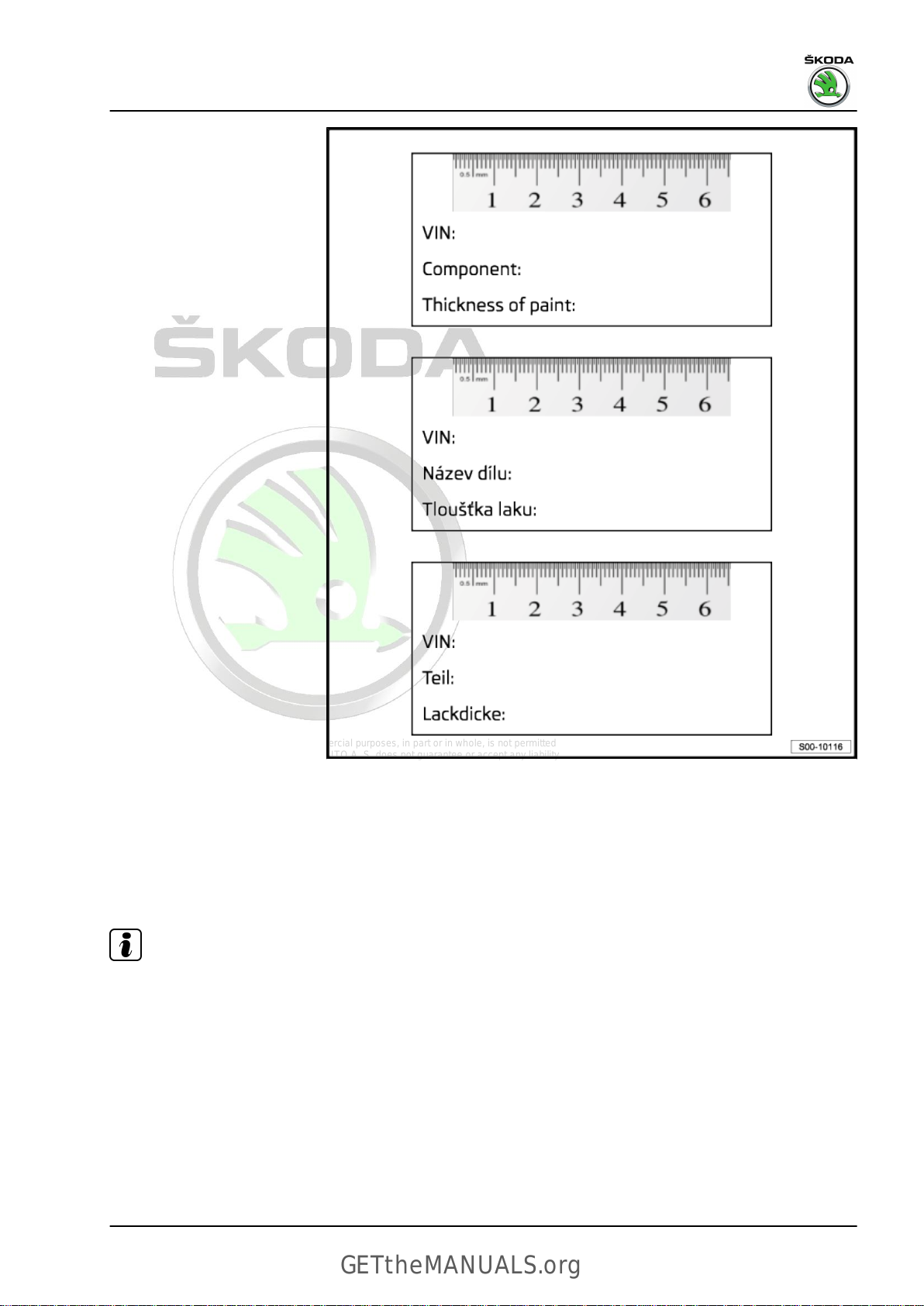

General overview

Reported part with the damage marked

Detailed image of damage with attached -label with ruler-

Label with ruler

6 Rep. gr.00 - Technical data

Page 11

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

– Print photo at actual size (test dimensions of image frame: 132

x 157mm).

–

Cut out -label with ruler-.

2.5 Work instructions for underseal and an‐

ti-chip coating

Note

♦

For repair, the structure of the underseal and anti-chip coating

must be restored to original thickness and appearance.

♦

Water drain holes must be left clear.

♦

All threaded bolts and weld nuts with M-thread and all other

bolts and contact surfaces for assembly must be fully func‐

tional all along the seal.

Damage following an accident (spare part replacement)

– Clean new part with silicone remover .

– Roughen the factory primer.

– Clean again with silicone remover .

2. General Instructions 7

Page 12

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

– Apply e.g. 2K wash primer - LHV 043 000 A2- or -LLS MAX

230 M1- to sanded-through areas.

– Leave to dry (note drying time).

– Then filler with 2K HS performance filler .

– Leave to dry (note drying time).

– Dry filler and sand with sandpaper (P400-500), avoiding sand‐

ing through.

–

Clean surface with silicone remover .

– Apply suitable anti-chip coating

⇒ “3.6 Protection against stone chipping”, page 37 .

– Leave to dry (note drying time).

– Touch up/smooth structure slightly, if necessary.

– Clean substrate with silicone remover .

– Then filler with 2K HS performance filler .

– Leave to dry (note drying time).

– Dry and roughen filler.

– Clean surface with silicone remover .

– Then establish structure with base and clear coat.

Damage following an accident (repair)

– Thoroughly clean damaged component/surface.

– Remove undercoat with e.g. brush grinder - VAS 6446- or -

VAS 6776- .

– Flatten damaged area and sand down to the blank metal.

– Remove any

-VAS 6776- , then fine-sand (P180-240).

– Clean substrate with silicone remover .

– Apply e.g. 2K wash primer - LHV 043 000 A2- or -LLS MAX

230 M1- .

– Leave to dry (note drying time).

– Then filler with 2K HS performance filler .

– Leave to dry (note drying time).

– Roughen with sandpaper (P320).

– Clean substrate with silicone remover .

– Apply suitable filling paste.

– Sand filling paste with sandpaper (P80-P240), thoroughly

sanding transitions at the same time.

– Clean substrate with silicone remover .

– Apply e.g. 2K wash primer -LHV 043 000 A2- or -LLS MAX

230 M1- .

– Then filler with 2K HS performance filler .

– Leave to dry (note drying time).

– Roughen with sandpaper (P400-500).

– Clean surface with silicone remover .

– Apply suitable anti-chip coating

⇒ “3.6 Protection against stone chipping”, page 37 .

corrosion with e.g. brush grinder - VAS 6446- or

8 Rep. gr.00 - Technical data

Page 13

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

– Touch up/smooth structure slightly, if necessary.

– Clean substrate with silicone remover .

– Then filler with 2K HS performance filler .

– Leave to dry (note drying time).

– Dry and roughen filler.

– Clean surface with silicone remover .

– Then establish structure with base and clear coat.

2.6 Instructions for repairing fold corrosion

Corrosion at the fold edges, e.g. on bonnet, door or rear lid

– Remove areas of corrosion with e.g.

⇒ “4.1.6 Brush emitter , e.g. VAS 6446 or VAS 6776 ”,

page 94 or

⇒ “4.1.7 Brush grinder set , e.g. VAS 6776 ”, page 95 .

– Sand out transitions with sandpaper P360-P400.

– Clean substrate with silicone remover .

– After repairing corrosion and before sealing, the substrate

must be

LLS MAX 230 M1- , then filled with 2K HS performance filler .

– After applied filler has dried, sand the filled area with sandpa‐

per while dry (P400-500), avoiding “sanding through” in all

cases. Then clean all sanded areas with silicone remover .

– The fold edges of the sheet metal must then be sealed All

sheet overlaps must be sealed with sealing compound

⇒ “3.8 Sealant materials”, page 49 . The fine joint seal must

be compared

hicle.

insulated with 2K wash primer -LHV 043 000 A2- or -

with the original conditions of the applicable ve‐

Paint - general information - Edition 10.2017

Note

♦

For repair, the joint seal must be restored to its original thick‐

ness and appearance.

♦

To avoid damage and failures, the seal welds in the area of

the assembly-specific add-on parts must be coated smoothly.

♦

Water drain holes must be left clear.

♦

All threaded bolts and weld nuts with M-thread and all other

bolts and contact surfaces for assembly must be fully func‐

tional all along the seal.

♦

The sealant material must not be applied to bare sheet metal,

but only on to filled substrates.

– The rest of the paintwork structure must be restored according

to the manufacturer's specifications.

2. General Instructions 9

Page 14

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

– Apply preservation coating around the edge of the fold area

using e.g.

⇒ “4.1.8 Pressurised cap gun , e.g. V.A.G 1538 ”, page 96

(cavity) ⇒ “3.4 Preservation”, page 22 .

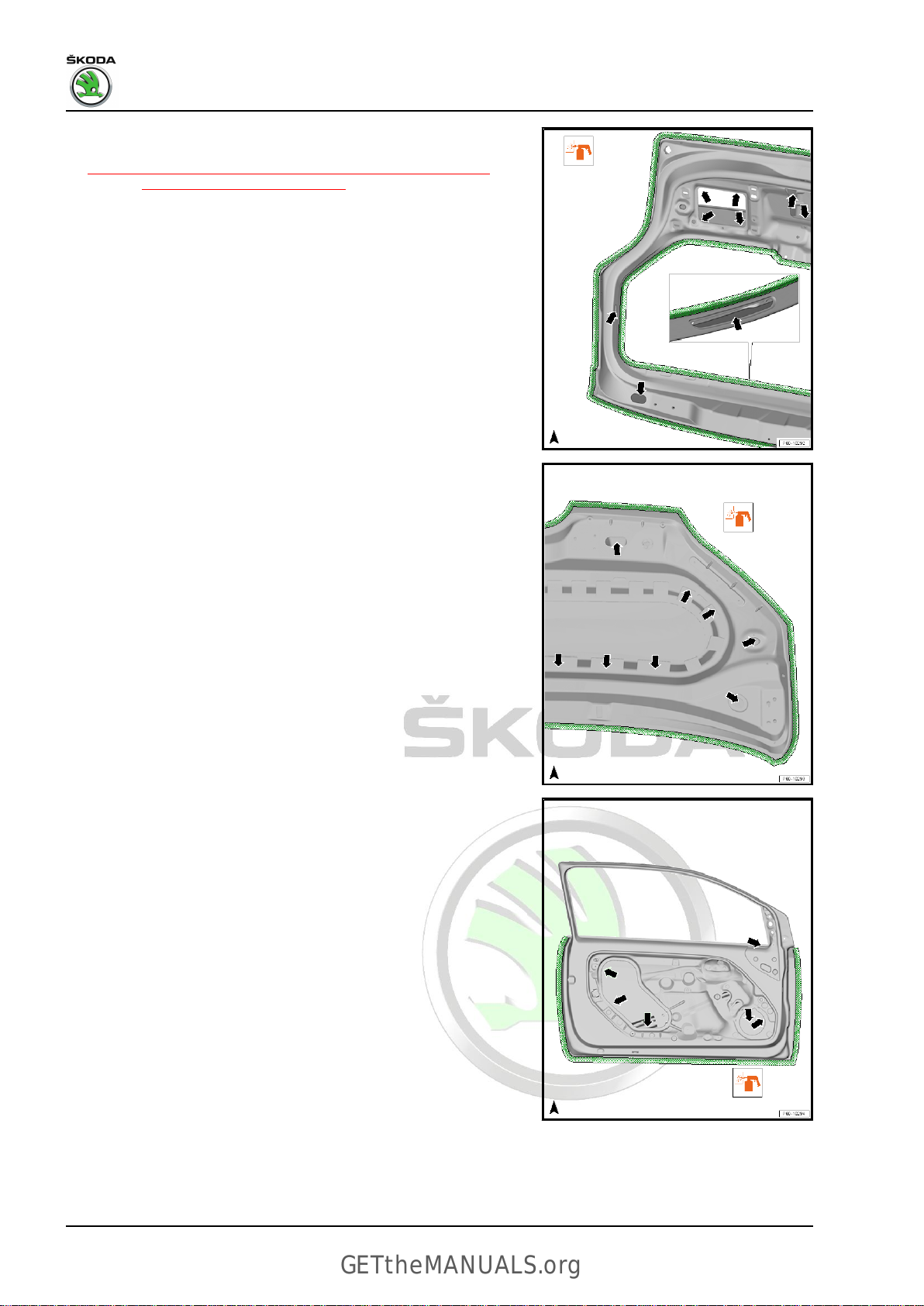

Area of cavity preservation on rear lid as example

Area of cavity preservation on bonnet as example

Area of cavity preservation on a door as example

10 Rep. gr.00 - Technical data

Page 15

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

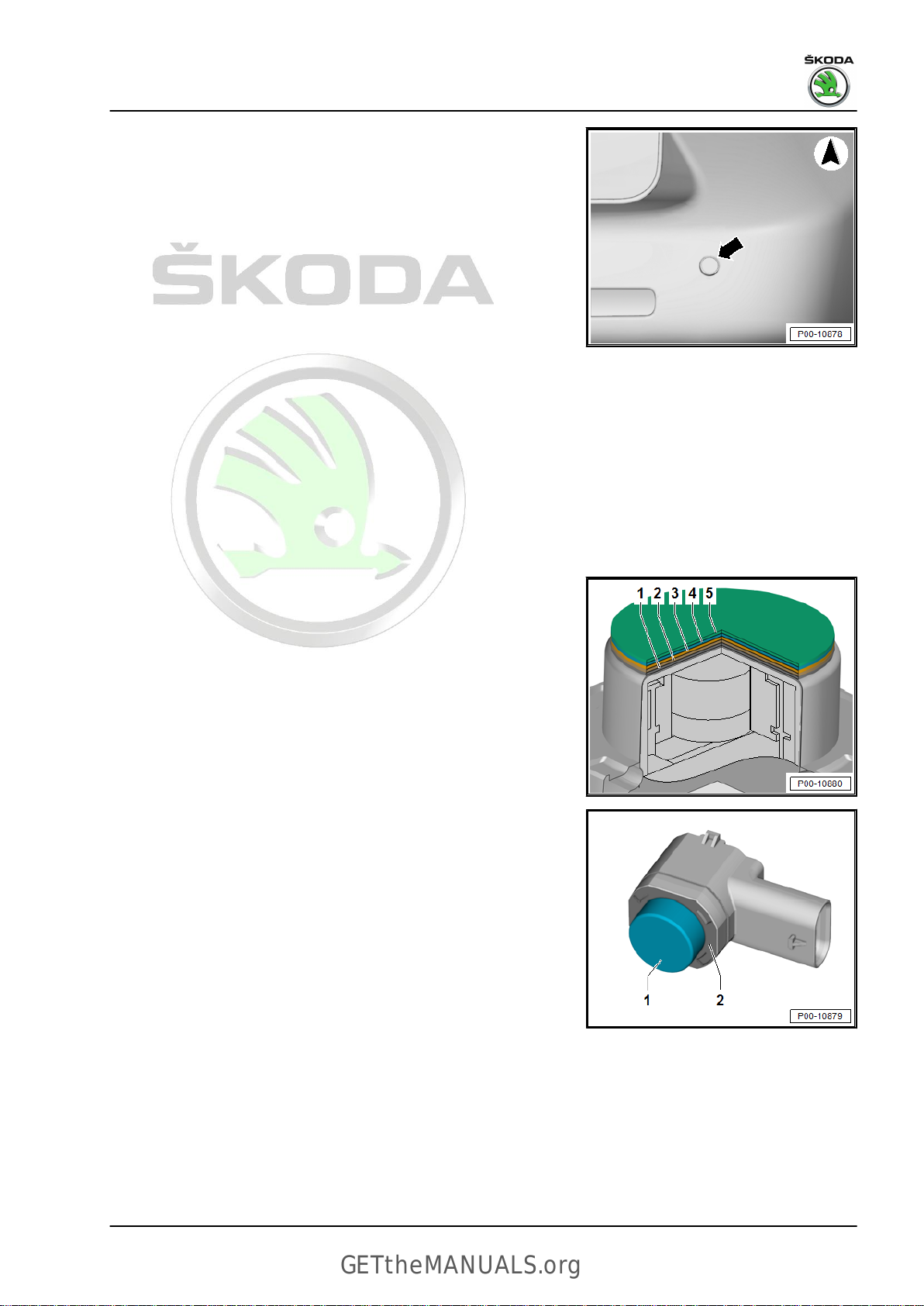

2.7 Painting the parking aid transmitter

To prevent malfunctions of the parking aid transmitter, the follow‐

ing parameters must be complied with when painting:

Painting a new part

♦ Maximum layer thickness: 125µm; you must measured the

layer thickness after painting

♦ Maximum hardening temperature: 1 hour at 90°C

Painting an old part

♦ Only remove paint (sand) down to primer

♦ Minimum layer thickness of 5-10µm must be maintained

♦ Maximum layer thickness: 125µm

♦ Maximum hardening temperature: 1 hour at 90°C

Electrical conductivity

♦ Paint or paint mist must not get into the plug.

Functional test:

♦ Connect vehicle diagnosis tester and test function ⇒ Electrical

System -

measurement and information system .

general notes; Rep. gr. 97 ; Lines; vehicle diagnosis,

Repair paintwork structure and layer thicknesses

1 - Primed new part with spare part primer: 2 - 10 μm

2 - Filler: 30 to 40 µm

3 - Uni base coat: 10 - 20 μm

4 - Metallic base coat / pearl effect: 20 - 15 μm

5 - Clear coat: 35 to 50 µm

Paint area

1 - The paint area of the sensors is the face and side surface

of the membrane. The side surface is painted by at least

3mm to maximum 4mm from the face of the membrane to

the rear.

2 - There must be no paint is this area.

2. General Instructions 11

Page 16

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

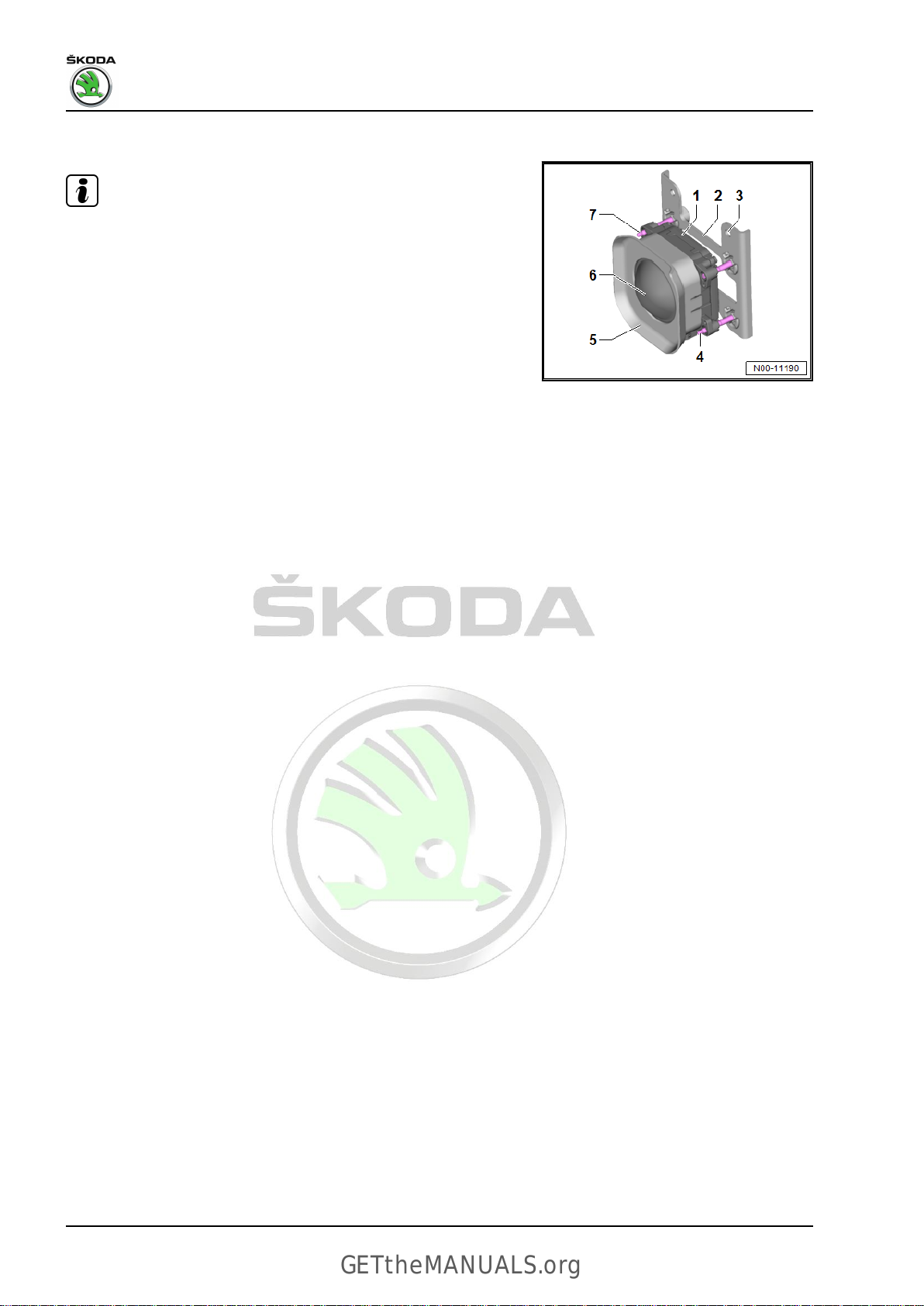

2.8 Adaptive cruise control (ACC)

Note

♦

For vehicles with ACC, the trim in the right cover part of the

front bumper must not be painted when applying repair paint

or replacement. The ACC system behind it may cease to func‐

tion if the thickness of the paint layer increases.

♦

The cover of the transmitter for cruise control in the bumper

trim grille is made of radar-permeable material. The cover can

be heated to avoid functional impairment in case of snow or

ice.

♦

All changes to the surface, such as subsequent painting, stick‐

ers and other items attached subsequently may cause mal‐

functions.

Control unit for clearance control

The illustration shows the adaptive cruise control unit . This may

be different for other vehicle models.

1 - Adapter plate

2 - Mounting bracket

3 - Mounting hole

4 - Vertical adjustment screw:

5 - Trim

6 - Transmitter for cruise control/adaptive cruise control unit

7 - Horizontal adjustment screw:

12 Rep. gr.00 - Technical data

Page 17

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

3 Original products

⇒ “3.1 Paint products for customer service”, page 13

⇒ “3.2 Filler”, page 13

⇒ “3.3 Corrosion prevention”, page 18

⇒ “3.4 Preservation”, page 22

⇒ “3.5 Underseal”, page 26

⇒ “3.6 Protection against stone chipping”, page 37

⇒ “3.7 Underbody sealing wax”, page 44

⇒ “3.8 Sealant materials”, page 49

⇒ “3.9 Cleaning agent”, page 56

⇒ “3.10 SprayMax system”, page 61

3.1 Paint products for customer service

Note

♦

ŠKODA AUTO notes that only ŠKODA AUTO original prod‐

ucts or products from paint suppliers approved by the manu‐

facturer can be used for warranty work and must be used

according to the manufacturer's instructions. Only these prod‐

ucts meet the requirements to maintain the paint warranty.

♦

In the case of paint claims for paint applications using products

approved by the manufacturer from paint suppliers, warranty

claims must be made to the applicable supplier of the paint

materials (via the importer).

3.2 Filler

⇒ “3.2.1 2K steel filler set”, page 13

⇒ “3.2.2 2K diamond aluminium filler”, page 15

3.2.1 2K steel filler set

Designation

♦ 2K steel filler set - DA 787 300 A2Product description

This filler is a polyester filler with a metal powder mixture for cre‐

ating correctly

This filler is an especially good substitute for lead filling solder.

This filler is easy to apply and to sand, is very strong and heatresistant, and so is especially suitable for overpainting.

Application instructions

Base surface

Suitable base surfaces:

♦ Steel

♦ Metallic base surfaces in general

♦ Galvanised sheet steel

contoured surfaces on highly stressed body areas.

3. Original products 13

Page 18

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Preparing base surfaces:

– Thoroughly degrease

must be prepared with e.g.

⇒ “4.1.6 Brush emitter , e.g. VAS 6446 or VAS 6776 ”,

page 94 . This means down to the bare metal with grit P40.

– Clean again with a silicone remover before working over.

Processing

and sand base surface. The substrates

Filling

Mixing ratio

– The two components are mixed at a ratio of 1 part by volume

liquid hardener to 2.5-3 parts by volume powder or 10 grams

liquid

hardener

product.

Note

and 58 grams powder to make a suitable filler

Avoid excessive liquid hardener as it will reduce the final strength

and adhesive characteristics of the filler.

Processing time:

– Pot life is approx. 4-6 minutes at +20°C.

Reaction temperature:

– The reaction temperature must be at least +5°C.

14 Rep. gr.00 - Technical data

Page 19

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Drying

– Hardening with short-wave infrared heater

♦ Flash off for approx. 10 minutes at +20°C.

♦ Pre-curing: 10 minutes at approx. 50°C

♦ 1st stage curing: 10 minutes at 75°C

♦ 2nd stage curing: 10 minutes at 85°C

Paint - general information - Edition 10.2017

Suitability for sanding:

– Then sand with dry sandpaper (grit P80) to contour or use the

body plane.

Storage

guaranteed storage stability is 12 months from date of man‐

The

ufacture. It can be processed on or before the date indicated on

label if stored in unopened, original containers at +20°C.

Storage conditions

– Store in a cool and dry place. Storage temperature: +20°C.

Note

♦

Process only in well ventilated spaces.

♦

You are advised to wear protective gloves and a dust mask.

♦

A sanding dust extraction system is recommended.

3.2.2 2K diamond aluminium filler

Designation

♦ 2K diamond aluminium filler, powder - DA 004 200 A2♦ 2K diamond aluminium filler, powder - DA 004 201 A1♦ 2K diamond aluminium filler, powder - DA 004 211 A1-

3. Original products 15

Page 20

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Product description

This filler is a polyester filler for universal application, and is es‐

pecially suited to aluminium sheet repairs.

It is designed for use in automobile repairs.

This filler is easy to apply and to sand, is very strong and heat-

resistant

Application instructions

Suitable base surfaces:

♦ Aluminium

Preparing base surfaces:

– Carefully degrease base surface.

– Carefully sand base surface.

– Carefully degrease base surface.

16 Rep. gr.00 - Technical data

Page 21

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Mixing ratio:

– The two components are mixed at a ratio of 1 part by volume

liquid hardener to 2.5-3 parts by volume powder or 10 grams

liquid hardener

and 25 grams powder to make a suitable filler

product.

Processing

Application:

– Filling

Note

Avoid excessive liquid hardener as it will reduce the final strength

and adhesive characteristics of the filler.

Processing time:

– The pot life is approx. 4-6 minutes at +20°C room temperature.

Reaction temperature:

– at least +5 ℃

Drying

– Flash off for approx. 10 minutes

– Hardening with short-wave infrared heater

♦ Pre-hardening: 10 minutes at 50 °C

♦ 1st stage curing: 10 minutes at 75 °C

♦ 2nd stage curing: 10 minutes at 85 °C

3. Original products 17

Page 22

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Suitability for sanding:

– Then sand with dry sandpaper (grit P80) to contour or use the

body plane.

Note

♦

Only process in a well-ventilated space.

♦

You are advised to wear protective gloves and a dust mask.

♦

A sanding dust extraction system is recommended.

Storage

The guaranteed storage stability is 12 months from date of man‐

ufacture. It can be processed on or before the date indicated on

label if stored in unopened, original containers at +20°C.

Storage conditions

– Store in a cool and dry place.

– Storage temperature: +20°C.

3.3 Corrosion prevention

⇒ “3.3.1 2K wash primer”, page 18

3.3.1 2K wash primer

Designation

♦ 2K wash primer - LHV 043 000 A2Product description

This 2K wash primer is a zinc chromate- and phenol-free acid-

hardening two-component wash primer.

♦ Outstanding corrosion protection based on its passivating

characteristics

♦ For metallic substrates, in particular aluminium and galvanised

steel sheets

♦ Easy to process

♦ Shade: Olive grey

Application instructions

Base surface

Suitable base surfaces:

♦ Bare sheet steel, cleaned and sanded

♦ Cleaned and sanded galvanised or electroplated steel panels

or soft aluminium

♦ Sanded factory primer

18 Rep. gr.00 - Technical data

Page 23

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

♦ Well-sanded factory paint or old paint (with the exception of

thermoplastic paint)

♦ Surfaces prepared with 2K polyester products and then finely

sanded

Preparing base surfaces:

– Clean carefully with silicone remover .

– Clean and sand factory paint or old paint, completely remove

any rust spots and spot-sand the transitions to the old paint.

– Use a suitable cleaning agent to ensure a clean, residue-free

surface prior to reworking.

Mixing ratio:

– 1:1 by volume with 2K additive solution - LHA 004 000 A2Processing time:

– Ready-to-spray preparation: 8-10 hours at +20°C

Note

Material must be mixed and applied on the same day.

3. Original products 19

Page 24

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Application “Spray application”

– Processing viscosity: 4mm at +20°C, DIN 53211

Processing viscosity: 4 mm “Compliant” and “HVLP” gravity feed

spray gun:

DIN 4 mm: 16 - 18 seconds

– Adjust the spray nozzle (see manufacturer data): “Compliant”

1.2 - 1.4 mm.

Adjust the spray nozzle (see manufacturer data): “HVLP” 1.3

–

- 1.5 mm.

– Spraying pressure (see manufacturer's instructions): “Compli‐

ant” 2.0...2.5 bar.

– Adjust the atomiser pressure (see manufacturer data): “HVLP”

0.7 bar.

– The specified layer thickness is 8-12 µm.

20 Rep. gr.00 - Technical data

Page 25

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Drying

Air drying at +20°C room temperature, can be over-sprayed after

30 minutes

Caution

Forced drying and infrared drying are not possible, because

they cause issues with intercoat adhesion.

Working over

After the flash-off time at +20°C, can be over-sprayed with 2K HS

filler.

Then can be overpainted with:

♦ Water-based base coat

♦ 2K top coat

Caution

Do not use with polyester, epoxy or water-thinnable products

for subsequent processing.

Do not use on thermoplastic paintwork.

Do not rework directly with water-based base coat or 2K HS

top coat.

Personal protective equipment:

♦ Comply with the safety datasheet

♦ Wear personal protective equipment during the application

process

Storage

The guaranteed storage stability is 24 months from date of man‐

ufacture. It can be processed on or before the date indicated on

label if stored in unopened, original containers at +20°C.

3. Original products 21

Page 26

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

3.4 Preservation

⇒ “3.4.1 Preservative wax”, page 22

⇒ “3.4.2 Cavity preservation agent”, page 23

⇒ “3.4.3 Preservative wax (spray can)”, page 26

3.4.1 Preservative wax

Designation

♦ Preservative wax - AKR 321 M15 4♦ Preservative wax - AKR 321 M16 10Product description

Preservative wax - AKR 321 M15 4- and preservative wax - AKR

321 M16 10- is a sprayable, wax-based rust corrosion inhibitor.

When dry it forms an adhesive, flexible, tear and water-resistant

film that is virtually colourless.

Because the drip point of the dried material is above 100°C, no

running or dripping is to be anticipated, even within the engine

compartment.

The dry film bonds securely to bare and painted sheet metal.

Application instructions

Application

♦ Used as preservation for automotive seams, surfaces and

cavities.

♦ Its light colour makes it especially suitable for protecting

seams on the bonnet and in the luggage compartment.

♦ This material is also a favoured product for treating cleaned

engine compartments.

Processing

Note

♦

Before starting work it is important to consult the safety regu‐

lations for information on mandatory precautions and sugges‐

ted safety procedures.

♦

All standard safety precautions for chemical products must be

observed, even when using substances not subject to special

labelling requirements.

– Before being treated, the parts should be thoroughly cleaned

and dried, and rust should be removed.

– Shake can before use. Spray on preservative wax and allow

to dry. The product should not be sprayed onto visible external

surfaces, as the dry layer produces a dull effect.

Caution

When this wax protectant is applied to engine compartments

in motor vehicles and engines in other devices, the engines

should not be started until the wax has thoroughly aired. There

is a risk that the evaporating solvent will explode!

22 Rep. gr.00 - Technical data

Page 27

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Technical data

Colour Transparent in thin layers

Odour Mild odour

Viscosity (DIN

12 - 14 s

53211, 4mm)

Drip point approx. 100 °C.

Cleaning with white spirit, cold cleaner or paraffin

Processing

+15 °C to +30 °C

temperature

3.4.2 Cavity preservation agent

Designation

♦ Cavity preservation agent - D 330 KD1 A2♦ Cavity preservation agent - D 330 KD2 A1Product description

Cavity preservation agent - D 330 KD1 A2- and cavity preserva‐

tion agent

agent for sealing cavities and enclosed areas with a high solid

content.

It is available as a thoroughly dispersed thixotropic solution de‐

signed to provide optimal protection in areas that are difficult to

access and narrow areas between sheet-metal surfaces.

The cavity preservation agent penetrates and disperses moisture;

it contains a high proportion of rust inhibitors.

The cavity preserving agent atomizes very fine during spraying,

has extremely good creep properties, penetrates well into the

spaces to be protected (e.g.: welds) and does not leak too much

from the lower seams.

Although this material can be applied at any temperature above

10°C, the penetrating ability is improved if both product and body

are allowed to stabilise at “room temperature”.

After curing, the material forms a flexible, water-resistant film,

transparent beige in colour.

Application instructions

Application

♦ Primarily used at the workshop to spray cavities, to comple‐

ment existing cavity protection treatment on new vehicles, to

post-treat cavity protection treatments and after repairs fol‐

lowing accidents.

- D 330 KD2 A1- is a solvent-containing anti-corrosion

Note

♦

Before starting work it is important to consult the safety regu‐

lations for information on mandatory precautions and sugges‐

ted safety procedures.

♦

All standard safety precautions for chemical products must be

observed, even when using substances not subject to special

labelling requirements.

Processing the cavity preservation agent - D 330 KD1 A2♦ The cavity preservation agent - D 330 KD1 A2- is easy to apply

using the suction-feed spray gun and the appropriate probe

attachments.

3. Original products 23

Page 28

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

♦ The application pressure with the suction-feed spray gun is

5-6 bar.

♦ If stored for longer periods or at temperatures under +10 °C,

the material becomes more thixotropic. However, it becomes

less thixotropic again during spraying at normal application

temperatures. The product displays its usual properties after

spraying.

The material pressure governor should be set to 5 bar.

Note

Depending upon the type of cavity being treated, the drying proc‐

ess may extend over a number of days. Adequate ventilation

should be provided during drying.

Processing the cavity preservation agent - D 330 KD2 A1♦ Trim panels and components should be removed when pos‐

sible. Any rust should be removed as thoroughly as possible.

♦ The tube-equipped spray attachment in the cap is installed to

reach areas that are difficult to access (semi-cavities in doors,

etc.).

♦ The material should be at room temperature for application.

♦ If stored for longer periods or at temperatures under +10 °C,

the material becomes more thixotropic. This is why it is impor‐

tant to shake the can vigorously before use, with the agitator

ball audible within the can.

♦ With the can held upright, an even layer is sprayed onto the

dust and grease-free body part.

♦ When the “applicator tube” is being used, it can be slowly ro‐

tated in all directions during the spray application.

♦ The applicator with its circular nozzle pattern allows finely dis‐

persed and even application on surfaces such as vehicle floor

panels, and thereby restores a flawless appearance.

Note

The cavity preservation agent - D 330 KD2 A1- is a product that

contains flammable propellant. You must ensure that cavities are

ventilated before they are closed again (e.g. door trims) and that

the whole vehicle is ventilated during the drying phase. Depend‐

ing upon the type of cavity being treated, the drying process may

extend over a number of days.

Caution

Functional parts, such as brake and exhaust systems, must not

be sprayed!

Rubber and plastic parts should also not be sprayed.

Cleaning

♦ Escaping drips of preservation agent can easily be wiped

away.

♦ The plastic cleaner - D 195 850 A1- , for example, is suitable

for cleaning the material when it has dried on to surfaces.

♦ Larger areas can be cleaned with the steam cleaner. Splashes

on painted surfaces should be removed immediately.

24 Rep. gr.00 - Technical data

Page 29

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

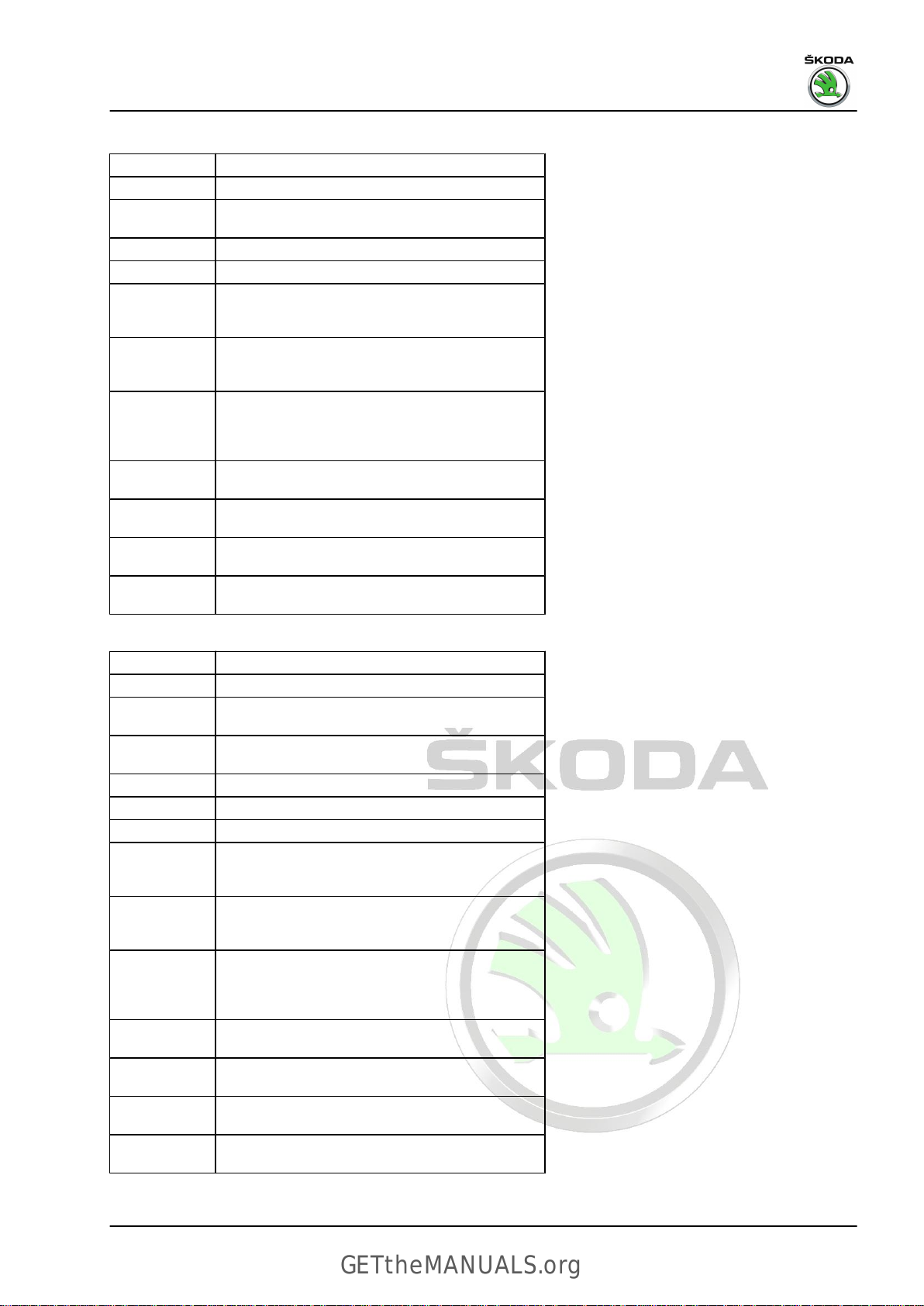

Technical data for the cavity preservation agent - D 330 KD1 A2-

Colour Transparent beige

Odour Typical, distinctive odour

Solid matter

approx. 60 % (active ingredient)

content

Consistency Thixotropic

Durability min. 100 μm

Suitability for

No permanent changes in the paint

use with top

coats

Can be re‐

Dried material can be easily removed

moved after

24 hours

Properties in

No dripping

drying oven

(1.5 h at 90 °

C)

Resistance to

No cracking

cold

Resistance to

No corrosion

corrosion

Processing

+10 °C to +25 °C

temperature

Application

-40 °C to +90 °C

temperature

Technical data for the cavity preservation agent - D 330 KD2 A1-

Colour Transparent beige (almost transparent)

Odour Typical, distinctive odour

Solid matter

approx. 60 % (active ingredient)

content

Drip point of

approx. 150 °C.

solid

Consistency Thixotropic

Durability min. 100 μm

Penetration >16 cm

Suitability for

No permanent changes in the paint

use with top

coats

Can be re‐

Dried material can be easily removed

moved after

24 hours

Properties in

No dripping

drying oven

(1.5 h at 90 °

C)

Resistance to

No cracking

cold

Resistance to

No corrosion

corrosion

Processing

+10 °C to +25 °C

temperature

Application

temperature

-40 °C to +90 °C (+120 °C for short periods up

to 1 hour)

3. Original products 25

Page 30

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

3.4.3 Preservative wax (spray can)

Designation

♦ Preservative wax - D 308 SP5 A1Product description

The preservative wax - D 308 SP5 A1- provides optimal corrosion

protection for corrosion-susceptible areas on bodywork such as

double panels (folds, gaps, flanges), edges and surfaces.

This long-life corrosion protection has very good penetration qual‐

ities and excellent adhesion to metallic surfaces.

It is suitable for applying to and removing from the top coat and

is also compatible with rubber and plastic components.

Application instructions

Application

♦ The recommended dry layer thickness is approx. 30 μm.

Technical data

Propane-bu‐

tane content

Active ingre‐

dient content

Solvent con‐

tent

Viscosity

(DIN 53211,

4mm)

Drip point (of

solid)

Cleaning with white spirit

Processing

temperature

Flash point

PM (DIN EN

22719)

Colour Light beige

Application

temperature

Resistance

to cold

45 - 49%

22 - 26 %

27 - 31 %

16 - 22 s

> 150 °C

+18 °C to +25 °C

+27 to +33 ℃

+10 °C to +30 °C

up to -30 °C

3.5 Underseal

⇒ “3.5.1 Long-life underseal D 314 D36 M2 grey”, page 26

⇒ “3.5.2 Long-life underseal D 314 D37 M2 black”, page 29

⇒ “3.5.3 Long-life underseal D 314 D38 M2 light”, page 32

3.5.1 Long-life underseal - D 314 D36 M2grey

Designation

♦ Long-life underseal - D 314 D36 M2- grey

26 Rep. gr.00 - Technical data

Page 31

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Product description for long-life underseal - D 314 D36 M2- grey

The long-life underseal - D 314 D36 M2- is a grey coating com‐

pound based on an aqueous polymer dispersion, which is

sprayed on using a UBS spray gun.

Drying time depends on the coat thickness as well as the ambient

temperature and

humidity. Good ventilation and higher tempera‐

tures accelerate drying.

The dried film adheres well to galvanised or CDP coated sheet

metal as well as painted base surfaces. Due to the great resist‐

ance to abrasion and flexibility under cold conditions, the long-life

underseal exhibits excellent stone chip protection.

The long-life underseal can be quickly overpainted with waterbased paints after a short time.

After air drying (approx. 2-3 hours), the material can be overpain‐

ted with conventional (solvent-based) paint systems as well.

The dried coating can be easily sanded once it is fully hardened.

The long-life underseal is suitable for restoring the original struc‐

ture following repairs.

The material is only temporarily resistant to spirit and cold clean‐

ers.

Application

♦ The long-life underseal - D 314 D36 M2- is suitable for repair‐

ing underbodies, wheel housings, and front and rear ends and

can be applied to visible parts such as side rails, as paintable

protection against stone chipping, road salt and corrosion due

to moisture.

♦ The material is suitable for restoring various surface structures

following repairs to all types of vehicle.

♦ The long-life underseal is also suitable for sound absorption

in boots, on bonnets, wheel arches and side walls, as well as

to cover and seal repair points, weld seams and overlappings.

Paint - general information - Edition 10.2017

Note

♦

Before starting work it is important to consult the safety regu‐

lations for information on mandatory precautions and sugges‐

ted safety procedures.

♦

All standard safety precautions for chemical products must be

observed, even when using substances not subject to special

labelling requirements.

Processing

♦ The surfaces to be treated must be cleaned thoroughly be‐

forehand, and any rust must be removed.

♦ The surfaces must be dry and free of dirt, dust and grease.

♦ Areas not to be coated should be masked with tape.

♦ Bare steel surfaces must be primed before application of long-

life underseal.

♦ The long-life underseal is applied from a 1 litre can using a

UBS spray gun. The processing pressure is 4-5 bar.

♦ The can contents must be shaken vigorously for one minute

before use.

3. Original products 27

Page 32

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Caution

Do not spray onto joints, engine, gearbox, propshaft, exhaust,

catalytic converter or brake systems.

The UBS spray gun must be sprayed empty and then flushed

with plastic cleaner - D 195 850 A1- .

A blocked gun may cause the can to explode!

You must following the operating instructions for the UBS spray

gun!

Overpainting

Note

The long-life underseal can be overpainted with water-based

base coats. As there are many systems on the market, tests must

be performed.

1 - Overpainting with water-thinnable paints:

– The long-life underseal can be overpainted with water-thinna‐

ble paints after a short initial drying period (matt surface) and

up to 72 hours after application.

2 - Overpainting with conventional (solvent-containing) paints:

– The long-life underseal can be overpainted with conventional

(solvent-containing) paints after through drying and up to 72

hours after application. The material is a fast-drying thick-coat

system. When accelerating drying with forced air, ensure that

the fast-developed skin is not blown away over the still-wet

material on which it is floating. This may cause cracks to form.

Cleaning

♦ Splashes on painted surfaces should be removed immediately

with plastic cleaner - D 195 850 A1- .

♦ Equipment and soiled parts must be cleaned with water im‐

mediately after application, if necessary using a water-based

cleaning agent. Do not use any solvent-based cleaning

agents, as they cause coagulation. After drying, long-life un‐

derseal can only be removed mechanically.

Technical data

Technical data:

Colour grey

Odour Slight ammonia odour

Density approx. 1.22 g/cm³

Solid matter

content

Viscosity: 0.5 Pas

Measuring in‐

strument

Measurement

system

Wet layer

thickness

approx. 67 %

Physica

Z 4

1 mm

28 Rep. gr.00 - Technical data

Page 33

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Thinner/

Distilled water

cleaning

agent

Processing

+10 °C to +25 °C

temperature

Application

temperature

-25 °C to +80 °C (100 °C for short periods up to

1 hour)

Acoustic data:

Loss factor

approx. 0.10

DIN 53440

Temperature 20 °C

Frequency 200 Hz

Material Steel sheet, 1 mm

Thickness ra‐

2:1

tio of coating

to sheet

Storage

The guaranteed storage stability is 12 months from date of man‐

ufacture. It can be processed on or before the date indicated on

label if stored in unopened, original containers at +20°C.

Storage conditions

The recommended storage temperature for the long-life under‐

seal is +10 °C to 25 °C.

The long-life underseal is susceptible to frost, so the temperature

must not fall below +5 °C.

3.5.2 Long-life underseal - D 314 D37 M2black

Designation

♦ Long-life underseal - D 314 D37 M2- black

Product description for long-life underseal - D 314 D37 M2- black

The long-life underseal - D 314 D367 M2- is a black coating com‐

pound based on an aqueous polymer dispersion, which is

sprayed on using a UBS spray gun.

Drying time depends on the coat thickness as well as the ambient

temperature and

humidity. Good ventilation and higher tempera‐

tures accelerate drying.

The dried film adheres well to galvanised or CDP coated sheet

metal as well as painted base surfaces. Due to the great resist‐

3. Original products 29

Page 34

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

ance to abrasion and flexibility under cold conditions, the long-life

underseal exhibits excellent stone chip protection.

The long-life underseal can be quickly overpainted with waterbased paints after a short time.

After air drying (approx. 2-3 hours), the material can be overpain‐

ted with conventional (solvent-based) paint systems as well.

The dried coating can be easily sanded once it is fully hardened.

The long-life underseal is suitable for restoring the original struc‐

ture following repairs.

The material is only temporarily resistant to spirit and cold clean‐

ers.

Application

♦ The long-life underseal - D 314 D37 M2- is suitable for repair‐

ing underbodies,

can be applied to visible parts such as side rails, as paintable

protection against stone chipping, road salt and corrosion due

to moisture.

♦ The material is suitable for restoring various surface structures

following repairs to all types of vehicle.

♦ The long-life underseal is also suitable for sound absorption

in boots, on bonnets, wheel arches and side walls, as well as

to cover and seal repair points, weld seams and overlappings.

wheel housings, and front and rear ends and

Note

♦

Before starting work it is important to consult the safety regu‐

lations for information on mandatory precautions and sugges‐

ted safety procedures.

♦

All standard safety precautions for chemical products must be

observed, even when using substances not subject to special

labelling requirements.

Processing

♦ The surfaces to be treated must be cleaned thoroughly be‐

forehand, and any rust must be removed.

♦ The surfaces must be dry and free of dirt, dust and grease.

♦ Any surfaces that are not being coated should be masked with

masking paper.

♦ Bare steel surfaces must be primed before application of long-

life underseal.

♦ The long-life underseal is applied from a 1 litre can using a

UBS spray gun. The processing pressure is 4-5 bar.

♦ The can contents must be shaken vigorously for one minute

before use.

30 Rep. gr.00 - Technical data

Page 35

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Caution

Do not spray onto joints, engine, gearbox, propshaft, exhaust,

catalytic converter or brake systems.

The UBS spray gun must be sprayed empty and then flushed

with plastic cleaner - D 195 850 A1- .

A blocked gun may cause the can to explode!

You must following the operating instructions for the UBS spray

gun!

Overpainting

Note

The long-life underseal can be overpainted using water-based

and solvent-containing paints. As there are many systems on the

market, tests must be performed.

1 - Overpainting with water-thinnable paints:

– The long-life underseal can be overpainted with water-thinna‐

ble paints after a short initial drying period (matt surface) and

up to 72 hours after application.

2 - Overpainting with conventional (solvent-containing) paints:

– The long-life underseal can be overpainted with conventional

(solvent-containing) paints after through drying and up to 72

hours after application. The material is a fast-drying thick-coat

system. When accelerating drying with forced air, ensure that

the fast-developed skin is not blown away over the still-wet

material on which it is floating. This may cause cracks to form.

Cleaning

♦ Splashes on painted surfaces should be removed immediately

with plastic cleaner - D 195 850 A1- .

♦ Equipment and soiled parts must be cleaned with water im‐

mediately after application, if necessary using a water-based

cleaning agent. Do not use any solvent-based cleaning

agents, as they cause coagulation. After drying, long-life un‐

derseal can only be removed mechanically.

Technical data

Technical data:

Colour black

Odour Slight ammonia odour

Density approx. 1.22 g/cm³

Solid matter

content

approx. 67 %

Viscosity: 0.5 Pas

Measuring in‐

Physica

strument

Measurement

Z 4

system

Wet layer

1 mm

thickness

3. Original products 31

Page 36

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

Thinner/

cleaning

agent

Processing

temperature

Application

temperature

Loss factor

DIN 53440

Temperature 20 °C

Frequency 200 Hz

Material Steel sheet, 1 mm

Thickness ra‐

tio of coating

to sheet

Storage

The guaranteed storage stability is 12 months from date of man‐

ufacture. It can be processed on or before the date indicated on

label if stored in unopened, original containers at +20°C.

Distilled water

+10 °C to +25 °C

-25 °C to +80 °C (100 °C for short periods up to

1 hour)

Acoustic data:

approx. 0.10

2:1

Storage conditions

The recommended storage temperature for the long-life under‐

seal is +10 °C to 25 °C.

The long-life underseal is susceptible to frost, so the temperature

must not fall below +5 °C.

3.5.3 Long-life underseal - D 314 D38 M2light

Designation

♦ Long-life underseal - D 314 D38 M2- light

Product description

The long-life underseal - D 314 D38 M2- is a light transparent i.e.

translucent non-opaque

polymer dispersion, which is sprayed on using a UBS paint or filler

gun.

Drying time depends on the coat thickness as well as the ambient

temperature and humidity. Good ventilation and higher tempera‐

tures accelerate drying.

The dried film adheres well to galvanised or CDP coated sheet

metal as well as painted base surfaces. Due to the great resist‐

coating compound based on an aqueous

32 Rep. gr.00 - Technical data

Page 37

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

ance to abrasion and flexibility under cold conditions, the long-life

underseal exhibits excellent stone chip protection.

The long-life underseal can be quickly worked on or overpainted

with water-based paints.

After air drying (approx. 2-3 hours), the material can be overpain‐

ted with conventional (solvent-based) paint systems as well.

The long-life underseal may be pigmented and mixed with waterbased paints

and may be thinned with demineralised water. When

adding pigment, up to 30% by volume ready-to-spray waterbased paint may be added.

The mixing ratio, spray pressure and spray distance may be var‐

ied to achieve smooth surfaces or fine or coarse structures.

The material is only temporarily resistant to spirit and cold clean‐

ers.

Application

♦ The long-life underseal - D 314 D38 M2- is suitable for repair‐

ing underbodies, wheel housings, and front and rear ends and

can be applied to visible parts such as side rails, as paintable

protection against stone chipping, road salt and corrosion due

to moisture.

♦ The material is suitable for restoring various surface structures

following repairs to all types of vehicle.

♦ A particular advantage is the ability to colour the material. Any

scratches and stone impacts are therefore almost invisible.

Note

♦

Before starting work it is important to consult the safety regu‐

lations for information on mandatory precautions and sugges‐

ted safety procedures.

♦

All standard safety precautions for chemical products must be

observed, even when using substances not subject to special

labelling requirements.

Processing

♦ The surfaces to be treated must be cleaned thoroughly be‐

forehand, and any rust must be removed.

♦ The surfaces must be dry and free of dirt, dust and grease.

♦ Any surfaces that are not being coated should be masked with

masking paper.

♦ Bare steel surfaces must be primed before application of long-

life underseal.

♦ The long-life underseal may be applied to all common sealing

materials except silicone and exhibits good adhesion.

♦ Sealants containing softeners may cause the surface of long-

life underseal to soften or exhibit slight stickiness. However,

the material will not lose its adhesive property as a result.

♦ Shake the can thoroughly before use.

♦ The long-life underseal must be applied with rust-proof filler

guns or paint guns. The material may be thinned with up to

10% by volume distilled or demineralised water to achieve the

necessary viscosity.

♦ The first coat should not be applied too heavily (12 coat).

3. Original products 33

Page 38

Protected by copyright. Copying for private or commercial purposes, in part or in whole, is not permitted

unless authorised by ŠKODA AUTO A. S. ŠKODA AUTO A. S. does not guarantee or accept any liability

with respect to the correctness of information in this document. Copyright by ŠKODA AUTO A. S.�

Citigo 2012 ➤ , Fabia 2000 ➤ , Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fab ...

GETtheMANUALS.orgGETtheMANUALS.org

Paint - general information - Edition 10.2017

♦ The long-life underseal can be mixed with up to 30% by vol‐

ume ready-to-spray water-based paints.

♦ To recreate common structures, best results will be achieved

with 10-15% ready-to-spray paint mixture.

♦ The material should be filtered through a paint sieve before

application.

Caution

Do not spray onto joints, engine, gearbox, propshaft, exhaust,

catalytic converter or brake systems.

The UBS spray gun must be sprayed empty and then flushed

with plastic cleaner - D 195 850 A1- .

A blocked gun may cause the can to explode!

You must following the operating instructions for the UBS spray

gun!

Overpainting

Note

The long-life underseal can be overpainted using water-based

and solvent-containing paints. As there are many systems on the

market, tests must be performed.

1 - Overpainting with water-thinnable paints:

– The long-life underseal can be overpainted with water-thinna‐

ble paints after a short initial drying period (matt surface) and

up to 72 hours after application.

2 - Overpainting with conventional (solvent-containing) paints:

– The long-life underseal can be overpainted with conventional

(solvent-containing) paints after through drying and up to 72

hours after application. The material is a fast-drying thick-coat

system. When accelerating drying with forced air, ensure that

the fast-developed skin is not blown away over the still-wet

material on which it is floating. This may cause cracks to form.

Cleaning

♦ Splashes on painted surfaces should be removed immediately

with plastic cleaner - D 195 850 A1- .

♦ Equipment and soiled parts must be cleaned with water im‐

mediately after application, if necessary using a water-based

cleaning agent. Do not use any solvent-based cleaning

agents, as they cause coagulation. After drying, long-life un‐

derseal can only be removed mechanically.

Technical data

Colour Whitish, not opaque

Odour Slight ammonia odour

Density approx. 1.25 g/cm³

Solid matter

content

Viscosity: 1 Pas

Measuring in‐

strument

approx. 70 %

Rheomat STV

34 Rep. gr.00 - Technical data

Technical data:

Page 39