SKODA Self Study Program 27 – Octavia 1.4L engine and gearbox 002 ssp-27-octavia-14-l-engine-and-gearbox-002

Page 1

Š

KODA is enlarging its range of petrol engines in the

OCTAVIA with a new 1.4-ltr. OHV engine.

This compact and lightweight engine is a

Š

KODA

development and is based on tried-and-tested

components of the 1.3-ltr. light-alloy engine.

The engine is classified as conforming with the EU II

emission standard.

You can find out more regarding design and operation of this

new engine in this Self Study Programme.

SP15_02

SP27_18

2

Page 2

34

36

37

4

6

8

8

10

14

15

16

18

19

20

21

22

23

Contents

Part I – 1.4-ltr./44 kW Engine

Summary of New Features 4

The technical data

The engine characteristics

Mechanical Components 6

Valve gear

Valve timing

Crankshaft

Crankshaft bearings

Survey of Systems 10

Simos 3PB engine management

Engine speed sensor G28

Camshaft position sensor G163

Simos 3PB system function

Fuel injection

Electronic Throttle Function 18

Electrically operated throttle flap

Accelerator pedal

Self-diagnosis/emergency running to accelerator pedal

Throttle flap control unit

Function positions of throttle flap control unit

Basic setting of throttle flap control unit

Self-diagnosis/emergency running to throttle flap control unit 24

Fault lamp for electronic throttle

5

9

17

25

Sensors 26

Function Diagram 31

Part II – 5-Speed Manual Gearbox 002

Technical Data 34

Technical features

Gearbox diagram

Engine/Gearbox Mounting 36

Engine mount

Gearbox mount

Pendulum support

Clutch Mechanism 38

External Shift 39

Final Drive/Speedometer Drive 42

Service 43

You will find notes on inspection and maintenance,

setting and repair instructions in the Workshop

Manual.

Service

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

Service

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

Service Service Service Service

Service

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

35

37

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

Service

3

Page 3

Summary of New Features

The technical data

New!

SP27_61

Code letter: AMD

Type: 4-cylinder in-line engine

Displacement:

Bore: 75.5 mm

Stroke: 78 mm

Compression ratio: 10.0 : 1

Rated output: 44 kW (60 HP)

Max. torque: 120 Nm at 2500 rpm

Engine management:Simos 3PB

Valves per cylinder: 2

Emission control: Lambda control,

Emission standard: Complies with EU II

Fuel: 95 RON unleaded

Petrol engine

1397 cm

at 4500 rpm

(electronically

controlled sequential

fuel injection and fully

mapped ignition with

cylinder-selective knock

control)

1 catalytic converter

3

The basic design of the 1.4-ltr. engine is

derived from the tried-and-tested 1.3-ltr. lightalloy engine fitted to the FELICIA.

– Cross-flow cylinder head with 2 valves for

each cylinder.

– Bottom-mounted camshaft driven by a

duplex roller chain.

– Valves driven by tappets, tappet rods and

rocker arms.

– Replaceable cylinder liners, cooled directly

by coolant.

– Crankshaft mounted in 3 bearings.

– Oil pump driven by camshaft.

Note:

The engine can also be operated with

91 RON unleaded fuel although this

results in torque and power losses as

a result of the knock control.

4

Page 4

The engine characteristics

New!

1000

2000 3000 4000

The technical highlights

– The displacement has been increased as a

result of enlarging the stroke to 78 mm

while maintaining the original bore of

75.5 mm.

– The valve tappets of the valve gear have

been replaced by hydraulic valve tappets

which ensure automatic compensation of

the valve clearance. This makes it possible

to eliminate the setting of the valve

clearance as part of the service interval.

At the same time, a reduction in valve gear

noise has been achieved.

– The following measures have been

implemented with the aim of reducing

vibrations and improving the noise

characteristics:

Forged crankshaft with eight balancing

weights for achieving optimal mass

balance.

n (1/min)

5000

6000

SP27_17

The stiffness of the crankshaft mounting in

the housing is enhanced by combining the

bearing caps in a ladder frame (bearing

unit).

The oscillating masses of the crank gear

have been reduced by opting for a smaller

size of piston pins (Ø 17 mm) and lighter

weight pistons.

The stiffness of the crankcase has also

been enhanced by new type of ribbing.

The flexural stiffness of the engine-gearbox connection has been enhanced by a

new stiffening to the oil pan flange.

– The Simos 3PB system with sequential fuel

injection and electronic throttle flap control

(electronic throttle) has been used for the

first time as the engine management

system in a

Š

KODA engine.

5

Page 5

Mechanical Components

Valve gear

New!

Rocker arm

Rocker arm adjusting

bolt

Tappet rod

Oil feed from engine

oil circuit

Hydraulic tappet

(tappet for hydraulic valve

clearance compensation)

The valves of the 1.3-ltr. engine are driven by

the bottom-mounted camshaft through tappet

rods.

Valve clearance compensation is achieved by

the hydraulic system in the tappet, while

incorporating the engine oil pressure.

Advantage

The valve clearance remains constant during

the entire engine operating life, which has a

positive impact in reducing exhaust emissions.

It is not necessary to re-set the valve clearance

during service work.

Camshaft

203/3.3

After replacing parts of the valve gear, a basic

setting of the hydraulic tappet should be

performed.

This is done by means of the rocker arm

adjusting bolt. Please refer to the Workshop

Manual OCTAVIA, 1.4-ltr./44 kW Engine for

further information on this step.

Note:

For repair work, always stop the

tappets in the installed position in

order to retain the oil supply.

Scrupulous cleanliness is essential for

all work.

6

Page 6

New!

Tappet casing

Annular spring

Tappet plunger

Leak gap

Tappet rod

Vent drilling

Oil feed

Oil groove running all round

High-pressure chamber

Piston spring

Cam

Function of the hydraulic tappet

– The tappet plunger moves within the

cylindrical tappet casing which is closed at

the bottom, and is supported by the piston

spring.

– Tappet plunger and tappet casing form the

high-pressure chamber at the bottom in

which an oil cushion is enclosed. This

forms the power connection between cam

and valve gear (tappet rods, rocker arms).

– An annular spring between tappet casing

and tappet plunger ensures that the power

connection is free of play.

– At the commencement of the valve stroke,

the cam exerts a force on the hydraulic

tappet. The ball valve seals off the oil

chamber to the high-pressure chamber.

The pressure in the high-pressure chamber

rises.

A slight, defined quantity of oil is forced

out of the high-pressure chamber through

the leak

Oil chamber

Ball valve with

valve spring

Track

203/2

gap, and this oil flows around the oil

groove into the oil chamber.

As a result, the tappet plunger is moved

and the gap of 0.03 mm to 0.06 mm which

is required for proper operation of the

valve timing, is thus assured.

– As the cam rotates around the circular

track, the missing oil in the high-pressure

chamber flows out of the oil chamber

through the ball valve.

– The oil supply in the hydraulic tappet is

constantly topped up from the oil circuit of

the engine through drillings in the tappet

casing and plunger.

– Longitudinal changes in the valve gear

caused by temperature or wear are

constantly compensated.

7

Page 7

Mechanical Components

Valve timing

The timing of the valves influences the gas

change cycles in the engine and the level of

pollutant emissions.

Engine torque has been boosted by enlarging

3

the displacement to 1397 cm

achieved by an increase in stroke from 72 mm

to 78 mm.

The shape of the cam of the inlet and exhaust

valves has been optimised to match these

new parameters.

As a result of this modification to the cam

shape, the following valve timings now exist:

A1 = Outlet valve opens 44

A2 = Exhaust valve closes 13

B1 = Inlet valve opens 17

B2 = Inlet valve closes 40

This results in a marked range of valve

overlap at the gas change TDC.

, this being

° before BDC

° after TDC

° before TDC

° after BDC

1

B

1 7

B

2

4 0

Exhaust valve

Inlet valve

New!

O

°

°

U

T

A

2

1 3

°

1

A

°

4 4

T

SP27_42

TDC = top dead centre

BDC = bottom dead centre

Crankshaft

The crankshaft features eight balancing

weights in order to enhance smooth engine

running and to achieve good mass balancing.

The crankshaft is located axially by means of

the middle main bearing with two guide

segments.

New!

SP27_43

Balancing weight

8

Page 8

The crankshaft bearings

The stiffening of the crankshaft

bearings in the cylinder block is

enhanced by the connection of the

bearing caps to form a single unit.

The crankshaft bearing unit is an iron

casting.

New!

SP27_44

Cylinder block

Crankshaft bearing

unit

Longitudinal sections connect the

3 bearing caps to form a self-contained

frame.

The bottom bearing shells of the

crankshaft bearings are located directly

in the frame, as is the case for single

bearing caps.

An important point to note during

installation is that the bearing shells

are installed with the matching bearing

caps because the middle bearing shell

is wider.

Bottom bearing shells

SP27_45

Crankshaft bearing unit

9

Page 9

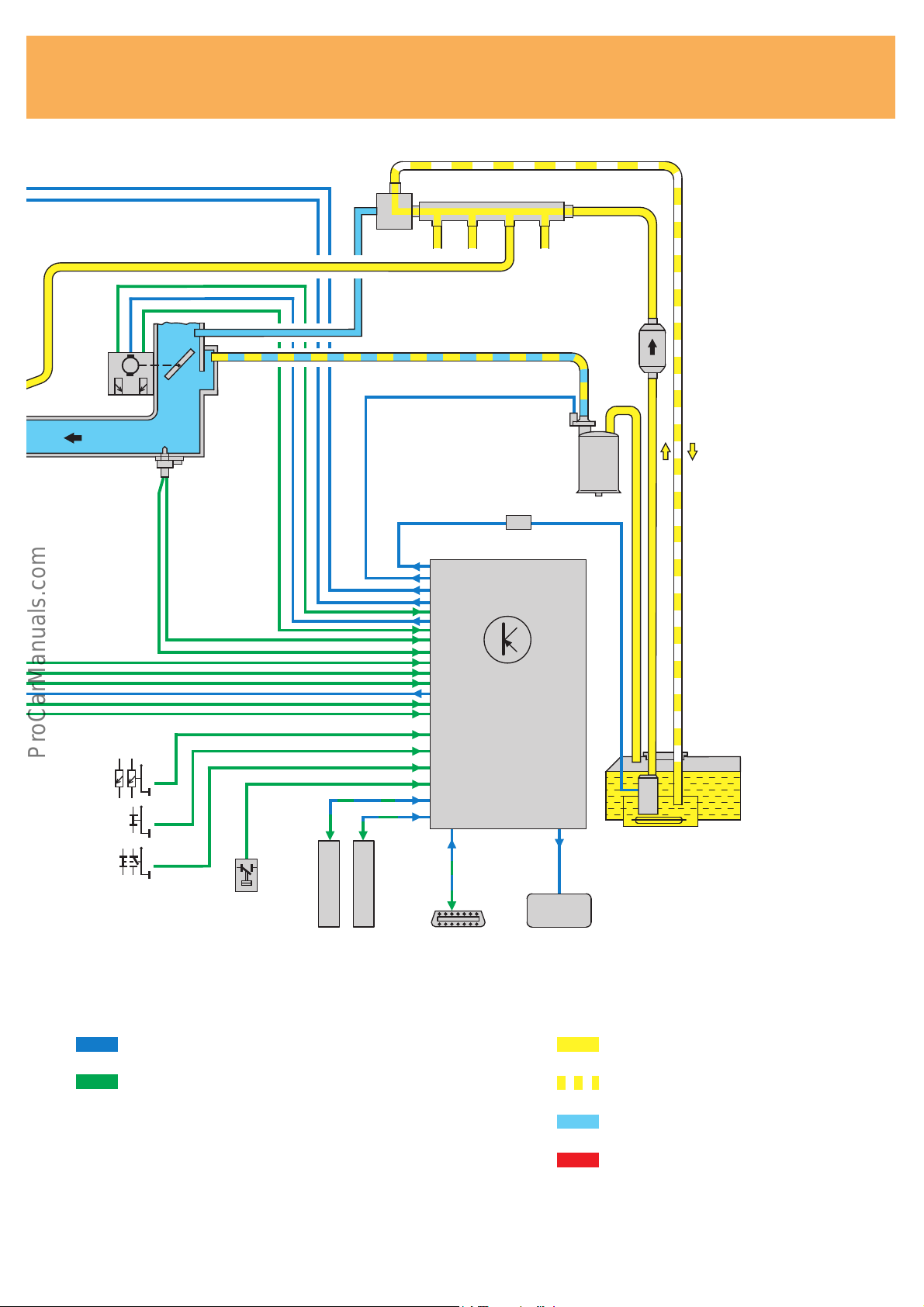

System Overview

S

Simos 3PB engine management

The Simos engine management system

controls the fuel injection and the ignition in

line with the current engine load. The engine

load is detected by the engine speed sensor

and by the intake manifold pressure sensor.

The control unit uses this information to

calculate the ignition timing point and period

of injection, taking into account the correction

factors.

The correction factors are:

– Cylinder-selective knock control

– Lambda control

– Idle speed control

– Activated charcoal filter control

G39

Z19

N152

P/Q

N30

The position of the throttle flap is controlled

electrically.

Additional signals regarding the clutch pedal

and brake pedal position and load supplied by

the power steering pump, are integrated in the

control system of the engine management.

The engine control unit is designed to operate

with CAN data transfer.

Legend

F/F47 Brake light/brake pedal switch

F36 Clutch pedal switch

F88 Power steering pressure switch

G6 Fuel pump

G39 Lambda sensor

G28 Engine speed sensor

G61 Knock sensor

G62 Coolant temperature sensor

G71 Intake manifold pressure sensor

G72 Intake manifold temperature sensor

G79 Accelerator pedal position sensor

G163 Camshaft position sensor

G185 Sensor 2 for accelerator pedal position

G186 Throttle flap drive

G187 Angle sensor 1 for throttle flap drive

G188 Angle sensor 2 for throttle flap drive

J17 Fuel pump relay

J338 Throttle flap control unit

J361 Simos 3PB control unit

K132 Electronic throttle fault lamp

N30 Injector

N80 Activated charcoal filter solenoid valve

N152 Ignition transformer

P Spark plug connector

Q Spark plugs

Z19 Lambda probe heater

G163

Simos 3PB

G62

G61

G28

3rd generation with

electronic throttle and

CAN BUS

iemens e ngine c ontrol

10

Page 10

11

J338

G186

G187

G188

M

G71 G72

B

C

A

N80

D

J17

J361

G79

G185

F36

F

F47

= Output signal

= Input signal

-

+

F88

E

CAN - BUS

CAN - BUS

A = Fuel filter

B = Fuel pressure regulator

C = Fuel rail

D = Activated charcoal filter

E = Diagnostic connection

SIMOS 3PB

G6

EPC K132

SP27_13

= Fuel feed

= Fuel return

= Intake air

= Exhaust

Page 11

System Overview

The processor-based Simos 3PB engine

management system is matched to the

requirements of the electronic throttle.

Sensors

Engine speed sensor G28

Camshaft position sensor G 163

Intake manifold pressure sensor

G71 and

Intake manifold temperature sensor

G72

Throttle flap control unit J338

(electronic throttle positioner)

Angle sensors for throttle flap

drive G187 and G188

New or additional components compared to

the familiar Simos 2P system are outlined in

colour.

Sensors for accelerator pedal position

G79 and G185

Coolant temperature sensor G62

Lambda sensor G39

Knock sensor G61

Power steering pressure switch F88

Clutch pedal switch F36

Brake light switch F and

Brake pedal switch F47

*

CAN - BUS H

CAN - BUS L

Air conditioning (pressure sensor)

AC compressor (AC switch operation)

AC compressor

Road speed signal

12

* in preparation

Page 12

Simos 3PB control unit

J361

Actuators

Fuel pump relay J17

Fuel pump G6

W

4

3

1/min x 1000

5

2

6

1

7

120

100

140

km/h

80

160

60

180

40

200

20

220

J218

240

Combination

processor in dash

panel insert/

immobiliser

K

Injectors N30 … N33

Ignition transformer (4x)

N152 (ignition block)

Throttle flap control unit J338

Throttle flap drive G186

Lambda probe heater Z19

Diagnostic connection

SP27_09

Activated charcoal filter solenoid

valve N80

Electric throttle control fault

EPC

lamp K132

Vehicle speed signal (dash panel insert)

AC compressor

Fuel consumption signal (dash panel insert)

13

Page 13

System Overview

Engine speed sensor G28

Installation point

The sensor is installed at the gearbox above

the flywheel.

Use of signal

The engine speed sensor is an inductive

sensor.

It detects the engine speed and the exact

angular position of the crankshaft.

Operation and design

Sensor segments are integrated around the

circumference of the flywheel, in addition to

the starter ring gear. The circumference is

divided into 60 segments for this purpose and

features a gap of two segments.

When the segments rotate past the sensor, the

magnetic field of the sensor is altered. This

change in the magnetic field induces an

electric voltage in the coil winding of the

sensor. Its frequency changes in line with

engine speed. The frequency is a measure of

engine speed. The electric voltage is passed to

the control unit.

The position of the crankshaft is fixed by

means of the segment gap. Together with the

camshaft position sensor, the exact position

of the engine mechanical components, i.e. the

ignition TDC of cylinder 1, is detected.

This serves as a basis for defining the

injection and ignition timing points.

Flywheel with

sensor segments

Starter ring gear

Engine speed

sensor

SP27_03

Segment gap

Electric circuit

Substitute function and self-diagnosis

The signal supplied by the engine speed

sensor is checked for plausibility together with

the signal supplied by the camshaft position

sensor. If the Simos control unit does not

detect any signal from the engine speed

sensor, the engine stops. It can, however, be

started again. In this case, it operates in the

emergency running programme and uses

signals supplied by the camshaft position

sensor G163.

Self-diagnosis detects:

“G28 no signal” and “G28 implausible

signal”.

14

SP27_10

Page 14

Camshaft positions sensor G163

The camshaft position sensor operates on the

Hall sensor principle. It is located next to the

oil filter at the level of the camshaft.

Use of signal

It is essential to accurately define cylinder 1

for the cylinder-selective knock control and

the sequential fuel injection.

Ignition TDC of cylinder 1 is detected

(synchronisation of cylinder 1) by means of

the signal supplied by the camshaft position

sensor together with the signal supplied by

the engine speed sensor G28 (engine speed

sensor and reference mark).

Once both signals have been received

simultaneously, initial fuel injection and

ignition is then activated.

Operation and design

The “camshaft pulse generation” is effected

directly by the orifice rotor, which is part of

the camshaft. it has a 180° window and a

continuous segment of 180°.

The 180° segment passes through the

magnetic field of the sensor and intersects the

lines of magnetic force.

As it passes, it generates a voltage.

In contrast, the 180° window does not affect

the magnetic field.

The Simos control unit processes this signal

sequence.

Orifice rotor

180° window

Camshaft

SP27_11

Camshaft position sensor G163

Electric circuit

Substitute function and self-diagnosis

In the event that the camshaft position sensor

fails, the engine control unit switches off the

knock control and the ignition angle is

retarded.

The engine continues running using as a

substitute the signal supplied by the engine

speed sensor G28.

Self-diagnosis detects:

“G40 implausible signal” and “G40 signal too

small”.

J361

89 105 111

+

G163

-

SP27_12

15

Page 15

System Overview

Simos 3PB system function

In the diagram below, we see the signal

pattern of the engine speed sensor and the

camshaft sensor.

The signal patterns can also be rendered

visible with the oscilloscope function of

VAS 5051.

They illustrate how the signals are processed

in the Simos control unit in order to determine

the position of the engine mechanical

components for defining the fuel injection and

ignition timing points.

TDC TDC TDC TDC TDC

Firing order

Tooth No.

61 74 88 104 118 1 14 28 44 58 61 74

58

Cyl. 4 Cyl. 2 Cyl. 1 Cyl. 3 Cyl. 4

Note:

2 crankshaft revolutions with 2 x

(60 – 2) teeth (teeth are numbered

consecutively up to 120) and

1 camshaft revolution with

1 x 180° window, form an analysis

cycle.

The top dead centre is at the same

time the ignition top dead centre.

1st falling tooth edge after gap is at 78° crank

angle before ignition TDC of cylinder 1 or 4

Crankshaft signal from

sensor G28

Camshaft signal from

camshaft position sensor

G163

Effects in the event of signal failure

refer to pages 14 and 15

2nd crankshaft revolution 1st crankshaft revolution

o

-window

180

Falling edge located at tooth 88, i.e.

14 teeth after ignition TDC of cylinder 4

1 camshaft revolution

SP27_16

Rising edge is located at tooth 28 after

gap, i.e. 14 teeth (84°) after ignition TDC

of cylinder 1

16

Page 16

Fuel injection

Intake manifold pressure

and intake manifold

temperature sensor

Throttle flap control unit

Fuel rail

To air filter

Pressure regulator

Injector

Intake module

Intake module

The intake module houses the throttle flap

control unit and the fuel rail together with the

injectors and the pressure regulator. The

intake manifold pressure and intake manifold

temperature sensor is located at the side of

the intake manifold.

Fuel injection

Each cylinder features an electro-magnetic

injection valve which is positioned in the

intake manifold upstream of the inlet valve.

The valves are supplied with fuel by the fuel

pump and actuated through earth by the

engine control unit.

The fuel injected gathers first of all in the

intake port and is inducted into the

combustion chamber together with the air

when the inlet valve opens.

SP27_38

The injectors are operated in line with the

firing order of 1 – 3 – 4 – 2 (sequential fuel

injection).

The commencement of injection angle is

always related to the ignition TDC of the

corresponding cylinder.

The control unit takes into account the

following correction factors for determining

the opening time of the injectors:

– Cylinder-selective knock control

– Lambda control

– Idle speed control

– Activated charcoal filter control

17

Page 17

Electronic Throttle Function

Electrically operated throttle flap

Pedal value sensor

Sensors for accelerator pedal

position G79 and G185

* Central Processor Unit

Engine control unit

Input signals Output signals

CPU*

Safety module

New!

Throttle flap control

unit J338

Throttle flap

drive G186

SP27_26

Angle sensors for

throttle flap drive G187

and G188

There is no mechanical and no direct electrical

link in the Simos 3PB engine management

system between accelerator pedal and throttle

flap. These are replaced by an electronic

control.

The system includes:

– Pedal value sensor (at accelerator pedal)

– Engine control unit

– Throttle flap control unit

The driver input at the accelerator pedal is

detected by the pedal value sensor and

transmitted to the engine control unit.

The engine control unit alters the position of

the throttle flap by means of a dc motor.

The position of the throttle flap is, in turn,

continuously signalled back to the engine

control unit.

Advantages

In addition to the intake air control, functions

such as

– idle speed control

– vehicle speed control

– engine speed limit

are achieved in a simple and convenient way.

The throttle flap can be opened irrespective of

the position of the accelerator pedal.

The electronic throttle makes it possible to

achieve significantly improved emission and

fuel consumption levels in certain engine load

states.

A wide range of measures in terms of hardware and software (duplicate sensors, selfmonitoring processor structure) are intended

to ensure high operational reliability.

18

Page 18

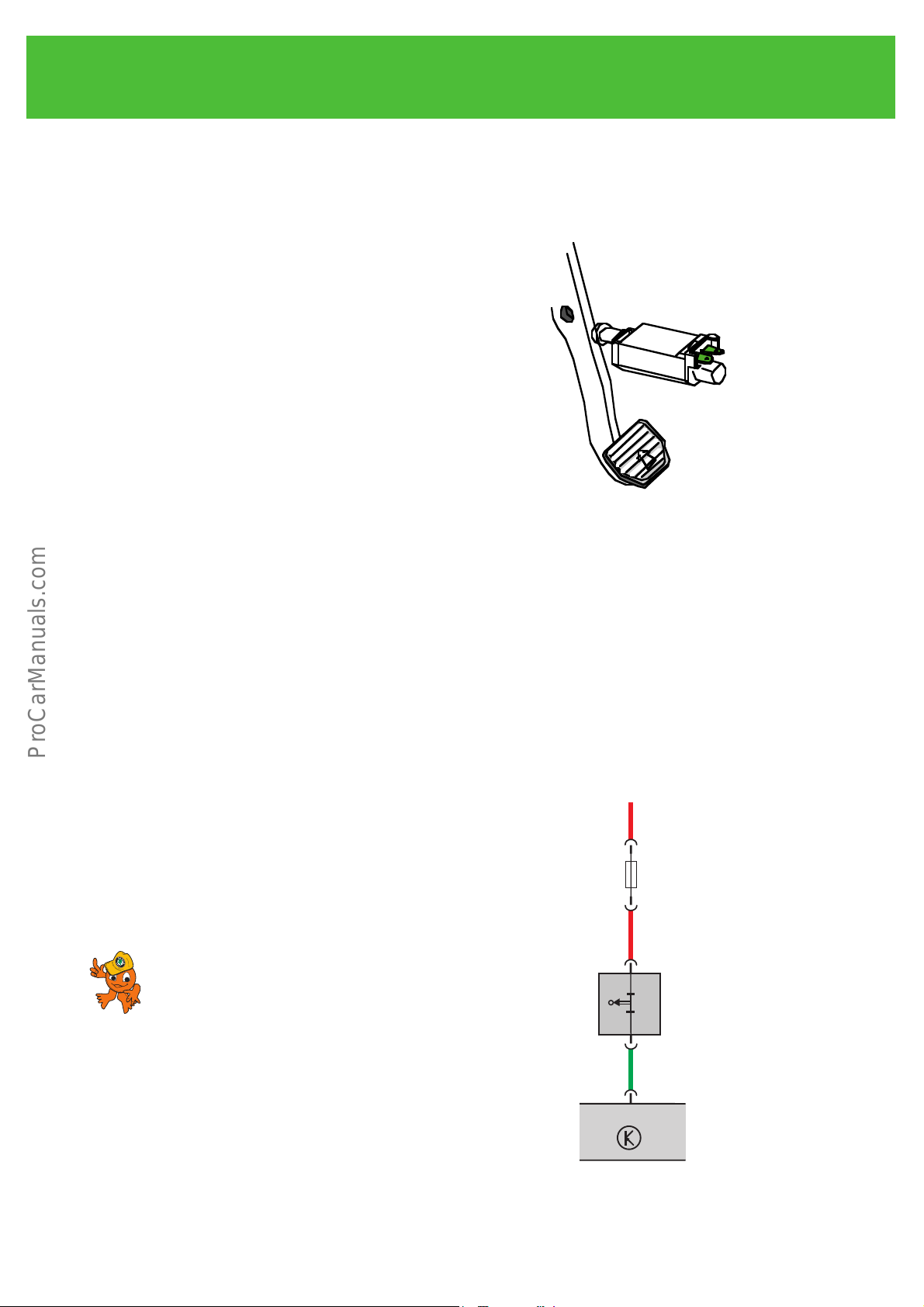

Accelerator pedal with pedal value

sensor (sensors for accelerator

position G79 and G185)

Accelerator pedal and pedal value sensor

form a single unit and are also known as the

accelerator pedal module.

The mechanism is housed in the module

housing.

The sensors – accelerator pedal position

sensor G79 and G185 – are located in the

housing.

Two sensors operating independently, are

used in order to provide reliable operation of

the electronic throttle.

The pedal value sensor operates as a slidingcontact potentiometer.

A stabilised voltage of 5 V is supplied by the

engine control unit to each potentiometer for

detecting the position of the accelerator pedal

at the sliding-contact potentiometer.

The signal regarding the position of the

accelerator pedal is passed as a voltage signal

to the engine control unit.

Module housing with

pedal value sensor

Accelerator pedal

SP27_27

The characteristic curves of the two sensors

differ in pattern (see chart).

The engine control unit monitors the function

and plausibility of the two sensors.

If one sensor fails, the other acts as a

substitute.

The entire module is pre-set.

It is replaced as a complete unit in the event of

repairs.

SP27_28

Sensor for accelerator pedal position G79 and

sensor 2 for accelerator pedal position G185 in

module housing

kΩ

2,0

1,6

1,2

0 % 100 %

Accelerator pedal travel

Idle speed Full throttle

G185

G79

SP27_29

19

Page 19

Electronic Throttle Function

Self-diagnosis/emergency running

to accelerator pedal

If a fault occurs at the pedal value sensor or in

the wiring, two emergency running

programmes are available, depending on the

type of fault.

Failure of one sensor for accelerator pedal

position

– Electronic throttle fault lamp K132 comes

on.

– Fault is stored.

– Engine continues running normally.

– The customer should take the car to a

service workshop.

Requirement for emergency running

programme:

Idle throttle position must be detected

once by the operating sensor.

– The signal of the brake light switch F

and brake pedal switch F47 is used for

detecting idle speed.

– Convenience features such as cruise

control system are disabled.

Emergency running programme 1

Failure of both sensors for accelerator pedal

position = not possible to detect driver input

– Electronic throttle fault lamp K132 comes

on.

– Fault is stored.

– Engine runs at increased speed of approx.

1500 rpm.

– Customer should take car to a service

workshop.

20

Emergency running programme 2

Page 20

Throttle flap control unit J338 with

throttle flap drive G186, angle

sensor 1 G187 and 2 G188 for

throttle flap drive

Throttle flap housing

with throttle flap

Throttle flap drive G186 (electric

throttle operation)

Angle sensors for throttle flap

drive G187 and G188

The throttle flap control unit consists of

– throttle flap housing with throttle flap

– throttle flap drive G186

– angle sensors for throttle flap drive G187

and G188

The throttle flap is moved by the throttle flap

drive (dc motor). It is operated by the engine

control unit and in this way regulates the air

flow required for producing the torque. The

feedback signal regarding the current throttle

flap angle is supplied by two angle sensors

(potentiometers) to the engine control unit.

These sensors are attached to the throttle flap

shaft.

The throttle flap is limited in the top and

bottom position by a mechanical stop.

Two angle sensors are used for safety

reasons. Their resistance characteristic curves

are inversed (see chart).

If one angle sensor fails, the engine

control unit activates an emergency running

programme and the operation of the electronic throttle is maintained. If the drive is deenergized, the throttle flap is moved into an

emergency running position by the force of a

spring.

Spiral spring

Stop at housing

Note:

The throttle flap control unit must not

be opened.

The angle sensors must be “learned”

in a basic position.

Please refer to the information in the

Workshop Manual.

kΩ

1,5

1,0

0,5

0 % 100 %

Throttle flap opening

SP27_05

G188

G187

SP27_36

21

Page 21

Electronic Throttle Function

Function position of the throttle

flap control unit

The engine control unit detects four important

function positions.

Lower mechanical stop

Throttle flap is fully closed. This position is

required for adapting the angle sensors.

Stop at housing

Throttle flap is

word linearly

Rotary disc with

stop cam

SP27_32

Lower electrical stop

Is defined by the engine control unit. Is

positioned only slightly above the bottom

mechanical stop.

In operation, the maximum closed position of

the throttle flap is fixed by this stop.

This prevents the throttle flap “working into”

the housing.

Emergency running position

Position of throttle flap in the de-energized

state. Adequate air flow is assured in the

event of the electronic throttle failing. Fast

engine idling speed of approx. 1500 rpm.

Car can continue to be driven with severe

restrictions.

M

SP27_33

M

SP27_34

Upper mechanical stop

Full throttle position of throttle flap.

Of little significance in operational terms.

Full throttle is set by the “upper electrical

stop”, which is defined by the engine control

unit.

22

M

SP27_35

Page 22

Basic setting (adaptation) of

throttle flap control unit

The angle sensors of the throttle flap drive

G187 and G188 have to be learned to enable

the exact angle position of the throttle flap to

be detected.

Learning is done by initiating function 04 –

Basic setting.

This can be performed using the vehicle

system tester V.A.G 1552, the fault reader

V.A.G 1551 or with the vehicle diagnosis

measurement and information system

VAS 5051.

Adaptation of the throttle flap position is

performed when function 04 Basic setting is

activated with “display group number 60”.

1

2

3

4

5

6

7

8

9

C

O

HELP

Q

V.A.G.

1552

When this is done, the throttle flap positioner

is moved out of the “emergency running

position” (de-energized state) to the MIN and

MAX positions. The values of the potentiometer voltages which are measured in these

positions, are then stored in the control unit.

Adaptation conditions!

“Engine not running, ignition on”.

If an attempt is made to activate the throttle

flap adaptation if the vehicle is not in this state

or if throttle flap adaptation is prevented for

other reasons (e.g. throttle flap positioner

opened mechanically, diagnostic fault of

positioning motor, etc.), this is displayed with

a text at the vehicle system tester.

Measured value blocks for throttle flap

actuation can be retrieved with function 08 –

Reading measured value blocks.

202_CZ_002

SP17-29

Note:

Pay attention to the adaptation

conditions!

“Function is unknown or cannot be

carried out at the moment.”

23

Page 23

Electronic Throttle Function

Self-diagnosis/emergency running

to throttle flap control unit

If a fault occurs at the throttle flap control

unit or in the wiring, emergency running

programmes are available, depending on the

type of fault.

Failure of one angle sensor for throttle flap

drive or implausible signal

– System activations which increase engine

torque (e.g. cruise control system, engine

braking torque control) are suppressed.

– Electronic throttle fault lamp K132 comes

on.

Failure or control fault of throttle flap drive

– The throttle flap drive is switched off. The

throttle flap moves into the emergency

running position. This is noticeable from a

sharp drop in engine output and fast

engine idling speed.

– Electronic throttle fault lamp K132 comes

on.

Note:

A faulty throttle flap control unit is

not repaired. If a fault occurs at the

throttle flap positioner or at the angle

sensors, the complete control unit

must be replaced.

Emergency running programme 1

Requirement

One angle sensor is operating properly.

Plausible air mass flow is detected (intake

manifold pressure sensor G71 and intake

manifold temperature sensor G72 operating

normally).

Emergency running programme 2

Requirement

The emergency running programme is only

activated if the emergency running position is

detected by both angle sensors of the throttle

flap drive.

No clear detection of throttle flap position

possible or if it is not certain that throttle flap

is not in the emergency running position

– The throttle flap drive is switched off. The

throttle flap moves into the emergency

running position, if possible. This is

noticeable from fast engine idling speed.

– Engine speed is limited to approx.

1500 rpm by switching off fuel injection.

– Electronic throttle fault lamp K132 comes

on.

24

Emergency running programme 3

Page 24

Electronic throttle fault lamp K132

4

3

1/min x 1000

2

1

When the ignition is switched on, the EPC

fault lamp comes on in the indicator lamp

panel of the dash panel insert. It must go out

again after 3 seconds (operational test of

lamp).

The fault lamp is operated directly by the

engine control unit J361 through an earth

voltage to the combination processor in the

dash panel insert J218.

If a fault occurs in the electronic throttle

system, this is detected by the self-diagnosis

and indicated by the separate EPC fault lamp.

In this case, the fault lamp comes on and

remains on.

At the same time, an entry is stored in the

fault memory.

120

100

5

6

7

80

60

40

20

km/h

140

160

180

200

220

240

SP27_08

Note:

EPC means

Electronic Power Control (electronic

throttle)

Electric circuit

J218

If a fault occurs in the electronic throttle

system, a matching emergency running

programme is activated (refer also to sensors

for accelerator pedal position and throttle flap

control unit).

73

J361

SP27_60

25

Page 25

Sensors

Brake light switch F and brake pedal

switch F47

Task

The information “brake operated” is used for

controlling two systems:

– Backup interrogation of electronic

throttle function (idle speed detection in

emergency running mode of pedal value

sensor)

– Operation of cruise control system (on

models fitted with this).

(The main function is switching on the brake

lights; on models fitted with ABS, this signal is

used for informing the ABS control unit.)

Function

The brake light switch F and the brake pedal

switch F47 are combined to form a single

component. For safety reasons, both act as

information senders for “brake operated”. The

combination switch has four connections.

The brake light switch F is open in the off

position and is supplied with voltage through

terminal 30.

It is the switch for operating the brake lights

and acts as an additional information input for

the Simos control unit.

Brake light switch F and

Brake pedal switch F47

Electric circuit

+

30

+

SP26_40

15

The brake pedal switch F47 is closed in the off

position and is supplied with voltage through

terminal 15.

Its only purpose is to act as an information

input for the Simos control unit.

Self-diagnosis

Both switches are checked mutually for

plausibility by the self-diagnosis.

Note:

If an accelerator pedal position sensor

fails, the electronic throttle function

uses the signal from the brake light

switch or brake pedal switch to detect

idle speed.

26

F

53

F47

63

J361

SP27_48

Page 26

Clutch pedal switch F36

Task

The information “clutch operated” is used for

controlling two systems:

– On models fitted with a cruise control

system, the function of the cruise control

system is switched off.

– The load change functions are deactivated

during a gearshift. The load change

function is controlled by influencing the

ignition angle and by the closing rate of

the throttle flap.

Function

Like the brake pedal switch, the clutch pedal

switch is closed in the off position.

It is supplied with voltage through terminal 15.

cal resistance.

When the clutch pedal is operated, the information passes directly to the Simos control

unit.

Substitute function and self-diagnosis

The clutch pedal switch is not detected by the

self-diagnosis.

Consequently, no substitute functions are

derived. If no signal is received, the function is

not activated.

Electric circuit

+

15

SP23_32

Note:

In the event of an incorrect setting,

electrical malfunction or incorrect

operation (driver leaves foot on clutch

pedal), this can result in operating

problems (load change jolts, sudden

increases in engine speed).

F36

65

J361

SP27_49

27

Page 27

Sensors

Power steering pressure switch F88

All OCTAVIA models are fitted as standard

with a power-assisted steering.

The hydraulic pump of the power steering,

which is driven by the engine through the

ribbed V-belt, increases the load on the engine

when the steering is turned to full lock; when

the engine is idling, this may result in a sharp

drop in engine revs.

The Simos 3PB system control compensates

for this situation and additionally processes a

signal which supplies information regarding

the additional load resulting from the power

steering.

The engine control unit detects the additional

engine load at an early stage by means of the

signal supplied by the power steering

pressure switch F88 and controls the idle

speed accordingly.

Power steering

hydraulic pump

SP27_46

Power steering pressure

switch F88

Operating principle

The power steering pressure switch is located

at the hydraulic pump.

The pressure switch is open at a pressure of

< 0.28 MPa (28 bar).

If the pressure rises, the switch is closed at

0.4 MPa (40 bar).

The signal passes to the Simos engine control

unit.

The engine control unit in turn operates the

throttle flap drive G186 which opens the

throttle flap by a particular angle.

Idle speed is thus stabilised to compensate for

the increased load of the hydraulic pump.

Self-diagnosis

Self-diagnosis is performed in the functions

02 - Interrogating fault memory

08 - Reading measured value block

Electric circuit

F88

30 47

J361

121 119

+

-

M

G186

SP27_47

28

Page 28

Lambda sensor G39

A new generation of lambda sensors is used

on the 1.4-ltr./44 kW engine.

The planar (= flat) lambda sensor is a further

development of familiar finger-shaped

lambda sensor and has a step characteristic at

λ = 1.

Advantage

– Short heating-up time and thus improved

emission levels in the warming-up phase

– Reduced heating capacity demand

– More stable control characteristic

Rapid response of the lambda sensor is

essential in order to be able to ensure efficient

emission control. This necessitates the

lambda sensor achieving its operating

temperature in the shortest possible time.

This is made possible by the planar (= flat)

design of the sensor.

The sensor heater is integrated in the sensor

element. The operating temperature is

reached more rapidly with a reduced heating

capacity.

Particular feature

The sensor heater generates the necessary

minimum temperature of 350°C at an exhaust

temperature as low as 150°C.

The lambda control reaches operational

readiness about 10 seconds after engine start.

Sensor element

with heater

Double protective

tube

Sensor section

Sensor heater

+

New!

Insulating layer

S243

10A

SP198_37

Exhaust

Porous protective layer

ceramic

ZrO

2

Reference air

The sensor element consists of circon dioxide

).

(ZrO

2

A porous, ceramic protective layer is applied

to the sensor element. This prevents any

damage occurring as a result of residues in

the exhaust gases.

High operational life and reliable achievement

of the high operational demands are assured.

Substitute function

Open-loop control mode by means of map.

Z19

G39

λ

04 31 14

J361

SP27_20

29

Page 29

Sensors

Intake manifold pressure sensor

G71 and intake manifold

temperature sensor G72

The sensor is located at the middle part of the

intake manifold directly downstream of the air

inlet. Pressure sensor and air temperature

sensor thus are in direct contact with the air

inducted into the intake manifold.

Use of signal

Intake manifold pressure and intake manifold

temperature are transmitted to the engine

control unit. They are required in order to

calculate the quantity of air inducted by the

engine. This information is used to calculate

the injection time required as well as the

ignition timing point.

Substitute function

If the signals are not received, the engine

control unit uses the signal of the throttle

valve position and of the engine speed for

calculating the injection time as well as the

ignition timing point.

The engine is operated in accordance with an

emergency running map!

If the signal from the intake manifold

temperature sensor is not received,

a substitute value based on the coolant

temperature is then used.

Intake manifold pressure and

intake manifold temperature

sensor

Intake

manifold

SP27_39

Electric circuit

J361

96 9395 107

Self-diagnosis

Self-diagnosis checks both input signals.

The following faults can be detected:

– Short circuit to earth

– Short circuit to positive voltage and

reference voltage

– Open circuit

30

G71

G71 Intake manifold pressure sensor

G72 Intake manifold temperature sensor

J361 Simos control unit

G72

SP27_40

Page 30

Function Diagram

Legend to function diagram of page 32

The function diagram represents a simplified

current flow diagram.

It shows all the connections of the Simos 3PB

engine management system for the 1.4-ltr./

44 kW engine.

Additional signals

A Engine speed

B Fuel consumption signal

C Diagnostic cable

D Vehicle speed signal (in)

E AC standby (in)

F AC compressor on/off

G AC pressure signal

H Signal to electronic throttle fault

lamp

Colour coding/Legend

= Input signal

= Output signal

= Battery positive

Components

A Battery

F Brake light switch

F36 Clutch pedal switch

F47 Brake pedal switch

F88 Power steering pressure switch

G6 Fuel pump

G28 Engine speed sensor

G39 Lambda sensor

G61 Knock sensor

G62 Coolant temperature sensor

G71 Intake manifold pressure sensor

G72 Intake manifold temperature

sensor

G79 Accelerator pedal position sensor

G163 Camshaft position sensor

G185 Sensor -2- for accelerator pedal

position

G186 Throttle flap drive (electric throttle

operation)

G187 Angle sensor -1- for throttle flap

drive (electric throttle operation)

G188 Angle sensor -2- for throttle flap

drive (electric throttle operation)

J17 Fuel pump relay

J361 Simos control unit

J338 Throttle flap control unit

M Brake light

N152 Ignition transformer

N30...33 Injectors

N80 Activated charcoal filter system

solenoid valve

P Spark plug connector

Q Spark plugs

S Fuse

Z19 Lambda probe heater

= Earth

= Bidirectional

31

Page 31

Function Diagram

Simos 3PB

30

15

86 30

J17

4

85 87

S132

50A

A

S228

15A

+

-

S232

10A

Z19

S243

10A

G39

S134

10A

F36

N80

λ

N30

80 88 87 85 86 04 31 14 61 65

91 90 97 92 121 119 89 105 111 20 21 41

N31

N32

N33

+

-

+

M

-

+

-

S113

10A

14

J361

32

31

M

G6

G187

G188 G186

J338

G163

CAN - BUS

CAN - BUS

Page 32

30

15

+

30

M

F/F47

63 53 18 51 50 19 64 45 22 75 17 9 28 76 29 73 62 03

G79/G185

A

C D E H

F

GC

106 98 99 109 101 100 30 47 96 9395 107 104 83 01 02 113 112

+

-

S10

10A

S120

15A

G28

in out

G61

F88

G71

G72

G62

I IV III

II

N152

Q

P

31

SP27_02

33

Page 33

Technical Data

Technical features

New!

SP27_14

The 1.4-ltr./44 kW engine is fitted to the

ŠKODA OCTAVIA in combination with the

manual gearbox M5 002.

The manual gearbox is based on the triedand-tested gearbox 14 SK.

It is matched to the engine characteristics and

to the pendulum mounting in the OCTAVIA.

Transmission code letter: DTQ

– 5-speed manual gearbox.

– Light-alloy two-section housing, with

compact gearbox end cover.

– Gearbox end cover designed as bearing

bracket for mounting the gearbox bearing

for the pendulum mounting of the engine

block.

– Connection of pendulum support with a

bolt on the underside of the gearbox

housing.

– 5 all-synchromesh forward gears, non-

synchromesh reverse gear.

– Common oil supply for gearbox and final

drive.

– Final drive with flange shafts for attaching

the CV joint shafts.

– Overhead starter.

– Hydraulic clutch mechanism.

– External shift designed as cable shift.

34

Page 34

Block diagram of gearbox

– Helical gears are used for the gearing of

the sliding and fixed forward speed gears.

– The sliding gears (loose gears) of 1st to 4th

speed run in friction bearings while 5th

speed is mounted in needle bearings.

– The gears are shifted by means of shift

forks.

– Mechanical tapping of engine speed for the

speedometer with drive gear and pinion at

final drive. Vehicle speed signal to electric

speedometer by means of pulse generator.

SP27_15

Gear reduction i =

Teeth of driven gear z

Teeth of driving gear z

z

2

z

1

2

1

i

1st gear 45 13 3.462

2nd gear 45 23 1.957

3rd gear 38 28 1.357

4th gear 40 38 1.053

5th gear 36 42 0.857

Reverse 29

38

13

29

2.923

Final drive 72 17 4.235

Speedometer 16 27 0.593

35

Page 35

Engine/Gearbox Mounting

Complete engine/gearbox mounting

Engine mount

Gearbox mount

You will be familiar with the principle of the

engine/gearbox mounting in the OCTAVIA

(pendulum mounting) from Self Study Programme 15.

Appropriate adaptations have been made to

the engine and gearbox for the design of the

engine mount, the gearbox mount and the

pendulum support.

Engine mount

The combination of housing for coolant pump

and supporting arm for engine mount has

been retained.

Pendulum support

SP15_50

Recess for engine

mount

Housing of coolant

pump

The housing of the coolant pump has been

matched to the conditions of increased

mechanical stress and designed for directly

accommodating the engine mount.

36

SP27_25

Page 36

Gearbox mount

The rear gearbox end cover is designed at the

same time as a bracket for accommodating

the gearbox mount.

Bracket for gearbox

mount

SP27_23

Rear gearbox end

cover

Pendulum support

As on gearboxes 02K and 02J, the pendulum

support is attached directly to the bottom of

the gearbox with two bolts.

The gearbox housing is strengthened locally

at the point at which the pendulum support is

attached at the front.

The light-alloy housing is reinforced by a steel

insert at the bolt attachment point.

SP27_24

Pendulum support

Bolt connection

37

Page 37

Clutch Mechanism

Slave cylinder

New!

Plunger

Clutch release lever

Release bearing

Guide sleeve

Input shaft

The clutch mechanism is matched to the

installation conditions in the OCTAVIA and is

operated hydraulically. The slave cylinder is

located at the clutch housing.

It presses on the clutch release lever by means

of a plunger.

The clutch release lever is supported by

means of a ball head at the clutch housing.

The release bearing is mounted on a guide

sleeve which is bolted to the clutch housing.

The clutch is operated through the release

bearing.

Clutch housing

Ball stud

SP27_37

The clutch release lever is guided at the

release bearing, which is secured by the guide

sleeve to prevent it slipping out.

Consequently, it is not necessary to carry out

any additional securing work when removing

the gearbox.

Note:

After removal and installation work at

clutch mechanism, the system should

be bled with a brake filling and

bleeding appliance.

38

Page 38

External Shift

Two cables are used to transmit the shift

movements (selecting and shifting). The

operating principle is similar to that of manual

gearbox 02J.

The shift pattern and the position of the

reverse gear are the same as on the shift

mechanism familiar from the FELICIA.

The shift movements of the gearshift lever are

transmitted to the inner shift mechanism of

the gearbox by means of an outer shift relay.

Outer shift relay

Balancing weight

A balancing weight on the shift relay lever is

designed to absorb vibrations and as a shift

force assist.

The two cables are supported by a support

bracket.

The support bracket is guided at the front at

the gearbox and at the rear at the steering

gear in Silent bushes.

Shift relay lever

Support bracket

55

33

R

11

Shift cable

44

22

SP27_51

Shifting and selecting at gearshift lever

Selector cable

If the gearshift lever is moved when selecting,

the pivot point is located in the selector

housing. The gearshift lever guide is linked for

this purpose to the selector housing. The latter

is mounted in the shift housing.

The ball head attached to the bottom of the

selector housing performs an opposite movement. It is surrounded by the selector angle.

This converts the movement of the gearshift

lever during selection into a pull/push movement.

If the gearshift lever is moved in the direction

of a gear (shifting), the pivot point is located in

the gearshift lever guide. The shift cable

transmits the forward/reverse movement

through the relay mechanism to the shift shaft

of the gearbox.

Shift lever

guide

Pivot point

when shifting

Shift housing

SP27_50

Selector housing

Pivot point

when selecting

Selector angle

SP27_52

39

Page 39

External Shift

Selection operation

The selector cable is connected to the selector

angle lever. This absorbs the pull/push movement of the selector cable.

The selector movement is transmitted down

through the selector rod and through the gearbox shift lever to the shift shaft of the gearbox.

Gearbox shift lever and shift shaft are bolted

together.

The linear movement coming from the

selector cable is thus converted into the

circular selector movement of the shift shaft of

the gearbox.

Connection of

selector cable

Selector

angle lever

Selector rod

Shift operation

The shift cable is connected at the shift

intermediate lever.

This absorbs the forward/backward movement of the shift cable and transmits it

through the shift coupling rod to the shift

relay lever.

The shift relay lever has a fixed pivot point

and at the bottom runs into the gearbox shift

lever by means of a ball head.

During a gearshift, the linear movement of the

shift cable which is initiated at the top is transmitted linearly, as a result of the double

reversal, to the shift shaft of the gearbox.

Gearbox shift lever

Connection of

shift cable

Shift relay

lever

Pivot point

SP27_53

Shift shaft of gearbox

Shift intermediate lever

Shift coupling rod

The ball head of the shift relay lever compensates for different angle positions, caused by

the selector movements.

(Note: Balancing weight not illustrated)

40

Gearbox shift lever

SP27_54

Shift shaft of gearbox

Page 40

Adjusting outer shift

The components of the outer shift mechanism

have to be adjusted relative to the inner gearbox shift mechanism to ensure smooth and

proper gearshifts.

Gearshift lever

In Neutral, the gearshift lever should be in

position x. In this position, the gearshift lever

is angled back 3° and to the right 4°. This

position is fixed by means of a gauge.

The gearshift lever and gearbox are in Neutral

in the gate of 3rd/4th gear for this step.

Selector cable

The selector cable should not have any play in

the fixed position. A slot is provided for this

purpose at the gearbox shift lever to enable

the selector rod to be set free of play.

x

SP27_57

Selector rod

Shift cable

The shift cable is set at the shift intermediate

lever with a gear engaged (e.g. 1st gear

engaged manually, gearshift lever set to

1st gear position).

A slot is provided for this setting.

Note:

Please refer to the Workshop Manual

OCTAVIA, 5-Speed Manual Gearbox

002 for the exact setting procedure.

After completing the setting, once

again shift through all gears. Pay

particular attention to the reverse

gear lock.

Setting selector cable at

gearbox shift lever

SP27_55

Setting shift cable at shift

intermediate lever

SP27_56

41

Page 41

Final Drive/Speedometer Drive

Inner CV ball joint

Outer CV ball joint

Flexible joint

Connection of drive shafts

All the manual gearboxes fitted to the

OCTAVIA have drive shafts which feature

outer and inner constant-velocity ball joints.

The flange shafts of the gearbox have been

matched to these requirements.

Flange shaft

SP27_19

New!

Differential

Both flange shafts are inserted into the

differential with a spline section.

A circlip holds the flange shaft in position to

prevent it dropping out when the gearbox is

removed.

Speedometer drive

The vehicle speed signal is supplied electromechanically by the gearbox to the speedometer.

Mechanical tapping in gearbox (input gear/

pinion).

The vehicle speed sensor G22 is installed at

the gearbox in place of the speedometer shaft.

It is driven by the pinion (in the same way as

automatic gearbox in OCTAVIA).

Engine speed is transmitted not mechanically

with a speedometer shaft, but electrically in

the form of pulses from the sensor to the

combination processor in the dash panel

insert. The pulses are processed there for

displaying the vehicle speed and the distance.

Advantage: greater accuracy and smoother

operation.

Vehicle speed sensor G22

Input gear

SP27_21

Pinion

SP27_62

42

Page 42

Service

Service information

Oil filling

The oil filling is designed for the entire

operating life of the gearbox.

The opening for inspecting oil level is located

at the bottom in the gearbox end cover.

Correct oil level = Oil filling extends up to

the thread of inspection

opening

The screw plug is inserted with sealant.

The oil level is no longer checked in a service

workshop at the opening of the speedometer

drive with the aid of the speedometer pinion.

Note:

Please refer to Workshop Manual

OCTAVIA, 5-Speed Manual Gearbox

002 for the quantity and specification

of the oil.

New!

Screw plug for inspecting

oil level

SP27_22

Oil filling

Bleeder plug

Bleeding gearbox and topping up gearbox oil

The bleeder plug is located above a labyrinth

which is cast into the top of the gearbox

housing.

It is also possible to top up the oil, if

necessary, through the bleeder hole.

Magnet for metal abrasion

A magnet for collecting metallic abrasion is

now provided at the lowest point of the gearbox housing in a recess.

Bleeder hole

Gearbox

housing

SP27_30

SP27_31

HousingMagnet

43

Loading...

Loading...