SKODA Self Study Program 21 – The automatic gearbox 01M in the OCTAVIA embodies matured engineering in the automatic- shift gearbox SSP-21-Automatic-gearbox-01M

Page 1

EVERY SECOND ONE IN THE

WORLD DRIVES AUTOMATIC!

The automatic gearbox 01M in the OCTAVIA embodies matured engineering in the automatic-shift gearbox.

The automatic gearbox offers the choice between the different shift programmes - depending on the driver's accelerator pedal movements and the driving situation. If the

driver adopts a moderate style of driving, the gearbox switches to "Economy", and if

the driver's movements of the accelerator are sharper, it selects "Sport".

When climbing or descending hills the shift points are automatically selected as a function of the position of the accelerator pedal and the speed of the vehicle.

Thanks to a sophisticated electric-hydraulic control the automatic gearbox combines

performance, economy and driving comfort to offer a convincing automatic driving sensation.

Comprehensive self-diagnosis monitors the electrical/electronic control and ensures

that any irregularities which occur are rapidly detected.

SP21-30

The Self Study Programme is intended to help you acquire the appropriate knowledge

regarding components, design and operation of the automatic gearbox.

2

Page 2

Service Service Service ServiceService

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

xxxxxxxxxxxxxxxx

OCTAVIA

XXXXXXXXXXXXX

XXXXXXXXXXXXXXX

XXXXXXXX

Contents

Introduction 4

The automatic gearbox 01M 4

Selector lever positions 8

Mechanical Components 10

Planetary gear system 10

Planet gear set 12

Final drive/Differential 13

ATF Circuit 14

ATF circuit (block diagram) 14

Oil pump (ATF pump) 15

Torque Converter 16

The hydrodynamic torque converter 16

Torque Converter Lock-up Clutch 18

Torque converter lock-up clutch 17

Flow of hydraulic power 19

Flow of mechanical power 19

Operating principle of the lock-up clutch 20

Shift Elements 22

Multi-disc clutches 22

Multi-disc brake 24

Freewheel 25

Power Flow 26

Overview of System 32

Sensors 34

Actuators 43

Subsystems 48

Selector lever lock 48

Park lock 50

Emergency Programme/Emergency Running 51

Self-Diagnosis 52

Function Diagram 54

You can find information on inspection and

maintenance, setting and repair instructions in

the Workshop Manual.

3

Page 3

Introduction

The automatic gearbox 01M

Planetary gear

Oil cooler

(ATF cooler)

Oil pump

(ATF pump)

Intermediate

gear stage

Differential

Torque converter with lock-up

clutch

Flange shaft

SP21-5

4

Page 4

The automatic gearbox 01M has been developed for models with a power range from 55 up to

128 kW.

The gearbox is also transversely mounted relative to the direction of travel to match the installation position of the engine in the OCTAVIA.

The mechanical components of the automatic gearbox operate on the principle of the planetary

gear system.

The gearbox features a hydraulic-electronic control.

The hydraulic shift control unit is positioned below the gearbox in the oil sump.

The electronic control unit (ECU) is installed in the vehicle (in the plenum chamber).

It processes input information and selects a matching shift programme in line with the style of

driving.

The gears are then shifted automatically.

The gearbox and torque converter are matched in their overall ratio to the particular power output of the engine.

The power from the engine is passed by a hydrodynamic torque converter with integrated lockup clutch into the gearbox.

The 4 forward gears and reverse gear are formed by means of a Ravigneaux planetary gear

system.

The power is passed on to the differential and to the flange shafts through an intermediate

gear stage.

Tripod constant velocity joint shafts link the gearbox to the final drive.

A separate cooler is located directly on the gearbox for cooling the automatic transmission fluid

(ATF).

The ATF cooler is integrated in the coolant circuit of the vehicle.

5

Page 5

Introduction

Depending on the ratio required, sun wheels

or the planet carrier in the Ravigneaux planet

gear set are held fixed or driven and the 4 forward gears and reverse gear formed in this

way.

The shift elements required for this are the

clutches K1 to K3,

the brakes B1 and B2 and the freewheel F.

F B1 K3 K1 K2 B2

Ravigneaux planetary gear system

K

SP21-12

Hydraulic shift control unit

(control valve housing)

6

Page 6

The shift elements are assigned as follows

R

1

2

3

4

B1 B2 K1 K2 K3 F K

H

M

H

M

H

M

H

M

K1 = 1st to 3rd gear clutch

K2 = Reverse gear clutch

K3 = 3rd and 4th gear clutch

B1 = Reverse gear brake

B2 = 2nd and 4th gear brake

F = Freewheel

K = Torque converter lock-up clutch

All the gears are shifted hydraulically.

The torque converter lock-up clutch (K) is closed hydraulically at a fixed

engine load and vehicle speed.

It then drives all the forward gears mechanically.

The table below shows you the shift elements which are operated in the individual gears:

X = Clutches, brakes or freewheel

closed

H = Hydraulic

M = Mechanical

SP21-28

7

Page 7

Introduction

Selector lever positions

Starting the engine

The engine can be started only if the selector

lever is in position P or N.

Selector lever lock

The selector lever is locked in the positions P

and N if the ignition is switched on. The lock is

indicated by the warning lamp next to the selector display coming on.

The brake pedal has to be depressed in order to

override the lock.

The purpose of the selector lever lock is to prevent a gear being engaged unintentionally and

the vehicle setting off in an uncontrolled manner.

In other words, it is necessary to depress the

brake pedal and at the same time to press the

selector lever lock button in order to move the

selector lever out of positions P or N.

Touchbutton for selector

lever lock

Indicator lamp for selector lever lock

Selector level

SP21-29

Position/Function

P = Park position

The gearbox output is locked mechanically.

R = Reverse gear range

N = Neutral. No torque is transmitted.

D = Drive position of automatic gearbox.

3 = Automatic shift from 1st to 3rd and 3rd to 1st gear

2 = Automatic shift from 1st to 2nd and 2nd to 1st gear

1 = Car moves off only in 1st gear.

"P" can only be engaged if the vehicle is stationary.

The ignition key can be withdrawn.

Also start position.

Must only be engaged when the vehicle is stationary and engine idling.

Also start position.

Position for normal driving in 1st to 4th gear.

4th gear cannot be engaged. Select this drive position if position D would result in

frequent gear changes in certain driving situations.

Also recommended for lengthy downhill stretches.

3rd and 4th gears cannot be engaged.

Select this drive position when travelling in mountainous regions with lengthy uphill and

downhill stretches.

2nd to 4th gears cannot be engaged.

Recommended for extreme downhill stretches in order to achieve maximum engine

braking effect.

8

Page 8

Push-tow-starting

It is not possible to start the engine by

pushing or tow-starting the car if it is fitted

with an automatic gearbox.

The control pressure required for shifting a

gear is produced by the ATF pump only when

the engine is running.

Towing the car

SP21-14

It is therefore not possible, for technical reasons, to transmit the thrust energy of the

vehicle to the engine.

It is possible to tow a car fitted with an automatic gearbox.

The selector lever should be shifted into position N for this purpose.

The speed when towing the car should not be

greater than 50 km/h. The car should not be

towed for more than 50 km.

If it is necessary to tow the car over greater

distances, the front wheels of the car should

then be raised clear of the ground.

SP21-13

It is necessary to raise the front wheels of the

car clear of the ground when towing because

the rotating gearbox components are not lubricated when the engine is not running.

For the same reason, the car cannot be

towed with the rear wheels raised clear of the

ground.

If the rear wheels are raised clear of the

ground, the drive shafts rotate in the reverse

direction.

The gears in the automatic gearbox will then

attain such high speeds that the gearbox

would suffer major damage within a very short

time.

9

Page 9

Mechanical Components

Planetary gear system

General view (main components)

12 11 10 9 8 7 6

Input gear

Planetary gear

Turbine shaft

ATF pump

SP21-10

10

Page 10

5 4 3 2 1

SP21-11

1 ATF pump (forms the front gearbox end with its housing)

2 Supporting tube with brake B2 (2nd and 4th gear)

3 Reverse gear clutch K2

The components are linked by splines.

Clutches K1 and K3 and the turbine shaft are connected by an interference fit (item 4).

4 1st to 3rd gear clutch K1 / 3rd and 4th gear clutch K3 / turbine shaft

5 Small input shaft (projects into planet carrier)

6 Large input shaft (projects into small sun wheel)

7 Large sun wheel

8 Circlips for supporting tube and freewheel

9 Planet carrier with freewheel. The planet carrier contains the small sun wheel

and the short and long planet gears

10 Reverse gear brake B1

11 Hollow gear of planet gear system, forms a unit with the input gear (12)

12 Input gear (runs in gearbox housing in two taper roller bearings), also contains

the pulse rotor for the road speed sender G68

11

Page 11

Mechanical Components

Planet gear set

The four forward gears and reverse gear

Hollow gear

Large sun wheel

are formed by means of a Ravigneaux

planet gear system.

Input gear

Long planet

gear

Small sun wheel

Short planet

gear

Planet carrier

SP21-16

It features two planet gear sets in the

common planet carrier:

large sun wheel,

small sun wheel,

planet carrier with three long planet

gears and three short planet gears

hollow gear

Depending on the ratio required (gear

selection), the sun wheels or planet carrier are driven or braked (refer also to the

description of power flow).

The long planet gear is stepped which

makes it possible to produce good ratios

and gear steppings.

This, in particular, provides a good gear

step from 3rd to 4th gear.

Operating principle

Large sun wheel

Hollow gear

Short planet gear

Small sun wheel

Planet carrier

Long planet gear

SP21-17

Large sun – meshes into the large

wheel diameter of the long

planet gear

Small sun – meshes into the short

wheel planet gear

Short planet – meshes into the small

gear diameter of the long

planet gear

Hollow gear – meshes into the small

diameter of the long

planet gear

The power to the intermediate gear set is

always transmitted through the hollow

gear which is permanently connected to

the input gear.

12

Page 12

Final drive/Differential

The power from the planetary gear

system to the drive shafts is transmitted through a drive pinion (intermediate gear set) and a differential.

Input gear at the planetary gear system

The design of the differential is similar

to that of other automatic gearboxes

Output gear

with large and small differential bevel

gears.

The differential runs in taper roller bearings.

The connection to the drive shafts features

joint flanges which are housed within the differential.

The differential has a separate oil chamber

from the planetary gear system.

This oil chamber is sealed to the planetary

gear by means of a bearing supporting ring

with a gasket on the drive pinion.

The grade of oil used for lubricating the differential flows from that in the planetary

gear. It does not circulate together in the oil

circuit.

Differential

Drive pinion

Bearing supporting

ring with gasket

Joint flange

SP21-9

Note:

The oil level for the final drive is inspected separately from the planetary

gear.

The drive for the speedometer is used as an inspection point.

Please refer to the current Workshop Manual for the specification and

capacity of oil for the final drive.

The oil is extracted and poured in separately!

The final drive - starting at the input gear at the planetary gear system - should be set exactly after

completing removal and installation operations and after replacing components.

You can find precise instructions and setting examples in the workshop manual for the automatic

gearbox.

13

Page 13

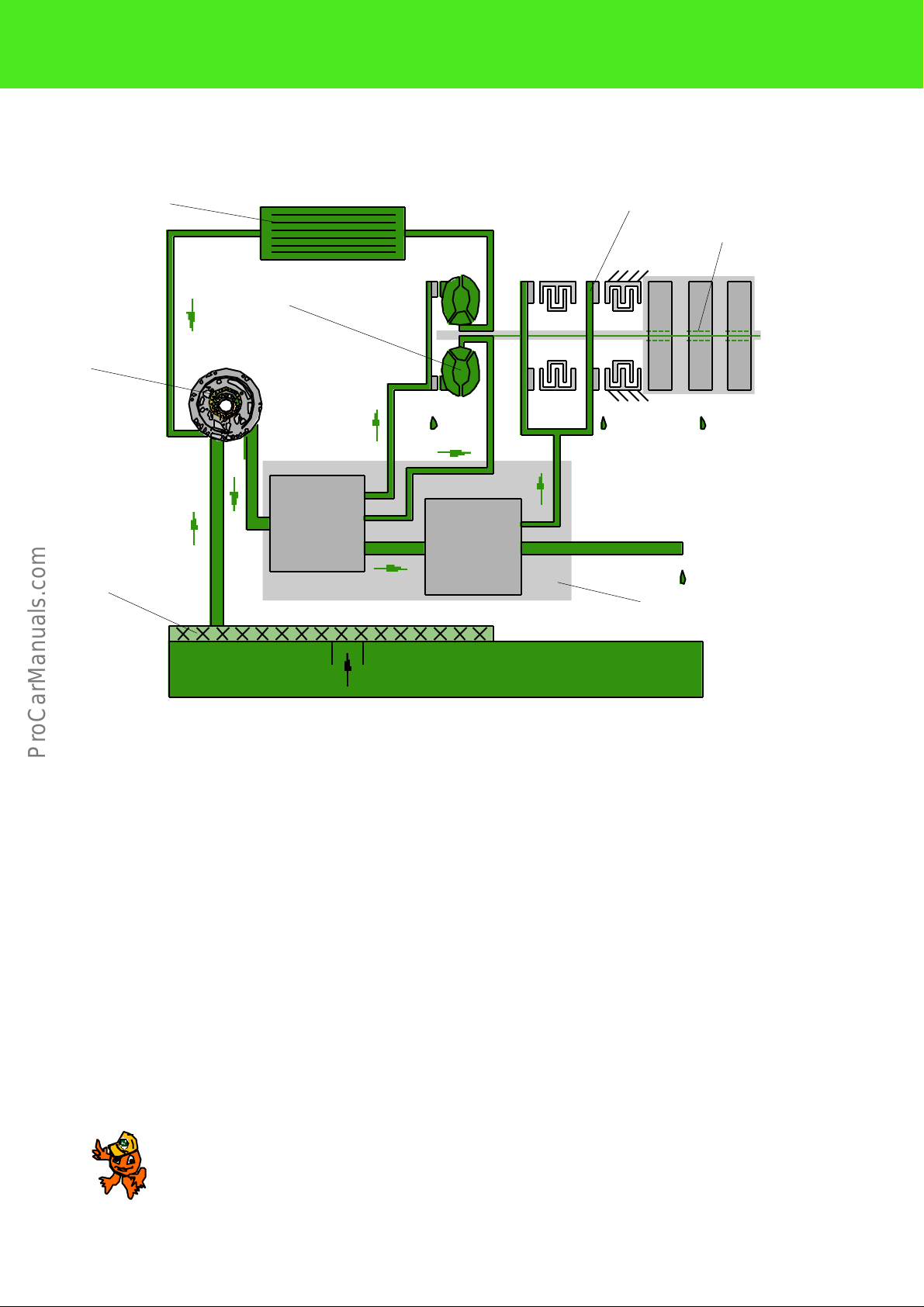

ATF Circuit

ATF circuit (block diagram)

ATF cooler

ATF pump

Filter

Torque converter

Pressure

control

Shift elements

Lubrication points

Pressure

distribution

Hydraulic shift

control unit

The ATF (= Automatic Transmission Fluid) is located in the oil sump below the gearbox.

An oil pump is required as the ATF is used not

only for lubrication (as with a manual gearbox) but

also as the working medium for the torque converter and the automatic gearshifts. The oil pump

draws the ATF out of the sump through an oil filter, produces the working pressure (up to 25 bar)

and pumps the pressurized oil to the operating

components.

The pressure control (pressure control valves) reduces the oil pressure to different levels matching

the different functions of the gearbox.

(e.g. lubrication pressure 3 to 6 bar, shift pressure

1 to 12 bar).

SP21-19

The pressure distribution takes place in the hydraulic shift control unit.

A separate ATF circuit is used to supply ATF to

the torque converter, to lubricate the bearing

points of all the rotating parts and to cool the ATF

by passing it through the ATF cooler.

The latter is integrated in the coolant circuit of the

vehicle.

The automatic transmission fluid which flows out

of the zero outlets of the valves as well as out of

the lubrication points of the gearbox, is gathered

again in the oil sump.

14

Note:

Carry out an inspection of the ATF level only when engine running

and at an inspection temperature of not more than 30 °C with selector lever in position P.

Page 14

Oil pump (ATF pump)

The oil pump is located between the torque

converter and planetary gear.

The housing at the same time forms the front

end of the gearbox tunnel.

The housing of the pump is provided with a

friction bearing for mounting the torque converter.

The oil pump is driven directly through the

hub at the housing of the torque converter.

In other words, it always runs at engine

speed.

The oil pump is an internally-toothed gear

pump and is a "crescent moon pump" in

terms of its design.

It supplies adequate pressure from the

moment the engine is idling to supply all the

downstream hydraulic systems with the necessary working pressure and to ensure

proper lubrication.

The oil pump therefore supplies automatic

transmission fluid to the gearbox and to the

hydraulic shift control unit.

Outer gear

Crescent moon

Inner gear

Housing

SP21-18

Intake passagePressure passage

When the teeth move apart, the space

between the teeth is enlarged - automatic

transmission fluid is drawn in and pumped.

The fluid in the tooth gaps passes the crescent moon.

This shuts off the intermediate spaces of the

teeth to each other and thus prevents the

fluid from flowing back.

After the intermediate space passes the

crescent moon, it becomes narrower and the

pressure of the ATF rises.

The working pressure is available directly at

the pump outlet.

The working pressure is as much as 25 bar.

It is regulated by a controlled zero outlet

through the working pressure control valve.

Excess ATF flows back directly into the suc-

tion side at higher engine speeds.

15

Page 15

Torque Converter

The hydrodynamic torque converter

The torque converter is located between the

engine and the automatic gearbox, in a

comparable position to the clutch of a manual gearbox.

The interior design of the torque converter

is matched to the engine torques, depending on the engine to which it is assigned.

Letters are used to assign the torque converter to the relevant gearbox.

The torque converter consists of the familiar

three main parts:

- Pump wheel

(which at the same time forms the

housing of the torque converter)

- Turbine wheel

(connected to the turbine shaft by

a splined section)

- Impeller

(with freewheel)

The torque converter is in itself a compact

unit which is filled with hydraulic fluid which

is pressurized.

SP21-32

The oil pump of the automatic gearbox is also

driven through the torque converter housing.

In addition, the torque converter also contains the

torque converter lock-up clutch.

The ring gear for the starter is positioned on the

outside of the torque converter.

Three bolts are used for attaching the torque converter to the driven plate which is in turn bolted to

the crankshaft of the engine.

The torque converter is filled with hydraulic fluid

from the supply of the automatic gearbox.

It does not have its own separate oil chamber - in

contrast to the differential, which is filled separately.

When carrying out repairs, in contrast - in other

words when the torque converter has been

removed - the hydraulic fluid in the torque converter should be drained separately.

It has to be extracted, for example with extractor

V.A.G 1358.

16

Page 16

Gearbox side

Pump wheel

Oil pump drive

Impeller shaft

Engine side

Torque converter housing

Turbine wheel

Freewheel

Turbine shaft

(Input shaft of gearbox)

Impeller

Starter ring gear

The operating principle of the torque converter is described in greater detail in SSP 20 Automatic

Torque converter lockup clutch

SP21-31

Gearbox Fundamentals. As a reminder:

The pump wheel is driven by the engine.

It accelerates the hydraulic fluid from the inside to the outside as a result of the centrifugal force.

The fluid is deflected at the inner wall of the housing toward the turbine wheel.

The ATF flow drives the turbine wheel.

The hydrodynamic energy of the fluid is converted into mechanical rotational movement.

The turbine wheel is connected to the turbine shaft (input shaft of the gearbox) and transmits the rotational movement into the gearbox.

Note:

The torque converter makes it possible to engage a gear when the car is not

moving and the engine is idling.

It already transmits a slight torque in this situation, the car tends to "creep" forward.

That is why you should always hold the car with the footbrake when the engine

is idling (refer also to selector lever lock).

It is not possible to carry out repairs to the torque converter. If any damage has occurred to the

converter, starter ring gear or lock-up clutch, the parts have to be replaced.

17

Page 17

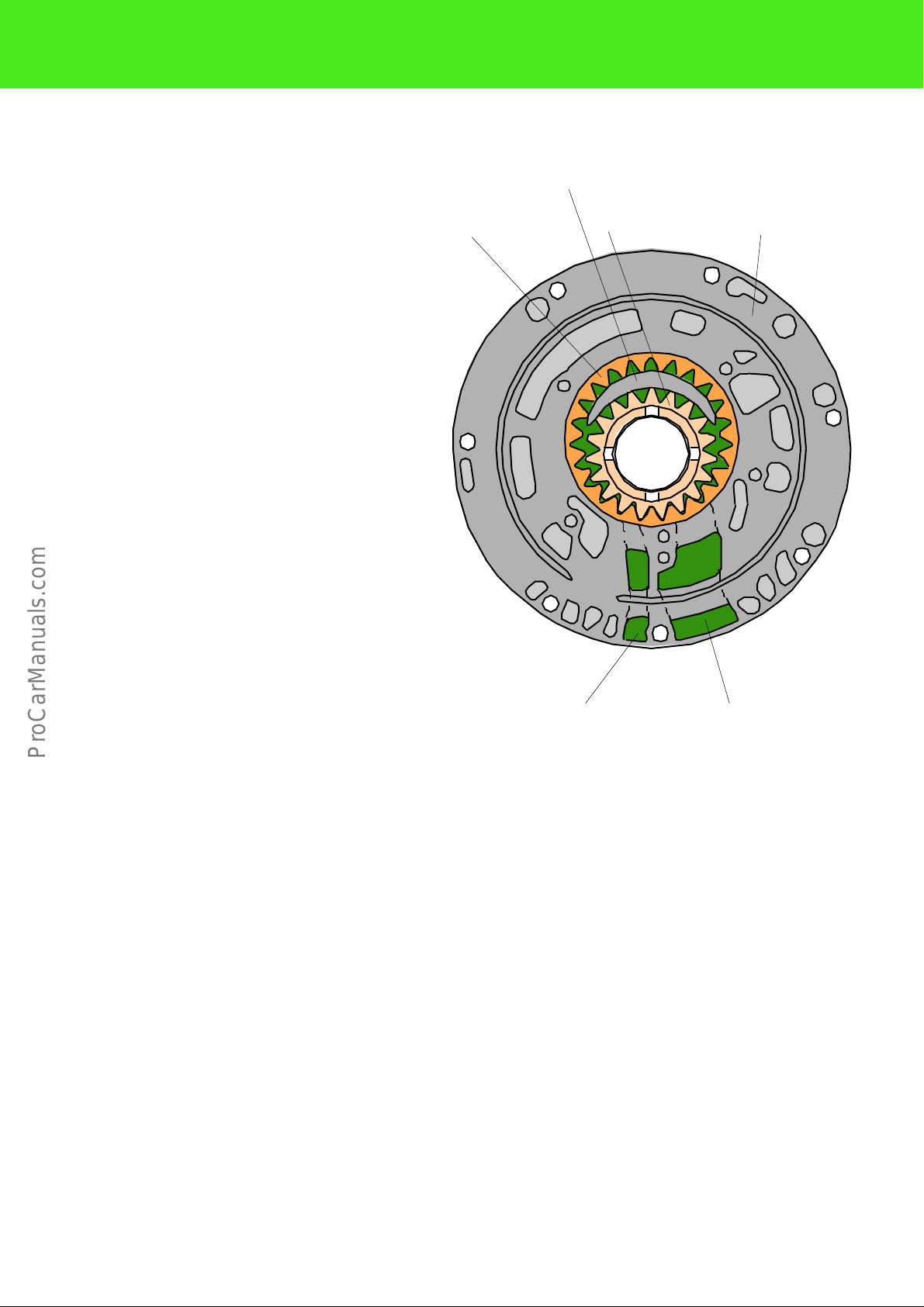

Torque Converter Lock-up Clutch

Torque converter lock-up clutch

Torque converter

housing

Friction lining

From engine

Torsion damper

SP21-6

It is a known fact that a torque converter becomes less economic as its rotational speed increases.

It does not transmit the full engine torque at high speeds.

That is why a lock-up clutch is integrated in the housing of the torque converter to ensure the entire

engine torque is transmitted.

The lock-up clutch is a mechanical clutch.

It is the means of creating a mechanical connection from the engine to the automatic gearbox by

means of the friction lining.

The torque converter is locked up (and thus is taken out of action) in certain driving situations.

It is disengaged and engaged electro-hydraulically by solenoid valve N91 in line with the actuation by

the control unit. The working medium for this is the gear oil (automatic transmission fluid).

The lock-up clutch is connected to the turbine wheel.

Torsion dampers around the circumference of the lock-up clutch reduce the torsional oscillations of

the engine during the mechanical disengaging and engaging operation.

The torque converter lock-up clutch is operated irrespective of the gear engaged.

18

Page 18

Flow of hydraulic power -

the lock-up clutch is open

From engine

Pump wheel

Turbine wheel

Turbine shaft

SP21-33

Flow of mechanical power -

the lock-up clutch is closed

From engine

Torque converter housing

Lock-up clutch

Turbine shaft

SP21-34

19

Page 19

Torque Converter Lock-up Clutch

Operating principle of the lock-up clutch

It is the control unit which defines the

moment for closing or opening the

torque converter lock-up clutch. This

is controlled through the modulation

valve N91.

Oil pressure is applied alternately to 3 oil

passages for closing and opening the lockup clutch.

The 3-line principle together with the modulation valve N91 makes it possible to specifically increase and reduce the pressure

when the lock-up clutch is closed and

opened.

The result is smooth jerk-free closing.

The lock-up clutch is open

Hydraulic fluid flows through the passages

B and C.

Passage A is closed.

The hydraulic fluid leaving passage B flows

to the planetary gear where it lubricates the

components.

SP21-35

20

Oil passages

SP21-36

Page 20

Rear of lock-up clutch

The lock-up clutch closes

For closing the lock-up clutch, hydraulic

fluid is fed to passage A.

Passage C is opened. As a result, the oil

pressure at the rear of the lock-up clutch is

higher than at the front.

The friction lining moves against the torque

converter housing.

The mechanical power flow from the engine

to the gearbox is completed.

The planetary gear is lubricated through

passages A and B.

Friction lining

Torque converter housing

Front of lock-up

clutch

SP21-37

The lock-up clutch is opened

The hydraulic fluid is again fed through passage C.

Passage A is closed.

As a result, the pressure on the front of the

lock-up clutch increases.

The lock-up clutch opens.

The power now flows once again hydraulically from the pump wheel to the turbine

wheel.

Lubricating fluid is once again supplied

through passages B and C.

Front of lockup clutch

SP21-38

21

Page 21

Shift Elements

All the shift elements are active in addition to the torque converter lock-up clutch, multi-disc clutches

and multi-disc brakes. The purpose of the shift elements is to carry out gearshifts under load without

any interruption to the power flow. They are operated hydraulically.

Externally-toothed discs

Internally-toothed discs

Hydraulic plunger

Piston cover

Oil feed

Oil chamber downstream of hydraulic

plunger

Compression spring

Block diagram of multi-disc clutch K1 and K3

Multi-disc clutches

The multi-disc clutches (K1, K2, K3) consist of

internally-toothed discs (which are at the same

time the friction lining) and externally-toothed

discs and are connected by the disc carriers to

the rotating parts.

The number of internally-toothed and externally-toothed discs differs according to the

gearbox code and clutch.

The hydraulic plunger rotates together with its

oil filling.

The oil is supplied through the hollow turbine

shaft.

Oil chamber upstream of hydraulic

SP21-39

Clutch open

The multi-disc clutches K1 and K3 are "centrifugal force pressure-balanced" to ensure

smooth gearshifts.

A compression spring holds the multi-disc

clutch open at any speed when it is in the nonoperating state.

Hydraulic fluid in a pressureless state is constantly present upstream and downstream of

the hydraulic plunger.

It ensures a centrifugal force pressure balance

when the clutch is open and holds the clutch in

a defined initial state.

plunger

22

Page 22

Clutch closes

In order to close the multi-disc clutch, oil is

forced under pressure into the chamber

upstream of the hydraulic plunger.

As a result of the oil pressure the compression spring and the discs of the clutch are

compressed.

The turbine shaft and the small input shaft

are connected by means of the disc carriers

to the multi-disc clutch (in this case clutch

K3 for 3rd/4th gear).

Power transmission is possible; the power

flows into the planet carrier.

Externally-toothed

discs

Small input shaft (internallytoothed disc carrier)

Internally-toothed discs

Oil chamber upstream of hydraulic

plunger

Turbine shaft (externally-toothed

disc carrier)

SP21-40

Clutch opens

To open the clutch, the chamber upstream

of the hydraulic plunger is again made

pressureless.

As a result of the dropping oil pressure the

compression spring which is resting against

the hydraulic cylinder pushes the plunger

back into its initial position.

Clutch K3 opens.

Power transmission to the planet carrier is

again interrupted.

Hydraulic plunger

SP21-39

23

Page 23

Shift Elements

Multi-disc brake

Gearbox housing

Supporting in gearbox housing

Externally-toothed

discs

Dished washer

Internally-toothed

discs

Internally-toothed

disc carrier (=

planet carrier)

The automatic gearbox 01M features two

multi-disc brakes for holding the gearbox

components of the planet gear sets fixed.

Brake B1 = Reverse gear brake

Brake B2 = 2nd and 4th gear brake

The internally-toothed discs each are

positioned on the rotating internally-toothed disc carrier.

They are connected to the carrier by

means of a splined section.

Hydraulic plunger

Freewheel

housing

SP21-41

Block diagram of brake B1

The externally-toothed discs have

shaped lugs on the outside.

These permit them to be supported in the

slots in the gearbox housing.

The multi-disc brake is operated hydraulically in a similar way to the multi-disc

clutches.

The hydraulic plunger which is located in

the freewheel housing compresses the

disc set by means of a dished washera.

24

The number of discs differs according to

the gearbox/engine combination.

Page 24

Freewheel

Freewheel direction

Blocking direction

Gearbox housing

Outer race of freewheel

Inner race (planet

carrier)

Rollers

SP21-42

The freewheel is designed as a roller freewheel.

The rollers are located between the outer race -

which at the same time is the mounting for the

plunger of the multi-disc brake B1 - and the

inner race which is part of the planet carrier.

The outer race is supported by means of a lug in

the gearbox housing.

The rollers have play in the direction of rotation;

they permit the rotation.

The rollers move into the narrowing gap in the

blocking direction.

Inner race and outer race are connected. As a

result, rotation of the planet carrier is prevented.

The freewheel, in combination with the shift elements, are used to achieve smooth power

engagement.

25

Page 25

Power Flow

F B1

Let us recall:

The control unit operates the clutches and brakes through

the solenoid valves in the control valve housing in line

with the gear engaged.

The clutches K1, K2 and K3 pass the force on to the

planet gear set. They

The brake B1 holds the planet carrier fixed.

The freewheel F by means of which the

planet carrier is supported in 1st gear

(see example of 1st gear).

are multi-disc clutches with

internally-toothed discs and externally-toothed

discs, both are

connected to the rotating parts;

power flow in a controlled manner into a planet

gear set or to connect two parts of a planet gear

set to each other.

The hydraulic plunger rotates together with its

hydraulic fluid filling.

Clutch K2 drives the large sun wheel.

Clutch K1 drives the small sun wheel.

Clutch K3 drives the planet carrier.

The brake B2 holds the large sun wheel fixed.

Brakes B1, B2

are multi-disc brakes, the

internally-toothed discs being connected to the

rotating gearbox part,

externally-toothed discs fixed,

hydraulic plunger compresses the disc set,

are used for holding one part of the planet gear

set fixed.

26

Page 26

K

K3 K1 K2 B2

The torque converter lock-up clutch K with which the

mechanical force is passed from the engine to the gearbox (see example of 4th gear).

SP21-46

27

Page 27

Power Flow

Selector lever position N or P

Direction of travel

Turbine wheel

Differential with flange shafts

Intermediate gear set

(drive pinion)

Pump wheel

From engine

No torque is transmitted when the selec-

tor lever is in position N or P. This Neutral position is what we use to explain the

power flow diagram.

– The power flow diagram shows the

top part of the gearbox.

The bottom part has been deleted

to simplify the illustration.

– The power flow which exists is indi-

cated in the individual gears by

using colour

– Gears and shafts are represented

by rectangles or dashes.

– Parts held fixed are connected to

broken lines.

B 2

K 2

Large sun wheel

K 1

K 3

Small sun wheel

F

Planet carrier

B 1

Hollow gear

Hollow gear

Input gear

SP21-20

Input gear

Planet carrier

SP21-16

are symbols for freewheel

are symbols for clutches or brakes

28

The power transmitted from the planet gear set

to the intermediate gear set passes in all the

gears through the hollow gear which is permanently connected to the input gear.

The hollow gear has been represented in the

diagram as a dash to simplify the illustration.

Page 28

K 1

F

Selector lever position R = Reverse

K 2

B 1

SP21-27

Pump wheel Turbine wheel

Selector lever position D or 1 = 1st gear

Brake B1 holds the

planet carrier fixed

Ratio of reverse = 2.88

Clutch K2 is closed by the

selector lever, large sun

wheel driven

Pump wheel Turbine wheel

Clutch K1 drives

the small sun wheel

Ratio of 1st gear = 2.71

SP21-21

Planet carrier orbits around freewheel F

29

Page 29

Power Flow

B 2

K 1

K 1

K 3

Selector lever position D or 2 = 2nd gear

SP21-22

Pump wheel Turbine wheel

Selector lever position D or 3 = 3rd gear

Clutch K1 drives

the small sun

wheel

Ratio of 2nd gear = 1.44

Brake B2 holds the large

sun wheel fixed

Pump wheel Turbine wheel

As the small sun wheel and the planet carrier are

driven, the entire planetary gear set rotates.

30

Clutch K1 drives

the small sun wheel

Ratio of 3rd gear = 1.00

SP21-23

Clutch K3 drives

the planet carrier

Page 30

Selector lever position D = 4th gear

B 2

K 3

B 2

K 3

SP21-25

Pump wheel Turbine wheel

The planet gear set rotates around the large sun

wheel.

4th gear with lock-up clutch

Brake B2 holds the

large sun wheel

fixed

Ratio of 4th gear = 0.74

Clutch K3 drives the planet carrier

Torque converter housing

Lock-up clutch

Brake B2 holds the

large sun wheel

fixed

Ratio of 4th gear = 0.74

SP21-26

Clutch K3 drives

the planet carrier

31

Page 31

Overview of System

Sensors

Throttle valve potentiometer G69 (through

engine control unit)

Gearbox speed sender G38

Automatic gearbox control unit

J217

Road speed sender G68

Engine speed sender G28

(through engine control unit)

Multifunction switch F125

Brake light switch F

Kickdown switch F8

Gear oil temperature

sender G93

32

Connection for self-diagnosis

Page 32

Actuators

Control valve body with solenoid

valves N88 - N94

Selector lever lock solenoid N110

Starter lockout and reversing light

relay J226

Additional signals

Engine control unit

Air conditioning/shut-off of magnetic coupling through AC control

unit

SP21-3

33

Page 33

Sensors

SP172/21

Engine speed sender G28

The control unit of the automatic gearbox uses

the engine speed signal of the relevant engine

management system.

Use of signal

– The control unit compares the engine speed

and the road speed.

The control unit detects the slip of the lockup clutch from the difference in the speeds.

– If the slip is too large (speed difference) the

control unit increases the contact pressure of

the lock-up clutch and thus reduces the slip.

– The signal supplied by the engine speed

sender is used by the control unit as a substitute parameter

Engine control unit

Substitute function

In the event of a signal failure, the control unit

moves into the emergency running mode.

Self-diagnosis

If an engine speed of less than 450 rpm exists at

a gearbox input speed of at least 2000 rpm, this

is detected as a fault. This is the case in the

event of an open circuit, short circuit or a signal

level which is too low.

Electric circuit

19 Signal wire

42 Screening

64 Supply voltage

J217 Automatic gearbox control unit

34

SP21-55

Page 34

SP172/18

Gearbox oil temperature sender

G93

The gearbox oil temperature sender G93 is an

NTC resistor.

It reduces its resistance as the oil temperature

rises.

Use of signal

If the ATF temperature reaches the limit of

150˚C, the lock-up clutch is closed.

This reduces the load on the torque converter

and the ATF cools down.

Should this measure not be adequate, the control unit shifts the gearbox down a gear.

Substitute function

If an excessively high temperature has already

been detected, the gearshifts are carried out at

higher shift points. Otherwise, an ATF temperature below the limit temperature is assumed.

Overheating can no longer be determined.

Self-diagnosis

Short circuit to earth and open circuit are

detected as faults in the self-diagnosis.

A particular feature should be noted in respect of

fault diagnosis.

The processor is not able to electrically distinguish a cold sensor from an open circuit in the

wiring. That is why a gearbox state has to exist

in which the sensor is reliably warm.

Electric circuit

6 ATF temperature signal

67 Supply voltage

J217 Automatic gearbox control unit

SP172/20

35

Page 35

Sensors

SP21-7

Road speed sender G68

The sender is an inductive sensor. The information regarding road speed is detected from the

pulse rotor at the input gear.

Use of signal

The information regarding road speed is

required in the control unit for

– determining which gear should be engaged

– controlling torque converter slip

Substitute function

In the event of a signal failure, the engine speed

is used as a substitute function.

The lock-up clutch is no longer closed.

Self-diagnosis

"No signal" is detected in self-diagnosis.

Electric circuit

SP21-45

20 Signal wire

43 Screening

65 Output voltage

J217 Automatic gearbox control unit

SP21-56

36

Page 36

Gearbox speed sender G38

The sender is an inductive sensor.

It is located in the gearbox housing and detects

the speed of the large sun wheel in the planet

gear.

SP21-44

SP21-8

Use of signal

The speed of the large sun wheel makes it possible for the control unit to exactly detect the

moment of a gearshift.

The speed signal is used by the control unit for

more accurately calculating the following functions:

– Reducing engine torque during the gearshift

by retarding the ignition angle

– Controlling the multi-disc clutches during the

gearshift

Substitute function

In the event of a signal failure, the control unit

moves into the emergency running mode.

Self-diagnosis

"No signal" is detected in self-diagnosis.

Electric circuit

21 Signal wire (pulses)

44 Screening

66 Output voltage

J217 Automatic gearbox control unit

SP21-57

37

Page 37

Sensors

Throttle valve potentiometer G69

The throttle valve potentiometer is connected to

the throttle valve. It constantly supplies information regarding the position of the throttle valve

and the operating rate of the accelerator pedal to

the control unit.

The information passes through the engine control unit to the automatic gearbox control unit.

SP21-50

Use of signal

The information is used for:

– Computing the load-related shift point

– Setting the load-dependent oil pressure in line

with the gear

The control unit computes the shift points for the

automatic gearbox on the basis of the operating

rate of the accelerator pedal.

Substitute function

A signal failure results in the following effects:

– The control unit assumes a moderate engine

load for the shift point.

– The ATF pressure is set to full throttle pres-

sure in line with the gear.

– The shift programmes can no longer be car-

ried out by the control unit.

Self-diagnosis

The throttle valve potentiometer G69 is included

in the self-diagnosis.

38

Electric circuit

41 Load signal through engine control unit

13 Influencing ignition timing

G69 Throttle valve potentiometer

J217 Automatic gearbox control unit

J220 Engine control unit

depending on

J361 Engine control unit

engine assignment

SP21-58

depending on

}

engine assignment

Page 38

SP172/23

Kickdown switch F8

The kickdown switch is integrated in the accelerator cable.

It is the means of detecting when the accelerator

pedal is depressed beyond the full throttle point.

It operates as an NO contact to earth.

The contact is closed when the switch is operated.

Use of signal

When the switch is operated, the gearbox shifts

immediately into the appropriate gear.

The control unit takes into account engine

speed. In addition, upshifts are carried out at

higher engine speeds.

If a high engine power is required in the kickdown mode, the air conditioning is switched off

for up to 8 seconds.

Substitute function

In the event of a signal failure, the kickdown shift

point is effected at approx. 95 % of the full throttle value of the load potentiometer.

Self-diagnosis

When the switch is operated, the engine control

unit checks with the aid of the load potentiometer

whether the throttle valve is fully opened. If a

non-conformity situation exists, this is detected

as a fault. No check is conducted if the vehicle is

not moving.

Electric circuit

16 Kickdown signal

J217 Automatic gearbox control unit

SP21-59

39

Page 39

Sensors

SP21-49

Multifunction switch F125

The multifunction switch is located above the

shift shaft in the gearbox housing.

It is operated directly by means of a cable in line

with the movement of the selector lever.

Selector lever positions P, R, N, D, 3, 2, 1 result

from the shift contacts.

Use of signal

– The multifunction switch transmits the selector

lever position to the automatic gearbox control

unit. It analyses this information and operates

the gearbox control accordingly.

– Actuation of the reversing light relay

– Blocking the starter when a gear is engaged

Substitute function

In the event of a fault, the automatic gearbox

control unit assumes selector lever position "D".

This results in the following reactions:

In selector lever position "D", "3" and "2" = all 4

gears are engaged automatically, manual selection of 3rd and 2nd gear is inactive.

A special case applies to engaging 1st gear. If

4th gear was engaged, it then remains engaged.

If 3rd, 2nd or 1st gear was engaged, 1st gear is

engaged. Selector lever positions "P", "R", "N"

remain;

starting is possible in "P", not in "N"

Self-diagnosis

Open circuits as well as short circuits to the control unit can be detected as faults if they result in

an incorrect combination.

An unplugged connector is detected as a fault.

Electric circuit

F125 Multifunction switch

J217 Automatic gearbox control unit

J226 Starter lockout and reversing light relay

Refer to selector lever positions for PIN number.

40

SP21-47

Page 40

Selector lever positions

The selector lever position is transmitted to the

gearbox control by the multifunction switch F125

along four coding wires.

Switch contacts 1, 2, 5 and 6 run directly to pins

63, 40, 18 and 62 of the gearbox control unit.

The switch is connected by 2 wires to terminal

15 (system voltage) and to terminal 31 (earth).

Shift stages

6/62 2/40

P

R

N

D

3

The four two-pin switches of the multifunction

switch result in the seven shift combinations of

the shift stages for the selector lever positions.

P = Gearbox output locked mechanically

1/633/5/187/ +

R = Reverse gear range

N = Neutral, no torque transmission

D = Forward gear range, all 4 gears shifted

automatically

3 = Forward gear range, 3 gears are shifted

automatically

4th gear is not engaged

2 = Forward gear range, 2 gears are shifted

automatically

3rd and 4th gear are not engaged

2

1 = Forward gear range, only 1st gear is

used

1

SP21-48

Note:

The position of selector lever relative to the multifunction switch is of importance for

the gearbox function.

Positions P, R, N and D are also transmitted mechanically to the selector slide valve in

the hydraulic shift control unit.

That is why the selector lever cable has to be exactly set.

Information regarding this is provided in the Workshop Manual OCTAVIA, Automatic

Gearbox.

41

Page 41

Sensors

Brake light switch F

The brake light switch F is located at the brake

pedal.

It operates as a NO contact to terminal 30.

When the brake is operated, information is supplied to the automatic gearbox control unit.

Use of signal

The "brake operated" information is required for

cancelling the "selector lever lock" function.

The selector lever can be moved out of position

P or N when the vehicle is stationary only if the

brake pedal is depressed.

SP172/99

Substitute function

In the event of a signal failure, the brake light

switch is assumed to be operated.

The selector lever lock (shiftlock) is cancelled,

the selector lever is no longer blocked.

Self-diagnosis

The brake light switch is detected in function 08,

Reading measured value block.

Electric circuit

F Brake light switch

15 Signal wire

30 Positive

J217 Automatic gearbox control unit

M9 Brake light

M10 Brake light

SP21-51

42

Page 42

SP21-67

Actuators

Selector lever lock solenoid N110

(shiftlock solenoid)

The solenoid is located at the shift mechanism.

It is connected on the one side to terminal 15, is

operated with the ignition and mechanically locks

the selector lever to prevent a gear being engaged.

The second connection is linked to the automatic

gearbox control unit.

The shiftlock is only cancelled when the brake

pedal is depressed (refer also to brake pedal

switch F).

The selector lever can be moved into any drive

position.

A visual indication is provided in the illuminated

selector lever display to show that the shiftlock is

engaged.

This indicator goes out when the brake pedal is

operated.

Reaction in the event of a fault

If an open circuit exists, the selector lever lock is

cancelled.

If a short to earth exists, the selector lever is

blocked in position "P" or "N".

Self-diagnosis

The solenoid is checked for open circuit and short

to earth and is included in function 08, Reading

measured value block.

Electric circuit

15 Terminal 15

29 Signal output (earth) of control unit

L19 Bulb for illuminating selector lever display

J217 Automatic gearbox control unit

N110 Selector lever lock solenoid

SP21-52

43

Page 43

Actuators

SP172/29

Solenoid valves N88 to N94

Solenoid valves N88 to N94 are located in

the control valve housing of the gearbox.

The control valve housing is the actual

hydraulic shift control unit of the automatic

gearbox.

All the solenoid valves are directly connected to the automatic gearbox control unit.

They are supplied with the output information which is required for the hydraulic gearshifts in line with the shift programme, by the

automatic gearbox control unit.

Use of signal

Solenoid valves N88, N89, N90, N92 and

N94 are OPEN/CLOSED valves.

N94

SP172/30

N89

N88

N92

N90

They are either open or closed and open or

close an oil passage each.

– The gears defined by the control unit

are engaged by means of the valves

N88, N89 and N90 (shift solenoid

valves).

– The smoothness of the gearshift is

influenced by the valves N92 and N94

(control solenoid valves.

Solenoid valves N91 and N93 (control

solenoid valves) are modulation valves.

The level of the clutch pressure required is

set by means of these two valves. The control is carried out steplessly. The control unit

determines the level of the amperage. The

clutch pressure alters in line with the amperage.

– Valve N91 controls the clutch pres-

sure for the lock-up clutch.

– Valve N93 controls the pressure of the

multi-disc clutches and multi-disc

brakes.

N93

N91

SP172/31

44

Page 44

SP172/105

Substitute function

In the event of a fault, the automatic gearbox

control unit switches to the emergency running

mode.

In this case, the gearbox shifts into hydraulic 3rd

gear when driving, taking into account the speed

of the vehicle and the position of the selector

lever.

Self-diagnosis

All the valves are checked for open circuit and

short to earth as soon as the ignition is switched

on.

The check is continued on a permanent basis.

The solenoid valves can be interrogated individually in function 02, Interrogating fault memory.

Electric circuit

9 Solenoid valve N90

10 Solenoid valve N94

22 Supply voltage N93

47 Solenoid valve N91

54 Solenoid valve N89

55 Solenoid valve N88

56 Solenoid valve N92

58 Solenoid valve N93

67 Supply voltage of solenoid valves

J217 Automatic gearbox control unit

SP21-53

45

Page 45

Actuators

Starter lockout and reversing

light relay J226

The relay is a combination relay.

In the OCTAVIA it is located at relay position 11

of the additional relay carrier.

The relay is connected directly to the output of

the automatic gearbox control unit (pin 11).

The output is connected to earth if the selector

lever is in position P or N (Park/Neutral signal).

It is only possible to start the car in these positions.

In the event of an open circuit in the wiring, it is

only possible to start the car in "P".

SP21-64

The reversing lights are also operated through

this relay if reverse gear is engaged.

The signal in this case comes from the multifunction switch once the selector lever is in position

"R".

Self-diagnosis

Not included in self-diagnosis.

Electric circuit

F125 Multifunction switch

J217 Automatic gearbox control unit

J226 Starter lockout and reversing light

relay

B/50 Starter terminal 50

D/50 Ignition/starter switch terminal 50

M16/17 Reversing lights

11 P, N signal

18 P, R, N signal

63 P signal

46

SP21-54

Page 46

8 s

OT

Additional signals

To engine control unit

The automatic gearbox control unit is linked

directly to the engine control unit.

Information flows through this output if engine

torque is to be reduced during a gearshift by

altering the ignition timing.

Gear shift

The engine control unit makes use of this signal

to briefly retard the ignition timing in order to

reduce engine torque.

This improves the quality of the gearshifts by

achieving smoother shifting.

SP21-62

To air conditioning system

The automatic gearbox control unit signals to the

air conditioning control unit when the kickdown

switch is operated

The magnetic clutch of the AC compressor is

switched off in this case for up to 8 seconds.

Full engine output is then available for accelerating.

The air conditioning is likewise switched off for

up to 8 seconds after the engine is started.

This minimises the load on the engine after it is

started.

SP21-61

47

Page 47

Subsystems

Selector lever lock (shiftlock)

Shift linkage with locking link

The selector lever lock (shiftlock) is a technical

safety measure on automatic gearboxes. This

makes it possible to eliminate incorrect operation on

the part of the driver.

It operates electro-mechanically.

The P/N position.

The selector lever is locked electro-mechanically in

selector lever positions P and N.

This eliminates any risk of unintentionally starting off

when a gear is engaged mechanically (R, D, 3, 2, 1).

SP21-66

A locking pin is inserted mechanically into the

locking link of the shift mechanism of the selector lever when it is in position P and N by

means of a solenoid (refer also to the section

on Actuators - selector lever lock solenoid).

This lock is released only when the brake

pedal is depressed.

Locking pin of selector lever

lock solenoid

48

Page 48

Function diagram for P/N position

(block diagram)

F125

J217

N110

P

P

R

N

N

D

3

2

1

the driver into position P or N.

This position is detected by the multifunction

switch F125 and signalled to the automatic

gearbox control unit J217.

The control unit activates the lock through the

selector lever lock solenoid N110 and the

selector lever is locked mechanically by the

solenoid.

When the footbrake is depressed, a pulse is

supplied by the brake light switch F to the

The selector lever is moved mechanically by

F

control unit.

The control unit thereupon actuates the

selector lever lock solenoid to cancel the

mechanical lock.

SP21-60

The selector lever lock solenoid releases the

locking pin

It is now possible to engage a gear.

Note:

A time lag element is incorporated in the functional sequence.

This ensures that the selector lever is not locked if it is shifted briskly through "N"

(e.g. from R to D and D to R for "rocking" free a car which has become stuck in

snow).

The selector lever lock function is activated, however, if the selector lever

remains in position "N" for more than 2 seconds.

The selector lever lock in position "N" is automatically switched off if the vehicle

speed is greater than 5 km/h.

49

Page 49

Subsystems

Park lock

Park lock gear

Drive gear

Intermediate gear stage

Driving shaft

SP21-9

Detent lever

Engaging lever

The park lock is a means of securing the vehicle

from moving off, in addition to the parking brake.

It is engaged purely mechanically when the selector lever is in position "P" and the vehicle is

stationary.

The park lock acts on the intermediate gear

stage of the automatic gearbox.

The park lock gear, like the drive gear of the

intermediate gear stage, is permanently attached to the driving shaft.

If the selector lever is moved into position "P",

the shift shaft moves the engaging lever against

the detent lever.

The detent lever moves up into the tooth gap of

the park lock gear.

The intermediate gear stage is blocked, the vehicle is secured.

Shift shaft

SP21-65

If the detent lever strikes against a tooth and

does not move into the gap when the selector

lever is moved into position "P", it is tensioned by

a spring.

The slightest movement of the vehicle then

causes the detent lever to jump into the gap.

Detent lever and the teeth of the park lock gear

are shaped so that the detent lever cannot

engage if the park lock gear is rotating at a high

speed.

This eliminates any risk of the gearbox blocking

when driving.

50

Page 50

Emergency Programme/Emergency Running Mode

The electronic system in the automatic gearbox

01M is a rugged design.

Fault analysis shows that 90% of all failures are

likely to be caused by wiring, plug connections,

sensor or actuators.

The electronic system is designed so as to

switch to a substitute signal or to assume a substitute value in the event of an input signal not

being received (see substitute functions under

Sensors/Actuators)

= emergency programme.

The electronic control system actuates the func-

SP21-63

tions so as to avoid any consequential damage.

The car can still be driven!

If an essential signal is not received or if an actuator or the electronic control itself fails, and no

substitute signal can be formed, the system

switches into

= emergency running mode.

The gearbox then operates as a purely hydraulic

gearbox. The torque converter lock-up clutch is

switched off.

The selector lever remains coupled mechanically

to the selector lever slide valve to enable the

vehicle to move.

The gearbox can still be shifted manually into the

selector lever positions.

In selector lever positions D, 3 and 2, however,

only 3rd gear is available.

In selector lever position 1 and R the relevant

gear is available.

Note:

Failure of a secondary signal can be felt by a deterioration in the smoothness of the

gearshifts (shift jolts are noticeable).

The emergency programme sets a fault memory which can be read in self-diagnosis.

The emergency running mode is retained until the fault is rectified.

51

Page 51

Self-Diagnosis

The self-diagnosis

monitors the signals of the sensors and also the operation of the actuators electrically and carries out a

self-test of the gearbox control unit.

If a fault occurs, substitute functions are activated.

The faults are stored in the permanent fault memory

of the control unit.

Consequently, the fault messages are retained even

if the battery is disconnected or the connector of the

control unit is unplugged.

The diagnostic connection

acts as a diagnostic interface and makes it possible

to rapidly transfer data from the gearbox control unit

to the vehicle system tester and in the opposite

direction.

The faults can be read using the vehicle system

tester V.A.G 1552 with programme card 3.

Note:

It is also possible to use fault reader V.A.G 1551.

In this case, use programme card 7.

The integrated printer makes it easier to structure the detection of the measured

values.

By selecting the address word

SP17-29

02 Gearbox electronics

it is possible to select the following functions of data transfer:

01 – Interrogating control unit version

02 – Interrogating fault memory

04 – Initiating basic setting

05 – Erasing fault memory

06 – Ending output

08 – Reading measured value block

52

Page 52

All the sensors and actuators which are colour-coded are monitored by the self-diagnosis and can be

tested using function 08 - Reading measured value block.

Note:

After completing certain repairs or replacing components, it is

then necessary to restore the system to the basic setting (function 04 - Initiating basic setting).

This is the case, for example, after:

replacing the engine,

replacing the engine control unit,

replacing the throttle valve control unit,

replacing the automatic gearbox control unit,

or replacing clutches or the control valve housing.

For the precise procedure regarding self-diagnosis refer to the Workshop Manual OCTAVIA, Automatic

Gearbox

SP21-43

53

Page 53

Function Diagram

The function diagram represents a

simplified current flow diagram

and shows how all the system

components of the gearbox control are interlinked.

Components

A Battery

B/50 Starter (terminal 50)

D/50 Ignition/starter switch

(terminal 50)

F Brake light switch

F8 Kickdown switch

F125 Multifunction switch

G28 Engine speed sender

G38 Gearbox speed sender

G68 Road speed sender

G69 Throttle valve potentiometer

G93 Gearbox oil temperature

sender

J226 Starter lockout and reversing

light relay

J217 Automatic gearbox control unit

J220 Motronic control unit

J361 Simos control unit

L19 Bulb for illuminating selector

lever display

M16/M17 Bulbs for reversing lights

M9/M10 Bulbs for brake and tail light

N88 Solenoid valve 1

N89 Solenoid valve 2

N90 Solenoid valve 3

N91 Solenoid valve 4

N92 Solenoid valve 5

N93 Solenoid valve 6

N94 Solenoid valve 7

N110 Selector lever lock solenoid

valve

S... Fuses

Additional signals

Colour coding/Legend

1

AC cut-off at kickdown

54

= Input signal

= Output signal

= Positive

= Earth

Page 54

A2

A40

U2

Positive connection 15 in wiring loom

Positive connection 30 in wiring loom

Positive connection 15 in wiring loom

SP21-15

55

Loading...

Loading...