SKODA Fabia II 2007, Fabia II 2009, Fabia II 2011, Rapid NH 2013, Roomster 2006 Workshop Manual

...Page 1

Service

Workshop Manual

Fabia II 2007 ➤ , Fabia II 2009 ➤ ,

F

Rapid NH 2013 ➤ , Rapid NH 2014 ➤ ,

Roomster 2006 ➤

abia II 2011 ➤ , Rapid India 2011 ➤ ,

1.6/77 kW MPI engine

Engine ID

BTS

CFN

A

CLSA

Edition 03.2014

Service Department. Technical Information

Page 2

Service

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

R

ep ai r Gr ou p

00 - Technical data

01 - Self-diagnosis

10 - Removing and installing engine

13 - Crankshaft group

15 - Cylinder head, valve gear

17 - Lubrication

19 - Cooling

20 - Fuel supply system

24 - Mixture preparation - injection

26 - Exhaust system

28 - Ignition system

Page 3

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

Contents

00 - Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.1 Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Engine characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

01 - Self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 Self diagnosis, safety measures, cleanliness regulations, directions . . . . . . . . . . . . . . . . . . 3

1.1 Self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Safety precautions when working on the fuel supply system . . . . . . . . . . . . . . . . . . . . . . . . 3

1.3 Rules of cleanliness to observe when working on the fuel supply system . . . . . . . . . . . . . . 4

1.4 Safety measures to apply when working on the fuel injection and ignition system . . . . . . 4

1.5 General notes on the injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.6 General notes on the ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.7 Supplementary instructions and assembly work on vehicles with an air conditioning

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

10 - Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1 Removing and installing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.1 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.2 Securing the engine to the assembly stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.3 Install . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.4 Assembly bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

13 - Crankshaft group . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1 Cylinder block - Belt pulley side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.1 V-ribbed belt drive - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

1.2 Removing and installing V-ribbed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.3 Camshaft drive - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.4 Camshaft drive - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

1.5 Removing and installing the timing case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2 Cylinder block, sealing flange and flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.1 Cylinder block - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

2.2 Replacing crankshaft seal on belt pulley side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

2.3 Tightening process of the screw for crankshaft belt pulley . . . . . . . . . . . . . . . . . . . . . . . . . . 33

2.4 Removing and installing flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

2.5 Removing and installing drive plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

2.6 Replacing the sealing flange for crankshaft - gearbox side . . . . . . . . . . . . . . . . . . . . . . . . 39

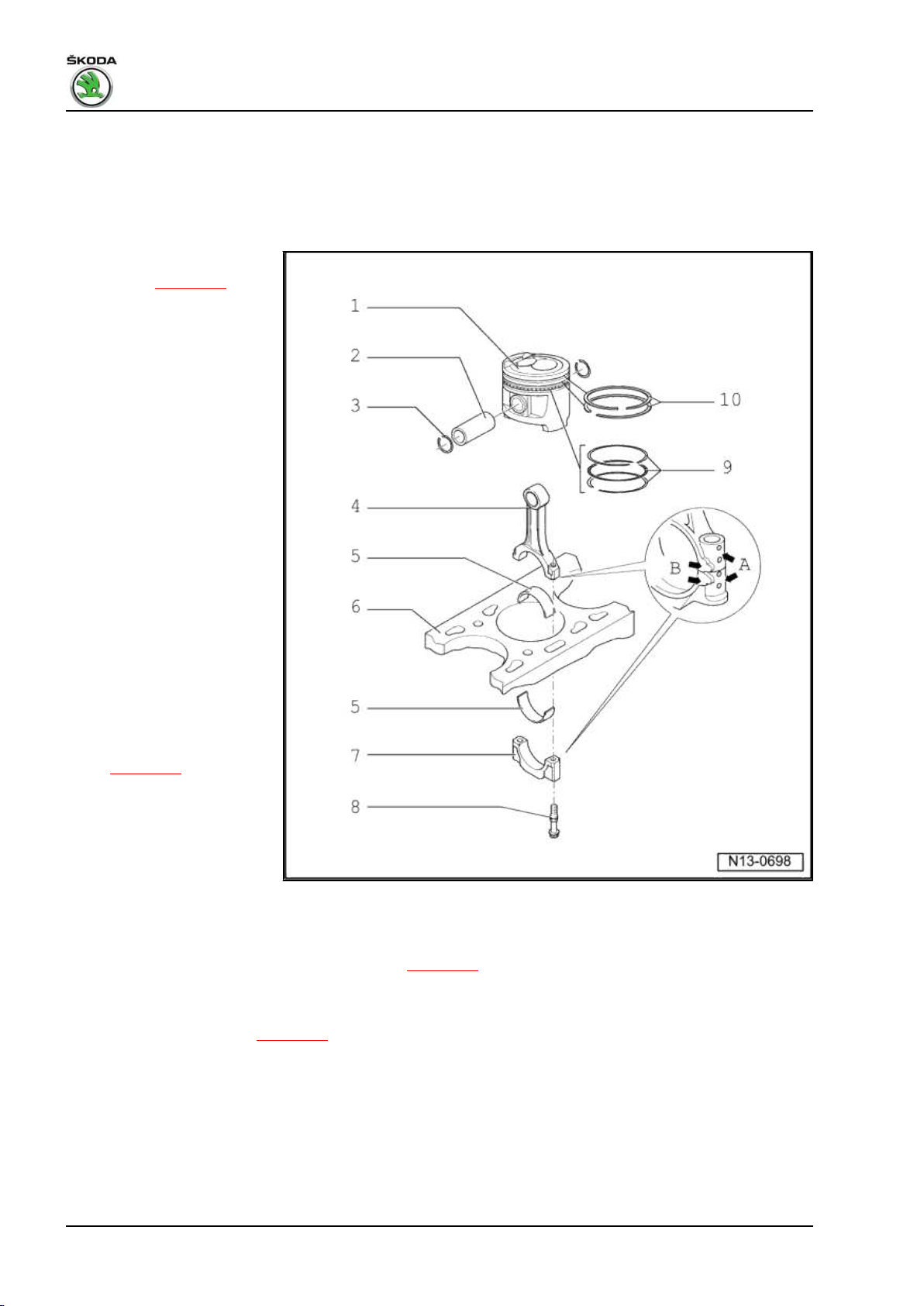

3 Pistons and conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.1 Piston and conrod - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

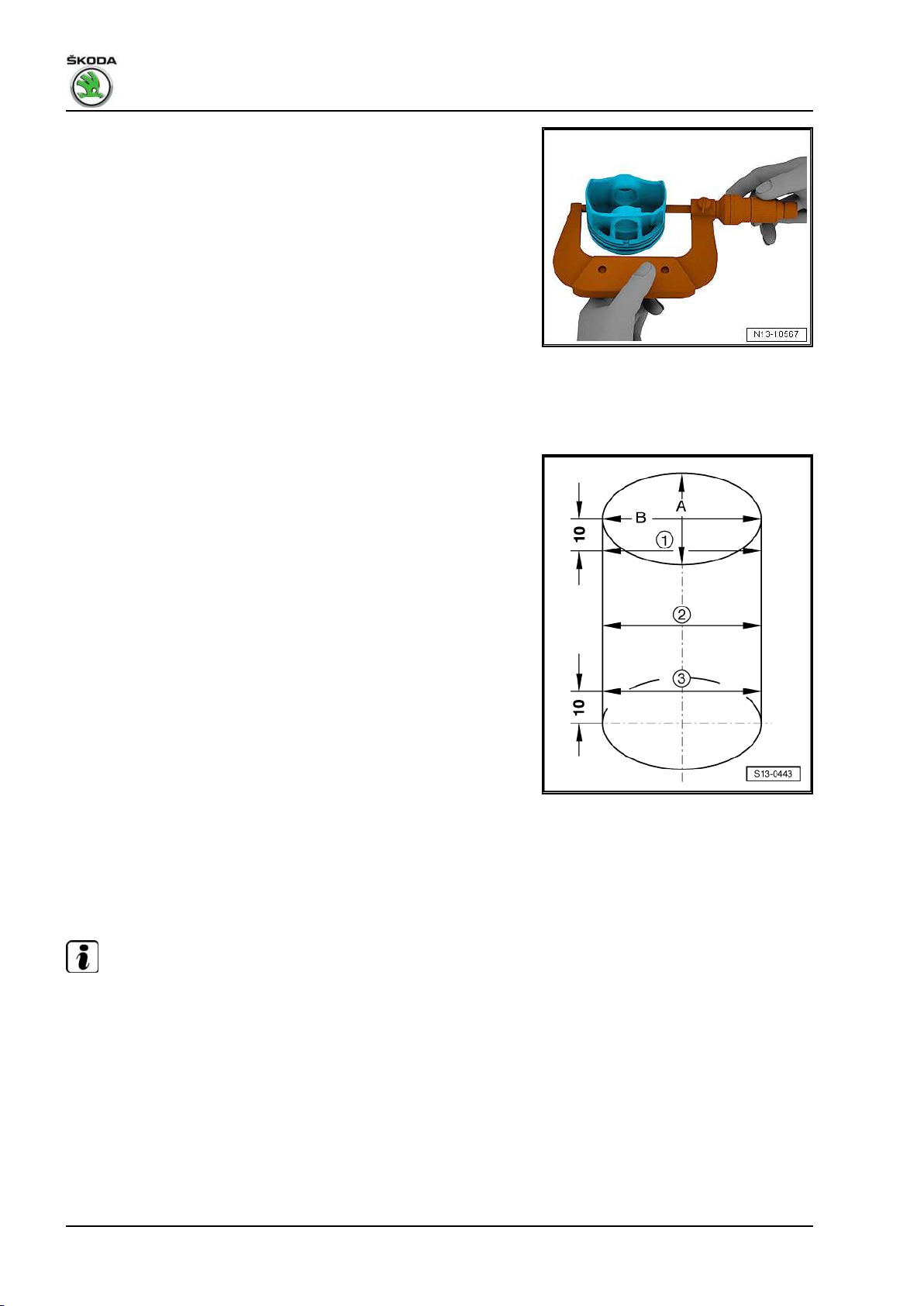

3.2 Inspect piston, piston rings and cylinder bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.3 Separating new conrod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

15 - Cylinder head, valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

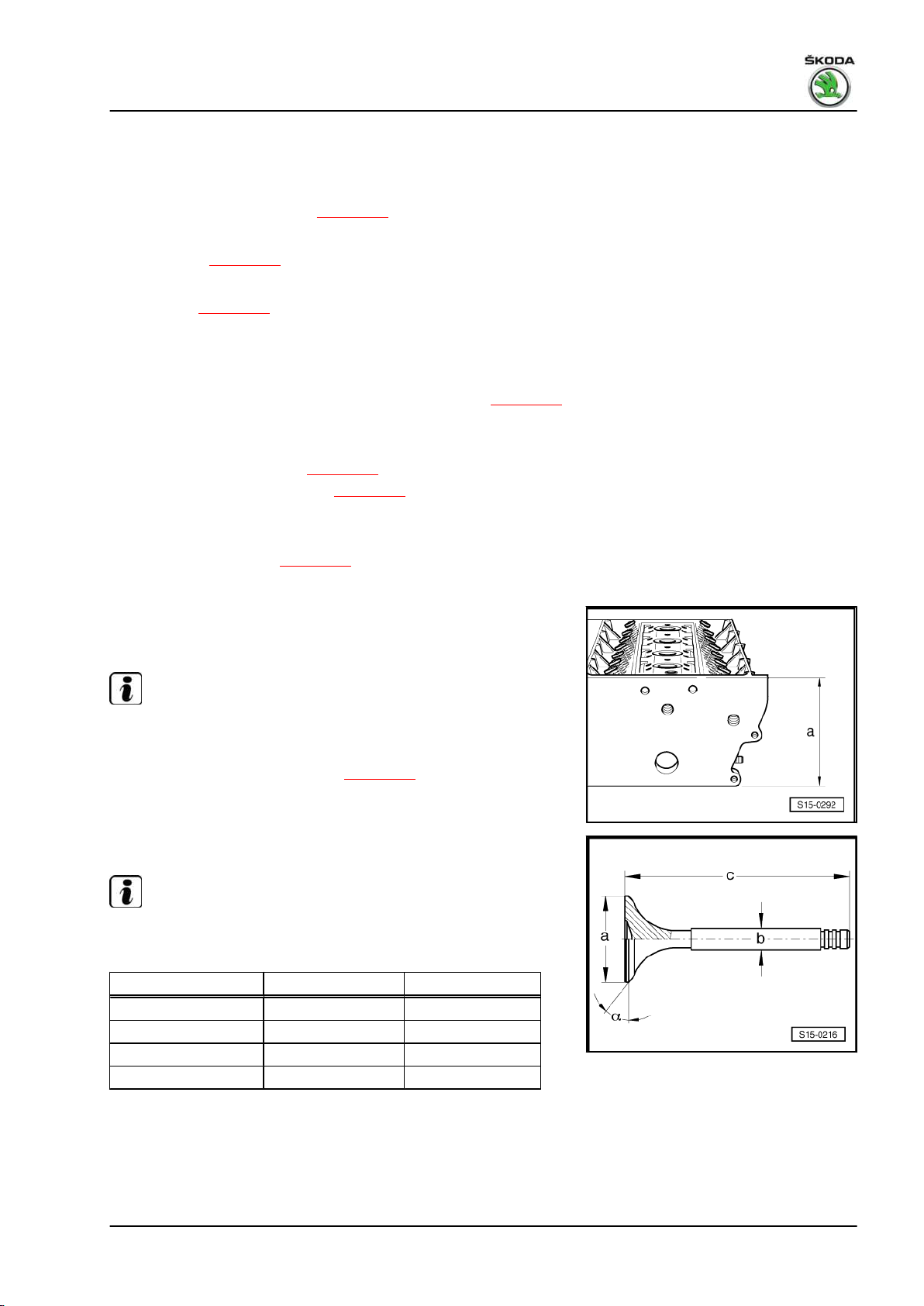

1 Cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.1 Distinguishing features of cylinder heads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

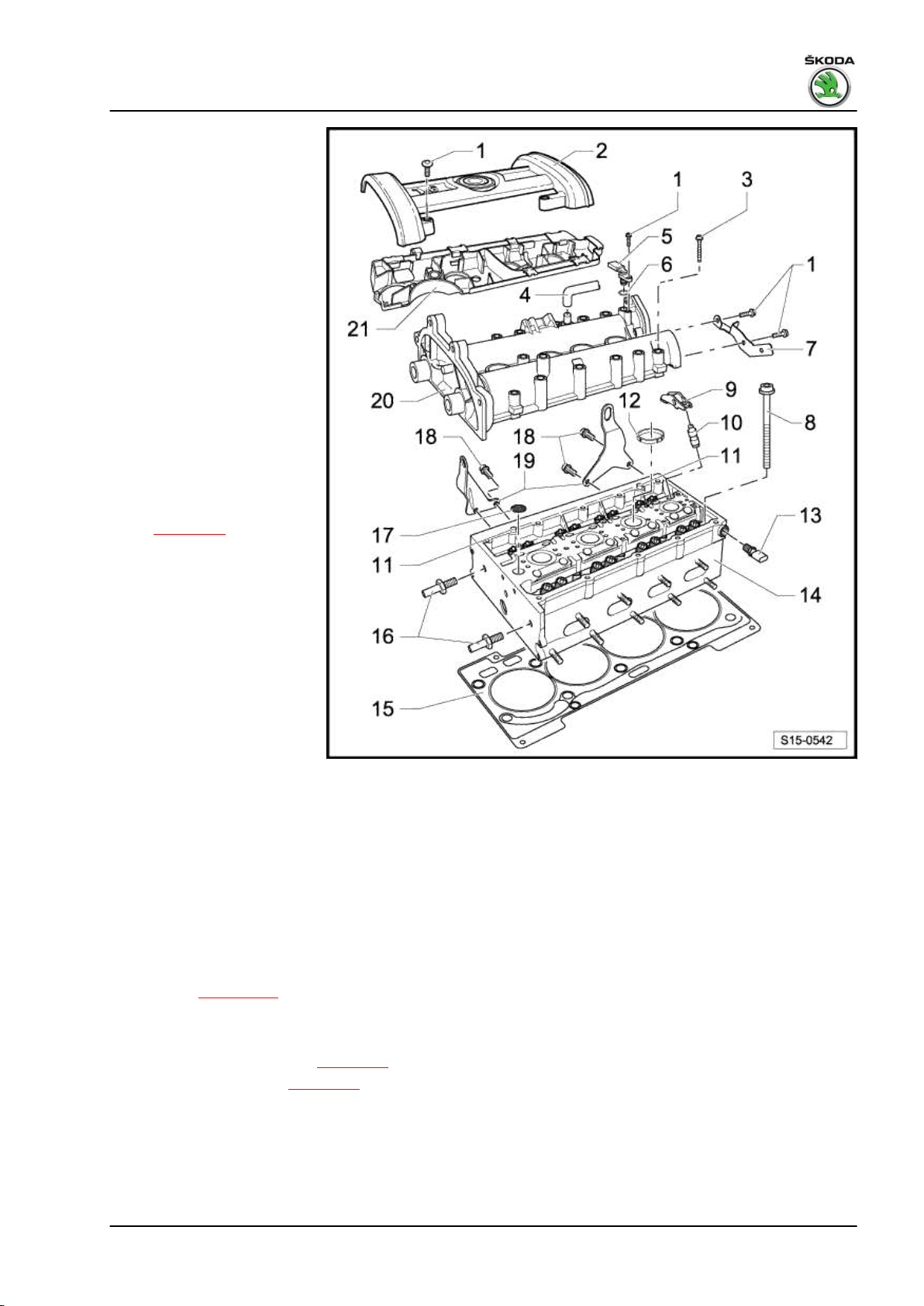

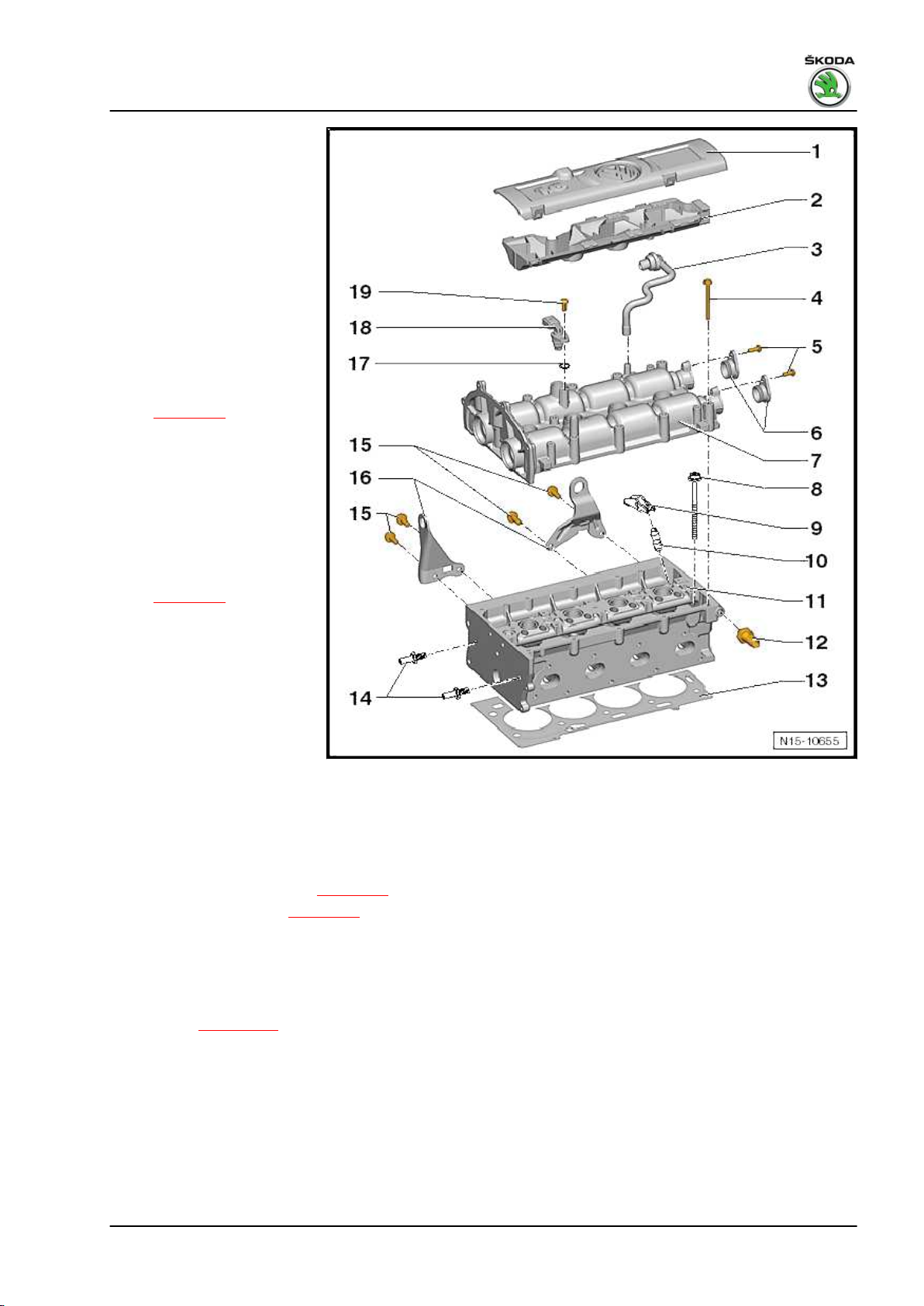

1.2 Cylinder head - Summary of components (version A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

1.3 Cylinder head - Summary of components (version B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

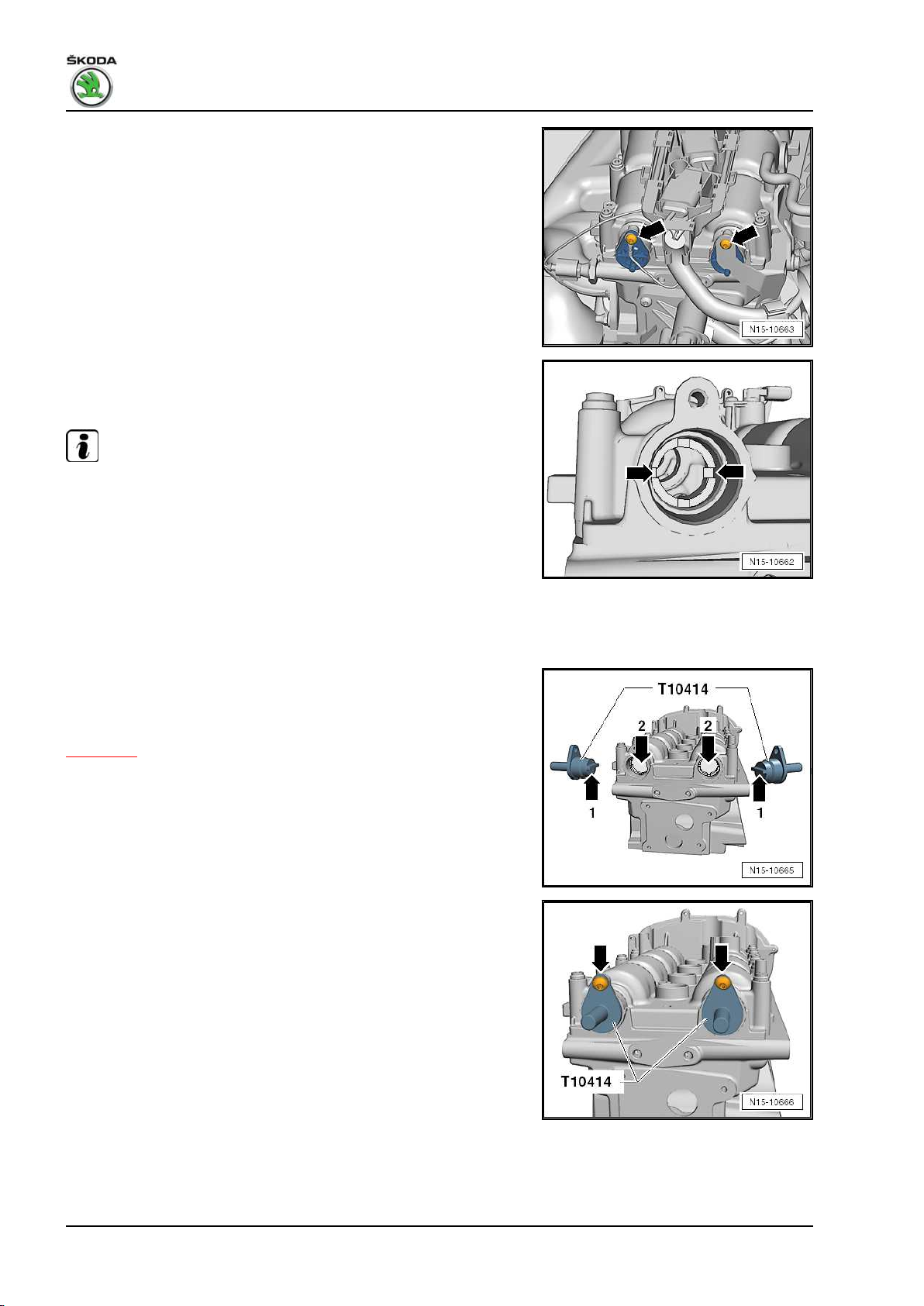

1.4 Check the timing for the cylinder head version A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

1.5 Check the timing for the cylinder head version B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

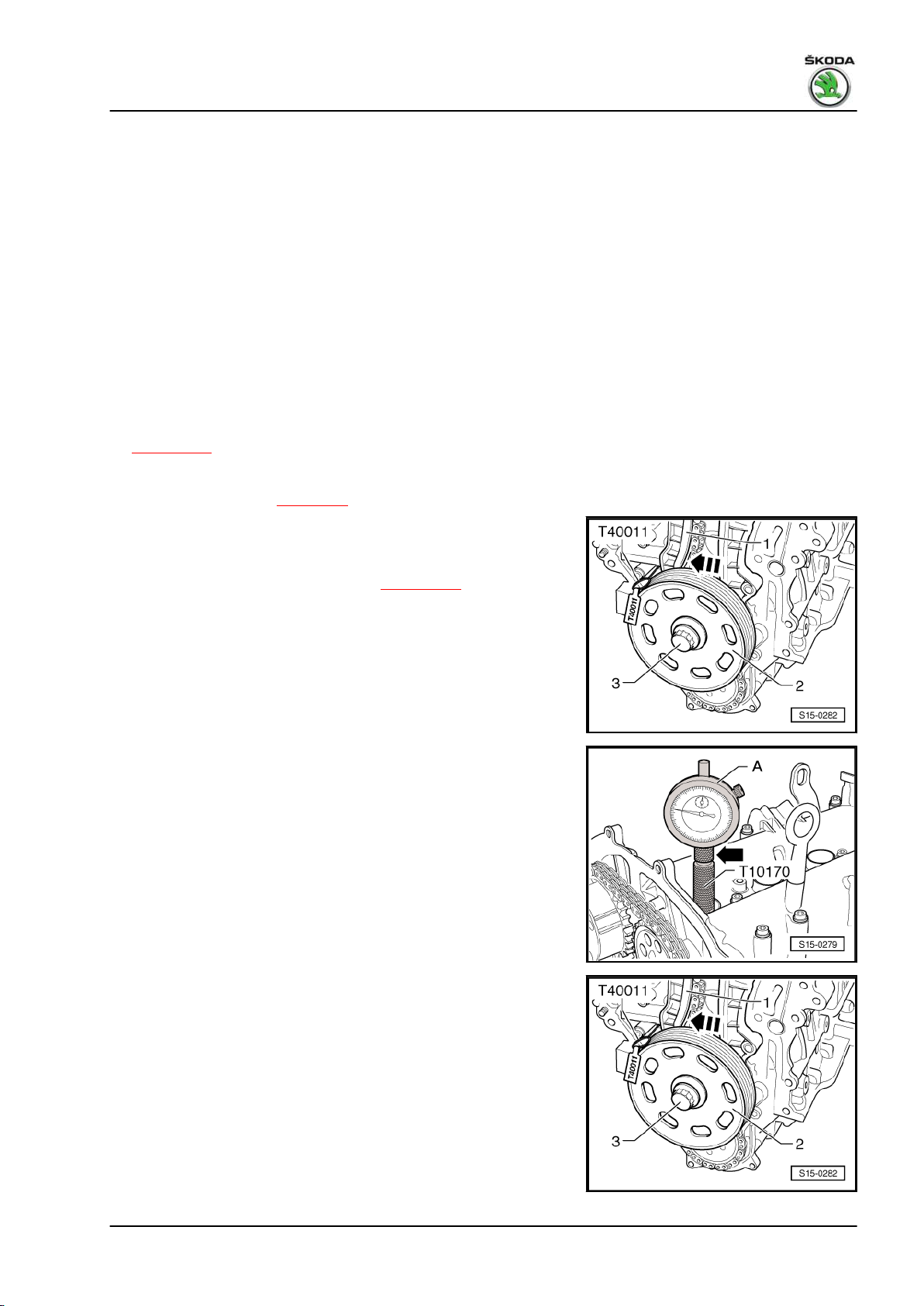

1.6 Setting the timing for the cylinder head version A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

1.7 Setting the timing for the cylinder head version B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

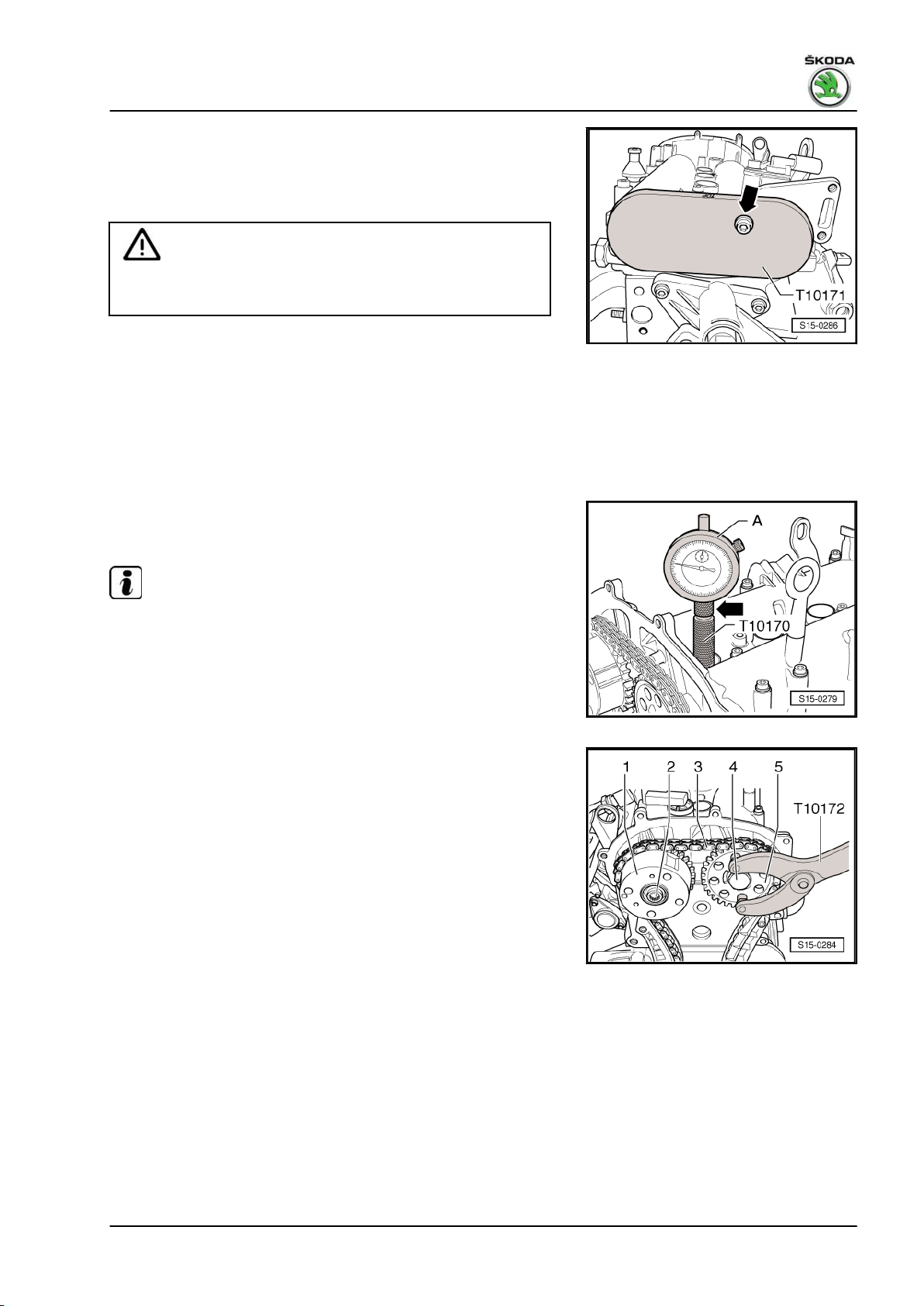

1.8 Removing and installing timing chain and drive chain for cylinder head version A . . . . . . 67

Contents i

Page 4

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

1.9 Removing and installing timing chain and drive chain of the oil pump for cylinder head version

B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

1.10 Removing and installing camshaft housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

1.11 Removing and installing the cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

1.12 Testing the compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

2 Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

2.1 Valve gear - Summary of components (version A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

2.2 Valve gear - Summary of components (version A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

2.3 Valve gear - Summary of components (version B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

2.4 Reworking valve seats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

2.5 Inspect valve guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

2.6 Removing and installing valve stem seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

17 - Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

1 Removing and installing parts of the lubrication system . . . . . . . . . . . . . . . . . . . . . . . . . . 100

1.1 Lubrication system - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

1.2 Lubrication system - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

1.3 Removing and installing oil pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

1.4 Removing and installing oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

1.5 Testing oil pressure and oil pressure switch F1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

19 - Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

1 Removing and installing parts of the cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

1.1 Parts of cooling system on the side next to the body - Summary of components . . . . . . . . 111

1.2 Cooling system attached to engine - Summary of components . . . . . . . . . . . . . . . . . . . . . . 116

1.3 Connection diagram for coolant hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

1.4 Draining and filling up coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

1.5 Removing and installing radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

1.6 Checking the coolant system for leaktightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

1.7 Removing and installing coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

20 - Fuel supply system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

1 Removing and installing parts of the fuel supply system . . . . . . . . . . . . . . . . . . . . . . . . . . 124

1.1 Fuel tank with attached parts and fuel filter - Summary of components . . . . . . . . . . . . . . . . 124

1.2 Fuel tank with attached parts and fuel filter - Summary of components . . . . . . . . . . . . . . . . 126

1.3 Fuel tank with attached parts and fuel filter - Summary of components . . . . . . . . . . . . . . . . 128

1.4 Extract fuel from the fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

1.5 Removing and installing fuel delivery unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

1.6 Removing and installing the sender for fuel gauge display G . . . . . . . . . . . . . . . . . . . . . . 134

1.7 Removing and installing the fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

1.8 Separating quick couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

2 Testing parts of fuel supply system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

2.1 Testing fuel pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

2.2 Venting air from the fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

2.3 Switching off the fuel delivery unit using the crash signal . . . . . . . . . . . . . . . . . . . . . . . . . . 149

3 Accelerator pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

3.1 Accelerator pedal module - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

4 Activated charcoal container system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

4.1 Activated charcoal container system - Summary of components . . . . . . . . . . . . . . . . . . . . 151

4.2 Activated charcoal container system - Summary of components . . . . . . . . . . . . . . . . . . . . 152

4.3 Activated charcoal container system - Summary of components . . . . . . . . . . . . . . . . . . . . 153

4.4 Checking the fuel tank venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

4.5 Checking the fuel tank venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

4.6 Checking the fuel tank venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

24 - Mixture preparation - injection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

ii Contents

Page 5

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

1 Fuel Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

1.1 Injection and ignition system - Overview of fitting locations . . . . . . . . . . . . . . . . . . . . . . . . 157

1.2 Intake manifold - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

1.3 Fuel strip with injection valves - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . 160

1.4 Air filter housing - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

1.5 Removing and installing engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

1.6 Removing and installing air filter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

1.7 Removing and installing injection valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

1.8 Checking the tightness of the injection valves and the fuel injection rate . . . . . . . . . . . . . . 164

1.9 Clean throttle valve control unit J338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

2 Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

2.1 Removing and installing engine control unit J623 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

26 - Exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

1 Removing and installing parts of the exhaust system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

1.1 Exhaust manifold and pre-exhaust pipe - Summary of components . . . . . . . . . . . . . . . . . . 171

1.2 Exhaust manifold and pre-exhaust pipe - Summary of components . . . . . . . . . . . . . . . . . . 172

1.3 Exhaust gas system - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

1.4 Exhaust gas system - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

1.5 Middle and rear silencer - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

1.6 Middle and rear silencer - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 177

1.7 Middle and rear silencer - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

1.8 Middle and rear silencer - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 179

1.9 Replacing middle or rear silencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

1.10 Aligning exhaust system free of stress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 181

1.11 Inspecting the exhaust system for leaktightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

28 - Ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

1 Ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

1.1 Ignition system - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

1.2 Removing and installing ignition coils with power output stages . . . . . . . . . . . . . . . . . . . . 184

Contents iii

Page 6

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

iv Contents

Page 7

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

00 – Technical data

1 Technical data

(SRL000678; Edition 03.2014)

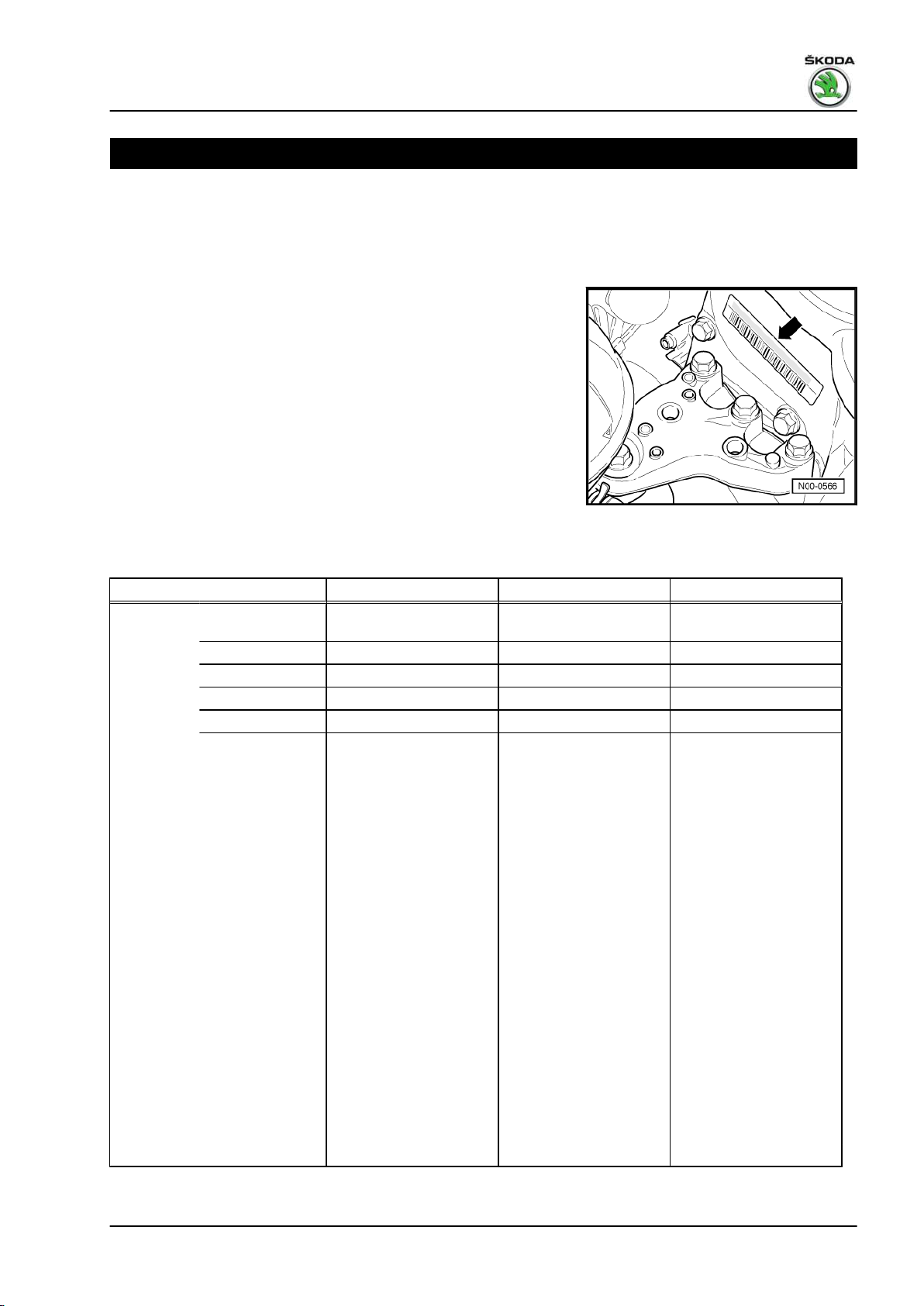

1.1 Engine number

The engine identification characters and the engine number can

be found on the sticker -arrow- at the timing case.

In addition, the engine identification characters are indicated on

the vehicle data sticker and also at the front on the cylinder block

on the connecting flange for gearbox.

The engine number consists of 9 characters. The first part repre‐

sents the “engine code” (a maximum of 3 identification letters),

the second part the “serial number”. If more than 999.999 engines

with the same engine code were produced then the first digit of

the six part section will be replaced by a letter.

1.2 Engine characteristics

Edition 03.2014; version 4.0

Identification characters BTS CFNA CLSA

Manufac‐

tured

Exhaust limit values conform‐

ing to

Displace‐

ment

Power out‐

put

Torque Nm at rpm 153/3800 153/3800 153/3800

Bore ∅ mm 76.5 76.5 76.5

Stroke mm 86.9 86.9 86.9

Compres‐

sion

Cylinder / valves per cylinder 4/4 4/4 4/4

Fuel - RON min.

Ignition system, fuel injection Motronic ME 7.5.20 Magneti Marelli 7GV Magneti Marelli 7GV

Firing order 1-3-4-2 1-3-4-2 1-3-4-2

Knock control yes yes yes

Self-diagnosis yes yes yes

Lambda control yes yes yes

Catalytic converter yes yes yes

Balancing shaft no no no

Exhaust gas recirculation no no no

Fabia II 04.07 ► 07.10 06.10 ► 08.10 ►

Roomster 05.06 ► 07.10 06.10 ►

Rapid NH

Rapid NK

Rapid NA

kW at rpm 77/5600 77/5600 77/5600

cm

EU-4, EU-2 DDK EU-4, EU-2 DDK EU-4 IND (BS4)

3

unleaded 95

1598 1598 1598

10.5 : 1 10.5 : 1 10.5 : 1

1)

02.13 ►

03.14 ►

unleaded 95

1)

unleaded 95

09.11 ►

1)

1. Technical data 1

Page 8

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

1)

At least 91 RON in exceptional cases; although engine output

is reduced.

2 Rep. gr.00 - Technical data

Page 9

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

01 – Self-diagnosis

1 Self diagnosis, safety measures,

cleanliness regulations, directions

1.1 Self-diagnosis

This Rep.-Gr. is deleted.

For this use “Vehicle self-diagnosis”, “Measuring method” and

“Fault finding” ⇒ Vehicle diagnostic tester.

1.2 Safety precautions when working on the fuel supply system

WARNING

The fuel feed line is pressurized! Place a clean cleaning cloth

around the connection point before detaching wiring. Reduce

pressure by carefully removing the wiring.

WARNING

When undertaking all assembly work, particularly in the engine

compartment due to its cramped construction, please observe

the following:

♦ Lay lines of all kinds (e.g. fuel, hydraulic fluid, the activated

charcoal container system, cooling fluid and refrigerant,

brake fluid, vacuum) and electrical lines in such a way that

the original line guide is re-established.

♦ Ensure that there is adequate free access to all moving or

hot components.

When removing and installing the fuel gauge sender or the fuel

delivery unit from a full or partly filled fuel tank, pay attention to

the following points:

♦ The extraction hose of an exhaust extraction system which is

switched on, must be positioned close to the assembly open‐

ing of the fuel tank in order to extract the released fuel vapours,

even before the work is commenced. If no exhaust extraction

system is available, a radial fan (motor not in air flow of fan)

with a delivery volume of more than 15 m3/h must be used.

♦ Avoid skin contact with fuel! Wear fuel-resistant gloves!

1. Self diagnosis, safety measures, cleanliness regulations, directions 3

Page 10

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

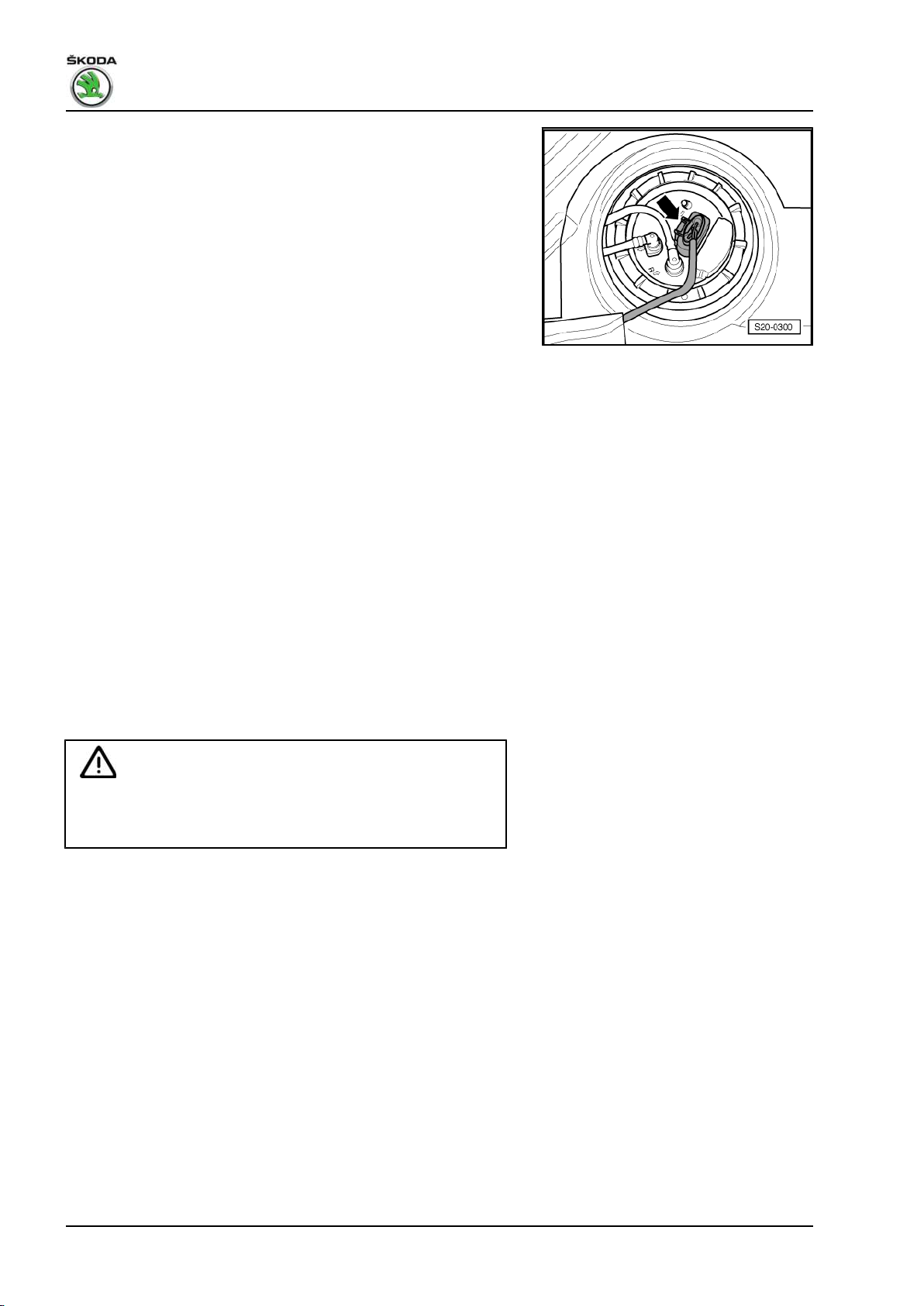

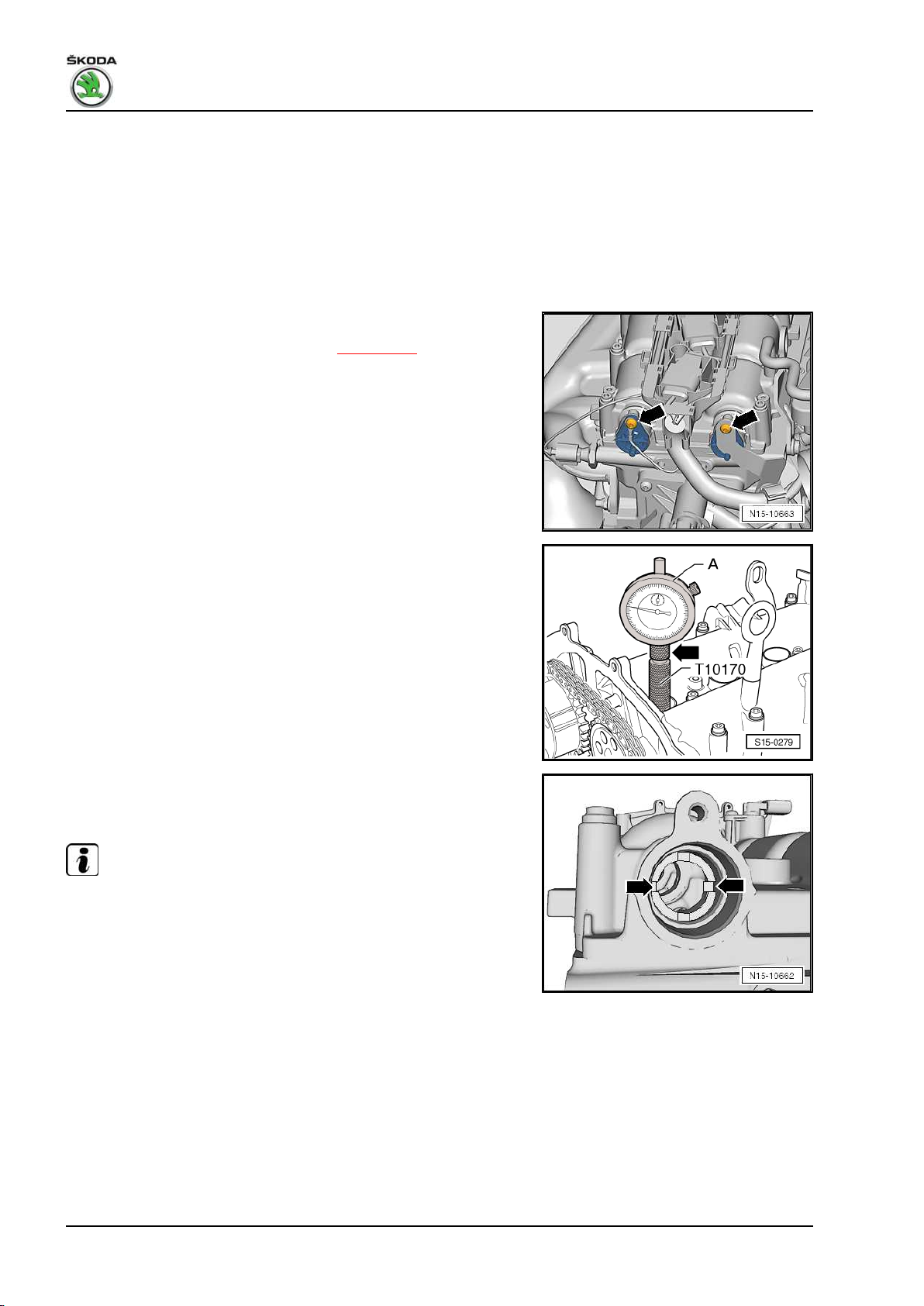

♦ The fuel delivery unit is activated when the ignition is switched

on and by the door contact switch of the driver door. For safety

reasons, before opening the fuel system and in the event that

the battery is not disconnected, the plug -arrow- must be dis‐

connected from the fuel delivery unit or the fuse for the voltage

supply of the fuel delivery unit must be pulled out according to

⇒ Current flow diagrams, Electrical fault finding and Fitting lo‐

cations.

1.3 Rules of cleanliness to observe when working on the fuel supply system

Pay careful attention to the following rules of cleanliness when

working on the fuel supply or fuel injection systems:

♦ Thoroughly clean the connection points and their surroundings

before releasing.

♦ Place removed parts on a clean surface and cover. Do not use

fuzzy cloths!

♦ Carefully cover or seal opened or removed components if the

repair is not carried out immediately.

♦ Only install clean parts: Remove spare parts from their wrap‐

ping immediately before fitting. Do not use any parts which

have been stored unwrapped (e.g. in tool boxes).

♦ When the system is open: Avoid using compressed air when‐

ever possible. Avoid moving the vehicle.

1.4 Safety measures to apply when working on the fuel injection and ignition system

WARNING

The fuel system is under pressure! Before opening the system

lay cleaning cloths around the connection point. Reduce pres‐

sure by carefully releasing the connection point.

Observe the following points to prevent injury to persons and/or

damage to the injection and ignition system:

♦ Do not touch or remove ignition leads with the engine running

or at start speed.

♦ Ignition must be switched off before disconnecting and re-

connecting the cables of the fuel injection and the ignition

system as well as of the test equipment.

♦ If the engine must be operated at starter speed, without it

starting, e.g. during compression pressure testing: open the

cover on the fuse holder underneath the dash panel and pull

out the fuse for the injection valves - N30, N31, N32, N33⇒ Current flow diagrams, Electrical fault finding and Fitting

locations.

If test and measuring devices are required during test drives ob‐

serve the following:

♦ Always secure the test and measuring devices on the rear seat

and have a second person operate them there.

4 Rep. gr.01 - Self-diagnosis

Page 11

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

♦ If the test and measuring devices are operated from the pas‐

senger seat, the passenger could be injured by the release of

the passenger airbag in the event of an accident.

1.5 General notes on the injection system

♦ The engine control unit is equipped with self-diagnosis. Before

repairs as well as for fault finding first interrogate the fault

memory ⇒ Vehicle diagnostic tester.

♦ Fuel hoses in the engine compartment must be secured with

spring band clamps. The use of clamp-type or screw-type clips

is not allowed.

♦ A minimum voltage of 11.5 V is required for perfect functioning

of the electrical components.

♦ Do not use sealants containing silicone. Traces of silicone el‐

ements drawn in by the engine are not burnt in the engine and

damage the lambda probes.

♦ Certain inspections may cause the control unit to detect and

store a fault. It is therefore necessary to interrogate the fault

memory after having completed all inspections and repairs,

and if necessary delete ⇒ Vehicle diagnostic tester.

Safety measures ⇒ page 4

1.6 General notes on the ignition system

Setting data, spark plugs:

♦ ⇒ Maintenance ; Booklet Fabia II .

♦ ⇒ Maintenance ; Booklet Roomster .

♦ ⇒ Maintenance ; Booklet Rapid NH .

♦ ⇒ Maintenance ; Booklet Rapid NA .

Repairing ignition ⇒ page 183 .

♦ Switch off the ignition before disconnecting and connecting the

battery, as this may damage the 4AV control unit.

♦ The engine control unit and further components are equipped

with self-diagnosis; inspect ⇒ Vehicle diagnostic tester.

♦ A minimum voltage of 11.5 V is required for perfect functioning

of the electrical components.

♦ Certain inspections may cause the control unit to detect and

store a fault. It is therefore necessary to interrogate the fault

memory after having completed all inspections and repairs,

and if necessary delete ⇒ Vehicle diagnostic tester.

Safety measures ⇒ page 4 .

1.7 Supplementary instructions and assem‐

bly work on vehicles with an air condi‐

tioning system

WARNING

Do not open the refrigerant circuit of the air conditioning sys‐

tem.

1. Self diagnosis, safety measures, cleanliness regulations, directions 5

Page 12

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

Note

In order to avoid damage to the condenser as well as to the re‐

frigerant lines and hoses of the air conditioning system, ensure

that the lines and hoses are not over-tensioned, kinked or bent.

Steps which should be taken in order to remove and install the

engine without opening the refrigerant circuit:

– Unscrew the holding clamp(s) on the refrigerent lines

– Remove V-ribbed belt ⇒ page 18 .

– Remove AC compressor ⇒ Heating, Air Conditioning; Rep.

gr. 87 .

– Mount the air conditioning compressor and the condenser in

such a way that the refrigerent lines/hoses are not under ten‐

sion.

6 Rep. gr.01 - Self-diagnosis

Page 13

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

10 – Removing and installing engine

1 Removing and installing engine

Special tools and workshop equipment required

♦ Engine mount - T40075 A♦ Engine mount - MP1-202- for assembly stand - MP9-101♦ Assembly stand - MP9-101♦ Lifting device - MP9-201 (2024 A)♦ Workshop crane , e.g. -V.A.S 6100♦ Catch pan , e.g. -VAS 6208♦ Double ladder

♦ Pliers for spring strap clamps

♦ Wire

♦ Grease - G 000 100♦ Hot screw paste - G 052 112 A3-

1.1 Removing engine

Note

♦

The engine is removed downwards together with the gearbox.

♦

All cable straps that have been loosened or cut open when the

engine was removed must be fitted again in the same locations

when the engine is installed again.

♦

Collect drained coolant in a clean container for reuse or proper

disposal.

♦

Jacking up points for raising the vehicle:

♦ ⇒ Maintenance ; Booklet Fabia II .

♦ ⇒ Maintenance ; Booklet Roomster .

♦ ⇒ Maintenance ; Booklet Rapid NH .

♦ ⇒ Maintenance ; Booklet Rapid NA .

– Observe all safety measures and notes for assembly work on

the fuel supply, injection and ignition system; as well as the

rules for cleanliness ⇒ page 3 .

WARNING

Observe measures when disconnecting the battery ⇒ Electri‐

cal System; Rep. gr. 27 .

– Remove battery and battery tray ⇒ Electrical System; Rep.

gr. 27 .

– Remove air filter housing with air guide ⇒ page 161 .

– Remove the sound dampening system ⇒ Body Work; Rep.

gr. 50 .

1. Removing and installing engine 7

Page 14

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

– Remove the front wheelhouse liners ⇒ Body Work; Rep. gr.

66 .

– Drain coolant ⇒ page 118 .

– Remove the coolant hoses from the radiator to the coolant

regulator housing.

– Pull off coolant hoses from heat exchanger for heating.

– Detach coolant hoses from coolant expansion bottle.

– Disconnect plugs from radiator fan - V7- and from thermos‐

witch for radiator fan - F18- .

– Pull out the fuel feed line -2- (catch the fuel which flows out

with a cleaning cloth) and the vent line -1-. Unlock the quick

coupling and disconnect ⇒ page 138 .

– Seal the lines in order to prevent any dirt from penetrating into

the fuel system.

– Disconnect the vacuum and bleeder hoses from the engine or

from other components.

8 Rep. gr.10 - Removing and installing engine

Page 15

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

– Unplug connector -1- from the engine control unit.

– Unplug connector -2-.

– Unclip cable clip -3- -arrows-.

The engine is removed together with the wiring loom.

– Disconnect all cables for the engine, gearbox and starter mo‐

tor which will get in the way during removal.

Vehicles fitted with a manual gearbox

– Remove shift mechanism from gearbox ⇒ Gearbox; Rep. gr.

34 .

– Remove slave cylinder ⇒ Gearbox; Rep. gr. 30 .

Note

Do not depress the clutch pedal.

Vehicles with automatic gearbox

– Remove shift mechanism from gearbox ⇒ Automatic Gear‐

box; Rep. gr. 37 .

Vehicles with air conditioning

WARNING

Do not open the refrigerant circuit of the air conditioning sys‐

tem.

Note

In order to avoid damage to the AC compressor as well as to the

refrigerant lines and hoses, ensure that the lines and hoses are

not over-tensioned, kinked or bent.

– Remove V-ribbed belt ⇒ page 18 .

– Remove AC compressor from holder ⇒ Heating, Air Condi‐

tioning; Rep. gr. 87 .

– Secure the air-conditioning compressor with attached lines to

the assembly carrier.

Continued for all vehicles

– Remove pre-exhaust pipe:

♦ Fabia II and Roomster vehicles with engine identification char‐

acters BTS ⇒ page 171 .

♦ Fabia II and Roomster vehicles with engine identification char‐

acters CFNA ⇒ page 172 .

♦ Fabia II vehicles with engine identification characters CLSA

⇒ page 174

♦ Rapid NH, NK vehicles with engine identification characters

CFNA ⇒ page 175

♦ Rapid NA vehicles with engine identification characters CLSA

⇒ page 175

1. Removing and installing engine 9

Page 16

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

– Unbolt the pendulum support -arrows-.

– Unscrew drive shaft to the right and left of the gearbox and tie

up ⇒ Body; Rep. gr. 40 .

– First of all tighten the bolt of the engine mount - T40075 A- at

the front on the engine.

– Position the engine mount - T40075 A- in the engine/gearbox

jack - V.A.G 1383 A- .

– Tighten engine mount - T40075 A- at the bolt.

– Screw engine mount - T40075 A- onto cylinder block reverse

side to 20 Nm -arrows-.

– Slightly raise the engine/gearbox unit.

Note

Use double ladder to release the screws for the assembly bracket.

For vehicles with assembly bracket version 1

– Unscrew bolts -1-.

10 Rep. gr.10 - Removing and installing engine

Page 17

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

For vehicles with assembly bracket version 2

– Unscrew nut -3- and disconnect earth lead from engine mount.

– Unscrew bolts -2-.

For all vehicles

– Unscrew screws -arrows- and remove gearbox mount.

Note

♦

Check whether all hose and line connections between engine,

gearbox and body are released.

♦

Carefully lower engine with gearbox in order to avoid damage.

– Pull engine/gearbox unit as far forward as possible and lower

slowly downwards.

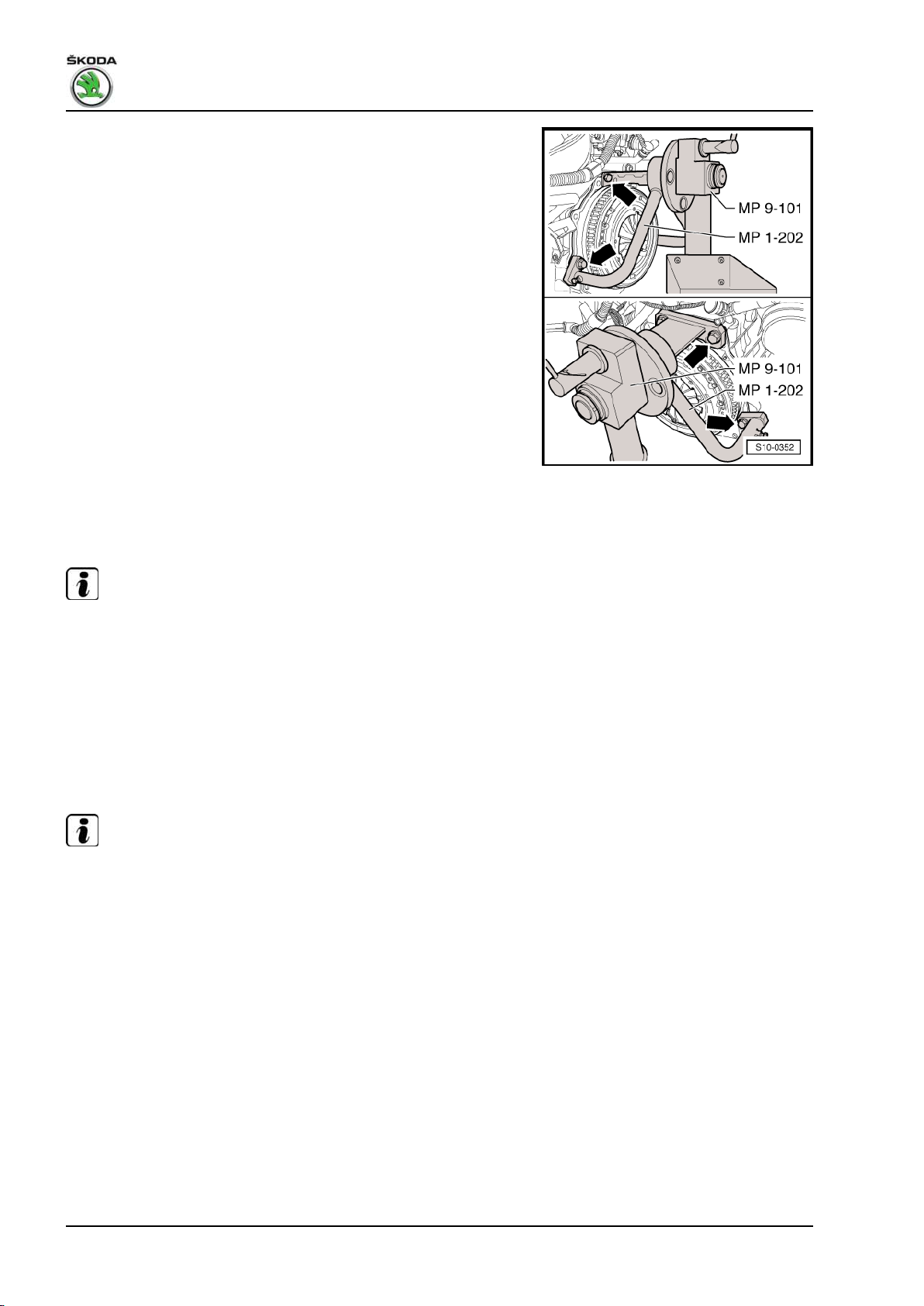

1.2 Securing the engine to the assembly stand

Special tools and workshop equipment required

♦ Lifting device - MP9-201 (2024 A)♦ Engine mount - MP1-202- for assembly stand - MP9-101- ,

where necessary engine and gearbox jack - VAS 6095♦ Assembly stand - MP9-101♦ Workshop crane , e.g. -V.A.S 6100Secure the engine with engine mount - MP1-202- on the assem‐

bly stand - MP9-101- before performing assembly work.

– Unscrew gearbox from engine:

♦ ⇒ Manual gearbox; Rep. gr. 34 .

♦ ⇒ Automatic gearbox; Rep. gr. 37 .

– Hang lifting device - MP9-201- as follows and slightly raise

engine with the workshop crane .

On the belt pulley side: 2. Hole of the extension in Position 1

On the flywheel side: 1. Hole of the extension in Position 5

WARNING

Use securing pins on the hooks and rig pins -arrows-.

– Remove coolant regulator housing from the cylinder head.

1. Removing and installing engine 11

Page 18

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

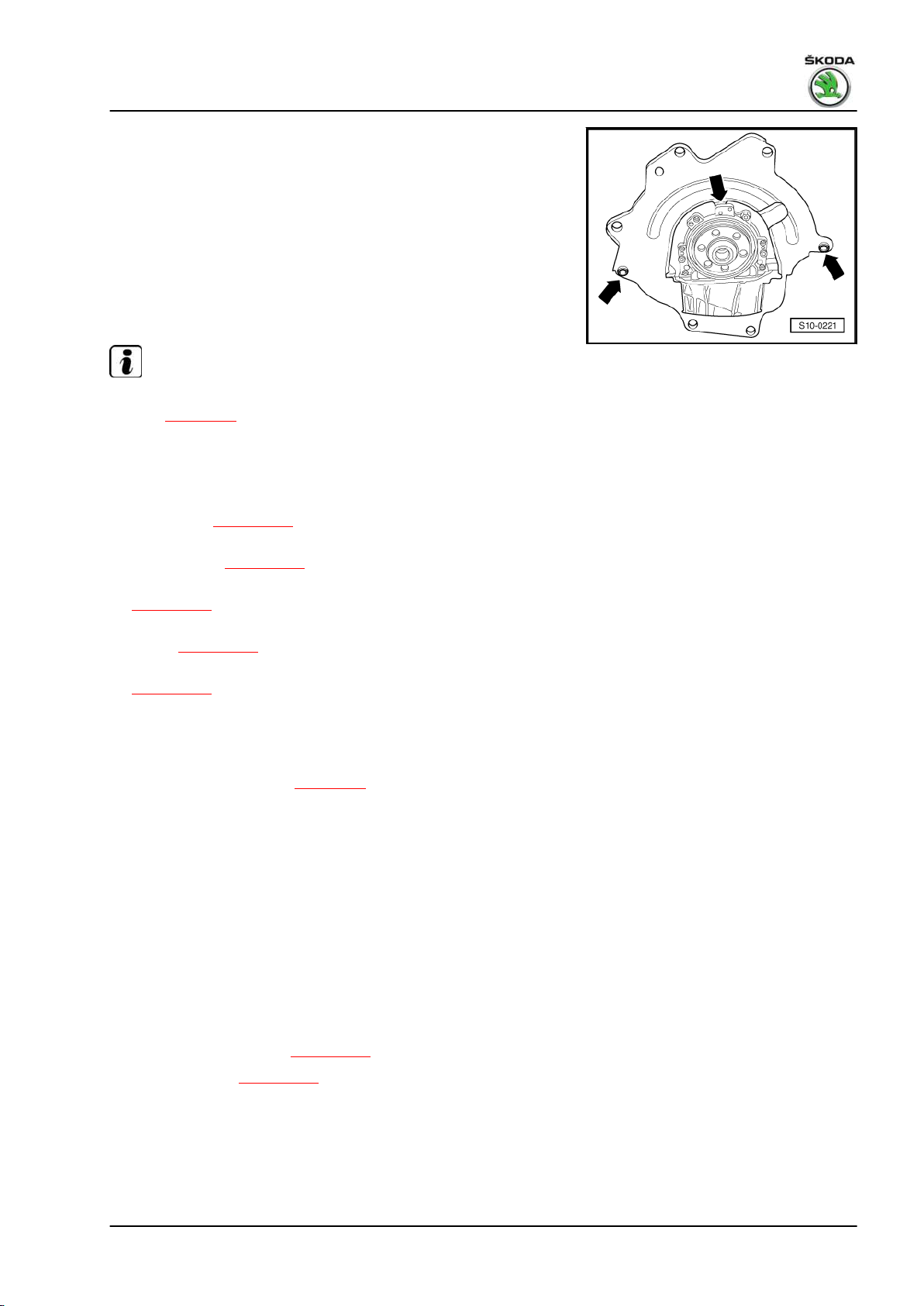

– Screw engine mount - MP1-202- to engine and secure to the

assembly stand - MP9-101- .

1.3 Install

Installation is performed in the reverse order, pay attention to the

following points:

Note

♦

When performing installation work replace the self-locking

nuts.

♦

Replace screws which have been tightened to a torquing angle

as well as gasket rings and seals.

♦

All cable straps should be fitted on again in the same place

when installing.

♦

Secure all hose connections with corresponding hose clips.

Vehicles fitted with a manual gearbox

Note

Clean the drive shaft serration and hub serration on used clutch

discs, remove corrosion. Apply a very thin layer of grease - G 000

100- onto the serration. Subsequently move the clutch disc up

and down on the drive shaft until the hub fits smoothly on the shaft.

Remove all excess grease so that it does not get onto the friction

surfaces of the clutch.

– Inspect clutch release bearing for wear, replace if necessary.

– Grease the clutch release bearing and guide bushing for re‐

lease bearing with grease - G 000 100- .

Continued for all vehicles

– Check whether the dowel sleeves for centering the gearbox

are present in the cylinder block, insert if necessary.

12 Rep. gr.10 - Removing and installing engine

Page 19

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

– Insert intermediate plate on sealing flange and push onto the

dowel sleeves -arrows-.

– Install gearbox on engine:

♦ ⇒ Manual gearbox; Rep. gr. 34 .

♦ ⇒ Automatic gearbox; Rep. gr. 37 .

– When swiveling the unit, ensure adequate clearance particu‐

larly to the drive shafts.

– Align the engine and gearbox mounting so that it is stress-free

through tapping movements.

Note

Tightening order and tightening torques of screws for assembly

bracket ⇒ page 14 .

– Install drive shafts ⇒ Chassis; Rep. gr. 40 .

– Install pre-exhaust pipe:

♦ Fabia II and Roomster vehicles with engine identification char‐

acters BTS ⇒ page 171 .

♦ Fabia II and Roomster vehicles with engine identification char‐

acters CFNA ⇒ page 172 .

♦ Fabia II vehicles with engine identification characters CLSA

⇒ page 174

♦ Rapid NH, NK vehicles with engine identification characters

CFNA ⇒ page 175

♦ Rapid NA vehicles with engine identification characters CLSA

⇒ page 175

Vehicles with air conditioning

– Install AC compressor at holder ⇒ Heating, Air Conditioning;

Rep. gr. 87 .

– Install the V-ribbed belt ⇒ page 18 .

Continued for all vehicles

– Electrical connections and proper routing ⇒ Electrical System;

Rep. gr. 97 .

Vehicles fitted with a manual gearbox

– Install slave cylinder ⇒ Gearbox; Rep. gr. 30 .

– Attach shift mechanism ⇒ Gearbox; Rep. gr. 34 .

Vehicles with automatic gearbox

– Attach the selector lever control cable at the gearbox ⇒ Au‐

tomatic gearbox; Rep. gr. 37 .

Continued for all vehicles

– Install air filter housing ⇒ page 161 .

– Top up coolant ⇒ page 118 .

– Adapt the engine control unit to the throttle valve control unit

- J338- ⇒ Vehicle diagnostic tester.

– Interrogate fault memory, rectify any faults existing and erase

the fault memory ⇒ Vehicle diagnostic tester.

– Perform a test drive.

1. Removing and installing engine 13

Page 20

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

– Interrogate fault memory, rectify any faults existing and erase

the fault memory ⇒ Vehicle diagnostic tester.

1.3.1 Tightening torques

Component

Screws and nuts M6 9

deviations:

Fixing screws of engine/gearbox:

♦ ⇒ Manual gearbox; Rep. gr. 34 .

♦ ⇒ Automatic gearbox; Rep. gr. 37 .

Screws for assembly bracket ⇒ page 14 .

M7 13

M8 20

M10 40

M12 70

Nm

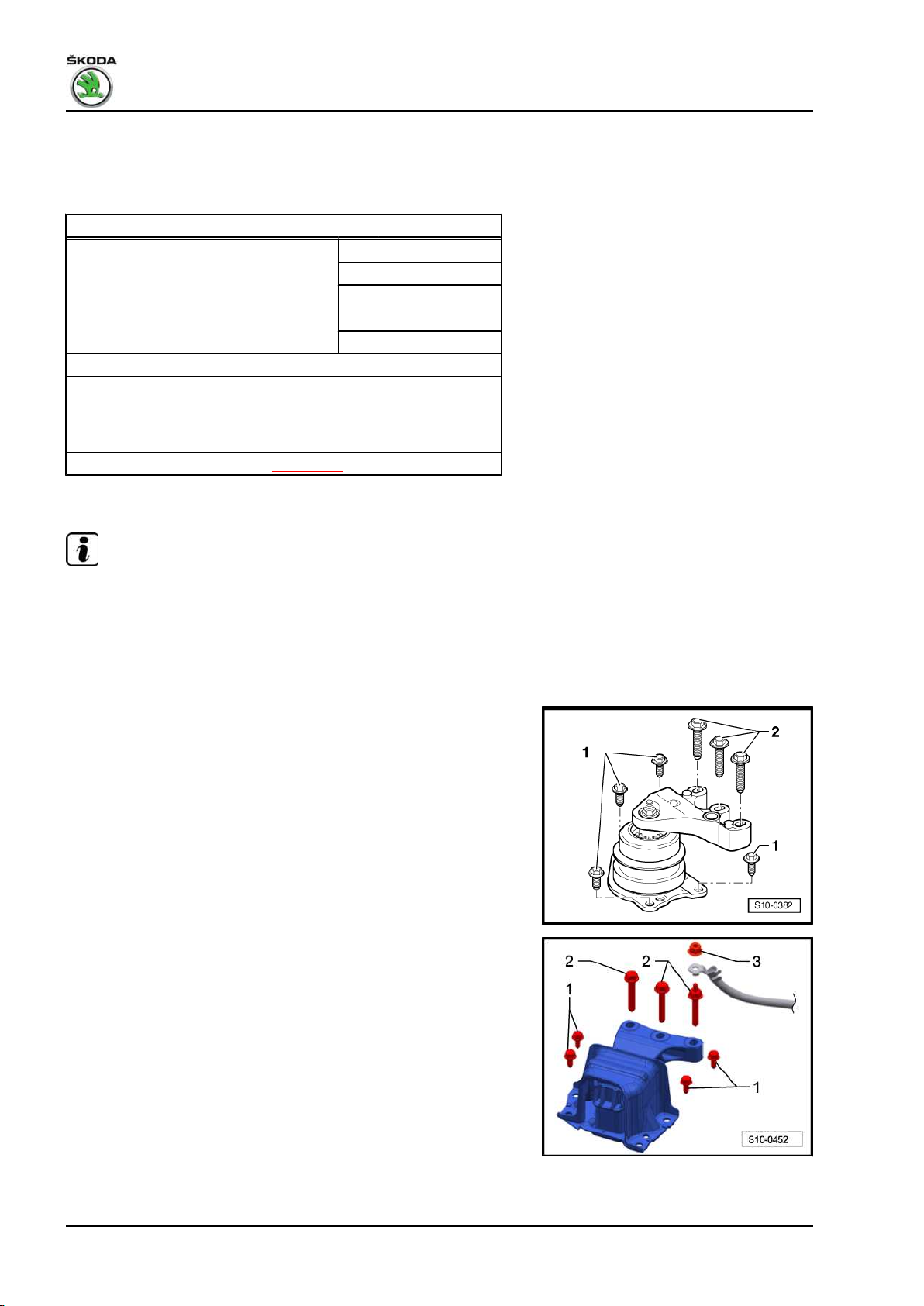

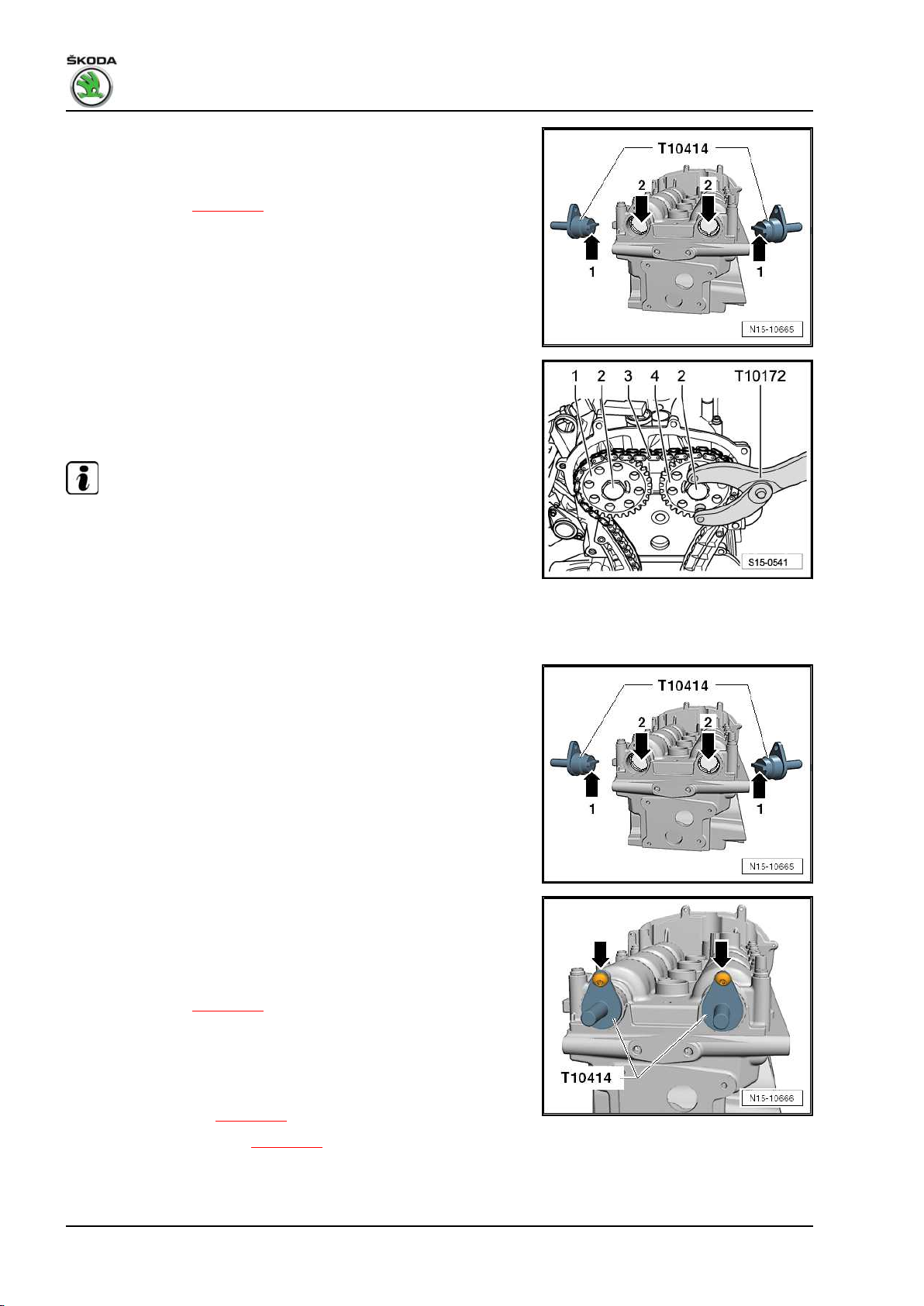

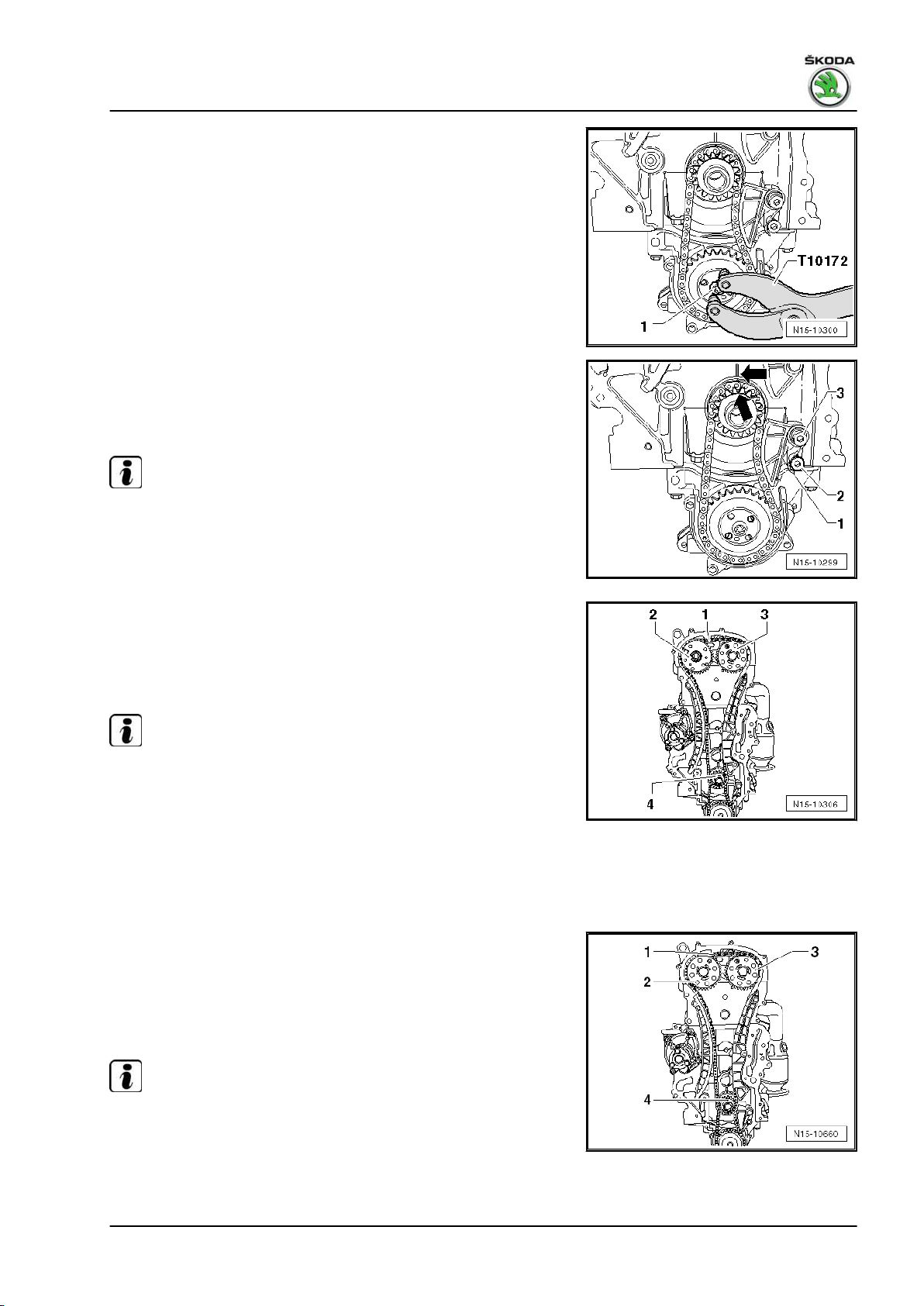

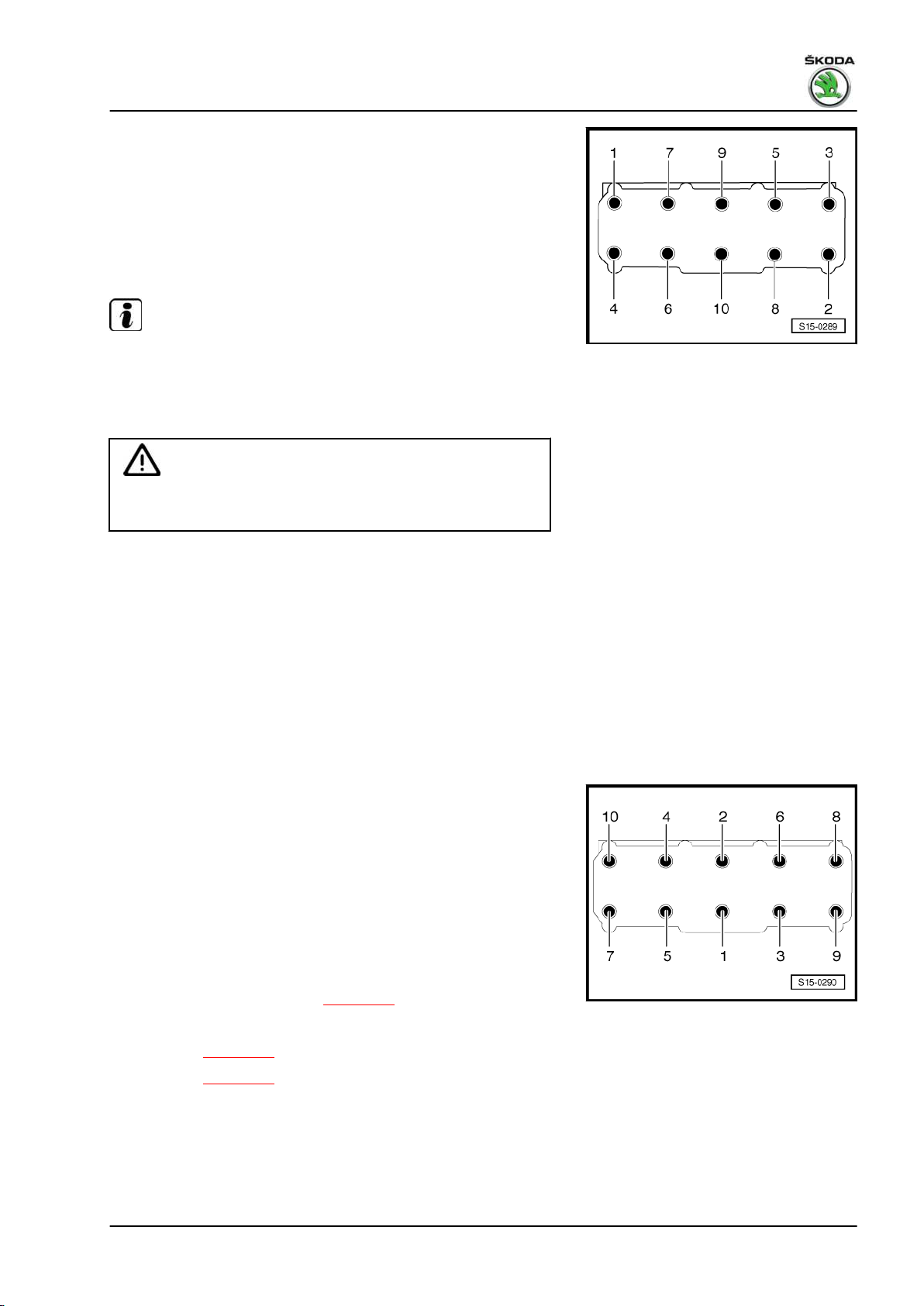

1.4 Assembly bracket

Note

♦

During installation, first insert all bolts for the bearing and tight‐

en by hand at least 2 - 3 turns.

♦

Tighten screws for bracket in the sequence according to the

numerical marking in the figures.

1.4.1 Tightening torques

Assembly bracket - engine, version 1

1 - 20 Nm + torque a further 90° (1/4 turn) - replace

2 - 30 Nm + torque a further 90° (1/4 turn) - replace

Assembly bracket - engine, version 2

1 - 20 Nm + torque a further 90° (1/4 turn) - replace

2 - 30 Nm + torque a further 90° (1/4 turn) - replace

3 - 16 Nm

14 Rep. gr.10 - Removing and installing engine

Page 21

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

Assembly bracket - gearbox

Note

Śruby -1- dokręcić w następującej kolejności: od tyłu, z przodu,

następnie od góry.

1 - 50 Nm + torque a further 90° (1/4 turn) - replace

2 - 40 Nm + torque a further 90° (1/4 turn) - replace

Pendulum support

Note

Before tightening the screws -1- press off gearbox in the elonga‐

ted holes of the pendulum support to the front in such a way that

there is maximum distance between the gearbox and the assem‐

bly carrier.

1 - 30 Nm + torque a further 90° (1/4 turn) - replace

2 - 40 Nm + torque a further 90° (1/4 turn) - replace

1. Removing and installing engine 15

Page 22

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

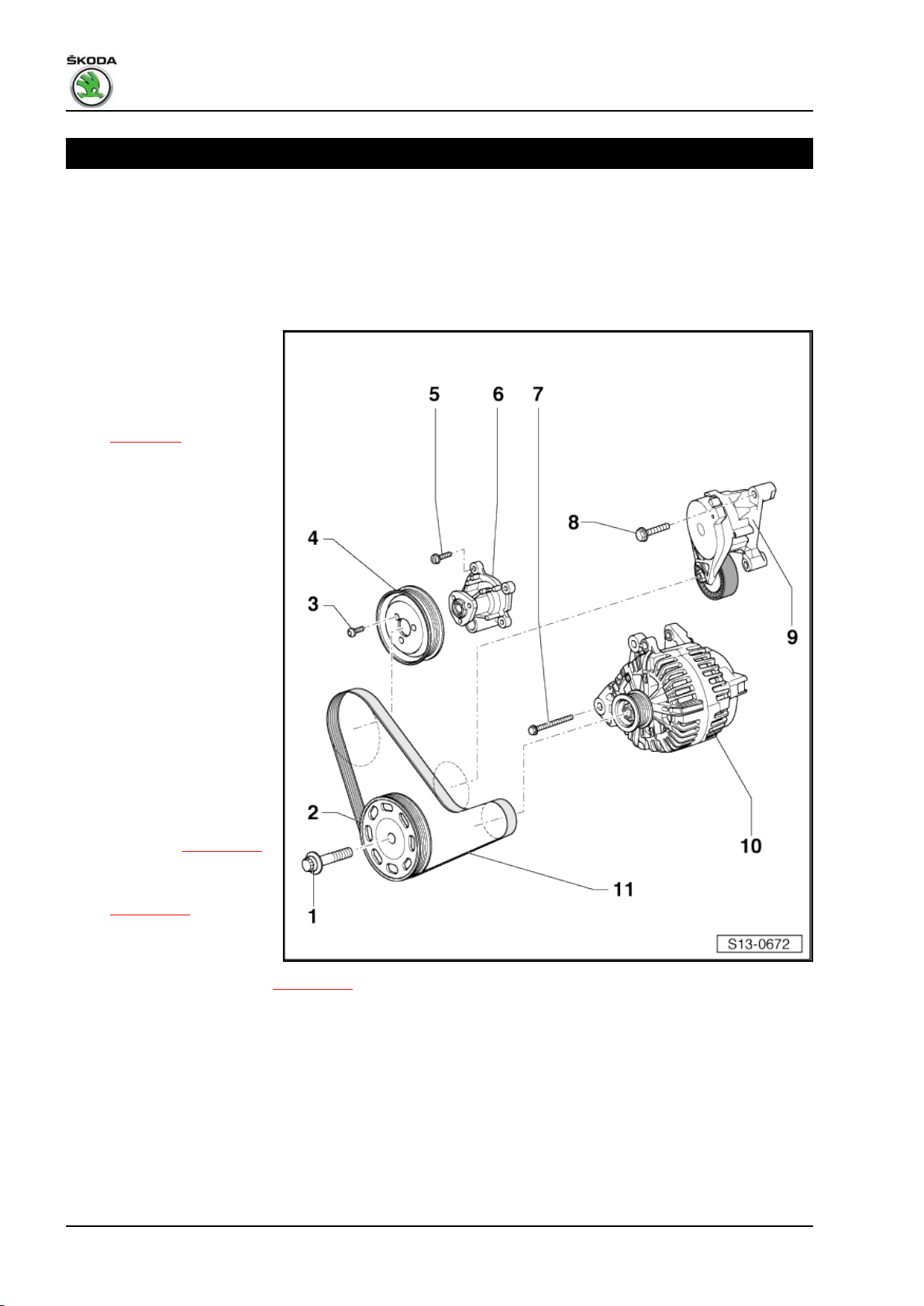

13 – Crankshaft group

1 Cylinder block - Belt pulley side

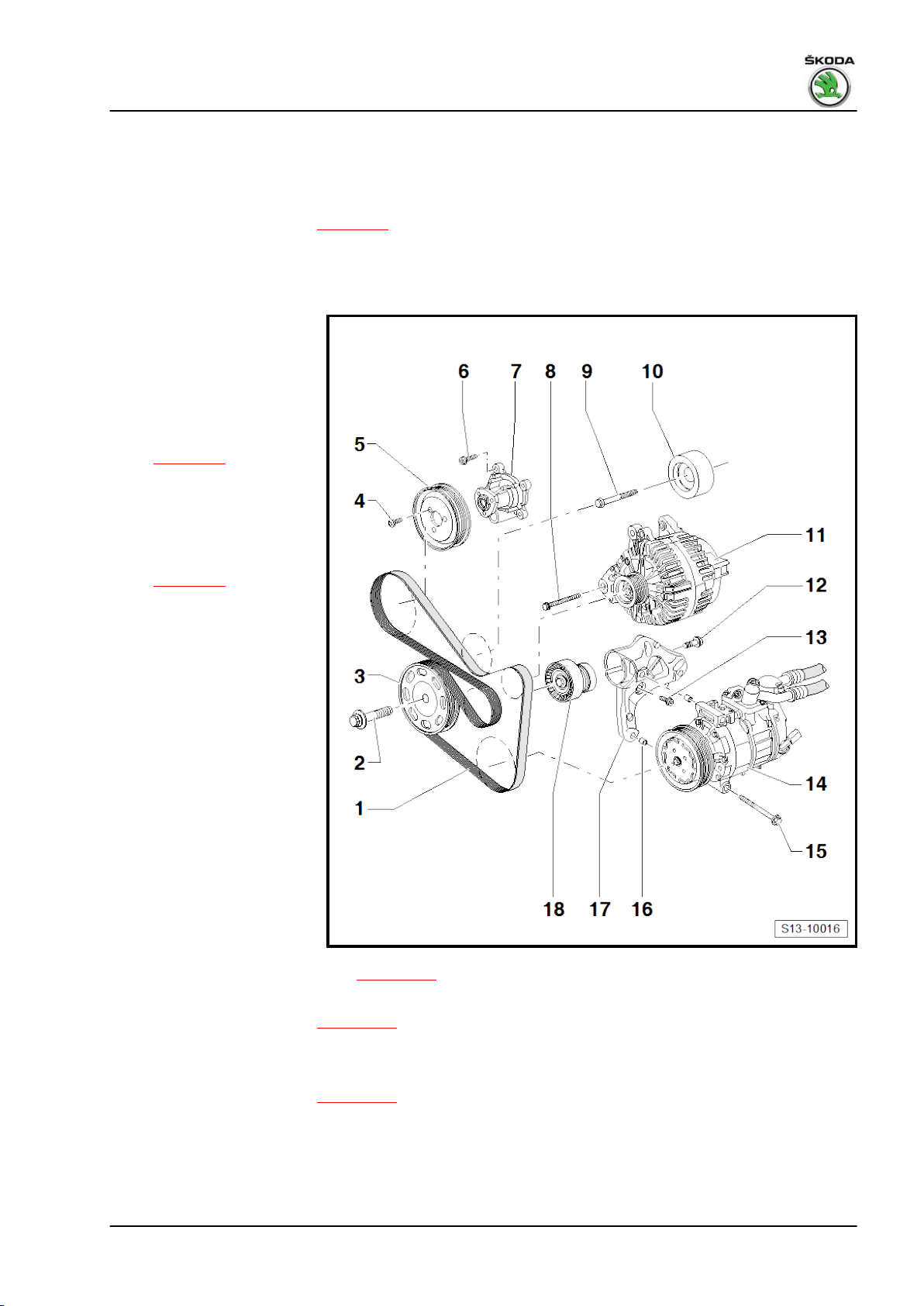

1.1 V-ribbed belt drive - Summary of components

Vehicles without air conditioning

1 - Fixing screw

❑ replace

❑ pay attention to different

version

❑ order of tightening

⇒ page 33

❑ The clamping surface of

the fixing screw must be

free of grease and oil.

❑ When loosening and

tightening counterhold

the belt pulley with the

counterholder - T30004

(3415)- with bolts T30004/1 (3415/1)- .

2 - Crankshaft-belt pulley

❑ Clamping surfaces must

be free of oil and grease.

3 - 20 Nm

❑ When loosening and

tightening, counterhold

with adapted wrench for

the water pump and

power-assisted steering

- MP1-308- .

❑ Adapt wrench for the

water pump and powerassisted steering MP1-308- ⇒ page 123

4 - Belt pulley for coolant pump

❑ removing and installing

⇒ page 123

5 - 10 Nm

6 - Coolant pump

❑ removing and installing ⇒ page 123

7 - 25 Nm

8 - 23 Nm

9 - Tensioning pulley

❑ swivel tensioning device for V-ribbed belt with open-end wrench to slacken the V-ribbed belt

❑ can be interlocked in released position with locating pin - T10060- or 4 mm hexagon socket wrench.

10 - Generator

❑ removing and installing ⇒ Electrical System; Rep. gr. 27

❑ to facilitate positioning, drive the threaded bushings of the retaining screws at the generator slightly

backwards

16 Rep. gr.13 - Crankshaft group

Page 23

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

11 - V-ribbed belt

❑ mark the direction of rotation with chalk or a felt-tip pen before removing

❑ check for wear

❑ do not kink

❑ removing and installing ⇒ page 18

Vehicles with air conditioning

1 - V-ribbed belt

❑ mark the direction of ro‐

tation with chalk or a felt-

tip pen before removing

❑ check for wear

❑ do not kink

❑ removing and installing

⇒ page 18

2 - Fixing screw

❑ replace

❑ pay attention to different

version

❑ order of tightening

⇒ page 33

❑ The clamping surface of

the fixing screw must be

free of grease and oil.

❑ When loosening and

tightening counterhold

the belt pulley with the

counterholder - T30004

(3415)- with bolts -

T30004/1 (3415/1)- .

3 - Crankshaft-belt pulley

❑ Clamping surfaces must

be free of oil and grease.

4 - 20 Nm

❑ When loosening and

tightening, counterhold

with adapted wrench for

the water pump and

power-assisted steering

- MP1-308- .

❑ Adapt wrench for the

water pump and power-

assisted steering - MP1-308- ⇒ page 123

5 - Belt pulley for coolant pump

❑ removing and installing ⇒ page 123

6 - 10 Nm

7 - Coolant pump

❑ removing and installing ⇒ page 123

1. Cylinder block - Belt pulley side 17

Page 24

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

8 - 25 Nm

9 - 40 Nm

10 - Guide pulley

11 - Generator

❑ removing and installing ⇒ Electrical System; Rep. gr. 27

❑ to facilitate positioning, drive the threaded bushings of the retaining screws at the generator slightly

backwards

12 - 20 Nm + torque a further 90° (1/4 turn)

❑ replace

13 - 25 Nm

14 - AC compressor

❑ removing and installing ⇒ Air conditioning; Rep. gr. 87

15 - 25 Nm

16 - Fitting sleeve

17 - Bracket for AC compressor

18 - Tensioning pulley

❑ swivel with ring spanner to slacken the belt

❑ secure in the untensioned position with locking pin - T10060A- or 4 mm external hex socket

❑ to remove, release screw -Pos. 12-

1.2 Removing and installing V-ribbed belt

Special tools and workshop equipment required

♦ Locking pin - T10060A- or 4 mm hexagon wrench

Removing

– Mark the rotation direction of the V-ribbed belt.

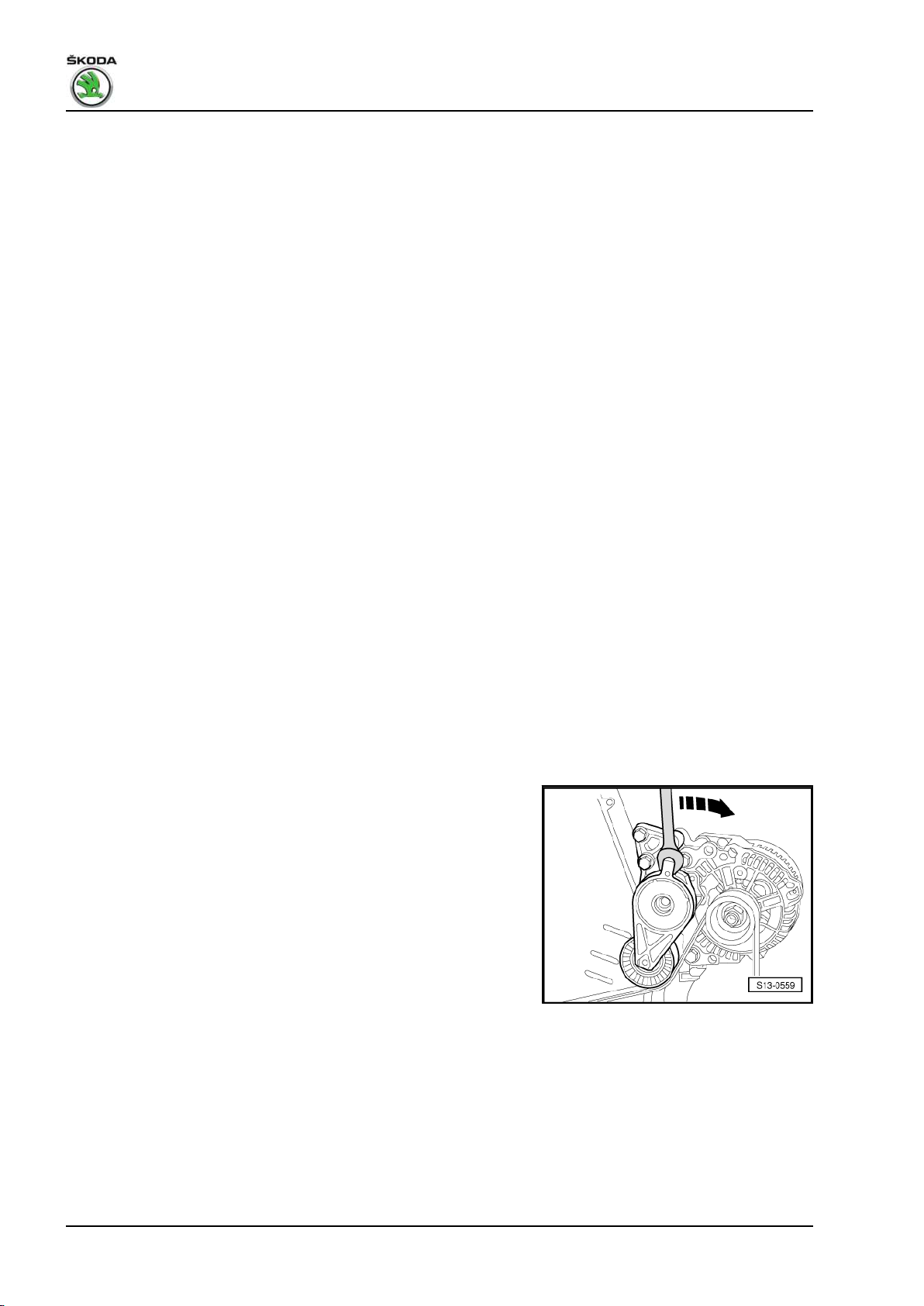

Vehicles without air conditioning

– Swivel tensioning pulley with an open-end wrench in

-direction of arrow-.

18 Rep. gr.13 - Crankshaft group

Page 25

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

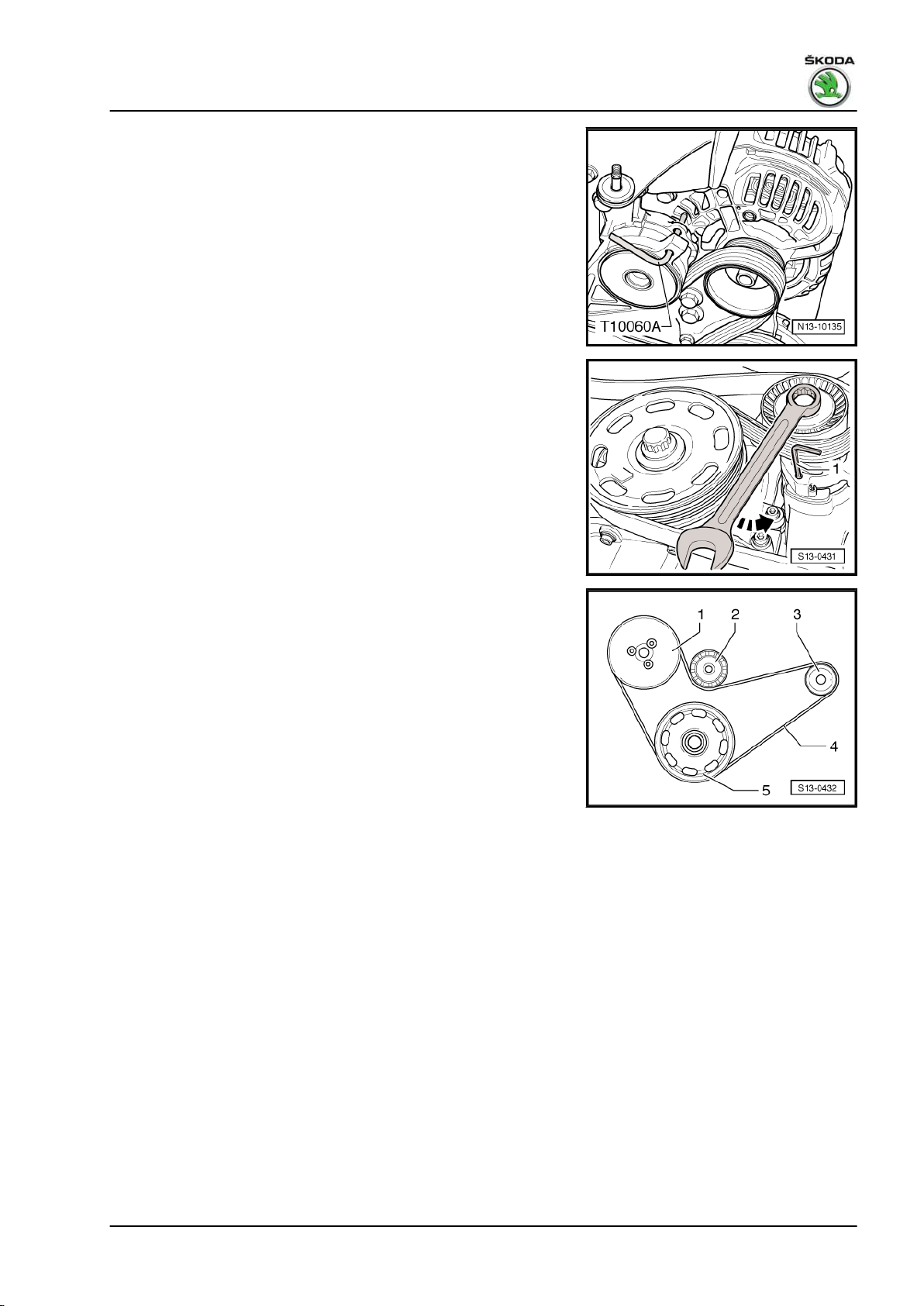

– Lock the tensioning pulley with the locking pin -T10060A- or

with the 4 mm hexagon wrench.

Vehicles with air conditioning

– Swivel tensioning pulley with an open-end wrench in

-direction of arrow-.

– Lock the tensioning pulley with the locking pin -T10060A- or

with the 4 mm hexagon wrench -1-.

Continued for all vehicles

– Remove the release ribbed V-belt.

Install

Installation is performed in the reverse order, pay attention to the

following points:

Routing of the ribbed V-belt - Vehicles without air conditioning

1 - Belt pulley for coolant pump

2 - Tensioning pulley

3 - Belt pulley for AC generator

4 - V-ribbed belt

5 - Crankshaft-belt pulley

1. Cylinder block - Belt pulley side 19

Page 26

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

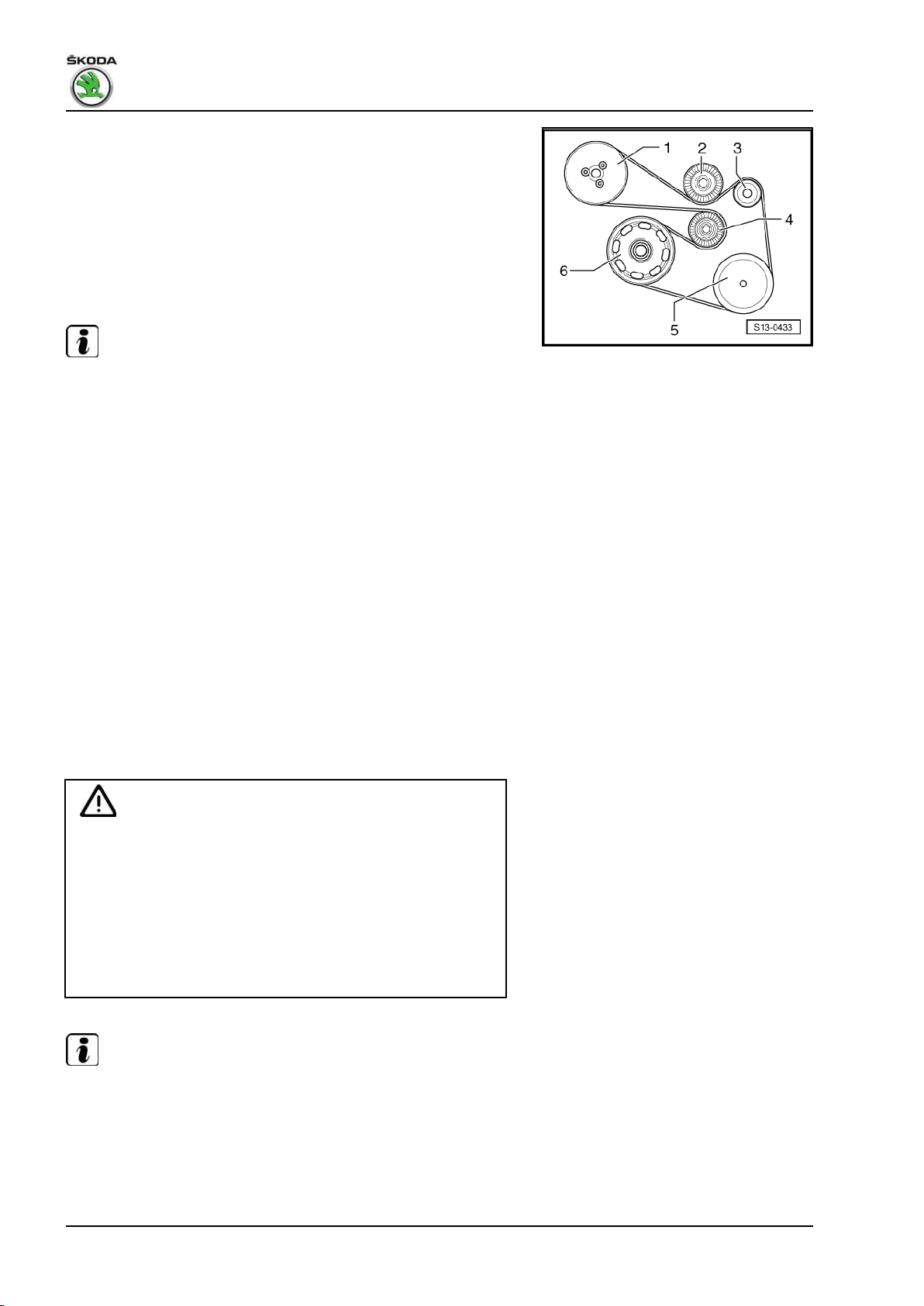

Routing of the ribbed V-belt - Vehicles with air conditioning

1 - Belt pulley for coolant pump

2 - Guide pulley

3 - Belt pulley for AC generator

4 - Tensioning pulley

5 - Belt pulley for AC compressor

6 - Crankshaft-belt pulley

Note

♦

Before fitting the V-ribbed belt make sure that all assemblies

(generator, coolant pump, if necessary AC compressor) belt

pulleys, tensioning and guide rollers are securely mounted.

♦

Replace damaged V-ribbed belt.

♦

If the belt is considerably worn it must be replaced.

♦

Do not bend or buckle the belt!

♦

Pay attention to the correct position and rotation direction of

the V-ribbed belt in the belt pulley and rollers when installing

it.

– Lay the V-ribbed belt on the crankshaft belt pulley. Finally lay

the V-ribbed belt on the tensioning pulley.

– Check correct positioning of the ribbed V-belt on the belt pul‐

leys.

– Start engine and check ribbed V-belt run.

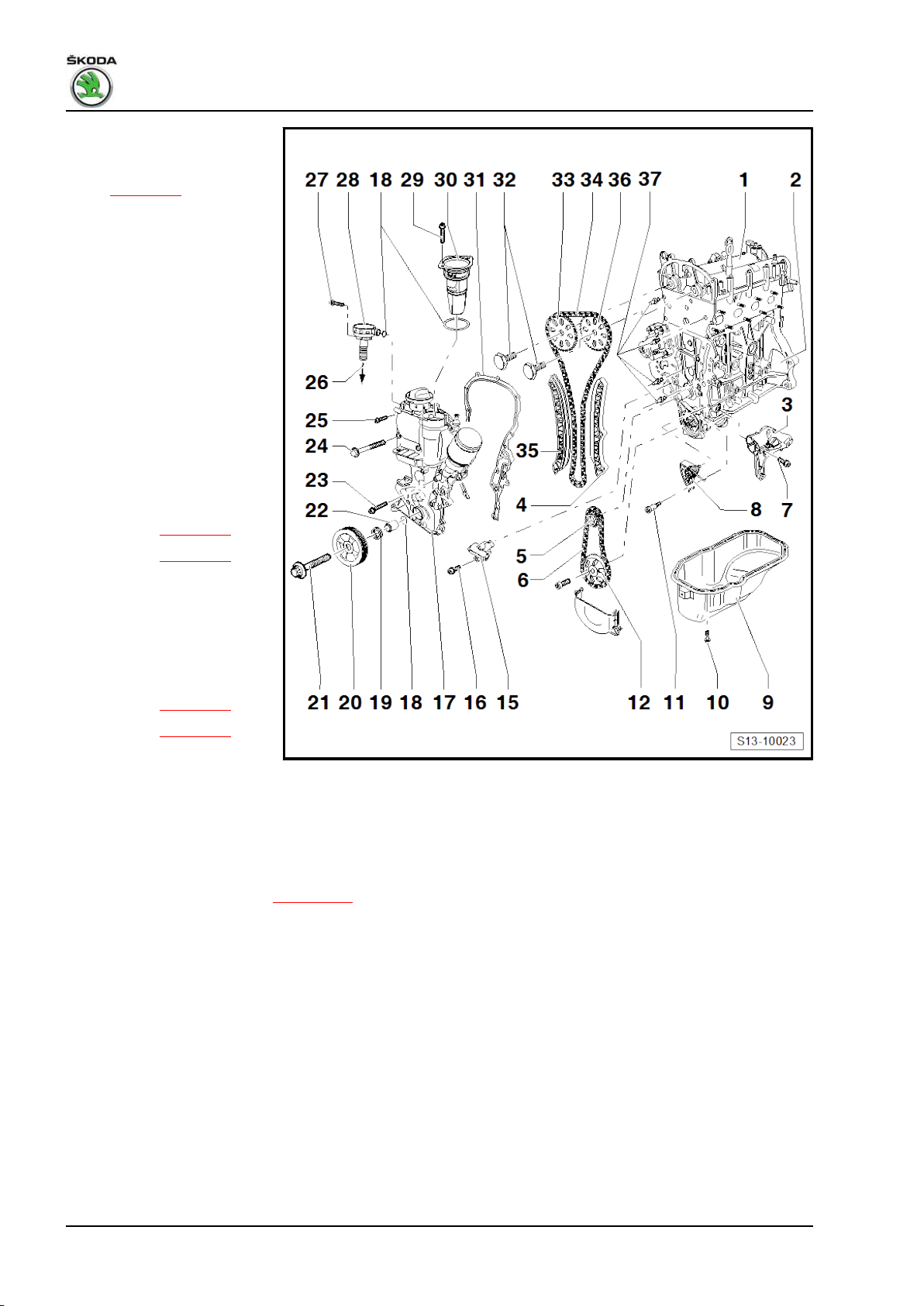

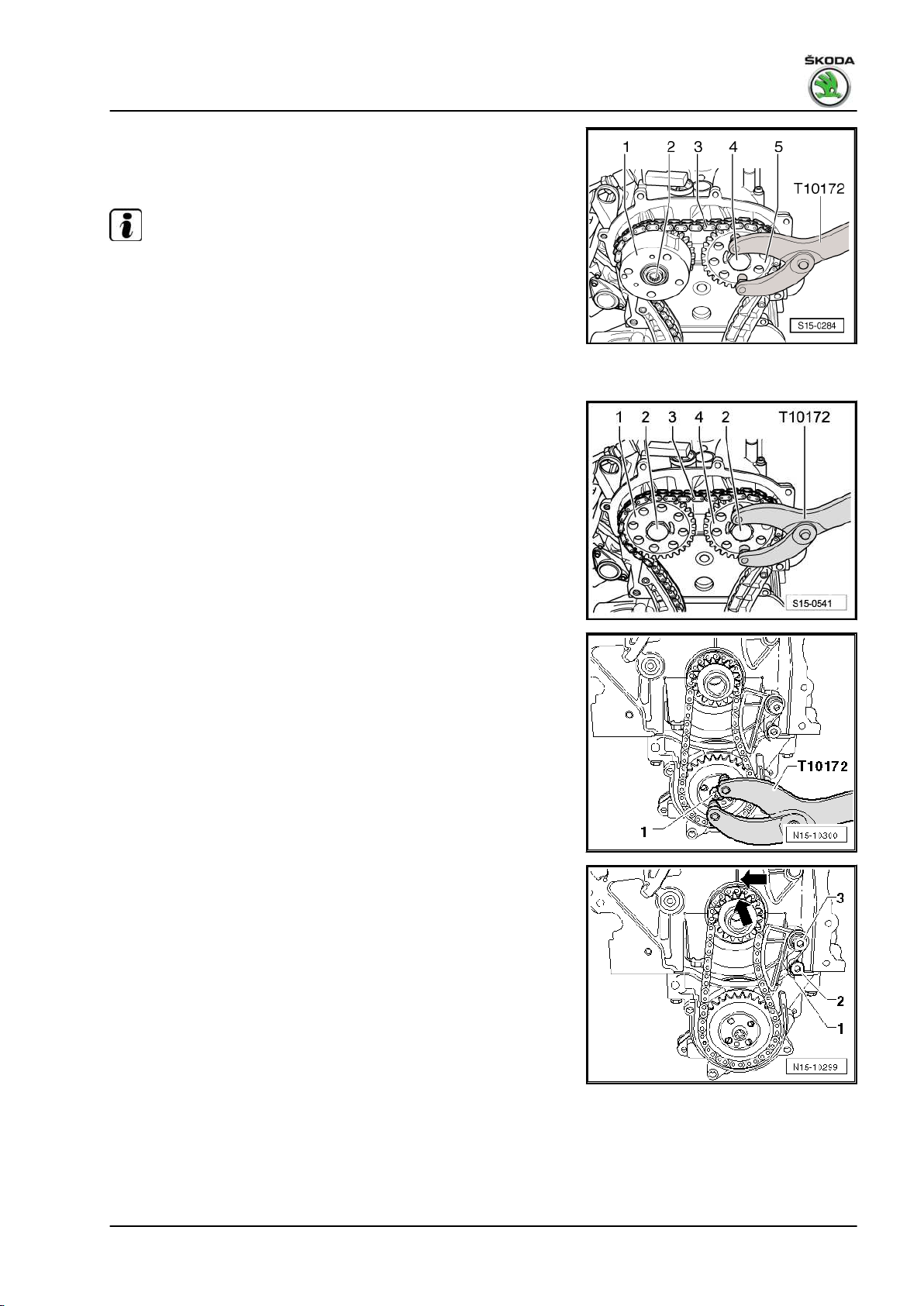

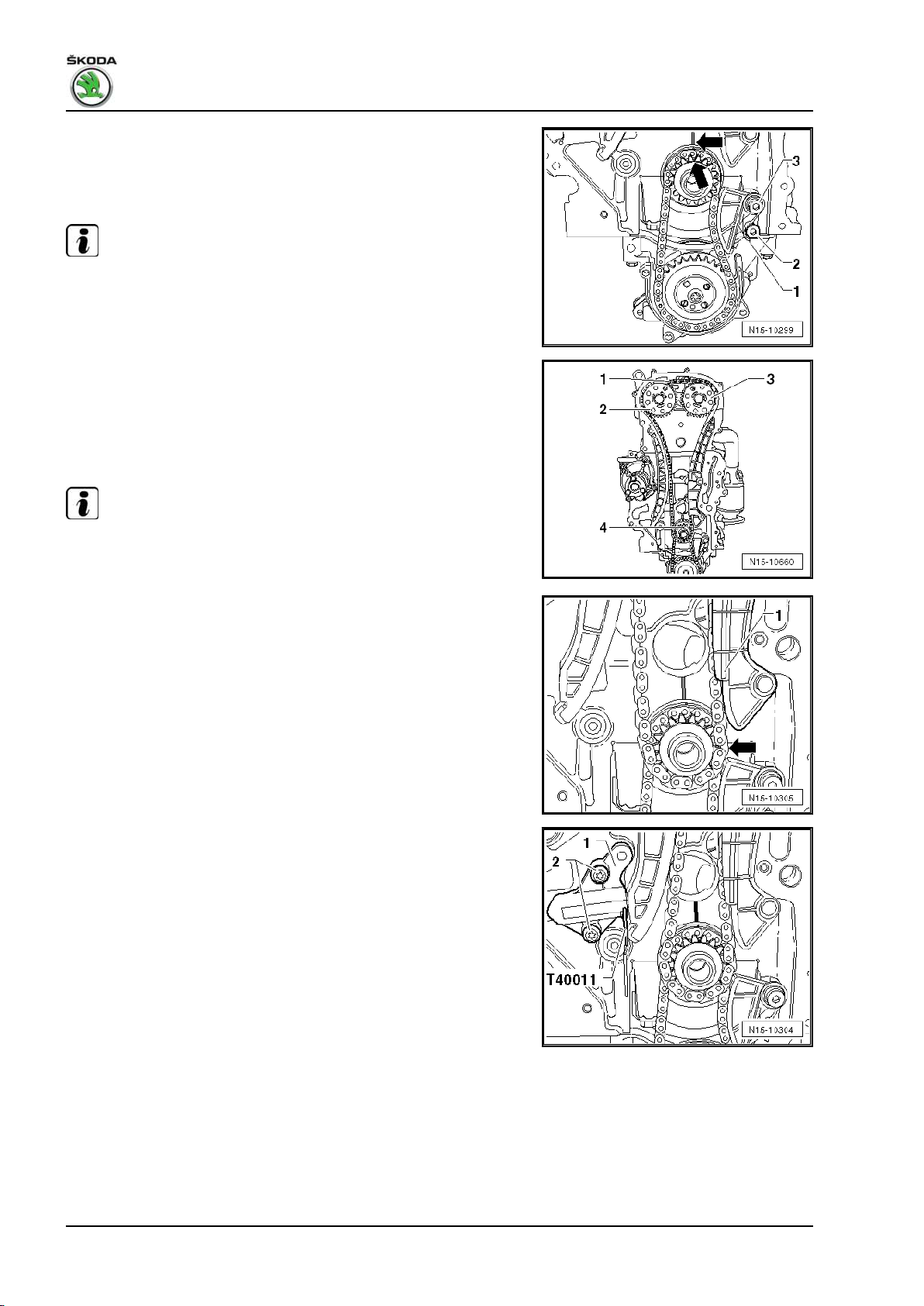

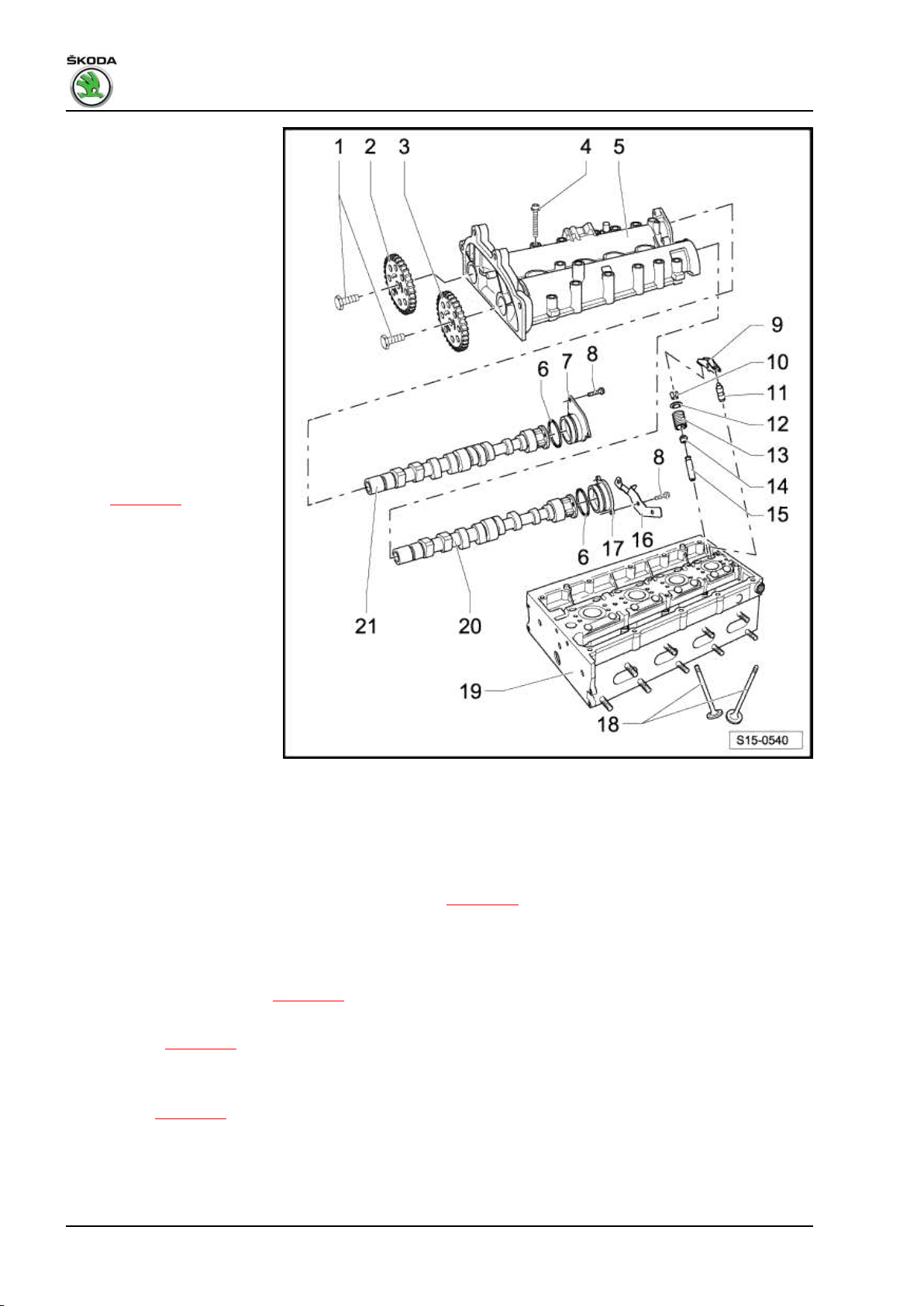

1.3 Camshaft drive - Summary of compo‐

nents

For engine with identification characters BTS

Caution

If considerable quantities of metal swarf or abrasion is found

when carrying out engine repairs, this can be subject to dam‐

age to the crankshaft and conrod bearings. In order to avoid

consequential damage, after the repair perform the following

tasks:

Carefully clean the oil galleries.

Replace engine oil cooler.

Replace oil filter element.

Note

Before assembly oil all bearing and contact surfaces.

20 Rep. gr.13 - Crankshaft group

Page 27

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

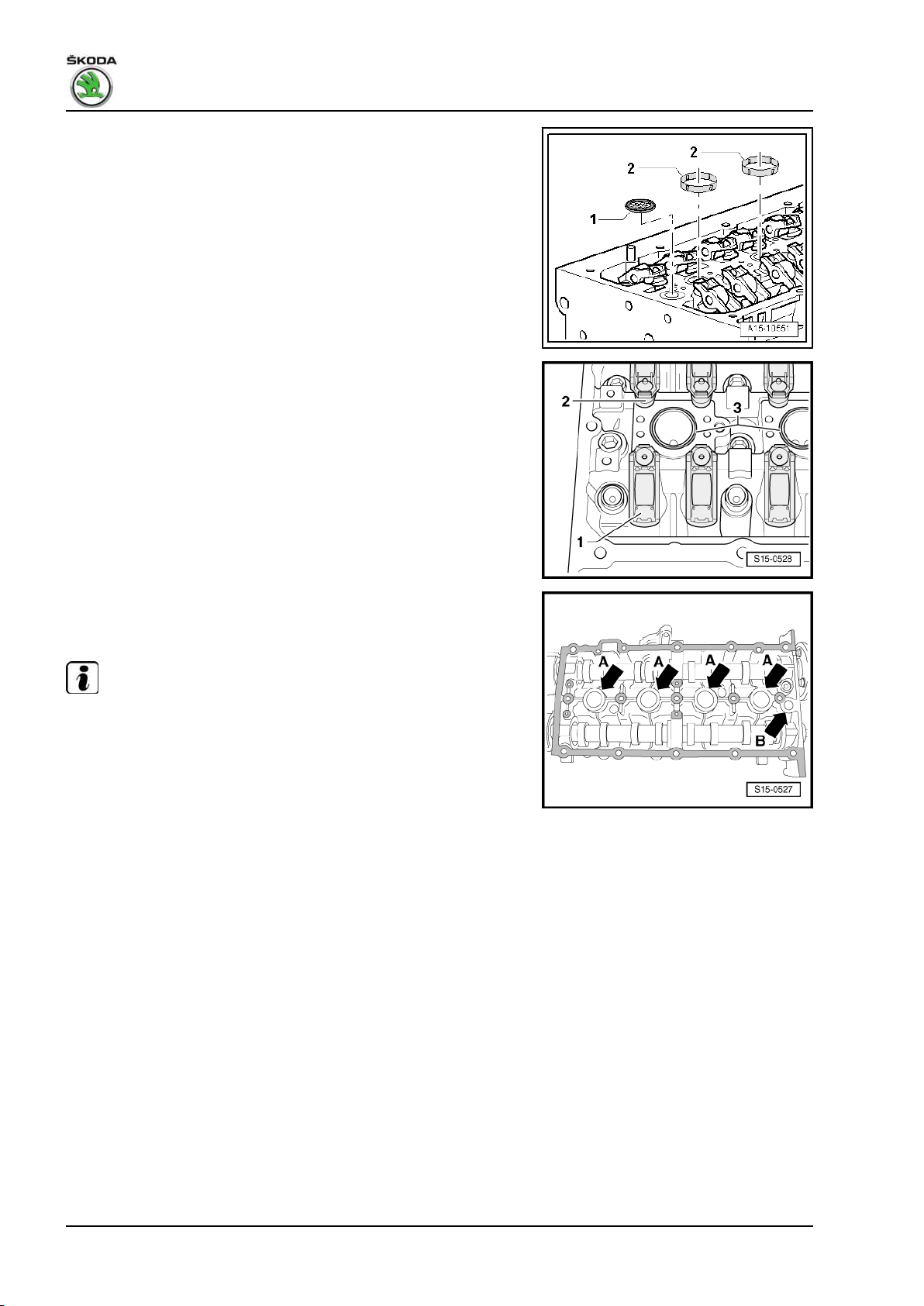

1 - Cylinder head with cam‐

shaft housing

❑ removing and installing

⇒ page 83

❑ Camshaft housing with

integrated camshaft

bearings

2 - Cylinder block

3 - Support

❑ for tensioning pully and

AC compressor

4 - Sliding rail

❑ for timing chain

5 - Sprocket

❑ for oil pump drive and

timing chain

❑ Clamping surfaces must

be free of oil and grease.

❑ removing and installing

⇒ page 67

6 - Drive chain

❑ for oil pump

❑ mark running direction

(installed position) be‐

fore removing

❑ removing and installing

⇒ page 67

7 - 25 Nm

8 - Chain tensioner with ten‐

sioning rail and tensioning

spring

❑ for oil pump drive

❑ Tightening torque: 15 Nm

❑ only be replaced as a complete unit

9 - Oil pan

❑ removing and installing ⇒ page 105

10 - 13 Nm

11 - 15 Nm

12 - Sprocket

❑ for oil pump

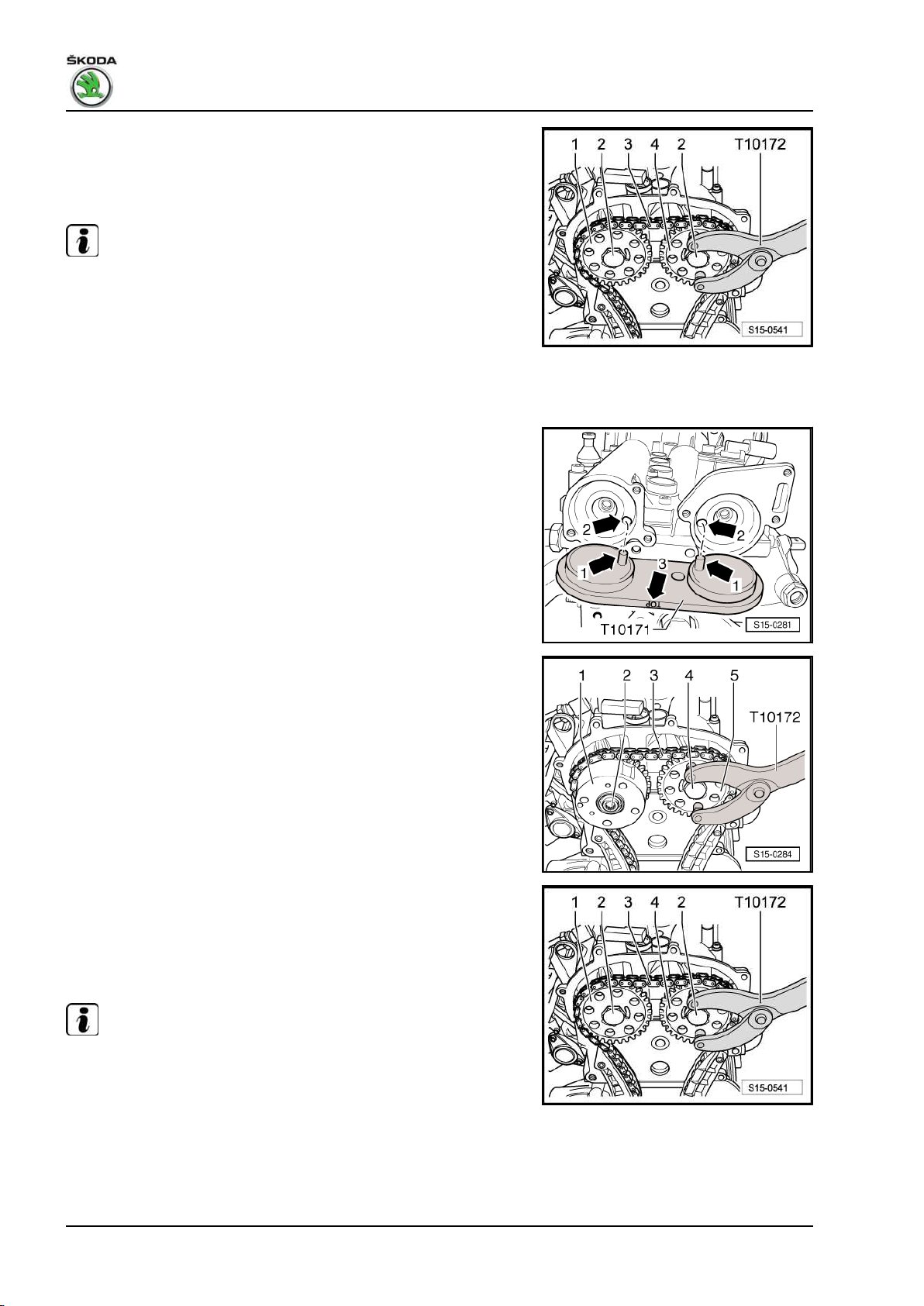

❑ Counterhold sprocket with counterholder - T1017213 - Cover

1.6/77 kW MPI engine - Edition 03.2014

14 - 20 Nm + torque a further 90° (1/4 turn)

❑ replace

15 - Chain tensioner

❑ for timing chain

16 - 9 Nm

17 - Timing case

❑ removing and installing ⇒ page 26

❑ to facilitate installation, screw two pin screws -M6 x 80- into the camshaft housing and the cylinder block

1. Cylinder block - Belt pulley side 21

Page 28

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

❑ to better guide the timing case, position the oil pan with two screws

18 - O-ring

❑ replace

❑ in the spacer sleeve -Position 19-

19 - Spacer sleeve

❑ Clamping surfaces must be free of oil and grease.

❑ Fitting position ⇒ page 34

❑ install with new O-ring -Position 18-

20 - Crankshaft-belt pulley

❑ Clamping surfaces must be free of oil and grease.

❑ Removing and installing V-ribbed belt ⇒ page 18

21 - Fixing screw

❑ for crankshaft - belt pulley

❑ replace

❑ The clamping surface of the fixing screw must be free of grease and oil.

❑ insert oiled (thread)

❑ tighten ⇒ page 33

22 - Gasket ring for crankshaft in timing case

❑ replace

❑ replace ⇒ page 32

23 - 10 Nm

❑ M6 x 45mm

24 - 50 Nm

25 - 10 Nm

❑ M6 x 22 mm

❑ insert using locking agent - D 000 600 A226 - To intake manifold

27 - 10 Nm

28 - The vacuum regulating valve (PCV valve)

❑ with ventilation hose

29 - 10 Nm

30 - Oil separator

31 - Gasket

❑ replace

32 - 40 Nm + torque a further 90° (1/4 turn)

❑ replace

❑ Screw with left-hand thread

❑ Counterhold camshaft adjuster with counterholder - T10172-

33 - 50 Nm + torque a further 90° (1/4 turn)

❑ replace

❑ Counterhold sprocket with counterholder - T1017234 - Camshaft adjuster

❑ must not be disassembled

❑ removing and installing ⇒ page 67

22 Rep. gr.13 - Crankshaft group

Page 29

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

35 - Tensioning rail

36 - Timing chain

❑ removing and installing ⇒ page 67

37 - Sprocket

❑ for exhaust camshaft

❑ removing and installing ⇒ page 67

38 - Guide bushing

39 - Guide bolt

❑ Tightening torque: 18 Nm

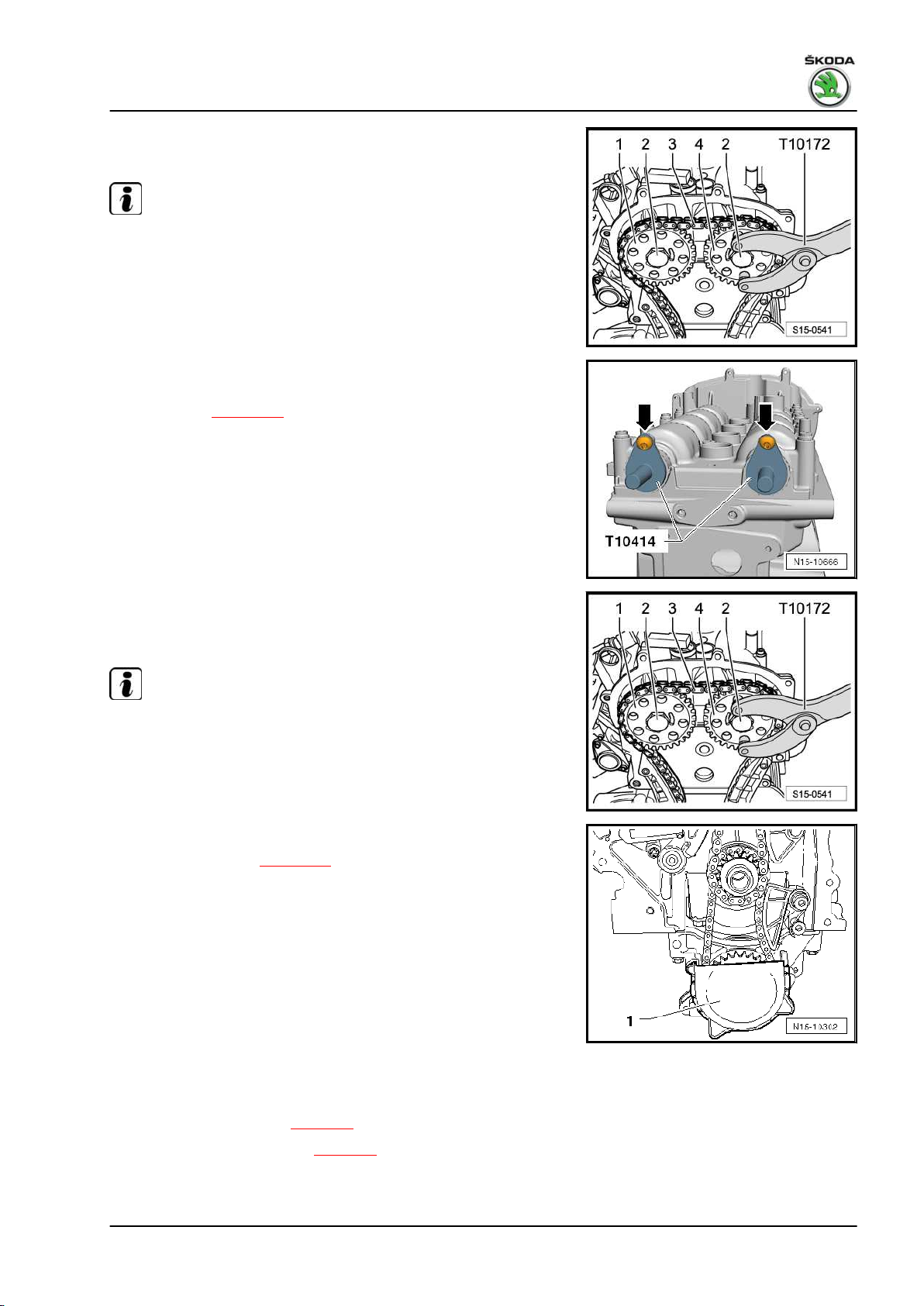

1.4 Camshaft drive - Summary of compo‐

nents

For engines with identification characters CFNA and CLSA

Caution

If considerable quantities of metal swarf or abrasion is found

when carrying out engine repairs, this can be subject to dam‐

age to the crankshaft and conrod bearings. In order to avoid

consequential damage, after the repair perform the following

tasks:

1.6/77 kW MPI engine - Edition 03.2014

Carefully clean the oil galleries.

Replace engine oil cooler.

Replace oil filter element.

Note

Before assembly oil all bearing and contact surfaces.

1. Cylinder block - Belt pulley side 23

Page 30

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

1 - Cylinder head with cam‐

shaft housing

❑ removing and installing

⇒ page 83

❑ Camshaft housing with

integrated camshaft

bearings

2 - Cylinder block

3 - Support

❑ for tensioning pully and

AC compressor

4 - Sliding rail

❑ for timing chain

5 - Sprocket

❑ for oil pump drive and

timing chain

❑ Clamping surfaces must

be free of oil and grease.

❑ removing and installing:

♦ Version A ⇒ page 67

♦ Version B ⇒ page 73

6 - Drive chain

❑ for oil pump

❑ mark running direction

(installed position) be‐

fore removing

❑ removing and installing:

♦ Version A ⇒ page 67

♦ Version B ⇒ page 73

7 - 25 Nm

8 - Chain tensioner with tensioning rail and tensioning spring

❑ for oil pump drive

❑ Tightening torque: 15 Nm

❑ only be replaced as a complete unit

9 - Oil pan

❑ removing and installing ⇒ page 105

10 - 13 Nm

11 - 15 Nm

12 - Sprocket

❑ for oil pump

❑ Counterhold sprocket with counterholder - T1017213 - Cover

14 - 20 Nm + torque a further 90° (1/4 turn)

❑ replace

15 - Chain tensioner

❑ for timing chain

24 Rep. gr.13 - Crankshaft group

Page 31

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

16 - 9 Nm

17 - Timing case

❑ Illustration for engine with identification characters CFNA

❑ The illustration of the housing for engine with identification characters CLSA is identical to the illustration

for engine with identification characters BTS

❑ removing and installing ⇒ page 26

❑ to facilitate installation, screw two pin screws -M6 x 80- into the camshaft housing and the cylinder block

❑ to better guide the timing case, position the oil pan with two screws

18 - O-ring

❑ replace

❑ in the spacer sleeve -Position 22-

19 - Gasket ring for crankshaft in timing case

❑ replace

❑ replace ⇒ page 32

20 - Crankshaft-belt pulley

❑ Clamping surfaces must be free of oil and grease.

❑ Removing and installing V-ribbed belt ⇒ page 18

21 - Fixing screw

❑ for crankshaft - belt pulley

❑ replace

❑ The clamping surface of the fixing screw must be free of grease and oil.

❑ insert oiled (thread)

❑ tighten ⇒ page 33

22 - Spacer sleeve

❑ Clamping surfaces must be free of oil and grease.

❑ Fitting position ⇒ page 34

❑ install with new O-ring -Position 18-

23 - 10 Nm

❑ M6 x 45 mm

24 - 50 Nm

25 - 10 Nm

❑ M6 x 22 mm

❑ insert using locking agent - D 000 600 A2-

26 - To intake manifold

27 - 10 Nm

28 - The vacuum regulating valve (PCV valve)

❑ with ventilation hose

29 - 10 Nm

30 - Oil separator

31 - Gasket

❑ replace

32 - 50 Nm + torque a further 90° (1/4 turn)

❑ replace

❑ Counterhold sprocket with counterholder - T10172-

33 - Sprocket

❑ for inlet camshaft

1. Cylinder block - Belt pulley side 25

Page 32

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

❑ removing and installing:

♦ Version A ⇒ page 67

♦ Version B ⇒ page 73

34 - Timing chain

❑ removing and installing:

♦ Version A ⇒ page 67

♦ Version B ⇒ page 73

35 - Tensioning rail

36 - Sprocket

❑ for exhaust camshaft

❑ removing and installing:

♦ Version A ⇒ page 67

♦ Version B ⇒ page 73

37 - Guide bolt

❑ Tightening torque: 18 Nm

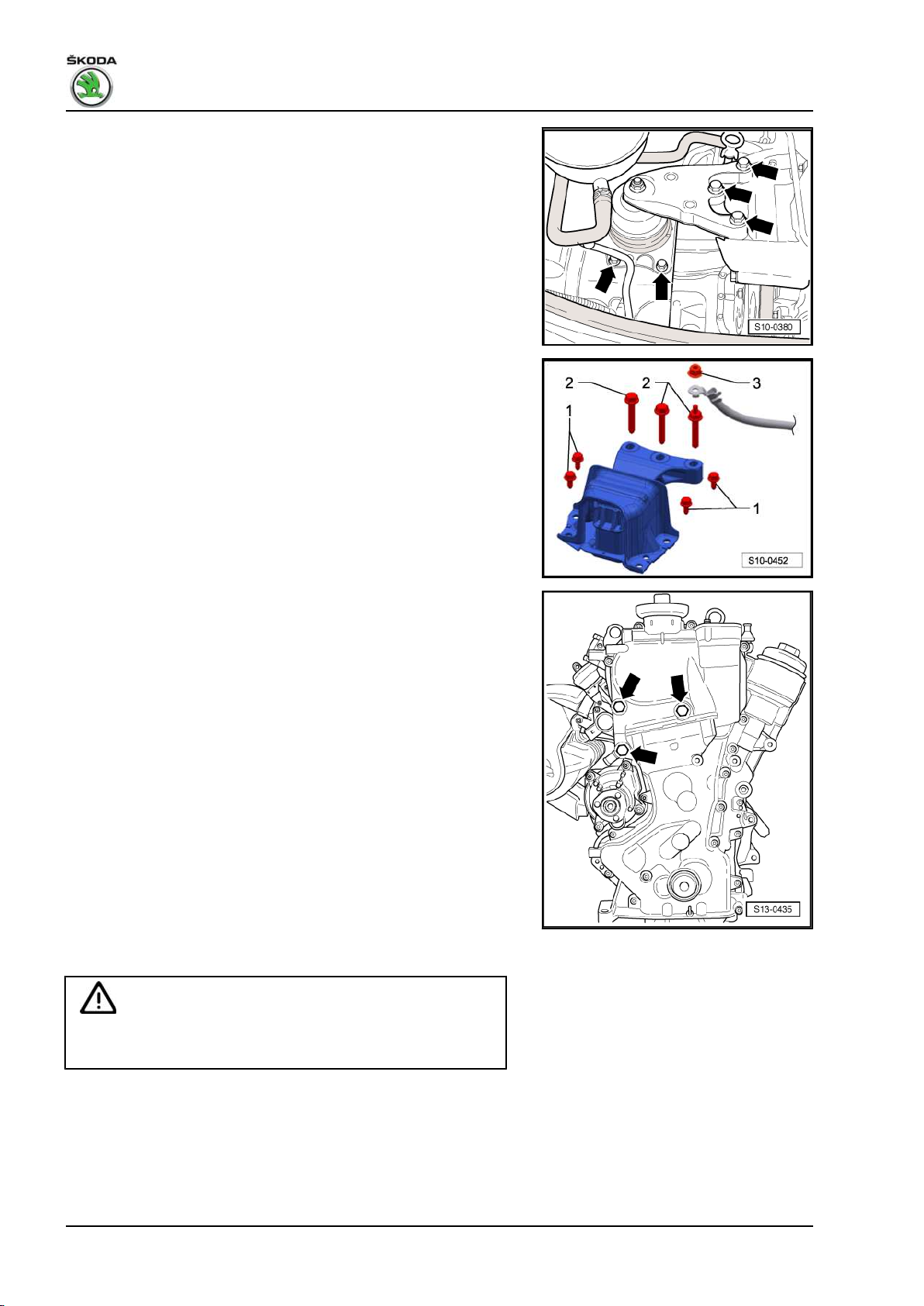

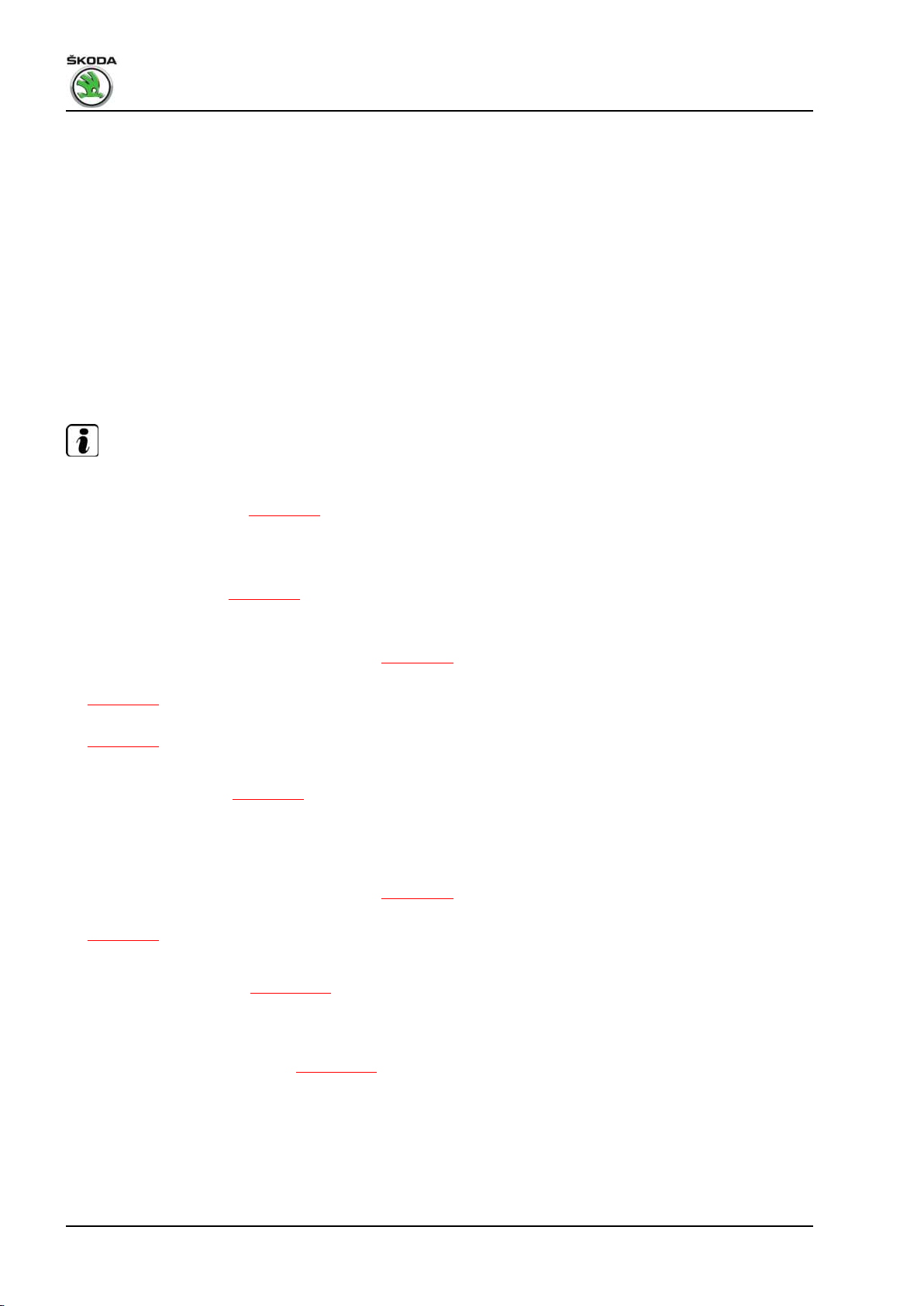

1.5 Removing and installing the timing case

Special tools and workshop equipment required

♦ Supporting device - MP9-200 (10-222A)♦ Counterholder - T30004 (3415)♦ Bolt - T30004/1 (3415/1)♦ Sealant remover gasket stripper (bearing code GST, bearing

article no. R 34402), manufacturer Retech s.r.o.

♦ Cleaning and degreasing agent , e.g. -D 009 401 04♦ Protective goggles and gloves

1.5.1 Removing

– Remove the air filter housing ⇒ page 161 .

– Unscrew vacuum regulating valve (PCV valve).

26 Rep. gr.13 - Crankshaft group

Page 33

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

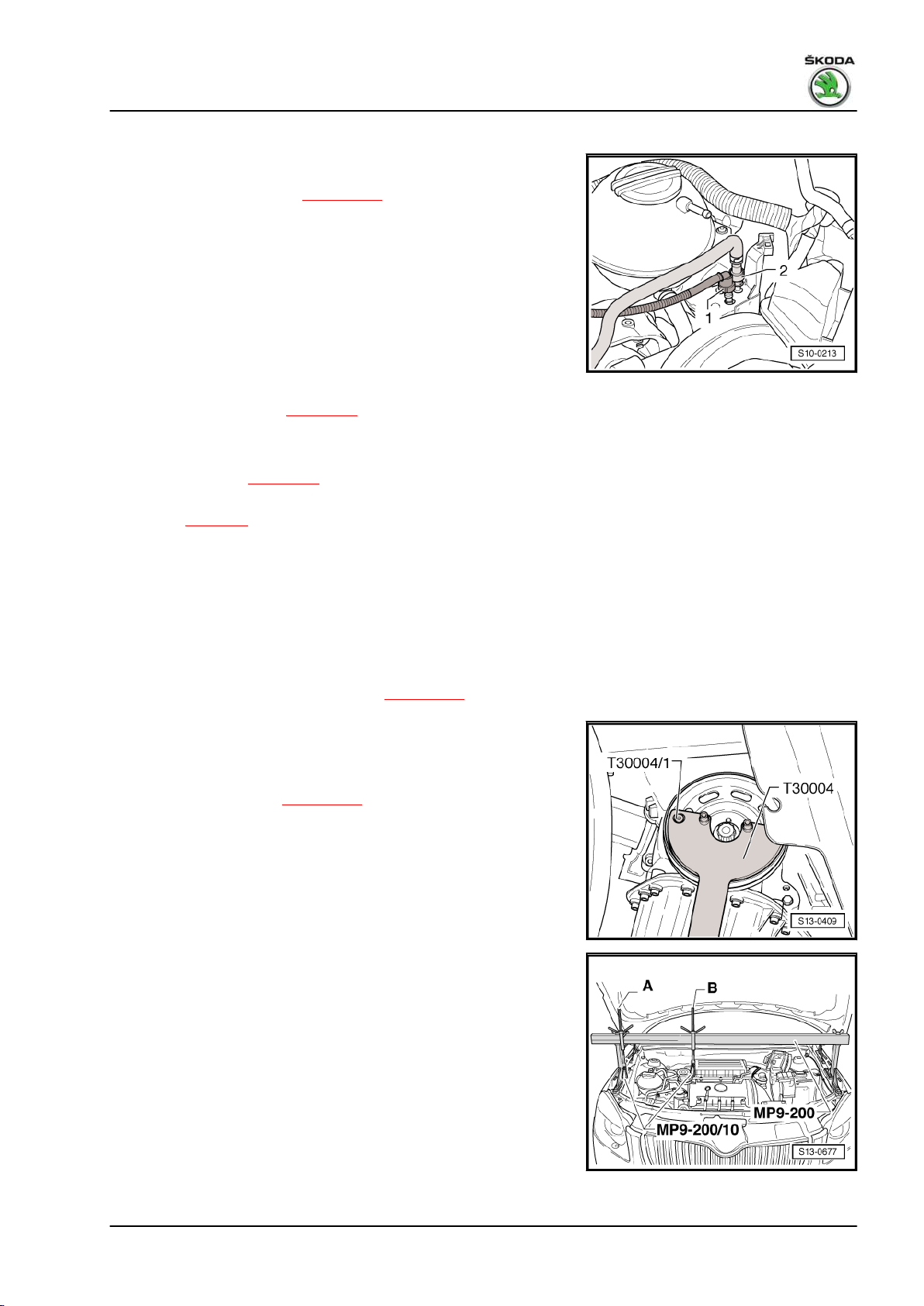

For vehicles Roomster

– Pull out the fuel feed line -2- (catch the fuel which flows out

with a cleaning cloth) and the vent line -1-. Unlock the quick

coupling and disconnect ⇒ page 138 .

– Remove activated charcoal filter and bracket.

Continued for all vehicles

– Remove the expansion reservoir and lay it to one side.

The coolant hoses remain connected.

– Remove the sound dampening system ⇒ Body Work; Rep.

gr. 50 .

– Remove the front right wheelhouse liner ⇒ Body Work; Rep.

gr. 66 .

– Remove V-ribbed belt ⇒ page 18 .

For vehicles with air conditioning

– Remove AC compressor with the refrigerant lines connected

from the bracket ⇒ page 16 .

Observe instructions for assembly work on the air-conditioning

system ⇒ page 5 .

– Remove holder for tensioning pulley and V-ribbed belt-guide

pulley.

For vehicles without air conditioning

– Remove tensioning pulley for V-ribbed belt.

Continued for all vehicles

– Remove alternator ⇒ Electrical System; Rep. gr. 27 .

– Remove belt pulley for control pump ⇒ page 123 .

– Remove crankshaft belt pulley.

Counterhold belt pulley with counterholder - T30004- with bolt

- T30004/1- .

– Removing the oil pan ⇒ page 105 .

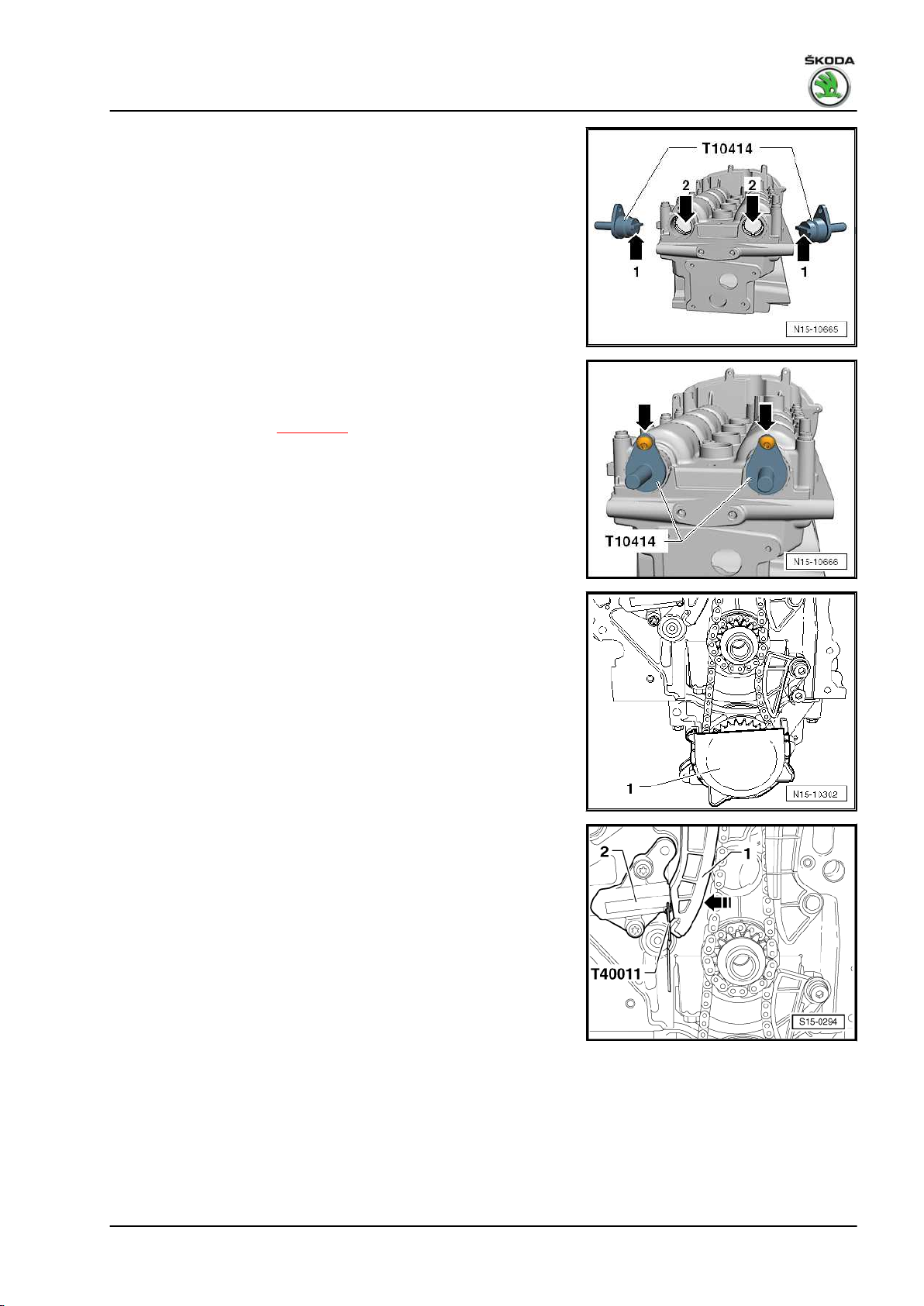

– Fit supporting device - MP9-200 (10-222A)- .

– Raise engine slightly via spindle -B-, allow spindle -A- to hang

loosely.

1. Cylinder block - Belt pulley side 27

Page 34

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

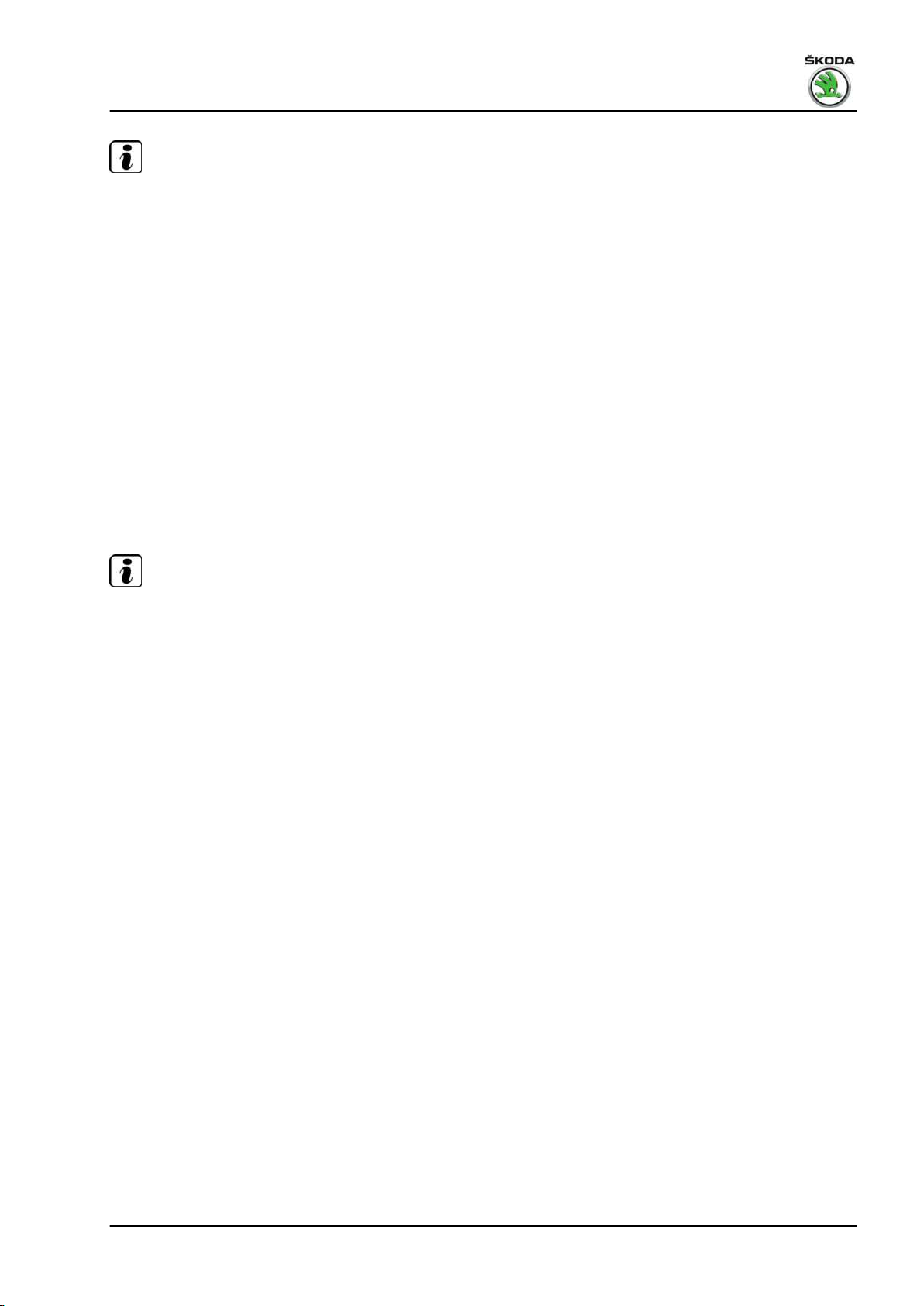

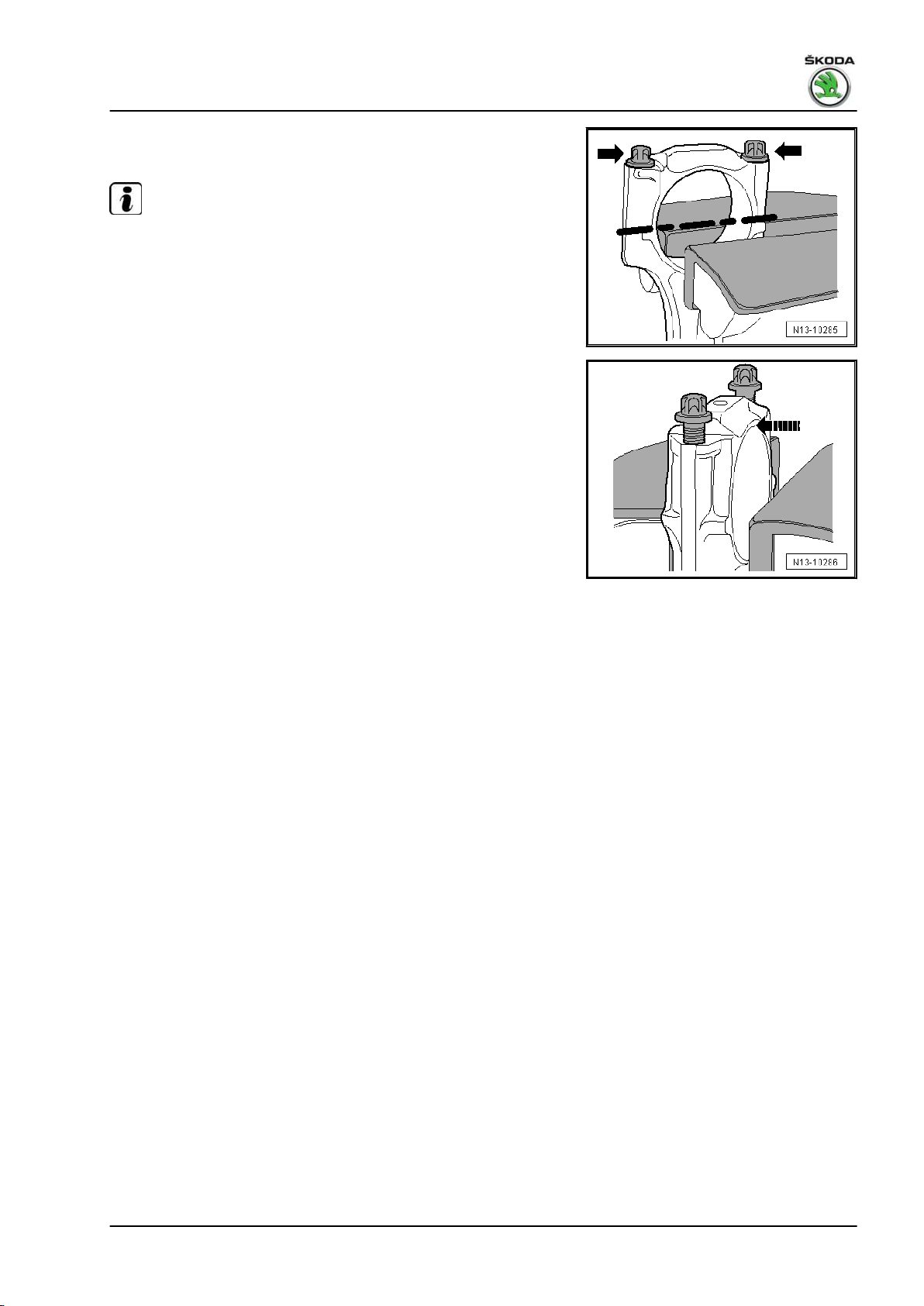

For vehicles with assembly bracket version 1

– Screw out screws -arrows- and remove engine mount.

For vehicles with assembly bracket version 2

– Unscrew nut -3- and disconnect earth lead from engine mount.

– Release screws -2 and 1- and remove engine mounting.

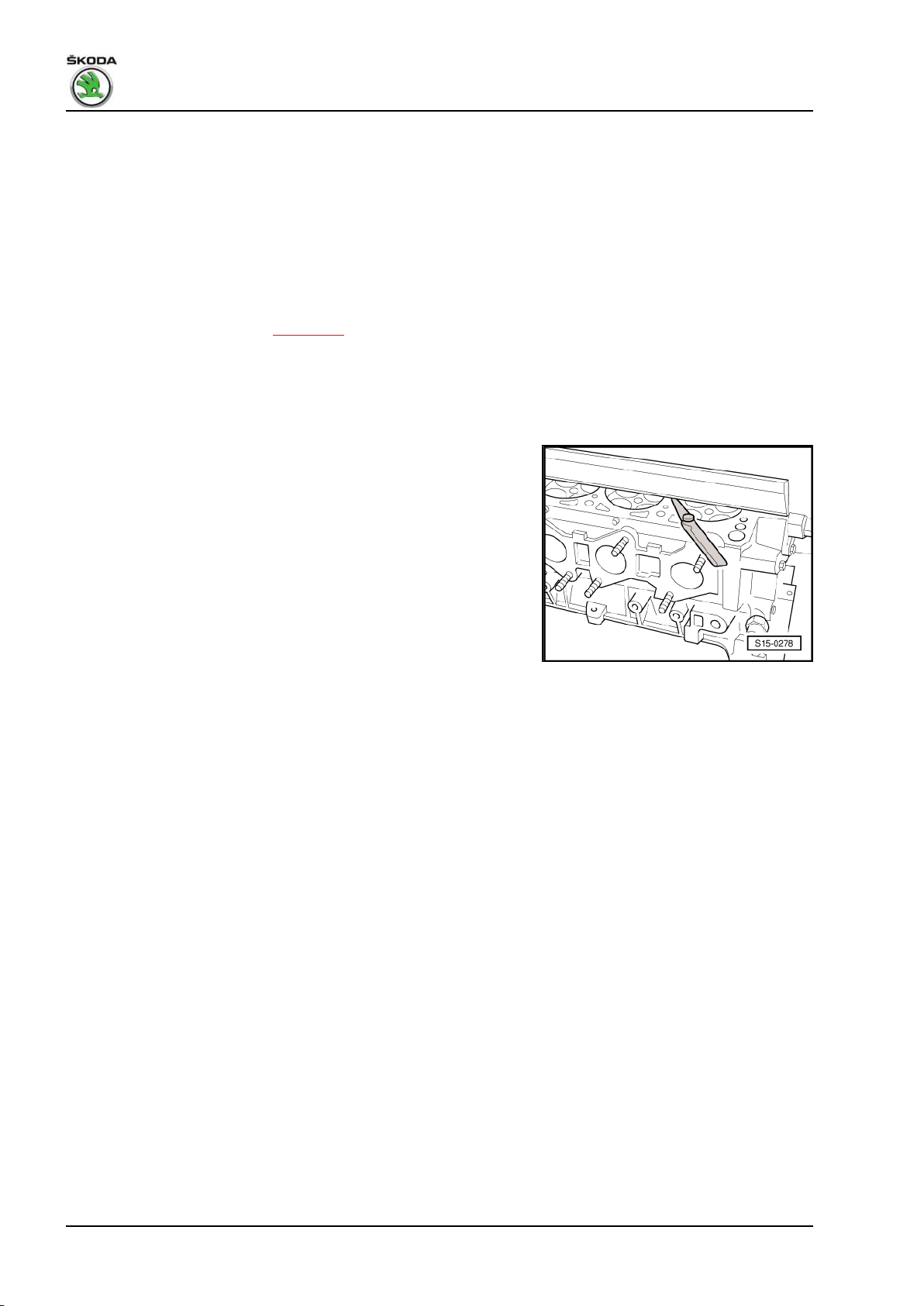

For all vehicles

– Release the Allen screws of the control unit and the screws

marked with the -arrows-.

– Remove timing case.

– Remove gasket of timing case.

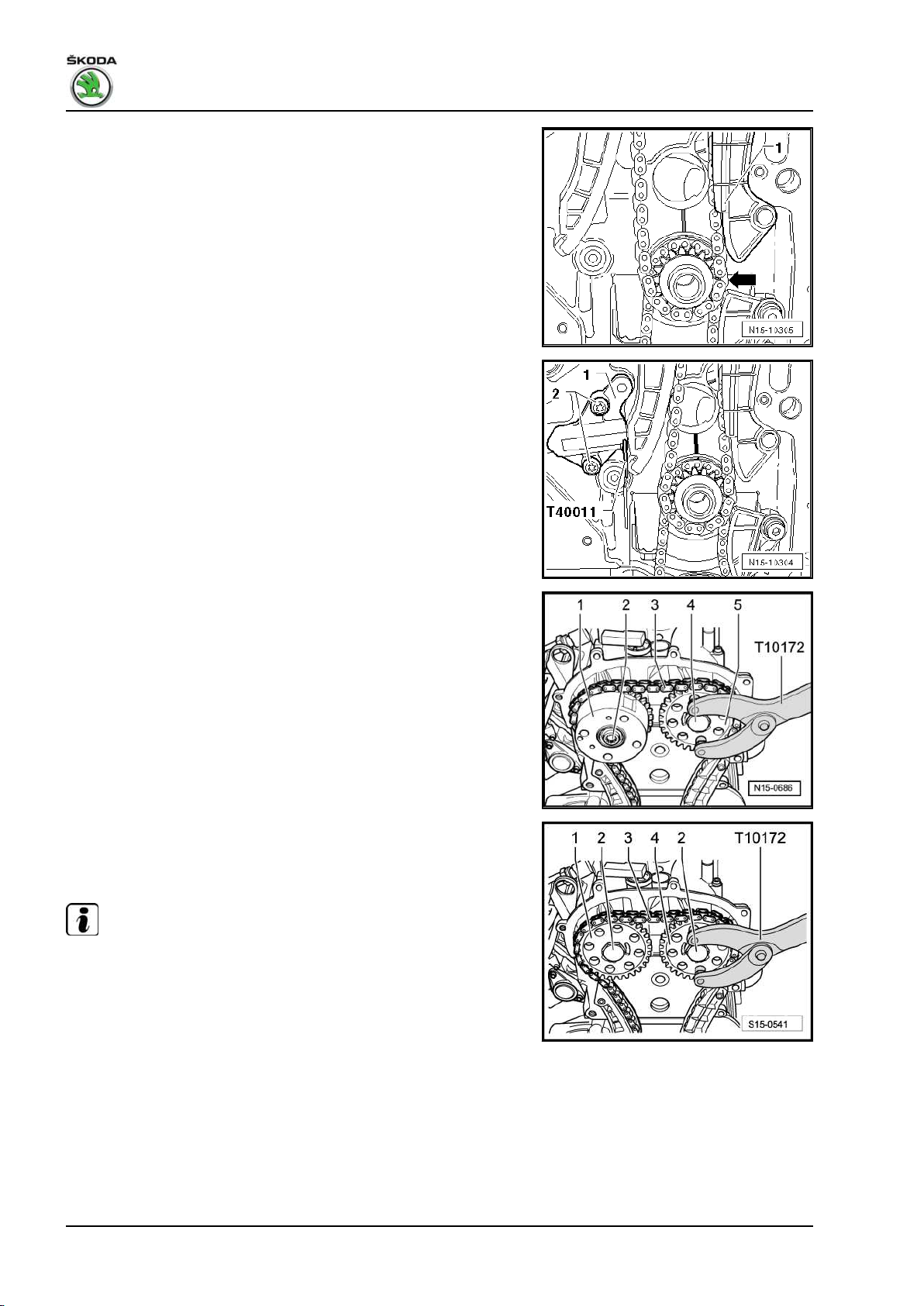

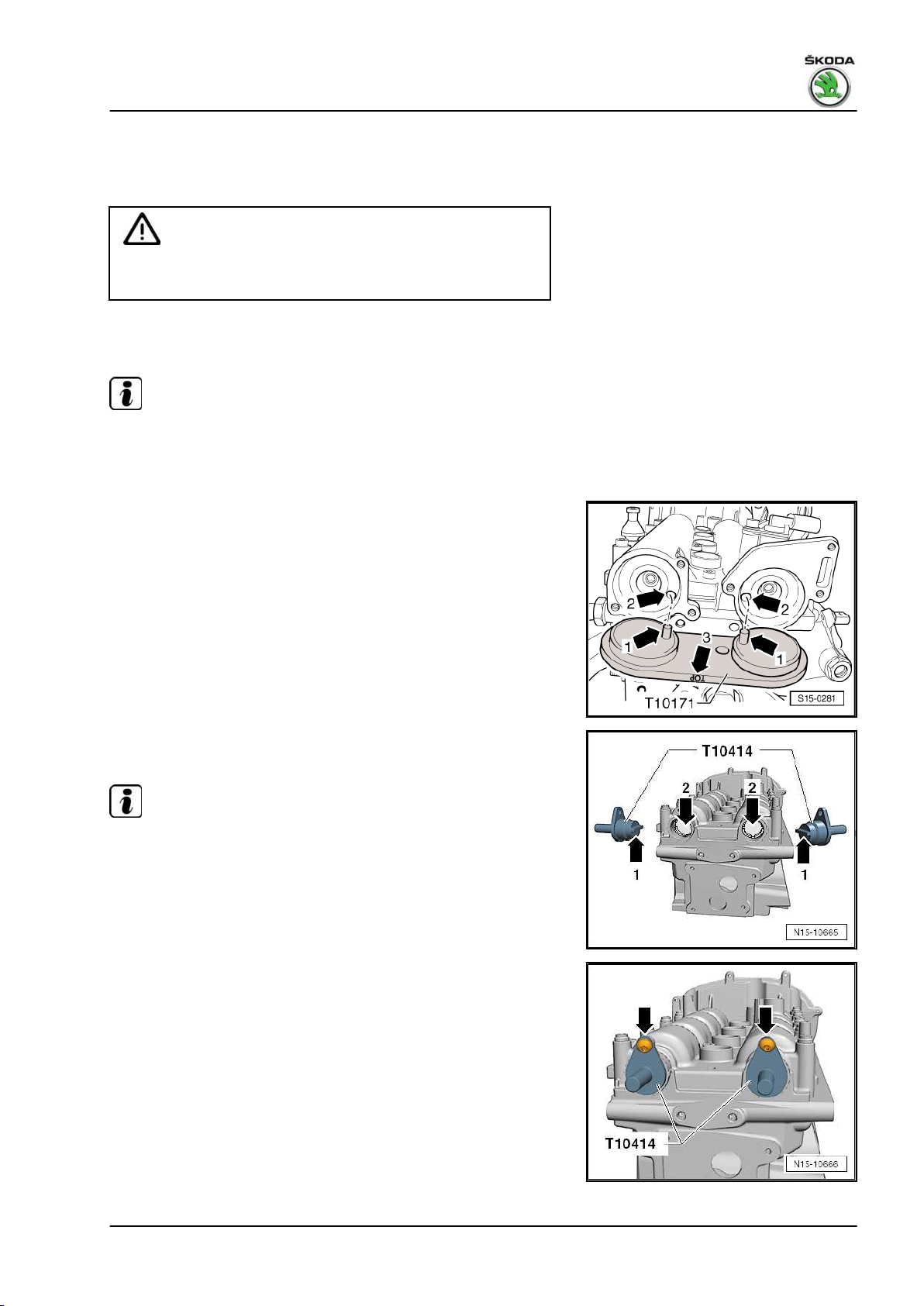

1.5.2 Install

WARNING

Wear protective gloves when working with sealant and grease

remover!

– Remove gasket residues on sealing surfaces with chemical

sealant remover.

– Degrease the sealing surfaces.

28 Rep. gr.13 - Crankshaft group

Page 35

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

Note

♦

Make sure that the clamping surfaces of the belt pulley, the

fixing screw, the spacer sleeve, the double chain sprocket and

the front crankshaft journal are free of oil and grease.

♦

Make sure that the camshaft housing is not offset or tilted.

– Carefully place the new gasket of the timing case onto the

dowel pins.

– To facilitate installation, screw two pin screws -M6 x 80- into

the cylinder head and the cylinder block.

– Position the timing case onto the pin screws and the dowel

pins.

– Tighten the fixing screws of the timing case diagonally and

evenly:

♦ Tightening torque for screws M6: 10 Nm

♦ Tightening torque for screws M10: 50 Nm

The further assembly is carried out in reverse order to disassem‐

bly. Pay attention to the following:

Note

Install crankshaft belt pulley ⇒ page 33 .

1. Cylinder block - Belt pulley side 29

Page 36

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

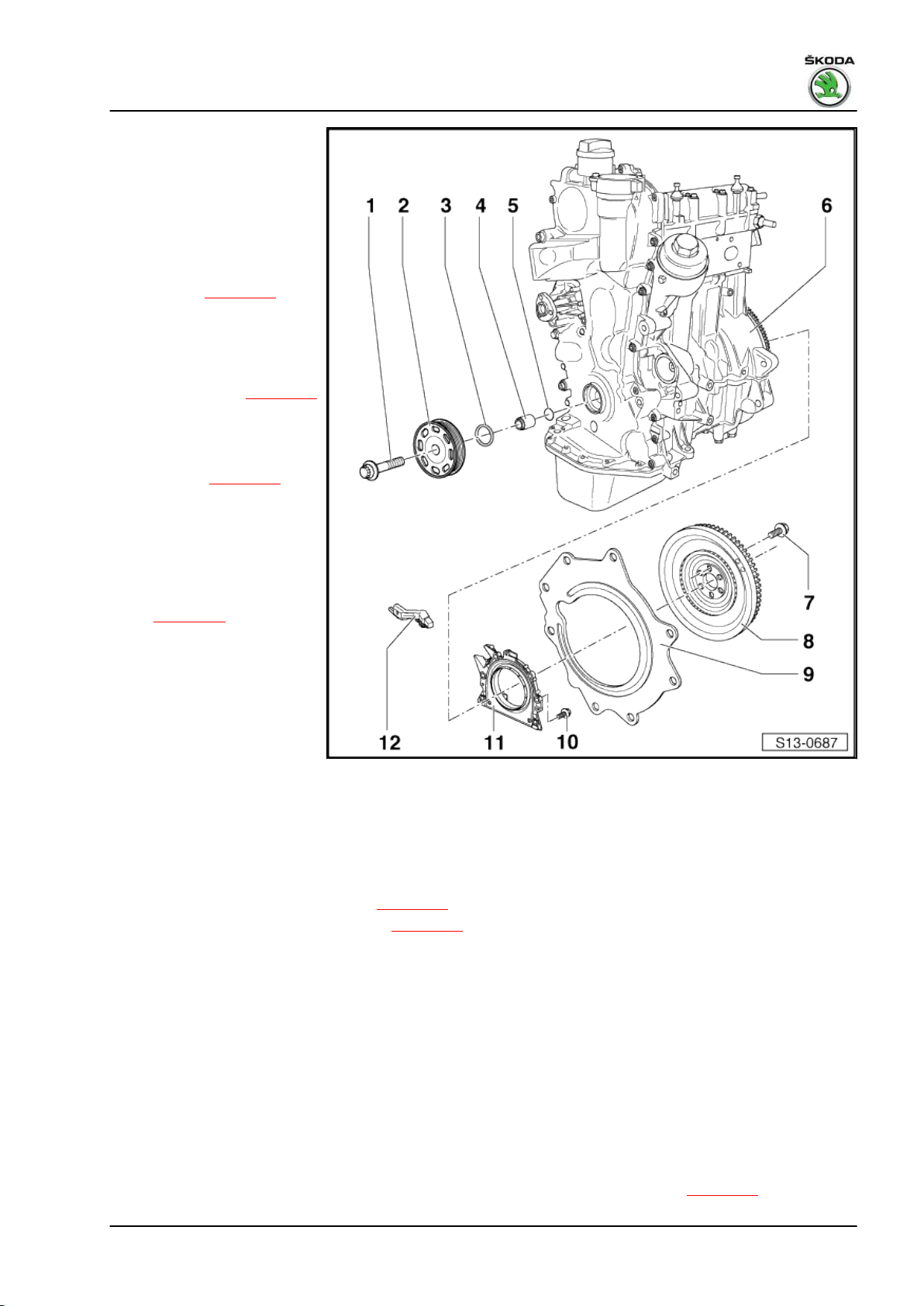

2 Cylinder block, sealing flange and fly‐

wheel

2.1 Cylinder block - Summary of components

WARNING

The crankshaft must not be removed. Merely releasing the

crankshaft bearing cover screws will result in deformations of

the bearing seats of the cylinder block. These deformations

reduce the bearing clearance. Even if the bearing shells were

not replaced, the changed bearing clearance may cause dam‐

age to the bearing.

If the bearing cover screws have been released, replace the

complete cylinder block together with the crankshaft.

It is not possible to measure the crankshaft bearing clearance

under workshop conditions.

Note

Repairs to the clutch ⇒ Gearbox; Rep. gr. 30 .

30 Rep. gr.13 - Crankshaft group

Page 37

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

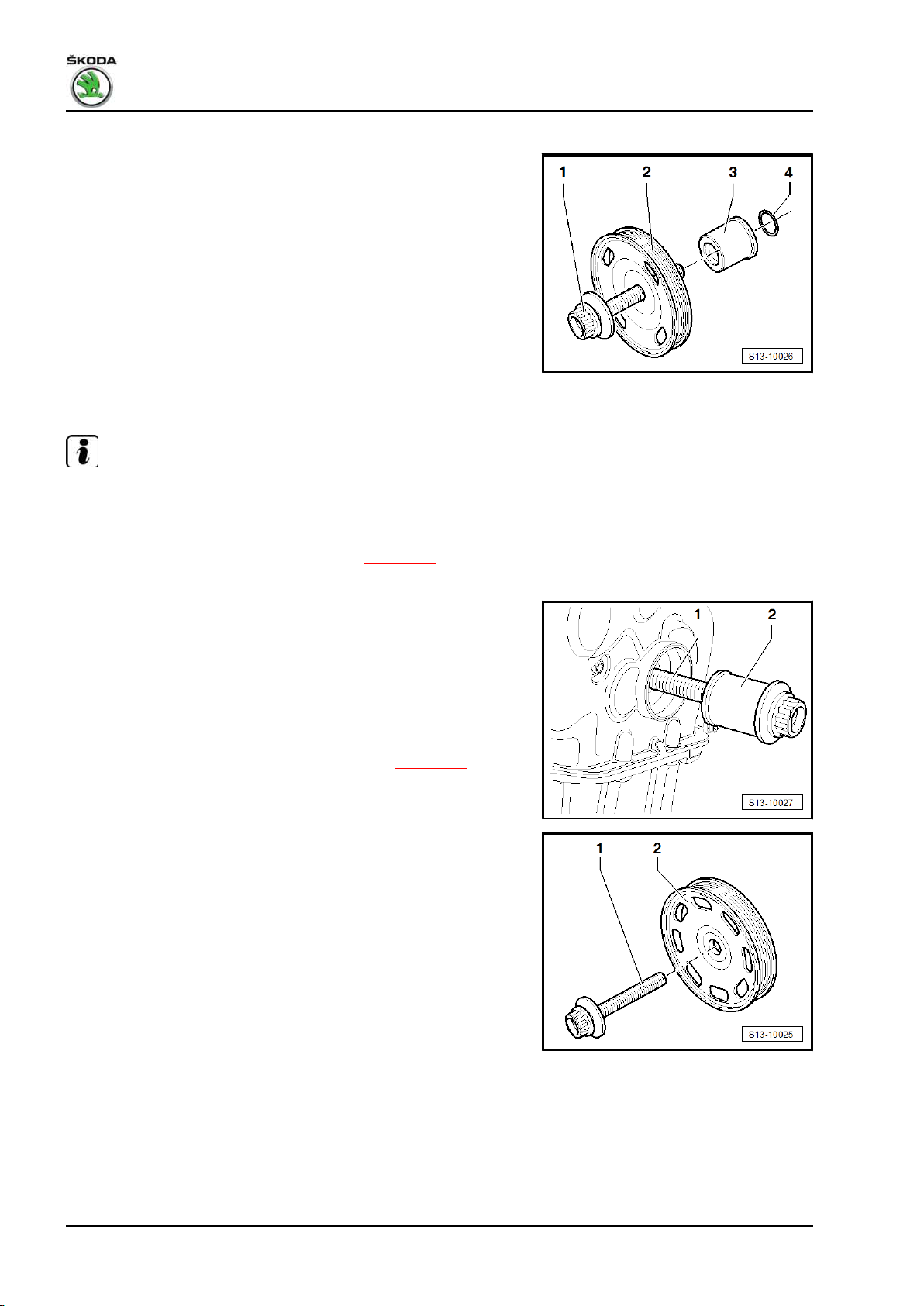

1 - Fixing screw

❑ for crankshaft - belt pul‐

ley

❑ replace

❑ The clamping surface of

the fixing screw must be

free of grease and oil.

❑ insert oiled (thread)

❑ tighten ⇒ page 33

2 - Belt pulley

❑ Clamping surfaces must

be free of oil and grease.

❑ Removing and installing

ribbed V-belt ⇒ page 18

3 - Gasket ring for crankshaft

in timing case

❑ replace

❑ replace ⇒ page 32

4 - Spacer sleeve

❑ Clamping surfaces must

be free of oil and grease.

❑ install with new O-ring

-Position 5-

❑ Fitting position

⇒ page 34

5 - O-ring

❑ replace

❑ in the spacer sleeve

-Position 4-

6 - Cylinder block

❑ Aluminium cylinder

block with timing case

shown for engine with identification characters BTS, CFNA

❑ for engine with identification characters CLSA made of grey cast iron

7 - 60 Nm + torque a further 90° (1/4 turn)

❑ replace

8 - Flywheel/drive plate

❑ removing and installing flywheel ⇒ page 36

❑ removing and installing driver disc ⇒ page 37

9 - Intermediate plate

❑ must be positioned on dowel sleeves

❑ do not damage during assembly work

10 - Screw

❑ replace

❑ Observe part number ⇒ ETKA - Electronic Catalogue of Original Parts

❑

Tighten to tightening torque for engine with grey cast iron block 8 Nm + 90° (1/4 turns)

❑

Tighten to tightening torque for engine with aluminium block 8 Nm + 45° (1/8 turns)

11 - Sealing flange with rotor and gasket ring

❑ always replace complete with rotor and gasket ring

❑ pay attention to different versions for manual gearbox and automatic gearbox ⇒ page 39

2. Cylinder block, sealing flange and flywheel 31

Page 38

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

❑ replace the sealing flange for the crankshaft ⇒ page 39

12 - Engine speed sender - G28-

❑ with captive screw

❑ Tightening torque: 5 Nm

❑ Pay attention to the part number

❑ removing and installing ⇒ page 161

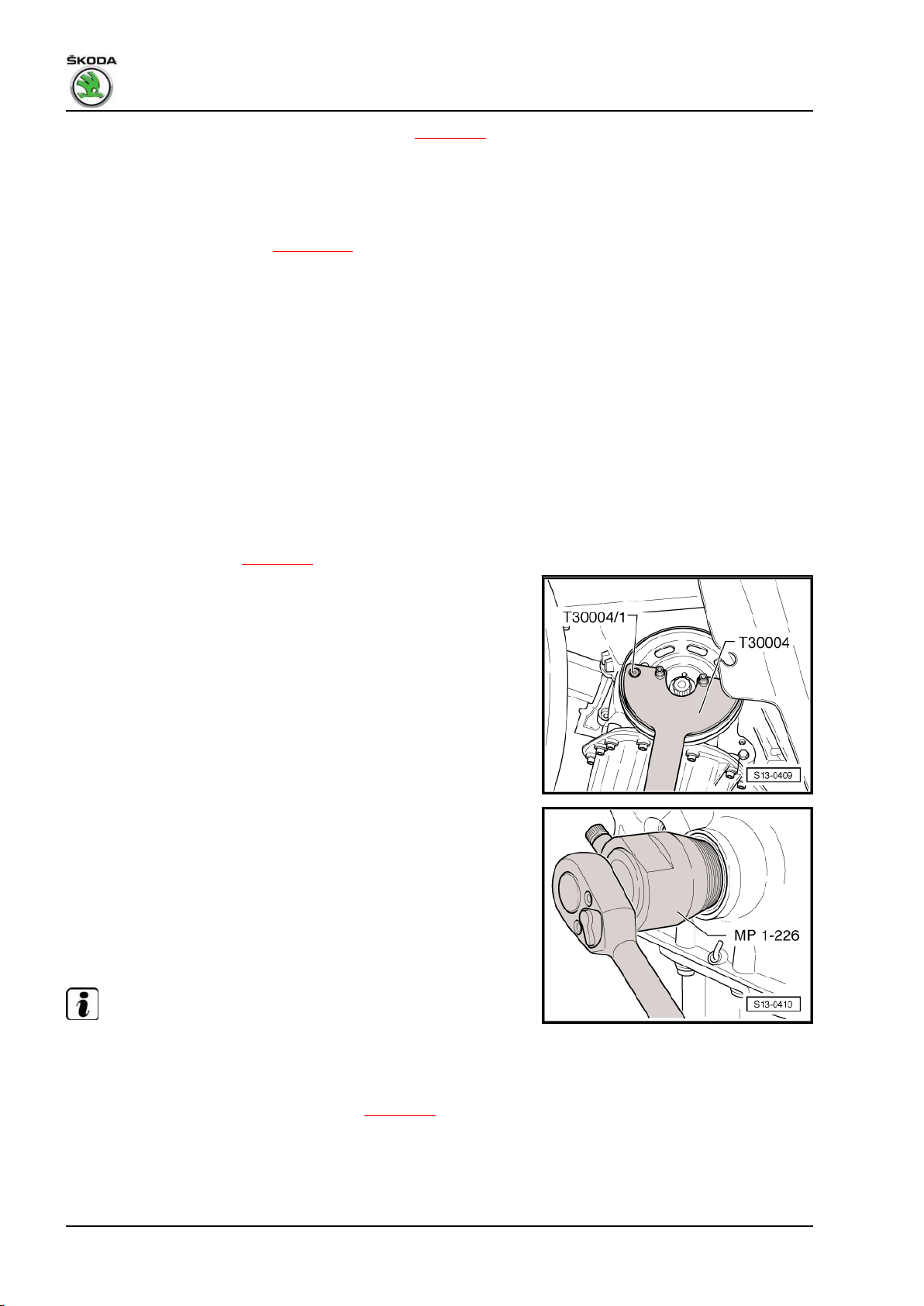

2.2 Replacing crankshaft seal on belt pulley side

Special tools and workshop equipment required

♦ Gasket ring extractor - MP1-226 (3203)♦ Assembly device - T10117♦ Counterholder - T30004 (3415)♦ Bolt - T30004/1 (3415/1)Removing

– Remove the bottom part of the right wheelhouse liner ⇒ Body

Work; Rep. gr. 66 .

– Remove V-ribbed belt ⇒ page 18 .

– Release fixing screw for crankshaft belt pulley.

Counterhold crankshaft belt pulley with counterholder -

T30004 - and bolt - T30004/1- .

– Release the fixing screw and remove the belt pulley from the

crankshaft.

– Unscrew inner part of the gasket ring extractor - MP1-226-

three turns (approx. 5 mm) out of the outer part and lock with

knurled screw.

– Oil the thread head of the gasket ring extractor - MP1-226- ,

position and forcefully screw it into the gasket ring as far as

possible.

– Release knurled screw and turn the inner side against the

crankshaft until the gasket ring is pulled out.

– Remove the spacer sleeve from the crankshaft journal and

clean the clamping surfaces of the crankshaft chain sprocket.

Install

Note

Make sure that the clamping surfaces of the fixing screw, the belt

pulley, the spacer sleeve and the crankshaft chain sprocket are

free of oil and grease.

– Replace the O-ring in the spacer sleeve ⇒ page 34

-Position 4-.

32 Rep. gr.13 - Crankshaft group

Page 39

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

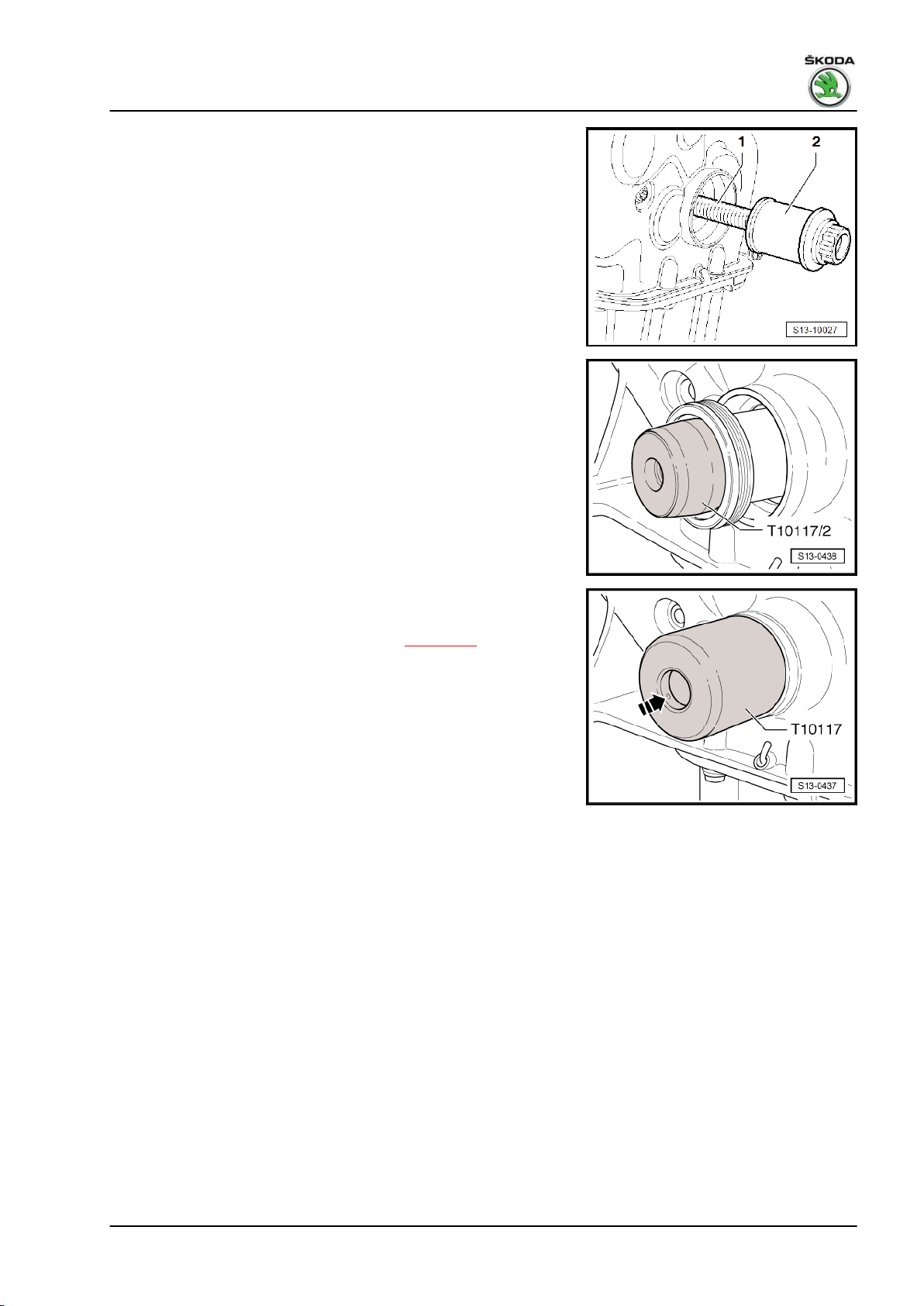

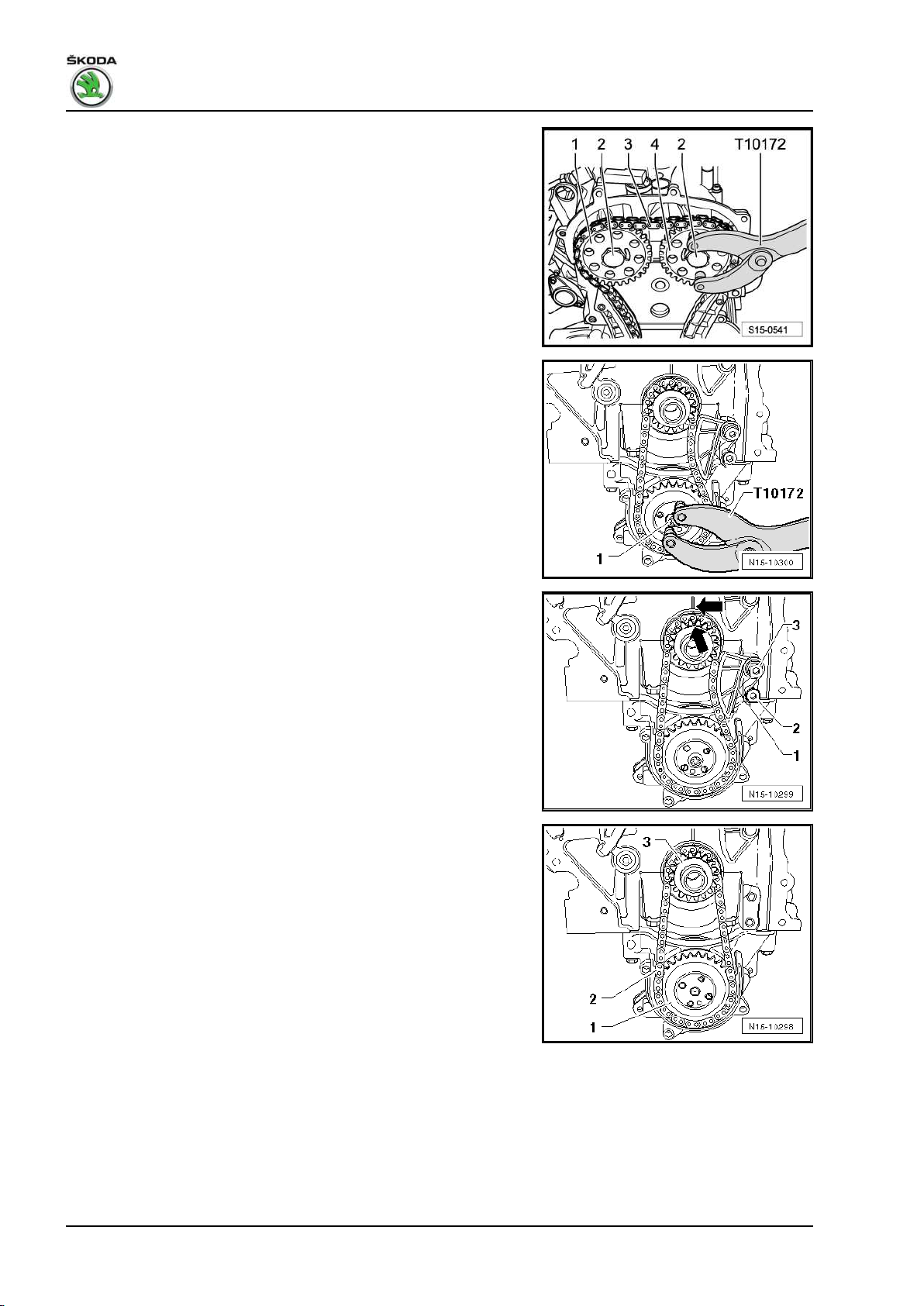

– First of all, slide a new spacer sleeve -2- onto the holding down

bolt -1-.

– Screw the fixing screw -1- by about 2 turns into the crankshaft.

– Slide the spacer sleeve -2- onto the crankshaft journal as far

as it will go.

– Release fixing screw (at the same time press the spacer

sleeve against the crankshaft).

– Position the assembly device - T10117/2- in front of the spacer

sleeve and slide the gasket ring onto the spacer sleeve.

– Remove the assembly device - T10117/2- from the spacer

sleeve.

– Press the gasket ring with the assembly device - T10117- by

striking uniformly up to the stop in the timing case.

– Tighten screw for crankshaft belt pulley ⇒ page 33 .

Further installation occurs in a similar way in reverse order to re‐

moval.

2.3 Tightening process of the screw for

crankshaft belt pulley

Special tools and workshop equipment required

♦ Counterholder - T30004 (3415)♦ Bolt - T30004/1 (3415/1)-

2. Cylinder block, sealing flange and flywheel 33

Page 40

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

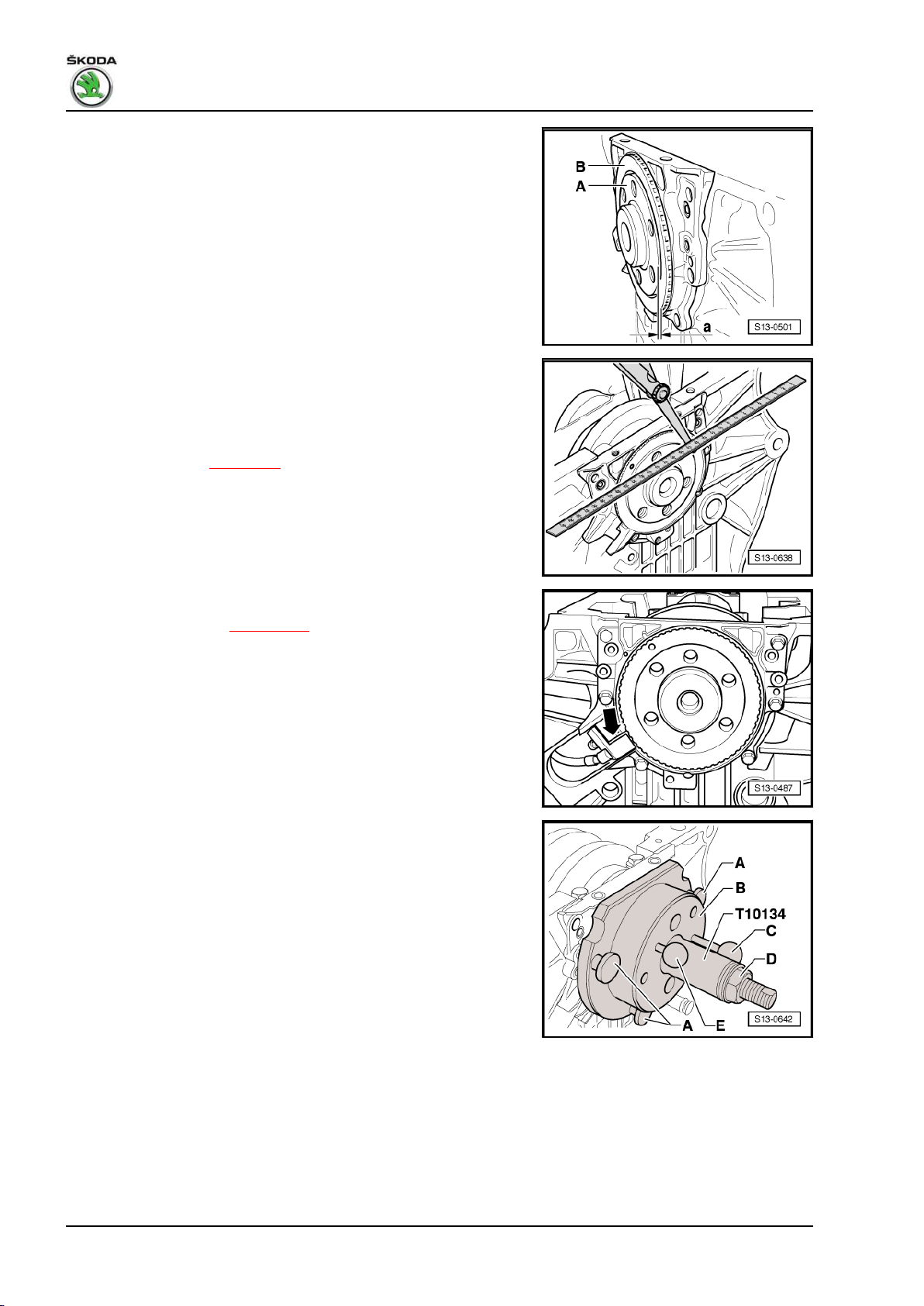

Conditions

• Timing o.k.

• Gasket ring for crankshaft in timing case removed.

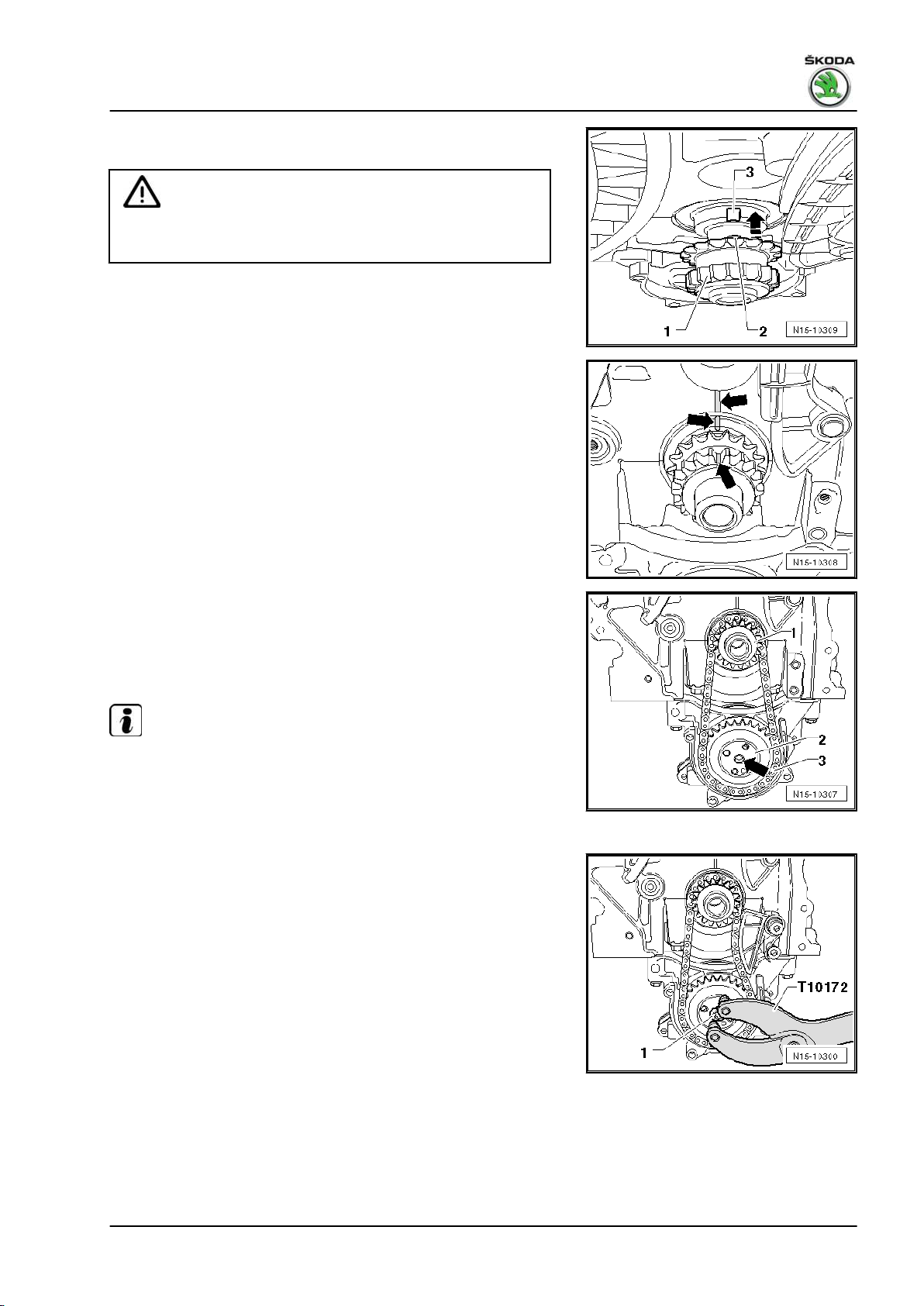

Fitting position of the spacer sleeve

1 - Fixing screw

2 - Crankshaft-belt pulley

3 - Spacer sleeve

4 - O-ring in the spacer sleeve

– Remove camshaft housing plastic cover and intake hose to air

filter housing.

– Remove cap of outlet camshaft. Collect any engine oil which

flows out with a cloth.

Note

Observe that all clamping surfaces of the fixing screw for the

crankshaft belt pulley to the crankshaft chain sprocket are free of

oil and grease.

– Replace the O-ring in the spacer sleeve ⇒ page 34

-Position 4-.

– First of all, slide the spacer sleeve -2- onto the holding down

bolt -1-.

– Screw the fixing screw -1- by about 2 turns into the crankshaft.

– Slide the spacer sleeve -2- onto the crankshaft journal as far

as it will go.

– Release fixing screw (at the same time press the spacer

sleeve against the crankshaft).

– Install the new gasket ring for the crankshaft ⇒ page 32 .

– Slightly oil the first third of the thread of the new fixing screw.

– Rotate the new holding down bolt -1- with crankshaft-belt pul‐

ley -2- into the crankshaft journal.

Always use a new fixing screw -1-.

34 Rep. gr.13 - Crankshaft group

Page 41

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

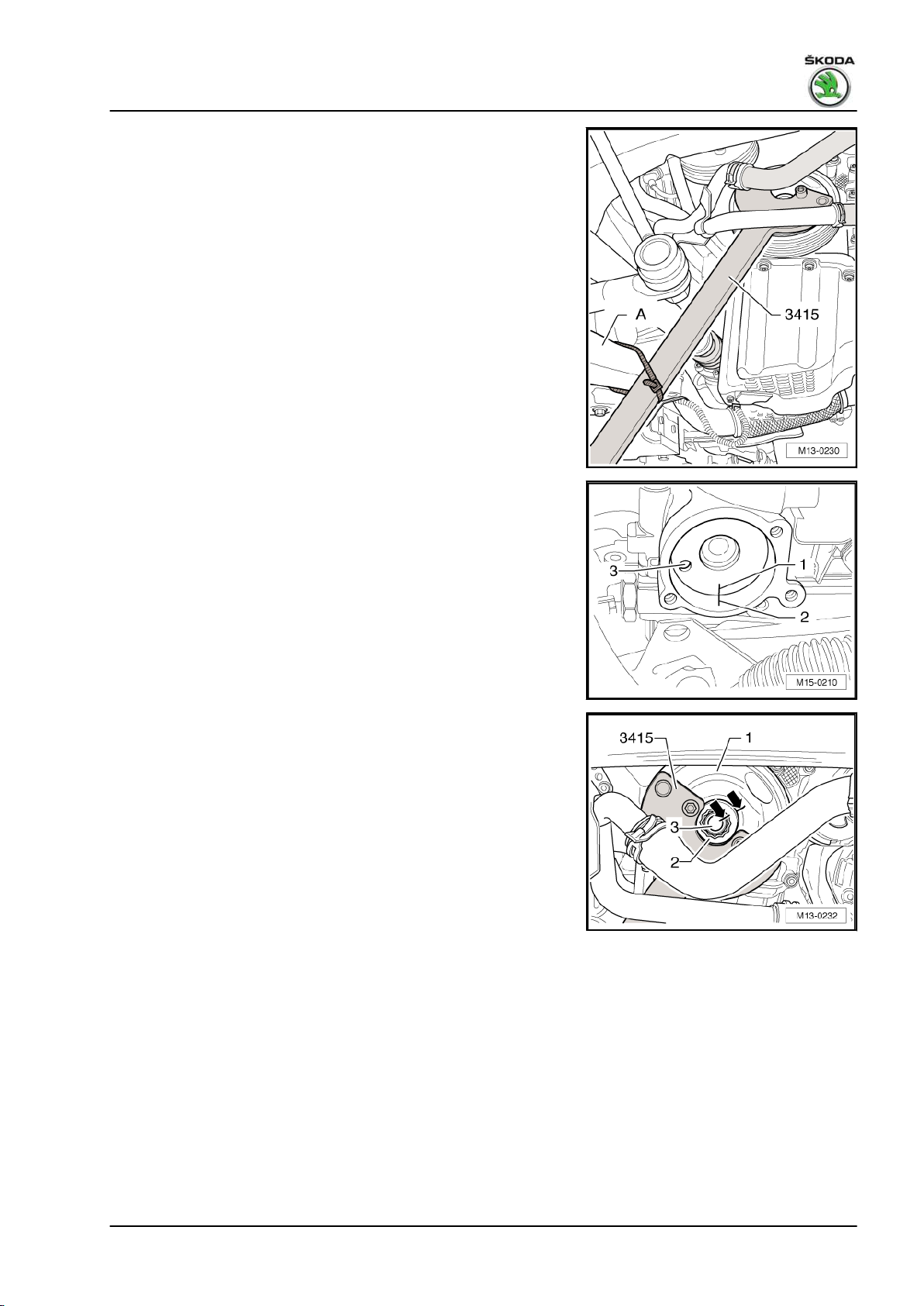

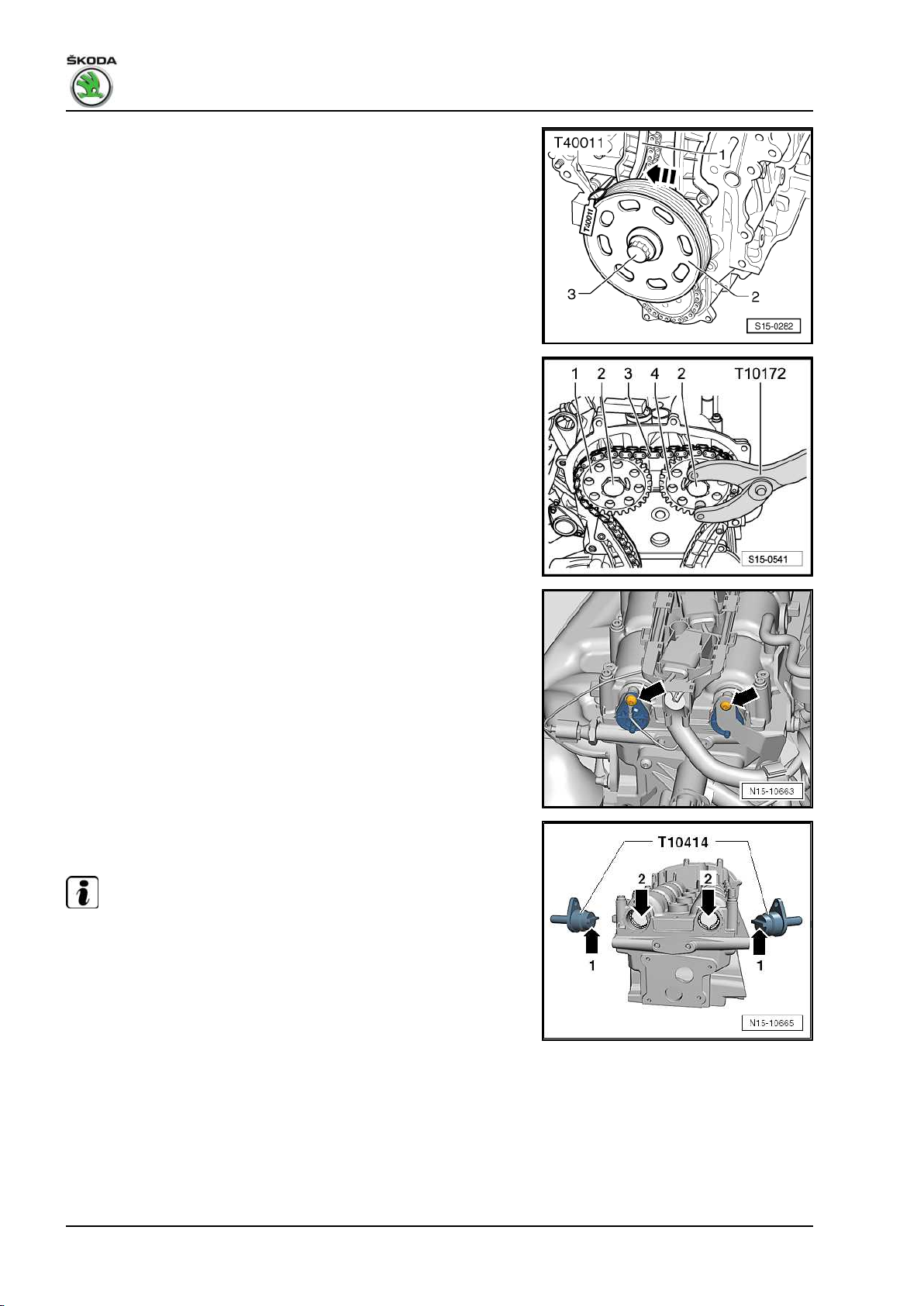

– Insert counterholder - 3415- with the bolt - 3415/1- into the

holes of the crankshaft belt pulley, support counterholder at

track control arm -A- and secure in this position with a cable

strap. Tighten cable strap.

– Tighten fixing screw for crankshaft belt pulley to the 1st step

as follows:

Tightening torque: 150 Nm

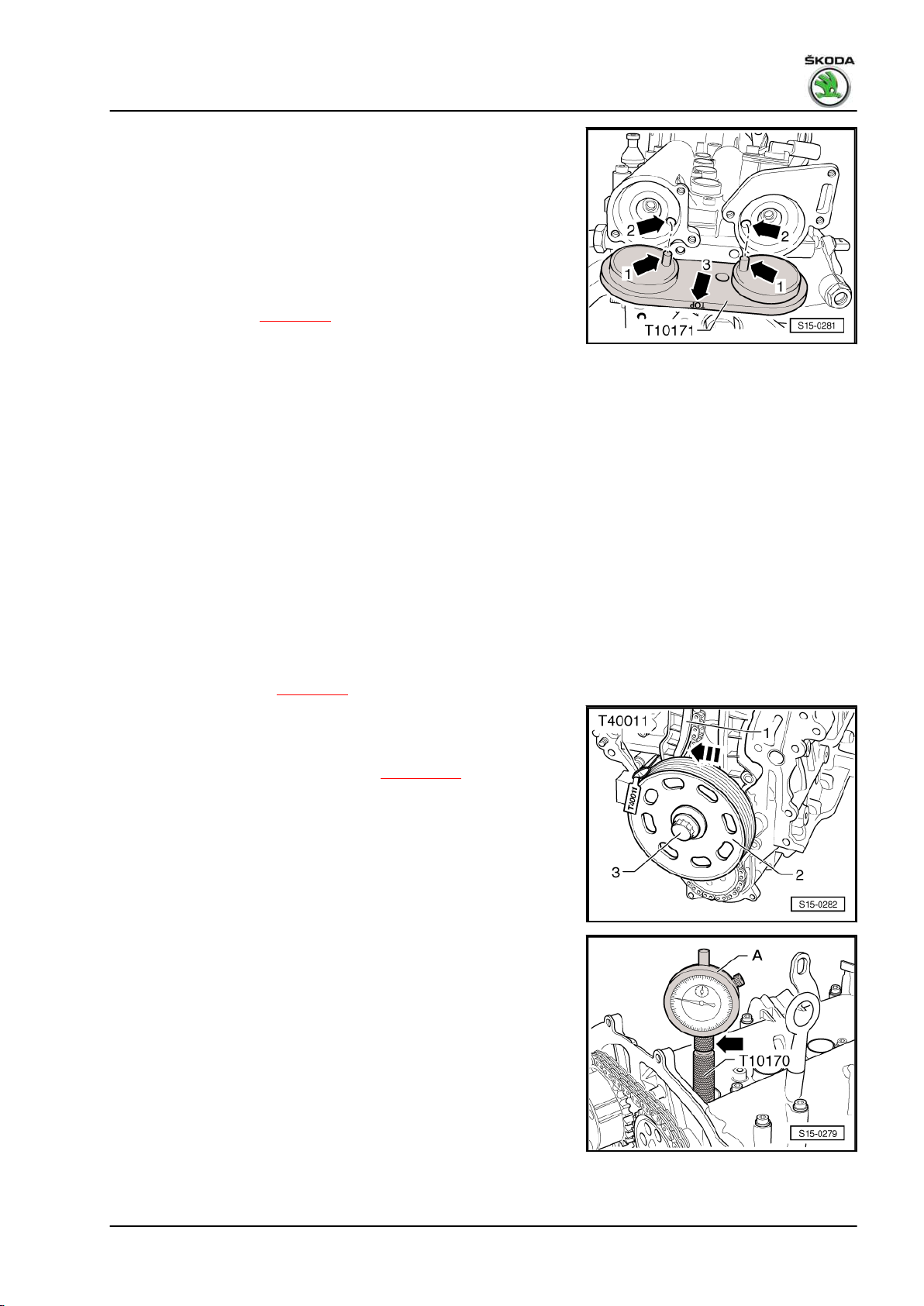

– Now mark the position of the outlet camshaft -1- to the cam‐

shaft housing -2- with a felt-tip pen. The position of the hole

-3- is of no importance for the following inspection.

– Mark at this stage the position of the fixing screw -3- to the

crankshaft belt pulley -1- -arrows-. The marking must not be

performed on the washer -2-, because it does not turn along

when tightening.

– Tighten fixing screw for crankshaft belt pulley to the 2nd step

as follows:

Torque screw a further 180° (1/2 turn).

Tightening may occur in successive stages.

2. Cylinder block, sealing flange and flywheel 35

Page 42

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

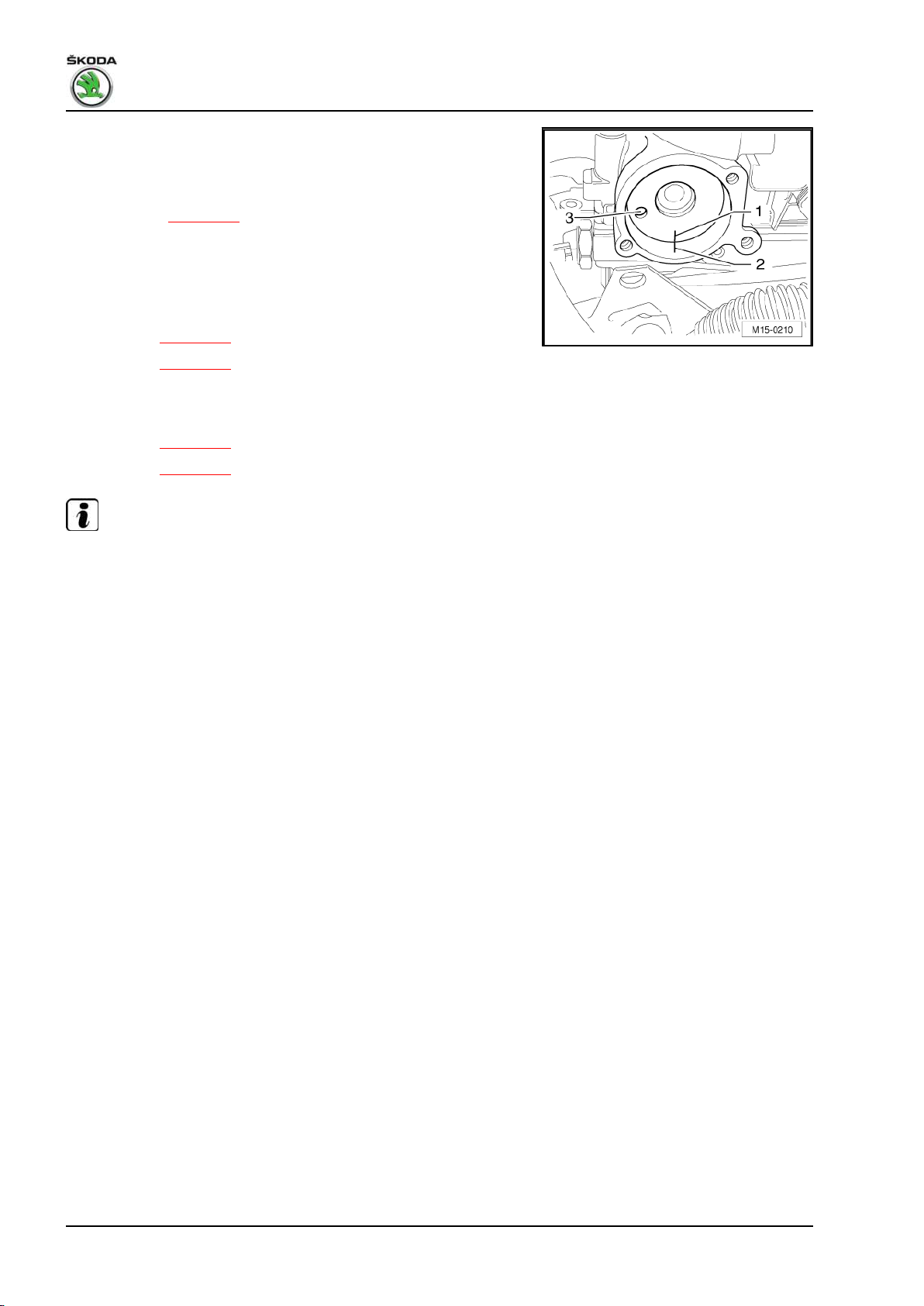

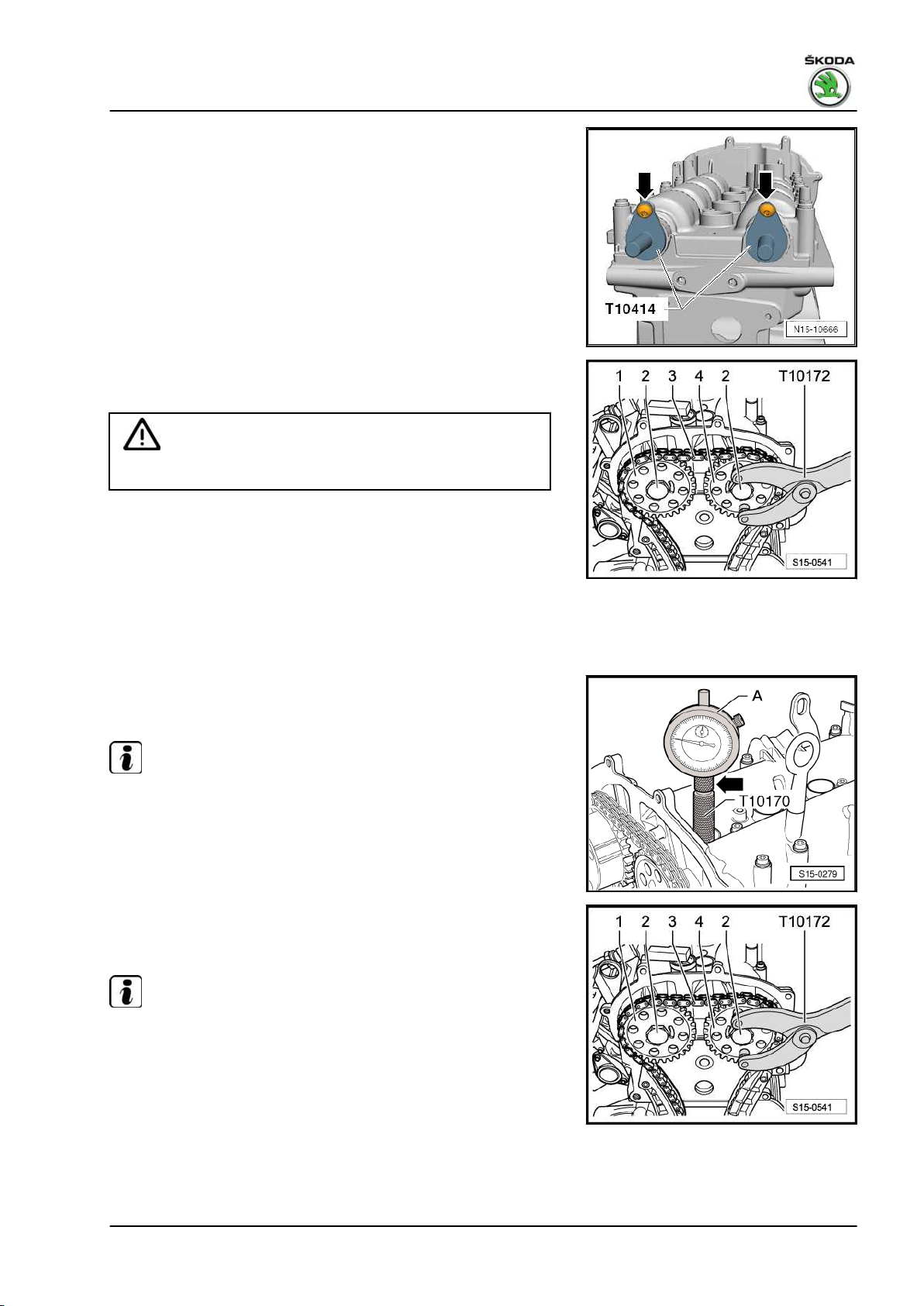

– Check the position of the outlet camshaft.

• Both markings -1- and -2- must be aligned.

If both markings -1- and -2- are aligned:

– Test timing ⇒ page 56 .

This checks if the chain sprocket on the crankshaft has turned

along when tightening the screw for the crankshaft belt pulley.

If both markings -1- and -2- are not aligned:

– Test timing:

♦ Version A ⇒ page 56 .

♦ Version B ⇒ page 57 .

If the timing is not correct:

– Setting the timing:

♦ Version A ⇒ page 59 .

♦ Version B ⇒ page 63 .

Note

First of all determine if the peg of the chain sprocket is still in the

slot of the crankshaft.

– If the peg of the chain sprocket is no longer in the slot of the

crankshaft, remove the chain sprocket and inspect for dam‐

age.

Replace the damaged chain sprocket.

If the timing is correct:

The crankshaft has turned to the crankshaft belt pulley.

– Remove crankshaft belt pulley, gasket ring and spacer sleeve.

– Clean all parts thoroughly. They must be free of oil and grease.

– Replace damaged component parts.

– Also throughly clean the clamping surface on the chain sprock‐

et.

– Re-install component parts with new screw for crankshaft belt

pulley.

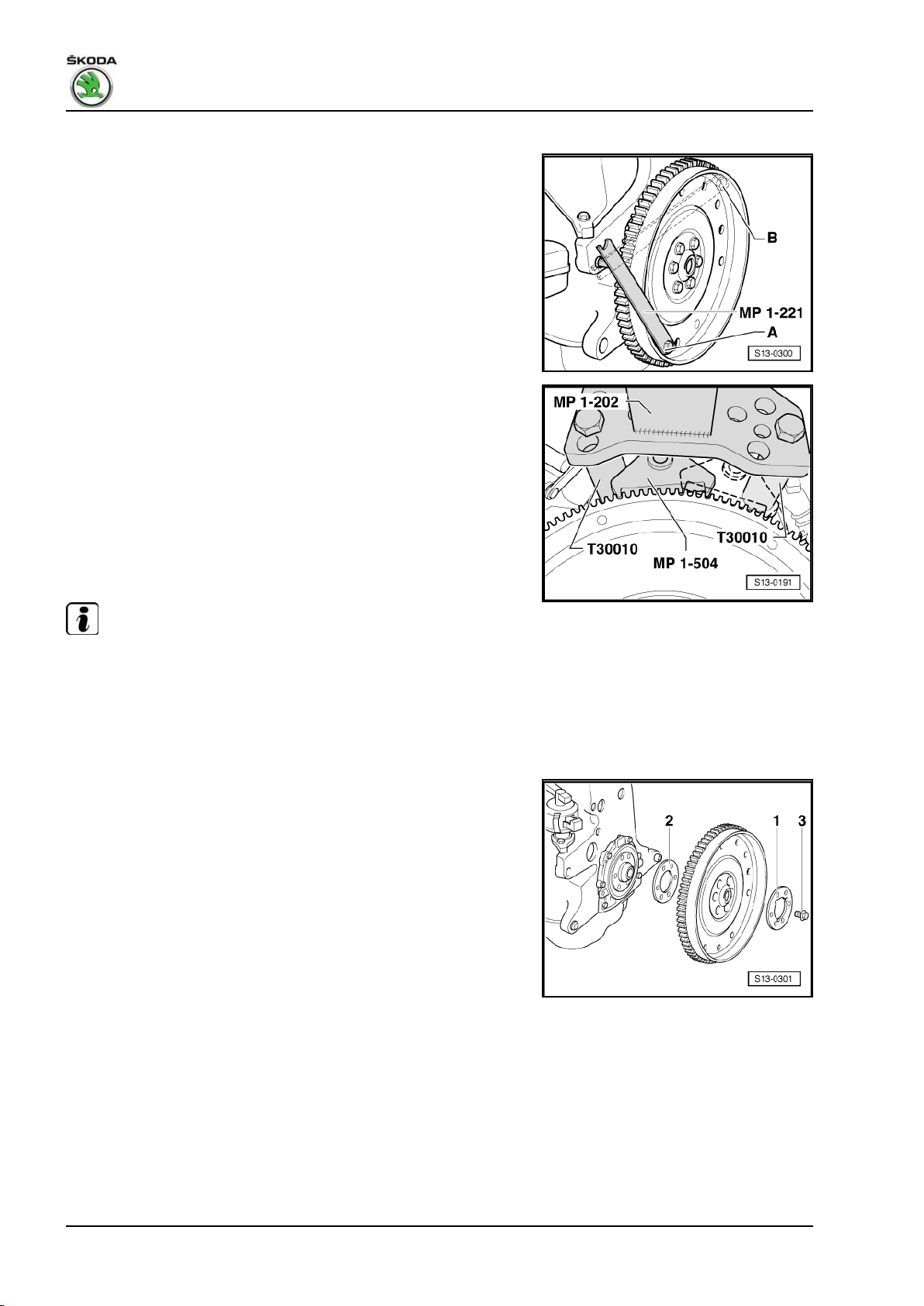

2.4 Removing and installing flywheel

Special tools and workshop equipment required

♦ Counterholder - MP1-223 (3067)or

♦ Engine mount - MP1-202 (VW 540)♦ Bushing - T30010 (VW 540/1B)♦ Flywheel lock - MP1-504Removing

• Gearbox is removed.

– Remove clutch on vehicles with manual gearbox ⇒ Gearbox;

Rep. gr. 30 .

36 Rep. gr.13 - Crankshaft group

Page 43

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

Engine installed

– Insert the counterholder - MP1-223 (3067)- into the bore hole

on the cylinder block.

• Fitting position of the tool:

A - for tightening

B - for slackening

Engine removed

– Position the flywheel lock - MP1-504- on the starter ring gear

of the flywheel disk and turn crankshaft until it rests against

the sleeve - T30010- .

Continued for all

– Release screws and remove flywheel.

Install

Installation is performed in the reverse order, pay attention to the

following points:

Note

Use new screws for attaching.

1. Screw in all the screws by hand.

2. Tighten all the screws crosswise to 60 Nm.

3.

Torque all the screws crosswise a further 90° (1/4 turn).

2.5 Removing and installing drive plate

Special tools and workshop equipment required

♦ Counterholder for clutch - MP1-221 (VW 558)♦ Hexagon screw M8 x 45 and two nuts M10

♦ Depth gauge

or

♦ Engine mount - MP1-202 (VW 540)♦ Bushing - T30010 (VW 540/1B)♦ Flywheel lock - MP1-504Removing

• Gearbox is removed.

2. Cylinder block, sealing flange and flywheel 37

Page 44

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

Engine installed

– Attach counterholder for clutch - MP1-221 (VW 558)- with

M8x45 screw to the drive plate. Place two M10 nuts between

the counterholder and the driver disc.

• Fitting position of the counterholder:

A - for slackening

B - for tightening

Engine removed

– Position the flywheel lock - MP1-504- on the starter ring gear

of the drive plate and turn crankshaft until it rests against the

sleeve - T30010- .

Continued for all

– Release screws and remove drive plate.

Install

Installation is performed in the reverse order, pay attention to the

following points:

Note

Use new screws for attaching.

1. Screw in all the screws by hand.

2. Tighten all the screws crosswise to 60 Nm.

3.

Torque all the screws crosswise a further 90° (1/4 turn).

– Insert the drive plate using the washer with recesses -1-.

– Insert new bolts -3- and tighten to 30 Nm.

38 Rep. gr.13 - Crankshaft group

Page 45

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

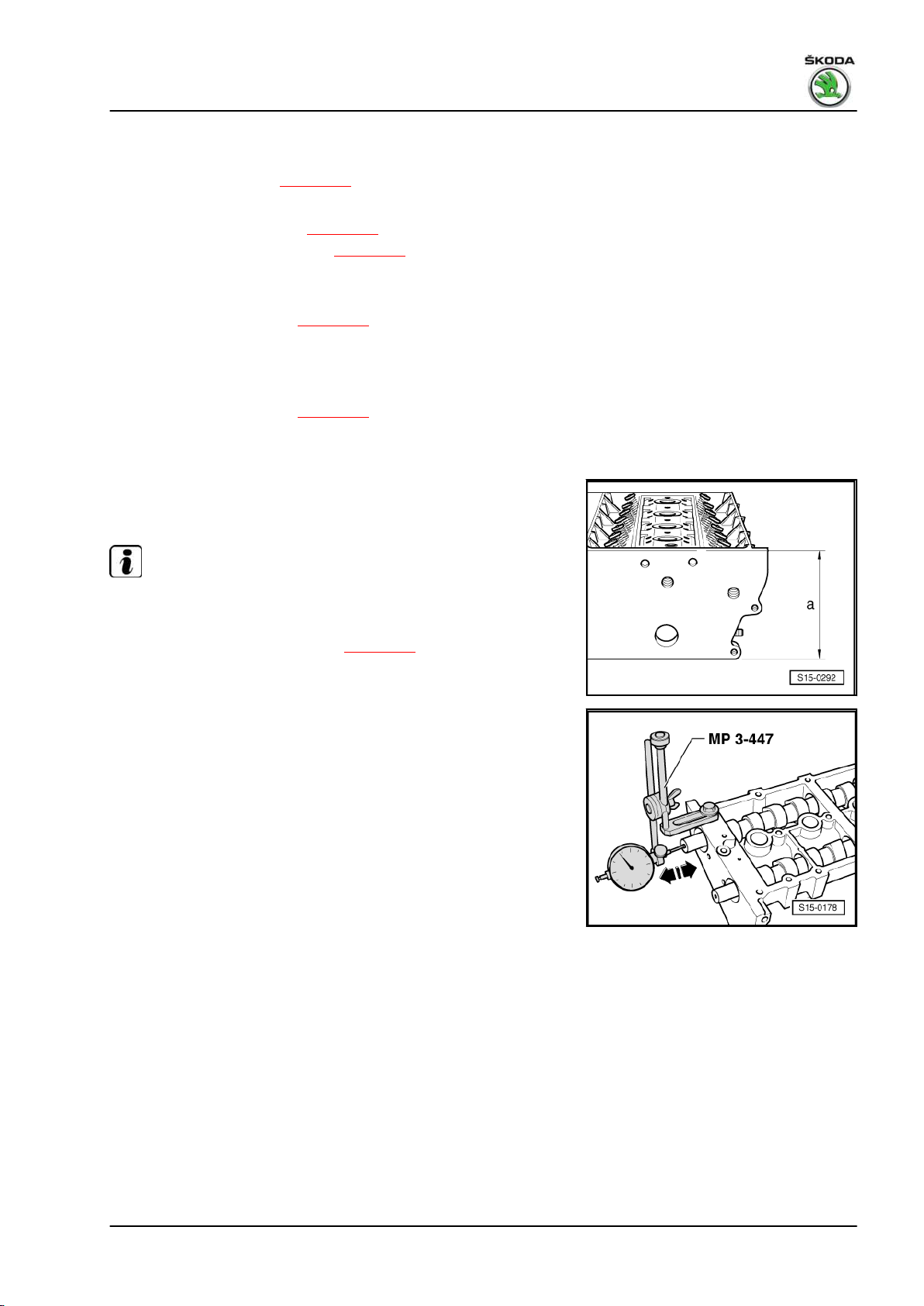

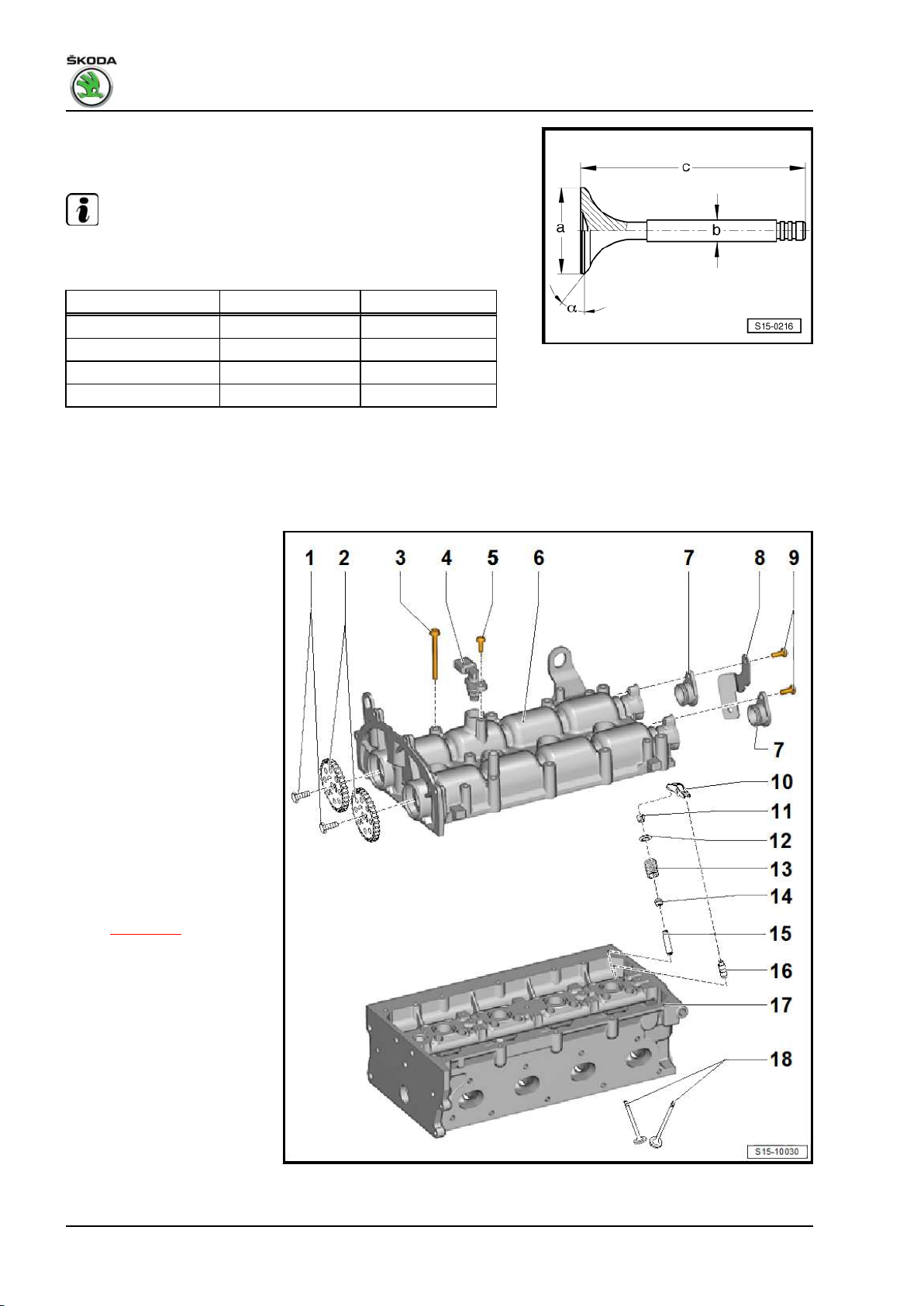

– Check dimension -a- in three points and determine the mean

value. Specified value: 19.7...21.3 mm.

Note

The measurement is made through the hole of the drive plate to

the milled surface of the cylinder block.

If the specified value is not reached:

– Remove driver disc and use compensating washer -2-. Tight‐

en screws -3- again to 30 Nm and again check the dimension

-a-.

If the specified value is reached:

–

Tighten screws -3- to 60 Nm and torque a further 90° (1/4 turn)

(the tightening may occur in several stages).

2.6 Replacing the sealing flange for crank‐

shaft - gearbox side

Special tools and workshop equipment required

♦ Assembly fixture - T10017- or -T10134♦ 3 hexagon screws M6 x 35 mm

♦ Feeler gauge

♦ Steel straightedge

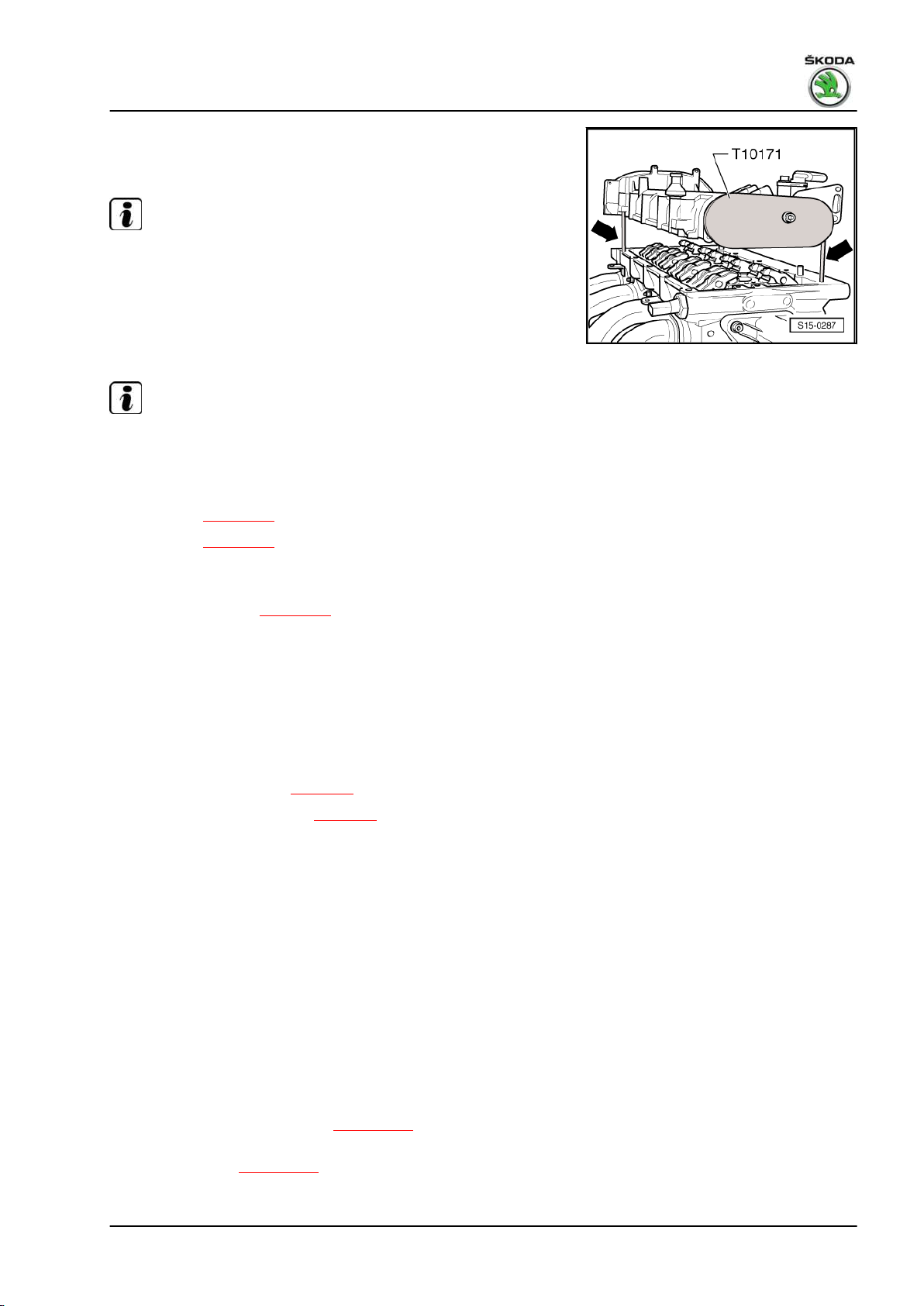

2.6.1 Distinguishing features of the sealing

flange of the assembly devices T10017- and -T10134-

Note

♦

Note that different sealing flanges may be installed depending

on what transmission was used ⇒ ETKA - Electronic Cata‐

logue of Original Parts .

♦

Use the corresponding assembly device for the relevant seal‐

ing flange.

2. Cylinder block, sealing flange and flywheel 39

Page 46

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

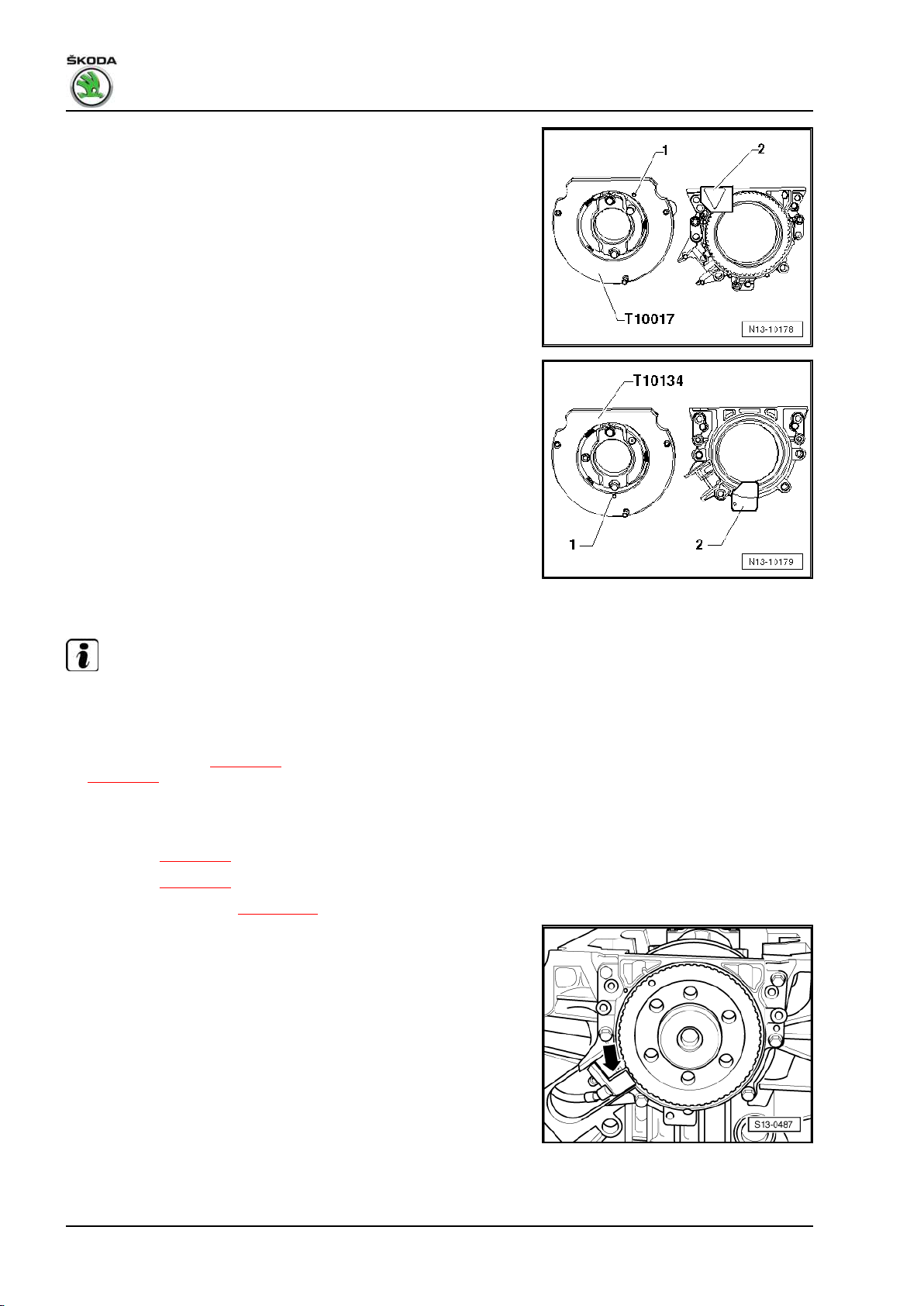

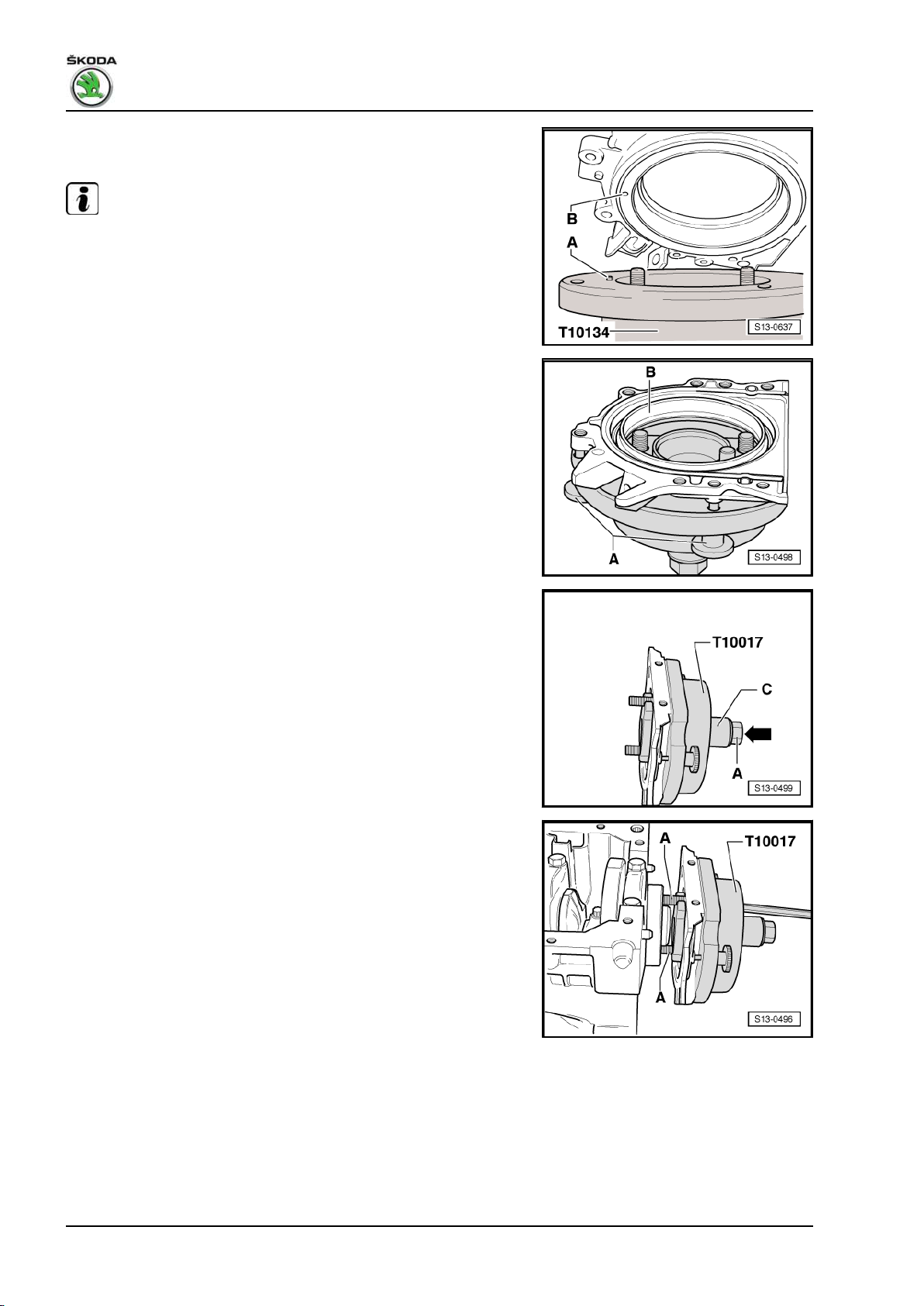

Install sealing flange for automatic gearbox with assembly device

- T100171 - Dowel pin

2 - Transport security (remove immediately before assembly)

Install sealing flange for manual gearbox with assembly device T10134-

1 - Dowel pin

2 - Transport security (remove immediately before assembly)

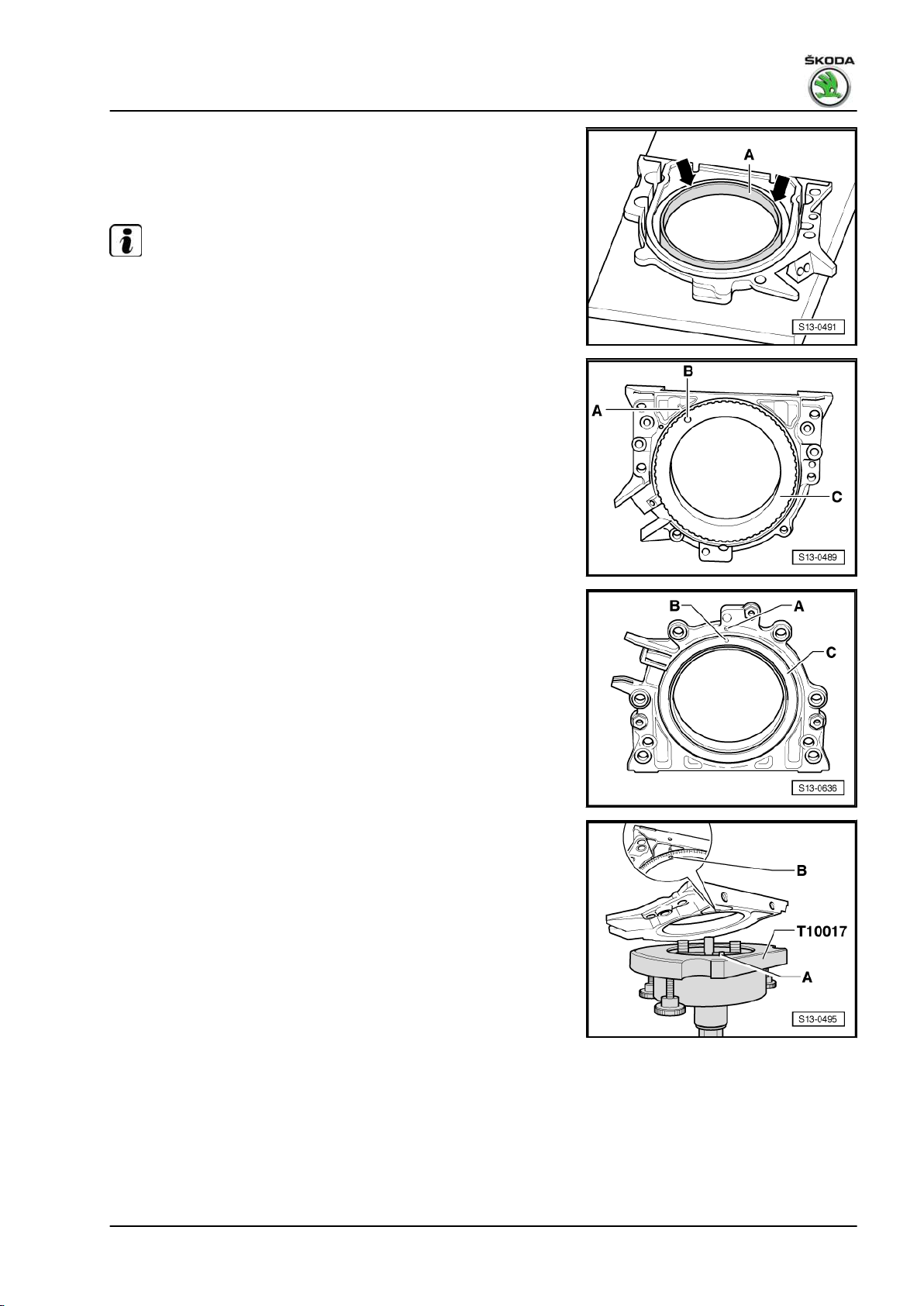

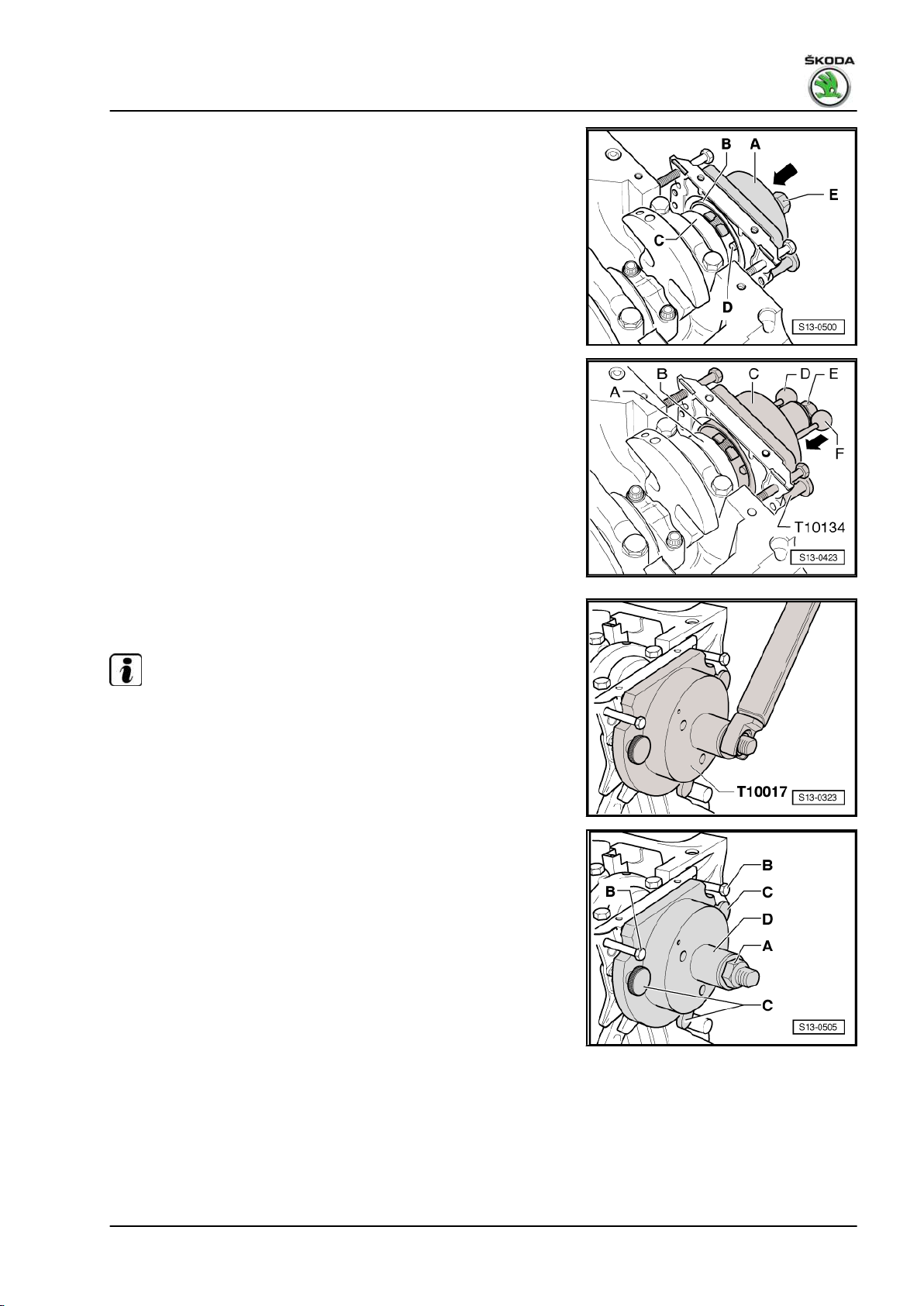

2.6.2 Removing sealing flange with rotor

Note

These work sequences with the engine removed are shown for

purposes of clear presentation. The work sequences are identical

with the engine installed and gearbox removed.

– Remove flywheel ⇒ page 36 , if necessary drive plate

⇒ page 37 .

– Remove intermediate plate.

– Position crankshaft on TDC for cylinder 1:

♦ Version A ⇒ page 56 .

♦ Version B ⇒ page 57 .

– Removing the oil pan ⇒ page 105 .

– Remove engine speed sender -arrow-.

– Unscrew the fixing screws of the sealing flange.

40 Rep. gr.13 - Crankshaft group

Page 47

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

– Screw 3 screws M6 x 35 mm into the threaded bores of the

sealing flange -arrows-.

– Press out sealing flange together with rotor from the crank‐

shaft by alternately screwing the screws into the sealing

flange.

2.6.3 Installing sealing flange with rotor

Note

♦

The sealing flange with PTFE gasket ring is provided with

sealing lip supporting ring. This supporting ring is intended as

an assembly sleeve and must not be removed before instal‐

ling.

♦

Do not separate or turn to each other the sealing flange and

rotor after removing them from the spare part package.

♦

The rotor is given its fitting location by positioning the assem‐

bly device - T10017- or - T10134- onto the positioning pin.

♦

The rotor has an elastomer layer on its sealing surface with

the crankshaft. This layer must not be brought into contact with

dirt or grease.

♦

The sealing flange and gasket ring form one unit and must be

replaced together with the rotor.

♦

The fitting location of the assembly device - T10017- , or T10134- to the crankshaft is determined by means of a guide

bolt, which is guided through the threaded bore of the crank‐

shaft.

♦

Unless otherwise indicated, the method for the assembly de‐

vice - T10017- and -T10134- is identical.

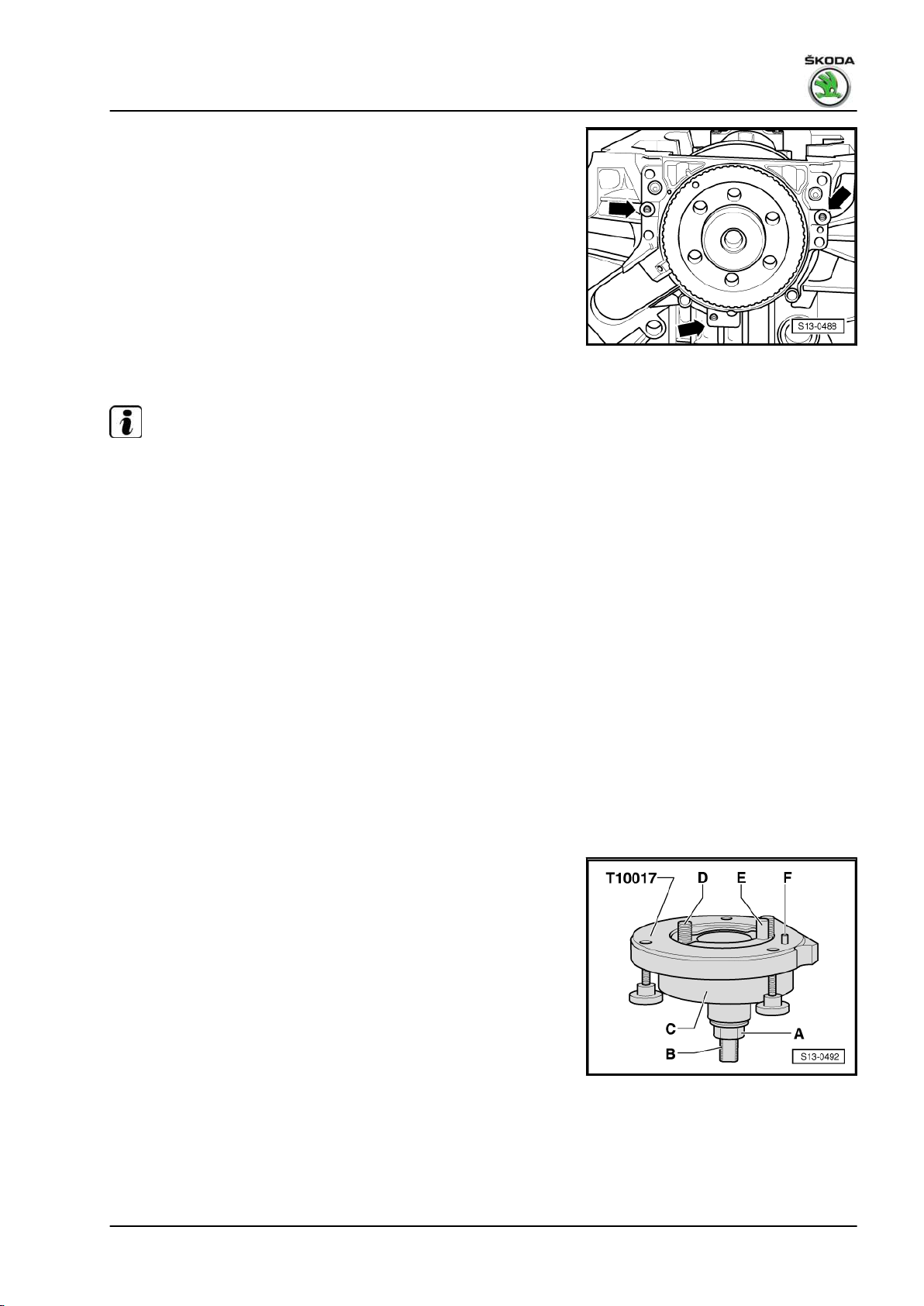

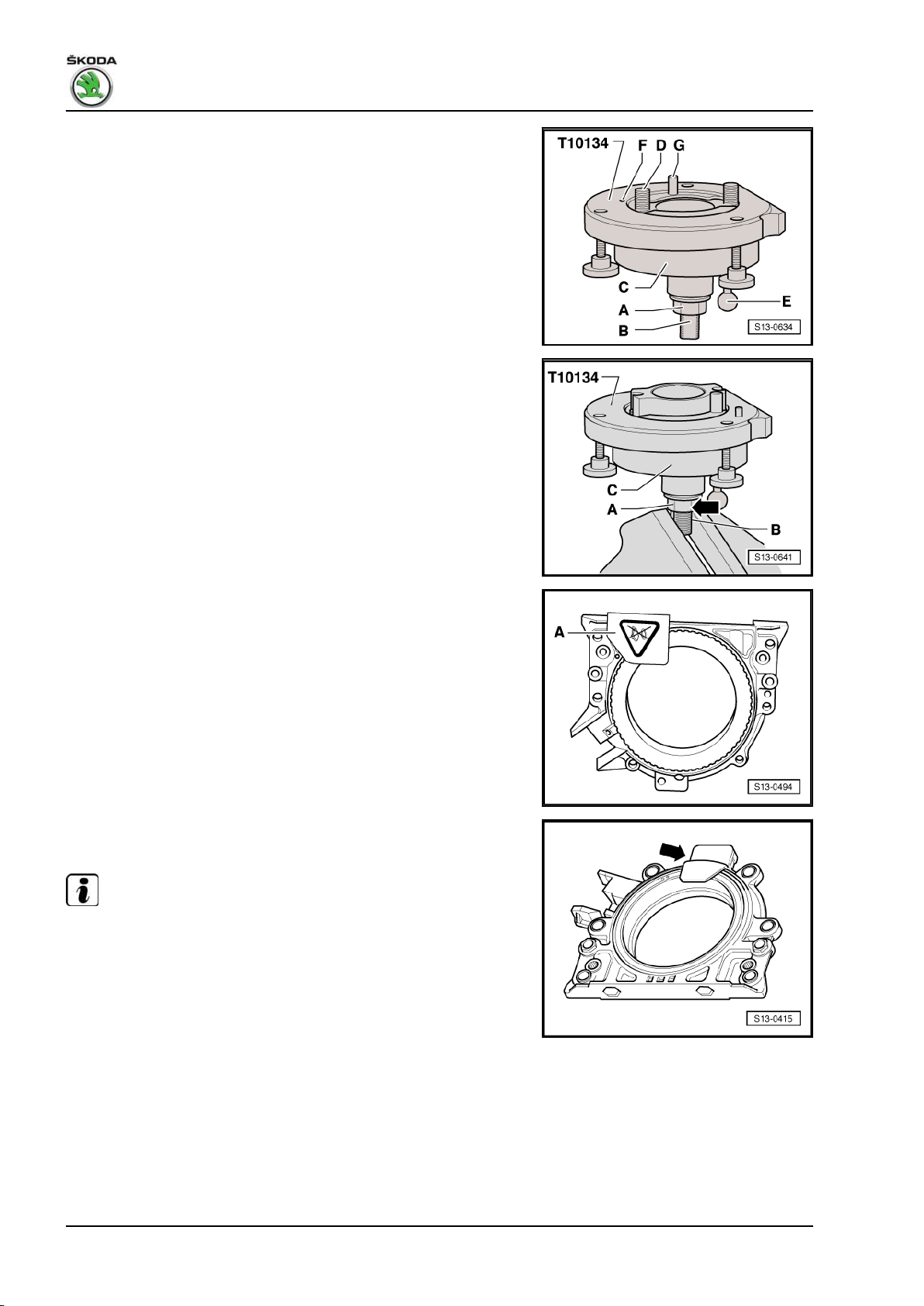

Assembly device - T10017- or -T10134A - Hexagon nut

B - Clamping surface

C - Assembly cup

D - Allan screw

2. Cylinder block, sealing flange and flywheel 41

Page 48

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Rapid India 2011 ...

1.6/77 kW MPI engine - Edition 03.2014

E - Guide bolts (for the assembly device - T10134- with red handle

- for petrol engine)

F - Positioning pin