Page 1

Service

GETtheMANUALS.org

Workshop Manual

Rapid NH 2013 ➤

Rapid NH 2014 ➤

Brake systems

Edition 07.2017

Service Department. Technical Information

Page 2

List of Workshop Manual Repair Groups

GETtheMANUALS.org

Re pa ir G ro up

00 - Technical data

45 - Anti-lock brake system

46 - Brakes - mechanism

47 - Brakes - hydraulics

Service

Technical information should always be available to the foremen and mechanics, because their

careful and constant adherence to the instructions is essential to ensure vehicle road-worthiness and

safety. In addition, the normal basic safety precautions for working on motor vehicles must, as a

matter of course, be observed.

Page 3

Contents

GETtheMANUALS.org

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

Brake systems - Edition 07.2017

00 - Technical data

1 Safety instructions

1.1 Safety precautions when working on vehicles with start-stop system . . . . . . . . . . . . . . . . 1

1.2 Safety precautions during road tests in which testing and measuring equipment is used . . 1

2 Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2.1 PR number assignment – brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

3 Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

3.1 Technical data for brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

4 Brake inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.1 General points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.2 Checking vehicles with front-wheel drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

45 - Anti-lock brake system

1 General points

1.1 Repair instructions for repair work on ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 Installation location overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.1 Installation location overview - ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2.2 Installation location overview - ABS/ESC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Control unit and hydraulic unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Exploded view – control unit and hydraulic unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3.2 Removing and installing ABS control unit J104 / ABS hydraulic unit N55 . . . . . . . . . . . . . . 25

3.3 Disconnecting the control unit from the hydraulic unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

3.4 Fitting the control unit to the hydraulic unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

4 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.1 Removing and installing front speed sensors G45 / G47 . . . . . . . . . . . . . . . . . . . . . . . . . . 36

4.2 Removing and installing the rear speed sensors G44 / G46 . . . . . . . . . . . . . . . . . . . . . . . . 36

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

46 - Brakes - mechanism

1 Front brakes

1.1 Assembly overview - front brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

1.2 Removing and installing brake pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

1.3 Removing and installing brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

2 Rear brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

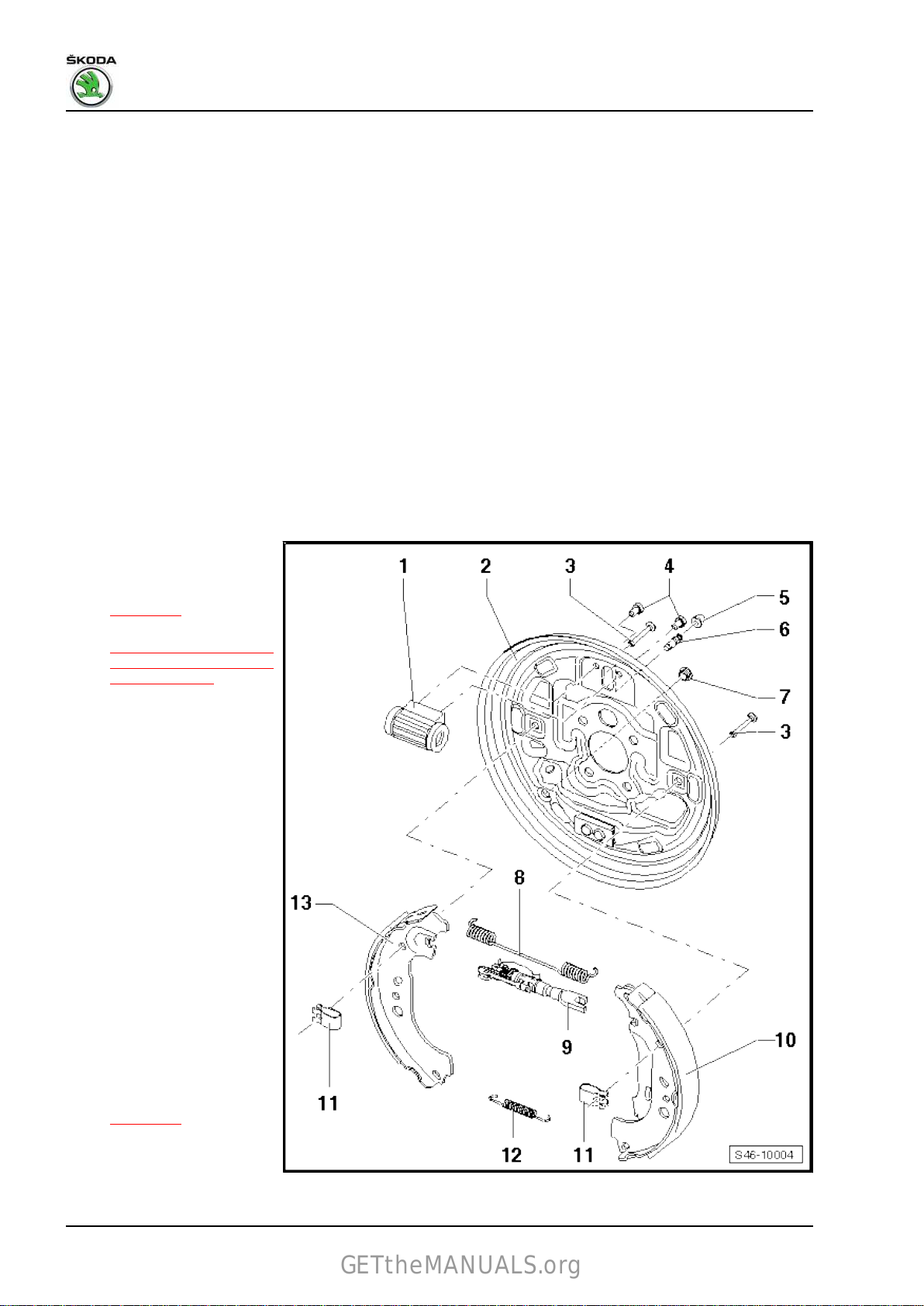

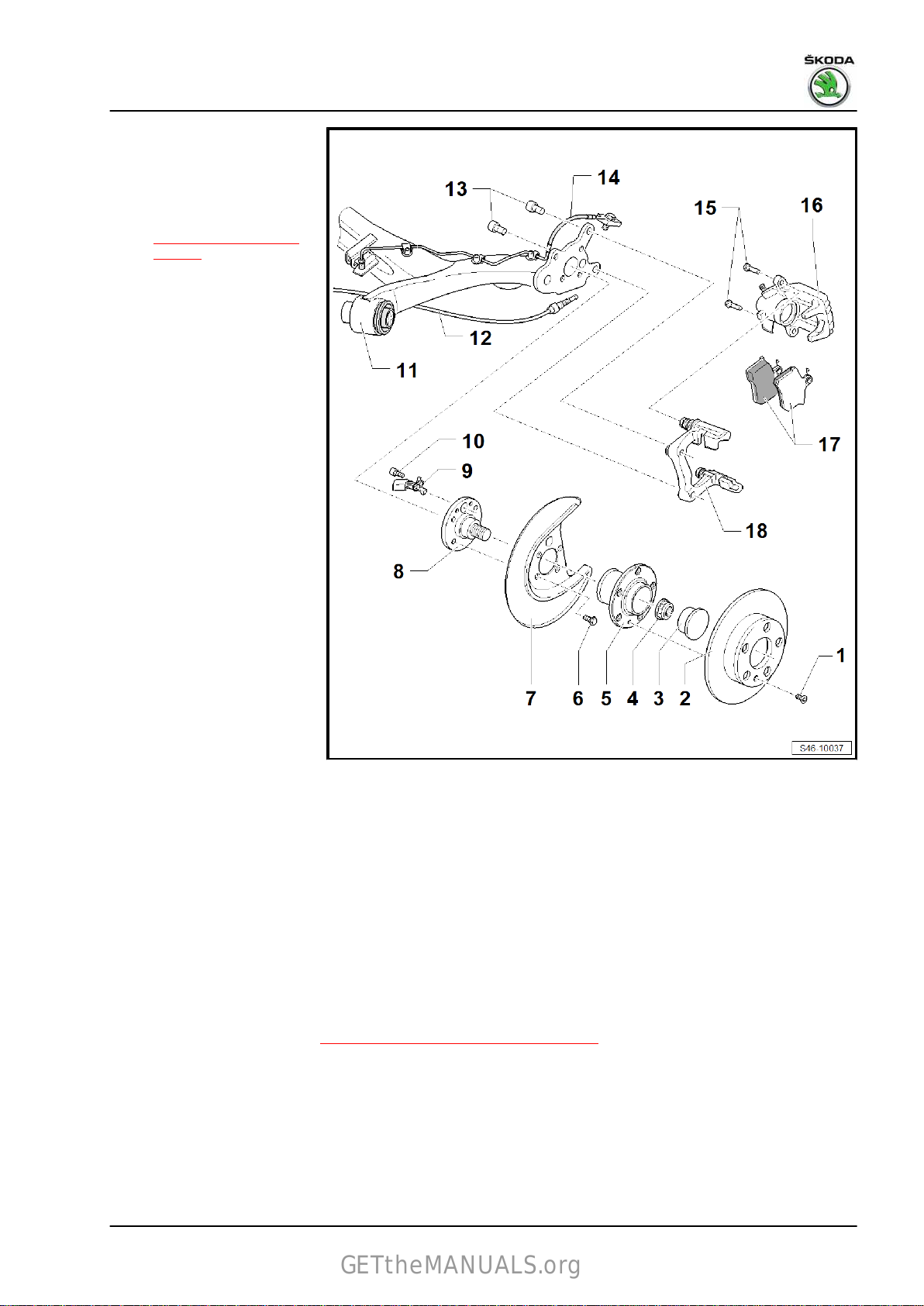

2.1 Assembly overview - rear brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

2.2 Removing and installing brake pads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

2.3 Removing and installing brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

2.4 Resetting brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

2.5 Removing and installing brake anchor plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

2.6 Removing and installing wheel-brake cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

2.7 Removing and installing brake shoes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

3 Handbrake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.1 Assembly overview - parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

3.2 Adjusting parking brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

3.3 Removing and installing the rear handbrake cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

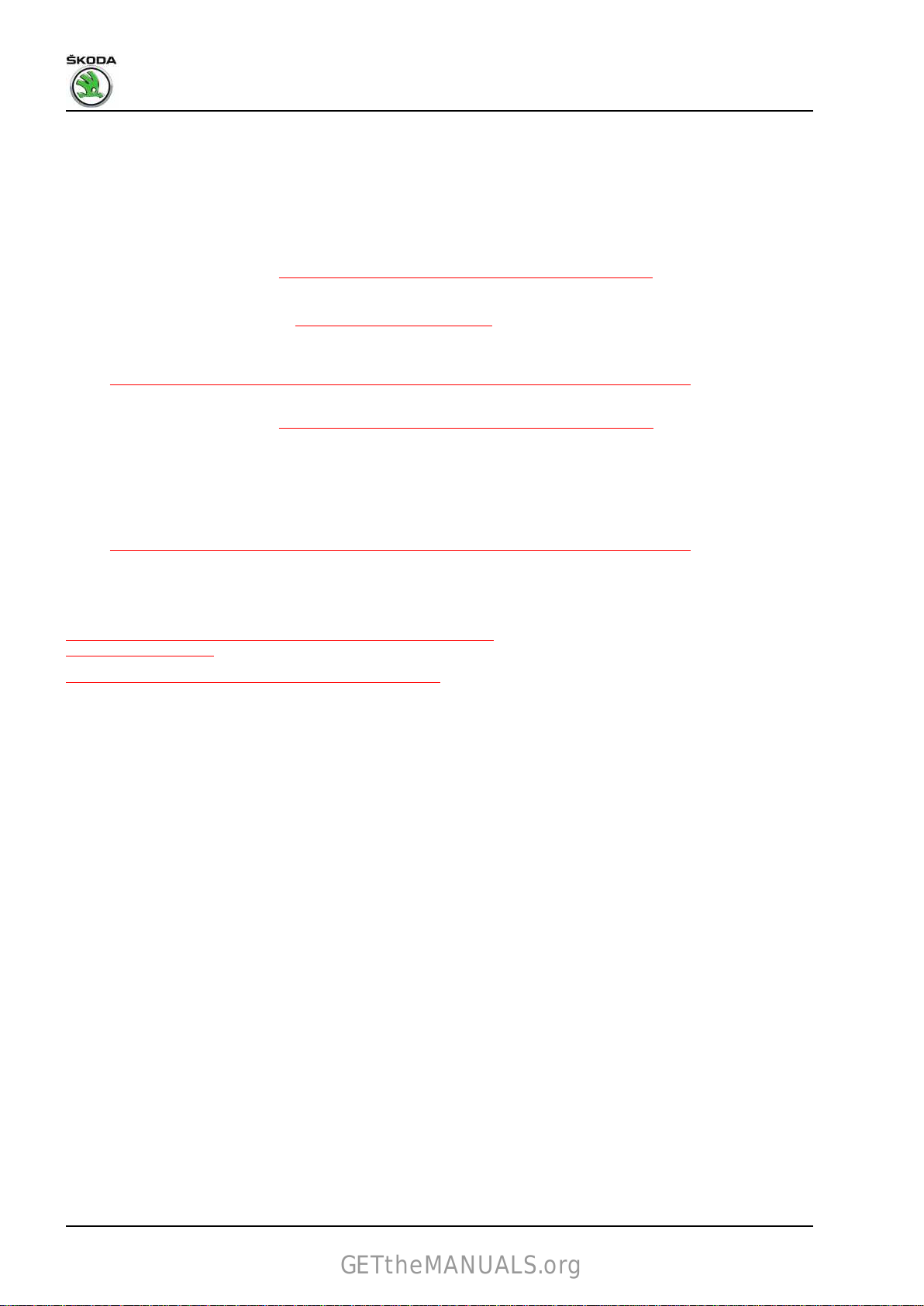

4 Brake pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.1 Assembly overview - brake pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

4.2 Removing and installing bearing bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4.3 Separating brake pedal from brake servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.4 Clipping the brake pedal onto the brake servo unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.5 Removing and installing brake pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

47 - Brakes - hydraulics

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Contents i

Page 4

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

1 Front brake calipers

1.1 Summary of components - front brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

1.2 Removing and installing brake caliper piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

2 Rear brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.1 Summary of components - rear brake caliper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.2 Removing and installing brake caliper piston . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

3 Brake servo unit and master brake cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3.1 Summary of components - brake servo unit and master brake cylinder . . . . . . . . . . . . . . 101

3.2 Check the operation of the brake servo unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3.3 Removing and installing brake light switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.4 Checking the master brake cylinder for tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

3.5 Removing and installing master brake cylinder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

3.6 Removing and installing brake servo . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

4 Vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.1 Exploded view – vacuum pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

4.2 Checking the non-return valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4.3 Checking the vacuum system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4.4 Connecting vacuum gauge for brake servo VAS 6721 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

4.5 Checking vacuum generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

4.6 Checking for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

4.7 Vacuum generation with manual vacuum pump VAS 6213 . . . . . . . . . . . . . . . . . . . . . . . . 143

4.8 Removing and installing the pressure sensor for the brake servo unit . . . . . . . . . . . . . . . . 144

4.9 Removing and installing vacuum sensor G608 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

4.10 Removing and installing electric vacuum pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

5 Brake lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

5.1 Repairing brake lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

6 Hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

6.1 General notes on brake fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

6.2 Prebleeding the hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

6.3 Bleeding hydraulic system following standard procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 153

6.4 Subsequent bleeding of hydraulic system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

6.5 Testing leak-tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

ii Contents

Page 5

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

00 – Technical data

1 Safety instructions

(SRL001107; Edition 07.2017)

⇒ “1.1 Safety precautions when working on vehicles with startstop system”, page 1

⇒ “1.2 Safety precautions during road tests in which testing and

measuring equipment is used”, page 1

1.1 Safety precautions when working on ve‐

hicles with start-stop system

When working on vehicles with start/stop system, please observe

the following instructions:

CAUTION

Risk of injury as a result of automatic engine start in vehicles

with start/stop system.

♦ In vehicles with the start/stop system activated (identifiable

by

an indication in the dash panel insert) the engine can start

automatically if required.

♦ Make sure that the start-stop system is deactivated when

carrying out work on the vehicle (switch ignition off, if nec‐

essary switch ignition on again).

Brake systems - Edition 07.2017

1.2 Safety precautions during road tests in

which

testing and measuring equipment

is used

Note the following if testers and measuring instruments have to

be used during a road test:

WARNING

There is a risk of accident from deflection and insufficient se‐

curing of testers and measuring instruments.

♦ Using testers and measuring instruments during driving op‐

eration causes distraction.

♦ There is an increased risk of injury from unsecured testers

and measuring instruments.

♦ Always attach the testing and measurement equipment to

the rear seat.

♦ Always have the testing and measurement equipment op‐

erated by a 2nd person.

♦ Always operate the testing and measurement equipment

from the rear seat.

♦ Do not operate the testing and measurement equipment

from the front passenger seat.

♦ Persons can be injured by the release of the passenger air‐

bag in the event of an accident.

1. Safety instructions 1

Page 6

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

2 Identification

⇒ “2.1 PR number assignment – brake”, page 2

2.1 PR number assignment – brake

The brake type installed in the vehicle is indicated by PR num‐

bers.

The PR numbers are indication on the vehicle data sticker in the

luggage compartment floor as well as in the Service Schedule.

Information about the installed brakes can be found in the ELSA

Pro vehicle data system.

Assignment is dependent on the engine type ⇒ Electronic Cata‐

logue of Original Parts .

2 Rep. gr.00 - Technical data

Page 7

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

3 Technical data

⇒ “3.1 Technical data for brakes”, page 3

3.1 Technical data for brakes

⇒ “3.1.1 Master brake cylinder and brake servo”, page 3

⇒ “3.1.2 Front brakes”, page 3

⇒ “3.1.3 Rear brake”, page 4

⇒ “3.1.4 Brake fluid”, page 4

3.1.1 Master brake cylinder and brake servo

Assignment is dependent on the engine type ⇒ Electronic Cata‐

logue of Original Parts .

Brake systems - Edition 07.2017

Master brake cyl‐

inder - ∅

Brake servo unit

- ∅

mm 20.64

InchLeft-hand drive: 10

Right-hand drive: 7"/8"

3.1.2 Front brakes

Assignment is dependent on the engine type ⇒ Electronic Cata‐

logue of Original Parts .

Explanations concerning PR Numbers

⇒ “2.1 PR number assignment – brake”, page 2 .

Front brake FS-III

Front brake caliper (type denomination) FS-III

PR number

Front brake caliper, piston - ∅ m

Front brake disc – ∅ m

Brake disc, thickness m

Brake disc, minimum thickness m

Pad thickness with supporting plate m

Minimum pad thickness without sup‐

porting plate

m

m

m

m

m

m

m

1ZG

54.0

256.0

22.0

19.0

19.6

2.0

Front brake FN3

Front brake caliper (type denomination) FN3

PR number

Front brake caliper, piston - ∅ m

Front brake disc – ∅ m

Brake disc, thickness m

Brake disc, minimum thickness m

m

m

m

m

1ZC

54.0

288.0

25.0

22.0

3. Technical data 3

Page 8

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

Front brake caliper (type denomination) FN3

PR number

Pad thickness with supporting plate m

Minimum pad thickness without sup‐

porting plate

m

m

m

1ZC

20.6

2.0

3.1.3 Rear brake

Assignment is dependent on the engine type ⇒ Electronic Cata‐

logue of Original Parts .

Explanations concerning PR Numbers

⇒ “2.1 PR number assignment – brake”, page 2 .

Rear disc brake C 38

Rear brake caliper (type denomination) C 38

PR number

Rear brake caliper, piston - ∅ m

Rear brake disc – ∅ m

Brake disc, thickness m

Brake disc, minimum thickness m

Pad thickness with supporting plate m

Minimum pad thickness without sup‐

porting plate

m

m

m

m

m

m

m

1KT

38

230

9

7

16.9

2.0

Rear drum brake

Rear drum brake

PR number

Brake drum - diameter ∅ m

Wheel-brake cylinder - ∅ m

Brake pad, width m

Pad thickness without supporting shoe m

Minimum pad thickness without sup‐

porting shoe

3.1.4 Brake fluid

m

m

m

m

m

m

1KL

228

19.05

4.4

1.0

32

4 Rep. gr.00 - Technical data

Page 9

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

Classification Only use new original brake fluid N.052.766.Z0 as per US standard FMVSS 571.116, DOT 4 and VW standard 501 14

Top-up ⇒ Maintenance ; Booklet Rapid NH

5

Page 10

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

4 Brake inspection

⇒ “4.1 General points”, page 6

⇒ “4.2 Checking vehicles with front-wheel drive”, page 6

4.1 General points

♦ The test stand is used as drive.

♦ During the testing, the idling speed must be set on vehicles

with manual gearbox and the driving position »N« must be

engaged on vehicles with automatic gearbox.

♦ When conducting the test, observe the specifications provided

by the manufacturer of the test rig.

Note

The brake regulation systems do not function when ignition is off.

4.2 Checking vehicles with front-wheel drive

The brake test must be performed on a single-axle roller dyna‐

mometer.

The test speed must not exceed 6 km/h.

The test stands approved by Škoda comply with these conditions.

6

Page 11

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

45 – Anti-lock brake system

1 General points

⇒ “1.1 Repair instructions for repair work on ABS”, page 7

1.1 Repair instructions for repair work on ABS

The following configurations are possible on vehicles with ABS

from TRW:

♦ ABS

♦ ABS/ESC

The ABS brake system is split diagonally. Brake servo assistance

is provided pneumatically by the vacuum brake servo.

Vehicles fitted with ABS do not have a mechanical brake pressure

regulator.

J104- regulates the brake pressure distribution on the rear axle.

Specifically matched software in the ABS control unit -

Brake systems - Edition 07.2017

Note

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control

unit - J104- must be fully replaced with the ABS hydraulic unit

- N55- .

♦

The ABS control unit - J104- can be separated from the ABS

hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”,

page 32 .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must

not be separated from each other.

♦

Faults in the ABS do not influence the brake system and servo

assistance. The conventional braking system remains fully

functional even without ABS. There will be a change in braking

behaviour. After the ABS warning lamp comes on, the rear

wheels may lock prematurely during braking.

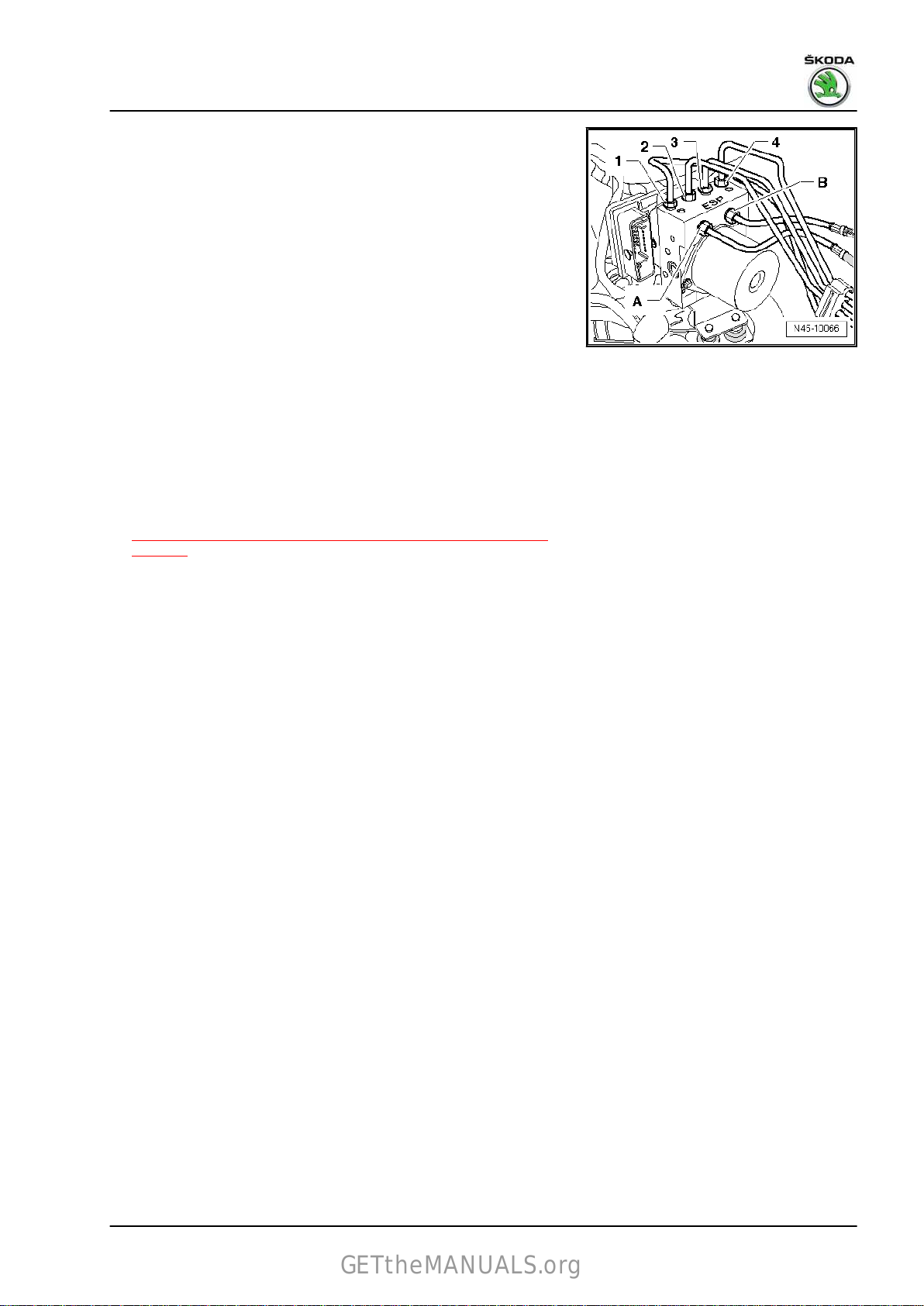

ABS arrangement, left-hand drive to CW 21/2015

1 - ABS hydraulic unit - N55- with ABS control unit - J1042 - Brake servo

1. General points 7

Page 12

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

ABS arrangement, left-hand drive to CW 22/2015

1 - Brake servo

2 - ABS hydraulic unit - N55- with ABS control unit - J104-

Arrangement of the ABS, right-hand drive vehicle

1 - Brake servo

2 - ABS hydraulic unit - N55- with ABS control unit - J104Vehicles with ABS

The ABS control unit - J104- -1-

-2- form a single unit and cannot be separated. The hydraulic

pump -3- must not be separated from the ABS hydraulic unit N55- -2-.

Vehicles with ABS / ESC to 04/2015

The ABS control unit - J104- -1-

-2- form a single unit and cannot be separated. The hydraulic

pump -3- must not be separated from the ABS hydraulic unit N55- -2-.

Vehicles with ABS / ESC from 05/2015

and the ABS hydraulic unit - N55-

and the ABS hydraulic unit - N55-

8 Rep. gr.45 - Anti-lock brake system

Page 13

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

The ABS control unit - J104- -1-

-2- form a single unit. They can only be separated after the

complete unit is removed. The ABS control unit - J104- can be

separated from the ABS hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page

32

. The hydraulic pump -3- must not be separated from the ABS

hydraulic unit - N55- -2-.

New control units supplied by the spare parts area are not coded.

They must be coded after installation ⇒ Vehicle diagnostic tester.

Continued for all vehicles

♦ Before starting work on anti-lock brake systems, query the

event memory to check for complaints and conduct guided

fault finding ⇒ Vehicle diagnostic tester.

♦ Do not separate plug connections unless the ignition is switch‐

ed off.

♦ Before working on anti-lock braking systems, switch off the

ignition and disconnect the ground strap from the battery ⇒

Electrical system; Rep. gr. 27 ; Battery; Disconnect and con‐

nect battery .

♦ If the battery earth strap is disconnected and connected, carry

out additional operations ⇒ Electrical System; Rep. gr. 27 ;

Battery .

♦ Welding work using electric welding equipment may affect the

ABS system.

♦ Do the following before commencing welding work using elec‐

trical welding tool:

– Disconnect the earth strap from the negative terminal of the

battery and cover the negative terminal.

– Connect the earth connection of the electric welding tool di‐

rectly to the part to be welded. There must not be any electri‐

cally insulated parts between the earth connection and the

welding point.

– Electronic control units and electrical wiring must not touch the

earth connection or the welding electrode.

♦ During painting operations, the ABS control unit - J104- may

be exposed to a maximum temperature of 95 °C for only a

short period, and to a maximum of 85 °C for longer periods

(approx. 2 hours).

♦ Do not drive the vehicle if the connector is unplugged from the

ABS control unit - J104- .

♦ Absolute cleanliness is required when working on the anti-lock

brake system. It is not permitted to use any products which

contain mineral oil, such as oils, greases etc.

♦ Thoroughly clean connection points and the surrounding area

before disconnecting, but do not use any aggressive cleaning

agents, such as brake cleaner, petroleum, thinner or similar.

♦ Place removed parts on a clean surface and cover.

♦ Carefully cover or close opened components if the repair is not

completed immediately (use plugs from the repair kit - 1H0 698

311 A- ).

♦ Only use lint-free cloths.

♦ Do not remove spare parts from their wrappings until immedi‐

ately before installation.

♦ Use only genuine wrapped parts.

and the ABS hydraulic unit - N55-

1. General points 9

Page 14

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

♦ When the system is open, do not work with compressed air

and do not move the vehicle.

♦ The valve coils in the ABS control unit - J104- must not be

calibrated.

♦ The valve coils in the ABS control unit - J104- cannot be re‐

placed.

♦ The pressure sensor must not be modified or damaged.

♦ The pressure sensor cannot be replaced.

♦ The sensor housing must not be subjected to mechanical load.

♦ No measurements must be carried out at the contact points of

the ABS control unit - J104- .

♦ No measurements must be carried out at the contact points of

the ABS hydraulic unit - N55- .

♦ The valve domes of the ABS hydraulic unit - N55- must not be

damaged or bent.

♦ The contacts on the ABS control unit - J104- and the ABS hy‐

draulic unit - N55- cannot be replaced.

♦ Do not use contact spray.

♦ No contamination or foreign object may located between ABS

control unit - J104- and ABS hydraulic unit - N55- .

♦ Ensure that no brake fluid enters connectors.

♦ Observe the relevant instructions when handling brake fluid.

♦ After completing work which involved opening the brake sys‐

tem,

bleed the brake system with the brake filling and bleeding

device , e. g. -VAS 5234- ,

⇒ “6.3 Bleeding hydraulic system following standard proce‐

dure”, page 153 .

♦ During the subsequent road test, ensure that at least one con‐

trolled

brake application is performed (pulsing must be felt on

the brake pedal).

10 Rep. gr.45 - Anti-lock brake system

Page 15

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

2 Installation location overview

⇒ “2.1 Installation location overview - ABS”, page 11

⇒ “2.2 Installation location overview - ABS/ESC”, page 13

2.1 Installation location overview - ABS

Note

The hydraulic pump and the ABS hydraulic unit - N55- must not be separated from each other.

1 - ABS control unit - J104-

❑ Fitting location: on the

ABS hydraulic unit N55- in engine compart‐

ment

⇒ “1.1 Repair instruc‐

tions for repair work on

ABS”, page 7

do not disconnect the

❑

plug connection before

the self-diagnosis is

complete; switch off the

ignition before discon‐

necting the plug con‐

nection

The following components are

integrated in the ABS control

unit - J104- :

♦ Lateral acceleration sender

- G200♦ Yaw rate sender - G202♦ Longitudinal acceleration

sender - G251- (depending

on equipment fitted)

♦ the components cannot be

changed individually

❑ Check ⇒ Vehicle diag‐

nostic tester

❑ Removing and installing

the ABS control unit J104- with the ABS hy‐

draulic unit - N55-

⇒ “3.2 Removing and

installing ABS control

unit J104 / ABS hydraul‐

ic unit N55 ”, page 25

2 - ABS hydraulic unit - N55The ABS hydraulic unit - N55- consists of these components:

ABS return flow pump - V39-

♦

♦ Valve block (contains inlet and outlet valves).

❑ The ABS return flow pump - V39- and the valve block must not be separated from each other

❑ Removing and installing

⇒ “3.2 Removing and installing ABS control unit J104 / ABS hydraulic unit N55 ”, page 25

3 - ABS warning light - K47-

Fitting location: in the dash panel insert

❑

2. Installation location overview 11

Page 16

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

4 - Dual circuit and hand brake system warning light - K7 -

❑

Fitting location: in the dash panel insert

5 - Diagnostic connection

❑ Fitting location: behind bottom part of dash panel, driver side

6 - Brake light switch - F-

❑ Including brake pedal switch - F47❑ Removing and installing

7 - Front right and left wheel speed sensors - G45- / -G47-

❑

Check ⇒ Vehicle diagnostic tester

❑ Removing and installing

8 - Wheel hub with wheel bearing

❑

Sensor ring for ABS is built into the wheel hub

9 - Rear right and left wheel speed sensors - G44- / -G46-

❑ Check ⇒ Vehicle diagnostic tester

❑ Removing and installing

⇒ “4.2 Removing and installing the rear speed sensors G44 / G46 ”, page 36

10 - Wheel hub with wheel bearing

❑

Sensor ring for ABS is built into the wheel hub

⇒ “3.3 Removing and installing brake light switch”, page 105

⇒ “4.1 Removing and installing front speed sensors G45 / G47 ”, page 36

12 Rep. gr.45 - Anti-lock brake system

Page 17

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

2.2 Installation location overview - ABS/ESC

Note

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control unit - J104- must be fully replaced with the

ABS hydraulic unit - N55- .

♦

On vehicles manufactured from 05/2015 (⇒ Electronic Catalogue of Original Parts ), you can disconnect

the ABS control unit - J104- from the ABS hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page 32 .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must not be separated from each other.

1 - ABS control unit - J104-

❑ Fitting location: on the

ABS hydraulic unit -

N55- in engine compart‐

ment

❑ do not disconnect the

plug connection before

the self-diagnosis is

complete; switch off the

ignition before discon‐

necting the plug con‐

nection

The following components are

integrated in the ABS control

unit - J104- :

♦ Lateral acceleration sender

- G200♦ Yaw rate sender - G202♦ Longitudinal acceleration

sender - G251- (depending

on equipment fitted)

♦ the components cannot be

changed individually

❑ Check ⇒ Vehicle diag‐

nostic tester

❑ Removing and installing

the ABS control unit J104- with the ABS hy‐

draulic unit - N55-

⇒ “3.2 Removing and

installing ABS control

unit J104 / ABS hydraul‐

ic unit N55 ”, page 25

Vehicles as of 05/2015

❑ Disconnecting the con‐

trol unit from the hy‐

draulic unit ⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page 32

❑ Fitting the control unit to the hydraulic unit

⇒ “3.4 Fitting the control unit to the hydraulic unit”, page 34

2 - ABS hydraulic unit - N55The ABS hydraulic unit - N55- consists of these components:

❑ ABS return flow pump - V39❑ Brake pressure sender 1 - G201-

Valve block (contains inlet and outlet valves).

2. Installation location overview 13

Page 18

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

❑ The ABS return flow pump - V39- and the valve block must not be separated from each other

❑

Removing and installing

⇒ “3.2 Removing and installing ABS control unit J104 / ABS hydraulic unit N55 ”, page 25

3 - Warning light 2 for ESC and TCS - K216-

❑

Fitting location: in the dash panel insert

4 - ABS warning light - K47-

❑ Fitting location: in the dash panel insert

5 - Warning light for ESC and TCS - K155-

❑ Fitting location: in the dash panel insert

6 - Dual circuit and hand brake system warning light - K7 -

❑ Fitting location: in the dash panel insert

7 - Warning light for tyre pressure display - K220-

❑ Fitting location: in the dash panel insert

8 - Brake light switch - F-

❑ Including brake pedal switch - F47❑ Removing and installing

9 - TCS and ESP button - E256-

❑

Fitting location: in the dash panel

10 - Diagnostic connection

❑ Fitting location: behind bottom part of dash panel, driver side

11 - Steering angle sender - G85-

❑ Fitting location: on the steering column between the steering wheel and the steering column switch

❑ Removing and installing ⇒ Electrical System; Rep. gr. 94

12 - Front right and left wheel speed sensors - G45- / -G47-

❑ Check ⇒ Vehicle diagnostic tester

❑ Removing and installing

13 - Wheel hub with wheel bearing

❑

Sensor ring for ABS is built into the wheel hub

14 - Rear right and left wheel speed sensors - G44- / -G46-

❑ Check ⇒ Vehicle diagnostic tester

❑ Removing and installing

⇒ “4.2 Removing and installing the rear speed sensors G44 / G46 ”, page 36

15 - Wheel hub with wheel bearing

❑

Sensor ring for ABS is built into the wheel hub

⇒ “3.3 Removing and installing brake light switch”, page 105

⇒ “4.1 Removing and installing front speed sensors G45 / G47 ”, page 36

14 Rep. gr.45 - Anti-lock brake system

Page 19

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

3 Control unit and hydraulic unit

⇒ “3.1 Exploded view – control unit and hydraulic unit”,

page 15

⇒ “3.2 Removing and installing ABS control unit J104 / ABS hy‐

draulic unit N55 ”, page 25

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page

32

⇒ “3.4 Fitting the control unit to the hydraulic unit”, page 34

3.1 Exploded view – control unit and hy‐

draulic unit

⇒ “3.1.1 Summary of components - control unit and hydraulic unit

for ABS, left-hand drive vehicles”, page 15

⇒ “3.1.2 Summary of components - control unit and hydraulic unit

for ABS, right-hand drive vehicles”, page 17

⇒ “3.1.3 Summary of components - control unit and hydraulic unit

for ABS/ESC, left-hand drive vehicles up to 21/2015”, page 19

⇒ “3.1.4 Summary of components - control unit and hydraulic unit

for ABS/ESC, right-hand drive vehicles from 22/2015”,

page 21

⇒ “3.1.5 Summary of components - control unit and hydraulic unit

for ABS/ESC, right-hand drive vehicles”, page 23

Brake systems - Edition 07.2017

3.1.1 Summary of components - control unit and hydraulic unit for ABS, left-hand

drive vehicles

Note

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control unit - J104- must be fully replaced with the

ABS hydraulic unit - N55- .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must not be separated from each other.

3. Control unit and hydraulic unit 15

Page 20

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

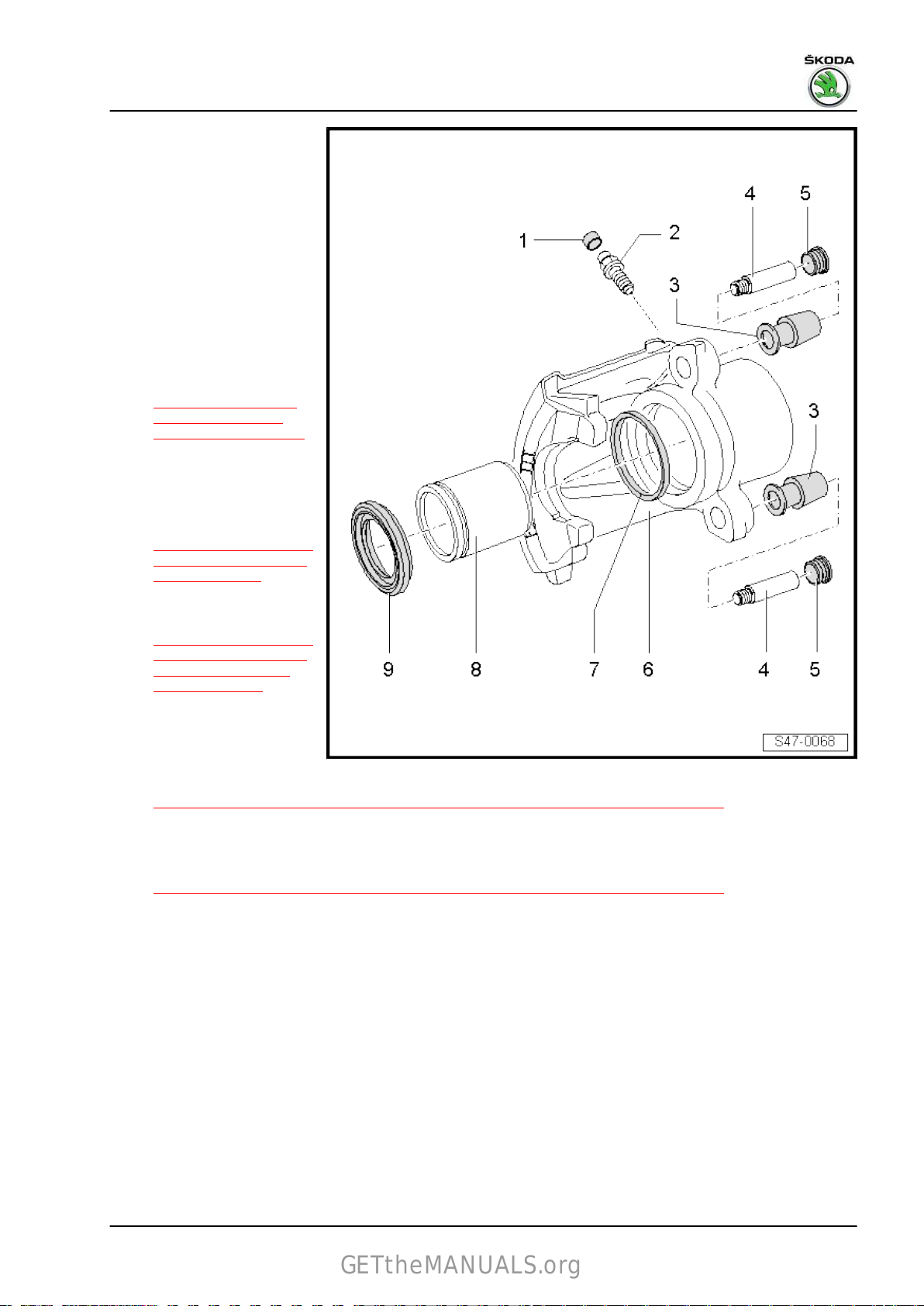

1 - ABS control unit - J104-

❑ with

❑ Removing and installing

2 - Brake line

❑

❑ Marking on the ABS hy‐

❑ With thread M10 x 1

❑ 14 Nm

3 - Brake line

❑ to rear left brake caliper/

❑ Marking on the ABS hy‐

❑ With thread M12 x 1

❑ 14 Nm

4 - Brake line

❑ to rear right brake cali‐

❑ Marking on the ABS hy‐

❑ With thread M10 x 1

❑ 14 Nm

5 - Brake line

❑ to front left brake caliper

❑ Marking on the ABS hydraulic unit - N55- -Front left (VL)❑ With thread M12 x 1

❑ 14 Nm

6 - Brake line

❑ from master brake cylinder (push rod piston circuit) to ABS hydraulic unit - N55❑ Marking on the ABS hydraulic unit - N55- -Hydraulic cylinder 2 (HZ2)❑ With thread M12 x 1

❑ 14 Nm

7 - Brake line

❑ from master brake cylinder (floating piston circuit) to ABS hydraulic unit - N55❑ Marking on the ABS hydraulic unit - N55- -Hydraulic cylinder 1 (HZ1)❑ With thread M12 x 1

❑ 14 Nm

8 - Brake servo

❑ Removing and installing

9 - Nut

❑

ABS hydraulic unit -

N55-

⇒ “3.2 Removing and in‐

stalling ABS control unit

J104 / ABS hydraulic

unit N55 ”, page 25

to front right brake cali‐

per

draulic unit - N55-

-Front right (VR)-

wheel-brake cylinder

draulic unit - N55-

-Rear left (HL)-

per/wheel-brake cylin‐

der

draulic unit - N55-

-Rear right (HR)-

⇒ “3.6 Removing and installing brake servo”, page 114

self-locking

16 Rep. gr.45 - Anti-lock brake system

Page 21

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

❑ 20 Nm

10 - Mounting bracket

11 - Screw

❑

8 Nm

12 - Mounting bracket

❑ Moisten the bolt of the support with lubricant, e.g. -D 007 000 A2- , before inserting into the rubber

bearings

❑ after installing, check for firm seating

3.1.2 Summary

of components - control unit and hydraulic unit for ABS, right-hand

drive vehicles

Note

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control unit - J104- must be fully replaced with the

ABS hydraulic unit - N55- .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must not be separated from each other.

1 - Brake line

❑ from master brake cylin‐

der (push rod piston cir‐

cuit) to ABS hydraulic

unit - N55-

❑ Marking on the ABS hy‐

draulic unit - N55-

3. Control unit and hydraulic unit 17

Page 22

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

-Hydraulic cylinder 2 (HZ2)-

❑

With thread M12 x 1

❑ 14 Nm

2 - Brake line

❑ from master brake cylinder (floating piston circuit) to ABS hydraulic unit - N55❑ Marking on the ABS hydraulic unit - N55- -Hydraulic cylinder 1 (HZ1)❑ With thread M12 x 1

❑ 14 Nm

3 - Brake line

❑ to front right brake caliper

❑ Marking on the ABS hydraulic unit - N55- -Front right (VR)❑ With thread M10 x 1

❑ 14 Nm

4 - Brake line

❑ to rear left brake caliper/wheel-brake cylinder

❑ Marking on the ABS hydraulic unit - N55- -Rear left (HL)❑ With thread M12 x 1

❑ 14 Nm

5 - Brake line

❑ to rear right brake caliper/wheel-brake cylinder

❑ Marking on the ABS hydraulic unit - N55- -Rear right (HR)❑ With thread M10 x 1

❑ 14 Nm

6 - Brake line

❑ to front left brake caliper

❑ Marking on the ABS hydraulic unit - N55- -Front left (VL)❑ With thread M12 x 1

❑ 14 Nm

7 - ABS control unit - J104-

❑ with ABS hydraulic unit - N55❑ Removing and installing

⇒ “3.2 Removing and installing ABS control unit J104 / ABS hydraulic unit N55 ”, page 25

8 - Mounting bracket

9 - Screw

❑

8 Nm

10 - Nut

❑ self-locking

❑ 20 Nm

11 - Mounting bracket

❑ Moisten the bolt of the support with lubricant, e.g. -D 007 000 A2- , before inserting into the rubber

bearings

❑ after installing, check for firm seating

12 - Brake servo

❑ Removing and installing

⇒ “3.6 Removing and installing brake servo”, page 114

18 Rep. gr.45 - Anti-lock brake system

Page 23

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

3.1.3 Summary of components - control unit and hydraulic unit for ABS/ESC, left-

hand drive vehicles up to 21/2015

Note

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control unit - J104- must be fully replaced with the

ABS hydraulic unit - N55- .

♦

On vehicles manufactured from 05/2015 (⇒ Electronic Catalogue of Original Parts ), you can disconnect

the ABS control unit - J104- from the ABS hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page 32 .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must not be separated from each other.

1 - ABS control unit - J104-

❑ with ABS hydraulic unit -

N55-

❑ Disconnecting the con‐

trol unit from the hy‐

draulic unit

⇒ “3.3 Disconnecting

the control unit from the

hydraulic unit”,

page 32

❑ Fitting

❑ Removing

2 - Brake line

❑

❑ Marking on the ABS hy‐

❑ With thread M10 x 1

❑ 14 Nm

3 - Brake line

❑ to rear left brake caliper/

❑ Marking on the ABS hy‐

❑ With thread M12 x 1

❑ 14 Nm

4 - Brake line

❑ to rear right brake caliper/wheel-brake cylinder

❑ Marking on the ABS hydraulic unit - N55- -Rear right (HR)-

❑ With thread M10 x 1

❑ 14 Nm

the control unit to

the hydraulic unit

⇒ “3.4 Fitting the control

unit to the hydraulic

unit”, page 34

and installing

⇒ “3.2 Removing and in‐

stalling ABS control unit

J104 / ABS hydraulic

unit N55 ”, page 25

to front right brake cali‐

per

draulic unit - N55-

-Front right (VR)-

wheel-brake cylinder

draulic unit - N55-

-Rear left (HL)-

3. Control unit and hydraulic unit 19

Page 24

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

5 - Brake line

❑

to front left brake caliper

❑ Marking on the ABS hydraulic unit - N55- -Front left (VL)❑ With thread M12 x 1

❑ 14 Nm

6 - Brake line

❑ from master brake cylinder (push rod piston circuit) to ABS hydraulic unit - N55❑ Marking on the ABS hydraulic unit - N55- -Hydraulic cylinder 2 (HZ2)❑ With thread M12 x 1

❑ 14 Nm

7 - Brake line

❑ from master brake cylinder (floating piston circuit) to ABS hydraulic unit - N55❑ Marking on the ABS hydraulic unit - N55- -Hydraulic cylinder 1 (HZ1)❑ With thread M12 x 1

❑ 14 Nm

8 - Brake servo

❑ Removing and installing

9 - Nut

❑

self-locking

❑ 20 Nm

10 - Mounting bracket

11 - Screw

❑ 8 Nm

12 - Mounting bracket

❑ Moisten the bolt of the support with lubricant, e.g. -D 007 000 A2- , before inserting into the rubber

bearings

❑ after installing, check for firm seating

⇒ “3.6 Removing and installing brake servo”, page 114

20 Rep. gr.45 - Anti-lock brake system

Page 25

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

3.1.4 Summary of components - control unit and hydraulic unit for ABS/ESC, right-hand drive vehicles from 22/2015

Note

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control unit - J104- must be fully replaced with the

ABS hydraulic unit - N55- .

♦

On vehicles manufactured from 05/2015 (⇒ Electronic Catalogue of Original Parts ), you can disconnect

the ABS control unit - J104- from the ABS hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page 32 .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must not be separated from each other.

1 - Brake servo

❑ Removing and installing

⇒ “3.6 Removing and in‐

stalling brake servo”,

page 114

2 - Brake line

❑ from

❑ Marking on the ABS hy‐

master brake cylin‐

der (push rod piston cir‐

cuit) to ABS hydraulic

unit - N55-

draulic unit - N55-

-Hydraulic cylinder 2 (HZ2)-

❑ With thread M12 x 1

❑ 14 Nm

3 - Brake line

❑ from master brake cylinder (floating piston circuit) to ABS hydraulic unit - N55❑ Marking on the ABS hydraulic unit - N55- -Hydraulic cylinder 1 (HZ1)❑ With thread M12 x 1

3. Control unit and hydraulic unit 21

Page 26

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

❑ 14 Nm

4 - Brake line

❑

to front right brake caliper

❑ Marking on the ABS hydraulic unit - N55- -Front right (VR)❑ With thread M10 x 1

❑ 14 Nm

5 - Brake line

❑ to rear left brake caliper/wheel-brake cylinder

❑ Marking on the ABS hydraulic unit - N55- -Rear left (HL)❑ With thread M12 x 1

❑ 14 Nm

6 - Brake line

❑ to rear right brake caliper/wheel-brake cylinder

❑ Marking on the ABS hydraulic unit - N55- -Rear right (HR)❑ With thread M10 x 1

❑ 14 Nm

7 - Brake line

❑ to front left brake caliper

❑ Marking on the ABS hydraulic unit - N55- -Front left (VL)❑ With thread M12 x 1

❑ 14 Nm

8 - ABS control unit - J104-

❑ with ABS hydraulic unit - N55❑ Disconnecting the control unit from the hydraulic unit

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page 32

❑

Fitting the control unit to the hydraulic unit

⇒ “3.4 Fitting the control unit to the hydraulic unit”, page 34

❑

Removing and installing

⇒ “3.2 Removing and installing ABS control unit J104 / ABS hydraulic unit N55 ”, page 25

9 - Mounting bracket

❑

with rubber bearings

❑ attached to the ABS hydraulic unit - N55- by 2 bolts

❑ 8 Nm

10 - Mounting bracket

❑ Moisten the bolt of the support with lubricant, e.g. -D 007 000 A2- , before inserting into the rubber

bearings

❑ after installing, check for firm seating

11 - Nut

❑ self-locking

❑ 20 Nm

22 Rep. gr.45 - Anti-lock brake system

Page 27

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

3.1.5 Summary of components - control unit and hydraulic unit for ABS/ESC, right-hand drive vehicles

Note

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control unit - J104- must be fully replaced with the

ABS hydraulic unit - N55- .

♦

On vehicles manufactured from 05/2015 (⇒ Electronic Catalogue of Original Parts ), you can disconnect

the ABS control unit - J104- from the ABS hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page 32 .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must not be separated from each other.

1 - Brake line

❑ from master brake cylin‐

der (push rod piston cir‐

cuit) to ABS hydraulic

unit - N55-

❑ Marking on the ABS hy‐

draulic unit - N55-

-Hydraulic cylinder 2 (HZ2)❑ With thread M12 x 1

❑ 14 Nm

2 - Brake line

❑ from master brake cylinder (floating piston circuit) to ABS hydraulic unit - N55❑ Marking on the ABS hydraulic unit - N55- -Hydraulic cylinder 1 (HZ1)❑ With thread M12 x 1

❑ 14 Nm

3. Control unit and hydraulic unit 23

Page 28

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

3 - Brake line

❑

to front right brake caliper

❑ Marking on the ABS hydraulic unit - N55- -Front right (VR)❑ With thread M10 x 1

❑ 14 Nm

4 - Brake line

❑ to rear left brake caliper/wheel-brake cylinder

❑ Marking on the ABS hydraulic unit - N55- -Rear left (HL)❑ With thread M12 x 1

❑ 14 Nm

5 - Brake line

❑ to rear right brake caliper/wheel-brake cylinder

❑ Marking on the ABS hydraulic unit - N55- -Rear right (HR)❑ With thread M10 x 1

❑ 14 Nm

6 - Brake line

❑ to front left brake caliper

❑ Marking on the ABS hydraulic unit - N55- -Front left (VL)❑ With thread M12 x 1

❑ 14 Nm

7 - ABS control unit - J104-

❑ with ABS hydraulic unit - N55❑ Disconnecting the control unit from the hydraulic unit

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”, page 32

❑

Fitting the control unit to the hydraulic unit

⇒ “3.4 Fitting the control unit to the hydraulic unit”, page 34

❑

Removing and installing

⇒ “3.2 Removing and installing ABS control unit J104 / ABS hydraulic unit N55 ”, page 25

8 - Mounting bracket

9 - Screw

❑

8 Nm

10 - Nut

❑ self-locking

❑ 20 Nm

11 - Mounting bracket

❑ Moisten the bolt of the support with lubricant, e.g. -D 007 000 A2- , before inserting into the rubber

bearings

❑ after installing, check for firm seating

12 - Brake servo

❑ Removing and installing

⇒ “3.6 Removing and installing brake servo”, page 114

24 Rep. gr.45 - Anti-lock brake system

Page 29

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

3.2 Removing and installing ABS control unit - J104- / ABS hydraulic unit - N55-

⇒ “3.2.1 Removing and installing ABS control unit J104 / ABS

hydraulic unit N55 , left -hand drive vehicles up to 21/2015”, page

25

⇒ “3.2.2 Removing and installing ABS control unit J104 / ABS

hydraulic unit N55 , left -hand drive vehicles from 22/2015”, page

28

⇒ “3.2.3 Removing and installing ABS control unit J104 / ABS

hydraulic unit N55 , right-hand drive vehicles”, page 30

3.2.1 Removing and installing ABS control unit - J104- / ABS hydraulic unit - N55- , left -hand drive vehicles up to 21/2015

Special tools and workshop equipment required

♦ Brake pedal load , e.g. -V.A.G 1869/2♦ Brake filling and bleeding device , e. g. -VAS 5234♦ Repair kit - 1H0 698 311 ARemoving

Fitting location:

The ABS control unit - J104- is bolted to the ABS hydraulic unit -

N55-

and is located in the engine compartment on the right side.

Brake systems - Edition 07.2017

Note

Do not bend the brake lines in the area of the hydraulic unit.

– Read out and note the actual control unit coding ⇒ Vehicle

diagnostic tester.

– Disconnect battery ⇒ Electrical System; Rep. gr. 27 .

– If present, remove engine cover ⇒ Engine; Rep. gr. 10 .

Vehicles with engines TDI Common Rail DPF (diesel particle fil‐

ter)

– Remove plenum chamber cover ⇒ Body Work; Rep. gr. 66 .

– If present, open heat shield collar.

– Take

– Remove the connector holder from the bulkhead plenum

– Remove intake hose and air filter ⇒ Engine; Rep. gr. 23 .

– Pull the engine control unit out of the bracket and lay to the

– Remove engine control unit bracket.

– Remove the insulation from the bulkhead plenum chamber.

– Remove bulkhead plenum chamber ⇒ Body Work; Rep. gr.

Continued for all vehicles

plug connections -1- to -4- out of the bracket, disconnect

and expose electric cables.

chamber.

side.

50 .

3. Control unit and hydraulic unit 25

Page 30

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

– Press down the red fuse -arrow-.

– Unlock the plug connection of the control unit -arrow- and pull

out towards the front.

– Attach the bleeder hose of the bleeding bottle onto the vent

valves of the front left and rear left brake caliper and open vent

valves.

– Press down brake pedal with brake pedal load , e.g. -V.A.G

1869/2- , at least 60 mm.

– Close front left and rear left bleeder valves.

– Do not remove brake pedal load , e. g. -V.A.G 1869/2- .

– Place a sufficient non-fluffing cloths under and around the ABS

control unit - J104- and the ABS hydraulic unit - N55- .

NOTICE

Make sure that no brake fluid gets onto the contacts of the ABS

control unit - J104- .

26 Rep. gr.45 - Anti-lock brake system

Page 31

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

– Mark

– Unscrew the brake lines from the ABS hydraulic unit - N55- ,

– Close the brake lines and threaded holes immediately with

– Mark the brake lines (for brake calliper) -1- to -4-, unscrew and

– Pull ABS hydraulic unit - N55- with ABS control unit - J104-

– Slacken nuts and remove bracket (if it is necessary to remove

♦

brake lines -A- and -B- from the ABS hydraulic unit - N55-

to the master brake cylinder.

unclip from the brackets and lay to the side.

plugs from the repair kit - 1H0 698 311 A- .

close with plugs from the repair kit - 1H0 698 311 A- .

upwards out of the bracket.

the bracket).

Note

If the ABS hydraulic unit - N55- is damaged, the ABS control

unit - J104- must be fully replaced with the ABS hydraulic unit

- N55- .

♦

The ABS control unit - J104- can be separated from the ABS

hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”,

page 32 .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must

not be separated from each other.

Installing

Installation is performed in the reverse order; pay attention to the

following points:

Note

♦

Only remove plugs from the new ABS hydraulic unit - N55- if

the relevant brake line is installed.

♦

If the plugs were already removed from the ABS hydraulic unit

- N55- , then brake fluid may escape and adequate filling and

bleeding of the unit can no longer be guaranteed.

♦

Make sure that the rubber bearings are not pressed out of the

console when installing the bracket. After installing, check for

tight fight, otherwise failure may be caused by a malfunction

of the ABS hydraulic unit - N55- .

• Make sure that the multi-pin plug connection latches correctly

with the ABS control unit - J104- .

– Remove brake pedal load , e.g. -V.A.G 1869/2- .

– Bleed brake system.

– Connect the battery and carry out any additional measures

after reconnecting the battery ⇒ Electrical System; Rep. gr.

27 .

– Code new ABS control unit - J104- ⇒ Vehicle diagnostic tester

and adapt.

While doing so, a basic setting of the steering angle sender G85- , the lateral acceleration sender - G200- , the brake pressure

sender 1 - G201- and the longitudinal acceleration sender - G251must be performed ⇒ Vehicle diagnostic tester.

3. Control unit and hydraulic unit 27

Page 32

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

Tightening torques

♦ ⇒ “3.1.3 Summary of components - control unit and hydraulic

unit for ABS/ESC, left-hand drive vehicles up to 21/2015”,

page 19

♦ Bulkhead plenum chamber ⇒ Body Work; Rep. gr. 50 .

♦ Air filter ⇒ Engine; Rep. gr. 23

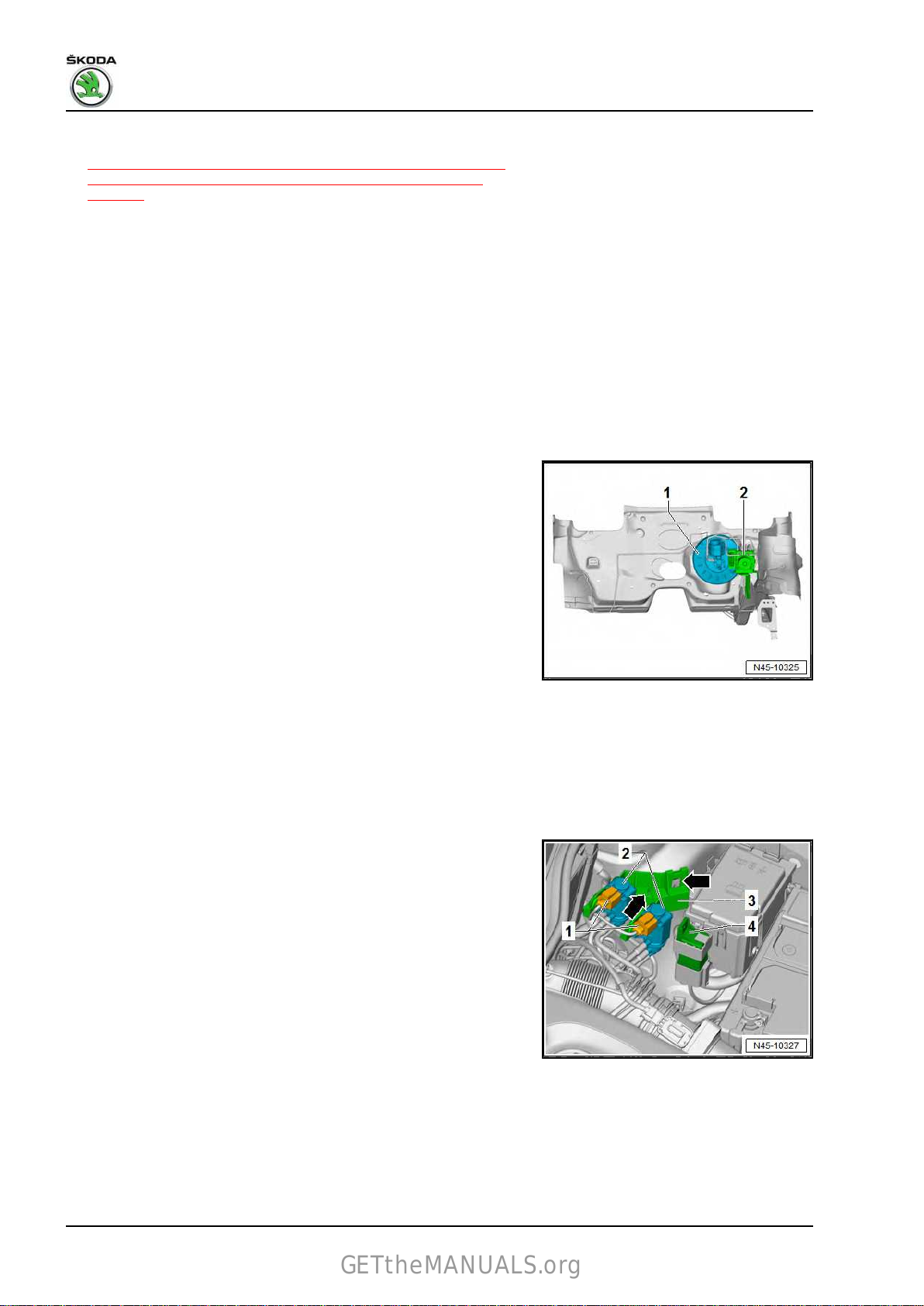

3.2.2 Removing and installing ABS control

unit - J104- / ABS hydraulic unit - N55- ,

left -hand drive vehicles from 22/2015

Special tools and workshop equipment required

♦ Brake pedal load , e.g. -V.A.G 1869/2♦ Brake filling and bleeding device , e. g. -VAS 5234♦ Repair kit - 1H0 698 311 AThe ABS control unit - J104- is bolted to the ABS hydraulic unit -

N55- and is located in the engine compartment

-2-.

Note

Do not bend the brake lines in the area of the hydraulic unit.

Removing

– Read out and document the current control unit coding ⇒ Ve‐

hicle diagnostic tester.

– Disconnect battery ⇒ Electrical System; Rep. gr. 27 .

For vehicles with 1.6 MPI engine with automatic gearbox

– Remove battery ⇒ Electrical System; Rep. gr. 27 .

– Undo the mounting bracket with the automatic gearbox control

unit - J217- and place the ⇒ gearbox; Rep. gr. 37 down to the

side.

For vehicles with a 1.4 TDI engine

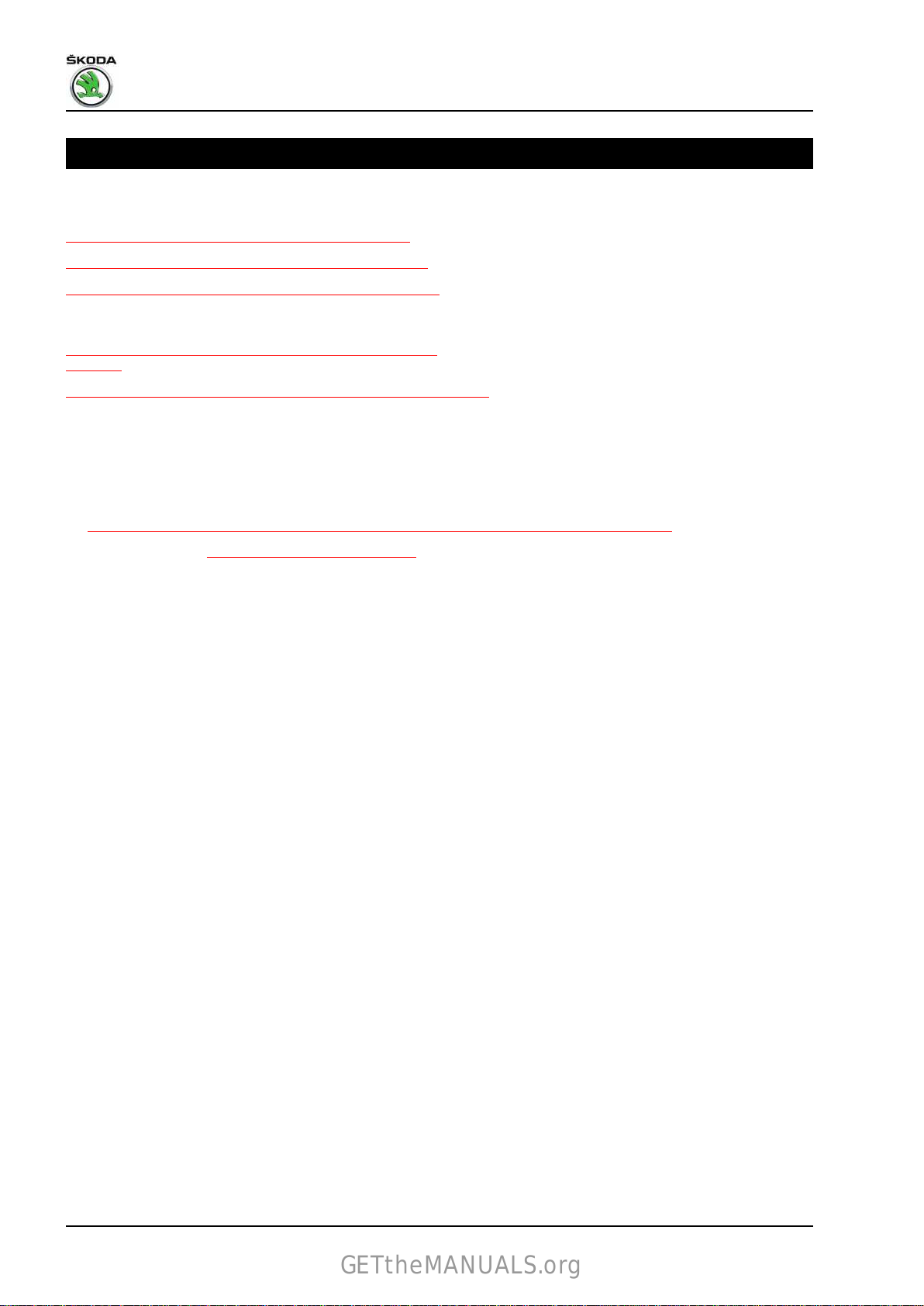

– Mark

– Remove bracket -3- together with the boost pressure actuator

– Remove bracket with -automatic glow period control unit- J179

For vehicles with a 1.6 TDI engine

– Remove engine cover ⇒ Engine; Rep. gr. 10 .

and pull off connector -1- of the boost pressure actuator

- V465- and the change over valve for the intake manifold valve

- N239- -2-.

- V465- and the change over valve for the intake manifold valve

- N239- , place down to the side.

-4- from the E-box and place to the side.

28 Rep. gr.45 - Anti-lock brake system

Page 33

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

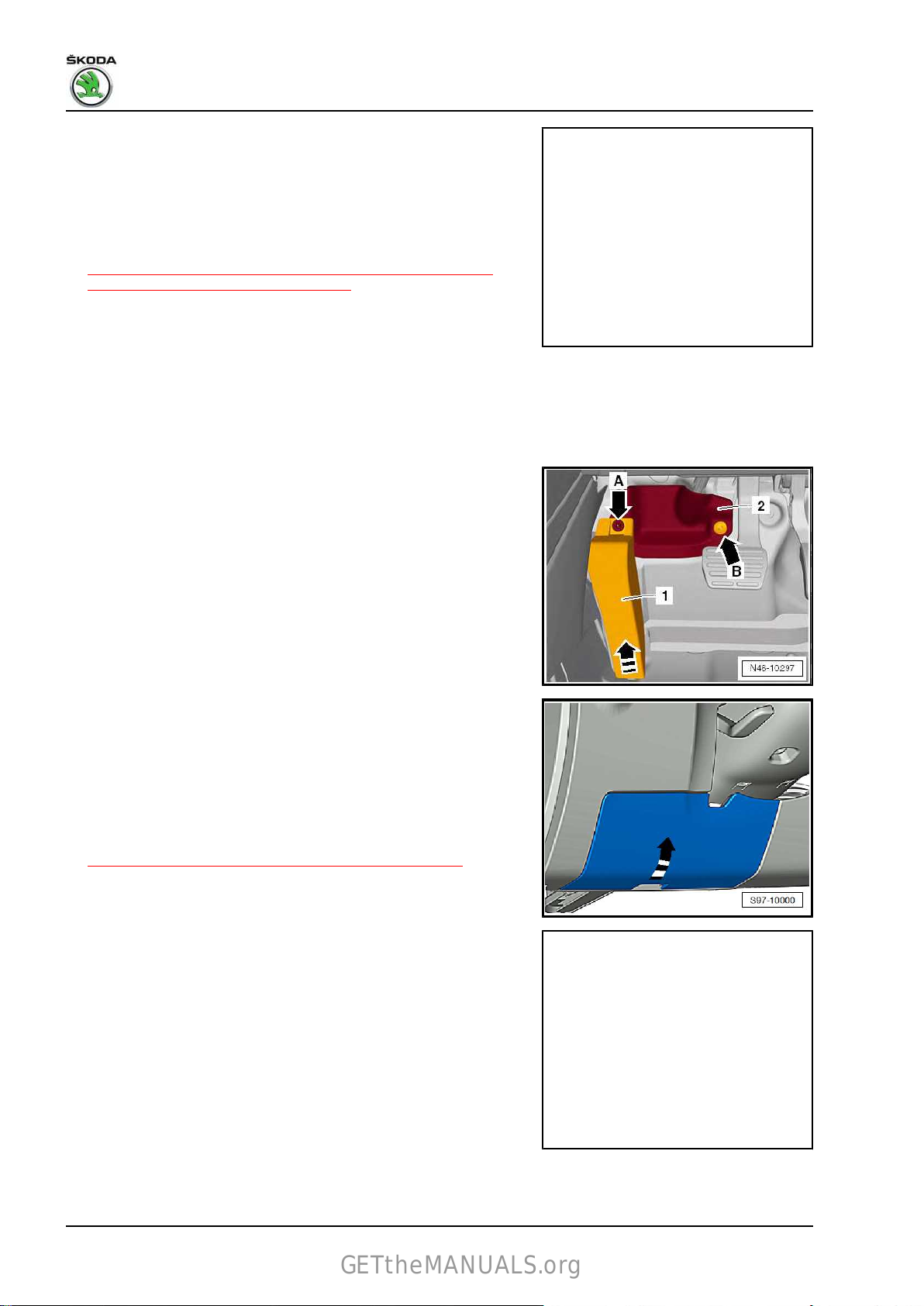

– Loosen hose clamp -1- and remove the complete air filter

housing -2- ⇒ Engine; Rep. gr. 23 .

Continued for all vehicles

– Press fuse -1- upwards in -direction of arrow-.

– Press locking element -2- upwards in -direction of arrow- and

unlock connector -3-.

– Disconnect connector -3- from ABS control unit - J104- and

place to side.

– Place a sufficient non-fluffing cloths under and around the ABS

control unit - J104- and the ABS hydraulic unit - N55- .

NOTICE

Make sure that no brake fluid gets onto the contacts of the ABS

control unit - J104- .

Brake systems - Edition 07.2017

– Drain the brake fluid from the brake fluid reservoir using the

brake filling and bleeding device e.g. -VAS 5234- .

– Mark brake lines -A- and -B- from the ABS hydraulic unit - N55-

to the master brake cylinder.

– Screw off brake lines -A- and -B- from the ABS hydraulic unit

- N55- and brake cylinder.

– Close the openings on the ABS hydraulic unit - N55- and the

master brake cylinder with screw plugs from the repair kit H0 698 311 A- .

– Unscrew brake lines (to the brake calipers) -1-4- from the ABS

hydraulic unit - N55- .

– Close the brake lines with the screw plugs from the repair kit

- H0 698 311 A- .

3. Control unit and hydraulic unit 29

Page 34

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

– Pull ABS hydraulic unit - N55- with ABS control unit - J104-

upwards out of the bracket.

Note

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control

unit - J104- must be fully replaced with the ABS hydraulic unit

- N55- .

♦

The ABS control unit - J104- can be separated from the ABS

hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”,

page 32 .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must

not be separated from each other.

Installing

Installation is performed in the reverse order; pay attention to the

following points:

Note

♦

Only remove plugs from the new ABS hydraulic unit - N55- if

the relevant brake line is installed.

♦

If the plugs were already removed from the ABS hydraulic unit

- N55- , then brake fluid may escape and adequate filling and

bleeding of the unit can no longer be guaranteed.

♦

Make sure that the rubber bearings are not pressed out of the

console when installing the bracket. After installing, check for

tight fight, otherwise failure may be caused by a malfunction

of the ABS hydraulic unit - N55- .

– Bleed brake system

– Connect the battery and carry out any additional measures

after reconnecting the battery ⇒ Electrical System; Rep. gr.

27 .

– Code the control unit - J104- ⇒ Vehicle diagnostic tester.

While doing so, a basic setting of the steering angle sender -

G85-

, the lateral acceleration sender - G200- , the brake pressure

sender 1 - G201- and the longitudinal acceleration sender - G251must be performed ⇒ Vehicle diagnostic tester.

Tightening torques

⇒ “3.1.4 Summary of components - control unit and hydraulic

♦

unit for ABS/ESC, right-hand drive vehicles from 22/2015”,

page 21

⇒ “6 Hydraulic system”, page 152 .

3.2.3 Removing and installing ABS control

unit

- J104- / ABS hydraulic unit - N55- ,

right-hand drive vehicles

Removing

Special tools and workshop equipment required

♦ Brake pedal load , e.g. -V.A.G 1869/2♦ Brake filling and bleeding device , e. g. -VAS 5234♦ Repair kit - 1H0 698 311 A-

30 Rep. gr.45 - Anti-lock brake system

Page 35

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

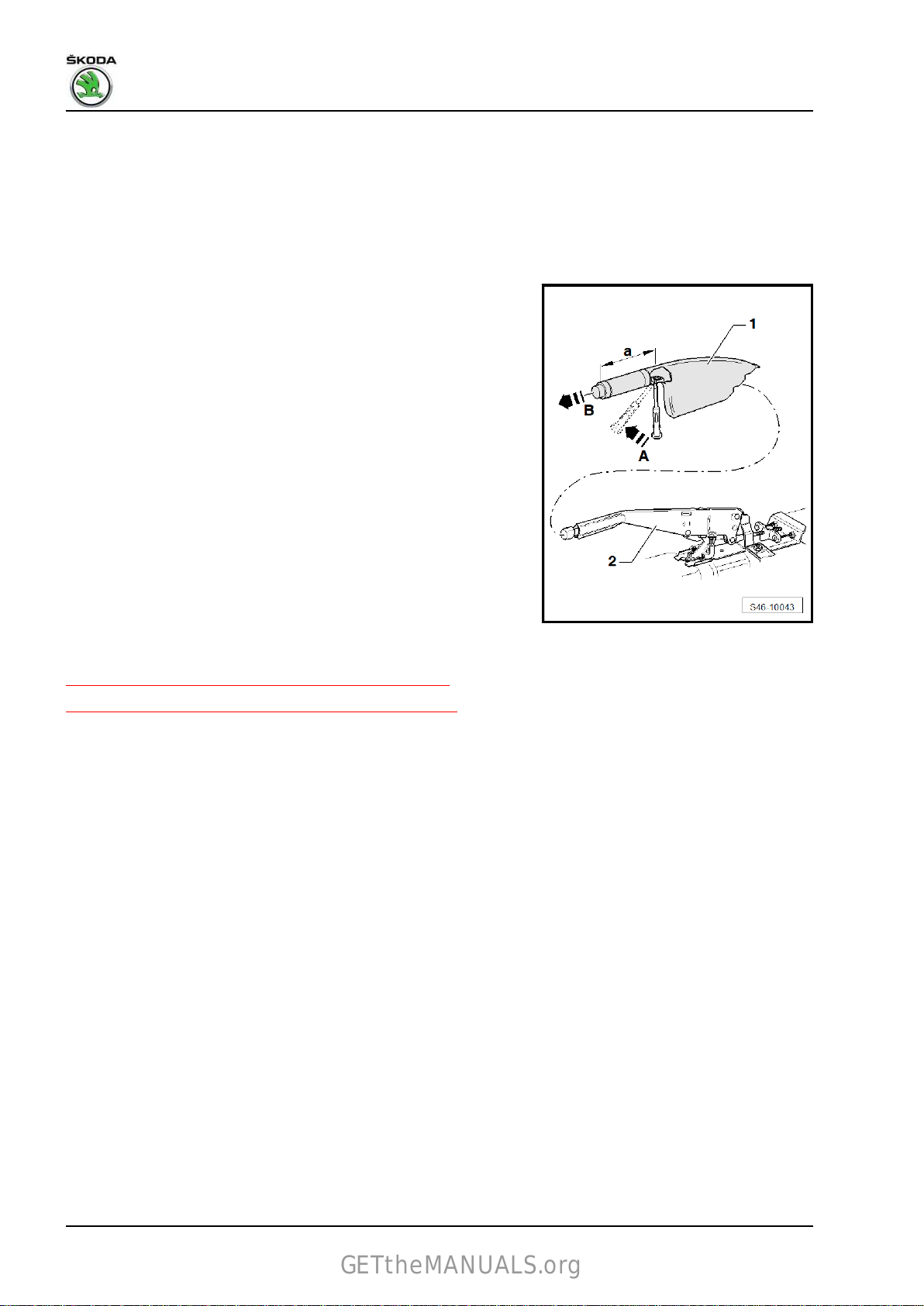

Fitting location:

The ABS control unit - J104- is bolted to the ABS hydraulic unit -

N55- and is located in the engine compartment on the left side.

– Disconnect battery ⇒ Electrical System; Rep. gr. 27 .

– Remove engine cover ⇒ Engine; Rep. gr. 10 .

– Remove air filter ⇒ Engine; Rep. gr. 24 (fuel engines) or ⇒

Engine; Rep. gr. 23 (diesel engines).

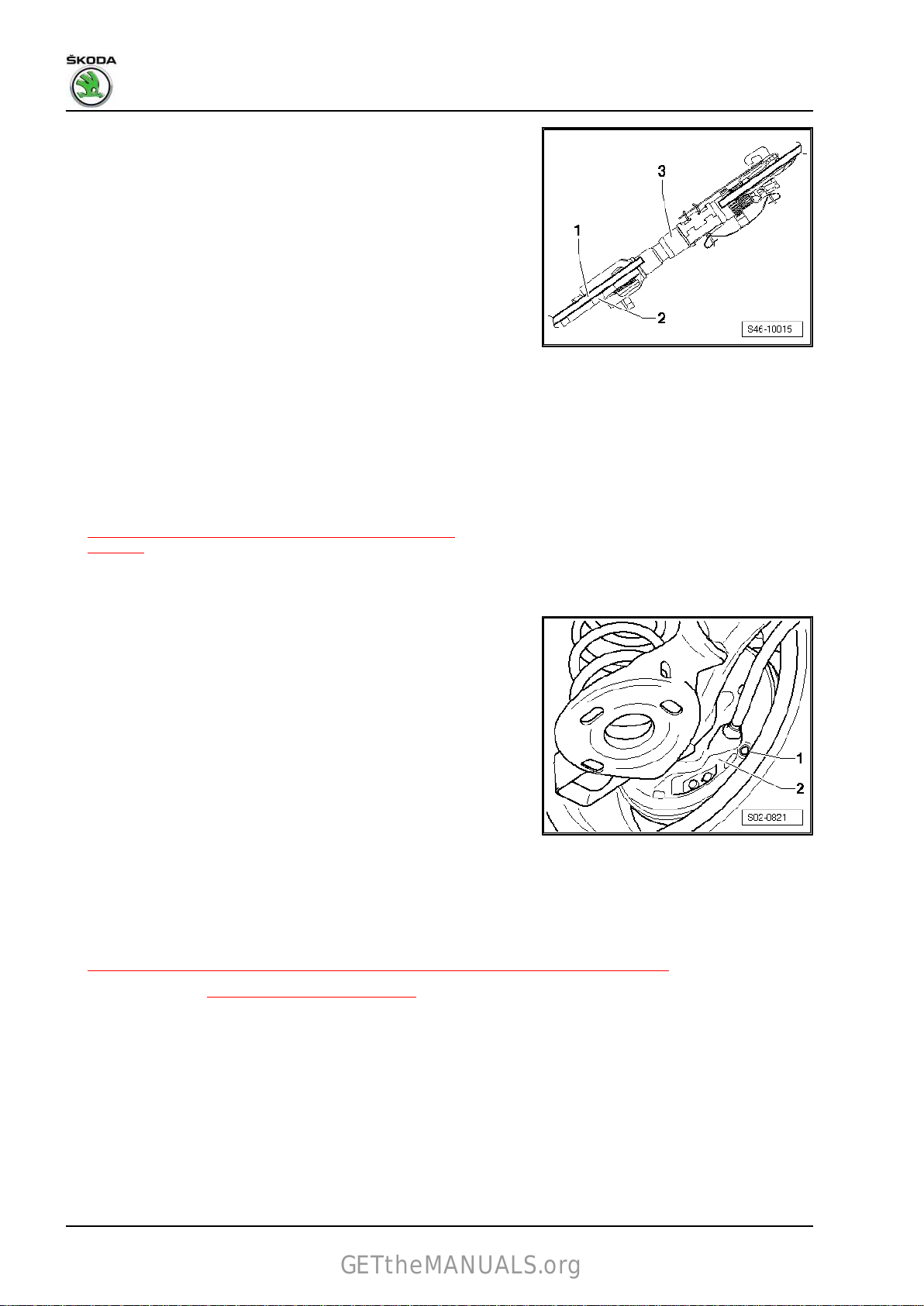

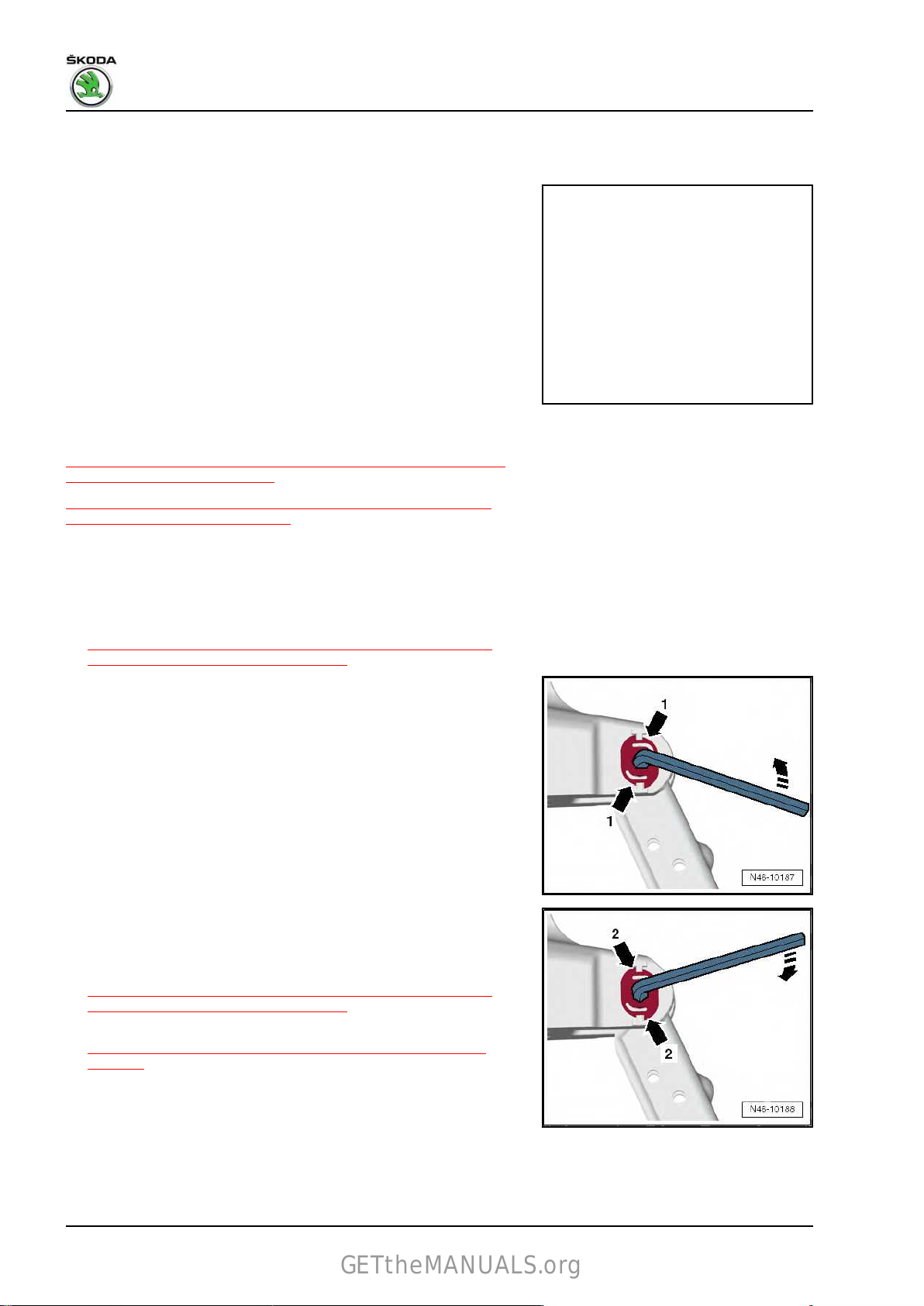

– Press fuse -2- in -direction of arrow-.

– Unlock fuse -1- for plug -3-.

– Disconnect connector -3-.

Brake systems - Edition 07.2017

– Position brake pedal load , e.g. -V.A.G 1869/2- .

– Attach the bleeder hose of the bleeding bottle onto the vent

– Press down brake pedal with brake pedal load , e.g. -V.A.G

– Close front left and rear left bleeder valves.

– Do not remove brake pedal load , e. g. -V.A.G 1869/2- .

– Place a sufficient non-fluffing cloths under and around the ABS

of the front left and rear left brake caliper and open vent

valves

valves.

1869/2- , at least 60 mm.

control unit - J104- and the ABS hydraulic unit - N55- .

NOTICE

Make sure that no brake fluid gets onto the contacts of the ABS

control unit - J104- .

– Mark brake lines -A- and -B- from the master brake cylinder

and unscrew from the ABS hydraulic unit - N55- .

– Close the brake lines and threaded holes immediately with

plugs from the repair kit - 1H0 698 311 A- .

– Mark

– Close the brake lines and threaded holes immediately with

the remaining brake lines -1- to -4- and unscrew from the

ABS hydraulic unit - N55- .

plugs from the repair kit - 1H0 698 311 A- .

3. Control unit and hydraulic unit 31

Page 36

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

– Pull ABS hydraulic unit - N55- with ABS control unit - J104-

upwards out of the bracket.

– Slacken

the bracket).

♦

If the ABS hydraulic unit - N55- is damaged, the ABS control

nuts and remove bracket (if it is necessary to remove

Note

unit - J104- must be fully replaced with the ABS hydraulic unit

- N55- .

♦

The ABS control unit - J104- can be separated from the ABS

hydraulic unit - N55-

⇒ “3.3 Disconnecting the control unit from the hydraulic unit”,

page 32 .

♦

The hydraulic pump and the ABS hydraulic unit - N55- must

not be separated from each other.

Installing

Installation is performed in the reverse order; pay attention to the

following points:

Note

♦

Only remove plugs from the new ABS hydraulic unit - N55- if

the relevant brake line is installed.

♦

If the plugs were already removed from the ABS hydraulic unit

- N55- , then brake fluid may escape and adequate filling and

bleeding of the unit can no longer be guaranteed.

♦

Make sure that the rubber bearings are not pressed out of the

console when installing the bracket. After installing, check for

tight fight, otherwise failure may be caused by a malfunction

of the ABS hydraulic unit - N55- .

– Bleed brake system

– Connect the battery and carry out any additional measures

after reconnecting the battery ⇒ Electrical System; Rep. gr.

27 .

– Code the control unit - J104- ⇒ Vehicle diagnostic tester.

While doing so, a basic setting of the steering angle sender -

G85-

, the lateral acceleration sender - G200- , the brake pressure

sender 1 - G201- and the longitudinal acceleration sender - G251must be performed ⇒ Vehicle diagnostic tester.

Tightening torques

⇒ “3.1.5 Summary of components - control unit and hydraulic

♦

unit for ABS/ESC, right-hand drive vehicles”, page 23

⇒ “6 Hydraulic system”, page 152 .

3.3 Disconnecting the control unit from the

hydraulic unit

♦ In the case of a malfunction of the ABS control unit - J104- ,

the

control unit must be disconnected from the ABS hydraulic

unit - N55- and replaced individually.

♦ In the case of a malfunction of the ABS hydraulic unit - N55- ,

the ABS hydraulic unit - N55- must be completely replaced

together with the ABS control unit - J104- .

32 Rep. gr.45 - Anti-lock brake system

Page 37

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

NOTICE

♦ The hydraulic pump - V64- and ABS hydraulic unit - N55-

must not be separated from each other.

♦ On a disconnected ABS control unit - J104- , the printed cir‐

cuit board is exposed.

♦ No moisture and no dirt particles must penetrate into the in‐

terior of the ABS control unit - J104- .

♦ Before handling the ABS control unit - J104- , the technician

must discharge himself electrostatically. The electrostatic

discharge is achieved by touching earthed metal parts. Do

not grab directly at the plug contacts or electronic compo‐

nents.

Note

Electrostatic charge can cause malfunctions of the ABS control

unit - J104- .

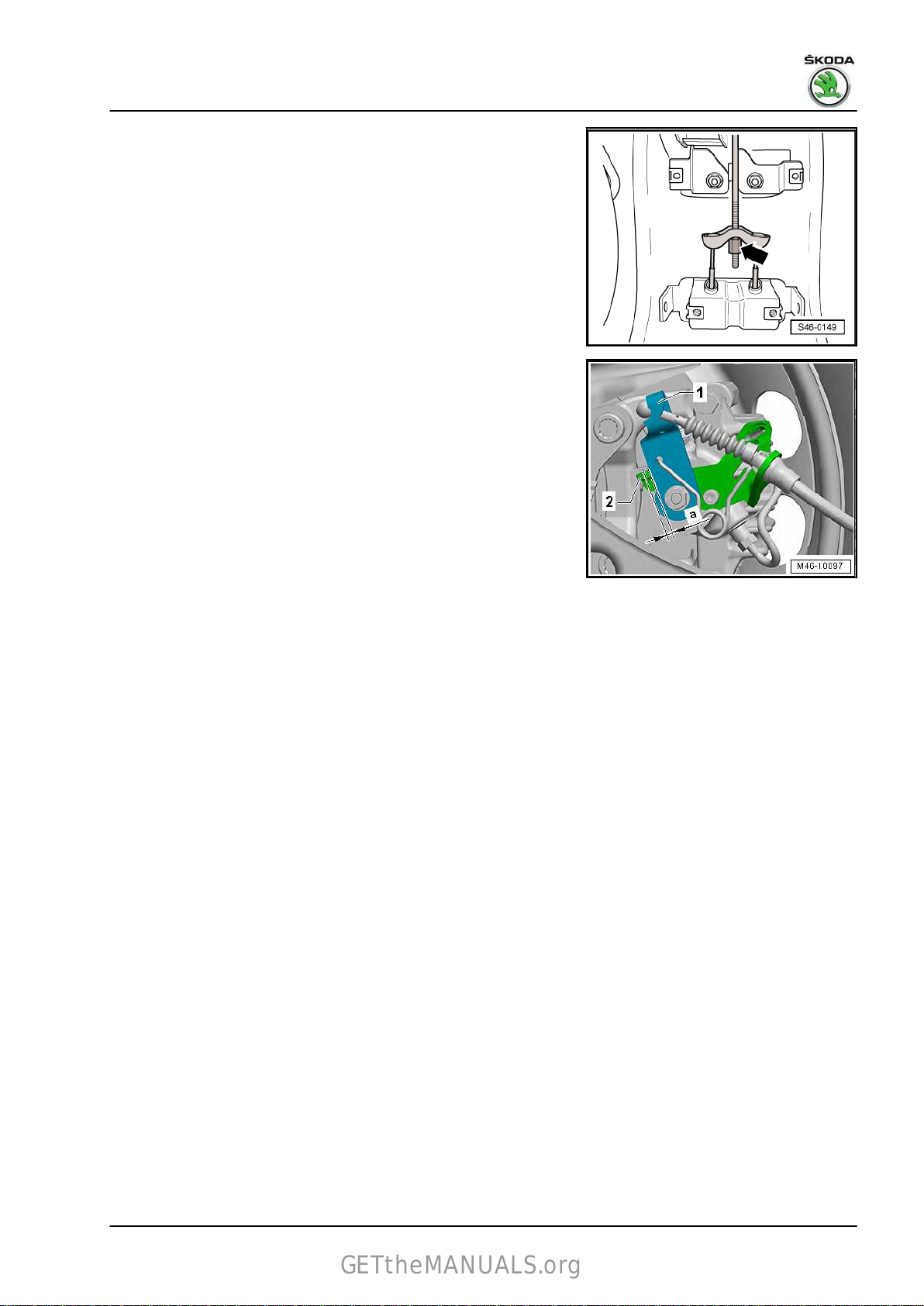

– Remove the ABS hydraulic unit - N55- with the ABS control

unit - J104-

⇒ “3.2 Removing and installing ABS control unit J104 / ABS

hydraulic unit N55 ”, page 25 .

– Lay the ABS hydraulic unit - N55- with the ABS control unit -

J104- on a clean flat surface facing upwards.

– Unscrew the fixing screws -arrows- of the ABS control unit -

J104- -1new screws).

and place aside immediately (danger of mix-ups with

Brake systems - Edition 07.2017

3. Control unit and hydraulic unit 33

Page 38

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

– Separate

unit - N55- in the -direction of arrow-.

The ABS control unit - J104- may not tilt when it is pulled off from

the ABS hydraulic unit - N55- .

– Cover the solenoid coils of the ABS control unit - J104- with a

non-fluffing cloth.

After separating from the ABS control unit - J104- and the ABS

hydraulic unit - N55- , use the transport protection for valve

domes.

– Check the sealing surface of the ABS hydraulic unit - N55- for

cleanliness. If necessary clean with white spirits and a nonfluffing cloth.

♦

The sealing surface of the ABS control unit - J104- may not be

repaired using a file, metal scraper or similar.

♦

If the sealing surface is damaged, replace the sealing surface

of the ABS control unit - J104- .

♦

The seal of the ABS control unit - J104- must not be damaged.

♦

The seal is not designed as spare part, so it is part of the new

ABS control unit - J104- .

the ABS control unit - J104- from the ABS hydraulic

Note

Note

3.4 Fitting the control unit to the hydraulic

unit

NOTICE

Strong vibrations (e.g. fall, knock) can destroy the ABS control

unit - J104- . The ABS control unit - J104- must no longer be

used.

• The contact surfaces must be cleaned before assembling.

• The seal of the ABS control unit - J104- must not be damaged.

– Position the ABS control unit - J104- without tilting it onto the

ABS hydraulic unit - N55- .

34 Rep. gr.45 - Anti-lock brake system

Page 39

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

– Tighten

⇒ page 35 .

♦

The threads in the ABS hydraulic unit - N55- must not be re‐

the screws in the order -1-, -2-, -3-, -4- in three stages

Note

paired or recut.

♦

If the thread is damaged, the ABS hydraulic unit - N55- must

be replaced.

Note

A new control unit may only be installed on the same hydraulic

unit twice as a maximum to ensure that the elastic seal is still leaktight.

Tightening torques

Component Tightening torque

ABS hydraulic unit - J104- to ABS control unit - N55- - 1st stage 1.5

ABS hydraulic unit - J104- to ABS control unit - N55- - 2nd stage 2.5 Nm

ABS control unit - J104- to ABS hydraulic unit - N55- - 3rd stage 3.5 Nm

3. Control unit and hydraulic unit 35

Page 40

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

4 Sensors

⇒ “4.1 Removing and installing front speed sensors G45 / G47 ”,

page 36

⇒ “4.2 Removing and installing the rear speed sensors G44 / G46

”, page 36

4.1 Removing and installing front speed

sensors -G45- / -G47-

Removing

– Raise vehicle.

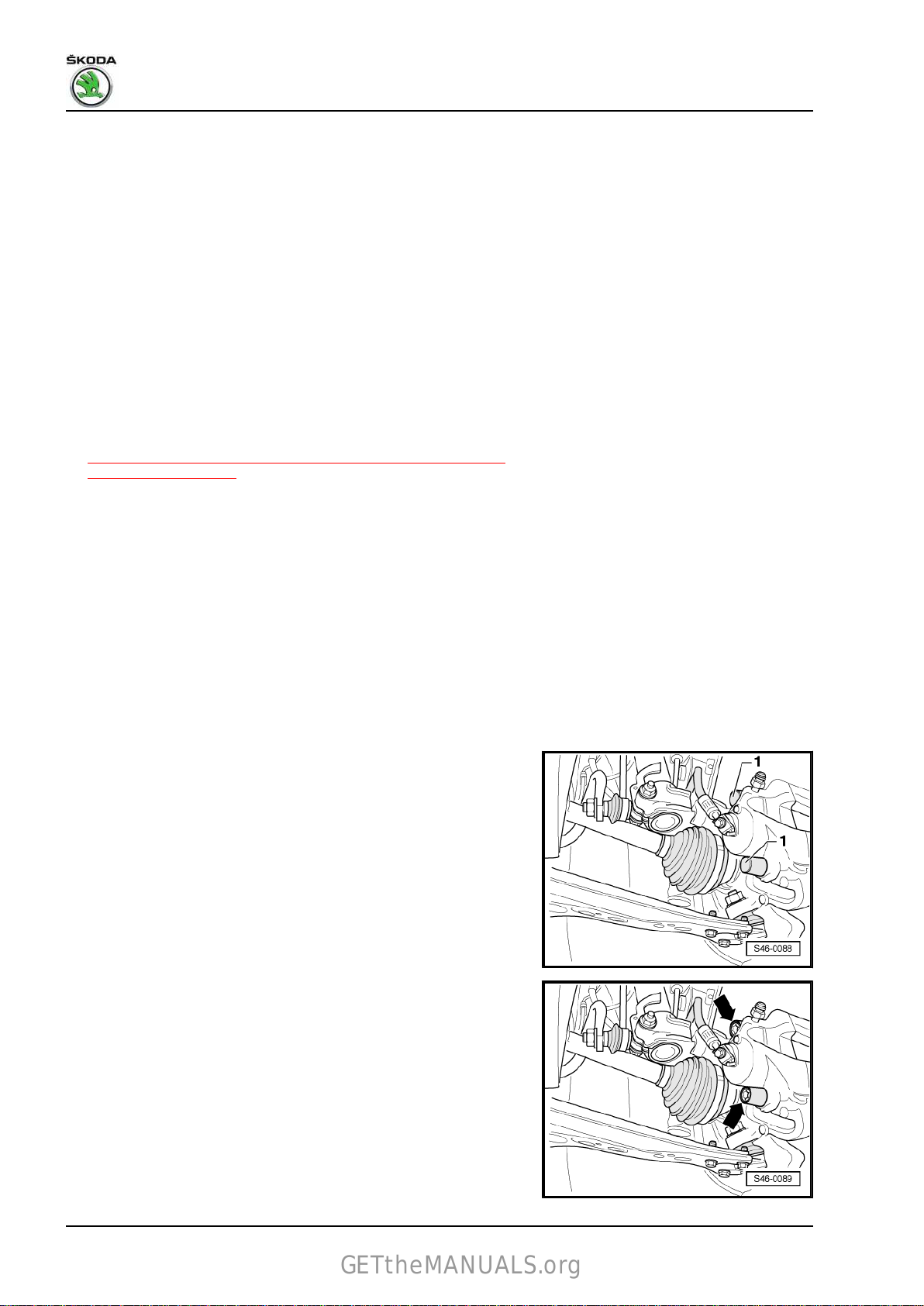

– Disconnect connector -1- on the front wheel speed sensor .

– Release screw -3-.

– Pull front speed sensor -2- out of the wheel bearing housing.

Installing

– Installation is performed in the reverse order; pay attention to

the following points:

– Before inserting the front speed sensor , clean the inner sur‐

face of the hole and moisten with hot bolt paste - G 052 112

A3- .

Tightening torques

♦ ⇒ “1.1 Assembly overview - front brakes”, page 38

4.2 Removing and installing the rear speed

sensors -G44- / -G46-

Note

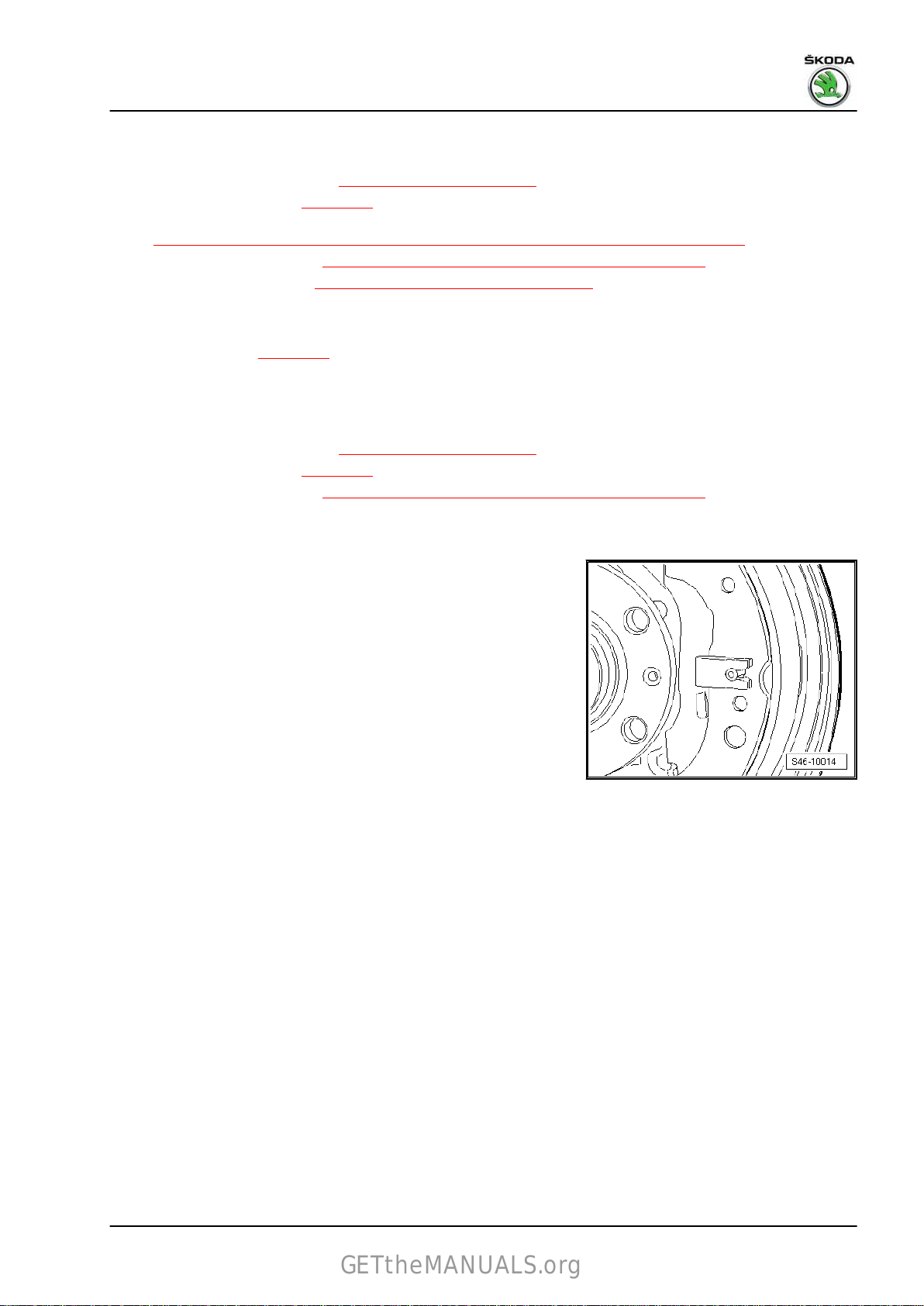

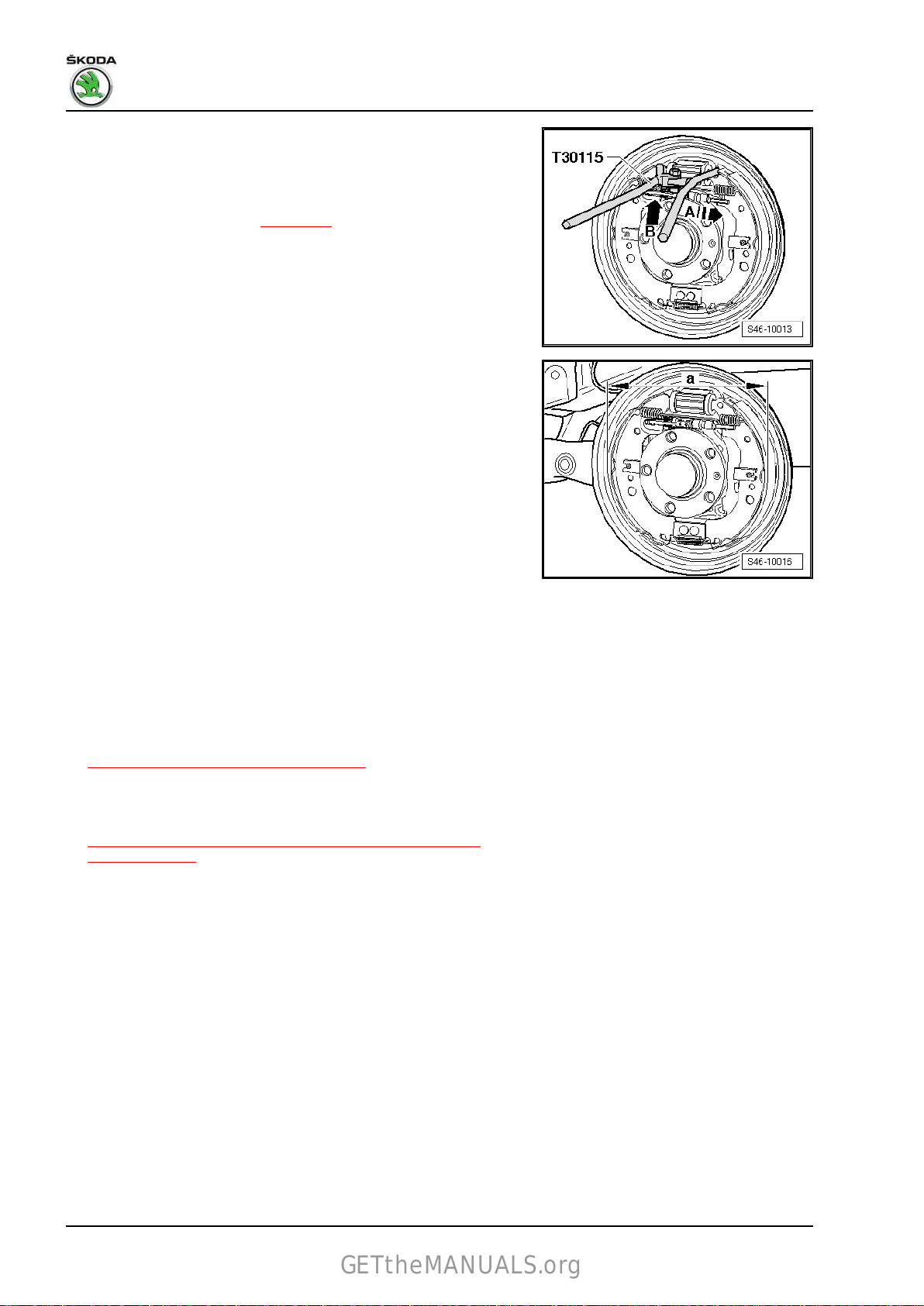

The procedure for removal and installation of the speed sensor is

identical for vehicles with drum brakes and for vehicles with disc

brakes.

Removing

– Raise vehicle.

– Disconnect connector -1- on the rear speed sensor .

36 Rep. gr.45 - Anti-lock brake system

Page 41

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

– Unscrew screw -arrow-.

Note

The wheel speed sensor is shown on the vehicle with disc brakes.

– Pull the rear speed sensor -1- out of the opening in the axle

stud and unclip its cables on the axle.

Installing

– Installation is carried out in the reverse order.

Tightening torques

♦

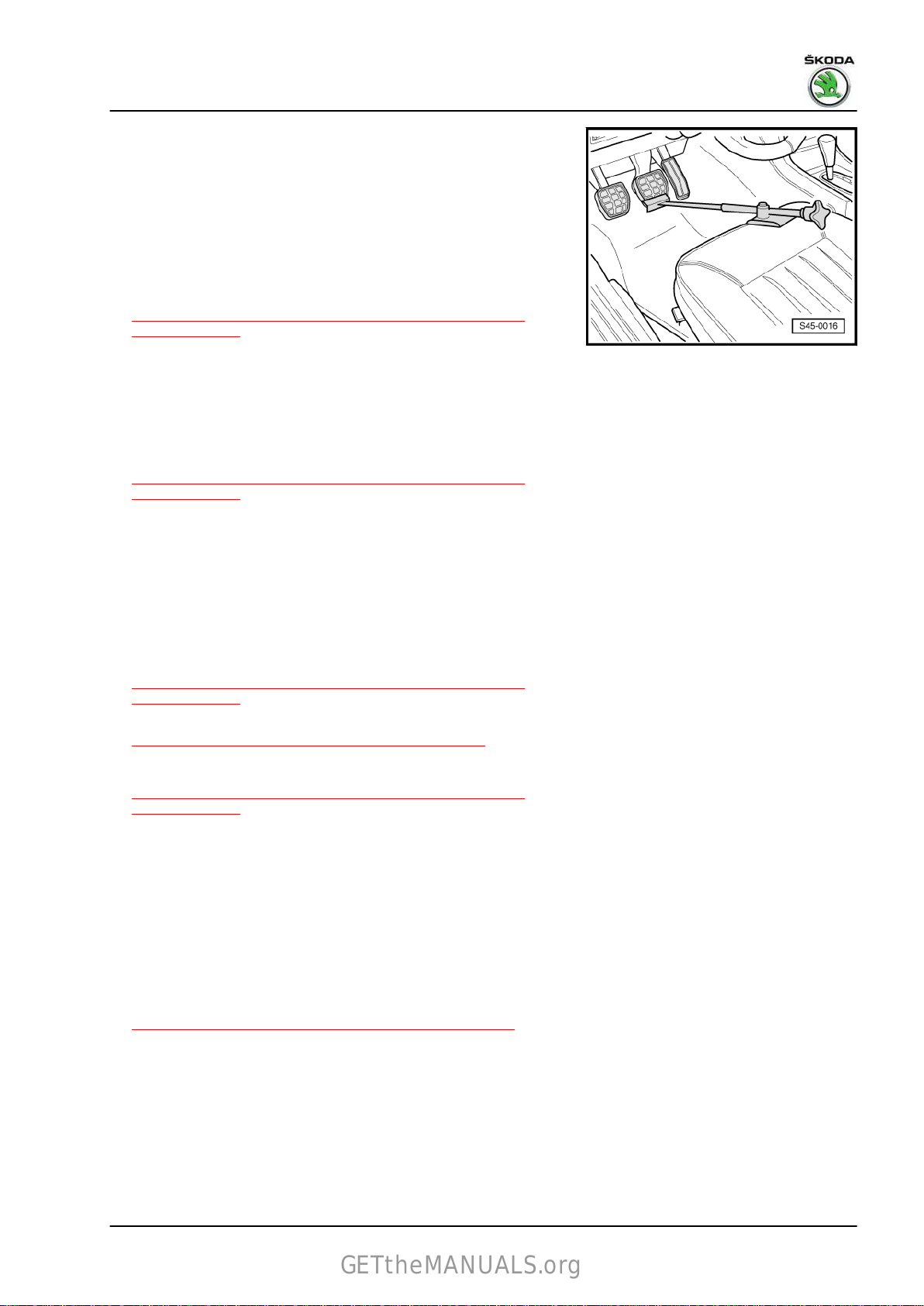

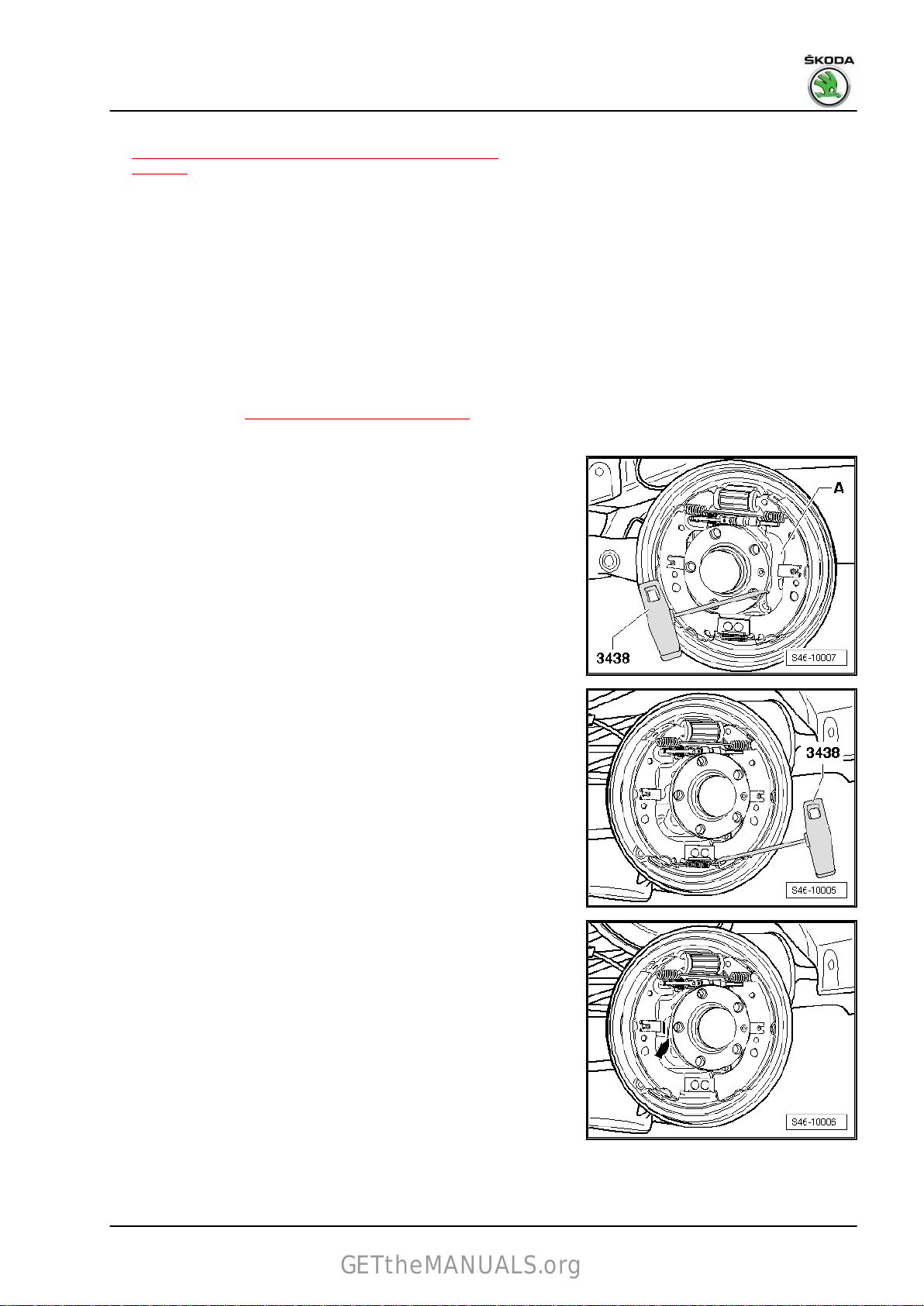

⇒ “2.1.1 Summary of components - rear axle brake, drum

brake”, page 52

♦ ⇒ “2.1.3 Summary of components - rear axle brake, disc

brake”, page 56

Brake systems - Edition 07.2017

4. Sensors 37

Page 42

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

46 – Brakes - mechanism

1 Front brakes

⇒ “1.1 Assembly overview - front brakes”, page 38

⇒ “1.2 Removing and installing brake pads”, page 41

⇒ “1.3 Removing and installing brake caliper”, page 46

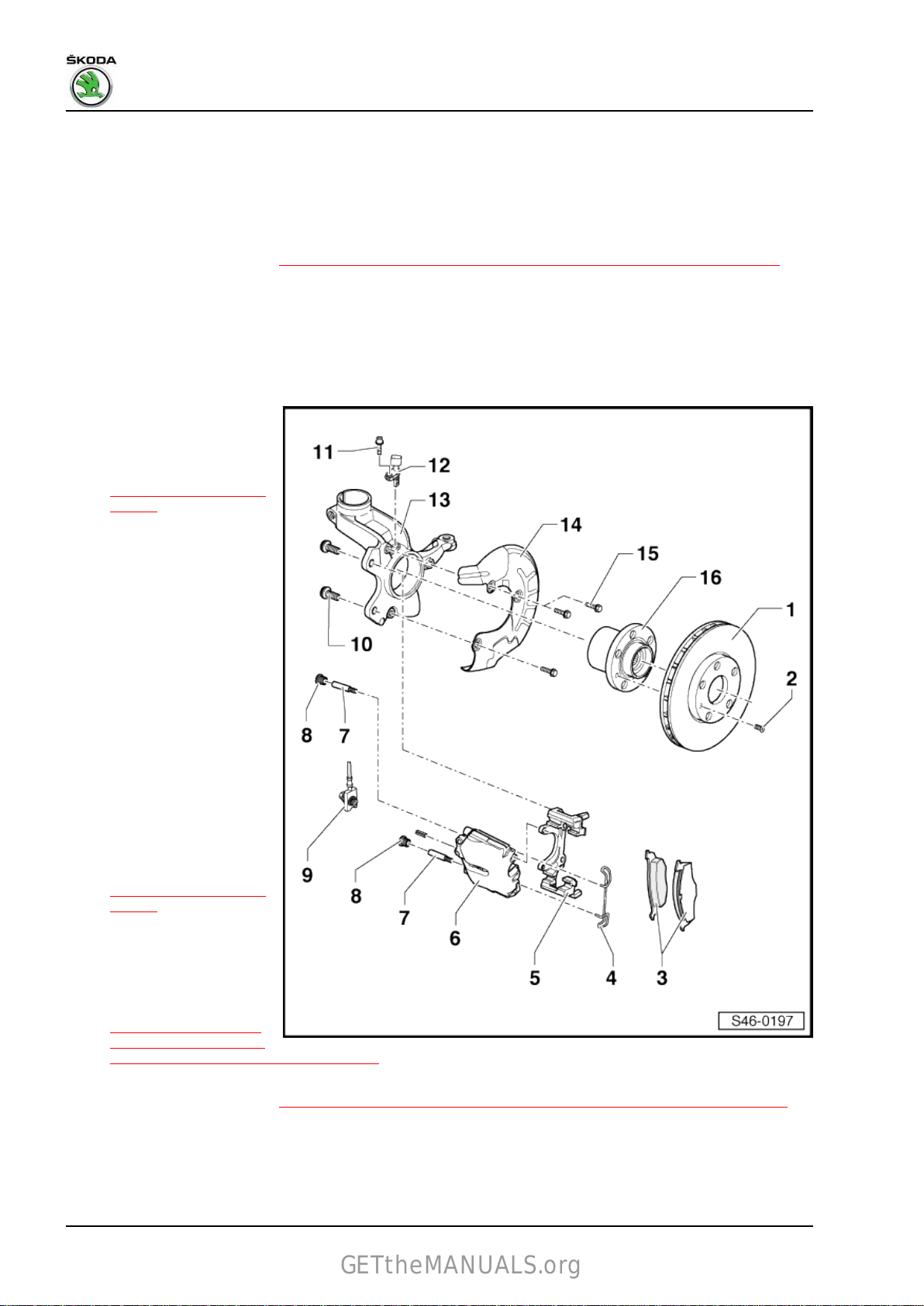

1.1 Assembly overview - front brakes

⇒ “1.1.1 Summary of components - front brake FS-III”,

page 38

⇒ “1.1.2 Summary of components - front brake FN3”, page 40

1.1.1 Summary of components - front brake FS-III

Note

♦

Observe the instructions for changing the pad

⇒ “1.2.1 Changing the brake pads of the front brake - Mounting instructions”, page 41

♦

Brake inspection ⇒ “4 Brake inspection”, page 6 .

♦

After replacing the brake pads, depress brake pedal firmly several times when the vehicle is stationary to

ensure the brake pads are properly seated in their normal operating position.

♦

Use the brake filling and bleeding device , e.g. -VAS 5234- , to drain the brake fluid from the brake fluid

reservoir.

♦

Use the brake pedal load , e.g. -V.A.G 1869/2- , before removing a brake calliper or separating a brake hose

from the brake calliper.

38 Rep. gr.46 - Brakes - mechanism

Page 43

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

1 - Brake disc

❑ internally ventilated

❑ Dimensions and wear

limit

⇒ “3.1.2 Front brakes”,

page 3

❑ always replace axle-

wise

❑ unscrew the brake cali‐

per before removing

❑ Do not use force to sep‐

arate the brake discs

from the wheel hub, if

necessary use rust sol‐

vent; as you could oth‐

erwise damage the

brake discs.

❑ Assignment ⇒ Electron‐

ic Catalogue of Original

Parts

2 - Screw

❑ 8 Nm

3 - Brake pads

❑ Dimensions and wear

limit

⇒ “3.1.2 Front brakes”,

page 3

❑ Inspect thickness

⇒ Maintenance ; Book‐

let Rapid NH

❑ Observe the instruc‐

tions for changing the

pad

⇒ “1.2.1 Changing the

brake pads of the front

brake - Mounting in‐

structions”, page 41

❑ always replace axle-wise

❑ Removing and installing

⇒ “1.2.2 Removing and installing brake pads, floating caliper disc brake FS-III”, page 42

4 - Brake caliper

❑ Removing and installing ⇒ “1.3.1 Removing and installing brake caliper FS-III”, page 46

❑ Summary of components ⇒ “1.1.1 Exploded view – front brake caliper - brake FS III”, page 90

❑ Assignment ⇒ Electronic Catalogue of Original Parts

5 - Guide bolt

❑ 30 Nm

6 - Cap

❑ Disconnect

7 - Tensioning sleeve

8 - Brake hose

❑ with banjo union and hollow screw

❑ 35 Nm

9 - Wheel hub with wheel bearing

❑ for vehicles with ABS the sensor ring is built into the wheel hub

1. Front brakes 39

Page 44

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

10 - Screw

❑

12 Nm

11 - Cover plate

12 - Wheel bearing housing

13 - ABS wheel speed sensor

❑ Removing and installing

14 - Screw

❑

8 Nm

⇒ “4.1 Removing and installing front speed sensors G45 / G47 ”, page 36

1.1.2 Summary of components - front brake FN3

1 - Brake disc

❑ internally ventilated

❑ Dimensions and wear

limit

⇒ “3.1.2 Front brakes”,

page 3

❑

always replace axle-

wise

❑ To remove, detach the

brake caliper -6- and

brake carrier -5- first

❑ Do not use force to sep‐

arate the brake discs

from the wheel hub, if

necessary use rust sol‐

vent; as you could oth‐

erwise damage the

brake discs.

❑ Assignment ⇒ Electron‐

ic Catalogue of Original

Parts

2 - Screw

❑ 8 Nm

3 - Brake pads

❑ Dimensions and wear

limit

⇒ “3.1.2 Front brakes”,

page 3

❑

Inspect thickness

⇒ Maintenance ; Book‐

let Rapid NH

❑ Observe the instruc‐

tions for changing the

pad

⇒ “1.2.1 Changing the

brake pads of the front

brake - Mounting instructions”, page 41

❑

always replace axle-wise

❑ Removing and installing

4 - Spring

❑

inserted into both bore holes of the brake caliper

5 - Brake carrier

❑ screwed onto the wheel-bearing housing

⇒ “1.2.3 Removing and installing brake pads, brake calliper FN3”, page 44

40 Rep. gr.46 - Brakes - mechanism

Page 45

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

6 - Brake caliper

❑

Removing and installing

❑

Summary of components

❑

Assignment ⇒ Electronic Catalogue of Original Parts

7 - Guide bolt

❑ 30 Nm

8 - Cap

❑ remove

9 - Brake hose

❑ with banjo union and hollow screw

❑ 35 Nm

10 - Screw

❑ clean when using again

❑ 124 Nm

11 - Screw

❑ 8 Nm

12 - ABS wheel speed sensor

❑ Removing and installing

13 - Wheel bearing housing

14 - Cover plate

15 - Screw

❑

12 Nm

16 - Wheel hub with wheel bearing

❑ for vehicles with ABS the sensor ring is built into the wheel hub

⇒ “1.3.2 Removing and installing brake caliper FN3”, page 49

⇒ “1.1.2 Exploded view – front brake caliper - brake FN3”, page 92

⇒ “4.1 Removing and installing front speed sensors G45 / G47 ”, page 36

Brake systems - Edition 07.2017

1.2 Removing and installing brake pads

⇒ “1.2.1 Changing the brake pads of the front brake - Mounting

instructions”, page 41

⇒ “1.2.2 Removing and installing brake pads, floating caliper disc

brake FS-III”, page 42

⇒ “1.2.3 Removing and installing brake pads, brake calliper FN3”,

page 44

1.2.1 Changing the brake pads of the front

brake - Mounting instructions

When changing the pads, pay attention to the following points:

– Check protective collar of brake calliper piston.

Replace protective cap if damaged.

When replacing the protective cap:

– Check the contact surfaces of the brake piston and the brake

caliper for any dirt (oxidation).

Carefully clean the piston as well as the brake caliper if dirty and

replace the sealing cap.

– Check the brake piston and the brake caliper (corrosion,

grooves on the outside of the cylinder surface), replace the

brake caliper completely if damaged.

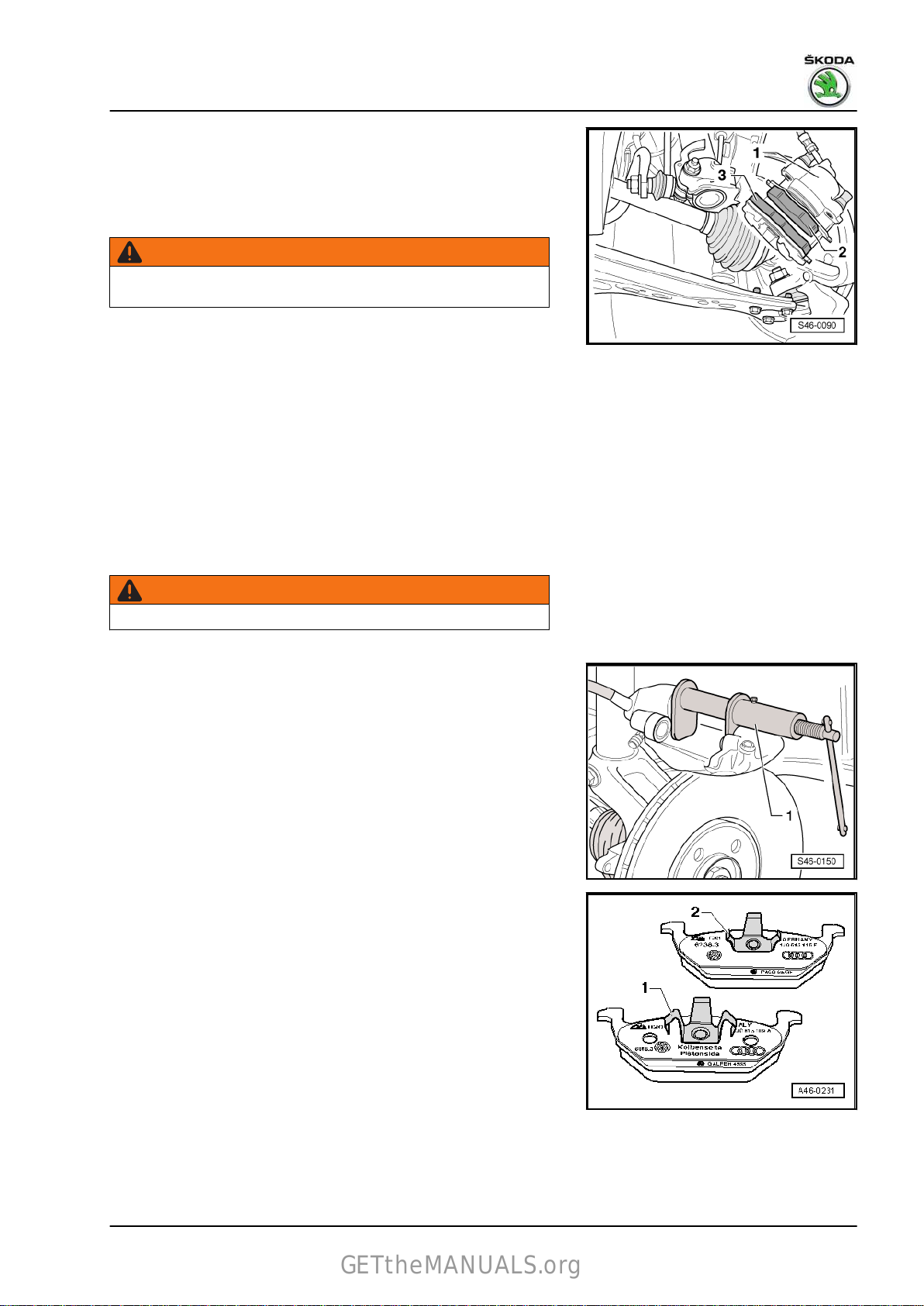

For brake caliper piston, press into the initial position:

1. Front brakes 41

Page 46

Rapid NH 2013 ➤ , Rapid NH 2014 ➤

GETtheMANUALS.org

Brake systems - Edition 07.2017

– Check if the piston can be slightly pressed into the brake cal‐

iper.

If the piston cannot be slightly pressed into the brake caliper:

– Check

replace sealing sleeve and protective cap.

Replace the brake caliper completely if damaged.

and clean the brake piston as well as the brake caliper,

1.2.2 Removing and installing brake pads,

floating caliper disc brake FS-III