SKODA Fabia II 2007, Fabia II 2009, Fabia II 2011, Octavia II 2004, Octavia II 2010 Workshop Manual

...

Service

GETtheMANUALS.org

Workshop Manual

Fabia II 2007 ➤ , Fabia II 2009 ➤ ,

Fa

Octavia II 2010 ➤ , Rapid NH 2013 ➤ ,

Roomster 2006 ➤ , Yeti 2010 ➤ ,

Yeti 2011 ➤

bia II 2011 ➤ , Octavia II 2004 ➤ ,

1,2/63; 77 kW TSI engine

Engine ID

CBZACBZ

B

Edition 09.2012

Service Department. Technical Information

Service

GETtheMANUALS.org

List of Workshop Manual Repair GroupsList of Workshop Manual

Repair GroupsList of Workshop Manual Repair Groups

Re

pa ir G ro up

00 - Technical data

01 - Self-diagnosis

10 - Removing and installing engine

13 - Crankshaft group

15 - Cylinder head, valve gear

17 - Lubrication

19 - Cooling

20 - Fuel supply system

21 - Turbocharging/supercharging

24 - Mixture preparation - injection

26 - Exhaust system

28 - Ignition system

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

Contents

00 - Technical data

1 Technical data

1.1 Engine number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

1.2 Engine characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

01 - Self-diagnosis

1 Self diagnosis, safety measures, cleanliness regulations, directions

1.1 Self-diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1.2 Regulations concerning safety precautions when working on the fuel system . . . . . . . . . . 3

1.3 Release pressure in the high pressure area of the fuel system . . . . . . . . . . . . . . . . . . . . . . 4

1.4 Rules of cleanliness to observe when working on the fuel supply system . . . . . . . . . . . . . . 5

1.5 Safety measures to apply when working on the fuel injection and ignition system . . . . . . 6

1.6 General notes on the injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.7 General notes on the ignition system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

1.8 General instructions for charge air system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1.9 Additional instructions when undertaking assembly work on the air-conditioning system . . 9

10 - Removing and installing engine

1 Removing and installing engine

1.1 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.2 Removing engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.3 Securing the engine to the assembly stand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.4 Installing the engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2 Assembly bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.1 Assembly bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.2 Unit mounting - summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

2.3 Checking and adjusting the assembly bracket . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

13 - Crankshaft group

1 V-ribbed belt drive

1.1 V-ribbed belt - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

1.2 Removing and installing V-ribbed belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

1.3 Removing and installing bracket for top auxiliary units . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1.4 Removing and installing bracket for bottom auxiliary units . . . . . . . . . . . . . . . . . . . . . . . . 38

2 Camshaft drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.1 Camshaft drive - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.2 Removing and installing the top timing case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

2.3 Removing and installing the bottom timing case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

3 Sealing flanges and flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.1 Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.2 Removing and installing flywheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

3.3 Replacing crankshaft seal on belt pulley side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

3.4 Removing and installing crankshaft-belt pulley . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

3.5 Replace sealing flange on the gearbox side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

4 Crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

4.1 Replace needle bearing for crankshaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

5 Pistons and conrods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.1 Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

5.2 Inspect piston, piston rings and cylinder bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

5.3 Separating new conrod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

15 - Cylinder head, valve gear

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Contents i

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

1 Cylinder head - part 1

1.1 Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

1.2 Test timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

1.3 Setting the timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

1.4 Removing and installing timing chain and drive chain for oil pump . . . . . . . . . . . . . . . . . . 77

2 Cylinder head - part 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

2.1 Removing and installing cylinder head cover and camshaft . . . . . . . . . . . . . . . . . . . . . . . . 84

2.2 Removing and installing the cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

2.3 Testing the compression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

2.4 Testinf the combustion chamber for tightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

3 Valve gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.1 Valve gear - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

3.2 inspect camshaft, axial play . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3.3 Inspect valve guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

3.4 Replacing valve stem seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

17 - Lubrication

1 Lubrication system

1.1 Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

1.2 Removing and installing oil pan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

1.3 Removing and installing oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

1.4 Removing and installing engine oil cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

1.5 Testing oil pressure and oil pressure switch F1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

19 - Cooling

1 Cooling system

1.1 Connection diagram for coolant hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

1.2 Connection diagram for coolant hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

1.3 Draining and filling up coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

2 Parts of cooling system engine side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

2.1 Coolant regulator - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

2.2 Removing and installing belt pulley for coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

2.3 Removing and installing coolant pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

2.4 Removing and installing coolant recirculation pump V50 . . . . . . . . . . . . . . . . . . . . . . . . . . 125

3 Radiator and radiator fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

3.1 Parts of cooling system on the side next to the body - Summary of components . . . . . . . . 126

3.2 Parts of cooling system on the side next to the body - Summary of components . . . . . . . . 128

3.3 Removing and installing fan shroud for radiator fan V7 . . . . . . . . . . . . . . . . . . . . . . . . . . 131

3.4 Removing and installing fan shroud for radiator fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

3.5 Removing and installing radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

3.6 Removing and installing radiator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

3.7 Checking the coolant system for leaktightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 136

20 - Fuel supply system

1 Fuel tank and fuel delivery unit

1.1 Fuel tank - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

1.2 Fuel tank - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

1.3 Fuel tank version I. - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

1.4 Fuel tank version Il. - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

1.5 Fuel filter - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1.6 Extract fuel from the fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1.7 Removing and installing the fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

1.8 Removing and installing fuel tank version I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

1.9 Removing and installing fuel tank version Il. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

1.10 Removing and installing fuel delivery unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

ii Contents

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

1.11 Removing and installing fuel delivery unit version I.

1.12 Removing and installing fuel delivery unit version Il. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

1.13 Removing and installing the sender for fuel gauge display G . . . . . . . . . . . . . . . . . . . . . . 165

1.14 Testing fuel pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 166

1.15 Removing and installing fuel gauge sender -2- G169 - fuel tank version Il. . . . . . . . . . . . . 184

1.16 Removing and installing suction jet pump - fuel tank version Il. . . . . . . . . . . . . . . . . . . . . . . 186

2 Separating quick couplings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

3 Electronic Engine Power Control (Electronic throttle) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

3.1 Accelerator pedal module - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

3.2 Accelerator pedal module - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

3.3 Removing and installing accelerator pedal module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4 Activated charcoal container system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

4.1 Activated charcoal container system - Summary of components . . . . . . . . . . . . . . . . . . . . 195

4.2 Activated charcoal container system - Summary of components . . . . . . . . . . . . . . . . . . . . 196

4.3 Activated charcoal container system - Summary of components . . . . . . . . . . . . . . . . . . . . 197

4.4 Checking the fuel tank venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

4.5 Checking the fuel tank venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

21 - Turbocharging/supercharging

1 Exhaust gas turbocharger

1.1 Exhaust turbocharger - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

1.2 Removing and installing exhaust gas turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

2 Charge air system with exhaust gas turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

2.1 Charge air system - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 208

2.2 Charge air system - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 209

2.3 Removing and installing charge air cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 211

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

24 - Mixture preparation - injection

1 Fitting location of the injection system

1.1 Fitting location of the injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

1.2 Fitting location of the injection system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214

2 Intake manifold and fuel distributor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

2.1 Intake manifold - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

2.2 Removing and installing the throttle valve control unit J338 . . . . . . . . . . . . . . . . . . . . . . . . 220

2.3 Clean throttle valve control unit J338 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

2.4 Removing and installing intake manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

3 Air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

3.1 Air filter - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

3.2 Air filter - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

3.3 Removing and installing air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 226

3.4 Removing and installing air filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 227

4 High pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

4.1 High pressure pump - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 229

4.2 Removing and installing the high pressure pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

5 Injection valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

5.1 Removing and installing injection valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 233

5.2 Replace Teflon gasket ring and supporting washer at injection valve . . . . . . . . . . . . . . . . 235

6 Testing components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

6.1 Check fuel pressure sender G247 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

7 Engine control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

7.1 Removing and installing engine control unit J623 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 242

7.2 Removing and installing engine control unit J623 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213

26 - Exhaust system

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Contents iii

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

1 Removing and installing parts of the exhaust system

1.1 Catalytic converter and component parts - Summary of components . . . . . . . . . . . . . . . . 245

1.2 Catalytic converter and component parts - Summary of components . . . . . . . . . . . . . . . . 246

1.3 Middle and rear silencer - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 248

1.4 Middle and rear silencer - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

1.5 Middle and rear silencer - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250

1.6 Middle and rear silencer for vehicles manufactured up to 06.10 - Summary of components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 251

1.7 Middle and rear silencer for vehicles manufactured as of 06.10 - Summary of components

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 252

1.8 Removing and installing catalytic converter with pre-exhaust pipe . . . . . . . . . . . . . . . . . . 253

1.9 Replacing middle or rear silencer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 255

1.10 Aligning exhaust system free of stress . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 256

1.11 Inspecting the exhaust system for leaktightness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 257

28 - Ignition system

1 Ignition system

1.1 Ignition system - Summary of components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

1.2 Removing and installing engine speed sender G28 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 260

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 259

. . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

iv Contents

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

00 – Technical data

1 Technical data

(SRL000530; Edition 09.2012)

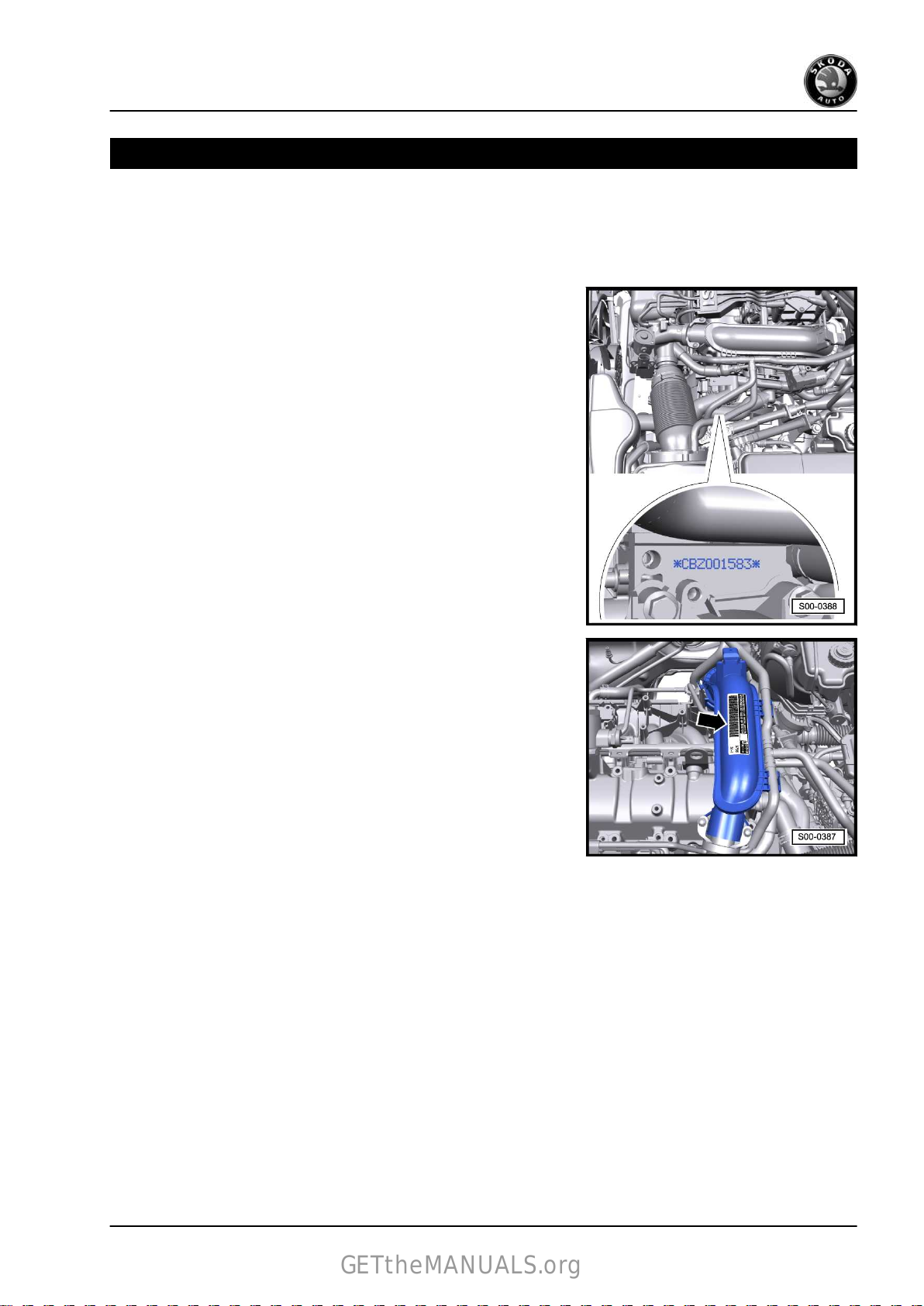

1.1 Engine number

The engine number (“engine identification characters” and “serial

number”) is located on the engine closely above the connection

of the engine with the gearbox.

In addition, the “engine identification characters” and the “serial

number”

located on the air guide pipe.

♦ The engine identification characters have 4 digits starting with

♦ The first 3 digits of the engine identification characters refer to

♦ The 4th digit refers to the output and torque of the engine and

are indicated on the vehicle data sticker -arrow- which is

the letter “C”.

the displacement and the mechanical construction of the en‐

gine. They are type-punched in the cylinder block including the

serial number.

depends upon the engine control unit.

1.2 Engine characteristics

Edition: 07.2012

Version: 3.0

1. Technical data 1

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

Engine identification characters CBZA CBZB

Manufactured Fabia II 03.10 ► ----

Exhaust limit values conforming to EU5 EU5

Displacement

Power output kW at rpm 63/4800 77/5000

Torque Nm at rpm 160/1500-3500 175/1550-4100

Bore ∅ mm 71,0 71,0

Stroke mm 75,6 75,6

Compression ratio 10:1 10:1

Cylinder / valves per cylinder 4 / 2 4 / 2

RON

Ignition system, fuel injection Simos 10 Simos 10

Type of fuel preparation Direct injection homogeneous Direct injection homogeneous

Knock control 1 sensor 1 sensor

Lambda control 2 Lambda probes 2 Lambda probes

Three-way catalytic converter yes yes

Exhaust gas recirculation no no

Intake manifold change-over no no

Camshaft adjustment no no

Secondary air system no no

Exhaust gas turbocharger yes yes

Balancing shaft no no

Roomster 03.10 ► ---Octavia II ---- 02.10 ►

Yeti ---- 09.09 ►

Rapid NH 07.12 ► 07.12 ►

cm

3

1197 1197

unleaded 95

1)

unleaded 95

1)

1)

At least 91 RON in exceptional cases, although engine output

is reduced

2 Rep. gr.00 - Technical data

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

01 – Self-diagnosis

1 Self diagnosis, safety measures,

cleanliness regulations, directions

1.1 Self-diagnosis

This Rep.-Gr. is deleted.

For this use the “Vehicle self-diagnosis”, “Measuring method” and

“Fault finding” ⇒ Vehicle diagnostic tester.

1.2 Regulations concerning safety precau‐

tions when working on the fuel system

WARNING

♦ The safety measures for the pressure reduction in the high

pressure area of the fuel system must be observed

⇒ page 4 .

♦ The fuel system is under pressure! Wear safety goggles

and safety clothing, in order to avoid injuries and skin con‐

tact with fuel. Place a clean cleaning cloth around the

connection point before detaching wiring. Reduce pres‐

sure by carefully removing the wiring.

For vehicles Fabia II, Roomster, Rapid NH

♦ The fuel delivery unit is activated when the ignition is switched

on and by the door contact switch of the driver door. Before

opening

is not disconnected, the plug -2- must be disconnected from

the fuel pump control unit.

For the vehicles Octavia II, Yeti

the fuel system and for reasons of safety, if the battery

1. Self diagnosis, safety measures, cleanliness regulations, directions 3

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

♦ The fuel delivery unit is activated when the ignition is switched

on and by the door contact switch of the driver door. For rea‐

sons of safety, if the battery is not disconnected, the plug -3must be disconnected from the fuel pump control unit

before opening the fuel system.

Continued for all vehicles

Caution

When undertaking all assembly work, particularly in the engine

compartment due to its cramped construction, please observe

the following:

♦ Lay lines of all kinds (e.g. for fuel, hydraulic fluid, cooling

fluid and refrigerant, brake fluid, vacuum) and electrical

lines in such a way that the original line guide is re-estab‐

lished.

♦ In order to avoid damage to the cables, ensure that there

is adequate free access to all moving or hot components.

When removing and installing the fuel gauge sender or the fuel

delivery unit from a full or partly filled fuel tank, pay attention to

the following points:

♦ The extraction hose of an exhaust extraction system which is

switched on, must be positioned close to the assembly open‐

ing

of the fuel tank in order to extract the released fuel vapours,

even before the work is commenced. If no exhaust extraction

system is available, a radial fan (motor not in air flow of fan)

with a delivery volume of more than 15 m3/h must be used.

♦ Avoid skin contact with fuel!

♦ Wear fuel-resistant gloves!

-1-

1.3 Release pressure in the high pressure area of the fuel system

WARNING

♦ The injection system consists of a high pressure part

(max. pressure of 12 MPa = 120 bar) and a low pressure

part (pressure of approx. 0.6 MPa = 6 bar).

♦ Before opening the high pressure area, e.g. removing the

high pressure pump, the fuel distributor, the injection

valves, the fuel pipes or the fuel pressure sender -G247- ,

the fuel pressure in the high pressure area with a remain‐

ing pressure of approx. 0.6 MPa (6 bar) must be reduced.

The procedure for this is described below.

– Connect

geted function “remove high fuel pressure”.

– Switch off ignition.

the ⇒ Vehicle diagnostic tester and carry out the tar‐

4 Rep. gr.01 - Self-diagnosis

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

For vehicles Fabia II, Roomster, Rapid NH

– For

For the vehicles Octavia II, Yeti

safety reasons before opening the fuel system disconnect

the plug from the fuel pump control unit -2-.

1,2/63; 77 kW TSI engine - Edition 09.2012

– For

Continued for all vehicles

safety reasons before opening the fuel system disconnect

the plug from the fuel pump control unit -3-.

WARNING

The fuel lines are pressurized! Wear safety goggles and safety

clothing, in order to avoid injuries and skin contact with fuel.

Before opening the high pressure area, lay cleaning cloths

around the connection point.

– Now lay a clean cleaning cloth around the connection point

and

carefully open it up, in order to reduce the remaining pres‐

sure of approx 0.6 MPa (6 bar). Collect the fuel which flows

out.

Note

♦

Interrogate the fault memory of the engine control unit at the

end of the following work and delete all the fault entries.

♦

If the fault memory was erased, the readiness code must be

generated ⇒ Vehicle diagnostic tester.

1.4 Rules of cleanliness to observe when working on the fuel supply system

Carefully observe the following five rules for cleanliness when

working on the fuel supply/injection system:

♦ Thoroughly clean the connection points and their surroundings

before releasing.

♦ Place removed parts on a clean surface and cover. Do not use

fuzzy cloths!

♦ Carefully cover or close opened components if the repair is not

completed immediately.

♦ Only install clean parts: Remove spare parts from their wrap‐

♦ When the system is opened: Avoid using compressed air.

immediately before installing. Do not use any parts which

ping

have been stored unwrapped (e.g. in tool boxes).

Avoid moving the vehicle.

1. Self diagnosis, safety measures, cleanliness regulations, directions 5

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

1.5 Safety measures to apply when working on the fuel injection and ignition system

WARNING

♦ The safety measures for the pressure reduction in the high

pressure area of the fuel system must be observed

⇒ page 4 .

♦ The fuel system is under pressure! Wear safety goggles

and safety clothing, in order to avoid injuries and skin con‐

tact with fuel. Place a clean cleaning cloth around the

connection point before detaching wiring. Reduce pres‐

sure by carefully removing the wiring.

Observe the following points to prevent injury to persons and/or

damage to the injection and ignition system:

♦ Do not touch or remove ignition leads and ignition coils with

power

output stages with the engine running or at start speed.

♦ Ignition must be switched off before disconnecting and re-

connecting the cables of the fuel injection and the ignition

system as well as of the test equipment.

♦ If the engine must be operated at start speed without it starting,

as for example, when checking the compression pressure,

open lid of fuse carrier in the engine compartment and unplug

fuse for Motronic current supply relay -J271- ⇒ Current flow

diagrams, Electrical fault finding and Fitting locations.

For vehicles Fabia II, Roomster, Rapid NH

♦ The fuel delivery unit is activated when the ignition is switched

on and by the door contact switch of the driver door. Before

opening the fuel system and for reasons of safety, if the battery

is not disconnected, the plug -2- must be disconnected from

the fuel pump control unit.

For the vehicles Octavia II, Yeti

6 Rep. gr.01 - Self-diagnosis

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

♦ The fuel delivery unit is activated when the ignition is switched

on and by the door contact switch of the driver door. Before

opening

is not disconnected, the plug -3- must be disconnected from

the fuel pump control unit.

Continued for all vehicles

the fuel system and for reasons of safety, if the battery

Caution

When undertaking all assembly work, particularly in the engine

compartment due to its cramped construction, please observe

the following:

♦ Lay lines of all kinds (e.g. for fuel, hydraulic fluid, the active

charcoal container-unit, cooling fluid and refrigerant,

brake fluid, vacuum) and electrical lines in such a way that

the original line guide is re-established.

♦ In order to avoid damage to the cables, ensure that there

is adequate free access to all moving or hot components.

If test and measuring devices are required during test drives ob‐

serve the following:

♦ Always secure the test and measuring devices on the rear seat

and have a second person operate them there.

♦ If the test and measuring devices are operated from the pas‐

senger

the passenger airbag in the event of an accident.

seat, the passenger could be injured by the release of

1.6 General notes on the injection system

Repairing ignition ⇒ page 259 .

♦ The engine control unit is equipped with self-diagnosis. Before

repairs

memory. Also check the vacuum hoses and connections (un‐

metered air).

♦ Fuel hoses in the engine compartment must only be secured

with spring-type clips ⇒ electronic catalogue of original parts .

The use of clamp-type or screw-type clips is not allowed.

♦ A minimum voltage of 11.5 V is required for perfect functioning

of the electrical components.

♦ Do not use sealants containing silicone. Traces of silicone el‐

ements drawn in by the engine are not burnt in the engine and

damage the lambda probe.

♦ If after fault finding, repair or inspection of components the

engine starts briefly and then stops, it is possible that the im‐

mobiliser blocks the engine control unit. Then if necessary the

control unit must be adapted ⇒ Vehicle diagnostic tester.

♦ When opening the driver door the fuel pump is activated for 2

seconds in order to build up the pressure in the fuel system.

♦ Certain inspections may cause the control unit to detect and

store a fault. It is therefore necessary to interrogate the fault

memory after having completed all inspections and repairs,

and if necessary delete ⇒ Vehicle diagnostic tester.

Safety measures

and also for fault finding, first of all interrogate the fault

⇒ page 6 .

1.7 General notes on the ignition system

♦ Switch off the ignition before disconnecting and connecting the

battery, as this may damage the 4AV control unit.

1. Self diagnosis, safety measures, cleanliness regulations, directions 7

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

♦ The engine control unit is equipped with self-diagnosis; in‐

spect ⇒ Vehicle diagnostic tester.

♦ A minimum voltage of 11.5 V is required for perfect functioning

of the electrical components.

♦ Certain inspections may cause the control unit to detect and

store a fault. It is therefore necessary to interrogate the fault

memory after having completed all inspections and repairs,

and if necessary delete ⇒ Vehicle diagnostic tester.

♦ If after fault finding, repair or inspection of components the

engine starts briefly and then stops, it is possible that the im‐

mobiliser

control unit must be adapted ⇒ Vehicle diagnostic tester.

Safety measures

Setting data, spark plugs:

♦ ⇒ Maintenance ; Booklet Fabia II .

♦ ⇒ Maintenance ; Booklet Roomster .

♦ ⇒ Maintenance ; Booklet Octavia II .

♦ ⇒ Maintenance ; Booklet Yeti .

♦ ⇒ Maintenance ; Booklet Rapid NH

blocks the engine control unit. Then if necessary the

⇒ page 6 .

1.8 General instructions for charge air sys‐

tem

WARNING

When undertaking all assembly work, particularly in the engine

compartment due to its cramped construction, please observe

the following:

♦ Lay lines of all kinds (e.g. for fuel, hydraulic fluid, cooling

fluid and refrigerant, brake fluid, vacuum) and electrical

lines in such a way that the original line guide is re-estab‐

lished.

♦ Ensure that there is adequate free access to all moving or

hot components.

Caution

In case a mechanical damage to the exhaust gas turbocharger

is found, e.g. damage to the compressor wheel, it is not suffi‐

cient to only replace the turbocharger. In order to avoid con‐

sequential damage, perform the following tasks:

♦ Clean all oil lines.

♦ Change engine oil and oil filter.

♦ Inspect the air filter housing, the air filter element and the

intake hoses for contaminations.

♦ Inspect the whole charge-air routing and the charge air

cooler for foreign bodies.

If foreign bodies are detected in the charge air system, the

complete

the charge air cooler must also be replaced.

charge-air routing must be cleaned and if necessary

♦ The charge-air system must be tight.

8 Rep. gr.01 - Self-diagnosis

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

♦ Always replace self-locking nuts.

♦ Hose connections and hoses of the charge air system must

be free of oil and grease before being installed.

♦ Only use approved clamps for securing the hose connections

⇒ Electronic Catalogue of Original Parts .

♦ Use pliers for spring strap clamps to fit the spring strap clips.

♦ Before connecting the oil feed line, fill the exhaust turbocharg‐

er via the connection fitting with engine oil.

♦ After installing the turbocharger, run engine at idling speed for

about

1 minute to ensure that oil is supplied to the turbocharg‐

er.

1.9 Additional instructions when undertak‐

ing assembly work on the air-condition‐

ing system

WARNING

Do not open the refrigerant circuit of the air conditioning sys‐

tem.

Note

In order to avoid damage to the condenser as well as to the re‐

frigerant lines and hoses, ensure that the lines and hoses are not

over-tensioned, kinked or bent.

Steps which should be taken in order to remove and install the

engine without opening the refrigerant circuit:

– Remove the holding clamp(s) of the refrigerant lines.

– Remove AC compressor from the bracket

– Mount the AC compressor in such a way that the refrigerant

lines/hoses are not under tension.

⇒ page 34 .

1. Self diagnosis, safety measures, cleanliness regulations, directions 9

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

10 – Removing and installing engine

1 Removing and installing engine

1.1 Removing engine

(Fabia II, Roomster, Rapid NH)

Special tools and workshop equipment required

♦ Engine/gearbox jack , e.g. -V.A.G 1383 A♦ Double ladder , e. g. -VAS 5085♦ Engine mount -T10416♦ Pliers for spring strap clamps

♦ Catch pan , e.g. -VAS 6208-

Note

♦

The engine is removed downwards together with the gearbox.

♦

All cable straps that have been loosened or cut open when the

engine was removed must be attached again in the same lo‐

cation when the engine is installed again.

♦

Leave the ignition key in the ignition lock so that the steering

lock does not click into place.

♦

Collect drained coolant in a clean container for reuse or proper

disposal.

Caution

When undertaking all installation work, particularly in the en‐

gine compartment due to its cramped construction, please

observe the following:

♦ Lay lines of all kinds (e.g. for fuel, hydraulic fluid, cooling

fluid and refrigerant, brake fluid, vacuum) and electrical

lines in such a way that the original line guide is re-estab‐

lished.

♦ In order to avoid damage to the cables, ensure that there

is adequate free access to all moving or hot components.

Observe all safety measures and notes for assembly work on the

fuel system, on the injection and ignition system and the charge

air system as well as rules for cleanliness ⇒ page 3 .

WARNING

Release pressure in the high pressure area of the fuel system

⇒ page 4 .

– Before disconnecting the battery, if necessary remove the

adapter for the anti-theft wheel bolts from the luggage com‐

partment.

– Remove battery ⇒ Electrical System; Rep. gr. 27 .

10 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Remove air filter ⇒ page 226 .

– Remove battery tray ⇒ Electrical System; Rep. gr. 27 .

– Remove the right and left wheelhouse liner ⇒ Body Work;

Rep. gr. 66 .

– Remove the sound dampening system ⇒ Body Work; Rep.

gr. 50 .

– Drain coolant ⇒ page 118 .

– Remove drive shaft to the right ⇒ Chassis; Rep. gr. 40 .

– Unscrew the left drive shaft from the flange shaft of the gear‐

box.

– Unscrew

coupling rod from the anti-roll bar.

– Unscrew the nuts for the left steering joint -3- and press the

steering joint out of the suspension arm.

the nut from the left coupling rod -2- and press off the

– Unscrew the nut -2- from the front left track control arm on

installed front left vehicle level sensor -G78- .

– Turn steering to full left lock.

– Swivel the steering joint outwards and secure the drive shaft

-1- with a band -A- in the wheelhouse.

– Detach coolant hoses -2- and -5-.

– Remove

-4-. Collect the fuel which flows out with a cleaning cloth.

fuel line (press in the securing ring to the top) -3- and

1. Removing and installing engine 11

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Loosen retaining clip for coolant hose -3-.

– Slacken the clamp -1- and detach the coolant hose -2- from

the engine.

– Detach the coolant hoses at the heat exchanger -arrows-.

– Detach vacuum hose -1- from intake manifold.

– Slacken clamps -2- and detach coolant hoses -3 ... 5-.

For models with automatic gearbox

– Remove the selector lever control cable from the gearbox ⇒

Gearbox; Rep. gr. 34 .

For vehicles with manual gearbox

– Remove

34 .

– Remove hydraulic clutch control from gearbox ⇒ Gearbox;

Rep. gr. 30 .

shift mechanism from gearbox ⇒ Gearbox; Rep. gr.

WARNING

After removing the slave cylinder or after separating the hy‐

draulic line, do not depress the clutch pedal.

Continued for all vehicles

– Remove/unclamp all electrical lines from the gearbox, gener‐

ator and starter motor and uncover them.

– Remove/unclamp all other necessary electrical cables from

the engine.

– Disconnect the vacuum and bleeder hoses from the engine.

12 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Disconnect

engine control unit

– Unplug connector -2-.

– Unclip cable clip -3- -arrows-.

– Remove engine wiring harness and attach to engine control

unit.

– Disconnect plugs -1 and 2- and release cable strap -5-.

– Remove catalytic converter with pre-exhaust pipe

⇒ page 253 .

the plug of the engine wiring harness -1- from the

⇒ page 242 .

– Unscrew

-2-.

– Unbolt the pendulum support -arrows-.

For vehicles with air conditioning

– Remove V-ribbed belt ⇒ page 35 .

the screws -1, 3- and remove the bottom coolant pipe

1. Removing and installing engine 13

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Disconnect plug connection -1- for magnetic coupling at AC

compressor.

WARNING

Risk of injury through refrigerant.

♦ Do not open the refrigerant circuit of the air conditioning

system.

Caution

Risk of damaging refrigerant lines and hoses.

♦ Do not over-tension, buckle or bend refrigerant lines and

hoses.

– Release screws -arrows- for AC compressor.

– Attach AC compressor to lock carrier.

Continued for all vehicles

– Removing fan shroud ⇒ page 131 .

In order to lower the engine with the gearbox, the engine holder

-T10416- with the adapters -/1-, -/2- and -/3- is required.

– Turn

the adapter T10416/1 up to the stop in the cylinder block.

14 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Fit the engine mount -T10416- with the adapters -/2- and -/3-

to the cylinder block.

– Attach

at the cylinder block.

– Tighten all screws on the engine mount -T10416- to 20 Nm.

– Place the engine/gearbox jack - V.A.G 1383 A- on the engine

mount -T10416 - and slightly raise the engine with the gear‐

box.

♦

Check whether all hose and line connections between engine,

the engine mount -T10416- with the screw -1- by hand

Note

gearbox and body are released, if necessary release them.

♦

Use the double ladder -VAS 5085- for removing the fixing

bolts.

– Unscrew nut -3- and disconnect earth lead -4- from engine

mount.

– Release screws -2- from engine mount -1-.

– Release screws -2- from gearbox mount -1-.

Note

♦

The engine/gearbox assembly should be lowered with the help

of a second mechanic.

♦

Carefully lower engine with gearbox in order to avoid damage.

– Pull engine/gearbox unit as far forward as possible and lower

carefully and slowly downwards.

– Remove the gearbox from the engine ⇒ gearbox; Rep. gr.

34 .

1.2 Removing engine

(Octavia II, Yeti)

Special tools and workshop equipment required

♦ Engine/gearbox jack , e.g. -V.A.G 1383 A♦ Double ladder , e. g. -VAS 5085♦ Engine mount -T10416♦ Pliers for spring strap clamps

♦ Catch pan , e.g. -VAS 6208-

1. Removing and installing engine 15

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

Note

♦

The engine is removed downwards together with the gearbox.

♦

All cable straps that have been loosened or cut open when the

engine was removed must be attached again in the same lo‐

cation when the engine is installed again.

♦

Leave the ignition key in the ignition lock so that the steering

lock does not click into place.

♦

Collect drained coolant in a clean container for reuse or proper

disposal.

Caution

When undertaking all assembly work, particularly in the engine

compartment due to its cramped construction, please observe

the following:

♦ Lay lines of all kinds (e.g. for fuel, hydraulic fluid, the active

charcoal container-unit, cooling fluid and refrigerant,

brake fluid, vacuum) and electrical lines in such a way that

the original line guide is re-established.

♦ In order to avoid damage to the cables, ensure that there

is adequate free access to all moving or hot components.

Observe all safety measures and notes for assembly work on the

fuel system, on the injection and ignition system and the charge

air system as well as rules for cleanliness ⇒ page 3 .

WARNING

Release pressure in the high pressure area of the fuel system

⇒ page 4 .

– Remove air filter ⇒ page 227 .

– Before disconnecting the battery, if necessary remove the

adapter for the anti-theft wheel bolts from the luggage com‐

partment.

– Remove battery and battery tray ⇒ Electrical System; Rep.

gr. 27 .

– Remove the right and left wheelhouse liner ⇒ Body Work;

Rep. gr. 66 .

– Remove the sound dampening system ⇒ Body Work; Rep.

gr. 50 .

– Drain the coolant from the cooling system ⇒ page 118 .

– Remove drive shaft to the right ⇒ Chassis; Rep. gr. 40 .

– Unscrew the left drive shaft from the flange shaft of the gear‐

box.

16 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Unscrew

coupling rod from the anti-roll bar.

– Unscrew the nuts for the left steering joint -3- and press the

steering joint out of the suspension arm.

– Unscrew the nut -2- from the left track control arm if the front

left vehicle level sensor -G78- is present.

– Turn steering to full left lock.

– Swivel the steering joint outwards and secure the drive shaft

-1- with strap -A- in the wheelhouse.

the nut from the left coupling rod -2- and press off the

– Pull off top coolant hose -2- and bottom coolant hose from

expansion reservoir.

– Disconnect the fuel feed line -3- (press in the securing ring to

the top) and catch the fuel which flows out with a cleaning

cloth.

– Detach

system.

– Remove the hose -1- from the activated charcoal filter and

from the activated charcoal filter solenoid valve 1 -N80- .

– Remove activated charcoal filter -2-.

– Slacken the clamp -4- and detach the coolant hose -3- from

the engine.

the connecting hose -4- to the activated charcoal filter

1. Removing and installing engine 17

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Release

pull them off.

– Detach vacuum hose -1- from intake manifold.

– Slacken clamps -2- and detach coolant hoses -3 ... 5-.

For models with automatic gearbox

– Remove the selector lever control cable from the gearbox ⇒

Gearbox; Rep. gr. 34 .

For vehicles with manual gearbox

– Remove shift mechanism from gearbox ⇒ Gearbox; Rep. gr.

34 .

– Remove hydraulic clutch control from gearbox ⇒ Gearbox;

Rep. gr. 30 .

the coolant hoses at the heat exchanger -arrows- and

WARNING

After removing the slave cylinder or after separating the hy‐

draulic line, do not depress the clutch pedal.

– Disconnect

starter motor and uncover them.

– Remove/unclamp all other necessary electrical cables from

the engine.

– Disconnect the vacuum and bleeder hoses from the engine.

– Disconnect the plug from the thermal switch and the radiator

fan.

– Disconnect

gine control unit (front plug)

– Release

-arrow-.

all electrical lines from the gearbox, generator and

the plug of the engine wiring harness from the en‐

⇒ page 243 .

guide for engine wiring harness and pull out upwards

18 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Open

– Open other attachments of the engine wiring harness, remove

– Attach the cables with a cable strap at the engine.

– Disconnect plugs -1 and 2-.

– Remove pre-exhaust pipe Pos. 9 ⇒ page 246 .

all fuses for the engine wiring harness at frame side rail

-arrows-.

engine wiring harness and attach to engine.

– Unscrew the screw -2- and remove the bottom coolant pipe

-1-.

Vehicles with auxiliary heating.

– Slacken clamps -3- and pull off the coolant hoses -4 and 5-.

– Unscrew the screws -1 and 2- of the brackets for the coolant

pipes for the auxiliary heating

Continued for all vehicles

-3-.

1. Removing and installing engine 19

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Disconnect plug -2- from oil level and oil temperature sender

-G266- .

– Remove the hold-down device for the cable guide of the oil

level and oil temperature sender -G266- from the assembly

carrier at the front and place down on the assembly carrier.

– Unbolt the pendulum support -arrows-.

For vehicles with air conditioning

– Remove V-ribbed belt ⇒ page 35 .

– Disconnect plug connection -1- for magnetic coupling at AC

compressor.

WARNING

Risk of injury through refrigerant.

♦ Do not open the refrigerant circuit of the air conditioning

system.

Caution

Risk of damaging refrigerant lines and hoses.

♦ Do not over-tension or buckle refrigerant lines and hoses.

– Release screws -arrows- for AC compressor.

– Attach AC compressor to lock carrier.

Continued for all vehicles

20 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

In order to lower the engine with the gearbox, the engine mount

-T10416- with the adapters

– Turn the adapter T10416/1 up to the stop in the cylinder block.

-/1-, -/2- and -/3- is required.

– Fit the engine mount -T10416- with the adapters -/2- and -/3-

to the cylinder block.

– Attach

at the cylinder block.

– Tighten all screws on the engine mount -T10416- to 20 Nm.

– Place the engine/gearbox jack - V.A.G 1383 A- on the engine

mount -T10416 - and slightly raise the engine with the gear‐

box.

♦

Check whether all hose and line connections between engine,

the engine mount -T10416- with the screw -1- by hand

Note

gearbox and body are released, if necessary release them.

♦

Use the double ladder -VAS 5085- for removing the fixing

bolts.

– Release

the screws -2- of the assembly bracket at the engine.

1. Removing and installing engine 21

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Release the screws -2- of the assembly bracket at the gear‐

box.

Note

♦

The engine/gearbox assembly should be lowered with the help

of a second mechanic.

♦

When lowering carefully guide the engine/gearbox assembly,

in order to avoid damage.

– Pull engine/gearbox unit as far forward as possible and lower

carefully and slowly downwards.

– Remove the gearbox from the engine ⇒ gearbox; Rep. gr.

34 .

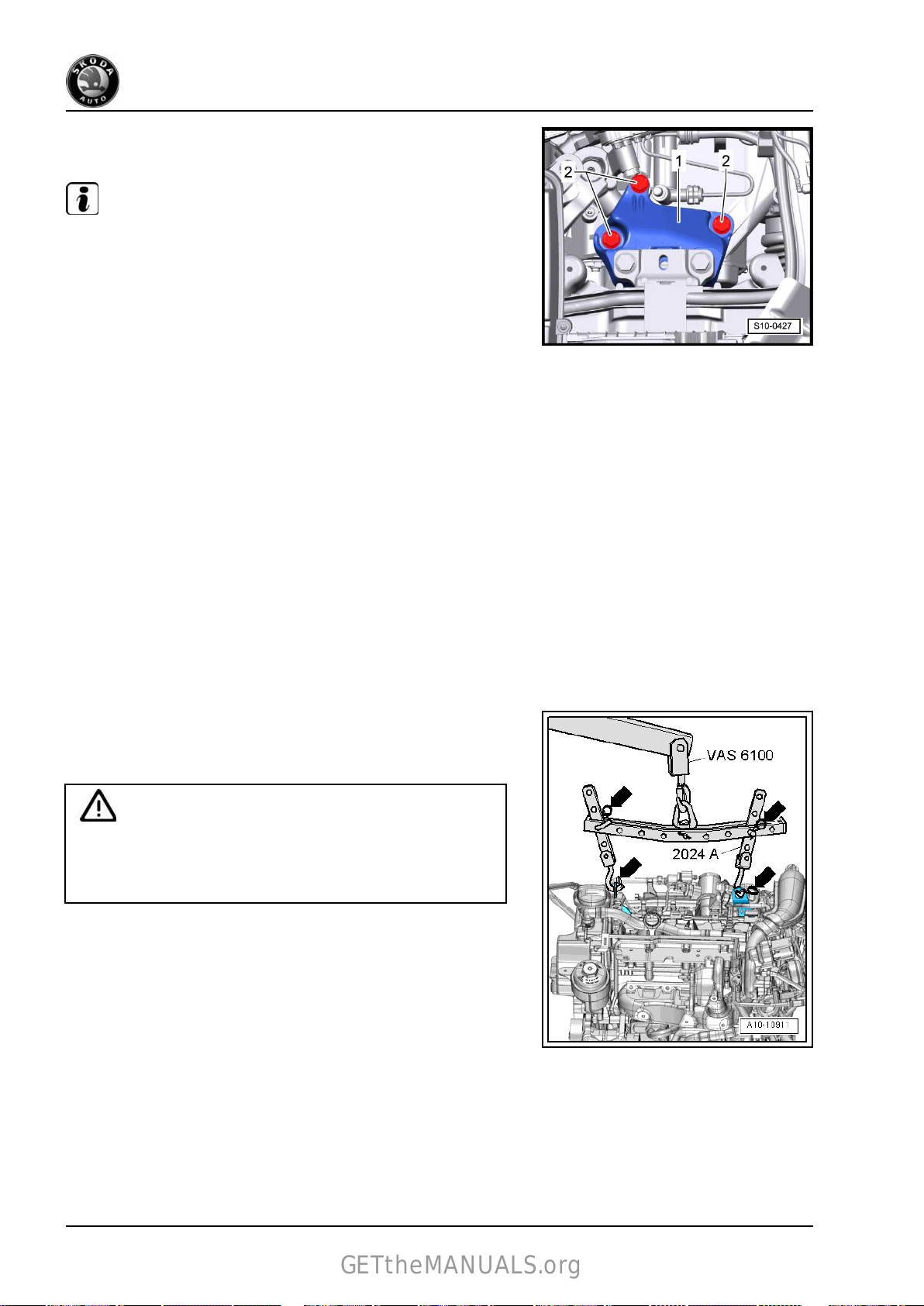

1.3 Securing the engine to the assembly stand

Special tools and workshop equipment required

♦ Lifting device -MP 9-201 (2024 A)♦ Engine mount -MP 1-202♦ Assembly stand -MP 9-101♦ Adapter -MP1-202/8♦ Adapter -MP1-202/9♦ Workshop crane , e.g. -VAS 6100Work procedure

• Separate engine from gearbox.

– Attach the lifting device -MP9-201 (2024 A)- at the workshop

crane (e.g. -VAS 6100- ) and at the engine, as shown in the

figure. (The figure shows the 1.4 ltr./90 kW TSI Engine; the

fixing system is identical).

WARNING

Use securing pins on the hooks and rig pins to prevent release.

Use securing pins on the hooks and rig pins -arrows-, in order

to avoid injuries and damages to the engine.

off engine with installed engine mount -T10416- with work‐

– Lift

shop crane e.g. -VAS 6100- from engine/gearbox jack - V.A.G

1383 A- .

– Remove engine mount -T10416- .

22 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Screw engine mount -MP 1-202- with adapters -MP1-202/8-

and

-MP1-202/9- to engine -arrows- and secure to the assem‐

bly stand -MP 9-101- .

1.4 Installing the engine

Special tools and workshop equipment required

♦ Double ladder , e. g. -VAS 5085♦ Catch pan , e.g. -VAS 6208♦ Pliers for spring strap clamps

♦ Grease -G 000 100♦ Cable strap

Precondition

• Fit engine and gearbox using engine mount -T10416- to the

engine/gearbox jack -V.A.G 1383 A- .

Work procedure

Installation is carried out in the reverse order. Pay attention to the

following:

Caution

When undertaking all assembly work, particularly in the engine

compartment due to its cramped construction, please observe

the following:

♦ Lay lines of all kinds (e.g. for fuel, hydraulic fluid, the active

charcoal container-unit, cooling fluid and refrigerant,

brake fluid, vacuum) and electrical lines in such a way that

the original line guide is re-established.

♦ In order to avoid damage to the cables, ensure that there

is adequate free access to all moving or hot components.

1. Removing and installing engine 23

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

Note

♦

All cable straps should be fastened again in the same place

when installing.

♦

Secure all hose connections with hose clamps ⇒ Electronic

Catalogue of Original Parts .

♦

Replace the self-locking nuts and screws when undertaking

assembly work.

♦

Replace screws which have been tightened to a torquing angle

as well as gasket rings and seals.

Observe all safety measures and notes for assembly work on the

fuel system, on the injection and ignition system and the charge

air system as well as rules for cleanliness

For vehicles with manual gearbox

– Clean

– After installing the coupling, check the centering of the clutch

– Check the clutch release bearing for wear. Replace release

For models with automatic gearbox

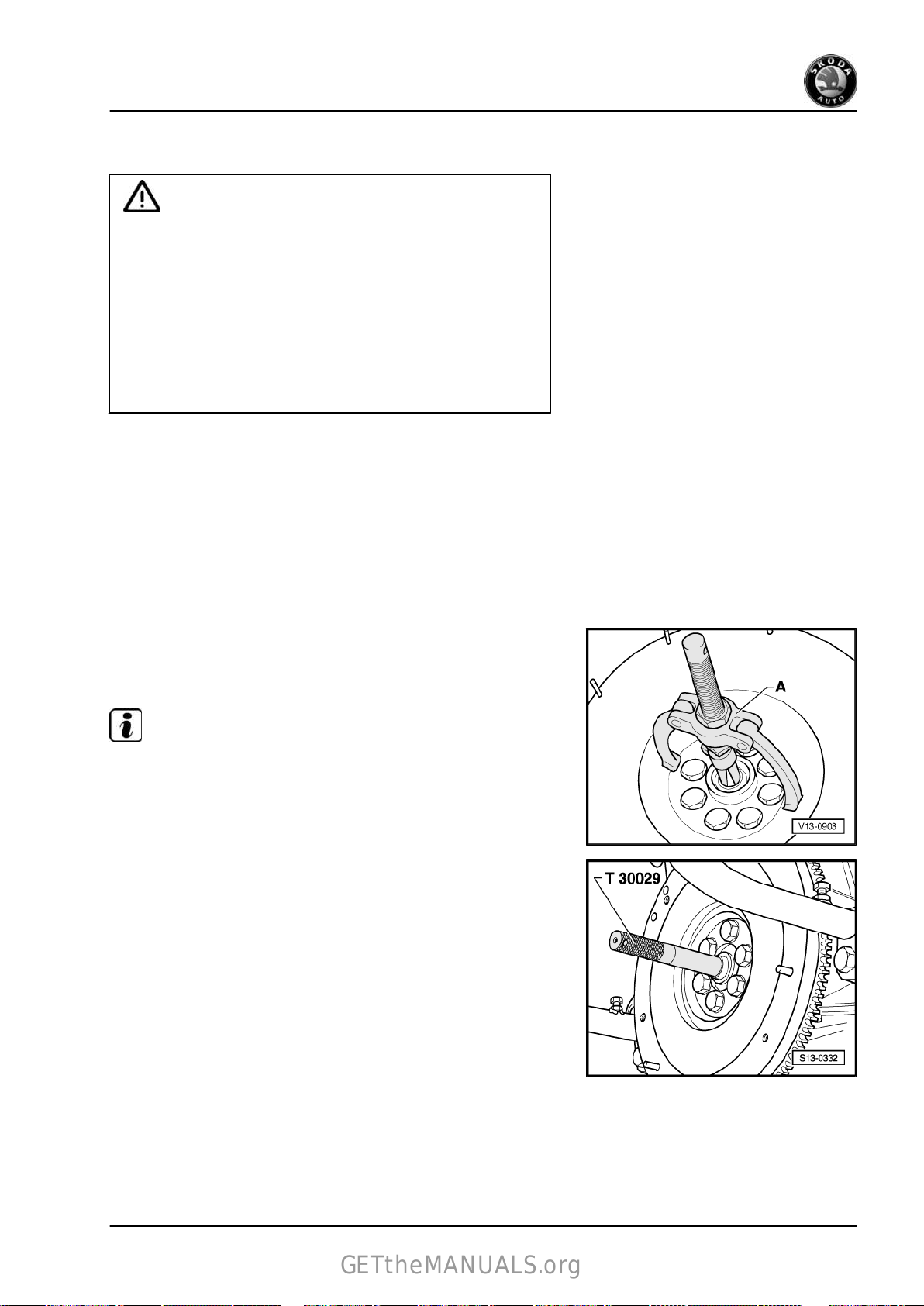

– Replace the needle bearing -arrow- in the crankshaft

– Attach

Continued for all vehicles

– Check whether the dowel sleeves for centering the engine/

the serration of the drive shaft and if the clutch disc has

been used clean the hub serration, remove corrosion and only

apply a very thin layer of grease -G 000 100- to the serration

of the drive shaft. Subsequently move the clutch disc up and

down on the drive shaft until the hub fits smoothly on the shaft.

Always remove excess grease.

disc ⇒ Gearbox; Rep. gr. 30 .

bearing if worn ⇒ Gearbox; Rep. gr. 30 .

⇒ page 61 .

the selector lever control cable at the gearbox ⇒ Gear‐

box; Rep. gr. 34 .

gearbox are present in the cylinder block; insert if necessary.

⇒ page 3 .

24 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Ensure that the intermediate plate has been inserted on the

sealing flange and is pushed onto the dowel sleeves

-arrows-.

– Screw on gearbox to engine ⇒ Gearbox; Rep. gr. 34 .

– When installing the engine/gearbox assembly, ensure clear‐

ance

to the assembly carrier, AC compressor as well as to the

radiator fans.

– Tighten the new screws by hand for attaching the engine/

gearbox assembly at the engine and gearbox mounts.

For the vehicles Fabia II, Roomster

– Adjust assembly bracket and tighten screws

– Install pendulum support ⇒ page 28 .

For the vehicles Octavia II, Yeti

– Adjust assembly bracket ⇒ page 29 and tighten screws

⇒ page 28 .

– Install pendulum support ⇒ page 28 .

Continued for all vehicles

– Install drive shafts ⇒ Chassis; Rep. gr. 40 .

For vehicles with air conditioning

– Install AC compressor ⇒ page 34 .

– Install the V-ribbed belt ⇒ page 35 .

Continued for all vehicles

– Install slave cylinder ⇒ Gearbox; Rep. gr. 30 .

– Attach shift mechanism and adjust if necessary ⇒ Gearbox;

Rep. gr. 34 .

– Install the engine wiring harness and connect to the engine

control unit ⇒ page 242 .

For the vehicles Fabia II, Roomster

– Install catalytic converter with exhaust pipe ⇒ page 253 .

For the vehicles Octavia II, Yeti

– Install exhaust system ⇒ page 246 .

Continued for all vehicles

– Install

– Checking the oil level:

♦ ⇒ Maintenance ; Booklet Fabia II .

♦ ⇒ Maintenance ; Booklet Roomster .

♦ ⇒ Maintenance ; Booklet Octavia II .

♦ ⇒ Maintenance ; Booklet Yeti .

♦ ⇒ Maintenance ; Booklet Rapid NH .

– Top up and bleed cooling system

– Interrogate

the battery and pay attention to the necessary work after

re-connecting the battery ⇒ Electrical System; Rep. gr. 27 .

⇒ page 118 .

all fault memories and delete all fault entries, which

are caused by removing and installing the engine ⇒ Vehicle

diagnostic tester.

After deleting the fault memory of the engine control unit the

readiness code must be re-generated.

⇒ page 27 .

1. Removing and installing engine 25

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Perform a test drive.

– Then

Tightening torques

perform a vehicle system test and if necessary eliminate

the resulting faults.

Component

Screws and nuts M6 10

deviations:

Engine/gearbox connecting screws ⇒ Gearbox; Rep. gr. 34

Screws for assembly bracket:

♦ Fabia II, Roomster, Rapid NH ⇒ page 27

♦ Octavia II, Yeti ⇒ page 28

M7 13

M8 20

M10 45

M12 60

Nm

26 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

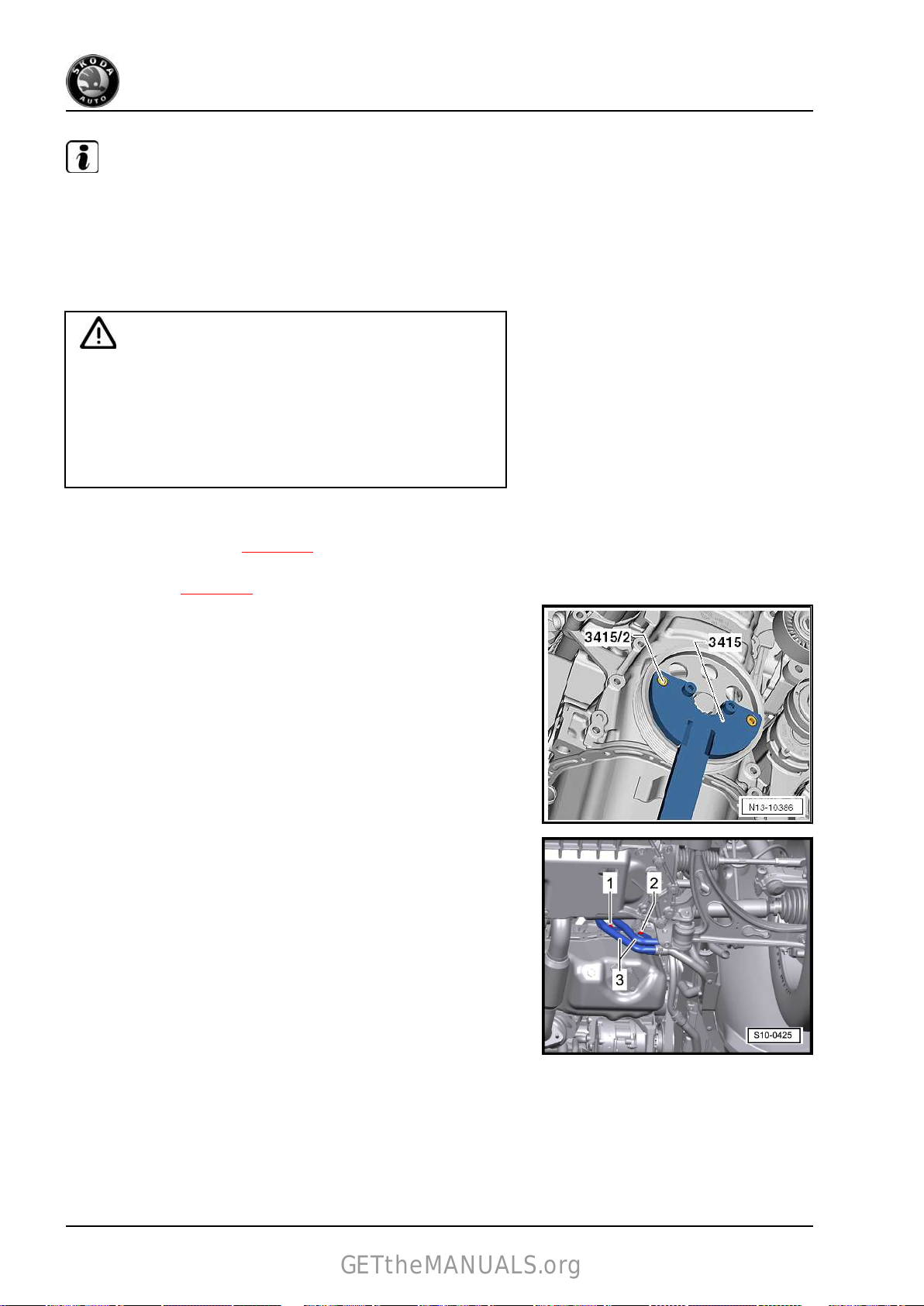

2 Assembly bracket

2.1 Assembly bracket

(Fabia II, Roomster, Rapid NH)

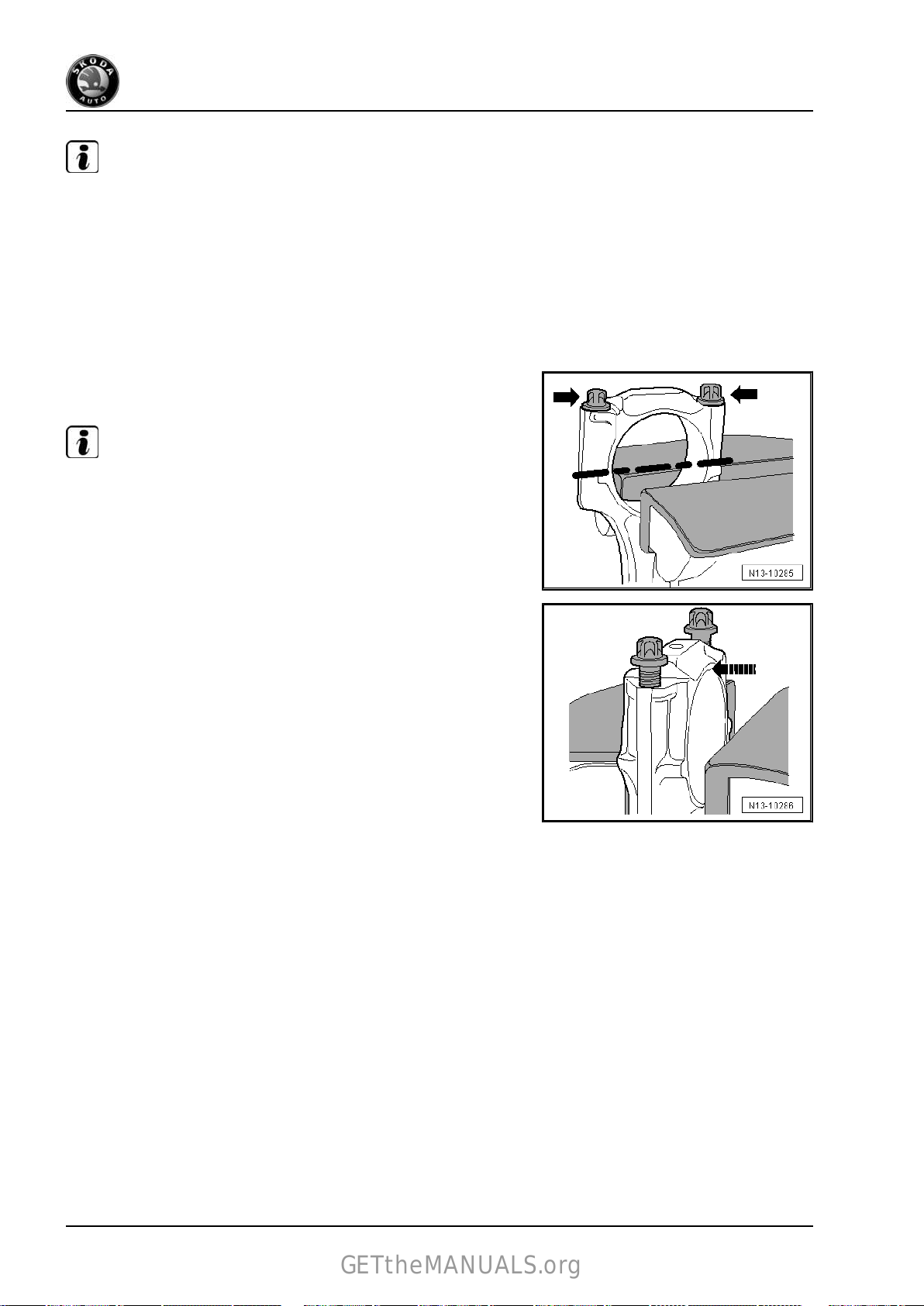

Note

♦

When installing, first of all insert all screws for bracket and

screw in by hand by at least two - three turns.

♦

Tighten screws for bracket in the sequence according to the

numerical marking in the figures.

2.1.1 Tightening torques

Assembly bracket - engine

2 - 20 Nm + torque a further 90° (1/4 turn) - replace

3 - 30 Nm + torque a further 90° (1/4 turn) - replace

4 - 16 Nm

Note

The assembly bracket can be fitted with a dynamic vibration

damper -1-. This damper is an inseparable component part of the

assembly bracket - it is not removed.

Assembly bracket - gearbox

Note

Tighten screws -1- in the following sequence: rear, front and then

upwards.

1 - 50 Nm + torque a further 90° (1/4 turn) - replace

2 - 40 Nm + torque a further 90° (1/4 turn) - replace

Pendulum support

Note

Before tightening the screws -1- press off gearbox in the elonga‐

ted holes of the pendulum support to the front in such a way that

there is maximum distance between the gearbox and the assem‐

bly carrier.

A - 30 Nm + torque a further 90° (1/4 turn) - replace

B - 40 Nm + torque a further 90° (1/4 turn) - replace

2. Assembly bracket 27

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

2.2 Unit mounting - summary of compo‐

nents

(Octavia II, Yeti)

1 - Gearbox support bracket

2 - Screw

❑

Tightening torque ⇒

Gearbox; Rep. gr. 34

3 - Engine mounting

4 - 40 Nm + torque a further 90°

(1/4 turn)

❑ replace

5 - Bracket for activated char‐

coal filter

6 - 9 Nm

7 - 9 Nm

8 - 20 Nm + torque a further 90°

(1/4 turn)

❑ replace

9 - 20 Nm + torque a further 90°

(1/4 turn)

❑ replace

10 - Connecting part

11 - 40 Nm + torque a further

90° (1/4 turn)

❑ replace

12 - 60 Nm + torque a further

90° (1/4 turn)

❑ replace

13 - Pendulum support

❑ removing: First remove

screw -14-, then screws

-15-.

❑ installing: First tighten screws -15-, then screw -14-.

14 - 100 Nm + torque a further 90° (1/4 turn)

❑ replace

15 - Bolts

❑ replace

❑

Strength category 8.8: 40 Nm + torque a further 90° (1/4 turn)

❑

Strength category 10.9: 50 Nm + torque a further 90° (1/4 turn).

16 - 60 Nm + torque a further 90° (1/4 turn)

❑ replace

17 - 40 Nm + torque a further 90° (1/4 turn)

❑ replace

18 - Gearbox mount

28 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

2.3 Checking and adjusting the assembly bracket

(Octavia II, Yeti)

2.3.1 Checking the assembly bracket

(Octavia II, Yeti)

– Check

• Between engine bracket and engine support there must be a

distance -a- = 10 mm.

• The cast iron edge on the engine support -2- must be parallel

to the supporting arm -1- the dimension -x- must be the same

at the front and rear.

The distance -a- can also be checked e.g. with suitable round

bars.

Only if there is an acoustic complaint (engine or gearbox knock

on the frame side rail when cornering) and the dimension -a- is

not 10 mm:

– Adjust the assembly bracket

dimensions on the right hanger for engine/gearbox unit:

Note

⇒ page 29 .

2.3.2 Adjusting the unit mounting

(Octavia II, Yeti)

Special tools and workshop equipment required

♦ Supporting device -T30099♦ Surface -T30099/1♦ Adapter -MP9-200/3 (10-222A/3)♦ Lifting eye -10-222A/12♦ Snap hook

– Remove battery and battery tray ⇒ Electrical System; Rep.

gr. 27 .

– Remove

66 .

the cooling water tank cover ⇒ Body Work; Rep. gr.

2. Assembly bracket 29

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Install

– Uniformly pre-tension the engine/gearbox assembly at both

– Release

supporting device -T30099- and support engine in fitting

position. The figure shows the version with the 1.4 ltr./90 kW

TSI Engine; the hanger is identical.

spindles, but do not raise.

the screws -2- of the assembly bracket at the engine.

– Slightly

box (less than 1 revolution).

– Successively replace all the screws of the assembly bracket

(as long as it has not already been performed when installing

the engine) and insert these loosely.

loosen the screws -2- of the unit mounting at the gear‐

30 Rep. gr.10 - Removing and installing engine

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

– Move the engine/gearbox assembly with an assembly lever

between the supporting arm of the engine mount

engine support -2- until the following dimensions are set:

• Between engine bracket and engine support there must be a

distance -a- of 10 mm.

• The cast iron edge on the engine support -2- must be parallel

to the supporting arm of the engine mount -1-; the dimension

-x- must be the same at the front and rear.

Note

-1- and the

The distance -a- = 10 mm can also be checked e.g. with suitable

round bars.

– Tighten the screws for the engine side assembly bracket

⇒ page 28 .

– Make

• The dimension -x- must be the same on both mount sides.

– Tighten the screws for the gearbox side assembly bracket

Further installation occurs in reverse order.

sure that on the gearbox side the edges of the support‐

ing arm of the gearbox mount -2- and the gearbox support

-1- are parallel.

⇒ page 28 .

2. Assembly bracket 31

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

13 – Crankshaft group

1 V-ribbed belt drive

1.1 V-ribbed belt - Summary of components

1.1.1 Summary of components - Vehicles without air conditioning

1 - V-ribbed belt

❑

Routing of the ribbed V-

⇒ page 33

belt

❑

mark the direction of ro‐

tation with chalk or a felt-

tip pen before removing

❑ check for wear

❑ do not kink

❑ removing and installing

⇒ page 35

2 - Crankshaft-belt pulley

❑

removing and installing

⇒ page 51

❑ Clamping

be free of oil and grease.

3 - Fixing screw

❑ for crankshaft - belt pul‐

ley

❑ replace

❑ The clamping surface of

the fixing screw must be

free of grease and oil.

❑ insert oiled (thread)

❑ Tightening torque;

slacken and tighten

⇒ page 51

4 - Diamond coated washer

❑ diamond

pressed onto the belt

pulley

❑ replace if damaged

5 - 20 Nm

❑ When loosening and

tightening, counterhold with the wrench for the water pump and power-assisted steering -MP 1-308

(V.A.G 1590)- to this end rework wrench for the water pump and power-assisted steering -MP 1-308

(V.A.G 1590)-

6 - Belt pulley for coolant pump

❑

removing and installing

7 - 9 Nm

8 - Vacuum hose

❑

to solenoid valve for coolant circuit -N492- at intake manifold

surfaces must

coated washer

⇒ page 123

⇒ page 123

32 Rep. gr.13 - Crankshaft group

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

9 - Coolant pump

❑

removing and installing

10 - 23 Nm

11 - AC generator

❑

removing and installing ⇒ Electrical System; Rep. gr. 27

❑ to facilitate the positioning of the AC generator drive the threaded bushings on the generator slightly

backwards

12 - 25 Nm

13 - Tensioning device for V-ribbed belt

❑ swivel tensioning device for V-ribbed belt with wrench to slacken the V-ribbed belt

❑ Secure the tensioning device with a 4 mm hexagon wrench or a locating pin -T10060 A-

Routing of the V-ribbed belt

1 - Belt pulley for coolant pump

2 - Tensioning pulley

3 - Belt pulley for generator

6 - Crankshaft-belt pulley

⇒ page 124

1. V-ribbed belt drive 33

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

1.1.2 Summary of components - Vehicles with air conditioning

1 - V-ribbed belt

❑

Routing of the ribbed V-

⇒ page 35

belt

❑

mark the direction of ro‐

tation with chalk or a felttip pen before removing

❑ check for wear

❑ do not kink

❑ removing and installing

⇒ page 35

2 - Fixing screw

❑

for crankshaft - belt pul‐

ley

❑ replace

❑ The clamping surface of

the fixing screw must be

free of grease and oil.

❑ insert oiled (thread)

❑ Tightening torque;

slacken and tighten

⇒ page 51

3 - Crankshaft-belt pulley

❑

removing and installing

⇒ page 51

❑ Clamping

be free of oil and grease.

4 - Diamond coated washer

❑ diamond coated washer

pressed onto the belt

pulley

❑ replace if damaged

5 - 20 Nm

❑ When loosening and

tightening, counterhold with the wrench for the water pump and power-assisted steering -MP 1-308

(V.A.G 1590)- to this end rework wrench for the water pump and power-assisted steering - MP 1-308

(V.A.G 1590)-

6 - Belt pulley for coolant pump

❑

removing and installing

7 - 9 Nm

8 - Vacuum hose

❑

to solenoid valve for coolant circuit -N492- at intake manifold

9 - Coolant pump

❑ removing and installing

10 - Guide pulley, 40 Nm

11 - 25 Nm

12 - Plastic cover

13 - Bracket for top auxiliary units

❑

with oil filter and engine oil cooler

❑ removing and installing

surfaces must

⇒ page 123

⇒ page 123

⇒ page 124

⇒ page 36

34 Rep. gr.13 - Crankshaft group

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

14 - AC generator

❑

removing and installing ⇒ Electrical System; Rep. gr. 27

❑ to facilitate the positioning of the AC generator drive the threaded bushings on the generator slightly

backwards

15 - 40 Nm + torque a further 90° (1/4 turn)

❑ replace

16 - 25 Nm

17 - AC compressor

❑ removing and installing ⇒ Heating, Air Conditioning; Rep. gr. 87

18 - 25 Nm

19 - Fitting sleeve

20 - Bracket for bottom auxiliary units

❑ for tensioning device and AC compressor

❑ removing and installing

21 - Tensioning device for V-ribbed belt

❑

swivel tensioning device for V-ribbed belt with wrench to slacken the V-ribbed belt

❑ Secure the tensioning device with a 4 mm hexagon wrench or a locating pin -T10060 A❑ to remove, release screw Pos. 12

⇒ page 38

Routing of the V-ribbed belt

1 - Belt pulley for coolant pump

2 - Guide pulley

3 - Belt pulley for generator

4 - Tensioning pulley

5 - Belt pulley for AC compressor

6 - Crankshaft-belt pulley

1.2 Removing and installing V-ribbed belt

Special tools and workshop equipment required

♦ Locking pin -T10060 ARemoving

– Remove the sound dampening system ⇒ Body Work; Rep.

gr. 50 .

Caution

Risk of damage through reversing the rotation direction of an

already used V-ribbed belt.

♦ Mark the direction of rotation with chalk or a felt-tip pen for

the re-installation before removing the V-ribbed belt.

1. V-ribbed belt drive 35

Fabia II 2007 ➤ , Fabia II 2009 ➤ , Fabia II 2011 ➤ , Octavia II 2004 ➤ ...

GETtheMANUALS.org

1,2/63; 77 kW TSI engine - Edition 09.2012

For vehicles without air conditioning

– Loosen the V-ribbed belt by swivelling the tensioning device

with a ring spanner

– Interlock the tensioning element with the locking pin -T10060

A- .

For vehicles with air conditioning

– Loosen the V-ribbed belt by swivelling the tensioning device

with a ring spanner -in direction of arrow-.