Page 1

Service

5

Service Department. Technical Information

Printed in Czech Republic

S00.5301.00.20

Workshop Manual

FABIA 2000 ➤

Inspection and Maintenance

Edition 08.99

Page 2

Service

5

The Workshop Manual is intended only for use within the Organisation Škoda.

It is not permitted to pass it on to other persons.

© ŠKODA AUTO a. s.

Printed in Czech Republic

S00.5301.00.20

Page 3

FABIA 2000 ➤ Inspection and Maintenance

List of SupplementsEdition 09.04

S00.5301.14.20

List of Supplements to Workshop Manual

FABIA 2000 ➤

Inspection and Maintenance

Edition 08.99

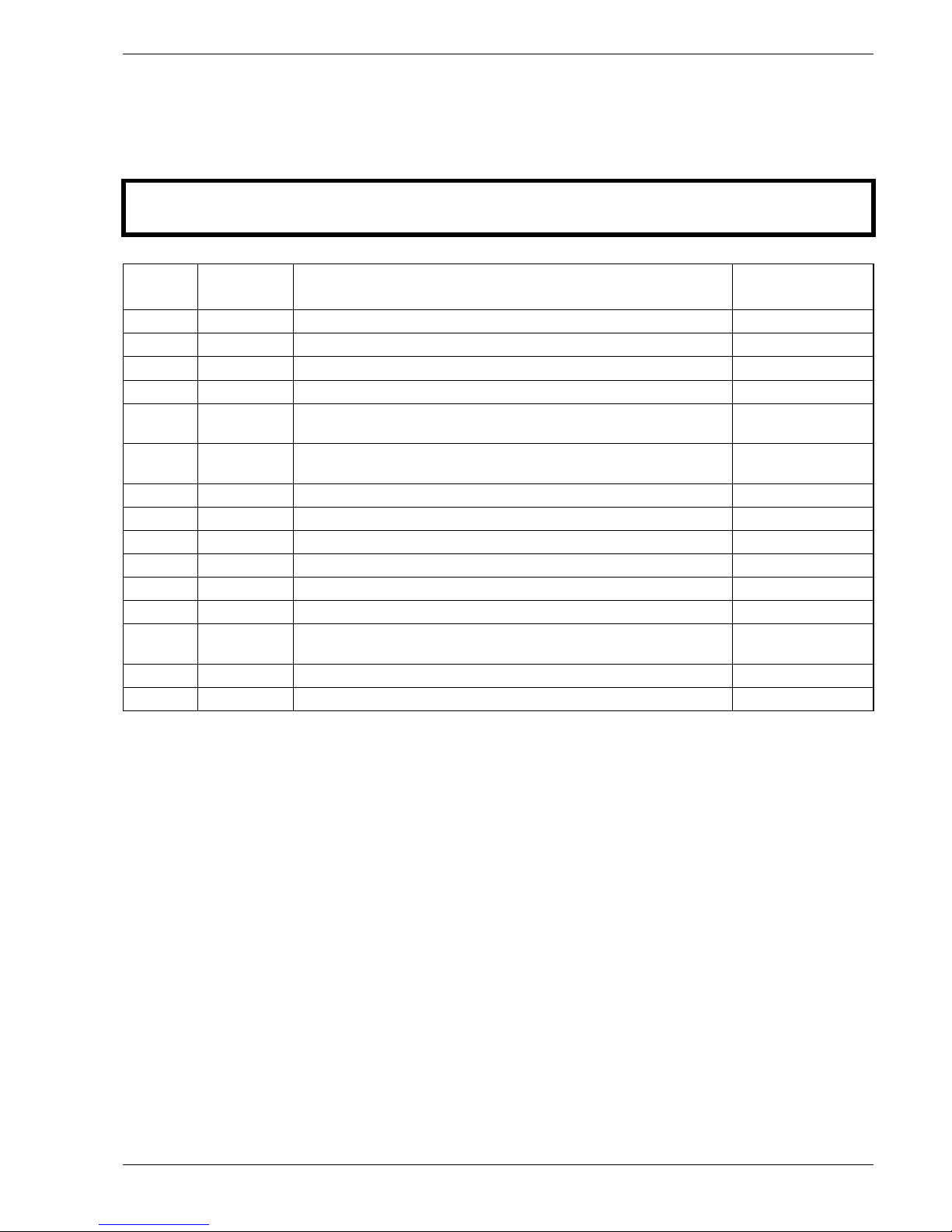

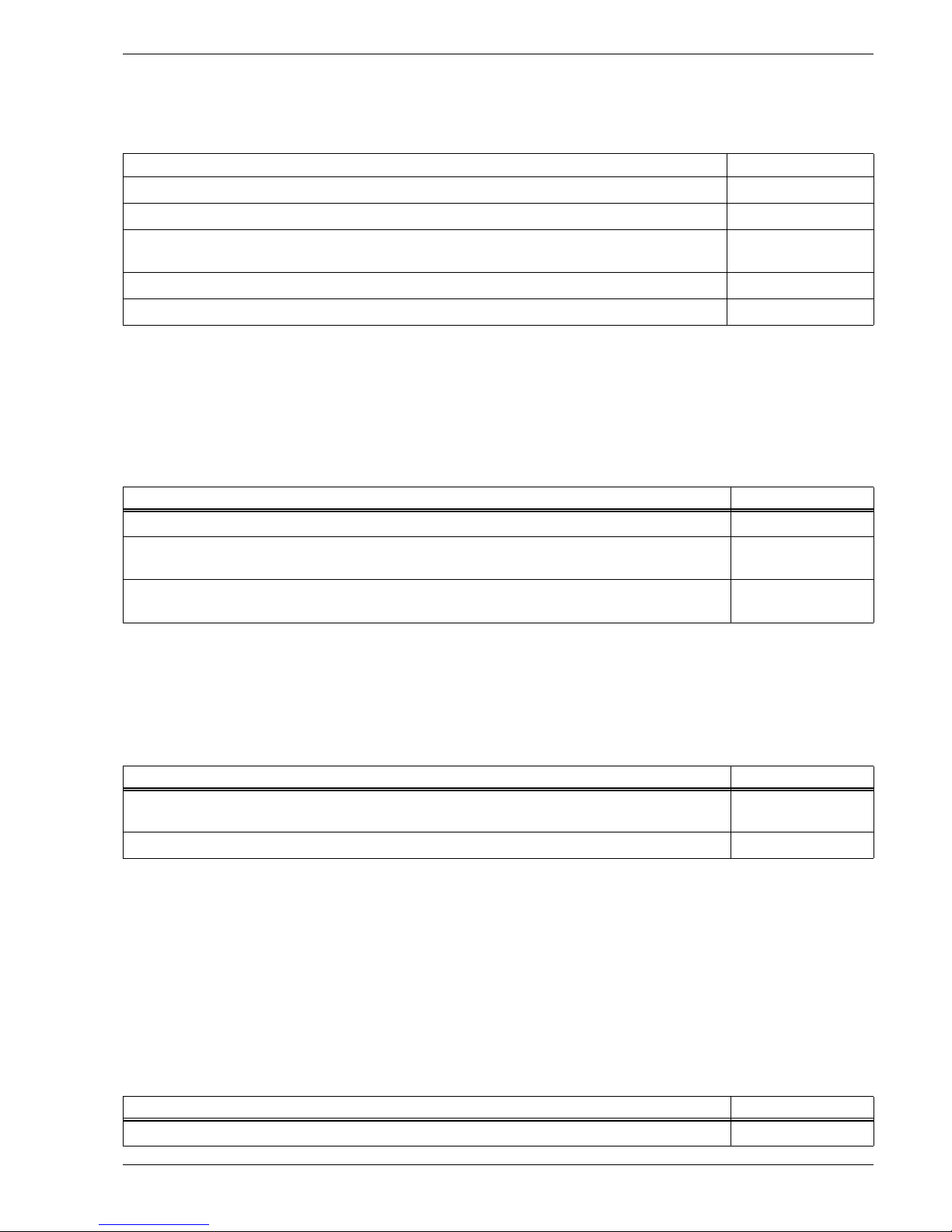

Supple-

ment

Edition Subject Article Number

08.99 Basic Edition S00.5301.00.20

1 12.99 Supplement to Basic Edition S00.5301.01.20

2 02.00 Vehicle identification number S00.5301.02.20

3 03.00 Inspection Service every 90.000 km; exhaust-emission analysis S00.5301.03.20

4 11.00 FABIA COMBI, new engines and gearboxes, exhaust-emission

analysis

S00.5301.04.20

5 12.00 Vehicle identification number, exhaust-emission analysis, text

modifications

S00.5301.05.20

6 06.01 FABIA SEDAN, text modifications S00.5301.06.20

7 11.01 Additional text S00.5301.07.20

8 02.02 Engines AWY and BBY S00.5301.08.20

9 06.02 Engine BBZ, coolant G12 Plus S00.5301.09.20

10 10.02 Additions and alterations to the text, exhaust-emission analysis S00.5301.10.20

11 04.03 AZQ Engine, addit ion s and alt er ations to the text S00.5301.11.20

12 07.03 Exhaust-emission analysis according to EOBD, engine oil capacity

at oil change, engines AMF and ASZ

S00.5301.12.20

13 02.04 Exhaust gas, addition to text S00.5301.13.20

14 09.04 BMD, BKY engine, addition to text S00.5301.14.20

Page 4

FABIA 2000 ➤ Inspection and Maintenance

List of Supplements Edition 09.04

S00.5301.14.20

Page 5

FABIA 2000 ➤ Inspection and Maintenance

Table of ContentsEdition 09.04

S00.5301.14.20

I

Table of Contents

02 – Inspection and Maintenance

General points ..................................................................................... .....

- Vehicle identification data ........................... ............... ............... .............. .....

- Storage of ŠKODA new vehicles ....................................................................

- Vehicle handover from stock ........................................................................

- Additional customer information regarding inspection and maintenance .....................

Inspection ............................................................................. ...................

- Pre-Delivery Inspection -PDI- (Export) .............................................................

- Pre-sales Inspection - (the Czech Republic) ......................................................

- Delivery Inspection (Export) .........................................................................

- Oil Change Service every 15.000 km

1)

(QG0) ....................................................

- Annual Inspection (every 12 months) (QG0) ......................................................

- Every 30 000 km (QG0) ..............................................................................

- Every 60 000 km (QG0) ..............................................................................

- Every 90 000 km (QG0) ..............................................................................

- Every 120 000 km (QG0) .............................................................................

- Every 150.000 km (QG0) .............................................................................

- Every 240 000 km (QG0) .............................................................................

- Inspection Service (QG1, QG2) .....................................................................

- O il cha nge (QG1, QG2) ............... ...............................................................

Engines .............................................................................................. .....

- Engine overvie w .......................................................................................

- Engine fitted ............................................................................................

- Visual inspection: Engine for leaks and damage .................................................

- Replace engine oil filter ...............................................................................

- Replacing timing belt and tensioning pulley for camshaft drive (1.9 TDI engines) ..........

- Replacing timing belt and tensioning pulley for camshaft drive (1.4 TDI engines) ..........

- Inspecting timing belt for camshaft drive for wear and running (petrol engine) ..............

- Replacing toothed belt and guide pulley for camshaft drive (1.9 SDI engines) ..............

- Inspecting engine oil level ............................................................................

- Change engine oil .....................................................................................

- Inspecting antifreeze protection, replenishing coolant additive if necessary .................

- Inspecting coolant level (volume) ...................................................................

- Ribbed V-belt: Inspect condition ....................................................................

- Routing of V-ribbed belt ..............................................................................

- Replace spark plugs ..................................................................................

- Replace air filter element .............................................................................

- Replacing the fuel filter (diesel engine) ............................................................

- Draining the fuel filter (diesel engine) ..............................................................

Gearbox ..................... ..............................................................................

- Gearbox/Final drive: Check the oil level and top it if neces sary ................................

- Inspecting ATF level, if necessary topping up ....................................................

Chassis ...................................................................................................

- Inspecting thickness of front and rear brake pads/linings .......................................

- Inspecting brake system for leaks and damage ..................................................

02-1

page 1

02-1

page 1

02-1

page 3

02-1

page 3

02-1

page 3

02-2

page 1

02-2

page 1

02-2

page 2

02-2

page 3

02-2

page 5

02-2

page 5

02-2

page 6

02-2

page 7

02-2

page 7

02-2

page 7

02-2

page 7

02-2

page 8

02-2

page 8

02-2

page 10

02-3

page 1

02-3

page 1

02-3

page 4

02-3

page 6

02-3

page 7

02-3

page 7

02-3

page 7

02-3

page 7

02-3

page 8

02-3

page 8

02-3

page 8

02-3

page 10

02-3

page 12

02-3

page 14

02-3

page 14

02-3

page 17

02-3

page 18

02-3

page 18

02-3

page 19

02-4

page 1

02-4

page 1

02-4

page 2

02-5

page 1

02-5

page 1

02-5

page 2

Page 6

FABIA 2000 ➤ Inspection and Maintenance

Table of Contents Edition 09.04

S00.5301.14.20

II

- Changing brake fluid (every 2 years) .................................................... ...........

- Inspecting the brake fluid level ......................................................................

- Track rod ends: Inspect play, correct attachment and joint boots .............................

- Inspecting tyres (including spare wheel) ...........................................................

- Inspecting the tyre tread depth (including spare wheel) and entering ........................

- Tightening wheel bolts to specific torque ..........................................................

- Inspecting the tyre inflation pressure (including spare wheel) and correcting the tyre

inflation pressure if necessary .......................................................................

Electrical System .......................................................................................

- Power windows: Inspecting positioning ............................................................

- Electrical components: Check for proper operation ..............................................

- Battery: Testi ng no-load voltage ....................................................................

- Battery: Inspecting electrolyte level, topping up with distilled water if necessary ...........

- Radio: Check for proper operation ..................................................................

- Setting clock ...................... ............... .............. ............... ............... ...........

- Connect vehicle system tester and interrogate fault memory ..................................

- Resetting service interval display (SID) QG0 .....................................................

- Resetting service interval display (SID) QG1 and QG2 .........................................

- Changing the code of the service intervals .............................. ..........................

- Inspecting headlight beam setting and adjusting if necessary .................................

- Setting the headlight beam ..........................................................................

- Replace emergency battery for alarm system ...................................................

Body .............................................................. .........................................

- Airbag units: Visual inspection ......................................................................

- Inspect key switch for deactivation of front passenger airbag ..................................

- Check underbod y protection and body paintwork for damage .................................

- Inspecting plenum chamber and water drain openings for dirt, cleaning if necessary .....

- Windscreen wiper/washer system: Chec k for proper operation ................................

- Sun roof: Cleaning and greasing runners .........................................................

- Door locks, locking buttons, child safety locks: Check for proper operation .................

- Replacing the dust and odour filter eleme nt ......................................................

- Sticking the vehicle data sticker .....................................................................

- ....................................... .......................................... Inspect trailer coupling

Exhaust-emission Analysis ..........................................................................

- Exhaust-Emission Analysis on Models with Fuel Engines ......................................

- Test Values for Exhaust-Emission Analysis on Models with Fuel Engines ..................

- Exhaust-Emission Analysis on Models with Diesel Engines ....................................

- Test Values for Exhaust-Emission Analysis on Diesel Engines ................................

Miscellaneous ................................................................. ..........................

- Tow starting/Towing ....................................................................... ...........

- Perform a test drive ...................................................................................

- Raising the veh icle ....................................................................................

02-5

page 2

02-5

page 4

02-5

page 5

02-5

page 5

02-5

page 6

02-5

page 6

02-5

page 6

02-6

page 1

02-6

page 1

02-6

page 1

02-6

page 1

02-6

page 2

02-6

page 2

02-6

page 2

02-6

page 3

02-6

page 4

02-6

page 7

02-6

page 9

02-6

page 10

02-6

page 12

02-6

page 13

02-7

page 1

02-7

page 1

02-7

page 2

02-7

page 2

02-7

page 3

02-7

page 3

02-7

page 4

02-7

page 4

02-7

page 5

02-7

page 6

02-7

page 6

02-8

page 1

02-8

page 1

02-8

page 2

02-8

page 5

02-8

page 6

02-9

page 1

02-9

page 1

02-9

page 2

02-9

page 2

Page 7

FABIA 2000 ➤ Inspection and Maintenance

General pointsEdition 09.04

S00.5301.14.20

02-1 page 1

02

02-1 General points

Vehicle identification data

Vehicle identification number

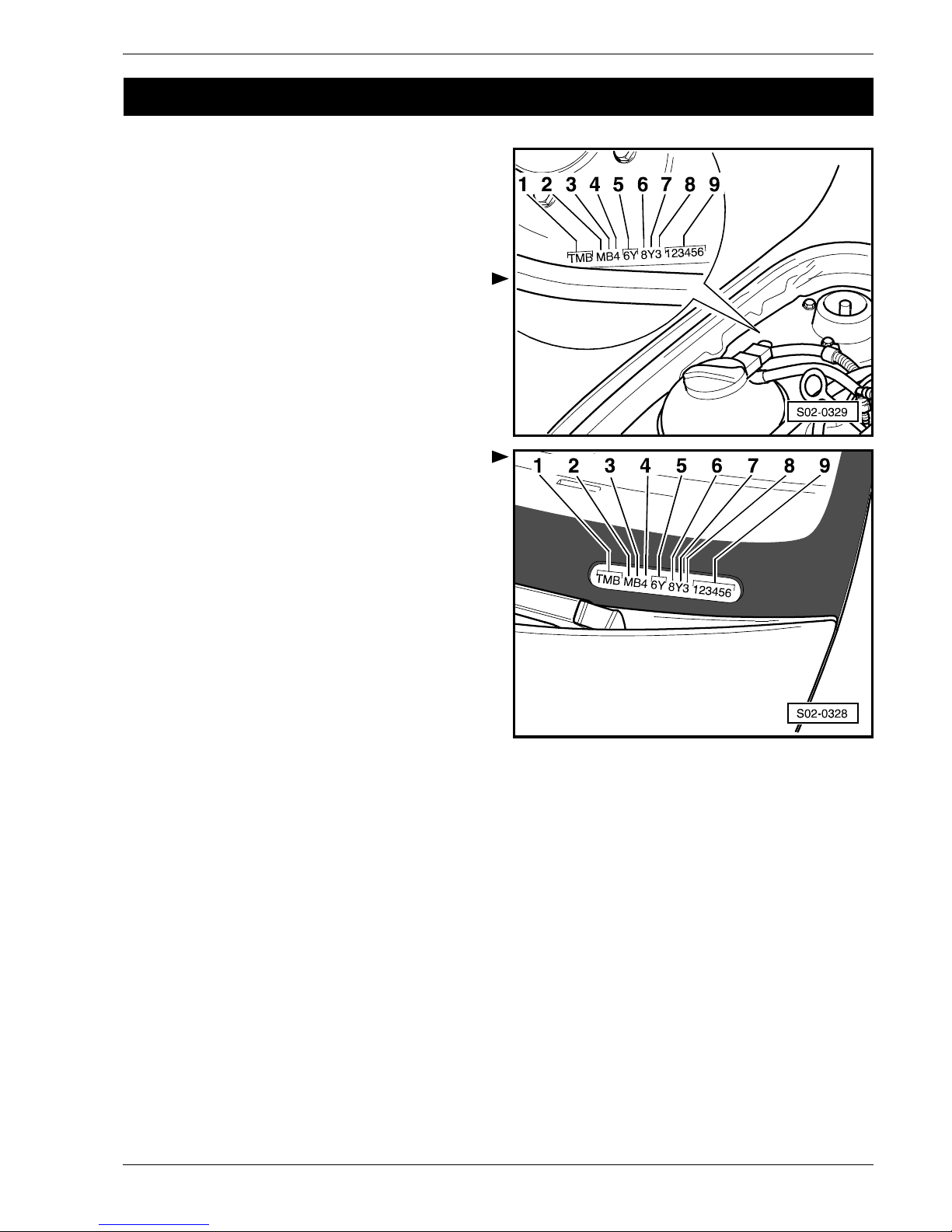

The vehicle identification number (chassis number)

is attached to the right suspension dome.

The vehicle identification number (chassis number)

can also be found bottom left of the front window corner.

1 - Manufacturer's world code

2 - Model and version:

B - FABIA SEDAN Elegance

C - FABIA SEDAN Comfort/Ambiente

D - FABIA SEDAN Classic

G - FABIA COMBI Elegance

H - FABIA COMBI Comfort/Ambiente

J - FABIA COMBI Classic

M - FABIA Elegance

N - FABIA Comfort/Ambiente

P - FABIA Classic/ Junior

T - FABIA PRAKTIK

W - FABIA RS

3 - Engine type:

A - 1.0 ltr./37 kW/petrol engine

B - 1.4 ltr./50 kW/petrol engine

C - 1.4 ltr./55 kW/petrol engine

D - 1.4 ltr./74 kW/petrol engine

E - 2.0 ltr./85 kW/petrol engine

F - 1.9 ltr. SDI/47kW/diesel engine

H - 1.4 ltr./44 kW/petrol engine

S - 1.9 ltr. TDI PD/74 kW/diesel engine

02 – Inspection and Ma in ten a nc e

Page 8

FABIA 2000 ➤ Inspection and Maintenance

General points Edition 09.04

S00.5301.14.20

02-1 page 2

02

U - 1.9 ltr. TDI PD/96 kW/diesel engine

W - 1.2 ltr./40 kW/petrol engine

Y - 1.2 ltr./47 kW/petrol engine

Z - 1.4 ltr. TDI PD/55 kW/diesel engine

4 - Airbag System:

0 - no airbag

1 - 1 Front airbag

2 - 2 Front + 2 side airbags

4 - 2 Front airbags

8 - light weight utility vehicle

5 - Model:

6Y - FABIA, FABIA COMBI, FABIA SEDAN, FABIA

PRAKTIK, FABIA RS

6 - Internal code

7 - Model year:

Y - 2000

1 - 2001

2 - 2002

3 - 2003

4 - 2004

5 - 2005

8 - Manufacturing plant:

3 and 4 - Mladá Boleslav

6 - Kvasiny

7 - Vrchlabí

B - Solomonovo

N - Mladá Boleslav

X - Poznan

9 - Vehicle body number

Type plate

The type plate -arrow- is attached to the front of the left

wheel house.

Page 9

FABIA 2000 ➤ Inspection and Maintenance

General pointsEdition 09.04

S00.5301.14.20

02-1 page 3

02

Vehicle data sticker

The vehicle data sticker is located at the rear left on the

floor of the boot.

Storage of ŠKODA new vehicles

Notes on storage of new vehicles ⇒ Technical Service

Handbook.

Vehicle handover from stock

– Before starting a stock vehicle, carry out a Pre-sales

Inspection.

– If the vehicle has been in stock for more than 6

months, replace the brake fluid.

– Inspect the electrolyte level of the battery and top up,

if necessary.

– Before the vehicle is sold, the recharging table must

be removed from the battery.

– If the battery is more than 52 weeks old or has been

recharged more than twice, it must be replaced with

a new battery.

Additional customer information regarding inspection and maintenance

Information regarding the use of vehicles under

„severe conditions“:

– The service advisor should always point out to the

customer that the inspection intervals are based on

normal operating conditions.

– Under „severe conditions“ the inspection intervals

must be shortened.

„Severe conditions“ exist, for instance, if the vehicle is operated continuously in one or several of the conditions

stated below:

♦ Towing a trailer or when fitted with a roof rack.

♦ Operated on dusty, poor, muddy roads or roads treat-

ed with road salt.

♦ Driven for short distances and at ambient tempera-

tures below freezing point.

– If one or several of these „severe conditions“ exists,

please advise your customer whether it is necessary

to have work carried out between the normal service

intervals, such as:

♦ Changing the engine oil before the normal specified

interval.

♦ Cleaning or replacing the air filter element in the air fil-

ter housing.

Page 10

FABIA 2000 ➤ Inspection and Maintenance

General points Edition 09.04

S00.5301.14.20

02-1 page 4

02

General information:

– Inform your customer about this so that he has each

inspection carried out at the right time and none are

forgetten.

– Draw the attention of your customer to the sticker af-

fixed to the side of the dash panel (driver's side) indicating when the next service event is due.

– In addition, enter in the boxes provided in the pages of

the Service Schedule when the next service or other

additional operations should be carried out.

– An oil change service should be undertaken at the

prescribed interval ⇒ Chapter 02-2.

– Advise your customer that to mainta in the vehicl e in a

safe and roadworthy condition and also to ensure that

the warranty terms are complied with, it is essential to

have the additional following operations carried out in

addition to the annual inspections:

♦ Every 2 years change the br ak e fl uid (have this d one

if possible during an inspection service).

Page 11

FABIA 2000 ➤ Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.20

02-2 page 1

02

02-2 Inspection

Pre-Delivery Inspection -PDI- (Export)

The operations marked with * apply to all countries; other

operations are applicable to certain countries only!

Compare as-delivered condition of vehicle with order form Chapter

♦ Engine fitted

♦ Type plate in the engine compartment

♦ Vehicle data sticker (compare with stamped identification number)

♦ Colour of paintwork, badges, inscriptions

♦ Seats (cover, colour) interior trim (colour)

♦ Radio, spe ak ers, aerial

♦ Central locking system, anti-theft alarm system

♦ Wheels, tyres

♦ Sun roof

♦ Vehicle log book - for completion: Operating manual and service plan (in the correct lan-

guage and with the correct edition data), short introduction, technical data, support in the

case of a breakdown, other manuals (radio,...) ) - all in the vehicle log book pouch

♦ Other equipment (all equipment fitted in proper condition)

* Check transport damage (bodywork, paintwork, upholstery, interior trim, carpeting, footmats,

tyres, wheels)

02-5, 02-7

Vehicle (exterior)

– Check that all car keys and key number fobs have been provided; check that the sticker

for the key number for the electronic immobiliser is complete and legible

– Proper operation of door handles outside, door locks, child safety locks, door contact

switches and proper operation of all locks and keys (including spare keys), doors, boot lid/

tailgate, fuel filler cap, bonnet lock

02-7

– Proper operation of anti-theft alarm system

Engine compartment (from above)

– Check battery no-load voltage, recharge battery if necessary

02-6

– Check tight connection of electric cables and plug connections (in particular battery ca-

bles)

– Inspect engine, gearbox, cooling system, brake system and fuel system for leaks

02-3, 02-5

– Engine oil level (in-between markings on dipstick)

02-3

– Brake fluid level (at „MAX“ marking)

02-5

– Coolant level (in-between marking), special equipment antifreeze down to -35°C

02-3

– Fill up fluid in washer reservoir, in the winter add antifreeze

Vehicle interior

– Proper operation of seat belts, seat belt height adjuster, power windows and sun roof

– Check car tool kit, spare wheel and accessories for completeness and proper attachment

Underside of vehicle (on lift platform)

– Inspect underbody (underbody protection for damage)

02-7

– Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system

02-3, 02-5

Page 12

FABIA 2000 ➤ Inspection and Maintenance

Inspection Edition 09.04

S00.5301.14.20

02-2 page 2

02

Pre-sales Inspection - (the Czech Republic)

Compare as-delivered condition of vehicle with order form Chapter

♦ Engine fitted

♦ Type plate in the engine compartment

♦ Vehicle data sticker (compare with stamped identification number)

♦ Colour of paintwork, badges, inscriptions

♦ Seats (cover, colour) interior trim (colour)

♦ Radio, speakers, aerial

♦ Central locking system, anti-theft alarm system

♦ Wheels, tyres

♦ Sun roof

♦ Vehicle log book - for completion: Operating manual and service plan (in the correct lan-

guage and with the correct edition data), a list of dealers, short introduction, technical da-

ta, other manuals (radio......) ) - all in the vehicle log book pouch

♦ Other equipment (all equipment fitted in proper condition)

♦ Vehicles in stock for more than 6 months: Change brake fluid

Inspections and operations to be completed

Vehicle (exterior)

– Plastic and rubber parts - cleanliness and damage

– Inspect bodywork and paintwork for damage

02-7

– Check that all car keys and key number fobs have been provided; check that the sticker

for the key number for the electronic immobiliser is complete and legible

– Proper operation of door handles outside, door locks, child safety locks, door contact

switches and proper operation of all locks and keys (including spare keys), doors, boot lid/

tailgate, fuel filler cap, bonnet lock

02-7

– P rope r opera t ion of anti-theft alarm system

– Tighten the wheel bolts to specified torque (steel and light alloy wheels 120 Nm), fit wheel

caps

02-5

– Check the tyre inflation pressure (including spare wheel), if necessary correct the tyre in-

flation pressure, fit valve caps

02-5

– Fit roof aerial

Engine compartment (from above)

– Check battery no-load voltage, recharge battery if necessary

02-6

– Check tight connection of electric cables and plug connections (in particular battery ca-

bles)

– Inspect engine, gearbox, cooling system, brake system and fuel system for leaks

02-3, 02-5

– Engine oil level (in-between markings on dipstick)

02-3

– Brake fluid level (at „MAX“ marking)

02-5

– Coolant level (in-between marking)

02-3

– Fill up fluid in washer reservoir, in the winter add antifreeze

– Windscreen wiper/washer system and headlamp cleaning system: Check for proper oper-

ation

02-7

Vehicle interior

Page 13

FABIA 2000 ➤ Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.20

02-2 page 3

02

Delivery Inspection (Export)

– Proper operation of seat belts, seat belt height adjuster, power windows and sun roof

– Inspect upholstery, interior trim, carpeting and footmats for cleanliness and damage

– Inspect all switches, all electrical components, gauges/indicators and controls

02-6

– Radio: Inspect for proper operation, store stations, set clock, encode

02-6

– Reset service interval display

02-6

– Power windows: Inspecting positioning

02-6

– Key switch for airbag deactivation, front passenger side: Check function „ON/OFF“ and

switch-over to the position „ON“

02-7

– Fit net in luggage compartment (if available)

– Check the car tool kit, spare wheel and accessories, that they have all been supplied and

are properly secured

– Install the carpets supplied in the vehicle

– Perform a test drive

Underside of vehicle (on lift platform)

– Inspect underbody (underbody protection for damage)

02-7

– Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system

02-3, 02-5

– Inspect tyres and wheels for damage

02-5

Concluding operations

– Interrogate fault memory of all systems, if necessary erase

02-6

– Remove protective seat covers

– Remove recharging table (if affixed)

– Complete the service schedule, affix the vehicle data sticker in the Service Schedule to

the floor of the luggage compartment next to the spare wheel„Next Service Date“ sticker

and affix to the side of the dash panel on the driver's side, hand the card „Škoda Assistance“ to the customer

02-7

– Final inspection to ensure proper condition for handover to the customer

Inspections and operations to be completed Chapter

Vehicle (exterior)

– Plastic and rubber parts: Inspect for cleanliness and damage

– Inspect bodywork and paintwork for damage

02-7

– Check operation of the tailgate lock and the fuel filler cap, door contact switch, operation

of the door handles, door locks and safety buttons, central locking from outside as well as

inside, child safety locks, ability to close all locks on the vehicle using all keys (including

the spare key)

02-7

– Check operation of the anti-theft alarm system

– Tighten the wheel bolts to specified torque (steel and light alloy wheels 120 Nm), fit wheel

caps

02-5

– Check the tyre inflation pressure (including spare wheel), if necessary correct the tyre in-

flation pressure, fit valve caps

02-5

– Vehicles in stock for more than 6 months: Change brake fluid

02-5

Page 14

FABIA 2000 ➤ Inspection and Maintenance

Inspection Edition 09.04

S00.5301.14.20

02-2 page 4

02

– Fit roof aerial

Engine compartment (from above)

– Check battery no-load voltage; recharge if necessary

02-6

– Check tight connection of electric cables and plug connections (in particular battery ca-

bles)

– Brake fluid level (at „MAX“ marking)

02-5

– Check the engine oil level (to be in-between the marking on the dipstick)

02-3

– Check the coolant level (in-between marking), for special equipment antifreeze down to -

35 °C

02-3

– Fill up fluid in washer reservoir, in the winter add antifreeze

– Check windscreen wiper and washer system, the spray nozzle adjustment and the resting

position of the windscreen wipers

02-7

Vehicle interior

– Inspect upholstery, interior trim, carpeting and footmats for cleanliness and damage

– Inspect all switches, all electrical components, gauges/indicators and controls

02-6

– Radio: Inspect for proper operation, store stations, encode, set clock

02-6

– Fit net in luggage compartment (if available)

– Vehicle log book - for completion: Operating manual and service plan (in the correct lan-

guage and with the correct edition data), short introduction, technical data, support in the

case of a breakdown, other manuals (radio,...) ) - all in the vehicle log book pouch

– Reset service interval display

02-6

– Power windows: Inspecting positioning

02-6

– Key switch for airbag deactivation, front passenger side: Check function „ON/OFF“ and

switch-over to the position „ON“

02-7

Underside of vehicle (on lift platform)

– Inspect underbody (underbody protection for damage)

02-7

– Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system

02-3, 02-5

– Inspect tyres and wheels for damage

02-5

Concluding operations

– Perform a test drive

02-9

– Interrogate fault memory of all systems, if necessary erase

02-6

– Complete the service schedule, affix the vehicle data sticker in the Service Schedule to

the floor of the luggage compartment next to the spare wheel, complete the „Next Service

Date“ sticker and affix to the side of the dash panel on the driver's side

02-7

– Remove recharging table (if affixed)

– Remove protective seat covers

– Install the carpets supplied in the vehicle

– Final inspection to ensure proper condition for handover to customer

Page 15

FABIA 2000 ➤ Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.20

02-2 page 5

02

Oil Change Service every 15.000 km1) (QG0)

An Oil Change Service need only be carried out if the vehicle has covered 15 000 km before one year has

elapsed

1)

. If the Oil Change Service is due only a few months prior to the Annual Inspection, it is recommend-

ed to carry out the Annual Inspection at the same time.

Annual Inspection (every 12 months) (QG0)

1)

The 7500 km interval applies for diesel operation with high sulphur content - it does not apply for the Czech Republic (for further information

refer to Technical Service Handbook)

Work involved Chapter

– Change engine oil

– Replace engine oil filter

02-3

– Disc brake pads: Inspect thickness

02-5

– Reset service interval display

02-6

– Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

– Complete „Next service date“ sticker (max. 1 year or 15 000 km) and affix sticker to the

side of the dash panel (on the driver's side)

– Complete and attach service mirror tag to the interior rear-view mirror

– Hand customer the completed and signed form

Chapter

♦ For vehicles with a high mileage carry out an Oil Change Service no later than after 15

000 km

1)

. Carry out Annual Inspection after 30 000 km prior to the scheduled date

02-3

♦ Every 2 years - in addition change brake fluid 02-5

♦ Every 4 years - in addition, change air filter element and clean air filter housing - vehicles

driven less than 60 000 km within 4 years - replace contents set for tyre repair

02-3

♦ Every 5 years - replace the emergency battery for the alarm 02-6

♦ Exhaust-emission analysis (EEA): Expiry date - see EEA tag on the vehicle identification

plate (only valid for some countries)

♦ Recommendation: Replace windscreen wiper blades every 2 years

♦ At each inspection - check the 'use by date' of the first aid kit

Work involved

– Interrogate fault memory of all systems, if necessary erase

02-6

– Inspect engine and components in the engine compartment for leaks and damage

02-3

– Change engine oil

– Replace engine oil filter

02-3

– Airbag units: Perform visual inspection for external damage

02-7

– Reset service interval display

02-6

– Inspecting brake system for leaks and damage

02-5

– Check the thickness of the brake pads on all wheels

02-5

– Check gearbox, final drive, drive shafts and joint boots for leaks and damage

– Axle joints: Inspect boots for leaks and damage

Page 16

FABIA 2000 ➤ Inspection and Maintenance

Inspection Edition 09.04

S00.5301.14.20

02-2 page 6

02

Every 30 000 km (QG0)

Includes: Annual inspection and additional operat ions stated in the table below

– Track rod ends: Inspect play and correct attachment of boots

– Check the tyre inflation pressure (including spare wheel), correct if necessary

02-5

– Inspect tyre wear (including spare wheel)

02-5

– Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)

02-5

– Inspect exhaust system for leaks, damage and attachment

– Brake fluid volume: Check level, if necessary top up

02-5

– B att ery: tes t

02-6

– Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary

02-3

– Flap lock for the engine bonnet: grease

– Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation

02-6

– Windscreen wiper and washer system: Inspect condition of wiper blades, wiper opera-

tion, washer system: if necessary top up fluid

02-7

– Inspect plenum chamber for dirt, clean if necessary

02-7

– Fuel filter: Drain away water (vehicles with diesel engine with fuel operation, which does

not comply with DIN EN 590-standard)

02-3

– Inspect trailer coupling (with removable arm - manufacturer Profsvar)

02-7

After each inspection

– Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

– Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection

02-9

– „Mirror tag“ - complete and attach to interior mirror

– Hand customer the completed and signed form

Work involve d Chapter

– Headlights: Inspect, if necessary adjust

02-6

– Gear oil: Inspect level and top up if necessary (manual gearbox)

02-4

– Fuel filter: Drain away water (vehicles with diesel engine with fuel operation, which does

not comply with DIN EN 590-standard)

02-3

– Check underbody protection and body paintwork for damage

02-7

– Dust and odour filter element for the passenger compartment: replace

02-7

– Inspect operation of tilting roof and grease the runners

02-7

– Inspect timing belt (petrol engines) - every 90 000 km, then every 30 000 km

02-3

Page 17

FABIA 2000 ➤ Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.20

02-2 page 7

02

Every 60 000 km (QG0)

Includes: Inspection every 30 000 km and additional operations stated in the table below

Every 90 000 km (QG0)

Includes: Inspection every 30 000 km and additional operations stated in the table below

Every 120 000 km (QG0)

Includes: Inspection every 60 000 km and additional operations stated in the table below

Every 150.000 km (QG0)

Includes: Inspection every 60 000 km and additional operations stated in the table below

Work involved Chapter

– Air filter: Clean housing, replace filter element

02-3

– Fuel filter: replace (vehicles with diesel engine)

02-3

– Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion

02-3

– Spark plugs: replace

02-3

– Automatic gearbox: Inspect ATF

1)

level, if necessary top up

1)

Automatic transmission fluid for the automatic gearbox

02-4

Work involved Chapter

– Timing belt for camshaft drive: replace (ASY diesel engines up to 04.2001)

02-3

– Timing belt and tensioning pulley for camshaft drive: replace (PD diesel engine up to

07.03)

02-3

– Timing belt for camshaft drive: inspect (petrol engines) - every 90 000 km, then every 30

000 km

02-3

Work involved Chapter

– Timing belt and tensioning pulley (038 109 244 H)

1)

for camshaft drive: replace (diesel en-

gines other than the PD engine) - vehicles as of 05.2001 to 04.2002

1)

When the tensioning pulley Spare Part No. 038 109 244 M is mounted after 120 000 km. on vehicles with a diesel engine during replacement of

the timing belt and the tensioning pulley the change interval of the ti ming belt should be altered from 120 000 km to 150 000 km. The customer

should be informed about the new service interval when the tensioning pulley is first replaced by a new tensioning pulley Spare Part No. 038

109 244 M by making an entry in the service plan, in the section „Workshop entries“. Only the timing belt will be replaced at each next service

interval at 150 000 km.

02-3

– Timing belt for camshaft drive: replace (PD diesel engine as of 08.03)

02-3

Work involved Chapter

– Timing belt: replace (diesel engines other than the PD engine) - vehicles as of 05.2002

02-3

Page 18

FABIA 2000 ➤ Inspection and Maintenance

Inspection Edition 09.04

S00.5301.14.20

02-2 page 8

02

Every 240 000 km (QG0)

Includes: Inspection every 120 000 km and additional operations stated in the table below

Inspection Service (QG1, QG2)

♦ Vehicles with WIV (QG1) must be filled with oils which conform to the VW standard 503 00 (petrol engines) VW

506 00 (SDI, TDI diesel engines) or VW 506 01 (TDI PD diesel engines), possibility of damage when using other

oils.

♦ Vehicles with WIV which have been filled with oils which do not conform to the VW standard 503 00 or VW 506 00

or VW 506 01, must be coded in the WIV with a fixed oil change limitation (QG2) ⇒ Chapter 02-6.

Work involved Chapter

– Replace tensioning pulley (PD diesel engine as of 08.03)

02-3

♦ Every 2 years - in addition change brake fluid

♦ Every 4 years - replace contents set for tyre repair

♦ Every 90 000 km - replace the guide pulley and the tensioning pulley (PD diesel engine up to 07.03)

♦ Every 120 000 km - replace the timing belt and the guide pulley (038 109 244 H) (diesel engines as of 05.01 to

04.02 except the PD engine)

♦ Every 120 000 km - Replace the timing belt (PD Diesel engine as of 08.03)

♦ Every 150 000 km - replace the timing belt (diesel engines as of 05.02 and with the guide pulleyr 038 109 244

M) - except on the TDI PD engine

♦ Every 240 000 km - Replace the tensioning pulley (PD Diesel engine as of 08.03)

♦ Exhaust-emission analysis (EEA). Expiry date - see EEA tag on the vehicle identification plate (only valid for

some countries)

♦ At each inspection - check the 'use by date' of the first aid kit

♦ Recommendation: Replace windscreen wiper blades every 2 years

Note

Work involved Chapter

– Interrogate fault memory of all systems, if necessary erase

02-6

– Visual inspection: Engine and components in the engine compartment for leaks and dam-

age

02-3

– Change the engine oil, replace the oil filter

02-3

– Conduct a visual inspection of the airbag units for external damage

02-7

– Reset service interval display

02-6

– Inspecting brake system for leaks and damage

02-5

– Check the thickness of the brake pads on all wheels

02-5

– Check gearbox, final drive, drive shafts and joint boots for leaks and damage

– Axle joints: Inspect boots for leaks and damage

– Track rod ends: Inspect play and correct attachment of boots

Page 19

FABIA 2000 ➤ Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.20

02-2 page 9

02

– Check the tyre inflation pressure (including spare wheel), correct if necessary

02-5

– Inspect tyre wear (including spare wheel)

02-5

– Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)

02-5

– Inspect exhaust system for leaks, damage and attachment

– Brake fluid volume: Check level, if necessary top up

02-5

– Battery: test

02-6

– Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary

02-3

– Flap lock for the engine bonnet: grease

– Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation

02-6

– Windscreen wiper and washer system: Inspect condition of wiper blades, wiper operation,

washer system: if necessary top up fluid

02-7

– Inspect plenum chamber for dirt, clean if necessary

02-7

– Inspect operation of tilting roof and grease the runners

02-7

– Headlights: Inspect, if necessary adjust

02-6

– Gear oil: Inspect level and top up if necessary (manual gearbox)

02-4

– Draining the fuel filter (diesel engine)

– Inspect trailer coupling (with removable arm - manufacturer Profsvar)

02-7

– Check underbody protection and body paintwork for damage

02-7

– Dust and odour filter element for the passenger compartment: replace

02-7

– Air filter: Clean the housing, replace the insert every 4 years or 60.000 km.

02-3

– Replace the fuel filter (diesel engine with fuel operation, which does not comply with DIN

EN 590-standard)

– Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion - every 60.000 km

02-3

– Replace the fuel filter (diesel engine) - every 60.000 km

– Spark plugs: replace - every 60.000 km.

02-3

– Automatic gearbox: Check the ATF level, and top up if necessary , every 60.000 km

– Check the timing belt for the camshaft on a 4-cylinder petrol engine at 90.000 km and

then every 30.000 km after that

– Replace the emergency battery for the alarm system - every five years

02-6

After each inspection

– Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

– Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection

02-9

– „Mirror tag“ - complete and attach to interior mirror

– Hand customer the completed and signed form

Work involved Chapter

Page 20

FABIA 2000 ➤ Inspection and Maintenance

Inspection Edition 09.04

S00.5301.14.20

02-2 page 10

02

Oil change (QG1, QG2)

Work involve d Chapter

– Change engine oil

– Replace engine oil filter

02-3

– Disc brake pads: Inspect thickness

02-5

– Reset service interval display

02-6

– Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

– Enter the next service date on the „Next Service“ sticker and affix sticker to the side of

the dash panel on the driver's side, that is according to the indicator or the kilometer

schedule (also the date for changing the brake fluid)

– Complete and attach service mi rror tag to the interior rear-view mirror

– Hand customer the completed and signed form

Page 21

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 1

02

02-3 Engines

Engine overview

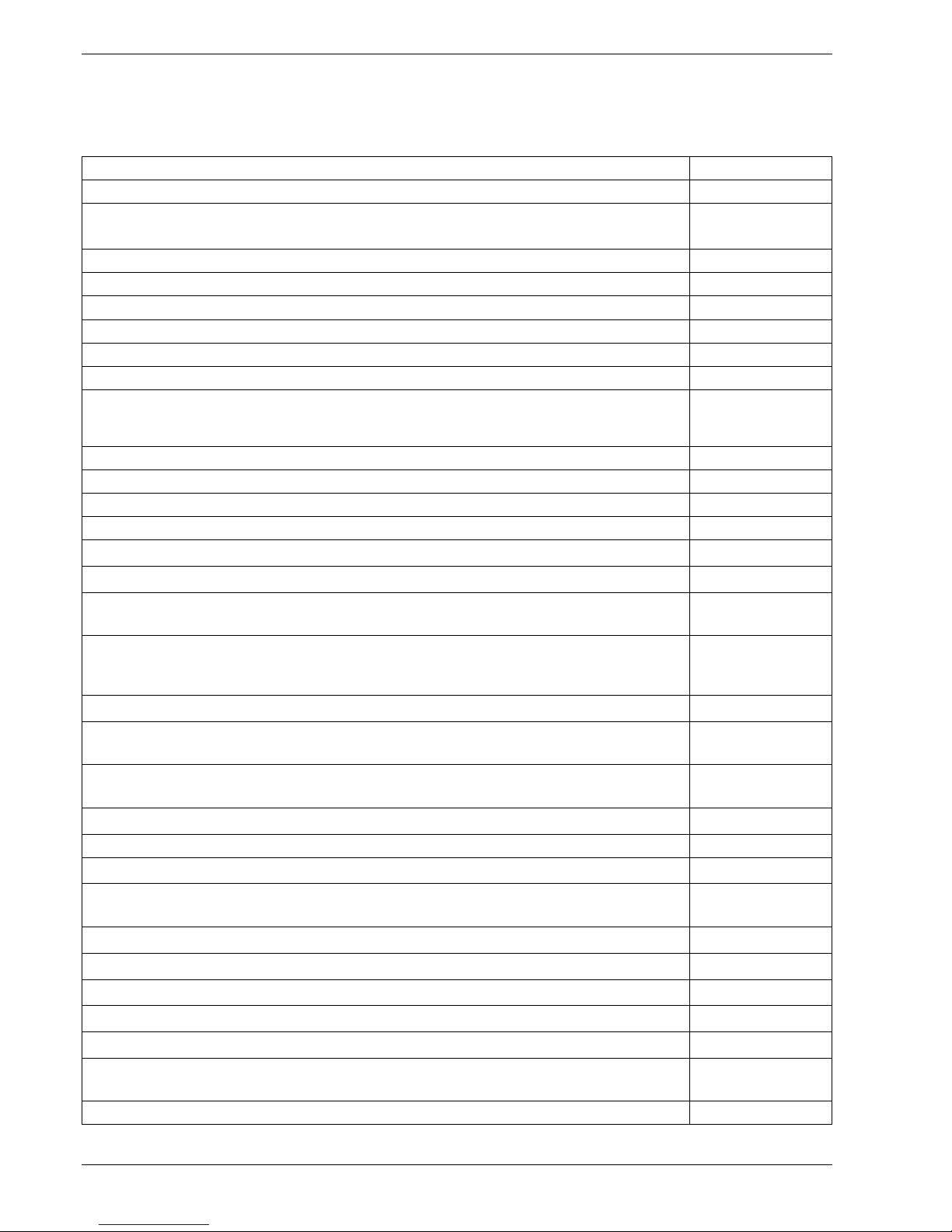

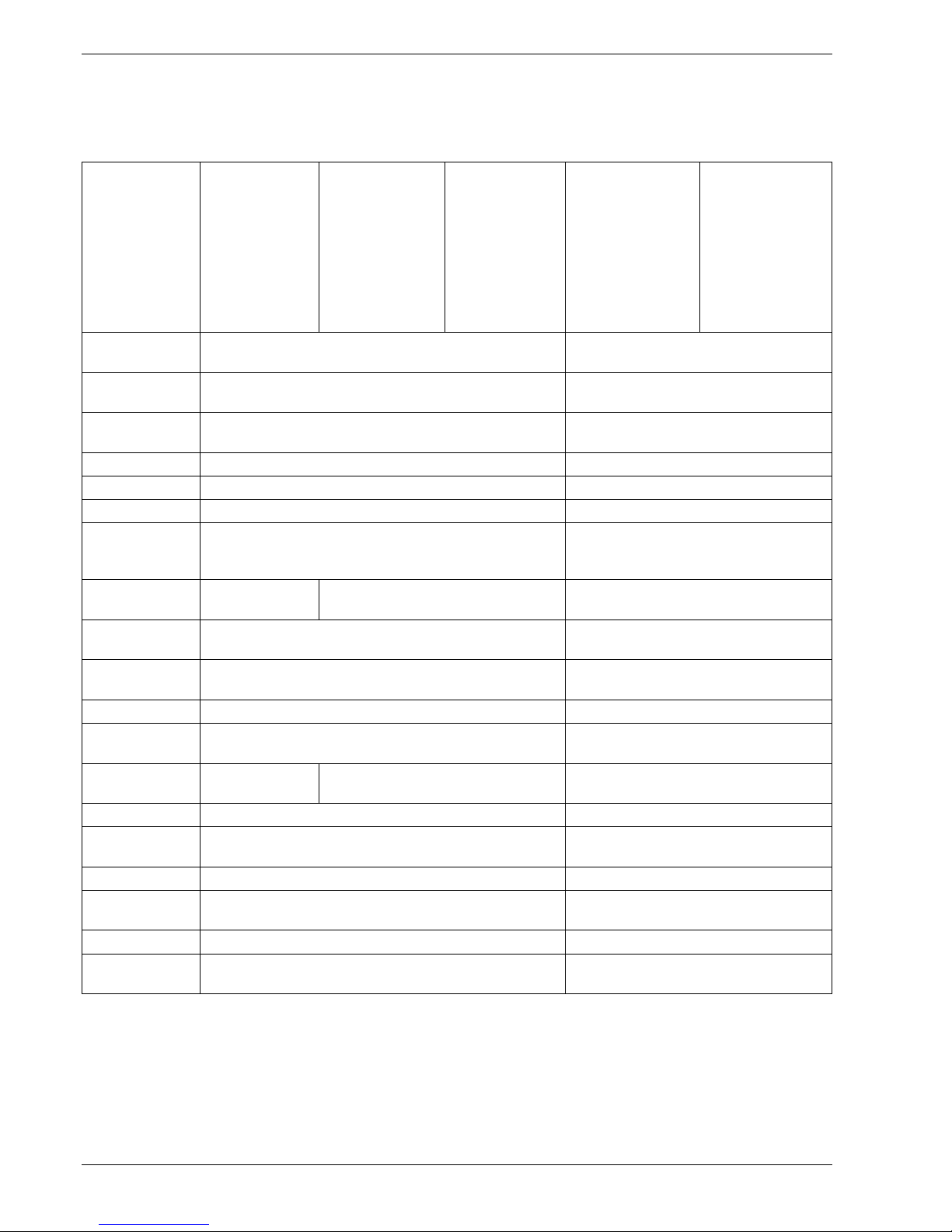

Engine

identifica-

tion charac-

ters

ARV AQV AWY AZQ AZE AZF

Emission

standard

EU2 EU3 EU4,

EU2 DDK,

EU3 DDK

EU4,

EU2 DDK,

EU3 DDK

EU2 EU4

Manufactur-

ing

(from...throu

gh)

01.01 ... 07.02 02.02 ... 05.04 01.03 04.00 ... 03.03

Displace-

ment in litres

1,0 1,2 1,2 1,4

Output (kW

at rpm)

37 / 5000 40 / 4750 47 / 5400 44 / 5000

Max. torque

(Nm at rpm)

84 / 2750 106 / 3000 112 / 3000 118 / 2600

Bore (∅

mm)

72 76,5 76,5 75,5

Stroke (m m) 61,2 86,9 86,9 78

Compres-

sion

10 10,3 10,5 10

Hydraulic

valve clear-

ance com-

pensation

XXX X

Mixture for-

mation

Simos 3PB Simos 3PA Simos 3PD Simos 3PE Simos 3PB Simos 3PA

Fuel RON

(minimum)

unleaded 95

1)

unleaded 951)unleaded 95

1)

unleaded 95

1)

Fuel CN

(minimum)

--- -

Firing order 1-3-4-2 1-2-3 1-2-3 1-3-4-2

Exhaust gas

recirculation

--X -

Ignition sys-

tem/fuel in-

jection

Simos 3PB Simos 3PA Simos 3PD Simos 3PE Simos 3PB Simos 3PA

Self-diagno-

sis

XXX X

Catalytic

converter

XXX X

Turbocharg-

ing

--- -

Charge air

cooler

--- -

Lambda

probe

XXX X

Camshaft

adjustment

--- -

Page 22

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 2

02

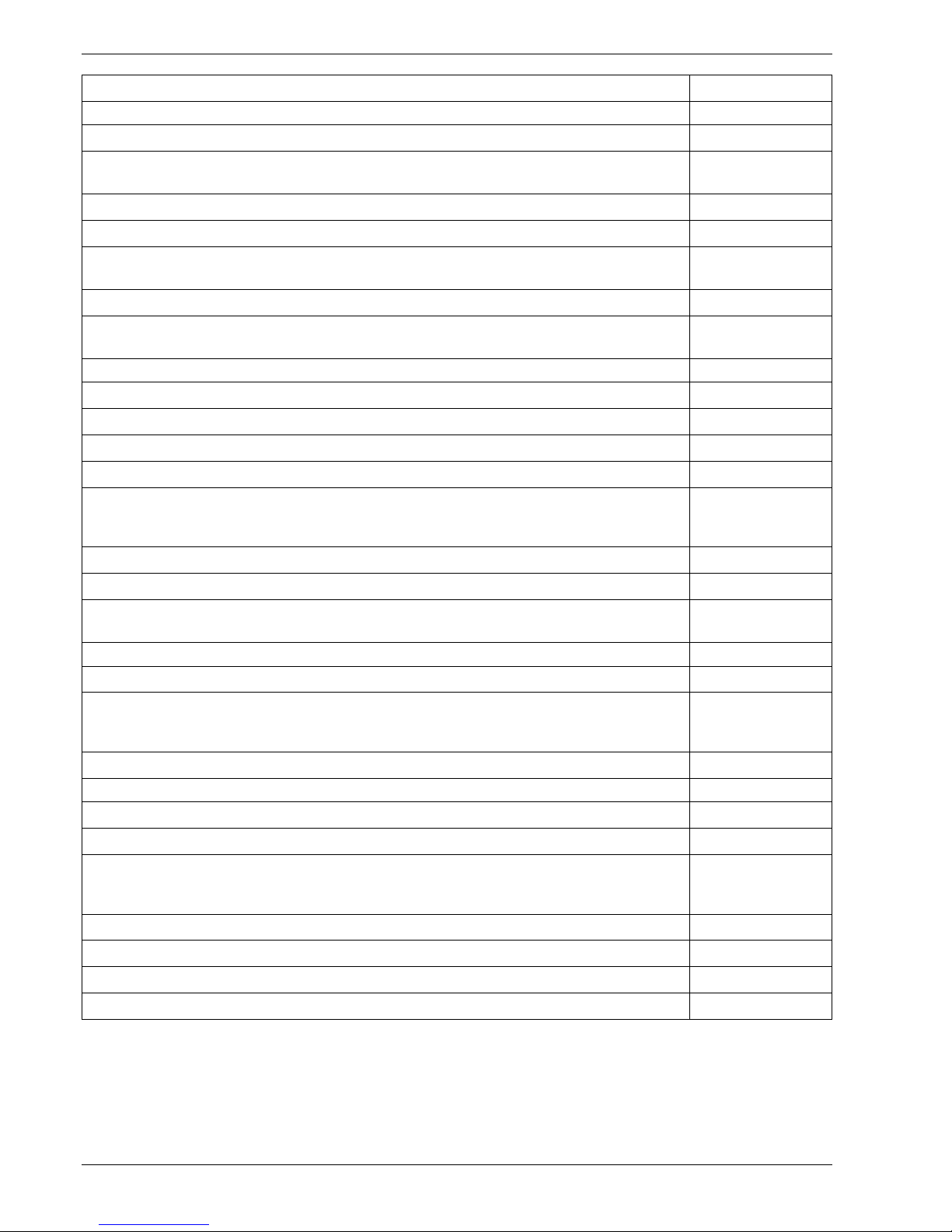

1)

Regular grade unleaded petrol (min. 91 ROZ) can be used although engine power output is slightly reduced.

Engine identifi-

cation charac-

ters

AME ATZ AQW AUA BBY

Emission stand-

ard

EU2 D4 EU4,

EU3 DDK

EU3,

EU4,

EU2 DDK,

EU3 DDK

EU4,

EU2 DDK,

EU3 DDK

Manufacturing

(from...through)

08.99 ... 04.03 11.99 ... 07.00 08.00 ... 03.03 05.00 ... 03.02 03.02 ... 05.04

Displacement in

litres

1,4 1,4

Output (kW at

rpm)

50 / 5000 55 / 5000

Max. torque

(Nm at rpm)

120 / 2500 126 / 3800

Bore (∅ mm) 75,5 76,5

Stroke (m m) 78 75,6

Compression 10 10,5

Hydraulic valve

clearance com-

pensation

XX

Mixture forma-

tion

Simos 3PB Simos 3PA Magneti Marelli 4LV

Fuel RON (mini-

mum)

unleaded 95

1)

1)

Regular grade unleaded petrol (min. 91 ROZ) can be used although engine power output is slightly reduced.

unleaded 95

1)

Fuel CN (mini-

mum)

--

Firing order 1-3-4-2 1-3-4-2

Exhaust gas re-

circulation

-X

Ignition system/

fuel injection

Simos 3PB Simos 3PA Magneti Marelli 4AV

Self-diagnosis X X

Catalytic con-

verter

XX

Turbocharging - -

Charge air cool-

er

--

Lambda probe X X

Camshaft ad-

justment

--

Page 23

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 3

02

Engine identification

characters

AMF AUB BBZ ASY

Emission standard EU3 EU4

EU2 DDK,

EU3 DDK

EU4,

EU2 DDK,

EU3 DDK

EU3

Manufacturing

(from...through)

05.03 08.99 ... 05.02 05.02 08.99

Displacement in litres 1,4 1,4 1,9

Output (kW at rpm) 55 / 4000 74 / 6000 47 / 4000

Max. torque (Nm at rpm) 195 / 2200 126 / 4400 125 / 1600 - 2800

Bore (∅ mm) 79,5 76,5 79,5

Stroke (mm) 95,5 75,6 95,5

Compression 19,5 10,5 19,5

Hydraulic valve clearance

compensation

XXX

Mixture formation Bosch PDE - injec-

tors

Magneti Marelli 4LV Bosch VP

Fuel RON (minimum) -

unleaded 98

1)

1)

Regular grade unleaded petrol (min. 95 ROZ) can be used although engine power output is slightly reduced.

-

Fuel CN (minimum) 49 - 49

Firing order 1-2-3 1-3-4-2 1-3-4-2

Exhaust gas recirculation X X X

Ignition system/fuel injec-

tion

Bosch PDE - injec-

tors

Magneti Marelli 4AV Bosch VP

Self-diagnosis X X X

Catalytic converter X X X

Turbocharging X - -

Charge air cooler X - -

Lambda probe - X -

Camshaft adjustment - - -

Engine identification char-

acters

ATD ASZ AZL BMD BKY

Emission standard EU3 EU3 EU4,

EU2 DDK,

EU3 DDK

EU4,

EU2 DDK

EU4,

EU2 DDK

Manufacturing (from...through) 02.00 06.03 08.00 05.04 05.04

Displacement in litres 1,9 1,9 2,0 1,2 1,4

Output (kW at rpm) 74 / 4000 96 / 4000 85 / 5400 40 / 4750 55 / 5000

Max. torque (Nm at rpm) 240 / 1800 -

2800

310 / 1900 170 / 2400 108 / 3000 126 / 3800

Bore (∅ mm) 79,5 79,5 82,5 76,5 76,5

Stroke (mm) 95,5 95,5 92,8 86,9 75,6

Page 24

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 4

02

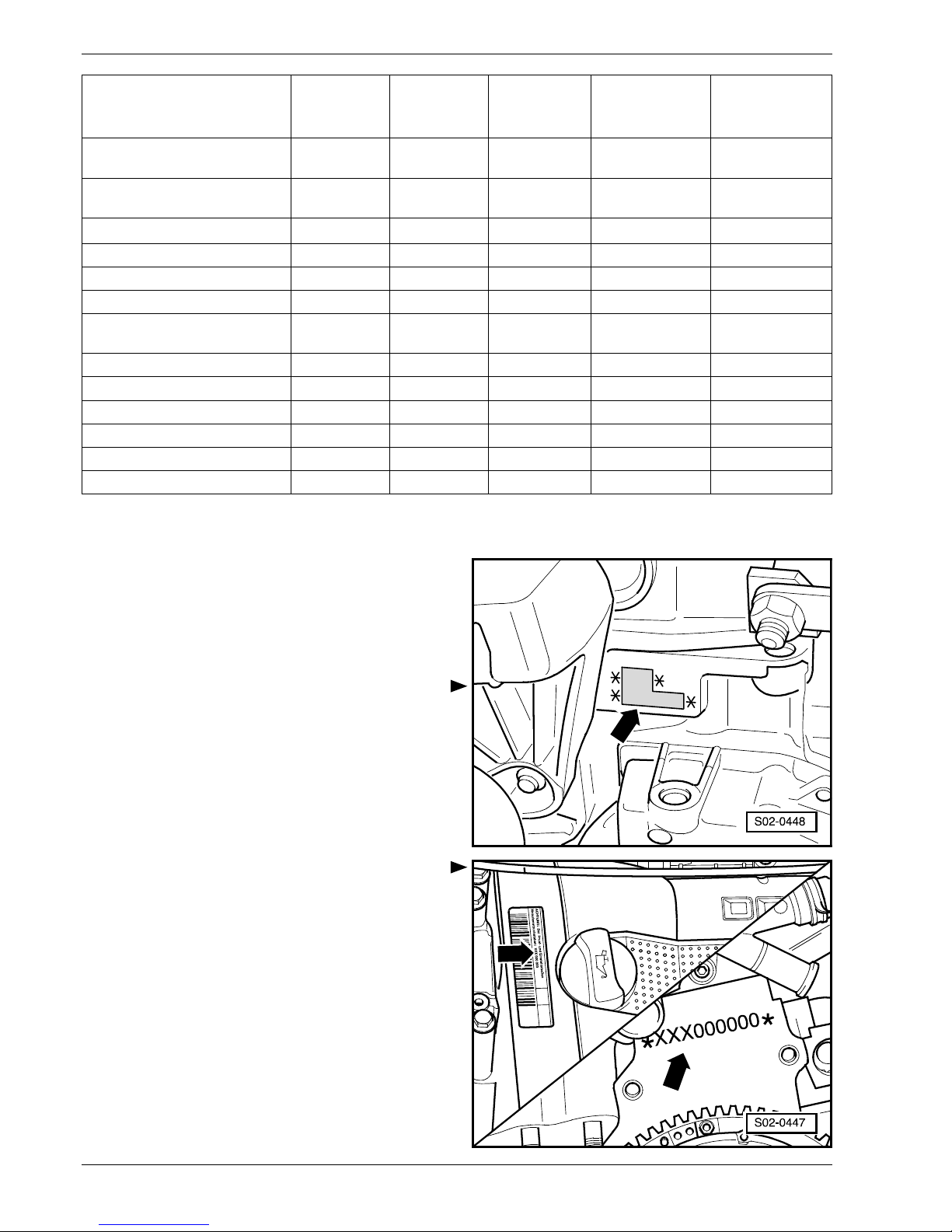

Engine fitted

The engine identification characters and serial number

are located in the front at the engine/gearbox joint.

In addition, a sticker with the engine identification characters and serial number is affixed to the timing belt guard.

Engine with identification characters ARV, AQV, AZE,

AZF, AME, ATZ and AQW.

Engine with identification characters AUA, AUB, BBY,

BBZ, BKY.

Compression 19 19 10,5 10,3 10,5

Hydraulic valve clearance

compensation

XXX X X

Mixture formation Bosch PDE -

injectors

Bosch PDE -

injectors

Bosch ME 7.5 Simos 3PG Magneti Marelli

4TV

Fuel RON (minimum) - -

unleaded 95

1)

unleaded 95

1)

unleaded 95

1)

Fuel CN (minimum) 49 49 - - -

Firing order 1-3-4-2 1 -3 -4- 2 1 -3- 4-2 1-2-3 1-3-4 -2

Exhaust gas recirculation X X - - X

Ignition syste m/fuel injection Bosch PDE -

injectors

Bosch PDE -

injectors

Bosch ME 7.5 Simos 3PG Magneti Marelli

4TV

Self-diagnosis X X X X X

Catalytic converter X X X X X

Turbocharging X X - - -

Charge air cooler X X - - -

Lambda probe - - X X X

Camshaft adjustment - - - - -

1)

Regular grade unleaded petrol (min. 91 ROZ) can be used although engine power output is slightly reduced.

Engine identification char-

acters

ATD ASZ AZL BMD BKY

Page 25

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 5

02

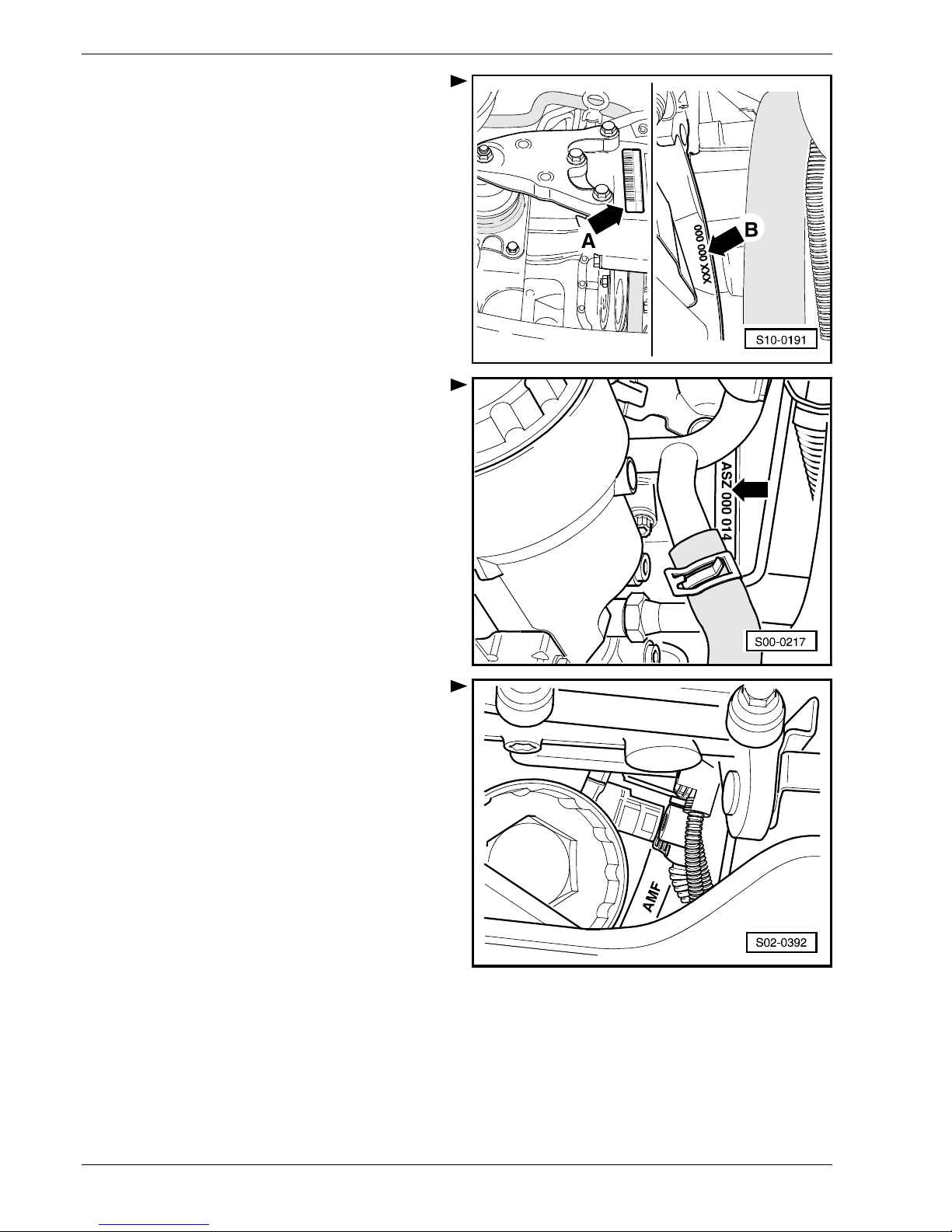

Engine with identification characters ASY.

Engine with identification characters AZL.

Engine with identification characters ATD.

S02-0338

Page 26

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 6

02

Engine with identification characters AWY, AZQ, BMD.

Engine with identification characters ASZ.

Engine with identification characters AMF.

Visual inspection: Engine for leaks and

damage

– Inspect engine for leaks and damage.

– Inspect all lines, hoses and connections of the fuel

system and of the cooling and heating system for

leaks, chafing points, porous and brittle joints.

– Inspect gearbox or final drive for leaks (e.g. drain plug,

drive shafts, shift linkage etc.).

– Inspect steering, sealing boots of track rod ends as

well as steering boots for damage and correct installation.

– Inspect boots of steering joints for damage, leaks and

correct installation.

M

o

t

o

r

k

e

n

n

b

u

c

h

s

t

a

b

e

n

:

X

X

X

0

0

0

0

0

0

A

C

H

T

U

N

G

!

B

e

i

P

r

u

e

f

u

n

d

E

i

n

s

t

e

l

l

a

r

b

e

i

t

e

n

Page 27

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 7

02

Replace engine oil filter

Vehicles with petrol engine

Special tools, test and measuring equipment and

auxiliary items required

♦ Oil filter wrench

– Release oil filter (e.g. Würth, Hazet) and remove.

– Clean sealing surface at engine.

– Oil rubber seal slightly.

– Screw in new filter and tighten by hand.

– After filling with oil, run engine until it is at operating

temperature and inspect for leak s.

Vehicles with diesel engine

Special tools, test and measuring equipment and

auxiliary items required

♦ Oil filter wrench -3417- or wrench 36

– Release cap -1-.

– Replace O-rings -2- and -3- as well as oil filter element

-4-.

– Tighten cap -1-.

Tightening torque of the cap: 25 Nm

Replacing timing belt and tensioning

pulley for camshaft drive (1.9 TDI engines)

– Removing and installing the timing belt

⇒ Rep. Gr. 13; 1.9/74 TDI Engine, Mechanics, or

⇒ Rep. Gr. 13; 1.9/96 TDI Engine, Mechanics.

Replacing timing belt and tensioning

pulley for camshaft drive (1.4 TDI engines)

– Re mov ing and ins tal ling the tooth ed bel t

⇒ Rep. Gr. 13; 1.4/55 TDI Engine, Mechanics.

Inspecting timing belt for camshaft drive

for wear and running (petrol engine)

Check timing belt for:

♦ Tears or splits -A-, cross-sectional fractures

♦ Lateral catches -B-

♦ Fraying or chunking -C-

♦ Crack in the base tooth -D-

♦ Separation of layers (timing belt housing, cords)

♦ Traces of oil and grease

S02-0339

2

1

4

3

Page 28

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 8

02

The timing belt must most definitely be replaced if any

shortcomings are found. This will help prevent any failures or operational problems. Replacing the timing belt is

a repair measure.

Replacing toothed belt and guide pulley

for camshaft drive (1.9 SDI engines)

– Removing and installing the toothed belt

⇒ Rep. Gr. 13; 1.9/47 SDI engine, Mechanics.

Inspecting engine oil level

When inspecting, pay attention to the following points:

Before inspecting, warm up the engine to normal temper-

ature.

Wait at least 3 minutes after switching off the engine to al-

low the oil to flow back into the oil pan.

– Withdraw dipstick, wipe off with a clean cloth and re-

insert dipstick fully.

– Withdraw dipstick once again and read off oil level.

Fig. 1: Oil dipstick version I

Fig. 2: Oil dipstick version ll

The oil level in area -a-

– The oil must be topped up. It is sufficient when the oil

level rises to the area -b-.

The oil level in area -b-

– The oil can be topped up. It is possible that the oil level

will rise to the area -c-.

The oil level in area -c-

– The oil must not be topped up.

♦ The oil level must not, under any circumstances, be

above area -a- - danger of damage to the catalytic

converter.

♦ The vehicle must be standing on level ground when

measuring the oil level. Wait a few minutes after

switching off the engine to allow the oil to flow back

into the oil pan.

Change engine oil

♦ The engine oil should always be changed, if possible,

when the engine is at normal operating temperature.

♦ If the engine oil is drained, replace the seal of the oil

drain plug.

Note

Note

Note

Page 29

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 9

02

♦ It is absolutely necessary to observe the oil disposal

instructions!

♦ It is not permitted to clean and re-use the oil filter!

– Remove oil filler cap.

– Remove the noise insulation.

– Screw out the oil drain plug and collect the oil in a suit-

able vessel.

– Clean the drain plug, screw in with a new seal and

tighten to the specified tightening torque:

Engine-oil pan: 30 Nm

– Pour in oil as stated in the specifications.

Engine oil capacities:

♦ with oil filter cha nge appr ox. :

2.4 litres (1.2 litre/40 kW - engine)

2.8 litres (1.2 litre/47 kW - engine)

3.2 litre (1.4 litre/55 kW (petrol) and 1.4 litre/74kW - en-

gine)

4.0 litre (1.0 litre/37 kW, 1.4 litre/44 kW, 1.4 litre/50 kW

and 2.0 litre/85 kW engine)

4.2 litre (1.4 litre/55 kW TDI PD - engine)

4.3 litre (1.9 litre/47 kW SDI, 1.9 litre/74 kW TDI PD and

1.9 litre/96 kW TDI PD - engine)

The engine is factory-filled with quality multigrade oil,

which can also be used as an all-season oil, except in extremely cold climatic zones.

Specification for petrol engines:

The given specifications must be indicated on the can individually or together with other specifications.

Only use engine oils:

QGO, QG2

Standard: VW 500 00, VW 501 01 or VW 502 00

Oils may be intermixed when topping up.

In exceptional cases:

Multigrade oils according to ACEA A2 or A3. Such oils

must only be used once for topping up within the specified oil change interval if, in exceptional cases, no approved engine oil is available.

QG1

Specification VW 503 00

Specification for diesel engines:

The given specifications must be indicated on the can individually or together with other specifications.

Page 30

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 10

02

Only use engine oils:

QGO, QG2

Specification VW 505 01 or VW 505 00 (oil according

to VW 505 00 cannot be used for TDI PD - engines)

Oils may be intermixed when topping up.

In exceptional cases:

Multigrade oils according to ACEA B3 or B4. Such oils

must only be used once for topping up within the specified oil change interval if, in exceptional cases, no approved engine oil is available.

QG1

Specification VW 506 01 or VW 506 00 (oil according

to VW 506 00 cannot be used for TDI PD - engines)

– Close the oil filler opening again.

– Start engine and check for leaks.

– Check the engine oil level again and top up with oil if

necessary.

– Wait at least 3 minutes after topping up the oil again

before inspecting the oil level again.

– Install the noise insulation.

The oil level must not be above the -max- marking to

avoid damage to the catalytic converter. See Inspecting

engine oil level ⇒ 02-3 page 8.

Inspecting antifreeze protection, replenishing coolant additive if necessary

♦ Collect drained coolant for proper disposal.

♦ Observe the disposal instructions for the drained cool-

ant.

Special tools, test and measuring equipment and

auxiliary items required

♦ Refractomer -T10007-

Inspecting antifreeze protection of the coolant

♦ The refractometer -T10007- may, for example, be

used for inspecting the antifreeze protection of the

coolant.

Note

WARNING!

Coolant additives are toxic!

Do not inhale coolant vapours, do not swallow

coolant, avoid contact with skin and eyes; hazardous if consumed!

Note

Page 31

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 11

02

– Extract a small quantity of coolant with the pipette and

place on the measuring glass. Hold unit against a light

source and read off the temperature down to which

antifreeze protection exists on the scale for ethylene

glycol.

♦ Antifreeze protection must be ensured down to about

-25 C.

♦ Down to about -35 C in countries with an arctic cli-

mate.

♦ If a greater antifreeze concentration is required for cli-

matic reasons, the concentration may be increased up

to 60 % (i.e. antifreeze protection down to about -40

C). Any further increase in concentration increase

would reduce the antifreeze protection and impair

cooling efficiency.

Replenishing coolant additive

♦ Coolant additive G12 - red in colour, complying with

standard TL VW 774 D, must not be mixed with other

coolant additives which comply with standard TL VW

774 C(B) -bluish-green in colour-. If these two coolant

additives are mixed the coolant will turn brown. Brown

coolant must be drained immediately, the cooling system flushed out with drinking water and filled with

fresh coolant. If this is not done the engine and cooling

system may suffer damage.

♦ Coolant additives complying with standard TL VW 774

C (G11) -bluish-green in colour-, must only be used

for topping up on vehicles fitted with a cooling system

which is already filled with this coolant.

♦ Vehicles produced as of MJ 03 are filled with coolant

additive G12 PLUS which has a lilac colour and conforms with the standard TL VW 774 F.

♦ Coolant additive G12 PLUS must only be mixed with

coolant additives G12 and G11.

♦ Coolant additive G12 PLUS is recommended for use

on all vehicles when changing the coolant.

If the vehicle is filled with the recommended coolant and

the antifreeze protection is not adequate, drain part of the

coolant from the cooling system.

– After this, fill the cooling system with concentrated

coolant additive.

The coolant capacity is:

Note

Note

Page 32

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 12

02

– Perform a test drive and again check the coolant anti-

freeze protection.

Inspecting coolant level (volume)

– The coolant expansion reservoir is located on the right

of the engine compartment.

– Inspect coolant level only when the engine is not run-

ning.

Specified coolant level for the Inspection Service:

• Engi ne col d: betw een„M AX “ and „MIN“ marki ng.

• Engine warm: slightly above the „MAX“ marking.

♦ The cooling system is filled all year round with a mix-

ture of water and antifreeze/anti-corrosion agent.

Coolant additives prevent damage from frost and cor-

rosion and the accumulation of lime scale while also

raising the boiling point of the coolant. For these rea-

sons the cooling system must always be filled all year

round with radiator antifreeze and anti-corrosion

agent offering these properties.

♦ Coolant additive G12 - red in colour, complying with

standard TL VW 774 D, must not be mixed with other

coolant additives which comply with standard TL VW

774 C(B) -bluish-green in colour-. If these two coolant

additives are mixed the coolant will turn brown. Brown

coolant must be drained immediately, the cooling sys-

tem flushed out with drinking water and filled with

fresh coolant. If this is not done the engine and cooling

system may suffer damage.

Engine Coolant capacity

1.2 ltr./40 kW and 1.2

ltr./47 kW

approx. 5.1 ltr.

1.4 ltr./55 kW and 1.4

ltr./74 kW

approx. 5.5 ltr.

1.0 ltr./37 kW; 1.4 ltr/

44 kW and 1.4 ltr./50

kW

approx. 6.0 ltr.

1.4 ltr./55 TDI PD approx. 6.2 ltr.

1.9 ltr./47 kW SDI approx. 6.6 ltr.

1.9 ltr./74 kW TDI PD

and 1.9 ltr./96 kW TDI

PD

approx. 6.8 ltr.

2.0 ltr./85 kW approx. 6.9 ltr.

S02-0303

WARNING!

Coolant additives are toxic!

Do not inhale coolant vapours, do not swallow

coolant, avoid contact with skin and eyes; hazardous if consumed!

Note

Page 33

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 13

02

♦ Coolant additives complying with standard TL VW

774C (G11) -bluish-green in colour-, must only be

used for topping up on vehicles fitted with a cooling

system which is already filled with this coolant.

♦ Vehicles produced as of MJ 03 are filled with coolant

additive G12 PLUS which has a lilac colour and conforms with the standard TL VW 774 F.

♦ Coolant additive G12 PLUS must only be mixed with

coolant additives G12 and G11.

♦ Coolant additive G12 PLUS is recommended for use

on all vehicles when changing the coolant.

Do not use coolant additives that have not been recommended by ŠKODA AUTO a.s.

Other coolant additives may specifically impair the provided corrosion protection.

The resulting corrosion damage may lead to a loss of

coolant and subsequently cause major engine damage.

Coolant additives conforming to the standard TL VW 774

D (G12) or TL VW 774F (G12 PLUS) prevent frost and

corrosion damage, as well as the formation of scale, and

also increase the boiling point of the coolant.

For these reasons you must use coolant additives 12

months a year.

The engine's reliability is also increased when the engine

is stressed, especially in countries with a tropical climate.

Coolant additives G12 - an overview

Coolant additives from the ŠKODA Genuine Parts List

which comply with Standard TL VW 774 D:

The indicated G12 coolant additives may be intermixed.

Coolant additives G12 PLUS - an overview

Coolant additives from the ŠKODA Genuine Parts List

which comply with the standard TL VW 774 F:

Coolant additive Manufacturer

Glysantin G 30-72 BASF AG

XT 4030 ELF OIL AG

Coolant ETX 6280 TEXACO

FROSTOX SF-D 12 HENKEL HÄRTOL GmbH

Note

Coolant additive Manufacturer

Havoline XLC+B (VL

02)

ARTECO

Glysantin G 30-81 BASF AG

Frostox SF D12 PLUS HENKEL HÄRTOL GmbH

Page 34

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 14

02

The listed G12 PLUS coolant additives may be intermixed.

Ribbed V-belt: Inspect condition

Special tools, test and measuring equipment and

auxiliary items required

♦ Wrench socket

Perform the following procedure:

– Raise vehicle.

– Remove bottom engine compartment cover at right.

– Use a socket wrench to crank the engine at the belt

pulley -2-.

– Check ribbed V-belt for:

♦ Splits in the carcass (initial splits, splits in core, splits

across carcass).

♦ Separation of layers (top layer, cords).

♦ Sections of carcass broken out.

♦ Fraying of cords.

♦ Wear to sides (abrasion of material, frayed sides,

hardening of sides, glazed and hardened su rfa ce s).

♦ Traces of oil and grease.

♦ Correct tension (vehicles without tensioning pulley).

♦ It is essential to replace the V-ribbed belt if defects are

found. This will help prevent any operational prob-

lems. Replacing the ribbed V-belt is a repair measure.

♦ Engines fitted with an AC compressor are equipped

with a double ribbed V-belt.

Routing of V-ribbed belt

1.0 litre/37 kW (ARV and AQV), 1.4 litre/44 kW (AZE

and AZF), 1.4 litre/50 kW (AME, ATZ and AQW) without air-conditioning

1 - Crankshaft

2 - Tensioning pulley

3 - Coolant pump

4 - AC generator

Note

S02-0025

Note

Page 35

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 15

02

1.0 litre/37 kW (ARV and AQV), 1.4 litre/44 kW (AZE

and AZF), 1.4 litre/50 kW (AME, ATZ and AQW) with

air-conditioning

1 - Crankshaft

2 - Tensioning pulley

3 - Coolant pump

4- AC compressor

5 - G ui de pul ley

6 - AC generator

1.2 litre/40 kW (AWY, BMD), 1.2 litre/47 kW (AZQ)

without air-conditioning

1 - Coolant pump

2 - AC generator

3 - Crankshaft

4 - Tensioning pulley

1.2 litre/40 kW (AWY, BMD), 1.2 litre/47 kW (AZQ) with

air-conditioning

1 - AC generator

2 - G ui de pul ley

3- AC compressor

4 - Crankshaft

5 - Tensioning pulley

6 - Coolant pump

1

S02-0311

4

2

3

5

6

Page 36

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 16

02

1.4 litre/55 kW (AUA, BKY) and 1.4 litre/74 kW (AUB,

BBZ) without air-conditioning

1 - AC generator

2 - Crankshaft

1.4 litre/55 kW (AUA, BKY) and 1.4 litre/74 kW (AUB,

BBZ) with air-conditioning

1 - AC generator

2 - AC compressor

3 - Crankshaft

4 - Tensioning pulley

1.4 litre/55 kW (AMF) without air-conditioning

1 - AC generator

2 - Crankshaft

3 - Tensioning pulley

1

S02-0312

2

S13-0206

3

4

2

1

Page 37

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 17

02

1.4 litre/55 kW (AMF) with air-conditioning

1 - AC generator

2- AC compressor

3 - Crankshaft

4 - Tensioning pulley

1.9 litre/47 kW (ASY), 1.9 litre/74 kW (ATD), 1.9 litre/96

kW (ASZ), 2.0 litre/85 kW (AZL) without air-conditioning

1 - AC generator

2 - Crankshaft

3 - Tensioning pulley

1.9 litre/47 kW (ASY), 1.9 litre/74 kW (ATD), 1.9 litre/96

kW (ASZ), 2.0 litre/85 kW (AZL) with air-conditioning

1- AC compressor

2 - Crankshaft

3 - Tensioning pulley

4 - AC generator

Replace spark plugs

♦ To replace the spark plugs use the special spark plug

wrench.

♦ Observe all disposal instructions for the spark plugs.

♦ Change interval: every 60 000 km.

♦ Tightening torque: 30 Nm.

♦ Use assembly tool -T10029- for unplugging the spark

plug connector (not applicable to cable with fixture).

2

S02-0314

1

3

4

S02-0315

1

2

3

Note

Page 38

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 18

02

Replace air filter element

– Open the filter hou sing.

– Replace the filter element and clean the filter housing.

– Close filter housing and check correct fitting.

Replacing the fuel filter (diesel engine)

♦ Make sure no diesel fuel comes into contact with the

coolant hoses. If necessary clean the hoses immedi-

ately!

♦ It is absolutely necessary to observe the oil disposal

instructions!

♦ Observe the disposal instructions!

Removing

– Remove retaining clips -3-.

– Remove regulating valve -4- with the connected fuel

hoses.

– Remove fuel hoses -1- and -2- on the filter.

Engine fitted Spark plug manufac-

turer's designation

Parts No. Electrode spacing

1.0 litre/37 kW NGK BKR 6ETA-10 101 000 065

AA

1.0 mm

1)

1)

Distance between earth electrode and spark plug insulator.

1.2 ltr./40 kW AWY NGK PZFR5J-11 101 905 600

1.0 mm

1)

NGK ZFR 5P-G 101 905 617

0.9 mm

1)

BOSCH F7 HER2 101 905 601 B

0.9 mm

1)

BMD NGK ZFR 5P-G 101 905 617

0.9 mm

1)

BOSCH F7 HER2 101 905 601 B

0.9 mm

1)

Brisk DOX 15 LE 101 905 618

0.9 mm

1)

1.2 ltr./47 kW BOSCH F7 HER2 101 905 601 B

0.9 mm

1)

NGK ZFR5P-G 101 905 617

0,8 mm

1)

1.4 ltr./44 kW Brisk DR 15 TC 101 000 060

AA

0,8 mm

1)

1.4 ltr./50 kW Champion RC-89 PYC 101 000 049

AC

0.8 mm

1)

1.4 ltr./55 kW AUA, BBY NGK BKUR 6ET-10 101 000 033

AA

1.0 mm

1)

BKY BERU 14F-7 HUR 2 101 905 603 B

0.9 mm

1)

1.4 ltr./74 kW NGK BKUR 6ET-10 101 000 033

AA

1.0 mm

1)

2.0 ltr./85 kW NGK BKUR 6ET-10 101 000 033

AA

1.0 mm

1)

Note

1

2

3

4

S02-0323

Page 39

FABIA 2000 ➤ Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.20

02-3 page 19

02

– Unlock hooks -arrows-.

– L oos en the fuel filter and remov e.

Installing

– Install new fuel filter.

– Lock hooks -arrows-.

– Fit the new O-ring for the regulating valve.

– Install regulating valve -4- with the connected fuel

hoses.

– Attach retaining clips -3-.

– Install the fuel hoses -1- and -2- and secure with hose

clamps.

The direction of flow is indicated with arrows (do not

switch connections).

– Inspect the fuel system for tightness (visual inspec-

tion).

Draining the fuel filter (diesel engine)

♦ Make sure no diesel fuel comes into contact with the

coolant hoses. If necessary clean the hoses immediately!

♦ Collect fuel in a suitable vessel!

♦ It is absolutely necessary to observe the oil disposal

instructions!

– Remove retaining clip -2- and remove regulating valve

-1- with the connected fuel hoses.

– Unlock hooks -arrows-.

– L oos en the fuel filter and remov e.

Note

Note

S02-0324

1

2

1

2

3

4

S02-0323

Page 40

FABIA 2000 ➤ Inspection and Maintenance

Engines Edition 09.04

S00.5301.14.20

02-3 page 20

02

– Loosen the drain plug -arrow- and drain off approxi-

mately 0.1 litres of fluid.

– Tighten the drain plug.

– Carry out the installation again in the reverse order.

– Inspect the fuel system for tightness (visual inspec-

tion).

Page 41

FABIA 2000 ➤ Inspection and Maintenance

GearboxEdition 07.03

S00.5301.12.20

02-4 page 1

02

02-4 Gearbox

Gearbox/Final drive: Check the oil level

and top it if necessary

5 speed gearbox 002

Gearbox oil specification: G50 SAE 75W90 (synthetic oil)

– Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

– Tighten plug -arrow-, 25 Nm.

When topping up, pay attention to the following

points:

– Unscrew plug for inspecting gear oil -arrow-.

– Pour in gear oil up to lower edge of the filler hole.

– Screw in plug -arrow-.

– Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

– Switch off engine, unscrew plug -arrow- and top up

gear oil to lower edge of the filler hole.

– Tighten plug -arrow-, 25 Nm.

5 speed gearbox 02R

Gearbox oil specification: G50 SAE 75W90 (synthetic oil)

– Remove noise insulation panel -arrows-.

– Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

– Tighten plug -arrow-, 30 Nm.

When topping up, pay attention to the following

points:

– Unscrew plug for inspecting gear oil -arrow-.

– Pour in gear oil up to lower edge of the filler hole.

– Screw in plug -arrow-.

– Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

– Switch off engine, unscrew plug -arrow- and top up

gear oil to lower edge of the filler hole.

– Tighten plug -arrow-, 30 Nm.

5 speed gearbox 02T

Special tools, test and measuring equipment and

auxiliary items required

♦ Socket wrench insert -T30023 (3357)-

S34-0408

S10-0101

S34-0498

Page 42

FABIA 2000 ➤ Inspection and Maintenance

Gearbox Edition 07.03

S00.5301.12.20

02-4 page 2

02

Gearbox oil specification: G50 SAE 75W90 (synthetic

oil).

– Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

– Tig hte n plug -arrow-, 25 Nm.

When topping up, pay attention to the following

points:

– Unscrew plug for inspecting gear oil -arrow-.

– Pour in gear oil up to lower edge of the filler hole.

– Screw in plug -arrow-.

– Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.