Page 1

Service

5

Workshop Manual

FABIA 2000 ³

Body Work

Edition 08.99

Service Department. Technical Information

Printed in Czech Republic

S00.5319.00.20

Page 2

5

Service

The Workshop Manual is intended only for use within the Organisation Škoda.

It is not permitted to pass it on to other persons.

© ŠKODA AUTO a. s.

Printed in Czech Republic

S00.5319.00.20

Page 3

FABIA 2000 ³ Body Work

List of Supplements to Workshop Manual

FABIA 2000 ³

Body Work

Edition 08.99

Supple-

ment

1 11.99 Supplement to Basic Edition S00.5319.01.20

2 12.99 Self-diagnosis for convenience system S00.5319.02.20

3 03.00 Final diagnosis for airbag S00.5319.03.20

4 06.00 Supplement to Rep. - Gr. 50 - 70 S00.5319.04.20

5 07.00 Supplement to Rep. - Gr. 01 - 74 S00.5319.05.20

6 11.00 Supplement to Rep. - Gr. 01 - 70 S00.5319.06.20

7 04.01 Supplement to Rep. - Gr. 01 - 74 S00.5319.07.20

8 08.01 Supplement to Rep. - Gr. 01 and 64 S00.5319.08.20

9 02.02 Fabia Praktik S00.5319.09.20

10 03.02 Supplement to Rep. - Gr. 70 and 72 S00.5319.10.20

1 1 07.02 Supplement to Rep. - Gr. 01 - 70 S00.5319.11.20

12 05.03 Supplement to Rep. - Gr. 70 S00.5319.12.20

13 10.03 Supplement to Rep. - Gr. 01 - 70 S00.5319.13.20

14 04.04 Supplement to Rep. - Gr. 01, 57, 58 and 69 S00.5319.14.20

15 01.05 Self-diagnosis for convenience system with LIN databus cable

Edition Subject Article Number

08.99 Basic Edition S00.5319.00.20

S00.5319.15.20

and Supplement to Rep. - Gr. 55, 57, 58 , 63, 68, 69 and 70

S00.5319.15.20

List of SupplementsEdition 01.05

Page 4

FABIA 2000 ³ Body Work

List of Supplements Edition 01.05

S00.5319.15.20

Page 5

FABIA 2000 ³ Body Work

00 – Technical Data

Table of Contents

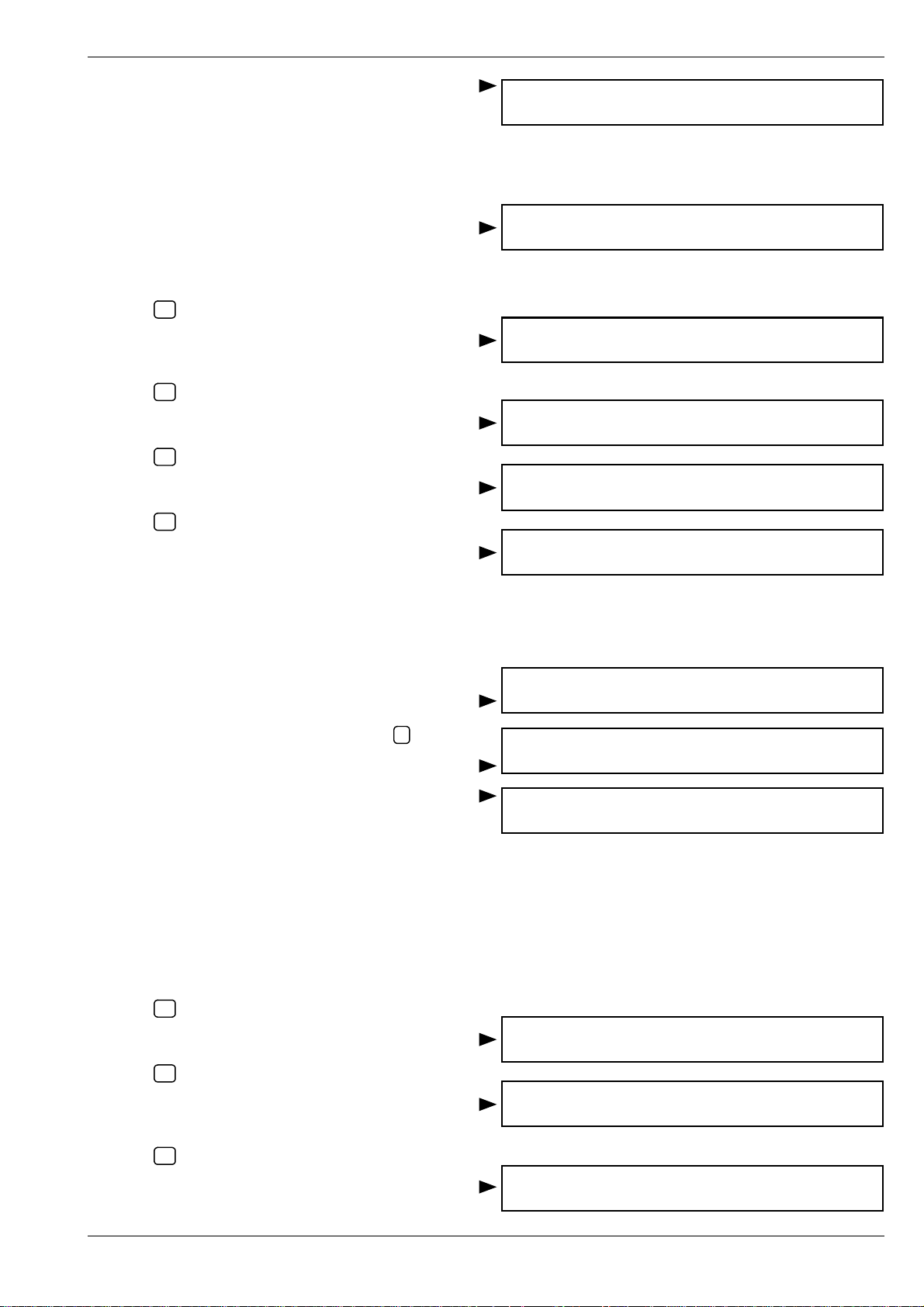

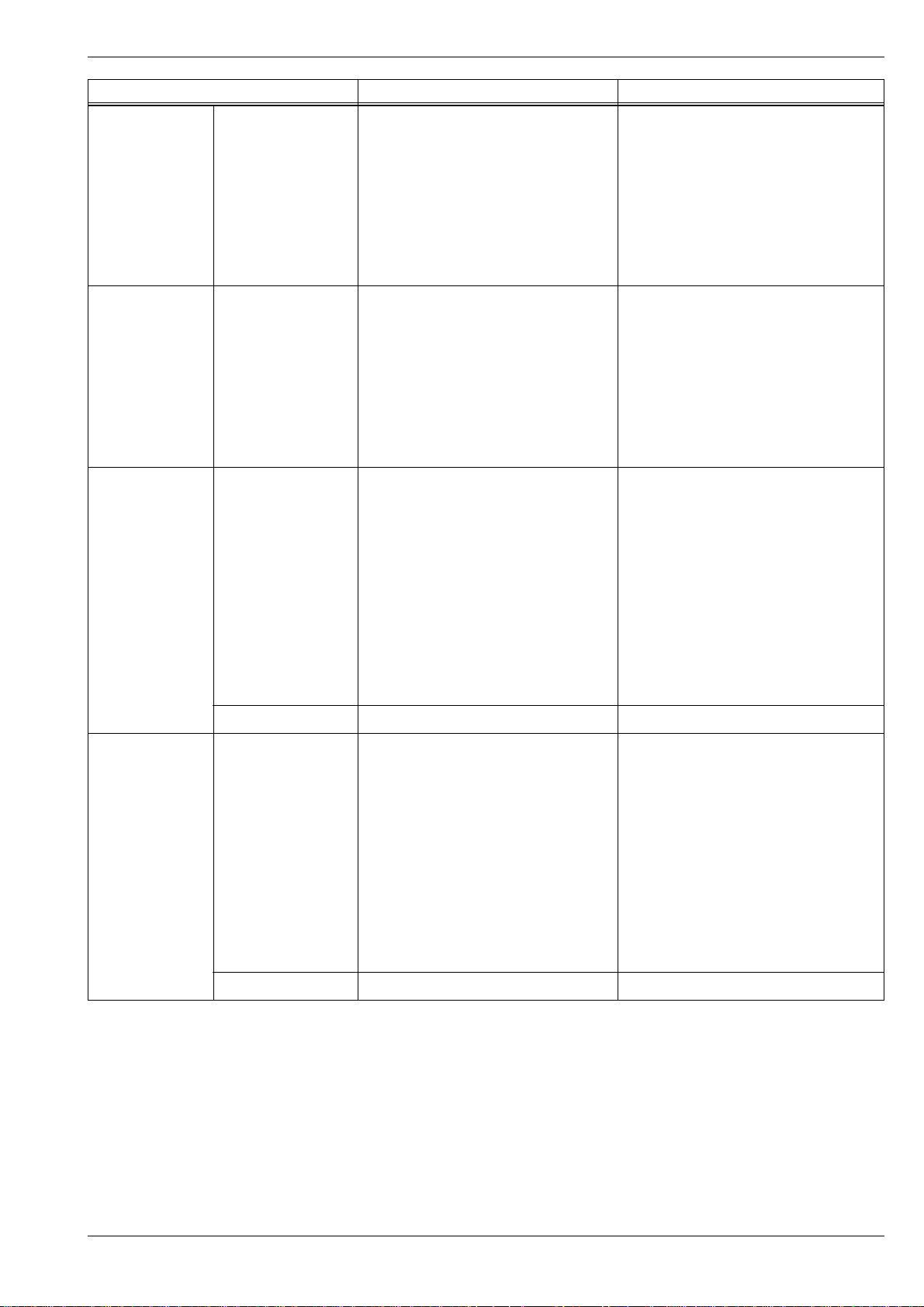

Technical Data ....................................................................................... ...

- Vehicle identification data ............................................................................

01 – Self-diagnosis

Self-diagnosis for convenience system ............ ...............................................

- Notes concerning self-diagnosis for convenience syste m ......................................

- Types and description of convenience system ...................................................

- Overview of the selectable functions of the diagnosis for the convenience system ........

- Connect vehicle system tester -V.A.G 1552- ......................................................

- Interrogating control unit version ....................................................................

- Interrogating fault memory ...........................................................................

- Actuator diagnosis .....................................................................................

- Erasing fault memory .................................................................................

- Ending output ..........................................................................................

- Coding control unit ....................................................................................

Self-diagnosis for convenience system with CAN databus cable ..........................

- Overview of the selectable functions of the self diagnosis for convenience system with CAN

databus cable ..........................................................................................

- Overview of the control units for c onvenience system with CAN databus cable ............

- Coding control unit with CAN databus cable ......................................................

- Fault table Convenience system with CAN databus cable ......................................

- Reading measured value block for c onvenience system with CAN databus cable .........

- Test table for convenience system with CAN databus cable ...................................

00-1 page 1

00-1 page 1

01-1 page 1

01-1 page 1

01-1 page 1

01-1 page 3

01-1 page 4

01-1 page 5

01-1 page 6

01-1 page 6

01-1 page 7

01-1 page 8

01-1 page 8

01-2 page 1

01-2 page 1

01-2 page 1

01-2 page 3

01-2 page 4

01-2 page 15

01-2 page 16

Self-diagnosis for convenience system with LIN databus cable ............................

- Overview of the selectable functions of the self-diagnosis for convenience system with LIN

databus cable ..........................................................................................

- Overview of the control units for c onvenience system with LIN databus cable ..............

- Coding control unit with LIN databus coding ......................................................

- Fault table of control unit for convenience system with LIN databus cable ..................

- Fault table of LIN databus/control units for window control in the i ndividual doors .........

- Reading measured value block with LIN databus cable .........................................

- Test table with LIN databus cable ..................................................................

Adapting the convenience system ( for all convenience system types) ..................

- Adjustment ..............................................................................................

Self-diagnosis for Airbag System I .................................................................

- Function of the airbag system .......................................................................

- Connect vehicle system tester -V.A.G 1552- and select address word „Airbag“ ............

- Overview of selectable functions ....................................................................

- Interrogating control unit version ....................................................................

- Interrogating fault memory ...........................................................................

- Actuator diagnosis .....................................................................................

- Erasing fault memory .................................................................................

- Ending output ..........................................................................................

- Coding airbag control unit ............................................................................

Self-diagnosis for airbag system II .................................................................

01-3 page 1

01-3 page 1

01-3 page 1

01-3 page 2

01-3 page 2

01-3 page 7

01-3 page 10

01-3 page 10

01-4 page 1

01-4 page 1

01-5 page 1

01-5 page 1

01-5 page 3

01-5 page 4

01-5 page 5

01-5 page 6

01-5 page 6

01-5 page 7

01-5 page 8

01-5 page 8

01-6 page 1

S00.5319.15.20

Table of ContentsEdition 01.05

I

Page 6

FABIA 2000 ³ Body Work

- Fault table ..............................................................................................

- Reading measured value block .....................................................................

- Test table ................................................. ....... ....... ........ ........................

- Parts inspection with t est box -VAS5056- ........................................................

Deactivating and activating airbag units (adaptation) .........................................

- Deactivating and activating passenger-side airbag units (adaptation) ........................

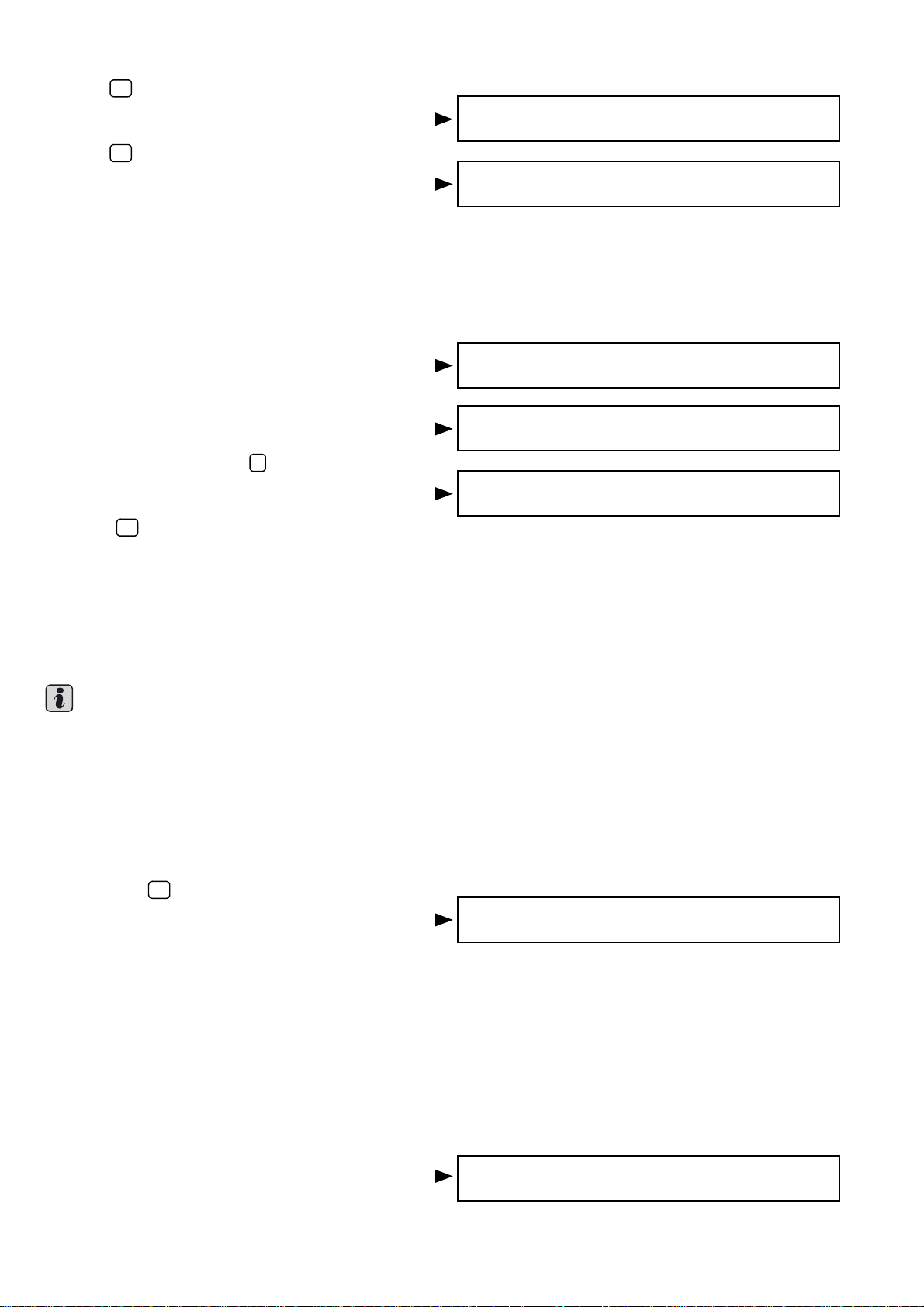

50 – Front body

Front body ...............................................................................................

- Removing and installing lock carrier with component parts ....................................

Front wing ......................................... ......................................................

- Removing and installing the front w ing ............................................................

55 – Bonnet, tailgate

Front bonnet .............................................................................................

- Summary of front bonnet components .............................................................

- Summary of radiator grill components .............................................................

- Disassembling and assembling radiator grill ......................................................

- Adjusting front bonnet ................................................................................

Tailgate ............................................................ .......................................

- Removing the pressurized gas strut ................................................................

- Degassing the pressurized gas strut .............................................. ........ ....... ..

- Summary of components of tailgate lock ..........................................................

- Summary of components of remote release ......................................................

- Removing and installing luggage compartment lid hinges (Sedan) ...........................

- Adjusting luggage compartment lid .................................................................

01-6 page 2

01-6 page 6

01-6 page 7

01-6 page 13

01-7 page 1

01-7 page 1

50-1 page 1

50-1 page 1

50-2 page 1

50-2 page 1

55-1 page 1

55-1 page 1

55-1 page 2

55-1 page 2

55-1 page 3

55-2 page 1

55-2 page 1

55-2 page 1

55-2 page 2

55-2 page 3

55-2 page 3

55-2 page 4

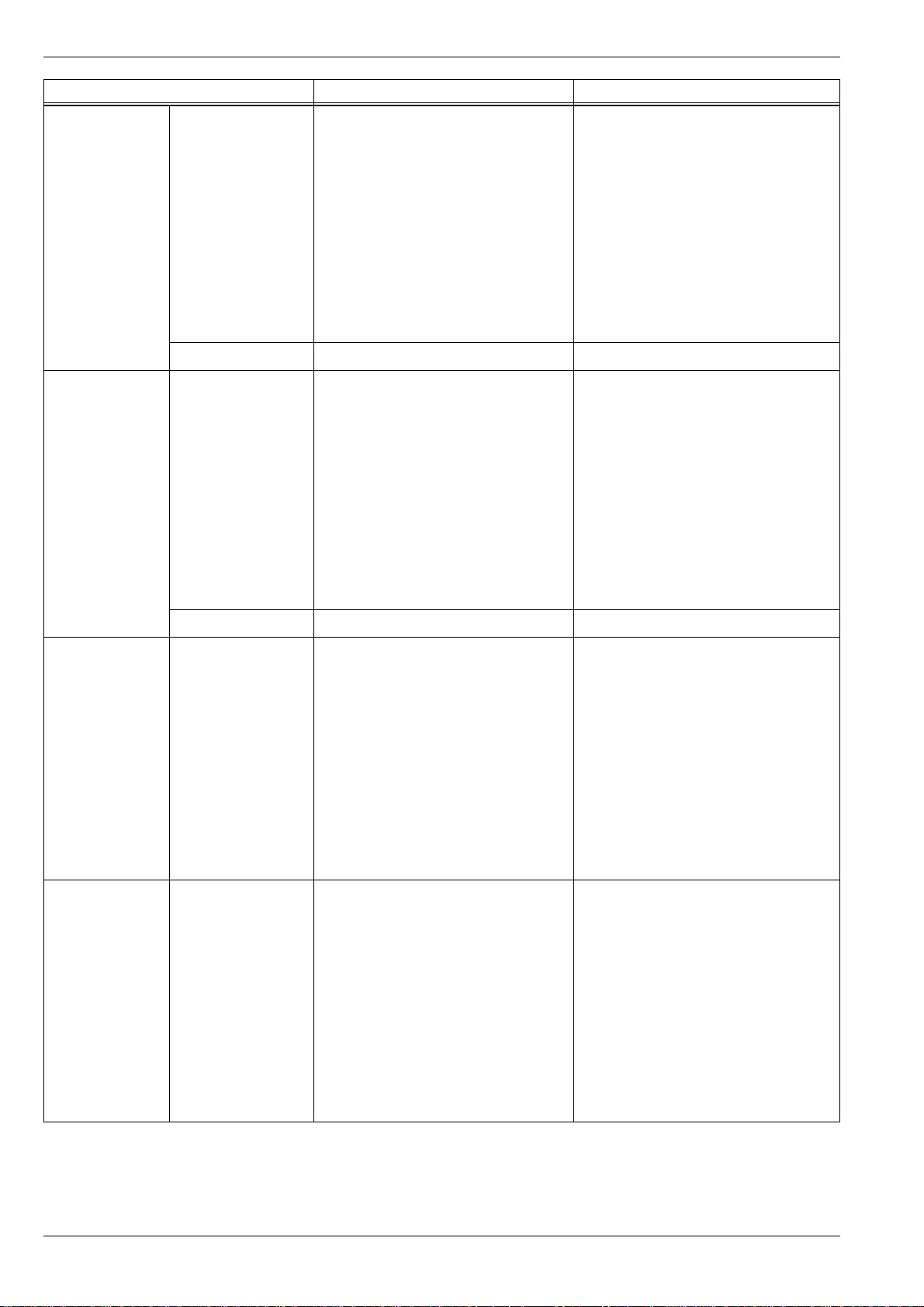

Fuel-tank lid unit ..................................................................................... ..

- Summary of components of the fuel-tank lid unit .................................................

57 – Front doors/door internal parts/central locking

Front door ................................... .............................................................

- Summary of components ............................................................................

- Removing and installing the door ...................................................................

- Door adjustment .......................................................................................

- Removing and installing assembly carrier .........................................................

- Removing and installing door window ..............................................................

- Removing and installing window lifter motor ......................................................

- Summary of components of door handle and door lock ................. ....... ........ ....... ..

- Removing and installing the lock cylinder housing ...............................................

- Removing and installing the door handle ..........................................................

- Removing and installing the door l ock .............................................................

- Removing and installing the locki ng button for locking rod .....................................

- Summary of components of front door seals ......................................................

- Central locking system ...............................................................................

58 – Rear doors/door internal parts

55-3 page 1

55-3 page 1

57-1 page 1

57-1 page 1

57-1 page 2

57-1 page 2

57-1 page 2

57-1 page 4

57-1 page 4

57-1 page 5

57-1 page 5

57-1 page 6

57-1 page 7

57-1 page 9

57-1 page 10

57-1 page 10

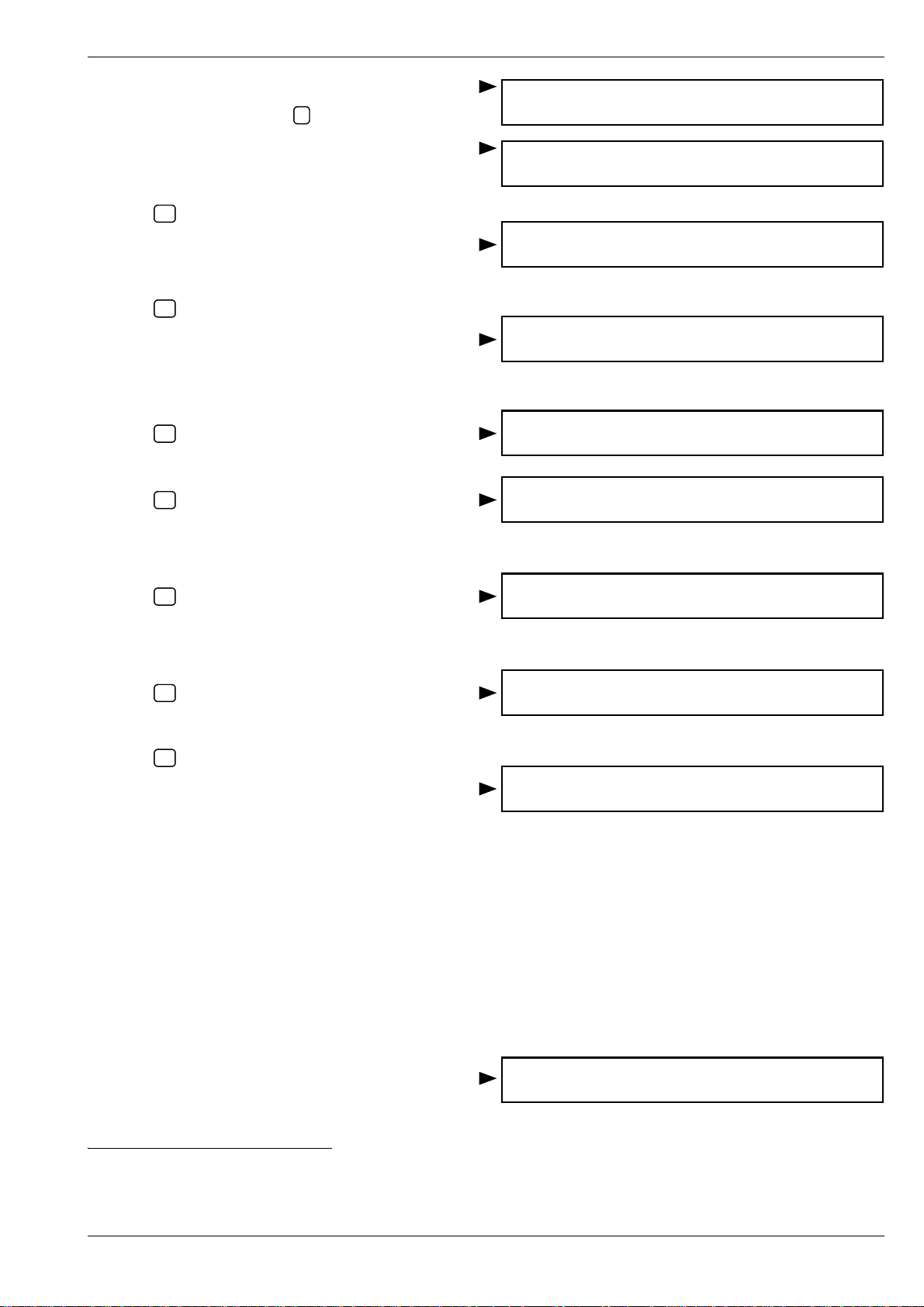

Rear door ........................................... ......................................................

- Summary of components ............................................................................

- Removing and installing the door ...................................................................

II

Table of Contents Edition 01.05

58-1 page 1

58-1 page 1

58-1 page 2

S00.5319.15.20

Page 7

FABIA 2000 ³ Body Work

- Door adjustment .......................................................................................

- Summary of components of door handle and door lock .........................................

- Removing and installing the door handle .... ......................................................

- Removing and installing the door lock .......................................................... ...

- Removing and installing assembly carrier .........................................................

- Removing and installing door window .............................. ................................

- Summary of components of door seals .................................................. ....... ...

Rear door (Praktik) ............................................. ........................................

- Rear door .................................................................Summary of components

- Removing and installing the door lock .......................................................... ...

60 – Sliding/tilting roof

Sliding/tilting roof with glass panel ................................ ................................

- Summary of components of sliding/tilting roof with glass panel ................................

- Removing and installing the glass roof .......................................................... ...

- Removing and installing sun screen ................................................................

- Removing and installing E-drive ...... ..............................................................

- Setting E-drive (0 position) ...... ....... ........ ....... ....... ........ ................................

- Adapting drive ................................................................................ ..........

- Inspecting parellel run ................................................................................

- Setting parallel run ................................................................................. ...

- Removing and installing assembly unit ............................................................

- Cleaning the water drain hoses .....................................................................

58-1 page 2

58-1 page 3

58-1 page 3

58-1 page 5

58-1 page 6

58-1 page 7

58-1 page 8

58-2 page 1

58-2 page 1

58-2 page 2

60-1 page 1

60-1 page 1

60-1 page 1

60-1 page 6

60-1 page 6

60-1 page 7

60-1 page 8

60-1 page 8

60-1 page 8

60-1 page 9

60-1 page 9

63 – Bumpers

Front bumper ............................................. ...............................................

- Summary of components on the front bumper ....................................................

- Summary of components on the front bumper (RS) .............................................

- Removing and installing the bumper bracket .................................................. ...

Rear bumper .. ...........................................................................................

- Summary of components of rear bumper ..........................................................

- Removing and installing the bumper bracket .................................................. ...

- Removing and installing rear apron (RS) ..........................................................

64 – Glazing

Glued windows ........................................................................ .................

- Removing and installing glued windows ...........................................................

- Removing and installing side window (Combi) ................................................. ...

- Prepare new windscreen for fitting ..................................................................

- Prepare flange for fitting .............................................. ....... ........ ....... ....... ...

- Glueing ............................. .....................................................................

- Waiting time .................................................... ........ ....... ........ ....... ....... ...

- Eliminating paint damage ............................................ ....... ........ ....... ....... ...

- Remove glue and clean ..............................................................................

63-1 page 1

63-1 page 1

63-1 page 2

63-1 page 3

63-2 page 1

63-2 page 1

63-2 page 2

63-2 page 2

64-1 page 1

64-1 page 1

64-1 page 7

64-1 page 8

64-1 page 9

64-1 page 10

64-1 page 11

64-1 page 11

64-1 page 11

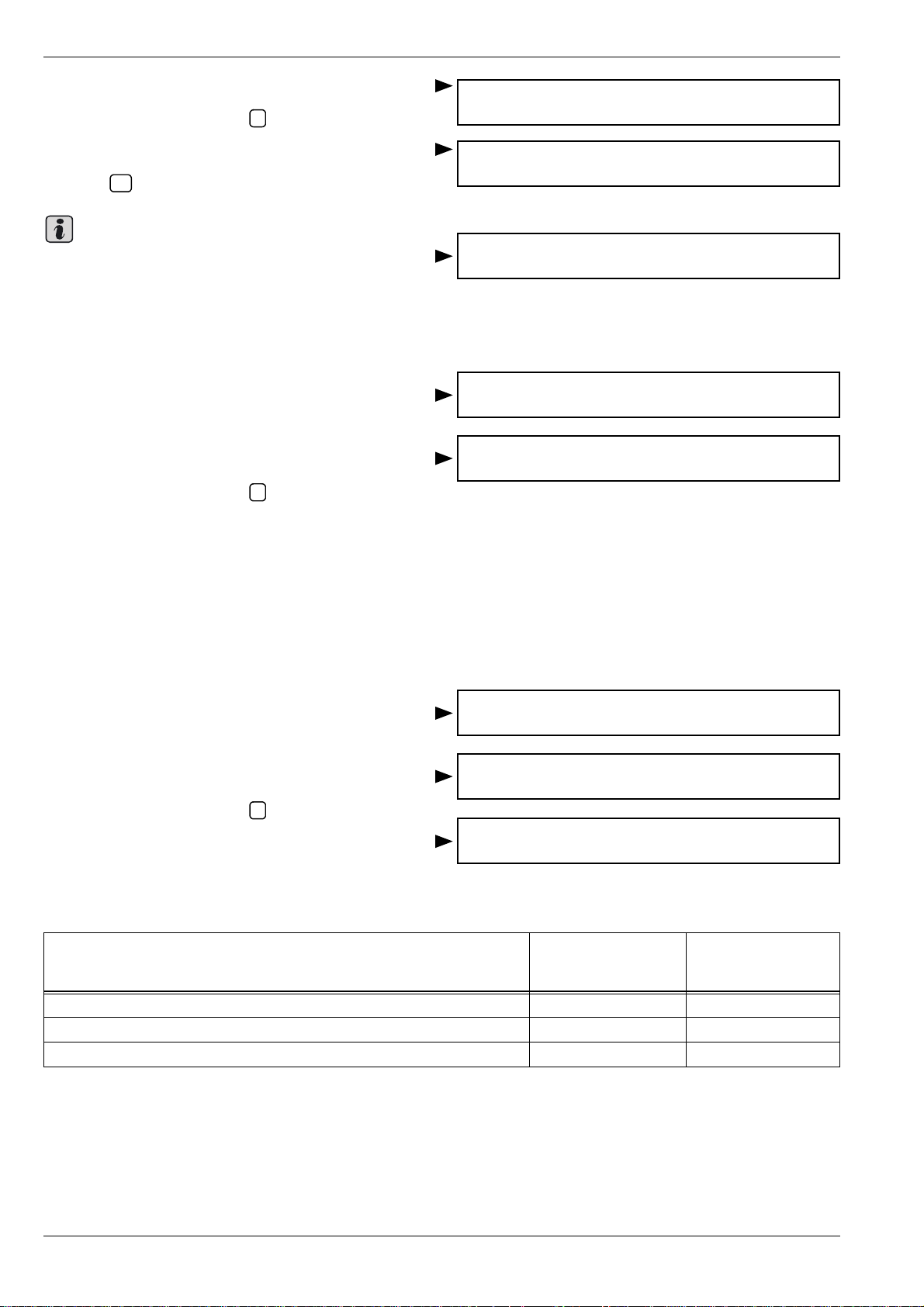

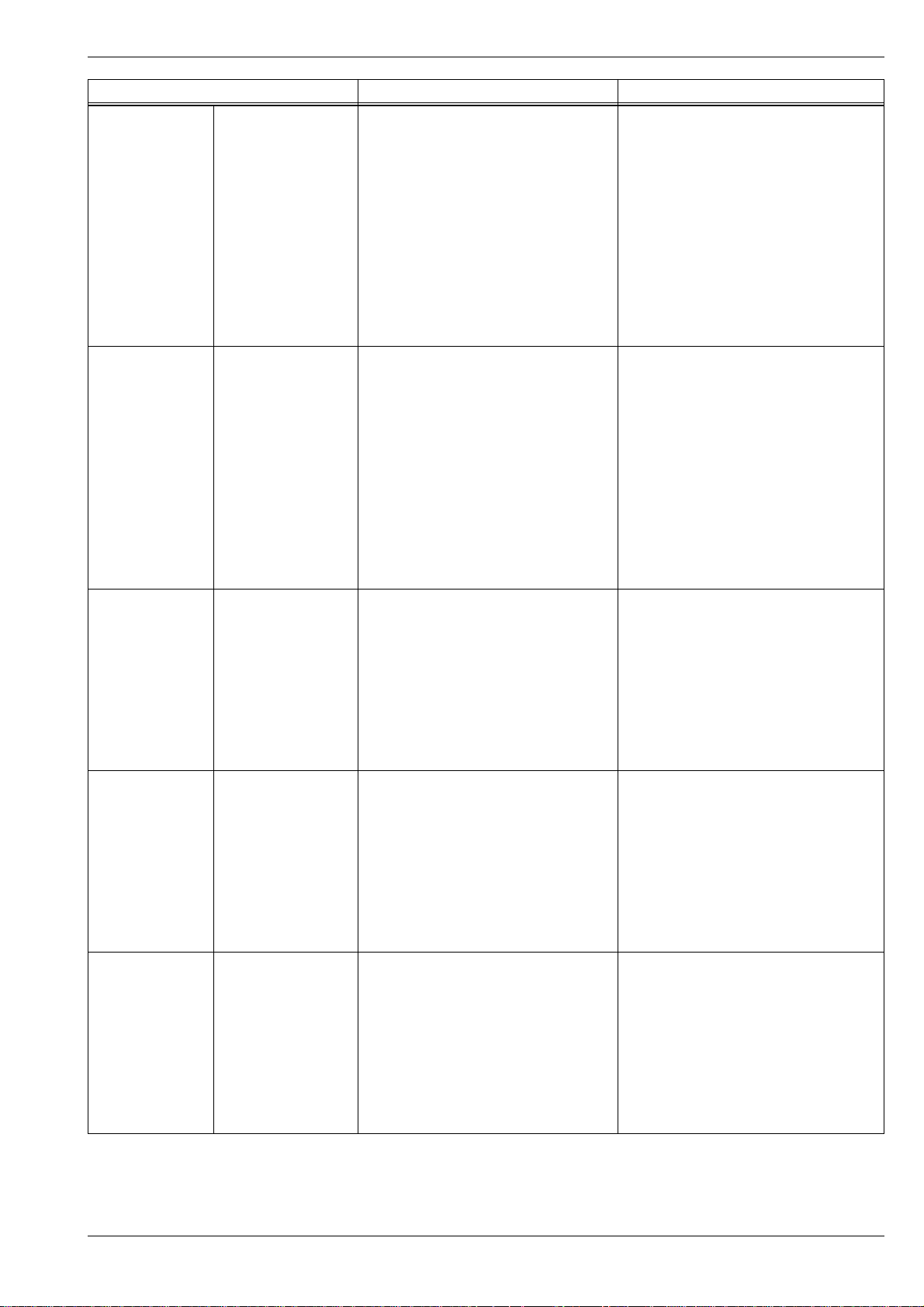

66 – Exterior equipment

Wheelhouse liner ................................. ......................................................

- Removing and installing the front wheelhouse liner ...... ........................................

- Removing and installing the rear wheelhouse liner ..............................................

Table of ContentsEdition 01.05

S00.5319.15.20

66-1 page 1

66-1 page 1

66-1 page 1

III

Page 8

FABIA 2000 ³ Body Work

Rear-view mirror ............ ............................................................................

- Summary of components of rear-view mirror ............................. ....... ........ ....... ..

Water box cover ................................................. .......................................

- Removing and installing water box cover ..........................................................

Roof drip moulding ........ ............................................................................

- Removing and installing roof drip moulding .......................................................

Protective strips ........................... .............................................................

- Removing and installing protective side strips ....................................................

Trailer coupling .........................................................................................

- Summary of components trailer coupling ..........................................................

Roof railing (Combi) ........................................................... ........................

- Removing and installing the roof rack ..............................................................

Rear spoiler ..................................................................................... .........

- Summary of the components - for the complete rear spoiler (Combi) ........................

- Removing and installing rear spoiler completely (Combi) .......................................

- Summary of the components - for the complete rear spoiler (RS) ............................

- Removing and installing rear spoiler completely (RS) ...........................................

Decorative strips (Combi) ............... .............................................................

- Removing and installing decorative strips .........................................................

66-2 page 1

66-2 page 1

66-3 page 1

66-3 page 1

66-4 page 1

66-4 page 1

66-5 page 1

66-5 page 1

66-6 page 1

66-6 page 1

66-7 page 1

66-7 page 1

66-8 page 1

66-8 page 1

66-8 page 1

66-8 page 1

66-8 page 2

66-9 page 1

66-9 page 1

68 – Interior equipment

Interior rear-view mirror .............................................. ................................

- Removing interior rear-view mirr or .................................................................

- Installing rear-view mirror ............................................................................

- Repair method with glass-metal adhesive .........................................................

Covers, storage areas and trim panels .................... .......................................

- Summary of components of centre console .......................................................

- Removing and installing the front can holder .....................................................

- Removing and installing the sun visor .............................................................

- Removing and installing the centr e sun visor .....................................................

- Removing and installing the stora ge area (Praktik) ..............................................

- Removing and installing the mould ed headliner (Prakti k) .......................................

Recessed handle ...................................................................... .................

- Removing and installing recessed handle .........................................................

Partition panel and protective grating (Praktik) .................................................

- Summary of components for the partition panel ..................................................

- Removing and installing the protective grating for the tailgate .................................

Floor partition (Praktik) ............................................................................. ..

- Removing and installing the front floor partition ..................................................

- Removing and installing the rear floor partition ...................................................

68-1 page 1

68-1 page 1

68-1 page 1

68-1 page 1

68-2 page 1

68-2 page 1

68-2 page 2

68-2 page 2

68-2 page 2

68-2 page 2

68-2 page 3

68-3 page 1

68-3 page 1

68-4 page 1

68-4 page 1

68-4 page 1

68-5 page 1

68-5 page 1

68-5 page 1

Front entrance plates (RS) ......................................................................... ..

- Removing and installing the front entrance plates ...............................................

69 – Occupant protection

Seat belts ......................................................................... ........................

- Safety instructions f or work on seat belt tensioners .............................................

- Summary of components of front seat be lts ......................................................

IV

Table of Contents Edition 01.05

68-6 page 1

68-6 page 1

69-1 page 1

69-1 page 1

69-1 page 2

S00.5319.15.20

Page 9

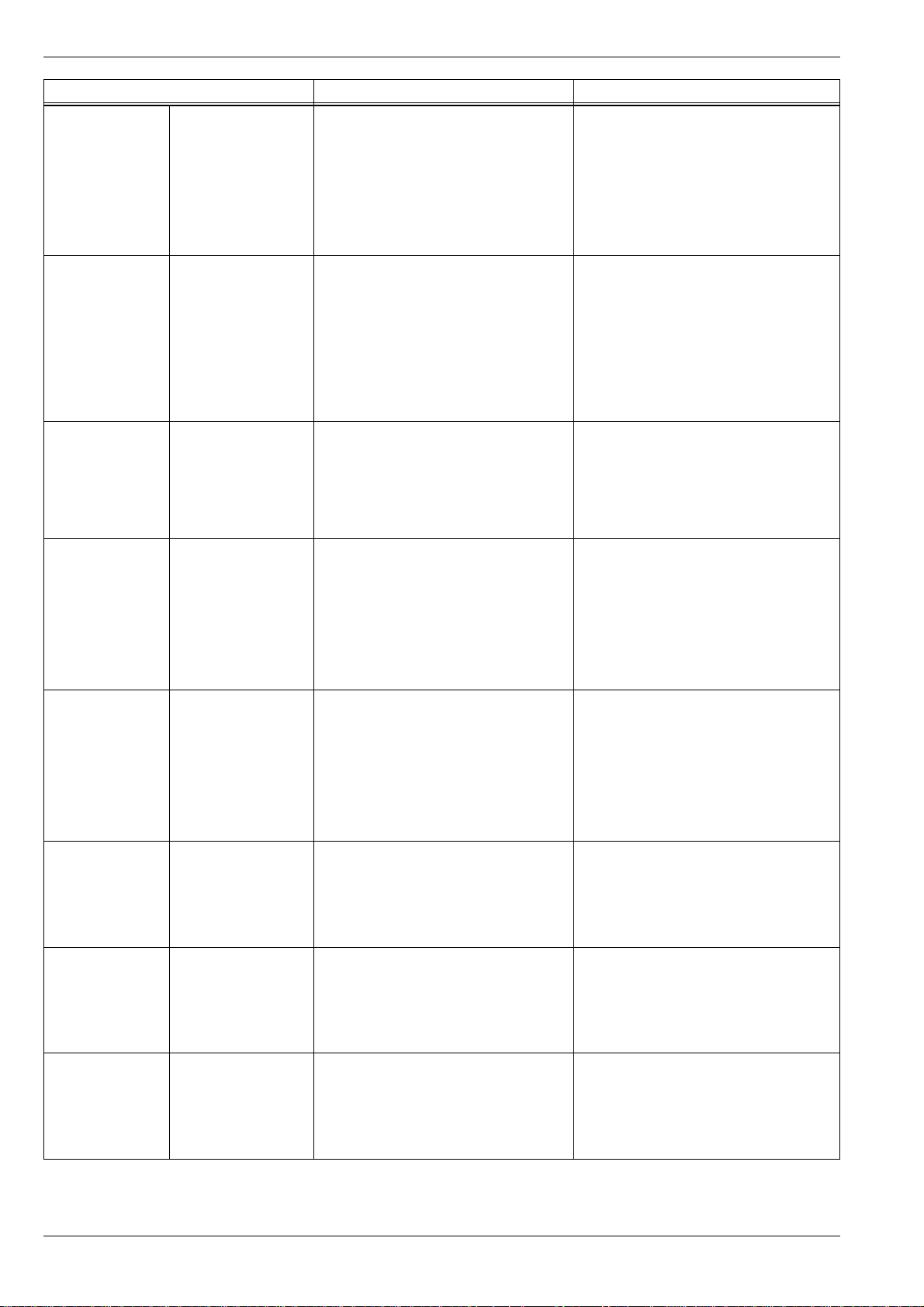

FABIA 2000 ³ Body Work

- Removing and installing the rear seat belts .......................................................

- Summary of components - middle three-point seat belt at the rear ...........................

Inspecting seat belts ................................... ...............................................

- Checks ..................................................................................................

Airbag ............................................... ......................................................

- Airbag system .................................... ......................................................

- Safety precautions when working on the airbag system ........................................

- Replacing parts of the airbag system ..............................................................

- Removing and installing driver airbag unit ................. ........................................

- Summary of components of four-armed steering wheel .........................................

- Summary of components of three-armed steering wheel .......................................

- Removing and installing restoring ring with slip ring .............................................

- Removing and installing passenger airbag unit ...................................................

- Removing and installing a side airbag crash sensor .............................................

- Removing and installing side airbag units ................................ .........................

- Removing and installing airbag control unit -J234- ...............................................

- Removing and installing the front passenger airbag switch .......................... ..........

Removal of pyrotechnic parts before scrapping the vehicle ............... .................

- Disposal of the airbag units before scrapping the vehicle ......................................

69-1 page 3

69-1 page 4

69-2 page 1

69-2 page 1

69-3 page 1

69-3 page 1

69-3 page 1

69-3 page 3

69-3 page 4

69-3 page 5

69-3 page 6

69-3 page 6

69-3 page 7

69-3 page 8

69-3 page 8

69-3 page 10

69-3 page 10

69-4 page 1

69-4 page 1

70 – Trim panel/insulation

Dash panel ...................................................................... .........................

- Removing and installing the dash panel ...........................................................

- Removing and installing the central tube/dash panel ............................................

- Removing and installing the convenience system central control unit ........................

Door trim panels ......................................... ...............................................

- Summary of components of front door trim panels ...............................................

- Removing and installing the front door trim panel ................................................

- Summary of components of rear door trim panels ...............................................

- Removing and installing the rear door trim panel ................ ................................

- Removing and installing the rear door trim panel (Praktik) .....................................

Pillar and side trim panels ...........................................................................

- Removing and installing top trim panel of pillar A ............................................. ...

- Removing and installing bottom trim panel of pillar A ............................................

- Summary of components of trim panels of pillar B ............................................ ...

- Removing and installing bottom trim panel of pillar B ............................................

- Removing and installing top trim panel of pillar C ................................................

- Removing and installing bottom trim panel of pillar C ...........................................

- Removing and installing top trim panel of pillar C (Fabia Combi) ............. .................

- Removing and installing top trim panel of pillar D ................................................

- Removing and installing the base plate (notchback) .............................................

- Summary of components of entrance plate .......................................................

- Removing and installing the tailgate/luggage compartment cover (Praktik) ..................

70-1 page 1

70-1 page 1

70-1 page 4

70-1 page 5

70-2 page 1

70-2 page 1

70-2 page 1

70-2 page 3

70-2 page 4

70-2 page 4

70-3 page 1

70-3 page 1

70-3 page 1

70-3 page 2

70-3 page 2

70-3 page 3

70-3 page 3

70-3 page 4

70-3 page 5

70-3 page 5

70-3 page 6

70-3 page 7

Door trim panels in the luggage compartment ... ...............................................

- Summary of components of luggage compartment cover ......................................

- Summary of components of side trim panel of luggage compartment ....... ....... ....... ...

- Removing and installing bases for luggage compartment floor ................................

Table of ContentsEdition 01.05

S00.5319.15.20

70-4 page 1

70-4 page 1

70-4 page 2

70-4 page 3

V

Page 10

FABIA 2000 ³ Body Work

- Summary of components of rear cargo opening cover ..........................................

- Summary of components of trim panels of tailgate ..............................................

- Removing and installing holder for luggage com partment cover (estate car) ................

- Removing and installing the side luggage compartment trim panel (estate car) ............

- Removing and installing the bonnet at the rear (Praktik) ........................................

- Removing and installing the bonnet at the rear (Praktik) ........................................

- Removing and installing the finishing strip ........................................................

Moulded headliner .....................................................................................

- Removing and installing moulded headliner ......................................................

- Removing and installing the mould ed headliner (Prakti k) .......................................

- Summary of components of the moulded headliner noise insulation panels (Fabia Combi)

72 – Seat racks

Front seats .................................. .............................................................

- Removing and installing the front seats ............................................................

- Removing and installing the grip for the seat height adjuster ..................................

- Removing and installing the backrest rack fo r the seat rack ...................................

- Removing and installing seat height adjusting elemen ts ........................................

Rear seats .................... ............................................................................

- Removing and installing seat bench and backrest ...............................................

- Removing and installing the rear armrests ........................................................

70-4 page 4

70-4 page 5

70-4 page 6

70-4 page 6

70-4 page 7

70-4 page 7

70-4 page 8

70-5 page 1

70-5 page 1

70-5 page 2

70-5 page 4

72-1 page 1

72-1 page 1

72-1 page 2

72-1 page 2

72-1 page 4

72-2 page 1

72-2 page 1

72-2 page 2

74 – Seat Upholstery, Covers

Front seat upholstery and covers ............ ......................................................

- Assembly overview of covers and upholstery for front seats ...................................

- Assembly overview of covers and upholstery for backre sts ....................................

Rear seat upholstery and covers ........................................... ........................

- Assembly overview of covers and upholstery for rear seats ....................................

- Assembly overview of covers and upholstery for rear backrest ................................

74-1 page 1

74-1 page 1

74-1 page 2

74-2 page 1

74-2 page 1

74-2 page 2

VI

Table of Contents Edition 01.05

S00.5319.15.20

Page 11

FABIA 2000 ³ Body Work

00 – Technical Data

00-1 Technical Data

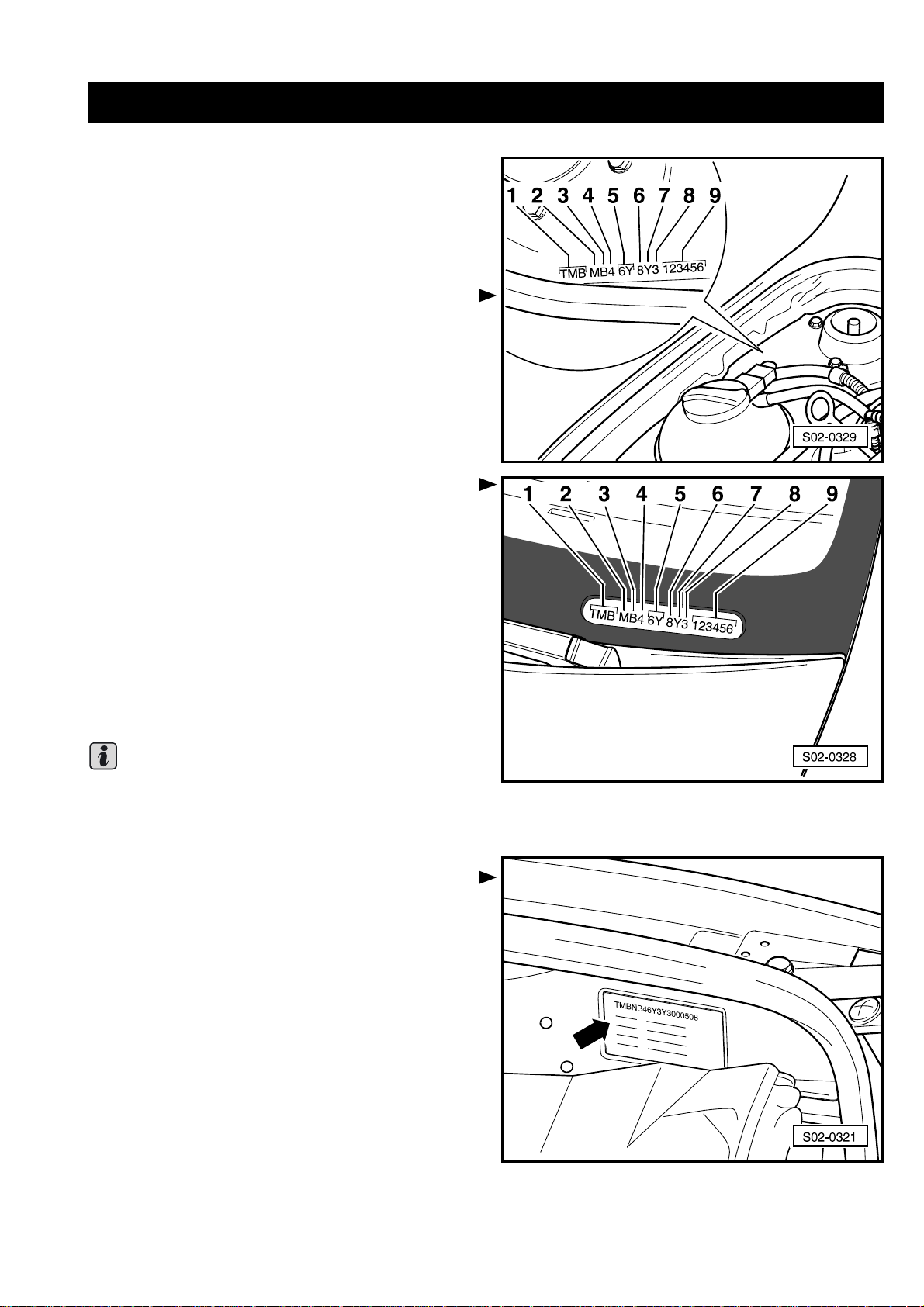

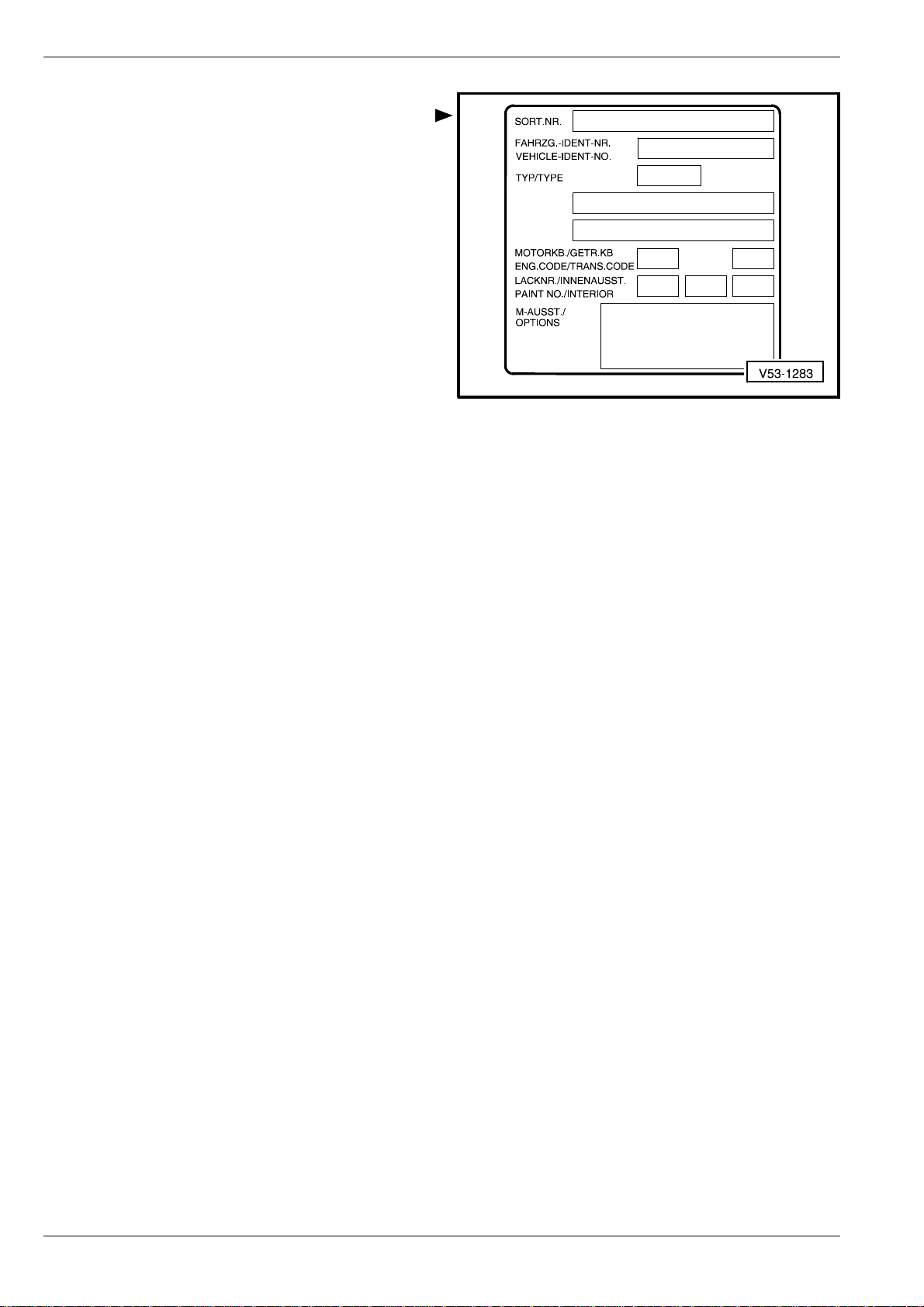

Vehicle identification data

Vehicle identification number

The vehicle identification number (chassis number) is attached to the right suspension dome.

The vehicle identification number (chassis number) can

also be found bottom left of the front window corner.

00

1 - Manufacturer's world code

2 - Model and version

3 - Engine type

4 - Airbag system

5 - Vehicle type

6 - Internal code

7 - Model year

8 - Manufacturing plant

9 - Body number

Note

Detailed information on the meaning of individual signs

⇒ Inspection and Maintenance, Chap. 02-1.

Type plate

The type plate -arrow- is attached to the left wheel house.

S00.5319.03.20

Technical DataEdition 03.00

00-1 page 1

Page 12

00

Vehicle data sticker

The vehicle data sticker is located at the rear left on the

floor of the luggage compartment.

FABIA 2000 ³ Body Work

00-1 page 2

Technical Data Edition 03.00

S00.5319.03.20

Page 13

FABIA 2000 ³ Body Work

01 – Self-diagnosis

01-1 Self-diagnosis for con-

venience system

Notes concerning self-diagnosis for convenience system

The central control unit for convenience system -J393- is

located above the accelerator pedal in the dash panel. It

is clipped into the bracket on the heating housing. The diagnostic connector is located behind the storage tray under the light switch.

Removing and installing the control unit for convenience

system ⇒ Chap. 70-1.

Initiate self-diagnosis at the start of fault finding and interrogate the fault memory with diagnostic device

-V.A.G 1552- or -V.A.G 1551- or -VAS 5052-.

01

Note

♦ The description which follows relates to the vehicle

system tester -V.A.G 1552- using program card -6.0(and higher version).

♦ The use of fault read-out scan tool -V.A.G 1551- with

program card -9.0- (and later version) is almost identical except for specific deviations (e.g. other display,

possibility of using a printer etc.).

♦ To end the output or to switch to another address se-

lect function 06 „End output“.

WARNING!

When replacing the central control unit for the convenience system or the alarm system with an independent power supply disconnect the power

supply for at least 30 sec. in order to allow the

alarm to be adapted. If necessary, disconnect the

communication cable.

The convenience system can be adapted to the customer

wish ⇒ Chapter 01-4.

Types and description of convenience

system

Two different systems of databus cables are used in the

convenience system:

♦ for vehicles manufactured until 07.2004 the CAN dat-

abus cable

♦ for vehicles manufactured as of 08.2004 the LIN dat-

abus cable

The difference is the operation of the window control,

the fault tables, the measured value blocks and the

coding of the control unit.

Self-diagnosis for convenience systemEdition 01.05

S00.5319.15.20

01-1 page 1

Page 14

01

In case of repairs or self-diagnosis of the convenience system first the system of the communication

cable must be defined. This is detected by means of

the connection of the diagnostic device and by entry

of the address word 46 „Central module co nvenience

system“ ⇒ 01-1 page 4.

Convenience system with CAN databus cable

The convenience system comprises the electric equipment in the doors:

♦ electrical central locking system with SAFE function

♦ power-window lifter with jamming protection

♦ electrically adjustable and heated exterior mirror

It also comprises other systems in the vehicle:

♦ Cut-off delay for interior lamp

♦ Monitoring and disconnection of all interior and lug-

gage compartment lights as a batter y disc ha rg e pr o tection

♦ Sliding roof closing function via outside closing com-

mand

♦ Radio control for anti-theft alarm system and central

locking

♦ the optical Safe function indicator (is a LED mounted

in the door equipment of the driver's door)

FABIA 2000 ³ Body Work

The system comprises the control unit for convenience system and control units in the individual

doors whose communication between each other is

performed via the CAN databus cable. The communication between the central control unit for convenience system and other electrical systems in the

vehicle is performed via the CAN databus cable .

The control unit for convenience system detects

faults in the convenience system (including faults a t

control units in the individual doors) and stores them

in a permanent memory.

The displayed fault messages refer to a fault table including indications on the possible causes as well as targeted

repairs.

Faults due to a temporary line interruption or loose contact are also stored. These faults are displayed as sporadic faults „SP“.

Convenience system with LIN databus cable

The convenience system comprises the electric equipment in the doors:

♦ electrical central locking system with SAFE function

♦ power-window lifter with jamming protection

It also comprises other systems in the vehicle:

01-1 page 2

Self-diagnosis for convenience system Edition 01.05

S00.5319.15.20

Page 15

FABIA 2000 ³ Body Work

♦ Sliding roof closing function via outside closing com-

mand

♦ Radio control for anti-theft alarm system and central

locking

♦ the optical Safe function indicator (is a LED mounted

in the door equipment of the driver's door)

The system comprises the control unit for convenience system. Its communication with other electrical

systems in the vehicle is performed via the CAN databus cable.

Control units are also located in the individual doors,

which however only operate the window lifters. Their

communication is performed via the LIN databus cable.

The LIN databus cable is not self-diagnostic with any

diagnostic device. This cable consists of an independent electrical circuit, which has no connection

to other electrical systems in the vehicle.

The control unit for convenience system detects

faults in the convenience system (including faults in

the individual doors relating to the lock) and stores

them in a permanent memory. The faults relating to

the window control can be stored in the fault memory

of the convenience system.

01

WARNING!

If the window control is restricted or fully non-operational, proceed according to „functionality of

individual windows“ ⇒ Chap. 01-3, Fault table LIN

databus/control units for window control in the individual doors. This table is used for the diagnosis

of faults from the LIN databus.

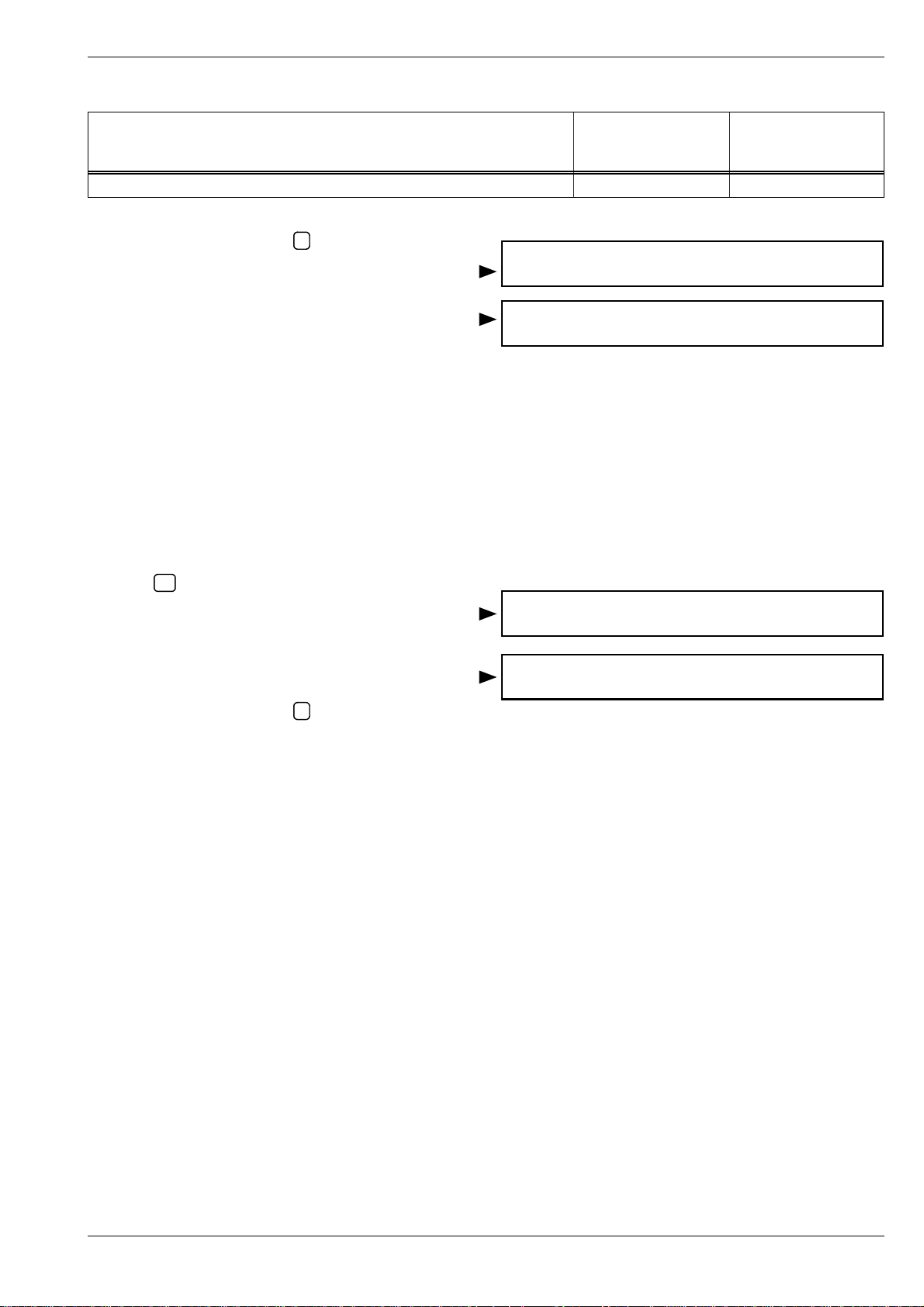

Overview of the selectable functions of

the diagnosis for the convenience system

Operation Page

01 Interrogating control

unit version

02 Interrogating fault

memory

03 Actuator diagnosis ⇒ 01-1 page 6

05 Erasing fault memory ⇒ 01-1 page 7

06 Ending output ⇒ 01-1 page 8

07 Coding control unit ⇒ 01-1 page 8

08 Reading measured val-

ue block

10 Adjustment ⇒ Chapter 01-4

⇒ 01-1 page 5

⇒ 01-1 page 6

⇒ Chap. 01-2,

⇒ Chap. 01-3

S00.5319.15.20

Self-diagnosis for convenience systemEdition 01.05

01-1 page 3

Page 16

01

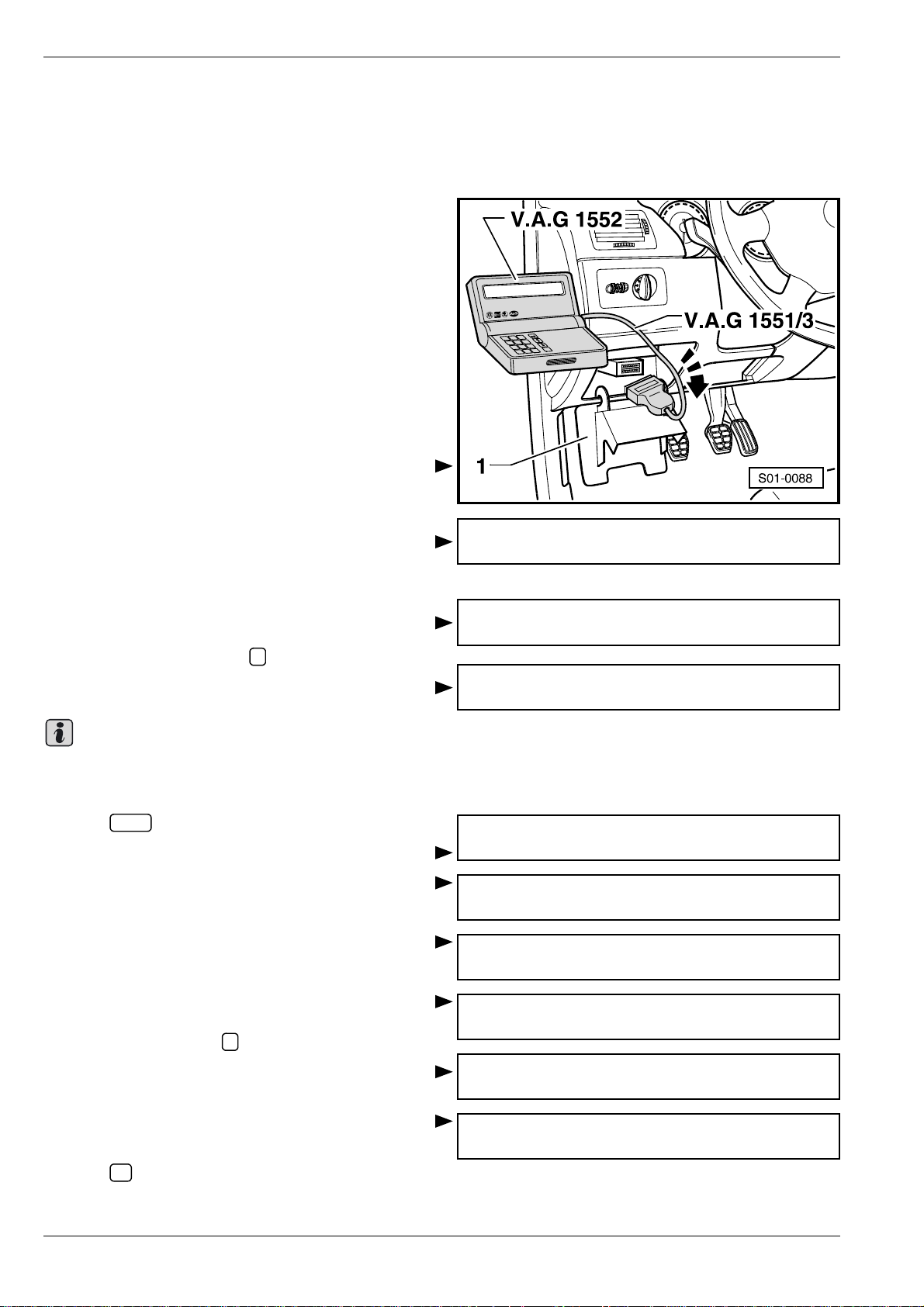

Connect vehicle system tester

-V.A.G 1552-

Special tools, test and measuring equipment and

auxiliary items required

♦ Vehicle system tester -V.A.G 1552-

♦ Diagnostic cable -V.A.G 1551/3, 3A, 3B, 3C-

Test conditions

• All fuses must be OK in compliance with the current

flow diagram.

• Battery voltage at least 9 V.

Procedure

– Open the storage tray -1- under the light switch -ar-

row-.

– Switch off ignition and connect vehicle system tester

-V.A.G 1552-.

– Switch on ignition.

Readout on display:

– Select address word 46 „Central module convenience

system“.

Readout on display:

– Confirm the entry with key .

Readout on display:

Q

FABIA 2000 ³ Body Work

3

2

1

6

5

4

9

8

7

E

H

Q

O

C

Vehicle system test HELP

Enter address word XX

Vehicle system test Q

46 Central module convenience system

Vehicle system test

Tester sends address word 46

2

5

5

1

.

G

.

A

.

V

P

L

Note

♦ One of the following four displays will appear in the

event of a communication set-up failure between vehicle system tester -V.A.G 1552- and the control unit.

♦ Press key to display the possible fault causes.

HELP

The ignition must be on!

Malfunctions occurred at the start of or during the pro-

gram (external sources of interference).

– Check connection of the vehicle system tester

-V.A.G 1552-.

– After removing the possible fault causes re-enter ad-

dress word 46 „Central module convenience system“

and confirm entry with .

Read-out on display after entering address word „46“:

The display shows the control unit identification number,

e.g.:

– Press key.

→

Q

Vehicle system test HELP

The control unit does not respond

Vehicle system test HELP

K cable does not connect to pos. term.

Vehicle system test →

No signal from the control unit

Vehicle system test →

Fault in communication set-up

Vehicle system test

Tester sends address word 46

6Q0959433C OM convenience unit 0002 →

Coding 00259 WSCXXXXX

01-1 page 4

Self-diagnosis for convenience system Edition 01.05

S00.5319.15.20

Page 17

FABIA 2000 ³ Body Work

01

The following display relates to the system with LIN

databus cable:

In this case continue the self-diagnosis ⇒ Chap. 01-

3.

The following display relates to the system with CAN

databus cable:

Readout on display, e.g.: (Door control unit driver's side)

In this case continue the self-diagnosis ⇒ Chap. 01-

2.

– Press key.

→

Readout on display, e.g.: (Door control unit passenger's

side)

– Press key.

→

Readout on display, e.g.: (Door control unit RL)

– Press key.

→

Readout on display, e.g.: (RR door control unit)

– Press key.

→

Readout on display:

Vehicle system test HELP

Select function XX

6Q1959801 OM D.contr unit DDCU TFK 0001→

6Q1959802 OM D.contr unit PDCU TFK 0001→

6Q1959811 OM D.contr unit RL TFK 0001→

6Q1959812 OM D. contr unit RR TFK 0001→

Vehicle system test HELP

Select function XX

Interrogating control unit version

– Connecting vehicle system tester -V.A.G 1552- and

selecting the address word for the convenience system ⇒ 01-1 page 4.

Readout on display:

– Select function 01 and confirm entry with .

Readout on display:

The control unit identification appears in the display of the

vehicle system tester -V.A.G 1552- e.g.:

♦ 6Q0959433 OM = Part No. of the control unit (current

control unit version ⇒ Electronic catalogue of original

parts)

♦ Convenience unit = system description

♦ 0002; (TFK 0001) = Program number

♦ Coding 00259 = Coding variant

♦ WSC = Workshop code

– Press key.

Readout on display, e.g.: (Door control unit driver's side)

– Press key.

Readout on display, e.g.: (Door control unit passenger's

side)

→

→

Q

Vehicle system test HELP

Select function XX

Vehicle system test Q

01 - Interrogating control unit version

6Q0959433C OM convenience unit 0002 →

Coding 00259 WSC XXXXX

6Q1959801 OM door control.DD TFK 0001→

6Q1959802 OM door control.PD TFK 0001→

– Press key.

→

Readout on display, e.g.: (Door control unit RL)

Self-diagnosis for convenience systemEdition 01.05

S00.5319.15.20

6Q1959811 OM door control.RL TFK 0001→

01-1 page 5

Page 18

01

FABIA 2000 ³ Body Work

– Press key.

Readout on display, e.g.: (RR door control unit)

– Press key.

Readout on display:

→

→

– Ending output ⇒ 01-1 page 8.

Interrogating fault memory

– Connecting vehicle system tester -V.A.G 1552- and

selecting the address word for the convenience system ⇒ 01-1 page 4.

Readout on display:

– Select function 02.

Readout on display:

– Confirm the entry with key .

The number of faults stored appears on the display.

Press key to display the stored faults consecutively.

→

Q

6Q1959812 OM door control.RR TFK 0001→

Vehicle system test HELP

Select function XX

Vehicle system test HELP

Select function XX

Vehicle system test Q

02 - Interrogating fault memory

X faults detected →

Cause and elimination:

Convenience system with CAN databus cable ⇒ Chap.

01-2.

Convenience system with LIN databus cable ⇒ Chap.

01-3.

Note

♦ If a fault is detected:

♦ 1. Remove fault.

♦ 2. Erase fault memory (Function 05).

♦ 3. Perform a functional test of the convenience sys-

tem.

♦ 4. Interrogate fault memory (Function 02) again.

If „No fault detected“ the program returns to its initial position after key is pressed.

Readout on display:

If anything else appears on the display: ⇒ Operating in-

structions of the vehicle system tester.

→

– Ending output ⇒ 01-1 page 8.

No fault detected! →

– Switch off ignition and switch off vehicle system tester.

Actuator diagnosis

– Connecting vehicle system tester -V.A.G 1552- and

selecting the address word for the convenience system ⇒ 01-1 page 4.

Readout on display:

01-1 page 6

Self-diagnosis for convenience system Edition 01.05

Vehicle system test HELP

Select function XX

S00.5319.15.20

Page 19

FABIA 2000 ³ Body Work

01

– Enter function 03.

– Confirm the entry with key .

Readout on display:

Door handle switches are lit.

– Press key.

Readout on display:

Warning lamp in door trim panel flashes.

– Press key.

Readout on display:

Exit warning light lights up.

Readout on display:

– Press key.

Sliding roof closes.

– Press key.

Turn signals on.

→

→

→

2)

→

3)

Q

1)

Vehicle system test Q

03 Actuator diagnosis

Actuator diagnosis →

Inside door handle lighting

Actuator diagnosis →

CL warning lamp Safe

Actuator diagnosis →

Exit warning light

Actuator diagnosis →

Close sliding roof signal

Actuator diagnosis →

Turn signal control

Readout on display:

– Press key.

Alarm horn activated.

→

3)

Readout on display:

– Press key.

→

Readout on display:

– Press key.

→

Readout on display:

– Ending output ⇒ 01-1 page 8.

Erasing fault memory

Conditions:

♦ Fault memory was interrogated.

♦ Fault was eliminated.

♦ Functional test was performed.

– Connecting vehicle system tester -V.A.G 1552- and

selecting the address word for the convenience system ⇒ 01-1 page 4.

Readout on display:

– Enter function 05.

Actuator diagnosis →

Alarm horn - H12

Actuator diagnosis →

END

Function unknown or cannot →

be carried out at the moment

Vehicle system test HELP

Select function XX

1)

Not fitted on FABIA.

2)

Only on vehicles equipped with sliding roof.

3)

Only on vehicles with remote control or alarm function.

S00.5319.15.20

Self-diagnosis for convenience systemEdition 01.05

01-1 page 7

Page 20

01

FABIA 2000 ³ Body Work

Readout on display:

– Confirm the entry with key .

Readout on display:

– Press key.

♦ If the following message is displayed the test se-

quence is incorrect:

♦ Carefully follow the test sequence step by step: First

interrogate the fault memory and then erase.

→

Note

Q

Ending output

Readout on display:

– Enter function 06.

Readout on display:

– Confirm the entry with key .

– Switch off ignition.

Q

Vehicle system test Q

05 Erase fault memory

Vehicle system test →

The fault memory is erased

Caution!

Fault memory was not interrogated

Vehicle system test

Select function XX

Vehicle system test Q

06 End output

– Disconnect vehicle system tester -V.A.G 1552- from

the connector.

Coding control unit

– Connecting vehicle system tester -V.A.G 1552- and

selecting the address word for the convenience system ⇒ 01-1 page 4.

Readout on display:

– Enter function 07.

Readout on display:

– Confirm the entry with key .

Readout on display:

Q

– Enter code number following table:

Table of codes for vehicles with CAN databus cable

Vehicle equipment Code number indi-

Central locking without power-window lifter 00018 00019

Central locking with 2 power-window lifters 00066 00067

Central locking with 4 power-window lifters 00258 00259

Vehicle system test HELP

Select function XX

Vehicle system test Q

07 Coding control unit

Coding control unit

Enter code number XXXXX (0-32767)

Code number over-

vidual door open-

ing

all door opening

01-1 page 8

Self-diagnosis for convenience system Edition 01.05

S00.5319.15.20

Page 21

FABIA 2000 ³ Body Work

Table of codes for vehicles with LIN databus cable

01

Vehicle equipment Code numbe r indi-

vidual door open-

ing

Central locking without power-window lifter 00018 00019

– Confirm the entry with key .

The control unit identification number, the control unit

code number and the workshop code are displayed.

If the control unit rejects an entered code number the following message will be displayed:

In this case the control unit was not coded with the data

required for the vehicle. Check whether the right control

unit was fitted on the vehicle (compare part number and

character index), or whether possibly a wrong co de was

entered.

Q

6Q09959433 OM convenience unit. 0002

Coding 00259 WSC xxxxx

Fault →

Coding XXXXX not accepted

Code number over-

all door opening

– Repeat coding.

If the control unit cannot be coded (correct control unit,

correct code number) the control unit is defective.

End funtion:

– Press key.

Readout on display:

→

– Enter function 06.

Readout on display:

– Confirm the entry with key .

Q

Vehicle system test HELP

Select function XX

Vehicle system test Q

06 End output

S00.5319.15.20

Self-diagnosis for convenience systemEdition 01.05

01-1 page 9

Page 22

01

FABIA 2000 ³ Body Work

01-1 page 10

Self-diagnosis for convenience system Edition 01.05

S00.5319.15.20

Page 23

FABIA 2000 ³ Body Work

01-2 Self-diagnosis for con-

venience system with

CAN databus cable

Overview of the selectable functions of

the self diagnosis for convenience system with CAN databus cable

Operation Page

01 Interrogating control

unit version

02 Interrogating fault

memory

03 Actuator diagnosis ⇒ Chapter 01-1

05 Erasing fault memory ⇒ Chapter 01-1

06 Ending output ⇒ Chapter 01-1

07 Coding control unit ⇒ Chap. 01-1 ⇒ 01-2

08 Reading measured val-

ue block

10 Adjustment ⇒ Chapter 01-4

⇒ Chap. 01-1,

⇒ Chapter 01-1

page 3

⇒ 01-2 page 15

01

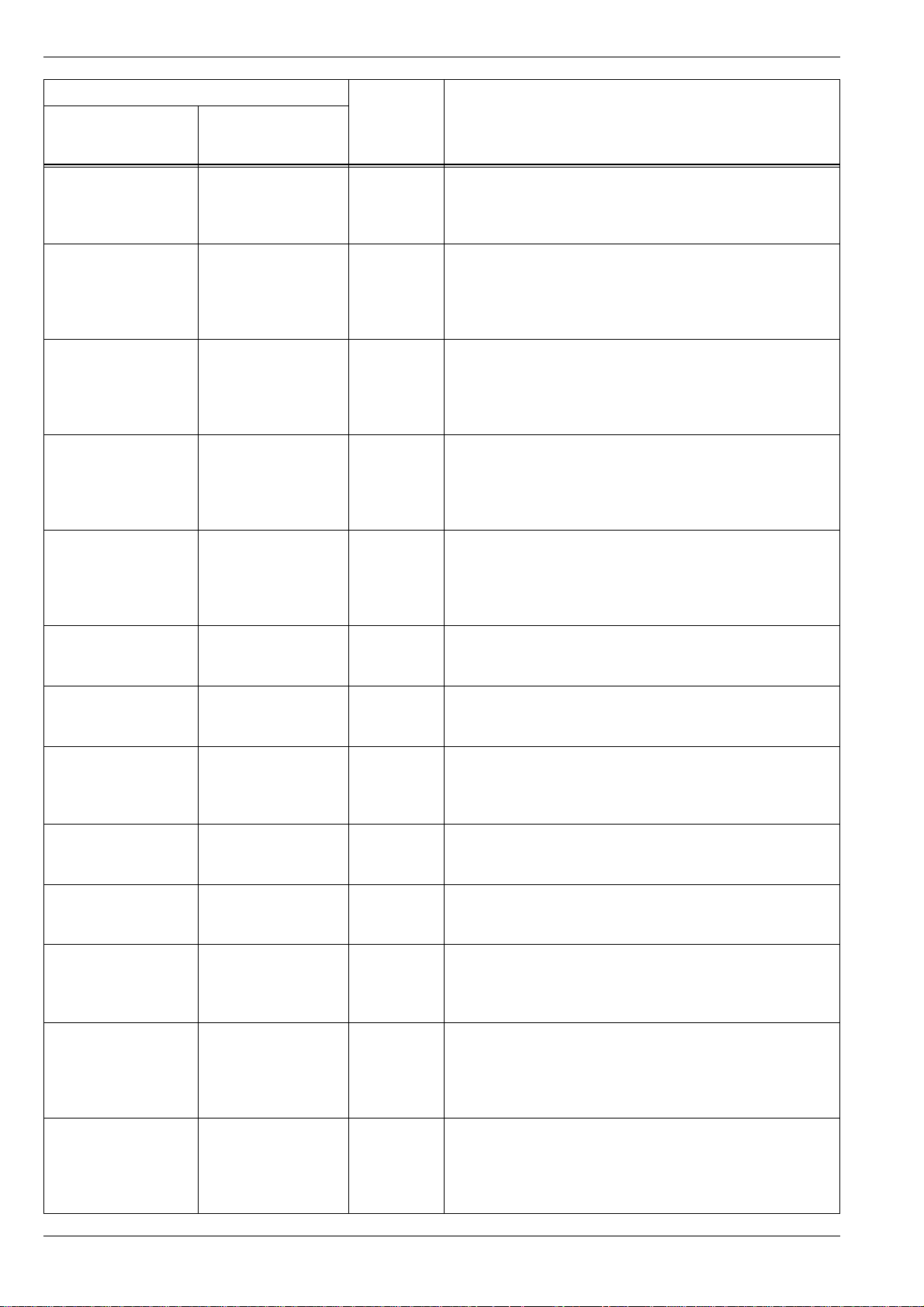

Overview of the control units for convenience system with CAN databus cable

Control unit part No.

Central control

unit for convenience system

6Q0959433A 01

6Q0959433H 35

6Q0959433C 02

6Q0959433E 3A

6Q0959433C OK - 0002 Control unit without power-window lifter, with radio con-

6Q0959433C 03

6Q0959433E 2P

6Q0959433A 04

6Q0959433H 2Q 6Q1959 801 04/2Q

6Q0959433C 06

6Q0959433E 2S 6Q1959801 06/2S

6Q0959433C 08

6Q0959433E 2U 6Q1959801 08/2U

Door control unit

6Q1959 802 04/2Q

6Q1959802 06/2S

6Q1959802 08/2U

1)

- 0002 Control unit without power-window lifter, without radio

- 0002 Control unit without power-window lifter, with radio con-

- 0002 Control unit without power-window lifter, with radio con-

Program

number

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

Control unit function

control and without alarm function

LHD

trol without alarm function

LHD

trol and alarm function (with interior monitoring) without

alarm system with independent power supply

LHD

trol and alarm function (with interior monitoring) and

alarm system with independent power supply

LHD

Control unit with 2 power-window lifters, without radio

control and alarm function

LHD

Control unit with 2 power-window lifters, with radio control and without alarm function

LHD

Control unit with 2 power-window lifters, with radio control and alarm function (with interior monitoring) and

alarm system with independent power supply

LHD

S00.5319.15.20

Self-diagnosis for convenience system with CAN databus cableEdition 01.05

01-2 page 1

Page 24

01

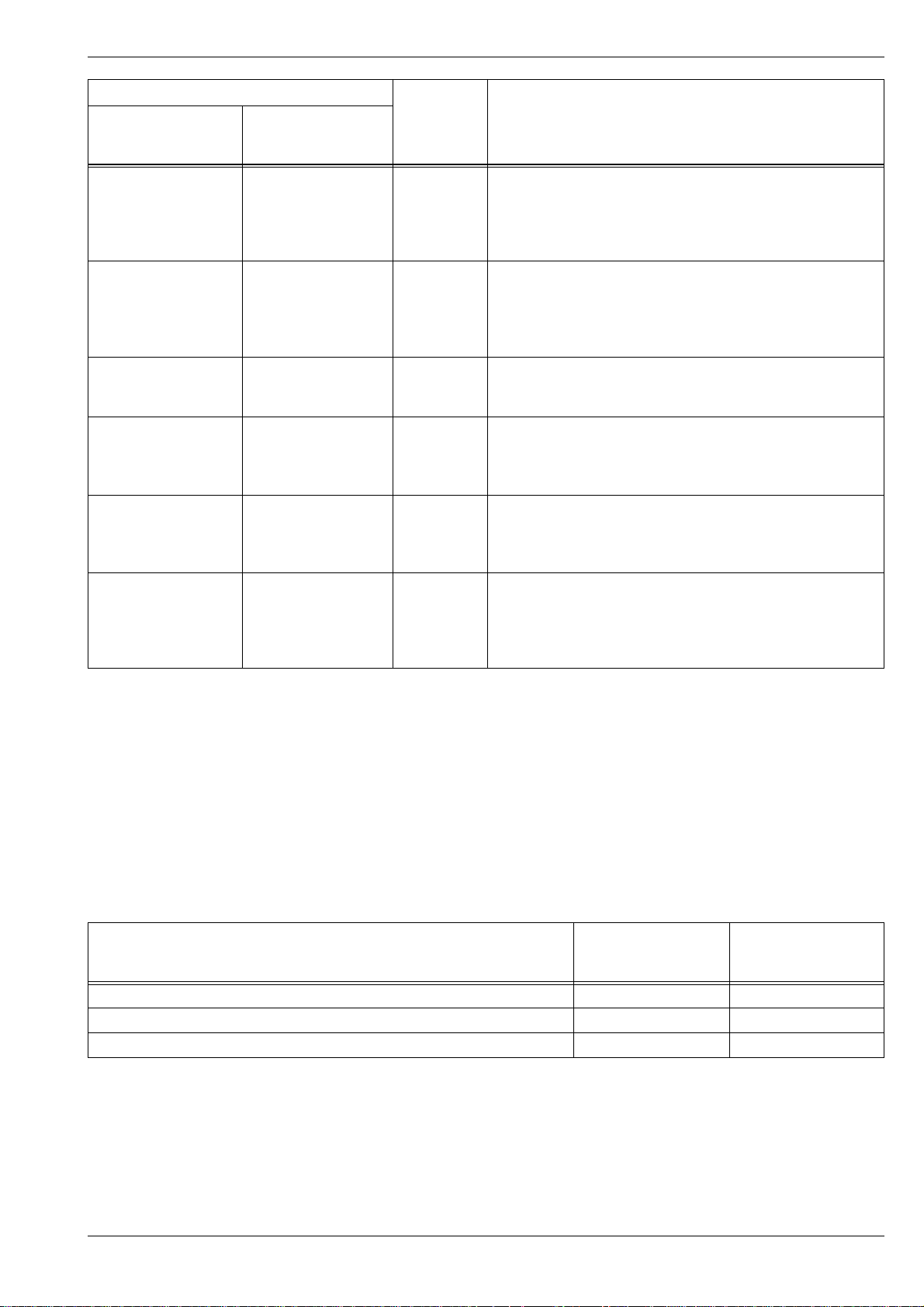

FABIA 2000 ³ Body Work

Control unit part No.

Central control

unit for convenience system

6Q0959433C OL

6Q0959433E OL 6Q1959801 OL

6Q0959433A 05

6Q0959433H 2R 6Q1959801 05/2R

6Q0959433C 07

6Q0959433E 2T 6Q1959801 07

6Q0959433C 09

6Q0959433E 2V 6Q1959801 09/2V

6Q0959433C OM

6Q0959433E OM 6Q1959801 OM

6Q0959433A 0A

6Q0959433H 2E

6Q0959433C 0B

6Q0959433E 2X

6Q0959433F 2X

6Q0959433C 0C

6Q0959433E 2Y

6Q0959433A 0D

6Q0959433H 2Z 6Q1959801 0D/2Z

6Q0959433C 0F

6Q0959433E 31

6Q0959433F 31

6Q0959433C 0H

6Q0959433H 33 6Q1959801 0H/33

6Q0959433A 0E

6Q0959433H 30 6Q1959801 0E30

6Q0959433C 0G

6Q0959433E 32

6Q0959433F 32

Door control unit

6Q1959802 OL

6Q1959802 05/2R

6Q1959811 05

6Q1959812 05

6Q1959802 07/2T

6Q1959811 07/2T

6Q1959812 07

6Q1959802 09/2V

6Q1959811 09/2V

6Q1959812 09/2V

6Q1959 02 OM

6Q1959811 OM

6Q1959812 OM

6Q1959802 0D/2Z

6Q1959801 0F/31

6Q0959802 0F/31

6Q0959802 0H/33

6Q1959802 0E/30

6Q1959811 0E/30

6Q1959 812 0E/30

6Q1959801 0G/32

6Q1959802 0G/32

6Q1959811 0G/32

6Q1959812 0G/32

1)

- 0002 Control unit without power-window lifter, without radio

- 0002 Control unit without power-window lifter, with radio con-

- 0002 Control unit without power-window lifter, with radio con-

Program

number

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

Control unit function

Control unit with 2 power-window lifters, with radio control and alarm function (with interior monitoring) without

alarm system with independent power supply

LHD

Control unit with 4 power-window lifters, without radio

control and alarm function

LHD

Control unit with 4 power-window lifters, with radio control and without alarm function

LHD

Control unit with 4 power-window lifters, with radio control and alarm function (with interior monitoring) and

alarm system with independent power supply

LHD

Control unit with 4 power-window lifters, with radio control and alarm function (with interior monitoring) without

alarm system with independent power supply

LHD

control and without alarm function

RHD

trol and without alarm function

RHD

trol and alarm function (with interior monitoring) and

alarm system with independent power supply

RHD

Control unit with 2 power-window lifters, without radio

control and alarm function

RHD

Control unit with 2 power-window lifters with radio control and without alarm function

RHD

Control unit with 2 power-window lifters, with radio control and alarm function (with interior monitoring) and

alarm system with independent power supply

RHD

Control unit with 4 power-window lifters, without radio

control and alarm function

RHD

Control unit with 4 power-window lifters with radio control and without alarm function

RHD

01-2 page 2

Self-diagnosis for convenience system with CAN databus cable Edition 01.05

S00.5319.15.20

Page 25

FABIA 2000 ³ Body Work

01

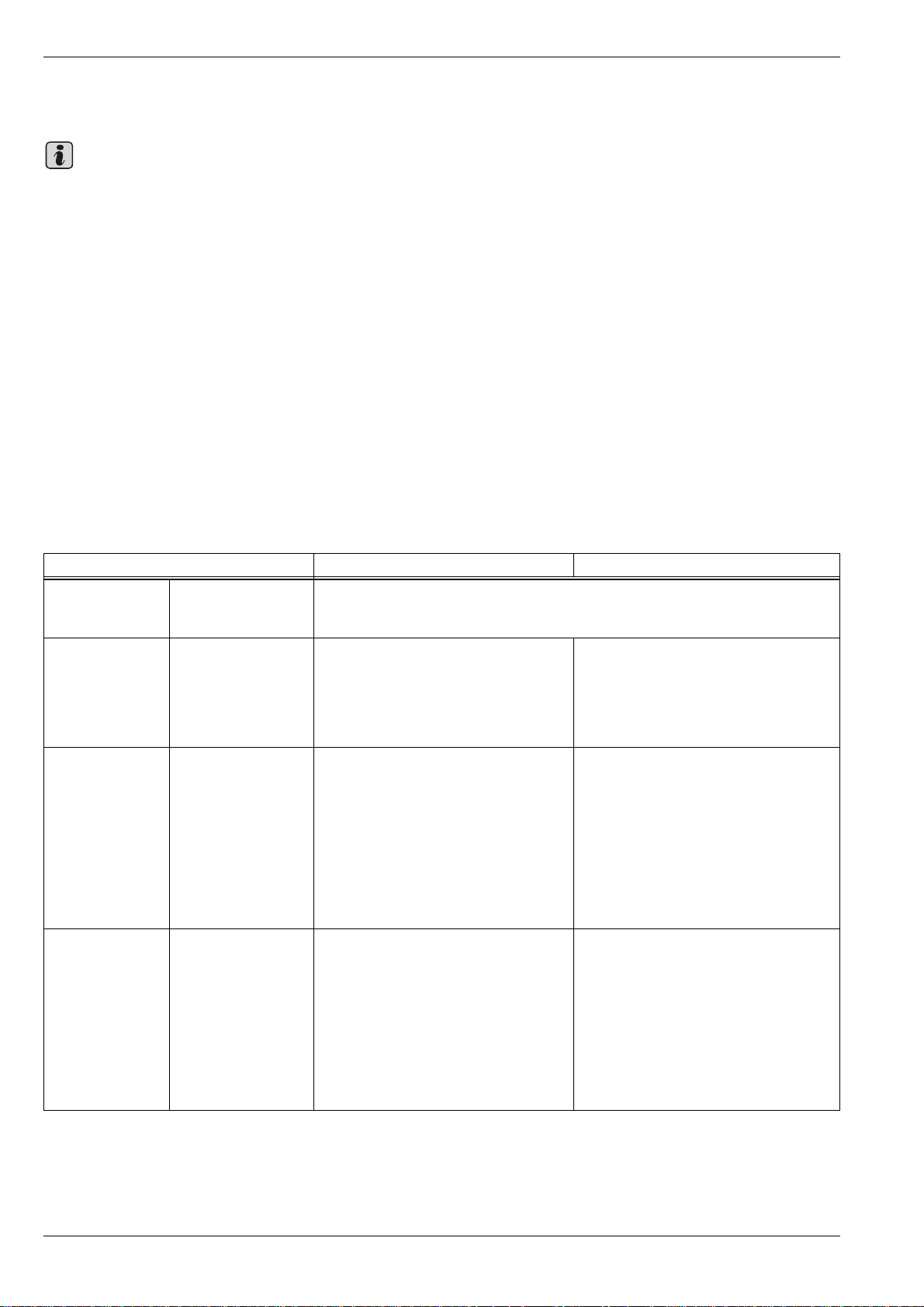

Control unit part No.

Central control

unit for convenience system

6Q0959433C 0J

6Q0959433E 34 6Q1959801 0J/34

6Q0959433C 0N

6Q0959433G 3B 6Q1959801 09/3B

6Q0959433G 36

6Q0959433 F 37 0002

6Q0959433F 38

6Q0959433F 39

1)

Current control unit version ⇒ electronic catalogue of original parts

Door control unit

6Q1959802 0J/34

6Q1959811 0J/34

6Q1959812 0J/34

6Q1959802 09/3B

6Q1959811 09/3B

6Q1959812 09/3B

6Q1959801 36

6Q1959802 36

6Q1959801 38

6Q1959802 38

6Q1959801 39

6Q1959802 39

6Q1959811 39

6Q1959812 39

1)

Program

number

0002

TFK 0001

0002

TFK 0001

0002

TFK 0001

TFK 0001

0002

TFK 0001

0002

TFK 0001

Control unit function

Control unit with 4 power-window lifters, with radio control and alarm function (with interior monitoring) and

alarm system with independent power supply

RHD

Control unit with 2 power-window lifters, without radio

control and alarm function

LHD

Control unit with 2 power-window lifters, without radio

control and alarm function

RHD

Control unit without power-window lifter, with 315 MHz

radio control and alarm function (with interior monitoring) and alarm system with independent power supply

RHD

Control unit with 2 power-window lifters, with 315 MHz

radio control and alarm function (with interior monitoring) and alarm system with independent power supply

RHD

Control unit with 4 power-window lifters, with 315 MHz

radio control and alarm function (with interior monitoring) and alarm system with independent power supply

RHD

Coding control unit with CAN databus

cable

– Connecting vehicle system tester -V.A.G 1552- and

selecting function 07 „code control unit“. ⇒ Chap. 01-

1.

– Enter code number following table:

Vehicle equipment Code numbe r indi-

vidual door open-

ing

Central locking without power-window lifter 00018 00019

Central locking with 2 power-window lifters 00066 00067

Central locking with 4 power-window lifters 00258 00259

Code number over-

all door opening

S00.5319.15.20

Self-diagnosis for convenience system with CAN databus cableEdition 01.05

01-2 page 3

Page 26

01

Fault table Convenience system with

CAN databus cable

Note

♦ Below is a list of all possible faults detected by the

central control unit for convenience system -J393- and

displayed on -V.A.G 1552 -, arranged according to

their 5-digit fault code.

♦ SAE code, may be displayed on the right next to the

fault number (e.g. 4214), ignore.

♦ If „Info in literature“ appears in the display of the vehi-

cle system tester, look for the text required in the fault

table under the fault code.

♦ After repair always interrogate the fault memory using

vehicle system tester -V.A.G 1552- and erase the

memory.

♦ If parts are output as faulty: First check all cables and

connectors to these components as well as the earth

connections according to the Current Flow Diagram.

Then check whether all plug connections are properly

plugged into the relay plate. Replace the component

only if this test does not reveal any fault. This applies

in particular if faults are shown as „sporadic“ (SP).

FABIA 2000 ³ Body Work

Display on V.A.G. 1552 Possible cause of fault Rectifying fault

65535

no fault detected

00849

S contact on ignition starter

switch D -D-

00912

Switch for FL

window lifter

-E40-

00913

Switch for FR

window lifter,

driver's side

-E81-

undefined switch

status

Implausible signal

Implausible signal

If after repair „No fault detected“ is displayed, the self-diagnosis is completed.

♦ Terminal 15 O.K., S contact de-

fective

♦ Cables or plug connections de-

fective

♦ Cables or plug connections de-

fective

♦ Switch for FL window lifter -E40-

defective at central switch

♦ Switch for FL window lifter -E40-

loose at central switch

♦ Cables or plug connections de-

fective

♦ Switch for FR window lifter -E81-

defective at central switch

♦ Switch for FR window lifter -E81-

loose at central switch

– Reading measured value block

⇒ 01-2 page 16

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check wiring and plug connec-

tions according to the current flow

diagram

– Replace central switch for win-

dow lifter

– Check switch FL fastening

– Reading measured value block

⇒ 01-2 page 16

– Check wiring and plug connec-

tions according to the current flow

diagram

– Replace central switch for win-

dow lifter

– Check switch FR fastening

– Reading measured value block

⇒ 01-2 page 16

01-2 page 4

Self-diagnosis for convenience system with CAN databus cable Edition 01.05

S00.5319.15.20

Page 27

FABIA 2000 ³ Body Work

Display on V.A.G. 1552 Possible cause of fault Rectifying fault

00914

Switch for RL

window lifter,

driver's side

-E53-

00915

Switch for RR

window lifter,

driver's side

-E55-

00928

Locking unit for

CL driver's side

-F220-

00929

Locking unit for

CL front passenger's side

-F221-

Implausible signal

Implausible signal

Implausible signal

wrong equipment

Implausible signal

wrong equipment

♦ Cables or plug connections de-

fective

♦ Switch for RL window lifter -E53-

defective at central switch

♦ Switch for RL window lifter -E53-

loose at central switch

♦ Cables or plug connections de-

fective

♦ Switch for RR window lifter -E55-

defective at central switch

♦ Switch for RR window lifter -E55-

loose at central switch

♦ Locking unit defective

♦ Cables or plug connections de-

fective

♦ No supply voltage for CL on driv-

er's door

♦ Resistance in the mechanism of

the locking unit and control elements

♦ other locking unit type fitted

♦ Locking unit defective

♦ Cables or plug connections de-

fective

♦ No supply voltage for CL on pas-

senger's door

♦ Resistance in the mechanism of

the locking unit and control elements

♦ other locking unit type fitted

1)

1)

– Check wiring and plug connec-

tions according to the current flow

diagram

– Replace central switch for win-

dow lifter

– Check switch RL fastening

– Reading measured value block

⇒ 01-2 page 16

– Check wiring and plug connec-

tions according to the current flow

diagram

– Replace central switch for win-

dow lifter

– Check switch RR fastening

– Reading measured value block

⇒ 01-2 page 16

– Reading measured value block

⇒ 01-2 page 16

– Replace locking unit

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check supply voltage

– Check mechanism and ensure

smooth operation

– Replace locking unit

– Reading measured value block

⇒ 01-2 page 16

– Replace locking unit

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check supply voltage

– Check mechanism and ensure

smooth operation

– Replace locking unit

01

S00.5319.15.20

Self-diagnosis for convenience system with CAN databus cableEdition 01.05

01-2 page 5

Page 28

01

Display on V.A.G. 1552 Possible cause of fault Rectifying fault

00930

Locking unit for

RL CL -F222-

00931

Locking unit for

CL rr -F223-

00932

Window lifter

motor driver's

side -V147-

00933

Window lifter

motor passenger's side

-V148-

Implausible signal ♦ Locking unit defective

♦ Cables or plug connections de-

fective

♦ No supply voltage for CL on rear

left door

♦ Resistance in the mechanism of

the locking unit and control elements

wrong equipment

Implausible signal

wrong equipment

No setting or incor-

rect setting

No setting or incorrect setting

♦ other locking unit type fitted

♦ Locking unit defective

♦ Cables or plug connections de-

fective

♦ No supply voltage for CL on rear

right door

♦ Resistance in the mechanism of

the locking unit and control elements

♦ other locking unit type fitted

♦ missing or incorrectly set window

lifter mechanism

♦ Window lifter motor driver's side

-V147- defective

♦ Cables or plug connections de-

fective

♦ No supply voltage for CL on driv-

er's door

♦ Resistance in window lifter

mechanism

♦ missing or incorrectly set window

lifter mechanism

♦ Window lifter motor passenger's

side -V148- defective

♦ Cables or plug connections de-

fective

♦ No supply voltage for CL on pas-

senger's door

♦ Resistance in window lifter

mechanism

2)

2)

– Reading measured value block

– Replace locking unit

– Check wiring and plug connec-

– Check supply voltage

– Check mechanism and ensure

1)

– Replace locking unit

– Reading measured value block

– Replace locking unit

– Check wiring and plug connec-

– Check supply voltage

– Check mechanism and ensure

1)

– Replace locking unit

– Initialisation for automatic lift/low-

– Replace window lifter motor driv-

– Check wiring and plug connec-

– Check supply voltage

– Check mechanism and ensure

– Initialisation for automatic lift/low-

– Replace window lifter motor pas-

– Check wiring and plug connec-

– Check supply voltage

– Check mechanism and ensure

FABIA 2000 ³ Body Work

⇒ 01-2 page 16

tions according to the current flow

diagram

smooth operation

⇒ 01-2 page 16

tions according to the current flow

diagram

smooth operation

er lift mechanism

er's side -V147-

tions according to the current flow

diagram

smooth operation

er lift mechanism

senger's side -V148-

tions according to the current flow

diagram

smooth operation

01-2 page 6

Self-diagnosis for convenience system with CAN databus cable Edition 01.05

S00.5319.15.20

Page 29

FABIA 2000 ³ Body Work

Display on V.A.G. 1552 Possible cause of fault Rectifying fault

00934

Window lifter

motor rl -V26-

00935

Window lifter

motor RR -V27-

00936

Window lifter

switch passenger's side

-E107-

00937

Window lifter

switch RL -E52-

00938

Window lifter

switch RR -E54-

No setting or incorrect setting

No setting or incorrect setting

Implausible signal

♦ missing or incorrectly set window

lifter mechanism

♦ Window lifter motor RL -V26- de-

fective

♦ Cables or plug connections de-

fective

♦ No supply voltage for CL on rear

left door

♦ Resistance in window lifter

mechanism

♦ missing or incorrectly set window

lifter mechanism

♦ Window lifter motor RR -V27-

defective

♦ Cables or plug connections de-

fective

♦ No supply voltage for CL on rear

right door

♦ Resistance in window lifter

mechanism

♦ Window lifter switch passen-

ger's side -E107- defective

♦ Cables or plug connections de-

fective

♦ Window lifter switch passen-

ger's side -E107- loose

♦ Window lifter switch RL -E52-

defective

♦ Cables or plug connections de-

fective

♦ Window lifter switch RL -E52-

loose

♦ Window lifter switch RR -E54-

defective

♦ Cables or plug connections de-

fective

♦ Window lifter switch RR -E54-

loose

2)

2)

– Initialisation for automatic lift/low-

er lift mechanism

– Replace window lifter motor RL

-V26-

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check supply voltage

– Check mechanism and ensure

smooth operation

– Initialisation for automatic lift/low-

er lift mechanism

– Replace window lifter motor RR

-V27-

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check supply voltage

– Check mechanism and ensure

smooth operation

– Replace window lifter switch pas-

senger's side -E107-

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check switch fastening

– Reading measured value block

⇒ 01-2 page 16

– Replace window lifter motor RL

-E52-

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check switch fastening

– Reading measured value block

⇒ 01-2 page 16

– Replace window lifter switch RR

-E54-

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check switch fastening

– Reading measured value block

⇒ 01-2 page 16

01

S00.5319.15.20

Self-diagnosis for convenience system with CAN databus cableEdition 01.05

01-2 page 7

Page 30

01

Display on V.A.G. 1552 Possible cause of fault Rectifying fault

00939

Replace mirror

adjustment motor driver's side

-V149-

00940

Mirror adjustment motor passenger's side

-V150-

00948

Close sliding

roof signal

Short circuit to positive

♦ Replace mirror adjustment motor

driver's side -V149- defective

♦ Cables or plug connections de-

fective

♦ No supply voltage on driver's

door

♦ Replace mirror adjustment motor

passenger's side -V150- defective

♦ Cables or plug connections de-

fective

♦ No supply voltage on passen-

ger's door

♦ Cables or plug connections de-

fective

♦ Sliding roof switch defective

– Replace mirror adjustment motor

– Check wiring and plug connec-

– Check supply voltage

– Replace mirror adjustment motor

– Check wiring and plug connec-

– Check supply voltage

– Check wiring and plug connec-

FABIA 2000 ³ Body Work

Replace driver's side -V149-

tions according to the current flow

diagram

passenger's side -V150-

tions according to the current flow

diagram

tions according to the current flow

diagram

– Replace sliding roof switch

♦ Sliding roof motor defective

– Replace sliding roof motor

00949

Motor for CL

tailgate -V53-,

LOCK

00950

Motor for CL

tailgate -V53-,

UNLOCK

00955

Key 1

00956

Key 2

00957

Key 3

undefined switch

status

undefined switch

status

Adaptation threshold (mul) exceeded

Adaptation threshold (mul) exceeded

Adaptation threshold (mul) exceeded

♦ Motor for CL tailgate defective

♦ Cables or plug connections de-

fective

♦ Resistance in lock control mech-

anism

♦ Motor for CL tailgate defective

♦ Cables or plug connections de-

fective

♦ Resistance in lock control mech-

anism

♦ Key not adapted

♦ Key was operated over 200

times outside the reception

range

♦ Key not adapted

♦ Key was operated over 200

times outside the reception

range

♦ Key not adapted

♦ Key was operated over 200

times outside the reception

range

– Replace motor for CL tailgate

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check lock control mechanism

and ensure smooth operation

– Replace motor for CL tailgate

– Check wiring and plug connec-

tions according to the current flow

diagram

– Check lock control mechanism

and ensure smooth operation

– Reading measured value block

⇒ 01-2 page 16

– Perform adaptation ⇒ Chap. 01-4

– Reading measured value block

⇒ 01-2 page 16

– Perform adaptation ⇒ Chap. 01-4

– Reading measured value block

⇒ 01-2 page 16

– Perform adaptation ⇒ Chap. 01-4

01-2 page 8

Self-diagnosis for convenience system with CAN databus cable Edition 01.05

S00.5319.15.20

Page 31

FABIA 2000 ³ Body Work

Display on V.A.G. 1552 Possible cause of fault Rectifying fault

00958

Key 4

01030

Lock the CL key

switch on the

driver's side

01031

Unlock the CL

key switch on

the driver's side

01032

Lock the CL key

switch on the

passenger's

side

01033

Unlock the CL

key switch on

the passenger's

side

01034

Window lifter:

Activation of

thermo fuse,

driver's side

01035

Window lifter:

Activation of

thermo fuse,

front passenger's side

01036

Window lifter:

Activation of

thermo fuse, RL

Adaptation threshold (mul) exceeded

Short circuit to

earth

Short circuit to

earth

Short circuit to

earth

Short circuit to

earth

♦ Key not adapted

♦ Key was operated over 200

times outside the reception

range

♦ Cables or plug connections de-

fective

♦ Lock cylinder defective

♦ Lock cylinder loose

♦ Cables or plug connections de-

fective

♦ Lock cylinder defective

♦ Lock cylinder loose

♦ Cables or plug connections de-

fective

♦ Lock cylinder defective

♦ Lock cylinder loose

♦ Cables or plug connections de-

fective

♦ Lock cylinder defective

♦ Lock cylinder loose

♦ Cables or plug connections de-

fective

♦ Window lifter mechanism loose

or stiff

♦ Resistance in window lifter motor

♦ Resistance in the window run

during lifting and lowering of

door window

♦ Cables or plug connections de-

fective

♦ Window lifter mechanism loose

or stiff

♦ Resistance in window lifter motor

♦ Resistance in the window run

during lifting and lowering of

door window

♦ Cables or plug connections de-

fective

♦ Window lifter mechanism loose

or stiff

♦ Resistance in window lifter motor

♦ Resistance in the window run

during lifting and lowering of

door window

– Reading measured value block

⇒ 01-2 page 16

– Perform adaptation ⇒ Chap. 01-4

– Reading measured value block

⇒ 01-2 page 16