SKIPPER Electronics AS

Enebakkveien 150 Telephone: +47 23 30 22 70

P. O. Box 151, Manglerud E-mail: support@skipper.no

0612 Oslo Co. reg. no: NO-965378847-MVA

Norway www.skipper.no

Document no: DM-BSB100-SB

Rev 1349A

Date: 2019-02-12

Single Bottom Sea Valve

SB-100-SB

Operation and Installation Manual

Page 2 of 18

Date: 2019-02-12

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Weitergabe sowie vervielfältigung dieser unterlage, verwertung

und mitteilung ihres inhaltes nicht gestattet, soweit nicht

ausdrücklich zugestanden. Zuwiderhandlungen verpichten zu

schadenersatz.

Toute communication ou reproduction de ce document,

toute exploitation ou communication de ou son contenu sont

interdites, sauf autorisation expresse. Tout manquement à

cette règle est illicite et expose son auteur au versement de

dommeges et intèrèts.

Copying of this document, and giving it to others and the use

or communication of contents thereof, are forbidden without

express authority. Offenders are liable to the payment of

damages.

Sin nuestra expresa autorización, queda terminantemente

prohibida la reproducción total o parcial de este documento,

asì como su uso indebido y/o su exhibición o comunicación

a terceros. De los infractores Se exigirá el correspondiente

resarcimiento de daños y perjuicios.

Page 3 of 18

Date: 2019-02-12

Contents

1. INSTALLATION .............................................................................................................................4

2. SPACE CONSIDERATIONS ..........................................................................................................6

3. WELDING THE BOTTOM FLANGE ............................................................................................ 7

4. SEA VALVE ASSEMBLY (ORIENTATION NOT NECESSARY). ...............................................8

5. ASSEMBLING OF EXTENSION TUBE AND SENSOR .............................................................9

6. SENSOR INSTALLATION ...........................................................................................................10

7. CLAMP UNIT MOUNTING .........................................................................................................11

8. FINAL ASSEMBLY ......................................................................................................................13

9. SENSOR REMOVAL ....................................................................................................................14

10. RE-INSTALLATION ...................................................................................................................15

11. DB-100 SENSORS ......................................................................................................................16

12. 100 MM SINGLE BOTTOM BALL VALVE .............................................................................17

13. MAINTENANCE ........................................................................................................................18

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual

Page 4 of 18

Date: 2019-02-12

SKIPPER SB (Single Bottom) Sea Valve 100 mm

1. Installation

The SKIPPER SB Sea Valve 100 mm is used for installation of:SKIPPER speed log sensors and Echo

sounder transducers tted with adaptor for XB-100-XX .

Caution!

Be aware that the Sea Valve contains high precision parts and therefore proper

handling when mounting is essential for the nal result.

When handling the Sea Valve, all lifting devices must be attached on the outside of the

valve. It is very important to not insert any chains, wire, rope or any other device into

the valve chamber. This to avoid damaging and any kind of pollution of the Sea Valve.

Caution must be taken when mounting seavalves that all parts are aligned correctly, and that the inside is

clean. DO NOT use liguid sealants, and DO NOT paint the inside of a valve.

The SKIPPER SB Sea Valve 100 mm is delivered partly assembled for transport. The parts necessary for

nal assembly will be found packed in a box delivered with the Sea Valve. First of all, it must be decided

where the Sea Valve should be installed. Normally, this will be in the fore part of the ship, in the centerline,

or as close to the centerline as possible. Optimal system operation is achieved by tting the transducer/

sensor as deep as possible on the hull.

• The active surface of the sensor must be installed with front face a maximum of +/-1 degree to the ships

horizontal plane. (Speed Logs).

• The active surface of the transducer must be installed with front face a maximum of +/-7 degree to the

ships horizontal plane. (Echo Sounder).

Do not mount transducers close to the bow thruster propeller outlets, or aft of other hull installations (outlets,

vents or other protruding details) who may create aeration or turbulence.

It is necessary to select a part of the hull that is submerged and free from turbulence and aeration under all

load and speed conditions, and to avoid positions where air is trapped in heavy weather.

If a at, horizontal section is not available for transducer tting, the shipyard must construct a suitable bed.

Welding seams in this area should be smoothed and rounded off, in order not to create turbulence or aeration

at speed.

Protect the active element of the transducer/sensors during transport and installation, and

do not paint the surface.

The Sea Valve should be placed in a service accessible place, large enough for installation and disassembly

of the sensor unit. See drawing: “Space considerations”.

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Page 5 of 18

Date: 2019-02-12

Important

”Sensors for Speed Log and Echo Sounder are delivered with a xed cable. Attention must be taken

to allow easy replacement/pulling of new cable during maintenance”.

SKIPPER Electronics AS will recommend installation positions if GA-drawings (General

arrangements), lines drawings and frame drawings are made available for study.

Condition.

The welding to hull structures and structural support of the items may be subject to separate approval by

classication societies for each installation on board a ship.

Note: All “Item (X)” references on the following pages, can be found on drawing 100 mm Single Bottom

Ball Valve.

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual

Page 6 of 18

Date: 2019-02-12

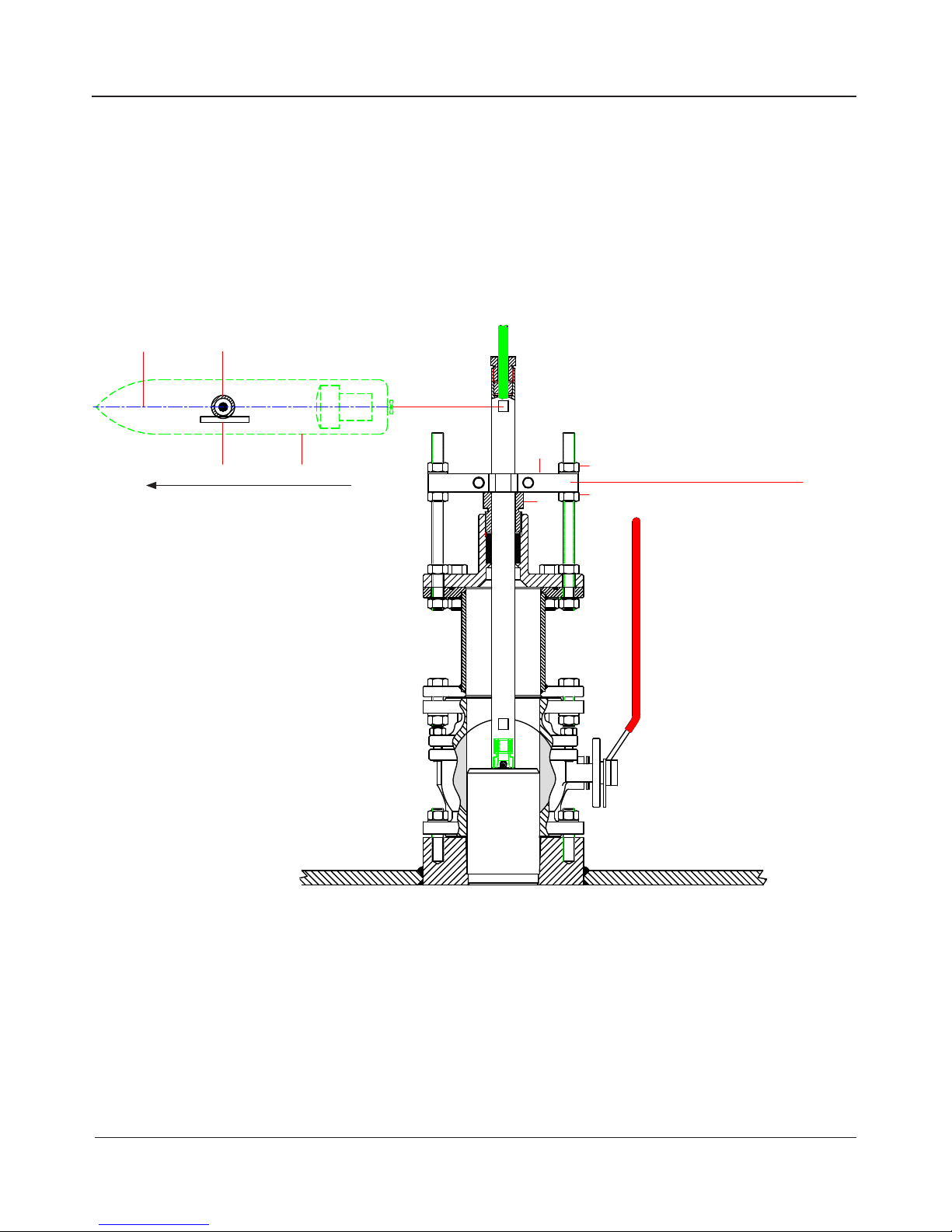

The Sea Valve should be placed in a service accessible place large enough for installation and disassembly

of the sensor unit.

2. Space considerations

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Page 7 of 18

Date: 2019-02-12

8

3. Welding the bottom ange

• When the position has been decided, a 220 mm hole is cut in the hull.

• The bottom ange, Item (1), is welded into the hull. Standard welding practice, methods and procedures

should be observed, but may vary. (See welding notes).

Attention:

The bottom ange is a part of the Sea Valve that is machined with high accuracy and it should be

protected after mounting to avoid damage to the bottom ange surfaces. This to avoid leakage. If the

valve is pre-mounted, be sure to protect the valve from being polluted by welding debris.

WELDING NOTES!

All bottom parts and anges for welding are precisely machined parts. During welding of these parts

to the ship’s hull plates, careful attention must be paid to avoid construction strain on the bottom

parts and anges.

• Let parts cool down during welding.

• Over heating may change t and form and result in non-conformity with intended sensor/

transducer.

• Welding to thick hull steel plates will exert high stress on bottom parts and anges.

• Especially care must be taken during welding of stainless steel anges.

• Work must be performed by a qualied and certied welder.

Welding the bottom ange in ship’s hull.

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual

Page 8 of 18

Date: 2019-02-12

4. Sea Valve Assembly (Orientation not necessary).

Step 1

• Place 1.5 mm gasket, on top of Bottom Flange.

• Then place the Ball Valve element on top of the Bottom Flange. The 16 mm nuts and washers should be

mounted, not tightened.

• Place a 1.5 mm gasket on top of the Ball Valve element.

• Mount the intermediate element on top of the Ball Valve element. The track for o-ring to be upwards.

• All 8 nuts and washers should be mounted, not tightened.

Step 2

• Place the plastic alignment tube, all the way, into the sea valve.

• Tighten 8 nuts ball valve to bottom ange.

• Tighten 8 nuts Intermediate element to ball valve.

• Remove the plastic alignment tool.

Caution must be taken when mounting seavalves that all parts are aligned correctly, and that the inside is

clean. DO NOT use liguid sealants, and DO NOT paint the inside of a valve.

Step 1

Step 2

Intermediate element

Ball valve

Plastic alignment tube

Bottom ange

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Page 9 of 18

Date: 2019-02-12

5. Assembling of Extension Tube and Sensor

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual

Page 10 of 18

Date: 2019-02-12

Sensor installation

• Place the O-ring, Item (36) in the groove on

top of the intermediate element, Item (7).

• Apply grease to the O-ring.

• Insert the 2 thread bolts, Item (11) through

the ange and secure with 2 x M16 counter

nuts, Item (28).

• Torque 130 Nm.

• Lower the sensor housing carefully down

to the top of the valve piston.

6. Sensor installation

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Page 11 of 18

Date: 2019-02-12

Clamp Unit mounting

Mount Top Flange, Item (8). Secure with 8 washers, Item (29) and nuts, Item (28). Torque: 130 Nm.

Mount in following order:

• 2 x gasket, Item (12).

• Washer, Item (17).

• Nut M50, Item (13).

• 2 x M16 nuts, Item (28 ).

• Clamp Unit, Item (10).

• 2 x M16 nuts, Item (28) with spring washer, Item (29).

7. Clamp Unit mounting

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual

Page 12 of 18

Date: 2019-02-12

• Open Ball Valve piston, lower sensor unit.

• Tighten up the 2 x screw M8, Item (31).

• Open Sea Valve, lower sensor unit and

Extension Tube.

• Rotate the Extension Tube to align the

sensor to point forward (ahead), (only

needed for Speed Log).

• Use the attened area on the Extension

Tube to nd correct direction. (See g.

8 Final Assembly.

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Page 13 of 18

Date: 2019-02-12

Check that the transducer sensor housing, when fully inserted, is ush with the lower surface of the bottom

ange.

After the ship is aoat, it is necessary to let the air out of the Sea Valve:

• Loosen the nut M50, let the air out and tighten nut again.

Protect sensor!

• When launching ship, lift sensor 50 mm.

• When dry docking ship, lift sensor 50 mm.

Forward (Ahead)

8. Final assembly

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual

Page 14 of 18

Date: 2019-02-12

9. Sensor removal

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Page 15 of 18

Date: 2019-02-12

Reinstallation

Same procedure as first-time mounting.

1. Tighten the Nut M50, Item (13), Torque : 98 Nm.

2. Push down the Clamp Unit, Item (10) onto the Nut M50.

and tighten the 2 screws M8 (with lock washer).Torque : 40Nm

3. Screw the 2 Nuts M16 sligtly up to the Clamp Unit.

4. Tighten the 2 Nuts M16 (with lock washer) on

1

2

3

4

Mounting order Nut M50 and Clamp Unit :

the opposite side: Torque : 130 Nm

The Clamp Unit must be fitted on Top of Nut M50

to lock the Nut.

(This is done to give extra security.)

Extension TubeCentre Line

Guide Bar Ship

Forward (Ahead)

10. Re-installation

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual

Page 16 of 18

Date: 2019-02-12

Cover

Press Element

Housing

DB-2023-Rev-02

DB-2041-Rev-02

DB-2022-Rev-00

Ring J90 DIN 472 A4 St.steel

ETN050BEL 50kHz 25m cable

ETN050G 50kHz 25m cable

Screw M5 x 20 DIN 912(4x)

EML224 Sensor

DB-2047-Rev-01

Ahead

Electro magnectic log sensor

AA

Cross-cut A-A

Ahead

Notice

Stud hole M4

O-ring 59,69mm x 5,33

Before inserting the Sensor, be sure

that the Ahead Mark is in rihgt position.

Cover

Press Element

Housing

DB-2023-Rev-02

DB-2049-Rev-01

DB-2022-Rev-00

Ring J90 DIN 472 A4 St.steel

ETN050BELX 50kHz 40m cable

ETN050XGI 50kHz 40m cable

Protection Plate DB-2050-Rev-00

TC-2019-Rev-00

DB-2023-Rev-02

DL850S27G-LA

40m

40m

ETN050GI 50kHz 25m cable

ETN050BEL 50kHz 25m cable

ETN200SG 200kHz 25m cable

ETN200FSX 200kHz 40m cable

Transducer for echo sounder

Transducer for echo sounder with Ice Protection

ETN050XG 50kHz 40m cable

ETN200SXG 200kHz 40m cable

ETN050BELX 50kHz 40m cable

ETN200FS 200kHz 25m cable

Doppler log sensor

EML224SDB-SB

All units premounted by Skipper Electronics

Ahead

Notice

Stud hole M4

Ahead

Scale: 2:1

DL850S27G-SA

Washer M5 DIN127B

Grease on O-ring

Lock Nut M8 DIN 985 St.steel A4(2x)

SB-3029- REV-00

11. DB-100 Sensors

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Page 17 of 18

Date: 2019-02-12

12. 100 mm Single Bottom Ball Valve

F

1

E

D

32

C

B

A

1

2 3

4

File name

Title/Name, designation, material, dimension etc

Checked by

Itemref

Designed by

Quantity

76

Approved by - date

8

Article No./Reference

Date

Draw. Edition

Sheet

Scale

F

E

D

5

RevNo

Revision note

6 7

C

B

Checked

8

Date

Signature

A

Revision

SB-100-XB

SKIPPER Electronics AS

VF

A.Matre

2007.05.07

Illustrated parts list SB-100-SB

162

190

685

220

22,5°

22,5°

350

65

40

01

02

14

30

31

32

16 14

15

13 12

17

36

0810

11

2928 06 07

15

181833

Weight: 59 kg

(Complete with 0,5 meter

Extention Tube)

Handle location

A

View A

EN10204, 3.1

AISI 316L/WNO 1.4404

SB-2019-00

1

DB-2042-00

Gasket

2

1

DB-2040-00

Washer

DB-2039-00Nut M28

DB-2038-00Gasket

DB-2037-00

Washer

DB-2036-00Nut M50

DB-2035-00Gasket

DB-2034-00

DB-2033-00

Clamp Unit

DB-2031-00

Top Flange

DB-2026-01

Extention Tube - 0.5m

DWG. NO.

142

2

2

1

17

16

141315

1

110810

12

18

1

06

1

QTY.

01

IT

Bottom Flange-SB

07

DESCRIPTION

2

36

Spring Washer M8 DIN 127B

A4 St.steel

2

2

A4 St.steel

Screw M8 x 30 DIN 933

Material

A4 St.steel

Screw M4 x 8 DIN 7991

30

32

O-ring 139,29 x 3,53 Nitril (NBR 70 shore)

1

31

A4 St.steel

Spring Washer M16 DIN 127B

28

29

A4 St.steel

Nut M16 DIN934

30

DESCRIPTION

28

QTY.

40

1

Ball Valve Element

02 1

DB-100-Sensors

DB-2046-01

1

Intermediate Element

DB-2051-00

33

14

Screw M16 x 50 DIN 933

A4 St.steel

A4 St.steel

EM

SB-2019

DB-2042

DB-2040

DB-2039

DB-2038

DB-2037

DB-2036

DB-2035

DB-2034

DB-2033

DB-2031

DB-2026

DL850S27G

DB-2051

PART. NO

IT

EM

*

***

* *

*

*

*****

ZCC-01015

ZOA-01024

ZOA-01075

ZOA-01083

ZOA-01069

ZOA-01035

ZOA-01091

*) Mounted partly on Valve or in mounting Kit: SB-100-XB-M-KIT

02

2019.02.11

01

*

Thread Bolt

) Spare parts in service Kit: Module-SB-DB-S-KIT.1042A

SKIPPER Electronics AS

SB-100-SB Operation and Installation Manual

Page 18 of 18

Date: 2019-02-12

There are two areas to consider maintenance:

1: Speed log performance may be effected by growth, shell, etc on sensor head.

Sensors may need carefully cleaned for growth to regain performance.

2: Sea valves consist of moving mechanical parts.

Greasing of mechanical parts may be considered to ensure operation and avoid corrosion.

Sea valves installed in wet areas (ballast tank etc) should be regularly inspected and greased.

Maintenance Tasks for inactive sensors

(If the system is to be off / and the vessel static for over 6 months (cold water), 3 months warm water).

When closing the vessel.

• Turn off unit at power, both Display and transceiver.

• Mark the alignment of the sensor on the gate valve and sensor ange/pole.

• Lift the sensor into the gate valve and close the valve.

• Grease the valves external moving parts

When restarting

• Heat the areas containing display, to allow condensation to evaporate.

• Lift and inspect the sensor head (or send diver). Carefully clean away growth.

• Redeploy the sensor taking care with alignment.

• Start the system.

• On rst test, check alignment (Head Err in the calibration screen).

Dry docking in temperatures below freezing point

If vessel is to be dry docked in temperatures below freezing point water remained inside sea valve may cause

damage to sea valve or sensor/transducer.

13. Maintenance

SKIPPER Electronics AS SB-100-SB Operation and Installation Manual

Loading...

Loading...