REVISED 16. JUNE. 2017

SKIPIO

Commercial Refrigerators & Freezers

User Manual

REACH-IN (UPRIGHT)

SRT, SFT & SRFT series

Chiller, Freezer & Dual Temperature

Turbo Air Warranty

WARRANTY CLAIMS – The user must report to its dealership, hence the dealer

can accumulate all pertinent information supporting the existence of the alleged

defect.

TWO YEARS PARTS & LABOUR WARRANTY

Turbo Air warrants to the original purchaser of every new Turbo Air refrigerated unit, the cabinet

and all parts thereof, to be free from defects in material or workmanship, under normal use and

service, for a period of two (2) year from the date of original installation.

Any parts covered by this warranty that are examined and determined by Turbo Air to have been

defective within two (2) year of original installation shall be repaired or replaced as stated below.

Turbo Air shall be deemed to have full complied with its obligation under the foregoing warranties

by electing either one of the following procedures, at the sole discretion of Turbo Air:

(a) Furnishing a replacement part, freight collect, in even exchange for the returned part,

freight collect;

(b) Receiving the defective part, freight collect; repairing it, freight collect.

What is NOT covered by this warranty?

Turbo Air’s sole obligation under this warranty is limited to either repair or replacement of parts,

subject to the additional limitations below. This warranty neither assumes nor authorizes any

person to assume obligations other than expressly covered by this warranty.

1. Warranty is NOT TRANSFERABLE. This warranty is not assignable and applies only in

favour of the original purchaser/user to whom delivered. ANY SUCH ASSIGNMENT OR

TRANSFER SHALL VOID THE WARRANTIES HEREIN MADE AND SHALL VOID ALL

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

REVISED 16. JUNE. 2017

2. NO CONSEQUENTIAL DAMAGES, TURBO AIR IS NOT RESPONSIBLE FOR

ECONOMIC LOSS; PROFIT LOSS OR SPECIAL, INDIRECT, OR CONSEQUENTIAL

DAMAGES, INCLUDING WITHOUT LIMITATION, LOSSES OR DAMAGES ARISING

FROM FOOD OR PRODUCT SPOILAGE CLAIMS WHETHER OR NOT ON ACCOUNT

OF REFRIGERATION FAILURE.

3. ALTERATION, NEGLECT, ABUSE, MISUSE, ACCIDENT, DAMAGE DURING TRANSIT

OR INSTALLATION, FIRE, FLOOD, ACTS OF GOD, TURBO AIR is not responsible for

the repair or replacement of any parts that Turbo Air determines have been subjected after

the date of manufacture to alteration, neglect, abuse, misuse, accident, damage during

transit or installation, fire, flood, or an Act of God.

4. TRANSPORTANTION COSTS – Turbo Air will accept parts covered under this warranty

freight collect, provided that shipment has received prior approval. Turbo Air is not

responsible for any other transportation costs, but will ship freight collect parts either

repaired or replaced under this warranty.

5. Any services from an unauthorized person including owner – Turbo Air will not accept

misuse of display controller which is not mentioned on user manual.

6. Warranty does not cover any services from any unauthorized technician including owner.

7. Consumable parts such as door gaskets, castors, legs, etc. are excluded from the

warranty.

REVISED 16. JUNE. 2017

Contents

1. MODELS ........................................................................ 5

2. INSTALLATION ............................................................. 6

Warning & Safety Instructions ................................................................................................. 6

Installing the Unit ........................................................................................................................... 7

1. Avoid heat source ....................................................................................................................... 7

2. Levelling ......................................................................................................................................... 7

3. Ventilation ...................................................................................................................................... 8

Shelving ................................................................................................................................................ 8

Loading Product ............................................................................................................................... 9

3. OPERATION ......................................................................................................................... 10

Start Up .............................................................................................................................................. 10

Electronic Controller ................................................................................................................... 10

Power On/Off .................................................................................................................................... 11

Lock/Unlock the display controller ...................................................................................... 11

Controller Alarms for users ...................................................................................................... 12

4. SERVICING ........................................................................................................................... 13

Cleaning Cabinet ........................................................................................................................... 13

Cleaning Condenser ..................................................................................................................... 13

Troubleshooting ............................................................................................................................. 14

Model

Type

Config.

Doors

Operating temperature range

SRT25-1

Refrigerator

Solid Door

1

+1°C to +8°C up to 38°C ambient

SRT25-2

Refrigerator

Solid Door

2

SRT45-2

Refrigerator

Solid Door

2

SRT45-4

Refrigerator

Solid Door

4

SRT65-3

Refrigerator

Solid Door

3

SRT65-6

Refrigerator

Solid Door

6

SFT25-1

Freezer

Solid Door

1

-21°C to -12°C up to 38°C ambient

SFT25-2

Freezer

Solid Door

2

SFT45-2

Freezer

Solid Door

2

SFT45-4

Freezer

Solid Door

4

SFT65-3

Freezer

Solid Door

3

SFT65-6

Freezer

Solid Door

6

Model

Type

Config.

Doors

Operating temperature range

SRFT25-2

Dual Temp

Solid Door

2

R-Compartment

+1°C to +8°C up to 38°C ambient

F-Compartment

-21°C to -12°C up to 38°C ambient

SRFT45-2

Dual Temp

Solid Door

2

SRFT45-4

Dual Temp

Solid Door

4

SRFT65-3

Dual Temp

Solid Door

3

SRFT65-6

Dual Temp

Solid Door

6

Model

Type

Config.

Doors

Operating temperature range

SRT25-1G

Refrigerator

Glass Door

1

+1°C to +8°C up to 38°C ambient

SRT45-2G

Refrigerator

Glass Door

2

SRT65-3G

Refrigerator

Glass Door

3

SRT25-2G

Refrigerator

Glass Door

2

SRT45-4G

Refrigerator

Glass Door

4

SRT65-6G

Refrigerator

Glass Door

6

SFT25-1G

Freezer

Glass Door

1

-21°C to -12°C up to 38°C ambient

SFT25-2G

Freezer

Glass Door

2

SFT45-2G

Freezer

Glass Door

2

SFT45-4G

Freezer

Glass Door

4

SFT65-3G

Freezer

Glass Door

3

1.MODELS

UPRIGHT SOLID DOOR

REVISED 16. JUNE. 2017

UPRIGHT SOLID DOOR – Dual Temperature

UPRIGHT GLASS DOOR

REVISED 16. JUNE. 2017

2. INSTALLATION

Warning & Safety Instructions

This appliance conforms to current safety requirements. However, inappropriate use can cause

injury and damage to property.

Do not cover the grilles or block the entry of airflow (condenser) or exhaust of airflow by

placing objects up against the refrigeration unit;

Ensure adequate ventilation provided for the appliance as this is essential to

performance, at least 50 mm from the wall;

Ensure the safe power supply and current draw for the appliance as overload of the

power supply can damage the entire unit;

Ensure to install the appliance indoor;

Avoid damp and dusty environment which may cause electric shock;

Use casters or legs for the unit;

Must disconnect the unit from the power supply prior to cleaning or maintenance;

Ensure not to put hot food in the unit;

Preferred to use the leakage protector to prevent the short circuit;

Ensure not to store volatiles and combustibles inside cabinet.

REVISED 16. JUNE. 2017

Installing the Unit

1. Avoid heat source

Avoid direct sunlight, uneven surface, hot environment beyond recommended ambient

temperature of the cabinet.

The unit must NOT be situated where it is affected by hot air from adjacent equipment as this will

compromise the airflow and performance of the cabinet.

2. Levelling

If the cabinet is installed on an even surface or not levelled, water from condensate tray may

overflow.

Once, water leakage occurs by inappropriate levelling, the unit has to be re-levelled. Turbo Air is

not obligated to provide warranty service in case of operator error.

A spanner and four spacers are included in a package. A scissor jack (car jack) is required to lift

up the cabinet for easy placement of the spacers.

Loosen the screw to provide enough gap for spacers and fasten it.

REVISED 16. JUNE. 2017

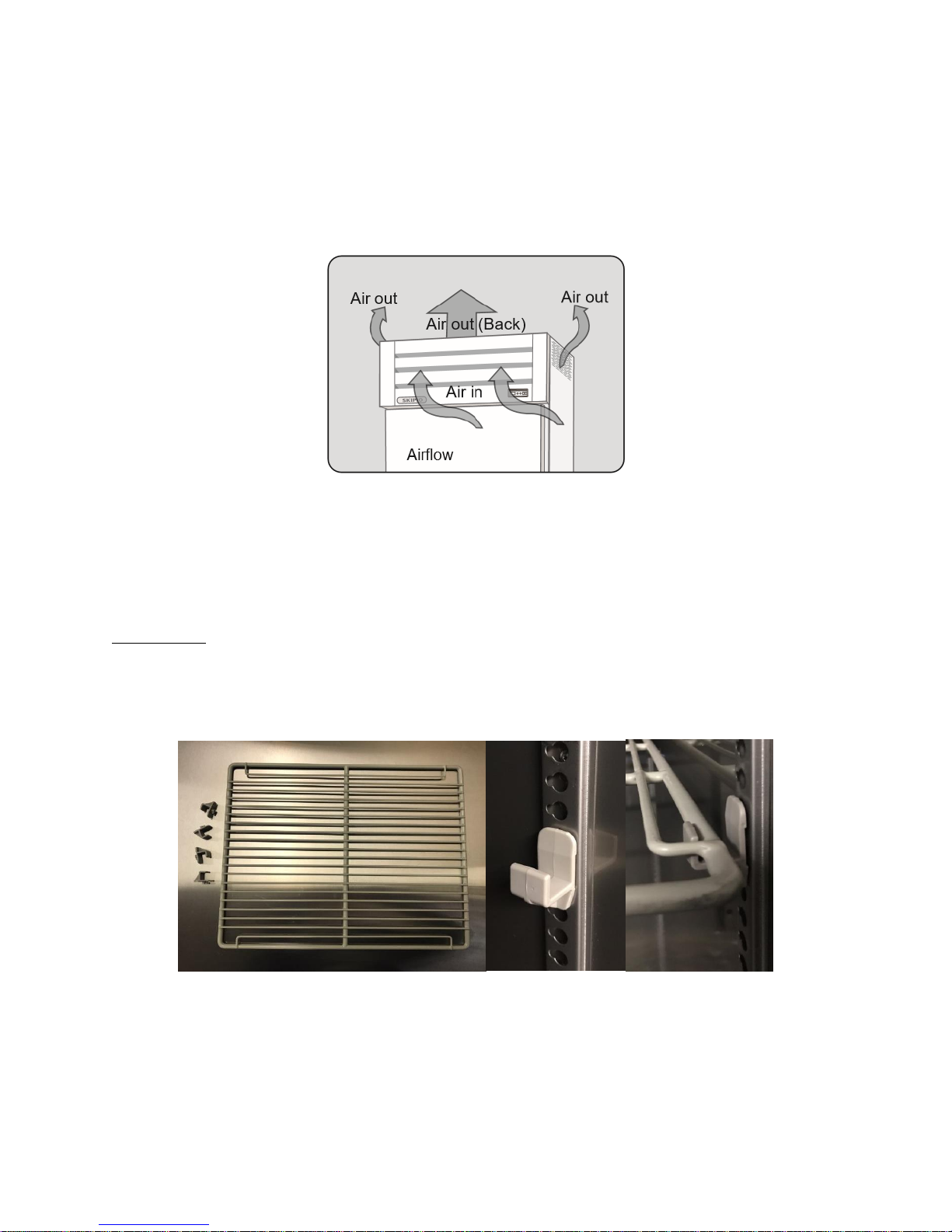

3. Ventilation

Providing an environment with good ventilation prolongs the life of compressor and performance.

Air flows into condenser (front) and the outflow of the used air is exhausted via outlets. For efficient

operation of the cabinet, providing adequate ventilation and ambient temperature (below 38°) is

essential.

Prior to installation of the unit, a gap of at least 50 mm must be left from the walls as outlets of

the used air are located at the back of the unit.

Shelving

Inside the cabinet, there is a shelf package. Remove all packaging material. Each shelf is paired

with 4 support brackets (shelf clips).

The shelves can be positioned at different heights for customer’s preference. Always ensure that

the support brackets are securely engaged in each of the shelf support rail.

It is recommended that the cabinet operates for 30 minutes prior to loading product.

REVISED 16. JUNE. 2017

Loading Product

Do not overload products: a maximum loading of 20kg per shelf

Do not allow products to overhang the front of the shelf which may prevent the door from

shutting

Place products with air space for even cooling and efficient operation

REVISED 16. JUNE. 2017

3.OPERATION

Start Up

Plug into the main power supply and check operation of the unit, front display and lighting. The

compressor and the condenser and evaporator fans should all operate within 2 minutes from the

moment the unit is plugged in. The cabinet light (inside) will go on when a door is opened.

Electronic Controller

Turbo Air electronic controller controls and displays the internal cabinet temperature. For general

operation, no initial setup or additional programing is required. When the cabinet is connected to

the power supply, the current cabinet temperature will be displayed on the electronic controller.

Generally, the compressor and evaporator fan will operate within 2 minutes after power supply to

the cabinet.

1. Electronic controller for freezers (SRT/SFT-series)

Factory setup temperature of SFT-series is - 18°C. By pressing either up or down button, setting

temperature can be adjusted according to customer’s preference.

Factory setup temperature of SRT-series is 2°C. By pressing either up or down button, setting

temperature can be adjusted according to customer’s preference.

REVISED 16. JUNE. 2017

Power On/Off

Plugging into the power automatically turns on the cabinet. There are several ways manually

power on and off while pugging in.

1. There is a power switch located at the top of the cabinet (near condenser).

2. Alternatively, the cabinet can be turned on and off by pressing down button on the front

display for 10 seconds.

Lock/Unlock the display controller

To prevent anyone adjusting setting, press up button for 10 seconds, which will lock the display

controller.

Pressing up button for 10 seconds will unlock the display controller.

REVISED 16. JUNE. 2017

Controller Alarms for users

Electric controller When the inside temperature is lower than - 45°C, the panel will display ‘LO’,

and higher than +18°C, ‘HI’ will be displayed.

Defrost starts when the icing on the evaporator occurs: usually 4 ~ 6 times a day.

It will take 20 ~ 30 minutes to finish defrost. The compressor drops the cabinet temperature down

to further – 7°C on the current setting temperature.

REVISED 16. JUNE. 2017

4.SERVICING

Cleaning Cabinet

Using a damp cloth for cleaning both the interior and exterior of the cabinet is recommended when

it requires. Before cleaning, the cabinet should be disconnected from the power supply.

Cleaning Condenser

Cleaning condenser coils is the most important thing a customer’s can do to maintain a

freezer/refrigerator’s longevity. The condenser coil is located behind the top grile. The condenser

coil must be maintained clean for reliable and efficient operation. Condenser blockage may cause

shortening the life of the compressor and, increasing power consumption.

To ensure trouble free performance, the condenser coil should be brushed once a month.

Easy access to the condenser from the top will allow simple and quick cleaning environment.

As shown the picture above, condenser is located at the top of the unit. A ladder is required to

access to the top of the unit. On the top of the unit there is a cover which can be removed by a

REVISED 16. JUNE. 2017

Issue

Possible cause

Resolution

Warm cabinet temperature

Condenser blockage

Poor ventilation environment

Clean condenser

Provide good ventilation around the side

and back of the unit

Power consumption is higher

than supposed to be

Dirty Condenser

Unit operating in too high temperature

Cabinet doors are opened excessively

Clean condenser

Provide good ventilation around the side

and back of the unit

Keep door/s open for minimum time

Water leakage inside cabinet

Unit is not levelled properly

Level the unit

(Ref: 2 Installation – Levelling)

No power to unit

Unplugged

Accidently turned off via display

(Ref: 3 Operation – Power On/Off)

Power switch off in the condensing unit

(Ref: 3 Operation – Power On/Off)

Plug in

Press down button for 10 seconds

(Ref: 3 Operation – Power On/Off)

Power switch on in the condensing unit

(Ref: 3 Operation – Power On/Off)

Display controller does not

work

Locked (Ref: 3 Operation – Lock/Unlock

the Display Controller)

Press up button for 10 seconds

(Ref: 3 Operation – Lock/Unlock the Display

Controller)

screw driver or a hand drill. Once, open up the top cover, brush the condenser and reassemble

the cover.

Over time, dust may accumulate within the condenser that cannot be removed with a brush. If

this occurs, contact Turbo Air to arrange for a Turbo Air authorized service agent to clean the

condenser with compressed air.

Troubleshooting

Loading...

Loading...