Page 1

Owner’s Manual

Guide d’utilisation

Manual del propietario

Model/ Modelo/ Modèle: ID574401

12V Brushless Impact Driver

Clé à chocs sans balai de 12 V

Destornillador de impacto sin cepillo de 12 V

WARNING: To reduce the risk of injury, the user must read and understand the

Owner’s Manual before using this product. Save these instructions for future reference.

AVERTISSEMENT : Afin de réduire les risques de blessure, l’utilisateur doit lire et

comprendre le guide d’utilisation avant d’utiliser cet article. Conservez le présent guide

afin de pouvoir le consulter ultérieurement.

ADVERTENCIA : Para reducir el riesgo de lesiones, el usuario debe leer y comprender

el Manual del operador antes de utilizar este producto. Guarde estas instrucciones para

consultarlas en caso sea necesario.

For Customer Service

Pour le service à la clientèle

Servicio al cliente

1-877-SKIL-999 OR www.skil.com

TM

Page 2

TABLE OF CONTENTS

General Power Tool Safety Warnings . ............................3-5

Safety Warnings for Impact Driver. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Symbols .....................................................6-9

Get to Know Your Impact Driver ..................................10

Specications .................................................10

Operating Instructions .......................................11-15

Maintenance ...................................................16

Troubleshooting ...............................................16

Limited Warranty of SKIL Cordless Tool ............................17

WARNING

•

Some dust created by power sanding, sawing, grinding, drilling and other construction

activities contains chemicals known to the State of California to cause cancer, birth defects

or other reproductive harm. Some examples of these chemicals are:

–

Lead from lead-based paints.

–

Crystalline silica from bricks, cement, and other masonry products.

–

Arsenic and chromium from chemically-treated lumber.

•

Your risk from these exposures varies, depending upon how often you do this type of work.

To reduce your exposure to these chemicals:

–

Work in a well-ventilated area.

–

Work with approved safety equipment, such as dust masks that are specially designed to

lter out microscopic particles.

–

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and

other construction activities. Wear protective clothing and wash exposed areas with soap

and water. Allowing dust to get into your mouth or eyes or to lie on the skin may promote

absorption of harmful chemicals.

2

Page 3

GENERAL POWER TOOL SAFETY WARNINGS

WARNING

below may result in electric shock, re and/or serious injury.

Read all safety warnings, instructions, illustrations and specications

provided with this power tool. Failure to follow all instructions listed

SAVE ALL WARNINGS AND INSTRUCTIONS FOR FUTURE

REFERENCE.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

Work area safety

Keep work area clean and well lit. Cluttered or dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

ammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

Electrical safety

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tools. Unmodied plugs and matching

outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces, such as pipes, radiators,

ranges and refrigerators. There is an increased risk of electric shock if your body is earthed

or grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or entangled

cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a ground fault circuit

interrupter (GFCI) protected supply. Use of a GFCI reduces the risk of electric shock.

Personal safety

Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the inuence of drugs,

alcohol or medication. A moment of inattention while operating power tools may result in

serious personal injury.

Use personal protective equipment. Always wear eye protection. Protective equipment

such as a dust mask, non-skid safety shoes, hard hat or hearing protection used for

appropriate conditions will reduce personal injuries.

Prevent unintentional starting. Ensure the switch is in the off-position before

connecting to power source and/or battery pack, picking up or carrying the tool.

Carrying power tools with your nger on the switch or energising power tools that have the

switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

3

Page 4

Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of dust collection can reduce dust-

related hazards.

Do not let familiarity gained from frequent use of tools allow you to become complacent

and ignore tool safety principles. A careless action can cause severe injury within a fraction

of a second.

Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source and/or remove the battery pack, if

detachable, from the power tool before making any adjustments, changing accessories,

or storing power tools. Such preventive safety measures reduce the risk of starting the

power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools and accessories. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many accidents are

caused by poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the

power tool for operations different from those intended could result in a hazardous situation.

Keep handles and grasping surfaces dry, clean and free from oil and grease.

Slippery handles and grasping surfaces do not allow for safe handling and control of the tool

in unexpected situations.

Battery tool use and care

Recharge only with the charger specied by the manufacturer. A charger that is suitable

for one type of battery pack may create a risk of re when used with another battery pack.

Use power tools only with specically designated battery packs. Use of any other battery

packs may create a risk of injury and re.

When battery pack is not in use, keep it away from other metal objects, like paper clips,

coins, keys, nails, screws or other small metal objects, that can make a connection

from one terminal to another. Shorting the battery terminals together may cause burns or a

re.

Under abusive conditions, liquid may be ejected from the battery; avoid contact. If

contact accidentally occurs, ush with water. If liquid contacts eyes, additionally seek

medical help. Liquid ejected from the battery may cause irritation or burns.

Do not use a battery pack or tool that is damaged or modied. Damaged or modied

batteries may exhibit unpredictable behaviour resulting in re, explosion or risk of injury.

4

Page 5

Do not expose a battery pack or tool to re or excessive temperature. Exposure to re or

temperature above 265 °F may cause explosion.

Follow all charging instructions and do not charge the battery pack or tool outside the

temperature range specied in the instructions. Charging improperly or at temperatures

outside the specied range may damage the battery and increase the risk of re.

Service

Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

Never service damaged battery packs. Service of battery packs should only be performed

by the manufacturer or authorized service providers.

SAFETY WARNINGS FOR IMPACT DRIVER

Hold the power tool by insulated gripping surfaces, when performing an operation

where the fastener may contact hidden wiring. Fasteners contacting a “live” wire may

make exposed metal parts of the power tool “live” and could give the operator an electric

shock.

5

Page 6

SYMBOLS

Safety Symbols

The purpose of safety symbols is to attract your attention to possible dangers. The safety

symbols and the explanations with them deserve your careful attention and understanding.

The symbol warnings do not, by themselves, eliminate any danger. The instructions and

warnings they give are no substitutes for proper accident prevention measures.

WARNING

“WARNING,” and “CAUTION” before using this tool. Failure to following all instructions listed

below may result in electric shock, re, and/or serious personal injury.

Be sure to read and understand all safety instructions in this Owner's

Manual, including all safety alert symbols such as “DANGER,”

The denitions below describe the level of severity for each signal word. Please read the manual

DANGER

WARNING

CAUTION

and pay attention to these symbols.

This is the safety alert symbol. It is used to alert you to potential

personal injury hazards. Obey all safety messages that follow this

symbol to avoid possible injury or death.

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could

result in death or serious injury.

CAUTION, used with the safety alert symbol, indicates a hazardous

situation which, if not avoided, will result in minor or moderate injury.

Damage Prevention and Information Messages

These inform the user of important information and/or instructions that could lead to equipment

or other property damage if they are not followed. Each message is preceded by the word

“NOTICE”, as in the example below:

NOTICE: Equipment and/or property damage may result if these instructions are not followed.

WARNING

in severe eye damage. Before beginning power tool operation, always

wear safety goggles or safety glasses with side shields and a full face

shield when needed. We recommend a Wide Vision Safety Mask for use

over eyeglasses or standard safety glasses with side shields. Always use

eye protection which is marked to comply with ANSI Z87.1.

The operation of any power tools can result in

objects being thrown into your eyes, which can result

foreign

6

Page 7

SYMBOLS (CONTINUED)

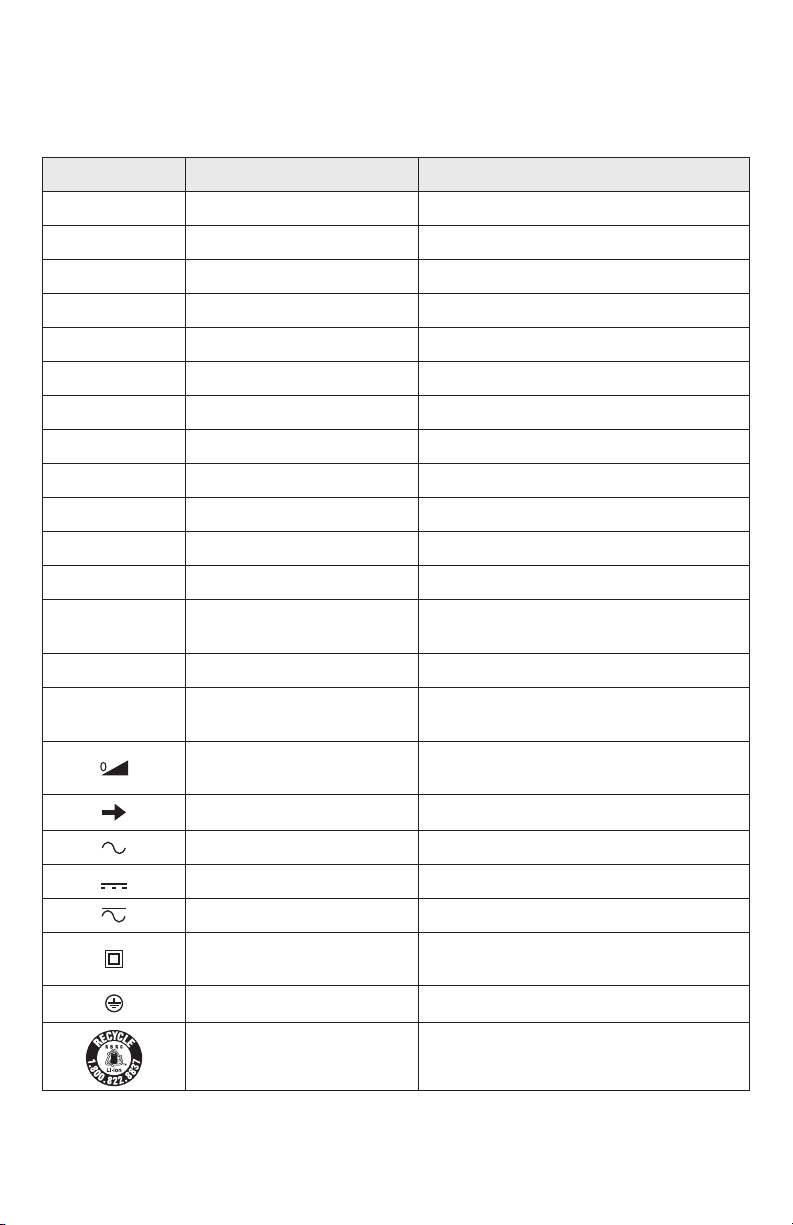

IMPORTANT: Some of the following symbols may be used on your tool. Please study them

and learn their meaning. Proper interpretation of these symbols will allow you to operate the

tool better and more safely.

Symbol Name Designation/Explanation

V Volts Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Wh Watt-hours Battery capacity

Ah Ampere-Hours Battery capacity

Ø Diameter Size of drill bits, grinding wheels, etc.

n

0

n Rated speed Maximum attainable speed

…/min

0 Off position Zero speed, zero torque...

1,2,3,…

I,II,III,

No-load speed Rotational speed, at no load

Revolutions or

reciprocations per minute

Selector settings

Innitely variable selector

with off

Arrow Action in the direction of arrow

Alternating current Type or a characteristic of current

Direct current Type or a characteristic of current

Alternating or direct current Type or a characteristic of current

Class II construction

Earthing terminal Grounding terminal

Li-ion RBRC seal

Revolutions, strokes, surface speed,

orbits, etc. per minute

Speed, torque or position settings. Higher

number means greater speed

Speed is increasing from 0 setting

Designates Double Insulated Construction

tools.

Designates Li-ion battery recycling

program

7

Page 8

Symbol Name Designation/Explanation

Ni-Cad RBRC seal

Read manual symbol Alerts user to read manual

Wear eye protection symbol

Designates Ni-Cad battery recycling

program

Always wear safety goggles or safety

glasses with side shields and a full face

shield when operating this product.

8

Page 9

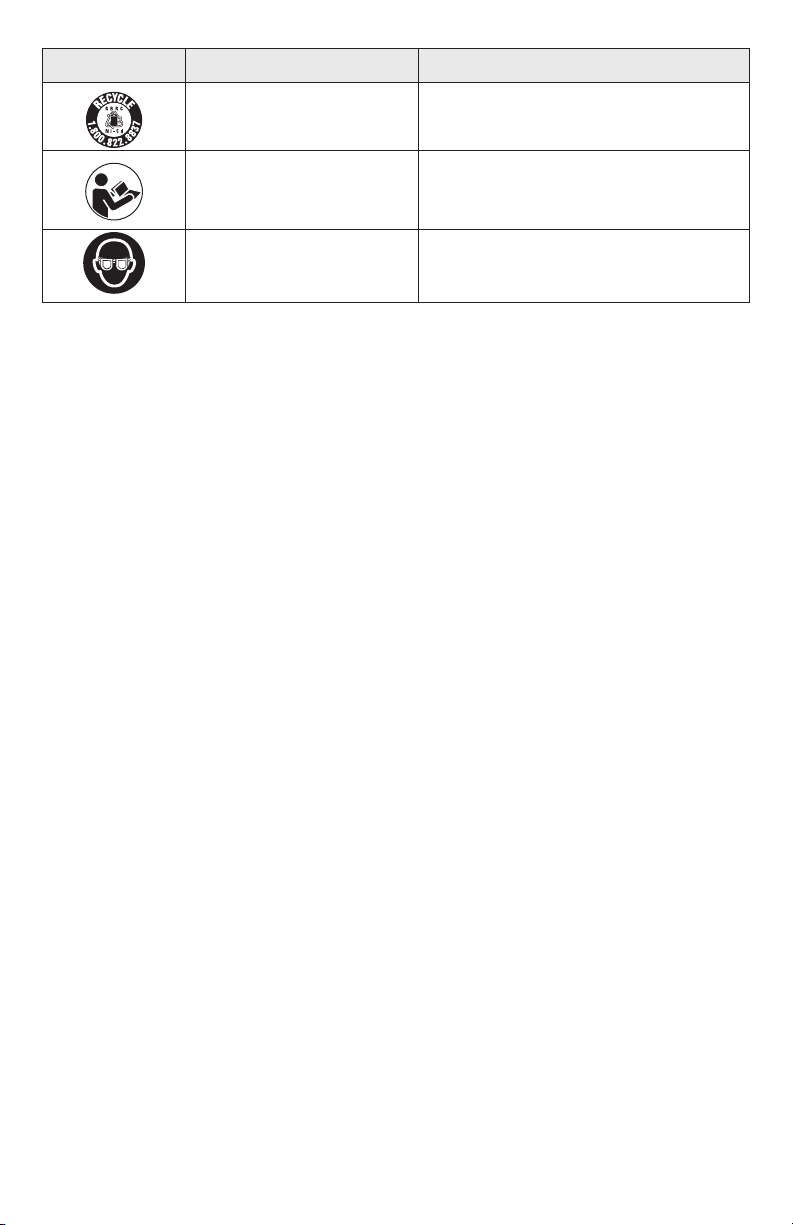

SYMBOLS (CERTIFICATION INFORMATION)

IMPORTANT: Some of the following symbols for certication information may be used on your

tool. Please study them and learn their meaning. Proper interpretation of these symbols will

allow you to operate the tool better and more safely.

Symbol Designation/Explanation

This symbol designates that this tool is listed by Underwriters Laboratories.

This symbol designates that this tool is recognized by Underwriters

Laboratories.

This symbol designates that this tool is listed by Underwriters

Laboratories, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Canadian

Standards Association.

This symbol designates that this tool is listed by the Canadian

Standards Association, to United States and Canadian Standards.

This symbol designates that this tool is listed by the Intertek Testing

Services, to United States and Canadian Standards.

This symbol designates that this tool complies to NOM Mexican

Standards.

9

Page 10

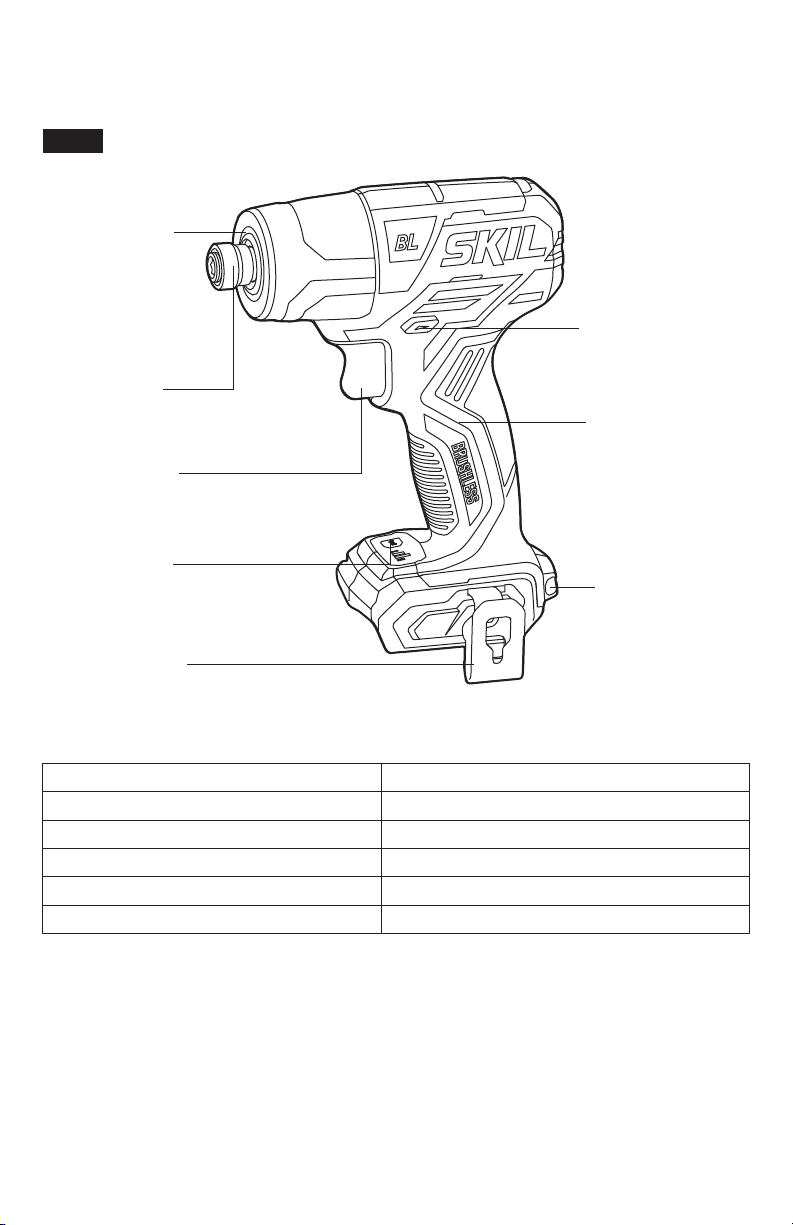

GET TO KNOW YOUR IMPACT DRIVER

12V Brushless Impact Driver

Fig. 1

Halo Light

Quick-change

Collet

Variable-Speed

Trigger Switch

Mode Selector

Direction-of-

Rotation (forward/

center-lock/reverse)

Selector

Soft Grip

Bit Storage Area

Removable Belt

Clip

SPECIFICATIONS

Rated voltage 12V d.c.

Collet size / Type 1/4" Hex

No-load speed 0~1600/0~2600 /min

Impacts per minute 0~2500/0~3500 /min

Recommended working temperature 14~104°F (-10~40

Recommended storage temperature 32~104°F (0~40

10

o

C)

o

C)

Page 11

OPERATING INSTRUCTIONS

WARNING

uid or allow a uid to ow inside them. Corrosive or conductive uids, such as seawater,

certain industrial chemicals, and bleach or bleach-containing products, etc, can cause a short

circuit.

WARNING

could result in serious personal injury.

WARNING

modication is misuse and could result in a hazardous condition leading to possible serious

injury.

WARNING

assembling parts.

This cordless impact driver must be used only with the battery packs and charger listed

below:

To reduce the risk of re, personal injury, and product damage due

to a short circuit, never immerse your tool, battery pack or charger in

If any parts are damaged or missing, do not operate this product until

the parts are replaced. Use of this product with damaged or missing parts

Do not attempt to modify this impact driver or create accessories not

recommended for use with this impact driver. Any such alteration or

To prevent accidental starting that could cause serious personal

injury, always remove the battery pack from the impact driver when

Battery Pack

2Ah 4Ah

SKIL BY500101 SKIL BY519801 SKIL QC535701

NOTICE: Please refer to the battery and charger manual for detailed operating information.

To Attach/Detach Battery Pack

(Fig. 2)

Lock the trigger switch “OFF” on the tool by

placing the direction-of-rotation (forward/

center-lock/reverse) selector in the center

position before attaching or detaching the

battery pack.

To attach the battery pack:

Align the raised rib on the battery pack with the

grooves of the tool, and then slide the battery

pack onto the tool.

NOTICE: Make sure that the latch on the

battery pack snaps into place and that the

battery pack is secured to the tool before

beginning operation.

To detach the battery pack:

Depress the battery-release button located on the front of the battery pack to release the

battery pack. Pull the battery pack out and remove it from the tool.

Charger

Fig. 2

Battery-Release Button

Detach

Attach

11

Page 12

NOTICE: When placing the battery pack in the tool, be sure that the raised rib on battery pack

aligns with the groove inside the tool and that the latches snap into place properly. Improper

attachment of the battery pack can cause damage to internal components.

WARNING

be locked in center position when not in use or carrying at your side.

Battery tools are always in operating condition. Therefore, the Direction-of-Rotation (forward/center-lock/reverse) Selector should always

Direction-of-Rotation (Forward/Center-Lock/Reverse) Selector

WARNING

Your tool is equipped with a direction-of-rotation selector located above the trigger switch. This

selector is designed for changing the direction of rotation of the bit and for locking the trigger

in the “OFF” (center-lock) position.

a. Position the direction-of-rotation selector to the far left of the tool for forward rotation.

b. Position the direction-of-rotation selector to the far right of the tool for reverse rotation.

c. Setting the switch in “OFF” (center-lock) position helps to reduce the possibility of accidental

starting when not in use (Fig. 3).

NOTICE: To prevent gear damage, always allow the impact driver to come to a complete stop

before changing the direction of rotation.

NOTICE: The impact driver will not run unless the direction-of-rotation selector is engaged

fully to the left or right.

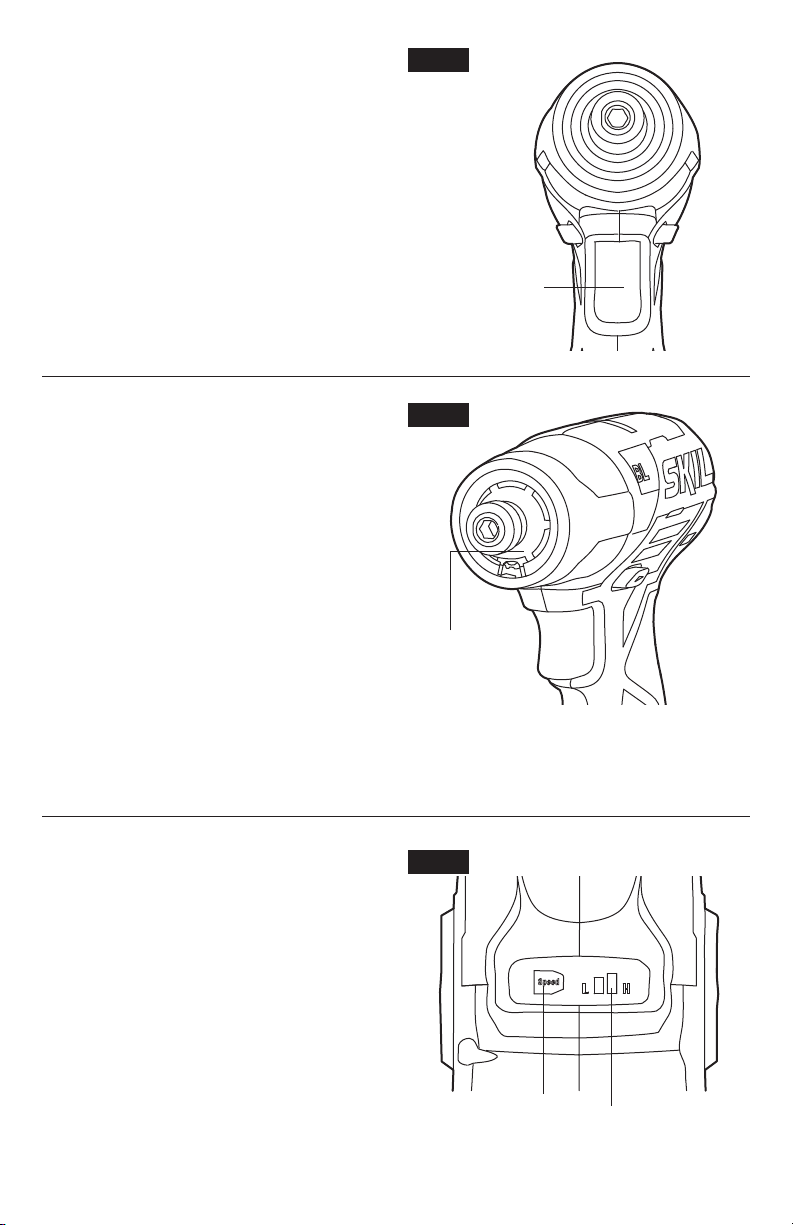

Fig. 3

After tool use, lock the direction-of-rotation selector in the “OFF”

position (center-lock) to help prevent accidental starts and injury.

12

Forward ReverseCenter-Lock

Page 13

Variable-Speed Trigger Switch

Your tool is equipped with a variable-speed

trigger switch. The tool can be turned “ON” or

“OFF” by depressing or releasing the trigger.

The variable-speed trigger switch delivers higher speed with increased trigger pressure and

lower speed with decreased trigger pressure

(Fig. 4).

Fig. 4

Variable Speed

Trigger Switch

Halo Light

Your tool is equipped with a Halo light, located

on the head of the tool, This provides additional light without shadows on the surface of the

work piece for operation in lower-light areas.

The Halo light will automatically turn on with

a slight squeeze on the variable-speed trigger switch before the tool starts running, and

will turn off 8 to 12 seconds after the variable-speed trigger switch is released.

When the tool and/or battery pack becomes

overloaded or too hot, the internal sensors will

turn the tool off. If the tool and/or battery pack

are overloaded, the halo light will ash rapidly.

Rest the tool for a while or place the tool and

battery pack separately under air ow to cool.

The Halo light will ash more slowly to indicate that the battery is at low-battery capacity, Recharge the battery pack.

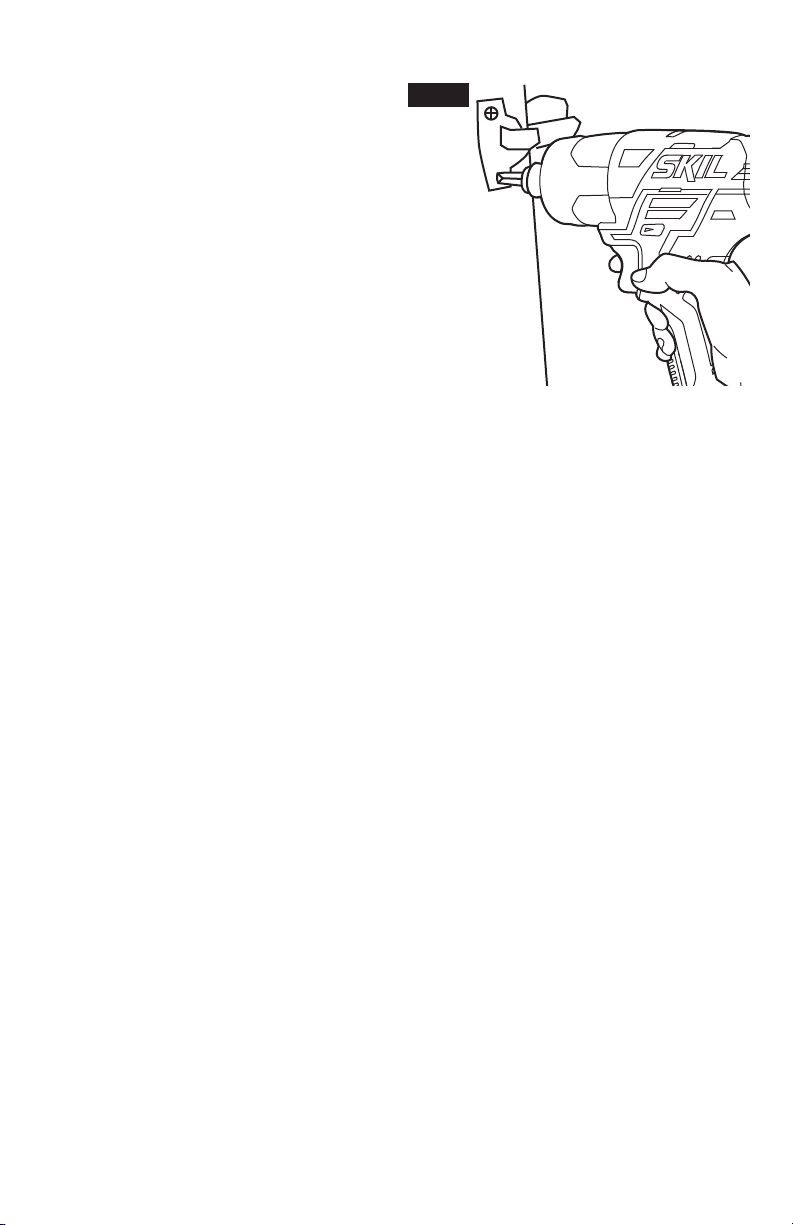

Mode Selector

Your tool is equipped with a speed-adjusting

interface to provide speed adjustment for 2

modes (low/high).

When the trigger is squeezed slightly, the

mode indicator will automatically shine green.

Depress the mode selector to adjust the speed

mode (Fig. 6).

One indicator light shines for “L” to indicate

“low-speed mode”.

Both indicator lights shine for “H” to indicate

“high-speed mode”.

Fig. 5

Halo Light

Fig. 6

Mode Selector Mode Indicator

13

Page 14

The speed mode will be stored and applied in the next operation when the tool is turned on

again or when the direction of rotation has been changed. Reset the speed modes as desired.

NOTICE: To prevent gear damage, always allow the impact driver to come to a complete stop

before changing between high speed and low speed. The speed mode can only be changed

when the mode-indicator light is on and the trigger switch is not depressed. The mode

selector cannot be activated when the motor is running. The mode-indicator light will turn off

automatically in about one minute after operation ceases.

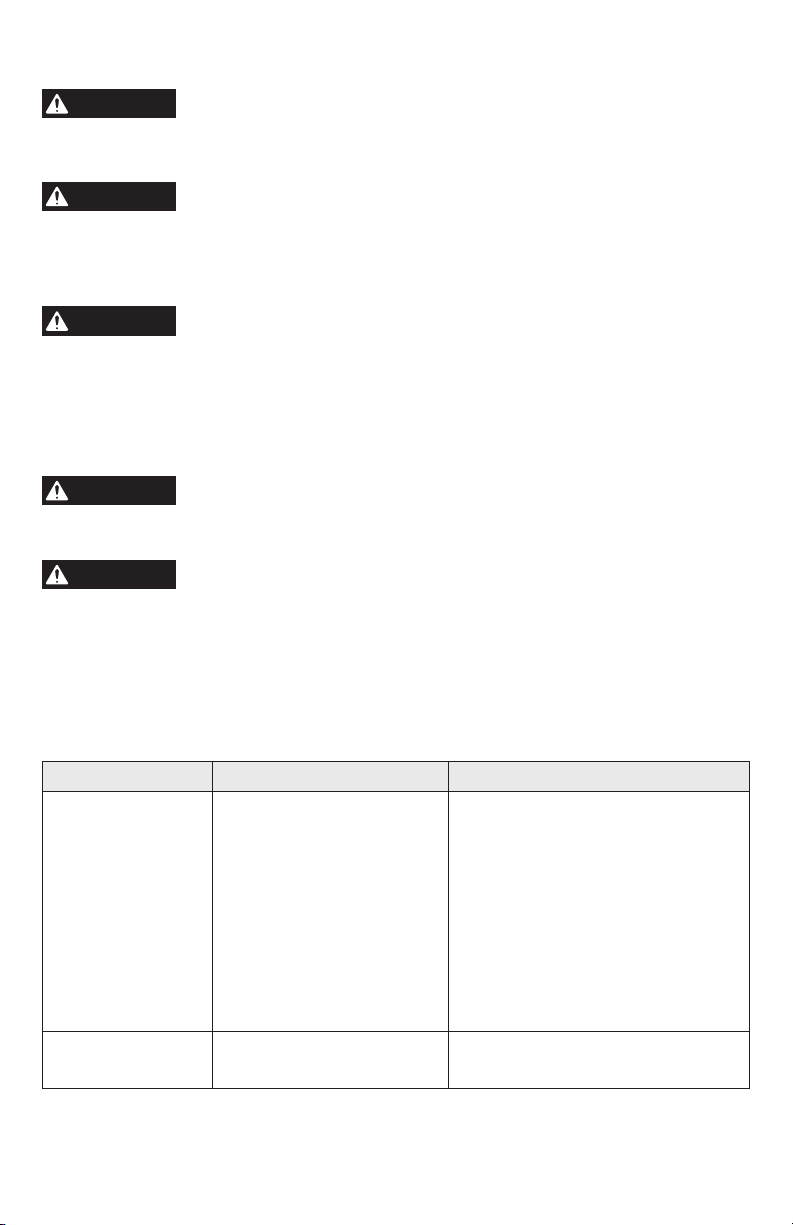

Removable Belt Clip (Fig. 7)

Your tool is equipped with removable belt clip,

which can be positioned on the left side of the

tool for convenient transport.

Install the belt clip onto the tool:

a. Remove the battery pack from the tool.

b. Align the rib of the belt clip with the threaded

hole on the base of the tool.

c. Insert the screw and securely tighten the

screw with a screwdriver.

Remove the belt clip from the tool:

d. Remove the battery pack from the tool.

e. Use a screwdriver to loosen the screw that

attaches the belt clip to the impact driver.

f. Remove the screw and the belt clip.

Install and Remove Bits

Your tool is equipped with a quick -change

collet, making bit installation and removal very

easy.

Lock the trigger switch “OFF” by placing the

direction-of-rotation selector in the center position.

a. To install the bit:

Push the black sleeve forward, insert the bit

into the collet, and then release the black

sleeve. Check to make sure that the bit is

rmly in place.

b. To remove the bit:

Push the black sleeve forward, pull the bit

from the collet, and then release the black

sleeve. (Fig.8)

WARNING

Use protective gloves when removing the bit from the tool, or rst

allow the bit to cool down. The bit may be hot after prolonged use.

Fig. 7

Belt Clip

Fig. 8

Sleeve

14

Page 15

Tighten and Loosen Nuts and Bolts

Variable-speed control must be used with

caution when driving nuts and bolts with

socket-set attachments. The best technique is

to start slowly and increase speed as the nut

or bolt runs down. Set the nut or bolt snugly by

slowing the tool to a stop. If this procedure is

not followed, the tool will have a tendency to

torque or twist in your hands when the nut or

bolt seats.

a. Install a suitable bit.

NOTICE: Always use the correct type and size

of bit for your application.

b. Apply just enough pressure to keep the bit

engaged on the screw or nut.

c. Apply minimal pressure to the trigger switch

initially. Increase the speed only when full

control can be maintained.

NOTICE: Do not over-tighten, as the force of the impact driver can break the fastener. Keep

the impact driver at a right angle to the fastener to avoid damaging the fastener head.

Fig. 9

15

Page 16

MAINTENANCE

WARNING

Service

WARNING

cause serious hazard. We recommend that all tool service be performed by a SKIL Factory

Service Center or Authorized SKIL Service Station.

General Maintenance

WARNING

Periodically inspect the entire product for damaged, missing, or loose parts such as screws,

nuts, bolts, caps, etc. Tighten securely all fasteners and caps and do not operate this product

until all missing or damaged parts are replaced. Please contact customer service or an

authorized service center for assistance.

Cleaning

WARNING

Ventilation openings and switch selectors must be kept clean and free of foreign matter. Do

not attempt to clean by inserting pointed objects through openings.

WARNING

ammonia and house hold detergents that contain ammonia.

To avoid serious personal injury, always remove the battery pack

from the tool when cleaning or performing any maintenance.

Preventive maintenance performed by unauthorized personnel may

result in misplacing of internal wires and components which could

When servicing, use only identical replacement parts. Use of any

other parts could create a hazard or cause product damage.

The tool may be cleaned most effectively with compressed dry air. Always

wear safety goggles when cleaning tools with compressed air.

Certain cleaning agents and solvents damage plastic parts. Some of

these are: gasoline, carbon tetrachloride, chlorinated cleaning solvents,

Storage

Store the tool indoors in a place that is inaccessible to children. Keep it away from corrosive

agents.

TROUBLE SHOOTING

Problem Cause Remedy

Tool does not work. 1. Battery pack is depleted. 1. Charge the battery.

Bit cannot be

installed.

16

2. Tool is over-loaded. 2. Release the variable-speed trigger

3. Battery pack is overtemperature

4. Battery pack is not installed

properly.

5. Damaged switch. 5. Have the switch replaced by an

1. Sleeve is not released. 1. Release the sleeve.

2. Bit does not t the sleeve. 2. Use a suitable adapter.

switch and try again.

3. Turn off the impact driver and cool

the battery pack under air ow.

4. Conrm that the battery is locked

and secured to the tool.

Authorized SKIL Service Center or

Service Station.

Page 17

LIMITED WARRANTY FOR SKIL CORDLESS TOOL

5 YEARS LIMITED WARRANTY

Chervon North America, Inc. (“Seller”) warrants to the original purchaser only, that all SKIL

consumer POWER TOOLS will be free from defects in material or workmanship for a period

of ve years from date of purchase, if original purchaser registers the product within 30 days

from purchase. BATTERIES AND CHARGERS are warranted for 2 years. Product registration

can be completed online at www.Registermyskil.com. Original purchasers should also retain

their receipt as proof of purchase. THE FIVE-YEAR WARRANTY PERIOD FOR POWER

TOOLS IS CONDITIONED ON REGISTRATION OF THE PRODUCT WITHIN 30 DAYS OF

PURCHASE. If original purchasers do not register their product timely, the foregoing limited

warranty will apply for a duration of three years for power tools. All batteries and chargers will

remain under the two-year limited warranty.

Notwithstanding the foregoing, if a SKIL consumer portable power tool is used for industrial,

professional or commercial purposes, the foregoing warranty will apply for a duration of ninety

days, regardless of registration.

SELLER’S SOLE OBLIGATION AND YOUR EXCLUSIVE REMEDY under this Limited

Warranty and, to the extent permitted by law, any warranty or condition implied by law, shall

be the repair or replacement of parts, without charge, which are defective in material or

workmanship and which have not been misused, carelessly handled, or repaired by persons

other than Seller or Authorized Service Station. To make a claim under this Limited Warranty,

you must return the complete product, transportation prepaid, to any SKIL Factory Service

Center or Authorized Service Station. For Authorized SKIL Power Tool Service Stations,

please visit www.Registermyskil.com or call 1-877-SKIL-999 (1-877-754-5999).

THIS LIMITED WARRANTY DOES NOT APPLY TO ACCESSORY ITEMS SUCH AS

CIRCULAR SAW BLADES, DRILL BITS, ROUTER BITS, JIGSAW BLADES, SANDING

BELTS, GRINDING WHEELS AND OTHER RELATED ITEMS.

ANY IMPLIED WARRANTIES APPLICABLE TO A PRODUCT SHALL BE LIMITED IN

DURATION EQUAL TO THE DURATION OF THE EXPRESS WARRANTIES APPLICABLE

TO SUCH PRODUCT, AS SET FORTH IN THE FIRST PARAGRAPH ABOVE. SOME STATES

IN THE U.S., SOME CANADIAN PROVINCES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO

YOU.

IN NO EVENT SHALL SELLER BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL

DAMAGES (INCLUDING BUT NOT LIMITED TO LIABILITY FOR LOSS OF PROFITS)

ARISING FROM THE SALE OR USE OF THIS PRODUCT. SOME STATES IN THE U.S.

AND SOME CANADIAN PROVINCES DO NOT ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM STATE TO STATE IN THE U.S., PROVINCE

TO PROVINCE IN CANADA AND FROM COUNTRY TO COUNTRY.

THIS LIMITED WARRANTY APPLIES ONLY TO PRODUCTS SOLD WITHIN THE UNITED

STATES OF AMERICA, CANADA AND THE COMMONWEALTH OF PUERTO RICO. FOR

WARRANTY COVERAGE WITHIN OTHER COUNTRIES, CONTACT YOUR LOCAL SKIL

DEALER OR IMPORTER.

© Chervon North America, 1203 E. Warrenville Rd, Naperville, IL 60563.

07/18

17

Page 18

TABLE DES MATIÈRES

Avertissements de sécurité généraux relatifs aux outils électriques ....19-21

Avertissements de sécurité relatifs à la clé à chocs ..................21

Symboles ..................................................22-25

Apprenez à connaître votre clé à chocs ............................26

Caractéristiques techniques .....................................26

Mode d’emploi ..............................................27-31

Entretien ......................................................32

Dépannage ....................................................33

Garantie limitée de l’outil sans l SKIL ..........................34-35

AVERTISSEMENT

•

La poussière créée pendant le ponçage, le sciage, le polissage, le perçage et d’autres

activités liées à la construction peut contenir des produits chimiques reconnus par l’État

de la Californie comme étant la cause de cancer, d’anomalies congénitales et d’autres

problèmes liés aux fonctions reproductrices. Voici des exemples de ces produits chimiques :

–

du plomb provenant de peintures à base de plomb;

–

de la silice cristalline provenant de la brique, du ciment ou d’autres matériaux de

maçonnerie;

–

de l’arsenic et du chrome provenant du bois d’œuvre traité avec un produit chimique.

•

Les risques liés à l’exposition à ces produits varient selon le nombre de fois où vous

pratiquez ces activités. An de limiter votre exposition à ces produits chimiques :

–

travaillez dans un endroit bien ventilé;

–

munissez-vous de l’équipement de sécurité approuvé tel que des masques antipoussières

conçus spécialement pour ltrer les particules microscopiques;

–

évitez l’exposition prolongée à la poussière causée par le ponçage mécanique, le sciage, le

polissage, le perçage et d’autres activités liées à la construction; Portez des vêtements de

protection et lavez à l’eau et au savon toutes les parties exposées. Les poussières pénétrant

dans votre bouche ou dans vos yeux et les poussières se déposant sur votre peau peuvent

causer l’absorption de produits chimiques dangereux.

18

Page 19

AVERTISSEMENTS DE SÉCURITÉ GÉNÉRAUX RELATIFS

AUX OUTILS ÉLECTRIQUES

AVERTISSEMENT

respect des consignes de sécurité ci-dessous peut occasionner un choc électrique, un

incendie ou des blessures graves.

Lisez tous les avertissements, instructions, illustrations et

spécifications fournis avec cet outil électrique. Le non-

CONSERVEZ TOUS LES AVERTISSEMENTS ET TOUTES

LES INSTRUCTIONS AFIN DE POUVOIR LES CONSULTER

ULTÉRIEUREMENT.

L’expression « outil électrique » utilisée dans les avertissements correspond aux outils

électriques alimentés sur secteur (à l) ou alimentés par piles (sans l).

Mesures de sécurité dans l’aire de travail

L’aire de travail doit être propre et bien éclairée. Une aire de travail encombrée et peu

éclairée augmente le risque d’accident.

N’utilisez pas d’outils électriques dans un milieu explosif, par exemple où il y a

présence de liquides, de vapeurs ou de poussières inammables. Les outils électriques

produisent des étincelles susceptibles d’enammer ces poussières ou ces vapeurs.

Gardez les enfants et les autres personnes à l’écart lorsque vous utilisez un outil

électrique. Une distraction peut vous faire perdre la maîtrise de l’outil.

Consignes de sécurité relatives à l’électricité

Les ches des outils électriques doivent correspondre à la prise. Ne modiez jamais

la che de quelque façon que ce soit. N’utilisez pas d’adaptateur avec les outils

électriques mis à la terre. L’utilisation de ches non modiées dans les prises compatibles

réduit les risques de choc électrique.

Évitez de toucher à des surfaces mises à la terre, par exemple, un tuyau, un radiateur,

une cuisinière ou un réfrigérateur. Le contact du corps avec une surface mise à la terre

augmente les risques de choc électrique.

N’exposez pas les outils électriques à la pluie ou à tout autre environnement humide.

Les risques de choc électrique sont plus élevés si l’eau s’inltre dans un outil électrique.

N’utilisez pas le cordon d’alimentation de façon abusive. Ne transportez jamais un

outil électrique en le tenant par son cordon ou ne tirez jamais sur le cordon pour le

débrancher. Tenez le cordon d’alimentation éloigné des sources de chaleur, de l’huile,

des objets coupants et des pièces mobiles. Les risques de choc électrique sont plus

élevés si le cordon d’alimentation est endommagé ou emmêlé.

Lorsque vous utilisez un outil électrique à l’extérieur, servez-vous d’une rallonge

conçue pour être utilisée à l’extérieur. L’utilisation de ce type de rallonge réduit les risques

de choc électrique.

Si vous n’avez d’autre choix que d’utiliser un outil électrique dans un endroit humide,

utilisez une alimentation protégée par un disjoncteur différentiel. L’utilisation d’un

disjoncteur différentiel réduit les risques de choc électrique.

Sécurité personnelle

Soyez vigilant, prêtez attention à ce que vous faites et usez de votre jugement lorsque

vous utilisez un outil électrique. N’utilisez pas un outil électrique lorsque vous êtes

fatigué ou sous l’effet de drogues, d’alcool ou de médicaments. Un moment d’inattention

pendant que vous utilisez des outils électriques peut occasionner des blessures graves.

19

Page 20

Portez de l’équipement de protection individuelle. Portez toujours des lunettes de

sécurité. Le port d’équipement de protection, comme un masque antipoussières, des

chaussures de sécurité antidérapantes, un casque de protection et des protecteurs auditifs,

lorsque les conditions l’exigent, réduit les risques de blessures.

Prenez des mesures an d’éviter que l’outil se mette en marche accidentellement.

Assurez-vous que l’interrupteur est sur la position d’arrêt avant de brancher l’outil sur

une source d’alimentation ou un bloc-piles, de ramasser l’outil ou de le transporter.

Transporter les outils électriques avec le doigt sur la gâchette ou brancher les outils lorsque

l’interrupteur est à la position de marche augmente les risques d’accident.

Retirez toutes les clés de réglage de l’outil électrique avant de mettre celui-ci en

marche. Une clé de réglage oubliée sur une pièce rotative de l’outil électrique peut

occasionner des blessures graves.

Ne vous étirez pas pour étendre votre portée. Gardez une posture sécuritaire et un bon

équilibre en tout temps. Cela vous permet de mieux maîtriser l’outil électrique lorsque des

situations inattendues se présentent.

Habillez-vous convenablement. Ne portez pas de vêtements amples ni de bijoux.

Gardez vos cheveux, vos vêtements et vos gants loin des pièces mobiles. Les

vêtements amples, les bijoux et les cheveux longs risquent de se prendre dans les pièces en

mouvement.

Si un dispositif permet de raccorder un dépoussiéreur, assurez-vous que celui-ci est

branché et utilisé de manière appropriée. L’emploi d’un dépoussiéreur contribue à réduire

les dangers liés à la poussière.

Restez toujours sur vos gardes et suivez les principes de sécurité des outils, même s’il

s’agit d’un outil que vous utilisez fréquemment. Il suft d’être négligent une fraction de

seconde pour se blesser gravement.

Utilisation et entretien d’un outil électrique

Ne forcez pas l’outil électrique. Utilisez l’outil électrique approprié à l’utilisation que

vous envisagez. L’utilisation de l’outil électrique approprié permet d’obtenir de meilleurs

résultats, de façon plus sécuritaire, selon le régime de fonctionnement prévu.

N’utilisez pas l’outil électrique si l’interrupteur ne fonctionne pas. Tout outil qui ne peut

pas être contrôlé par l’interrupteur est dangereux et doit être réparé.

Déconnectez la prise de la source d’alimentation ou retirez le bloc-pile de l’outil

électrique avant de le ranger ou de procéder à un ajustement ou un changement

d’accessoire. Ces mesures de sécurité préventives réduisent les risques de mise en marche

accidentelle de l’outil électrique.

Rangez les outils électriques inutilisés hors de la portée des enfants et ne laissez

pas les personnes ne connaissant pas bien l’outil ou ces instructions utiliser l’outil.

Les outils électriques sont dangereux s’ils se retrouvent entre les mains d’utilisateurs qui ne

savent pas s’en servir.

Entretenez les outils électriques et les accessoires. Vériez les pièces mobiles pour

vous assurer qu’elles ne sont pas désalignées, enrayées, brisées, ou dans un état qui

pourrait nuire à leur fonctionnement. Si elles sont endommagées, faites-les réparer

avant d’utiliser l’outil électrique. De nombreux accidents sont provoqués par des outils

électriques mal entretenus.

Gardez vos outils tranchants affûtés et propres. Des outils tranchants bien entretenus et

dont les lames sont affûtées risquent moins de se bloquer et sont plus faciles à maîtriser.

Utilisez l’outil électrique, les accessoires, les embouts et les autres éléments

conformément aux présentes instructions, en tenant compte des conditions de travail

et du travail à effectuer. L’utilisation de l’outil électrique à des ns autres que celles pour

lesquelles il a été conçu pourrait entraîner une situation dangereuse.

20

Page 21

Gardez les poignées et les prises sèches, propres et exemptes d’huile et de graisse.

Les poignées et autres surfaces de préhension glissantes ne permettent pas de manipuler et

de contrôler l’outil de façon sécuritaire en cas de situations inattendues.

Utilisation et entretien d’un outil alimenté par un bloc-piles

Rechargez uniquement le bloc-piles à l’aide du chargeur approuvé par le fabricant. Un

chargeur conçu pour un type de bloc-piles peut causer un incendie s’il est utilisé avec un autre

bloc-piles.

Utilisez les outils électriques uniquement avec les blocs-piles désignés. L’utilisation de

tout autre bloc-piles peut constituer un risque de blessure et d’incendie.

Lorsque vous n’utilisez pas le bloc-piles, conservez-le à l’écart d’autres objets

métalliques, comme des trombones, des pièces de monnaie, des clés, des clous, des

vis et d’autres petits objets métalliques qui peuvent connecter une borne à une autre.

Un court-circuit entre les bornes du bloc-piles peut occasionner des brûlures ou un incendie.

En cas d’usage abusif, du liquide peut s’échapper des piles; évitez tout contact avec

celui-ci. En cas de contact accidentel, rincez à l’eau. En cas de contact avec les yeux,

consultez un médecin. Le liquide provenant des piles peut causer de l’irritation ou des

brûlures.

N’utilisez pas un bloc-piles ou un outil endommagé ou modié. Les blocs-piles modiés

ou endommagés peuvent fonctionner de façon imprévisible et présenter un risque d’incendie,

d’explosion ou de blessures.

N’exposez pas un bloc-piles ou un outil à un feu ou à une température excessive.

L’exposition au feu ou à une température supérieure à 129,4 °C peut provoquer une

explosion.

Suivez toutes les instructions pour le chargement et ne chargez pas le bloc-piles ou

l’appareil en dehors de la plage de température spéciée dans les instructions. Une

recharge inadéquate ou effectuée à des températures en dehors de la plage spéciée peut

endommager le bloc-piles et augmenter le risque d’incendie.

Réparation

Demandez à un technicien qualié qui utilise seulement des pièces de rechange

identiques aux pièces d’origine d’effectuer l’entretien de votre outil électrique. Cela

permet de maintenir l’outil électrique sécuritaire.

Ne réparez jamais un bloc-piles endommagé. Seuls le fabricant et les fournisseurs de

services autorisés peuvent effectuer la réparation d’un bloc-piles.

AVERTISSEMENTS DE SÉCURITÉ RELATIFS À LA CLÉ À

CHOCS

Tenez l’outil électrique par la poignée isolée lors des opérations au cours desquelles

les pièces de xation sont susceptibles d’entrer en contact avec des ls dissimulés

ou du câblage électrique. Lorsque les pièces de xation entrent en contact avec un l

sous tension, les parties métalliques exposées de l’outil électrique peuvent donner un choc

électrique à l’utilisateur.

21

Page 22

SYMBOLES

Symboles de sécurité

L’objectif des symboles de sécurité est d’attirer votre attention sur les dangers potentiels.

Vous devez examiner attentivement et bien comprendre les symboles de sécurité et les

explications qui les accompagnent. Les symboles d’avertissement en tant que tels n’éliminent

pas le danger. Les consignes et les avertissements qui y sont associés ne remplacent en

aucun cas les mesures préventives adéquates.

AVERTISSEMENT

guide d’utilisation, notamment toutes les consignes de sécurité indiquées par « DANGER »,

« AVERTISSEMENT » et « ATTENTION ». Le fait de ne pas respecter toutes les consignes

de sécurité ci-dessous peut causer un choc électrique, un incendie ou des blessures graves.

Avant d’utiliser cet outil, assurez-vous de lire et de comprendre

toutes les consignes de sécurité présentées dans le présent

Les dénitions ci-dessous décrivent le degré de gravité pour chaque mot-indicateur. Veuillez

DANGER

WARNING

CAUTION

vous assurer de lire ce manuel et de prêter attention à ces symboles.

Voici le pictogramme d’alerte de sécurité. Il sert à vous indiquer les

risques potentiels de blessures. Respectez toutes les consignes

de sécurité associées à ce pictogramme pour éviter les risques de

blessures ou de mort.

DANGER indique un danger imminent qui, s’il n’est pas évité, causera

des blessures graves ou la mort.

AVERTISSEMENT indique un risque pouvant entraîner des blessures

graves ou la mort s’il n’est pas prévenu.

ATTENTION, utilisée avec le symbole d’alerte de sécurité, indique un

risque potentiel qui, s’il n’est pas éliminé, provoquera des blessures

mineures ou moyennement graves.

Messages d’information et de prévention des dommages

Ces messages fournissent à l’utilisateur de l’information et des consignes importantes. Les

ignorer pourrait occasionner des dommages à l’équipement ou d’autres dommages matériels.

Le mot « AVERTISSEMENT » précède chaque message, comme dans l’exemple ci-dessous :

AVIS : Ne pas suivre ces consignes pourrait occasionner des dommages à l’équipement ou

d’autres dommages matériels.

AVERTISSEMENT

dans les yeux et ainsi causer des lésions oculaires graves. Avant

d’utiliser un outil électrique, veillez à toujours porter des lunettes de

sécurité couvrantes ou à écrans latéraux, ou un masque complet au

besoin. Nous recommandons le port d’un masque de sécurité

panoramique par-dessus les lunettes de vue ou de lunettes de sécurité

standard avec écrans latéraux. Portez toujours des protecteurs oculaires

conformes à la norme ANSI Z87.1.

L’utilisation de tout outil électrique peut

entraîner la projection de corps étrangers

22

Page 23

SYMBOLS (CONTINUED)

IMPORTANT : Les symboles suivants peuvent gurer sur votre outil. Familiarisez-vous avec

eux et apprenez leur signication. En comprenant ces symboles, vous serez en mesure de

faire fonctionner cet outil de façon adéquate et sécuritaire.

Symbole Nom Forme au long et explication

V Volts Tension (possible)

A Ampère Courant

Hz Hertz Fréquence (cycles par seconde)

W Watt Puissance

kg Kilogrammes Poids

min Minutes Durée

s Secondes Durée

Wh Wattheures Capacité de la pile

Ah Ampères-heures Capacité de la pile

Ø Diamètre Taille des forets, des meules, etc.

n

0

n Vitesse nominale Vitesse maximale atteignable

…/min

0 Position d’arrêt Vitesse nulle, couple nul...

1,2,3,…

I,II,III,

Vitesse à vide Vitesse de rotation à vide

Tours ou va-et-vient par

minute

Réglages du sélecteur

Sélecteur à réglages innis

avec mode d’arrêt

Flèche

Courant alternatif

Courant continu

Courant alternatif ou continu

Appareil de classe II

Borne de mise à la terre Borne de mise à la terre

Tours, coups, battements, vitesse de

surface, orbites, etc., par minute

Réglages de vitesse, de couple ou de

position. Plus le chiffre est élevé, plus la

vitesse est rapide

La vitesse augmente à partir du réglage 0

L’activation se fait dans le sens de la

èche

Type de courant ou caractéristique de

courant

Type de courant ou caractéristique de

courant

Type de courant ou caractéristique de

courant

Désigne les outils de construction à

double isolation

23

Page 24

Symbole Nom Forme au long et explication

Sceau du programme de

recyclage des piles au

lithium-ion

Sceau du programme de

recyclage des piles au

nickel-cadmium

Symbole de lecture du

manuel

Symbole du port de lunettes

de sécurité

Désigne le programme de recyclage des

piles au lithium-ion

Désigne le programme de recyclage des

piles au nickel-cadmium

Invite l’utilisateur à lire le manuel

Lorsque vous utilisez ce produit, portez

toujours des lunettes de protection ou de

sécurité à écrans latéraux et un masque

de protection complet.

24

Page 25

SYMBOLES (RENSEIGNEMENTS EN MATIÈRE

D’HOMOLOGATION)

IMPORTANT : Certains des symboles suivants, qui fournissent des renseignements en

matière d’homologation, peuvent gurer sur l’outil. Familiarisez-vous avec eux et apprenez

leur signication. En comprenant ces symboles, vous serez en mesure de faire fonctionner cet

outil de façon adéquate et sécuritaire.

Symbole

Forme au long et explication

Ce symbole indique que cet outil est répertorié par Underwriters

Laboratories.

Ce symbole indique que cet outil est reconnu par Underwriters

Laboratories.

Ce symbole indique que cet outil est répertorié par Underwriters

Laboratories, selon les normes américaines et canadiennes.

Ce symbole indique que cet outil est répertorié par l’Association

canadienne de normalisation.

Ce symbole indique que cet outil est répertorié par l’Association

canadienne de normalisation et qu’il est conforme aux normes

américaines et canadiennes.

Ce symbole indique que cet outil est répertorié par Intertek Testing et

qu’il est conforme aux normes américaines et canadiennes.

Ce symbole indique que cet outil est conforme aux normes mexicaines

ofcielles (NOM).

25

Page 26

APPRENEZ À CONNAÎTRE VOTRE CLÉ À CHOCS

Clé à chocs sans balai de 12 V

Fig. 1

Lampe

halogène

Mandrin à

changement

rapide

Interrupteur à

vitesse variable

Sélecteur de

sens de rotation

(serrage/vissage,

verrouillage

au centre,

desserrage/

dévissage)

Poignée à prise

souple

Sélecteur de

mode

Pince à ceinture

amovible

CARACTÉRISTIQUES TECHNIQUES

Tension nominale 12 V c.c.

Taille du mandrin/type de mandrin 1/4 po (hexagonal)

Vitesse à vide 0 à 1600/0 à 2600 par minute

Chocs par minute 0 à 2500/0 à 3500 par minute

Température de fonctionnement

recommandée

Température de rangement recommandée 0 à 40 °C (32 à 104 °F)

-10 à 40 °C (14 à 104 °F)

Espace de

rangement pour

mèches

26

Page 27

MODE D’EMPLOI

AVERTISSEMENT

cuit, ne plongez jamais l’outil, le bloc-piles ou le chargeur dans un liquide et ne laissez

aucun liquide s’écouler sur ceux-ci.Les liquides corrosifs ou conducteurs, tels que l’eau de

mer, certains produits chimiques industriels, l’eau de javel, des produits contenant de l’eau de

Javel, etc., peuvent causer un court-circuit.

AVERTISSEMENT

été remplacées. Le fait d’utiliser cet article avec des pièces endommagées ou manquantes

pourrait entraîner des blessures graves.

AVERTISSEMENT

dernière. Toute modication est considérée comme un usage inapproprié et pourrait occasionner des risques allant jusqu’à des blessures graves.

AVERTISSEMENT

de la clé à chocs avant d’assembler des pièces.

Utilisez cette clé à chocs sans l uniquement avec les blocs-piles et les chargeurs

indiqués ci-dessous :

Pour réduire les risques d’incendie, de blessures corpo-

relles et de détérioration de l’outil découlant d’un court-cir-

S’il y a des pièces manquantes ou endommagées, ne tentez

pas d’utiliser cet article tant que ces pièces n’auront pas

Ne tentez pas de modier cette clé à chocs ou de créer

des accessoires qui ne sont pas recommandés pour cette

Pour empêcher une mise en marche accidentelle pouvant

causer des blessures graves, retirez toujours le bloc-piles

Bloc-piles

2Ah 4Ah

SKIL BY500101 SKIL BY519801 SKIL QC535701

AVIS : Veuillez consulter le manuel relatif aux blocs-piles et aux chargeurs pour davantage

de détails au sujet du fonctionnement de l’outil.

Fixation et retrait du bloc-piles

(gure 2)

Avant de xer ou de retirer le bloc-piles,

verrouillez l’interrupteur de l’outil en position «

OFF » (arrêt) en plaçant le sélecteur de sens

de rotation (serrage/vissage, verrouillage au

centre, desserrage/dévissage) en position

centrale.

Fixation du bloc-piles :

Alignez les nervures du bloc-piles avec les

rainures situées sur l’outil, puis faites glisser le

bloc-piles de manière à ce qu’il s’insère dans

l’outil.

AVIS : Assurez-vous que le verrou du blocpiles s’enclenche et que le bloc-piles est bien

xé à l’outil avant d’utiliser celui-ci.

Retrait du bloc-piles :

Appuyez sur le bouton de déverrouillage situé à l’avant du bloc-piles pour dégager ce dernier.

Tirez le bloc-piles et retirez-le de l’outil.

Chargeur

Fig. 2

Bouton d’éjection

du bloc-pile

Retirer

Fixez

27

Page 28

AVIS : Lorsque vous insérez le bloc-piles dans l’outil, assurez-vous que les nervures du bloc-

piles sont alignées sur les rainures de l’outil et que le verrou s’enclenche correctement. Une

mauvaise installation du bloc-piles peut endommager des composants internes.

AVERTISSEMENT

vissage, verrouillage au centre, desserrage/dévissage) devrait toujours être verrouillé à

la position centrale lorsque vous n’utilisez pas l’outil ou que vous le transportez à vos

côtés.

Les outils à pile sont toujours en état de fonctionnement.

Par conséquent, le sélecteur de sens de rotation (serrage/

Sélecteur de sens de rotation (serrage/vissage, verrouillage au

centre, desserrage/dévissage)

AVERTISSEMENT

c’est-à-dire à la position de verrouillage au centre, pour aider à empêcher une mise en

marche accidentelle pouvant causer des blessures graves.

L’outil est muni d’un sélecteur de sens de rotation situé au-dessus de l’interrupteur. Ce

sélecteur est conçu pour changer le sens de rotation de la mèche et pour verrouiller la

gâchette en position « OFF » (arrêt), c’est-à-dire en position de verrouillage au centre.

a. Placez le sélecteur de sens de rotation à gauche de l’outil pour une rotation de serrage/

vissage.

b. Placez le sélecteur de sens de rotation à droite de l’outil pour une rotation de desserrage/

dévissage.

c. Placez le sélecteur à la position « OFF » (arrêt), c’est-à-dire à la position de verrouillage

au centre, pour réduire les risques de mise en marche accidentelle lorsque l’outil n’est pas

utilisé (gure 3).

AVIS : Pour éviter d’endommager l’engrenage, attendez toujours l’arrêt complet de la clé à

chocs avant de modier le sens de rotation.

AVIS : La clé à chocs ne fonctionnera pas tant que le sélecteur de sens de rotation ne sera

pas entièrement enclenché vers la gauche ou la droite.

Lorsque vous avez terminé d’utiliser l’outil, placez le

sélecteur de sens de rotation à la position « OFF » (arrêt),

Fig. 3

Verrouillage au centre Avant Marche arrière

28

Page 29

Interrupteur à vitesse variable

L’outil est muni d’un interrupteur à vitesse

variable. L’outil peut être allumé ou éteint en

appuyant sur la gâchette ou en la relâchant.

La vitesse de l’outil dépend de la pression

exercée sur l’interrupteur à vitesse variable. Si

vous augmentez

la pression, la vitesse augmente, et si vous la

réduisez, la vitesse diminue (gure 4).

Fig. 4

Interrupteur à

vitesse variable

Lampe halogène

L’outil est muni d’une lampe halogène située

sur la tête de l’outil. Celle-ci offre un éclairage

supérieur dans les zones moins éclairées,

sans créer d’ombre sur la surface de travail.

La lampe halogène s’allume automatiquement

à l’aide d’une légère pression sur l’interrupteur

à vitesse variable avant le démarrage de l’outil,

et s’éteint de 8 à 12 secondes après que vous

avez relâché l’interrupteur à vitesse variable.

Lorsque l’outil ou le bloc-piles sont surchargés

ou trop chauds, les capteurs internes éteignent

l’outil. Si l’outil ou le bloc-piles sont surchargés,

la lampe halogène clignote rapidement. Laissez l’outil refroidir pendant un moment ou

placez l’outil et le bloc-piles, que vous aurez

préalablement retiré, près d’un courant d’air pour qu’ils refroidissent.

Si la capacité du bloc-piles est faible, la lampe halogène clignote lentement. Rechargez le

bloc-piles.

Fig. 5

Lampe

halogène

29

Page 30

Sélecteur de mode

L’outil est muni d’une interface qui permet

de régler la vitesse selon 2 modes (basse ou

élevée).

Lorsque vous appuyez doucement sur la

gâchette, l’indicateur de mode s’allume automatiquement en vert. Appuyez sur le sélec-

teur de mode pour régler la vitesse (gure 6).

Un seul indicateur s’allume pour le symbole

« L », ce qui indique une « vitesse basse ».

Les deux indicateurs s’allument pour le

symbole « H », ce qui indique une « vitesse

élevée ».

Le mode de vitesse sera enregistré et restera

le même la prochaine fois que vous utiliserez

l’outil ou lorsque vous modierez le sens de

rotation. Réinitialisez la vitesse lorsque vous le souhaitez.

AVIS : Pour éviter d’endommager l’engrenage, attendez toujours l’arrêt complet de la clé

à chocs avant de modier la vitesse. Vous pouvez seulement modier la vitesse lorsque

l’indicateur de mode est allumé et que l’interrupteur n’est pas enfoncé. Vous ne pouvez pas

activer le sélecteur de mode pendant que le moteur est en marche. L’indicateur de mode

s’éteint automatiquement environ une minute après que vous avez cessé d’utiliser l’outil.

Fig. 6

Sélecteur de mode Indicateur de mode

Pince à ceinture amovible (gure 7)

L’outil est muni d’une pince à ceinture amovible pouvant être placée sur le côté gauche de

l’outil an de faciliter le transport.

Installation de la pince à ceinture sur l’outil :

a. Retirez le bloc-piles de l’outil.

b. Alignez la languette de la pince à ceinture

sur le trou leté situé à la base de l’outil.

c. Insérez la vis et serrez-la fermement avec

un tournevis.

Retrait de la pince à ceinture de l’outil :

d. Retirez le bloc-piles de l’outil.

e. Utilisez un tournevis pour desserrer la vis

qui relie la pince à ceinture à la clé à chocs.

f. Retirez la vis et la pince à ceinture.

30

Fig. 7

Pince à

ceinture

Page 31

Installation et retrait des mèches

L’outil est muni d’un mandrin à changement

rapide, ce qui facilite grandement l’installation

et le retrait des mèches.

a. Installation d’un embout :

Poussez le manchon noir vers l’avant,

insérez l’embout dans le mandrin, puis

relâchez le manchon noir. Assurez-vous que

l’embout est fermement en place.

b. Retrait de l’embout :

Poussez le manchon noir vers l’avant,

retirez l’embout du mandrin, puis relâchez le

manchon noir. (Fig. 8)

AVERTISSEMENT

protecteurs lorsque vous retirez l’embout

de l’outil ou laissez l’embout refroidir avant

de le retirer. L’embout peut devenir chaud après une utilisation prolongée.

Portez des

gants

Fig. 8

Manchon

Serrage et desserrage d’écrous et de boulons

Utilisez la commande à vitesse variable

prudemment lorsque vous serrez des écrous

et des boulons à l’aide d’un ensemble de

douilles. La façon de faire idéale consiste

à démarrer lentement et à augmenter la

vitesse à mesure que l’écrou ou le boulon

est vissé. Serrez bien l’écrou ou le boulon en

ralentissant la vitesse, jusqu’à l’arrêt de l’outil.

Si vous ne respectez pas cette procédure,

l’outil aura tendance à tourner dans vos mains

une fois que l’écrou ou le boulon est en place.

a. Installez une mèche appropriée.

AVIS : Utilisez toujours le type et la taille de

mèche qui conviennent à l’utilisation que vous

envisagez.

b. Appliquez juste assez de pression pour

maintenir l’embout en place contre la vis ou l’écrou.

c. Appliquez d’abord une pression minimale sur l’interrupteur. Augmentez la vitesse

uniquement lorsque vous pouvez assurer un plein contrôle de l’outil.

AVIS : Évitez de serrer excessivement, car la clé à chocs pourrait briser la xation. Gardez la

clé à chocs à un angle adéquat par rapport à la xation an d’éviter d’endommager la tête

de celle-ci.

Fig. 9

31

Page 32

ENTRETIEN

AVERTISSEMENT

Réparation

AVERTISSEMENT

et des composants internes, ce qui peut représenter un grave danger. Tout entretien

d’outil devrait être effectué dans un centre de service de l’usine de SKIL

ou dans un centre de service autorisé de Skil.

Entretien général

AVERTISSEMENT

toute autre pièce peut constituer un danger ou endommager l’article.

Inspectez périodiquement l’intégralité du produit pour y déceler des pièces endommagées,

manquantes ou lâches telles que les vis, les écrous, les boulons, les capuchons, etc.

Resserrez fermement toutes les xations et tous les capuchons et ne faites pas fonctionner ce

produit tant que toutes les pièces manquantes ou endommagées n’ont pas été remplacées.

Veuillez communiquer avec le service à la clientèle ou avec un centre de service autorisé pour

obtenir de l’aide.

Nettoyage

AVERTISSEMENT

vous nettoyez des outils avec de l’air comprimé. Les orices de ventilation et les

interrupteurs doivent être propres et exempts de toute substance étrangère. Ne tentez pas de

nettoyer l’outil en insérant des objets pointus dans les ouvertures.

AVERTISSEMENT

l’essence, le tétrachlorure de carbone, les solvants nettoyants chlorés, l’ammoniac et les

détergents ménagers qui contiennent de l’ammoniac.

Pour éviter des blessures graves, retirez toujours le bloc-pile

avant de procéder à l’entretien ou au nettoyage de l’outil.

Un entretien préventif effectué par du personnel non

autorisé peut entraîner un mauvais positionnement des ls

Lors de l’entretien, utilisez seulement des pièces de

rechange identiques aux pièces d’origine. L’utilisation de

L’utilisation d’air sec comprimé est la meilleure technique de

nettoyage. Portez toujours des lunettes de sécurité lorsque

Certains agents nettoyants et solvants peuvent

endommager les pièces en plastique. Notamment :

Rangement

Rangez l’outil à l’intérieur dans un endroit inaccessible aux enfants. Rangez-le à l’écart des

agents corrosifs.

32

Page 33

DÉPANNAGE

Problème Cause Solutions

L’outil ne

fonctionne pas.

Il est impossible

d’installer

l’embout.

1. Le bloc-pile est déchargé. 1. Chargez le bloc-pile.

2. L’outil est surchargé. 2. Relâchez l’interrupteur à vitesse

3. Le bloc-piles est trop

chaud.

4. Le bloc-piles n’est pas

installé correctement.

5. L’interrupteur est

endommagé.

1. Le manchon n’est pas

desserré.

2. La mèche n’entre pas

dans le manchon.

variable, puis réessayez.

3. Éteignez la clé à chocs et faites refroidir

le bloc-piles près d’un courant d’air.

4. Assurez-vous que le bloc-piles est bien

xé à l’outil et bien verrouillé.

5. Faites remplacer l’interrupteur dans un

centre de service autorisé par SKIL.

1. Relâchez le manchon.

2. La mèche n’entre pas dans le manchon.

33

Page 34

GARANTIE LIMITÉE DE L’OUTIL SKIL

GARANTIE LIMITÉE DE 5 ANS

Chervon North America, Inc. (le « vendeur ») garantit à l’acheteur initial seulement que tous

les OUTILS SKIL destinés à un usage résidentiel seront exempts de défauts de matériaux

ou de fabrication pour une période de cinq ans à compter de la date d’achat si l’acheteur

initial enregistre l’article dans les 30 jours suivant la date d’achat. LES PILES ET LES

CHARGEURS sont garantis pour une période de 2 ans. L’enregistrement de l’article peut être

effectué en ligne au www.Registermyskil.com. De plus, nous recommandons aux acheteurs

initiaux de conserver leur reçu comme preuve d’achat. LA PÉRIODE DE GARANTIE DE CINQ

ANS SUR LES OUTILS EST CONDITIONNELLE À L’ENREGISTREMENT DE L’ARTICLE

DANS LES 30 JOURS SUIVANT LA DATE D’ACHAT. Si les acheteurs initiaux n’enregistrent

pas leur article dans le délai prévu, la garantie limitée sur les outils électriques susmentionnée

ne s’appliquera que pour une période de trois ans. Toutes les piles et tous les chargeurs

demeureront couverts par la garantie limitée de deux ans.

Nonobstant les dispositions précédentes, si un outil SKIL destiné à un usage résidentiel est

utilisé à des ns industrielles, professionnelles ou commerciales, la garantie susmentionnée

ne s’appliquera que pour une période de quatre-vingt-dix (90) jours, que l’article ait été

enregistré ou non.

LA SEULE OBLIGATION DU VENDEUR ET VOTRE RECOURS EXCLUSIF au titre de cette

garantie limitée et, dans les limites permises par la loi, de toute garantie ou condition prévue

par la loi, est la réparation ou le remplacement, sans frais, des pièces qui présentent un défaut

matériel ou de fabrication, qui n’ont pas fait l’objet d’un usage abusif ou inapproprié et qui n’ont

pas été réparées par des personnes autres que le vendeur ou un technicien d’un centre de

service autorisé. Pour effectuer une réclamation au titre de la présente garantie limitée, vous

devez retourner, port payé, l’article en entier à un centre de service de l’usine de SKIL ou à

un centre de service autorisé. Pour communiquer avec un centre de service autorisé de SKIL

Power Tools, veuillez visiter le www.Registermyskil.com ou composer le 1 877 SKIL-999

(1 877 754-5999).

CETTE GARANTIE LIMITÉE NE S’APPLIQUE PAS AUX ACCESSOIRES TELS QUE LES

LAMES DE SCIE CIRCULAIRE, LES FORETS, LES FRAISES À TOUPIE, LES LAMES

DE SCIE SAUTEUSE, LES COURROIES DE PONÇAGE, LES MEULES ET LES AUTRES

ACCESSOIRES CONNEXES.

TOUTE GARANTIE IMPLICITE APPLICABLE À UN ARTICLE EST LIMITÉE À UNE DURÉE

ÉGALE À LA DURÉE DES GARANTIES EXPRESSES APPLICABLES À UN TEL ARTICLE,

COMME IL EST INDIQUÉ AU PREMIER PARAGRAPHE DE CETTE GARANTIE. CERTAINS

ÉTATS DES ÉTATS-UNIS ET CERTAINES PROVINCES DU CANADA NE PERMETTENT

PAS DE LIMITATIONS QUANT À LA DURÉE DES GARANTIES IMPLICITES, DE SORTE

QUE LES LIMITATIONS INDIQUÉES CI-DESSUS PEUVENT NE PAS S’APPLIQUER À

VOUS.

LE VENDEUR NE SERA EN AUCUN CAS TENU RESPONSABLE DES DOMMAGES

ACCESSOIRES OU CONSÉCUTIFS (Y COMPRIS, SANS TOUTEFOIS S’Y LIMITER,

DES PERTES DE PROFIT) RÉSULTANT DE LA VENTE OU DE L’USAGE DE CET

ARTICLE. CERTAINS ÉTATS DES ÉTATS-UNIS ET CERTAINES PROVINCES DU

CANADA NE PERMETTENT PAS L’EXCLUSION OU LA LIMITATION DES DOMMAGES

ACCESSOIRES OU CONSÉCUTIFS, DE SORTE QUE LA LIMITATION OU L’EXCLUSION

SUSMENTIONNÉE POURRAIT NE PAS S’APPLIQUER À VOUS.

CETTE GARANTIE LIMITÉE VOUS CONFÈRE DES DROITS PRÉCIS. IL EST POSSIBLE

QUE VOUS DISPOSIEZ ÉGALEMENT D’AUTRES DROITS, QUI VARIENT D’UN ÉTAT,

D’UNE PROVINCE OU D’UN PAYS À L’AUTRE.

34

Page 35

CETTE GARANTIE LIMITÉE S’APPLIQUE UNIQUEMENT AUX ARTICLES VENDUS AUX

ÉTATS-UNIS D’AMÉRIQUE, AU CANADA ET À L’ÉTAT LIBRE DE PORTO RICO. POUR

CONNAÎTRE LA COUVERTURE DE LA GARANTIE DANS D’AUTRES PAYS, VEUILLEZ

COMMUNIQUER AVEC VOTRE DÉTAILLANT OU IMPORTATEUR SKIL LOCAL.

© Chervon North America, 1203 E. Warrenville Rd, Naperville, IL 60563.

07/18

35

Page 36

ÍNDICE

Advertencias de seguridad general en el

manejo de herramientas eléctricas .............................37-39

Advertencias de seguridad para el destornillador de impacto ..........39

Símbolos ..................................................40-42

Conozca su destornillador de impacto .............................43

Especicaciones ...............................................43

Instrucciones de funcionamiento ..............................44-48

Mantenimiento .................................................49

Solución de problemas ..........................................50

Garantía limitada de la herramienta inalámbrica SKIL .............51-52

ADVERTENCIA

•

Parte del polvo causado por el lijado eléctrico, el serruchado, la trituración, el taladro y

otras actividades de construcción contiene sustancias químicas que, según el estado

de California, causan cáncer, defectos congénitos u otros daños reproductivos. Algunos

ejemplos de estos productos químicos son:

–

Plomo de pinturas a base de plomo.

–

Sílice cristalina de ladrillos, cemento y otros productos de mampostería.

–

Arsénico y cromo de madera tratada con químicos.

•

El riesgo que corre debido a la exposición a estos químicos varía según la frecuencia con

que realiza este tipo de trabajo. Para reducir la exposición a estas sustancias químicas:

–

Trabaje en un área bien ventilada.

–

Trabaje con equipo de seguridad aprobado, como las mascarillas antipolvo especialmente

diseñadas para ltrar partículas microscópicas.

–

Evite estar en contacto prolongado con el polvo provocado por el lijado, el aserrado, la

trituración y el taladrado, y otras actividades de construcción. Use ropa protectora y lave

todas las áreas expuestas del cuerpo con agua y jabón. Si permite que el polvo llegue a

su boca o a sus ojos, o que caiga sobre la piel, podría fomentar la absorción de productos

químicos dañinos.

36

Page 37

ADVERTENCIAS DE SEGURIDAD GENERAL EN EL MANEJO

DE HERRAMIENTAS ELÉCTRICAS

ADVERTENCIA

herramienta eléctrica. No seguir todas las instrucciones que se detallan a continuación

podría provocar descargas eléctricas, incendios o lesiones graves.

Lea todas las advertencias de seguridad, las instrucciones, las

ilustraciones y las especificaciones que se incluyen esta

GUARDE TODAS LAS ADVERTENCIAS E INSTRUCCIONES PARA

REFERENCIA FUTURA.

El término “herramienta eléctrica” que aparece en las advertencias se reere a la herramienta

eléctrica que se conecta a la línea principal (con cable) o a la herramienta eléctrica que

funciona con batería (inalámbrica).

Seguridad en el área de trabajo

Mantenga el área de trabajo limpia y bien iluminada. Las áreas desordenadas u oscuras

aumentan las posibilidades de accidentes.

No utilice herramientas eléctricas en atmósferas en las que exista riesgo de explosión,

como por ejemplo en presencia de líquidos inamables, gases o polvo. Las herramientas

eléctricas producen chispas que podrían encender el polvo o el humo.

Mantenga a los niños y transeúntes alejados mientras opera una herramienta eléctrica.

Las distracciones pueden hacerle perder el control.

Seguridad eléctrica

Los enchufes de las herramientas eléctricas deben encajar en el tomacorriente. Nunca

modique el enchufe de ninguna manera. No utilice ningún enchufe adaptador con

herramientas eléctricas con puesta a tierra. Los enchufes sin modicaciones y que encajan

en los tomacorrientes reducen el riesgo de descarga eléctrica.

Evite el contacto del cuerpo con supercies con puesta a tierra, como tuberías,

radiadores, estufas o refrigeradores. Existe un riesgo adicional de descarga eléctrica si su

cuerpo tiene puesta a tierra.

No exponga las herramientas eléctricas a la lluvia o a condiciones de humedad. Si

ingresa agua en una herramienta eléctrica, el riesgo de descarga eléctrica aumentará.

No maltrate el cable. Nunca use el cable para transportar, jalar ni desenchufar la

herramienta eléctrica. Mantenga el cable alejado del calor, el aceite, los bordes losos

o las piezas en movimiento. Los cables dañados o enredados aumentan el riesgo de

descarga eléctrica.

Cuando utilice una herramienta eléctrica en exteriores, use una extensión eléctrica

adecuada para uso en exteriores. El uso de un cable apto para uso en exteriores reduce el

riesgo de descarga eléctrica.

Si debe utilizar una herramienta eléctrica en un área húmeda, use un suministro

protegido con un interruptor de circuito de falla de puesta a tierra (GFCI, por sus siglas

en inglés). El uso de un interruptor GFCI disminuye el riesgo de descarga eléctrica.

Seguridad personal

Manténgase alerta, preste atención a lo que hace y utilice el sentido común cuando

utilice una herramienta eléctrica. No utilice una herramienta eléctrica si está cansado

o bajo los efectos de drogas, alcohol o medicamentos. Un momento de desatención

mientras opera herramientas eléctricas puede provocar lesiones personales graves.

37

Page 38

Use un equipo de protección personal. Use siempre lentes de protección. Los equipos

de protección, como mascarillas antipolvo, zapatos de seguridad antideslizantes, cascos

protectores o protección auditiva, utilizados para las condiciones adecuadas, disminuyen el

riesgo de lesiones personales.

Evite un arranque accidental. Asegúrese de que el interruptor esté en la posición de

apagado antes de conectar la herramienta a la fuente de alimentación o la batería, o

antes de levantarla o transportarla. Transportar herramientas eléctricas con el dedo en el

interruptor o enchufar herramientas eléctricas que tienen el interruptor encendido aumenta las

posibilidades de sufrir accidentes.

Retire todas las llaves de ajuste o llaves inglesas antes de encender la herramienta

eléctrica. Si se deja una llave inglesa o una llave conectada a una pieza giratoria de la

herramienta eléctrica, se podrían producir lesiones personales.

No se extienda demasiado. Mantenga una postura y un equilibrio adecuados en

todo momento. Esto permite un mejor control de la herramienta eléctrica en situaciones

inesperadas.

Use ropa adecuada. No use ropa holgada ni joyas. Mantenga el cabello, la ropa y los

guantes lejos de las piezas en movimiento. La ropa holgada, las joyas o el cabello largo

pueden quedar atrapados en las piezas en movimiento.

Si se proporcionan dispositivos para la conexión de instalaciones de extracción

y recolección de polvo, asegúrese de que se conecten y se usen debidamente. La

recolección de polvo puede disminuir los peligros relacionados con el polvo.

No permita que la familiaridad del uso frecuente de las herramientas lo haga no tener

en cuenta los principios de seguridad de las herramientas. Un descuido puede ocasionar

una lesión grave en cuestión de segundos.

Uso y cuidado de las herramientas eléctricas

No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica adecuada para su

tarea. La herramienta eléctrica adecuada realizará un trabajo más seguro y de mejor calidad

al ritmo para el que se diseñó.

No utilice la herramienta eléctrica si el interruptor no la enciende o apaga. Cualquier

herramienta eléctrica que no pueda controlarse con el interruptor es peligrosa y debe

repararse.

Desconecte el enchufe de la fuente de alimentación o retire el paquete de baterías

de la herramienta eléctrica (si es posible) antes de realizar cualquier ajuste, cambiar

accesorios o almacenar herramientas eléctricas. Este tipo de medidas de seguridad

preventivas reduce el riesgo de arranques accidentales de la herramienta eléctrica.

Almacene las herramientas eléctricas que no estén en uso fuera del alcance de

los niños y no permita que personas no familiarizadas con la herramienta o estas

instrucciones la operen. Las herramientas eléctricas son peligrosas en manos de usuarios

sin capacitación.

Realice mantenimiento a las herramientas eléctricas y a los accesorios. Revise si

hay piezas móviles desalineadas o torcidas, si hay piezas rotas y cualquier otra

condición que pueda afectar el funcionamiento de la herramienta eléctrica. Si se daña

la herramienta eléctrica, hágala reparar antes de usarla. Muchos accidentes son producto

del mantenimiento incorrecto de las herramientas eléctricas.

Mantenga las herramientas de corte aladas y limpias. Las herramientas de corte que

se mantienen adecuadamente, con sus bordes de corte alados, son menos propensas a