Page 1

Vestil Manufacturing Corporation

2999 North Wayne St., Angola, IN 46703

Ph 260-665-7586 Fax: 260-665-1339

www.vestil.com E-mail: sales@vestil.com

Loading Dock Solutions

Contents

Warnings and Safety Instructions.................. 1

Receiving Instructions ................................... 1

Loading Instructions ...................................... 2

Unpacking and Handling Instructions ............ 2

Operating Instructions ................................... 2

Installation Instructions ............................... 3-5

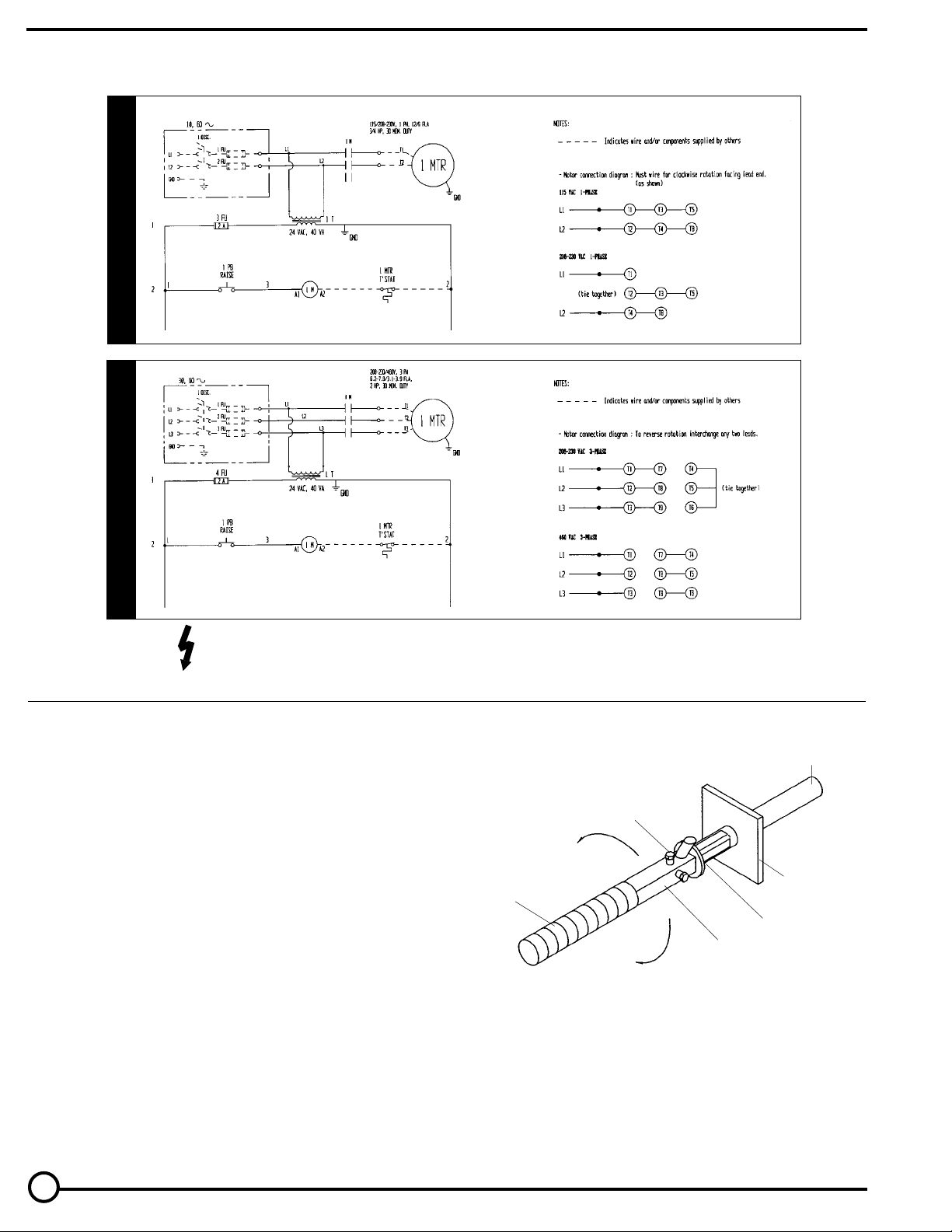

Electrical Schematic ...................................... 6

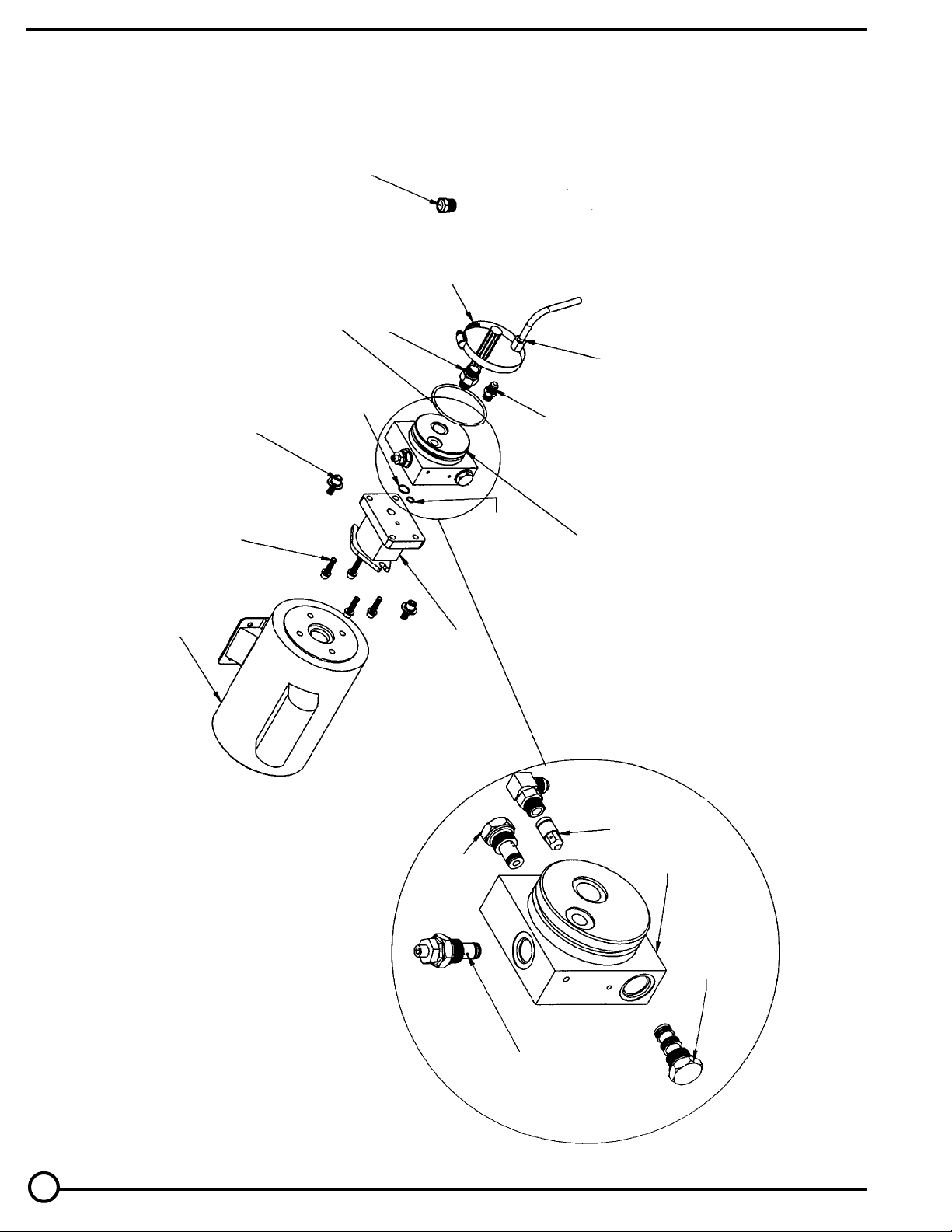

Power Unit Exploded Parts Drawing ............. 8

WARNINGS & SAFETY INSTRUCTIONS

Read owner's manual completely before operating unit!

• Read and understand the owner's manual before using

or servicing the leveler.

• The lip plate should be secured outward before any work

is preformed on the leveler.

• Ensure that the safety and warning labels stay in place

and are legible. See the labels page in this manual.

• The Edge-O-Dock leveler must be securely welded and

anchored to the dock face. See the installation

instructions.

• Do not use the leveler if any damage or unusual noise is

observed.

• Always watch the leveler carefully when it is in

operation.

• Be sure nothing is on the top of the leveler before

operating it.

• Do not perform any modifications to the leveler without

the manufacturer's approval. Failure to receive

authorization for changes to the equipment could void

the warranty.

• Maintenance and repairs are to be performed only by

personnel qualified to perform the required work.

• Do not use brake fluid or jack oils in the hydraulic

system. If oil is needed, use an antiwear hydraulic fluid

with an SUS viscosity of 150 - 200 at 100°F, (SAE

viscosity grade 32), or Dexron transmission fluid.

• Use only replacement parts either supplied or approved

by the manufacturer.

Revised 06-04 07-126-101

A company dedicated to solving loading dock and

material handling problems since 1955

.

OWNER'S

MANUAL

EDGE-O-DOCK • MODEL FM / PP / PE

Spring Adjusting Instructions (FM Series) ..... 6

PE Hydraulic & Troubleshooting Guide 7

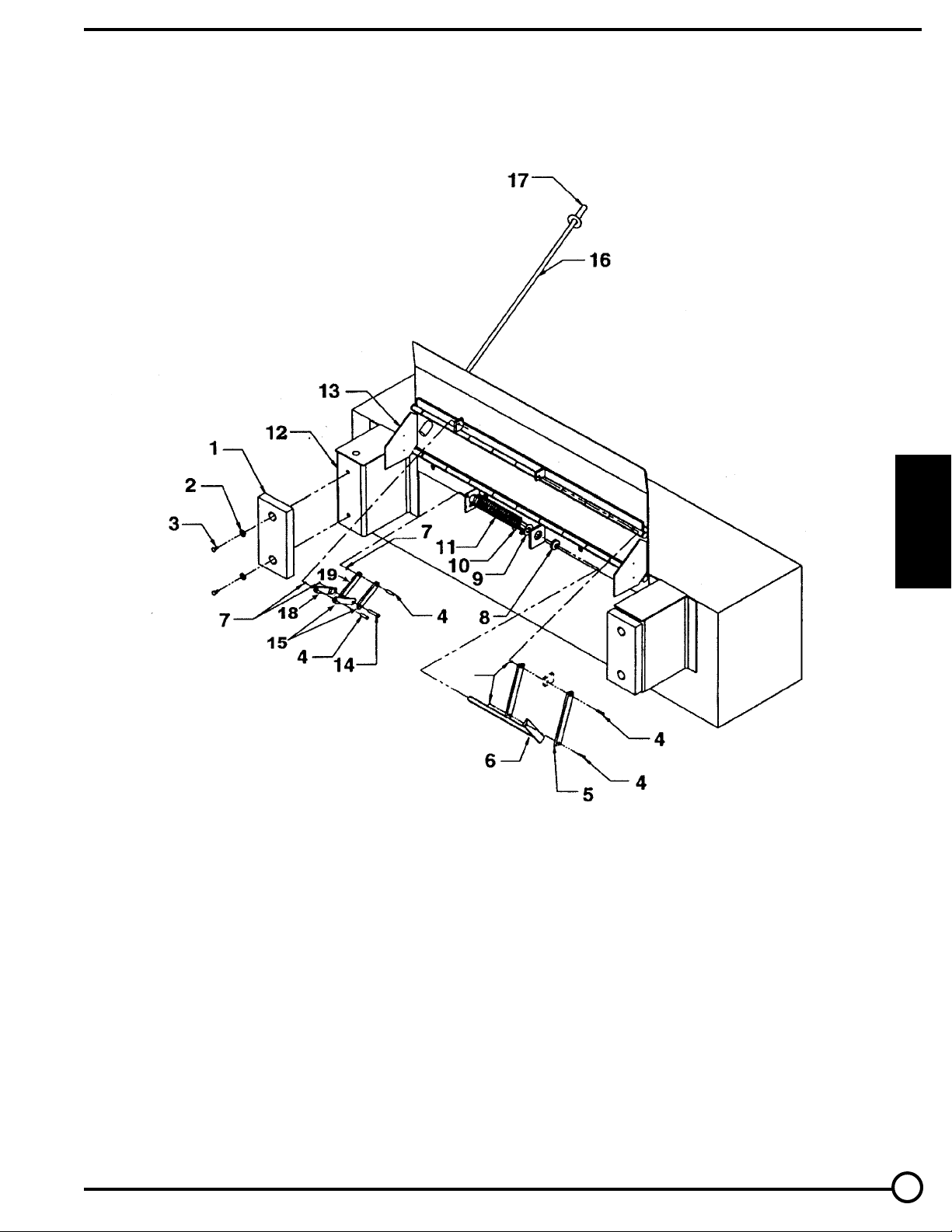

Exploded Parts Drawing (FM Series) ............9

Parts List (FM Series) ..................................10

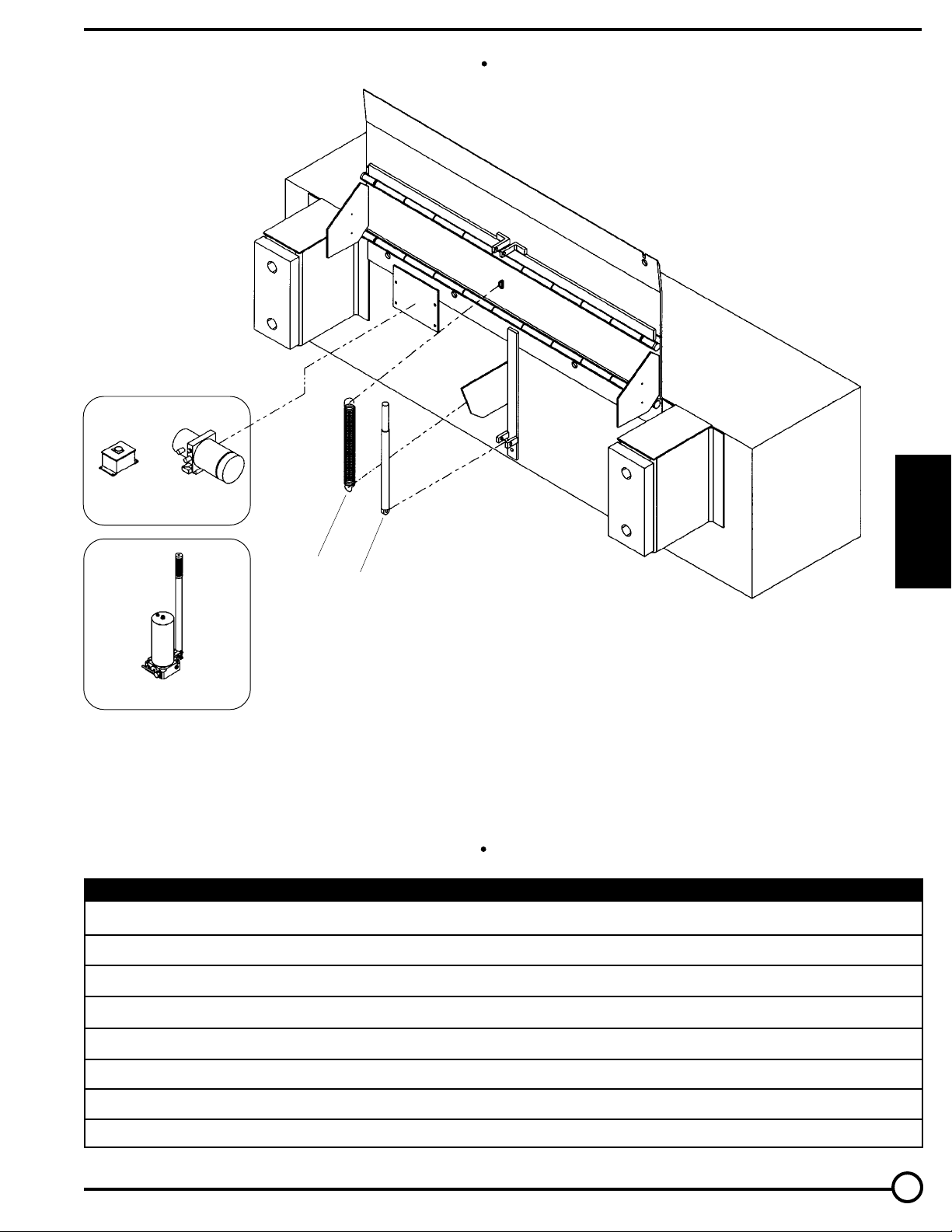

Exploded Parts Drawing (PP & PE) ............11

Parts List .....................................................11

Warning Label Identification ........................ 12

Limited Warranty/Service Record ................13

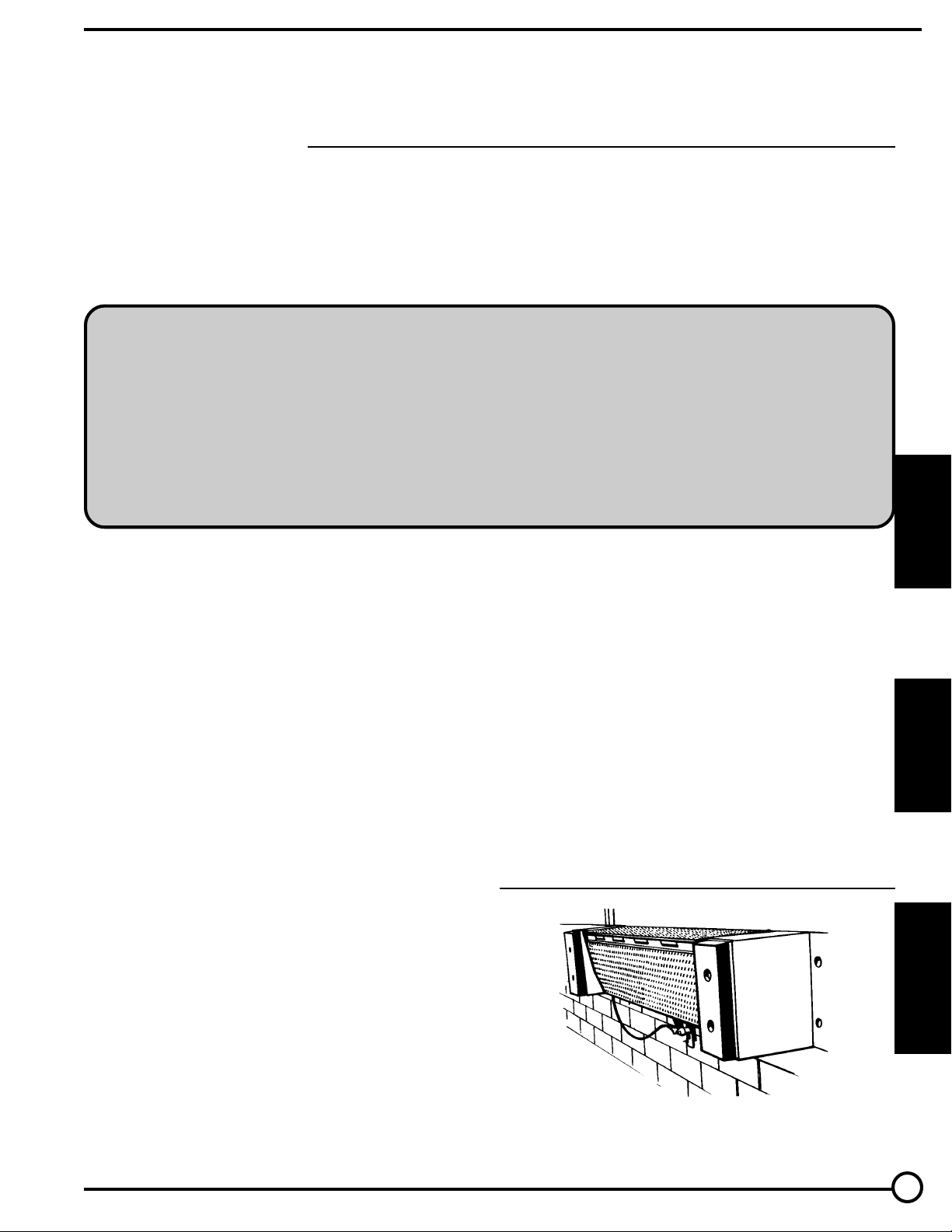

RECEIVING INSTRUCTIONS

Every unit is thoroughly tested and inspected

prior to shipment. However, it is possible that the unit

may incur damage during transit. If you see damage

when unloading, make a note of it on the BILL OF

LADING.

Remove all packing and strapping material,

inspect for damage. IF DAMAGE IS EVIDENT, FILE A

CLAIM WITH THE CARRIER IMMEDIATELY! Also,

check the unit size, type of power unit, etc., to see that

the unit is correct for the intended application.

MODEL NUMBER AND CAPACITIES

The model number, serial number and capacities

are inscribed on the nameplate. Please remember to

include these numbers in any correspondence with your

dealer or the factory.

EDGE-O-DOCK

FM / PP / PE SERIES

E

N

G

L

I

S

H

E

S

P

A

N

O

L

F

R

A

N

Ç

A

I

S

1

Page 2

LOADING INSTRUCTIONS

Mechanical Operation • Series FM

The load capacity rating as inscribed on the

nameplate of your unit designates its net capacity. This

capacity must never be exceeded, as permanent damage or

personel injury may result.

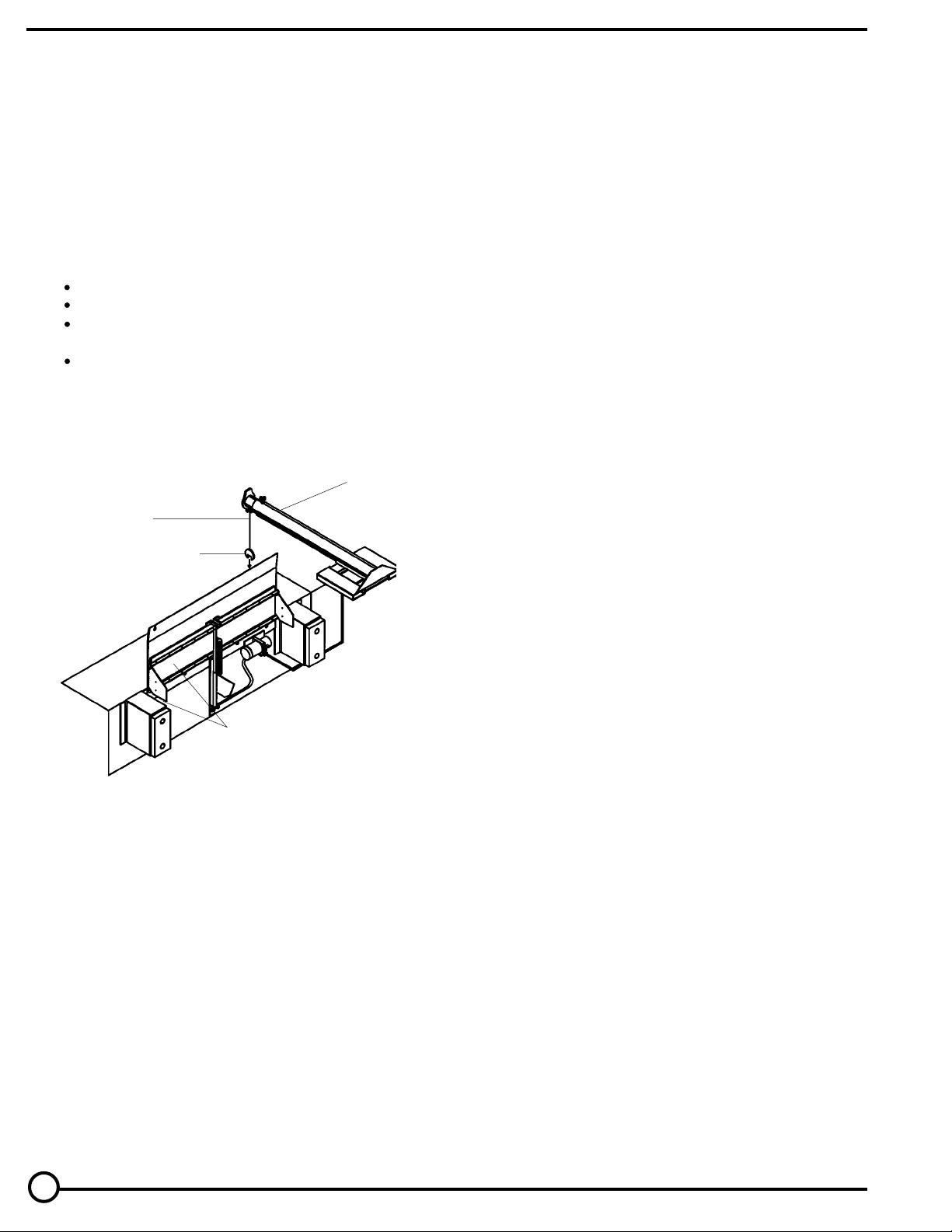

UNPACKING AND HANDLING INSTRUCTIONS

CAUTION

Read instructions completely before adjusting.

Follow instructions carefully.

Use end wrench, not crescent wrench, as crescent

may slip.

Recommended unpacking and handling is shown

below.

Recommended dock height is 50".

Service range is +5" to -5".

Fork Truck

Boom

Chain

Self-locking

Clamp

1.) Remove the lever from right side of bumper box and

insert it into the socket of the back plate (the socket is

on right hand side).

2.) Pull the handle back until the leveler plate is fully

extended and leaning back towards the ramp.

3.) Push the handle forward to allow the lip

plate to extend and fall on the bed of the trailer.

Do not operate without a truck in place as the operator

could be thrown over the dock edge by the lever.

4.) Remove the lever and place it in the bumper box.

5.) When loading and unloading is complete, remove

chocks and allow trailer to pull away. The Edge-ODock will return to its original position.

Hand Pump Operation • Series PP

1.) Rotate the valve on the pump clockwise to close the

fluid return valve. Raise the dockleveler with the hand

pump. When the dockleveler clears the trailer bed and

fully extends, open the return valve to allow the lip

to settle on the trailer bed.

Be sure to leave the

fluid return valve open to allow the dockleveler to

float with the trailer.

WARNING:

KEEP HANDS AND

FINGERS OUT OF

HINGE AREA!

OPERATING INSTRUCTIONS

I.) Back trailer slowly against Edge-O-Dock bumpers.

Turn off the engine and set the emergency brake on

truck. Position wheel chocks (by others) per OSHA

requirements to prevent trailer movement.

II.) Follow the instructions below according to the model

of Edge-O-Dock you have.

2.)

Electric Operation • Series PE

1.) Push "RAISE" button on control box. The dockleveler

2.) When loading/unloading is complete, remove the

When loading/unloading is complete, remove the

chocks and allow the trailer to pull away. The

Edge-O-Dock will return to its original position.

will begin to rise. When the dockleveler lip reaches

full extension, release the button. It will lower and

settle on the trailer bed.

chocks and allow the trailer to pull away. The

Edge-O-Dock will return to its original position.

Ordering Replacement or Extra Parts

Our company takes pride in using the finest available

parts for our equipment. We are not responsible for equipment

failure resulting from the use of unapproved replacement parts.

To order replacement or extra parts for your equipment contact

Customer Service at the factory. In any correspondence with

the factory please include the Serial Number which is inscribed

on the nameplate of the piece of equipment. Use only the part

numbers provided in this Owner's Manual. Please indicate the

motor phase and voltage that the equipment is operating on.

2

Page 3

INSTALLATION INSTRUCTIONS

(READ ALL INSTRUCTIONS BEFORE PROCEEDING!)

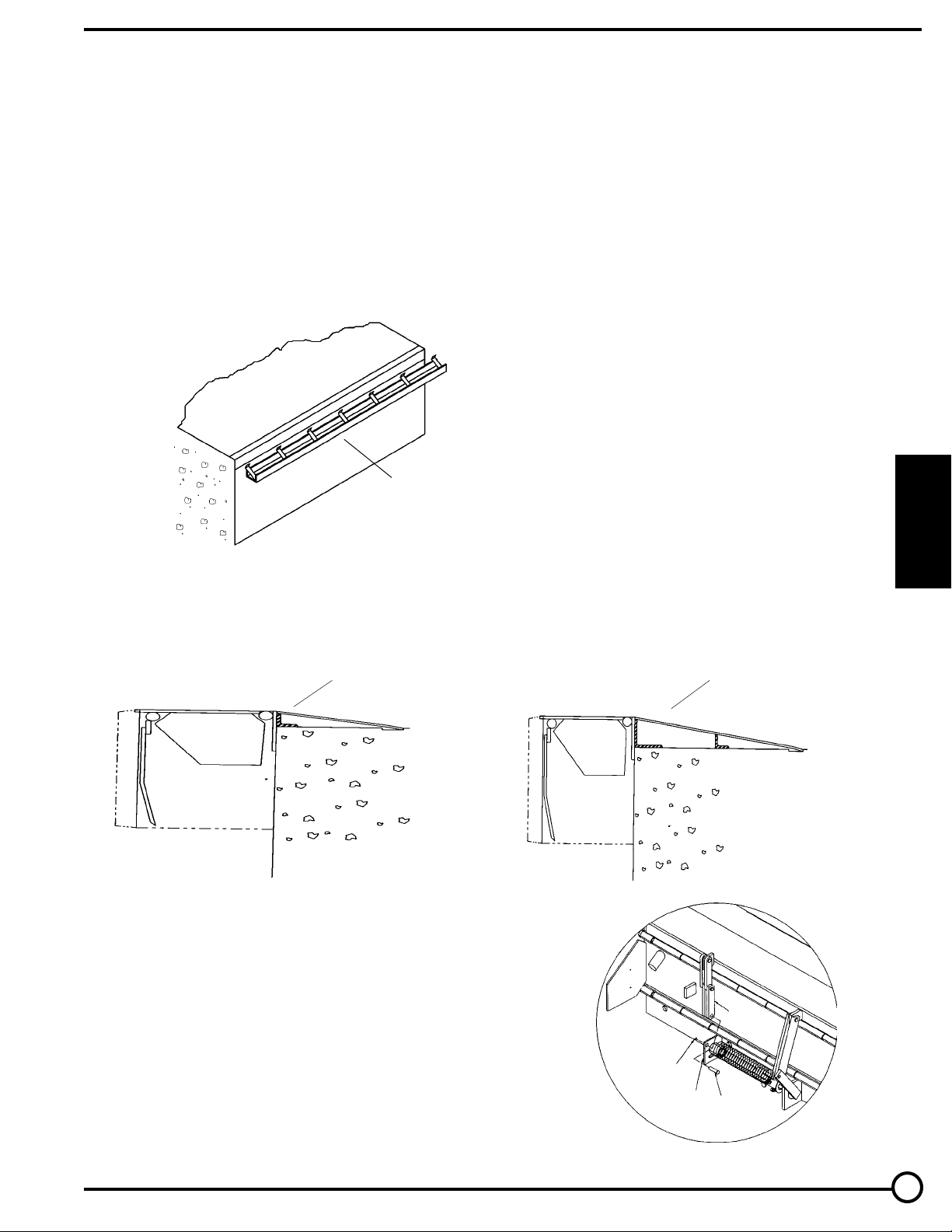

Dock Edge Construction

The procedure for the installation of the Edge-O-Dock dockleveler varies with the dock edge construction and the

height differential. The recommended dock edge for installing an Edge-O-Dock unit is a well anchored six inch channel. With

a six inch channel embedded in to the dock edge, the installer can weld the ramp and bumper blocks securely into position.

The ramp and blocks cannot be welded into position if the dock edge steel is less than six inches. For installations with less

than six inches of steel edging a combination of anchor bolts and welding is required. If the dock has no steel edging, a steel

plate must be anchored to the floor to provide a surface to weld the ramp to in order to maintain the capacity of the leveler.

Failure to follow the proper installation procedure will decrease capacity of dockleveler.

Recommended dock edge for new construction

The recommended dock edge for new

construction is a well anchored 6 inch

channel (8.2 lb. minimum). Concrete "J"

anchors shall be 1½ inches wide with a

length of 6 inches plus 1½ inches bent at

90 degrees on the end. Minimum material

6" Channel

thickness shall be ¼ inch. One anchor

shall be installed every 12 inches.

Height Differential

The optimum dock height in most cases is 50". On dock heights significantly different than 50", ramps and ramp

support angles as shown below must be employed.

E

N

G

L

I

S

H

Ramp Plate

96"W x 12"L x 2"H

48" High Dock 46" High Dock

Linkage Installation Instructions

FOR MECHANICAL EDGE-O-DOCK

1.) Remove the cotter pin from the clevis pin.

2.) Remove the clevis pin from the linkage arms.

3.) Move the lip plate down until the hole in the mounting bracket is

aligned with the holes in the link arms.

4.) Insert the clevis pin through the aligned holes and fasten with the

cotter pin.

COTTER PIN

MOUNTING

BRACKET

Ramp Plate

96"W x 24"L x 4"H

LINK

ARMS

CLEVIS

PIN

3

Page 4

INSTALLATION OF EDGE-O-DOCK • FM SERIES

Weld On Installation

(dock edge steel is 6" or greater)

Continuous weld

Bolt And Weld On Installation

(dock edge steel is less than 6")

Continuous weld

Mounting plate

1. Remove all material and protrusions from the face

of the dock.

2. Center the ramp in the doorway and tack weld at

each end. Be certain the mounting plate does not

extend above the edge of dock.

3. Continuously weld the mounting plate to the steel

dock edge.

4. Weld bumper blocks on each side of ramp. Weld

continuously across tops and down both sides.

1. Remove all material and protrusions from the face of

the dock.

2. Center the ramp in the doorway and tack weld at the

end. Be certain the mounting plate does not extend

above the edge of the dock.

3. Continuously weld the mounting plate to the steel

dock edge.

4. Weld bumper blocks on each side of ramp.

Weld continuously across top and down both sides.

5. Install one lag bolt 5/8" x 5" on the outside and

inside flanges of each bumper block.

6. Install at least two lag screws 3/4" x 5" along the

bottom of the mounting plate. Install four if the

concrete is flaky or steel is not rigid.

Bolt On Installation

(for docks without steel edges)

Approach

plate

1. Remove all material and protrusions from the face of

dock.

2. In installations where cartons or pallets are slid

along the building floor into the truck, the approach

plate must be recessed into a groove in the floor.

3. To install the groove, locate and mark the center of

the dock where ramp is to be mounted. Make a

centered chalk line 1/2 inch longer than ramp plate,

12 inches back from the face of the dock.

4. Using a SKIL ROTO Hammer No. 736, or similar

tool, cut a groove 3/8" deep x 2" wide x ramp

length plus 1/2 inch on the outside of the line. (The

groove will start 10" from the dock face and end

12" from dock face.)

5. Position the beveled and turned-down edge of

approach plate in the groove with opposite edge `

flush with the dock edge.

6. Anchor the plate to floor with four 5/8" x 5" lag bolts.

Do not tighten yet.

7. Center the mounting plate of leveler against the

approach plate anchored to floor. Tack weld the

mounting plate in place.

8. Continuously weld across the top. Chip and grind

as required.

9. Drill holes into the dock the through the holes in the

mounting plate. Depending on the cement condition,

up to 8 may be required.

10. Install anchors and bolts. Do not tighten.

11. Install bumper blocks on each side of ramp

mounting plate. Weld the top of the bumper blocks

to the ramp plate, and the side of the bumper blocks

to the ramp mounting the plate. Install two anchors

on each side of bumper blocks.

12. Tighten the anchor bolts on the face of the dock,

then on top of dock.

13. Weld and round-off (with grinder) the lag bolts on the

ramp plate.

4

Page 5

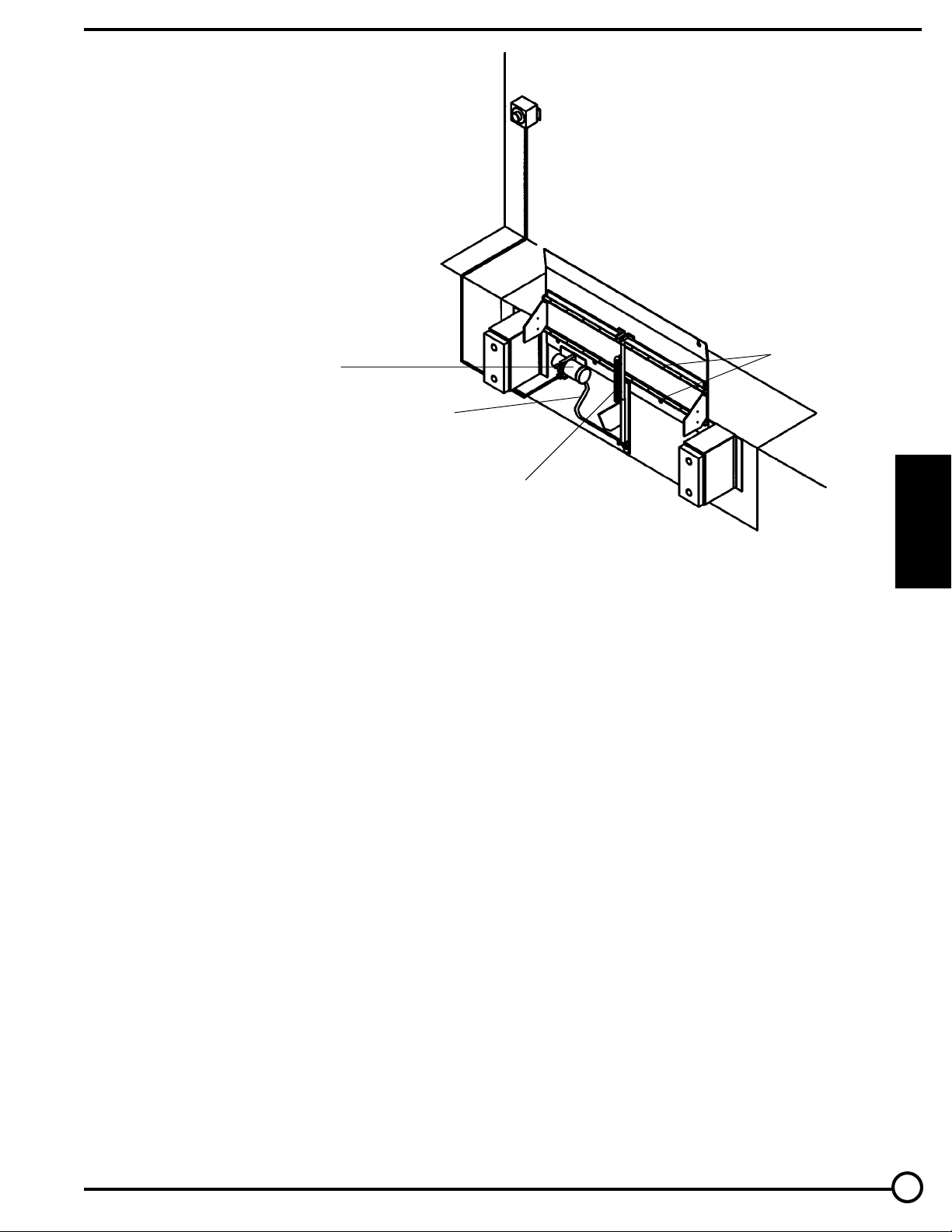

INSTALLATION OF EDGE-O-DOCK

PE AND PP SERIES

PE Series

Control Box

Hydraulic Power Unit

(Fill with AW-32 hydraulic oil)

Hydraulic Hose

Hydraulic Cylinder

Grease Fittings

E

N

G

L

S

H

Installation of PP Series

1. Install the PP leveler and bumpers per the preceding instructions.

2. Install the cylinder with the supplied parts (rod end up) at bottom only. Keep the cylinder closed (piston retracted).

3. Mount the hand pump adjacent to the leveler on a post or wall. Drill a hole thru the wall for hydraulic hose.

4. Attach the hydraulic line to the pump, run to the cylinder and loosely attach to the cylinder.

5. Fill the pump reservoir with the oil. Pump oil into line. Continue pumping slowly until air ceases to escape from cylinder.

6. Tighten fitting on cylinder and continue pumping until cylinder extends enough to attach to top bracket. Attach cylinder.

I

Installation of PE Series

1. Install the PE leveler and bumpers per preceding instructions.

2. Install the cylinder with the supplied parts (rod end up).

3. Remove the shipping plug in the reservoir and install the breather vent.

4. Mount the control box on the inside wall of the building at a convenient height. Drill a hole through the wall for 1/2"

conduit. Run the conduit from the hydraulic pump motor, below the bumper, and up through the hole previously drilled.

5. Follow standard electrical procedures and all applicable codes when installing the control box to the hydraulic unit

(See electrical the schematic on page 6).

6. Check the operation of the leveler. Push the RAISE button and hold it in until the cylinder is fully extended. Release the

button and the leveler should descend to a work position. If the leveler fails to operate, check the electrical connections

to verify proper connections, power source on, and fuses installed and functioning. Operate at least 6 full cycles.

7. Grease all hinge fittings at the time of installation and every 3 months thereafter.

5

Page 6

H

A

H

A

ELECTRICAL SCHEMATIC

1

P

S

E

3

P

S

E

BE SURE ALL POWER IS OFF BEFORE ATTEMPTING TO WORK ON THIS EQUIPMENT!

CAUTION: SERVICE WORK SHOULD BE PERFORMED ONLY BY TRAINED & QUALIFIED PERSONNEL

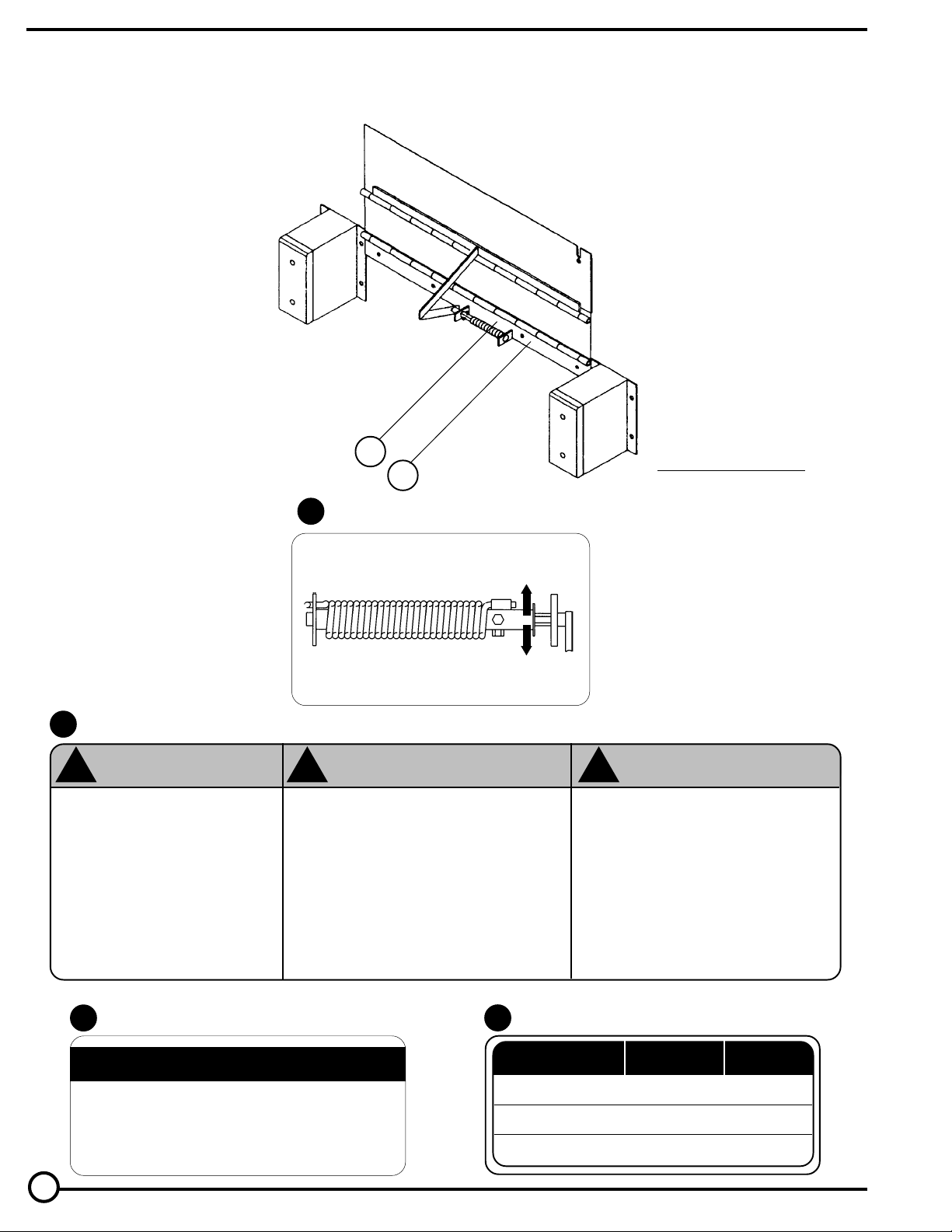

MECHANICAL EDGE-O-DOCK ADJUSTING INSTRUCTIONS

1.) Stand on the ground in front of the leveler. Raise the leveler to

to its vertical position. Place fork truck forks under lip to hold lip

out at nearly level position. Never work directly under fork truck forks.

2.) To adjust the counterbalancing force use the pipe lever

supplied with the dockleveler and a 3/4" open

end wrench or socket. Place the open end of the pipe

over the protrusion on the casting and rotate

down. We recommend one person to rotate the spring

with the pipe handle to the desired strength and

a second person to tighten the 3/4" bolts onto the milled flats.

3.) When the required lifting torsion is reached, return to

leveler to normal operating position. Check the

adjustments made, and, if not lifting properly, repeat the

previous steps to either increase or decrease spring

lifting torsion. If the leveler is bouncing or floating when

the lip is extended, there is too much lifting torsion.

Repeat the previous steps in reverse to reduce lifting torsion.

Torsion

spring

Decrease

Locking

bolt

Increase

Interior bar

Mounting

plate

Milled flats

Spring

winding tube

NOTE:

This is an excellent time to lubricate the grease zerks on the hinges. A standard grease gun will service

these. This must be done regularly for ease of operation and maintenance, as we recommend monthly.

6

Page 7

THE POWER UNIT'S OPERATION - PE

The electric / hydraulic edge-o-dock leveler utilizes an electric motor directly coupled to a gear-type hydraulic pump to produce the

needed fluid pressure and flow to allow the cylinder(s) to perform the work of lifting the dockplate.

A hydraulic manifold houses the hydraulic control components, and is bolted directly onto the gear pump.

The power unit's hydraulic components are all rated for 3,000 psi working pressure.

Important parts of power unit included:

• The electric motor. Motors are available for operaton on single- or three-phase AC supplies (all are dual-voltage capable.)

• The gear pump. Its shaft is coupled directly to the shaft of the electric motor.

• The check valve. Its purpose is to prevent the backflow of fluid through the pump.

• The pressure relief valve. Its job is to open a path for fluid to flow back to the reservoir in the event that the fluid pressure built up by

the pump exceeds 1,500 psi. Thus the system cannot see more than 1,500 psi.

• The pilot-operated check valve. This is a hydraulically-operated cartridge valve. It closes to allow oil flow to the cylinder(s) when the

system is under pressure, then opens to allow the levelers lip to fall when the system pressure drops after the motor turns off.

• The pressure-compensated flow control. This regulates the fluid flow from the cylinder(s) back to the reservoir when the

pilot-operated valve opens. It allows for the adjustment of the lip fall rate.

• The hydraulic lift cylinders(s).

• The hydraulic fluid. The system uses HO150 hydraulic fluid. Any anti-wear hydraulic fluid with an SUS viscosity of 150 - 200 at

100°F (SAE viscosity grade of 32) such as AW-32 or Dextron transmission fluid are acceptable.

When the leveler is to be extended, the operator presses the "RAISE" pushbutton. The motor turns, and in turning it spins the

hydraulic gear pump. Oil is drawn from the reservoir and into the pump. System pressure builds and causes the pilot-operated check

valve to close.

Once the lip extends out, the operator releases the pushbutton. The check valve prevents oil from from returning to the

reservoir through the pump. When the pressure in the hydraulic system drops sufficiently, the pilot-operated check valve opens

to allow the oil in the cylinder(s) to return back to the reservoir through the pressure-compenated flow control valve, which will

regulate the rate at which the lip lowers.

In the event that the lip won't raise, it will be necessary to remove the pilot-operated check valve for inspection and cleaning, as

follows:

• Secure the lip plate in the extended position to allow access to the power unit.

• Disconnect and lock out the leveler's power supply

• Remove the cartridge valve from the cavity marked POCV.

• Inspect for contaminants in the valve or the valve cavity.

• Wash the valve in mineral spirits or kerosene if possible. Blow off the valve with a compressed-air gun.

• Replace the valve and cycle the leveler several times.

E

N

G

L

I

S

H

Troubleshooting Guide for "PE" Series

Only qualified individuals trained to understand mechanical devices and their associated electrical and hydraulic circuits should

attempt troubleshooting and repair of this equipment.

Care should be taken to identify all potential hazards and comply with applicable safety procedures before beginning work.

Consult the factory for problems at time of installation, or for any problems not addressed below.

Before working on the power unit, always secure the lip plate outward and disconnect the power supply.

PROBLEM

Lever doesn't cycle when the

"RAISE" button is pressed.

POSSIBLE CAUSE

Motor doesn't run

Motor runs properly, but the deck doesn't

move or the lip doesn't extend. Motor and

pump not noisy.

Leveler raises but won't lower, or lowers

only slowly.

CORRECTIVE ACTION

• Use a multimeter to check: for proper supply (all

legs) and control voltage; for an "open anywhere

in the control circuit.

• Visually check for loose wiring or pushbutton

components.

• Verify the motor shaft rotates CCW.

• Ensure that the reservoir is full and that its fill

hole plug has been replaced by a breather plug.

• Check for items resting on the leveler.

• Install a pressure gauge to check hydraulic

system pressure. If it doesn't build to 1,500 psi,

consult the factory for a replacement pump.

• Remove, check and clean the pilot-operated

check valve.

• Remove, check and clean the pilot-operated

check valve and the flow control valve.

• Check for any binding of the mechanical parts;

hinge, etc.

7

Page 8

POWER UNIT ASSEMBLY, PE

BREATHER,

3/8" NPT

STRAINER,

O-RING,

PUMP RETAINING BOLT,

3/8"-16 x 1" SHCS

01-031-005

34ø-B47ø

O-RING, PARKER

O-RING ø15-8N7ø

TUBE,

99-031-009

MANIFOLD RETAINING

BOLT, 5/16"-18 x 1-1/4"

SHCS

ELECTRIC MOTOR,

01-135-032

O-RING

ø11-BN7ø

PUMP,

01-143-005

CHECK VALVE,

99-153-011

MANIFOLD ASSEMBLY,

99-627-015

FLOW

CONTROL,

99-153-022

MANIFOLD,

99-127-015

PILOT TO

CLOSE VALVE,

99-153-020

RELIEF,

99-153-006

8

Page 9

EDGE-O-DOCK FM SERIES

E

N

G

L

I

S

H

9

Page 10

PARTS IDENTIFICATION EDGE-O-DOCK

FM SERIES

KIT CODE

A

A, D

A,D

B, D, E

B,E

B,E

B, D,E

C,E

E

C, D,E

C,E

ITEM NO.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DESCRIPTION

Rubber bumper

Washer, 5/8"

Bolt 5/8"-11 UNC x 2 1/2"

Pin, 1/2" dia. x 1-3/4"

Secondary linkage arm

Main linkage arm

Cotter pin, 1/8" x 1-1/8"

Sealed roller bearing

Adjustment Collar

Bolt, 1/2"-13 UNC x 1"

Torsion spring

Bumper block

Toe guard (welding required)

Pin, 1/2" dia. x 2" long

ENGINEER NO.

29-005-001

33015

11313

06-112-003

07-040-003

07-612-001

65125

07-110-001

07-518-001

13205

07-146-009

30-048-001

07-024-002

07-112-007

PART NO.

EOD-RB

EOD-WSR

EOD-BOLT1

EOD-RP1

EOD-SLA

EOD-MLA

EOD-CP1

EOD-SRB

EOD-AC

EOD-BLT2

EOD-TS

EOD-BB

EOD-TG

EOD-CP2

QTY

2

4

4

4

2

1

5

1

1

1

1

2

2

1

15

16

17

18

19

Lip Extension Arm

Handle

Grip

Link Arm 2 (block welded on)

Link Arm 3 (knob on end)

A

B

C

D

E

F

Replacement bumper kit (items 1-3)

Replacement linkage kit (items 4-7)

Replacement spring kit (items 8,10,11)

Hardware kit (items 2-4,7,10)

Mechanical Kit (items 4-11)

Counter Balance Kit

07-016-018

07-025-004

07-025-005

07-516-009

07-016-021

07-154-001

07-154-002

07-154-004

07-154-003

07-154-005

07-154-006

EOD-LEA

EOD-HDL

EOD-PG

EOD-LEA-2

EOD-LEA-3

EOD-KIT-A

EOD-KIT-B

EOD-KIT-C

EOD-KIT-D

EOD-KIT-E

EOD-KIT-F

4

1

1

1

1

1

1

1

1

1

1

10

Page 11

12

PE SERIES ONLY

3

EDGE-O-DOCK PP AND PE SERIES

4

5

E

N

G

L

I

S

H

PP SERIES ONLY

ITEM NO.

1

2

3

4

5

6

7

8

DESCRIPTION

Control box

Power unit

Handpump

Extension spring

Hydraulic cylinder, 1" dia. x 14"

PP Hose Kit

PE Hose Kit

Cylinder Retaining Bolt

PARTS IDENTIFICATION

EDGE-O-DOCK PP AND PE SERIES

ENGINEER NO.

PE-CONBOX

PE-MOPU

PP-HDPUMP

15146001

06021001

06-623-007

06-623-006

n/a

PART NO.

PE-CONBOX

PE-MOPU

PP-HDPUMP

EOD-ES

EOD-HC

EOD-PP-HK

EOD-PE-HK

EOD-PP-PE-CYLP

QTY

1

1

1

1

1

1

1

2

11

Page 12

WARNING LABEL IDENTIFICATION

MAKE SURE ALL WARNING LABELS ARE IN PLACE!

*Product safety signs or labels should be

periodically inspected and cleaned by the

product users as necessary to maintain good

legibility for safe viewing distance ...

ANSI 535.4 (10.21)

Contact manufacturer for replacement labels.

2

FM SERIES ONLY

!

CAUTION

CONSULT OWNERS MANUAL BEFORE

SECURE AND HOLD LIP IN VERTICAL POSITION.

HOLD SQUARE TUBING SECURELY BEFORE

LOOSENING LOCKING BOLTS WITH ANOTHER

WRENCH. ADJUST IN DESIRED DIRECTION,

THEN TIGHTEN LOCKING BOLTS ON FLATS OF

INTERIOR ROUND BAR. CHECK FOR LIFTING

EFFORT AND REPEAT OPERATION IF NEEDED.

LIP AND PLATE SHOULD NOT FLOAT WHEN LIP

IS EXTENDED. DECREASE COUNTERBALANCE

IF NEEDED. GREASE HINGES, OIL LINKAGE, AND

CHECK FOR WEAR MONTHLY.

ADJUSTING

T & S EQUIPMENT CO. ANGOLA, IN

1

2

1

FM SERIES ONLY

DECREASE COUNTER BALANCE

REDUCIR EL CONTRA BALANCE

DIMINUER LE CONTRE-POIDS

INCREASE CONTER BALANCE

INCREMENTAR EL CONTRA BALANCE

AUGMENTER LE CONTRE-POIDS

!

PRECAUCION

CONSULTE EL MANUAL DEL PROPIETARIO ANTES

ASEGURE Y MANTENGA LA CEJA EN POSICION VERTICAL.

MANTENGA EL TUBO CUADRADO DE FORMA SEGURA ANTES DE SOLTAR LOS PERNOS CON OTRA LLAVE. AJUSTE

EN LA DIRECCION DESEADA. ENTONCES APRIETE LOS

PERNOS DE SEGURO EN LAS PARTES PLANAS DE LA

BARRA INTERIOR. COMPRUEBE EL ESFUERZO DE

LEVANTAMIENTO Y REPITA LA OPERACION SI ES

NECESARIO. LA CEJA Y LA PLATAFORMA NO DEBEN

FLOTAR CUANDO LA CEJA ESTA EXTENDIDA. REDUZCA EL

CONTRABALANCE SI ES NECESARIO. ENGRASE LAS

BISAGRAS, FUGAS DE ACEITE, Y REVISE POR DESGASTE

MENSUALMENTE.

DE AJUSTAR

T & S EQUIPMENT CO. ANGOLA, IN T & S EQUIPMENT CO. ANGOLA, IN

FM MODEL SHOWN

244

!

PRUDENCE

CONSULTER LE MANUEL DU PROPIÉTAIRE

ASSURER ET MAINTENIR LE REBORD EN POSITION

VERTICALE. BIEN TENIR LE TUBE CARRÉ AVANT DE

DESSERRER LES BOULONS DE VERROUILLAGE AVEC

UNE AUTRE CLÉ. AJUSTER À LA POSITION DÉSIRÉE.

PUIS SERRER LES BOULONS SUR LES SURFACES

PLANES À L’INTÉRIEUR DE LA BARRE. VÉRIFIER

L’EFFORT D’ÉLEVATION ET RÉPÉTER L’OPÉRATION SI

NÉCESSAIRE. LE REBORD ET LA PLAQUE NE

DEVRAIENT PAS FLOTTER LORSQUE LE REBORD EST

ÉTENDU. RÉDUIRE LE CONTRE-POIDS SI NÉCESSAIRE.

GRAISSER LES CHARNIÈRES, HUILER LES JOINTURES

ET VÉRIFIER L’USURE MENSUELLEMENT.

AVANT D’AJUSTER

245

PP & PE SERIES ONLY

3 4

LOCATED ON HAND PUMP OR POWER UNIT

ISO AW-32

HYDRAULIC OIL OR EQUIVALENT

ACEITE HIDRÁULICO O EQUIVALENTE

HUILE OU ÉQUIVALENT

12

206

PE SERIES ONLY

LOCATED ON POWER UNIT

NOTICE NOTA AVIS

POWER SUPPLY: 115 Volt/1 Phase/60 HZ

CONTROL VOLTAGE: 24 VOLT AC

CORRIENTE: 115 Volt/1 Fase/60 HZ

VOLTAJE DE CONTROL: 24 VOLT CA

ALIMENTATION ÉLECTRIQUE: 115 Volt/1 Phase/ 60 HZ

VOLTAGE DE CONTRÔLE: 24 VOLT AC

248

Page 13

LIMITED WARRANTY

ONE YEAR LIMITED WARRANTY. The manufacturer warrants for the original purchaser against

defects in materials and workmanship under normal use one year after date of purchase. (Not to exceed

15 months after date of manufacture.) Any part which is determined by the manufacturer to be defective

in material or workmanship and returned to the factory, shipping costs prepaid, will be, as the exclusive

remedy, repaired or replaced at our option. Labor costs for warranty repairs and/or modifications are not

covered unless done at manufacturer’s facilities. Any modifications performed without written approval

of the manufacturer may void warranty. This limited warranty gives purchaser specific legal rights which

vary from state to state.

LIMITATION OF LIABILITY. To the extent allowable under applicable law, the manufacturer’s

liability for consequential and incidental damages is expressly disclaimed.

The manufacturer’s liability in any event is limited to, and shall not exceed, the purchase price paid.

Misuse or modification may void warranty.

WARRANTY DISCLAIMER. Our company has made a diligent effort to illustrate and describe the

products shown accurately; however, such illustrations and descriptions are for the sole purpose of

identification, and do not express or imply a warranty that the products are merchantable, or fit for a

particular purpose, or that the products will necessarily conform to the illustrations or descriptions.

The provisions of the warranty shall be construed and enforced in accordance with the

UNIFORM COMMERCIAL CODE and laws as enacted in the State of Indiana.

DISPOSITION. Our company will make a good faith effort for prompt correction or other

adjustment with respect to any product which proves to be defective within the Limited Warranty.

Warranty claims must be made in writing within said year.

SERVICE RECORD

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

E

N

G

L

I

S

H

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

_______________________________________________________

DATE OF SERVICE:_____/_____/_____

WORK DONE BY:______________________________

SERVICE PERFORMED:__________________________________

_______________________________________________________

_______________________________________________________

13

Page 14

Vestil Manufacturing Corporation

2999 North Wayne St., Angola, IN 46703

Ph 260-665-7586 Fax: 260-665-1339

www.vestil.com E-mail: sales@vestil.com

Soluciones de Carga de Andén

Contenido

Avertencias e instrucciones de seguridad ..........14

Instrucciones de recibo ....................................... 15

Instrucciones de carga........................................ 15

Instrucciones de desempaque y de manejo........ 15

Instrucciones de uso ........................................... 15

Instrucciones de instalación........................... 16-18

Esquema eléctrico .............................................. 19

Instrucciones de ajuste del muelle (serie FM)..... 20

Revisado 06-04 07-126-101

Una compañia dedicada a resolver problemas

ergonómicos y de manejo del material desde 1955.

MANUAL DEL

PROPIETARIO

CANTO DE ANDEN • SERIE FM / PP / PE

Canto de andén (serie FM)

Dibujos explosivos de partes ................................. 20

Lista de partes ....................................................... 21

Canto de andén (serie PP y PE)

Dibujos explosivos de partes ................................. 22

Lista de partes ....................................................... 22

Identificación de las etiquetas de aviso ................. 23

Garantia limitada .................................................... 24

ADVERTENCIAS E INSTRUCCIONES DE

SEGURIDAD

Lea el manual del propietario completamente antes de

usar la unidad!

• Nunca exceda la capacidad máxima de carga inscrita en

la placa.

• Carge la unidad lo más uniforme posible.

E

• Consulte con el fabricante para cargas no uniformes.

S

• Nunca opere la unidad a no ser que usted la este

P

vigilando.

A

• Mantenga las manos y los pies alejados de las

N

areas de enganche.

• No use la unidad a no ser que las barras de

O

seguridad esten en su lugar.

L

• No agarre el cilindro ya que la cesta se podria torcer.

• No cambie la válvula de escape de presión (series PP y

PE).

• No continue apretando el botón"UP" si la unidad no se

eleva (serie PE).

• No continue bombeando la bomba de mano si la unidad

no se eleva (series PP).

• Quite el peso antes de usar la unidad.

• Desconecte la electricidad antes de reparar la unidad

(serie PE).

• No use liquidos de freno. Use aceite hidráulico AW-32 o

equivalente (series PP y PE).

• Consulte con la fábrica si se hacen modificaciones al

equipo original.

• Use solo partes de reemplazo provistas o aprobadas por

el fabricante.

• Asegurese de que todas las etiquetas de seguridad

estan en su lugar (p. 25).

INSTRUCCIONES DE RECIBO

Cada unidad está inspeccionada a fondo y

probada antes del envio. Aun asi, es posible que la unidad

se dañe durante el envio. Si ve algun daño durante la

descarga anótelo en el RECIBO DE ENVIO.

Quite todo el material de empaquetado y las

correas, inspeccione por daños. SI HAY DAÑOS

EVIDENTES, ARCHIVE UNA RECLAMACIÓN CON EL

TRANSPORITISTA IMMEDIATAMENTE. Tambien

compruebe el tamaño, el tipo de electricidad, etc. para

comprobar que la unidad que tiene es la correcta para el

trabajo.

NUMERO DE MODELO Y CAPACIDAD

El número de modelo, el número de serie y la

capacidad estan inscritos en la placa. Porfavor recuerde

incluir estos numeros en cualquier correspondencia con su

proveidor o con la fábrica.

14

CANTO DE ANDEN

SERIE FM / PP / PE

Page 15

INSTRUCCIONES DE CARGA

Operación Mecánica - Serie FM

La capacidad de carga que ha sido inscrita en la

placa de su unidad designa la capacidad neta, asumiendo

que la carga este centrada. Esta capacidad no se debe

exceder nunca, ya que podrian ocurrir daños permanentes.

INSTRUCCIONES DE DESEMPAQUE Y

MANEJO

PRECAUCION

• Lea las instrucciones completamente antes de ajustar.

• Siga las instrucciones con cuidado.

• Use una llave inglesa para que no resbale.

• Las recomendaciones de desempaque y de manejo se

muestran a continuación.

• La altura recomendada del andén es de 127 cm.

• El grado del servicio es de +12.7 cm a -12.7 cm.

Vara del

Camión

Cadena

Grapa

Autocerrante

1.) Desmonte la manivela de la parte derecha de la caja e

insertela en el agujero del plato trasero (el agujero este

en el lado derecho.

2.) Estire la manivela hacia atras hasta que el plato este

totalmente extendido y se caiga en la plataforma del

trailer

3.) Empuje la manivela hacia delante, esto hara que el

borde del plato se extienda y caiga en la plataforma del

trailer.

4.) Demonte la manivela y coloquela en la caja.

5.) Cuando la carga y descarga este completa, quite los

topes y permita que el trailer se separe. El borde de

reqressara a la posicion original.

Operación de Bombeo Manual - Serie PP

1.) Para cerrar la válvula de regreso gire la válvula de la

bomba hacia la derecha. Levante el nivel con la bomba

manual. Cuando el nivel esté libre de la base del

remolque y se extienda completamente, libere la

presión para dejar que el borde se asiente en la base

del remolque. Asegurese de dejar la válvula de regreso

abierta para dejar que el nivel flote con el remolque.

AVISO:

Mantenga las

Manos y los dedos

fuera del Area de

Engranaje

INSTRUCCIONES DE USO

I.) Retroceda el remolque lentamente contra los

parachoques del Canto-De-Andén. Apage el motor y

ponga el freno de emergencia del camión. Ponga los

topes de las ruedas (Topes de las ruedas; no incluidos)

por los requisitos de OSHA para prevenir que el

remolque se mueva.

II.) Siga las instrucciones abajo según el modelo de Canto-

De-Andén que tenga.

2.) Cuando la carga/descarga se haya completado,

remueva los topes y deje que el remolque se aparte.

El Canto-De-Andén regresará a la posición original.

Operación Eléctrica- Serie PE

1.) Apriete el botón UP (arriba) en la caja de control. El

nivel se empezará a elevar. Cuando el borde del nivel

alcance la extensión máxima se empezará a bajar para

asentarse en la base del remolque.

2.) Cuando la carga/descarga se haya completado

remueva los topes y deje que el remolque se aparte. El

Canto-De-Andén regresará a la posición original.

Pedido de partes extra o de reemplazo

Nuestra compañia está orgullosa de utilizar en nuestro

equipo las partes disponibles más buenas. No nos hacemos

responsables si el equipo no funciona correctamente si se han

usado partes de reemplazo sin aprobar. Para pedir partes

extras o de reemplazo para su equipo contacte el Servicio del

Cliente de la fábrica. En toda la correspondencia con la fábrica

porfavor incluya el número de serie que está inscrito en la

placa del equipo. Solo use los números de partes provistos en

este Manual del Propietario. Cuando pida partes para las

unidades eléctricas AC porfavor indique la fase y el voltaje del

motor que el equipo utiliza.

15

Page 16

INSTRUCCIONSES DE INSTALACIÓN

(LEA TODAS LAS INSTRUCCIONES ANTES DE SEGUIR!)

CONSTRUCCIÓN DEL CANTO-DE-ANDÉN

El procedimiento de instalación del Canto-De-Andén es una función entre el Canto-De-Andén y la altura diferencial. El borde

recomendado para instalar el Canto-De-Andén es un buen canal de seis pulgadas. Con un canal de seis pulgadas en el canto

del muelle, el instalador puede soldar la rampa y los topes de seguridad en posición. La rampa y los topes no pueden ser

soldados en posición si el canto-del andén de aluminio es menor de seis pulgadas. Para instalaciones de borde de aluminio

menor de seis pulgadas se recomienda una combinación de tornillos de anclaje y soldadura. Si el andén no tiene un extremo

de aluminio, un plato de aluminio debe de ser fijado al piso para proveer una pieza para poder soldar la rampa de esta manera

la capacidad del nivel se matendrá. Mal uso de alguna de las siguientes instalaciones podria dismimuir la capacidad del

nivel.

Borde de andén recomendado para construcción nueva

El borde recommendado para instalar el Canto-DeAndén es un buen canal de 15 cm (3.7 kg. minimio). Las

anclas "J" de hormigón deben de ser de 38 mm de ancho

con una longitud de 6 pulgadas más 38 mm en el extremo

15 cm Canal

con una doblez de 90 grados. El espesor minimo del

material debe de ser 6 mm. Cada 30 cm se debe instalar

un ancla.

ALTURA DIFERENCIAL

La altura optima del andén en la mayoria de los casos es de 127 cm. En andenes con una altura muy diferente a 127 cm,

una rampa y un ángulo de soporte deben de ser utilizados como se demuestra a continuación.

E

S

P

A

Plato de rampa

244 cm w x 30 cm

l x 5 cm h

Plato de rampa

244 cm w x 61 cm l

x 10 cm h

N

O

L

122 cm Altura del andén 117 cm Altura del andén

Instrucciones de Instalación del Enlace

PARA EL CANTO DE ANDÉN MECÁNICO

1.) Desmonte el pasador de la clavija.

2.) Desmonte la clavija del soporte de enlace.

3.) Mueva el labio hacia abajo hasta que el agujero de la repisa este

en linea con los agujeros del soporte de enlace.

4.) Inserte la clavija a traves de los agujeros en linea y apriete con el

pasador.

PASADOR

REPISA

SOPORTE DE

ENLACE

CLAVIJA

16

Page 17

INSTALACIÓN DEL CANTO DE ANDEN • SERIE FM

INSTALACIÓN CON SOLDADURA

(el borde de aluminio del andén es de 15 cm ó mayor)

1. Remueva todo el material y sobresalientes del andén.

2. Centre la rampa en la entrada y suelde a cada extremo.

Soldadura

Continua

3. Suelde el plato montante con continuidad al borde de

4. Suelde los bloques parachoques a cada lado de la

Asegurese que el plato montante no sobresalga por

encima del canto del andén.

aluminio del andén.

rampa. Suelde con continuidad a través de la parte

superior e inferior en ambos lados.

INSTALACIÓN CON TORNILLOS

(el borde de aluminio del andén es menor de 15 cm)

Soldadura

Continua

Plato Montante

INSTALACIÓN CON TORNILLOS

(

Para andén sin borde de aluminio)

Plato de

Aproximación

1. Remueva todo el material y sobresalientes del andén.

2. En instalaciones donde cajas ó transpaletas se deslizan

sobre el piso del edificio hasta el camión, el plato de

aproximación debe de ser insertado dentro de una

ranura en el piso.

3. Para crear la ranura, localice y marque el centro del

andén donde se va a montar al rampa. Marque con una

tiza una linecentrada 1.27 cm pulgada más larga que el

plato de la rampa, 30 cm más atras del frente del

andén.

4. Usando un martillo tipo SKIL ROTO no 736, ó una

herramienta similar, corte una ranura de 9 mm de

profundidad x 5 cm de ancho x longitud de la rampa

más 1.27 cm pulgada del exterior de la linea. (la ranura

1. Remueva todo el material y sobresalientes del muelle.

2. Centre la rampa en la entrada y suelde a cada extremo.

Asegurese que el plato montante no sobresalga por

encima del canto del andén.

3. Suelde el plato montante con continuidad al borde de

aluminio del andén.

4. Suelde los bloques parachoques a cada lado de la rampa.

Suelde con continuidad a través de la parte superior e

inferior en ambos lados.

5. Instale un tornillo de 15 mm x 12.7 cm fuera y dentro del

reborde de cada bloque parachoque.

6. Instale como mínimo dos tornillos autorodantes de 19 mm

x 12.7 cm a lo largo de la parte inferior del plato montante.

Instale cuatro si el hormigón está escamoso ó el aluminio

no es rigido.

empezará 25 cm desde el frente del andén y terminará

12.7 cm del frente del andén).

5. Ponga el bisel y gire el borde del plato de aproximación

hacia la ranura con el borde opuesto contra el canto del

andén.

6. Ancle el plato al piso con cuatro tornillos de 15.8 mm x

12.7 cm. No apriete todavia.

7. Centre el plato montante del nivel contra el plato de

aproximación anclado en el suelo. Suelde el plato

montante en posición.

8. Suelde con continuidad a traves de la parte superior.

Astille y afile.

9. Taladre agujeros en el andén a través de las

perforaciones del plato montante. Dependiendo de las

condiciones del cemento, hasta 8 agujeros podrian ser

necesarios.

10. Instale las anclas y tornillos. No apriete.

11. Instale los bloques parachoques a cada lado del plato

montante de la rampa. Suelde el bloque al plato

montante de la rampa. Instale dos anclas a cada lado

del bloque parachoque.

12. Apriete los tornillos del ancla a la cara del andén, y a la

parte superior del andén.

13. Suelde y redondee (con afilador) los tornillos del plato

de la rampa.

17

Page 18

INSTALACIÓN DEL CANTO DE ANDEN

SERIES PE Y PP

Unidad eléctrica hidráulica

(llene con aceite hidráulico AW-32)

Manga Hidráulica

Cilindro Hidráulico

INSTALACIÓN DE LA SERIE PE

1. Instale el nivel PE y los parachoques con las instrucciones anteriores.

Caja de control

serie PE

Ajustes

engrasados

2. Instale el cilindro con las partes provistas (extremo de varilla hacia arriba).

3. Remueva el tapón del depósito e instale un ventilador de respiración.

4. Monte la caja de control en la pared en el interior del edificio a una altura conveniente al mismo lado que la bomba/motor.

Taladre un agujero a través de la pared para un conductor de 12.7 mm. Lleve el conductor desde la bomba del motor

hidráulico, debajo del parachoque, a través del agujero previamente taladrado.

E

S

5. Siga los procedimientos y códigos standard de electricidad para conectar la caja de control a la unidad hidráulica

P

(vea el esquema eléctrico).

A

N

6. Compruebe la operación del nivel. Apriete el botón UP (Arriba) y aguántelo hasta que el cilindro se extienda

O

completamente. Libere el botón y el nivel deberá descender a la posición de trabajo. Si el nivel no funciona,

L

compruebe las conexiones eléctricas para verificar que están correctamente conectadas, la electricidad en la

posición ON, y los fusibles instalados y funcionando. Opere como minimo 6 ciclos enteros.

7. Engrase las bisagras al momento de instalar y cada 3 meses.

INSTALACIÓN DE LA SERIE PP

1. Instale el nivel PE y los parachoques con las instrucciones anteriores.

2. Instale el cilindro con las partes provistas (extremo de varilla hacia arriba) en solo la parte inferior. Mantenga el cilindro

cerrado (el pistón recogido).

3. Monte la bomba manual contigua a un poste ó pared. Taladre un agujero a traves de la pared para la manga hidráulica.

4. Fije la linea hidráulica a la bomba, lleve al cilindro y fije al cilindro sin apretar.

5. Llene el depósito con aceite. Bombee el aceite a la linea. Continue bombeando lentamente hasta que el aire cese de

escaparse del cilindro.

6. Apriete las bisagras al cilindro y continue bombeando hasta que el cilindro se extienda y llegue al soporte superior. Fije

el cilindro.

18

Page 19

P

H

A

S

E

P

H

A

S

E

ESQUEMA ELÉCTRICO

1

3

ASEGURESE QUE LA CORRIENTE ESTÁ APAGADA ANTES DE TRABAJAR EL ESTE EQUIPO!

AVISO: LAS REPARACIONES SOLO DEBEN DE SER EFECTUADAS POR PERSONAL ENTRENADO Y CALIFICADO.

INSTRUCCIONES DE AJUSTE DE CANTO - DE - ANDÉN MECÁNICO

1.) Situese en el piso delante del nivel. Levante el nivel a la posición vertical. Ánclelo fijamente en esta posición

(asegure la barra en posición fijando la cadena a través del agujero y anclando a la transpaleta ó al tope de la puerta).

2.) Para ajustar la fuerza de contrabalance use el mango de

tubo suministrado con el nivelador de andén y una llave

abierta de 3/4" o socket. Ponga el extremo abierto del

tubo sobre la protrusión de la rueda y gir hacia abajo.

Recomendamos que una persona gir el tubo con el

mango de tubo hasta la posición deseada y una segunda

persona aprite los tornillos de 3/4" hacia milled planos.

3.) Cuando la elevación requerida de torsión se ha conseguido,

vuelva el nivelador a la posición normal de operación.

Compruebe los ajustes hechos, y, si no se eleva

adecuadamente, repita los pasos anteriores para

incrementar o disminuir el muelle de torsión de elevación.

Si el nivelador brinca o flota cuando el labio se extiende,

hay demasiada torisión de elevación. Repita los pasos

anteriores para reducir la torsión de elevación.

Muelle de

torsión

Tornillo de

cierre

Disminuir

Incrementar

Tubo de

rosca

Barra interior

Molinillo

plano

Plato

montante

NOTA:

zerks grasos en las bisagras. Una pistola estandard de

engrase servirá para esto. Esto debe de ser hecho

regularmente para la fácil operación y mantenimiento,

recomendamos mensualmente.

Este es una excelente ocasión para lubricar los

19

Page 20

LA OPERACIÓN DE LA UNIDAD ELÉCTRICA - PE

El nivelador de borde de andén eléctrico/hidráulico utiliza un motor eléctrico directamente acoplado a una bomba hidráulica de tipomarcha para producir la presión de flujo necesaria y corriente para permitir que el cilindro(s) haga el tabajo de elevar el plato del andén.

Una caja hidráulicos contiene los componentes de control hidráulicos, y está atornillada directamente a la bomba de marcha.

Los componentes hidráulica contiene los componentes de control hidráulicos de la unidad eléctrica están tasados para trabajar con

una presión de 3,000 psi.

Partes importantes de la unidad eléctrica son:

• El motor eléctrico. Los motores están disponibles para operaciones de simple o tri-fase suministros de AX (ambos son capaces de

voltaje-dual)

• La caja de marcha. Su eje está sujeto direcamente al eje del motor eléctrico.

• La válvula de chequeo. Su propósito es prevenir la contracorriente de flujo a través de la bomba.

• La válvula de relieve de presión. Su trabajo es el de abrir un paso para que el flujo vuelva hacia el depósito en caso de que la

presión de flujo en la bomba exceda 1,500 psi. Ya que el sistema no puede tener más de 1,500 psi.

• La válvula de chequeo de operación-piloto. Esta es una válvula de cartucho de operación hidráulica. Se cierra para permitir que el

aceite fluya hacia el cilindro(s) cuando el sistema está bajo presión, entonces se abre permitiendo que el nivel del labio descienda

cuando la presión del sistema baja depués de que el motor se apage.

• El control de flujo de presión compensada. Este regula la corriente de flujo del cilindro(s) hacia el depósito cuando la válvula de

operación piloto se abre. Esto permite el ajuste de velocidad de caida del labio.

• El cilindro(s) hidráulico de elevación.

• El flujo hidráulico. El sistema usa flujo hidráulico HO150. Cualquier flujo hidráulico de anti-gasto com una viscosidad SUS de 150-

200 a 100 F (SAE viscosidad de grado 32) tal como AW-32 o flujo de transimisión Dextron son aceptables.

Cuando el nivel se tenga que extender, el operario aprieta el botón de elevar "RAISE". El motor gira y al mismo tiempo hace

girar la bomba hidráulica de la marchas. El aceite sale del depósito hacia la bomba. La presión del sistema se eleva y causa que la

válvula de chequeo de operación piloto se cierre.

Una vez el labio de ha extendido, el operario deja de apretar el botón. La válvula de chequeo previene que el aceite

regrese al depósito a través de la bomba. Cuando la presión del sistema hidráulico desciende lo suficiente, la válvula de chequeso

de operación piloto se abre para permitir que el aceite del cilindro(s) regrese al depósito a través de la válvula de control de flujo de

presión compensada, que regula la velocidad de descenso del labio.

En caso de que el labio no se eleve, será necesario desmontar la válvula de chequeo de operación piloto para poder

inspeccionarla ya limpiarla, tal como se explica a continuación:

• Asegure el plato del labio en la posición extendida para permitir el asseso a la unidad eléctrica

• Desconecte y cierre el suministro eléctrico del nivelador

• Desmonte el cartucho de la válvula de la cavidad marcada POCV

• Inspeccione los contaminantes de la válvula o la cavidad de la válvula.

E

• Limpie la válvula en minerales o petróleo si es posible. Sople la válvula con una pistola de aire comprimido.

S

• Vuelva a poner la válvula y cicle el nivelador varias veces.

P

A

N

Solo personal calificado entrenado para entendender aparatos mecánicos y sus asociados circuitos eléctricos e hidráulicos deben

O

intentar localizar averías y hacer reparaciones en este equipo.

L

Se debe tomar cuidado para identificar todos los potenciales riesgos y complacer con los procedimientos de seguridad necesarios

antes de empezar las reparaciones.

Consulte con el fabricante si tiene problemas de instalación, o cualquier otro problema no explicado a continuación.

Antes de trabajar en la unidad eléctrica, siempre asegure el plato del labio hacia afuera y desconecte la electricidad.

PROBLEMA

El elevador no funciona

cuando el botón de elevar

"RAISE" se aprieta.

Guia de localización de averias para la serie "PE"

CAUSA POSIBLE

El motor no funciona

El motor funciona correctamente, pero el

andén no se mueve o el lablo no se extiende.

El motor y la bomba no hacen ruido.

ACCION CORRECTIVA

• Use un multimetro para comprobar: para suministro correcto

(todas las patas) y para cntrol de voltaje; para una "abertura" en

cualquier lugar del control del circuito

• Compruebe visualmente cables sueltos o componentes del botón

• Verifique que el eje del motor gira CCW

• Asegurese de que el depósito está lleno y de que el tapón del

agujero de relleno ha sido reemplazado por un tapón de respiro

• Compruebe por qrticulos que reposen en el nivelador

• Instale un calibrador de presión para comprobar la presión del

sistema hidráulico. Si no se eleva a 1,500 psi, consulte con el

fabricante para reemplazo de la bomba.

20

El nivelador se eleva pero no desciende, o

desciende solo muy lentamente.

• Desmonte, compruebe y limpie la válvula de chequeo de

operación piloto.

• Desmonte, compruebe y limpie la válvula de chequeo de

operación piloto y la válvula de control de flujo

• Compruebe por torceduras de partes mecánicas, ejes, etc.

Page 21

ENSAMBLE DE LA BOMBA, PE

RESPIRADERO,

3/8" NPT

TENSOR,

ANNILLA DE O,

TORNILLO DE

RETENCIÓN DE LA

BOMBA, 3/8"-16 x 1" SHCS

01-031-005

34ø-B47ø

O-RING, PARKER

O-RING ø15-8N7ø

TUBE,

99-031-009

TORNILLO DE

RETENCIÓN DE LA

CAJA, 5/16"-18 x 1-1/4"

SHCS

MOTOR ELÉCTRICO,

01-135-032

ANILLA

BOMBA,

01-143-005

VÁLVULA DE

CHEQUEO

, 99-153-011

DE O

ø11-BN7ø

ENSAMBLE DE LA CAJA,

99-627-015

CONTROL DE

FLUJJO,

99-153-022

CAJA,

99-127-015

PILOTO A

VÁLVULA DE

CIERRE,

99-153-020

RELIEVE,

99-153-006

21

Page 22

CANTO DE ANDÉN • SERIE FM

E

S

P

A

N

O

L

22

Page 23

IDENTIFICACIÓN DE PARTES DEL CANTO DE ANDÉN • SERIE FM

JUEGO

A

A, D

A,D

B, D, E

B,E

B,E

B, D,E

C,E

E

C, D,E

C,E

NO. ARTICULO

1

2

3

4

5

6

7

8

9

10

11

12

13

14

DESCRIPCIÓN

Tope de goma

Arandela, 15.8 mm

Tornillo de hex, 15.8 mm-11 UNC x 63.5 mm

Pasador redondo, 12.7 mm dia. x 50 mm

Brazo de enlaze secundario

Brazo de enlace primario

Pasador, 4.76 mm x 28.5 mm

Cojinete redondo sellado

Collar de ajuste

Tornillo de hex, 12.7 mm-13 UNC x 25 mm

Muelle de torsión

Bloque del tope

Protección de los pies (soldadura requerida)

Pasador, 1/2" dia. x 2-3/8" largo

NO. INGENIERO

29-005-001

33015

11313

06-112-003

07-040-003

07-612-001

65125

07-110-001

07-518-001

13205

07-146-009

30-048-001

07-024-002

07-112-007

NO. PIEZA

EOD-RB

EOD-WSR

EOD-BOLT1

EOD-RP1

EOD-SLA

EOD-MLA

EOD-CP1

EOD-SRB

EOD-AC

EOD-BLT2

EOD-TS

EOD-BB

EOD-TG

EOD-CP2

CTD.

2

4

4

4

2

1

5

1

1

1

1

2

2

1

15

16

17

18

19

A

B

C

D

E

Borde del brazo de extension

Manivela

Agarradero de plastico

Link Arm 2 (block welded on)

Link Arm 3 (knob on end)

Juego de reemplazo del tope (partida 1-3)

Juego de reemplazo del enlace (partida 4-7)

Juego de reemplazo del muelle (partida 8,10,11)

Juego de ferreteria (partida 2-4,7,10)

Juego mecánico (partida 4-11)

F

Juego del contra balance

07-016-018

07-025-004

07-025-005

07-516-009

07-016-021

07-154-001

07-154-002

07-154-004

07-154-003

07-154-005

07-154-006

EOD-LEA

EOD-HDL

EOD-PG

EOD-LEA-2

EOD-LEA-3

EOD-KIT-A

EOD-KIT-B

EOD-KIT-C

EOD-KIT-D

EOD-KIT-E

EOD-KIT-F

4

1

1

1

E

1

S

1

P

A

1

N

O

1

L

1

1

1

23

Page 24

CANTO DE ANDÉN • SERIE PP Y PE

1

SOLO SERIE PE

3

E

S

P

A

N

O

L

SOLO SERIE PP

NO. JUEGO

1

2

2

DESCRIPCIÓN

Caja de control

Unidad eléctrica

4

5

IDENTIFICACION DE PARTES

CANTO DE ANDÉN • SERIE PP Y PE

NO. DE INGENIERO

PE-CONBOX

PE-MOPU

NO. PARTE

PE-CONBOX

PE-MOPU

CTD.

1

1

3

4

5

6

7

8

Nota: Para información en pedidos de otras partes, porfavor refierase a la página anterior (p 19).

Bomba manual

Muelle de extensión

Cilindro hidráulico, 25 mm dia. x 355 mm

Juego de la manga PP

Juego de la manga PE

Tornillo de retención del cilindro

PP-HDPUMP

15146001

06021001

06-623-007

06-623-006

n/a

24

PP-HDPUMP

EOD-ES

EOD-HC

EOD-PP-HK

EOD-PE-HK

EOD-PP-PE-CYLP

1

1

1

1

1

2

Page 25

IDENTIFICACIÓN DE LAS ETIQUETAS DE AVISO

ASEGURESE DE QUE TODAS LAS ETIQUETAS DE AVISO ESTAN EN SU LUGAR

*Las señas o etiquetas de seguridad de

los productos deben de ser

inspeccionadas y lipiadas periodicamente

por el usuario como sea necesario para

mantener una buena legibilidad a una

distancia de seguridad.

ANSI 535.4 (10.21)

Contacte al fabricante para etiquetas de

reemplazo.

1

2

1

SOLO LAS SERIES FM

MODELO FM DIBUJADO

DECREASE COUNTER BALANCE

REDUCIR EL CONTRA BALANCE

DIMINUER LE CONTRE-POIDS

INCREASE CONTER BALANCE

INCREMENTAR EL CONTRA BALANCE

AUGMENTER LE CONTRE-POIDS

2

SOLO LAS SERIES FM

!

CAUTION

CONSULT OWNERS MANUAL BEFORE

SECURE AND HOLD LIP IN VERTICAL POSITION. HOLD SQUARE TUBING SECURELY BEFORE LOOSENING LOCKING BOLTS WITH ANOTHER WRENCH. ADJUST IN DESIRED DIRECTION, THEN TIGHTEN LOCKING BOLTS ON

FLATS OF INTERIOR ROUND BAR. CHECK FOR

LIFTING EFFORT AND REPEAT OPERATION IF

NEEDED. LIP AND PLATE SHOULD NOT FLOAT

WHEN LIP IS EXTENDED. DECREASE

COUNTER-BALANCE IF NEEDED. GREASE

HINGES, OIL LINKAGE, AND CHECK FOR WEAR

MONTHLY.

T & S EQUIPMENT CO. ANGOLA, IN

3 4

ADJUSTING

SOLO LAS SERIES PP & PE

LOCALIZADO EN LA BOMBA

MANUAL O UNIDAD ELÉCTRICA

!

PRECAUCION

CONSULTE EL MANUAL DEL PROPIETARIO ANTES

ASEGURE Y MANTENGA LA CEJA EN POSICION VERTICAL.

MANTENGA EL TUBO CUADRADO DE FORMA SEGURA ANTES DE SOLTAR LOS PERNOS CON OTRA LLAVE. AJUSTE

EN LA DIRECCION DESEADA. ENTONCES APRIETE LOS

PERNOS DE SEGURO EN LAS PARTES PLANAS DE LA

BARRA INTERIOR. COMPRUEBE EL ESFUERZO DE

LEVANTAMIENTO Y REPITA LA OPERACION SI ES

NECESARIO. LA CEJA Y LA PLATAFORMA NO DEBEN

FLOTAR CUANDO LA CEJA ESTA EXTENDIDA. REDUZCA EL

CONTRABALANCE SI ES NECESARIO. ENGRASE LAS

BISAGRAS, FUGAS DE ACEITE, Y REVISE POR DESGASTE

MENSUALMENTE.

DE AJUSTAR

T & S EQUIPMENT CO. ANGOLA, IN T & S EQUIPMENT CO. ANGOLA, IN

244

!

PRUDENCE

CONSULTER LE MANUEL DU PROPIÉTAIRE

ASSURER ET MAINTENIR LE REBORD EN POSITION

VERTICALE. BIEN TENIR LE TUBE CARRÉ AVANT DE

DESSERRER LES BOULONS DE VERROUILLAGE AVEC

UNE AUTRE CLÉ. AJUSTER À LA POSITION DÉSIRÉE.

PUIS SERRER LES BOULONS SUR LES SURFACES

PLANES À L’INTÉRIEUR DE LA BARRE. VÉRIFIER

L’EFFORT D’ÉLEVATION ET RÉPÉTER L’OPÉRATION SI

NÉCESSAIRE. LE REBORD ET LA PLAQUE NE

DEVRAIENT PAS FLOTTER LORSQUE LE REBORD EST

ÉTENDU. RÉDUIRE LE CONTRE-POIDS SI NÉCESSAIRE.

GRAISSER LES CHARNIÈRES, HUILER LES JOINTURES

ET VÉRIFIER L’USURE MENSUELLEMENT.

SOLO LAS SERIES PE

LOCALIZADO EN LA UNIDAD ELÉCTRICA

AVANT D’AJUSTER

E

S

P

A

N

O

L

245

ISO AW-32

HYDRAULIC OIL OR EQUIVALENT

ACEITE HIDRÁULICO O EQUIVALENTE

HUILE OU ÉQUIVALENT

206

NOTICE NOTA AVIS

POWER SUPPLY: 115 Volt/1 Phase/60 HZ

CONTROL VOLTAGE: 24 VOLT AC

CORRIENTE: 115 Volt/1 Fase/60 HZ

VOLTAJE DE CONTROL: 24 VOLT CA

ALIMENTATION ÉLECTRIQUE: 115 Volt/1 Phase/ 60 HZ

VOLTAGE DE CONTRÔLE: 24 VOLT AC

248

25

Page 26

GARANTIA LIMITADA

GARANTIA LIMITADA DE UN AÑO. El fabricate garantiza al comprador original contra defectos

de material y de mano de obra en circunstancias de uso normal durante un año a partir de la fecha de

compra (sin exceder 15 meses despues de la fecha de fabricación). Cualquier parte que el fabricante

decida es defectuosa en material ó mano de obra y sea devuelta a la fábrica, previo envio flete pagado,

será, exclusivamente, reparada ó reemplazada a nuestra opción. El coste de trabajo de reparaciones ó

modificaciones de partes de garantia no está cubierto a no ser que sea reparado en la misma fábrica.

Cualquier modificación del producto sin la escrita autorización previa del fabricante puede anular la

garantia. Esta garantia limitada le da al comprador ciertos derechos legales que varian de estado a

estado.

RESPONSABILIDAD LIMITADA. Hasta cierto punto permitido por la ley, el fabricante renuncia a

la responsabilidad por daños accidentales. La responsabilidad del fabricante en todos los casos es

limitada, y no debe exceder, el precio de compra. Mal uso ó modificaciones podrian anular la garantia.

RENUNCIA DE GARANTIA. Nuestra compañia ha hecho un esfuerzo en ilustrar y describir los

productos con precisión; sin embargo, estos dibujos y descripciones son solo para el propósito de

identificación, y no expresan ó implican que el producto es comercial ó apto para uso particular, ó que

el producto se parezca a los dibujos ó descripciones.

Las provisiones de la garantia deben de ser interpretadas y reforzadas en acuerdo con el CODIGO

COMERCIAL UNIFORME y las leyes decretadas en el Estado de Indiana.

DISPOSICIÓN. Nuestra compañia hará un esfuerzo de buena voluntad para corregir rapidamente

ó ajustar cualquier producto que sea defectuoso dentro de la garantia limitada. Reclamaciones de

garantia deben de ser escritas durante el dicho año.

REGISTRO DE REPARACIÓN

E

S

P

A

N

O

L

FECHA DE REPARACIÓN:_____/_____/_____

TRABAJO COMPLETO EN: ___________________________

REPARACIÓN HECHA POR: __________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

FECHA DE REPARACIÓN:_____/_____/_____

TRABAJO COMPLETO EN: ___________________________

REPARACIÓN HECHA POR: __________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

FECHA DE REPARACIÓN:_____/_____/_____

TRABAJO COMPLETO EN: ___________________________

REPARACIÓN HECHA POR: __________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

FECHA DE REPARACIÓN:_____/_____/_____

TRABAJO COMPLETO EN: ___________________________

REPARACIÓN HECHA POR: __________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

26

FECHA DE REPARACIÓN:_____/_____/_____

TRABAJO COMPLETO EN: ___________________________

REPARACIÓN HECHA POR: __________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

FECHA DE REPARACIÓN:_____/_____/_____

TRABAJO COMPLETO EN: ___________________________

REPARACIÓN HECHA POR: __________________________

_________________________________________________

_________________________________________________

_________________________________________________

_________________________________________________

Page 27

Vestil Manufacturing Corporation

2999 North Wayne St., Angola, IN 46703

Ph 260-665-7586 Fax: 260-665-1339

www.vestil.com E-mail: sales@vestil.com

Solutions pour quai de chargement

Table des Matières

Instructions de sécurité et avertissements ................... 27

Instructions de réception .............................................. 27

Instructions de chargement .......................................... 28

Instructions de désemballage et de manutention ..........28

Instructions de fonctionnement .................................... 28

Instructions d'installation ......................................... 29-31

Shéma électrique .........................................................32

Instructions d'ajustage des ressorts (séries FM) .......... 32

Revisé 06-04 07-126-101

Une compagnie dévouée à résoudre les problèmes

ergonomiques et de prise en charge de matériel depuis

1955.

MANUEL

D'UTILISATION

BORDURE DE QUAI • MODÈLE FM / PP / PE

Shéma des pièces détachées pour bordure de qua

(séries FM) ................................................................. 35

Liste des pièces .......................................................... 36

Shéma des pièces détachées pour bordure

de quai (séries PP/PE)................................................ 37

Liste des pièces .......................................................... 37

Identification des etiquettes d'avertissement ............... 38

Garantie Limitée/Rapport de service ........................... 39

INSTRUCTIONS DE SÉCURITÉ ET

AVERTISSEMENTS

Lire le manuel d'utilisation complètement avant de faire

fonctionner l'unité!

• Ne jamais excéder la capacité maximale de chargement

inscrite sur la plaque de l'unité.

• Charger l'unité aussi uniformément que possible.

• Consulter l'usine pour des capacités de chargement

inégales.

• Ne jamais faire foncionner l'unité sans la surveiller.

• Garder mains et pieds à l'écart des aires de pincement.

• Ne pas faire fonctionner à moins que les blocs de

sécurité soient en place et bien enclenchés.

• Ne pas pincer le cylindre dans un étau; ceci peut

déformer le baril.

• Ne pas changer le réglage de la soupape de relâche de

pression (séries PP et PE)

• Ne pas continuer à appuyer sur le bouton "en haut" si

l'unité ne monte pas (séries PE).

• Ne pas continuer à pomper sur la pompe manuelle si

l'unité ne monte pas (séries PP).

• Retirer tout chargement avant de travailler sur l'unité.

• Couper le courant avant de travailler sur l'unité (séries

PE).

• Ne pas utiliser de liquides de freins ou d'huiles pour crics.

Utiliser de l'huile hydraulique AW-32 ou équivalent

(séries PP et PE).

• Consulter l'usine pour des ajouts ou des modifications de

l'équipement original.

• N'utiliser que des pièces de remplacement fournies ou

appouvées par le fabricant.

• S'assurer que toutes les étiquettes d'avertissement

soient en place (p. 39).

INSTRUCTIONS DE RÉCEPTION

Chaque unité est minutieusement testée et

inspectée avant expédition. Toutefois, il est possible que

l'unité soit endommagée pendant le transport. Si un

dommage est constaté lors du déchargement, le noter sur

LA FACTURE DE CHARGEMENT.

Retirer tout le matériel d'empaquetage et les

sangles et inspecter l'unité de nouveau pour constater tout

dommage. SI LE DOMMAGE EST ÉVIDENT, REMPLIR

IMMÉDIATEMENT UNE PLAINTE AVEC LE

TRANSPORTEUR! De plus, contrôler la taille de l'unité, le

type de courant de l'unité, etc. . . Pour s'assurer que celleci soit correcte pour l'utilisation désirée.

NUMÉRO DE MODÈLE ET CAPACITÉS

Les capacités, le numéro de modèle et le numéro de

série sont inscrits sur la plaque du fabricant. Prière d'inscrire

ces chiffres sur chaque correspondance avec votre revendeur

ou avec l'usine.

F

R

A

N

Ç

A

I

S

BORDURE DE QUAI

MODÈLE FM / PP / PE

27

Page 28

INSTRUCTIONS DE CHARGEMENT

Le taux de capacité de chargement tel qu' indiqué

sur la plaque de votre unité désigne sa capacité nette, en

assumant que la charge soit centrée. Cette capacité ne

doit jamais être excédée, car des dommages permanents

pourraient en résulter.

INSTRUCTIONS DE DÉSEMBALLAGE

ET DE MANUTENTION

PRUDENCE

Fonctionnement Mécanique • Séries FM

1.) Retirent le traitement du bon côté du cadre de butoir et

insèrent le plot dans le plat arrière (le plot est du côté

droit.

2.) Retirent le traitement jusqu'à ce que le plat de leveler

soit entièrement étendu et se penchant en arrièe vers la

rampe.

3.) Poussent le traitement en avant, ceci fera étendre et

tomber le plat de lèvre sur le lit du bas de page

• Lire les instructions complètement avant d'ajuster.

• Suivre les instructions soigneusement.

• Utiliser une clé plate, pas une clé à molette car celle-ci

pourrait glisser.

• Le désemballage ainsi que la manutention recommandés

sont montrés ci-dessous.

• La bordure de quai recommandé est de 127 cm.

• L'éventail de service est de +12.7 mm à -12.7 mm.

Bras du

Porte-Palette

Chaîne

Attache à

verrouillage

automatique

AVERTISSEMENT:

ÉCARTER MAINS

ET PIEDS DES

PARTIES

CHARNIÈRES

4.) Retirent le traitement et le placnt dans le cadre de butoir.

5.) En chargeant et en déchargeant est complet, retirez les

cales et permettez au bas de page d'écarter. Le bord-odock reviendra à son position initiale.

Fonctionnement avec pompe maneulle • Séries PP

1.) Tourner la soupape sur la pompe dans le sens des

aiguilles d'une montre pour fermer la soupape de retour

de fluide. Lorsque l'égaliseur de quai s'étend

complétement, relâcher la pression afin de permettre au

rabat de se poser sur la plate-bande de la remorque.

Bien s'assurer de laisser la soupape de retour de fuide

ouverte pour permettre à l'égaliseur de quai de flotter

avec la remorque.

2.) Lorsque le chargement/déchargement est terminé, retirer

les cales et autoriser la remorque à démarrer. La

bordure de quai retournera à sa position d'origine.

Fonctionnement Électrique • Séries PE

1.) Presser le bouton EN HAUT sur la boîte de commande.

L'égaliseur de quai commencera à s'élever. Lorsque le

rabat de l'égaliseur de quai atteindra sa complète

extension, il s'abaissera pour se poser sur la platebande de la remorque.

2.) Lorsque le chargement/déchargement est terminé, retirer

les cales et autoriser la remorque à démarrer. La

bordure de quai retournera à sa position d'origine.

INSTRUCTIONS DE FONCTIONNEMENT

I.) Reculer la remorque lentement contre les pare-

chocs de la bordure de quai. Arrêter le moteur et

activer le frein à main du camion. Positionner les

cales à roues (par quelqu'un d'autre) requises par

OSHA pour éviter un mouvement de la remorque.

II.) Suivre les instructions ci-dessous selon le modèle de

bordure de quai possedé.

28

Pour Commander des Pièces de Remplacement

ou Supplémentaires

Notre compagnie est fière d'utiliser les meilleures pièces

disponibles pour notre équipement. Nous ne sommes pas

responsable pour de mauvais fonctionnements d'équipment

résultant de l'utilisation de pièces de remplacement nonapprouvées. Pour commander des pièces de remplacement ou

des pièces supplémentaires, contacter le service clientèle de

l'usine. Sur chaque correspondance avec l'usine, prière d'inclure

le numéro de série qui est inscrit sur la plaque de la pièce

d'équipement. N'utiliser que les numéros fournis dans ce

manuel. Lors d'une commande de pièces pour des unités à

courant continu, prière d'indiquer la phase du moteur ainsi que

le voltage sur lequel l'équipement fonctionne.

Page 29

INSTRUCTIONS D'INSTALLATION

(LIRE TOUTES LES INSTRUCTIONS AVANT DE CONTINUER!)

CONSTRUCTION POUR BORDURE DE QUAI

La procédure pour l'installation de l'égalisateur de niveau Bordure-de-quai est une fonction de la construction de la bordure

du quai et de la hauteur différentielle. La bordure de quai recommendée pour installer une unité "Bordure - De - Quai" doit

présenter une cannelure de 15 cm. Avec une cannelure de 15 cm ancrée dans la bordure du quai, l'installateur peut souder

la rampe et les blocs pare-chocs solidemment en position. La rampe et les blocs ne peuvent être soudés en position si

l'acier de la bordure du quai mesure moins de 15 cm. Pour des installations de moins de 15 cm d'acier en bordure, une

combinaison de boulons d'ancrage et de soudure est recommandée. Si le quai n'a aucune bordure d'acier, une plaque d'acier

doit être soudée au sol afin de fournir une partie qui pourra être soudée à la rampe de façon à ce que la capacité de

l'égalisateur de niveau soit maintenue. Tout manquement à l'une des instructions d'installation suivantes peut diminuer la

capacité de l'égalisateur de niveau.

Bordure de quai recommandée pour nouvelle construction

La bordure de quai recommandée pour une

nouvelle construction doit présenter une cannelure

de 15 cm bien ancrée (minimum ou 3.7 kg min) les

chevilles en "J" pour ciment devraient messurer 38

mm de largeur et 15 cm de longueur plus 38 mm

courbé à 90 degrés à l'extrémité. L'épaisseur

minimale du matériau doit être de 6 mm. Une

cheville doit être installée à chaque 30 cm.

15 cm

Cannelure

HAUTEUR DIFFÉRENTIELLE

La hauteur de quai optimale est dans la plupart des cas de 127 cm. Sur des quais dont la hauteur est considérablement