Page 1

CIRCULAR SAW

5885 (F0125885..)

SKIL - Divisão de Ferramentas Elétricas F000.622.326

Caixa Postal 1195 - CEP 13065-9000 - Campinas/SP - Brasil 05/2010

GB ORIGINAL INSTRUCTIONS

E MANUAL ORIGINAL

P MANUAL ORIGINAL

www.skil.com.br

SKIL_IB5885_BR.indd 1 28-05-2010 09:41:42

Page 2

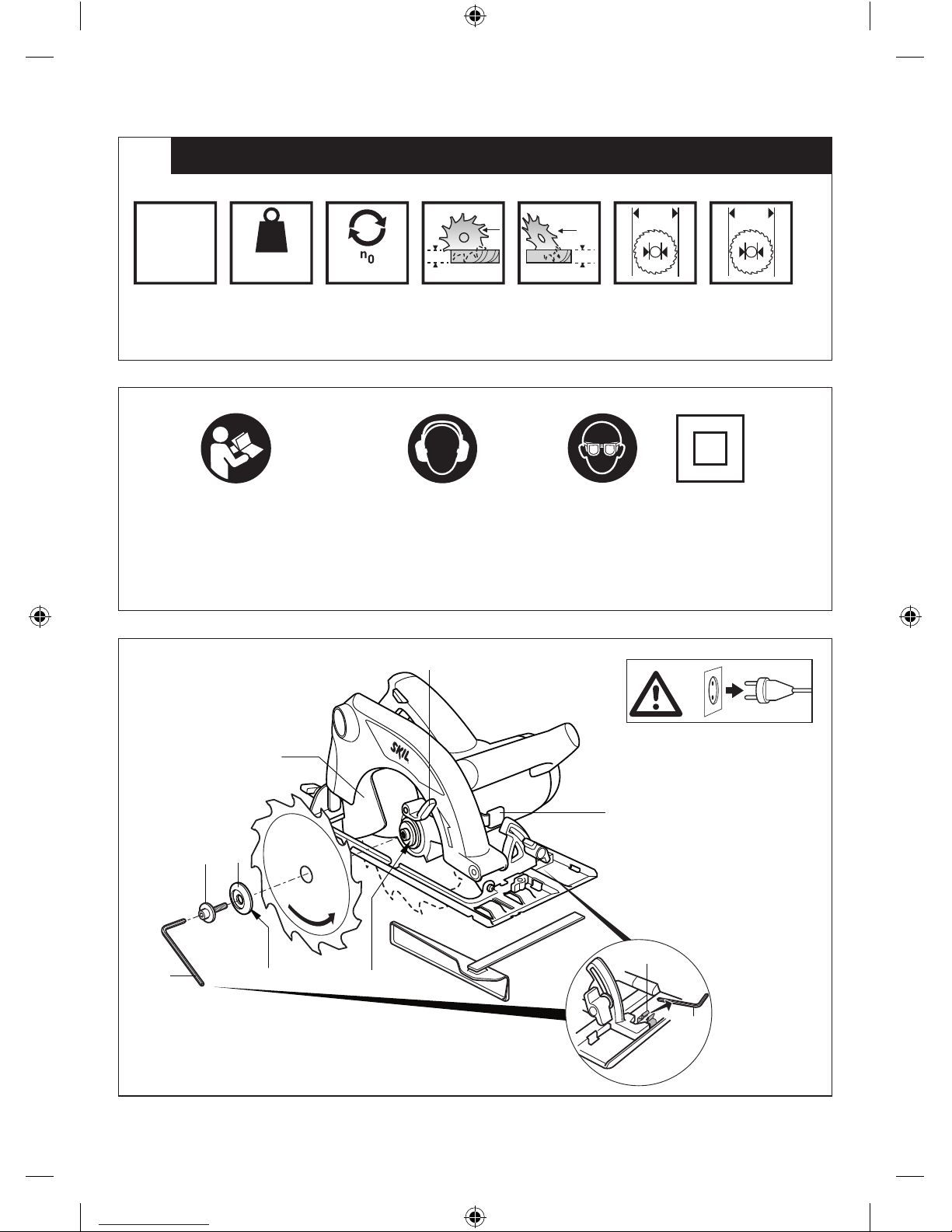

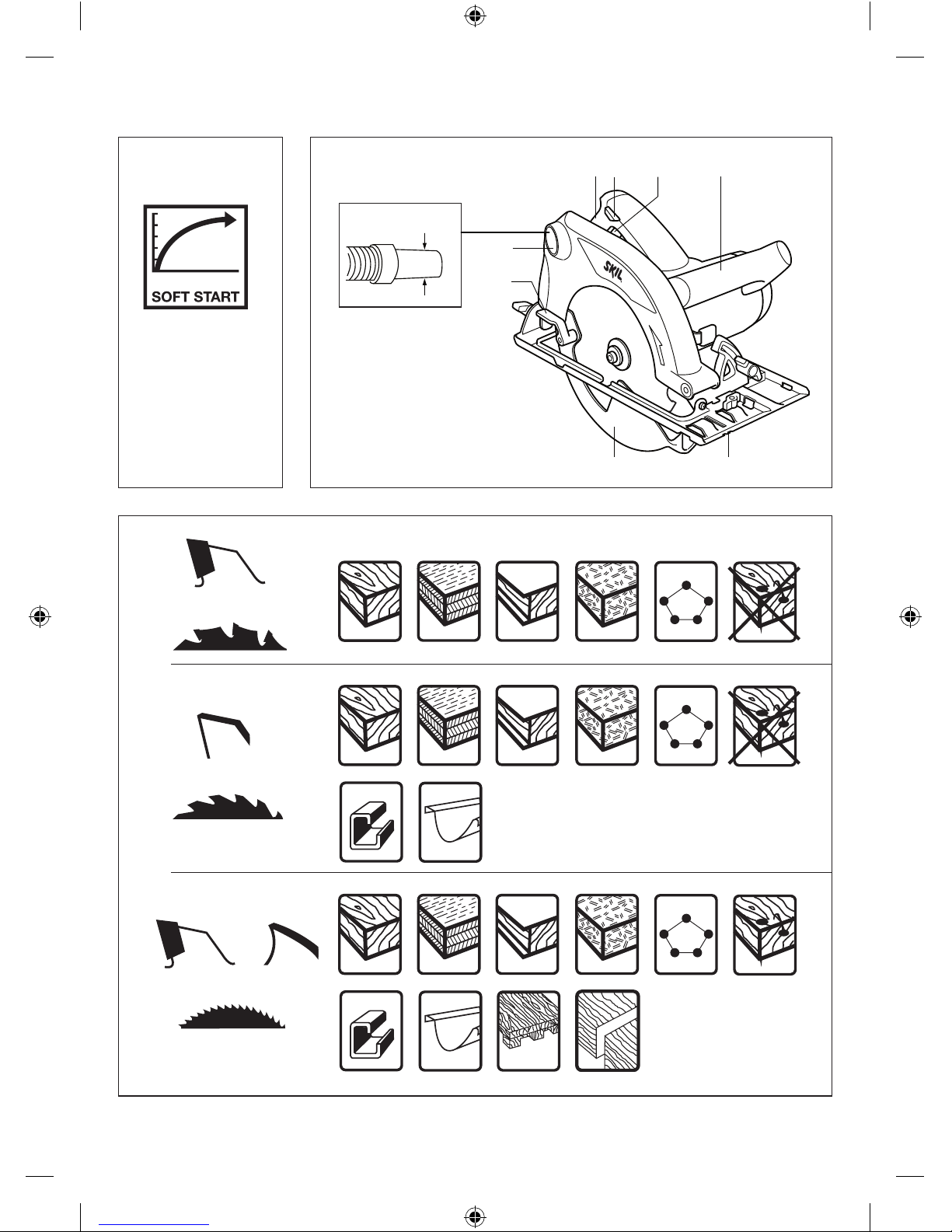

2

1

5885

E

D

A HH

F

G

C

A

B

3

/II

2

7,9 kg

EPTA 01/2003

5000 /min

65 mm

45°

235 mm

MAX.

30 mm

230 mm

MIN.

30 mm

Watt

2000

85 mm

90°

110 V/127 V =

1700 W

Leia o manual de instruções

antes de operar a ferramenta.

Leia el manual de instrucciones

antes de operar con la

herramienta.

Usar proteção auricular. Ruídos

podem provocar a surdez.

Utilice unos protectores

auditivos. El ruido intenso

puede provocar sordera.

Usar óculos

de proteção.

Colóquese

unas gafas de

protección.

Símbolo para classe de

proteção II

(completamente isolada)

Símbolo para clase de

protección II

(completamente aislada)

110 V/127 V =

5300 /min

Standard included:

reduction ring 25,4 mm

Incluye: anillo reductor 25,4 mm

Incluso: anel de redução 25,4 mm

SKIL_IB5885_BR.indd 2 28-05-2010 09:41:45

Page 3

3

K

J

L

3 mm

4

HF G

K

N

M

M

5

SKIL_IB5885_BR.indd 3 28-05-2010 09:41:46

Page 4

4

M

A D E H

P

M

A D E H

K

NOT STANDARD INCLUDED

ÍTEM NO INCLUSO

ITEM NÃO INCLUSO

6

Q

7

SKIL_IB5885_BR.indd 4 28-05-2010 09:41:48

Page 5

5

0

QF

G

R

S U V T

Ø 34-35 mm

9

ARRANQUE

ELETRÔNICO

SUAVE

ARRANQUE

SUAVE

ELECTRÓNICO

8

SKIL_IB5885_BR.indd 5 28-05-2010 09:41:49

Page 6

6

#

$

X

W

Q

!

Q

F

G

@

No caso de descarte não jogue no lixo comum.

En casos que quiera descartar su herramienta,

no tirar en la basura.

SKIL_IB5885_BR.indd 6 28-05-2010 09:41:50

Page 7

7

GB

Circular saw 5885

INTRODUCTION

• This tool is intended for lengthways and crossways

cutting of wood with straight cuts as well as angle cuts

to 45°; with the appropriate saw blades also non-ferrous

metals, light building materials and plastics can be cut

•

Read and save this instruction manual 2

TECHNICAL SPECIFICATIONS 1

SAFETY

GENERAL SAFETY INSTRUCTIONS

WARNING! Read all safety warnings and all

instructions. Failure to follow the warnings and

instructions may result in electric shock, fire and/or serious

injury. Save all warnings and instructions for future

reference. The term “power tool” in the warnings refers to

your mains-operated (corded) power tool.

1)

WORK AREA SAFETY

a)

Keep work area clean and well lit.

Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive

atmospheres, such as in the presence of flammable

liquids, gases or dust.

Power tools create sparks

which may ignite the dust or fumes.

c)

Keep children and bystanders away while operating

a power tool.

Distractions can cause you to lose

control.

2)

ELECTRICAL SAFETY

a)

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not use any

adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk

of electric shock.

b)

Avoid body contact with earthed or grounded

surfaces such as pipes, radiators, ranges and

refrigerators.

There is an increased risk of electric

shock if your body is earthed or grounded.

c)

Do not expose power tools to rain or wet conditions.

Water entering a power tool will increase the risk of

electric shock.

d)

Do not abuse the cord. Never use the cord for

carrying, pulling or unplugging the power tool.

Keep cord away from heat, oil, sharp edges or

moving parts.

Damaged or entangled cords increase

the risk of electric shock.

e)

When operating a power tool outdoors, use an

extension cord suitable for outdoor use.

Use of a

cord suitable for outdoor use reduces the risk of electric

shock.

f)

If operating a power tool in a damp location is

unavoidable, use an earth leakage circuit breaker.

Use of an earth leakage circuit breaker reduces the risk

of electric shock.

3)

PERSONAL SAFETY

a)

Stay alert, watch what you are doing and use

common sense when operating a power tool.

Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools

may result in serious personal injury.

b)

Use personal protective equipment. Always wear

eye protection. Protective equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce

personal injuries.

c)

Prevent unintentional starting. Ensure the switch is

in the off-position before connecting to power

source, picking up or carrying the tool.

Carrying

power tools with your finger on the switch or energising

power tools that have the switch on invites accidents.

d)

Remove any adjusting key or wrench before turning

the power tool on.

A wrench or a key left attached to a

rotating part of the power tool may result in personal

injury.

e)

Do not overreach. Keep proper footing and balance

at all times.

This enables better control of the power

tool in unexpected situations.

f)

Dress properly. Do not wear loose clothing or

jewellery. Keep your hair, clothing and gloves away

from moving parts.

Loose clothes, jewellery or long

hair can be caught in moving parts.

g)

If devices are provided for the connection of dust

extraction and collection facilities, ensure these are

connected and properly used.

Use of dust collection

can reduce dust-related hazards.

4)

POWER TOOL USE AND CARE

a)

Do not force the power tool. Use the correct power

tool for your application. The correct power tool will

do the job better and safer at the rate for which it was

designed.

b) Do not use the power tool if the switch does not turn

it on and off.

Any power tool that cannot be controlled

with the switch is dangerous and must be repaired.

c)

Disconnect the plug from the power source before

making any adjustments, changing accessories, or

storing power tools.

Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d)

Store idle power tools out of the reach of children

and do not allow persons unfamiliar with the power

tool or these instructions to operate the power tool.

Power tools are dangerous in the hands of untrained

users.

e)

Maintain power tools. Check for misalignment or

binding of moving parts, breakage of parts and any

other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired

before use.

Many accidents are caused by poorly

maintained power tools.

SKIL_IB5885_BR.indd 7 28-05-2010 09:41:51

Page 8

8

f) Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to control.

g)

Use the power tool, accessories and tool bits etc.,

in accordance with these instructions, taking into

account the working conditions and the work to be

performed.

Use of the power tool for operations

different from those intended could result in a

hazardous situation.

5)

SERVICE

a)

Have your power tool serviced by a qualified repair

person using only identical replacement parts.

This will ensure that the safety of the power tool is

maintained.

SAFETY INSTRUCTIONS FOR CIRCULAR SAWS

DANGER

•

Keep hands away from cutting area and the

blade; keep your second hand on front handle

(if both hands are holding the saw, they can not be cut

by the blade)

•

Do not reach underneath the workpiece

(the guard

cannot protect you from the blade below the workpiece)

•

Adjust the cutting depth to the thickness of the

workpiece

(less than a full tooth of the blade teeth

should be visible below the workpiece)

•

Never hold piece being cut in your hands or across

your leg

(it is important to support the work properly to

minimise body exposure, blade binding, or loss of

control)

•

Hold tool by insulated gripping surfaces when

performing an operation where the cutting tool may

contact hidden wiring or its own cord

(contact with a

“live” wire will also make exposed metal parts of the

tool “live” and shock the operator)

•

When ripping always use a rip fence or straight edge

guide

(this improves the accuracy of cut and reduces

the chance for blade binding)

•

Always use blades with correct size and shape of

arbor holes (diamond or round)

(blades that do not

match the mounting hardware of the saw will run

eccentrically, causing loss of control)

•

Never use damaged or incorrect blade washers or

bolts

(the blade washers and bolt were specially

designed for your saw, for optimum performance and

safety of operation)

KICKBACK - CAUSES

•

Kickback is a sudden r

eaction to a pinched, bound or

misaligned saw blade, causing an uncontrolled saw to

lift up and out of the workpiece toward the operator

• When the blade is pinched or bound tightly by the kerf

closing down, the blade stalls and the motor r

eaction

drives the unit rapidly back toward the operator

• If the blade becomes twisted or misaligned in the cut,

the teeth at the back edge of the blade can dig into the

top surface of the wood causing the blade to climb out

of the kerf and jump back towar

ds operator

KICKBACK - OPERATOR PREVENTION

Kickback is the result of tool misuse and/or incorrect

operating procedures or conditions and can be avoided by

taking proper precautions as given below

•

Maintain a firm grip with both hands on the saw and

position your arms to resist kickback forces;

position your body to either side of the blade, but

not in line with the blade

(kickback could cause the

saw to jump backwards, but kickback forces can be

controlled by the operator, if proper precautions are

taken)

•

When blade is binding, or when interrupting a cut for

any reason, release the trigger and hold the saw

motionless in the material until the blade comes to a

complete stop; never attempt to remove the saw

from the work or pull the saw backwards while the

blade is in motion or kickback may occur (investigate

and take corrective actions to eliminate the cause of

blade binding; avoid cutting nails or screws)

•

When restarting a saw in the workpiece, centre the

saw blade in the kerf and check that saw teeth are

not engaged into the material

(if saw blade is binding,

it may walk up or kickback from the workpiece as the

saw is restarted)

•

Support large panels to minimise the risk of blade

pinching and kickback

(large panels tend to sag under

their own weight; supports must be placed under the

panel on both sides, near the line of cut and near the

edge of the panel)

•

Do not use a dull or damaged blade

(unsharpened or

improperly set blades produce narrow kerf causing

excessive friction, blade binding and kickback)

•

Blade depth and bevel adjusting locking levers must

be tight and secure before making cut

(if blade

adjustment shifts while cutting, it may cause binding

and kickback)

•

Use extra caution when making a plunge cut into

existing walls or other blind areas

(the protruding

blade may cut objects that can cause kickback)

WARNING

•

Check lower guard for proper closing before each

use

• Do not operate the saw if lower guard does not

move freely and close instantly

• Never clamp or tie the lower guard into the open

position

• If saw is accidentally dr

opped, lower guard may be

bent; disconnect the plug, raise the lower guard with

the retracting handle and make sure it moves freely and

does not touch the blade or any other part, in all angles

and depths of cut

• Check the operation of the lower guard spring; if the

guard and the spring are not operating properly,

they must be serviced before use

(lower guard may

operate sluggishly due to damaged parts, gummy

deposits, or a build-up of debris)

•

Lower guard should be retracted manually only for

special cuts such as plunge cuts and compound

cuts; raise lower guard by retracting handle and as

soon as blade enters the material, the lower guard

must be released

(for all other sawing, the lower guard

should operate automatically)

SKIL_IB5885_BR.indd 8 28-05-2010 09:41:52

Page 9

9

• Always observe that the lower guard is covering the

blade before placing saw down on bench or floor (an

unprotected, coasting blade will cause the saw to walk

backwards, cutting whatever is in its path; be aware of

the time it takes for the blade to stop after switch is

released)

GENERAL

•

A

void damage that can be caused by screws, nails and

other elements in your workpiece; remove them before

you start working

• Secure the workpiece

(a workpiece clamped with

clamping devices or in a vice is held more securely than

by hand)

•

Use suitable detectors to find hidden utility lines or

call the local utility company for assistance

(contact

with electric lines can lead to fire or electrical shock;

damaging a gas line can result in an explosion;

penetrating a water pipe will cause property damage or

an electrical shock)

•

When you put away the tool, switch of

f the motor and

ensure that all moving parts have come to a complete

standstill

• Use completely unr

olled and safe extension cords with

a capacity of 16 Amps (U.K. 13 Amps)

• In case of jamming or electrical or mechanical

malfunction, immediately switch of

f the tool and

disconnect the plug

• SKIL can assur

e flawless functioning of the tool only

when the correct accessories are used which can be

obtained from your SKIL dealer

• Use only accessories with an allowable speed matching

at least the highest no-load speed of the tool

• Never use the tool without the original pr

otection guard

system

• This tool should not be used by people under the age of

16 years

• The noise level when working can exceed 85 dB(A);

wear ear pr

otection

• If the cor

d is damaged or cut through while working, do

not touch the cord, but immediately disconnect the plug

• Never use the tool when cor

d is damaged; have it

replaced by a qualified person

• Always check that the supply voltage is the same as the

voltage indicated on the nameplate of the tool (tools

with a rating of 230V or 240V can also be connected to

a 220V supply)

• Starting cycles generate brief voltage dr

ops;

interference with other equipment/machines may occur

in case of unfavourable mains system conditions

(malfunctions are not to be expected for system

impedances below 0.36 ohm) - if you need further

clarification, you may contact your local power supply

authority

•

This tool is not suitable for wet cutting

• After switching off your circular saw, never stop the

rotation of the saw blade by a lateral force applied

against it

• Never use cir

cular saw blades made of high speed steel

(HSS)

• Never use grinding/cutting discs with this tool

•

Do not work materials containing asbestos (asbestos

is considered carcinogenic)

• Dust fr

om material such as paint containing lead, some

wood species, minerals and metal may be harmful

(contact with or inhalation of the dust may cause

allergic reactions and/or respiratory diseases to the

operator or bystanders); wear a dust mask and work

with a dust extraction device when connectable

•

Certain kinds of dust are classified as carcinogenic

(such as oak and beech dust) especially in conjunction

with additives for wood conditioning; wear a dust

mask and work with a dust extraction device when

connectable

• Follow the dust-r

elated national requirements for the

materials you want to work with

• Do not attempt to cut extr

emely small workpieces

• Remove all obstacles on top of as well as underneath

the cutting path before you start cutting

• Do not work overhead with the tool

•

Only use a saw table provided with a switch that

prevents restarting of the motor after interruption of

voltage

• Only use a saw table pr

ovided with a kerf guide

• Always disconnect plug from power source before

making any adjustment or changing any accessory

WHEN CONNECTING NEW 3-PIN PLUG (U.K. ONLY):

• Do not connect the blue (= neutral) or br

own (= live) wire

in the cord of this tool to the earth terminal of the plug

• If for any r

eason the old plug is cut off the cord of this

tool, it must be disposed of safely and not left

unattended

USE

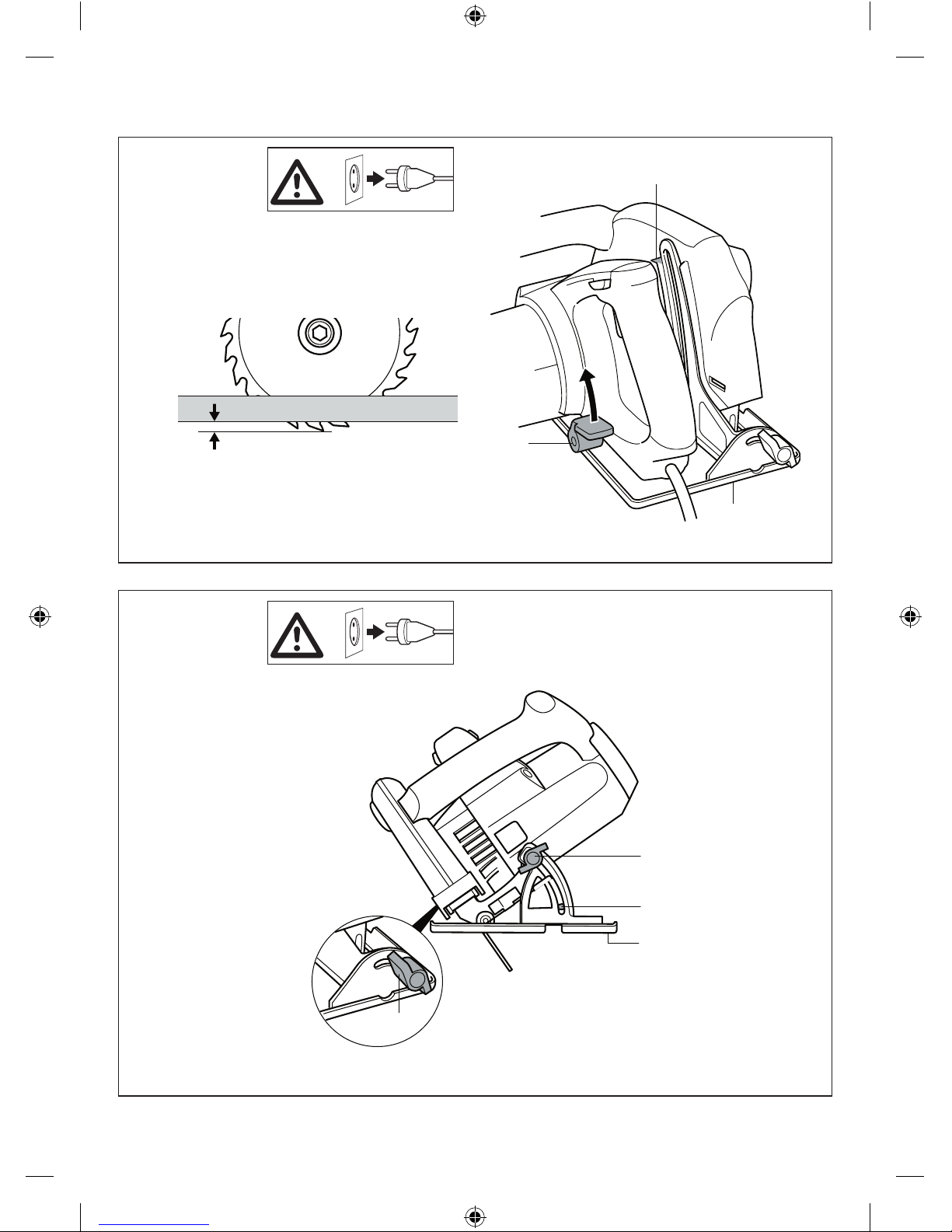

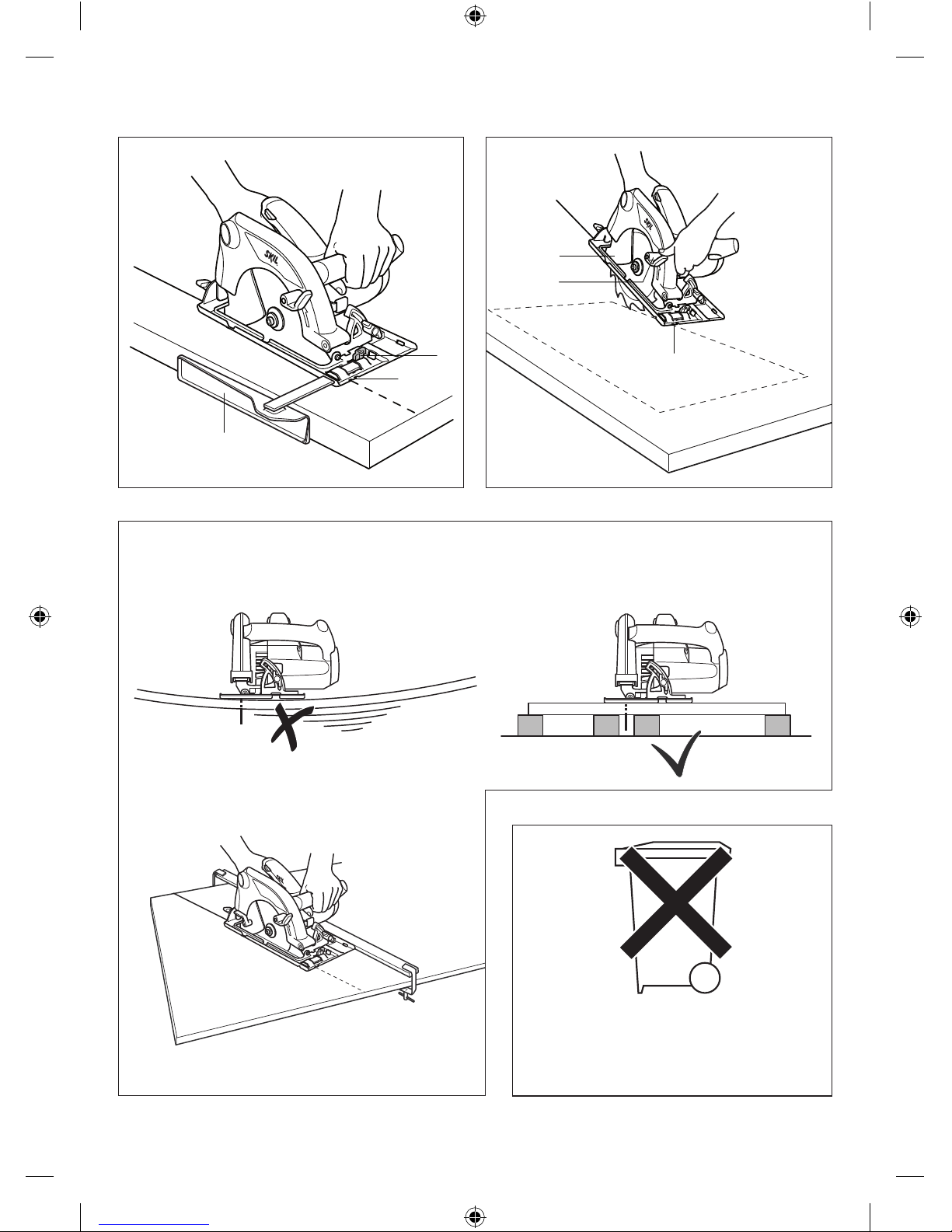

• Mounting saw blade 3

! disconnect the plug

- take hex key A from storage B

- push spindle-lock button C and hold it while you

remove blade bolt D with blade wrench

! push spindle-lock button C only when tool is at a

standstill

- r

elease spindle-lock button C

- remove flange E

- open lower guard F with lever G and hold it while you

mount saw blade with saw teeth and arrow printed

on saw blade pointing in same direction as arrow on

lower guard

-

r

elease lower guard F

- mount flange E

! make sure that clamping surfaces H of flanges

are perfectly clean and face the blade

- push spindle-lock button C and hold it while you

tighten blade bolt with hex key 1/8 tur

n past finger

tight (ensures slippage of saw blade when it

encounters excessive resistance thus reducing motor

overload and saw kickback)

- r

elease spindle-lock button C

• Adjusting cutting depth (0-85 mm)

4

- for an optimal quality cut the saw blade should not

extend mor

e than 3 mm below the workpiece

- loosen lever J

-

raise/lower foot K until desired cutting depth is set on

scale using indicator L

- tighten lever J

SKIL_IB5885_BR.indd 9 28-05-2010 09:41:52

Page 10

10

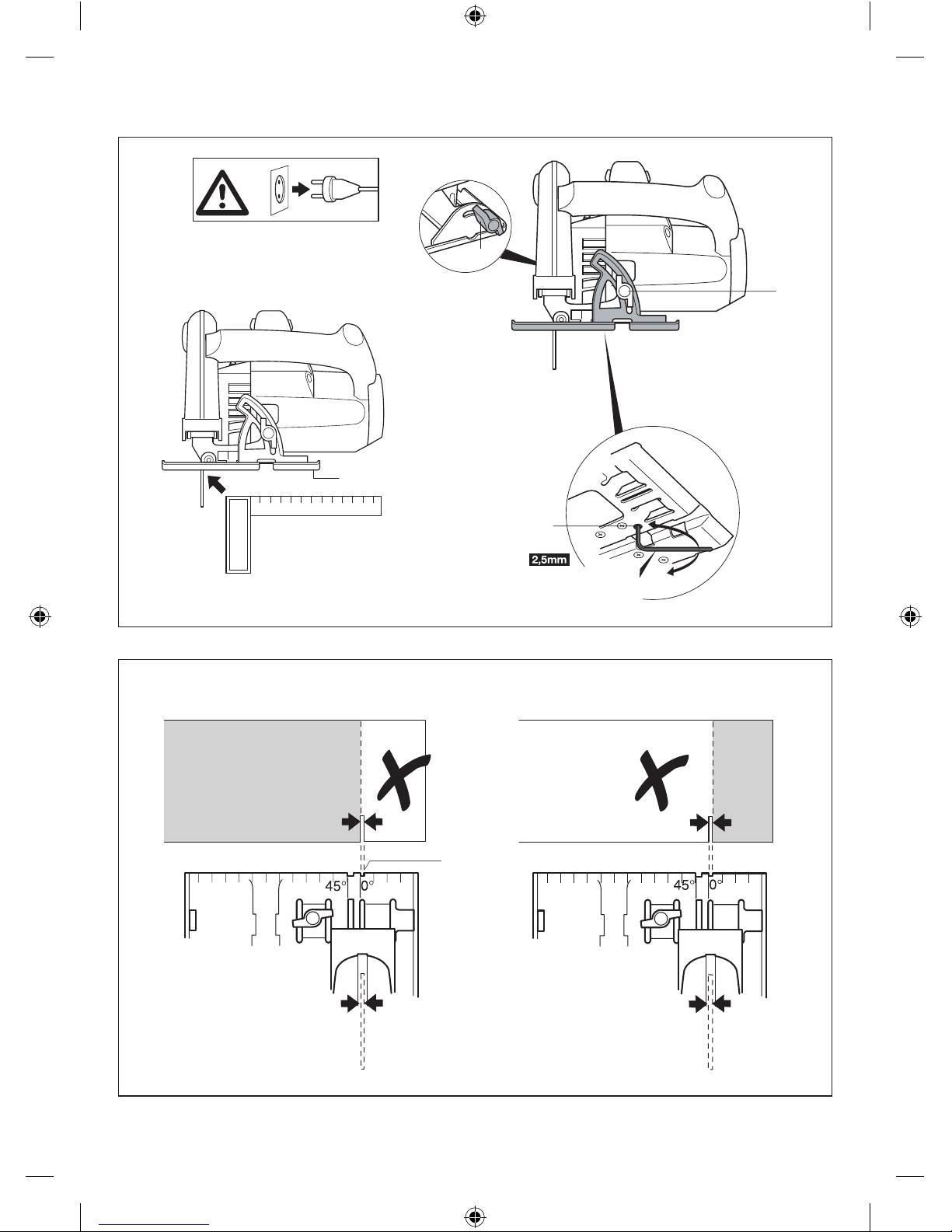

• Adjusting cutting angle (0-45°) 5

- loosen 2 knobs M

- tilt tool until desir

ed cutting angle is set on scale

using indicator N

- tighten 2

knobs M

! when bevel cutting, cutting depth does not

correspond with value on cutting depth scale

• 90° Cutting angle check 6

- a

djust and tighten foot K to maximum cutting depth 4

- adjust and tighten cutting angle to 0°

-

check for 90° angle between the blade and bottom of

foot with a square

- if adjustment is needed, loosen 2

knobs M and use

adjustment screw P as illustrated

•

Line-of-cut indicator Q 7

- for guiding tool along desir

ed line of cut marked on

the workpiece

- for a straight 0° cut or a 45° bevel cut use the

indicator line concer

ned

- allows you to choose whether waste material is on

inner or outer side of blade

! the wide part of the foot should rest on the

supported part of the workpiece

! cutting width is determined by width of blade

teeth and not by width of blade body

! always make trial cuts first to verify actual line of

cut

• Electr

onic soft-start 8

Ensures r

eaching the maximum speed smoothly without

a sudden impact when tool is switched on

• Dust suction

-

connect vacuum cleaner to extension R

9

! never let the vacuum cleaner hose interfere with

the lower guard or the cutting operation

- one may also use a dust bag (SKIL accessory

2610387402)

• Operating the tool 9

- connect plug to power sour

ce

- always hold handle S firmly with one hand and

handle T firmly with the other hand

- place tool with fr

ont end of foot flat on workpiece

! ensure that the saw teeth are not engaged into

the workpiece

- switch on tool by first pr

essing knob U (= safety

switch which cannot be locked) and then pulling

trigger V

! the tool should run at full speed before the blade

enters into the workpiece

- lower guar

d F opens automatically when saw blade

enters the workpiece (open lower guard manually by

using lever G only for special cuts such as plunge

cuts)

- do not for

ce the tool; apply light and continuous

pressure

- after completing the cut switch of

f tool by releasing

trigger V

! ensure that the blade has come to a complete

standstill, before you lift the tool from the

workpiece

APPLICATION ADVICE

• Always face the good side of the workpiece down to

ensure minimum splintering

• Only use sharp saw blades of the corr

ect type 0

- quality of cut impr

oves by the number of teeth

- carbide tipped blades stay sharp up to 30 times

longer than ordinary blades

• Rip fence W !

- for making exact cuts along a workpiece edge

-

can be inserted in either side of foot

Adjusting rip fence

- loosen knob X

- adjust to desired cutting width by using rip fence

scale (use line-of-cut indicator Q as 0-reference)

- tighten knob X

•

Plunge cutting

@

- set desir

ed cutting depth

- tilt tool forward with line-of-cut indicator Q lined up

with desired line of cut marked on the workpiece

- open lower guar

d F with lever G

- just before blade enters workpiece, switch on tool

and gradually lower back end of tool using front end

of foot as hinge-point

- gradually move tool downwar

d as well as forward

- as soon as blade enters the material, release lever G

! the tool should run at full speed before the blade

enters into the workpiece

! never pull tool backwards

•

Cutting large panels

#

- support panel close to the cut either on floor

, table or

workbench

! set cutting depth so that you cut through panel

and not through support

- in case rip fence does not allow desir

ed width of cut,

clamp or nail straight piece of wood to workpiece as

a guide, and use the left side of the foot against this

guide

• V

ibration level

The vibration emission level stated at the back of this

instruction manual has been measured in accordance

with a standardised test given in EN 60745; it may be

used to compare one tool with another and as a

preliminary assessment of exposure to vibration when

using the tool for the applications mentioned

-

using the tool for different applications, or with

different or poorly maintainted accessories, may

significantly increase the exposure level

- the times when the tool is switched of

f or when it is

running but not actually doing the job, may

significantly reduce the exposure level

! protect yourself against the effects of vibration by

maintaining the tool and its accessories, keeping

your hands warm, and organizing your work

patterns

MAINTENANCE / SERVICE

• Always keep tool and cord clean (especially the

ventilation slots)

! disconnect the plug before cleaning

•

Clean saw blade immediately after use (especially from

resin and glue)

SKIL_IB5885_BR.indd 10 28-05-2010 09:41:53

Page 11

11

• If the tool should fail despite the care taken in

manufacturing and testing procedures, repair should be

carried out by an after-sales service centre for SKIL

power tools

-

send the tool undismantled

together with proof of

purchase to your dealer or the nearest SKIL service

station (addresses as well as the service diagram of

the tool are listed on www.skil.com.br)

ENVIRONMENT

• Do not dispose of electric tools, accessories and

packaging together with household waste material

(only for EU countries)

-

in observance of Eur

opean Directive 2002/96/EC on

waste of electric and electronic equipment and its

implementation in accordance with national law,

electric tools that have reached the end of their life

must be collected separately and returned to an

environmentally compatible recycling facility

-

symbol $

will remind you of this when the need for

disposing occurs

DECLARATION OF CONFORMITY

• We declare under our sole responsibility that this

product is in conformity with the following standardized

documents: IEC 60745 series.

Robert Bosch Ltda.

www.skil.com.br

E

Sierra circular 5885

INTRODUCCIÓN

• Esta herramienta ha sido proyectada para efectuar

cortes longitudinales y transversales rectos y con un

ángulo de inglete hasta 45° en madera; al emplear las

hojas de sierra correspondientes pueden aserrarse

también materiales no férricos, materiales de

construcción ligeros y materiales sintéticos

•

Lea y conserve este manual de instrucciones 2

CARACTERISTICAS TECNICAS 1

SEGURIDAD

INSTRUCCIONES GENERALES DE SEGURIDAD

¡ATENCIÓN! Lea íntegramente estas advertencias

de peligro e instrucciones. En caso de no atenerse a las

advertencias de peligro e instrucciones siguientes, ello

puede ocasionar una descarga eléctrica, un incendio y/o

lesión grave. Guardar todas las advertencias de peligro

e instrucciones para futuras consultas. El término

“herramienta eléctrica” empleado en las siguientes

advertencias de peligro se refiere a herramientas eléctricas

de conexión a la red (con cable de red).

1)

SEGURIDAD DEL PUESTO DE TRABAJO

a)

Mantenga limpia y bien iluminada su área de trabajo.

El desorden o una iluminación deficiente en las áreas de

trabajo pueden provocar accidentes.

b)

No utilice la herramienta eléctrica en un entorno con

peligro de explosión, en el que se encuentren

combustibles líquidos, gases o material en polvo.

Las herramientas eléctricas producen chispas que

pueden llegar a inflamar los materiales en polvo o

vapores.

c)

Mantenga alejados a los niños y otras personas de

su área de trabajo al emplear la herramienta

eléctrica.

Una distracción le puede hacer perder el

control sobre la herramienta.

2)

SEGURIDAD ELÉCTRICA

a)

El enchufe de la herramienta debe corresponder a la

toma de corriente utilizada. No es admisible

modificar el enchufe en forma alguna. No emplear

adaptadores en herramientas dotadas con una toma

de tierra. Los enchufes sin modificar adecuados a las

respectivas tomas de corriente reducen el riesgo de una

descarga eléctrica.

b)

Evite que su cuerpo toque partes conectadas a

tierra como tuberías, radiadores, cocinas y

refrigeradores.

El riesgo a quedar expuesto a una

descarga eléctrica es mayor si su cuerpo tiene contacto

con tomas de tierra.

c)

No exponga las herramientas eléctricas a la lluvia o

a condiciones de humedad.

Existe el peligro de recibir

una descarga eléctrica si penetran líquidos en la

herramienta.

d)

No utilice el cable de red para transportar o colgar

la herramienta, ni tire de él para sacar el enchufe de

la toma de corriente. Mantenga el cable de red

alejado del calor, aceite, esquinas cortantes o

piezas móviles.

Los cables de red dañados o

enredados pueden provocar una descarga eléctrica.

e)

Al trabajar con la herramienta eléctrica en la

intemperie utilice solamente cables de prolongación

homologados para su uso en exteriores.

La utilización de un cable de prolongación adecuado

para su uso en exteriores reduce el riesgo de una

descarga eléctrica.

f)

Si el funcionamiento de una herramienta eléctrica

en un lugar húmedo fuese inevitable, utilice un

cortacircuito de fuga a tierra.

El uso de un

cortacircuito de fuga a tierra reduce el riesgo de

descarga eléctrica.

3)

SEGURIDAD DE PERSONAS

a)

Esté atento y emplee la herramienta con prudencia.

No utilice la herramienta eléctrica si estuviese

cansado, ni bajo los efectos de alcohol, drogas o

medicamentos. El no estar atento durante el uso de

una herramienta eléctrica puede provocarle serias

lesiones.

b)

Utilice un equipo de protección personal y en todo

caso unas gafas de protección. El riesgo a lesionarse

se reduce considerablemente si, dependiendo del tipo y

la aplicación de la herramienta eléctrica empleada, se

utiliza un equipo de protección adecuado como una

mascarilla antipolvo, zapatos de seguridad con suela

antideslizante, casco, o protectores auditivos.

SKIL_IB5885_BR.indd 11 28-05-2010 09:41:53

Page 12

12

c) Evite una puesta en marcha fortuita. Asegurarse de

que la herramienta eléctrica esté desconectada

antes de conectarla a la toma de corriente, al

recogerla, y al transportarla. Si transporta la

herramienta eléctrica sujetándola por el interruptor de

conexión/desconexión, o si introduce el enchufe en la

toma de corriente con la herramienta eléctrica

conectada, ello puede dar lugar a un accidente.

d)

Retire las herramientas de ajuste o llaves fijas

antes de conectar la herramienta eléctrica.

Una herramienta o llave colocada en una pieza

rotativa puede producir lesiones graves al accionar la

herramienta eléctrica.

e)

Sea precavido. Trabaje sobre una base firme y

mantenga el equilibrio en todo momento.

Ello le

permitirá controlar mejor la herramienta eléctrica en

caso de presentarse una situación inesperada.

f)

Lleve puesta una vestimenta de trabajo adecuada.

No utilice vestimenta amplia ni joyas. Mantenga su

pelo, vestimenta y guantes alejados de las piezas

móviles.

La vestimenta suelta, las joyas y el pelo largo

se pueden enganchar con las piezas en movimiento.

g)

Siempre que sea posible utilizar equipos de

aspiración o captación de polvo, asegúrese que

éstos estén montados y que sean utilizados

correctamente.

El empleo de estos equipos reduce los

riesgos derivados del polvo.

4)

CUIDADO Y UTILIZACIÓN DE HERRAMIENTAS

ELÉCTRICAS

a) No sobrecargue la herramienta. Use la herramienta

prevista para el trabajo a realizar. Con la herramienta

adecuada podrá trabajar mejor y con mayor seguridad

dentro del margen de potencia indicado.

b)

No utilice herramientas con un interruptor

defectuoso.

Las herramientas que no se puedan

conectar o desconectar son peligrosas y deben

repararse.

c)

Saque el enchufe de la red antes de realizar un

ajuste en la herramienta, cambiar de accesorio o al

guardar la herramienta.

Esta medida preventiva

reduce el riesgo de conectar accidentalmente la

herramienta.

d)

Guarde las herramientas fuera del alcance de los

niños y de las personas que no estén familiarizadas

con su uso.

Las herramientas utilizadas por personas

inexpertas son peligrosas.

e)

Cuide sus herramientas con esmero. Controle si

funcionan correctamente, sin atascarse, las partes

móviles de la herramienta, y si existen partes rotas o

deterioradas que pudieran afectar al funcionamiento

de la herramienta. Si la herramienta eléctrica

estuviese defectuosa haga repararla antes de volver

a utilizarla.

Muchos de los accidentes se deben a

herramientas con un mantenimiento deficiente.

f)

Mantenga los útiles limpios y afilados.

Los útiles

mantenidos correctamente se dejan guiar y controlar

mejor.

g)

Utilice herramientas eléctricas, accesorios, útiles,

etc. de acuerdo con estas instrucciones, teniendo

en cuenta las condiciones de trabajo y la tarea a

realizar.

El uso de herramientas eléctricas para trabajos

diferentes de aquellos para los que han sido

concebidas puede resultar peligroso.

5)

SERVICIO

a)

Únicamente haga reparar su herramienta eléctrica

por un profesional, empleando exclusivamente

piezas de repuesto originales. Solamente así se

mantiene la seguridad de la herramienta eléctrica.

INSTRUCCIONES DE SEGURIDAD PARA SIERRAS

CIRCULARES

PELIGRO

•

Mantenga las manos apartadas del área de corte

y de la hoja; mantenga su mano auxiliar en el asa

delantera (si ambas manos están sujetando la sierra,

no pueden ser cortadas por la hoja)

•

No meta la mano debajo de la pieza de trabajo

(la guar

da no puede protegerle contra la hoja debajo de

la pieza de trabajo)

•

Ajuste la profundidad de corte al grosor de la pieza

de trabajo

(por debajo de la pieza de trabajo debe

sobresalir al menos un diente de la hoja de sierra)

•

No sujete nunca la pieza que esté cortando con las

manos o sobre la pierna

(es importante soportar la

pieza de trabajo correctamente para minimizar la

exposición del cuerpo, el atasco de la hoja o la pérdida

de control)

•

Sujete la herramienta por las superficies de agarre

aisladas cuando realice una operación en la que la

herramienta de corte pueda hacer contacto con

alambres ocultos o su propio cable de alimentación

(el contacto con un cable bajo tensión también

conectará la corriente a la herramienta y dará una

sacudida eléctrica al operario)

•

Al aserrar con corte longitudinal utilice siempre una

guía de borde recto

(esto mejora la precisión del corte

y reduce las probabilidades de que la hoja se atasque)

•

Utilice siempre hojas del tamaño y la forma

apropiados para los agujeros del portaherramientas

(diamante o redonda)

(las hojas que no correspondan

a los accesorios de montaje de la sierra rodarán

excéntricamente, causando pérdida de control)

•

No utilice arandelas o pernos de hoja dañados o

incorrectos

(las arandelas y el perno de la hoja fueron

diseñados especialmente para su sierra, para

proporcionar un rendimiento y una seguridad de

funcionamiento óptimos)

ACCIÓN DE RETROCESO - CAUSAS

•

La acción de r

etroceso es una reacción repentina

producida en una hoja de sierra mal alineada, atascada

o enganchada, que causa que una sierra incontrolada

se levante y salga de la pieza de trabajo y salte hacia el

operario

• Cuando la hoja se engancha o queda atrapada debido

a que el corte de la sierra se cierra, la hoja se atasca y

la r

eacción del motor impulsa la unidad rápidamente

hacia atrás y contra el operador

SKIL_IB5885_BR.indd 12 28-05-2010 09:41:54

Page 13

13

• Si la hoja se tuerce o queda mal alineada en el corte,

los dientes del borde posterior de la sierra pueden

clavarse en la superficie superior de la madera

haciendo que la hoja se salga del corte y salte hacia

atrás y contra el operador

ACCIÓN DE RETROCESO - PREVENCIÓN POR PARTE

DEL OPERARIO

La acción de retroceso es causada por la utilización

incorrecta de la herramienta y los procedimientos o

condiciones operativas incorrectas y puede evitarse

tomando las precauciones apropiadas, que se describen a

continuación

•

Mantenga la sierra bien agarrada con ambas manos

y posicione los brazos para resistir las fuerzas de la

acción de retroceso; posicione el cuerpo a cualquier

lado de la hoja, pero no alineado con la hoja

(la

acción de retroceso podría causar que la sierra saltara

hacia atrás, pero las fuerzas de la acción de retroceso

pueden ser controladas por el operario si toma las

precauciones apropriadas)

•

Cuando la hoja está atascada o cuando se

interrumpe un corte por cualquier razón, deje de

pulsar el gatillo y sujete la sierra en el material hasta

que la hoja se pare completamente; nunca intente

retirar la hoja de la pieza de trabajo ni tire de la

sierra mientras la hoja está en movimiento o puede

producirse una acción de retroceso

(investigue y

tome medidas correctivas para eliminar la causa del

atasco de la hoja; evite cortar clavos o tornillos)

•

Cuando vuelva poner en marcha una hoja en la

pieza de trabajo, centre la hoja de la sierra en el

corte y compruebe que los dientes de la sierra no

estén enganchados en el material

(si la hoja de la

sierra está atascada, puede salirse o producir un acción

de retroceso desde la pieza de trabajo cuando la sierra

se vuelva a poner en marcha)

•

Soporte los paneles grandes para minimizar el

riesgo de que la hoja se enganche y produzca una

acción de retroceso (los paneles tienden a hundirse

bajo su propio peso, por lo tanto deberían colocarse

soportes debajo del panel en ambos lados, cerca de la

línea del corte y del borde del panel)

•

No utilice una hoja embotada o dañada

(las hojas sin

afilar o colocadas incorrectamente producen un corte

estrecho que causa fricción excesiva, enganche y

acción de retroceso en la hoja)

•

Las palancas de ajuste de profundidad y biselado de

la hoja deben estar apretadas y seguras antes de

realizar el corte

(si el ajuste de la hoja cambia durante

el corte, puede causar atascos y acción de retroceso en

la hoja)

•

Vaya con cuidado extra cuando realice un corte

profundo en paredes existentes u otras áreas ciegas

(la hoja que sobr

esale puede cortar objetos que pueden

causar acción de retroceso)

¡ATENCIÓN!

•

Compruebe que la guarda inferior se cierre

correctamente antes de cada utilización

• No haga funcionar la sierra si la guarda inferior no

se mueve libremente y no se cierra

instantáneamente

• No sujete nunca la guarda inferior en la posición de

apertura

• Si la sierra cae accidentalmente, la guarda inferior

puede doblarse; desenchufe la herramienta, levante la

guarda inferior con el asa de retracción y asegúrese de

que se mueva libremente y que no haga contacto con la

hoja ni ninguna otra pieza en todos los ángulos y

profundidades de corte

•

Compruebe el funcionamiento del resorte de la

guarda inferior; si la guarda y el resorte no

funcionan correctamente, se les debe prestar

servicio antes de utilizarlos

(es posible que la guarda

no funcione bien debido a piezas dañadas, acumulación

de residuos pegajosos y otros desechos)

•

La guarda inferior debe retraerse manualmente

solamente para cortes especiales como cortes

profundos y cortes compuestos; levante la guarda

inferior retrayendo el asa y tan pronto como la hoja

entre en el material, suelte la guarda inferior

(para

todos los otros tipos de aserrado, la guarda inferior

debería funcionar automáticamente)

•

Compruebe siempre que la guarda inferior cubra la

hoja antes de colocar la sierra sobre un banco de

trabajo o en el suelo (una hoja sin protección que no

esté completamente parada puede desplazarse hacia

atrás cortando todo lo que encuentre a su paso; sea

consciente del tiempo que la hoja tarda en pararse

completamente después de que se ha dejado de pulsar

el interruptor de activación)

GENERAL

•

Evite los daños que puedan causar los tor

nillos, clavos

y otros objetos sobre la pieza de trabajo; retírelos antes

de empezar a trabajar

• Asegure la pieza de trabajo

(una pieza de trabajo

fijada con unos dispositivos de sujeción o en un tornillo

de banco, se mantiene sujeta de forma mucho más

segura que con la mano)

•

Utilice aparatos de detección adecuados para

localizar posibles conductores o tuberías ocultas,

o consulte a su compañía abastecedora

(el contacto

con conductores eléctricos puede provocar una

descarga eléctrica e incluso un incendio; al dañar una

tubería de gas puede producirse una explosión; la

perforación de una tubería de agua pueden causar

daños materiales o una descarga eléctrica)

•

Ponga atención al guar

dar su herramienta de que el

motór está apagado y las partes móviles están parados

• Utilice cables de extensión segur

os y completamente

desenrollados con una capacidad de 16 amperios

• En caso de bloqueo o de un mal funcionamiento

eléctrico o mecánico, desconectar la herramienta

inmediatamente y sacar el enchufe del contacto

• SKIL únicamente puede garantizar un funcionamiento

corr

ecto de la herramienta, cuando se utilicen los

accesorios adecuados que podrá obtener de su

proveedor de SKIL

• Utilice únicamente accesorios cuyo límite de

r

evoluciones permitido sea como mínimo igual a las

revoluciones en vacío máximas de la herramienta

• Nunca utilice su herramienta sin la capa de pr

otección

original sistemática

SKIL_IB5885_BR.indd 13 28-05-2010 09:41:54

Page 14

14

• Esta herramienta no debe utilizarse por personas

menores de 16 años

• El nivel de ruido, con la herramienta trabajando, podrá

sobr

epasar 85 dB(A); usar protectores auditivos

• Si llega a dañarse o cortarse el cable eléctrico durante

el trabajo, no tocar el cable, sino extraer

inmediatamente el enchufe de la r

ed

• No utilizar la herramienta cuando el cable esté dañado;

hágalo cambiar por una persona calificada

• Compruebe siempr

e que la tensión de alimentación es

la misma que la indicada en la placa de características

de la herramienta (las herramientas de 230V o 240V

pueden conectarse también a 220V)

• Los pr

ocesos de conexión provocan una breve caída de

la tensión; si las condiciones de la red fuesen

desfavorables, ello puede llegar a afectar a otros

aparatos (en redes con impedancias inferiores a

0,36 ohmios es improbable que lleguen a perturbarse

otros aparatos) - si usted necesita alguna aclaración,

contacte con su proveedor de energía eléctrica

•

Esta herramienta no es adecuada para hacer cortes con

agua

• Al desconectar su sierra cir

cular, nunca frene la rotación

de la hoja empujando algo contra ella lateralmente

• No utilice nunca hojas de sierras cir

culares de HSS

• Nunca utilice discos de amolar/tronzar con esta

herramienta

• No trabaje materiales que contengan amianto

(el amianto es cancerígeno)

•

El polvo del material, como por ejemplo la pintura que

contiene

plomo, algunas especies de madera, minerales

y metal podrían ser dañinos (el contacto o inhalación

del polvo podría producir reacciones alérgicas y/o

transtornos respiratorios al operador u otras personas

cerca); utilice una máscara contra el polvo y trabaje

con un dispositivo de extracción de polvo cuando lo

conecte

•

Ciertos tipos de polvo están catalogados como

cancerígenos (por ejemplo el polvo de r

oble y de haya)

especialmente junto con aditivos para el

acondicionamiento de la madera; utilice una máscara

y trabaje con un dispositivo de extracción de polvo

cuando lo conecte

•

Siga la normativa nacional en cuanto a extracción de

polvo, en función de los materiales que vayan a ser

utilizados

• No intente cortar piezas extr

emadamente pequeñas

• Antes de empezar a cortar, aparte todos los obstáculos

que haya encima y debajo de la línea de corte

• No trabaje con herramientas a una altura por encima de

la cabeza

• Use unicamente mesas de serrar pr

ovistas de un

interruptor que prevenga el arranque del motor desoués

de que se interrumpa la corriente

• Use unicamente mesas de serrar pr

ovistas de una guía

de corte

• Desenchufar siempre la herramienta antes de

realizar cualquier ajuste o cambiar algún accesorio

USO

• Montaje de la hoja de sierra 3

! desenchufar la herramienta

- coger la llave hexagonal A del depósito B

- pulse el botón de cierre de husillo C y manténgalo

pulsado mientras quita el tornillo de hoja D con la

llave de la hoja

! apriete el botón de cierre de husillo C solamente

cuando la herramienta se haya detenido

- suelte el botón de cierre de husillo C

- retire la brida E

- abra la guarda inferior F con la palanca G y sujétela

mientras monta la hoja de sierra con los dientes de la

sierra y la flecha impresa en la hoja apuntanda en la

misma dirección que la flecha mostrada en la guarda

inferior

-

suelte la guarda inferior F

- monte la brida E

! asegúrese de que las superficies de enganche H

de las bridas estén perfectamente limpias y estén

encaradas a la hoja

- pulse el botón de cierr

e de husillo C y manténgalo

pulsado mientras aprieta el tornillo de la hoja con la

llave hexagonal dando 1/8 de giro después de que

esté apretado al máximo con los dedos (asegura que

la hoja de sierra resbale si encuentra excesiva

resistencia, y evita que el motor se sobrecargue y la

sierra retroceda)

-

suelte el botón de cierre de husillo C

• Ajuste de la profundidad de corte (0-85 mm)

4

- para obtener una óptima calidad de corte, la hoja no

debe de pr

ofundizar más de 3 mm en la pieza de

trabajo

- aflojar la palanca J

-

levantar/bajar la base K hasta la profundidad de

corte deseada, que se encuentra indicada en la

escala, usando para ello el indicador L

- apr

etar la palanca J

• Ajuste del ángulo de corte (0-45°)

5

- desapr

etar los 2 botones M

- inclinar la herramienta hasta el ángulo de corte

deseado, que se encuentra indicado en la escala,

usando para ello el indicador N

- apr

etar los 2 botones M

! para cortes biselados, la profundidad de corte se

corresponde con el valor en la escala de

profundidad de corte

• Compr

obación del ángulo de corte a 90° 6

- ajustar la base K para una máxima pr

ofundidad de

corte 4

- ajustar el ángulo de corte a 0°

-

comprobar el ángulo de corte de 90° entre la hoja y

la base con un cartabón

- si es necesario un ajuste, desapr

ete los 2 botones M,

e utilice el tornillo de ajuste P como muestra la figura

SKIL_IB5885_BR.indd 14 28-05-2010 09:41:55

Page 15

15

• Indicador Q de la línea de corte 7

- para guiar la herramienta a lo largo de la línea de

corte deseada, márquela en la pieza de trabajo

- para un corte r

ecto de 0° o para bisealar a 45°, use el

indicador de la línea adecuado

- para permitir escoger si el material de desecho está

en el lado inter

no o externo de la sierra

! la parte ancha de la base debe de reposar en el

soporte de la pieza de trabajo

! la anchura de corte viene determinada por el

ancho de los dientes de la hoja y no por el ancho

del cuerpo de la sierra

! realice siempre cortes de prueba para verificar la

línea actual de corte

• Arranque suave electr

onico 8

Asegura el alcance de la velocidad máxima suavemente

sin la reacción súbita de la herramienta al conectarla

• Aspiración de polvo

-

monte el aspirador a la extensión R

9

! nunca permita que la media del aspirador

interfiera con la chapa protectora o con la

operación de corte

- se puede utilizar también una bolsa de polvo

(accesorio SKIL 2610387402)

• Utilización de la herramienta 9

- enchufar a la r

ed

- siempre mantener la empuñadura S firmemente con

una mano y la empuñadura T firmemente con la otra

mano

- colocar la herramienta con la parte delantera de la

misma tendida sobr

e la pieza de trabajo

! asegurese de que los dientes de la hoja no estan

encalados en la pieza de trabajo

- poner en mar

cha su herramienta primero apretando

el botón U (= interruptor de seguridad que no puede

bloquearse) y luego tirando del gatillo V

! la sierra debe detener su velocidad máxima

antesde que usted pueda realizar el trabajo de

corte

- la chapa pr

otectora F se abre automáticamente

cuando la hoja de sierra penetra en la pieza de

trabajo (abrir la chapa protectora manualmente con

la palanca G solámente para cortes particulares

como cortes de emersión)

- no forzar la herramienta; trabaje com pr

esión ligera y

continua

- después de haber r

ealizado el corte, pare su

herramienta soltando el gatillo V

! asegurese que la hoja esté completamente

parada antes de que la levante de la pieza a

trabajar

CONSEJOS DE APLICACIÓN

• Poner siempre el lado bueno de la pieza de trabajo

hacia abajo, para asegurar un mínimo astillado

• Utilice únicamente hojas de sierra afiladas del modelo

adecuado

0

- cuanto más dientes, más lisado el corte

-

hojas de sierra con dientes de metal duro (Widia) se

mantienen 30 veces más afiladas que las hojas

normales

• Guía paralela W !

- para hacer cortes exactos a lo lar

go de una esquina

de la pieza de trabajo

- puede insertarse en ambos lados de la base

Ajuste de la guía paralela

-

desaflojar la tuerca X

- ajustar a la anchura del corte deseado, utilizando la

escala de la guía paralela (utilice el indicador de la

línea de corte Q como referencia 0)

-

apr

etar la tuerca X

• Cortes de emersión directa

@

- fijar la pr

ofundidad de corte deseada

- incline la herramienta hacia adelante con el indicador

de la línea de corte Q alineado con la línea de corte

deseada y marcada en la pieza de trabajo

- abrir la guar

da inferior F con la palanca G

- justo antes de que la sierra penetre en la pieza de

trabajo, desvíe la herramienta y baje gradualmente la

parte delantera de la herramienta, usando el frontal

de la base como punto de apoyo

- mover la herramienta gradualmente, tanto hacia

abajo, como hacia adelante

- tan pronto como la hoja entre en el material, suelte la

palanca G

! la sierra debe detener su velocidad máxima an-

tesde que usted pueda realizar el trabajo de corte

! nunca empuja la herramienta hacia atras

•

Cortar tableros largos

#

- sostener el tabler

o, bien en el suelo, mesa o banco

de trabajo

! fijar la profundidad de corte de tal manera, que

usted pueda cortar a través del tablero y no a

través del soporte

- e

n el caso de que la guía paralela no permita la

anchura de corte deseada, empalme o clave una pieza

de madera recta a la pieza de trabajo como guía, y use

la parte izquierda de la base contra esta guía

• Nivel de vibración

El nivel de emisión total de vibraciones (suma vectorial

de tr

es direcciones) determinado según el

procedimiento de medición fijado en la norma

EN 60745: valor de vibraciones generadas a

h

=

3,5 m/s², tolerancia K=1,5 m/s²; puede utilizarse para

herramienta con otra y como valoración preliminar de la

exposición a las vibraciones al utilizar la herramienta

con las aplicaciones mencionadas

-

al utilizarla para distintas aplicaciones o con

accesorios difer

entes o con un mantenimiento

deficiente, podría aumentar de forma notable el nivel

de exposición

- en las ocasiones en que se apaga la herramienta o

cuando está funcionando per

o no está realizando

ningún trabajo, se podría reducir el nivel de

exposición de forma importante

! protéjase contra los efectos de la vibración

realizando el mantenimiento de la herramienta y

sus accesorios, manteniendo sus manos

calientes y organizando sus patrones de trabajo

SKIL_IB5885_BR.indd 15 28-05-2010 09:41:55

Page 16

16

MANTENIMIENTO / SERVICIO

• Mantenga limpio el cable eléctrico y la herramienta

(sobre todo las ranuras de ventilación)

! desenchufar la herramienta antes de limpiar

•

Limpie la hoja de sierra después de cada uso

(especialmente de resina y cola)

• Si a pesar de los esmerados pr

ocesos de fabricación y

control, la herramienta llegase a averiarse, la reparación

deberá encargarse a un servicio técnico autorizado para

herramientas eléctricas SKIL

- envíe la herramienta sin desmontar

junto con una

prueba de su compra a su distribuidor o a la estación

de servicio más cercana de SKIL (los nombres así

como el despiece de piezas de la herramienta figuran

en www.skil.com.br)

-

si necesita del cambio de las escobillas de carbón,

envié tu herramienta para un servicio técnico

autorizado para r

eemplazo; en el caso del cable de

energía o el enchufe esté dañado, envié tu

herramienta para un servicio técnico autorizado para

reemplazo.

Argentina - Robert Bosch Argentina S.A.

Av. Córdoba 5160 - C1414BAW

Ciudad Autonoma de Buenos Aires

Atencion al Cliente

Tel.: +54 (0810) 555 2020

E-Mail: herramientas.bosch@ar.bosch.com

Bolivia - HANSA

(591) 2 240 7777

Chile - EMASA S.A.

Irarrázaval 259 – Ñuñoa - Santiago

Tel.: +56 (02) 520 3100

E-Mail: emasa@emasa.cl

Colombia - Robert Bosch Ltda

(57) 1 658 5000 ext. 308

Costa Rica - COFERSA

(506) 2205-25-25

Cuba - GRUPO JOAN BOLUFER S.L.

(53) 270 3820

Ecuador - TECNOVA

(59) 34 2200 500

El Salvador - HEACSA

(203) 2221 9000

Guatemala - EDISA

(502) 2234-4063

Honduras - CHIPS

(504) 556 9781

México - Robert Bosch S.A. de C.V.

Tel. Interior: +52 (01) 800 627 1286

Tel. D.F.: +52 (01) 52 84 30 62

E-Mail: arturo.fernandez@mx.bosch.com

Nicarágua - MADINISA

(505) 249 8152 / 249 8153

Panamá - ZENTRUM

(507) 229 2800

Paraguai - CHISPA

(595) 2155 3315

Peru - AUTOREX

(511) 706 1100 / 706 1143

Republica Dominicana - JOCASA

(1809) 372 6000 / 530 2720

Uruguay - EPICENTRO

(59) 82 200 6225

Venezuela - Robert Bosch Venezuela

(58) 212 207 4511/ 207 4420

AMBIENTE

• No deseche las herramientas eléctricas, los

accesorios y embalajes junto con los residuos

domésticos (sólo para países de la Unión Europea)

-

de conformidad con la Dir

ectiva Europea 2002/96/CE

sobre residuos de aparatos eléctricos y electrónicos

y su aplicación de acuerdo con la legislación

nacional, las herramientas eléctricas cuya vida útil

haya llegado a su fin se deberán recoger por

separado y trasladar a una planta de reciclaje que

cumpla con las exigencias ecológicas

-

símbolo $ llamará su atención en caso de necesidad

de tirarlas

DECLARACIÓN DE CONFORMIDAD

• Declaramos bajo nuestra sola responsabilidad que este

producto está en conformidad con las normas o

documentos normalizados siguientes: serie IEC 60745.

Robert Bosch Ltda.

www.skil.com

SKIL_IB5885_BR.indd 16 28-05-2010 09:41:57

Page 17

17

P

Serra circular 5885

INTRODUÇÃO

• Esta ferramenta foi projetada para realizar cortes em

madeiras, cortes longitudinais e transversais em cortes

retos e em ângulo de 45º; com lâminas de serras

apropriadas, também é possível serrar metais não

ferrosos, materiais leves e plásticos

•

Leia e guar

de este manual de instruções 2

ESPECIFICAÇÕES TÉCNICAS 1

SEGURANÇA

AVISOS DE SEGURANÇA PARA FERRAMENTAS EM

GERAL

ATENÇÃO! Leia todos os avisos de segurança e

todas as instruções. Falha em seguir todos os avisos e

instruções listados abaixo pode resultar em choque

elétrico, fogo e/ou em ferimento sério. Guarde todos os

avisos e instruções para futuras consultas. O termo

"ferramenta" em todos os avisos listados abaixo referemse a ferramenta alimentada através de seu cordão de

alimentação ou a ferramenta operada a bateria (sem

cordão).

1)

S

EGURANÇA DA ÁREA DE TRABALHO

a) Mantenha a área de trabalho limpa e iluminada.

As áreas desorganizadas e escuras são um convite aos

acidentes.

b)

Não opere ferramentas em atmosferas explosivas,

como na presença de líquidos inflamáveis, gases ou

poeira.

As ferramentas criam faíscas que podem

inflamar a poeira ou os vapores.

c)

Mantenha crianças e visitantes afastados ao operar

uma ferramenta.

As distrações podem fazer você

perder o controle.

2)

S

EGURANÇA ELÉTRICA

a)

Os plugues da ferramenta devem ser compatíveis

com as tomadas. Nunca modifique o plugue.

Não use nenhum plugue adaptador com as

ferramentas aterradas. Os plugues sem modificações

aliados a utilização de tomadas compatíveis reduzem o

risco de choque elétrico.

b)

Evite o contato do corpo com superfícies ligadas à

terra ou aterradas tais como as tubulações,

radiadores, fornos e refrigeradores. Há um aumento

no risco de choque elétrico se seu corpo for ligado à

terra ou aterramento.

c)

Não exponha a ferramentas à chuva ou às

condições úmidas.

A água entrando na ferramenta

aumenta o risco de choque elétrico.

d)

Não for

ce o cordão de alimentação. Nunca use o

cordão de alimentação para carregar, puxar ou o

para desconectar a ferramenta da tomada.

Mantenha o cabo elétrico longe do calor, óleo,

bordas afiadas ou das partes em movimentos.

Os cabos danificados ou emaranhados aumentam o

risco de choque elétrico.

e)

Ao operar uma ferramenta ao ar livr

e, use um cabo

de extensão apropriado para o uso ao ar livre.

O uso de um cabo apropriado ao ar livre reduz o risco

de choque elétrico.

f)

Se a operação de uma ferramenta em um local

segur

o não for possível, use alimentação protegida

por um dispositivo de corrente residual (RCD).

O uso de um RCD reduz o risco de choque elétrico.

3)

S

EGURANÇA PESSOAL

a)

Fique atento, olhe o que você está fazendo e use o

bom senso ao operar uma ferramenta. Não use a

ferramenta quando você estiver cansado ou sob a

influência de drogas, álcool ou de medicamentos.

Um momento de desatenção enquanto opera uma

ferramenta pode resultar em grave ferimento pessoal.

b)

Use equipamento de segurança. Sempre use óculos

de segurança. O equipamento de segurança tal como

a máscara contra a poeira, sapatos de segurança

antiderrapantes, capacete de segurança, ou protetor

auricular utilizados em condições apropriadas reduzirão

os riscos de ferimentos pessoais.

c)

Evite a partida não intencional. Assegur

e que o

interruptor está na posição desligada antes de

conectar o plugue na tomada e/ou bateria, pegar ou

carregar a ferramenta. Carregar as ferramentas com

seu dedo no interruptor ou conectar as ferramentas que

apresentam interruptor na posição “ligado” são

convites a acidentes.

d)

Remova qualquer chave de ajuste antes de ligar a

ferramenta. Uma chave de boca ou de ajuste

conectada a uma parte rotativa da ferramenta pode

resultar em ferimento pessoal.

e)

Não for

ce além do limite. Mantenha o apoio e o

equilíbrio adequado toda vez que utilizar a

ferramenta. Isto permite melhor controle da ferramenta

em situações inesperadas.

f)

V

ista-se apropriadamente. Não use roupas

demasiadamente largas ou jóias. Mantenha seus

cabelos, roupas e luvas longe das peças móveis.

A roupa folgada, jóias ou cabelos longos podem ser

presos pelas partes em movimento.

g)

Se os dispositivos são for

necidos com conexão

para extração e coleta de pó, assegure que estes

estão conectados e utilizados corretamente.

O uso destes dispositivos pode reduzir riscos

relacionados a poeira.

4)

U

SO E CUIDADOS DA FERRAMENTA

a) Não for

ce a ferramenta. Use a ferramenta correta

para sua aplicação. A ferramenta correta faz o trabalho

melhor e mais seguro se utilizada dentro daquilo para a

qual foi projetada.

b)

Não use a ferramenta se o interruptor não ligar e

desligar

. Qualquer ferramenta que não pode ser

controlada com o interruptor é perigosa e deve ser

reparada.

SKIL_IB5885_BR.indd 17 28-05-2010 09:41:58

Page 18

18

c) Desconecte o plugue da tomada antes de fazer

qualquer tipo de ajuste, mudança de acessórios ou

armazenamento de ferramentas. Tais medidas de

segurança preventivas reduzem o risco de se ligar a

ferramenta acidentalmente.

d)

Guar

de as ferramentas fora do alcance das crianças

e não permita que pessoas não familiarizadas com a

ferramenta ou com estas instruções operem a

ferramenta. As ferramentas são perigosas nas mãos

de usuários não treinados.

e)

Manutenção das ferramentas. Cheque o

desalinhamento ou coesão das partes móveis,

rachaduras e qualquer outra condição que possa

afetar a operação da ferramenta. Se danificada, a

ferramenta deve ser r

eparada antes do uso.

Muitos acidentes são causados pela inadequada

manutenção das ferramentas.

f)

Mantenha ferramentas de corte afiadas e limpas.

A manutenção apropriada das ferramentas de corte

com lâminas afiadas tornam estas menos prováveis ao

emperramento e são mais fáceis de controlar.

g)

Use a ferramenta, acessórios, suas partes etc. de

acor

do com as instruções e na maneira designada

para o tipo particular da ferramenta, levando em

consideração as condições e o trabalho a ser

desempenhado. O uso da ferramenta em operações

diferentes das designadas podem resultar em situações

de risco.

5)

REPAROS

a)

Tenha sua ferramenta reparada por um agente de

reparos qualificado que usa somente peças

originais. Isto assegura que a segurança da ferramenta

é mantida.

b) Caso necessite a tr

oca de escovas de carvão, envie a

uma assitência técnica autorizada para substituição.

c) Caso o cor

dão de alimentação ou o plugue esteja

danificado, envie a uma assistência técnica autorizada

para substituição.

INSTRUÇÕES DE SEGURANÇA PARA SERRA

CIRCULARES

PERIGO

•

Mantenha as mãos afastadas da área de corte e

da lâmina; mantenha sua segunda mão na

empunhadura auxiliar ou na carcaça do motor

(se ambas as mãos estiver segurando a serra, elas não

podem ser cortadas pela lâmina)

•

Não manipule nada abaixo da peça de trabalho

(a capa de pr

oteção não protege você da lâmina abaixo

da peça de trabalho)

•

Ajuste a profundidade do corte de acordo com a

espessura da peça de trabalho

(menos que um dente

completo dos dentes da lâmina deve ser visível abaixo

da peça de trabalho)

•

Nunca segure a peça a ser cortada com suas mãos

ou suas pernas; fixe a peça de trabalho em uma

plataforma estável

(isto é importante para realizar o

trabalho adequadamente para minimizar a exposição

do corpo, compressão da lâmina, ou perda de controle)

•

Segure a ferramenta pela superfície isolada da

empunhadura da ferramenta ao executar uma

operação de corte pode entrar em contato com uma

fiação não visível ou seu próprio cordão de

alimentação

(o contato com uma fiação energizadas e

tornar as partes metálicas expostas das ferramenta

energizadas causando choque elétrico ao operador)

•

Ao cortar sempre use uma régua ou um

guia

paralelo (isto melhora a precisão do corte e reduz

o risco de tocar a lâmina)

•

Sempre use lâminas com tamanho e formato de

furos corretos (losango verso redondo)

(lâminas que

não são compatíveis com a serra guiarão de forma

excêntrica causando perda de controle)

•

Nunca use parafusos ou arruelas danificadas ou

incorretas

(as arruelas da lâmina e parafusos foram

fabricados especificamente para a sua serra, para o

ótimo desempenho e segurança de operação)

C

ONTRA

-GOLPE - CAUSAS DO CONTRA-GOLPE AO

OPERADOR

O ressalto resulta de uma má utilização da ferramenta e/

ou de procedimentos de utilização ou condições

incorrectos e pode ser evitado tomando as devidas

precauções, conforme a seguir indicado

•

O contra-golpe é uma r

eação inesperada de uma

lâmina de serra apertada, presa ou desalinhada,

provocando um movimento repentino que levanta a

serra ao encontro do operador devido a perda de

controle

• Quando a lâmina é apertada ou pr

esa pelo corte que se

fecha na madeira, a lâmina trava e a reação do motor

levanta a serra repentinamente ao encontro do

operador

• Se a lâmina se entortar ou desalinhar no corte, o dente

oposto da lâmina pode cavar a superfície superior da

madeira levantnado a lâmina saltando do corte e indo

ao encontro do operador

CONTRA-GOLPE - PREVENÇÃO DO CONTRA-GOLPE

AO OPERADOR

O contra-golpe é o resultado do uso incorredo e/ou

procedimentos e condições de operação incorretos e

podem ser evitados tomando as precauções adequadas

como descritos abaixo

•

Manter uma empunhadura firme com ambas as

mãos na serra e posicionar seus braços para resistir

as forças do contra-golpe; posicionar seu corpo ao

lado da serra mas nunca alinhado com a serra

(o contra-golpe pode levantar e arremessar a serra para

traz, mas as forças do contra-golpe podem ser

controladas pelo operador se precauções adequadas

são tomadas)

•

Quando a lâmina estiver prendendo, ou quando

interromper um corte por qualquer razão, solte

o

interruptor e mantenha a serra imóvel no material

até que a lâmina pare de girar completamente.

Nunca tente remover ou puxar a serra da

peça

trabalahada enquanto a lâmina está em

movimento porque pode ocorrer um contra-golpe

(investigue e corrija, eliminanando a causa do

prendimento da lâmina)

SKIL_IB5885_BR.indd 18 28-05-2010 09:41:58

Page 19

19

• Ao religar a serra na peça trabalhada, centralize a

lâmina da serra no corte e verifique se o dente da

lâmina não está encaixado no material (se a lâmina

da serra estiver presa na peça trabalhada, esta pode

subir ou ocorrer um contra-golpe quando a serra é

religada)

•

Prenda

peças grandes a ser trabalhada para

minimizar o risco de aperto de lâmina e contragolpe. Peças grandes tendem a empenar devido ao

seu próprio peso (os suportes devem ser montados

em baixo do peça em ambos os lados, próximo a linha

de corte e próximo a borda da peça)

•

Não use lâminas cegas ou danificadas

(lâminas não

afiadas ou desajustadas produzem um corte estreito

causando excesso de fricção, pr

endendo

e ocorrendo o

contra-golpe)

• Alavancas de ajuste de profundidade e ângulo de

corte da lâmina devem estar apertadas e seguras

antes de executar o corte

(se o ajuste da lâmina

altera-se ao executar o corte, pode causar prendimento

e contra-golpe)

•

Use cuidado extra ao executar um corte de

bolso

em paredes ou em outras áreas cegas (a lâmina

excedente pode cortar objetos que podem causar

contra-golpe)

ATENÇÃO!

• Verifique o correto fechamento da capa de proteção

inferior antes de cada uso

• Não opere a serra se a capa de proteção inferior

não se movimenta facilmente e fecha

instantaneamente

• Nunca prenda ou prenda a capa de proteção inferior

na posição aberta

• Se a serra cair acidentalmente, a capa de pr

oteção

inferior pode entortar; levante a capa de proteção

inferior manualmente através de sua alavanca e

certifique que ela se movimenta livremente, não toca na

lâmina ou em qualquer outra parte, verificar em todos

os ângulos e profundidades de corte

•

Verifique a operação da mola da capa de proteção

inferior. Se a capa ou a mola não estão operando

corretamente, elas devem ser consertadas antes do

uso

(a capa de proteção inferior pode funcionar

lentamente devido a peças danificadas, depósito de

goma ou um acúmulo de detritos)

•

A capa de proteção inferior pode ser retraída

manualmente para cortes especiais como "cortes

de

bolso" e "cortes compostos"; levante a capa de

proteção inferior através da alavanca e assim que a

lâmina entrar no material, a capa de proteção

inferior deve ser liberada (para todos os outros tipos

de corte, a capa de proteção inferior deve operar

automaticamente)

•

Sempre observe se a capa de proteção inferior está

cobrindo a lâmina antes de colocá-la na bancada ou

no chão

(uma lâmina não protegida que se encosta

causará um movimento da serra para traz que cortará o

que estiver em seu caminho; esteja atento ao momento

que lâmina para após o interruptor se liberado)

INFORMAÇÃO

•

Evite danificar a ferramenta em superfícies com pr

egos

ou parafusos; remova-os antes de começar a trabalhar

• Fixe a peça de trabalho

(uma peça de trabalho fixa

com dispositivos de fixação ou num torno fica melhor

fixa do que manualmente)

•

Utilizar detectores apropriados para detectar tubos

e cabos de alimentação escondidos, ou consulte a

firma de alimentação local

(o contacto com um cabo

eléctrico pode levar a incêndio e choque eléctrico; a

danificação de um cano de gás pode levar à explosão;

a penetração de uma tubulação de água provoca danos

materiais ou pode provocar um choque eléctrico)

•

Quando guardar a ferramenta, deverá certificar-se que

o motor esta devidamente parado assim como todas as

peças rotativas

• Utilize extensões completamente desenr

oladas e

seguras, com uma capacidade de 16 Amp

• Em caso de bloqueio ou de anomalias eléctricas ou

mecânicas, desligue imediatamente a ferramenta e a

ficha da tomada

• A SKIL só pode garantir um funcionamento perfeito da

ferramenta, quando utilizada com os acessórios

adequados que poderá adquirir nos r

evendedores

autorizados SKIL

• Utilize apenas acessórios com um númer

o de rotação

admissível no mínimo tão alto como o mais alto número

de rotação em vazio da ferramenta

• Nunca utilize a ferramenta sem o sistema de pr

otecção

original

• Esta ferramenta não deve ser utilizada por pessoas

menor

es de 16 anos

• O nível de ruído durante o trabalho pode exceder

85 dB(A); utilize pr

otectores auriculares

•

Caso o fio for danificado ou cortado durante o trabalho,

não toque no fio, mas tir

e imediatamente a ficha da

tomada

• Não utilizar ferramenta caso o fio esteja danificado;

mandando-o substituir por pessoal qualificado

• Certifique-se sempr

e de que a tensão de alimentação

está de acordo com a tensão indicada na placa de

identificação da ferramenta (ferramentas com a

indicação de 230V ou 240V também podem ser ligadas

a uma fonte de 220V)

• Pr

ocessos de ligação provocam uma breve redução de

tensão; no caso de condições de rede desfavoráveis, o

funcionamento de outros aparelhos pode ser

prejudicado (em impedâncias de rede inferiores a

0,36 Ohm não se conta com avarias) - se necessita de

algum esclarecimento adicional, contacte o seu

fornecedor de energia eléctrica

•

Esta ferramenta não é aconselhada para cortar com

água

• Depois de desligar a sua serra cir

cular, nunca pare a

rotação da lâmina exercendo pressão lateral sobre a

mesma

• Nunca utilize lâminas para serras cir

culares em HSS

• Nunca utilize discos de rebarbe/corte com esta

ferramenta

• Não processar material que contenha asbesto

(asbesto é considerado como sendo cancerígeno)

SKIL_IB5885_BR.indd 19 28-05-2010 09:41:58

Page 20

20

• O pó do material, como tinta com chumbo, algumas

espécies de madeira, minerais e metais, pode ser

prejudicial (contacto ou inalação do pó pode provocar

reacções alérgicas e/ou doenças respiratórias ao

operador ou às pessoas presentes); use máscara

respiratória e trabalhe com um dispositivo de

extracção de pó quando ligado a

•

Determinados tipos de pó são classificados como

substâncias cancerígenas (como pó de carvalho e faia),

em especial, juntamente com aditivos para

acondicionamento da madeira;

use máscara

respiratória e trabalhe com um dispositivo de

extracção de pó quando ligado a

•

Siga o r

egulamento nacional quanto a extração de pó,

em função dos materiais que vão ser utilizados

• Não tente cortar peças de trabalho extr

emamente

pequenas

• Retir

e todos os obstáculos que se encontram no topo

superior e na parte inferior da peça a cortar antes de

iniciar o trabalho

• Não trabalhe em suspensão com a ferramenta

•

Apenas utilize mesas de serrar munidas de interruptor

de voltagem que previna o reiniciar do motor depois de

interrupcão de voltagem

• Apenas utilize mesas de serrar munidas de guia de

corte

• Desligue sempre a ficha da tomada antes de