Page 1

Operating Instructions

863 Valley View Road, Eighty Four, PA 15330 USA

Tel: 724-941-9701 • www.skcinc.com

SKC User-loaded Disposable

Parallel Particle Impactors (PPI)

The patented† impaction-based SKC Disposable Parallel Particle

Impactor (PPI

collection effi ciency curves for respirable and thoracic dust

specified by ISO 7708/CEN and adopted by ACGIH, CEN,

and other occupational hygiene organizations. Performance

data of the PPI Samplers relative to the ISO 7708/CEN criteria

was published in the Journal of Physics, Conference Series 151,

2009, and the data was made part of the OSHA Docket used

to develop the OSHA fi nal silica rule (fi nal rule page 16439).

The thoracic model meets the requirements of NIOSH Method 5524

for metalworking fl uids and compounds with ACGIH

Disposable PPI Samplers off er the convenience of single use to eliminate

sampler assembly and cleaning; small size for worker comfort, even under helmets or

other PPE; and a choice of fl ow rates for maximum fl exibility in pump options, sample

duration, and contaminant concentration. These instructions are for PPI models that

are NOT preloaded with fi lters and supports; these models contain only impaction

substrates.

Performance Profi le

Sampling Rate: 2 L/min respirable or thoracic and 4 or 8 L/min respirable

Sample Pump: • Universal or AirChek

• Leland Legacy for 8 L/min

Sample Time: Dependent on method used. Note: SKC tests indicate that a particulate

Sample Media 37-mm, 5.0-μm PVC fi lter, 37-mm, 2.0-μm PTFE fi lter*

(recommended): (NIOSH 5524), or 37-mm, 0.8-μm MCE fi lter

Impaction Four 3/8-in diameter pre-oiled porous plastic discs

Substrate: (assembled in all Disposable PPIs)

Analysis: Gravimetric and/or chemical

Body Material: Conductive ABS plastic

Dimensions:

Height: 4.25 in (10.8 cm) - clip to exhaust

Diameter: 1.8 in (4.6 cm)

Depth: 1.2 in (3 cm)

Weight: 1.1 oz (31.2 gm)

Shelf-life: 18 mos from date of manufacture

† U.S. Patent No. 7,073,402

* Back pressure on PTFE fi lters can vary within the same lot.

®

) Samplers are designed to match precisely the

®

thoracic TLV®s.

®

Series for 2 and 4 L/min

mass of up to 6.8 mg on the four impaction substrates would not aff ect PPI

performance. This amount is equivalent to sampling for 6 hours at 4 L/min in

environments where respirable mass concentration is 4.76 mg/m

3

and equals

50% of total dust. However, labs have reported to SKC that they prefer no more

than 2 mg on the fi lter for analytical reasons. Therefore, SKC recommends that

you work with your lab to determine optimum sample times for your unique

sampling conditions.

Use cellulose or stainless steel screen for support

Page 2

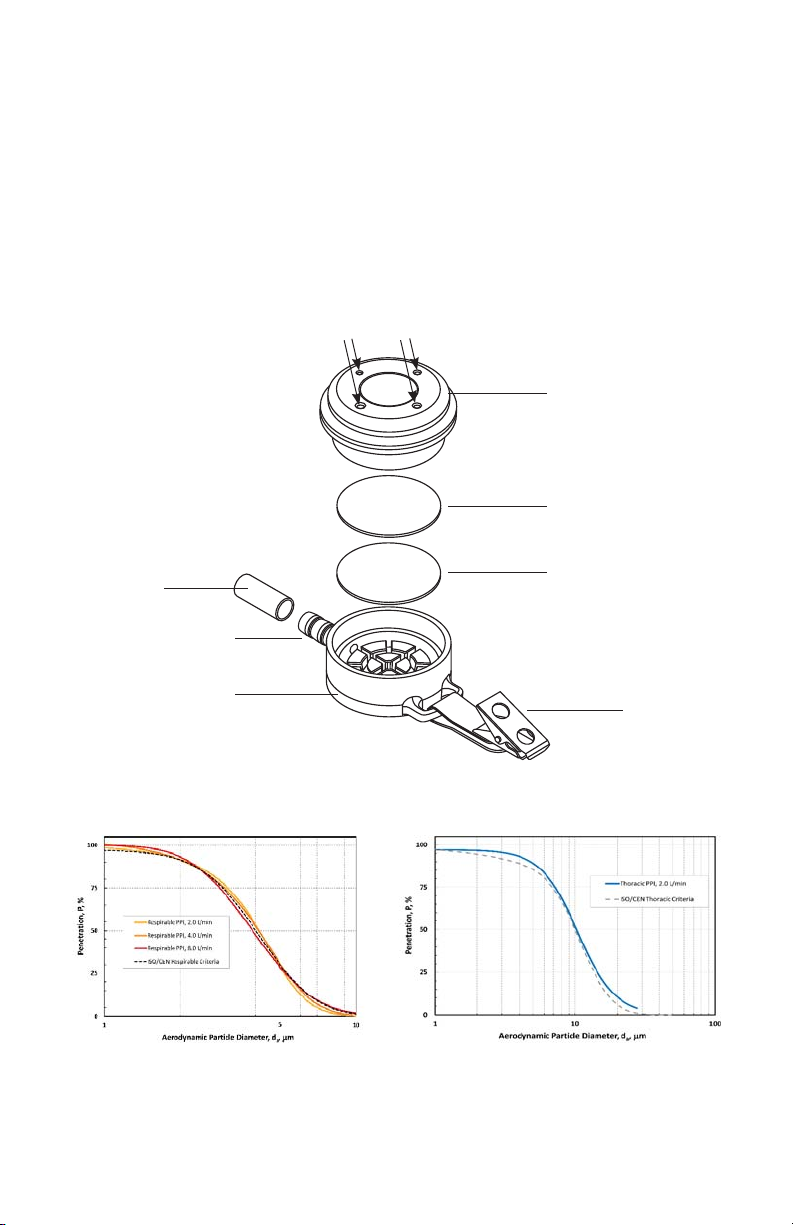

Principle of Operation

SKC Disposable PPI Samplers are impaction-based fi lter samplers that perform

precise size-selection for either thoracic or respirable dust, depending on the model.

PPI Samplers contain four small impactors in the inlet section of the device. Each

impactor features a unique 50% cut-point to target a specifi c one-quarter segment of

the ISO/CEN curve resulting in a precise fi t along the entire curve. A sample pump

operating at 2, 4, or 8 L/min (2 L/min only for thoracic) pulls air through the inlet

nozzle of each impactor in the inlet plate. Particles larger than each impactor’s 50%

cut-point are scrubbed and retained by impaction onto the porous oiled impaction

substrate contained in each impactor. Smaller particles continue to the standard

37-mm collection fi lter for analysis.

Dust enters here

Inlet plate (contains 4 impactors with unique cut-points

preloaded with 4 impaction

substrates and sonically

welded)

Standard 37-mm collection

fi lter (user installed)

Protective

end cap

Exhaust

to pump

Base plate

PPI Performance

Collection effi ciency of the 2, 4, and 8 L/min

respirable PPI Samplers compared to the

ISO respirable curve

37-mm support pad

(user installed)

Collar clip

Collection effi ciency of the 2 L/min

thoracic PPI Sampler compared to the

ISO thoracic convention

2

Page 3

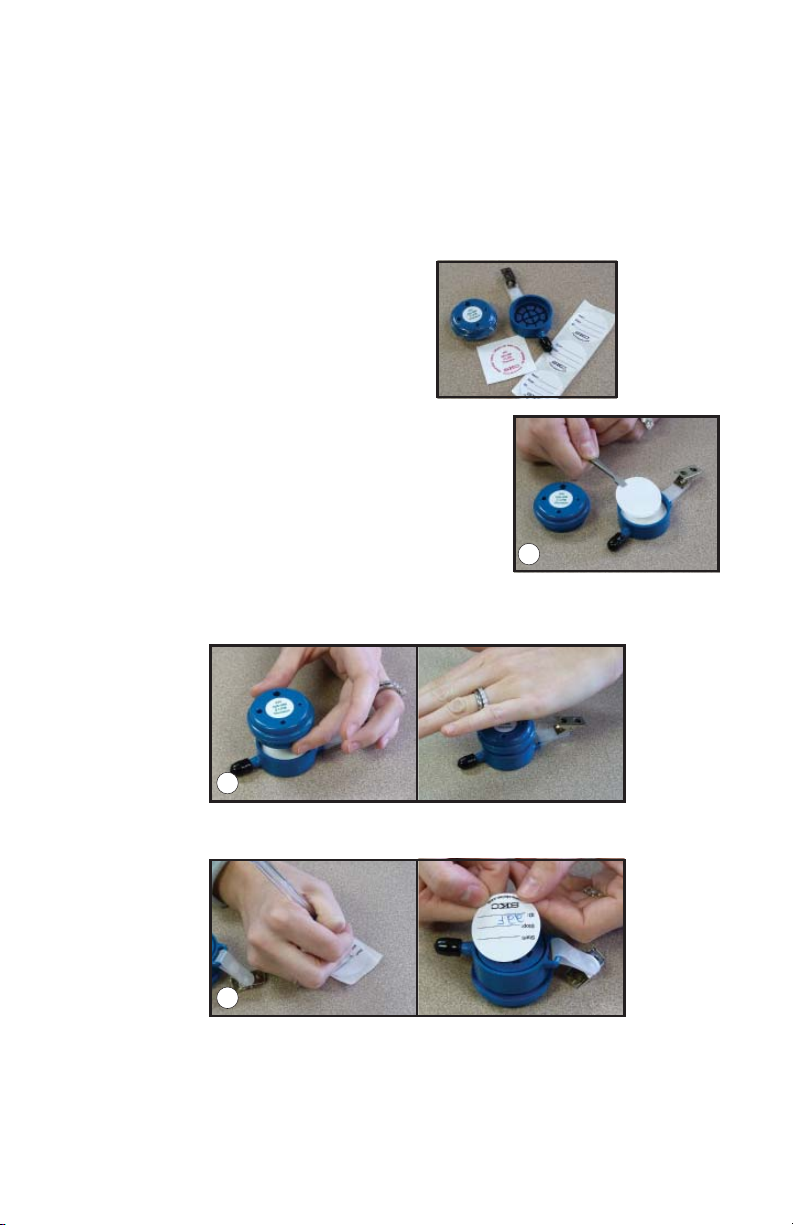

Media and Sampler Preparation

234

Media Preparation

Condition and weigh fi lters according to method used. Record the weight as the

pre-sample weight.

Sampler Preparation

The PPI will arrive with the inlet plate shrink wrapped and base plate separated.

1. Remove shrink wrap from inlet plate.

2. Using forceps, insert fi rst a 37-mm support pad

and then a conditioned and weighed 37-mm

collection fi lter (if using gravimetric analysis)

into the base plate.

3. Lay base plate on a fl at surface, align inlet plate with base, and press down

fi rmly to achieve an even seal.

4. Write sample ID on sampling label. Adhere sampling label to bo om of

base plate.

5. Remove protective end cap from exhaust.

Technical Tidbits:

• Use forceps to carefully insert or remove collection fi lter and support pad. See

Accessories for forceps.

3

Page 4

Calibration and Sampling

As the particle load on the fi lter increases during sampling, the pressure

Tip

drop will also increase. Therefore, use a compensating sample pump

such as the AirChek Series or Leland Legacy depending on fl ow rate

requirements.

Calibration

Calibrate pump fl ow rate with a representative Disposable PPI (support and fi lter

loaded) in line. See pump and calibrator operating instructions.

1. Ensure the pump has run for 5 minutes before calibrating.

2. Ensure representative impactor is loaded with a support and collection fi lter

and that it is fully assembled. See Sampler Preparation on page 3.

3. Align the bo om of the calibration adapter with the inlet plate of an assembled,

loaded representative Disposable PPI and press down firmly until the

calibration adapter’s O-ring is engaged and creates an even seal.

4. Use fl exible tubing to connect the exhaust of the Disposable PPI to the inlet of

a sample pump.

5. Use fl exible tubing to connect the inlet of the calibration adapter to the suction

port (outlet) of a calibrator.

6. Calibrate to 2 L/min for the 2 L/min respirable and thoracic model PPIs,

4 L/min for the 4 L/min respirable model, or 8 L/min for the 8 L/min respirable

model. Follow the calibration instructions in the pump and calibrator operating

instructions.

7. When calibration is completed, disconnect the tubing from the calibrator and

calibration adapter.

8. Grasp the Disposable PPI with one hand and the calibration adapter with

the other hand. Firmly pull/twist to remove the calibration adapter from the

Disposable PPI inlet plate.

9. Replace the representative Disposable

PPI used to set the fl ow with a new

loaded Disposable PPI for sample

collection.

Using excessive pressure to seal

the calibration adapter to the

Disposable PPI may make the

calibration adapter diffi cult to

remove.

Sample

pump

Calibration

adapter

Flexible

tubing

Disposable

PPI

Flexible

tubing

Calibrator

4

Page 5

Sampling

3

6-8

10

SKC tests indicate that a particulate mass of up to 6.8 mg on the four impaction

substrates would not affect PPI performance. This amount is equivalent to sampling

for 6 hours at 4 L/min in environments where respirable mass concentration is

4.76 mg/m

that they prefer no more than 2 mg on the fi lter for analytical reasons. Therefore,

SKC recommends that you work with your lab to determine optimum sample times

for your unique sampling conditions.

3

and equals 50% of total dust. However, labs have reported to SKC

1. As per good industrial hygiene practice, replace

representative sampler used for calibration with a

new, unused loaded sampler. See Media and Sampler

Preparation.

2. Record sample start time on label.

3. Clip Disposable PPI onto a worker’s collar or lapel in

the breathing zone or in the area to be sampled.

4. Clip sample pump at the worker’s waist or close to the

Disposable PPI.

5. Use fl exible tubing to a ach the Disposable PPI

exhaust to the inlet of the sample pump.

6. Turn on pump and record pertinent sample data.

7. After the desired sample time has elapsed, turn

off the pump and unclip sampler from sampling

location.

8. Apply Post-use label to inlet plate to seal the

sampler.

9. Record sample stop time on label on the bo om

of sampler.

10. Disconnect sampler from pump and reinstall

10

protective end cap on the exhaust.

11. Reinstate calibration train with representative Disposable PPI and verify fl ow

rate. See Calibration.

5

Page 6

Sample Transport and Analysis

Package and transport samples and blanks to an accredited laboratory for gravimetric

or chemical analysis.

References

Trakumas, S., Hall, P., Personal Respirable Sampler Containing Four Impactors Arranged in Parallel, Abstracts of

23rd Annual AAAR Conference, Atlanta, GA, 2004, p. 78

Trakumas, S., Salter, E., “Parallel Particle Impactor - Novel Size-selective Particle Sampler for

Accurate Fractioning of Inhalable Particles,” Journal of Physics: Conference Series 151 (2009), 16 pp., 012060,

www.skcinc.com/instructions/Parallel Particle Impactor Paper.pdf

Reference 2 is an author-created, non-copyrighted version of an article accepted for

publication in the Journal of Physics; Conference Series 151. IOP Publishing Ltd. is not

responsible for any errors or omissions in this version of the manuscript or any version

derived from it. The defi nitive publisher authenticated version is available online. Go to

h p://dx.doi.org, enter doi: 10.1088/1742-6596/151/1/012060.

Trakumas, S., “High-fl ow Personal Respirator Dust Sampler for Increased Sensitivity,” Poster 261, AIHce 2010,

Denver, CO

Trakumas, S., “High-fl ow Personal Sampler to Monitor Exposure to Respirable Crystalline Silica at New Lower

TLV,” IOHA 2010 8th Conference Book of Abstracts, Rome, p. 59

Trakumas, S., Salter, E., “High-Flow Personal Sampler to Monitor Exposure to Respirable Crystalline Silica at New

Lower TLV” PowerPoint Presentation

OSHA Final Rule on Respirable Crystalline Silica, www.osha.gov/silica/

ISO 7708:1995 (2008), Air Quality — Particle Size Fraction Defi nitions for Health-related Sampling, www.iso.

org, search on 7708

Stacey, P., Thorpe, A., and Echt, A., “Performance of High Flow Rate Personal Respirable Samplers When

Challenged with Mineral Aerosols of Diff erent Particle Size Distributions,” Ann. Occup. Hyg., 60, 2016, pp. 479-

492, h p://annhyg.oxfordjournals.org/content/60/4/479.full.pdf

Görner, P., Simon, X., Boivin, A., Bau, S., “Sampling Effi ciency and Performance of Selected Thoracic Aerosol

Samplers,” Annals of Work Exposure and Health, 2017, Vol. 61, No. 7, 784-796

6

Page 7

Ordering Information

User-loaded Disposable Plastic PPI Samplers, select the PPI for the

desired convention. Designed for one-time use. Cat. No.

User-loaded Disposable PPI Samplers contain four porous

disc impaction substrates. Require collection fi lter and support;

see information below and select based on application

Respirable PPI (red), 8 L/min, plastic

Respirable PPI (orange), 4 L/min, plastic

Respirable PPI (gold), 2 L/min, plastic

Thoracic PPI (blue), 2 L/min, plastic

Recommended Collection Filters for User-loaded Disposable PPI,

required for sampling. Select a fi lter based on your application.

PVC Filters, 37 mm, 5.0-μm pore size, pk/100 225-5-37

PTFE Filters,* 37 mm, 2.0-μm pore size, with laminated PTFE support,

for metalworking fl uids (NIOSH 5524), pk/50 Contact SKC

MCE Filters, 37 mm, 0.8-μm pore size, pk/100 225-5

Filter Supports, required for User-loaded Disposable PPI sampling.

Select either cellulose or stainless steel.

Support Pads, cellulose, 37 mm, pk/100 225-27

Support Pads, stainless steel, 37 mm, wide mesh, ea 225-26

Accessories

Calibration Adapter for Disposable PPI 225-389

Forceps, stainless steel, non-serrated fl at tips 225-8371

* Back pressure on PTFE fi lters can vary within the same lot.

225-384

225-387

225-385

225-386

SKC Limited Warranty and Return Policy

SKC products are subject to the SKC Limited Warranty and Return Policy, which

provides SKC’s sole liability and the buyer’s exclusive remedy. To view the complete

SKC Limited Warranty and Return Policy, go to h p://www.skcinc.com/warranty.

7

Page 8

www.skcinc.com

8

Form 38055 Rev 1901

Loading...

Loading...