Page 1

MAINTENANCE INSTRUCTIONS

L/I/H-LINE

Conveyors

ZSA030GB 2018-11-01

Page 2

Page 3

SKANDIA ELEVATOR

Your conveyor system must be assembled correctly and maintained

thoroughly if it is to operate satisfactorily. These maintenance instructions and

the separate assembly instructions for each machine must be followed for the

warranty to apply.

We hope you will be pleased with your Skandia conveyor equipment for a long

time.

Thank you for choosing Skandia Elevator!

Contents

Safety information ...................................................................................................................4

Safety decals ....................................................................................................................................................................6

Maintenance ...................................................................................................................................8

General ...................................................................................................................................................................................8

Bearings

.................................................................................................................................................................................8

Return rollers chain conveyors / Belt conveyor carrying idlers,

return idlers, snub idlers and tracking idlers

...............................................................................8

Belt conveyor return idlers, snub idlers, tail pulley and drive pulley

..............14

Transmission

.....................................................................................................................................................................8

Conveyor chain

...........................................................................................................................................................10

Conveyor belt

................................................................................................................................................................12

Forward driving end, sweep conveyor

...............................................................................................14

Troubleshooting ......................................................................................................................16

Poor capacity/stop .................................................................................................................................................16

Machine noisy

.............................................................................................................................................................18

Plastic ight bends

.................................................................................................................................................18

Lid/bottom plate in bend section gets warm

...........................................................................19

Motor stoppage

..........................................................................................................................................................19

Belt conveyor misalignment

........................................................................................................................19

2-3 way valve leaking

..........................................................................................................................................19

Technical specications ............................................................................................... 20

Geared motor rating plate .............................................................................................................................20

Density table

.................................................................................................................................................................20

L-Line

.....................................................................................................................................................................................21

I-Line

.....................................................................................................................................................................................22

H-Line

..................................................................................................................................................................................23

Page 4

4

SKANDIA ELEVATOR

The owner of the transport equipment is responsible for these maintenance

instructions always being available to the maintenance technicians and

engineering technicians concerned.

Inadequate maintenance and/or defective handling may lead to personal

injury or damage to the conveyor equipment and/or other equipment. It can

also cause malfunctions or a reduction in capacity.

Read these maintenance instructions carefully before maintenance or

operation commences. If any part of these instructions should be difcult to

comprehend, please get in touch with your reseller for assistance.

The safety information is presented and interpreted as follows:

!

WARNING!

Disregarding instructions given in warnings can cause serious personal

injury or death.

!

IMPORTANT!

Ignoring the instructions given in important texts may cause damage

to the conveyor equipment and/or other equipment. It can also cause

malfunctions or a reduction in capacity.

NB! indicates that the text contains information that will simplify the

assembly process.

General

!

WARNING!

• Ensure that everyone responsible for assembly, electrical connection,

maintenance and operation of the conveyor equipment has read and

understood the instructions and safety information.

• Use protective gloves, helmet, steel-toed boots, ear defenders,

protective goggles and high-vis vest when carrying out assembly,

electrical connection, maintenance and operation of conveyor

equipment.

• Stop the machinery and turn off electric power before attempting any

type of assembly, electrical connection or maintenance work.

• Do not start the machinery without the lid, hatches, covers, guards and

connections fitted in such a way they can only be opened with tools.

Safety information

Page 5

5

SKANDIA ELEVATOR

!

WARNING!

• All electrical equipment is to be connected by a qualified electrician.

See separate connecting directions for electronics.

• The power switch must be permanently mounted and located to allow

easy access when carrying out maintenance work.

• Ensure that sensors and switches for the pop up overloading flap/

inspection hatch (in the outlet hopper) & conveyor chain are active

when in operation. NB! Certain sensors/switches are optional

accessories only on certain machines.

Electrical connection

!

IMPORTANT!

• Ensure the motor protection is set to the correct ampere setting for the

motor.

Incorrect electrical connection may lead to personal injury or damage to the

conveyor equipment and/or other equipment. It can also cause malfunctions

or a reduction in capacity.

!

IMPORTANT!

• If the machine is being assembled outdoors, the motors and

transmissions must be fitted with a weather cover.

• If a machine or part thereof in any way needs moving/dismantling,

follow the directions given in the assembly instructions.

• The machine can be stopped and restarted when full of material but

this option must not be used for intermittent operation.

• If a short circuit should occur, ensure that the electrical equipment is

in working order before continuing operation.

• Ensure that the electrical equipment is kept free from dirt, dust,

moisture and electrostatic charge.

• The machine is not designed to stand or walk on.

!

WARNING!

• The sweep conveyor's conveyor chain and forward driving wheel are not

fully built-in for functional reasons. Do not remain in the vicinity of the

machine while it is operating.

• The silo's centre and intermediate outlet hoppers are not protected for

functional reasons. Do not remain in the vicinity of the outlet hoppers

while the machine is operating.

• Connections to, from and between machinery must be permanently

mounted and fully enclosed. If the design of the installation does not

allow this at an outlet, finish off with a 1 m pipe.

• Ensure the machine is anchored and braced as described in the

assembly instructions.

Page 6

6

SKANDIA ELEVATOR

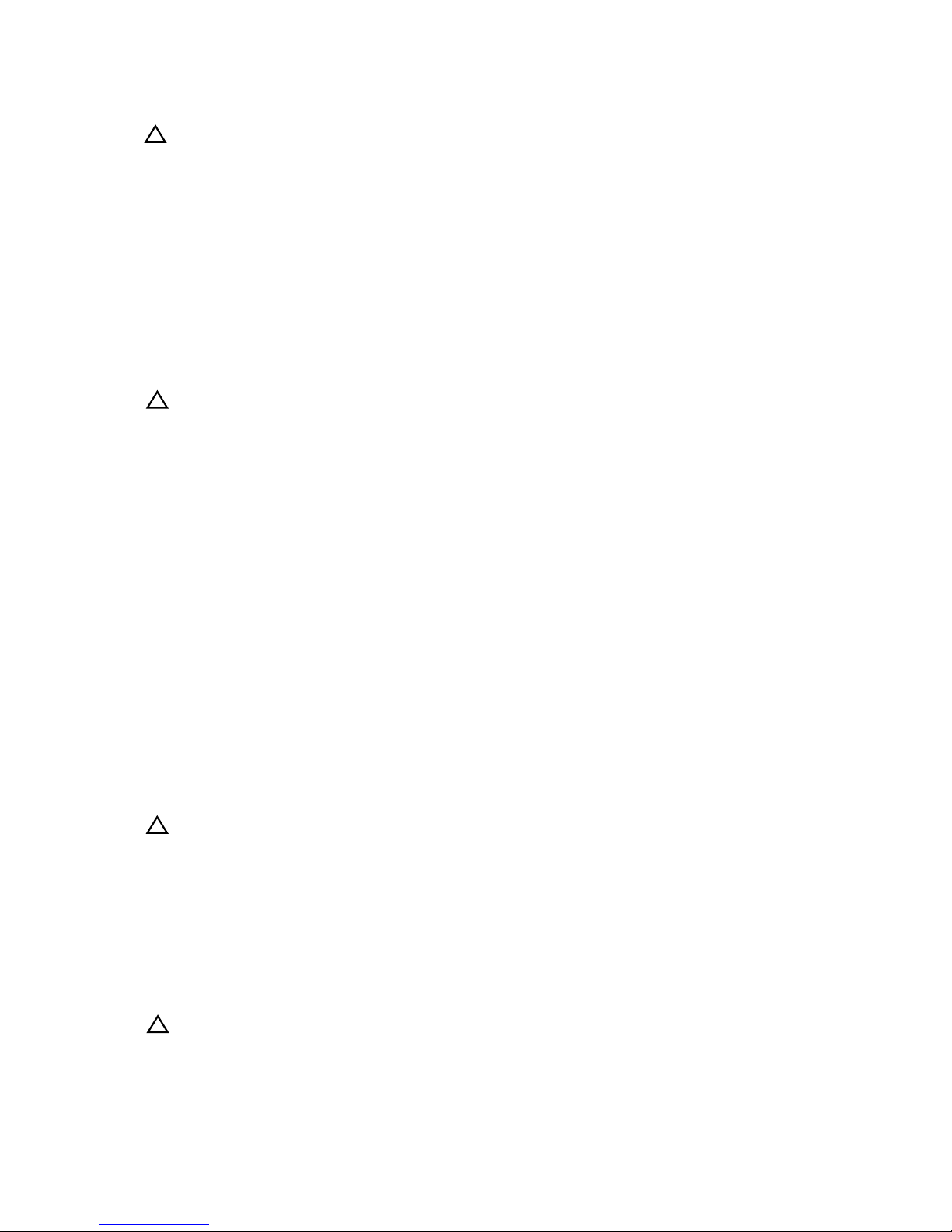

Safety decals

!

WARNING!

The machine is supplied with safety decals on delivery. They must not be

removed or defaced. If a safety decal becomes damaged, you can order a

new one free of charge from Skandia Elevator AB. Specify the part number

of the decal. See section below and the machine overview chapter in the

machine's assembly instructions.

There are safety decals for:

- Mandatory (white symbol on round blue background).

- Forbidden (black strike-through symbol on round white background with red

surround).

- Warning (black symbol on triangular yellow background with black surround).

Skandia Elevator machines may have the following safety decals:

!

WARNING!

The mandatory instruction, forbiddance or warning given on all safety decals

must be considered or serious injury or death may follow.

Part number/Safety decal

Refer to the "Machine Overview" chapter

for location.

Written denition

DEK3090

Read the "Back stop" section in the

elevator's assembly instructions before

test starting the motor for the rst time.

DEK3100

Do not place the valve with the motor

side face down.

DEK3140

Changing settings and equipment is

prohibited.

DEK3030

Warning for conveyor chain!

DEK3060

Warning for bucket belt!

S

K

A

N

D

I

A

E

L

E

V

A

T

O

R

–

D

E

K

3

0

9

0

SKANDIA ELEVATOR - DEK3030

SKANDIA ELEVATOR – DEK3060

S

K

A

N

D

I

A

E

L

E

V

A

T

O

R

–

D

E

K

3

1

0

0

S

K

A

N

D

I

A

E

L

E

V

A

T

O

R

–

D

E

K

3

1

4

0

Page 7

7

SKANDIA ELEVATOR

DEK3040

Warning for chain drive!

DEK3150

Warning for conveyor belt and idler!

DEK3070

Warning for rotating conveyor drive

shaft!

DEK3080

Warning for rotating elevator drive shaft!

Warning for moving machinery!

DEK3010

Warning for dust explosion!

DEK3130

Warning, maximum 2 persons = 200

kg/440 lbs may be on the platform and

ladders at one time!

SKANDIA ELEVATOR – DEK3040

SKANDIA ELEVATOR – DEK3070

SKANDIA ELEVATOR – DEK3080

SKANDIA ELEVATOR – DEK3125

SKANDIA ELEVATOR - DEK3010

SKANDIA ELEVATOR – DEK3130

MAX

200

440

/

=

kg

lb

SKANDIA ELEVATOR – DEK3120

SKANDIA ELEVATOR – DEK3110

DEK3110

DEK3120

DEK3125 DEK3160

SKANDIA ELEVATOR – DEK3160

SKANDIA ELEVATOR – DEK3150

Page 8

8

SKANDIA ELEVATOR

Maintenance

General

Check annually that the bolts are securely in place, that no components

are missing and that there is no rust on the machinery. Replace damaged

components.

!

IMPORTANT!

All maintenance instructions in this chapter must be considered as

important texts.

Bearings

NB! All bearings are greased-for-life and do not require additional lubrication.

Transmission

Geared motor / Angle gear motor

The geared motor is lled with mineral oil on delivery. For more information

on oil grade on delivery, see the separate information attachment from the

manufacturer Nord.

Check the oil level before taking into service and at regular intervals

thereafter.

Change oil every 10,000 operating hours or at least every other year.

The interval between changes can be doubled if synthetic oil is used. When

operating in severe conditions such as high humidity, aggressive environment

or large temperature variations, the oil must be changed more often.

Clean the gear when changing oil.

Return rollers chain conveyors / Belt conveyor carrying

idlers, return idlers, snub idlers and tracking idlers

Check rollers/idlers annually. Replace them immediately if they are worn.

Belt conveyor return idlers, snub idlers, tail pulley

and drive pulley

Ensure that material is not accumulated on return idlers, tail pulley, drive

pulley or the lower pulley in the discharge tripper. Check regularly and clean if

necessary. To reduce any problems, install a belt cleaner.

Page 9

9

SKANDIA ELEVATOR

Chain transmission - L-line

Adjust the tightness of the transmission chains continuously.

Oil the transmission chains annually.

Change transmission chains before they become noticeably worn.

A

B

C

D

Tension the intermediate shaft (B) laterally with tensioning bolts (C) so that

the outer chain (D) is sufciently tight.

Tighten the motor bridge (A) by hand and secure it.

1.

2.

Page 10

10

SKANDIA ELEVATOR

Conveyor chain

Chain tensioning

Check continuously that the conveyor chain is centred, is running freely and

is tensioned correctly. Check the rst time after 50 operating hours and then

according to the table:

L-line Once a season or at least every 200 operating hours.

I-line Twice a year or at least every 400 operating hours.

H-line 3 times a year or at least every 1000 operating hours.

!

IMPORTANT!

When transport takes place in both directions, the conveyor chain

tension must be checked twice as often.

On conveyors with return rollers, the conveyor chain tension is checked by

pressing it down between the two return rollers. If it can be pressed down

5-10 mm it is tensioned correctly.

On conveyors with intermediate trays/guide rails, the chain tensioning is

checked by pulling the conveyor chain sideways at the gear wheel in the tail

end. It is too taut if it cannot be pulled sideways. Release the tension until it

can be pulled slightly sideways.

5-10 mm

NB! If the lid and bottom plate of a bend section become warm during

operation then the conveyor chain is too taut.

NB! Make a test run after adjusting and then check again.

Page 11

11

SKANDIA ELEVATOR

If necessary, tighten by turning the tensioning bolts (2 or 4) in the tail end.

!

IMPORTANT!

Ensure the tail end shaft is at right angles to the conveyor chain.

Joining links and split pins

Check joining links and split pins annually. Replace them immediately if they

are worn.

KTIBU

Undo the screws (X & Y). Adjust the tension of the conveyor chain with

tensioning screws (Z) and then retighten the screws (X & Y).

When conveyor is not used for long periods

Lubricate the conveyor chain with food grade oil when the conveyor is not to

be used for long periods.

Z

X

Y

X

Page 12

12

SKANDIA ELEVATOR

Correct tension - Tail end with tension bolts

Measure how much the conveyor belt slackens (X) between 2 return idler sets

that are 3 metres apart, X = A - B.

Correct tension - Tail end for counterweight tension

Use the correct counterweight.

X

A

B

3000

Motor output

(kW)

BTI-xxx

(mm)

Sag X

(mm)

1,5 kW

400 39 mm

500 44 mm

650 30 mm

2,2 kW

400 26 mm

500 40 mm

650 30 mm

3,0 kW

400 19 mm

500 34 mm

650 30 mm

4,0 kW

400 22 mm

500 37 mm

650 30 mm

5,5 kW

400 18 mm

500 30 mm

650 28 mm

7,5 kW

400 14 mm

500 23 mm

650 21 mm

Motor output

(kW)

BTI-xxx

(mm)

Counter weight

(kg)

1,5 kW

400 170 kg

500 200 kg

650 380 kg

2,2 kW

400 260 kg

500 220 kg

650 380 kg

3,0 kW

400 340 kg

500 260 kg

650 380 kg

4,0 kW

400 300 kg

500 240 kg

650 380 kg

5,5 kW

400 380 kg

500 300 kg

650 400 kg

7,5 kW

400 500 kg

500 380 kg

650 520 kg

Conveyor belt

Conveyor belt steering and tension

Check continuously that the conveyor belt is properly tensioned; see picture

and table below. Also check the belt steering and if adjustments need to be

made, see instructions on the next page.

Check the rst time after 50 operating hours and then twice a year or at least

every 400 hours of operation.

!

IMPORTANT!

When conveying in both directions, more frequent checks of the belt steering

are required.

Page 13

13

SKANDIA ELEVATOR

M

L

Q

R

R

1.

2.

3.

4.

P

Belt steering adjustments

If the belt steering needs to be adjusted, it can be done using the following methods

and prioritized accordingly. NB! Only use Methods 3 and 4 if absolutely necessary. The

main principle is that you only adjust the position at one end of a idler to compensate for

misalignment.

1.

Adjust the position of a return idler (M) by tapping on the bracket on one end of the idler.

Start from the middle of the machine and then work toward the tail end. NB! A scribe

line marks the bracket's original position.

2.

Adjust the forward-angled "knocked" position of the carrying idlers (L) that need

adjustment. Loosen the screws (P), adjust the angle and tighten the screws again. The

more of the arrow that is shown, the greater the angle. The adjustment can be done in

both directions, and there is an arrow on each side.

3.

Adjust the position of the tail pulley (Q) by tensioning on one side.

4.

Adjust the position of the drive pulley (R) by tensioning on one side.

Page 14

14

SKANDIA ELEVATOR

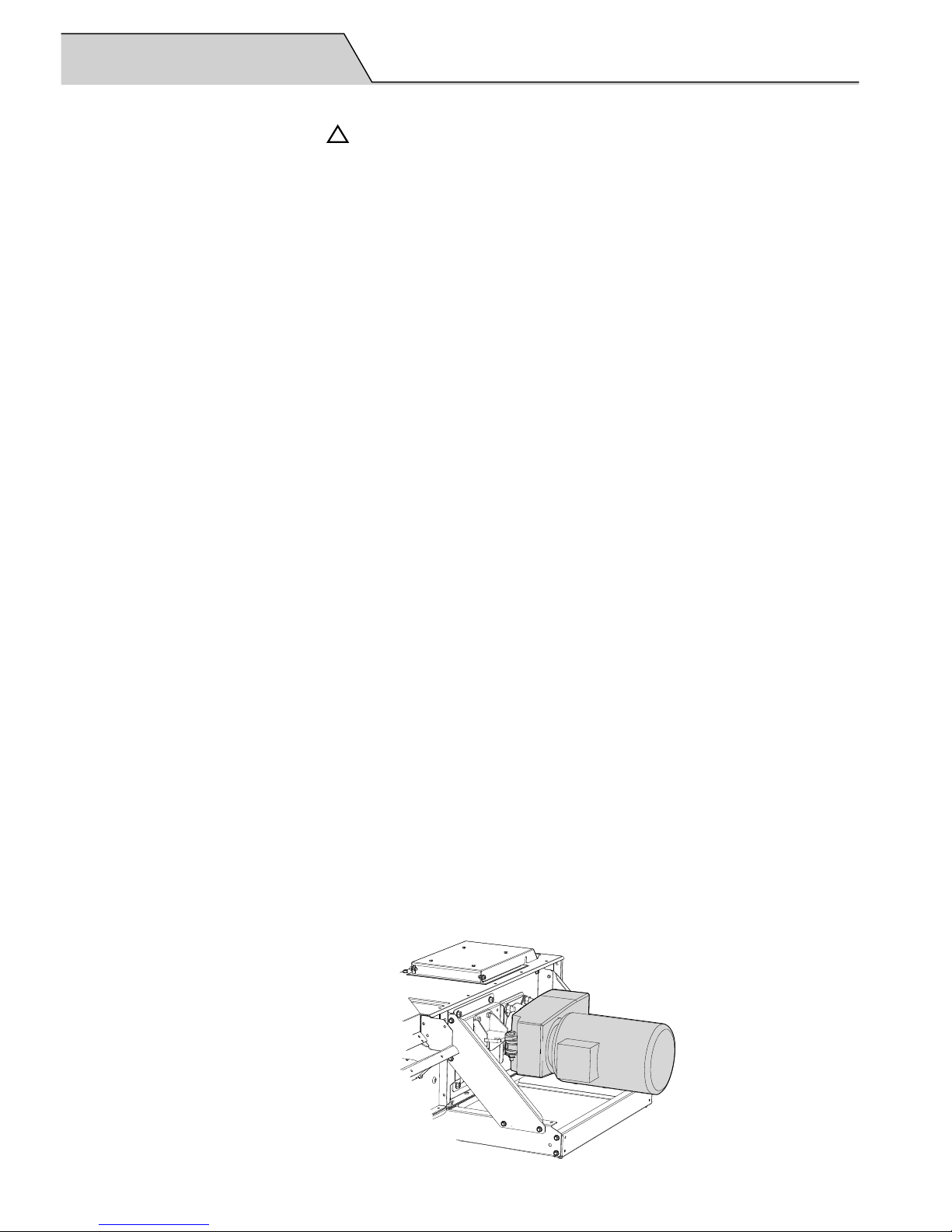

Forward driving end, sweep conveyor

!

WARNING!/IMPORTANT!

Lubricate moving parts in the forward driving end on a regular basis with

food grade lubricants.

Crankshaft springs

Check the crankshaft's spring screws (B1-2) if the forward driving is not

working properly.

The forward driving wheel's tractive force can be increased/decreased by

tensioning/slackening the connecting rod's spring screws (B1-2). If the wheel

slips then the springs are tensioned too much. If the machine does not drive

forward then they are too loosely tensioned.

NB! Tension/slacken evenly across the spring screws.

Crankshaft chain

Check the tension of the crankshaft chain (A) continuously.

If the chain needs to be tensioned:

1.

Undo the screws (A1-8), 4 pcs, on each side plate of the forward driving end.

2.

Tension the clamping nuts (A9-10) evenly until the crankshaft chain is

moderately tensioned.

3.

Tighten the bolts (A1-8).

Lubrication points Oil Grease

1 Ball joints x

2 Set screw in nut cradle x

3 Contact surfaces between the spring screws and the

holes in the connecting rod

x

4 Contact surfaces between the connecting rod's lower

section and upper section

x

5 Sliding surfaces by the spring's lower nut x

6 Crankshaft chain x

Page 15

15

SKANDIA ELEVATOR

B2

B1

A1-4

A1-4

A5-8

A9

A9

A10

A

2

5

1

3

4

6

A5-8

Page 16

16

SKANDIA ELEVATOR

Troubleshooting

All the machines in the conveyor system must be correctly adapted to each

other in order to provide the correct capacity for the given conditions.

Problems with capacity and stops can arise for different reasons:

Check:

• that capacity demands are realistic for the conditions in question. Capacity

will be reduced if the water content in the grain is increased/raised. Reckon

on a loss of capacity in the range 3-4% for every 1% water content above

15%. Especially installations with short trenches (2.5-4.5 m) will have

problems if the water content is high.

• that connections between machines are carried out correctly. See the

assembly instructions for respective machine.

• that the inlet is correctly assembled. See the assembly instructions for

respective machine.

• that the ducting is sufficiently dimensioned. Ø160 mm for 30 t/h, Ø200

mm for 40 and 60 t/h, Ø250 mm for 80 and 100 t/h and Ø300 mm for

120 and 150 t/h.

• that the ducting is sufficiently inclined, greater than 45°.

• that the machines and connections are free from waste.

• that the machines work at the correct speed in relation to the intended

capacity. See the section "Technical specifications".

• that the electrician has connected the motors to the correct voltage and

that the motor protection is set to the right values.

Poor capacity/stop

General

• that the machine feed rate is not too high. See the section "Technical

specifications".

If the material goes in reverse

Check:

• that the subsequent connection/machine is able to receive the capacity

from the feeding conveyor.

!

IMPORTANT!

If there is a risk of overloading, ensure a pop up overloading ap

(horizontal machines)/overload sensor (incline and bend machines) is

connected.

Page 17

17

SKANDIA ELEVATOR

Specic for feeding via (self regulating) side inlet/inlet in raised lid

Specic for feeding via (non-self regulating) inlet

Check:

• that the slide on the silo/storage bin can be fully opened.

Check:

• the capacity of the machine starting the chain of conveyors. A capacity of

a chain of conveyors is never higher than what is being input in the first

machine. NB! If feeding is done via an inlet from a silo/storage bin, the flow

must be controlled with a slide shutter.

Example: Inlet I-line

Example:

Inlet in raised lid I-line

Example:

Side inlet I-line

Specic for the sweep conveyor

Check:

• that the crankshaft's spring screws are correctly tightened and that the

crankshaft chain is correctly tensioned. See the section "Maintenance".

• that the machine/sweep moulding is running horizontally along the silo

floor. The machine's forward driving end, and sometimes also the drive end,

may need to be raised/lowered. See the chapter "Settings for the forward

driving end (height adjustment knob) and "Assembling the machine (shims

for drive end)" in the sweep conveyor's assembly instructions..

NB! The silo floor may have unevenness that is greater than the

compensation available in the machine's height setting options.

Page 18

18

SKANDIA ELEVATOR

Machine noisy

Check:

• that overlapping lid on a conveyor with upward bend section is assembled

from the drive to the tail end so that the inner joins are in the same

direction as the conveyor chain return travel.

• that the conveyor intermediate trays are joined correctly so that the flights

do not snag on the joins. See the assembly instructions for the conveyor.

• that the conveyor chain is not too taut or loose. See the section

"Maintenance".

• that the chain sprocket in the tail end is clear of material.

Plastic ight bends

Stops caused by overloading the machine can result in bent plastic ights.

See the last point under the heading "General" in "Poor capacity/stop" in this

section.

Check:

• that no foreign material has entered the conveyor.

Specic for belt conveyor

Check:

• the capacity of the machine starting the chain of conveyors. A capacity of

a chain of conveyors is never higher than what is being input in the first

machine. NB! If feeding is done via an inlet from a silo/storage bin, the flow

must be controlled with a slide shutter.

Example: Loading unit

Specic for the sweep conveyor

Check:

• that the forward driving end's moving parts are lubricated. See the section

"Maintenance".

Page 19

19

SKANDIA ELEVATOR

ImpulsesNB! The motors are designed for high operating temperatures.

If the motor stops:

1. check the cause of the stoppage. See the previous troubleshooting

directions concerning this.

2. cut the power and clear away any blockages.

!

IMPORTANT!

Do not try to remove a blockage by repeatedly attempting to restart.

3. check with the electrician that the motor has been connected to the correct

voltage and that the motor protection is set to the right value.

Motor stoppage

Lid/bottom plate in bend section gets warm

The conveyor chain is tensioned too much. Relieve the tension as described in

the section "Maintenance".

Belt conveyor misalignment

Check:

• the belt tension and make belt steering adjustments according to section in

previous maintenance chapter.

• that material is not accumulated on return idlers, tail pulley, drive pulley

or the lower pulley in the discharge tripper. Check regularly and clean if

necessary. To reduce any problems, install a belt cleaner.

2-3 way valve leaking

The valve is set correctly on delivery. If the setting has changed after delivery,

it could cause leakage. Reset as instructed in the separate connecting

directions for electronics.

Page 20

20

SKANDIA ELEVATOR

Technical specications

Geared motor rating plate/Angle gear motor

Each drive with geared motor is equipped with a rating plate that species:

A. type of NORD gear.

B. serial number.

C. total gear ratio.

D. nominal rpm for gear output shaft.

A

B

C

D

When transporting different material, the capacity can be converted to t/h

using the volume capacity of the machine in m³ and the density table shown

below.

Density table

Material Density kg/m³ Material Density kg/m³

Wheat 700-800

Wheat our 120-200

Rye 650-700

Wholemeal 400-600

Oats 500-600 Mashed cereal 300-400

Grain 600-700

Powdered milk 500-600

Rape 600-700 Grass seed 120-200

Rice 700-800 Coffee 350-450

Corn 600-700 Fishmeal 550-600

Peas 600-700 Fish pellets 500-900

Beans 700-800 Powdered lime 800-990

Page 21

21

SKANDIA ELEVATOR

L-Line

KTF & KTF/R KTFb

30 t/h 40 t/h 60 t/h 30 t/h 40 t/h 60 t/h

Capacity for 750 kg/m³ t/h 30 48 73 27 39 58

Capacity m³/h 45 64 97 36 52 77

Speed rpm 75 106 159 75 106 159

Chain speed m/s 0.46 0.65 0.98 0.46 0.65 0.98

Conveyor chain, type S45V

Pitch/ultimate tensile strength mm/33 kN

Flight, qty/m chain 3 4 6 3 4 6

Flight, material Plastic (Polythene)

Chain sprocket, teeth 9

Intermediate section, width (lid)/height mm 200 (250)/245

Plate thickness drive, tail end mm 1.50/2.50

Plate thickness intermediate section mm 1.50

Plate thickness Inlet and outlet hoppers mm 1.25

Drive system Chain transmission (std)/gearbox

L-Line

KTA & KTB KTAb

30 t/h 40 t/h 60 t/h 30 t/h 40 t/h 60 t/h

Capacity for 750 kg/m³ t/h 36 45 63 28 36 53

Capacity m³/h 48 60 84 37 48 71

Speed rpm 176 185 194 176 185 194

Chain speed m/s 1.08 1.14 1.19 1.08 1.14 1.19

Conveyor chain, type S45V

Pitch/ultimate tensile strength mm/33 kN

Flight, qty/m chain 3 4 6 3 4 6

Flight, material Plastic (Polythene)

Chain sprocket, teeth 9

Intermediate section, width (lid)/height mm 200 (250)/245

Plate thickness drive, tail end mm 1.50/2.50

Plate thickness intermediate section mm 1.50

Plate thickness Inlet and outlet hoppers mm 1.25

Drive system Chain transmission (std)/gearbox

L-Line

KTG

KTBU

30 t/h 40 t/h 60 t/h 30 t/h 40 t/h 60 t/h

Capacity for 750 kg/m³ t/h 29 41 58 30 41 59

Capacity m³/h 39 55 77 40 55 79

Speed rpm 88 123 176 88 123 176

Chain speed m/s 0.54 0.76 1.08 0.54 0.76 1.08

Conveyor chain, type S45V

Pitch/ultimate tensile strength mm/33 kN

Flight, qty/m chain 3 4 6 3 4 6

Flight, material Plastic (Polythene)

Chain sprocket, teeth 9

Intermediate section, width (lid)/height mm 200 (250)/245

Plate thickness drive, tail end mm 1.50/2.50

Plate thickness intermediate section mm 1.50

Plate thickness Inlet and outlet hoppers mm 1.25

Drive system Chain transmission (std)/gearbox

Page 22

22

SKANDIA ELEVATOR

I-Line

KTIA. KTIB. KTIBU* & KTIG

20/40(*33)

40 t/h

20/40(*33)

60 t/h

30/40(*33)

80 t/h

40/40(*33)

100 t/h

40/40(*33)

120 t/h

Capacity for 750 kg/m³ KTIA. KTIB t/h 49-51 65-67 88-92 109-117 129-133

Capacity for 750 kg/m³

KTIBU. KTIG t/h 40-42 54-57 77-83 91-97 113-118

Capacity KTIA. KTIB m³/h 65-68 87-89 117-123 145-156 172-177

Capacity KTIBU. KTIG m³/h 53-56 72-76 103-111 121-129 151-157

Speed KTIA. KTIB rpm 48-50 64-66 58-61 54-58 64-66

Speed KTIBU. KTIG rpm 43-45 58-61 54-58 47-50 58-61

Chain speed KTIA. KTIB m/s 0.64-0.67 0.85-0.88 0.77-0.81 0.72-0.77 0.54-0.88

Chain speed KTIBU. KTIG m/s 0.57-0.60 0.77-0.81 0.72-0.77 0.63-0.67 0.77-0.81

Conveyor chain, type M80

Pitch/ultimate tensile strength 100 mm/80kN

Chain sprocket, teeth 8

Flight, material Plastic

Intermediate section, width/height mm 200/400(*335)

300/400(*335) 400/400(*335)

Plate thickness drive, side plate/bottom plate

mm 5.00/2.50

Plate thickness tail end and intermediate section

mm 2.00/2.50

Inlet and outlet hoppers mm 3.00/□180 3.00/□250 3.00/□300

I-Line

KTIF. KTIFb & KTIFg

20/33

40 t/h

20/33

60 t/h

30/33

80 t/h

30/33

100 t/h

40/33

120 t/h

40/33

150 t/h

Capacity for 750 kg/m³ KTIF t/h 49-54 66-71 89-96 110-117 135-148 158-164

Capacity for 750 kg/m³

KTIFb. KTIFg t/h 41-45 56-60 76-82 94-100 111-122 145-150

Capacity KTIF m³/h 65-72 88-95 119-128 147-156 180-197 211-218

Capacity KTIFb. KTIFg m³/h 55-60 75-80 101-109 125-133 148-163 193-199

Speed rpm 32-35 43-46 38-41 47-50 43-47 50-52

Chain speed m/s 0.43-0.47 0.57-0.61 0.51-0.55 0.63-0.67 0.57-0.63 0.67-0.69

Conveyor chain, type M80

Pitch/ultimate tensile strength 100 mm/80kN

Chain sprocket, teeth 8

Flight, material Steel/Plastic

Intermediate section, width/height mm 200/335 300/335 400/335 400/335

Plate thickness drive, side plate/bottom plate

mm 5.00/2.50

Plate thickness tail end and intermediate section

mm 2.50/2.50

Inlet and outlet hoppers mm 3.00/□180 3.00/□250 3.00/□300 3.00/□300

Page 23

I-Line

BTI

BTI 400 BTI 500 BTI 650

40 t/h 60 t/h 80 t/h 100 t/h 120 t/h 150 t/h

Capacity for 750 kg/m³

t/h 46-47 63-70 86-92 105-116 135-141 154-164

Capacity

m³/h 61-63 84-93 115-123 140-155 180-188 205-219

Rotation speed, drive shaft rpm 126-131 175-194 143-153 175-194 126-149 143-153

Belt speed m/s 1.65-1.71 2.29-2.54 1.87-2.00 2.29-2.54 1.65-1.71 1.87-2.00

Belt width mm 400 400 500 500 650 650

Self supporting length m 6 6 6 6 6 6

Connection loading unit/outlet hopper/twoway valve discharge tripper

mm FK180 FK180 FK250 FK250 FK300 FK300

Belt type EP250/2 3+1,5 Y

23

SKANDIA ELEVATOR

I-Line

KTIS

40 t/h

60 t/h

Capacity for 750 kg/m³ t/h

38-39 53-56

Capacity m³/h

51-52 71-75

Rotation speed, drive shaft rpm

100-102 149-159

Chain speed m/s

0.63-0.64 0.93-0.99

Conveyor chain, type S45V

Pitch/ultimate tensile strength 41,5 mm/33kN

Chain sprocket, teeth 9

Number of ights per metre of chain 4 6

Flight, material Plastic

Transport space, width/height mm 150/165

Plate thickness, transport channel/return

channel

mm 3.0/2.0

Plate thickness, outlet hoppers mm 3.0

Page 24

24

SKANDIA ELEVATOR

H-Line

KTH. KTHb & KTHg

20/33

60 t/h

30/33

80 t/h

30/33

100 t/h

30/40

120 t/h

Capacity for 750kg/m³ KTH

Capacity for 750 kg/m³KTHb KTHg

Capacity KTH

Capacity KTHb KTHg

Speed

Chain speed

Conveyor chain, type

Pitch/ultimate tensile strength

Chain sprocket, teeth

Flight, material Steel

Intermediate section, width/height

Plate thickness drive, side plate/bottom plate

Plate thickness tail end and intermediate section

Thickness, plastic bottom

Inlet and outlet hoppers

KTH. KTHb & KTHg

40/40

150 t/h

40/51

200 t/h

50/51

250 t/h

50/51

300 t/h

Capacity for 750 kg/m³ KTH

Capacity for 750 kg/m³ KTHb KTHg

Capacity KTH

Capacity KTHb KTHg

Speed

Chain speed

Conveyor chain, type

Pitch/ultimate tensile strength

Chain sprocket, teeth

Flight, material Steel

Intermediate section, width/height

Plate thickness drive, side plate/bottom plate

Plate thickness tail end and intermediate section

Thickness, plastic bottom

Inlet and outlet hoppers

t/h 66-70 89-96 110-117 139-146

t/h 56-60 76-82 94-100 117-124

m³/h 88-93 119-128 147-156 185-195

m³/h 75-80 101-109 125-133 156-65

rpm 43-46 38-41 47-50 37-39

m/s 0.57-0.61 0.51-0.55 0.63-0.67 0.62-0.65

M80 M80-120 M80-M160

mm/kN 100/80kN 100/80-112kN

8 10

mm 200/335 200/400

mm 5.0/8.0 6.0/8.0

mm 2.5 3.0

mm 8.0

mm 3.0/□180 3.0/□250 3.0/□300

t/h 161- 176 209-226 262-284 317-338

t/h 141-154 188-204 235-255 284-304

m³/h 215-235 279-301 349-379 423-451

m³/h 188-205 251-272 313-340 379-405

rpm 32-35 24-26 24-26 29-31

m/s 0.53-0.58 0.51-0.55 0.51-0.55 0.62-0.66

M80-M160 M112-M224

mm/kN 100-125/80-160 160/112-224

10 8

mm 400/400 400/510 500/510

mm 6.0/8.0

mm 3.0 4.0

mm 8.0

mm 3.0/□300 3.0/□350 3.0/□400

KTH. KTHb & KTHg

50/64

400 t/h

70/64

500 t/h

70/64

600 t/h

Capacity for 750 kg/m³ KTH

Capacity for 750 kg/m³ KTHb KTHg

Capacity KTH

Capacity KTHb KTHg

Speed

Chain speed

Conveyor chain, type

Pitch/ultimate tensile strength

Chain sprocket, teeth

Flight, material

Intermediate section, width/height

Plate thickness drive, side plate/bottom plate

Plate thickness tail end/intermediate section, side/

bottom plate

Thickness, plastic bottom

Inlet and outlet hoppers

t/h 419-472 589-663 614-663

t/h 354-399 460-517 548-592

m³/h 559-629 784-884 819-884

m³/h 472-532 613-689 731-789

rpm 24-27 26-27

m/s 0.64-0.72 0.67-0.72

M112-M450

mm/kN 160-200/112-450

10

Steel

mm 400/640 700/640

mm 8.0/2.5

mm 4.0/2.5

mm 10

mm 4.0/□550 4.0/□550

Page 25

25

SKANDIA ELEVATOR

H-Line

KTHA. KTHB. KTHBU & KTHG

20/33

60 t/h

30/33

80 t/h

40/33

100 t/h

40/33

120 t/h

Capacity for 750kg/m³ KTHA KTHB t/h

65-67 88-92 109-117 129-133

Capacity for 750 kg/m³ KTHBU KTHG t/h

54-57 77-83 91-97 113-118

Capacity KTHA KTHB m³/h

87-89 117-123 145-156 172-177

Capacity KTHBU KTHG m³/h

72-76 103-111 121-129 151-157

Speed KTHA KTHB rpm

64-66 58-61 54-58 64-66

Speed KTHBU KTHG rpm

58-61 54-58 47-50 58-61

Chain speed KTHA KTHB m/s

0.85-0.88 0.77-0.81 0.72-0.77 0.85-0.88

Chain speed KTHBU KTHG m/s

0.77-0.81 0.72-0.77 0.63-0.67 0.77-0.81

Conveyor chain, type M80

Pitch/ultimate tensile strength mm/kN 100/80

Chain sprocket, teeth 8

Flight, material Steel

Intermediate section, width/height mm 200/335 300/335 400/335 400/335

Plate thickness drive, side plate/bottom plate mm 5.0/2.50

Plate thickness tail end and intermediate section mm 2.0 /2.00

Thickness, plastic bottom mm 8.0

Inlet and outlet hoppers mm 3.0/□180 3.0/□250 3.0/□300

H-Line

KTHA. KTHBU & KTHG

40/51

150 t/h

50/64

200 t/h

Capacity for 750 kg/m³ KTHA t/h 168-175 213-222

Capacity for 750 kg/m³ KTHBU KTHG t/h 148-151 198-202

Capacity KTHA m³/h 224-233 284-296

Capacity KTHBU KTHG m³/h 197-201 264-269

Speed KTHA rpm 50-52

Speed KTHBU KTHG rpm 47-48

Chain speed KTHA m/s 0.83-0.87

Chain speed KTHBU KTHG m/s 0.78-0.80

Conveyor chain, type M80-M160

Pitch/ultimate tensile strength mm/kN 100-125/80-160

Chain sprocket, teeth 8. 10

Flight, material Steel/Plastic

Intermediate section, width/height mm 400/510 500/510

Plate thickness drive, side plate/bottom plate mm 8.0/2.5

Plate thickness tail end/intermediate section, side/

bottom plate

mm 4.0/2.5

Thickness, plastic bottom mm 8.0

Inlet and outlet hoppers mm 3.0/□300 3.0/□350

Page 26

Page 27

Page 28

SKANDIA ELEVATOR AB

KEDUMSVÄGEN 14. ARENTORP

S-534 94 VARA. SWEDEN

PHONE +46 (0)512 79 70 00

FAX +46 (0)512 134 00

INFO@SKANDIAELEVATOR.COM

WWW.SKANDIAELEVATOR.COM

Loading...

Loading...