Skandia Elevator H, KTA, KTFb, KTB, KTAb Maintenance Instructions Manual

...

MAINTENANCE INSTRUCTIONS

L/I/H-LINE

Conveyors

ZSA030GB 2018-11-01

SKANDIA ELEVATOR

Your conveyor system must be assembled correctly and maintained

thoroughly if it is to operate satisfactorily. These maintenance instructions and

the separate assembly instructions for each machine must be followed for the

warranty to apply.

We hope you will be pleased with your Skandia conveyor equipment for a long

time.

Thank you for choosing Skandia Elevator!

Contents

Safety information ...................................................................................................................4

Safety decals ....................................................................................................................................................................6

Maintenance ...................................................................................................................................8

General ...................................................................................................................................................................................8

Bearings

.................................................................................................................................................................................8

Return rollers chain conveyors / Belt conveyor carrying idlers,

return idlers, snub idlers and tracking idlers

...............................................................................8

Belt conveyor return idlers, snub idlers, tail pulley and drive pulley

..............14

Transmission

.....................................................................................................................................................................8

Conveyor chain

...........................................................................................................................................................10

Conveyor belt

................................................................................................................................................................12

Forward driving end, sweep conveyor

...............................................................................................14

Troubleshooting ......................................................................................................................16

Poor capacity/stop .................................................................................................................................................16

Machine noisy

.............................................................................................................................................................18

Plastic ight bends

.................................................................................................................................................18

Lid/bottom plate in bend section gets warm

...........................................................................19

Motor stoppage

..........................................................................................................................................................19

Belt conveyor misalignment

........................................................................................................................19

2-3 way valve leaking

..........................................................................................................................................19

Technical specications ............................................................................................... 20

Geared motor rating plate .............................................................................................................................20

Density table

.................................................................................................................................................................20

L-Line

.....................................................................................................................................................................................21

I-Line

.....................................................................................................................................................................................22

H-Line

..................................................................................................................................................................................23

4

SKANDIA ELEVATOR

The owner of the transport equipment is responsible for these maintenance

instructions always being available to the maintenance technicians and

engineering technicians concerned.

Inadequate maintenance and/or defective handling may lead to personal

injury or damage to the conveyor equipment and/or other equipment. It can

also cause malfunctions or a reduction in capacity.

Read these maintenance instructions carefully before maintenance or

operation commences. If any part of these instructions should be difcult to

comprehend, please get in touch with your reseller for assistance.

The safety information is presented and interpreted as follows:

!

WARNING!

Disregarding instructions given in warnings can cause serious personal

injury or death.

!

IMPORTANT!

Ignoring the instructions given in important texts may cause damage

to the conveyor equipment and/or other equipment. It can also cause

malfunctions or a reduction in capacity.

NB! indicates that the text contains information that will simplify the

assembly process.

General

!

WARNING!

• Ensure that everyone responsible for assembly, electrical connection,

maintenance and operation of the conveyor equipment has read and

understood the instructions and safety information.

• Use protective gloves, helmet, steel-toed boots, ear defenders,

protective goggles and high-vis vest when carrying out assembly,

electrical connection, maintenance and operation of conveyor

equipment.

• Stop the machinery and turn off electric power before attempting any

type of assembly, electrical connection or maintenance work.

• Do not start the machinery without the lid, hatches, covers, guards and

connections fitted in such a way they can only be opened with tools.

Safety information

5

SKANDIA ELEVATOR

!

WARNING!

• All electrical equipment is to be connected by a qualified electrician.

See separate connecting directions for electronics.

• The power switch must be permanently mounted and located to allow

easy access when carrying out maintenance work.

• Ensure that sensors and switches for the pop up overloading flap/

inspection hatch (in the outlet hopper) & conveyor chain are active

when in operation. NB! Certain sensors/switches are optional

accessories only on certain machines.

Electrical connection

!

IMPORTANT!

• Ensure the motor protection is set to the correct ampere setting for the

motor.

Incorrect electrical connection may lead to personal injury or damage to the

conveyor equipment and/or other equipment. It can also cause malfunctions

or a reduction in capacity.

!

IMPORTANT!

• If the machine is being assembled outdoors, the motors and

transmissions must be fitted with a weather cover.

• If a machine or part thereof in any way needs moving/dismantling,

follow the directions given in the assembly instructions.

• The machine can be stopped and restarted when full of material but

this option must not be used for intermittent operation.

• If a short circuit should occur, ensure that the electrical equipment is

in working order before continuing operation.

• Ensure that the electrical equipment is kept free from dirt, dust,

moisture and electrostatic charge.

• The machine is not designed to stand or walk on.

!

WARNING!

• The sweep conveyor's conveyor chain and forward driving wheel are not

fully built-in for functional reasons. Do not remain in the vicinity of the

machine while it is operating.

• The silo's centre and intermediate outlet hoppers are not protected for

functional reasons. Do not remain in the vicinity of the outlet hoppers

while the machine is operating.

• Connections to, from and between machinery must be permanently

mounted and fully enclosed. If the design of the installation does not

allow this at an outlet, finish off with a 1 m pipe.

• Ensure the machine is anchored and braced as described in the

assembly instructions.

6

SKANDIA ELEVATOR

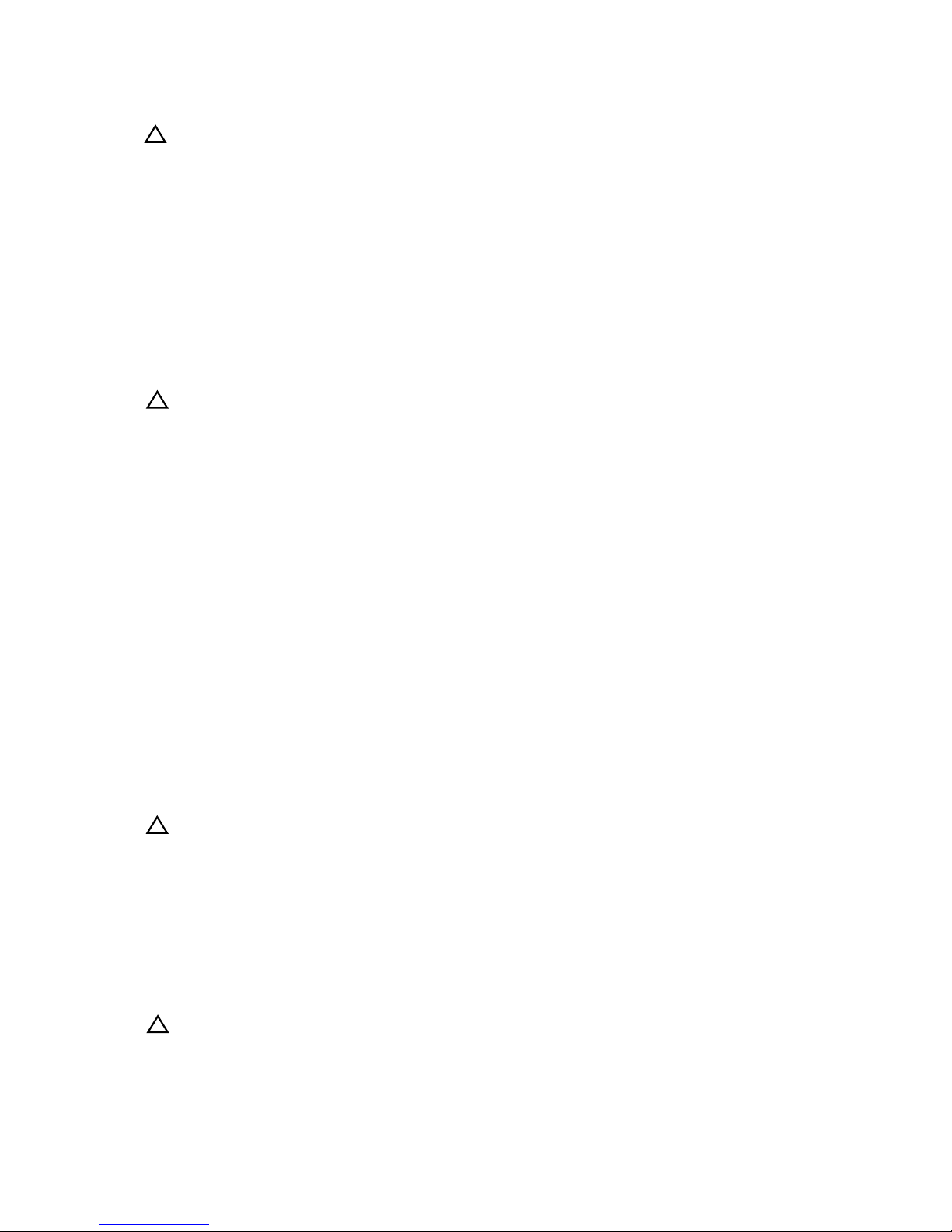

Safety decals

!

WARNING!

The machine is supplied with safety decals on delivery. They must not be

removed or defaced. If a safety decal becomes damaged, you can order a

new one free of charge from Skandia Elevator AB. Specify the part number

of the decal. See section below and the machine overview chapter in the

machine's assembly instructions.

There are safety decals for:

- Mandatory (white symbol on round blue background).

- Forbidden (black strike-through symbol on round white background with red

surround).

- Warning (black symbol on triangular yellow background with black surround).

Skandia Elevator machines may have the following safety decals:

!

WARNING!

The mandatory instruction, forbiddance or warning given on all safety decals

must be considered or serious injury or death may follow.

Part number/Safety decal

Refer to the "Machine Overview" chapter

for location.

Written denition

DEK3090

Read the "Back stop" section in the

elevator's assembly instructions before

test starting the motor for the rst time.

DEK3100

Do not place the valve with the motor

side face down.

DEK3140

Changing settings and equipment is

prohibited.

DEK3030

Warning for conveyor chain!

DEK3060

Warning for bucket belt!

S

K

A

N

D

I

A

E

L

E

V

A

T

O

R

–

D

E

K

3

0

9

0

SKANDIA ELEVATOR - DEK3030

SKANDIA ELEVATOR – DEK3060

S

K

A

N

D

I

A

E

L

E

V

A

T

O

R

–

D

E

K

3

1

0

0

S

K

A

N

D

I

A

E

L

E

V

A

T

O

R

–

D

E

K

3

1

4

0

7

SKANDIA ELEVATOR

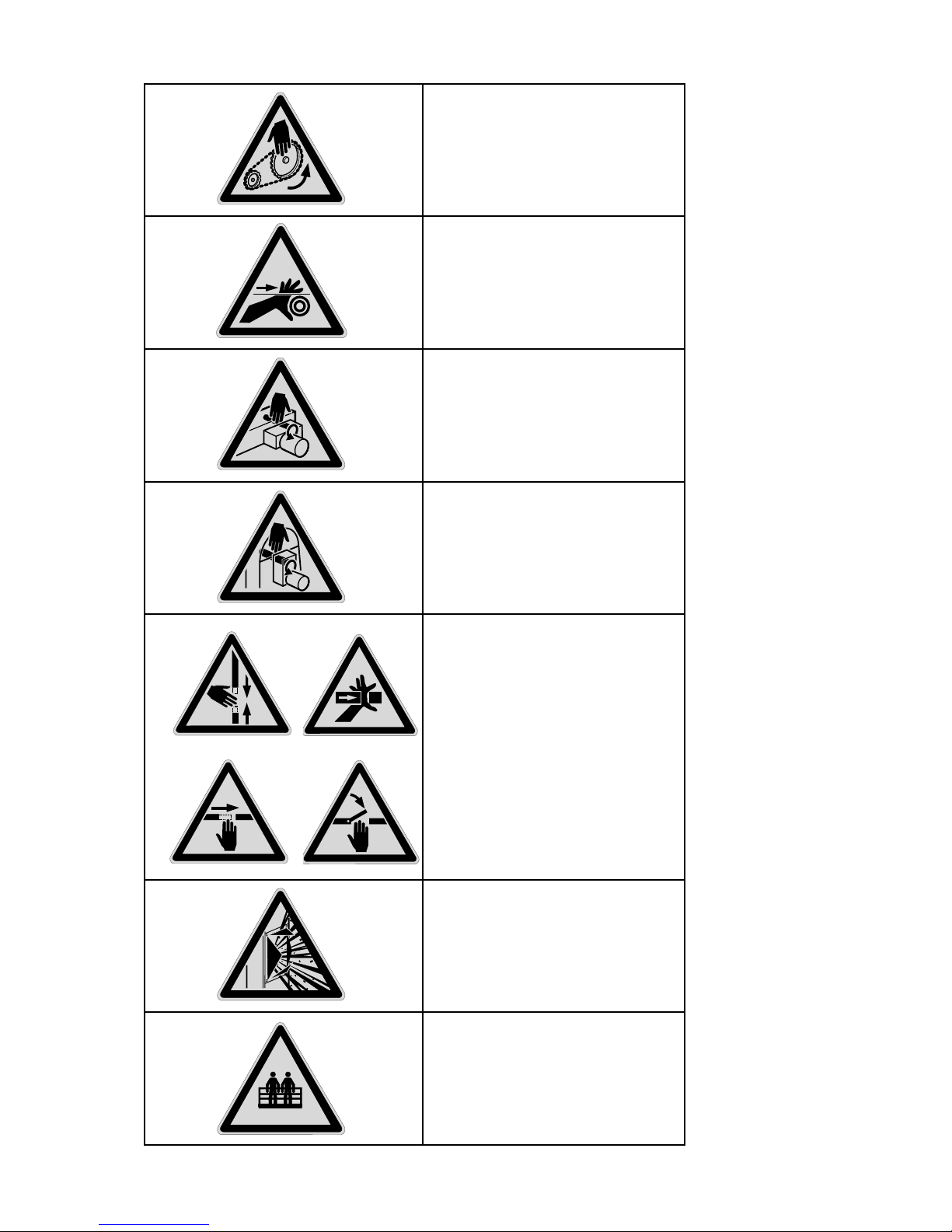

DEK3040

Warning for chain drive!

DEK3150

Warning for conveyor belt and idler!

DEK3070

Warning for rotating conveyor drive

shaft!

DEK3080

Warning for rotating elevator drive shaft!

Warning for moving machinery!

DEK3010

Warning for dust explosion!

DEK3130

Warning, maximum 2 persons = 200

kg/440 lbs may be on the platform and

ladders at one time!

SKANDIA ELEVATOR – DEK3040

SKANDIA ELEVATOR – DEK3070

SKANDIA ELEVATOR – DEK3080

SKANDIA ELEVATOR – DEK3125

SKANDIA ELEVATOR - DEK3010

SKANDIA ELEVATOR – DEK3130

MAX

200

440

/

=

kg

lb

SKANDIA ELEVATOR – DEK3120

SKANDIA ELEVATOR – DEK3110

DEK3110

DEK3120

DEK3125 DEK3160

SKANDIA ELEVATOR – DEK3160

SKANDIA ELEVATOR – DEK3150

8

SKANDIA ELEVATOR

Maintenance

General

Check annually that the bolts are securely in place, that no components

are missing and that there is no rust on the machinery. Replace damaged

components.

!

IMPORTANT!

All maintenance instructions in this chapter must be considered as

important texts.

Bearings

NB! All bearings are greased-for-life and do not require additional lubrication.

Transmission

Geared motor / Angle gear motor

The geared motor is lled with mineral oil on delivery. For more information

on oil grade on delivery, see the separate information attachment from the

manufacturer Nord.

Check the oil level before taking into service and at regular intervals

thereafter.

Change oil every 10,000 operating hours or at least every other year.

The interval between changes can be doubled if synthetic oil is used. When

operating in severe conditions such as high humidity, aggressive environment

or large temperature variations, the oil must be changed more often.

Clean the gear when changing oil.

Return rollers chain conveyors / Belt conveyor carrying

idlers, return idlers, snub idlers and tracking idlers

Check rollers/idlers annually. Replace them immediately if they are worn.

Belt conveyor return idlers, snub idlers, tail pulley

and drive pulley

Ensure that material is not accumulated on return idlers, tail pulley, drive

pulley or the lower pulley in the discharge tripper. Check regularly and clean if

necessary. To reduce any problems, install a belt cleaner.

9

SKANDIA ELEVATOR

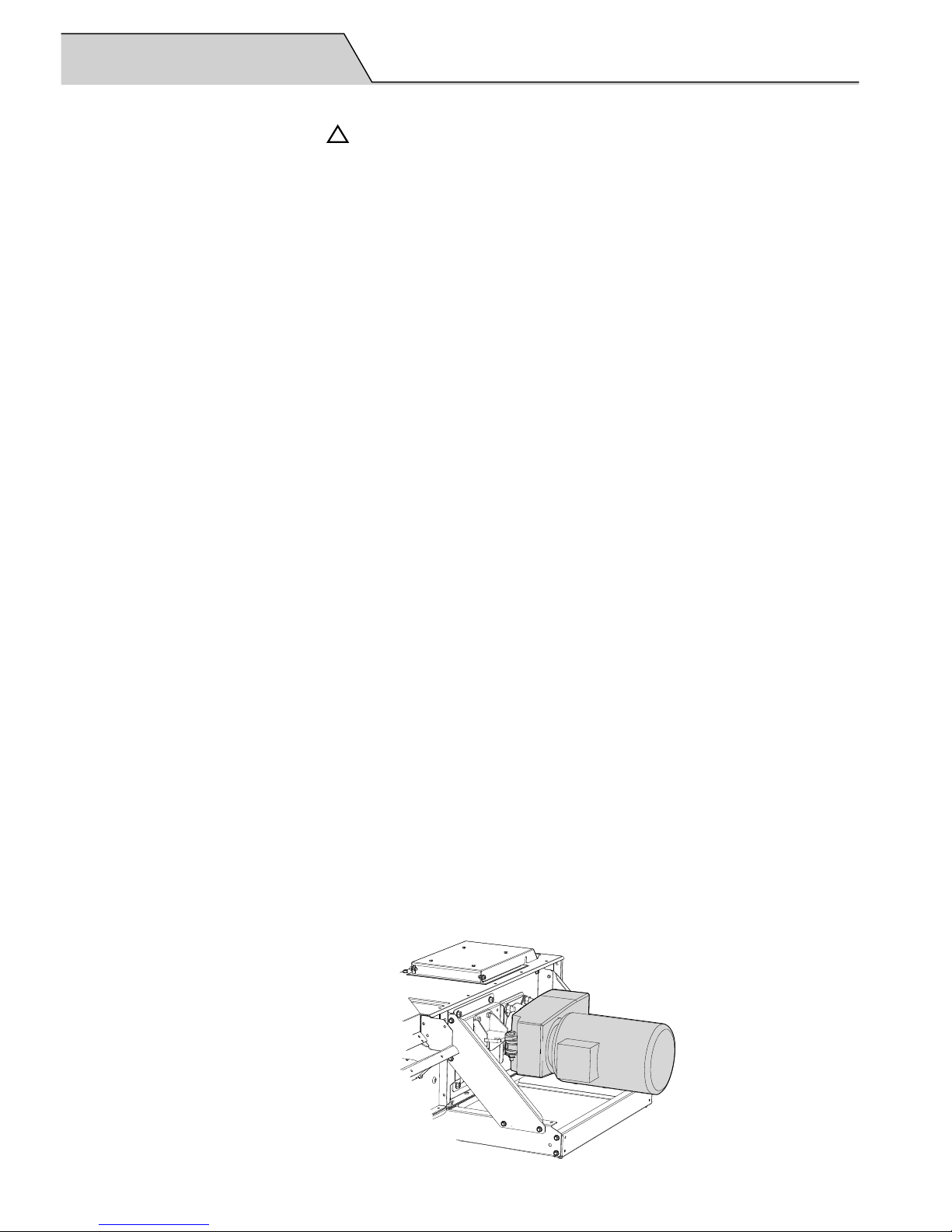

Chain transmission - L-line

Adjust the tightness of the transmission chains continuously.

Oil the transmission chains annually.

Change transmission chains before they become noticeably worn.

A

B

C

D

Tension the intermediate shaft (B) laterally with tensioning bolts (C) so that

the outer chain (D) is sufciently tight.

Tighten the motor bridge (A) by hand and secure it.

1.

2.

Loading...

Loading...