Page 1

Manual

Weighing Machine

AMV1

A/S SKALS MASKINFABRIK

HOVEDGADEN 56

DK-8832 SKALS, DENMARK

Tel.: +45 87 25 62 00

Fax: +45 86 69 49 99

Email: skals@skals.dk

http://www.skals.dk/

1

Page 2

1 Contents

1 Contents ........................................................................................................................ 2

2 Introduction ................................................................................................................... 3

3 Safety ............................................................................................................................ 4

3.1 Pictograms .......................................................................................................................... 4

4 In general ...................................................................................................................... 5

4.1 Feed belt ............................................................................................................................. 6

4.2 Vibration chutes .................................................................................................................. 6

4.3 Weighing tank ..................................................................................................................... 7

4.4 Cross conveyor ................................................................................................................... 8

4.5 Sack platform ...................................................................................................................... 9

4.6 Operating panel .................................................................................................................. 9

5 Operation ...................................................................................................................... 9

5.1 Set-up ................................................................................................................................. 9

5.2 Electrical connection ........................................................................................................... 9

5.3 Start-up ............................................................................................................................. 10

6 Control ......................................................................................................................... 11

6.1 Homescreen ..................................................................................................................... 11

6.2 Settings ............................................................................................................................. 11

6.3 Skals ................................................................................................................................. 12

6.4 Automatic operation settings ............................................................................................ 13

6.5 Manual operation settings ................................................................................................ 17

6.6 Emptying the machine ...................................................................................................... 18

7 Service and maintenance ............................................................................................ 18

7.1 Bearings ........................................................................................................................... 18

7.2 Gear .................................................................................................................................. 18

7.3 Belt ................................................................................................................................... 18

7.4 Vibration chutes ................................................................................................................ 20

7.5 Cleaning ........................................................................................................................... 21

8 Transport ..................................................................................................................... 22

9 Troubleshooting .......................................................................................................... 23

9.1 Fault described in display. ................................................................................................ 23

2

Page 3

9.2 Other faults. ...................................................................................................................... 24

10 Spare parts list ......................................................................................................... 25

10.1 Weighing tank ................................................................................................................... 26

10.2 Vibrator chute ................................................................................................................... 27

10.3 Feed belt ........................................................................................................................... 28

10.4 Cross conveyor ................................................................................................................. 29

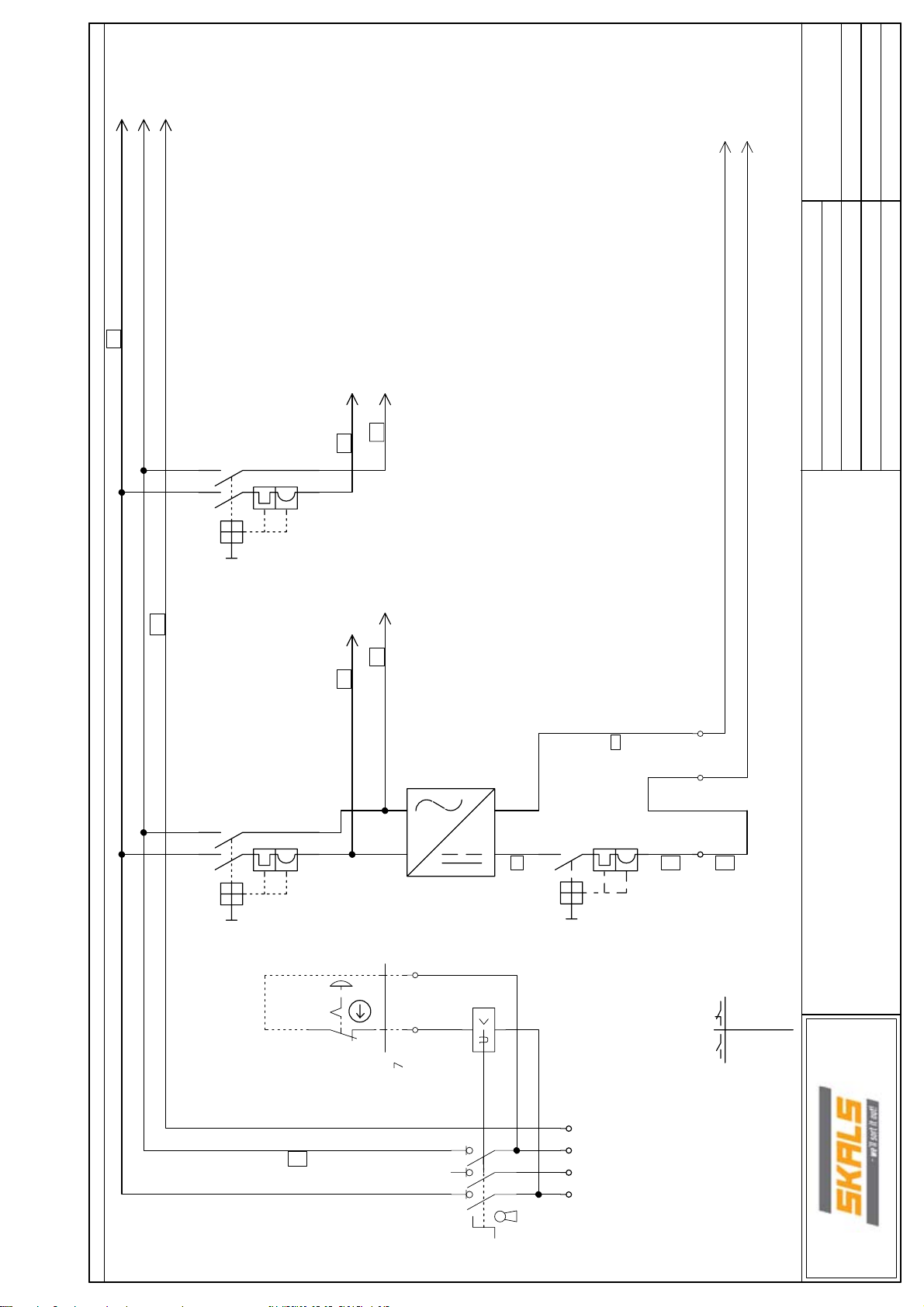

11 Diagrams .................................................................................................................. 31

12 EU Declaration of Conformity ................................................................................... 32

2 Introduction

Read this user manual thoroughly before using the machine.

The machine is use for weighing potatoes, onions, carrots and other similar products.

The machine can weight portion sizes from 1–50 kg.

The machine can weigh large portions up to 1000 kg.

The machine may be operated in a temperature range of -10 to +40 C°.

The information plate and CE label are positioned on the side of the machine, close to the

control panel.

3

Page 4

3 Safety

Any persons working in the close vicinity of the machine must not wear loose-fitting

clothing as this will be hazardous.

3.1 Pictograms

Two types of pictograms are positioned on the machine. Warnings and instructions.

Warnings

HAZARD - ROTATING PARTS.

Avoid touching or coming into contact with the machine's

moving parts. This applies to fingers and clothing, since this

can lead to mutilation.

CRUSH HAZARD.

Avoid touching or coming into contact with the machine's

moving parts. This applies to fingers and clothing, since this

can lead to mutilation.

Instructions

HOOK

Describes where the hook must be positioned when the machine is to be

lifted by a crane.

STRAP HERE

Describes where the machine shall be secured during transport.

FORKLIFT TRUCK

Describes where the forks must be positioned when lifting with a forklift

truck.

4

Page 5

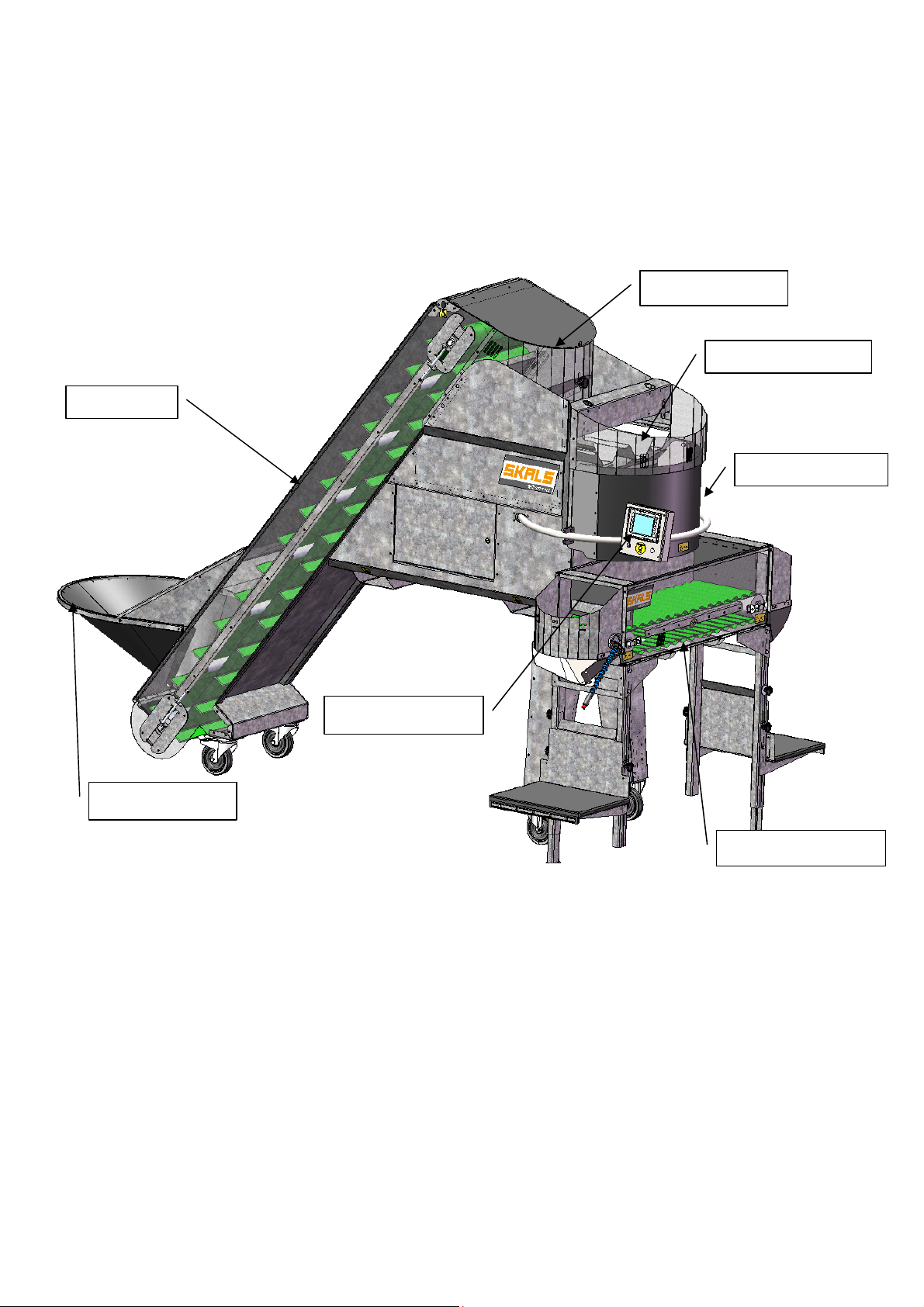

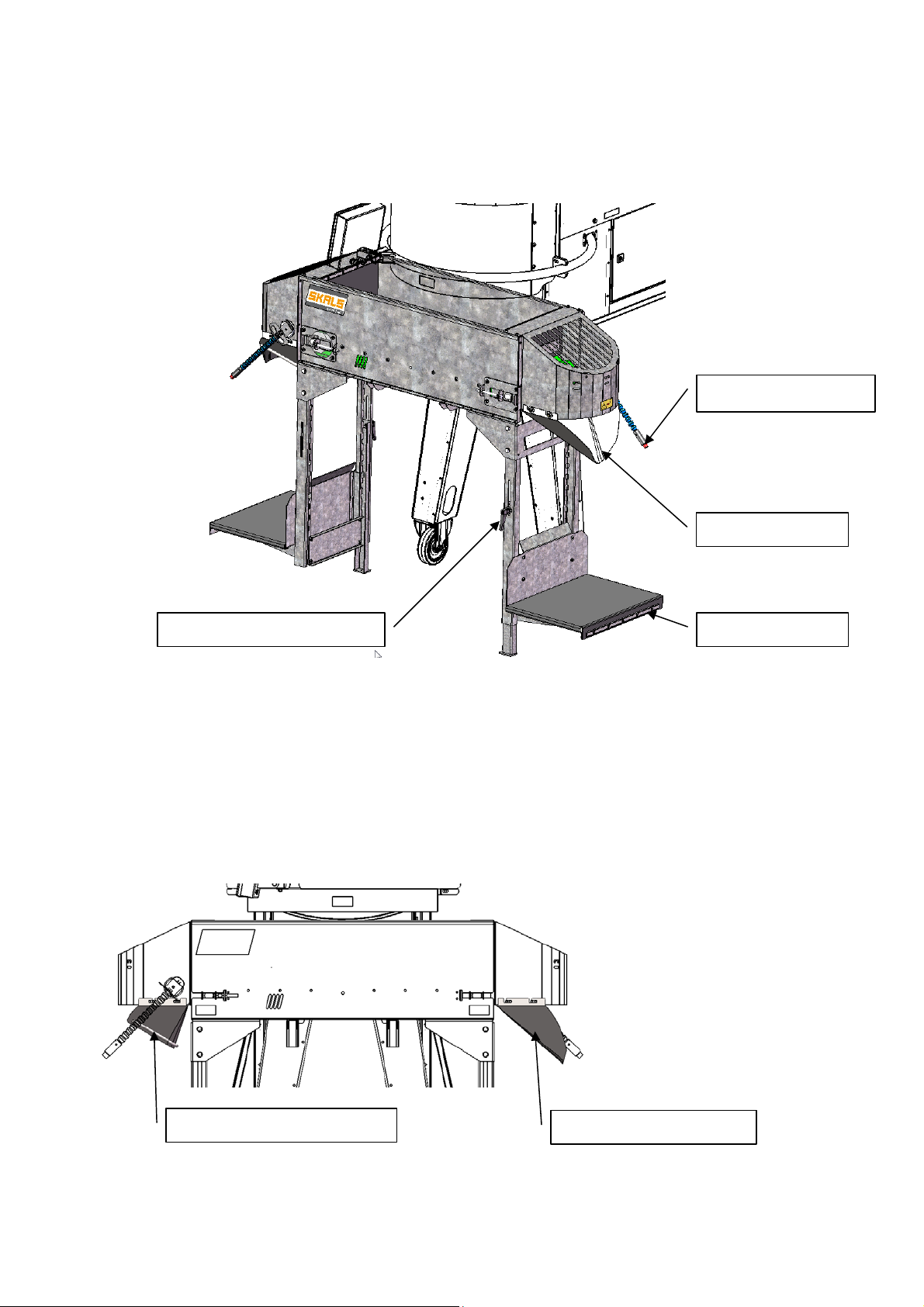

4 In general

Description of machine

Feed belt

Buffer tank

Vibration chutes

Weighing tank

Feed hopper

Operating panel

Cross conveyor

5

Page 6

4.1 Feed belt

The feed belt transports the products from the feed hopper up to the buffer tank above the

vibration chutes. The buffer tank has two sensors that activate and deactivate the feed

belt.

To achieve optimal operation, it is important that the feed hopper is always filled

with products.

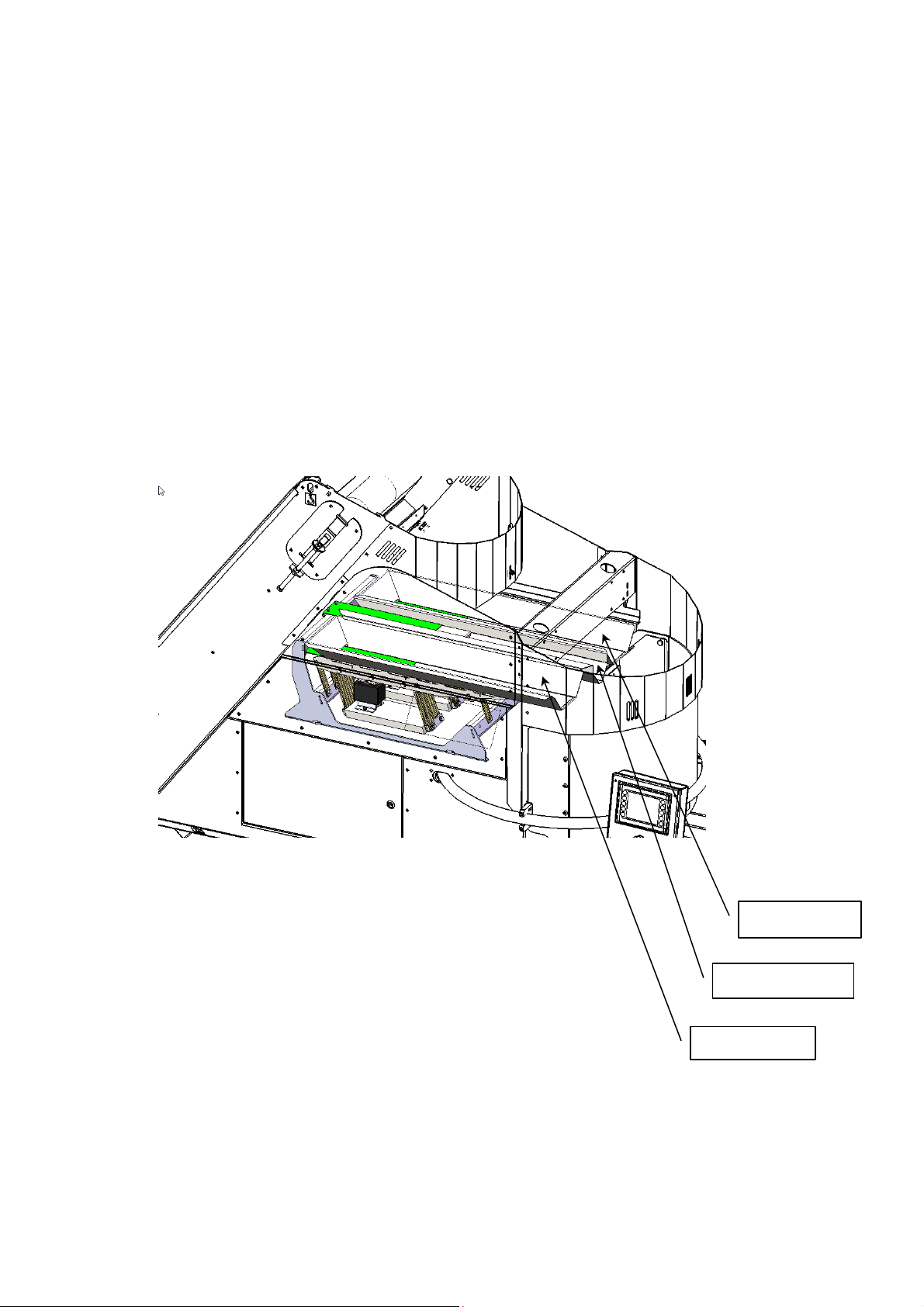

4.2 Vibration chutes

The machine is equipped with three vibration chutes, designed to fill and dose the

weighing tank.

All three of the vibration chutes switch on automatically when the weighing tank shall be

filled and only two of the chutes operate when dosing for the required weight.

Fill chute.

Dosing chute

Fill chute.

6

Page 7

4.3 Weighing tank

The weighing tanks' volume capacity is 57 l.

The weighing tank must be checked regularly and if required, cleaned of any soil that has

accumulated.

During operation, the weighing tank must not be touched otherwise the weighing result will

not be correct.

7

Page 8

4.4 Cross conveyor

The cross conveyor allows the machine to be operated by two people at the same time.

Operation sensor

Outlet hopper

Handle for stabiliser leg

Sack platform

When the operating sensor is activated on a specific side, the cross conveyor will transport

the next portion to that side.

NB: The machine 'remembers' an activation of the operating sensor, even though the

cross conveyor is not ready to deliver a portion!

The machine is supplied with four outlet hoppers as standard. Two hoppers for portion

sizes 1–9 kg and two hoppers for 10–50 kg.

Outlet hopper 10–50 kg

Outlet hopper 1–9 kg

8

Page 9

4.5 Sack platform

When the height of the sack platform shall be changed, loosen the two finger screws on

the platform and raised/lower the platform and then re-tighten the finger screws.

When weighing portions that weigh more than 10 kg, lower the stabiliser leg at the sack

platform until it supports on the level surface.

Handle for

stabiliser leg

Stabiliser leg

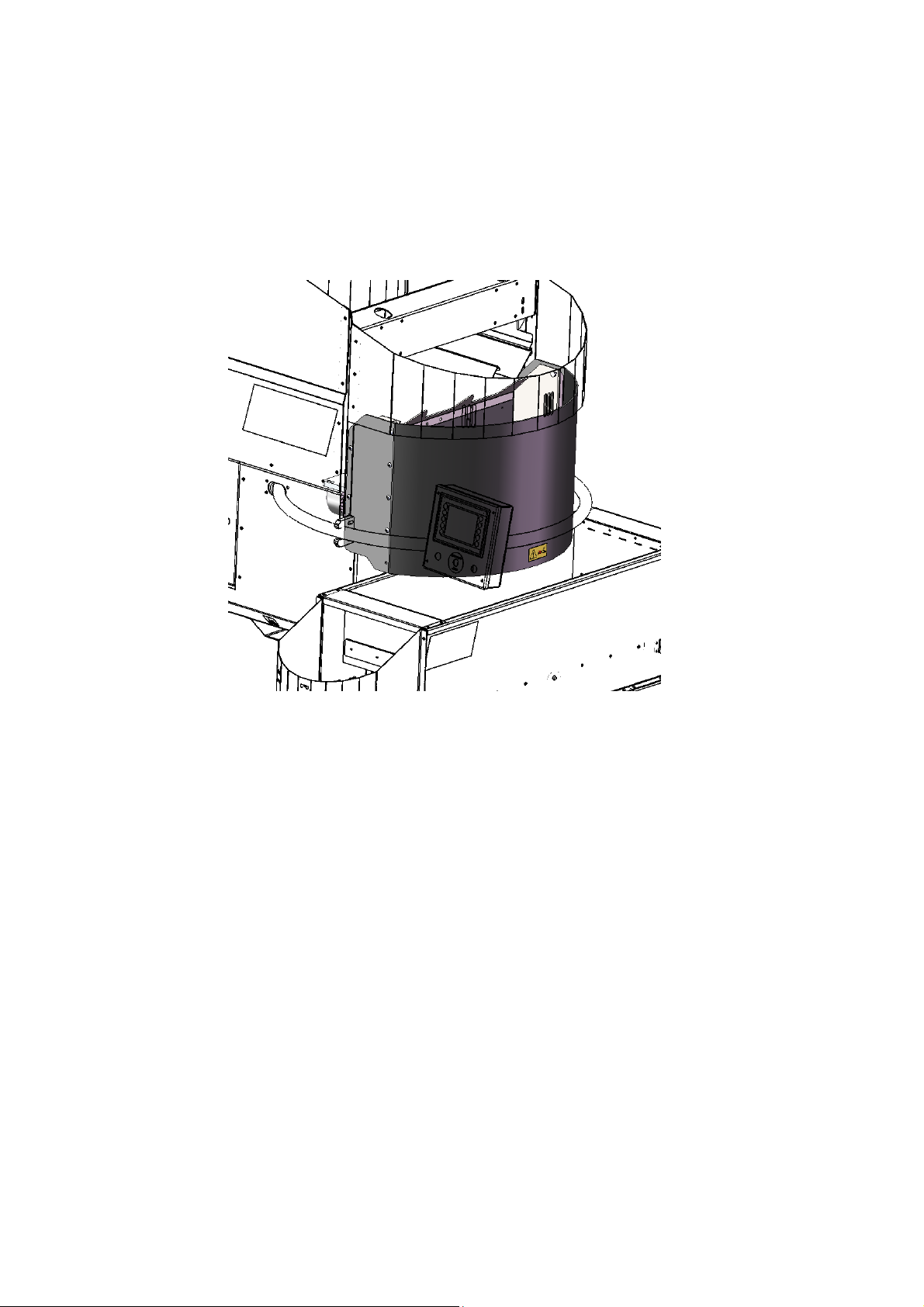

4.6 Operating panel

The operating panel consists of a touch display and a stop.

All of the machine's electrical functions are operated via the touch display.

5 Operation

Before commissioning the machine, check it to ensure it has not been damaged during

transport.

Any defects must be reported to the dealer immediately.

5.1 Set-up

To ensure correct weighing, the machine must be placed on a stable and level surface.

5.2 Electrical connection

The electrical connection must comply with national applicable regulations.

1 Phase 230 V - N + PE

9

Page 10

5.3 Start-up

1. Enter the desired portion size and total number of portions that are to be weighed

using the operating panel.

2. Next, select the programme that is to be used (potatoes, carrots, onions or

optional).

3. Press the "Start" button on the display.

4. The operating sensor is activated.

NB: In the case of start-up after the portion size has been changed the machine may

initially weigh inaccurately. The machine will regulate this automatically after a few

weighings.

10

Page 11

6 Control

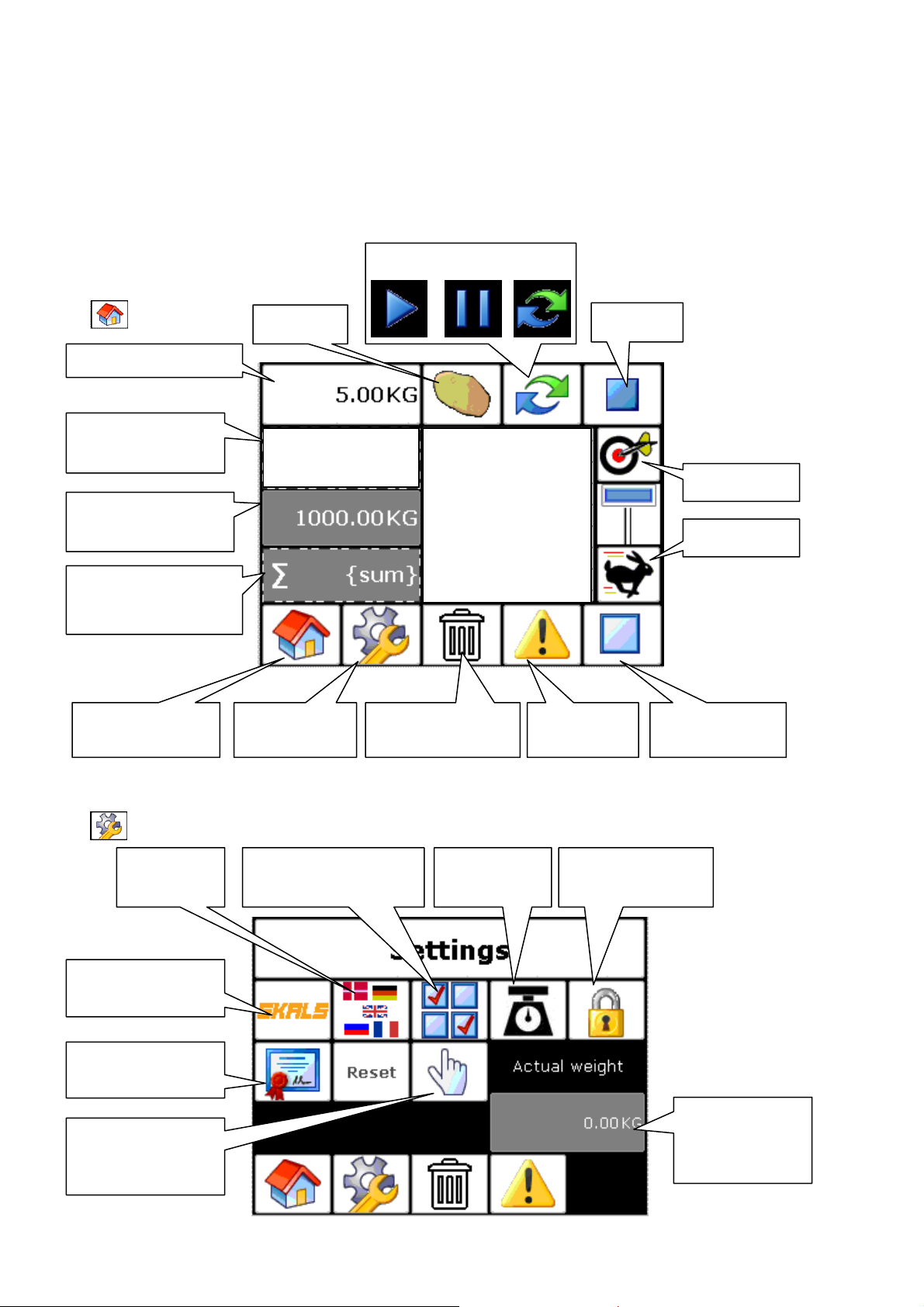

6.1 Homescreen

Portion sizes

Total number of

portions

Actual weight in

the weighing tank

∑ Sum of weighings

X Average value

Ϭ Standard deviation

Return to

homescreen

Start/Pause/Repeat

Product

6/10

Settings Empty function Alarms

6 5.01 kg

5 5.10 kg

4 5.04 kg

3 5.00 kg

2 5.03 kg

1 5.07 kg

Stop

Precision

Speed

Reset alarms

6.2 Settings

Language

setting

Skals contact

information

Verification

Manual

operation

settings

Automatic

operation settings

Calibration

of scales

Scales settings

locked

Actual weight

in the

weighing tank

11

Page 12

6.3 Skals

Skals contact information is shown here

Should you have any questions about the machine, contact your dealer in the first

instance.

Verification

The verification ID and date of last filling is show here.

12

Page 13

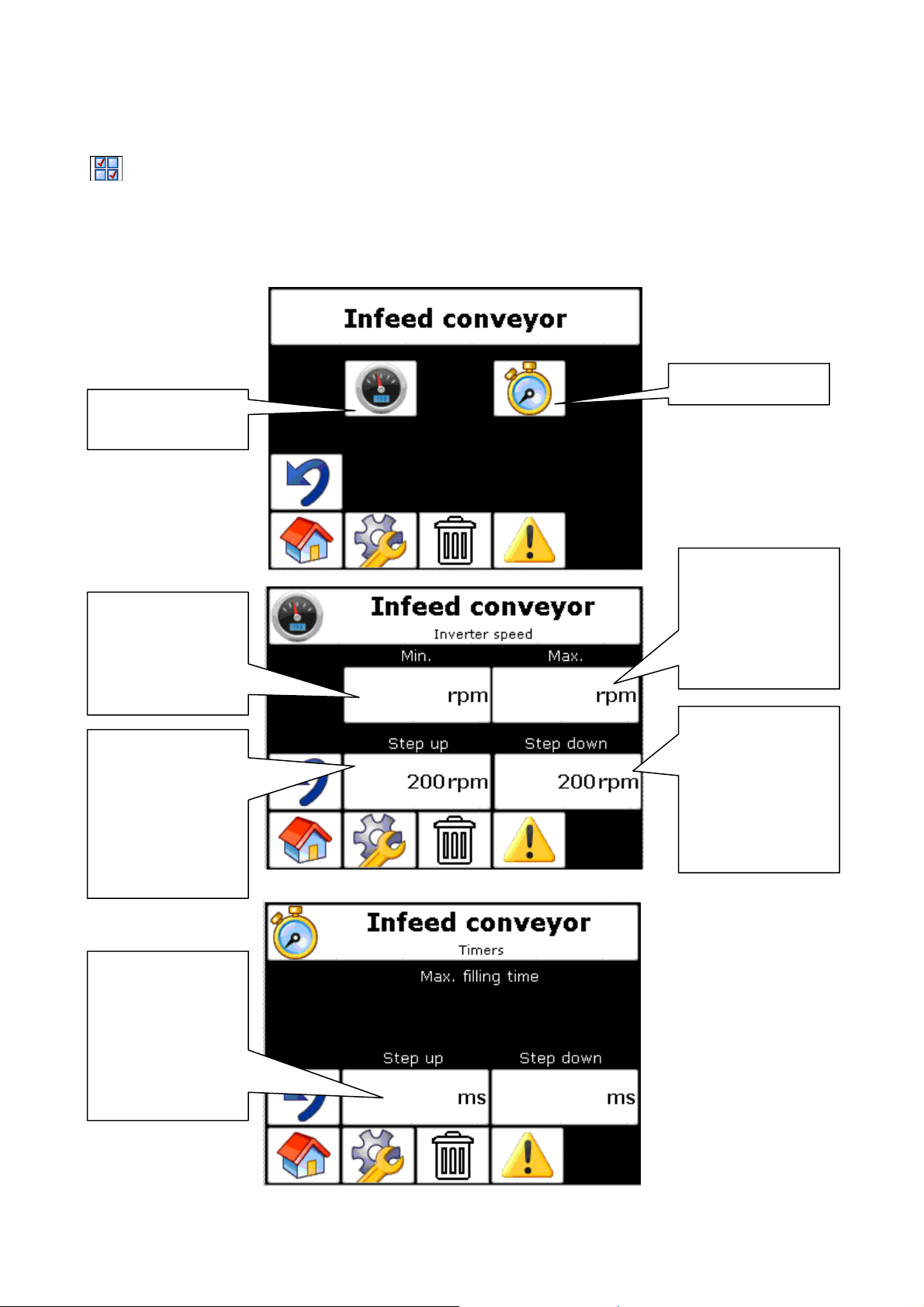

6.4 Automatic operation settings

There are four areas that can be set: Feed belt, vibration chutes, weight and cross

conveyor, of which the last three are relevant for normal operation.

Feed belt

Speed, see next

image

Time setting

Minimum rpm of

the drum motor

for the feed belt

should be set to

700 rpm.

Total rpm, the

drum motor

speed increases

every time it

accelerates.

Should not be

changed.

700 1500

Maximum rpm

of the drum

motor for the

feed belt should

be set to

1500 rpm.

Total rpm, the

drum motor

speed lowers

every time it deaccelerates.

Should not be

changed.

Time interval

between

automatic

change of

speed.

1000 2000

13

Page 14

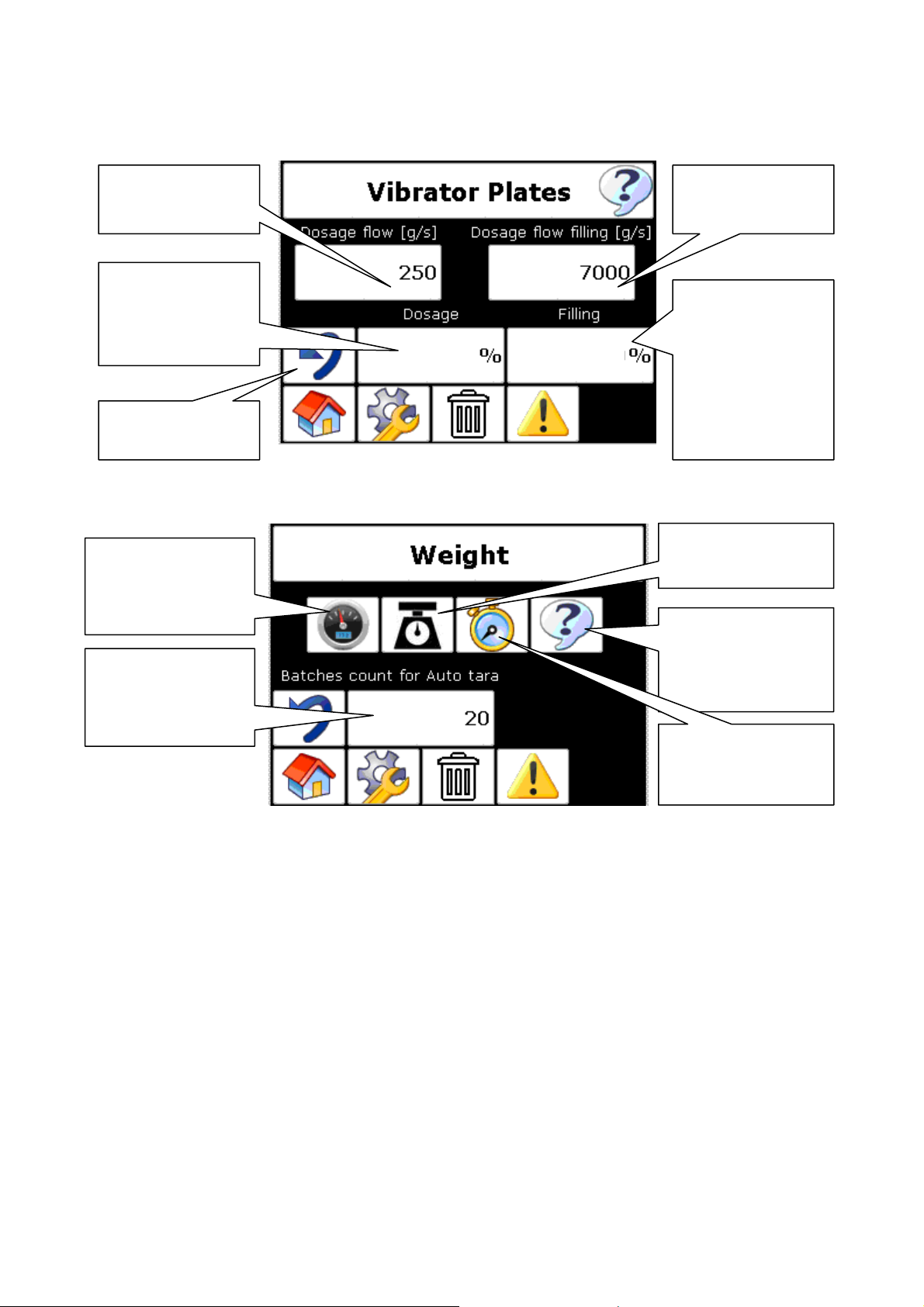

chute

Vibration chutes

Estimated flow

when dosing

Vibration power

in percent.

Should not be

less than 50%

Back to

previous menu

Scales

Motor speed for

tank shutter

Should not be

changed.

Total number of

portions between

each auto taring.

See explanation

Auto taring

Automatically tares the scales zero point after a set number of portions (e.g. 20).

In the case of dirty products, it is relevant to have a low total number of weighings between

each auto taring. Build up of dirt in the weighing tank affects the weighing result.

75

85

Estimated flow

when filling

Vibration power

in percent.

Should not be

less than 55%

and should

always be

greater than

2

Scales settings

See next image

Product specific

settings.

(potatoes, carrots

etc.)

Alarm times

Should not be

changed.

14

Page 15

Weight Speed

Weight settings

Back to

previous menu

Offset 25 kg:

When a double portion is made (over 25 kg), Offset 25 kg must be between 1500 and

3500 g to stop around the 25 kg. This is necessary to compensate for the run-on time and

prevent the weighing tank from becoming over filled with the first portion.

Tolerance

This is the limit for when the scales begins to be regulated.

If the products that are being weighed weigh up to 100 g, the tolerance must be the same

or 10 % greater.

Controller parameter

Parameter that determines how aggressive the controller reacts

Weigher opening

speed

Tolerance interval

in grams, see

explanation

Controller

parameter

15

Page 16

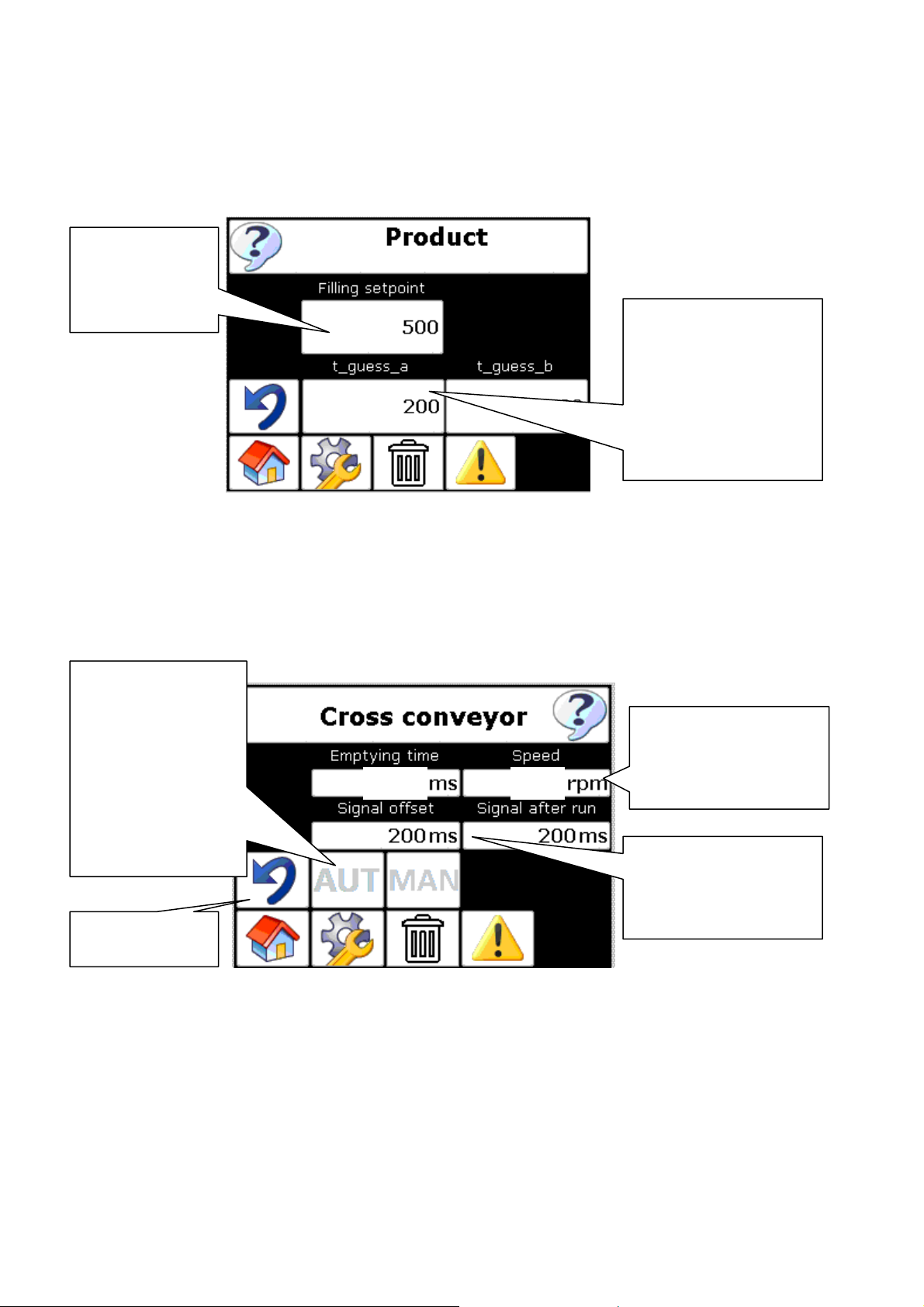

Product specific parameters

Filling setpoint

is controlled by

the slider on

the main page

Cross conveyor

Aut. or manual

outfeed mode.

Manual = sensor

Aut. = after first

touch of the

sensor, next

portions are

feeded

automatically

Back to

previous menu

Empty time

The time that is set to ensure that the belt is completely empty.

Speed

If there are problems with the products coming out of the outlet hopper, reduce the speed.

2300 700

Time guess_a is a

value used for

portions up to 10kg.

Lighter products =

higher value.

The speed of the

cross conveyor

should be between

600 and 900 rpm

Delay and run-signal

to next machine

External signal

16

Page 17

6.5 Manual operation settings

During manual operation, all of the functions can be set and the machine operated.

NB: In manual operation mode, all of the alarms and sensors are de-activated.

Language

Five languages are available.

English

German

Danish

French

Russian

Lock

When the scales are locked, there is limited access to certain functions.

Scales guide

Programme 0-3

Scales guide (calibration)

To calibrate the scales, follow the instructions in the display.

Place a known weight in the weighing tank during calibration.

The weighing tank must be clean inside.

Every time the scales are calibrated a new ID number is generated, which can be seen

under the verification ID and a date for the last calibration.

Alarms

All of the alarms that can be triggered are shown in the troubleshooting section.

When an error is observed and corrected, the alarm is reset

17

Page 18

6.6 Emptying the machine

If the machine is to be completely emptied, continue to weigh portions without filling the

intake hopper with any products. Once the vibration chutes have operated for a longer

period than normal, press Stop.

Next, empty the weighing tank and the cross conveyor by accessing the manual settings

and press to empty.

7 Service and maintenance

During service and maintenance, ensure power has been disconnected at the main switch

and the main switch is locked.

7.1 Bearings

All of the bearings and motors and the loose drum have been lubricated at the factory and

require no maintenance.

7.2 Gear

The worm gear that drives the weighing tank's open/close function has been lifetime

lubricated with synthetic grease for operation in standard temperature range (-10 to +40

°C).

7.3 Belt

The machine has two PVC belts fitted. A feed belt and a cross conveyor.

Both belts must be checked regularly and adjusted if required to ensure a long lifetime.

Tighten the belts by loosening the two nuts marked with blue (on both sides) and then

tighten the belt by tightening the top nut. Once the belt has been adjusted, re-tighten the

18

Page 19

bottom nut. The same procedure is used to adjust the belt to operate in the centre.

However, the tightening must only be done in the side the belt moves to.

At all times it is the responsibility of the owner to ensure the belts have been adjusted

correctly.

If the belts have not been adjusted correctly, the warranty for the belts is void.

19

Page 20

7.4 Vibration chutes

All bolts and vibration chutes should be re-tightened every 200 hours of operation.

To access the bolts, remove the screen marked in blue.

The bolts are marked in blue, and should be tighten to 18 Nm.

20

Page 21

7.5 Cleaning

In the case of high-pressure cleaning, direct spraying must be avoided in the following

areas: loose drum, gear motors, control cabinet, electronic control box, load cell,

connectors and motors on vibrators.

If products with loose skin are being weighed, the vibrator chutes should be cleaned on a

daily basis.

Good cleaning and maintenance are important to achieve a high degree of reliable

operation and low maintenance costs.

21

Page 22

8 Transport

If the machine shall be lifted by crane, this must be done using the integrated lifting points

in the top of the machine. If the machine shall be moved by forklift truck, this must be done

using the integrated fork pockets.

NB: Always stay well clear of suspended loads.

During transport the machine must be secured to the surface, as shown with the orange

lines.

22

Page 23

9 Troubleshooting

NB: The machine must ALWAYS be switched off at the main switch when work on

mechanical parts shall be carried out.

9.1 Fault described in display.

Alarm text Cause Solution

Shutter in weighing tank

taking too long to close.

Scales taking too long to fill

up.

Sensor is not adjusted

correctly.

Defective sensor. Check the conductor to the

Foreign bodies are blocking

the shutter in the weighing

tank.

There are not enough

products in the buffer tank.

Feed belt not regulating to

faster speed.

Products are blocked in the

buffer tank.

Adjust the sensor closer to

the crank plate

(distance 1-3 mm).

sensor. Replace sensor.

Remove foreign bodies.

Fill the intake hopper with

products.

See other faults.

Remove the blockage in the

buffer tank.

Set the plate in the buffer

tank to the applicable

product's size.

Fault on all of the frequency

converters.

Aborting of both belts and

scales.

Automatic fuse switched off. Switch on automatic fuse

(see control).

23

Page 24

9.2 Other faults.

Error Cause Solution

Weighing tank or cross

conveyor does not start with

operation of operation

Operation sensor is

defective.

Check the conductor to the

sensor. Replace sensor.

sensor.

Buffer tank is not full and the

feed belt is not operating.

The top sensor in the buffer

tank is dirty or defective.

Clean sensor and reflector.

Feed belt not regulating to

faster speed.

The bottom sensor in the

buffer tank is dirty or

defective.

Green LED on sensor must

be lit at all times (indicates

Clean sensor and reflector.

Check the conductor to the

sensor.

Replace sensor.

sensor is in contact with the

control system).

24

Page 25

10 Spare parts list

When ordering spare parts, please state machine type, serial number and any product

number.

25

Page 26

10.1 Weighing tank

26

Page 27

10.2 Vibrator chute

27

Page 28

10.3 Feed belt

28

Page 29

10.4 Cross conveyor

29

Page 30

Complete capacitive sensor

30

Page 31

11 Diagrams

31

Page 32

12 EU Declaration of Conformity

Manufacturer

Company name: A/S Skals Maskinfabrik

Address: Hovedgaden 56

DK-8832 Skals, Denmark

Telephone: +45 87 25 62 00

hereby declares that

Machine: Weighing machine

Brand:

Type, serial no., year:

Has been manufactured in conformity with the:

1 Machinery Directive 2006/42/EC

2 Low Voltage Directive (LVD) 2006/95/EC

3 Electromagnetic Compatibility (EMC) Directive 89/336/EEC and the

amended 93/68/EEC.

Title:

Name: Søren Lund Madsen

Company: A/S Skals Maskinfabrik

Date:____________ Signature:_____________________________

AMV1

Production Manager

32

Page 33

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:40 PM

Antal brugte sider: 25

Side F1 af 27

Sidst ændret: 11/18/2012

Godk.:

EL-DOKUMENTATION

Vægt 3 Render/ Weight 3 lines

EL - DOCUMENTATION

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

Page 34

T2

1

2

3

4

6

7

8

9

10

11

12

13

15

20

26

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Page number

5/27/2009 2:17:38 PM

10/22/2012 9:48:20 PM

Last corretion date

SIDSTE RETTE LSE TIDTITEL SIDE NUMMER

Antal brugte sider: 25

Sidst udskrevet: 12/10/2012 11:00:40 PM

Sidst ændret: 12/10/2012

Side I1 af 27

Godk.:

Sagsnr: 2010-11-24

Konstruktør: SGT

11/27/2012 9:42:28 AM

11/27/2012 9:49:32 AM

11/27/2012 9:49:16 AM

11/27/2012 9:48:42 AM

11/27/2012 9:40:46 AM

12/10/2012 10:54:12 PM

12/10/2012 10:47:24 PM

12/10/2012 10:51:56 PM

12/10/2012 10:51:38 PM

12/10/2012 10:55:16 PM

11/27/2012 9:37:28 AM

12/10/2012 10:56:02 PM

12/10/2012 10:55:02 PM

12/10/2012 10:56:48 PM

11/18/2012 5:14:22 PM

12/10/2012 10:56:48 PM

Contents

INDHOLDSFORTEGNELSE

Plant dataT1Plant data

Main circle

Main circle Inverter

Main circle Inverter

Main circle Inverter

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

Modul 4 - Output

Modul 1 - Input

Modul 1 - Input

Current PLC

Operatør / Panel

Modul 1 - Input

Modul 1 - Input

Modul 1 - Input

Sync signal

Part list

Mekanisk PLC25Components list

DATA

Diagram_Vægt

Part list

Layout

Page 35

DATA

Page 36

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:40 PM

Godk.:

Side T1 af 27

Antal brugte sider: 25

Sidst ændret: 5/27/2009

Side titel: Plant data

LEDNINGSNUMMER

STYRESTRØM

1. = + (plus)

2. = - ( minus)

3. Styre signal

4 - 21. = Styre signal

4 - 21 Pilot signal

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

Pilot power

Red 230/24 pilot power

Main power Pilot power

Light blue Neutral 2. = - (minus)

Black L1-L2-L3 - 380/230V 1. = + (plus)

Sort L1-L2-L3 - 380/230V

Hovedstrøm

Lyseblå Nul

Rød 230/24V styrestrøm

Grøn/Gul Jord

STYRESTRØM

Dark blue 24V DC pilot power

Mørke Blå 24V DC styrestrøm

Orange Fremmede styrestrøm

Lilla Analog

LEDNINGSFARVER

WIRE COLOR WIRE NUMBER

Projekt titel: Vægt 3 Render/ Weight 3 lines

Green/Yellow Grounding 3. Pilot signal

Orange External pilot power

Purple Analog

Page 37

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

: 1x230V+N+PE

: 3A

: 50 Hz

: TN-C-S

: 6KA

: 16 A

Sagsnr: 2010-11-24

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:40 PM

Godk.:

Side T2 af 27

Antal brugte sider: 25

Sidst ændret: 10/22/2012

Side titel: Plant data

Tavle data

Spænding

Fuldlaststrøm

Frekvens

Controlbox data

Current : 1x230V+N+PE

Full load current : 3 A

Styrestrøm

Maks. kortslutningstrøm

Maks. Forsikring

Kw forbrug : 2Kw

Hovedgaden 58

8832

Kunde: Skals Maskinfabrik

Frequency : 50 Hz

Control current : TN-C-S

Max. short-circuit current : 6 KA

Max. supply fuse : 16 A

Kw load : 2 Kw

Skals

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 38

Diagram_Vægt

Page 39

L1

Dc 1

NPE201

0V

201

+2

201

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

20

N_FR

201

L1_FR

201

15

NN`

NN`

21

21

10A

-F113

PE

14

31

901

30

901

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:40 PM

Godk.:

Side 1 af 27

Antal brugte sider: 25

Sidst ændret: 11/27/2012

Side titel: Main circle

31

30

NN`

NN`

21

21

10A

-F106

Emergency-stop

-S103

/

/>-W103

4

4

/

/

3

3

Power supply

>-T107

2

2

11

OPS1050.1

A1 A2

A1 A2

-K103

-

Fuse 4A

12

12

-F106/1

--

+2+2

+2

+2

+2

+2+

>-X1

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

PEPE

56

18

Projekt titel: Vægt 3 Render/ Weight 3 lines

56

34

34

12

12

VBF01

>-Q0101

NN

L1

>-X10

Supply

1Fase 230V - N + PE

50Hz

Load Kw

Max Fuse16A

12345678910111213141516171819

Page 40

L1_FR

301

PE

N_FR

301

301

0V

301

+2

301

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

SN

SN

RS485

RS485

SP

SP

RS485

RS485

Do1

Do1

GND

GND

-

15

14

+24V

+24V

R2C

R2C

R2A

R2A

SHILD

SHILD

X2X+

X2X+

X2X\

X2X\

X2x GND

X2x GND

X2X

X2X

Shild

308

X2X+

Rød/red308

X2X\

Blå/Blue308

X2X GND

Sort/Black308

X2X

Hvid/White308

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 2 af 27

Antal brugte sider: 25

Sidst ændret: 11/27/2012

Side titel: Main circle Inverter

115

115

119

PE PE

PE PE

W

W

N

N

L1

L1

-T205

Frekv. 0,37Kw

4PP045.0571-062

V

V

U

U

-W207

-W205

PE

PE

3

3

2

2

1

1

X2X

X2X\

Shild

X2X+

X2X GND

-

+2

1,56A

Weiging hopper

Hovedgaden 58

8832

3x200volt 0,37Kw

-M205

Skals

Kunde: Skals Maskinfabrik

123456789101112131415161718192021

Projekt titel: Vægt 3 Render/ Weight 3 lines

L1_FR

+2

PE

N_FR

119

0V

119

Page 41

L1_FR

401

PE

N_FR

401

401

0V

401

+2

401

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

SN

SN

RS485

RS485

SP

SP

RS485

RS485

Do1

Do1

GND

GND

-

15

14

+24V

+24V

R2C

R2C

R2A

R2A

SHILD

SHILD

X2X+

X2X+

X2X\

X2X\

X2x GND

X2x GND

X2X

X2X

Shild

408

X2X+

Rød/red408

X2X\

X2X GND

Blå/Blue408

Sort/Black408

X2X

Hvid/White408

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 3 af 27

Antal brugte sider: 25

Sidst ændret: 11/27/2012

Side titel: Main circle Inverter

220

220

220

PE PE

PE PE

W

W

N

N

L1

L1

-T305

Frekv. 0,37Kw

4PP045.0571-062

V

V

U

U

-W208

-W305

PE

PE

3

3

2

2

1

1

211

Shild

X2X+

Rød/red211

X2X\

X2X GND

Blå/Blue211

Sort/Black211

-M305

X2X

Hvid/White211

1,91A

Elevator_1

3x200volt 0,37kw

-

+2

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

123456789101112131415161718192021

Projekt titel: Vægt 3 Render/ Weight 3 lines

L1_FR

+2

PE

N_FR

220

0V

220

Page 42

L1_FRL1_FR

PE

N_FR

7

0V

7+27

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

SN

SN

RS485

RS485

SP

SP

RS485

RS485

Do1

Do1

GND

GND

-

15

14

+24V

+24V

R2C

R2C

R2A

R2A

SHILD

SHILD

X2X+

X2X+

X2X\

X2X\

X2x GND

X2x GND

X2X

X2X

ShildShild

X2X+

Rød/red1205

X2X\

X2X GND

Sort/Black1206

Blå/Blue1204

X2X

Hvid/White1203

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 4 af 27

Antal brugte sider: 25

Sidst ændret: 11/27/2012

Side titel: Main circle Inverter

320

320

320

PE PE

PE PE

W

W

N

N

L1

L1

-T405

Frekv. 0,37Kw

4PP045.0571-062

V

V

U

U

-W207

-W405

PE

PE

3

3

2

2

1

1

311

X2X+

Rød/red311

X2X\

X2X GND

Blå/Blue311

Sort/Black311

-M405

X2X

Hvid/White311

1,93A

Belt Outlet

3x400volt 0,55Kw

-

+2

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

123456789101112131415161718192021

+2

PE

N_FR

Projekt titel: Vægt 3 Render/ Weight 3 lines

320

0V

320

Page 43

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 6 af 27

Antal brugte sider: 25

Sidst ændret: 12/10/2012

Side titel: Current PLC

X20BT 9400

-K605

X20DO 2322

-K604

X20CS 1030

-K603

X20D02633

-K602

X20BT 9300

-K601

Input

Bus Output

Analog

Weight

modul

Vibration

BUS Panel

Kunde: Skals Maskinfabrik

12345678910111213141516171819

Hovedgaden 58

8832

Skals

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 44

+2 801

801

0V

PE

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

IF4_4

Sagsnr: 2010-11-24

PORT 1

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 7 af 27

Antal brugte sider: 25

Sidst ændret: 11/27/2012

Side titel: Operatør / Panel

D410

PP65B&R

/-EHT_1

/ -IF4_4

///

ETHERNET IF4PE

ETHERNET IF4PE

+-

+-

///

/

/-W103

PE

PE

/

/

2

2

/

/

1

1

PE

PE

--

++

-X1

-

PE

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

+2

12345678910111213141516171819

+2

420

0V

420

PE

PE_420

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 45

Dc

Dc0v0v

Page 46

3131

25

16

30

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Viberator Line 1+3

Viberator Line 1+3

Sagsnr: 2010-11-24

26

26

16

16

Konstruktør: SGT

25

25

15

15

24

24

14

14

1414

1313

30

31

4

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 9 af 27

Antal brugte sider: 25

Sidst ændret: 12/10/2012

Side titel: Modul 1 - Input

Viberator Line 2

Viberator Line 2

X20D02633

3

23

23

13

13

22

22

12

12

21

21

11

11

1414

13

13

12

12

1111

1

-K910

-K908

2

-K903

Magnet Line 3

Magnet Line 1

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

Magnet Line 2

-K602

(6/3)

30

111

110

12345678910111213141516171819

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 47

1101

Black/White

Green

Red

7

+2

1101

0V

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

26

26

16

16

Konstruktør: SGT

25

25

15

15

-

+2

24

24

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 10 af 27

Antal brugte sider: 25

Sidst ændret: 12/10/2012

Side titel: Modul 1 - Input

10088100

X20CS 1030

Analog/ Weight

14

14

23

23

LC

LC

13

13

Sort/Hvid

Sort/Hvid

22

22

Grøn

Grøn

12

12

Rød

Rød

21

21

11

11

-X1004

Amplifire

Loadcell

-

-

+

+

-W1007

+

+

DATADATA

-T1008

LoadCell

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

-K603

(6/3)

+2

0V

819

819

12345678910111213141516171819

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 48

+2

14

131413

0V

1201

1201

26

26

Sagsnr: 2010-11-24

Side 11 af 27

Antal brugte sider: 25

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

16

16

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Sidst ændret: 12/10/2012

Side titel: Modul 4 - Output

Konstruktør: SGT

25

25

15

15

24

24

14

14

23

23

13

13

-

+2

22

22

12

12

Hovedgaden 58

8832

21

21

11

11

5151

Empty To Left

.

551

Emty To Right

K1

0V

1019

+2

1019

12345678910111213141516171819

Skals

Kunde: Skals Maskinfabrik

-K604

10088070

X20DO 2322

(6/4)

Bus Output

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 49

1501

+2

1501

0V

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

26

26

16

16

Konstruktør: SGT

25

25

15

15

24

24

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 12 af 27

Antal brugte sider: 25

Sidst ændret: 12/10/2012

Side titel: Modul 1 - Input

10088060

X20BT 9400

Bus Input

14

14

23

23

13

13

-

Sort/Black411

Sort/Black

22

22

12

12

21

21

11

11

Sort/Black

Rød/Red

Rød/Red

Blå/Blue

Blå/Blue

Hvid/white

Hvid/white

X2X GND

Rød/Red411

X2X+

Blå/Blue411

X2X\

Hvid/White411

X2X

+2

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

-K605

(6/5)

-W207

+2

0V

1119

1119

12345678910111213141516171819

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 50

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

/-W1312

Multi/Multi

Sagsnr: 2010-11-24

21

21

Power

Power

21

21

8

8

Power1Bus In 32

Power1Bus In 32

5

5

Power24V / 0V

/-W1310

Multi/Multi

Weight Bottom Sensor

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 13 af 27

Antal brugte sider: 25

Sidst ændret: 11/27/2012

Side titel: Modul 1 - Input

Ready signal Left Ready signal Right

/-W1304

Multi/Multi

21

21

-X1305

X67DI1371

7

7

6

6

4

4

BUS OUT

BUS OUT

/-W1308

Multi/Multi

/-W1305

Multi/Multi

BUS Cabel

Dark Violet

Weight Close Sensor

Top Sensor input

Kunde: Skals Maskinfabrik

12345678910111213141516171819

Hovedgaden 58

8832

Skals

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 51

+2

0V0V

Filnavn:C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Sagsnr: 2010-11-24

-

+2

Konstruktør: SGT

Sidst udskrevet: 12/10/2012 11:00:42 PM

Godk.:

Side 15 af 27

Antal brugte sider: 25

Sidst ændret: 12/10/2012

Side titel: Sync signal

14 11

14 11

12

12

-K1

14 11

14 11

12

12

-K

(11/3)

(11/4)

/

66

-X43

55

-X43

44

-X43

33

-X43

--

-X1

+2+2

-X1

/-W1507

5

5

/

/

4

4

/

/-W1503

4

4

/

/

3

3

44

-X101

33

3030

2929

-X101

-9X

-9X

Emty To Right

Tømme signal Højre

Emty To Left

ømme signal Venstre

T

12345678910111213141516171819

Hovedgaden 58

8832

Skals

Kunde: Skals Maskinfabrik

1219

+2

1219

Projekt titel: Vægt 3 Render/ Weight 3 lines

Page 52

Part list

Page 53

PC|SCHEMATIC Automation Fil navn: C:\Scanstore\Scanstore\projekter\Skals - Vægt\Vægt_2 Render_V2

Part list

10065160..5703847533049

Varenummer Type MængdePos. Fabrikat

1

10065160 34PP045.0571-062

2

10088010

3

10088050

4

10088060

5

10088070

6

10088080

7

10088100

8

10088110

9

10088190

10

10088220

11

3250614565144

12

3303430215561

13

3389110201000

14

4PP045.0571-062

X20BT 9300

X20BT 9400

X20DO 2322

X20D02633

X20CS 1030

X67DI1371

OPS1050.1

RS185 69314011 4140

MZ528N

21556

VBF01

13

1

1

1

1

1

1

1

1

1

1

2

1

3389110888706

15

4008190077969

16

4008190444884

17

4008190996765

18

4008190996789

19

4536854407956

20

5703847533049

21

ZB4BS44

ZDU 2,5

ZDK 1.5 167430

ZDU 16 174523

ZPE 16 174525

G2R-1-SNDI 24DC

1492-RFB424

1

8

10

3

1

2

1

Kunde: Skals Maskinfabrik

Projekt titel: Vægt 3 Render/ Weight 3 lines

Sidetitel: Part list

Sidst udskrevet: 12/10/2012 11:00:42 PM

Sagsnr.: 2010-11-24

Projekt rev.:

Side rev.:

Sidst ændret: 12/10/2012

Side 20 af 27

Antal brugte sider: 25

Page 54

Layout

Page 55

Konstr.: SGT

Side rev: Sidst udskrevet: 12/10/2012

Godk.: Projekt rev:

Side 25 af 27Sidst ændret: 11/18/2012

Antal brugte sider: 25

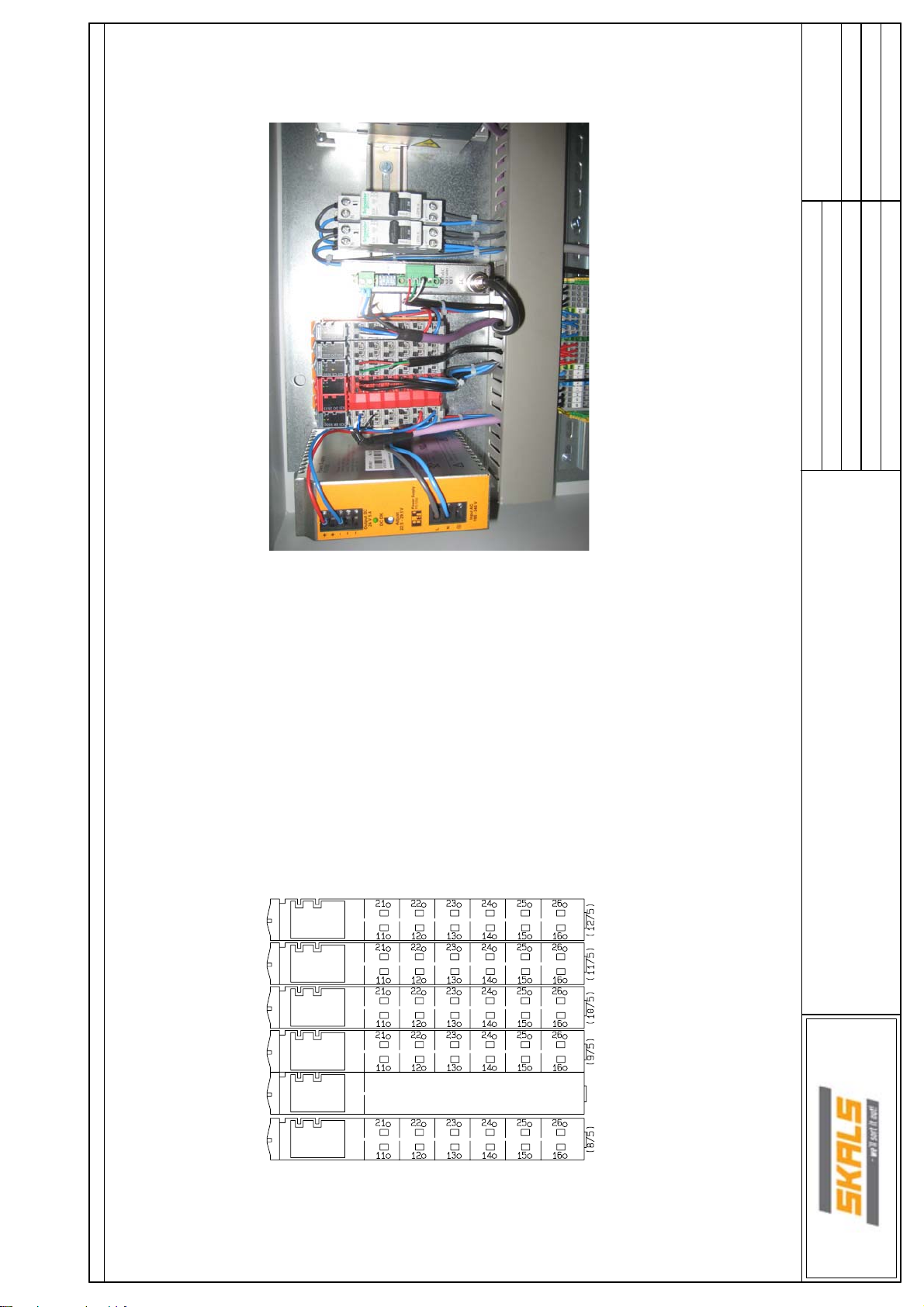

Inside cabinet Backside cabinet

Projekt t itel: Væg t 3 Render/ Weight 3 lines Sags nr: 2010-11-24

Kunde: Skals Maskinfabrik

Side titel: Mekanisk PLC

Side reference:

Side reference beskrivelse:

Page 56

15/4

2512/10/2012

25

27

1:1

7

7

6/1

6/3

6/3

6/4

6/5

9/3

9/8

9/10

11/3

11/4

2/5

3/5

4/5

1/1

1/7

2/6

3/6

4/6

10/8

1/3

2/4

2/8

PC|SCHEMATIC Automation

Page

Previous page:

Next page:

Number of pages:

Last printed:

Last correction:

Page rev.:

Project rev.:

Wexøe A/S Double feed through terminal

ZDK 1.5 167430

X20BT 9300

X20D02633

X20CS 1030

X20DO 2322

X20BT 9400

Relay, plug-in, 5-pin, SPDT, 10A, mech & LED indicators, coil suppress

Relay, plug-in, 5-pin, SPDT, 10A, mech & LED indicators, coil suppress

OMRON Electronics A/S

---

OMRON Electronics A/S

OMRON Electronics A/S

G2R-1-SNDI 24DC

G2R-1-SNDI 24DC

Telemecanique Main switch disconnector 20A 3P

Telemecanique

VBF01

OPS1050.1

4PP045.0571-062

4PP045.0571-062

4PP045.0571-062

Type SPSS 150kg

Appr. (date/sign.)

Constructor (project/page)

Drawing no.:

Project no.:Project title:

DCC: Scale:

Components list

Customer:

Vægt_2 Render_V2 12/10/2012

Page title:

Filename:

Page ref.:

Vægt 3 Render/ Weight 3 lines 26

Bus Dark Violet

4008190444884

-9X Weidmüller

Component Part no. ManufacturerPos. Type Source Description Position

1

10065160

-T305

20

10065160

-T405

-T1008

21

22

-W103

23

-W205

24

-W207

25

-W20826 Bus Dark Violet 3/8

-W30527 3/4

-W40528 4/4

3389110201000

10088190

-T107

18

10065160

-T205

19

10088050

10088080

10088100

10088070

10088060

-EHT_1

-IF4_4

-K601

-K602

-K603

-K604

-K605

-K903

-K908

2

3

4

5

6

7

8

9

10

4536854407956

-K910

-K1103

11

12

4536854407956

-M205

-K1104

13

-M305

14

15

-M405

16

-Q0101

17

Page 57

8/2

10/7

13/4

13/5

13/8

13/10

13/12

15/3

15/7

1/8

15/2

1/1

1/1

15/8

15/9

10/4

13/5

1/6

1/6

1/13

1/3

1/3

1/8

2512/10/2012

26

1:1

7

PC|SCHEMATIC Automation

Page

Previous page:

Next page:

Number of pages:

Last printed:

Last correction:

Page rev.:

Project rev.:

Feed through terminal

Double feed through terminal

Wexøe A/S

---

Weidmüller

Weidmüller

ZDU 2,5

ZDK 1.5 167430

Feed through terminal

---

Weidmüller

ZDU 16 174523

Double feed through terminal

PE terminal

---

---

Weidmüller

Weidmüller

ZDK 1.5 167430

ZPE 16 174525

Double feed through terminal

---

Weidmüller

ZDK 1.5 167430

RS185 69314011 4140

X67DI1371

Mcb iDPN 1P+N C10

Merlin Gerin

Merlin Gerin

21556

1492-RFB424

Mcb iDPN 1P+N C10

Merlin Gerin

Merlin Gerin

21556

Under voltage release MZ528N

Mushroom pushbutton red Ø30, push-turn

Feed through terminal

HAGER

Telemecanique

Wexøe A/S

HAGER

Telemecanique

Weidmüller

MZ528N

ZB4BS44

ZDU 2,5

4PP045.0571-062

Drawing no.:

Project no.:Project title:

DCC: Scale:

Components list

Vægt 3 Render/ Weight 3 lines 27

Customer:

Page title:

Appr. (date/sign.)

Constructor (project/page)

Vægt_2 Render_V2 12/10/2012

Filename:

Page ref.:

4008190444884

4008190444884

10088220

10088110

3303430215561

5703847533049

3303430215561

3250614565144

3389110888706

4008190077969

-X1

---

10088010

D410

4008190077969

4008190444884

4008190996765

4008190996789

-X43

-X101

-X1004

-X1305

-F106

-F106/1

-F113

-K103

-W802

-W1007

-W1304

-W1305

-W1308

-W1310

-W1312

-W1503

-W1507

-X1

-X1

-X10

-X10

---

Component Part no. ManufacturerPos. Type Source Description Position

---

-S103

---

---

=V1+K1

42

43

44

45

46

47

48

49

50

51

29

30

31

32

33

34

35

36

37

38

39

40

41

52

Loading...

Loading...