Page 1

The Sixth Sense AI-100

1/32 DIN Fuzzy Logic controller

User‘s Manual

a division of TTI, Inc.

8 Leroy Road, P.O. Box 1073, Williston, VT 05495-1073

1-800-884-4967• US & Canada

Fax: (802) 863-1193 • Phone: (802) 863-0085

www.ttiglobal.com • Email: sales

@

ttiglobal.com

sixth sense

Page 2

INTRODUCTION

General Description

The AI-100 is a fully programmable, microprocessor-based

temperature/process controller. It offers superior control with 200

msec sampling rate and by using fuzzy logic to enhance its P, I and

D parameters. The 4-digit 0.4” red LED display offers excellent

visibility on a unit that is 1/32 DIN in size.

The AI-100 is available with either 20-32V AC/DC or 90-264V AC

power supply. This is a single universal input unit that will accept

8 different thermocouple types, Pt100 RTDs, and a variety of linear

mA and VDC signals. The wide range of options for the two available outputs include relays, SSR drives, 4-20mA, 0-20mA, or

0-10VDC. Output #1 can be used in either a direct or reverse

action control situation with a programmable ramp rate. Output #2

can be used as a control output, as an alarm, or as a dwell timer.

Optional features include 2-wire RS-485 serial communications

with Windows 95™-based software, and Analog Retransmission of

process variable, setpoint variable or the percentage of control

output, as a 0-20 mA/4-20 mA DC signal.

The communications software package, COMM 4851, offers excellent graphics, bar and trend displays, and supports easy-to-use

database control and back-up capability.

FUZZY LOGIC

The function of Fuzzy Logic is to adjust the PID parameters

internally in order to make the control output more flexible and

adaptive to the process. One of the best analogies would compare Fuzzy Logic to the abilities of a good driver. The driver is

2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Fuzzy Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Input Range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Model Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Wiring & Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Negotiating the Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Learning the Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Primary Program Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Changing Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Begin Controlling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Auto-Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Flow Chart of Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Setting Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Scaling Analog Inputs/Setting Setpoint Limits . . . . . . . . . . . . . .24

Ramp Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Ramp & Soak/Dwell Function . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

Tool Program Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Manual Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Flow Chart of Tool Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Programmable Control Action . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Cooling Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Configurable Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

Locking Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37

Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

1

Page 3

4

SPECIFICATIONS

INPUT

Thermocouple(T/C): Type J,K,T,E,B,R,S,N

RTD: Pt100 ohm RTD (DIN or JIS)

Linear: Scalable. Refer to table on p.5

Accuracy: Refer to table on p.5

External Resistance: 100 ohm max.(for thermocouple)

Normal Mode Rejection: 60dB

Common Mode Rejection: 120dB

Sample Rate: 5 times/sec

CONTROL

Proportional Band: 0-360°F, 0-200°C, 0-3600 Process Units

Reset (Integral): 0-3600 seconds

Rate (derivative): 0-1000 seconds

Ramp rate: 0-55.55°C/min, 0-99.99°F/min,

0-99.99 Process Units(P.U.)/min

Dwell: 0-9999 minutes

Hysteresis: 0.1-11.0°C, 0.1-19.9°F, 0.1-199 P.U.

Cycle Time: 0-99 seconds

Control Action: Direct (cooling) and reverse(heating)

OUTPUT

Relay: SPST, 3A/240 VAC (resistive)

DC pulse: 24 VDC/20 mA max.

4 to 20 mA: Linear, max. load 500 ohms

0 to 20 mA: Linear, max. load 500 ohms

0 to 10 V: Linear, min. input impedance 500K ohms

ALARM

Relay: SPST, 3A/240 VAC (resistive)

INDICATION

Process Display: 0.4” red LED, 4 digits

Status Indicator: Control output and alarm

3

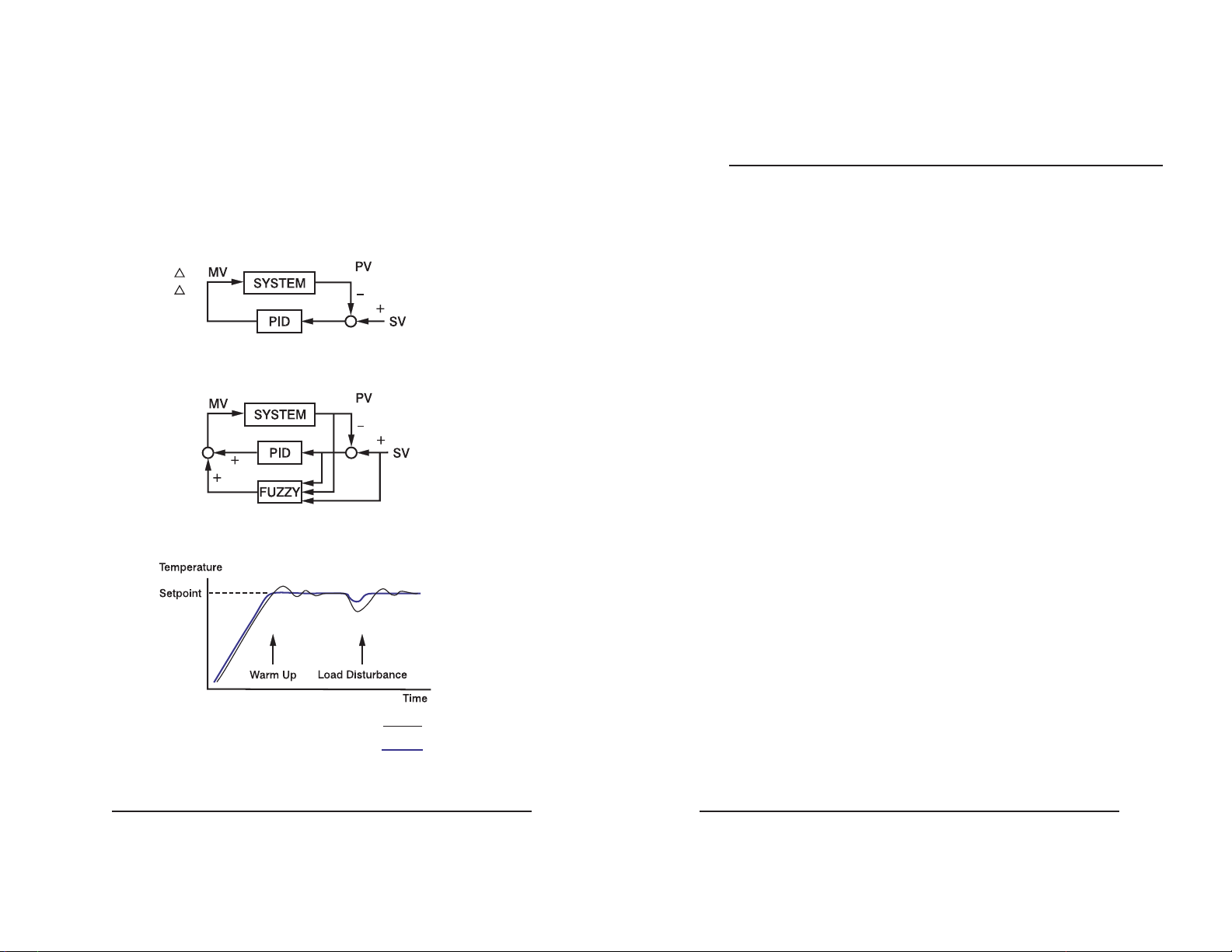

Figure 2. PID with fuzzy logic

Figure 3. PID vs. PID and fuzzy logic

PID control with proper tuning

PID + Fuzzy control

able to control a car well at a variety of speeds and under varying

circumstances by using knowledge gained through previous

experience.

Fuzzy Logic combined with PID control has been proven to be an

efficient method to improve control stability. This is illustrated in

figure 3.

Page 4

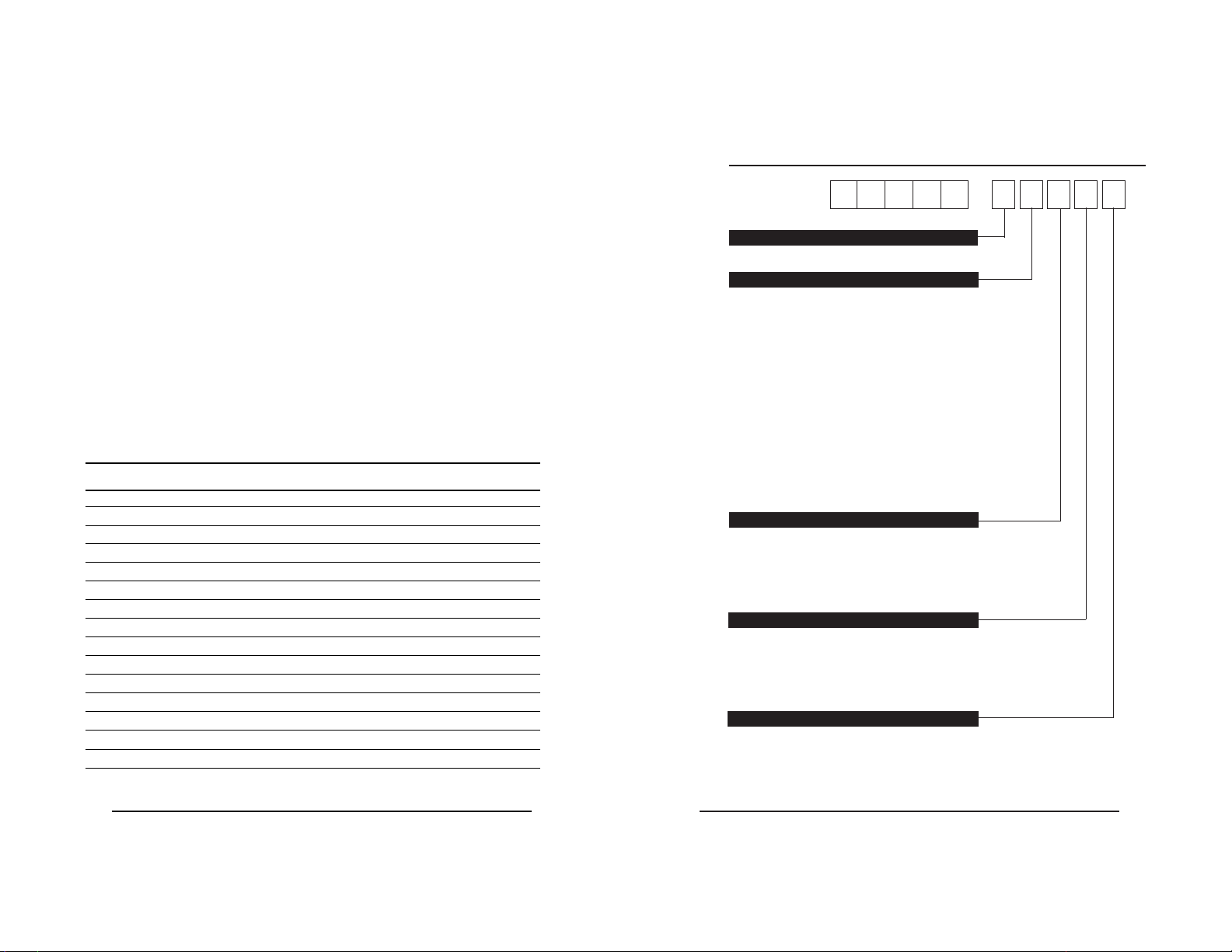

MODEL CONFIGURATION

6

A

I10 -

0

POWER INPUT

4 90-264VAC

5 20-32V AC/DC

INPUT SIGNAL

0 J - Iron-Constantan

1 K - Chromel-Alumel

2 T - Copper-Constantan

3 E - Chromel-Constantan

4 B - Pt30%Rh/Pt6%Rh

5 R - Pt13%Rh/Pt

6 S - Pt10%Rh/Pt

7 N - NICROSIL-NISIL

8 RTD - Pt100 (DIN)

9 RTD - Pt100 (JIS)

A 4-20mA

B 0-20mA

C 0-10V

D 1-5V

E 0-5V

F 0-1V

OUTPUT #1 OPTIONS

0 None

1 Relay

2 SSR Drive

3 4-20mA

4 0-20mA

5 0-10V

ALARM/OUTPUT #2 OPTIONS

0 None

1 Relay

2 SSR Drive

3 4-20mA

4 0-20mA

5 0-10V

AUXILIARY OPTIONS

0 None

1 RS-485 Communications

2 Retransmission 4-20mA/0-20mA

5

POWER

Rating: 90-264VAC, 50/60Hz or 20-32V AC/DC

Consumption: Less than 5VA

ENVIRONMENTAL & PHYSICAL

Safety: CE, UL & CSA Approved

Protection: NEMA 4X, IP66 (front panel)

Operating Temperature: -10 to 50°C (14 to 122°F)

Humidity: 0 to 90%RH (non-condensing)

Insulation: 20 Mohm min. (500 VDC)

Breakdown: AC2000V, 50/60Hz, 1 minute

Vibration: 10-55Hz, amplitude 1mm

Shock: 200 m/s2(20G)

Weight: 110 grams (3.87 oz.)

Dimension: 24(H) x 48(W) x 99mm (depth behind panel)

Panel cutout: 22.2mm(H) (+.3/-0) 45 mm(W) (+.5/-0)

Warranty: 2 years

RANGE AND ACCURACY OF INPUTS

SENSOR INPUT TYPE RANGE (°F) RANGE (°C) ACCURACY

J Iron-Constantan -58 to 1830 -50 to 999 ±3.6°F/±2°C

K Chromel-Alumel -58 to 2500 -50 to 1370 ±3.6°F/±2°C

T Copper-Constantan -454 to 752 -270 to 400 ±3.6°F/±2°C

E Chromel-Constantan -58 to 1382 -50 to 750 ±3.6°F/±2°C

B Pt30%Rh/Pt6%Rh 572 to 3272 300 to 1800 ±3.6°F/±2°C

R Pt13%Rh/Pt 32 to 3182 0 to 1750 ±3.6°F/±2°C

S Pt10%Rh/Pt 32 to 3182 0 to 1750 ±3.6°F/±2°C

N Nicrosil-Nisil -58 to 2372 -50 to 1300 ±3.6°F/±2°C

RTD Pt100 ohm (DIN) -328 to 842 -200 to 450 ±0.72°F/±0.4°C

RTD Pt100ohm (JIS) -328 to 842 -200 to 450 ±0.72°F/±0.4°C

LINEAR INPUTS (All scalable)

Input type Range Accuracy

4-20 mA, 0-20 mA, 0-1V, 0-5V, 1-5V, 0-10V -1400 to 9400 ±0.05% FS

Page 5

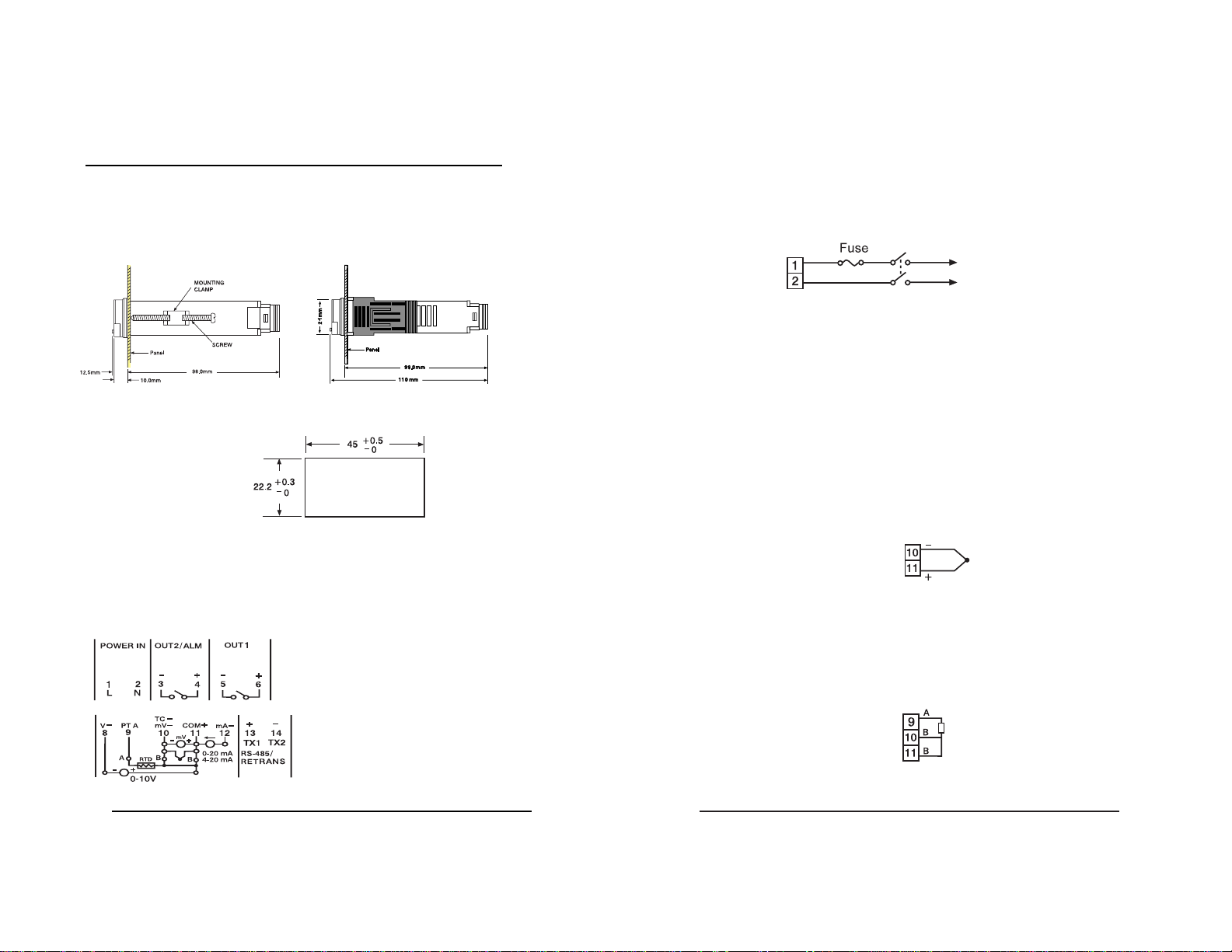

8

POWER SUPPLY

The controller is supplied to operate on either 90-264V AC or 2032V AC/DC. Check that the supply voltage corresponds to that

indicated on the product label before connecting power to the

controllers.

This equipment is designed for installation in an enclosure which

provides adequate protection against electric shock. The enclosure must be connected to earth ground.

THERMOCOUPLE INPUT

Thermocouple input connections are shown in the illustration

below. The thermocouple extension wire must be of proper type

and gauge, and should be run in a conduit, separate from any

power wiring. The resistance of the entire run should not exceed

100Ω.

Pt100 Ohm RTD INPUT

RTD connections are shown in the illustration below with the

compensating lead connected to terminal 11. For two-wire

RTD inputs, terminals 10 and 11 should be linked.

Power Supply Connections

Thermocouple Input Connections

RTD input Connections

Pt100

90~264V AC or

20-32V AC/DC

L

N

1A

INSTALLATION

MOUNTING

Install mounting clamp(s). Gently tighten clamp until the controller

fits snugly against the front panel.

Make panel cutout as

shown in figure

1.772”(W) X 0.874”(H)

WIRING

The following connections for outputs and inputs are provided on

the wiring diagram located at the rear of the housing:

7

NEMA brackets Mounting collar (non-NEMA)

Rear Terminal Connections

Units: mm

Page 6

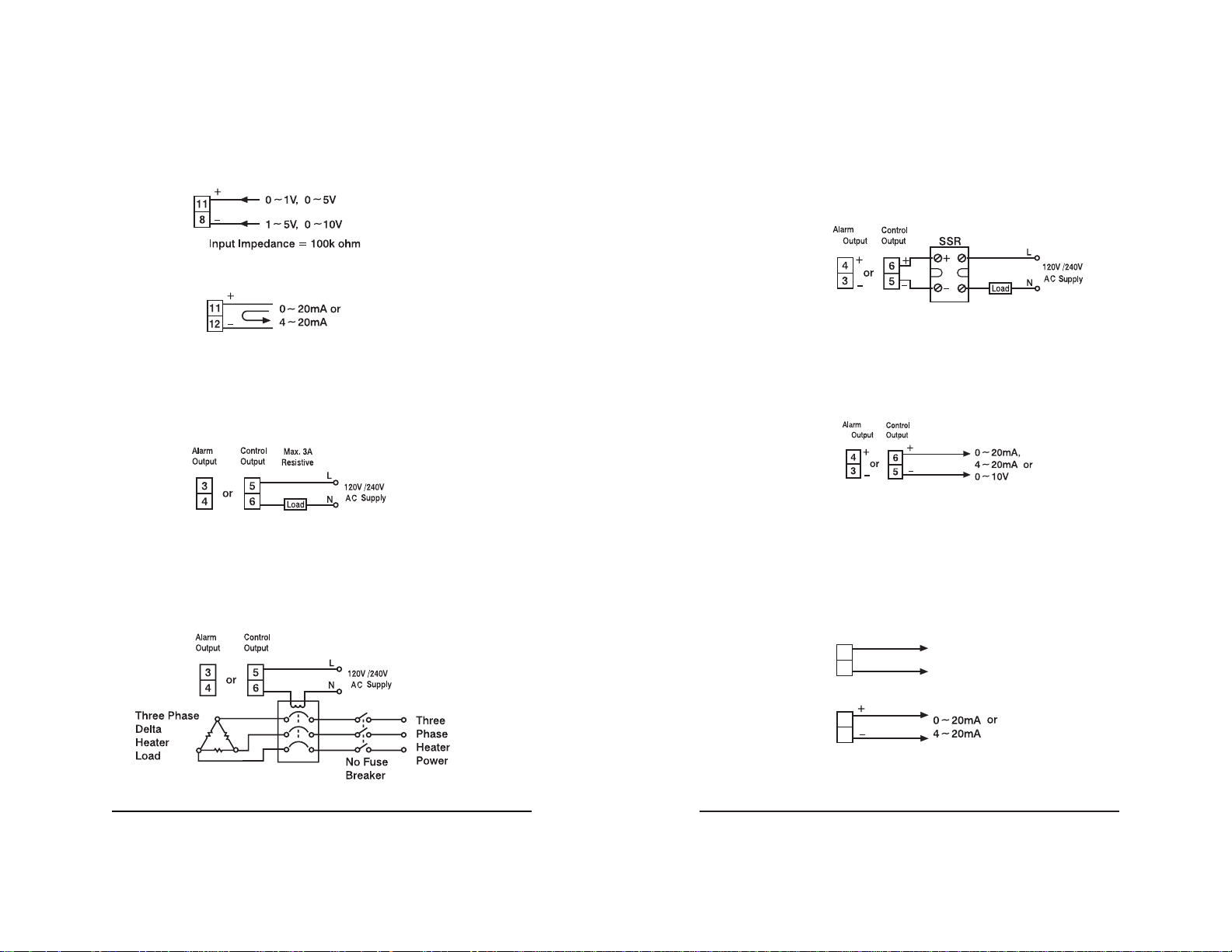

DC PULSE (SOLID-STATE RELAY DRIVE) OUTPUT

Controllers fitted with the DC pulse output produce a time-proportional non-isolated pulse voltage (0-24V nominal, output impedance 660Ω). The connections are shown in the illustration below.

DC LINEAR OUTPUT

There are three types of linear output modules that can be selected for the output. The connections are shown in the illustration

below.

RS-485 COMMUNICATIONS/ANALOG RETRANSMISSION

RS-485 serial communications or Analog retransmission of

process variable, setpoint, or manipulated variable can be selected as an optional feature. The connections are shown in the illustration below.

10

Pulsed DC output Connections

Linear DC output Connections

RS-485 Communications

Analog retransmission

DC LINEAR INPUT

DC linear voltage and current input connections are shown below.

RELAY OUTPUT DIRECT DRIVE

The illustration below shows connections for using the internal

relay to drive a small load. The current should not exceed 3 amps.

RELAY OUTPUT CONTACTOR DRIVE

The illustration below shows connections for using an external

relay to drive heavier loads.

9

VDC

mADC

Relay Contactor Drive Connections

Relay Direct Drive Connections

2nd

/

1

/

2nd

1

TX1

13

TX2

14

13

14

Page 7

12

LEARNING THE PARAMETERS

SV - Setpoint

This parameter is the target value for the process. It can be

adjusted throughout the range defined by the Low Scale Value

and High Scale Value

.

Set in degrees/engineering

units.

ASP1 - Alarm 1 Setpoint or Dwell Time

If output #2 is configured as an alarm this parameter sets the point

that the alarm will be activated. If output #2 is configured as a

Dwell Timer this parameter sets the amount of time to be counted.

Set in degrees/engineering units for alarms or minutes for timer.

Ramp - Ramp Rate

This determines the rate at which your process will approach setpoint. Setting this parameter to 0 will cause your system to

approach setpoint at maximum speed. Set in degrees/minute.

OFST - Offset Value for Manual Reset

For systems using proportional control only (Ti set to 0) this parameter will be adjusted to compensate for any deviation between

setpoint and process. Set 0-100% of Pb.

SHIF - Shift Process Value

This value will be added to the process value to correct for errors

or to synchronize a number of different units. Set in degrees/engineering units.

PB - Proportional Band

The proportional band is that area around main setpoint

where the control output is neither full on nor full off.

HYST - Hysteresis for ON/OFF Control

The hysteresis for output #1 is the area around the main setpoint

where the output does not change condition. It is intended to

eliminate relay chatter at setpoint for ON/OFF control applications.

11

NEGOTIATING THE MENU

When the controller is powered up, it automatically displays the

Process Variable (PV).

From the Process Variable (PV) display you can easily:

Press either the or key momentarily to view set-point.

or

Press the key momentarily to enter the Primary Program Menu.

or

Press the key and the key simultaneously to enter the

Tool Program Menu.

TOUCH KEYS FUNCTION DESCRIPTION

press for 3.2 seconds Enter key security level or to actuate selected tool program

&

&

press for 3.2 seconds parameters

&

&

&

press for 3.2 seconds start autotune.

OUT

ALM

F

Up key Press to select digit to change. Press and hold

Down key Press to select digit to change. Press and hold

Scroll key Press to select parameter in direct sequence

Long scroll/ Use to select protected parameters in higher

Reverse scroll/ Use to select parameter in reverse sequence or

Calibration to verify display accuracy for input types during

Verification calibration

Lock key Use to disable keypad operation to protect

Tool program key Press to select tool program in sequence

Reset/Exit key Press to unlock keypad operation, to reset

Autotune key Hold both keys for 3.2 seconds then release to

to increase value for parameter

to decrease value for parameter

or to select tool program parameters

display, to exit tool program, or to end autotune

and manual control execution.

Page 8

14

LOSC/HISC - Low/High Scale Range

If a thermocouple or RTD is being used these parameters will

establish the allowable range for the setpoint. If an analog input is

being used these parameters will establish the scaling range for

the process signal and the allowable range for the setpoint. Set in

temperature/engineering units.

PL1/PL2 - Power Limit for Heating and Cooling Outputs

These parameters limit the maximum percentage of power for the

control outputs. These are used on systems that cannot tolerate

100% power. Set from 0-100%.

INPT - Input Type Selection

Used to indicate what type of sensor input will be connected.

See

Range and Accuracy of Inputs on page 5 for available input types.

UNIT - Process Unit

Used to select the correct engineering units for the process.

(PU for Analog inputs, C or F for temperature applications).

RESO - Decimal Point Resolution

This parameter defines the position of the decimal point for the

process value and setpoint value. Set to 0,1 or 2 positions right

of the decimal point. (2 positions is reserved for linear inputs

only.)

CONA - Control Action of Output #1

Determines whether the output will be reverse acting, as in a

heating application, or direct, as in a cooling application. See

programmable control action on page 33.

A1MD - Alarm Mode Selection for Alarm #1

Refer to page 22 for the various alarm types available.

13

Code for “Addr” Retransmission

192 4~20mA, PV

193 4~20mA, SV

194 4~20mA, MV1 (Output 1)

195 4~20mA, MV2 (Output 2)

196 0~20mA, PV

197 0~20mA, SV

198 0~20mA, MV1 (Output 1)

199 0~20mA, MV2 (Output 2)

TI - Integral Time

The integral time is the speed at which a corrective increase or

decrease in output is made to compensate for offset which usually

accompanies proportional only processes. The more the integral time

entered, the slower the action. The less the integral time entered, the

faster the action. Enter a value that would eliminate offset without

overcompensation, resulting in process oscillation.

TD - Derivative Time

The derivative time is that time used in calculating rate of change

and thermal lag in helping eliminate overshoot which results in

response to process upsets. This overshoot usually accompanies

proportional only and proportional integral processes. The derivative action dampens proportional and integral action as it anticipates where the process should be. The more the derivative time

entered, the more the damping action. The less the derivative time

entered, the less damping action. Enter as much derivative time as

necessary to eliminate overshoot without overdamping the process

resulting in process oscillation.

ADDR -

Address of unit for serial communications/ Retransmission

This unit can be assigned a numerical address to identify it as one

of 191 stations on an RS-485 serial communications loop (set from

1-191) or for 4-20mA/0-20mA retransmission (set from 192-199).

Page 9

16

PRIMARY PROGRAM MENU

Press the key momentarily to enter the Primary Program

Menu.

Press the key momentarily to scroll through the Primary Program Menu.

Pause momentarily on a parameter to be changed. After 3.2 sec

the display will begin to toggle between the parameter and its current value.

Press either the or key momentarily to highlight the

numerical position to be changed.

Press and hold either the or key to increment or

decrement the desired position.

Press the key momentarily to continue scrolling through the

Primary Program Menu.

When you’ve reached the last parameter in a given level, press

and hold the key until that parameter stops flashing. This will

advance you to the next level of the Primary Program Menu.

15

A1SF - Alarm #1 Special Function

Selects a hold function or latch function for alarm #1. Also, used to

reconfigure alarm #1 as a dwell timer. Refer to page 22 for more infor-

mation. Set to

for cooling action on output #2.

CYC/CCYC - Proportional Cycle Time for Outputs #1 & #2

These parameters determine the duration of the duty cycle for time

proportioned outputs. Set from 0-99 seconds. Set to 0 for linear outputs.

CPB/DB - Cooling Proportional Band/Dead Band

Used only when output #2 is configured for cooling applications.

Refer to page 34 for a more detailed explanation.

Page 10

1817

CHANGING SETPOINT (SV)

Press either the or key momentarily to view set-point

Press either the or key momentarily to highlight the

numerical position to be changed.

Press and hold either the or key to increment or decrement the desired position.

After approximately 10 seconds the unit will automatically return

to reading the Process Variable (PV).

BEGIN CONTROLLING

1. Insure that the controller is properly wired for your application.

As soon as the unit is powered up it will begin trying to

control at the current setpoint.

2. Check the display of the controller. Make sure that it is

reading the actual temperature/engineering units.

3. If everything looks correct set the desired setpoint, go to the

auto-tune procedure (page 20) and initiate it. When autotune is

complete your system will be ready.

4. If you experience problems go to the troubleshooting section

(p.38).

AUTO-TUNING

Auto-tune is a procedure that will oscillate your process around

setpoint twice, testing the dynamics of your system and automatically setting the P, I, and D parameters.

You should auto-tune your system:

- during initial set-up.

- if setpoint is changed by a large amount.

- if sensor or output is changed.

TO COMPLETE THE AUTO-TUNE PROCEDURE;

1. Make sure all parameters are configured correctly.

2. Have system under normal load conditions.

3. Make sure Pb(Proportional band) is not 0.

4. Set the setpoint to the normal operating temperature.

Note: If system overshoot is likely to cause damage, reduce the

setpoint during autotune.

5. Press and hold the and keys for 3.2 seconds and then

release. The display will begin flashing and will continue to

flash throughout the auto-tune process.

Note: To abort the autotune process, press and release the

and keys during the first oscillation of the process.

Page 11

2019

FLOW CHART OF PARAMETERS

The following chart shows a typical (default) access sequence of parameters.

Normal Display Process value / setpoint value

Alarm 1 Set Point Value or Dwell

Time ( = or )

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

or

Long

Long

Ramp Rate

Offset Value for Manual Reset

(Integral Time TI=0 )

Shift Process Value

Proportional Band of Output 1

Integral (Reset) Time of Output 1

Derivative (Reset) Time of Output 1

Hysteresis of Alarm 1

Hysteresis of ON-OFF control

Address of the unit for the

communication

Low Scale of Range Adjust

for your process

High Scale of Range Adjust for

your process

Power Limit of Output 1

Power Limit of Output 2

Input Type Selection

Select Unit

Resolution Selection

Control Action of Output 1

Alarm 1 Mode

Alarm 1 Special Function

Proportional Cycle Time of Output 1

Cooling Cycle Time

Cooling P Band

Dead Band for PB and CPB

Low scale~high scale value (for Full Scale Alarm), -111.0 ~ 111.0°C or -199.9 ~199.9°F

(for Deviation and Deviation Band Alarm), 0~9999 minutes (for Dwell Time) **18.0°F

0-55.55°C/minute or 0 ~ 99.99°F/minute **0.00

0~100.0% **0.0

0~200.0°C or 0~360.0 °F, 0-3600 P.U.

0:For ON-OFF control

**18.0°F

-111.0~111.0 °C or -199.9~199.9°F **0.0°F

0~3600 seconds**120

0~1000 seconds**40

0~11.0°C or 0.1~ 19.9°F **00.1°F

0~11.0°C or 0.1~ 19.9°F **00.1°F

0~40 **00

Minimum value for the selected input (INPUT) to

High Scale (HISC) **000.0°F

Low Scale (LOSC) to maximum value for the

selected input (INPUT) **999.9°F

0~100%

**100

0~100%

**100

0~99 Seconds, 0 for

Linear current/Vol-

tage output. **20

0~99 Seconds, 0 for

Linear current/Vol-

tage output. **20

0.0~200.0°C or 0.1~

360.0°F **18.0°F

-111.0~111.0°C or

-199.9~199.9°F,

**000.0°F

:No Special Function

:Alarm with Latch Function

:Alarm with Hold Function

:Alarm with Latch & Hold Function

:Dwell Timer ON as Time Out.

:Dwell Timer OFF as Time Out.

:Proportional cooling

:J TYPE T/C

:K TYPE T/C

:T TYPE T/C

:E TYPE T/C

:B TYPE T/C

:R TYPE T/C

:S TYPE T/C

:N TYPE T/C

:PT100 DIN

:PT100 JIS

:4~20MA

:0~20MA

:0~1V

:0~5V

:1~5V

:0~10V

Note: Using the Tool Program the display sequence and the security level for any parameter are configurable. Also, any unused

parameter can be removed from the display sequence to simplify the operation.

**: Denotes the default setting

Long : Press and hold for at least 3.2 seconds

:Direct

(Cooling)

Action.

:Reverse

(Heating)

Action.

:degree C

:degree F

:process unit

Voltage or

Current Input)

:No Decimal

Point Used

:1 Digit Decimal

:2 Digit Decimal

(only for Linear

Voltage or

Current Input)

Level 0

Level 1

Level 2

or

or

or

Low scale to high scale value **212.0°F

**

:Deviation High

Alarm.

:Deviation Low

Alarm.

:Deviation Band

High Alarm.

:Deviation Band

Low Alarm.

:Full Scale High

Alarm.

Full Scale Low

Alarm.

**

or

**

**

**

**

Page 12

Alarm 1 mode - This parameter determines the alarm

type that is to be used, such as a deviation alarm, a

band alarm, or an absolute alarm.

Alarm 1 Spec. Func.- This parameter assigns special

functions to Alarm 1 such as a holding feature

that prevents an alarm during start up or a latch function that prevents the alarm from clearing

unless power is interrupted.

Example: Deviation low alarm with Hold function.

22

ALARMS

This controller is available with a second output that can be configured for a variety of alarm types. The following parameters in

the Primary Program Menu are used to configure the alarms;

Alarm 1 setpoint - This parameter determines the point

that alarm 1 will be activated.

Example: Deviation high alarm with no special function

SV= 100°C, ASP1= 10°C, AHY1= 4°C

Alarm 1 Hysteresis - This parameter establishes an area

around Alarm 1 setpoint where the alarm relay will not

change states.

21

Alarm ON

Low Alarm

Setpoint

Alarm OFF Alarm OFF

Low Alarm

Hysteresis

Setpoint

Main

High Alarm

Hysteresis

Alarm ON

High Alarm

Setpoint

Code

Type

1 Full scale high

2 Full scale low

3 Deviation high

4 Deviation low

7 Deviation band high

8 Deviation band low

Alarm Set point

Alarm Set point

Alarm Set point

Set point

Alarm Set point

Set point

Alarm Set point

Set point

Set point

PV

PV

PV

PV

PV

PV

Page 13

24

Press either the or key momentarily to highlight the

numerical position to be changed.

Press and hold either the or key to select the desired

alarm set point.

Press the key momentarily to continue scrolling through the

Primary Program Menu until you come to .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and its current setting.

Press either the or key momentarily to highlight the

numerical position to be changed.

Press and hold either the or key to select the desired

amount of alarm hysteresis.

SCALING ANALOG INPUTS/SETTING SETPOINT LIMITS

When an analog input such

as 4-20 mA signal is applied

to this unit it is necessary to

tell the unit how this signal

is to be scaled.

23

SETTING ALARMS

To set an alarm:

Press the key momentarily to enter the Primary Program

Menu.

Press the key momentarily to scroll through the Primary Program Menu until you come to .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and its current setting.

Press and hold either the or key to select the desired

alarm type.

Press the key momentarily to continue scrolling through the

Primary Program Menu until you come to .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and its current setting.

Press and hold either the or key to select the desired

alarm special function.

Press the key momentarily to continue scrolling through the

Primary Program Menu until you come to .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and its current setting.

SCALING 1-5V dc AND 4-20mA dcINPUT RANGES

Program a 4-20mA dc signal for 0 to 100 P.U.

Example:

Input Type

4-20mA dc

Program to 0

to 100

Full Range = (100-0) = 100 Engineering Units

-5 0 100 105

5% 5%

Minimum/Maximum Range

-1400...9400 Enginerring Units

Setpoint Range

Indicating Range

Page 14

26

RAMP FUNCTION

If the ramp function is enabled the process will increase or

decrease, during initial power up and setpoint changes, at a rate

determined by the parameter which can be adjusted in

units/minute. This function will be disabled when is set

to zero.

TO SET A RAMP RATE;

Press the key momentarily to enter the Primary Program

Menu.

Press the key momentarily to scroll through the Primary Program Menu until you come to .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and its current value.

Press either the or key momentarily to highlight the

numerical position to be changed.

Press and hold either the or key to increment or decrement the desired position.

Press the key momentarily to continue scrolling through the

Primary Program Menu.

25

When a thermocouple or RTD

is applied to this controller it

may be necessary to establish

limits that the setpoint can be

set within in order to protect

the system from over/ undertemperature situations.

Parameters (zero

point/lower setpoint limit) and (span point/upper setpoint

limit) are used to scale analog inputs or to establish setpoint

limits.

TO SET THESE PARAMETERS;

Press the key momentarily to enter the Primary Program

Menu.

Press the key momentarily to scroll through the Primary Program Menu until you come to / .

Pause momentarily. After 3.2 sec the display will begin to toggle

between / and its current setting.

Press either the or key momentarily to highlight the

numerical position to be changed.

Press and hold either the or key to enter the desired

value.

SCALING THERMOCOUPLE AND RTD(Pt100) INPUT RANGES

Program a J thermocouple for 50 to 500 F

Example:

Input Type

J Thermocouple

Program to 50

to 500

Full Range = (500-50) = 450 F

27.5 50 500 522.5

5% 5%

Minimum/Maximum Range

32 . . . . . . . . . . . . .1832 F

Setpoint Range

Indicating Range

Change of Setpoint

Page 15

28

Press and hold either the or key to increment or decrement to the desired position, to turn the relay on after the

amount of time defined by or to turn the relay off

after the amount of time defined by .

Press the key momentarily to continue scrolling through the

Primary Program Menu until you come to parameter .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and its current value.

Press either the or key momentarily to highlight the

numerical position to be changed.

Press and hold either the or key to increment or

decrement the desired time setting.

27

RAMP & SOAK/DWELL FUNCTION

A dwell timer has been incorporated into this controller.

Alarm #1 can be configured by setting = or

to provide either a dwell function or a soak function to be

used in conjunction with the ramp function.

The ramp and soak function will allow the system to be programmed to approach setpoint at a specific ramp rate, hold the

setpoint temperature for a set amount of time and then shut off the

alarm relay. When the output is wired in series with the alarm

relay, the output will turn off when the alarm relay shuts off. This

will end the soak cycle and return the process to ambient conditions until the controller is reset.

TO SET A SOAK/DWELL TIME

Follow the procedure outlined in Ramp Function to set a ramp rate.

While in the Primary Program Menu continue to scroll until you

come to parameter .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and its current value.

continued on page 28

Page 16

TOOL PROGRAM MENU

Press the key and the key simultaneously to enter the

Tool Program Menu.

Press the key and the key simultaneously to scroll

through the main headings of the Tool Program Menu.

Press the key to access the parameters under each main

heading within the Tool Program Menu.

Pause momentarily on a parameter to be changed. After 3.2 sec

the display will begin to toggle between the parameter and its current value.

Press either the or key momentarily to highlight the

numerical position to be changed.

Press and hold either the or key to increment or decrement the desired position.

Press the key momentarily to continue scrolling through the

parameters within that heading,

or

Press the key and the key simultaneously to continue

scrolling through the main headings of the Tool Program Menu.

MANUAL CONTROL

The outputs of this controller can be used in a manual mode. This

enables the operator to apply a specific percentage of power to

the system.

To use this unit in manual mode:

Enter the Tool Program Menu by pressing the and the

key simultaneously.

The display will toggle between and .

Press the key momentarily.

The display will toggle between the process variable and the cur-

rent output percentage .

To change output #1 skip this step, to change output #2 press the

key momentarily to display the output percentage for the

cooling output .

Press and hold the key for 3.2 seconds.

The display will begin flashing as it toggles between the process

variable and .

Use the and keys to highlight and change the display

to the desired output percentage.

Example:

is viewed with cycle

time =10 sec.

The output 1 will act as shown:

29 30

Page 17

3231

Enter the manual control mode.

Allow to adjust the percentage value of

Heating output by using or . 000~100%

Flow Chart of Tool Programs

or

View the percentage power

of Heating output.

or

or

or

or

or

or

or

or

or

View the percentage power

of Cooling output (Alarm).

View the maximum (peak) process value.

View the minimum (peak) process value.

Adjust the cold-junction

compensation code.

(-19.9~42.7 count)

Adjust the drift

compensation code.

(-6.6~6.6 count)

Select a proper status for Output .

:Output ON ** : : Output OFF

Select a proper status for Alarm .

** :Alarm ON : Alarm OFF

Select Lock or Free for the Security Level 0.

: Protect (Lock) all the Level 0 parameters.

** : Allow all the Level 0 parameters to be adjustable.

Select Lock or Free for the Security Level 1.

: Protect (Lock) all the Level 1 parameters.

** : Allow all the Level 1 parameters to be adjustable.

Select Lock or Free for the Security Level 2.

: Protect (Lock) all the Level 2 parameters.

** : Allow all the Level 2 parameters to be adjustable.

Change the value of

security level for the

selected parameter.

Change the value of

security level for the

selected parameter.

Display the rest of

parameters according

to the standard access

sequence.

Change the value of

security level for the

selected parameter.

Enter the updated

security level of ASP1.

Enter the updated

security level of RAMP.

Enter the manual control mode.

Allow to adjust the percentage value of

Cooling output (Alarm) by using or . 000~100%

Reset the maximum and

minimum process values.

Reset the maximum and

minimum process values.

Calibrate the A-D and enter the

cold-junction compensation

Calibrate the 0~20mA and enter it.

Enter the drift compensation code.

Enter the status.

Enter the status.

Enter the selection

Enter the selection

Enter the selection

Enter the updated

security level of DB.

Hand (manual)

control.

Read peak

process value.

Calibrate

A-D converter*.

Define protection

mode for the

status of control

and alarm

outputs 1 & 2 to

ensure a safe

condition while

the control fails.

Lock

parameters.

Configure

security

levels for all

parameters.

:Security LEVEL

= 0 :Put the parameter

in LEVEL 0.

= 1 :Put the parameter

in LEVEL 1.

= 2 :Put the parameter

in LEVEL 2.

=3 :Mask parameter

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

Long

* Do not proceed through this section unless there is a definite need to re-calibrate the controller.

All previous calibration data will be lost.

Page 18

34

COOLING CONTROL

This controller has the option of being configured as a single or a

dual output controller.

The alarm output can be used as a control output by setting

parameter in the Primary Program Menu to

.

Once this is done the following parameters are used as output #2

control parameters;

CPB: Cooling Proportional Band

DB: Dead Band

CCYC: Cooling Cycle Time

PROGRAMMABLE CONTROL ACTION

Output #1 can be used in a reverse action configuration (heating

applications) or in a direct action configuration (cooling applica-

tions) by adjusting parameter .

To adjust the control action of output #1;

Press the key momentarily to enter the Primary Program

Menu.

Press the key momentarily to scroll through the Primary Program Menu until you come to .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and its current setting.

Press and hold either the or key to select the desired

control action ( = direct / = reverse).

33

100%

Output

0%

Reverse Action

PB

Output

PV

100%

0%

Direct Action

PB

PV

Main Setpoint

Note: PB = Proportional Band

Main Setpoint

Page 19

36

TO ASSIGN PARAMETERS TO A SPECIFIC LEVEL

Press the key and the key simultaneously to enter the

Tool Program Menu.

Press the key and the key simultaneously to scroll

through the Tool Program Menu until you come to .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and .

Press the key to access the parameters under this, contained

within the primary program menu and their current menu level.

Pause momentarily on a parameter to be changed. After 3.2 sec

the display will begin to toggle between the parameter and the

level it is currently assigned to.

Press and hold either the or key to increment or decrement to the menu level desired.

Press and hold the key for 3.2 sec to register the selection.

35

CONFIGURABLE MENUS

This controller gives you the flexibility to configure the menus in a

way that is most convenient for your application. There are four

menu levels that parameters in the primary program menu can be

assigned to.

-

This is the first group of parameters within the Primary

Program Menu. Locate parameters here that need to

be changed frequently or that need to be accessed

easily.

-

This is the second group of parameters within the

Primary Program Menu. Locate parameters here that

need to be accessed but not frequently.

-

This is the third group of parameters within the

Primary Program Menu. Locate parameters here that

are specific to your application but are not going to be

changed.

-

This is a level used to mask parameters that are not

used for your application or parameters that are not to

be accessed by the operator.

continued on page 36

Page 20

ERROR MESSAGES

Symptom Probable Cause(s) Solution

Process display shows: - Sensor break - Replace RTD or sensor

- Use manual mode

operation

Process display shows: - Input signal beyond the - Replace sensor

low range, sensor fails - Check sensor or thermocouple

type, correct input selection

Process display shows: - Input signal beyond the - Replace sensor

high range, sensor fails - Check sensor or thermocouple

type, correct input selection

Process display shows: - A to D module damage - Replace module

- Check for outside source of

damage such as transient

voltage spikes

Process display shows: - Incorrect operation of - Repeat procedure.

auto tune procedure Increase Prop. band to a

- Manual mode is not number larger than 0.

allowed for an ON-OFF

control system

Process display shows: - Check-sum error, values - Check and reconfigure

in memory may have control parameters

changed accidentally.

Process display shows: - Fail to enter data into - Replace EEPROM

EEPROM

Process display shows: - Overflow error, data out - Check if there is noise

of range during coming in.

execution of program - Replace EEPROM.

Process Display shows: - Attempt to change a - UNLOCK procedure stated in

locked parameter the flow chart of tool programs.

38

LOCKING MENUS

The various menu levels within the Primary Program menu can be

left free so that information can be viewed as well as changed, or

any of the levels can be locked so that the information can only be

viewed but not changed.

TO LOCK A MENU LEVEL WITHIN THE PRIMARY PROGRAM MENU

Press the key and the key simultaneously to enter the

Tool Program Menu.

Press the key and the key simultaneously to scroll

through the Tool Program Menu until you come to .

Pause momentarily. After 3.2 sec the display will begin to toggle

between and .

Press the key to access the parameters -

.

Pause momentarily on a menu level to be changed. After 3.2 sec

the display will begin to toggle between the parameter and the

lock setting it is currently set to.

Press and hold either the or key to increment or decrement to the lock level desired ( = locked, =

accessible).

Press and hold the key for 3.2 sec to register the selection.

37

Loading...

Loading...