ASSEMBLY, USE AND MAINTENANCE

SPARE PARTS LIST

FINISHING MOWERS

SM/230

01/07

2

WARRANTY

On delivery, check that the machine has not been damaged during transport and that

all the attachments are present. Claims must be made in writing to the agent within 8

days of receipt.

The manufacturer warrants new machinery at the time of delivery to the original

purchaser to be free from defects in material and workmanship if properly set up and

operated in accordance with this Operator’s Manual.

The manufacturer undertakes to repair or replace free of charge any defective part

which should be returned by the purchaser (freight prepaid) and found to be defective

by inspection authorized by the manufacturer during the warranty period.

This warranty will be valid for 12 (twelve) months from the delivery of goods to the

original purchaser .

In case the customer is not in a position to return the defective part to the

manufacturer , the manufacturer cannot be held responsible for any cost due for

repair or replacement of any part of the machine , he will only supply the part(s)

required for the repair and/or replacement.

The warranty is null and void when it is evident that the machine has been improperly

used or however repaired without authorization.

The manufacturer undertakes no responsibility for any obligation or agreement

reached by any employers, agents or dealers, which are not in compliance whit the

above warranty . The manufacturer cannot be held responsible for the consequent

damages. This warranty substitutes any other warranty , express or implied , and any

other manufacturer’s obligation.

CHAPTHER

1) GUIDE TO THE SIGNS

2) General summary of safety and accident-prevention instructions

3) PRODUCT IDENTIFICATION

4) DELIVERY AND ASSEMBLY

5) ADJUSTMENT, PREPARATION AND USE

6) MAINTENANCE DIRECTIONS

7) SPARE PARTS LIST

3

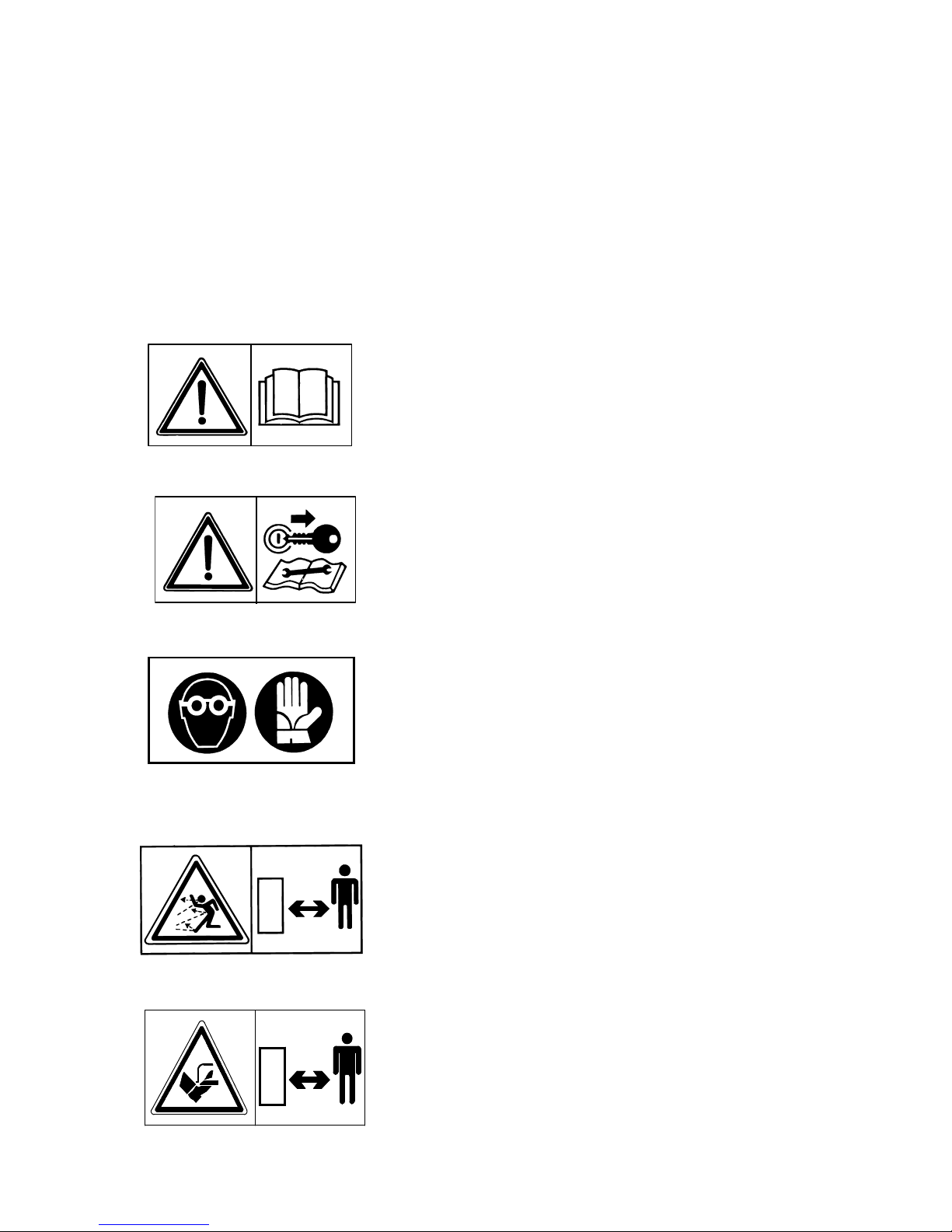

1) GUIDE TO THE SIGNS AND SYMBOLS USED ON THE

MACHINE

IMPORTANT

These signs and symbols give information to the operator on how to make the best

use of the machine so as to prolong life, avoid damage, optimise work and, above all,

to avoid injury to the operator and anyone within range of the machine.

WARNING SIGNS

1) Before beginning operations, read the instruction

manual carefully.

2) Before doing any maintenance or repair work,

stop the machine at a suitable spot. Turn off the

tractor motor, apply the brake, remove the key from

the ignition and consult this manual.

3) This is a warning to use proper accident

protection when carrying out maintenance and

repairs

DANGER SIGNS

4) Risk of possible ejection of blunt objects.

Keep a safe distance from the machine.

5) Indicates that there is a risk of cutting one’s foot.

Keep your distance.

4

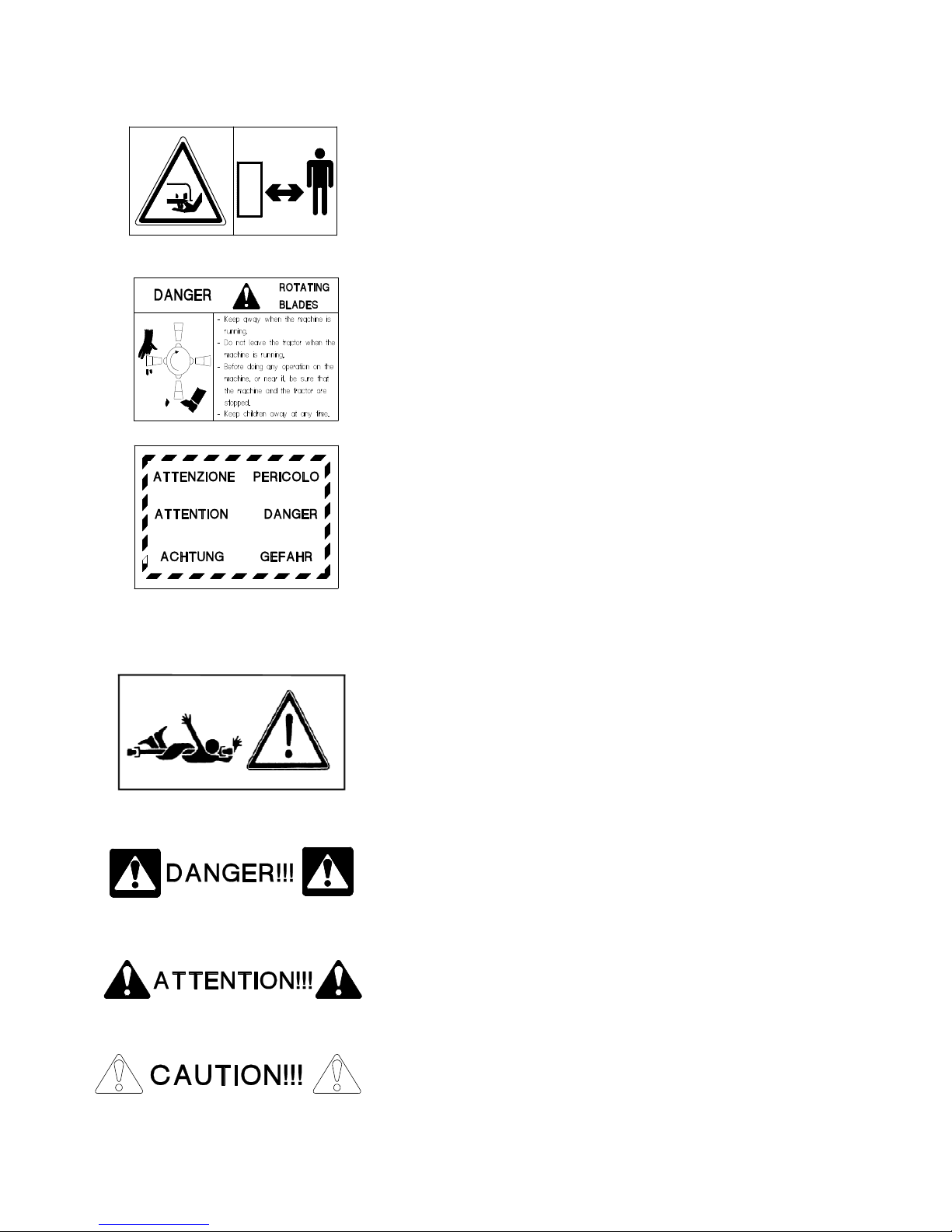

6) Indicates that there is a risk of cutting one’s hand.

Keep your distance.

7) Warns the danger of cutting blade.

8) Generic danger.

9) Indicates that it is dangerous to touch the cardan

(P.T.O.) shaft. For all the other information regarding the

cardan shaft, see the use and maintenance booklet

specifically for the cardan shaft which, together with this

manual, makes up the documentation on safety, use and

maintenance of the machine.

10) Indicates an impeding dangerous situation which, if

not avoided, will cause death or severe personal injury.

11) This indicates a potential danger which, if not

avoided, could cause serious personal injury. It also

indicates danger when removing protective guards.

12) Indicates a potentially dangerous situation which,

if not avoided, can provoke less severe or minor

injuries.

5

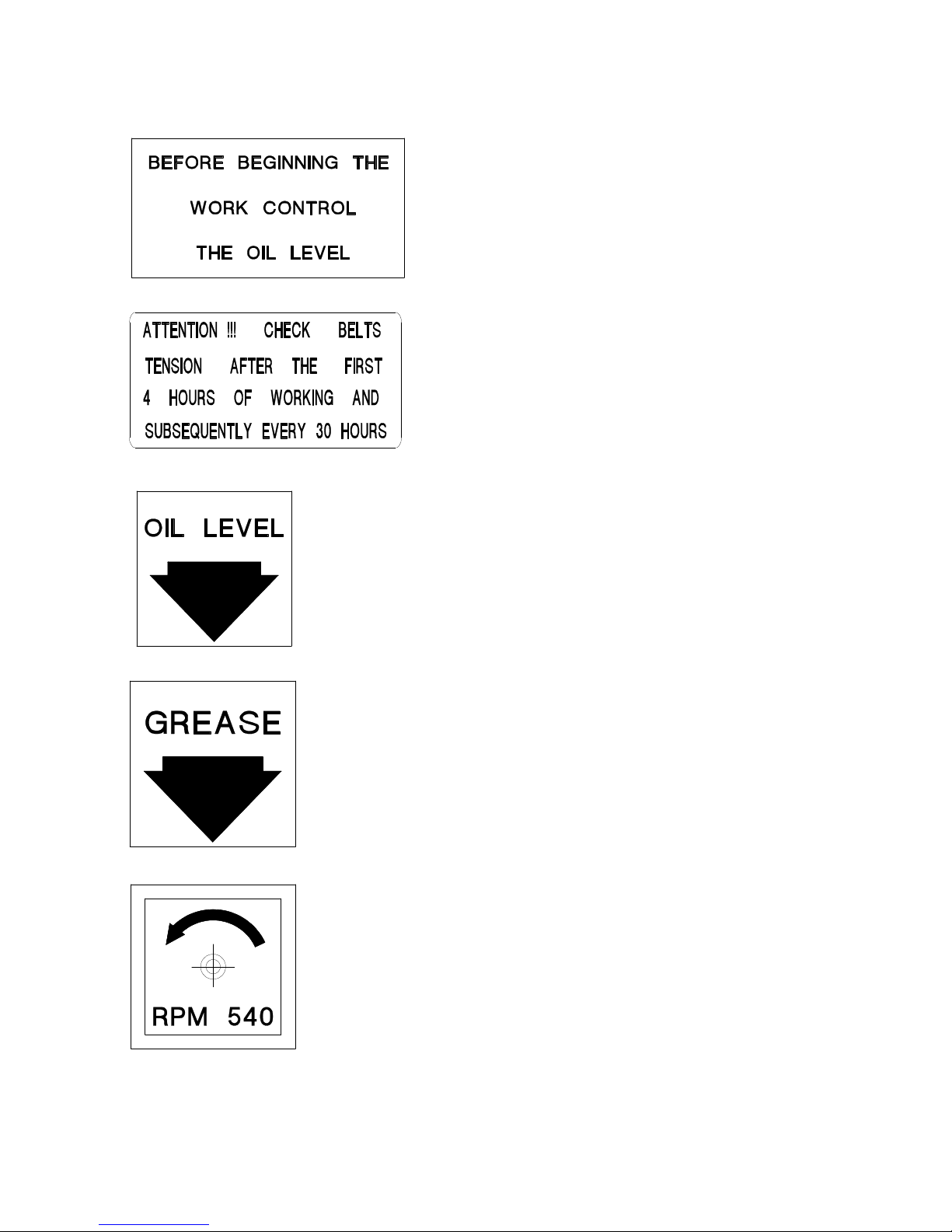

INDICATION SIGNS

13) This indicates to check the oil level.

14) This indicates to check the belts tension.

15) This indicates the cap oil level.

16) Indicates a greasing points.

17) Shows the direction of rotation of the power takeoff

and the maximum number of revolutions.

NOTE: All the signs and symbols so far shown appear in the manual. Some of these

are also on the machine: for their location, the diagram on page 10.

6

GENERAL SUMMARY OF SAFETY AND ACCIDENT

PREVENTION INSTRUCTIONS

Read all the directions carefully before using the machine. When in doubt, seek

advice from the manufacturers.

The manufacturing company declines all responsibility for non-compliance with the

following safety and accident-prevention instructions.

1- Pay attention to the danger signs and symbols in this manual and on the machine.

2- Do not touch moving parts.

3- All work on the machine (including adjustments) must always be carried out with

the tractor immobilized and the engine switched off.

4- On no account may persons or animals be carried on the machine.

5- Driving the tractor with the machine connected is absolutely forbidden to persons

lacking suitable experience, or who are in poor health, or who do not have a

suitable driving license.

6- All accident-prevention measures recommended in this manual should be

scrupulously observed.

7- Connecting the machine to the tractor creates a different weight distribution on the

axles and so it is essential to ensure that the tractor-machine combination is stable

in all anticipated working conditions. It is therefore necessary to have exact

instructions from the tractor manufacturers. If such instructions are not available,

suitable tests should be conducted in safe conditions in order to assess stability.

8- Once the machine is connected, it can only be controlled through a Cardan shaft

complete with the required overload protection and guard secured with the

appropriate small chains. Be aware of the rotational direction of the Cardan shaft.

9- Before operating the tractor and machine, check that all transport and operational

safety devices are complete and working.

10- When driving on public roads, you should comply with the Highway Code

regulations for the country concerned.

11- Do not exceed the tractor axle maximum weight and the total mobile weight. Heed

transport regulations.

12- Before starting work, familiarize yourself with the control devices and how they

work.

13- Wear suitable clothes. Do not wear clothing which is loose or which could

become entangled in rotating or moving parts.

14- Connect the machine to a suitably powerful tractor by using an appropriate lifting

unit and in accordance with instructions.

7

15- Take maximum care when connecting and disconnecting the machine to and from

the tractor.

16- The machine and any road transport attachments must bear the appropriate signs

and symbols and have suitable protection.

17- Never leave the driving seat when the tractor is running.

18- It is extremely important to appreciate that road holding, steering and braking may

be significantly affected with the machine attached.

19- When turning corners with the machine attached, be aware of the fact that the

centrifugal force will alter due to the change in the center of gravity.

20- Before engaging the power takeoff check the preset revolution speed. Do not

change speed from 540 rpm to 1000 rpm.

21- Under no circumstances should anybody stand near the machine or any moving

parts. It is the duty of the operator to ensure that this requirement is respected.

22- Before leaving the tractor, lower the machine with the lifting unit, stop the engine,

apply the parking brake and remove the ignition key from the instrument panel.

23- Under no circumstances should anybody go between the tractor and the machine

when the engine is running and the Cardan shaft is engaged, especially without

first having applied the parking brake and placed chocks against the wheels.

24- Before connecting or disconnecting the machine to or from the 3-point linkage,

put the lifting unit lever into the locked position.

25- The connection pins on the machine must match the connection sockets on the

lifting unit.

26- During transport, secure the lateral lifting arms with the appropriate chains and

tighteners.

27- When the machine is raised during road transport, put the tractor's hydraulic lifter

lever into the locked position.

8

28- Only use the Cardan shaft provided by the manufacturer and, in case of

replacement, substitute it with one having the same characteristics.

29- Regularly check all protection on the Cardan shaft. This should always be in

excellent condition and securely fixed.

30- It is important to ensure that the protection on the Cardan shaft is complete.

31- Connection and disconnection of the Cardan shaft must be carried out with the

engine switched off.

32- Pay particular attention to the correct connection and safety of the Cardan shaft

and the power takeoffs on the machine and the tractor.

33- Prevent the cardan shaft protection from rotating using the chains supplied.

34- Before engaging the power takeoff, make sure that there are no people or animals

in the vicinity and that the selected engine speed corresponds to that permitted.

Never go above the maximum permitted.

35- Do not engage the power takeoff when the engine is not running.

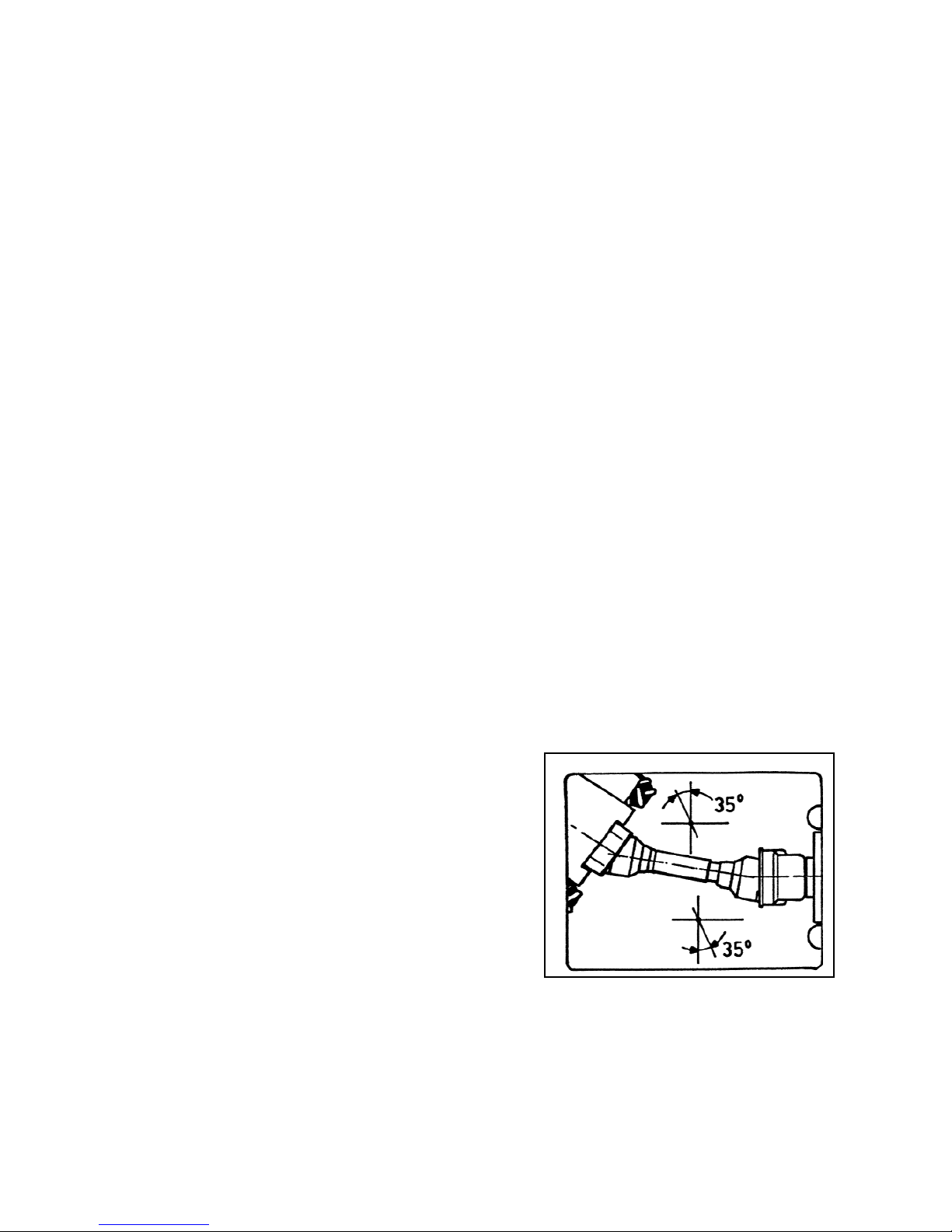

36- Always disengage the power takeoff when the Cardan shaft is at too wide an angle

(it should never be more than 35° Fig. 3.2) and when it is not in use.

37- Only clean and grease the Cardan shaft when the power takeoff is disengaged, the

engine is off, the parking brake is applied and the ignition key is removed.

38- On disconnecting the Cardan shaft, replace the protective hood on the power

takeoff shaft.

39- Prolonged use of the machine can cause the drive boxes to become hot. To avoid

any risk of getting burnt, avoid touching these areas both during se and some time

afterwards.

40- Periodically check screws and nuts for

tightness and grip. Tighten if necessary.

41- When carrying out maintenance work or

replacing the blades, raise the machine and

rest on adequate supports.

42- Use the quantities of grease and oil

advised.

43- Spare parts must meet the requirements as

defined by the manufacturer. Use only

original spare parts.

44- Safety decals must always be clearly

visible. They must be kept clean and

replaced if they become too illegible (they can be ordered from the agent if

necessary).

45- The instruction booklet must be available for the lifetime of the machine.

9

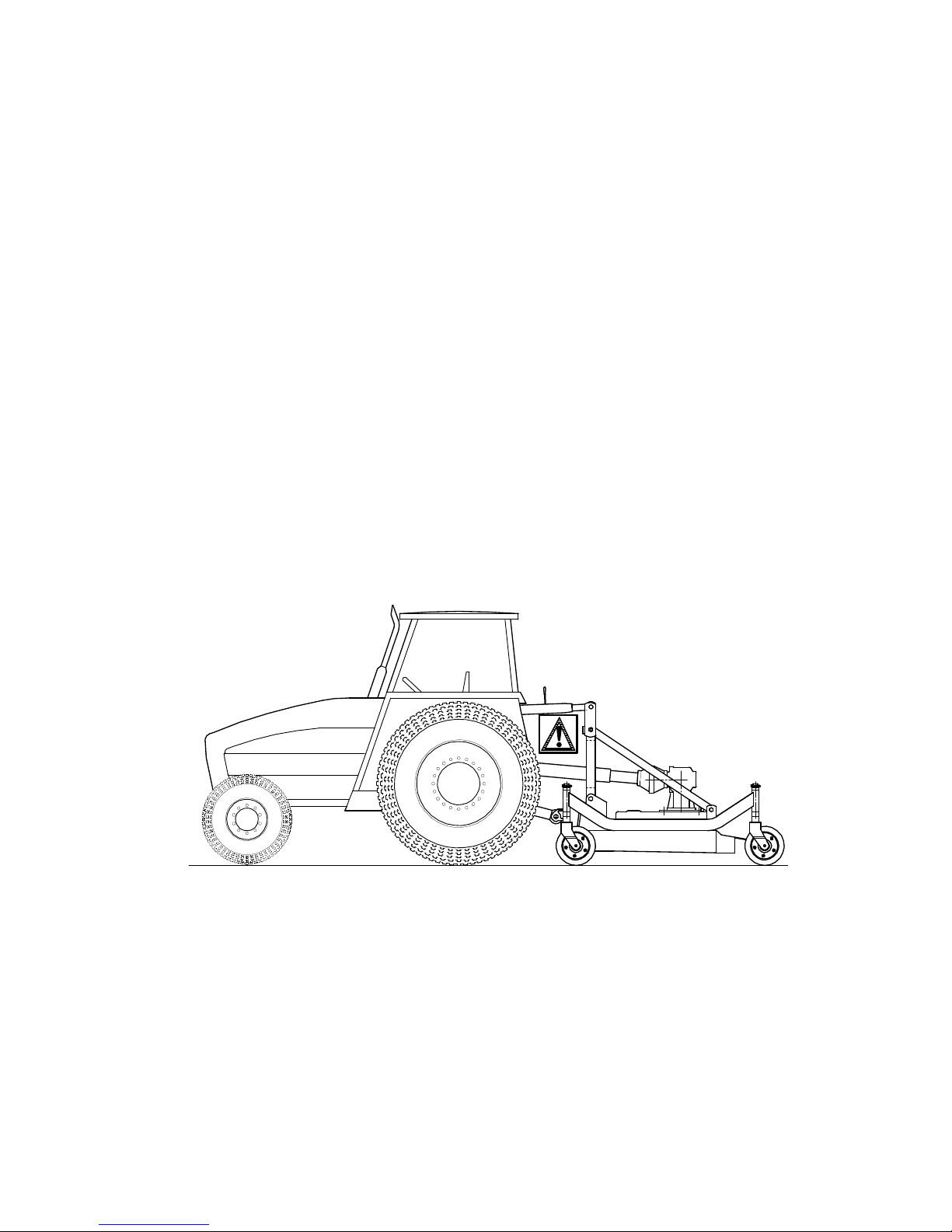

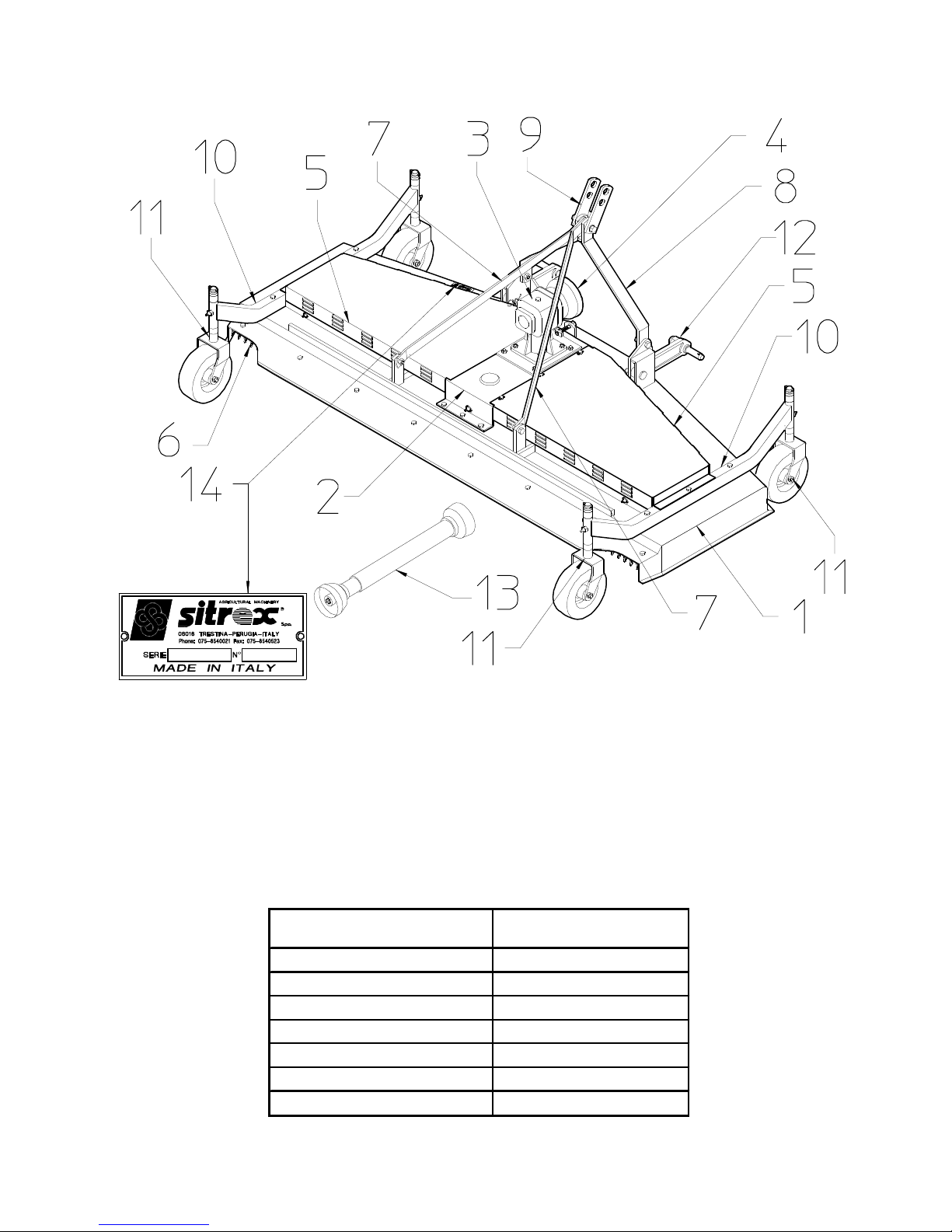

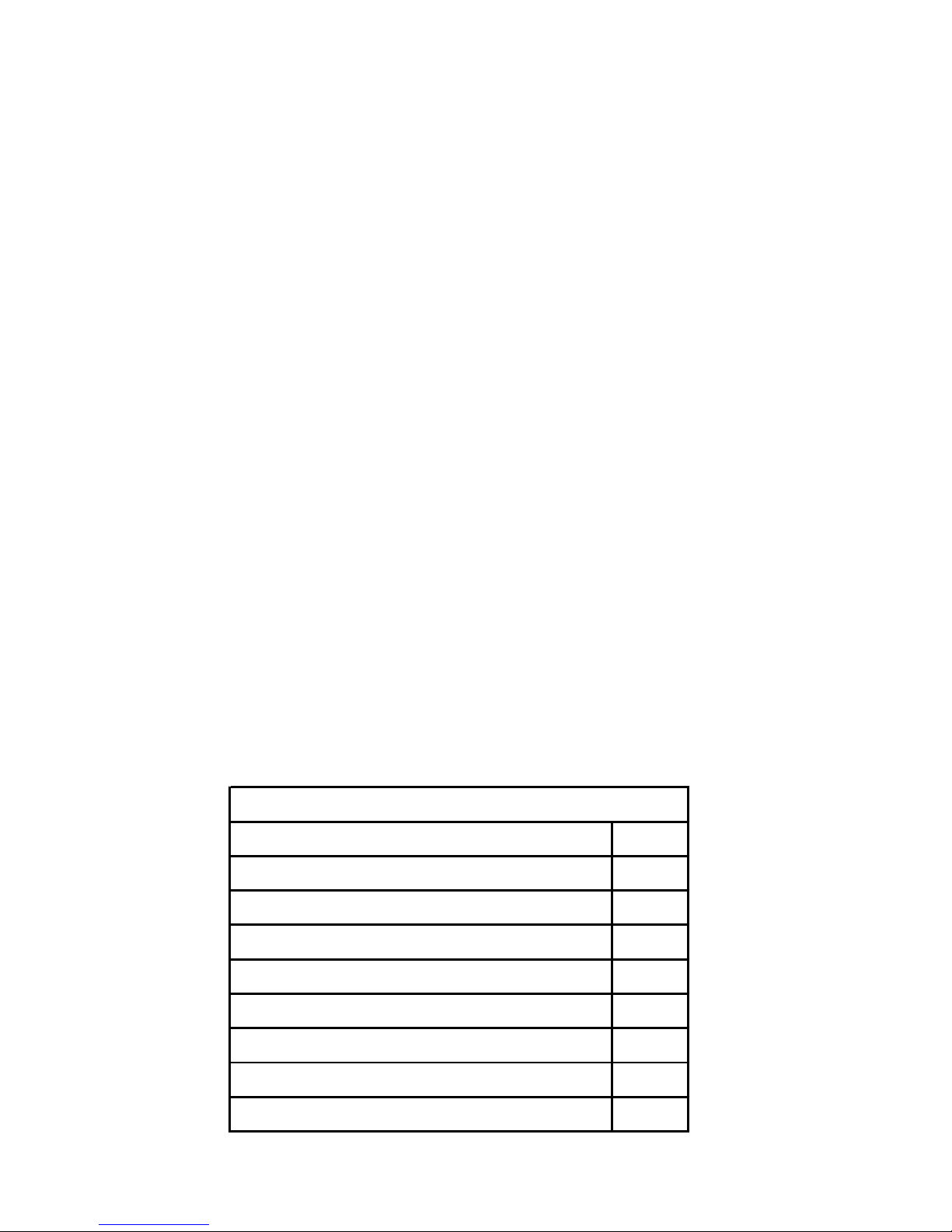

3) PRODUCT IDENTIFICATION

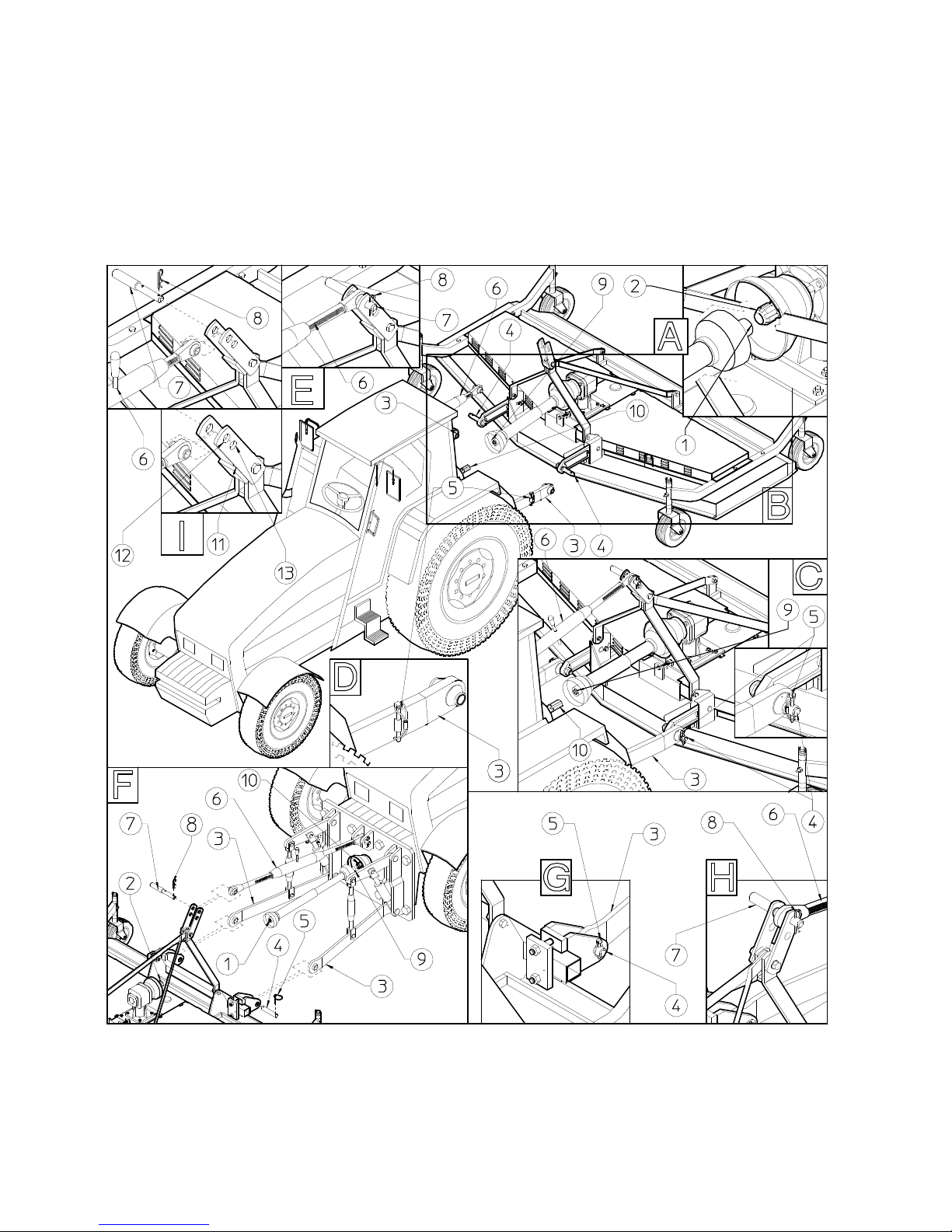

MAIN PARTS

1) MACHINE CASING 8) 3rd POINT HITCH

2) GEARBOX SUPPORT 9) HITCH

3) GEARBOX 10) AXLES

4) PROTECTIVE CAP 11) WHEEL UNIT

5) PROTECTIVE GUARDS 12) PIN LEVER

6) PROTECTIVE CHAIN 13) CARDAN SHAFT

7) TIE ROD 14) IDENTIFICATION PLATE

TECHNICAL DATA

All data are indicative. Sitrex reserves the right to change them without advance notice.

SPECIFICATIONS SM/230

Cutting width 90" - 2300 mm

Cutting heigth 1" to 4" - 25 to 100 mm

Number of blades 5

Blade RPM 2630

Standard PTO RPM 540

PTO Tractor requirement 30 to 60 HP

Weight 685 LBS - 310 KG

10

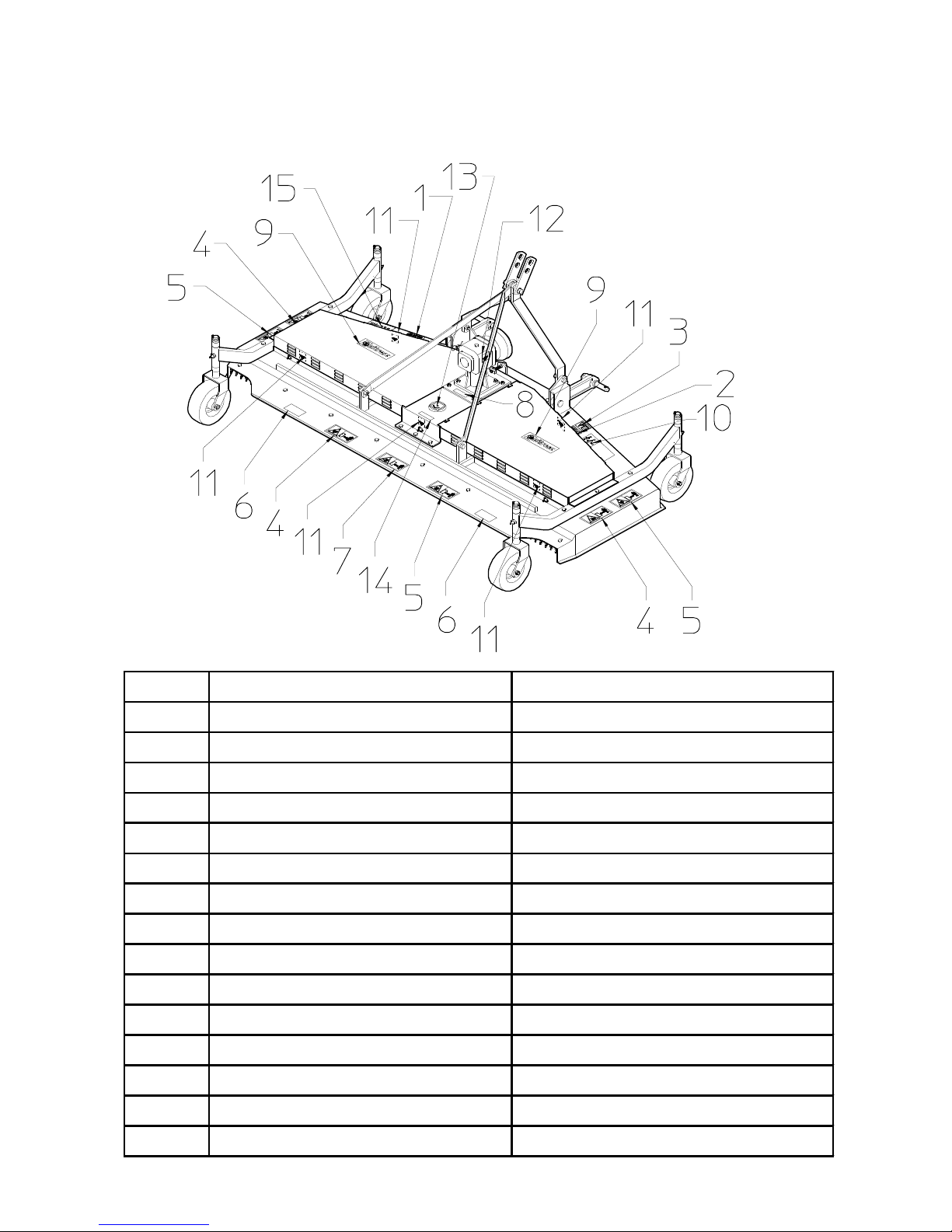

LOCATION OF SIGNS AND SYMBOLS ON THE MACHINE

EMPLACEMENT DES ETIQUETTES SUR LA MACHINE

ITEM DESCRIPTION DESCRIPTION

1 Serial number plate Plaquette d'identification

2 See drawing 2 page 3 Voir dessin 2 page 3

3 See drawing 1 page 3 Voir dessin 1 page 3

4 See drawing 5 page 3 Voir dessin 5 page 3

5 See drawing 6 page 4 Voir dessin 6 page 4

6 See drawing 8 page 4 Voir dessin 8 page 4

7 See drawing 4 page 3 Voir dessin 4 page 3

8 See drawing 13 page 5 Voir dessin 13 page 5

9 Sitrex decal Etiquette commerciale

10 See drawing 7 page 4 Voir dessin 7 page 4

11 See drawing 16 page 5 Voir dessin 16 page 5

12 See drawing 15 page 5 Voir dessin 15 page 5

13 See drawing 17 page 5 Voir dessin 17 page 5

14 See drawing 14 page 5 Voir dessin 14 page 5

15 Decal with model of machine Etiquette du modele de machine

11

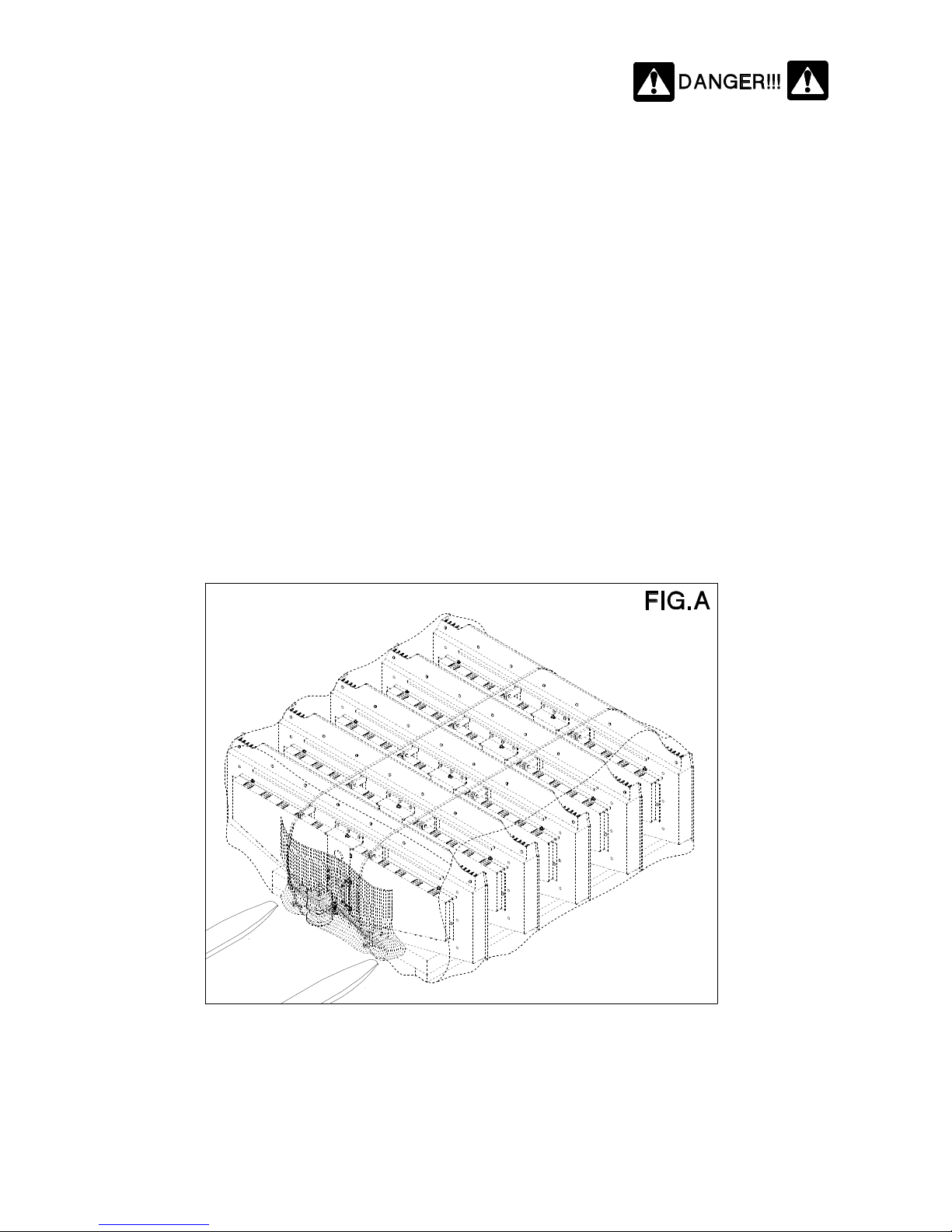

4) DELIVERY AND ASSEMBLY

CHECKING THE MACHINE ON DELIVERY

All parts are carefully checked before dispatch or delivery.

On receiving the machine, ensure that it not been damaged during transport. If

damage has occurred, contact the dealer concerned. How the machine is lifted will

depend on the model and the type of packing. Details are given below. The packing

can vary from country to country depending on transport requirements.

Lift the machine using a forklift truck, crane or other suitable equipment of sufficient

capacity after first checking the weight of the configurations in the table given below.

Check the stability and positioning of the load on the forklift truck forks or crane

hook. Keep the load as low as possible during movement for maximum stability and

to ensure that the operator has maximum visibility. If a forklift truck is used, ensure

that the forks are positioned as wide apart as possible.

Fig. A: represents the standard packaging for the lawn mower with rear grass ejector.

(Usually , there are 5 crated machines, except for orders of lower quantity )

12

Notes :

1) Slightly different packaging from those represented may occasionally be used,

depending on the methods of transport or handling.

2) The packing consist mainly of wood which should be disposed of according to

the laws in force in the country where the machine is used. The plastic film

should also be disposed of according to the laws in force in the country where

the machine is used.

3) In the case of further transportation, make sure the machine is well secure on

the transports means.

MOWERS WEIGHT (n°1 machine) KG – LBS : 310 – 685

In case of handling keep in mind the total weight of machines ( 5 machines

weight approximately kgs. 1.600 – Lbs.3.525 , standard crating ) otherwise,

calculate the weight based on the quantity of machines.

The unpacked machine is composed of the following parts (see pg.13) :

(SEE NEXT PAGE)

Machine with rear grass ejector

1) Machine casing Q.ty 1

2) Wheel axles Q.ty 2

3) Wheel unit Q.ty 4

4) 3rd Point hitch Q.ty 1

5) Tie rods Q.ty 2

6) Guard Q.ty 1

7) Cardan shaft Q.ty 1

8) Bag of nuts and bolts Q.ty 1

9) Bag accessories Q.ty 1

13

The contents of item 8 (bag) are as follows :

The contents of item 9 (bag) are as follows:

Standard mowers Front mowers

Shim ø30-40x2 - 1,18"-1,57"x0,08" Q.ty 4 Flat washer ø8,5 Q.ty 2

Shim ø30-40x6 - 1,18"-1,57"x0,24" Q.ty 4 Flat washer ø12,5 Q.ty 4

Shim ø30-40x12 - 1,18"-1,57"x0,47" Q.ty 4 Spring washer ø13 Q.ty 4

Shim ø30-40x25 - 1,18"-1,57"x0,98" Q.ty 4 Grease nipple M6 Q.ty 4

Shim ø30-40x32 - 1,18"-1,57"x1,26" Q.ty 4 Split pin ø8 (BS 8) Q.ty 4

Screw M12x35 Q.ty 4 Split pin ø3 (BC 3) Q.ty 2

Screw M12x90 Q.ty 5 Pin with grower and nut Q.ty 2

Screw M8x16 Q.ty 2 3rd Point bush Q.ty 2

Self locking nut M12 Q.ty 5 Pin ø19 Q.ty 2

3rd Hitch Q.ty 1

Lower hitch Q.ty 2

Counterplate Q.ty 2

3rd Hitch Q.ty 1 Screw M12x80 Q.ty 4

Lower hitch Q.ty 2 Nuts M12 DIN 980 Q.ty 4

Flat washer ø13 Q.ty 4

Pin ø22x110 Q.ty 2

Split pin ø10 (BS 10) Q.ty 4

14

ASSEMBLY

Assembly is highly dangerous and must be carried out in strict accordance with the

following instructions. We recommend that assembly be performed by qualified

personnel. We also recommend that assembly be carried out in a flat, open area with

no people (particularly children) nearby who could be severely injured if they were to

touch or move any parts of the machine.

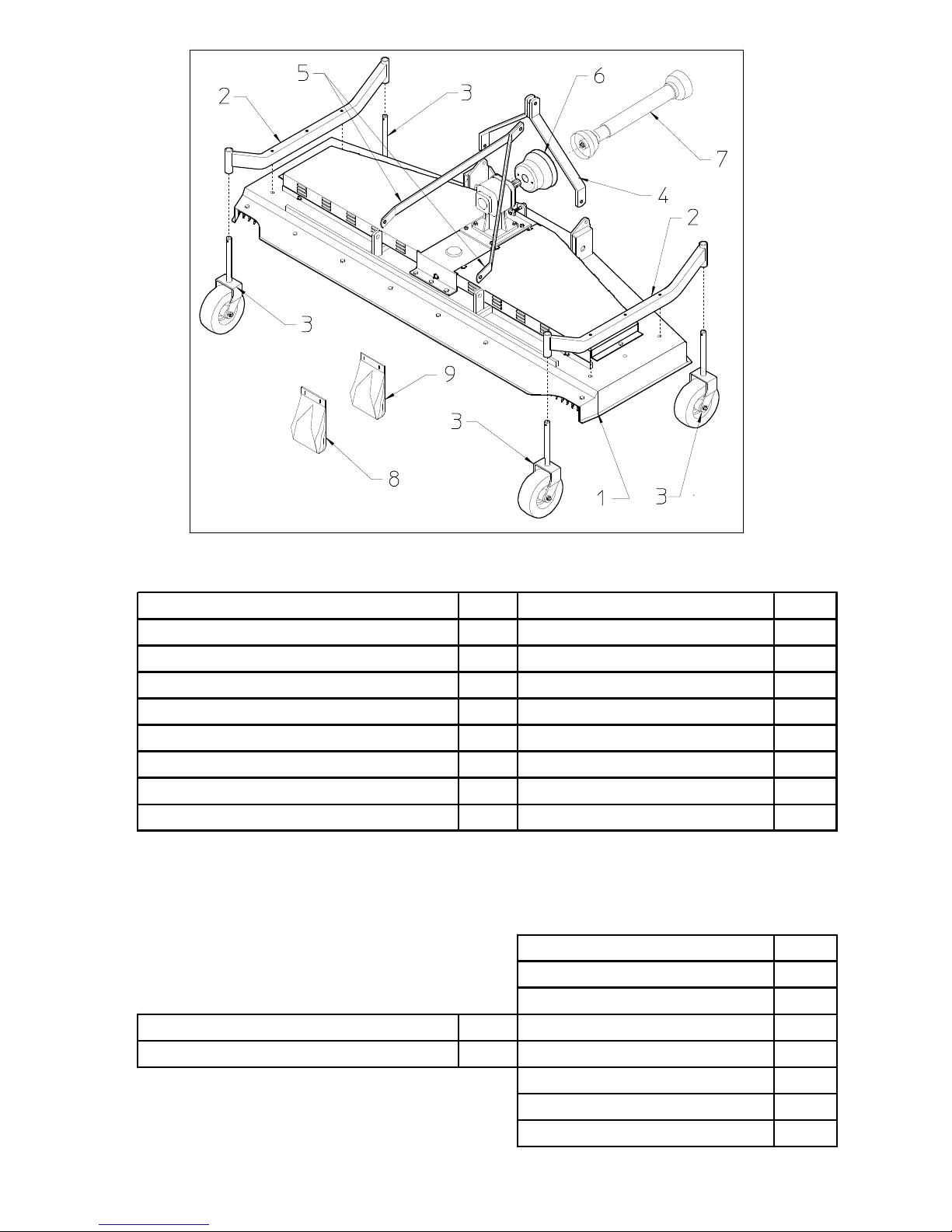

STEP “A”

Keep the main casing approx. 300-500

mm (12”-20”) above the ground, resting

it on suitable supports or on the forks

of a forklift.

Fit the guard 1 to the central gearbox 2

using the flat washers 3 and the screws 4.

In this step, you will use:

Item 3: 2 screws M8x16 (0.31” x 0.63”)

Item 4: 2 flat large washers ø8.5 (ø0.33”)

STEP “B”

Preliminarily remove screws 1 and

bushings 2 used for shipping.

Fit the axles 4 to the machine casing 3

using flat washers 6, spring washers5

and screws 1.

In this step, you will use:

Item 1: 6 screws M12x90 (0.47” x 3.54”)

Item 5: 6 spring washers ø13 (ø0.51”)

Item 5: 6 flat large washers ø13 (ø0.51”)

(Reuse the two M12x90 screws removed,

pos. 1; the two bushings are no longer

needed).

15

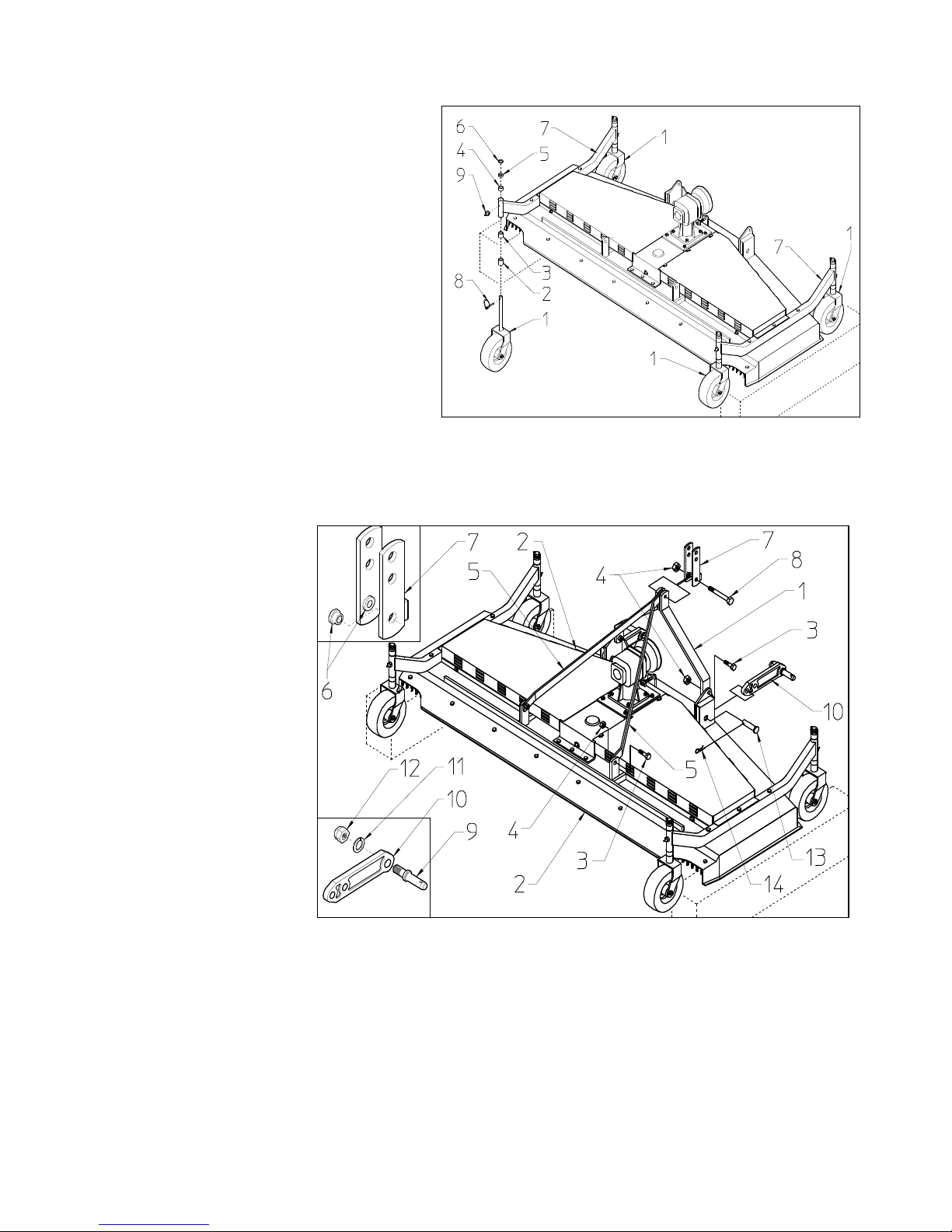

STEP “C”

The order of assembly for spacers 2-34-5-6 depends on the cutting height

you wish to obtain (see pg.21). A

standard assembly is described in this

step.

Add spacers 2-3 to the wheel assemblies

1 and then insert the entire assembly in

the axle seats 7. Add spacers 4-5-6 to

the wheel assemblies 1 now inserted in

the axle seats 7 and fasten the entire unit

with split pins 8.

Fit the grease nipples 9 to the axle

seats 7.

In this step, you will use:

Item 2: 4 shim ø30-40x32 (ø1.18”-1.57”x 1.26”)

Item 3: 4 shim ø30-40x25 (ø1.18”-1.57”x 1”) Item 6:4 shim ø30-40x2(ø1.18”-1.57”x0.08”)

Item 4: 4 shim ø30-40x12 (ø1.18”-1.57”x 0.47”) Item 8: 4 split pin ø8 (ø.31”)

Item 5: 4 shim ø30-40x6 (ø1.18”-1.57”x 0.24”) Item 9: 4 grease nipple M6 (0.24”)

STEP “D”

Fix the 3rd point hitch 1

to the correct seats on

the main casing 2 using

the screws 3 and nuts 4.

Do not fully tighten

nuts 4. Fix the tie rods

5 to the correct seats on

the main casing 2 using

the screws 3 and nuts 4.

Do not fully tighten

nuts 4. First fix the

bushes 6 onto the

hitch 7. The lug of the

bush 6 must be

positioned on the inside

of the hitch 7. The

hitch 7 with secured bushes 4 must be fixed to the 3

rd

point hitch 1 and tie rods 5 using

screw 8 and nut 4. Now fully tighten the nuts 4. Fit the levers 10 to the correct seats on the

main casing 2 and secure it with the pins 13 and split pins 14. Fix pin 9 on to the lever 10

and lock it with spring washer 11 and nuts 12. N.B.: There are two holes at one end of lever

10 in order to attach it to the machine. To choose which holes should be used, see page 22.

In this step, you will use:

Item 3: 4 screws M12x35 (0.47” x 1.38”)

Item 4:

5 nuts M12 (0.47”) Item 12: 2 nuts M22x1.5 (0.87” x 0.06”)

Item 8: 1 screw M12x90 (0.47” x 3.54”) Item 13: 2 pins ø19-25x50 (0.73”-1”x 2”)

Item 11: 2 spring washers ø23 (ø0.91”) Item 14: 2 split pins ø3 (ø0.12”)

16

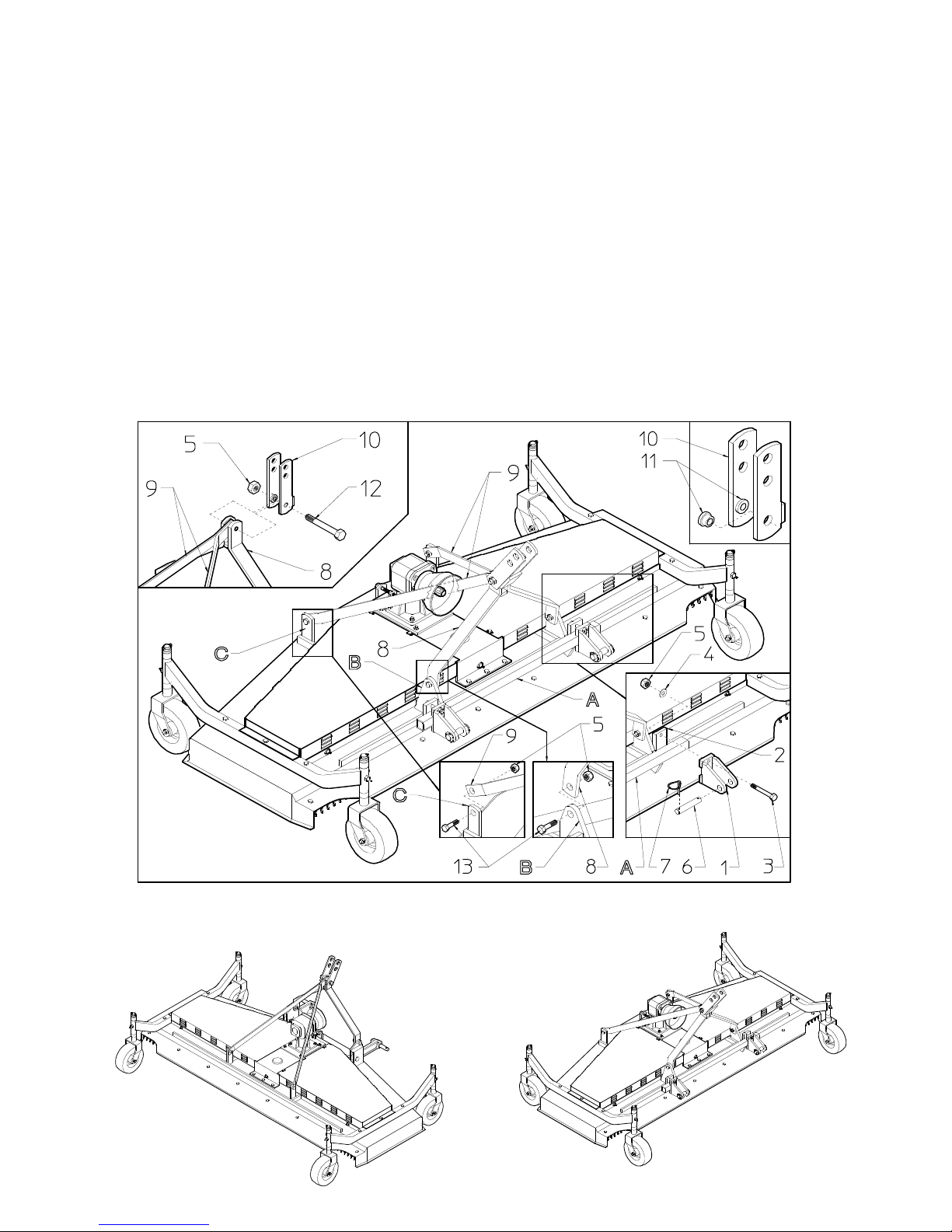

STEP “E”

SPECIAL MODELS

For the assembly of the front version of the mower, the preceding steps apply. Here we

describe briefly what is different. Fasten brackets 1 and counter plates 2 to part “A” of the

machine body using screws 3, washers 4 and nuts 5. Insert pin 6 into bracket 1 and fasten

with split pins 7. Fix the 3

rd

point hitch 8 to the correct seats “B” on the main casing using

the screws 14 and nuts 5. Do not fully tighten nuts 5. Fix the tie rods 9 to the correct seats

“C” on the main casing using the screws 14 and nuts 5. Do not fully tighten nuts. To

assemble together pieces 5(1 pc.)-8-9-10-11-12-13 shown in the details, follow the

instructions given in step “D”. When all pieces are assembled, finish tightening nuts 5.

In this step, you will use:

Item 3: 4 screws M12x70 (0.47” x 2.76”) Item 4: 4 washers ø13 (ø0.51”)

Item 5: 9 nuts M12 (0.47”) Item 6: 2 pins ø22x110 (0.87” x 4.33”)

Item 7: 4 split pins ø10 (ø0.39”) Item 7: 4 split pins ø10 (ø0.39”)

Assembly is now completed, and the machine should appear as shown in the illustration.

STANDARD MOWERS FRONT MOWERS

17

5) ADJUSTMENT,PREPARATION AND USE

INTRODUCTION

Connection to the tractor is highly dangerous. Take great care and carry out the entire

operation in strict compliance with the following instructions. Nobody should go near the

area between the tractor and the machine. Check that all warning and danger signs are in

place and legible. Check that the tractor is in good running order. Refer to the tractor

operator’s manual.

ATTACHMENT OF MACHINE TO THE TRACTOR

Note: If a safety system is provided, this should be fitted to the machine shaft,

not to the tractor shaft. Apply the end 1 of the cardan to the socket on the machine

18

2 (see Fig. A-F). Connect the lifting arm 3 to the pins 4 of the machine and fasten

with the split pins 5 (see Fig. B-C-D-F-G). Connect the tie-rod (or hydraulic cylinder)

6 to the 3

rd

point hitch and fasten with the pin 7 and the split pin 8. Hitch 11 has two

holes 12-13 to fit the variety of connecting tie-rods pins. (see Fig. B-C-E-F-H-I).

Connect part 9 of the cardan to the socket on the tractor 10 (see Fig. B-C-F-H).

(Fig. F-G-H are for the front-attachment models)

CONNECTING CARDAN SHAFT INFORMATION

More detailed information may be found in the cardan shaft manual which, together

with this manual, is an essential part of the accident-prevention documentation. It is

your responsibility to read and comply with this documentation. If information given

in this manual should conflict with that given in the cardan shaft manual, you should

follow the instructions given by the cardan shaft manufacturer.

After having connected the cardan shaft to the shaft of the machine gearbox and to

the tractor PTO as described previously, make sure that when working with or

transporting the mower no situations occur in which the maximum extension or

minimum contraction of the cardan shaft does not exceed the conditions described in

the notes below.

During both transport and use, avoid conditions where the cardan shaft is extended to

the maximum. In all working conditions, the telescopic tubes must overlap by at

least 1/3 of their length (fig. 1). Conversely, when the cardan shaft is contracted to

the maximum, there should still be a gap of approximately 50mm-2” (Fig. 2).

It is absolutely forbidden to use the machine if the application of the

cardan shaft isn’t included in the previously described and illustrated

conditions (see figure 1-2).

Fig.1

Fig.2

19

TRANSPORT INSTRUCTIONS FOR FINISHING MOWERS

Once the machine is attached to the tractor, before proceeding with the transport check to

make sure all attachment pins are fully inserted in place and correctly fastened with the

fastening pins. For transport, the machine must be raised by the tractor power-lift. If when

raised the position reached is not satisfactory, adjust the power-lift adjustment rods 1-2.

Check that the cardan shaft 3 does not interfere with the 3rd point hitch when the machine is

raised.

TRANSPORT BY ROAD

After the machine has been attached to the tractor as previously described and before

transporting it to or from fields or any other workplace, the following instructions should be

heeded:

Before setting off with the machine attached to the tractor, check the local road transport

regulations. During transport keep the machine fully raised with the power takeoff

disengaged and the lifting unit immobilised. Ensure that nobody leans against, or climbs on

to, the machine during transport. The finishing mowers is an agricultural machine NOT

designed for persons or goods. Consult the tractor maintenance and user manual where

necessary. Maintain constant control over the vehicle and ensure that you know how to stop

the tractor quickly and switch off the engine. When on a public road, observe all highway

code regulations. Drive near the edge of the road and try not to obstruct traffic. Do not park

the tractor and/or the machine where it might obstruct, or be a danger to, any public right of

way. Avoid going onto a public road if the tractor or machine is very dirty you could leave a

trail of soil, grass and other matter which could dirty the road and obstruct normal traffic.

20

USE IN THE FIELD

Once the machine is prepared, before beginning work read the chapter on

“General Instructions for Use in the Field” (see pg.27)

PRELIMINARY CHECK

Check that, depending on which is the case, the rotation direction “A”

(counterclockwise – standard) or “B” (clockwise) of the PTO of gearbox 1 matches

that of the tractor PTO 2.

Check that, depending on which is the case, the number of RPMs 540-1000-2000

counterclockwise or 540-1000-2000 clockwise of the PTO of gearbox 1 matches that

of the tractor PTO 2.

Check that, regardless of the number of RPMs and the rotation direction of gearbox

PTO 1 and tractor PTO 2, the rotation direction of the blades 3 is always

that

indicated by the arrows “C”.

Note: These preliminary checks must be done for machines with rear grass ejector as

well as for machines with side grass ejector and for front finishing mowers.

21

USE IN THE FIELD – PRELIMINARY ADJUSTING

ADJUSTING THE CUTTING HEIGHT

To adjust the cutting height in regard to the height of the grass to be mowed, spacers 1-2-34-5 must be suitably placed above and/or below the axle bushings 7 (see Fig. A-B). By

suitably combining spacers 1-2-3-4-5, a minimum cutting height of about 20 mm - 3/4” and

maximum cutting height of about 100 mm – 4” can be obtained (see Fig. A-B). The

minimum cutting height is obtained by putting spacers 1-2-3-4 above the axle bushings 7.

The maximum cutting height is obtained by putting spacers 1-2-3-4 below the axle bushings

7. Spacer 5 is always kept above the axle bushing 7 when spacers 1-2-3-4 are put below the

bushing, and below the bushing when spacers 1-2-3-4 are placed above, as it must act as an

antifriction washer. To carry out this operation, the machine must be in a suitable area and

must be raised by the tractor power-lift (see Fig. C-D) in order to facilitate the removal of

wheel assembly 6 from axle 7. To do this it is necessary to remove split pin 8, then slide out

6 and the spacers 1-2-3-4-5 from axle 7. At this point suitably arrange the spacers 1-2-3-4-5

so as to obtain the desired cutting height, and then fasten the wheel assembly 6 and spacers

1-2-3-4-5 to axle 7 using the split pin 8.

22

USE IN THE FIELD – PRELIMINARY ADJUSTING

ADJUSTMENT OF THE UPPER FLOATING HITCH

With the mower and tractor standing on a flat, level surface, adjust the upper floating hitch 9

(see Fig. A-E) so that it is in the middle position “G” between the farthest frontward “H”

and farthest rearward “I” positions (see Fig. E). This allows the machine to adapt to the

terrain during operation. The middle position “G” is obtained by adjusting the 3rd point

hitch rod 10. Choose among the hole Y and Y of the hitch 9, the most suitable one for your

requirements. (see Fig. A-E).

ADJUSTMENT OF THE LOWER FLOATING HITCH

The lower floating hitch 11 has two holes due (K-W) so that it can be adapted to fit various

types of lifting arms. Normally, floating hitch 11 is fastened to the mower frame using hole

“W”. If you have to mount lever 11 on hole “K” see pg.15 step “D”. With the mower and

tractor standing on a flat, level surface, adjust the lower floating hitch 11 (see Fig. A-F) so

that it is in the middle position “L” between the uppermost “M” and lowermost “N”

positions (see Fig. F). This allows the machine to adapt to the terrain during operation. The

middle position “L” is obtained by adjusting the rods of the lifting arms 12 (see Fig. A-F).

23

ADJUSTING THE BELT TENSION

The tension of the belts 5 is set correctly by the manufacturer, but the tension must be

checked periodically according to the time schedule given on pg..29, and reset to the proper

tension if necessary. This check is very important, because belts that are too loose or too

tight wear out quickly and impair the performance of the mower. This operation must be

done using maximum caution, and always with the tractor shut off and the cardan shaft

disconnected. First the protective covers 1-2 must be removed by unscrewing the screws at

points A-B. Next, loosen the nuts 3 that fasten the slide-reduction unit-pulley assembly 4.

Then loosen nut 6 and bring it back approx. 5/6 mm-1/4”. Now tighten screw 7 so as to

make the assembly 4 slide in direction “D”. In order to determine the proper tension for

belts 5, refer to the information in the following tables. Once belts 5 are correctly tensioned,

tighten nut 6 and nuts 3. Reattach the protective covers 1-2 using the screws and washers

removed previously at points A-B.

24

GENERAL RULE FOR CALCULATING THE TENSION OF

BELT TYPES B/ SPB/5V/15N/XPB/5VX

K x C

E = ------- 100

E = Flexure of a section of belt C subjected to a force F equivalent to 75N (approx.

7.5 Kg) applied to the center of the section C/2.

C = Longer section of belt of transmission.

C/2 = The middle of the longer belt of transmission where the force F must be

applied.

F = Force applied to check the tension of the belts, equivalent to 75N (approx. 7.5

Kg).

K = Flexure of 100 mm – 4” section of belt subjected to a force of 75N (approx. 7.5

Kg) applied to the center of the section.

VALUES OF K

Diameter of the smallest belt pulley K

From ø80 to ø160 3

From ø161 to ø224 2.55

From ø225 to ø355 2.22

Over ø356 2.1

FOR THE SM/120-150-180-230 MOWERS SEE THE K-C-E VALUES

IN THE FOLLOWING TABLE.

MOWER K C mm/inches E mm/inches

SM/120 3 422 - 16,6" 12,5 - 0,49"

SM/150-SM/230 3 522 - 20,6" 15,5 - 0,61"

SM/180 3 622 - 24,5" 18,5 - 0,73"

25

INSTRUCTIONS ON HOW TO CHANGE THE BELTS

The replacement of the belts 5 must be done using maximum caution, and always with the

tractor shut off and the cardan shaft disconnected. First the protective covers 1-2 must be

removed by unscrewing the screws at points A-B. Next, loosen the nuts 3 that fasten the

slide-reduction unit-pulley assembly 4. Then loosen nut 6 and unscrew screw 7 so as to

make the assembly 4 slide in direction “C” until it is possible to remove the belts 5 from the

grooves of the pulleys. Now remove the three screws on side “D” of the reduction unit

mount and then loosen the three screws on the inside of side “E” of the reduction unit mount

until it can be raised enough on side “D” to allow the belts to be pulled out from underneath

it. The new belts are put on by following the same procedure in reverse order. To determine

the right degree of tension for belts 5, follow the instructions and refer to the data described

previously. Once belts 5 are correctly tensioned, tighten nut 6 and nuts 3. Reattach the

protective covers 1-2 using the screws and washers removed previously at points A-B.

26

INSTRUCTIONS FOR REPLACING THE BLADES

The replacement of the blades 3 must be done using maximum caution, and always

with the tractor shut off and the cardan shaft disconnected. Raise the mower body to

the maximum height possible with the tractor power-lift so as to allow you to work

properly on the underneath part of the mower. To increase the lifting height, adjust

the rod (or hydraulic cylinder) 6. Now place suitable supports “B” under the mower

body or hook it onto a suitable hoist “C” (taking into consideration the mower

weight). Depending on the operator’s experience, the tools and equipment available,

and the area where the replacement is done (in the shop, in the field, etc.), other

procedures may be used provided that work is done fully observing all safety

measures and conditions. To remove blade 5 use wrench 1 on part “A” of the hub pin

2 and wrench 3 on nut 4, unscrewing the nut so that blade 5 can be removed. Replace

the blade and fasten it to the hub pin following the reverse procedure. Before using

the mower ensure that the blade has been correctly fastened in place, because a blade

that has not been adequately secured to the hub pin 2 can be extremely hazardous.

27

TEMPORARY PARKING

1) Choose a flat, hard open space away from frequented areas if possible.

2) Switch off the engine, leaving the tractor in gear.

3) Apply the parking brake and remove the ignition key.

4) Put the parking stand in the parking position.

5) Turn the angle adjustment crank so that the weight of the machine is on the parking stand,

thus avoiding the risk of having the machine tip over backwards.

6) Disconnect the cardan shaft at the tractor end.

7) Unhitch the tractor drawbar coupling pin.

28

6) MAINTENANCE DIRECTIONS

All cleaning, lubrication and maintenance operation must be carried out with the

machine disconnected from the tractor.

In an emergency with the machine still connected to the tractor, switch off the engine,

apply the parking brake, disengage the power takeoff and remove the ignition key

from the instrument panel.

Regular, correct maintenance and proper operation are the basic prerequisites for the

long-term efficiency and safe operation the machine.

Pay special attention to all instructions given on signs located on the machine.

All maintenance should be carried out in an area having the proper equipment readily

available and in good condition.

This area must always be kept clean and dry and must have enough surrounding

space to facilitate operations.

Any work must be carried out by trained personnel. Contact the dealer nearest to you.

Respect the warnings and procedures for maintenance and technical assistance given

in this manual.

Do not use petrol, solvents or other flammable liquids as detergents.

Use commercial non-flammable and non-toxic solvents, authorised by competent

bodies.

Do not use compressed air or water at high pressure to clean the machine. If this is

unavoidable, then wear goggles with side protection and limit the pressure as much as

possible. When the work is finished, and with the machine disconnected from the

tractor, inspect and check the machine completely.

29

MAINTENANCE POINTS

ITEM Q.ty DESCRIPTION OPERATION EVERY

HOURS

NOTES

1 5 BLADE HUBS LUBRICATE 8 Grease NLGI 2

2 4 WHEEL SUPPORTS LUBRICATE 25 Grease NLGI 2

3 1 GEARBOX OIL 50/500 SEE NOTE A

4 1 PTO SHAFT CLEAN * SEE NOTE B

5 2 ARM LINKAGE PINS CLEAN * SEE NOTE C

6 4

WHEELS (only

pneumatic version)

CHECK

PRESSURE

SEE

NOTE C

INFLATE TO 35

PSI

7 2 BELTS CHECK

TENSION

(**4) 30 SEE NOTE D

8 1 CARDAN SHAFT SEE CARDAN SHAFT MAINTENANCE

9 *

General checking of bolts, security pins and split pins to be carried out

initially after the first 8 hours of use. Subsequently every 50 hours and

whenever the machine is laid up for extended periods. (** First time

after 4 hours)

30

NOTE A: The first oil change must be done after 50 hours working time and then

after 400-500 hours of work. Keep in mind that intense and continuous working

conditions will necessitate more frequent oil changes and periodic checks. It is a good

practice to check the oil level every 50-60 hours of work. When changing the oil use

maximum caution, and always make sure the tractor is shut off and the cardan shaft

disconnected; it may be advisable to detach the mower entirely from the tractor.

However, depending on the situation and the operator’s experience, the tools and

equipment available, and the area where the oil change is done (in the shop, in the

field, etc.), other procedures may be used provided that the operator is always fully

aware of the hazards connected with this operation.

Cap 1 on the housing is for filling, and cap 2 for checking the level. To check the

level, simply unscrew cap 2 and see if the oil reaches the lower part of the cap 2

opening. To top up the oil, remove cap 1 and add oil until it starts to come out of the

cap 2 opening. Put caps 1-2 back in place. To change the oil, keeping in mind the

preceding safety recommendations, place the mower in a vertical position, or inclined

enough so that once caps 1-2 are removed the oil can drain out of the cap 2 opening.

Once the used oil has been completely drained, put the mower back in a level

position and add oil in the cap 1 opening until it starts to come out of the cap 2

opening. Put caps 1-2 back in place. For a full oil change, approx. 0.5 liters of ISO

320 VG (SAE 80W/90 EP) type oil are needed.

NOTE B: Each time the cardan shaft is disconnected and/or connected and

whenever the machine is stopped, we recommended that you clean the power takeoff

shaft and replace the protective cover (use additives of a type permitted by antipollution regulations).

NOTE C: Each time the machine is connected and/or disconnected to the tractor.

NOTE D: To carry out this operation following the instructions given on pg.23-24.

31

32

GENERAL INSTRUCTIONS FOR REPAIR WORK

Any repair work must be carried out with the machine at rest and disconnected from

the tractor.

Do not carry out welding without authorisation and instructions from the

manufacturers.

Disconnect the machine from the tractor before any welding work in order not to

damage the battery. Always use a protective mask, goggles and gloves when welding,

sanding or grinding or when using a hammer or drill.

Always work on the machine out of doors. If you have to operate the machine when

connected to the tractor in an enclosed are (for example when testing after repair

and/or maintenance) ensure that there is sufficient ventilation so as to prevent

noxious exhaust gases accumulating.

In order to acquire the necessary control and to operate in safety, practise various

manoeuvres by simulating those required in the workplace with the help of an

experienced person.

If you activate the machine while it is raised from the ground, make sure there is

nobody standing nearby or in a dangerous position.

LAYNING UP FOR EXTENDED PERIODS

At the end of the season, or when an extended period of inactivity is envisaged, it is

advisable to:

Clean the machine following instructions an allow it to dry.

Check it carefully and replace any damaged or worn parts.

Thoroughly tighten all screws and bolts.

Grease the machine thoroughly and then cover it completely and lay it up in a dry

place.

It is to the user’s advantage to carry out these operations carefully. In this way, he

will have a machine in perfect condition when work is restarted.

On recommencing work, repeat all the proper checks so as to be certain of working in

conditions of maximum safety.

33

NOISE AND VIBRATION

Noise affecting the tractor driver (from the machine only) is less than 80dB.

Vibration from the machine affecting the upper body and limbs of the driver is

insignificant and is lower than the values given in Point 3.6.3 of Enclosure 1 of the

Machine Directives (89/392/EEC, 91/386/EEC)

THE FOLLOWING SHOULD BE NOTED IF THE

MACHINE IS SCRAPPED

The machine consists mainly of ferrous material, which must be disposed of

according to the regulations in force in the country concerned.

There is also a small amount of plastic, which must be disposed of according to the

regulations in force in the country concerned.

There is very small amount of residual grease, which must be disposed of according

to the regulations in force in the country concerned.

********************************************************************

7) SPARE PARTS LIST

FOR CORRECT SPARE PARTS ORDER IT IS NECESSARY TO SPECIFICY:

TABLE NOMBER, ITEM, PART NO, DESCRIPTION AND QUANTITY OF

PARTS REQUIRED.

ITEMS DESCRIBED AS RH AND LH ARE MEANT FACING REAR OF

MACHINE.

34

35

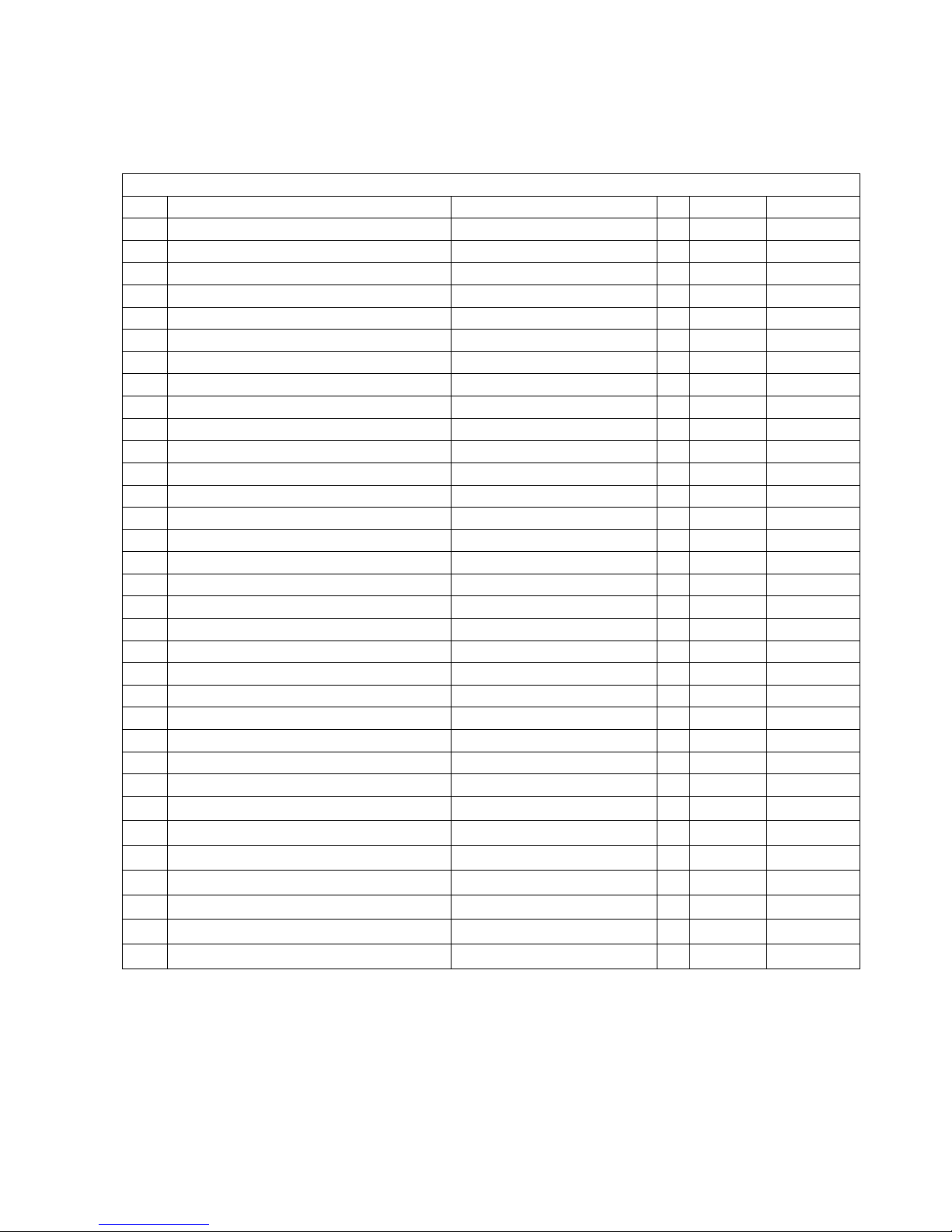

ITEM

Q.ty

PART NO

DESCRIPTION

NOTE

11110.062

COMPLETE HOOD

22110.070

WHEEL AXLE

34100.147

WHEEL SUPPORT

41100.136

BELT COVER, RH

51100.137

BELT COVER, LH

61100.135

GEARBOX SUPPORT

71100.126

SLIDING

81100.273

** GEARBOX

92100.037

TIE ROD

101100.038

3rd POINT HITCH

112100.062

SPACER

121100.041

HITCH

131110.066

RH PROTECTION

141110.067

LH PROTECTION

155100.047

COMPLETE HUB

165100.065

BLADE

173100.148

GREASE FITTING

182100.125

GREASE FITTING

191100.138

PULLEY 242 2B

201100.139

PULLEY 140 2B

214100.140

PULLEY 140 1B

2212100.050

SHIM

232100.039

PIN LEVER

244100.145

SHIM ø1.2" x 1,26" (ø30,5x32 mm)

254100.144

SHIM ø1,2" x 1" (ø30,5x25 mm)

264100.143

SHIM ø1,2" x 0,47" (ø30,5x12 mm)

274100.142

SHIM ø1,2" x 0,24" (ø30,5x6 mm)

284100.141

SHIM ø1,2" x 0,08" (ø30,5x2 mm)

294100.008

SPACER

308100.006

SHIM

315100.051

PIN

325100.052

BEARING COVER

335100.150

HUB

345100.048

SPACER

352105.091

PIN

362100.010

COMPLETE PIN

372100.040

PIN

3810600.117

BEARING 6205 Z

395600.122

LOCKING RING NUT M25x1,5

405600.123

LATCH B8x7x35

411600.181

LATCH B10x8x40

TABLE PART NO 910.065

** STANDARD GEARBOX: 540 RPM COUNTER CLOCK WISE

36

37

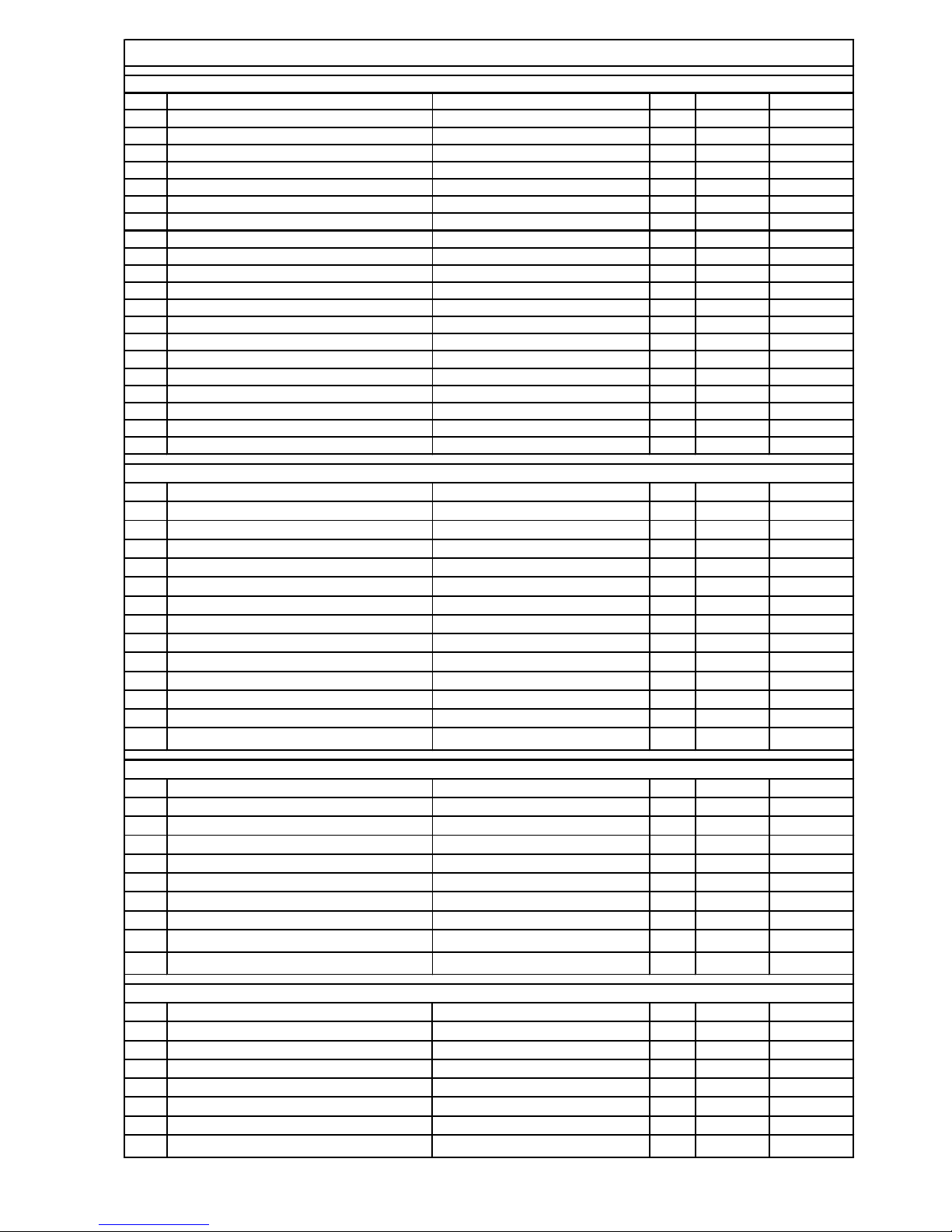

ITEM

Q.ty

PART NO

DESCRIPTION

NOTE

421600.335

WASHER ø25

431600.296

NUT M24x2

441600.347

SPLIT PIN ø5x50

455600.746

NUT M18x1,5

465600.034

GREASE NIPPLE M8

474600.124

GREASE NIPPLE M6

484600.116

LINCH PIN ø8

494600.165

WHEEL

502620.647

BELT XPB 2800

512600.019

CLIP ø3

524600.158

SCREW (M14x40)

531600.160

SCREW (M10x80)

544600.156

SCREW (M12x110)

5526600.006

SCREW (M10x25)

567600.162

SCREW (M10x80)

571100.042

SHIM (ø1" x 0,08" - ø25,4x2 mm)

584600.616

SCREW (M12x35)

598600.061

SCREW (M8x16)

6012600.702

SCREW (M8x25)

612600.214

SPRING WASHER ø23

624600.104

SPRING WASHER ø14,5

637600.322

WASHER ø10,5

646600.092

LARGE WASHER ø12/36

656600.634

SPRING WASHER ø13

6618600.100

SPRING WASHER ø8,5

678610.185

LARGE WASHER ø8,5

6814600.115

WASHER ø8,5

692600.249

NUT (M22x1,5)

704600.075

NUT (M14)

719600.077

NUT (M12)

7225600.010

NUT (M10)

7314600.037

NUT (M8)

742610.661

SCREW (M8x20)

7526600.102

SPRING WASHER ø10,5

761600.171

CAP L.110

761600.818

CAP L.190

771600.172

PROTECTION

784100.132

BELT TIGHTENER ø148

794100.133

BELT TIGHTENER ø64

8016600.872

BEARING 6004 2RS

818600.885

SNAP RING I 42

828600.600

SNAP RING E 20

TABLE PART NO 910.065

38

FRONT FINISHING MOWERS

TABLE PART NO 910.040

ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE

1 COMPLETE HOOD COFFRE COMPLET 1 110.117 120/P

1 COMPLETE HOOD COFFRE COMPLET 1 110.116 150/P

1 COMPLETE HOOD COFFRE COMPLET 1 110.115 180/P

1 COMPLETE HOOD COFFRE COMPLET 1 110.114 230/P

2 COMPLETE HOOD COFFRE COMPLET 1 100.084 120/L

2 COMPLETE HOOD COFFRE COMPLET 1 100.085 150/L

2 COMPLETE HOOD COFFRE COMPLET 1 100.086 180/L

3 HITCH ATTELAGE 2 100.079 SM/120-150-180

3 HITCH ATTELAGE 2 100.317 SM/230

4 COUNTERPLATE CONTRE-PLATE 2 100.080 SM/120-150-180

4 COUNTERPLATE CONTRE-PLATE 2 100.330 SM/230

5 SCREW (M12x70) VIS (M12x70) 4 600.210 SM/120-150-180

5 SCREW (M12x80) VIS (M12x80) 4 600.390 SM/230

6 WASHER RONDELLE 4 600.089 SM/120-150-180-230

7 NUT (M12-DIN 980) ECROU (M12-DIN 980) 4 600.077 SM/120-150-180-230

8 PIN PIVOT 2 100.102 SM/120-150-180-230

9 CLIP GOUPILLE 2 600.017 SM/120-150-180-230

NOTE: ITEMS FOR THE FRONT MOUNT MOWERS - PIECES POUR LA VERSION FRONTALE

FOR THE OTHER ITEMS SEE TABLES PART NOS 910.055-910.056-910.065

POUR LES AUTRES PIECES VOIR TABLES 910.055-910.056-910.065

39

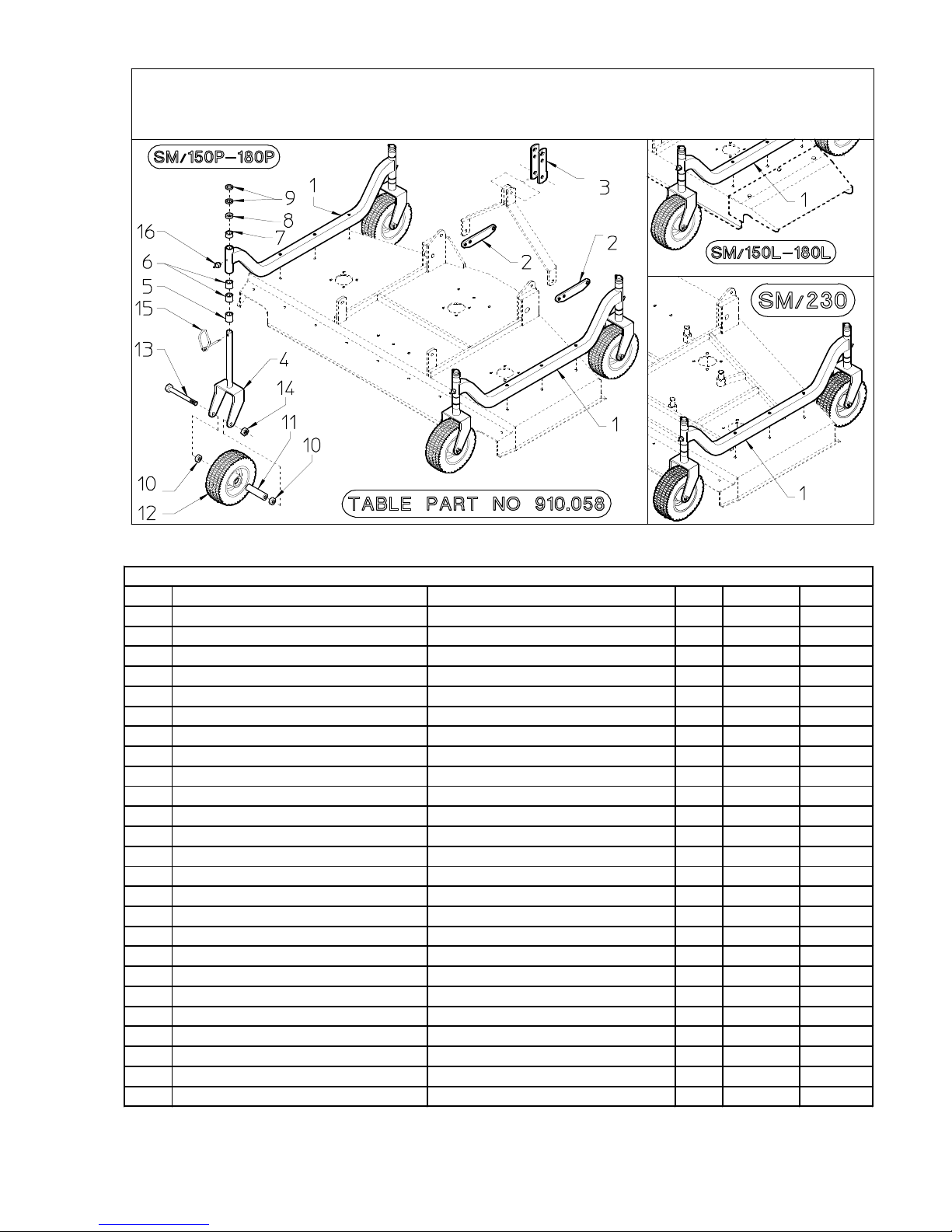

MOWERS WITH PNEUMATIC WHEEL

ITEM

DESCRIPTION

DESCRIPTION

Q.ty

PART NO

NOTE

1

WHEEL AXLE

ESSIEU ROUE

2

100.932

SM/150 P

1

WHEEL AXLE

ESSIEU ROUE

2

100.931

SM/180 P

1

WHEEL AXLE

ESSIEU ROUE

2

100.721

SM/230 P

1

WHEEL AXLE

ESSIEU ROUE

2

100.285

SM/150 L

1

WHEEL AXLE

ESSIEU ROUE

2

100.284

SM/180 L

2

SUPPORT

SUPPORT

2

100.297

3

HITCH

ATTELAGE

1

100.298

4

WHEEL SUPPORT

SUPPORT DE ROUE

4

100.291

5

SHIM ø1.2" x 1,26" (ø30,5x32 mm)

EPAISSEUR ø30,5x32 mm

4

100.145

6

SHIM ø1,2" x 1" (ø30,5x25 mm)

EPAISSEUR ø30,5x25 mm

8

100.144

7

SHIM ø1,2" x 0,47" (ø30,5x12 mm)

EPAISSEUR ø30,5x12 mm

4

100.143

8

SHIM ø1,2" x 0,24" (ø30,5x6 mm)

EPAISSEUR ø30,5x6 mm

4

100.142

9

SHIM ø1,2" x 0,08" (ø30,5x2 mm)

EPAISSEUR ø30,5x2 mm

8

100.141

10

SHIM

EPAISSEUR

8

100.338

11

SPACER

ENTRETOISE

4

100.339

12

WHEEL

ROUE

4

610.434

13

SCREW (M12x150)

VIS (M12x150)

4

610.271

14

NUT (M12-DIN 980)

ECROU (M12-DIN 980)

4

600.077

15

CLIP

GOUPILLE

4

610.466

16

GREASE NIPPLE M6

GRAISSEUR M6

4

600.124

*

COMPLETE WHEEL KIT AND ACCESSORIES GROUPE ROUE PNEUM. ET ACCESSORIES

1

100.933

SM/150 P

*

COMPLETE WHEEL KIT AND ACCESSORIES GROUPE ROUE PNEUM. ET ACCESSORIES

1

100.934

SM/180 P

*

COMPLETE WHEEL KIT AND ACCESSORIES GROUPE ROUE PNEUM. ET ACCESSORIES

1

100.935

SM/230 P

*

COMPLETE WHEEL KIT AND ACCESSORIES GROUPE ROUE PNEUM. ET ACCESSORIES

1

100.296

SM/150 L

*

COMPLETE WHEEL KIT AND ACCESSORIES GROUPE ROUE PNEUM. ET ACCESSORIES

1

100.295

SM/180 L

POUR LES AUTRES PIECES VOIR TABLES 910.055-910.056-910.065

FOR THE OTHER ITEMS SEE TABLE 910.055-910.056-910.065

MOWERS WITH PNEUMATIC WHEEL-TONDEUSE AVEC ROUE PNEUMATIQUE - TABLE PART NO 910.058

NOTE: ITEMS FOR THE PNEUMATIC WHEEL - PIECES POUR TONDEUSE PNEUMATIQUE

40

SOLID WHEEL KIT / KIT ROUES SOLIDE

41

SOLID WHEEL KIT FOR MOWERS -KIT ROUES SOLIDE POUR TONDEUSE - TABLE PART NO 910.063

ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE

1 WHEEL AXLE ESSIEU ROUE 2 110.068 SM/120 P

1 WHEEL AXLE ESSIEU ROUE 2 110.069 SM/150 P

1 WHEEL AXLE ESSIEU ROUE 2 100.699 SM/180 P

1 WHEEL AXLE ESSIEU ROUE 2 110.070 SM/230 P

1 WHEEL AXLE ESSIEU ROUE 2 100.207 SM/120 L

1 WHEEL AXLE ESSIEU ROUE 2 100.208 SM/150 L

1 WHEEL AXLE ESSIEU ROUE 2 100.209 SM/180 L

2 WHEEL SUPPORT SUPPORT DE ROUE 4 100.020 120-150-180

2 WHEEL SUPPORT SUPPORT DE ROUE 4 100.147 SM/230 P

3 SHIM ø1" x 1,26" (ø25,4x32 mm) EPAISSEUR ø25,4x32 mm 4 100.046 120-150-180

3 SHIM ø1.2" x 1,26" (ø30,5x32 mm) EPAISSEUR ø30,5x32 mm 4 100.145 SM/230 P

4 SHIM ø1" x 1" (ø25,4x25 mm) EPAISSEUR ø25,4x25 mm 4 100.045 120-150-180

4 SHIM ø1,2" x 1" (ø30,5x25 mm) EPAISSEUR ø30,5x25 mm 4 100.144 SM/230 P

5 SHIM ø1" x 0,47" (ø25,4x12 mm) EPAISSEUR ø25,4x12 mm 4 100.044 120-150-180

5 SHIM ø1,2" x 0,47" (ø30,5x12 mm) EPAISSEUR ø30,5x12 mm 4 100.143 SM/230 P

6 SHIM ø1" x 0,24" (ø25,4x6 mm) EPAISSEUR ø25,4x6 mm 4 100.043 120-150-180

6 SHIM ø1,2" x 0,24" (ø30,5x6 mm) EPAISSEUR ø30,5x6 mm 4 100.142 SM/230 P

7 SHIM ø1" x 0,08" (ø25,4x2 mm) EPAISSEUR ø25,4x2 mm 4 100.042 120-150-180

7 SHIM ø1,2" x 0,08" (ø30,5x2 mm) EPAISSEUR ø30,5x2 mm 4 100.141 SM/230 P

8 SHIM EPAISSEUR 8 100.006

9 SPACER ENTRETOISE 4 100.008

10 WHEEL ROUE 4 600.165

11 SCREW (M12x110) VIS (M12x110) 4 600.156

12 NUT (M12-DIN 980) ECROU (M12-DIN 980) 4 600.077

13 CLIP GOUPILLE 4 600.116

14 GREASE NIPPLE M6 GRAISSEUR M6 4 600.124

*

COMPLETE SOLIDE WHEEL KIT AND ACCESSORIESKIT ROUES SOLIDE ET ACCESSORIES

1 110.130 SM/120 P

*

COMPLETE SOLIDE WHEEL KIT AND ACCESSORIESKIT ROUES SOLIDE ET ACCESSORIES

1 110.203 SM/150 P

*

COMPLETE SOLIDE WHEEL KIT AND ACCESSORIESKIT ROUES SOLIDE ET ACCESSORIES

1 110.204 SM/180 P

*

COMPLETE SOLIDE WHEEL KIT AND ACCESSORIESKIT ROUES SOLIDE ET ACCESSORIES

1 110.133 SM/230 P

*

COMPLETE SOLIDE WHEEL KIT AND ACCESSORIESKIT ROUES SOLIDE ET ACCESSORIES

1 100.290 SM/120 L

*

COMPLETE SOLIDE WHEEL KIT AND ACCESSORIESKIT ROUES SOLIDE ET ACCESSORIES

1 100.289 SM/150 L

*

COMPLETE SOLIDE WHEEL KIT AND ACCESSORIESKIT ROUES SOLIDE ET ACCESSORIES

1 100.288 SM/180 L

42

43

ITEM

DESCRIPTION

DESCRIPTION

Q.ty

PART NO

NOTE

1

WHEEL SUPPORT

SUPPORT DE ROUE

1

100.020

120-150-180

1

WHEEL SUPPORT

SUPPORT DE ROUE

1

100.047

SM/230 P

2

SHIM

EPAISSEUR

2

100.006

3

SPACER

ENTRETOISE

1

100.008

4

WHEEL

ROUE

1

600.165

5

SCREW (M12x110)

VIS (M12x110)

1

600.156

6

NUT (M12-DIN 980)

ECROU (M12-DIN 980)

1

600.077

7

SHIM ø1" x 1,26" (ø25,4x32 mm)

EPAISSEUR ø25,4x32 mm

1

100.046

120-150-180

7

SHIM ø1.2" x 1,26" (ø30,5x32 mm)

EPAISSEUR ø30,5x32 mm

1

100.145

SM/230 P

8

SHIM ø1" x 1" (ø25,4x25 mm)

EPAISSEUR ø25,4x25 mm

2

100.045

120-150-180

8

SHIM ø1,2" x 1" (ø30,5x25 mm)

EPAISSEUR ø30,5x25 mm

2

100.144

SM/230 P

9

SHIM ø1" x 0,47" (ø25,4x12 mm)

EPAISSEUR ø25,4x12 mm

1

100.044

120-150-180

9

SHIM ø1,2" x 0,47" (ø30,5x12 mm)

EPAISSEUR ø30,5x12 mm

1

100.143

SM/230 P

10

SHIM ø1" x 0,24" (ø25,4x6 mm)

EPAISSEUR ø25,4x6 mm

1

100.043

120-150-180

10

SHIM ø1,2" x 0,24" (ø30,5x6 mm)

EPAISSEUR ø30,5x6 mm

1

100.142

SM/230 P

11

SHIM ø1" x 0,08" (ø25,4x2 mm)

EPAISSEUR ø25,4x2 mm

2

100.042

120-150-180

11

SHIM ø1,2" x 0,08" (ø30,5x2 mm)

EPAISSEUR ø30,5x2 mm

2

100.141

SM/230 P

12

SPLIT PIN ø8

GOUPILLE ø8

1

600.116

*

S

OLID WHEEL SUPPORT AND ACCESSORIES

G

ROUPE ROUES SOLIDE ET ACCESSORIES

1

110.213

120-150-180

*

SOLID WHEEL SUPPORT AND ACCESSORIES

G

ROUPE ROUES SOLIDE ET ACCESSORIES

1

110.214

SM/230 P

ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE

1 WHEEL SUPPORT SUPPORT DE ROUE 1 100.291

3 SHIM EPAISSEUR 2 100.338

3 SPACER ENTRETOISE 1 100.339

4 WHEEL ROUE 1 610.434

5 SCREW (M12x150) VIS (M12x150) 1 610.271

6 NUT (M12-DIN 980) ECROU (M12-DIN 980) 1 600.077

7 SHIM ø1.2" x 1,26" (ø30,5x32 mm) EPAISSEUR ø30,5x32 mm 1 100.145

8 SHIM ø1,2" x 1" (ø30,5x25 mm) EPAISSEUR ø30,5x25 mm 2 100.144

9 SHIM ø1,2" x 0,47" (ø30,5x12 mm) EPAISSEUR ø30,5x12 mm 1 100.143

10 SHIM ø1,2" x 0,24" (ø30,5x6 mm) EPAISSEUR ø30,5x6 mm 1 100.142

11 SHIM ø1,2" x 0,08" (ø30,5x2 mm) EPAISSEUR ø30,5x2 mm 2 100.141

12 SPLIT PIN ø8 GOUPILLE ø8 1 600.116

*

PNEUMATIC WHEEL SUPPORT AND ACCESSORIES ROUES PNEUMATIQUE ET ACCESSORIES

1 100.580

ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE

1 WHEEL SUPPORT SUPPORT DE ROUE 1 100.020 120-150-180

1 WHEEL SUPPORT SUPPORT DE ROUE 1 100.147 SM/230 P

2 SHIM EPAISSEUR 2 100.006

3 SPACER ENTRETOISE 1 100.008

4 WHEEL ROUE 1 600.165

5 SCREW (M12x110) VIS (M12x110) 1 600.156

6 NUT (M12-DIN 980) ECROU (M12-DIN 980) 1 600.077

*

SOLID WHEEL SUPPORT GROUPE ROUES SOLIDE 1 110.206 120-150-180

*

SOLID WHEEL SUPPORT GROUPE ROUES SOLIDE 1 110.207 SM/230 P

ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE

1 WHEEL SUPPORT SUPPORT DE ROUE 1 100.291

3 SHIM EPAISSEUR 2 100.338

3 SPACER ENTRETOISE 1 100.339

4 WHEEL ROUE 1 610.434

5 SCREW (M12x150) VIS (M12x150) 1 610.271

6 NUT (M12-DIN 980) ECROU (M12-DIN 980) 1 600.077

*

PNEUMATIC WHEEL SUPPORT GROUPE ROUES PNEUMATIQUE

1 110.208

SOLID WHEEL SUPPORT - GROUPE ROUES SOLIDE (SM/120-150-180=110.205/SM/230=110.193)

PNEUMATIC WHEEL SUPPORT - GROUPE ROUES PNEUMATIQUE (SM/150-180-230=100.208)

S

OLID WHEEL SUPPORT AND ACCESORIES-GROUPE ROUES SOLIDE ET ACCESSORIES (SM/120-150-180=100.578/SM/230=110.030)

TABLE PART NO.910.066

PNEUMATIC WHEEL SUPPORT AND ACCESORIES-GROUPE ROUES PNEUMATIQUE ET ACCESSORIES (SM/150-180-230=100.580)

44

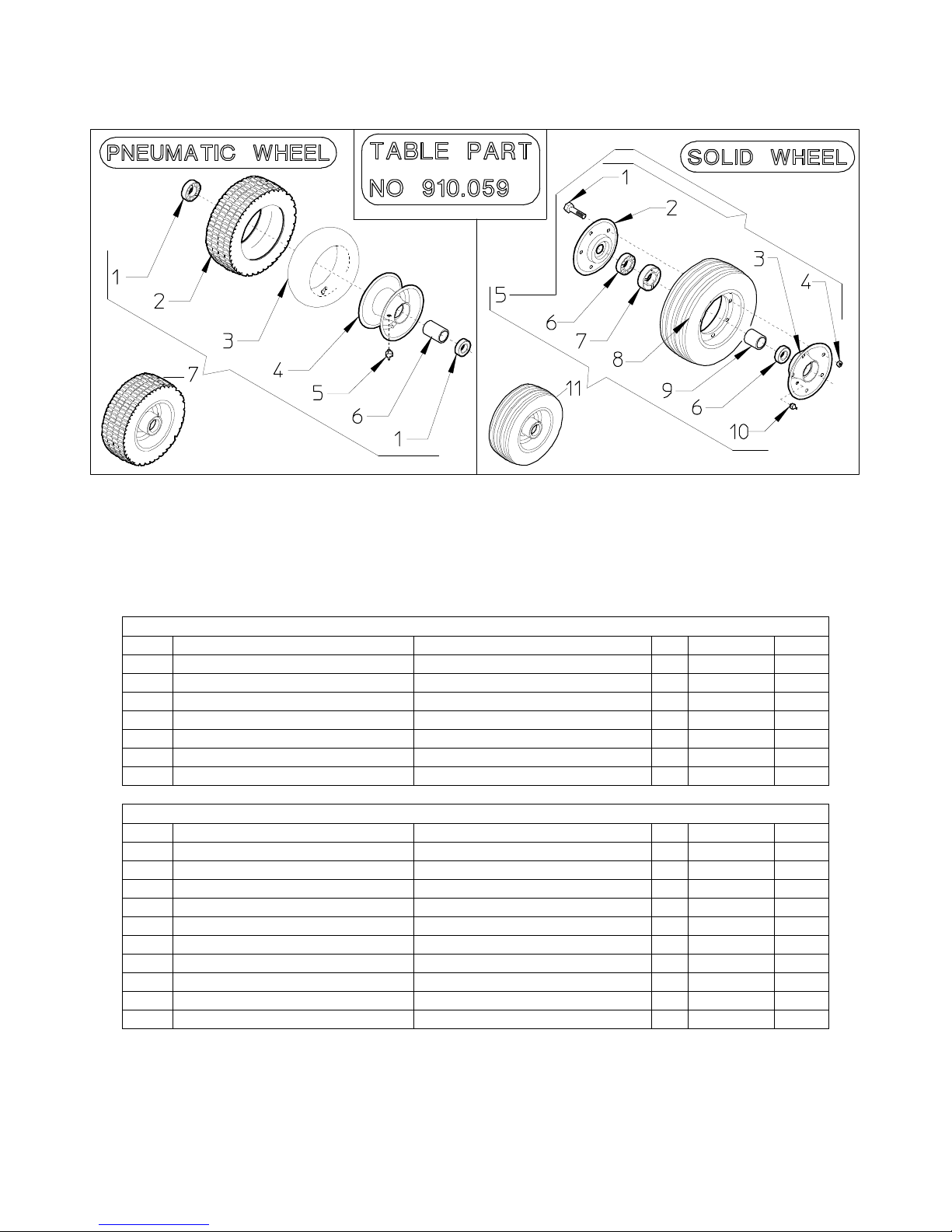

TABLE PART NO 910.059

PNEUMATIC WHHEL

ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE

1 BEARING 6005 Z PALIER 6005 Z 2 610.867

2 PNEU PENEU 1 610.321

3 TUBE CHAMBRE AD AIRE 1 610.315

4 RIM CIRCLE 1 610.468

5 GREASE NIPPLE M6 GRAISSEUR M6 1 600.124

6 SPACER ENTRETOISE 1 100.350

7 COMPLETE PNEU WHEEL ROUE PNEU COMPLETE 1 610.434

SOLID WHEEL

1 SCREW VIS 5 600.766

2 HALF RIM DEMI-CIRCLE 1 600.764

3 HALF RIM DEMI-CIRCLE 1 600.765

4 NUT (M8) ECROU (M8) 5 600.037

5 COMPLETE RIM CIRCLE COMPLET 1 620.680

6 BEARING 6205 Z PALIER 6205 Z 2 600.117

7 BUSH HAPPE 1 100.129

8 WHEEL ROUE 1 600.763

9 SPACER ENTRETOISE 1 100.128

10 GREASE NIPPLE M6 GRAISSEUR M6 1 600.124

11 COMPLETE SOLID WHEEL ROUE SOLIDE COMPLETE 1 600.165

45

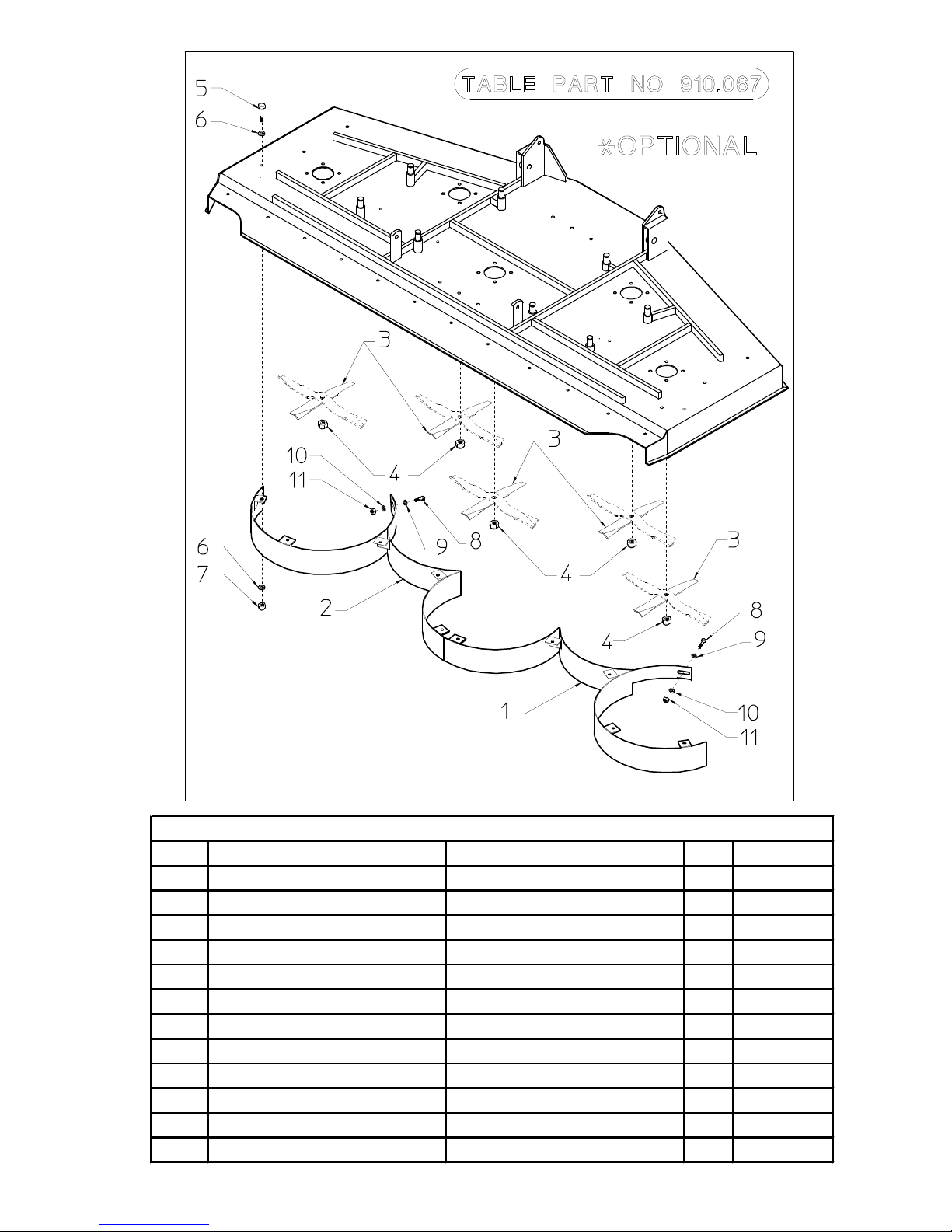

MULCHING KIT

ITEM DESCRIPTION DESCRIPTION Q.ty PART NO

1* RH CONVEYOR CONVOYEUR DROITE 1 100.739

2* LH CONVEYOR CONVOYEUR GAUCHE 1 100.740

3* BLADE LAME 5 100.358

4* NUT M16x1,5 ECROU M16x1,5 5 610.701

5* SCREW M10x25 VIS M10x25 10 600.006

6* WASHER ø10,5 RONDELLE ø10,5 20 600.322

7* NUT M10-DIN980 ECROU M10-DIN980 10 600.029

8* SCREW M8x20 VIS M8x20 2 600.223

9* WASHER ø8,5 RONDELLE ø8,5 2 600.115

10* LARGE WASHER ø8,5 RONDELLE LARGUE ø8,5 2 610.185

11* NUT M8-DIN980 ECROU M8-DIN980 2 600.076

* MULCHING KIT KIT MULCHING 1 100.735

TABLE PART NO 910.067

46

* OPTIONAL

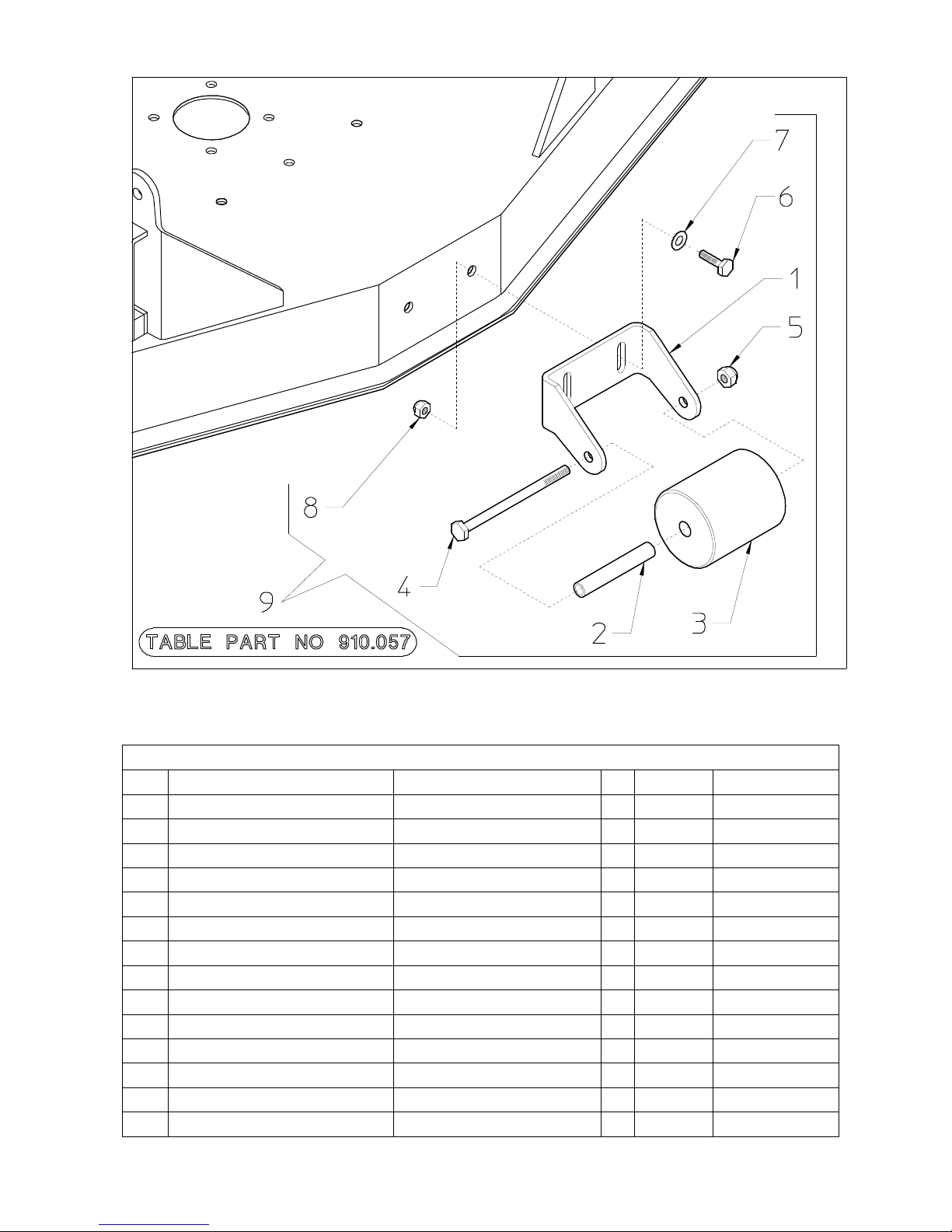

TABLE PART NO 910.057

ITEM DESCRIPTION DESCRIPTION Q.ty PART NO NOTE

1 SUPPORT SUPPORT 1 100.258 SM/120-150-180

1 SUPPORT SUPPORT 1 100.263 SM/230

2 SPACER ENTRETOISE 1 100.259 SM/120-150-180

2 SPACER ENTRETOISE 1 100.504 230/P

3 ROLLER ROULEAU 1 100.260 SM/120-150-180

3 ROLLER ROULEAU 1 100.505 SM/230

4 SCREW (M12x160) VIS (M12x160) 1 600.807 SM/120-150-180

4 SCREW (M12x220) VIS (M12x220) 1 610.676 SM/230

5 NUT (M12-DIN 980) ECROU (M12-DIN 980) 1 600.077

6 SCREW (M10x25) VIS (M10x25) 2 600.006

7 WASHER ø10,5 RONDELLE ø10,5 2 600.322

8 NUT (M10-DIN 980) ECROU (M10-DIN 980) 2 600.029

9

ANTISCALPING KIT, COMPLETE GROUPE ROLEAU FRONTALE

1 100.364 SM/120-150-180

9

ANTISCALPING KIT, COMPLETE GROUPE ROLEAU FRONTALE

1 100.503 SM/230

47

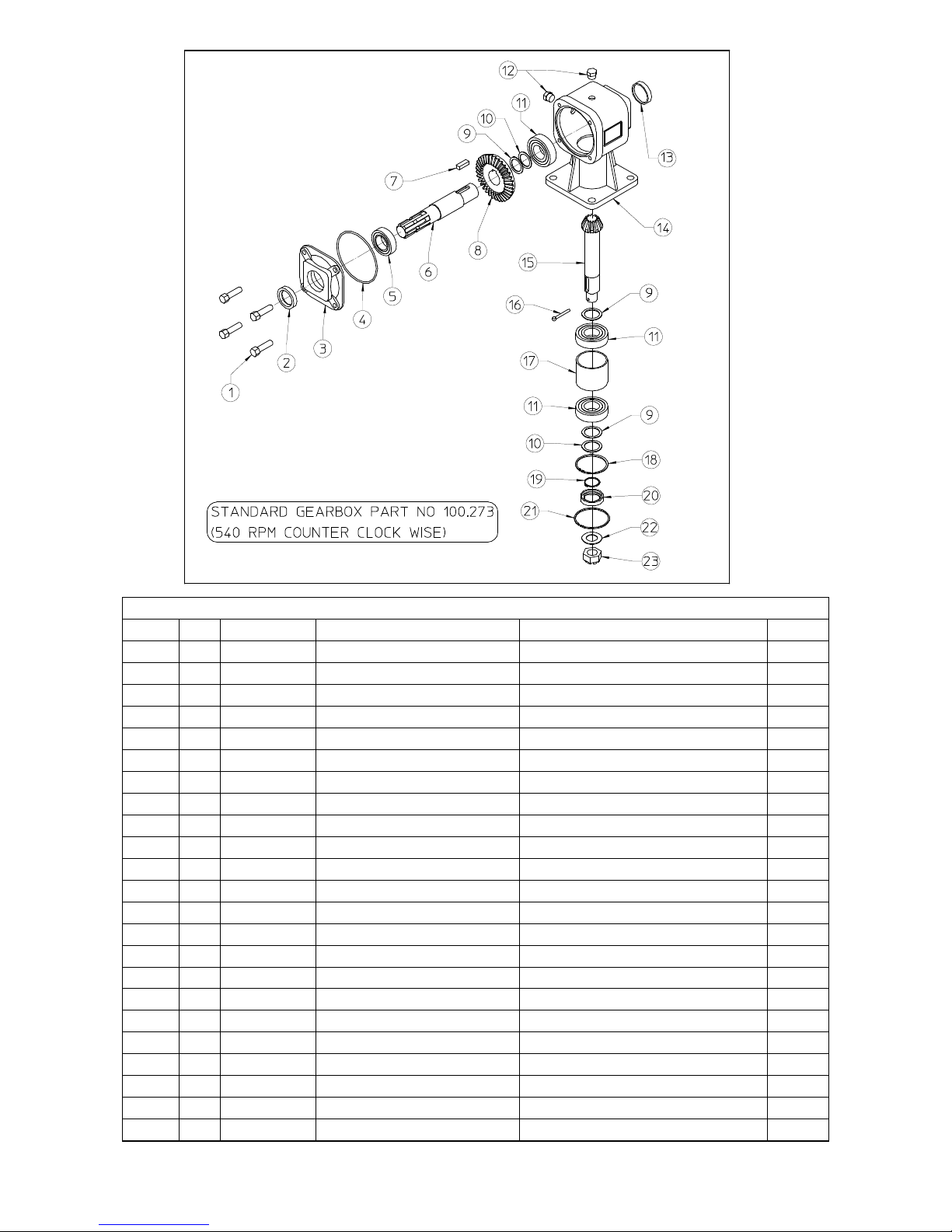

GEARBOX / MULTIPLIER PART NO 100.273

ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE

1 4 600.054 SCREW (M10x25) VIS (M10x25)

2 1 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7

3 1 100.272 COVER BOUCHON

4 1 600.345 OR GASCKET JOINT

5 1 600.342 BEARING 6007 PALIER 6007

6 1 100.268 PTO SHAFT ARBRE

7 1 600.325 LATCH A10x8x30 CLAVETTE A10x8x30

8 1 100.269 CROWN Z34 COURONNE Z34

9 3 200.274 SHIM ø35,2x0,5 EPAISSEUR ø35,2x0,5

10 2 200.490 SHIM ø35,2x0,3 EPAISSEUR ø35,2x0,3

11 3 600.327 BEARING 6207 PALIER 6207

12 2 600.560 PLUG 3/8" BOUCHON 3/8"

13 1 600.328 CAP CAPSULE

14 1 100.267 GEARBOX BOITE

15 1 100.271 PINION Z12 PIGNON Z12

16 1 600.347 SPLIT PIN ø5x50 GOUPILLE ø5x50

17 1 100.270 SPACER ENTRETOISE

18 1 600.332 SNAP RING I 72 SEGMENT D'ARRET I 72

19 1 600.333 SNAP RING E 35 SEGMENT D'ARRET E 35

20 1 600.338 GASCKET ø35-72x10 GARNITURE ø35-72x10

21 1 600.337 RING SB 72 ANNEAU SB 72

22 1 600.335 WASHER ø25 RONDELLE ø25

23 1 600.296 NUT M24x2 ECROU M24x2

48

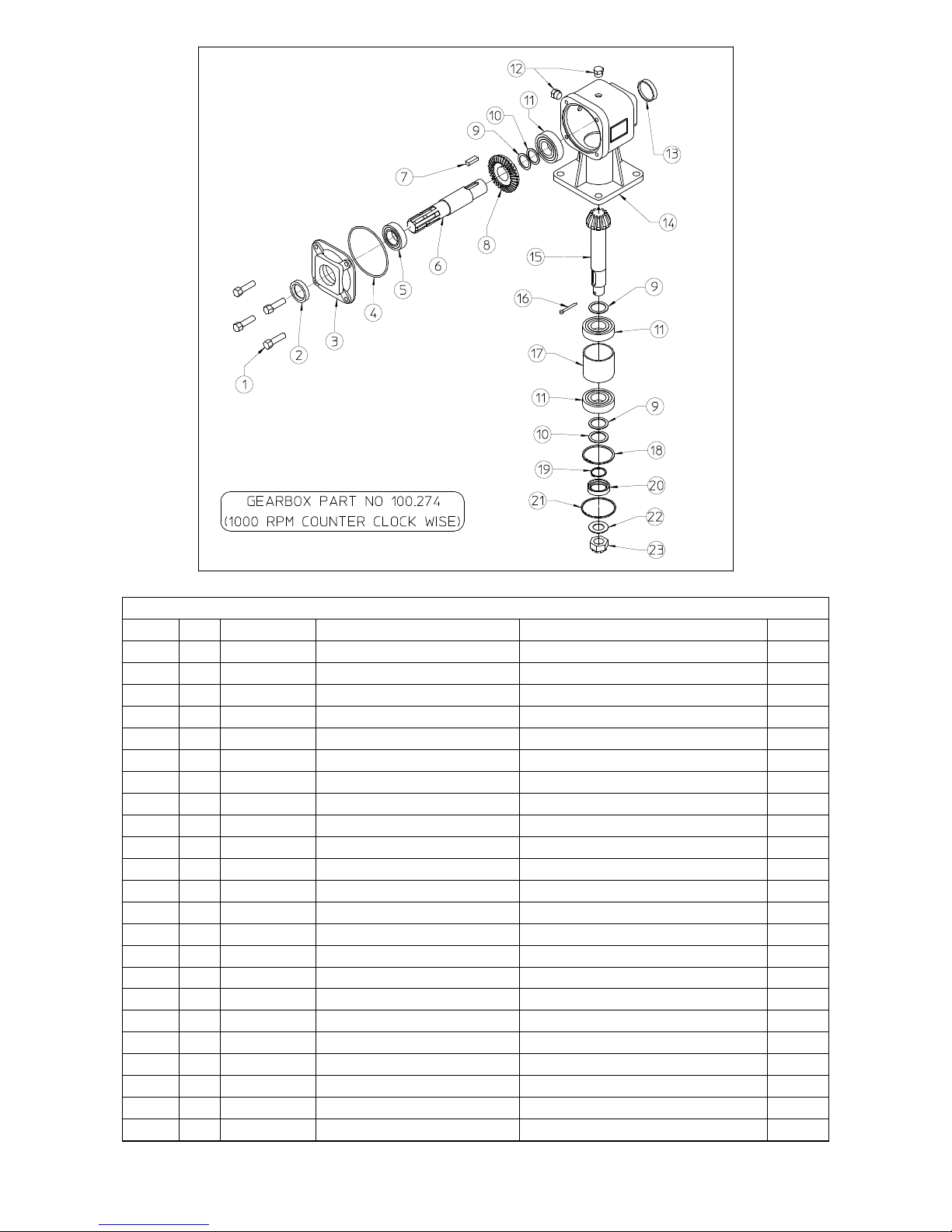

GEARBOX / MULTIPLIER PART NO 100.274

ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE

1 4 600.054 SCREW (M10x25) VIS (M10x25)

2 1 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7

3 1 100.272 COVER BOUCHON

4 1 600.345 OR GASCKET JOINT

5 1 600.342 BEARING 6007 PALIER 6007

6 1 100.268 PTO SHAFT ARBRE

7 1 600.325 LATCH A10x8x30 CLAVETTE A10x8x30

8 1 100.276 CROWN Z19 COURONNE Z19

9 3 200.274 SHIM ø35,2x0,5 EPAISSEUR ø35,2x0,5

10 2 200.490 SHIM ø35,2x0,3 EPAISSEUR ø35,2x0,3

11 3 600.327 BEARING 6207 PALIER 6207

12 2 600.560 PLUG 3/8" BOUCHON 3/8"

13 1 600.328 CAP CAPSULE

14 1 100.267 GEARBOX BOITE

15 1 100.277 PINION Z13 PIGNON Z13

16 1 600.347 SPLIT PIN ø5x50 GOUPILLE ø5x50

17 1 100.270 SPACER ENTRETOISE

18 1 600.332 SNAP RING I 72 SEGMENT D'ARRET I 72

19 1 600.333 SNAP RING E 35 SEGMENT D'ARRET E 35

20 1 600.338 GASCKET ø35-72x10 GARNITURE ø35-72x10

21 1 600.337 RING SB 72 ANNEAU SB 72

22 1 600.335 WASHER ø25 RONDELLE ø25

23 1 600.296 NUT M24x2 ECROU M24x2

49

GEARBOX / MULTIPLIER PART NO 100.275

ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE

1 4 600.054 SCREW (M10x25) VIS (M10x25)

2 1 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7

3 1 100.272 COVER BOUCHON

4 1 600.345 OR GASCKET JOINT

5 1 600.342 BEARING 6007 PALIER 6007

6 1 100.279 PTO SHAFT WITH PINION Z14 ARBRE AVEC PINION Z 14

7 1 600.325 LATCH A10x8x30 CLAVETTE A10x8x30

8 1 100.278 CROWN Z19 COURONNE Z19

9 3 200.274 SHIM ø35,2x0,5 EPAISSEUR ø35,2x0,5

10 2 200.490 SHIM ø35,2x0,3 EPAISSEUR ø35,2x0,3

11 3 600.327 BEARING 6207 PALIER 6207

12 2 600.560 PLUG 3/8" BOUCHON 3/8"

13 1 600.328 CAP CAPSULE

14 1 100.267 GEARBOX BOITE

15 1 100.304 SHAFT ARBRE

16 1 600.347 SPLIT PIN ø5x50 GOUPILLE ø5x50

17 1 100.270 SPACER ENTRETOISE

18 1 600.332 SNAP RING I 72 SEGMENT D'ARRET I 72

19 1 600.333 SNAP RING E 35 SEGMENT D'ARRET E 35

20 1 600.338 GASCKET ø35-72x10 GARNITURE ø35-72x10

21 1 600.337 RING SB 72 ANNEAU SB 72

22 1 600.335 WASHER ø25 RONDELLE ø25

23 1 600.296 NUT M24x2 ECROU M24x2

24 1 100.331 SHIM EPAISSEUR

50

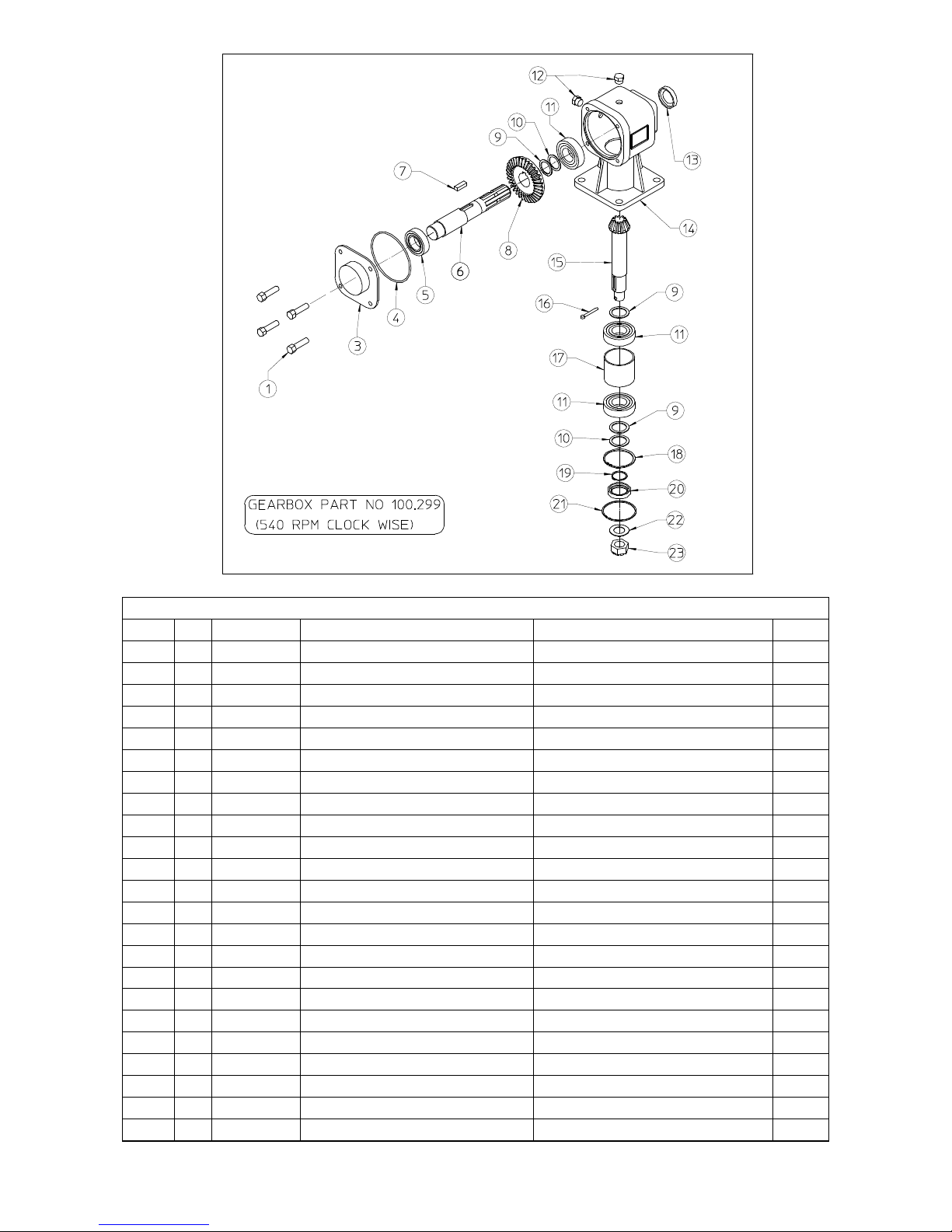

GEARBOX / MULTIPLIER PART NO 100.299

ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE

1 4 600.054 SCREW (M10x25) VIS (M10x25)

3 1 100.303 COVER BOUCHON

4 1 600.345 OR GASCKET JOINT

5 1 600.342 BEARING 6007 PALIER 6007

6 1 100.302 PTO SHAFT ARBRE

7 1 600.325 LATCH A10x8x30 CLAVETTE A10x8x30

8 1 100.269 CROWN Z34 COURONNE Z34

9 3 200.274 SHIM ø35,2x0,5 EPAISSEUR ø35,2x0,5

10 2 200.490 SHIM ø35,2x0,3 EPAISSEUR ø35,2x0,3

11 3 600.327 BEARING 6207 PALIER 6207

12 2 600.560 PLUG 3/8" BOUCHON 3/8"

13 1 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7

14 1 100.267 GEARBOX BOITE

15 1 100.271 SHAFT WITH PINION Z12 ARBRE AVEC PINION Z12

16 1 600.347 SPLIT PIN ø5x50 GOUPILLE ø5x50

17 1 100.270 SPACER ENTRETOISE

18 1 600.332 SNAP RING I 72 SEGMENT D'ARRET I 72

19 1 600.333 SNAP RING E 35 SEGMENT D'ARRET E 35

20 1 600.338 GASCKET ø35-72x10 GARNITURE ø35-72x10

21 1 600.337 RING SB 72 ANNEAU SB 72

22 1 600.335 WASHER ø25 RONDELLE ø25

23 1 600.296 NUT M24x2 ECROU M24x2

24 1 100.331 SHIM EPAISSEUR

51

GEARBOX / MULTIPLIER PART NO 100.300

ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE

1 4 600.054 SCREW (M10x25) VIS (M10x25)

3 1 100.303 COVER BOUCHON

4 1 600.345 OR GASCKET JOINT

5 1 600.342 BEARING 6007 PALIER 6007

6 1 100.302 PTO SHAFT ARBRE

7 1 600.325 LATCH A10x8x30 CLAVETTE A10x8x30

8 1 100.276 CROWN Z19 COURONNE Z19

9 3 200.274 SHIM ø35,2x0,5 EPAISSEUR ø35,2x0,5

10 2 200.490 SHIM ø35,2x0,3 EPAISSEUR ø35,2x0,3

11 3 600.327 BEARING 6207 PALIER 6207

12 2 600.560 PLUG 3/8" BOUCHON 3/8"

13 1 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7

14 1 100.267 GEARBOX BOITE

15 1 100.277 SHAFT WITH PINION Z13 ARBRE AVEC PINION Z13

16 1 600.347 SPLIT PIN ø5x50 GOUPILLE ø5x50

17 1 100.270 SPACER ENTRETOISE

18 1 600.332 SNAP RING I 72 SEGMENT D'ARRET I 72

19 1 600.333 SNAP RING E 35 SEGMENT D'ARRET E 35

20 1 600.338 GASCKET ø35-72x10 GARNITURE ø35-72x10

21 1 600.337 RING SB 72 ANNEAU SB 72

22 1 600.335 WASHER ø25 RONDELLE ø25

23 1 600.296 NUT M24x2 ECROU M24x2

52

GEARBOX / MULTIPLIER PART NO 100.301

ITEM Q.ty PART NO DESCRIPTION DESCRIPTION NOTE

1 4 600.054 SCREW (M10x25) VIS (M10x25)

3 1 100.303 COVER BOUCHON

4 1 600.345 OR GASCKET JOINT

5 1 600.342 BEARING 6007 PALIER 6007

6 1 100.314 SHAFT WITH PINION Z14 ARBRE AVEC PINION Z14

7 1 600.325 LATCH A10x8x30 CLAVETTE A10x8x30

8 1 100.278 CROWN Z19 COURONNE Z19

9 3 200.274 SHIM ø35,2x0,5 EPAISSEUR ø35,2x0,5

10 2 200.490 SHIM ø35,2x0,3 EPAISSEUR ø35,2x0,3

11 3 600.327 BEARING 6207 PALIER 6207

12 2 600.560 PLUG 3/8" BOUCHON 3/8"

13 1 600.346 GASCKET ø35-52x7 GARNITURE ø35-52x7

14 1 100.267 GEARBOX BOITE

15 1 100.304 SHAFT ARBRE

16 1 600.347 SPLIT PIN ø5x50 GOUPILLE ø5x50

17 1 100.270 SPACER ENTRETOISE

18 1 600.332 SNAP RING I 72 SEGMENT D'ARRET I 72

19 1 600.333 SNAP RING E 35 SEGMENT D'ARRET E 35

20 1 600.338 GASCKET ø35-72x10 GARNITURE ø35-72x10

21 1 600.337 RING SB 72 ANNEAU SB 72

22 1 600.335 WASHER ø25 RONDELLE ø25

23 1 600.296 NUT M24x2 ECROU M24x2

24 1 100.331 SHIM EPAISSEUR

53

CARDAN SHAFT E3 090 E PART NO 610.014

CARDAN SHAFT/ARBRE A CARDAN Part No. 610.014

Item

Part No.

Pos. Code

Q.ty DESCRIPTION DESCRIPTION

1

610.071

2

QUICK RELEASE YOKE 1 3/8" Z6

FOURCHE

2

610.070

2

CROSS JOURNAL SET

CROISILLION COMPLET

3

610.072

1

YOKE WITH OUTER TUBE

FOURCHE AVEC TUYAU EXT,

4

610.073

1

YOKE WITH INNER TUBE

FOURCHE AVEC TUYAU INT,

5

610.074

1

RING FOR OUTER TUBE

BAGUE EXT.

6

610.075

1

RING FOR INNER TUBE

BAGUE INT.

7

610.057

2

COMPLETE PUSH BUTTON

POUSSOIR COMPLET

8

610.076

1

OUTER HALF SHAFT-W ITHOUT GUARD

MOITIE ARBRE EXT.SANS PROT.

9

610.077

1

INNER HALF SHAFT-WITHOUT GUARD

MOITIE ARBRE INT.SANS PROT.

10

610.078

1

OUTER BEARING

FRETTE EXT.

11

610.079

1

INNER BEARING

FRETTE INT.

12

610.080

1

OUTER BASIC CONE

COIFFE COMPLETE EXT.

13

610.081

1

INNER BASIC CONE

COIFFE COMPLETE INT.

14

610.082

1

OUTER HALF GUARD

MOITIE PROTECTION EXT.

15

610.083

1

INNER HALF GUARD

MOITIE PROTECTION INT.

16

610.084

1

OUTER HALF SHAFT -WITH GUARD

MOITIE ARBRE EXT. AVEC PROT.

17

610.085

1

INNER HALF SHAFT -WITH GUARD

MOITIE ARBRE INT. AVEC PROT.

18

610.068

1

CHAIN

CHAINE

19

610.086

1

COMPLETE GUARD

PROTECTION

54

CARDAN SHAFT B3 090 B PART NO 610.326

CARDAN SHAFT/ARBRE A CARDAN Part No. 610.326

Item

Part No.

Pos. Code

Q.ty DESCRIPTION DESCRIPTION

1

610.057

2

COMPLETE PUSH BUTTON

POUSSOIR COMPLET

2

610.071

2

YOKE

FOURCHE

3

610.070

2

CROSS JOURNAL ASS.

CROISILLION COMPLET

4

610.205

8

CIRCLIP

BAGUE

5

610.206

2

GREASE NIPPLE

GRAISSEUR

6

610.207

1

OUTER TUBE YOKE

FOURCHE TUYAU EXT.

7

610.208

1

FLEXIBLE PIN

GOUPILLE

8

610.209

1

CM. CARDAN TUBE

TUYAU CARDAN

9

610.210

1

CM. CARDAN TUBE

TUYAU CARDAN

10

610.211

1

FLEXIBLE PIN

GOUPILLE

11

610.212

1

INNER TUBE YOKE

FOURCHE TUYAU INTERIEUR

12

610.341

1

HALF SHAFT (WITHOUT GUARD)

MOITIE ARBRE EXT.SANS PROT.

13

610.412

1

HALF SHAFT (WITHOUT GUARD)

MOITIE ARBRE INT.SANS PROT.

14

610.345

1

HALF SAFETY GUARD

MOITIE PROTECTION EXT.

15

610.346

1

HALF SAFETY GUARD

MOITIE PROTECTION INT.

16

610.343

1

HALF SHAFT (WITH GUARD)

MOITIE ARBRE EXT.AVEC PROT.

17

610.416

1

HALF SHAFT (WITH GUARD)

MOITIE ARBRE INT.AVEC PROT.

18

610.414

1

O. BEARING

FRETTE

19

610.415

1

I. BEARING

FRETTE

20

610.080

1

O. BASIC CONE

COIFFE COMPLETE EXT.

21

610.081

1

I. BASIC CONE

COIFFE COMPLETE INT.

22

610.338

1

CM. SAFETY TUBE

TUYAU PROTECTION EXT.

23

610.339

1

CM. SAFETY TUBE

TUYAU PROTECTION INT.

24

610.068

2

CHAIN

CHAINE

25

610.347

1

SAFETY GUARD

PROTECTION

55

56

Zona Industriale-Viale Grecia, 8

06018 TRESTINA-(Perugia)-ITALY

Tel. +39.075.8540021-Telefax +39.075.8540523

e-mail: sitrex@sitrex.it www.sitrex.com

Loading...

Loading...