S.p.A

OPERATOR'S MANUAL

SPARE PARTS LIST

RP/4-RP/5-RP/6-RP/8-RP/10-RP/12

TABLE OF CONTENT

1

MOUNTED SIDE-DELIVERY RAKES: RP/4-RP/5-RP/6-RP/8-RP/10-RP/12. ...................................... 2

1.1 INTRODUCTION .................................................................................................................................. 2

1.2 WARRANTEE ...................................................................................................................................... 2

1.3 CAUTION FOR USE ............................................................................................................................ 3

1.4 ASSEMBLY SOLUTION ...................................................................................................................... 3

1.5 SPECIFICATIONS ............................................................................................................................... 3

1.6 RP/4-RP/5 AND RP/6 RAKE ASSEMBLY INSTRUCTIONS ............................................................... 4

1.7 ASSEMBLING ...................................................................................................................................... 4

1.8 MOUNTING OF RP/4 AND RP/5 RAKE TO TRACTOR ..................................................................... 7

2

RP/8-RP/10 AND RP/12 V-RAKE ASSEMBLY INSTRUCTIONS.......................................................... 7

2.1 ASSEMBLING ...................................................................................................................................... 8

3

ON THE FIELD WITH RP/4-RP/5 AND RP/6 ......................................................................................... 9

3.1 RAKING..............................................................................................................................................10

3.2 SPREADING ......................................................................................................................................10

3.3 TURNING ...........................................................................................................................................10

4

ON THE FIELD WITH RP/8-RP/10 AND RP/12 V-RAKES ..................................................................11

5

FEATURES............................................................................................................................................12

6

MAINTENANCE ....................................................................................................................................12

7

Machine identification data and conformity declaration .................................................................12

8

SPARE PARTS LIST ........................................................................ Errore. Il segnalibro non è definito.

1

OPERATOR'S MANUAL

1

MOUNTED SIDE-DELIVERY RAKES:

RP/4-RP/5-RP/6-RP/8-RP/10-RP/12.

1.1 INTRODUCTION

This manual includes full instructions for a correct use and maintenance of the machinery, and the recommended spare parts list.

In order to prevent any possible damage of the machine and/or the operator(s) you are kindly requested to

go through this manual for a proper knowledge of the assembly of the implements, their use on the field, and

their maintenance. If any doubt, please contact your local dealer or distributor.

Should the machine be re-sold, you are kindly requested to supply this manual along with the machine to the

new purchaser.

1.2 WARRANTEE

The manufacturer warrants new machinery at the time of delivery to the original purchaser to be free from

defects in material and workmanship if properly set up and operated in accordance with this Operator's Manual.

The manufacturer undertakes to repair or replace free of charge any defective part which should be returned

by the purchaser (freight prepaid) and found to be defective by inspection authorized by the manufacturer

during the warranty period.

This warranty will be valid for 12 (twelve) months from the delivery of goods to the original purchaser.

In case the customer is not in a position to return the defectice part to the facturer, the manufacturer cannot

be held responsible for any cost due for repair or replacement of any part of the machine, he will only supply

the part(s) required for the repair and/or replacement.

The warranty is null and void when it is evident that the machine has been improperly used or repaired or

however repaired without authorization.

The manufacturer undertakes no responsibility for any obligation or agreement reached by any manufacturer

employers, agents or dealers, which are not in compliance with the above warranty. The manufacturer cannot be held responsible for the consequent damages. This warranty substitutes any other warranty, express

or implied, and any other manufacturer's obligation.

2

OPERATOR'S MANUAL

1.3 CAUTION FOR USE

It could be dangerous for people who are not familiar with this type of machine to use the rakes particularly

when kids are there during the assembly or operation on field. We therefore recommend the use of the only

to those people who are very familiar with the machine and the safety precautions.

1.4 ASSEMBLY SOLUTION

Our rakes are easily convertible into different sizes, as almost all parts are standard and interchangeable on

all sizes (wheel arms, wheels - etc.). With a special frame it is possible to attach together two RP/4-RP/5RP/6 rakes - R.H. and L.H. - and convert them into a V-rake.

Here are the advantages

1) Having a R.H. RP/4 rake or a R.H. RP/5 rake or a R.H. RP/6 rake you can convert them into a L.H.

RP/4 or L.H. RP/5 or L.H. RP/6 rake by replacing all wheel arms marked RIGHT with those marked

LEFT.

2) Having a R.H. RP/4 rake you can convert it into a RP/8 V-rake by attaching a L.H. RP/4 rake and the

relevant frame. To get one RP/10 V-rake from two RP/5 rake the procedure is still the same. To get

one RP/12 V-rake from two RP/6 rake the procedure is still the same.

3) You could also use your V-rake as two single ones, L.H. or R.H. rake, according to your requirements.

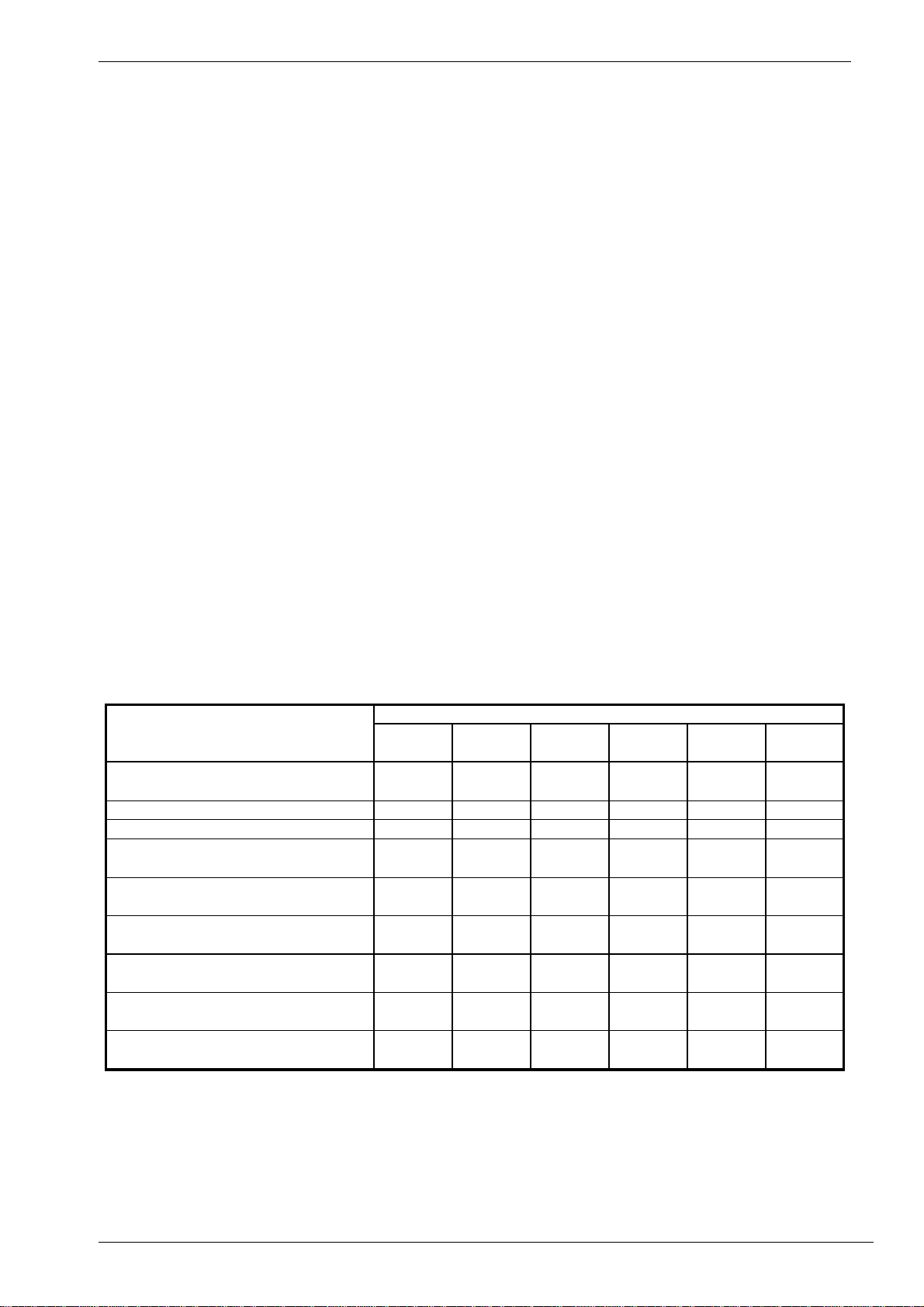

1.5 SPECIFICATIONS

MODELS

RP/4 RP/5 RP/6 RP/8 RP/10 RP/12

Weight

Number of wheels 4 5 6 8 10 12

Number of tines on each wheel 40 40 40 40 40 40

Wheel diam.

Raking working width

Turning and spreading working width

Transport width

Working speed

KW/HP required min.

180 Kg 200 Kg 250 Kg 460 Kg 520 Kg 620 Kg

396 lbs 440 lbs 551 lbs 1013 lbs 1146 lbs 1366 lbs

1,4 m 1,4 m 1,4 m 1,4 m 1,4 m 1,4 m

55" 55" 55" 55" 55" 55"

2,6 m 3,5 m 4,1 m 5,5 m 7,5 m 8,7 m

8' 6" 11" 6" 13' 6" 18' 1" 24' 7" 28' 6"

2,9 m 3,9 m 4,4 m 6,1 m 8,7 m 10 m

9' 6" 12' 10" 14' 5" 20' 28' 7" 32' 10"

2,2 m 2,3 m 2,3 m 3,6 m 4,7 m 4,7 m

7' 3" 7' 6" 7' 6" 11' 10" 15' 5" 15' 5"

22 kmh 22 kmh 22 kmh 22 kmh 22 kmh 22 kmh

14 mph 14 mph 14 mph 14 mph 14 mph 14 mph

22 Kw 22 Kw 22Kw 30 Kw 30Kw 30Kw

30 HP 30 HP 30HP 40HP 40HP 40HP

3

OPERATOR'S MANUAL

1.1

1.2

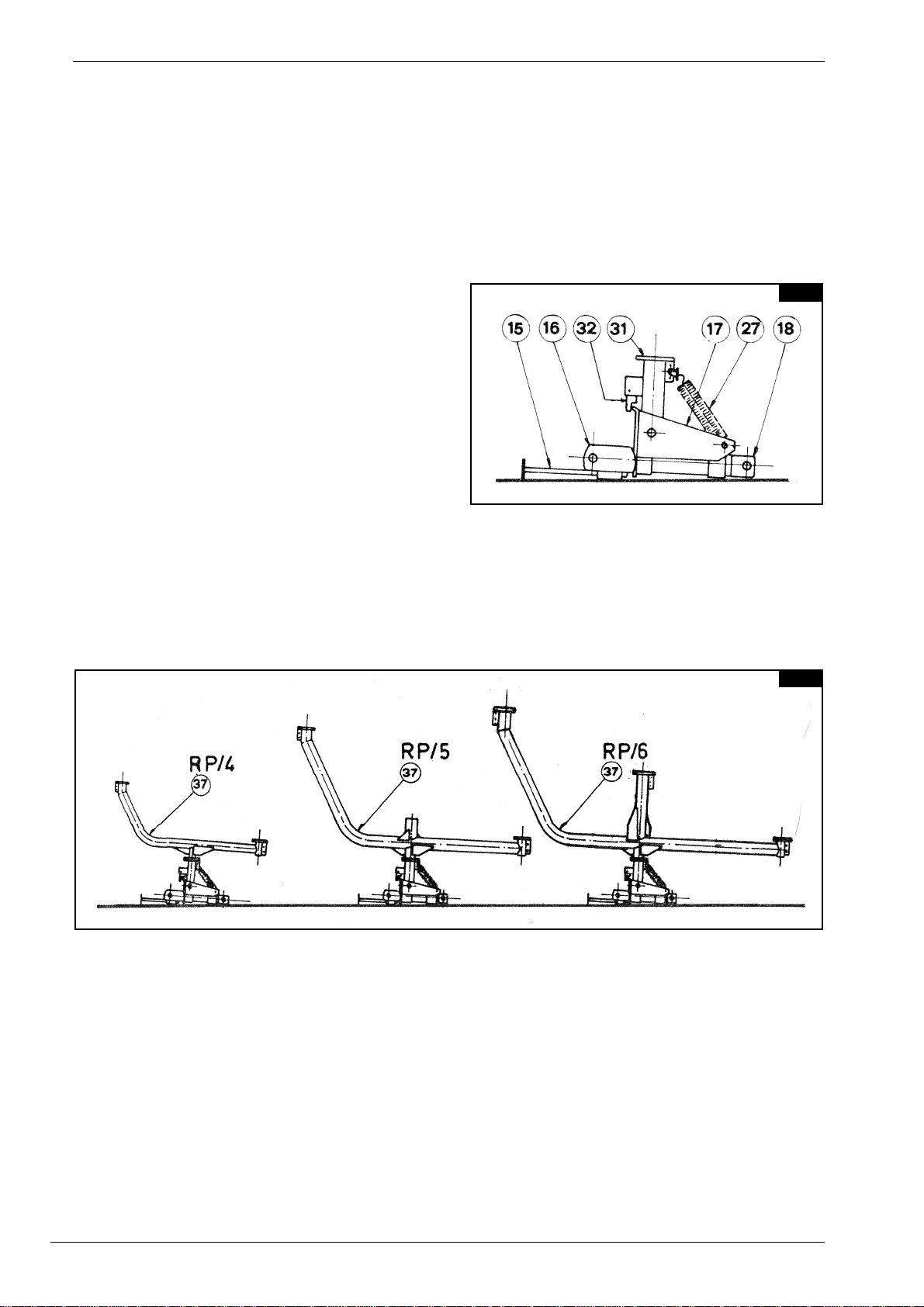

1.6 RP/4-RP/5 AND RP/6 RAKE ASSEMBLY INSTRUCTIONS

To room in the container we supply the partly knocked down. Here be-assembly instructions. For refer to

the enclosed breakdown.

1.7 ASSEMBLING

1.7.1

Position the parking stand (15) in its housing and

lock it with the pin (13), Next, lay the primary structure assembled) on the ground with the pipe (31)

upwards (pict 1.1).

1.7.2

Slide the pipe (37) into the swinging pipe (31) and retain with the supplied lever (33) and pin (36), so that it is

on axe with the three point hitch (pict. 1.2).

4

OPERATOR'S MANUAL

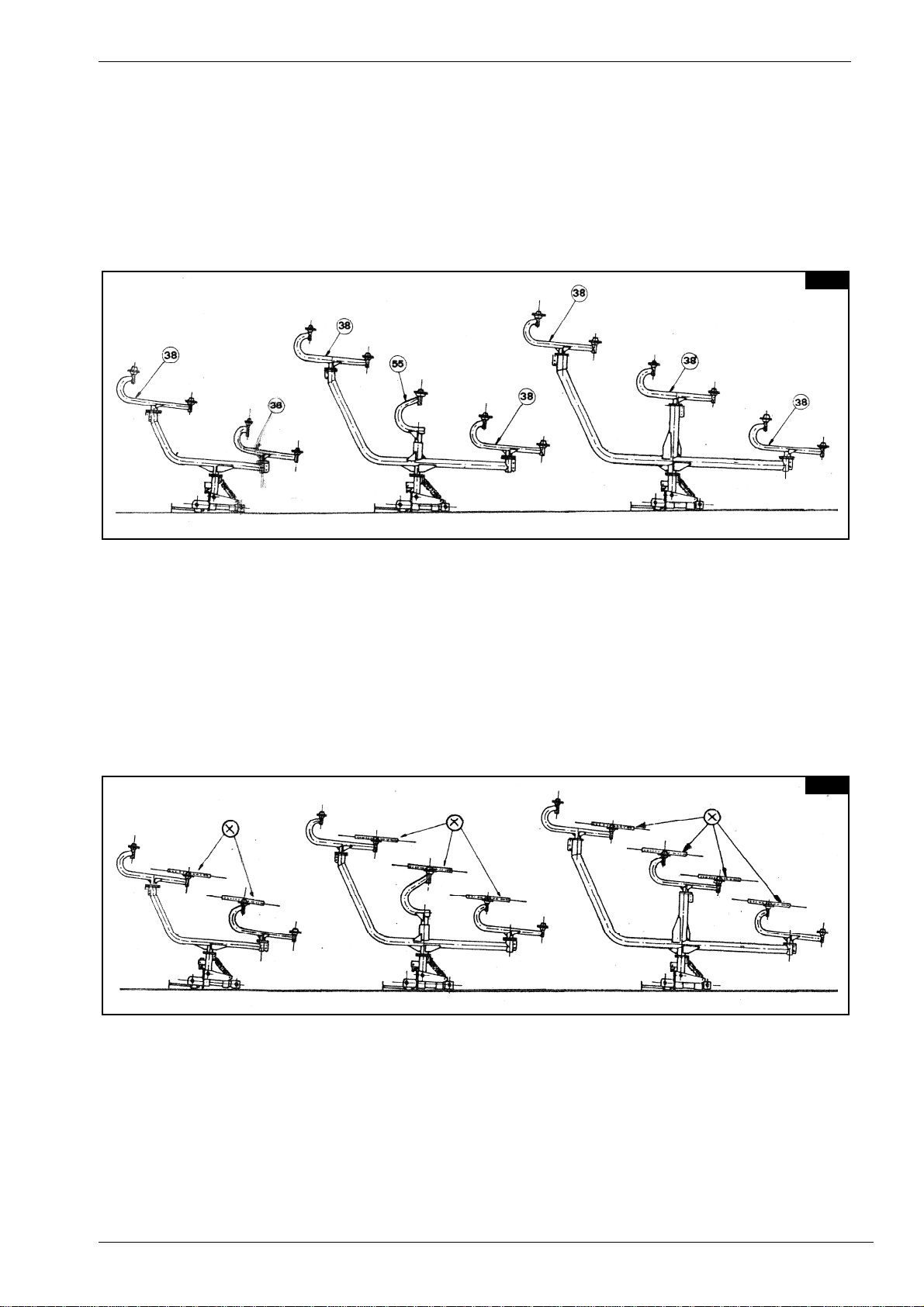

1.3

1.4

1.7.3

Attach the wheel arms (38) and lock them to the main pipe (37) with pins (36), so that they are on axe with

the main pipe (37). For the RP/5 rake, attach also the central arm (55) to the main pipe (37) and retain with

bolts (53-54-30) (pict. 1.3)

1.7.4

Attach the two central wheels (RP/4) or the three central wheels (RP/5) or the four central wheels (RP/6) to

the supplied arm flanges (38-55) and both them with the supplied bolts (pict. 1.4). when bolting the wheels

(x) check that the tine clamps (48) are turned toward the hub.

5

OPERATOR'S MANUAL

1.5

1.6

1.7.5

Lift the wheels (x) from the ground until they are in the working position (pict. 1.5).

1.7.6

Unlock the primary structure with the supplied lever (33) and pin (36), turn it by 90 degrees and lock it again

with the same pin. Now the is properly positioned on the ground and you only have to attach the remaining

wheels as explained above.

The rake is now fully assembled and ready to be mounted to the tractor (pict. 1.6)

IMPORTANT !

Above are the infractions for the R.H. rake assembly. Please refer to the above

instructions also for the L.H. rake assembly. Most parts are interchangeable for

both rakes, only the specific parts are marked RIGHT or LEFT

6

OPERATOR'S MANUAL

1.7 1.8

1.8 MOUNTING OF RP/4 AND RP/5 RAKE TO TRACTOR

When the rake Is ready to be to the tractor (pict. 1.6) attach the to the pins on both of the primary structure

(16).

Next, attach the three to the cap (18) of the pin. Now lift the rake to its setting and for transport lock with the

pin (32) for no rake floating (pict. 1.7).

Retain the part (17) to the crossbar (16) with the pin (19) into hole 1 (pict. 3.1) of the above said crossbar.

Now turn the main, pipe (37) the to the vertical position for transport (pict. 1.8).

IMPORTANT !

Never operate the rake with the pin (32) in the locked position. The locked position is for transport only (pict. 1.7).

2

RP/8-RP/10 AND RP/12 V-RAKE ASSEMBLY INSTRUCTIONS

RP/8 and RP/10 and RP/12 V-rakes are made as follows:

- no 1 main frame (1) complete of hitches (4-12).

- no 1 R.H. RP/4 or RP/5 or RP/6 rake, duly assembled as above.

- no 1 L.H RP/4 or RP/5 or RP/6 rake, duly assembled as above.

IMPORTANT !

On the R.H. and L.H. RP/4 and RP/5 and RP/6 rakes only the wheel arms and the

wheels are specific, all other parts are interchangeable for both rakes. The specific parts are marked RIGHT (for the R.H. rake) and LEFT (for the L.H. rake).

7

OPERATOR'S MANUAL

2.1 2.2

2.3 2.4

2.1 ASSEMBLING

2.1.1

Attach the hitches (4-12) and relevant counterplates (5) to both ends of the main frame (1) - in the position

show in picture 2.1 - with bolts (6-7-8) Attach hitches (4-12) to the opposite side of the tractor's hitches welded on the frame (1) (pict. 2.2).

2.1.2

Next, manually (pict, 2.3) or with a crane (pict. 2.4) lift the main frame (1) and bolt It to the tractor's lifting

arms.

8

OPERATOR'S MANUAL

2.5

3.1

2.1.3

Attach hitches (12) of frame (1) to the lateral pins welded on the primary structure (16) of rake with the pins

(11) the split pins (10). Attach the upper hitch (4) to the cap (18) the pin (9) and the split pin (10).

IMPORTANT !

For the V-rake transport please refer to the RP/4 and RP/5 and RP/6 rake

transport. Picture 2.5 below show the transport position of RP/8 and RP/10 and

RP/12 V-rakes.

3

ON THE FIELD WITH RP/4-RP/5 AND RP/6

Before operating the rake and after you have reached the field, unlock pin (32) (pict. 1.7 and relevant notes).

This will enable the rake to float independent of the main frame.

Next, adjust the rake working angle by positioning the pin (19) into the holes 2 to 7 (pict. 3.1). Hole 1 is for

transport only.

The rake is suitable for RAKING, SPREADING and TURNING as described below.

9

OPERATOR'S MANUAL

3.2

3.3

3.4

3.1 RAKING

(pict. 3.2) Turn the main

pipe (37) with the bend to

the left. Turn the wheel

arms (38) (on RP/5 turn

the wheel arm 55 as well)

with the bend to the left.

3.2 SPREADING

(pict. 3.3) Turn the main

pipe (37) with the bend to

the left.

Turn the wheel arms (38)

(on the RP/5 rake turn

the wheel arm 55 as well)

with the bend to the right.

3.3 TURNING

(pict. 3.4) Turn the main

pipe (37) with the bend to

the right. Turn the wheel

arms (38) (on RP/5 turn

the wheel arm 55 as well)

the bend to the left.

IMPORTANT !

Above we have described how to set a R.H. rake for the different operations. If

you to set a LH. rake for the above operations, please refer to pictures 3.2-3.4 of

V-rakes.

10

OPERATOR'S MANUAL

4.1

4.2

4

ON THE FIELD WITH RP/8-RP/10 AND RP/12 V-RAKES

RP/8 and RP/10 and RP/12 V-rakes are properly designed for windrowing, as ideal implement to complement the big balers. Slide the RP/4 or RP/5 or RP/6 on the frame (1) to get different working widths.

Below (pict. 4.1-4.2) the ideal positioning of the rake for a swath suitable for a 55 pick-up baler.

11

OPERATOR'S MANUAL

7.1

5

FEATURES

Our hayrakes are basically made of a primary structure of bent steel pipes, which make the Implement particularly sturdy and flexible. Tines are also very flexible, many are the possible adjustments of the rake, and

the implement can work fast and successfully even on slopes or on stony and rough soils. The wheel hubs

are made of pressed steel and are equipped with taper roller bearings, protected with a dust cover, so that

the wheels can properly turn.

6

MAINTENANCE

On our rakes no maintenance Is required. As a matter of fact no maintenance Is required for all gearings,

wheel hubs (equipped with 1st quality taper roller bearings and protected with a dust cover) and all setting

operations. No special tools are therefore required for servicing.

However, when the season is over, we recommend to clean the implement, to protect it from rust by oiling

and store it until next season.

IMPORTANT !

We recommend the use of our original spare parts only, to get your implement

working well for a long time. By ordering spare parts please always refer to the

parts breakdown provided with this manual.

Every our rake is provided with an identification label, as follows:

7

Machine identification data and conformity declaration

The machine is identified by means of the following technical data:

• Type of machine

• Registration number

• Year of manufacture

• Weight

stamped on the rating plate fastened to the frame of the machine. This data should be mentioned when requesting any replacements or information.

12

OPERATOR'S MANUAL

Have the wheels be turning

TROUBLES

1) Wheel does not unload

hay.

2) Tine failure.

3) The rake does not collect

the hay.

CAUSES

1) New tine, too much paint on it.

2) Mud on tine point due to moist

soil.

1) Going backwards with wheels

not lifted.

2) Too much pressure on the

wheels.

3) Tine rusted.

1) The wheel is too much inclined

to the ground.

2) Tine worn out.

REMEDIES

1)

on gravelly soil until the tine

is clean again.

2) The wheels are too close to

the ground.

1) Lift the wheels before going

backwards.

2) Lightly lift the rake.

3) Protect it by oiling.

1) By setting the 3rd point arm,

bring the wheel vertical to the

ground.

2) Replace it. We recommend

to replace all tines for uniform

height.

4) Too much floating of

wheels.

5) Bent tine.

1) Wheels too far from ground.

1) Going backwards with the

wheels not lifted.

2) Too much speed on rough soil.

3) Going across deep and narrow

ditches or prominences.

4) Too much weight on the

wheels.

1) Lightly lower the rake.

1) Lift the wheels when going

backwards

2) Reduce speed.

3) Reduce speed.

4) Lightly lift the rake.

13

OPERATOR'S MANUAL

14

ITEM

Q.ty

P ART NO

DESCRIP TION

NOTE

11200.055

RP /8 FRAME

22200.047

P IN

32600.017

SP LIT P IN

42200.056

UPP ER LINKAGE

56200.057

COUNTERP LATE

624600.001

SCREW M12x140

724600.018

SP R ING WASHER

824600.008

NUT

92200.058

3RD P OINT HITCH

1010600.019

SP LIT P IN

114200.059

P IN

124200.060

LOWER LINKAGE

134600.020

SP LIT P IN

142200.061

P ARKING STAND, FRAME

15

1(2)

200.062

P ARKING STAND, BASE

16

1(2)

210.369

BASE

17

1(2)

200.064

SUP P ORT

18

1(2)

200.065

CAP

19

1(2)

200.035

P IN

20

1(2)

200.067

P IN

21

2(4)

600.021

WASHER

22

2(4)

600.022

SP LIT P IN

23

1(2)

610.018

SCREW M14x120

24

1(2)

600.003

SCREW M14x100

25

1(2)

600.051

NUT

26

1(2)

200.068

UPP ER LINKAGE, SP RING

27

2(4)

200.069

SP R ING

28

1(2)

200.070

UPP ER LINKAGE, SP RING

29

1(2)

600.004

SCREW M12x30

30

1(2)

600.052

NUT

31

1(2)

200.071

SWINGING P IP E

32

1(2)

200.072

LOCK DEVIC E

33

3(6)

200.073

LEVER

34

6(12)

600.023

SNAP RING

35

3(6)

200.074

P IN

36

3(6)

200.075

P IN

37

1(2)

210.571

RP /4 MAIN P IPE

38

2(4)

200.077

WHEEL ARM, RH

38a

2(4)

200.078

WHEEL ARM, LH

39

4(8)

600.011

DUST COVER

40

4(8)

600.012

BEARING

41

4(8)

600.013

WHEEL HUB

42

4(8)

600.014

BEARING

43

4(8)

600.015

SELF LOCKING NUT

44

4(8)

600.016

SAFETY CAP

45

4(8)

200.010

FLANGE

46

4(8)

200.009

RIM

47

160/320

210.620

TINE DIA. 0,256" (6,5mm)

RP /4-RP /8 V

47

160/320

210.621

TINE DIA. 0,276" (7m m)

RP /4-RP /8 V

48

40(80)

200.012

TINE CAP

49

80(160)

600.005

SCREW

50

80(160)

600.029

NUT

51

24(48)

600.006

SCREW M10x25

52

24(48)

600.024

SP R ING WASHER

53

4(8)

205.277

P IN

54

24(48)

600.010

NUT

55

4(8)

600.301

SP LIT P IN

56

4(8)

205.041

HUB ASS Y

574210.180

WHEEL ASSY, RH

TINE DIA. 0,276" (7m m)

57a4210.181

WHEEL ASSY, LH

TINE DIA. 0,276" (7m m)

584210.182

WHEEL ASSY, RH

TINE DIA. 0,256" (6,5mm)

58a4210.183

WHEEL ASSY, LH

TINE DIA. 0,256" (6,5mm)

59

1(2)

600.075

NUT

TABLE P ART NO 920.255

15

16

ITEM

Q.ty

P ART NO

DESCRIPTION

NOTE

11200.081

RP /10 FR AME

22200.047

P IN

32600.017

SP LIT P IN

42200.056

UPP ER LINKAGE

56200.057

COUNTER P LATE

624600.001

SCREW M12x140

724600.018

SP RING WASHER

824600.008

NUT

92200.058

3RD P OINT HITCH

1010600.019

SP LIT P IN

114200.059

P IN

124200.060

LOWER LINKAGE

134600.020

SP LIT P IN

142200.061

P ARKING STAND, FRAME

15

1(2)

200.062

P ARKING STAND, BAS E

16

1(2)

210.369

BASE

17

1(2)

200.064

SUP P OR T

18

1(2)

200.065

CAP

19

1(2)

200.035

P IN

20

1(2)

200.067

P IN

21

2(4)

600.021

WASHER

22

2(4)

600.022

SP LIT P IN

23

1(2)

610.018

SCREW M14x120

24

1(2)

600.003

SCREW M14x100

25

1(2)

600.051

NUT

26

1(2)

200.068

UPP ER LINKAGE, SP RING

27

2(4)

200.069

SP RING

28

1(2)

200.070

UPP ER LINKAGE, SP RING

29

1(2)

600.004

SCREW M12x30

30

3(6)

600.052

NUT

31

1(2)

200.071

SWINGING P IP E

32

1(2)

200.072

LOCK DEVIC E

33

3(6)

200.073

LEVER

34

6(12)

600.023

SNAP RING

35

3(6)

200.074

P IN

36

3(6)

200.075

P IN

37

1(2)

210.199

RP /5 MAIN P IPE

38

2(4)

200.077

WHEEL ARM, RH

38a

2(4)

200.078

WHEEL ARM, LH

39

5(10)

600.011

DUST COVER

40

5(10)

600.012

BEARING

41

5(10)

600.013

WHEEL HUB

42

5(10)

600.014

BEARING

43

5(10)

600.015

SELF LOCKING NUT

44

5(10)

600.016

SAF ETY CAP

45

5(10)

200.010

FLANGE

46

5(10)

200.009

RIM

47

200/400

210.620

TINE DIA. 0,256" (6,5mm )

RP /5-RP /10 V

47

200/400

210.621

TINE DIA. 0,276" (7mm)

RP /5-RP /10 V

48

50(100)

200.012

TINE CAP

49

100(200)

600.005

SCREW

50

100(200)

600.029

NUT

51

30(60)

600.006

SCREW M10x25

52

30(60)

600.024

SP RING WASHER

53

2(4)

600.007

SCREW M12x85

54

2(4)

600.018

SP RING WASHER

551200.079

ARM, RH

55a1200.080

ARM, LH

56

5(10)

205.277

P IN

57

5(10)

600.301

SP LIT P IN

58

30(60)

600.010

NUT

59

4(8)

600.075

NUT

60

5(10)

205.041

HUB ASSY

615210.180

WHEEL ASSY, RH

TINE DIA. 0,276" (7mm)

615210.181

WHEEL ASSY, LH

TINE DIA. 0,276" (7mm)

625210.182

WHEEL ASSY, RH

TINE DIA. 0,256" (6,5mm )

625210.183

WHEEL ASSY, LH

TINE DIA. 0,256" (6,5mm )

63

1(2)

210.198

RP /5 P IPE

64

3(6)

600.310

SCREW M14x40

TABLE P ART NO 920.254

17

18

ITEM

Q.ty

PART NO

DESCRIPTION

NOTE

11200.081

FRAME

22200.047

PIN

32600.017

SPLIT PIN

42200.056

UPPER LINKAGE

56200.057

COUNTERPLATE

624600.001

SCREW M12x140

724600.018

SPRING WASHER ø13 DIN 127B

824600.008

NUT M12

92200.058

PIN

1011600.019

SPLIT PIN

114200.059

PIN

124200.060

LOWER LINKAGE

134600.020

SPLIT PIN

142200.061

PARKING STAND, FRAME

15

1(2)

230.163

PARKING STAND, BASE

16

1(2)

210.376

BASE

17

1(2)

230.202

SUPPORT

18

1(2)

200.094

CAP

19

1(2)

200.035

PIN

20

1(2)

230.203

PIN

21

1(2)

600.245

WAHER ø25

22

1(2)

600.725

NUT M24

23

1(2)

610.018

SCREW M14x120 DIN 931 8.8

24

1(2)

600.003

SCREW M14x100 DIN 931 8.8

25

1(2)

600.051

NUT M14

26

1(2)

200.121

UPPER LINKAGE, SPRING

27

2(4)

300.015

SPRING

28

1(2)

200.122

LOWER LINKAGE, SPRING

29

1(2)

600.004

SCREW M12x30 DIN 933 8.8

30

1(2)

600.052

NUT M12 DIN 934

31

1(2)

230.171

SWINGING PIPE

32

1(2)

200.072

LOCK DEVICE

33

4(8)

200.073

LEVER

34

8(16)

600.023

SNAP RING E 15 DIN 471

35

4(8)

200.074

PIN

36

4(8)

200.075

PIN

37

1(2)

210.612

MAIN PIPE

38

3(6)

200.077

RH WHEEL ARM

38a

3(6)

200.078

LH WHEEL ARM

39

6(12)

600.011

DUST COVER

40

6(12)

600.012

BEARING 30205

41

6(12)

600.013

WHEEL HUB

42

6(12)

600.014

BEARING 30204

43

6(12)

600.015

NUT M18x1,5

44

6(12)

600.016

SAFETY CAP

45

6(12)

200.010

FLANGE

46

6(12)

200.009

RIM

47

240(480)

210.620

TINE ø0,256"-6,5 mm

47

240(480)

210.621

TINE ø0,276"-7 mm

48

60(120)

200.012

TINE CLAMP

49

120(240)

600.005

SCREW M10x25 DIN 603 6.8

50

120(240)

600.029

NUT M10 DIN 980

51

60(120)

600.006

SCREW M10x25 DIN 933 8.8

52

60(120)

600.024

SPRING WASHER ø10,5 DIN 127B

53

6(12)

205.277

PIN

54

6(12)

600.301

SPLIT PIN

55

1(2)

600.075

NUT M14 DIN 980

56

60(120)

600.010

NUT M10 DIN 934

57

6(12)

205.041

HUB ASSY

58

3(6)

210.180

RH WHEEL ASSY (TINE ø0,276")

58

3(6)

210.181

LH WHEEL ASSY (TINE ø0,276")

59

3(6)

210.182

RH WHEEL ASSY (TINE ø0,256")

59

3(6)

210.183

LH WHEEL ASSY (TINE ø0,256")

60

1(2)

210.613

PIPE

61

3(6)

600.310

SCREW M14x40 DIN 933 8.8

62

3(6)

600.075

NUT M14 DIN 980

63

1(2)

620.629

SPRING PIN ø8x55

64

4(8)

600.808

BUSH

65

1(2)

600.034

GREASE NIPPLE M8

TABLE PART NO 920.248

19

20

ITEM

Q.ty

P ART NO

DESCRIP TION

NOTE

11210.575

P IP E

22600.020

SP LIT P IN

33600.075

NUT M14 DIN 980

41200.064

SUP P ORT

51200.067

P IN

62600.021

WASHER D.23 DIN 125A

72600.022

SP LIT P IN

81200.222

P IN

95600.019

SP LIT P IN

101610.018

SCREW M14x120 DIN 931 8.8

111210.369

BASE

123600.310

SCREW M14x40 DIN 933 8.8

131200.062

P ARKING STAND

141600.004

SCREW M12x30 DIN 933 8.8

151600.008

NUT M12 DIN 934-8

161200.068

UPP ER LINKAGE

172200.069

SP RING

181200.071

SWINGING P IPE

191200.070

LOWER LINKAGE, SP RING

201200.072

LOWER DEVICE

214200.073

LEVER

228600.023

SNAP RING E15 DIN 471

234200.074

P IN

244200.075

P IN

251210.576

MAIN P IP E

262200.077

WHEEL ARM, RH

272200.078

WHEEL ARM, LH

281210.067

ARM

291200.065

CAP

305205.277

P IN

315600.011

DUST COVER

325600.012

BEARING 30205

335600.013

WHEEL HUB

345600.014

BEARING 30204

355600.015

SELF LOCKING NUT M18x1.5-6

365600.301

SP LIT P IN

375600.016

SAFETY CAP

385205.041

HUB ASSY

3930600.006

SCREW M10x25 DIN 933 8.8

4030600.024

SP RING WASHER D 10.5

4130600.010

NUT M10 DIN 934-8

42

100

600.005

SCREW

4350200.012

TINE CLAMP

445200.010

FLANGE

45

100

600.029

NUT M10 DIN 980

465200.009

RIM

47

200

210.620

TINE DIA. 0,256" (6,5mm)

47

200

210.621

TINE DIA. 0,276" (7mm)

485210.180

WHEEL ASSY, RH

TINE DIA. 0,276" (7mm)

485210.181

WHEEL ASSY, LH

TINE DIA. 0,276" (7mm)

495210.182

WHEEL ASSY, RH

TINE DIA. 0,256" (6,5mm)

495210.183

WHEEL ASSY, LH

TINE DIA. 0,256" (6,5mm)

501600.003

SCREW M14x100 DIN 931 8.8

511600.051

NUT M14 DIN 934

TABLE P ART NO 920.146

21

22

Zona Industriale-Viale Grecia, 8

06018 TRESTINA-(Perugia)-ITALY

Tel. +39.075.8540021-Telefax +39.075.8540523

e-mail: sitrex@sitrex.it www.sitrex.com

Loading...

Loading...