sitrex Action 120, Action 120 L Use And Maintenance Manual

Before starting to

use the machine

read the

instructions

Use and maintenance manual

Round baler

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 2 -

INDEX

1 DESCRIPTION AND MAIN FEATURES 5

1.1 Presentation 5

1.1.1 Intended users of the manuals 5

1.2 Warranty 5

1.2.1 Exclusions from warranty 5

1.3 Markings 6

1.4 Description and use of the machine 6

1.5 Not forecasted use of the machine 6

1.6 Sound level 6

1.7 Technical data 8

2 SAFETY AND PREVENTION 10

2.1 Safety 10

2.1.1 Terminology used 10

2.1.2 General safety rules 10

2.1.3 Machine control operations 13

2.2 Safety signs (pictograms) 14

2.3 Indication signals 16

3 TRANSPORT AND HANDLING 18

3.1 General warnings 18

3.2 Load by crane 18

3.3 Load by loading ramps 19

3.4 Circulation on the road 19

3.4.1 Tires pressure 20

3.4.2 Admitted slopes 20

4 HARVESTING INSTRUCTIONS 21

4.1 General guidelines 21

4.2 Advantages with low and wide windrow

21

4.3 Disadvantages with high and narrow

windrow 21

4.4 Feeding procedure 21

4.4.1 Feeding with narrow windrow 21

4.4.2 Feeding with wide windrow 21

4.4.3 Start the feeding 21

4.4.4 Bale discharge 21

5 USE INSTRUCTIONS 23

5.1 Prior to use 23

5.1.1 Work position 23

5.2 Hitching to the tractor 23

5.3 P.T.O. Shaft 23

5.3.1 Torque limiter with shear bolt 25

5.4 Adjustment carriageway 25

5.5 Hydraulic connection 25

5.6 Electric system 26

5.7 Electric signal of final density of pressing

“M50” 26

5.8 Electric switch-board “M100” (optional)27

5.9 Automatic switch-board “M200” (optional)

27

5.9.1 Installation and linkage 27

5.9.2 Control description 27

5.9.3 Programming 28

5.9.4 Manual use 28

5.9.5 Semi-automatic use 28

5.9.6 Automatic use 28

5.10 Twine binding 29

5.10.1 Knotting twine 29

5.10.2 Side adjustment of binding 30

5.11 Net binding 30

5.11.1 Reset the net wrap binder 30

5.11.2 Number of net turning on the bale 31

5.12 In working 31

5.13 Adjusting round bale density 32

5.14 Pick-up height adjustment 32

5.15 Pick-up with adjustable wheels

(optional) 32

5.16 Rake adjustment 33

5.17 Machine jamming 33

5.18 Stopping the round baler 33

5.19 Parking 33

5.20 Safety device 33

5.21 Checks and tests 34

6 MAINTENANCE 35

6.1 Maintenance 35

6.2 Rear door safety block 35

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 3 -

6.3 P.T.O. shaft 35

6.4 After the first 8 hours of use 35

6.5 Every 8 hours of use 36

6.6 Every 24 hours of use 36

6.7 After the first 50 hours of use 36

6.8 Every 50 hours of use 36

6.9 Every 400 hours of use 36

6.10 Lubrication 36

6.11 Extraordinary maintenance 37

6.11.1 Lifting through hydraulic jacks 37

6.12 Storage 38

6.13 Hydraulic diagram 39

6.14 Troubleshotting: cause and possible

remedy 40

7 SPARE PARTS 42

7.1 Spare parts 42

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 4 -

Details mentioned in the identification plate:

Machine model

Serial number

Year of production

Machine weight

Authorized SITREX repair center to contact for

service in

The identification plate is located at the front right

side of the machine, near to the drawbar hooking.

In this manual, there are symbols and notes used

to highlight requirements of particular interest for

the machine and / or operator, their meaning is

indicated here below.

DANGERS CAN BE OF 3 LEVELS:

DANGER

The writing «DANGER» indicates the

maximum danger and warns that if the

described operations are not properly carried

out, this can cause serious injury, death or

long-term health risks.

WARNING

The signal «WARNING» warns that if the

described operations are not properly carried

out, this can cause serious injury, death or

long-term health risks.

CAUTION

This signal advises that if the described

operations are not properly carried out, they

can cause damages to the machine and/or to

the person.

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 5 -

1 DESCRIPTION AND MAIN

FEATURES

1.1 PRESENTATION

This manual contains information and instructions

and what deemed necessary for the knowledge,

the proper use and the regular maintenance of the

baler «ACTION 120», hereinafter also referred to

as the machine, is manufactured by SITREX of

Trestina (Perugia) Italy, hereinafter referred to

more simply as the Manufacturer.

The contents of this manual does not constitute a

detailed account of the various components and

how they work, the user, however, will find what is

normally useful for the safe use and proper

preservation of the machine. From the

observance and fulfilment of what described in

this manual, together with a careful and cautious

maintenance, depends the smooth operation,

durability and operating economy of the machine.

Failure to comply with the instructions given

herein, negligent operation, incorrect use of the

machine and the performance of unauthorized

modifications may cause the loss of any rights of

warranty provided by the Manufacturer.

WARNING

Consequently, the Manufacturer declines all

responsibility for damages resulting from

negligence or failure to observe the

instructions herein.

When in need of repairs or overhauling involving

complex operations, you must contact the

authorized Service Centres having their own

skilled personnel, or get in touch with the

Manufacturer directly. Remember that the

Manufacturer is available to ensure a prompt and

precise technical service and any other element

required to get the maximum efficiency from the

machine.

DANGER

This manual is an integral part of the machine

and must be kept with it at all times, even

when it is moved to a new location or sold.

It must be kept in a safe place known to the

authorized personnel. It is up to said personnel to

make sure it is kept safe and intact for

consultation for the entire duration of the

machine’s service life. Should it be damaged or

lost, apply immediately to the Manufacturer for a

new copy.

1.1.1 Intended users of the manuals

This manual represents the fundamental

instrument for the personnel authorized to perform

various operations concerning the machine, i.e.:

Personnel in charge of the transportation and

handling of the machine;

Personnel in charge to operate with the

machine;

Maintenance personnel;

Personnel in charge of the demolition.

1.2 WARRANTY

The Manufacturer warrants its brand new

products for a period of 12 (twelve) months from

the date of the purchase.

Check at the delivery that the machine has not

been damaged during transport and that the

accessories are integral and complete.

Any complaints must be made in writing within 8

(eight) days from the receipt of the machine. The

warranty shall consist in the free of charge repair

or replacement of any parts proving to be

defective after a careful examination carried out

by the Manufacturer’s Engineering Department

(and does not include the electrical parts or any

eventual implement).

Under no circumstances, the repair or

replacement of parts covered by the warranty

shall extend the warranty period.

The purchaser may only enforce its rights

concerning the warranty only as far as the

warranty service is concerned, also featured in the

supply contract.

1.2.1 Exclusions from warranty

Warranty becomes void (in addition to those

situations featured in the supply contract):

In the event of an incorrect operations

attributable to the operator.

In the event, the damage can be attributable

to poor maintenance.

In the event the machine is altered, following

repairs carried out by the user without the

Manufacturer’s permission or subsequent to

the fitting of non-original spare parts, and the

damage is the result of said alterations.

In the event the instructions featured in this

manual have not been followed.

Neither shall the warranty cover any damage

resulting from negligence, carelessness, bad

operation or improper use of the machine.

WARNING

The removal of the safety devices supplied

with the machine shall automatically cause the

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 6 -

warranty to become void and relieve the

Manufacturer of any responsibility.

In addition, the warranty shall become void in

the event non-original spare parts are used.

The machine, or parts of it, must be returned

carriage free, even when under warranty.

1.3 MARKINGS

Each machine features an identification plate,

featuring the following data:

Name and address of the Manufacturer;

EU. AP.: European road homologation

number (if is present);

Category: Machine category;

VIN: frame serial number;

LADEN MASS: Mass on the axes;

A-0: Mass on the towing eye;

A-1: Mass on the first axle;

A-2: Mass on the second axle (if is present);

DESIGNATION: Type of machine;

TYPE/VARIANT: Machine model;

MODEL YEAR: Model year;

CONSTRUCTION YEAR: Construction year

of the machine;

«CE» marking;

Identification plate

Data showed on the machine identification plate

have to be quoted at page 4 of this manual and

they have to be always mentioned for eventual

requests for spare parts or need of assistance.

The machine is standards equipped with:

Machine use and maintenance manual

Declaration of «CE» conformity

1.4 DESCRIPTION AND USE OF THE

MACHINE

«ACTION 120» Round Baler manufactured by

SITREX is a machine bearing the CE marking in

conformity with the provisions of the directive

98/37/EC, as described in the declaration of

conformity each round baler comes with

mechanisms for picking up the agricultural

products and for pressing them into cylindrical

bales. The round baler is mounted on an axis with

rubber wheels and is equipped with an adjustable

height drawbar for hooking to the tractor.

The motive power required for the machine’s

operation is transmitted from the tractor by means

of the power-takeoff shaft (bearing CE marking)

and the connection of the round baler’s electrical

system to the tractor’s 12V power socket.

To connect the electrical system, the power cable

must be connected to the tractor on the 12V

socket, and the light cable to the seven-pin plug.

The hydraulic system of the baler is controlled by

the tractor hydraulic distributor: the machine is

connected to two quick couplings by flexy tubes.

The outputs control the opening cylinder of the

tailgate and lift the pick-up (pick-up) respectively.

The round baler is a machine designed solely for

use in farming, for the picking up of hay, straw,

maize stubble and green forage and their pressing

into cylindrical-shaped bales.

A single operator seated in the tractor seat can

perform the various operations required to Pick-up

and bale the product lying in windrows.

1.5 NOT FORECASTED USE OF THE

MACHINE

DANGER

The operator should use the machine as

indicated in this manual, keeping in mind the

rules of accident, use conditions and technical

characteristics of the machine.

Any other not forecasted use of the machine

excludes the manufacturer from every kind of

responsibility to persons, animals and things.

1.6 SOUND LEVEL

The sound level (airborne noise) has been

measured with the machine running unlade, giving

the following results:

- Sound pressure level LpAm (A)…...82 dB

- Sound power level LwA (A).………102 dB

WARNING

The values measured reveal that the machine

has a high noise level. When operating the

machine, the operator must use ear

protection, such as appropriate safety

earmuffs or ear plugs, to prevent damage to

hearing (including long-term effects).

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 7 -

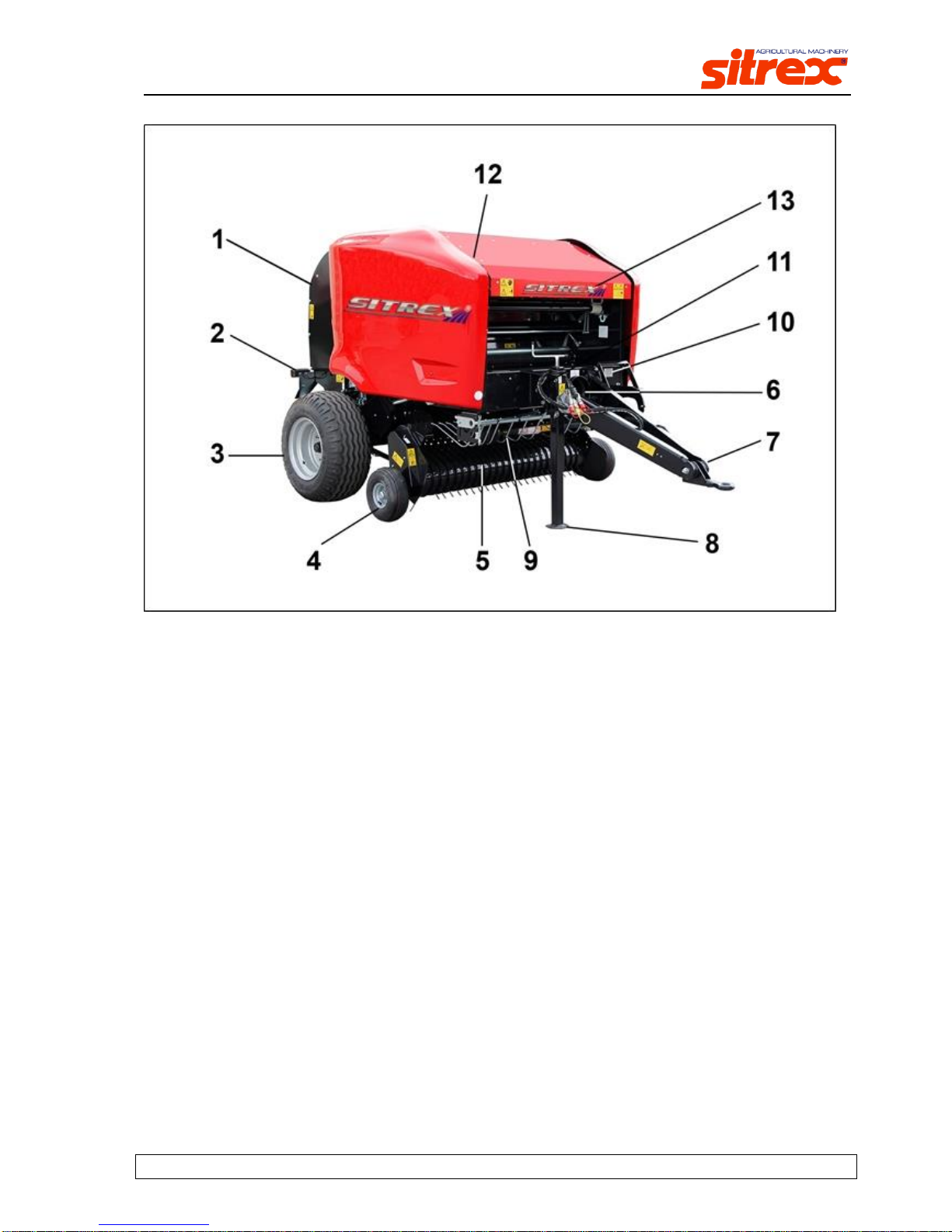

Pic.1 – Overall view of the machine with its main assemblies

1. Rear door for unloading of bales

2. Rear lights

3. Wheels

4. Wheels pick-up

5. Pick-up

6. P.T.O. shaft with protection cup

7. Towing link/draw bar with adjustable height

8. Parking jack

9. Rake

10. Identification plate

11. Flexible pipes oil-dynamic installation

12. Adjusting lever bales density

13. Front cover plate

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 8 -

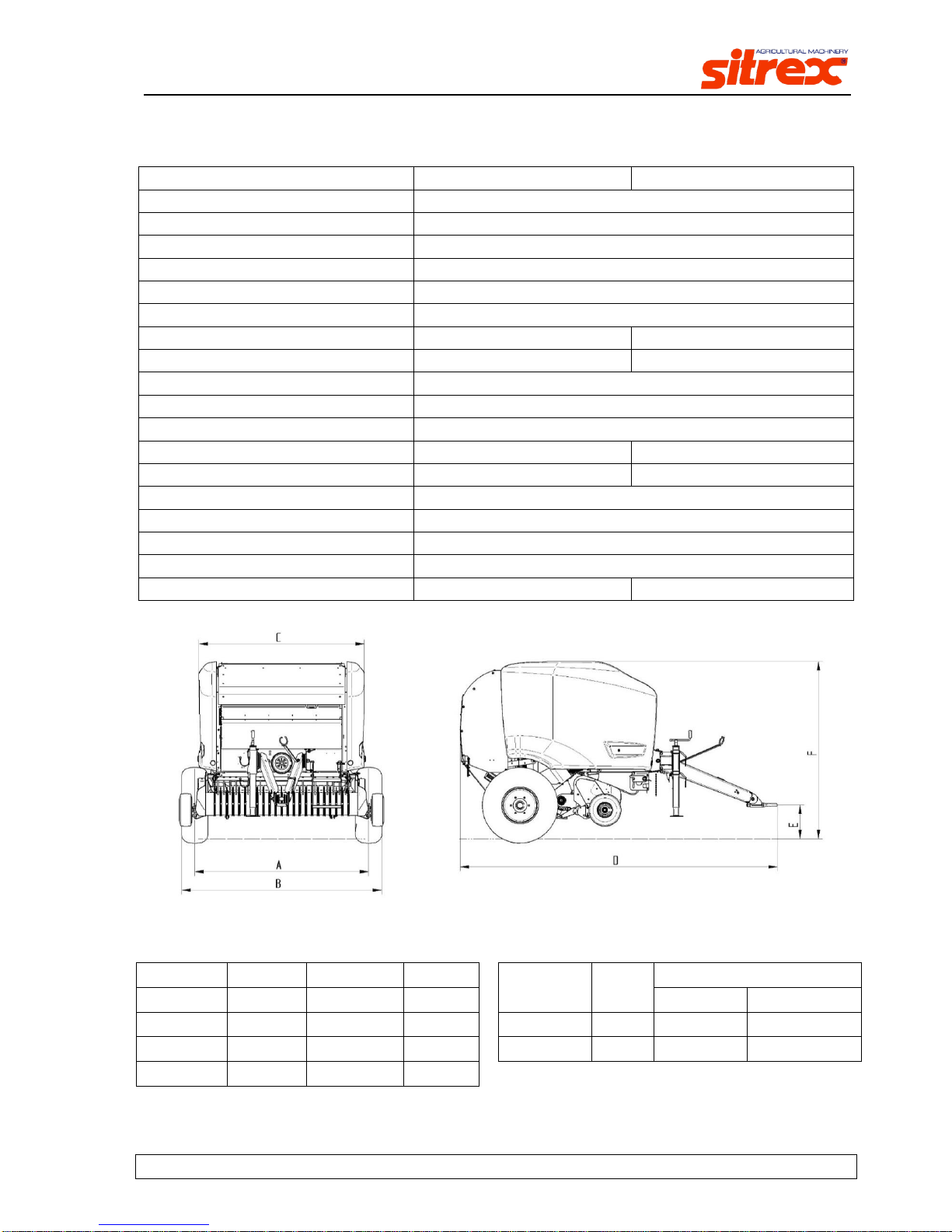

1.7 TECHNICAL DATA

MODEL

ACTION 120

ACTION 120L

Chamber type

Fixed

Bale width (cm)

120

Bale diameter (cm)

120

Bale rotation

Bars

Bars number

34

Minimum Power required kW (CV)

30(40)

Pick-up collection width (cm)

170

200

Tines rows/Tines for pick-up row

4/19

4/23

Regulation of bale density

Mechanic 3 positions

Electrical system

12 Volt

Tractor hydraulic system required

2 distributor single effect

Tires (standard)

10.0/75-15.3

11.5/80-15.3

Tires (optional)

11.5/80-15.3 15.0/55-17

15.0/55-17

Nr RPM at the P.T.O. (RPM/min)

540

P.T.O. shaft

Shearing bolt 1050 Nm

Weight on towing eye (kg)

340

Dimensions free towing eye* (mm)

Ø 35 - Ø 100

Empty weight (full optional) (kg)

2020 kg (2120 kg)

2070 kg (2170 kg)

(*) Available with towing eye Ø40 – Ø100 fix and with towing eye Ø45 – Ø105 (homologated France).

Pic. 2 – Overall dimensions of the machine

DIMENSIONS (cm) PICK-UP OVERALL DIMENSIONS (cm)

B

Narrow

Medium

Large

Pick-up

width

Fixed

wheels

Adjustable wheels

Tires

A = 189

A = 197

A = 205

With wheels

Without wheels

10.0/75-15.3

217

225

233

pick-up 170

199

209

182

11.5/80-15.3

219

227

235

pick-up 200

232

243

216

15.0/55-17

-

236

244

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 9 -

C = 188 cm D = 360 cm E = 35-100 cm F = 201 cm

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 10 -

2 SAFETY AND PREVENTION

2.1 SAFETY

The user is responsible for making sure the

personnel is instructed on the hazards rising from

accidents, and on the devices fitted for the

operator’s safety and the general safety

requirements prescribed by the directives and

legislation of the country where the machine is

used. The safety of the operator is one of the

primary concerns of a manufacturer. In designing

and producing a new machine, the manufacturer

tries to foresee all the possible hazards and, of

course, adopt appropriate safety measures.

Nevertheless, the level of accidents caused by

careless or inexpert use of various machines is

still high. Distraction, thoughtlessness and

overconfidence often lead to accidents, as can

fatigue and drowsiness. Consequently, this

manual, and the safety rules in particular, must be

read very carefully.

DANGER

The Manufacturer declines all responsibility

for the non-observance of the safety rules and

requirements prescribed by the legislation of

the country where the machine is used, and of

the instructions herein.

2.1.1 Terminology used

Here below you’ll find the definitions of the figures

and specific situations that might directly involve

the machine and/or persons in direct contact with

the machine.

USER: The user is the person, or

corporation or company, that has purchased

or hired the machine and that intends to use

it for the purposes for which it was designed.

The user is responsible for the machine and

for training personnel working on and around

the machine.

HAZARD ZONE: Any area inside and/or

near the machine in which the health and

safety of any exposed person is at risk.

EXPOSED PERSON: Any person to be

found in a hazard zone, whether fully or

partially.

OPERATOR: Description of the people, in a

general sense, in charge of installing,

operating, adjusting, performing routine

maintenance, cleaning, performing minor

repairs and transporting a machine.

SKILLED PERSONNEL: The term is used to

describe people specially trained and qualified to

perform any maintenance or repair needing for

specific knowledge of the machine, its operation,

the safety devices, the operating procedures,

and who are aware of the hazards rising from

the use of the machine and, consequently, are

able to avoid them.

AUTHORIZED SERVICE CENTRE: The

Authorized Service Centre is the structure

legally authorized by the Manufacturer

employing skilled personnel qualified to

perform all servicing, maintenance and repair

work, including complex operations, to keep

the machine working efficiently.

2.1.2 General safety rules

WARNING

Failure to comply with the rules described in

Section 2 – Safety and accident prevention –

and any tampering with the safety devices,

shall relieve the Manufacturer from any

responsability in the event of accidents,

damage of malfunctioning of the machine.

General Warnings:

The user undertakes to give the round baler to

skilled and trained personnel only.

The user is obliged to take all necessary

measures to deny to unauthorized personnel

the access to the machine.

The personnel must comply with the

instructions herein without exception, and

observe the general safety requirements

prescribed by the legislation of the country

where the machine is used.

The user undertakes to suitably instruct

his/her personnel on the application and

observance of the safety rules. To this

purpose, the user undertakes to ensure that

anybody operating the machine is aware of

the operating instructions and safety rules in

force.

The personnel must use personal safety

equipment, as prescribed by local legislation,

at all times, as well as follow the relevant

instructions herein.

The personnel must observe all the hazard

and caution signs applied on the machine.

The authorized personnel must not perform

any operations or work that do not fall within

its specific sphere of competence.

The personnel is obliged to report any

problem or hazardous situation that might

occur to the person concerned.

Personnel in training must always be

supervised by expert personnel.

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 11 -

Prima di iniziare il lavoro, familiarizzare con i

dispositivi di comando e le loro funzioni.

Before starting work, practice with the controls

and their functions.

WARNING

The operation of the machine by anyone who

has not read and assimilated the instructions

herein, as well as by unskilled personnel, or

by personnel not in good health or not holding

the right driving license, is strictly forbidden.

The area in which the machine is used is to be

considered a hazard zone, especially for

people not trained in the machine use. Before

starting up the machine, make sure there are

no people, animals or obstacles of any nature

around the work area.

When a person is «exposed», that is when

standing in a «hazardous area», the operator

must take immediate measures, stop the

machine and eventually make sure the person

is moved away.

During the operation of the machine, the

operator must seat in the tractor so that he

cannot fall accidentally and so that the whole

machine is under his control, and that

appropriate action can be taken whenever the

need arises.

Before starting the equipment, verify no

person, children or domestic animals are

around the machine and make sure to have a

perfect vision around the machine.

It is strictly forbidden to leave the driver’s seat

while the tractor is running.

Use suitable clothing. Avoid absolutely

wearing baggy or fluttery clothing as they

might get caught up in the rotating parts.

Before leaving the tractor it is compulsory to

stop the engine, enter the packing brake,

remove the key from the command panel.

It is strictly forbidden to carry people or

animals on the machine and on the tractor.

It is strictly forbidden to park the machine near

or under: terraces, balconies, haylofts, and

platforms of any kind that can be reached by

people and/or animals.

When work near electricity pylons is

unavoidable, it is advisable to ensure that all

parts of the machine are kept at a minimum

safety distance from them. Contact the

competent electricity board if you have any

enquiries. The machine is mainly made from

metal and consequently any contact with a

power line or a discharge may occur between

the line and the machine, the operator might

be involved, even with lethal consequences

It is strictly forbidden to work or get in contact

with the machine while the tractor engine is

on, before getting close to the machine or to

the P.T.O shaft, stop the P.T.O, stop the

tractor, enter the packing brake and remove

the key from the command panel.

During the machine operation, it is strictly

forbidden to let any part of your body get near

the moving mechanical parts.

During the machine’s operation, the unloading

device, when activated, represents a crushing

hazard.

The round baler «ACTION 120», has been

manufactured in conformity with the current

techniques and guarantees a safe working if

used in the proper way. The assembly of

pieces of other brands or any modifications

can vary the characteristics of the machine

and therefore compromise the security of the

operations. The Manufacturer consequently

declines any responsibility for all damages

caused by not original parts used in the

machine.

Machine must be utilized exclusively for the

purpose it was intended to.

User must inform the manufacturer in case of

defects or malfunctions of the safety system,

as well as of any supposed danger.

Machine doesn’t have to work with the

protections removed.

It is strictly forbidden to remove or tamper with

the safety devices (including carter).

In case carter is removed for maintenance

operations, make sure of its correct

repositioning before reusing the machine.

Before operating the machine, check the

perfect integrity of its safety systems for

transport and use; in case of malfunctions or

damages to the safety systems, proceed with

relative repair before operating the machine.

Pay attention to the dangerous signs indicated

in this manual or on the machine itself.

The round baler can be controlled only by the

suitable P.T.O. shaft (marked CE) complete

with all necessary safety systems and

protections secured with the proper chains.

Pay attention to the P.T.O. shaft when

rotating. Duly read also the use manual

supplied with it.

Pay duly attention to the correct assembly of

the P.T.O. shaft on the tractor P.T.O..

Never install the P.T.O. without having

connected the drawbar to the tractor.

Don’t leave the lever operating the P.T.O.

when the tractor is off.

Before starting the P.T.O., make sure the

RPM of the tractor P.T.O. correspond to the

RPM forecasted for the round baler.

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 12 -

Never exceed the prescribed RPM at the

power takeoff.

Always disengage the power takeoff when the

cardan shaft forms a too wide with the P.T.O.

(for shaft type) and when it is not in use.

Do not perform any work on the hydraulic

system without first relieving the pressure.

The Hydraulic system of the round baler

contains tanks that can remain under

pressure even after detachment from the

tractor, the maintenance on the hydraulic

system can be operated only by skilled

personnel.

It is strictly forbidden to stand in between the

tractor and the equipment (pic.3) with the

engine on, and without having activated the

packing brake and having inserted, under the

wheels, a clamping block of suitable

dimensions.

Pic. 3 – Hazard zones

In case of jamming of the collection and

harvesting group, it is strictly forbidden to

operate on the machine with the P.T.O. and

the tractor on. Stop the engine, pull on the

packing brake and take off the key from

the command panel.

Moving out from the working area, must be

carried on with the equipment in position of

transport.

Before starting the machine, verify the

standing foot is left up and that the machine

has been mounted and set properly; also

verify that all the parts subjected to usury and

deterioration are efficient.

Always keep oils and greases out of reach of

children.

Always carefully read advice and precautions

indicated on all containers.

Avoid contact with skin of dangerous

substances.

After using the above substances, wash

hands carefully.

All maintenance, regulations and work starting

operations, must be done compulsory with the

machine leaned on the ground by the standing

foot, tractor turned off, well stopped and key

off the dashboard.

Should the machine be used on public roads,

follow the traffic laws in force in the country

where the machine is used.

It’s very important to bear in mind that the

road grip, direction and brake capacity, can be

influenced, also remarkably, by the presence

of hold or towered equipment.

On the curves, pay attention to the centrifugal

force exercised in a different position, by the

center of gravity, with or without towered

equipment.

Hook the equipment, as foreseen, to a tractor

having a suitable power and configuration, by

the proper device (drawbar), as per the local

regulations of the country the machine is used

in.

Pay maximum attention during the hook and

unhook phases of the machine.

Respect the maximum foreseen weight on the

axis, the total moving weight, transport rules

and traffic laws of the country where

operating.

Eventual transport accessories must be

provided with suitable signs and protections.

Regularly verify the integrity of the machine

and protection devices.

Respect the conformity of suggested oils

indicated on the identification plates and on

this manual.

During repair and maintenance operations, it’s

compulsory to use protections clothing such

as: protection glasses, cut resistant gloves,

sturdy and anti-crushing shoes.

Duly operate the maintenance as indicated in

this manual: skilled personnel will have to take

care to substitute damaged and worn parts.

In case of use of the round baler together with

other machines (i.e.: bale wrappers or carts

for hay bales), make sure of the dimensions

and/or weight of the bales that can fit these

machines before proceeding with the work.

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 13 -

2.1.3 Machine control operations

CAUTION

Periodically check the locking of screws and

nuts and if it is necessary to fix them. For this

operation it’s suggested to use a

dynamometric key respecting the following

couple values of docking (twisting moment

expressed in Nm):

Bolt

Class 8.8

Class 10.9

M 4

3.0

4.4

M 5

5.9

8.7

M 6

10

15

M 8

25

36

M 10

49

72

M 12

85

125

M 14

135

200

M 16

210

310

M 18

300

430

M 20

425

610

M 24

700

990

For setting, maintenance, clearing, assembling,

etc. with the machine lifted up, keep as a

precaution adequate support equipment.

Spare parts must correspond to the specifications

defined by the Manufacturer.

Use original spare parts only.

The operating instructions provided in this manual

must be read and learned by heart, and the

manual itself kept safe for the entire service life of

the machine.

Round Baler ACTION 120

USE AND MAINTENANCE MANUAL - 14 -

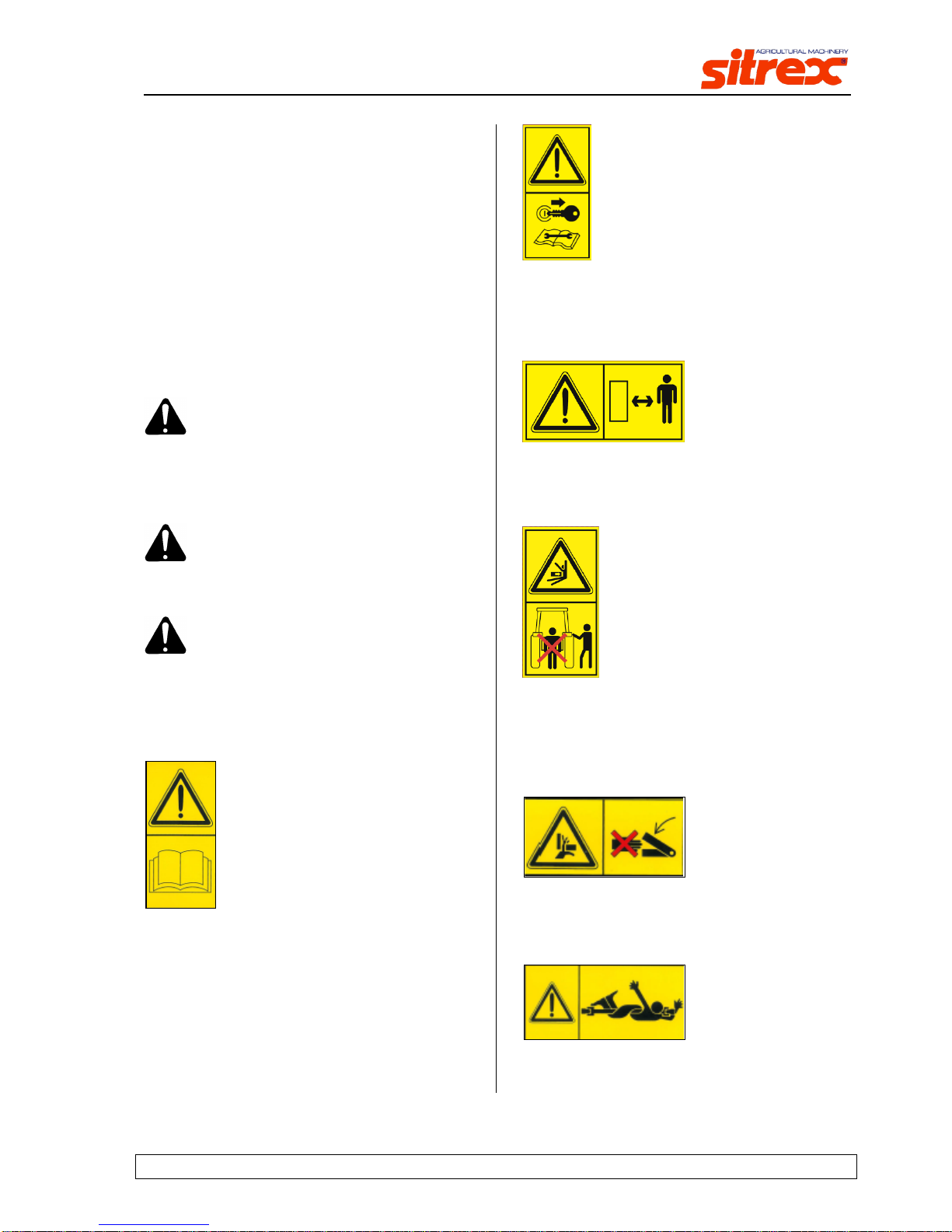

2.2 SAFETY SIGNS (PICTOGRAMS)

The machine has been designed and

manufactured in compliance with every possible

safety standard to assure the safety of the

operator.

Nonetheless, there are still a number of residual

hazards involved in the use of the machine, i.e.

those hazards that it has not been possible to

eliminate completely due to the specific nature of

the work the machine is designed for and certain

operating conditions.

These potential hazards are marked on the

machine with stickers (pictograms) that provide a

summary indication of the various unsafe and

hazardous situations.

WARNING

Keep stickers clean and replace them

immediately should they start peeling off or be

damaged; immediately request new ones from

your dealer or directly from the manufacturer

at the end of the manual.

WARNING

In case of replacement of a component with a

sticker on it, this one must be replaced and

affixed to the new component.

WARNING

All the safety signs positioned on one side of

the round baler and illustrated hereunder have

to be applied in exactly the same position on

the other side as well.

1)

Before starting to work, carefully read the

operating instructions.

2)

Before starting cleaning and maintenance

operations, stop the machine, remove the key

from the control panel and read the operating

instructions.

3)

Danger. While the machine is working, no one,

beside the operator, can get close to the machine

and the machine controls

4)

Crushing Hazard. Do not get close to the area

between the tractor and the round baler. Before

entering this area, turn off the engine, activate the

parking brake of the tractor and get sure of the

round baler stability.

5)

Crushing hazard/cutting of upper limbs. Do not

remove protections and do not get close to the

moving parts.

6)

Entanglement hazard. It is strictly forbidden to

get close to the rotating parts (in particular to the

P.T.O. shaft).

Loading...

Loading...