Technical Data Sheet

ød

f7/h6

øD

3x20°

øZ

H8

X

+0,2

H1

H2

H

HL

3

0

°

6

x

6

0

°

L1

AG

G

AG

T2

ød

f7/h6

øD

3x20°

øZ

H8

X

+0,2

H1

H2

H

HL

3

0

°

6

x

6

0

°

L1

AG

G

AG

Port:

release pressure

see

1

Alternativ port:

release pressure

see

4

Port:

pressure compensation

Proximity switch port:1

Signal „clamped“

see

3

Proximity switch port:2

Signal „unclamped“

see

3

L

T

1

2

LL

Information for KFH 18 - KFH 60:

Due to tolerances ports 1 can be

displaced up to +/-4°

Load direction 1

Load direction 2

5

Rod diameter 18mm - 60mm

SITEMA - Locking Unit KFH

Locking by Spring Force / Hydraulic Releasing

English translation of German original

TI-F50-EN-08/2011

Technical Data Sheet TI-F50

Locking Unit KFH

For detailed functional description refer to„Technical Information TI-F10“. Furthermore important practical advices are

given in the „Operating Manual BA-F50“.

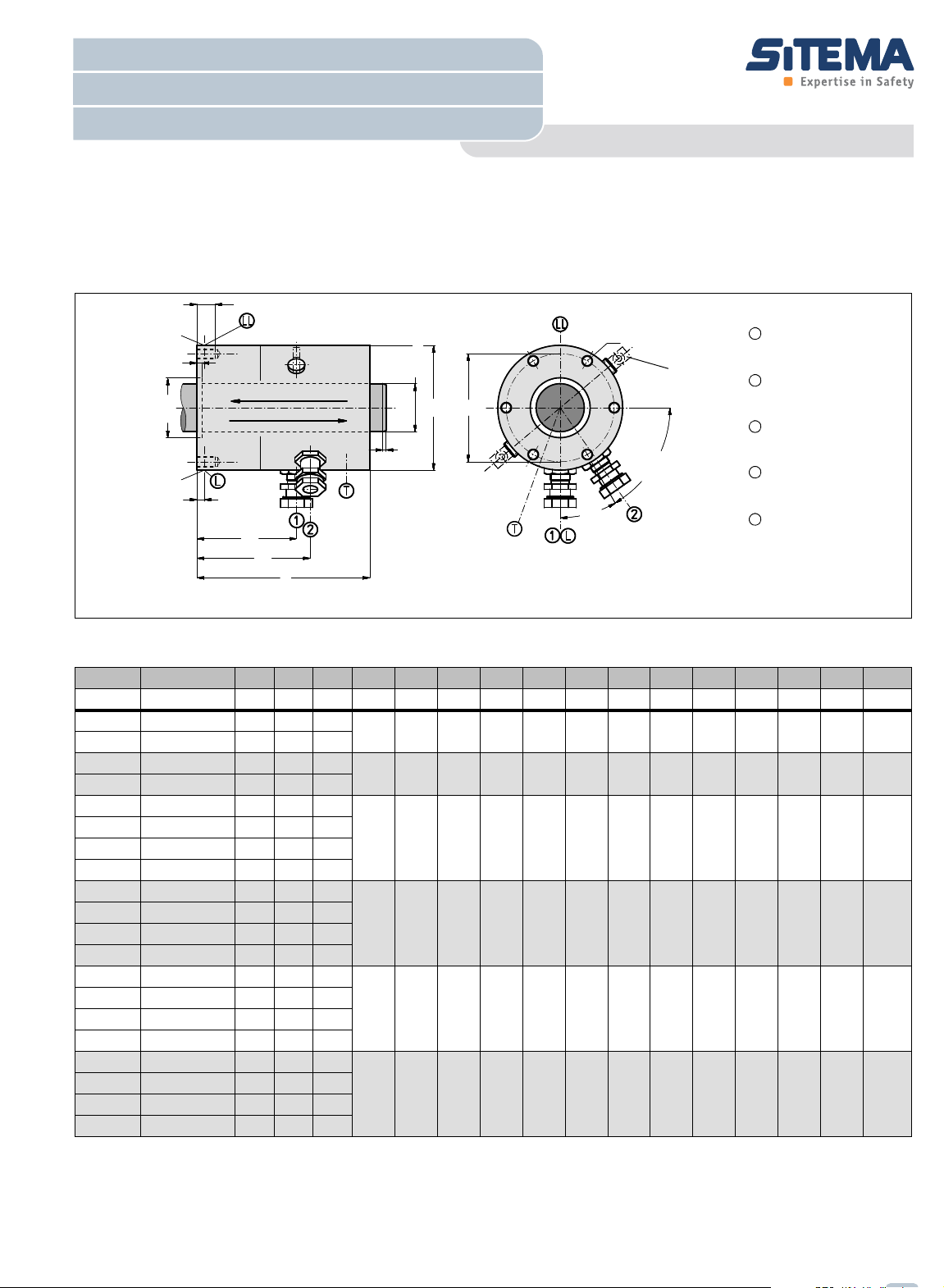

Fig. 1: Dimensions Locking Unit KFH ( CAD-Files download at www.sitema.com )

Type Ident.-No. d F p D H L1 T2 G Z X AG VL HL H1 H2 Weight

KFH 18

KFH 18

KFH 25

KFH 25

KFH 28

KFH 28

KFH 32

KFH 32

KFH 36

KFH 36

KFH 40

KFH 40

KFH 45

KFH 45

KFH 50

KFH 50

KFH 56

KFH 56

KFH 60

KFH 60

1 F is guaranteed as nominal (minimum) holding force for dry or mineral oil wetted shafts.

KFH 018 50

KFH 018 51

KFH 025 50

KFH 025 51

KFH 028 50

KFH 028 51

KFH 032 50

KFH 032 51

KFH 036 50

KFH 036 51

KFH 040 50

KFH 040 51

KFH 045 50

KFH 045 51

KFH 050 50

KFH 050 51

KFH 056 50

KFH 056 51

KFH 060 50

KFH 060 51

p is the pressure required for releasing. The permissible working pressure is 160 bar.

2 Hydraulic operating volume.

11 2

mm kN bar mm mm mm mm mm mm mm mm cm

18 10 70

18 5 40

25 20 100

25 12 50

70 122 60 12 M6 30 4 G1/8 6 23 88,5 96,5 3

95 140 82 15 M8 50 6 G1/8 12 21 89,5 83 7

28 40 100

28 20 50

32 40 100

115 178 96 18 M10 60 6 G1/4 23 20 118 112 13

32 20 50

36 50 100

36 35 55

40 50 100

138 200 115 18 M10 70 6 G1/4 28 19 109,5 119 18

40 35 55

45 75 100

45 45 75

50 75 100

50 45 75

56 100 100

56 70 70

60 100 100

155 213 135 20 M12 85 8 G1/4 43 20 147,5 140 26

180 228 160 20 M12 95 10 G1/4 62 22 151,5 144 36

60 70 70

3 Proximity switch holders are provided for standard proximity swit-

except KFH 18 and KFH 25: M8x1 with nominal distance 1,5 mm.

ches M12x1 shielded and with a nominal switching distance of 2 mm,

4 Plugged hydraulic port LL alternative to L, also usefull for bleeding.

5 Spacers are provided to keep released. To be removed after instal-

lation!

Subject to modification without prior notice

3

mm mm mm kg

Technical Data Sheet

ød

f7/h6

øD

3x20°

øZ

H8

X

+0,2

H1

H2

H

HL

3

0

°

6

x

6

0

°

L1

AG

G

AG

T1

ød

f7/h6

øD

3x20°

øZ

H8

X

+0,2

H1

H2

H

HL

3

0

°

6

x

6

0

°

L1

AG

G

AG

T2

Port:

release pressure

see

1

Alternativ port:

release pressure

see

4

Port:

pressure compensation

Proximity switch port:1

Signal „clamped“

see

3

Proximity switch port:2

Signal „unclamped“

see

3

Direction of load 1

Direction of load 2

L

T

1

2

LL

Rod diameter 70mm - 140mm

SITEMA - Locking Unit KFH

Locking by Spring Force / Hydraulic Releasing

TI-F50-EN-08/2011

Technical Data Sheet TI-F50

Locking Unit KFH

For detailed functional description refer to„Technical Information TI-F10“. Furthermore important practical advices are

given in the „Operating Manual BA-F51“.

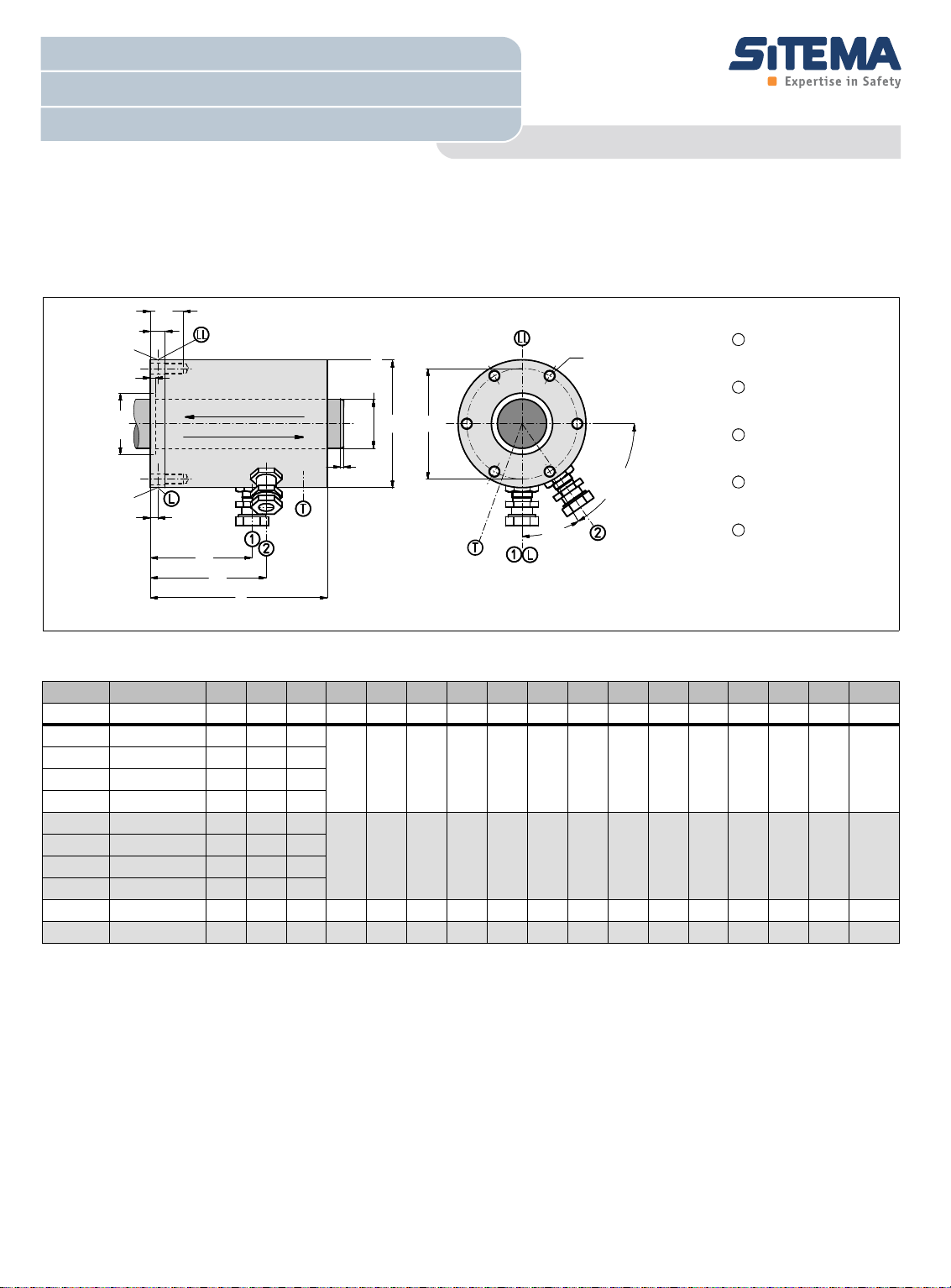

Fig. 2: Dimensions Locking Unit KFH ( CAD-Files download at www.sitema.com )

11 2

Type Ident.-No. d F p D H L1 T1 T2 G Z X AG VL HL H1 H2 Weight

3

mm mm mm kg

KFH 70

KFH 70

KFH 80

KFH 80

KFH 90

KFH 90

KFH 100

KFH 100

KFH 125

KFH 140

KFH 070 50

KFH 070 51

KFH 080 50

KFH 080 51

KFH 090 50

KFH 090 51

KFH 100 50

KFH 100 51

KFH 125 50

KFH 140 50

mm kN bar mm mm mm mm mm mm mm mm mm cm

70 150 100

70 80 60

80 150 100

225 302 195 26 56 M16 110 10 G1/4 86 13 192 185 79

80 80 60

90 250 130

90 190 100

100 250 130

260 360 225 30 65 M20 125 10 G3/8 100 15 221 214 118

100 190 100

125 330 100 350 405 300 40 90 M30 230 10 G3/8 220 26 244,5 235 225

140 600 100 430 514 370 50 95 M30 170 10 G3/8 250 30 346 334 458

Subject to modification without prior notice

1 F is guaranteed as nominal (minimum) holding force for dry or mineral oil wetted shafts.

p is the pressure required for releasing. The permissible working pressure is 160 bar.

2 Hydraulic operating volume.

3 Proximity switch holders are provided for standard proximity swit-

ches M12x1 shielded and with a nominal switching distance of 2 mm.

For easier service, the proximity switch holders have a positive stop

and are preset when deliverd from the factory.

4 Plugged hydraulic port LL alternative to L, also usefull for bleeding.

Technical Data Sheet

*)

**)

p

SITEMA - Locking Unit KFH

Locking by Spring Force / Hydraulic Releasing

TI-F50-EN-08/2011

Operational purpose

The Locking Device KFH clamps a shaft in any position. It is

commonly used on a cylinder rod or an other round shaft and

holds axial forces in both axial directions.

Load direction

A force in load dircetion 1 is always held without backlash

If the force acts in load direction 2 a backlash also does not oc-

cur, provided the force is not exceeding approx. 80% of the nominal holding force F. Otherwise the possible axial

displacement is 0.1 - 0.3 mm.

Choosing the right size

The table (Page1 and Page 2) shows the nominal holding force

F of the various items. The value F must be higher than the static load in the particular application.

In case a vertically moved mass is to be secured, a reasonable

safety factor must be applied by the designer. This factor depends on the kind of machinery, but shoudn't be less than 1.5.

If people have to be secured against dangers of lifted static

loads at the necessary regular testing must be performed with

at least 1.5 times the load.

T o guarantee the holding force during service even under unfavourable conditions, the actual holding force when new has to

be higher than the nominal holding force. It will not, however,

exceed twice the value. The fixing elements that absorb the

force (e.g. articulations for the holding rod) must therefore be

dimensioned for 2 x F.

In practice, suitable and commercially available rods are:

1. Piston rods, hard chrome plated (ISO tolerance f7)

Basic material: Yield strength, min. 580 N/mm²

Induction hardened HRC 56 - 64 / min. 1 mm deep

Hard chrome plating: 800-1100 HV min. 13 µm deep

Surface finish: RA 0,15 - 0,25

2. Shafts for linear ball bearings (ISO tolerance h6)

Induction hardened HRC > 60

Surface finish: RA 0,15 - 0,25

Pressure fluid

Hydraulic oil (HLP) in accordance with DIN 51524-2 must be

used as pressure medium. Please consult us before using any

other media.

Control

In most applications the actuation suggested in Abb.3 is used.

During every operational cycle the 3/2-way valve is actuated

electrically and releases the locking unit. In all other operational

conditions, as well as in cases of power failure, emergency

stop, etc. the locking unit becomes effective secures the rod

and stops the load. In case the pressure should fail, the load is

secured in the same way.

To avoid possible problems, the shaft should not be driven unless the proximity switch 2 indicates "unclamped".

T- port

The tapped hole marked T (tank, oil leakage) is used for pressure compensation (breathing). It is plugged with a filter e lement when supplied from the factory.

In case the Locking Unit KFH is to work in corrosive environment, e.g. coolant spray, port T must be connected to clean atmosphere or hydraulic tank by a pipe or hose

Rod material

The Locking Unit KFH will operate correctly only if the rod has

the correct surface:

• ISO tolerance field f7 or h6

• Surface roughness: Rz = 1 to 4 µm.

• Rod surface hardened (min HRC 56).

• Hardchrome plated surface recommended

• Lead-in chamfer 3x20°, rounded.

As the actual holding force can be as high as two times the nominal holding force F (for F see data sheets or dimensional drawing), care must be taken to ensure that the strength of rod

material is adequate. In the case of compression-loaded rods,

sufficient buckling resistance must be assured.

Fig. 3: Schematic diagramm of hydraulic circuit

* If impact noises are audible when pressuring the Locking Unit KFH

due to excess pressure, they can be suppressed by means of a flow

control valve in the p-line.

** If the pressure (p) is not suficiently constant (e.g. pressure drop at

the beginning of a downward stroke) we recommend a check valve

in the p-connection of the valve.

Under no circumstances may the hydraulic flow between connection L and the tank be impaired by any additional components.

If a particular quick response of the Locking Unit KFH is required, the following preconditions must be met:

• Short piping distances

• large valve and pipe cross-sections

• fast valve response times

Technical Data Sheet

SITEMA - Locking Unit KFH

Locking by Spring Force / Hydraulic Releasing

Operating conditions

The Locking Unit KFH is designed to operate in usual clean and

dry shop atmosphere.

In case of other environments at least the T-port for breathing

purposes is to be connected to a clen and dry volume (tank).

Should heavy soiling conditions (grinding dust, chips, other liquids, etc.) exist, please contact SITEMA.

Grease on the rod may reduce the holding force. T he permissible ambient temperature is 0 - 60°C.

Regular functional checks

The Locking Unit KFH must be functionally checked at regular

intervals. Regular checking is the only way to ensure that the

unit operate safely in the long run.

For applications in the field of personal safety (operater protection), testing must be carried out at least once every 6 months.

Depending on the relevant application parameters (soiling level, cycle time, control), significantly more frequent checks may

be advisable. In many cases, even (fully automatic) daily

checks may be necessary.

For testing a force at least equal to the working force, but normally equal to the nominal holding force F is applied.

In every case the criteria is, that the test force is held without

slipping.

TI-F50-EN-08/2011

Required risk assessment

It must be ensured that the dimensions and arrangement of

SITEMA - Safety Brakes in safety-relevant applications meet

the requirements of the risk evaluation DIN EN ISO 14121-1

and also comply with any further standards and regulations applying to the intended use. This is the duty of the system manufacturer and the user.

Maintenance

Maintenance is limited to the regular test of the holding force as

prescribed above.

The SITEMA - Locking Unit KFH is a safety element. Any repair

or refurbishing must be carried out by SITEMA. SITEMA cannot

take any responsibility for repairs by another party.

Loading...

Loading...