AUTO-ROTORAKE Mk.5

INSTRUCTION MANUAL

SP20008_REV3

MAY 2018

2

CERTIFICATE OF CONFORMITY

Auto-Rotorake CN Code: 8432 29 10

Manufacturer:- Howardson Ltd, Howardson Works, Kirk Langley , D erby , DE6 4N J. UK

Owner of Technical Document:- Mr I.D. Howard, Howardson Ltd, Howardson Works Kirk Langley, Derby, DE6 4NJ, UK

I the under signed Declare that these machines:-

The reliability and quality of performance of the SISIS Auto-rotorake depends upon some simple care maintenance

carried out regularly. This manual has been prepared to allow the user to carry out all such work.

It is advisable to read the instructions carefully . Proper care and attention w ill enable the machine to give a continuous,

satisfactory, and reliable serv ice. F ailure to carry out regular lubr ication and maintenance as outlined in this manual may

render any guarantee or warranty invalid.

In the case of any difficulty, or if further information or advice is required, our Service Depart ment is always at your call. In

the interests of speed and accuracy of information please quote the serial numbers of the machine and engine when

making enquiries.

For the machine, this is to be found on a plate attached to the side frame. T he engine number is stamped

on either the crank case or the gear casing facing tow ards the fr ont of the machine. We suggest you write

the numbers on the front page of this book.

INTRODUCTION

SERIAL NUMBERS

Ian Howard

Tested at:- Howardson Works test site September 2011

Complies with the applicable requirements of:-

- Machine Directive 2006/42/EC

- Noise Directive 2000/14/EC (Annex VI Procedure 1)

Managing Director

MODEL OPERATING

WIDTH

POWER

(HONDA)

MEASURED SOUND

POWER LEVEL

GUARANTEED SOUND

POWER LEVEL

SERIAL

NUMBER

ARR/5 20” (510MM) GX160 79dB Lwa 98dB Lwa See Product ID

range

ENGINE SERIAL NUMBER

MACHINE SERIAL NUMBER

NOTE:- MAKE A NOTE OF THE SERIAL NUMBERS OF YOUR MACHINE & ENGINE AND ALWAYS

QUOTE THEM IN ANY COMMUNICATION WITH PERSONNEL AT DENNIS.

SP20008_REV3

MAY 2018

3

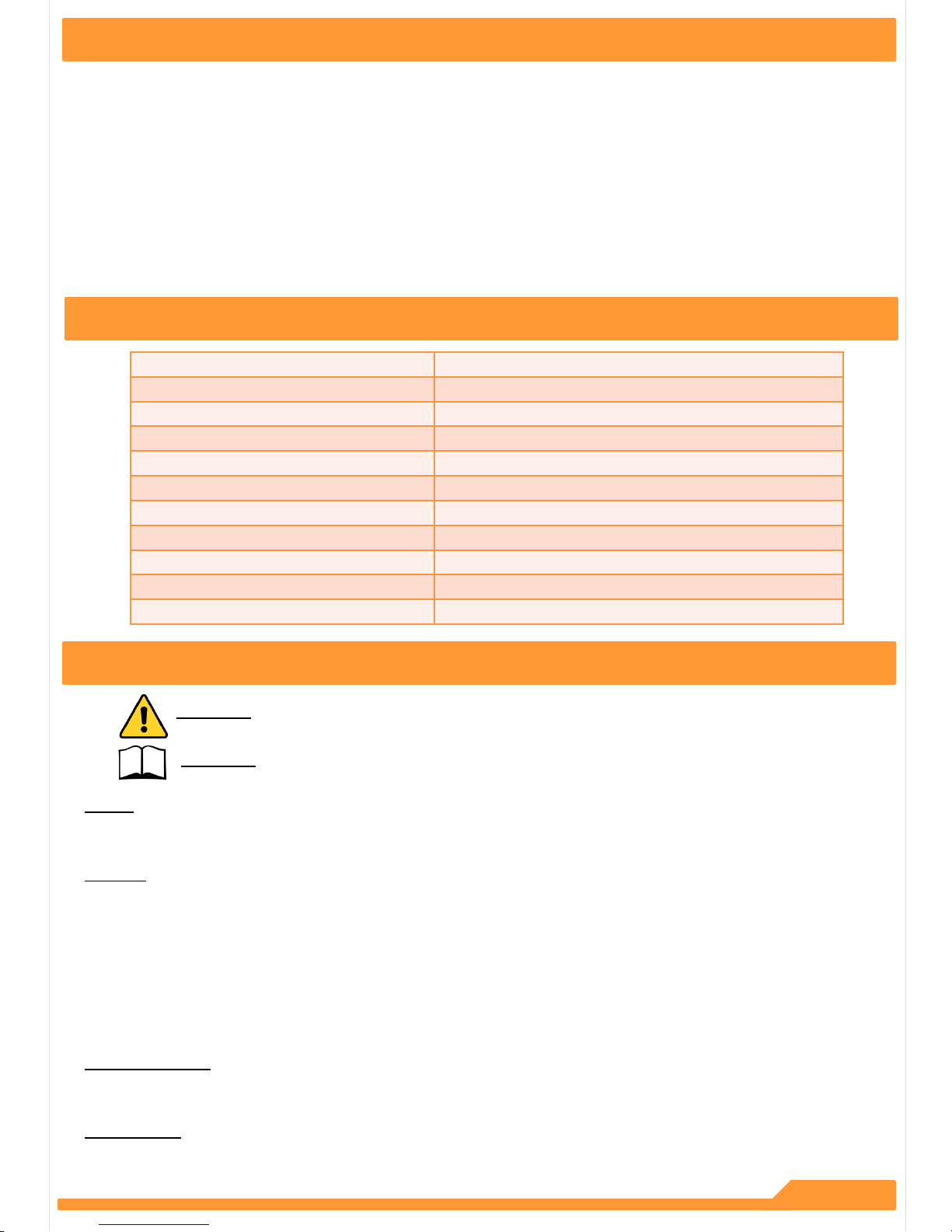

CONTENTS

IMPORTANT SAFETY INTRODUCTIONS

TECHNICAL DATA

WARNING:- WHEN WORKING WITHOUT THE GRASS BOX, LOW E R THE DEFLECTOR TO PROTECT

THE OPERATOR AND ENGINE AIR INTAKE FROM FLYING DEBRIS.

CAUTION:- READ THE INSTRUCTIONS CAREFULLY AND ALSO THE SEPARATE INSTRUCTION

DETAILS ON THE ENGINE..

NEVER

• carry out adjustments with the engine r unning.

ALWAYS

• read the operating instructions carefully and understand the controls before commencing work.

• be extra careful to avoid spillage, when using petrol or diesel fuel. DANGER no smoking or naked lights

• use safety guards and make sure they are correctly in position. they are supplied for your protection

• visually check machines before starting work for damage or wear to working parts such as blades,tines or loose fasteners

• respect powered machines. alw ay s keep hands and feet clear of moving par ts and remember that tine cylinders or

drums can continue to rotate even after the power unit is switched off

• switch off the power before making adjustments or repairs and never lift or carry a machine whilst any parts are

Moving

EYE PROTECTION

In dry, dusty or windy conditions it may be necessary to wear eye protection to protect your eyes from fly ing debris.

FIRE HAZARD

ALWAYS CLEAN THE MACHINE. REMOVE ALL DEBRIS FROM AROUND THE ENGINE. BLOCKED

ENGINE COOLING FINS CAN CAUSE THE ENGINE TO OVERHEAT

Page

Declaration of Conformity............................................................... .................. .................. .................. .................. ............ ... 2

Serial Numbers.................................................. ............ ............ ...... ............ ............ ............ .................. .................. ............ .. 2

Introduction............................................................................................................................................ .................. .............. 2

Technical Data.................................................... ...... ............ ............ ............ ............ ........................ .................. .................. . 3

Important Safety Instructions........................................................... .................. .................. .................. ............ ............... 3 - 4

Operating Instructions....................................................................................................................................................... 5 - 6

Reels...................................................................................................................................................................................... 7

Maintenance and Lubrication............................................................................................................................................ 8 - 9

Oiling Points......................................................................................................................................................................... 10

Parts Listings........................................................................................................................................ ............ .......... P0 - P12

MODEL AUTO-ROTORAKE MK.5

WIDTH (mm) 780

LENGTH WITH GRASS BOX (mm) 1850

LENGTH WITHOUT GRASS BOX (mm) 1450

HEIGHT (mm) 950

WEIGHT (Kg) 102

CUTTING WIDTH (mm) 20” (510mm)

ENGINE GX160

HAND ARM VIBRATION (m/sec) 4.85

MEASURED SOUND POWER LEVEL (dB(A)) 79

GUARANTEED SOUND POWER LEVEL (dB(A)) 98

SP20008_REV3

MAY 2018

4

IMPORTANT SAFETY INSTRUCTIONS

In order to operate the machine safely please follow these Health and Safety guidelines.

TRAINING

CAUTION

READ THE INSTRUCT IONS CONTAINED IN THIS MANUAL WITH CARE. IF YOU ARE IN

ANY DOUBT PLEASE ASK YOUR EMPLOYER OR CONTACT US DIRECT AT SISIS. CAUTION

• Be familiar with the controls and the proper use of the equipment.

• Never allow children or people unfamiliar with these instructions to use the machine. Local regulations or insurance

may restrict the age of the operator.

• Never operate while people, especially children, or pets are nearby.

• Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people or their

property.

PREPARATION

• While operating always wear substantial footwear and long trousers. D o not operate the machine barefoot or in open

sandals.

• Thoroughly inspect where the equipment is to be used and remov e all stones, sticks, wire, bones and other foreign

objects.

WARNING

PETROL IS HIGHLY FLAMMABLE AND WILL DAMAGE GRASS IF SPILT.

A) Store fuel in containers specifically designed for this purpose.

B) Refuel out doors and do not refuel whilst smoking.

C) Add fuel before starting the engine. Nev er remov e the cap of the fuel t ank or add petrol while the engine is running or

when the engine is hot.

D) If petrol is spilled do not attempt to start the engine but mov e the machine away from the area of spill and avoid

creating any sources of ignition until the vapours have dissipated.

• Replace damaged or faulty silencers.

• Before using the machine always inspect the safety dev ices including the cut off switch and the blades for ex cessive

wear or damage. Replace if necessary.

OPERATION

• Do not operate the engine in a confined space where dangerous CARBON MONOXIDE fumes can collect.

• Operate only in daylight or good artificial light.

• Always be sure of your footing on slopes.

• Walk. Never run.

• Exercise extreme care on slopes w hen changing direction.

• Do not operate excessively steep slopes.

• Use extreme caution when reversing or pulling the machine towards you.

• Stop the blades if the machine has to be tilted for transportation when crossing surfaces other than grass and when

transporting the machine to and from the area to be mown.

• Never operate the machine with defective guards or shields or without the safety devices, for example without the

deflector plate or grassbox in place.

• Do not change the engine governor settings or overspeed the engine.

• Disengage all blades and drive clutches before starting.

• Start the engine carefully following the instr uctions with feet well away from the blades.

• Do not tilt the machine when starting the engine.

• Do not put hands or feet near or under rotating parts. Keep clear of the discharge opening at all times.

• Never pick up or carry the machine while the engine is running.

SP20008_REV3

MAY 2018

CAUTION

PLEASE READ THESE OPERATING INSTRUCTIONS CAREFULLY BEFORE

COMMENCING WORK.

We want you to obtain the best performance from this machine. If you hav e any difficulty in carr y ing out the following

instructions please contact SISIS direct or your local SISIS Territory Manager or SISIS Dealer.

OPERATING PRINCIPAL

Power from the engine is transmitted through a v ee belt clutch mechanism. One belt powers the tine reel through a

cross shaft with a final chain drive. Forward travel power is supplied through a cross shaft, spur gearing and a

differential gearbox, to the ground wheels. The depth of cut is simple to alter w ith the micro-adjuster on the handle

connecting through to the front roller frame.

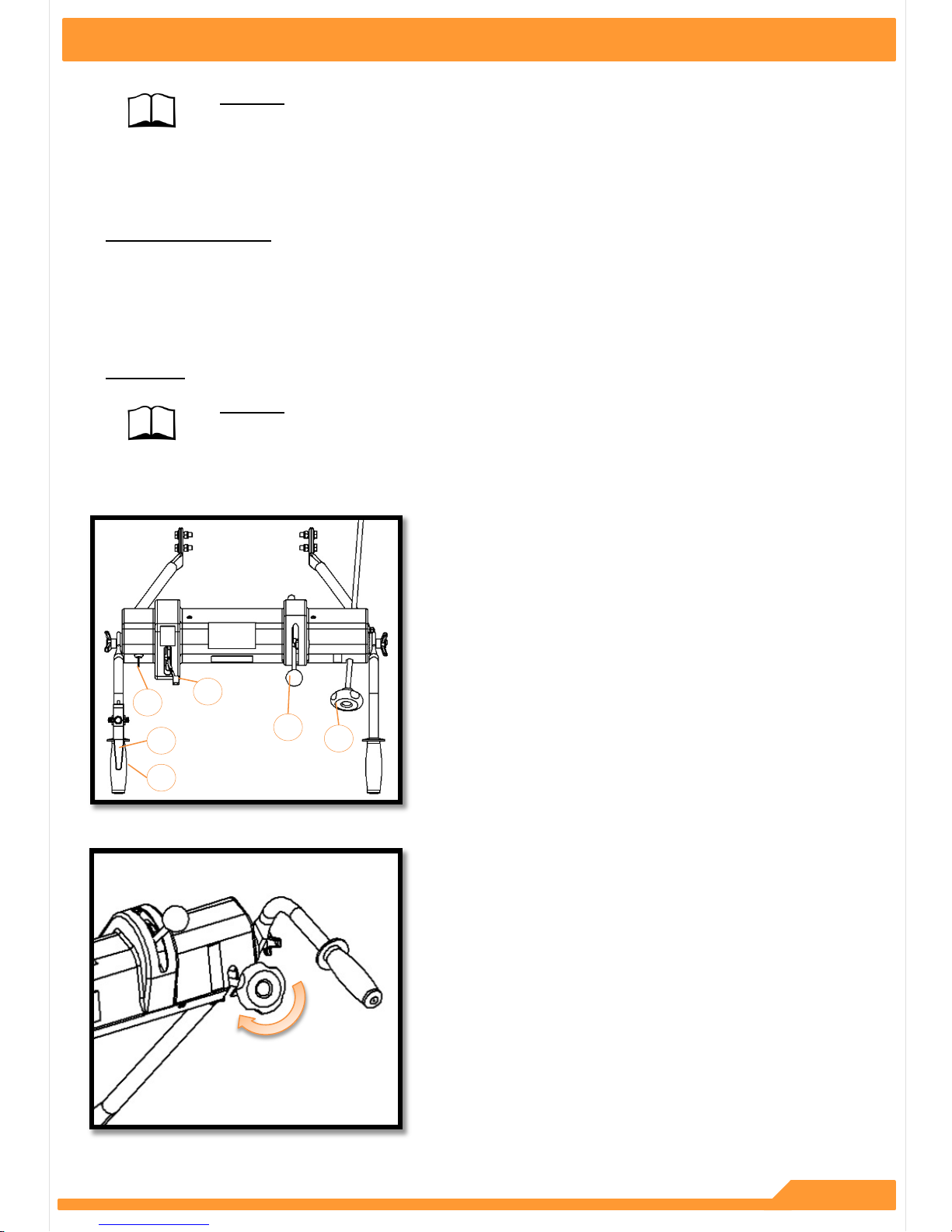

CONTROLS

CAUTION

DISENGAGE THE REEL CLUTCH BEFORE STARTING THE ENGINE. RAISE THE TINE

REEL CLEAR OF THE GROUND TO PREVENT CONTACT.

5

IMPORTANT SAFETY INSTRUCTIONS

A = Engine Cut-out Lever

B = Engine Run / Stop Key

C = Drive Lever

D = Throttle

E = Cut Depth Micro Adjuster

F = Tine Drive Lever

The blades must be CLEAR of the ground before adjustment

commences. The depth of cut is adjusted by varying the height

of the front rollers, using the micro adjuster. Start the engine

and allow to warm up. Engage the ground w heel and reel drives

and lower the reel using the micro adjuster until the required

amount of thatch is being removed. Always disengage the reel

drive when the machine is stationary on the green.

A

C

D

B

F

E

SP20008_REV3

MAY 2018

6

OPERATING INSTRUCTIONS

The Rotorake principle incorporates a series of blades rotating at

high speed in the opposite direction to that of the conventional

cylinder mower. The blades therefore cut upwards, continuousl y

taking grass fibre away from the surface rather than pushing it into

the surface of the turf. This also ensures that the machine is held

to the ground and a regular working depth maintained.

SISIS CONTRA-ROTATION PRINCIPLE

SP20008_REV3

MAY 2018

7

REELS

1MM LIGHT SCARIFYING REEL – Order reference number: FS1098

1mm replaceable, wear resistant tungsten tipped blades (12mm spacing)

can be used throughout the season.

1.6MM SCARIFYING/THATCH REMOVAL REEL – Order reference number: FS1093

1.6mm replaceable, wear resistant tungsten tipped blades (20mm

spacing). Ideal for pre and post playing season renovation work.

VERTICUTTER/THATCH CONTROL REEL – Order reference number: FS1095

Sharpened offset triangular blades (6mm spacing) used regularly

throughout the playing season to control lateral growth and improve

green speed.

VERTICUTTER – Order reference number: FS1200

Sharpened triangular blades, (12mm spacing) used regularly throughout

the playing season to control lateral growth and improve green speed.

BRUSH REEL – Order reference number: FS1088

Used throughout the year for debris collection and clean up. Also used

prior to mowing to stand grasses up and improve cut quality.

MULTI DENSE/SYNTHETIC BRUSH REEL – Order reference number: FS1090

Used throughout the year for debris collection and clean up. Also used

prior to mowing to stand grasses up and improve cut quality.

ROLASPIKE/SOREL ROLLER – Order reference number: FS1113

Provides fast and effective surface aeration. Used during the playing

season enables penetration of air, water and fertiliser.

CHANGING REELS

To Remove the Tine Reel

Raise the reel completely clear of the ground using the micro adjuster. Remove

the nuts and washers (on the right hand side of the machine) that secure the

bearing to the side plate. Slide the tine reel out of the socket on the stub shaft

(see image). Lower it to the ground and remove it f rom the machine. Rev erse

the procedure to fit alternative reel.

SP20008_REV3

MAY 2018

8

MAINTENANCE & LUBRICATION

CAUTION

ALWAYS SWITCH OFF THE ENGINE BEFORE ATTEMPTING ANY MACHINE MAINTENANCE WORK.

NOTE

CARRY OUT THE PROCEDURE FOR REMOVING THE REELS. FOR CONVEINIENCE PLACE THE REEL ON A BENCH

WHN WORKING ON IT.

REPLACING BLADES

THATCH REMOVAL REEL reference ARR5/TR

THATCH CONTROL REEL reference ARR5/TCR

Remove the washer and split pin at the end of the reel (opposite end to which the bearing is fitted) and strip off the knives and

rubber spacers. Replace the knives making sure that you follow the original spiral patter n, which is shown on the drawing.

Replace the washer and split pin. You w ill find it necessary t o compress t he assembly in order to replace the split pin. Use the

compression tool supplied with the machine. Replace the reel, reversing the procedure for removal.

It is not advisable to fit a few new knives. Always replace with a full set of new knives. On the thatch control reel ONLY, it is

possible to maintain ev en wear on the blades by removing the reel and replacing the blades in the reverse position on the

shaft.

ADJUSTING BELT TENSION

The ground wheel drive belt tension is adjusted by slackening the lock nuts on the cable adjuster, turning and then re-locking

adjuster under guard.

The reel drive belt tension is adjusted by slackening t he lock nut on the barrel of the pull rod. Remove split pin, turn r od to

desired position. Replace split pin and tighten lock nut.

A

B

A = Split Pin

B = Lock Nut

FRONT ROLLER ADJUSTMENT

An adjustment pivot nut is fitted at one side of the front r oller

frame assembly. This has been factory set, during assembly and

should not require further adjustment. However, if the machine

has been dismantled for maintenance purposes or mishandled at

any time, the front roller can be adjusted by placing the machine

on a level surface, with the tine reel removed and rotating the

pivot nut. The front roller is aligned correctly with the rear ground

wheels when all three are resting on the surface.

SP20008_REV3

MAY 2018

9

MAINTENANCE & LUBRICATION

FITTING NEW REEL DRIVE V BELTS

Ensure engine is switched off and key is removed. Remov e covers(2 top and 1 side). Slacken engine bolts and move

engine forward. Undo 2 setscrews securing the brake calliper and lift up and pull

away clear of the disc. Place some packing (cardboard is ideal) in-between the brake pads to keep them in position.

Remove belts on the bearing that is close to the disc and slacken the bolts on the bearing near the large chain pinion.

This allows the shaft to be tilted up and the belt can be removed. Fit a new belt and put shaft back into position.

Replace and tighten the bolts.

Disconnect brake rod from brake lever with the engine turned off. Put the tine reel into drive with the over centre lever.

Ensure that belt fingers on engine are not more than 2mm and not less than 1mm away from the tensioned tine drive

belt. Take the over centre lever out of drive and start engine. Put the ov er centre lever into drive and ensure that the

belts stop driving. When the over centre lever is out of driv e. If the belt stops driv ing, tur n off the engine and refit the

brake rod.

CAUTION

ALWAYS SWITCH OFF THE ENGINE BEFORE ATTEMPTING ANY MACHINE MAINTENANCE WORK.

SP20008_REV3

MAY 2018

10

OILING POINTS

NOTE

ENSURE THAT THE ENGINE IS FILLED TO THE CORRECT LEVEL WITH THE RECOMMENDED

GRADE OF OIL. ALWAYS CHECK THE OIL WITH THE ENGINE LEVEL.

= OIL EVERY 10 WORKING HOURS

= OIL EVERY 40 WORKING HOURS

= GREASE EVERY 40 WORKING HO U R S

SP20008_REV3

MAY 2018

AUTO ROTORAKE MK5 POWER UNIT - PARTS BOOK

P0

SP20008_REV3

MAY 2018

CHASSIS, ENGINE AND DRIVE SYSTEM

REF: 2.01 REF: 3.01

P1.01

SP20008_REV3

MAY 2018

A

B

9

8

12

13

1620

10

4

1419124

9

3

14 19 19 18

NOTE: SOME PARTS OMITTED FOR CLARITY

A

11

15 21

2 22

22

6

17

7

7

SECTION VIEW

B

13 5 23

ITEM NO.

PART NUMBER

DESCRIPTION

CHASSIS/QTY.

1

400996_REV1

FLAP HINGE

1

2

D1899_REV1

R-CLIP (REF S490009)

1

3

D7982_REV1

GEAR COVER

1

4

D8056_REV1

CIRCLIP D1400 - 015

1

5

E1-1060_REV0

M5 SPRING WASHER

1

6

F22132_REV1

SPRING

1

7

F22133_REV1

BUSH AM1016 - 10

2

8

F34110_REV3

WHEEL SCRAPER

2

9

F36617_REV8

CHASSIS ASSEMBLY

1

10

F36630_REV3

GRASSBOX FLAP

1

11

F36700_REV1

FLAP ADJUSTER

1

12

F37088_REV2

BRUSH STRIP

2

13

SP01004_REV0

HEX SET SCREW M5 X 20

5

14

SP01009_REV0

HEX SET SCREW M8 X 20

4

15

SP01019_REV0

BUTTON HEAD M6 X 16

9

16

SP02002_REV0

NUT M5 NYLOC (T)

4

17

SP02004_REV0

NUT M6 NYLOC

9

18

SP02006_REV0

NUT M8 NYLOC (T)

2

19

SP03008_REV0

WASHER M8 FORM A

8

20

SP03009_REV0

WASHER M5 FORM A

4

21

SP03010_REV0

WASHER M6 FORM A

9

22

SP03011_REV0

WASHER M10 FORM A

2

23

SP03013_REV0

WASHER M5 FORM C

1

24

SP03029_REV0

WASHER M8 SPRING LOCK

2

CHASSIS

P2.01

SP20008_REV3

MAY 2018

25

17

6

8

33

28

31

444442

36

40

30

37 44 44 42

15

41 44 44 42

5

9

28

30

37444442

3

12

29

18

37

112

9

26

10

42

19

18

47

34

21

30

25

21

17

6

12

29

3

37444442

10

13

16

11

39 45 45 43

15

8

31

14

28

37444442

95

5

37 44 44 42

41 44 44 42

37 46 44

37

32

22

22

7

7

4

CONTINUED ON P3.02

47

34

DRIVE SYSTEM

P3.01

SP20008_REV3

MAY 2018

112

16

24

23

13

1

23

16

42

19

3

9

37 44 44 42 39

39454543

26

27

35

20

20

10

CONTINUED ON P3.03

DRIVE SYSTEM

P3.02

SP20008_REV3

MAY 2018

ITEM NO.

PART NUMBER

DESCRIPTION

DRIVE/QTY.

1

229829_REV1

CIRCLIP D1300 0280

1

2

229833_REV1

BUSH AL1622 - 20

1

3

D1558_REV1

CHAIN 77P X 1/2INCHESINCHES PITCH

1

4

D1572_REV1

KEY PARRALLEL 3/16INCHESINCHES X 3/16INCHESINCHES X5/8I

1

5

D1588_REV0

BEARING BPFL5-16

2

6

D1801_REV1

BELT 'V' A 42 1DB COTTON

1

7

D1989_REV0

GRUB SCREW M6 X 10

2

8

D2924_REV2

PULLEY

1

9

D2991_REV1

BEARING BPFL4-12

3

10

D4317_REV1

SPROCKET 08B1 17T

1

11

D6182_REV1

TENSIONER PIVOT SHAFT

1

12

D6186_REV3

SPROCKET 08B1 38T

1

13

D6189_REV1

JOCKEY TENSIONER

1

14

D6603_REV1

GEAR 14 TOOTH

1

15

D7977_REV1

SPUR GEAR

1

16

D7979_REV1

JOCKEY TENSIONER ARM

1

17

D7988_REV2

SPECIAL PULLEY

1

18

D8032_REV0

BEARING BPFL5-25

2

19

D8042_REV1

EXTENSION SPRING

1

20

D8068_REV0

GRUB SCREW M6 X 6

2

21

D8153_REV1

GRUB SCREW M8 X 10

6

22

D8165_REV0

KEY PARALLEL 6 X 6 X 25

2

23

D8173_REV1

BEARING 6001 2RS

2

24

D8175_REV1

CIRCLIP D1400 - 012

1

25

D8989_REV1

BELT 'V' B 35 COTTON

1

26

F20077_REV1

BEARING BPFL7-35

1

27

F36694_REV4

STUB SHAFT

1

28

F36695_REV3

GEAR SHAFT

1

29

F37054_REV2

LAYSHAFT

1

30

F37082_REV2

PULLEY (125 PCD X 1B)

1

31

F37134_REV2

DIFFERENTIAL ASSEMBLY

1

32

F37158_REV2

SPACER

1

33

J20457_REV1

KEY 3/16" X 3/16" X 1" RD END

1

34

J20467_REV0

GRUB SCREW M8 X 8

4

35

J209030_REV1

KEY 3/16" X 3/16" X 3/4" RD END

1

36

J209249_REV0

WASHER 9 X 35 X 3

1

37

SP01009_REV0

HEX SET SCREW M8 X 20

12

37

SP01017_REV0

GRUB SCREW M6 X 12

2

39

SP01035_REV0

HEX SET SCREW M10 X 25

2

40

SP01036_REV0

HEX SET SCREW M8 X 35

1

41

SP01045_REV0

HEX SET SCREW M8 X 25

2

42

SP02006_REV0

NUT M8 NYLOC (T)

13

43

SP02008_REV0

NUT M10 NYLOC (T)

2

44

SP03008_REV0

WASHER M8 FORM A

26

45

SP03011_REV0

WASHER M10 FORM A

4

46

SP03029_REV0

WASHER M8 SPRING LOCK

2

47

SP23004_REV0

SPACER 25.4 X 38 X 13.5

2

DRIVE SYSTEM

P3.03

SP20008_REV3

MAY 2018

1

2

4

4

4

2

3

556

6

7 6

7 6

7 6

3

ITEM NO.

PART NUMBER

DESCRIPTION

ENGINE /QTY.

1

F22464_REV1

ENGINE 5.5 HP HONDA GX160 L

1

2

F37161_REV2

BELT GUIDE PEG

3

3

J209050_REV1

FIXING PLATE ASSY

2

4

SP01009_REV0

HEX SET SCREW M8 X 20

3

5

SP02006_REV0

NUT M8 NYLOC (T)

4

6

SP03008_REV0

WASHER M8 FORM A

7

7

SP03029_REV0

WASHER M8 SPRING LOCK

3

ENGINE DETAIL

P4.01

SP20008_REV3

MAY 2018

2

2

1

4553

1

1

1

3 5 5 4

ITEM NO.

PART NUMBER

DESCRIPTION

WHEELS/QTY.

1

D5155_REV1

BUSH AI1618 - 3/4"

4

2

F37135_REV3

WHEEL DETAIL

2

3

SP01022_REV0

HEX SET SCREW M8 X 50

2

4

SP02006_REV0

NUT M8 NYLOC (T)

2

5

SP03008_REV0

WASHER M8 FORM A

4

WHEELS

P5.01

SP20008_REV3

MAY 2018

2

1

5

6

3

8

71211

4

11

8 10 10 8

811

2

5

9

8

5

3310

10118

ITEM NO.

PART NUMBER

DESCRIPTION

GUARDS/QTY.

1

D3171-D7986_REV1

RUBBER GUARD SEAL

1

2

D7986_REV2

CHAIN GUARD

1

3

E1-5123_REV2

CHAIN GUARD STUD

2

4

F33384_REV1

LABEL CAUTION

1

5

F37047_REV3

BELT GUARD

1

6

F37060_REV1

LABEL AUTO-ROTORAKE

1

7

SP01009_REV0

HEX SET SCREW M8 X 20

2

8

SP02006_REV0

NUT M8 NYLOC (T)

10

9

SP02045_REV0

RIVNUT HEX M8 (4.0-6.0) [NO HEAD]

2

10

SP03008_REV0

WASHER M8 FORM A

4

11

SP03015_REV0

WASHER M8 FORM C

8

12

SP03029_REV0

WASHER M8 SPRING LOCK

2

GUARDS AND COVERS

P6.01

SP20008_REV3

MAY 2018

4

6

2

7

9

3

1189

5 10 1

8 11

11057

** SEE 7.02 FOR SUB ASSEMBLY DETAIL

ITEM NO.

PART NUMBER

DESCRIPTION

GRASS BOX/QTY.

1

290050_REV0

GRASSBOX ARM STOP

2

2

403077_REV0

GRASSBOX ARM L.H.

1

3

403078_REV0

GRASSBOX ARM R.H.

1

4

800519_REV0 **

GRASSBOX ASSEMBLY ROTORAKE

1

5

E1-1065_REV0

SPRING WASHER M12 SQUARE SECTION

2

6

F36332_REV0

DECAL SISIS WHITE 50MM HEIGHT

1

7

SP01065_REV0

HEX SET SCREW M12 X 30

2

8

SP02007_REV0

NUT M10 STD

2

9

SP02008_REV0

NUT M10 NYLOC (T)

2

10

SP03012_REV0

WASHER M12 FORM A

2

11

SP03018_REV0

WASHER M10 FORM G

4

GRASS BOX

P7.01

SP20008_REV3

MAY 2018

1

4

NOTE: SOME PARTS OMITTED FOR CLARITY

3

2

2

10

6

13

8

7

9 11

1312

1312

5

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

290070_REV0

GRASS COLLECTOR 24"

1

2

290071_REV0

WASHER 16 X 100 X 3

4

3

290072_REV0

GRASSBOX PIVOT

2

4

F36332_REV0

DECAL SISIS WHITE 50MM HEIGHT

1

5

J209064_REV2

HANDLE PLATE GRASS BOX

1

6

J209243_REV1

HANDLE GRASSBOX

1

7

J249062_REV1

MESH

1

8

J249063_REV1

24" GRASSBOX EDGING STRIP

1

9

SP01028_REV0

HEX SET SCREW M6 X 20

2

10

SP02028_REV0

NUT M16 NYLOC (T)

2

11

SP03010_REV0

WASHER M6 FORM A

2

12

SP03032_REV0

WASHER M5 REPAIR

7

13

SP05018_REV0

RIVET 4.8 X 18

7

GRASS BOX SUBASSEMBLY

P7.02

SP20008_REV3

MAY 2018

2

15

4

21

5

3

5

21

13

10

17 24 22

11

172422

12

19

8

14

19

8

1823

19 24 22

21

5

9

1

22

16

23 20

5

6

6

5

7

ITEM NO.

PART NUMBER

DESCRIPTION

FRONT ROLLER/QTY.

1

400971_REV0

FRAME ARM SPACER

2

2

D1879_REV1

HANDWHEEL

1

3

D7907_REV1

UNIVERSAL JOINT

1

4

D7993_REV2

ADJUSTMENT ROD

1

5

E1-1065_REV0

SPRING WASHER M12 SQUARE SECTION

5

6

F21064_REV1

ROD END MJ-12-M-STS

1

7

F32151_REV1

DEPTH ADJ SCREW

1

8

F36680_REV3

OFFSET PIVOT BUSH

2

9

F37083_REV2

CONNECTOR

1

10

F37138_REV3

ROLLER

1

11

F37140_REV6

ROLLER FRAME L.H.

1

12

F37141_REV4

ROLLER FRAME R.H.

1

13

F37172_REV2

MIDDLE PIVOT

1

14

F37273_REV2

SCRAPER

1

15

J209024_REV0

NUT 5/16 BSF LOCK (THIN)

1

16

SP01020_REV0

HEX SET SCREW M10 X 40

2

17

SP01035_REV0

HEX SET SCREW M10 X 25

2

18

SP02006_REV0

NUT M8 NYLOC (T)

2

19

SP02008_REV0

NUT M10 NYLOC (T)

3

20

SP02012_REV0

NUT M8 LOCK (THIN)

2

21

SP02014_REV0

NUT M12 LOCK (THIN)

3

22

SP03011_REV0

WASHER M10 FORM A

5

23

SP03029_REV0

WASHER M8 SPRING LOCK

4

24

SP03034_REV0

WASHER M10 SPRING LOCK

3

FRONT ROLLER ASSEMBLY

P8.01

SP20008_REV3

MAY 2018

31 37

43 41 2

41

43 37 30

33

40

12 39 35

36 36 28

32 32

13

17

4

18

7 37

20

32

6

5

2438

22

21

15

26

23

34

2738

2513539

15

10

14

6 29

19

31 37

16

11 9 8

3

42

CONTINUED ON P9.02

LINKAGE

P9.01

SP20008_REV3

MAY 2018

ITEM NO.

PART NUMBER

DESCRIPTION

LINKAGE/QTY.

1

400998_REV0

SPACER ENGINE FLANGE

2

2

401874_REV0

PULLEY BODY 19MM

1

3

D8068_REV0

GRUB SCREW M6 X 6

2

4

D8165_REV0

KEY PARALLEL 6 X 6 X 25

1

5

D8275_REV1

BUSH AM1519 - 30

1

6

D8485_REV1

ROD END R108-M8.

2

7

E1-1131_REV1

HEX SET SCREW M10 X 70

1

8

F20431_REV1

NUT M4 NYLOC

2

9

F20803_REV1

WASHER M4 FORM A

2

10

F21748_REV1

MICROSWITCH

1

11

F22043_REV1

HEX SET SCREW M4 X 30

2

12

F22240_REV1

HEX SETSCREW 5/16" UNC X 3/4"

2

13

F22241_REV1

BRAKE CALIPER

1

14

F22252_REV1

TENSION SPRING

1

15

F36635_REV4

TENSIONER BRACKET

1

16

F36636_REV4

BELT TENSIONER ARM

1

17

F37055_REV3

DISC BRAKE

1

18

F37084_REV2

BRAKE ADJUSTMENT ROD

1

19

F37085_REV3

BRAKE CONNECTOR STUD

1

20

F37086_REV4

TENSIONER ARM ASSY

1

21

F37087_REV2

BELT ADJUSTING ROD

1

22

F37100_REV3

MICROSWITCH PLATE

1

23

J209047_REV0

TENSIONER PULLEY

1

24

SP01004_REV0

HEX SET SCREW M5 X 20

2

25

SP01005_REV0

HEX SET SCREW M8 X 30

2

26

SP01071_REV0

HEX SET SCREW 3/8" UNF X 1 1/2"

1

27

SP02002_REV0

NUT M5 NYLOC (T)

2

28

SP02004_REV0

NUT M6 NYLOC

1

29

SP02006_REV0

NUT M8 NYLOC (T)

2

30

SP02007_REV0

NUT M10 STD

1

31

SP02008_REV0

NUT M10 NYLOC (T)

2

32

SP02012_REV0

NUT M8 LOCK (THIN)

4

33

SP02014_REV0

NUT M12 LOCK (THIN)

1

34

SP02015_REV0

NUT 3/8" UNF

1

35

SP03008_REV0

WASHER M8 FORM A

4

36

SP03010_REV0

WASHER M6 FORM A

2

37

SP03011_REV0

WASHER M10 FORM A

4

38

SP03013_REV0

WASHER M5 FORM C

4

39

SP03029_REV0

WASHER M8 SPRING LOCK

4

40

SP03034_REV0

WASHER M10 SPRING LOCK

1

41

SP06012_REV0

BEARING 6200-2RS

2

42

SP06022_REV0

BUSH AM1216 - 25

1

43

SP07012_REV0

CIRCLIP D1300 - 030

2

LINKAGE CONTINUED

P9.02

SP20008_REV3

MAY 2018

19

12

8 28

20

20

828

11

2

1

10

30

24

9

18

2525

16

17

10 30

13

263

12

21 4

26 3

2426

20

5

22

6

14

15 7

2926

23

27

CONTINUED ON P10.02

HANDLE BAR ASSEMBLY

P10.01

SP20008_REV3

MAY 2018

ITEM NO.

PART NUMBER

DESCRIPTION

HANDLE BARS/QTY.

1

176457_REV1

BLACK KNOB M10

1

2

229754_REV0

CLUTCH LEVER

1

3

D1040_REV0

SPLIT PIN 3/32" X 3/4""

2

4

D6619_REV1

OVER CENTRE ROD

1

5

D6620_REV1

LEVER

1

6

D8271_REV1

THROTTLE CONTROL

1

7

E1-1114_REV0

HEX BOLT M8 X 65

1

8

E1-1119_REV0

HEX SET SCREW M10 X 35

4

9

F20714_REV1

WING SCREW

1

10

F21063_REV1

LOCK KNOB

2

11

F21905_REV0

DEADMAN LEVER

1

12

F22019_REV1

HANDLE GRIP

2

13

F22238_REV1

SWITCH AND KEY

1

14

F22242_REV1

SCREW No 8 POSIPAN WITH FLANGE

5

15

F30963_REV1

DRIVE LEVER PIVOT SHAFT

1

16

F36639_REV3

UPPER HANDLE R.H.

1

17

F36640_REV3

UPPER HANDLE L.H.

1

18

F36696_REV3

ADJUSTMENT ROD SUPPORT

1

19

F37029_REV4

HANDLE SHROUD

1

20

F37051_REV3

LOWER HANDLE ASSY

1

21

J209026_REV0

NUT 5/16 UNF LOCK (THIN)

1

22

SP01149_REV0

CSK SOCKET SCREW M6 X 16

2

23

SP02004_REV0

NUT M6 NYLOC

2

24

SP02006_REV0

NUT M8 NYLOC (T)

2

25

SP02008_REV0

NUT M10 NYLOC (T)

4

26

SP03008_REV0

WASHER M8 FORM A

4

27

SP03009_REV0

WASHER M5 FORM A

2

28

SP03011_REV0

WASHER M10 FORM A

4

29

SP03029_REV0

WASHER M8 SPRING LOCK

2

30

SP03034_REV0

WASHER M10 SPRING LOCK

2

HANDLE BAR ASSEMBLY

P10.01

SP20008_REV3

MAY 2018

ITEM NO.

PART NUMBER

DESCRIPTION

WIRES/QTY.

1

F37118_REV1

HARNESS MICRO SWITCH TO NUTRAL

1

2

F37119_REV1

HARNESS KEY TO NUTRAL

1

3

F37120_REV1

HARNESS KEY TO ENGINE

1

4

F37121_REV1

HARNESS DEADMANS HANDLE TO ENGINE

1

5

F37122_REV1

HARNESS DEADMANS HANDLE TO MICRO SWITCH

1

6

F37166_REV5

CLUTCH CABLE

1

7

F37379_REV2

THROTTLE CABLE

1

8

HUHTM507_REV1

CONVOLUTED TUBING 1MTR

1

9

SP12014_REV0

ELECTRICAL CONNECTOR MALE BULLET (RED)

1

10

SP12015_REV0

ELECTRICAL CONNECTOR FEMALE BULLET (RED)

1

11

SP012029_REV1

HEAT SHRINK 12.7 1:2 (BLACK)

1

12

SP21003_REV0

PACKAGING BRACKET VEEMO

2

CABLES AND ELECTRICAL (ITEMS NOT SHOWN)

P11.01

SP20008_REV3

MAY 2018

4

1

4

1

2

3

ITEM NO.

PART NUMBER

DESCRIPTION

QTY.

1

D8757_REV0

CAP HEAD M10 X 25

2

2

F21868_REV0

8MM ALLEN KEY

1

3

F36305_REV1

TINE COMPRESSION TOOL

1

4

SP01061_REV0

CAP HEAD M10 X 80 FULL THREAD

2

TINE COMPRESSION TOOL ASSEMBLY

P12.01

SP20008_REV3

MAY 2018

NOTES

SP20008_REV3

MAY 2018

SISIS, Ashbourne Road, Kirk Langley , Derbyshire, DE6 4NJ, England

Tel: +44 (0) 1332 824 777

Fax: +44 (0) 1332 824 525

Email: info@sisis.com

www.sisis.com

A division of Howardson Ltd – a proudly British company

Company reg No: 641526 – Vat No GB 345 9918 12

SP20008_REV3

MAY 2018

Loading...

Loading...