Page 1

R718K/R728K

R~Jii1~f!iPIIDaJ

KAULIN MFG. CO.,LTn

ffffl

~t3~

=!=W*f1=

li1

INSTRUCTION BOOK & PARTS LIST

c~-

'

~

-

_.

The specification and/or appearances

list

are

subjectto

change because

of

the equipment described in

of

modification

without

this

previous notice. ODM14P31.JUNE.2013

instruction

book

and parts

C€

-.....

0

.,

.

-

w.l

®

S~Jii1S3~1l~fJEJ

1&111

KAULIN

MFG.

CO

..

LTD.

Page 2

EC DECLARATION

OF

CONFORMITY

According to the following

Machinery

The undersigned, ROBERT TSAI , representing KAULIN MFG. CO

Sec. 3 Min Shen

machine described hereafter:

Directive:

E.

98 I

37

I

EC

, as amended

Road, Taipei , Taiwan ROC., manufacturer, declares that the

EC

Directive

by

8913361

EEC

and

731231

..

LTD.

EEC.

11

F 128

Post-Bed Lockstitch Machine

Model:

Provided that it is used and maintained in accordance with the generally accepted

codes

essential safety and health requirements

of

good

practice and the recommendations of the instructions manual, meets the

P700K/R700K

of

the Machinery Directive.

For the most

requirements

EN

292

design.

The

compliance

established

Belgium

Machinery Directive).

specific

of

the Directive has been based on elements of : the European Standard

- 1 & - 2 :

of

by

AIB-VINCOTTE Inter n.f.p, Avenue A. Drouart

( Notified

1992

the model with the requirements

body

risks of the machine, safety and compliance with the essential

Safety

under the number

of

machinery ; basic concepts, general principles

of

EC

Machinery Directive was

27-29, B 1160,

26

for machinery listed in annex

Date:

Signature:

Qualification : R&D MANAGER

AUG. I 1 I

W..,<....(

·

for

Brussels,

IV

of

EC

2006

L'

Page 3

INDEX

J{/PAGE

General

Warning ! When using this machine, basic safety precautions should always be followed

risk of fire,

Read all these instructions before operating this product and save these instructions.

1.Keep

Cluttered areas and benches invite injuries.

2.Consider

Do not expose power to rain. Do not use machine tools in

Dot not use power tools where there is risk

3.Guard

Avoid body contact with earthed

4.Keep

Do not let visitors touch the tool

5.Dress properly.

Do not wear loose clothing or jewelry, they can be caught in moving parts. Wear protecting hair covering to

contain

6.Do

not

Never carry the machine by cord or yank it

oil and sharp edges.

7.Maintain

Follow instructions

damaged have it repaired by

&.Disconnect

When not in use, before servicing and when changing accessories.

9.Avoid

Do not carry a plugged in tool with a finger on the switch. Ensure switch is off when plugging

1 O.Check damaged parts.

Before further use of the tool, a guard or other part that is damaged should be carefully checked to

determine that it

11. Warning.

The use of any accessory

present a risk

12. Have

Repairs should only be carried out by qualified persons using original spare parts.

Safety

electric

work

work

against

children

long hair.

abuse

machine

unintentional

your

shock

area clean.

area environment.

electric

away.

the

for

machine

will operate properly and perform its intended function.

of

personal injury.

tool

repaired

Instructions

to

and personal injury, including the following.

damp

or

wet locations. Keep work area well lit.

to

cause fire or explosion.

shock.

or

grounded surfaces (e.g. pipes, radiators, ranges refrigerators).

or

extension code.

cord.

to

disconnect it from the socket. Keep the cord away from heat,

with

care.

lubrication and changing accessories. Inspect tool cord periodically and if

an

authorized serviced facility.

starting.

or

attachment, other than those recommended

by a qualified

person.

in

this instruction manual, may

reduce the

in.

~J!~~~lj[~ijij

~~U~JJi

m~

fi.l5it

tt!Y-J~~

~-rz•rw

fifaailltiJlJtzmJ~WMa

•ttz~a

-~~~~JI:jl~

tt~B!i~Jijj~

~~B!i~Jijj~

a~mz~tt

jiJlJt11!1.J

tt•W~H~~·

$t

00

"Fi!flftjlij'JI~~

~1ymJJt~·

~filii

~!l

~HI

rdl!Jt

IMPORTANT SAFETY INSTRUCTIONS 1

WARNING 5

SPECIFICATION 6

LUBRICATION 7

INSTALL THE NEEDLE 7

ASSEMBLE AND DISASSEMBLE THE BOBBIN 8

OPEN AND CLOSE THE ROLLER PRESSER FOOT 10

THREADING

ADJUST THE THREAD TENSION 12

ADJUST THE NEEDLE THREAD TENSION

ADJUST THE

ADJUST THE STITCH LENGTH 13

ADJUST THE PRESSURE OF THE PRESSER FOOT

ADJUST THE NEEDLE BAR AND THE

THE CLEARANCE BETWEEN THE NEEDLE AND 16

THE

HOOK

ADJUST THE LOWER FEEDING ROLLER HEIGHT

ADJUST THE

TABLE CUT-OUT OF FLAT BED R718-T1 20

TIP

HOOK

HOOK

11

12

THREAD TENSION 13

14

HOOK

OPENER

14

18

19

Special

1.1ncorporate this machine only with

2.Follow the instruction manual device

3.Aiways earth machine

4.Before adjustment, parts change or servicing must be sure

the hazard of

Warning For

appropriately during operation.

unintentionally start of machine.

Electric

"CE"

to

Connection!

certificate hold-to-run control device.

install control device.

to

pull out the plug from socket to prevent

Page 4

IMPORTANT

IN

STR U CTI

0 N S

SAFETY

~~•••*~•~7~~a~•~•~•

~~~~~~~~a~~~~~~~~mm

at~

B.

~m"M~1-rllllilt~~m~~:;;.

1~H~~~WHfm'E:.

!Ill

f~

~

:Lti!

J'j.

1.

~1fll~m

fl!!~*

2:fim~tBM.

IHJ~X1~lfli&J~~

*fim~~~~~~~-~~~qw~

3. st m ~

Mfim~w.

4.~tlft3i;.s.Uif1=~1ilia~.

~~~~tt~~AA~~~~•"""Fa~~~

~twa~.

~

~11

11

w

~~2f~~JI:~~ijij~JJitt3~

~ 7

J.1

""F•:IR9~.

ntg_

~7m*fim~~•9~.

t!f.

Jl:~9~.

~~lififf:~

~~~Alii!~~

~~:iE

~

J5Jf~~~~~1il~~

~~

~):tmx

~i¥111

t'-

~fl.

For operating safely and to get the most out

of the many functions of this machine, you

must operate it

follow the instructions of this manual, and

keep it at hand for future references.

confident that you

much

1.When you use this machine,

2.Before using this machine,

3.Piease use this machine after it has been

4.1t

-:ft~~-

correctly. Please read and

We

are

will enjoy this machine as

as

we enjoyed manufacturing it.

please pay

attention to the basis safety measures.

please read this

manual and all related instructions.

addition, please save this manual for your

future needs.

ascertained that it conforms with safety

standards and

is not allowed to operate this machine

without the specified safety devices.

safety devices must be

regulations of your country.

in

right position.

In

All

(2)

.]I!

ftttJIIIA.ttti.~A.mtt

W

~.

J.1

& X

1i!!

11M

.Ill~

}=l,PJ1Pj\,]J[11J

f-1:

a~.

When the machine is ready for operation.

5.This machine must be operated by an

appropriately trained operator.

6.For your own safety, we suggest you wear

goggles.

7.

Please turn

disconnect it before doing the

tasks:

(1

).Threading needle(s), adjusting thread

Take-up(s), thread guide(s), and

replacing bobbin(s).

(2).Replacing needles, presser feet, needle

plates,

folders, cloth guides and other parts or

accessories.

(3).Repairing this machine.

(4).When

working

off

the

power

switch

following

I or

feed dogs, needle guards,

the

operator

place or when the working

is leaving the

or

(5).lf'fi.ll.l

~~~~it3i;~~.Lt.

M~H.~

it

iffi1llAA]J[

J:1

~iiq,

-1-

place

(5).While clutch motors without brake pads

are

completely stop.

is

unattended.

used,

motors

must

come

to

Page 5

8.fi~~~~-~&~~~ffl~····~

8.By any chance, if you allow grease, oil, or

••~~.•~•~••.~n•~*••

~

lillliHiL

&

5\.t

~-

any fluid contact your skin or eyes, please

wash the contacted area completely with

clean water and

consult a medical doctor.

.a~

15

~~t

ll

~

~

1±

m!

lE

'm

HH'F

~n.~

Ill

if~

.•

it~

:lim

IJI

"F

:~t

J\U!!L.l:.

i'F.

.•

15.To level the machine on the ground is

essential

operation

operating

in

order to ensure a proper

and

a

machine

lower

noise.

at

a

Avoid

noisy

If the fluid was swallowed

medical

9.~~~~~·~~~~~~-~~&A~

~-~~~:.!!!:a

10.*It~.~Gil&

-~H~-~~a~.H~-R~~fflfi:l

SIRUBA:f:t:i:JE:~~~-

11.-~M~&~WI~A·fi:l~~~~~

~.A.~a~.

12.-~*~M~&--I~A-EI=lft~~

~~.Uilia~

w.

~~~¥1!f~~:~~a~.

~

13.{£

~I&~

~&

~~A3l't 7 J.~&

Ill!

A~ 7 J.~~I(J)\!i

Rm!EI=l~~~~~-~H~-M~a~

~!ll

1Uii

B

rm

ii!l:.

~~~I

.•

fi:l~l''m~M~.A.~~-&~~

:;:~:

1Hii.

1'F.

\Wl

El=l

~~lfUCWil

~:u:~a~!l:-~ii

~f!f

<

i§!J

~~

~

ifi.D.

-~i!Ul~~-&

ll

~.ll~

~.

Jl:t:9~~~&1'1m!~W

~

9i:f:f

~

~ M

i!!1i

~

iWi

II!~

9.Do not touch any parts and devices in

motion

Always pay attention to whether power

switch is on or off before conducting any

task.

1

O.Qualified

machine adjustment, modification, and

repair. Only genuine parts from SIRUBA

are

Damage resulted

are subject to your own risk.

11.Routine maintenance and check-up have

to be performed by appropriately trained

persons, or qualified technicians.

12.Qualified

persons

electronic

electronic

adjustment or repair tasks. Stop the

machine immediately when discover the

failure

components.

13.The air hose has

machine and the compressor or air

has

servicing

pneumatic parts such as

Qualified

persons are required for adjustment and

repairs.

14.To

periodically clean up on the machine is

necessary.

contact

doctor

while the machine is running,

recommended

to

be cut off before repairing and

ensure

immediately.

technicians

in

technician

are

required

components

is essential

of

any

to

the

machine

technicians

the

are required for

for

replacement.

using generic parts

or

well-trained

for

services

knowledge

for

conducting

of

the

electronic

be detached from the

equipped

an

air cylinder.

or

well-trained

best

performance,

a

to

of

supply

with

surrounding.

1 6 .JI

ffl

~

~

~

11

~

:f!fi

iifl.

ilfi

El=l

11

~ H ~ ~

~

I&

{£

ll

~

J:.,

A

:tal

~l't

A

\Wl

:tal

{£

~

:tm.Jm

J:..

1 7

.•

~

R :ft

~ ~

~

ffl

~

II

:lE:

ffl

iti

J:.,

iti:.!!!:

~

:ft

~!f.~-

1a.~

Gil•

if£

ll

~A

\WI

1.ll:

n~

'ii:

~

m

~,

l~m

:lllHISl

~

~

~

'ii:

~

r.Ht!i.

:;j;:

f}

:!JIHEfoJ

:f.t.

~

~tJ

~

Gil• w £

ll

~

I'JT

sl

~--

1 9

.tH!l·

m

7.iU~

Rii

~ ~

lJI!l~

:if-:

(1J.~Ht1'F~·~~~.A.~~fl~~llfi:a

it~M~~~I!i.

~:9~a&~~•m~a~~oo~*~

a.~~~iiJ1':E~ImJSi~ii.

:eli

'ii:

~

l.ll

f!f

b.a

7

illt~~li~Uitt.~-Bll"~

.11l.l~~.iiUV.'L&n~.

1,\'li

&

Ji~

it,

11fffoJ~~-

~~Himf.ffiiUnUft

~:l'I!J'fijjii

fl,

i!Hi M

!It

:9H.~

~:II

f'F.

~~UI~fiili.

®

llB

fli

)j§J

Ill

:tl!!

~

;J;t;

ft!l

:JE:

&

FiJ

~

Jre

m

~

iiJ

;J;t;

~

ffl

~

:iJ:

:Iii

7

a

tDl

16.A proper power

this

connect the power plug

receptacle.

17.This machine can

designed purpose.

machine are not

18.Any modification or conversion made on

this machine must be conformed with the

safety

Precaution is necessary.

responsibility

modification

machine.

19.Two safety warning signs are

(1

(2)Aiways keep

plug must be used with

machine

standards

)For the safety of operators and service

persons,

any electronic

other devices and don't touch any

components inside

shock hazards.

Please never operate this machine with

belt cover, finger guard or any safety

device removed to avoid

a.Piease keep your hair, fingers and

cloths away from the hand wheel

"bobbin

while the machine is

prevent the risk of injuries

into them.

b.Piease never put your fingers under

the needle or

cover when you turn on the power

switch or operate the machine.

by

electrician.

to

only be used for the

Other uses of this

allowed.

and

for

damage

or

conversion

please don't open the cover of

control boxes of motor or

in

mind :

winder", V belt and motor

in

the thread take up

regulations.

We

applies:

to

avoid electrical

physical injury

in

Please

a grounded

assume no

caused

operation to

by

by

of

this

tangled

-2-

-3-

Page 6

c.

~1~Him

'1=1.

I§

ti~~-~9~-

d.

'i:IIHiiQ'i=l,ttBl~~-lh.~

~If-¥

1¥-J-=¥-'fi~iiRfUtB~IWID:.

ft-TH~.

e.

~

Jlti

1'

ili6llm

RJ

IHifl:roG.H

Wf

1~.HI{J

=¥

JJl

{±

8{±iiQ

tt

1¥-1

"'F

15

'1=1.

7i!t

ilJ!Ii31

il~~j}j!m

:roGfflile•:e~a~.

®;L

fl~.

~1Hil~19!

!1:~9~.

IHI8Iill

r,JJ.

,J,,L-~

~

J!tl

Hf-=¥

:ro2

I

MWH'i=!.

f.~ 7 jl~lfH~~~Ihffii

9~

I 'i:

It

H~

ttl

~

:roG

3

H~.~

lUI

f-'11 H ..

g.~*1fl!

M

1¥-1.

~-9~.

1¥-111

13

.Lt

AA

f1B

it?,

7

i!t~-H~~I&ID

~aiUif-'IIHtj~t.

51{.

H ~ fi!iifii.I.Oii.l;it,

H~

.Jiffi

it

1m

Bl.1ili

:m:

1'

i31

m

ilJtt~a

:it .&

Bl.1ifli

llH

fi'

lf

~

PI

ffii

i31 ® ilJ

ff

c.Piease never put your fingers under

the needle

cover when you turn on the power

switch or operate the machine.

d.While the machine is

hook

rotates at a high speed. Please

keep your hands away from

of

hook

your hands.

sure

e.Be

inside the machine when moving

raising the machine head to avoid

possible

f.Piease turn

machine before

head

the

due

g.The

while the machine is at rest if your

machine is

motor.

of

to

machine

careful not

or

V

belt

to

motor

this machine to avoid possible

or

in

the thread take

in

operation, the

the

to prevent

In

turn off the

while

physical injuries.

off

removing the belt cover and

to avoid

abrupt

So, please turn

start of this machine.

does

equipped

possible

addition, please make

power

changing

to

place

the

power

tilting the machine

possible

not

produce

injury to

of

bobbins.

your fingers

of

accidents

noise

with a servo

off

the power

up

area

the

I

the

1.~19!~-~~~afl.

~liJi.)l~llH.

s.~1fm

~J.RH''~~'ii•1'~~.

•m

-;~~tuttf'FM".

B.

~~~1fm~t

WARNING

Please

malfunction and

1.Ciean

putting this machine in operation for the

first time after set up.

2.Ciean

transportation.

3.Confirm

and phase (single

4.Confirm that the power

connected

5.Never use the machine where the voltage

type is different

on

6.Confirm

the machine pulley is correct.

Warning:

Before

adjustment, please turn the power

prevent accidents caused by

the

confirm

this

all

dust

that

the

motor

that

doing

sewing machine.

the

damage

machine

and oil gathered during

the voltage are set correctly

to

the power supply.

to

nameplate.

the direction

the

following

to

this machine.

completely

or

3 phase)

plug

the

designated

of

following

to

avoid

before

of

motor.

is

properly

on shown

the rotation

operation

off

abrupt

start

of

or

to

of

h.~ 7 B~Mit;LfB~.9U~1'~tt3

OOS5JIBU&Mflflf'FWH

i.

~ 7

ile

:eX

ji~MS:roGS-T.1tll"ffii

;L

ilJ

~~~

fa 9

~I

~

$t

+J]

Iff

~

jJjjt

I :jij

tJt

f-'

mi

H~.

ill

i31

J:

accidents

machine.

h. Never operate the sewing machine

with the

avoid

i.

Please turn the power switch

prior

disconnection

prevent

electric

components.

due

to

abrupt start of the

ground

electrical

to

the

possible accidents

shock

wire removed to

shock

connection

of

the power

or

damaged

hazards.

electronic

off

plug

due

in

or

to

to

-4-

-5-

Page 7

--------------------------------------------------------------------------------------------

SPECIFICATION

I

I

LUBRICATION

~ID[

m~

~§~~

_LT

..

~

..

~

~~

ffl~

ft~@J

..

~

fOe

~-rr~

Model

Specification

Stitching Style

R718K--{)

-~/One

~~

Needle

Lock Stitch

1/02

R728K

R728K

~~!fwo

Upper & Lower Roller

Feeding

~YES

Roller Diameter

Needle Feed

036,30,26

R718K-01~

No

NO

R718K-02~

$~~,~~,~#~~m~~OOz8~

Yes

Application Stitching decorative derby edge

and mid-thick fabric.

Max Rotating Speed MAX. 2500 S.P.M.

Stitch Length

Needle

Bar

Stroke

R718K-01 0-4.5

R718K-02

41mm

0-7

mm

mm

0-4.5mm

-16-20-24

-28-32

Needles

of

shoes, leather

~~~w~m~oo•-~~~~~~~~~

9m~•~x~~~~~~~~~~~~

~Ill

'

J.j_

iiii~H!I$

o

(1111.

!112,

1113)

When starting

idling a while, please lubricate the

after

indicated points and other joints enough as

the arrows

protect the machine life. (Fig. 1, Fig.

to

operate a new machine or

show

in the figures in order

to

21

Fig,

1111/Fig.

1

3)

;RWff~

¥¥~rr~

;RW~~

~~

~~~

~11

~ffl~

~l*R-t

~~~

~~wmm

§111-171~

1JDntl1f~

~~

~m~ME

Wt~

Thread Take-Up Stroke

68mm

Presser Foot Stoke

7mm/12mm

Lift

by

Hand/Knee

Type ofThread Take-Up

Hook

Needle Width

Needle

Ring Type

7j(

ZjS~@]~

-

ORGSN DPx5#16/SCHMETZ 134

Bed Specification 5181178 (mm)

Bobbin Winder

Stitch Length Adjustment

Auto Thread Trimmer

Lubrication

Thread

~~Attached

'fflittiW1f

~None

~~ntl

1tMI*~#20-40

~:a.rt~~t~,ti!fij~~

Push Button

Manual

Stitching System

Post-bed, Lockstitch, and

fjlf§~

3

fl3

400W '

Motor

Single or 3 phases,

~1/Table

1

Rotay Hook Horizontal Type

1.6, 2.0, 2.4, 2.8, 3.2

I Polyester #20-40

Poller Feed

112HP

400W, 1/2

-~~Wt~

HP

Clutch Motor

1112/Fig.

1.

¥~

~-~~~tt~mAti.~tiR*·~m

¥~tf~ ' 'OOti~tiiiHI!!l~A~

!i=il~JJ

2

' M

lt!R!IIift*B o (114)

!113/Fig. 3

INSTALL THE NEEDLE

1.

Single needle

Insert

the

Make sure the

right side, and then tighten the screw

(Fig. 4)

the needle into the needle hole of

needle bar until reaching the end.

needle groove A facing the

B.

-6-

-7-

Page 8

2.

!Itt

~-tt~tt~S~M-2tt~~~-~~

I!$

'

'ffJI~

M 2

tt

1m

l!!l

IUil&tiUI**B o

~AfJHa)

(IllS)

~

ii

' :jij

114/Fig. 4

2.

Two

needles

Insert

needle clamp until reaching the end. Make

sure the

facing two sides and opposite

other, and then tighten the screw

the needle into the hole

needle grooves A

of

of

the

the needles

to

each

B.

(Fig.

2.

*I-T2~

~*I.:r~~*I~~~~-~~M~'~a

~-~.:r~~~~ffi~~o®=~~Mm

V~®~~Hffi.D@-~ili,~iliq.

tt•I!V@2~JJ ' M!M~~1

li:

0 (117)

Ocm•

116/Fig. 6

2.

Assemble the bobbin

Put the bobbin in the bobbin case and

rotate the bobbin a

in the figure. Then

thread path

pressing spring tongue

®.

little as the arrow show

pull the thread from the

go

beneath the thread

<D.

and pull out

S)

!IS/Fig.

·-

------------------------------------------------------------------------------------------1

~T

z~!D

ASSEMBLE AND DISASSEMBLE

S

THE BOBBIN

--------------------------------------------------------------------------------------------

from the thread

pulled out from the thread hole, it

is

should be upon the thead pressing spring

@, and have the therad left about 1 0

long. (Fig.

hole@. When the thread

7)

IF/Fig.

em

7

1.

1.

ft-T2t.f.FiP

Hf~ll(A~ie

(1116)

,

llPRJIDlliift~B&ft-TC

o

-8-

Disassemble the bobbin

Pull the latch lever

bobbin case

Band

A,

and then take out the

the bobbin

C.

(Fig.

6)

3.

ftr112~

~tt~-~tt~~~-~-9~ft~21!!l

~Do

(!SIB)

-9-

3.

Assemble the bobbin case

Place the bobbin case

thread through the groove D of the hook.

(Fig. 8)

in

the hook and

Page 9

I

'--------------------------------------------------------------------------------------------

1

i !l!ti ;ZJJli

THREADING

'--------------------------------------------------------------------------------------------

~~A~*fiffi~~~~~*~AM~~M

~-HM~~-~~tt~n·~~fl~og

M~ I j..:J.~&~Xff;fi11=

0

(1119 I 11110)

OPEN

PRESSER

Turn

to

lift the roller presser

the

roller presser

AND

CLOSE

FOOT

the

presser foot lifting switch

foot~·

foot~

down, and turn it left

1118/Fig.

THE

ROLLER

Then, press

ffi

upward

8

~-~~m~~M~~~~~~ti~~·~

il~1

Ocm;Z,IJ~

ii~t/Single

o

(1111 1 11112)

Needle

Please thread as the sequence shown in the

figures.

after threading through the

11, Fig. 12)

Please left

the

thread

about

needle hole. (Fig.

10 em

to

open. For closing the roller presser foot,

reverse the

Fig.

10)

steps

to

have the result. (Fig. 9.

III11/Fig.11

1!19/Fig. 9

-10-

1!11

0/Fig. 10

-11-

11112/Fig.

12

Page 10

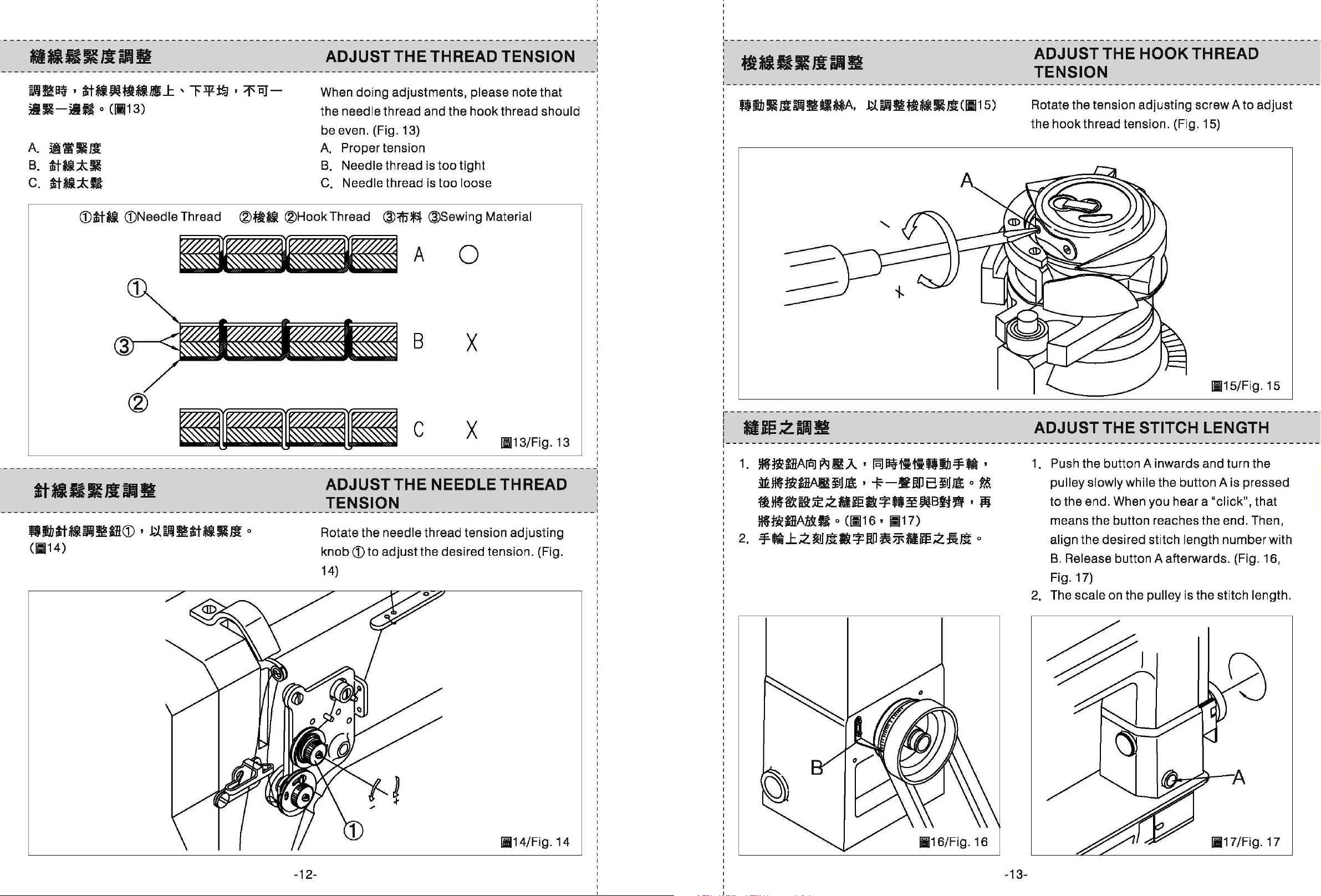

~~~'MMOO~MS~,~·~,~~

il~-illl

A.

ii'I:!RJI

B.

$tM:i\.M

C.

tt*i:i\.Ji

0

(11113)

ADJUST THE THREAD TENSION

When

the

be even. (Fig. 13)

A.

B.

C.

doing

needle thread and the hook thread should

Proper tension

Needle thread is

Needle thread is

adjustments, please note that

too

tight

too

loose

I

I

--------------------------------------------------------------------------------------------·

ADJUST THE HOOK THREAD

TENSION

Rotate the tension adjusting screw A

the

hook

thread tension. (Fig. 15)

to

adjust

CDtt*l

(j)Needle Thread

®~•

-AO

-c

Q~ti·~~O(j)'~~~ti-~Jfo

(11114)

®Hook

Thread

@:ffi'fl

@Sewing Material

B X

X

ADJUST THE NEEDLE THREAD

TENSION

Rotate the needle thread tension adjusting

knob

CD

to

adjust

14)

the desired tension. (Fig.

11113/Fig.

13

1.

~~lHAraJ

.tt~~&AI!

~~~~~z•~•*M¥OOB~•'M

HfniaHAl&fi

2.

=FM~z~m•*~~~•~zAm

P-1

ItA. '

~rJ

Ja

'

o

(11116 ' 11117)

lii.l~1i11Qih=FM

-F

-§fin

a

~rJ

Ja

o

o

'

~

11115/Fig.

15

ADJUST THE STITCH LENGTH

1.

Push the button A inwards and turn the

pulley slowly while the button A is pressed

to

the end. When you hear a "click", that

means the button reaches the end. Then,

align the desired stitch length number with

B.

Release button A afterwards. (Fig. 16,

Fig. 17)

2. The scale on the pulley is the stitch length.

-12-

11114/

Fig. 14

11116/

Fig. 16

-13-

11117/

Fig. 17

Page 11

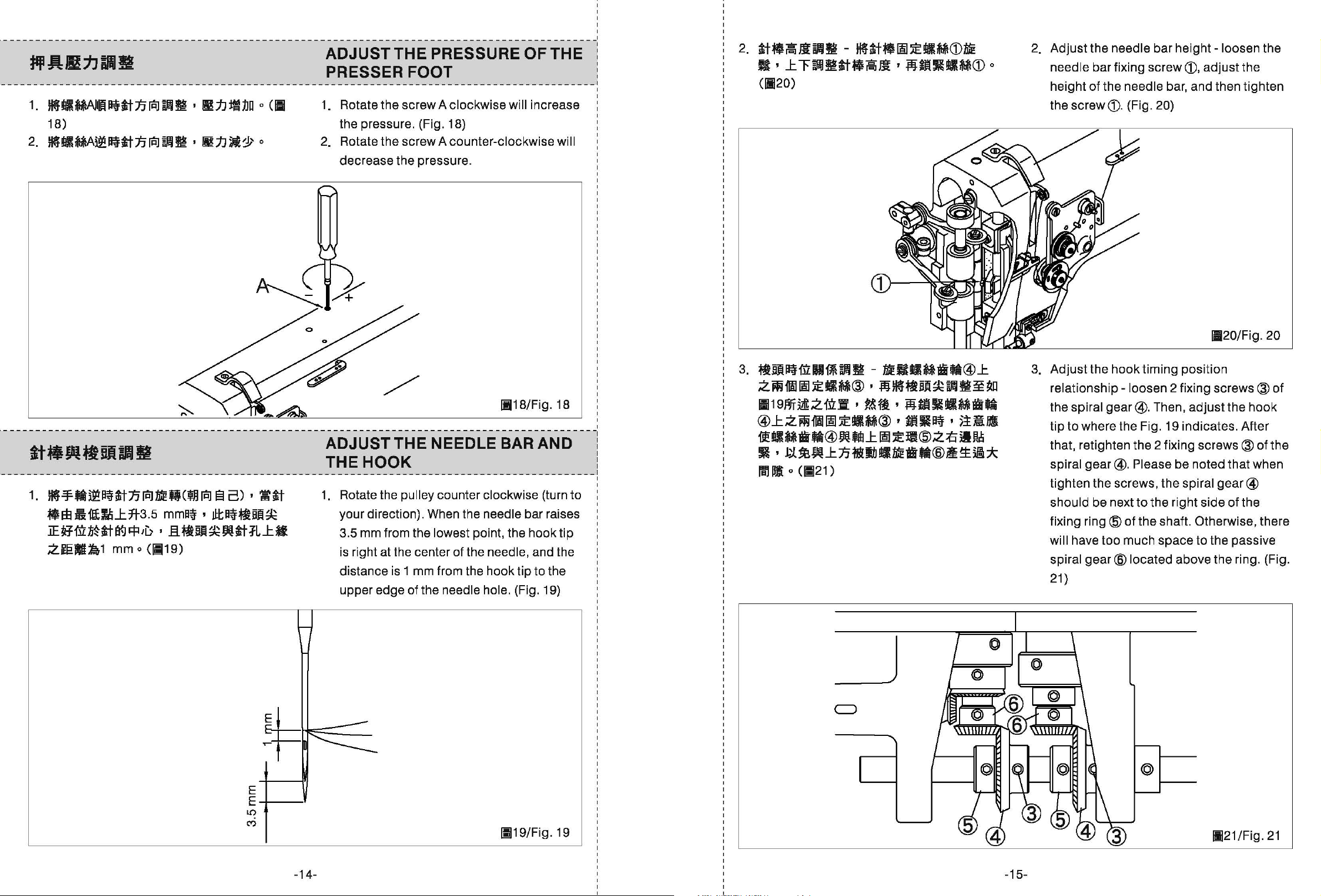

--------------------------------------------------------------------------------------------

ADJUST THE PRESSURE OF THE

PRESSER FOOT

1.

1.

~!ll~l~tt:nraJ~!I

18)

2.

~·~im~ttnraJim~

I

~n~1Jo

I

~Mn)i~

o

o

<II

Rotate the screw A clockwise will increase

the pressure. (Fig. 18)

2.

Rotate the screw A counter-clockwise

decrease the pressure.

wi

II

I

I

2.

2.

ttlfiSMillJ!i

B'L~~~tilfiSM'M--M~CDo

(11120)

-

~tt·llii~!IIMCDME

Adjust

needle bar fixing screw

height

the screw

the needle bar height

of

the needle bar, and then tighten

(j). (Fig. 20)

CD.

adjust

-loosen

the

the

1.

~=Ff~H~~ttnraJMEQC~

•w

ii1ltrJiL7t3.5

~&mMti~~~~H~mi~WtiRLa

.Zielf~1

mm o

mma~ ' JI:ta~~ml~

(!1119)

raJ

13

c) ' 'i:tt

ADJUST THE NEEDLE

THE

1.

HOOK

Rotate the pulley counter clockwise (turn

your direction). When the needle bar raises

3.5 mm from the lowest point, the hook tip

is right at the center

distance is

upper edge of the

1 mm from the hook tip to the

J

11118/Fig.

BAR

of

the needle, and the

needle hole. (Fig. 19)

AND

18

to

3.

~ml~ruH~im·-~--~-~@L

.Z~M~~-~@~M~~ml~~~~~

II19PJT~z

@LZ~M~~!IIM®,m•q,~~

~-~-~@ft~Lili!~~@.Z~~~

·~~~WLn-~U~§~@~~~*

0

ra,

Ill

'fiLii

(11!21)

I

~fl

,

MillM!IIMata

3.

Adjust

relationship

the spiral

tip

that, retighten the 2 fixing

spiral

tighten the screws, the

should be next

fixing

will have too much space

spiral

21)

the

hook

timing position

-loosen

gear@.

to

where the Fig. 19 indicates. After

gear@.

ring@

gear@

Please be noted that when

to

the right side

of the shaft. Otherwise, there

located above the ring. (Fig.

2 fixing

Then,

11120/Fig.

screws@

adjust

screws@

spiral

to

the passive

the

hook

gear@

of

the

of

20

of

the

E

E--'----1

L{)

C")

-14-

11!19/Fig. 19

_j

-15-

11121/Fig.

21

Page 12

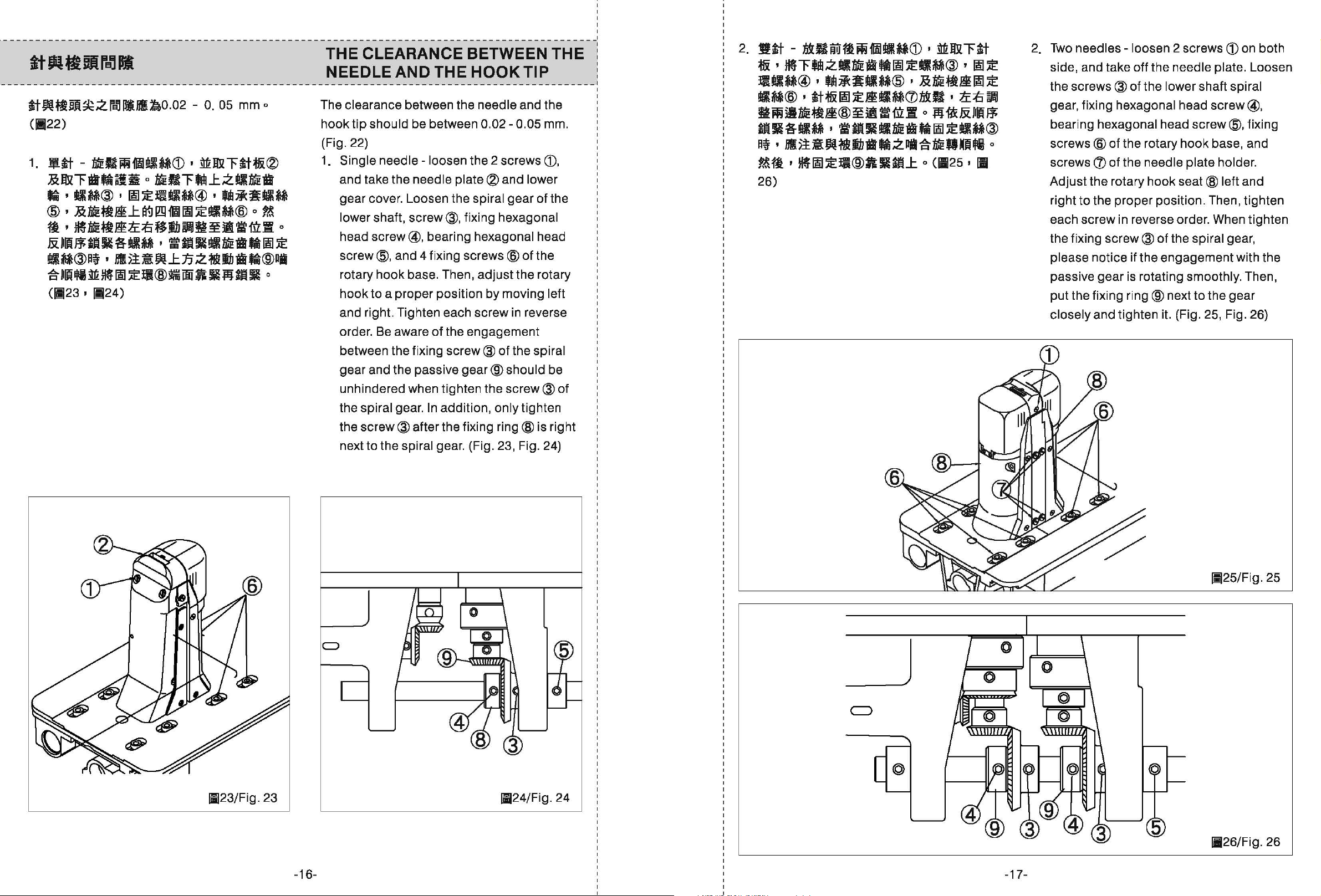

--------------------------------------------------------------------------------------------1

THE CLEARANCE BETWEEN THE

ttW~BJi~.:ZrdliJIS:1a0.02

(1!122)

1.

¥~-~•~oo~~~~~w~~~®

~w~••~~o~-~~L.:z•~•

··-~@·~~~~~@·~~~-~

@·~~~~L~~M~~-~@o~

~~~~~~~~3~~~¥~•mxo

-

o.

05 mm o

&~8-R&M~·=·-~~--~~

•M@q·a~~~L~.:Z-~8·®~

&~~~~~~~@~00~-~~-0

(11123

' 1124)

NEEDLE AND THE

The clearance between the needle and the

hook

tip should be between

(Fig. 22)

1.

Single needle

and take the needle

gear

cover. Loosen the spiral gear

lower shaft,

head

screw@,

screw@, and 4 fixing screws

rotary

hook

and right. Tighten each screw

order.

between the fixing

hook

to

a proper position by moving left

Be

-loosen

screw@,

bearing hexagonal head

base. Then,

aware

of

HOOK

0.02-

the 2 screws

plate®

fixing hexagonal

adjust

the engagement

screw@

TIP

0.05 mm.

and lower

of

@of

the

the rotary

in

reverse

of

the spiral

CD.

the

I

2.

Two

2.

Wtt-~BAA~~~-M~·~~~tt

~~~~~.:z·~·-~~-~@·~~

~-~@·~~~MM®·~~~~~~

•M®·tt~~~~~~~~-~~~~

~~~~~~@~~=m•o~•&•8

m~&MM···~-~--~~-M@

q,a~~w•tia•.:z~*~Qm~o

?&~'

26)

H~~~li®AR.L

o

(1125'

1B

needles-

side, and take off the needle plate. Loosen

the

screws@

gear, fixing hexagonal head screw@,

bearing

screws@

screws~

Adjust the rotary

right

each screw in reverse order. When tighten

the fixing

please notice if the engagement with the

passive gear is rotating

put the fixing

closely and tighten it. (Fig. 25, Fig. 26)

hexagonal head

to

the

loosen 2 screws

of

the lower shaft spiral

screw@,

of

the rotary hook base, and

of

the needle plate holder.

hook

seat@

proper

screw@

position. Then, tighten

of

the spiral gear,

smoothly. Then,

ring@

next

to

CD

left and

the

on both

fixing

gear

gear

and the passive

unhindered when tighten the

spiral gear.

the

screw@

the

next to the

In

after the fixing

spiral gear. (Fig. 23, Fig. 24)

gear®

addition, only tighten

should be

screw@

ring@

is right

of

11!25/Fig. 25

_j

11123/Fig.

23

-16-

1124/Fig. 24

-17-

11126/

Fig. 26

Page 13

--------------------------------------------------------------------------------------------1

ADJUST THE LOWER FEEDING

ROLLER HEIGHT

1.

1.

!itt

-

~"""Fti~JBHlUi*(flJJ)

fl~~~*!IIM®~~fl~~m*~~~

~~-~®·~!II~®TQti~~~~*

~~~@J.j_~~~fl~.:Z~Jl(ll27)

'

~-~

Single

the rotary hook seat (in the rear). Loosen

the

and the fixing

needle-

screw®

take off the side cover

of

the feeding roller holder

screw®

of

the adjusting

of

I

2.

Jltt

-

~~~fl~~tf*A.:Z~ii!II~CD

~~~-MBLZ~~~~!II~®'~

fl

' L

"""F311l~*~·~BUI~.:Z

tt~m•~fl·~~*•~oo~~~~fl

MCW~~.

mm

o (1128 '

MBrd:l L """F

11129)

.:Z

rdl

o

~!l

lft~O.

5

knob of the feeding

screw driver to adjust the feeding

height by turning the adjusting

the feeding

2.

Two

needlesthe feeding roller holder A, and the 2

screws®

moving the feeding

to

adjust. After that, tighten the screws

of

the feeding roller holder

the distance between feeding

feeding gear

29)

roller holder. (Fig. 27)

of

the feeding gear

B to be 0.5 mm. (Fig. 28, Fig.

roller holder. Use a

11127/Fig.

loosen the 2 screws

roller B

27

up

A,

roller

knob@

B.

Then,

and down

CD

of

of

CD

and adjust

roller C and

()

11129/Fig.

29

--------------------------------------------------------------------------------------------

I

~1\J~:J!I:iJJfi

I

tiQ~Mm~~~~A®ft~Mti*~~z

lli·A·ti·~-~~$U~@·Q~~~$

@'

iflmAW~:BJi~zrd:!Pl~0.1-

0.3

mm o

(ia30)

ADJUST THE

Rotate the

opener is at the position

from the

@of

the opener adjusting ring. Rotate the

adjust

opener

(Fig.

pulley until the stroke

needle plate. Then, loosen the screw

ring@) and keep the distance from the

to

the hook

30)

HOOK

A,

tip

to

be

OPENER

the farest point

0.1- 0.3 mm.

of

the hook

-18-

11128/Fig.

28

-19-

11130/Fig.

30

Page 14

TABLE CUT-OUT

OF

FLAT BED R718-T1

CONTENTS

§-m

/A.

L

1020

716

1\)

0

~

0

l

ll

~

4

~

R1

~

(

V\

·

A-A

HUifii

__J_

~=n

I

I I

I I

I

4-R19~

2-R19~

,/

~

p

U1

c-.

;;i

ts-

I I

i\4-R10

I

I

~

_]

J

A

T

(/)

1"'1

3::

.....

I

(/)

c

ID

~

::0

G)

1"'1

0

1.*1t1~fUR~~Ji*ftf:

2.--~~--

3.¥fillJ:B#.m•m

4.Mti*RilfM

5.7C~I!-

6 .J:

.W

~

.11l1!#

M

tl

tl

1 .J:ii,D-I!M

a.tt•••

9.~.5lMI!tl

1 O.jlfl1ftl.

1 1

.ez

i!Wi11i1l

12.1113~~--

1 3

.•

i!11:11J~t•

~t

m

MAIN FRAME

THREAD TENSION MECHANISM

SINGLE DIRECTION BEARING SHAFT MECHANISM

ROLLER PRESSER FOOT MECHANISM

THREAD TAKE-UP LEVER MECHANISM

UPPER SHAFT AND BALANLE WHEEL MECHANISM

UPPER SIDE SHAFT MECHANISM

NEEDLE BAR MECHANISM

NEEDLE BAR FEED MECHANISM

PRESSER FOOT BAR MECHANISM

TIMING BELT DRIVING MECHANISM

STITCH ADJUSTER MECHANISM

FEED SHAFT MECHANISM

AND

COVER PARTS

22

24

26

28

30

32

34

36

38

40

42

44

46

I~

1/

•

262~

195--

A 180

l

r--

40

0

R20 R25

~

I~

.....

0

1

~

~

//

/!)

I/

.6'

v

c c

~

It>

j

0

~

..,....,

I

II

~

)'

.1.

·

.....

lf-o

11

COl-"

I-"

w~--"1\l

t11CO

w

~

......

I

A

1 4-R6?

1\)

:b

.....

.I .I

1\)

0

U1

3-¢8.

jm

+

r--

1~

-f

~

f=

ss-cvr

I

1\)

·

Hl

co

U1

(J)

coo

W

t110

[t;

c-c

5

395

¢19

~

~

~~

¢18

320

311

236

189

162

5

5

ti

m

¥

50

d

.

11

~~

CO<O

OOt>

'U1

.j

t11

~

0

~

lj

R17

0

14.Mttifti'IM

15.¥~~~--

1

6.~Jm11M1111JIIM

11

.lcil~~

1B.lci~Jm1111JIIM

1

9.~il.mHIIbllfM

2 o .¥fill

21

.~ii.JIHIIJJIIM

22.~J*j!jc#

2 3

.!Jf;J

f-1:

2 4

.IJ!JJIHI

~mHiiD~tm

11

M11111

liM

CLUTCH SET MECHANISM

BEDPLATE FEED MECHANISM

BEDPLATE GEAR FEED MECHANISM

LEFT

LEFT BEDPLATE FEED MECHANISM

RIGHT SIDE BRACKET MECHANISM

FEED MECHANISM

RIGHT BEDPLATE FEED MECHANISM

SPECIAL PARTS

ACCESSORIES

PRESSER FEET

AND

MIDDLE FEED MECHANISM

48

50

52

54

56

58

60

62

64

66

68

-20-

-21-

Page 15

Sii=IUBFI

PARTS

LIST

Series

R718K/R728K

Subject

MAIN

FRAME

AND

COVER

PARTS

*lltlm~Htii*ftJ:

Page

1/2

Date

2013/6/27

Sii=IUBFI

PARTS LIST

Series

R718K/R728K

Subject

MAIN

FRAME

AND

COVER

PARTS

*lltlm~Htii*ftJ:

Page

2/2

Date

2013/6/27

1

9

I

~

-~

-8

Ref.

No

1 119687

2

3

4

5

6

7 314946

8

9

10 118430

11

14 119686

15

16

17

18

19

Part

108246

108234

168061

210210

119027

119039

700335

700335

700335

119092

108285-1

119091

108225

No.

Face

Plate

Screw

Screw

Thread

Screw

4

Hole

Screw

Arm

Side

Screw

Thread

Screw

Thread

Screw

Bracket

Screw

Bottom

Screw

Take-up

Thread

Cover

Guide

Guide

Cover

Name

Cover

Retainer

Wire

Wire

of

Part

Amt.req

R718K

liD~

~~*'*'

t-'*'*'

~H~

~~*'*'

II91U~MH*

~~*'*'

:k~.1Hi9>t&

~~*'*'

~~*~*

*'-*'*'

~~'R~*

~*'*'

l!i!IJEJf§ll:H

~*'*'

~~:lm

~~*'*'

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

2 2

1 1

1 1

1 1

1 1

1 1

2 2

1 1

5 5

R728K

Remarks

10-$

/

11

·-~

~

15

I

I

14

-22-

-23-

Page 16

Series

Sii=IUBA

PARTS LIST R718K/R728K

THREAD

Subject

TENSION

MECHANISM

Page

1/2

Date

2013/6/27

Sii=IUBA

PARTS LIST

Series

R718K/R728K

Subject

THREAD

TENSION

MECHANISM

--~~--

Page

2/2

Date

2013/6/27

2-

1

r

4

3

~~~

2-12

/

2-11

{)2-13

It

~

2-10~

2-9~

2-8---~

r

2-7

6-----0

2-11

~-5

FOR R728K

FOR R718K

Ref.

No

1 118553

2 119171

2-1

2-2

2-3

2-4

2-5

2-6

2-7

2-8

2-9

2-10

2-11

2-12

2-13

2-14

2-15

2-16

2-17

2-18

2-19

2-20

2-21

2-22

2-23

2-24

3

3-4

4

5 700412

6

Part

119171-1

119171-2

119171-3

119171-4

119171-5

119171-6

119171-7

119171-8

119171-9

119171-10

119171-11

119171-12

119171-13

119171-14

119171-15

119171-16

119171-17

119171-18

119171-19

119171-20

119171-21

119171-22

119171-23

119171-24

119766

119766-1

175096-1

700412-1

No.

Tension

Thread

Nut

Spring

Tensin

Thread

Tension

Thread

Screw

Thread

Tension

Tension

Tension

Screw

Tension

Nut

Upper

Thread

Thread

Thread

Thread

Thread

Screw

Tension

Screw

Screw

Thread

Thread

Screw

Screw

Bushing

Releasing

Tension

Guide

Spring

Take-up

Disc

Tension

Tension

Releasing

Releasing

Release

Release

Thread

Tension

Guide

Guide

Guide

Guide

disc

Tenison

Take-

Name

Regulator

Assy

Spring

Stud

Regulator

Plate

Spring

Tension

Stud

Bracket

Disc

Spring

Cap

Washer

Regulator

up

Sping

Pin

Pin

Pin

of

Plate

Part

Assy.

Bushing

Assy.

Amt.req

R718K R728K

~&

1 1

0 1

2 2

1 2

1 2

1 1

2 4

1 1

1 1

1 1

1 1

1 1

1 1

2 2

1 1

1 1

1 1

1 2

1 2

1 2

1 2

1 2

1 2

1 2

1

0 1

1

1 0

1 1

1 1

1 1

fi~m

~

~t5~!iliMJ.

!Ill~~

~~-*~

~~~-·

m~~••

~~-

~~!Ill**~

•**

~--~

fi*im

f§*i.m

~--;t&

!Ill~

~;t&~--

!Ill~~

J:.~

JM

::h

~~!Ill**~

~~~Le

~~~LIIIM

~~~--

~~~LI*Jji

!Ill~

~~~~-

!Ill~

!Ill~

¥~t5~!il*~

m~~••

!Ill~

!Ill**

ijllfJ.I

0

0

Remarks

(3-1~

21)

(3-1~

21)

-24-

-25-

Page 17

Series

Sii=IUaFI

PARTS LIST R718K/R728K

SINGLE

Subject

DIRECTION

~icJtS**lmMm

BEARING

SHAFT

MECHANISM

2013/6/27 2013/6/27

Page

1/2

Date

Sii=IUaFI

PARTS LIST

Series

R718K/R728K

SINGLE

Page

2/2

Date

DIRECTION

Subject

BEARING

SHAFT

MECHANISM

~icJtS**llll~tm

o-1

5

SJ-2

~

@)-3

o-1

-4

~-6

@--'{

©-8

u-12

-14

B-13

@)-8

©-7

~-6

u-12

-14

e-13

Ref. No

1

2

3

4

5

6

7

7-1

8

8-1

8-2

8-3

9

10

11

12

13

14

15

Part

No.

660290

119158

119158-1

756901

119150

119150-1

108294

640210

119159

119160

119886

119961

119962

119963

119507

174176

119087

061014

119505

119506

119503

Retaining

Bearing

Bearing

Bearing

Bearing

Bearing

Screw

E-Ping

Washer(l.O)

Washer(1.4)

Washer(0.1)

Washer(O.lS)

Washer(0.2)

Washer(O.OS)

Link

Ssrew

Oil

Felt

Needle

FreeFree

Shaft

Ring

Bracket

Bracket

Set

Set

Bearing

Wheeling

Bearing

Name

of

Part

C~t!:IJ.I

.IE:It&**~

(for·

t&**

.rE]t&***.H.

(for

·MS-119150) 1 1

·~~

E~t!:IJ.I

.E)

.E)

.E)

.E)

.E)

.E)

.IE:Iilff

·~*

5mmm

~tl!Xt&**

¥IE:It&**~

¥IE:It&***.H.

¥IE:It&**'lll

MS-119803)

Amt.req

R718K R728K

2 2

1 1

1 1

1 1

1 1

1 1

4 4

2 2

2 2

2 2

2 2

3 3

2 2

2 2

4 4

4 4

2 2

2 2

2 2

1 1

Remarks

(1~

3)

(12,

13)

@)-7

11

~>6

~-11

10

~,---10

~

11-~

-26- -27-

~

@-7

15

0

Page 18

Series

Sii=IUBA

PARTS LIST R718K/R728K

ROLLER

Subject

PRESSER

FOOT

MECHANISM

laJijftlt.

Page

1/2

Date

2013/6/27

Sii=IUBA

PARTS LIST

Series

R718K/R728K

ROLLER

PRESSER

la&j§lt.

Subject

FOOT

Page

2/2

MECHANISM

Date

2013/6/27

1 (Large)

I

4--

6-4-

6-5---'--

c

1

...

9-6

10-S

10-1-

10-S

11-~

20

\

~

@

I

-12

©-16

17

I

~

21

2 (Middle)

I

4--c

6-4-

6-5

---'-1

___

•

I

9-CQ)

I

10-~

10-1-@)

I

10-~

11--©

18

I

ytf

~

1@-16

11-~

~16

19

I

ytf

Ref.

No

1 119803

2

3

4 119469

5

6

6-1

6-2

6-3

6-4

6-5

6-6

6-7

7

7-1

7-2

7-3

8

8-1

8-2

8-3

9

10

10-1

11

12

13

14 119956

15

16

17

18

19

20 173174

Part

119803-1

119802

033145

175109

175109-1

175109-2

175109-3

175109-4

175109-5

175109-6

175109-7

175107

175107-1

175107-2

175107-3

175108

175108-1

175108-2

175108-3

664290

133116

133116-1

518210

119953

119943

210043

119491

119807

119955

119954

No.

Roller

Roller

Roller

Spring

Pin

Gear

Gear

Gear

Gear

Gear

Ball

Screw

Screw

Gear

Gear

Gear

Gear

Gear

Gear

Gear

Gear

Retaining

Ball

Washer

Retaining

Roller

Roller

Roller

Screw

Washer

Guide

Guide

Guide

Screw

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Presser

Bearing

Presser

Presser

Presser

Seat

Seat

Seat

Washer

Ring

Ring

Name

of

Part

Assy.

(large)

Assy.

(Middle)

Assy.

(Small)

Shaft

ShaftSeat(Front)

Shaft

Seat

Shaft

Shaft

Seat

Shaft

Shaft

Seat

Bracket

Bracket

Bracket

Amt.req

R718K R728K

~~~(:*::)

~~~(~)

~~~

.It~fti

(

Jj\)

zr.n:m

-~

'fttUih

-~-

~~.W~(iitr)

~~.w~

jld~

ffil~~

ffil~~

-~

'fti!J.W

-~-

~~.w~

-~

'fti!J.W

-~-

~~.w~

C~UI=III

51l~.W*

-~

C~WJI=III

~~~

~~~

~~~

ffil~~

-~

~~it~~(:*:)

~~it~~(~)

~~it~~

-~~

(

ql)

( Jj\ )

Remarks

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 2

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

2 1

-28-

~

-29-

Page 19

Series

Sii=IUaA

PARTS LIST R718K/R728K

THREAD

Subject

TAKE-UP

LEVER

~~-

MECHANISM

..

Page

1/2

Date

2013/6/27 2013/6/27

Sii=IUaA

PARTS LIST

R718K/R728K

Series

THREAD

Subject

TAKE-UP

LEVER

~~-

MECHANISM

..

Page

2/2

Date

~:------22

3 4

2

I I

~®®~

v-----

11--

13

12

I

5

----

4

1

7

I

~

22

~

21-~

14

17

~~

Ref.

No

1 118084

2

3 168039

4 215022

5

6

7 119049

8

9

10

11

12

13

14

15

16

17

18

19

20 118518

21

22

Part

119009

119008

119762

119007

167569

167570

119006

168046

168047

610210

039177

119013

119765

119763

218080

168041

314220

No.

Thread

Take-

up

Washer

Needle

Take-

up

Take-up

Bushing

Take-up

Ball

Bearing

Ball

Bearing

Take-

up

Washer

Screw

Retaining

Screw

Needle

Needle

Washer

Needle

Needle

Bushing

Screw

Take-

Lever

Bearing

Frame

Crank

Leer

Lever

Ring

Bar

Connecting

Bar

Connecting

Bearing

Bar

Guide

Name

up

Assy

Support

Pin

of

Slide

Part

Stud

Stud

Crank

Block

~W*H

~Wm¥$dl

~~

~t~:l:***

~w~

~WitH*~

~m

~w~

~a:~:***

~a:~:***

~w

m.~t

!k~**

C~t!:l~

!k~**

~t·l1il~3

Rod

~t-ilft~

jJ'§]

~t~:l:***

~Nf~~

~W$dl~~

15~i.l

!k~**

Amt.req

R718K R728K

1 1

1 1

2 2

2 2

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

2 2

1 1

1 1

1 1

1 1

1 1

1 1

1 1

3 3

Remarks

(2~

19)

(7~10)

~~

14-~

15 16

~

20

-30-

-31-

Page 20

Series

Sii=IUaFI

PARTS LIST R718K/R728K

UPPER

SHAFT

..tllb

Subject

AND

BALANLE

..

WHEEL

Blffll~

MECHANISM

...

Page

1/2

Date

2013/6/27

Sii=IUaFI

PARTS LIST

Series

R718K/R728K

UPPER

SHAFT

..tllb

Subject

AND

BALANLE

..

Blffll~

WHEEL

MECHANISM

...

Page

2/2

Date

2013/6/27

4

9

I

@)

IJ--5

12

11

14

~

~

•

13

7-1

15

~

13

I

~

I

13

u

I

8

16 11

dJ~1

18

17

22

Ref.

No

1

2 130224

3

4

5

6

7

7-1

8

9

10

10-1

11

12

13

14

15

16

17

18

19

20

21

22

Part

119702-2

119702-3

119702-4

700510

119702-5

119702-1

119702A

119702-6

018643

069160

169160-1

119707

335902

335902-1

016153

119705

069746

168480

210265

175048

170913

341902

210287

No.

Crank

Screw

Screw

Screw

Screw

Bushing

Upper

Upper

Bushing

Ball

Bearing

Timing

Timing

Timing

Screw

Screw

Ball

Bearing

Upper

Bushing

Washer

Screw

Feed

Regulator

Pulley

Screw

Screw

Cam

Sh

ft

Sh

ft

Belt

Belt

Belt

Shaft

Blance

Name

Assy

Wheel

Bushing

Scale

Wheel

of

Part

Amt.req

R718K R728K

8

..

-~~

-~~

-~~

-~~

...t$ib~~

...t$ib

...t$ib~~*~

~!;

)t~:l:g**

Bt~

Bt~

ilff~Bt~--

-~~

-~~

)t~:l:g**

...t$ib~~

...t$ib~~

.iS]

-~~

&!31~m!;

Bt~rnk

-~~

-~~

1 1

2 2

1 1

1 1

1 1

1 1

1 1

1 1

0

1 1

1 1

1 1

2 2

2 2

6 6

2 2

2 2

1 1

2 2

1 1

1 1

1 1

2 2

1 1

Remarks

1

f.tl*i220xl

~~~220xl

-32-

~~

-33-

Page 21

Sii=IUaA

PARTS

LIST

Series

R718K/R728K

Subject

UPPER

SIDE

SHAFT

MECHANISM

..till~\--

Page

1/2

Date

2013/6/27

Sii=IUaA

PARTS

LIST

Series

R718K/R728K

Subject

UPPER

SIDE

SHAFT

MECHANISM

..till~\--

Page

2/2

Date

2013/6/27

Ref.

No

1

2

3

4

9

8 I

10

I

7

~~~

17

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

Part

No.

119164

108177

119163

108225

119085

119511

118600

215124

133283

118504

118503

610370

119042-2

215028

175150

242810

119042

108225-2

130224

Clamp

Screw

Crank

Screw

Washer

Upper

Bushing

Needle

Washer

Collar

Screw

Retaining

Eccentic

Needle

Pin

Needle

Crank

Screw

Screw

Side

With

Shaft

Bearing

ring

With

Bearing

Bearing

Eccentric

Name

Rod

of

Part

-[E]~if.E~

-~~

-[E]~if.EWi

-~~

•m

..t.il~

~Hf~~Jft~~

~t:JX:J;~**

¥El

~Ii

-~~

c~~DII

8fifQ~'~

~t:JX:J;~**

re~~~(ml

~t:JX:J;~**

Jj\8.

-~~

-~~

Amt.req

R718K R728K

1 1

1 1

1 1

1 1

1 1

1 1

2 2

2 2

2 2

1 1

1 1

1 0

1 0

1 0

1 0

1 0

1 1

1 1

1 1

Remarks

(11)

12

I

()

FOR

MODEL

-34- -35-

14

R718K

18

Page 22

Series

Sii=IUaA

PARTS LIST R718K/R728K

Subject

NEEDLE

BAR

MECHANISM

~tmMm

Page

1/2

Date

2013/6/27

Sii=IUaA

PARTS LIST

Series

R718K/R728K

Subject

NEEDLE

BAR

MECHANISM

~tmMm

Page

2/2

Date

2013/6/27

~-2

~3

I

6

118195 (2.

118195-1 (2.

118195-2 (3.

8)

11

10 1

I

cY~

1

f--7

4)

9

2)

--18

11

'1

l3o

15

16-

22

I

'

29-~

2

9-1..._

;;;;::::_tliJ

~o

26-

©-19

~20

~25

31

Ref.

No

1 118197

2

3

4

5

6

7

8 174173

9

10

28

I

1

If/

~27

11

12

13

14

15

16

17

18

19

20

21

22

23 118857

24 118543

25 118544

26 118543A

27

28

29

29-1

30

31

Part

No.

118196

108174-1

700868

700868-1

118195

118195-1

118195-2

175096

175096-2

175150

215028

169137

305305

024191

118612

119718

030310

119046

119525-2

119718-2

118858

108285

640150

020490

130224

130224-1

134356

118545

Needle

Ring

Screw

Screw

Screw

Needle

Needle

Needle

Needle

Screw

Thread

Pin

Needle

Washer

Screw

Nut

Pin

Shaft

Pin

Connecting

Washer

Retaining

Spring

Screw

Spring

Crank

Pin

Crank

E-Ring

Spring

Screw

Screw

Needle

Washer

Bar

Clamp

Holder(2.8}

Holder(2.4)

Holder(3.2}

Bar

Guide

Bearing

Plate

Shaft

Plate

Rod

Ring

Name

of

Part

~~+~+~

~+~~!;

!Ill~~

!Ill~~

!Ill~~

~+~

~+~

~+~

•~+~+~

!Ill~~

~+~*!;

11i!JE:m(~l

~t~:l:-&**

¥El

!Ill~~

!Ill~~

11i!JE:m(~l

lllm:tlfl~flh

zp:n:m

it~

¥El

c~~DI;

~-

:l'l1il

JEt&

!Ill~~

~--

...t""F-~tf

~i:l:11i!JE:m

lllm:tlfl~ff

E~~D!;

~i:l'iiJt&

!Ill~~

!Ill~~

~+

¥El

...t""Fft

Amt.req

R718K R728K

0

0

0

0

0

0

0

0

1

1

1

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

0

0

0

1

2

2

2

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

Remarks

(4,

5)

(4,

5)

(24, 25)

FOR

R718K

~

17 -

<r::::J

-36-

-37-

Page 23

Series

Sii=IUaFI

PARTS LIST R718K/R728K

Subject

NEEDLE

BAR

FEED

MECHANISM

~t~m~t~m

Page

1/2

Date

2013/6/27

Sii=IUaFI

PARTS LIST

Series

R718K/R728K

Subject

NEEDLE

BAR

FEED

MECHANISM

~t~m~t~m

Page

2/2

Date

2013/6/27

11

10

t5-14

1 2

3

I

ll

~

~~~

8

Ref.

No

5

I

4

22

I

~

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

Part

No.

118600

215124

133283

118610

108285-1

130224

118594

100355

119014

119015

706169

119940

119940-5

119940-4

118521

108219

118520

314286

118520-1

118503

118504

Bushing

Needle

Washer

Crank

Screw

Screw

Needle

Screw

Oil

Felt

Holder

Screw

Needle

Needle

Needle

Needle

Screw

Bushing

Screw

Bushing

Screw

Collar

Bearing

Bar

Connecting

Bar

Holder

Bar

Bushing

Bar

Bushing

Bar

Support

Name

Frame

of

Link

Part

Guide

Retainer

~~

~+~~***

-~

~t~:tfi

-~

-~

~t·il~B~~

-~

5111~

5111~11!~&

-~

~t-:t#i~

~Nf~~

~+•~~

~Nf~~;t&

-~

~~

-~

~~

-~

~~

(..1:.)

(rl

Amt.req

R718K R728K

2 0

2

4 0

1

1 0

1

1 1

2 2

1 1

3 3

2 2

1 1

1 1

1 1

0

0 1

0 1

0 1

0 1

1 1

1 1

0

0

0

1

Remarks

(21)

~~

'1

I~~

11

12

I I 15

17 16

19

I

~@)

\JI

18

~

J

-38-

-39-

Page 24

Series

Sii=IUaA

PARTS LIST R718K/R728K

PRESSER

Subject

FOOT

BAR

MECHANISM

~~-

..

Page

1/2

Date

2013/6/27

Sii=IUaA

PARTS LIST

Series

R718K/R728K

PRESSER

Subject

FOOT

BAR

MECHANISM

~~~~~-

..

Page

2/2

Date

2013/6/27

/~

3-1

15

~-12

1 1.-

1

13

~

049657

049657-1 1/16n

<i}--15

24-·~

~0

25

21

~-28

3/32n

I

26

20-~

~F

22

21

--34

35

Ref.

No

1 119019

2

3

3-1

4

5

6

7

8

9

10

11

12

13

14 175135

15

16

17

18

19

20 100331

21

22

23

24 314286

25

26

27

28

29

30 118536

31

32 118539

33

34 118536A

35

Part

700785

119018

119018-1

118530

700510

119019-1

700510-1

119165-1

119165

173174

025874

054876

130173

700335

069079

317950

119004

118577

118535

343901

118105

700017

119016

049657

049657-1

108171

118542

118536-1

640150

343902

No.

Presser

Screw

Presser

Pin

Presser

Screw

Presser

Screw

Roller

Roller

Screw

Spring

Angle

Screw

Cover

Screw

Presser

Screw

Bushing

Cam

Shaft

Screw

Presser

Screw

Stud

Screw

Screw

Spring

Ptesser

Ptesser

Screw

Knee

Lifter

Spring

Pin

Bushing

E-Ring

Llifting

Bushing

Bar

Bushing(Upper)

Bar

Bar

Holder

Far

Bushing(Lower)

Presser

Presser

Foot

Lifter

Plate

Spring

Foot

Foot

Connecting

Plate

Lever

Assy

Name

Holder

Holder

of

Part

Lever

Amt.req

R718K R728K

11fl-~1f

~~~

(

..t.

11fl.

m-r

~-~~~

~~~

11fl*'~1f

~~~

-~..t.~

-~"""F~

~~~

ratm<:

.!liJ!i:"

nut~

~~~

Jj\~il>~&

~~~

11fl·~~

~~~

11fl·~~~1f

11fl•~~•m

~~~

~¥J:fJiH&

~~~

(

"""F

~~-

~~~

~~~

~--

11flDtill

11flDtill

~~~

Dtill~il~*~~

11fl..t.~

m-r

~1f

E~1D~

11fl..t.~*-ll

~~

1

)

1

1

1

1

2

1

)

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

0

0

0

1

1

1

1

1

1

1

Remarks

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

(30~33)

1

-40-

-41-

Page 25

Series

Sii=IUBA

PARTS LIST R718K/R728K

TIMING

Subject

BELT

DRMNG

MECHANISM

Page

1/2

Date

2013/6/27 2013/6/27

Sii=IUBA

PARTS LIST

R718K/R728K

Series

TIMING

Subject

BELT

DRMNG

MECHANISM

Bl~ilih~t•

Page

2/2

Date

8

I

~

l

@

Ref.

No

12

---11

8

6

5

I

1

2 610300

3 018624

4 119707

5

6 335902

7

8 700689

9

10

11

12

13

Part

No.

119097

335902-1

119121

018613

119708

069161

069161-1

119706

118726

Plug

Retaining

Ball

Bearing

Timing

Screw

Screw

Collar(Left)

Screw

Ball

Timing

Timing

Timing

Shaft

Collar(Righ

Belt

Bearing

Belt

Belt

Belt

Ring

Wheel

Wheel

t)

Name

of

Part

1¥~:!!:

C~t[]~

5tlEUdl]f(

iiJf~&:~~

-~~

-~~

$1b]f(~~(ir.)

-~

5tla$1b*

iiJf~&:~~

&:~

&:~

&:~~$1b

$1bjf(~~(;5)

Amt.req

R718K R728K

2 2

1 1

2 2

1 1

2 2

2 2

1 1

4 4

1 1

1 1

1 1

1 1

1 1

1 1

Remarks

II

13

3

1

~

/7

8

9

10

-42-

-43-

Page 26

Sii=IUBA

PARTS

LIST

Series

R718K/R728K

Subject

STITCH

ADJUSTER

MECHANISM

tiEl~~--

Page

1/2

Date

2013/6/27

Sii=IUBA

PARTS LIST

Series

R718K/R728K

Subject

STITCH

ADJUSTER

MECHANISM

tiEl~~--

Page

2/2

Date

2013/6/27

7-1

8-~

~--10

1-9

fl---u

db-

12

~-13

Ref. No

1 175038

2

3

4

5 118612

6 165356

7

8

9

10

11

12

13

14

14-1

14-2

14-3

14-4

14-5

14-6

14-7

14-8

14-9

14-10

14-11

14-12

14-13

Part

6906

175038A

215028

165356-1

165356-8

165356-5

165356-7

165356-6

165356-2

165356-3

175029

175029-1

175029-2

175029-3

175029-4

175029-5

175029-6

175029-7

175029-8

175029-9

175029-10

175029-11

175029-12

175029-13

No.

Connecting

Ball

Bearing

Crand

Needle

Bearing

Feeding

Screw

Nut

Spring

E-ring

Spring

Pin

Screw

CamAssy

Stitch

Stitch

Feed

Screw

Nut

Friction

Screw

Screw

Screw

Eccentric

Spring

Collar

Screw

Rod

Bearing

Stud

Adjusting

Regulating

Regulating

Adjusting

Plate

Rod

Set

Wheel

Name

Plate

Sear

Fix

Screw

of

Part

Seat

Amt.req

R718K R728K

it

5tlEUibjJt

=E.=E.il~ilrn.

at~~*

U'i];Efll}(~)

~~~~M&

!Ill~~

!Ill~~

~··

E~U!:Utl

ratmr::

.!p.JI{

m-r

!Ill~~

8.fn8*~

-§~~~

-§~~~;E~

-(i,c_,~~:s!t~

!Ill~~

!Ill~~

i§~J:f

!Ill~~

!Ill~~

!Ill~~

a§~~fi,c_,~

~··

~=

!Ill~~

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

2 2

Remarks

(1,

2)

2

3

-44-

14

-45-

Page 27

Series

Sii=IUaFI

PARTS LIST R718K/R728K

Subject

FEED

SHAFT

MECHANISM

M~flihMm

Page

1/2

Date

2013/6/27 2013/6/27

Sii=IUaFI

PARTS LIST

R718K/R728K

Series

Subject

FEED

SHAFT

MECHANISM

M~flihMm

Page

2/2

Date

~--g

~-8

Ref.

No

1 610280

2

3

4 215124

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Part

119085

133283

118600

119163

108225

119164

108177

119084

118601

119521

130224

335902-1

119521-1

700689

118603

118893

No.

Retaining

Washer

Washer

Needle

Bushing

Crank

Screw

Clamp

Screw

Shaft

Bushing

Crank

Screw

Screw

Crank

Screw

Bushing

Collar

Ring

Bearing

Name

of

Part

C~HI=I~

¥El

~t~fdljft~

~t~fdljft

·~

•rE:Ji!MWi

-~~

.rE:Jil~~

-~~

-~.±fill

·~

¥rE:Jff«~:Jtfi

-~~

-~~

¥rE:Jff«~:Jtfi

-~~

·~

_tif,c_,~fl

Amt.req

R718K R728K

1 1

1 1

6 6

3 3

1 1

1 1

1 1

1 1

1 1

1 1

1 1

1 1

3 3

2 2

1 1

3 3

1 1

1 1

Remarks

(16)

13

15

I

3

17 4 I

I

~ff\

0)~~

13

18

-46- -47-

Page 28

Series

Sii=IUBA

PARTS LIST R718K/R728K

Subject

CLUTCH

SET

MECHANISM

lliSH~t•

Page

1/2

Date

2013/6/27 2013/6/27

Sii=IUBA

PARTS LIST

R718K/R728K

Series

Subject

CLUTCH

SET

MECHANISM

lliSHtl.

Page

2/2

Date

~

2

3

1

5

~

@---6

~

4

i

5

Ref.

No

1 175025

2

3 119711

4

5

6

7

7-1

7-2

7-3

7-4

7-5

7-6

7-7

7-8

7-9

7-10

7-11

7-12

7-13

7-14

Part

518250

175019

341901

133109

119081A

700510

173263

013153

173261

009408

173264

065052

640150

175023

640130

013076

069037

009343

175126

No.

Shaft

Retaining

Shaft

Coupler

Screw

Connecting

Safety

Screw

Safety

Spring

Latch

Hinge

Coupler(right)

Pin

E-Ring

Stud

E-Ring

Drop-In

Washer

Spring

Ring

Ring

Clutch

Clutch

Seud

Pin

Plate

Seat

Name

of

Part

~rtilil*Efm

C~t!:IJ.;

~rtilil*Efm

(

~)

fmilK(if)

-~

il*~

fi*K*~

•**

Jt.g.K~

r"l!F

.!liN

Jt.g.Km.

11i!;E~

fmilft(;(:j) 1 1

-'P-fi~

E~t!:l!;

~~-~;E~

E~t!:IJ.;

11i!;E~

¥El

J.MIIH~jt=

11i!;E!IIl**

Amt.req

R718K R728K

1 1

1 1

1 1

1 1

4 4

1 1

1 1

2 2

1 1

2 2

1 1

1 1

2 2

1 1

2 2

1 1

1 1

1 1

1 1

1 1

Remarks

(7-1"'

7-14)

7-7

7-6

1

7-8

7-5

~

7-2

7

5

....

~-5

-48-

-49-

Page 29

Sii=IUaFI

PARTS LIST

Series

R718K

Subject

BEDPLATE

FEED

MECHANISM

••+cJ:IJmMm

Page

1/2

Date

2013/6/27

Sii=IUaFI

PARTS LIST

Series

R718K

Subject

BEDPLATE

FEED

MECHANISM

••+cJ:IJmMm

Page

2/2

Date

2013/6/27

2-~

1

--

Ref.

No

1 119145

2

0

16

058436(2.0)

058436-1

1-----3

8-@

9

(1.

~

~

6)

2

I

3

4 119144

5 130224

6 182451