Page 1

P717K/P727K

R~Jii1~f!iPIIDaJ

KAULIN MFG. CO.,LTn

ffffl

~t3~

=!=W*f1=

li1

INSTRUCTION BOOK&

PARTS LIST

I

~

The specification and/or appearances

list

are

subjectto

change because

of

the equipment described in

of

modification

without

this

previous notice. ODM14P30.JUNE.2013

instruction

book

and parts

C€

w.l

®

S~Jii1S3~1l~fJEJ

1&111

KAULIN

MFG.

CO

..

LTD.

Page 2

INSTRUCTION

This manual is prepared to permit the sewing machine to be used efficiently and for highest performance.

This machine

leather

Being equipped with spring return reverse lever type feed mechanism opener type vertical hook, and slide

type thread take-up provides perfect uniformed stitching.

works.

MANUAL

is post -bed industrial

You

can either select !-needle

FOR

sewing

POST

-BED

machine suitable for sewing shoes, bags, caps and general

or

2-needle machine according to your type

INDUSTRIAL

SEWING

MACHINE

of

works.

-INDEX-

Specification··· ... ········· ... ········· ... ······ ... ········· ... ········· ... ······ ... ········· ... ········· ... ······ ... · .. ······ ... ··· 2

Main parts name

of

machine head··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... ··· ... 3

I .Preparation for installation of machine

1 ). Place of installation of machine

2).

How to mount the machine head ·· ···· ··· ··· ··· ···· ······· ··· ··· ···· ··· ··· ···· ··· ··· ···· ··· ··· ···· ··· ··· ······· · ·4

3).

How to mount the

4).

How to connect the motor lever and foot pedaJ

5).

How

to mount the bobbin winder assembly ..

6).

How to mount and adjust the knee lifter mechanism

7).

How to mount the oil

8). How to mount the vibration preventing rubber············ .......

!!.

Preparation for

1). Selection of

2). How to attach the

3).

How to lead the upper thread .. ···············································································8

4).

How to wind the lower thread on the bobbin ..

5). How to adjust the bobbin winder assembly ..

6). How to place the bobbin into the book ..

ill.

How

to

operate······································································································13

1

).

Starting to

2). Sewing

IV. Stitching

1). Adjustment

2). Forward and Reverse stitching······ ..

3).

Adjustment

4). Adjustment

5). Proper timing between the hook and needle ...

6). Proper timing between the hook and opener .. ····•··•···•··••··•······•······•··••······•··•···•· ···21

7). Proper timing between the feed dog and needle .. ···••···••····•·········••··

over·····································································································

adjustment··············································

motor"···························

pan···························································································

operation····························································································

thread································································································7

needle·······················································································7

sewing·······························································································

of

stitch

length·················································································14

of

thread tension ··············································································14

of

feed dog height and pressure

...........................................................................

....................................................................................

.......

····················

............................................................

·························································

...................................................

··•·······•····•····•·······•···

···························································

··································································

..

··· ..

··········································

··························

of

··················································

..

presser

............

··········································

···············

..

························9

··········································14

on

matcrials

........................

.....

··•·····•····•·

4

4

··--······4

4

..........

.. 6

··6

·7

··10

·11

·13

····13

·14

17

....

18

·22

4

5

V.

Cleaning and Lubrication··

1).

Cleaning············································································································23

2). Lubrication·· ..

3).

Grease··················································

···········································

........................................................................................

..

···········································

......

······•·•·•·······•·•·•······••···•····

..

···········23

......

·····

23

·····24

P1

Page 3

UCtiOn

* Specification and main parts name

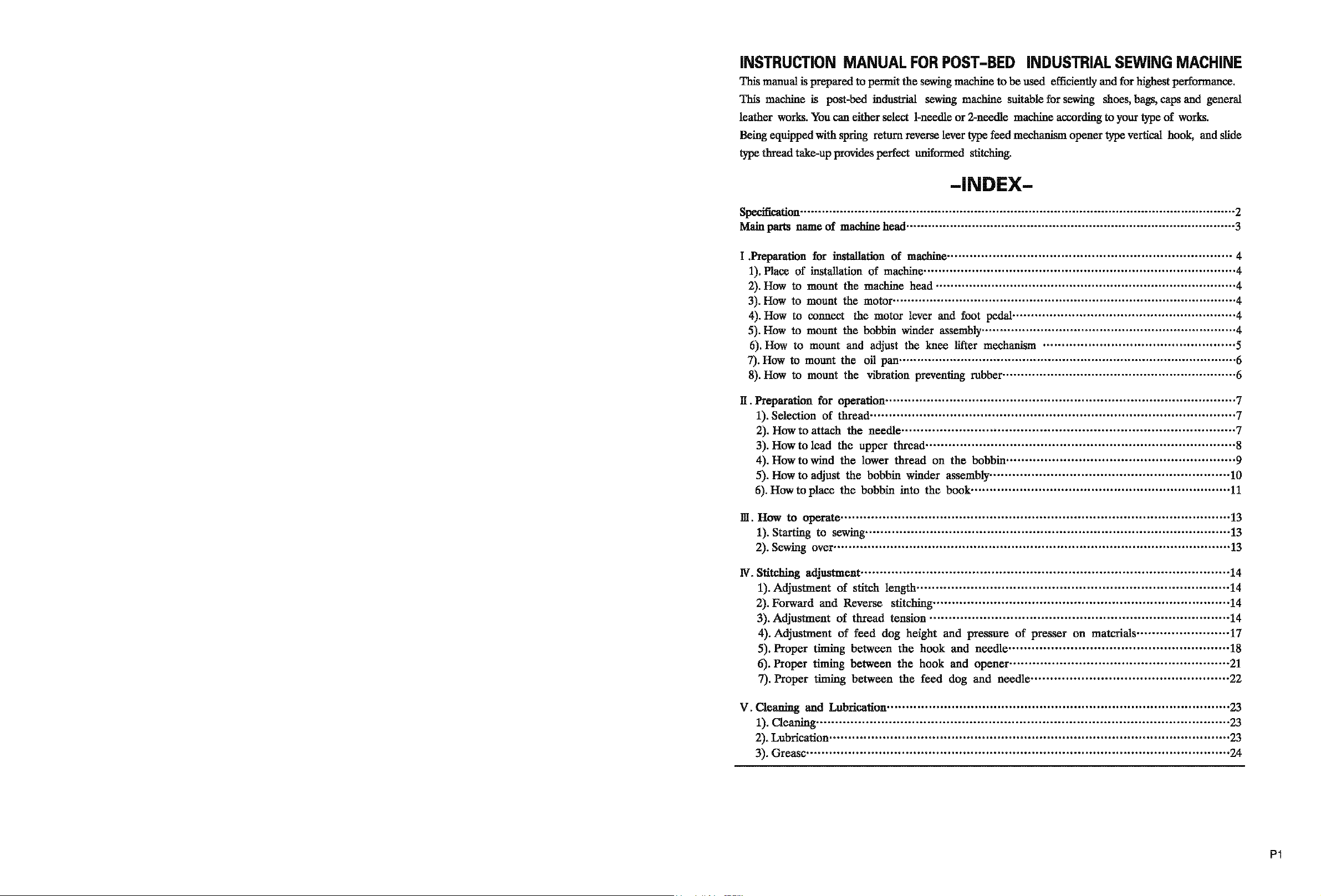

•sPECIFICATION

Sewing materials • .. ·

Speed · ...................

Need1e·······

Needle

Thread

Stitch length

Presser

Presser

bar

take

bar

foot

..............

stroke

up • ........

............

stroke····

............

••

Shoes,Bags,Caps,and

works.

· 3000

RPM.

Dp

x 5(135 x

......

33.4mm(1-5/16")

Slide

type

0-5mm(0-3/16")

..

8mm(5/16")

1-Needle

1-Needle(l/16'')Roller foot

2-Needle(1/4")Usual foot

......

5)

Roller

of

machine head.

leather

foot

Hook

...............

Stitch length adjustment · · ·

Reverse

Post height

Lubrication

Oil circulation ·

Knee

Thble

Motor

stitching............

mechanism............

...........................

...........................

··......

....

........... • ... · .....

.................

··

···

... · ....

Vertical

Dial

Spring

178mm(7")

• Manual oiling, provided with

tow oil reservoir

· Auto matic capillary cation

with oil wicks

Lever system

"DN"

Clutch motor( 400W)

hook

with

regulator type

return

manual tacker

at

type

opener

arm

(Two

Needle

* Main parts name

Type)

of

machine head

Spool

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

pin

Oil

reservoir( right)

Balance

Stitch regulating dial

Reverse lever

Post

Hook

post

Hook

post

Hook

shaft bracket

Slide

plate

Needle

Roller foot

Thread

wheel

holder

cover plate(back)

plate

guide(

needle

bar)

Needle

(14)

(15)

Thread

{16)

Presser

Faceplate

(17)

{18)

Thread

(19)

Thread

(20)

Thread

(21)

Presser

Thread

(22)

Thread

{23)

(24) Oil reservoir(left)

Pre-tension

(25)

P2

bar

guide( needle

bar

tension

guide(

take

regulating

take

retainer

regulator

arm)

up

lever

up

lever

thumb

bar

bushing)

guard

screw

(1) Spool

(2) Oil reservoir( right)

(3)

(4)

(5) Reverse lever

(6)

(7)

(8)

pin

Balance wheel

Stitch regulating dial

Post

Hook

post cover plate(lower)

Hook

post cover plate( upper)

(9)

Hook

shaft

Slide

(10)

(11)

(12) Roller foot

(13)

(14)

(15)

{16)

plate

Needle

Needle

Presser

Thread

Thread

plate

guide (21) Presser regulating thumb screw

bar

guide(lower) (23)

controller disc

bracket

(17)

(18)

(19)

(20)

(22)

(24)

Face

plate

Thread

Thread

Thread take

Thread

Oil

Pre-tension

tension regulator

guide(

take

reservoir(left)

upper)

up

lever guard

up

lever

P3

Page 4

*

Preparation

I

PREPARATION

MACHINE

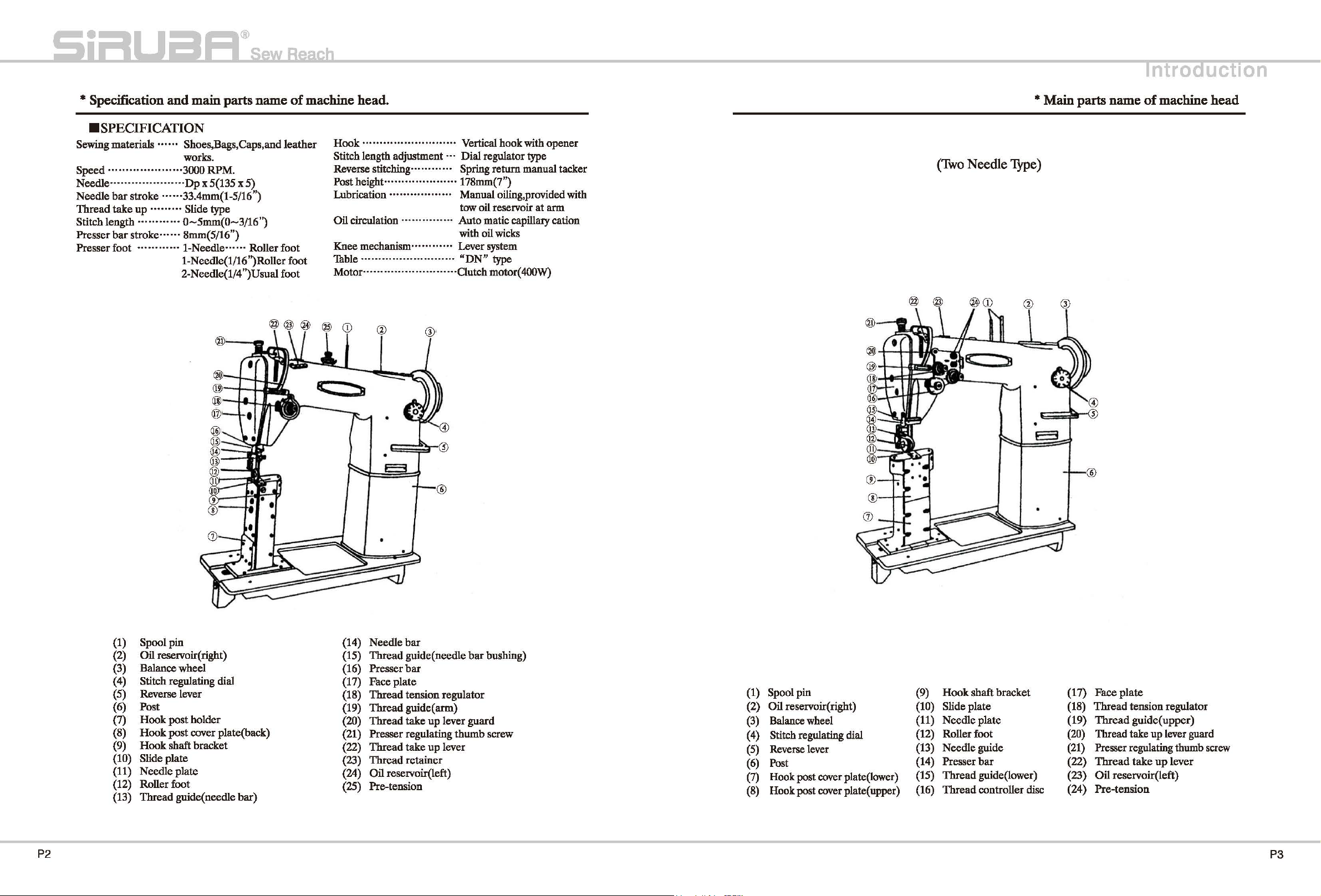

1.

PlACE

The

leveled floor in order to ensure smooth operat-

ing

vibration.

2.

HOW TO MOUNT

ON

1U

Instal the hinge with screws, provided in

accessory,at hole

hook to the hinge plate

head is set

3.

MOUNTING OF THE MOTOR

+ The motor

nuts,and washers as provided.

for

installation

FOR

of

machine

INSTAUATlON OF

HEAD

OF

INSTAllATION OF MACHINE.

machine shoule

of

your

machine

1HE

TABLE.

on

the table.

is

mounted generally with bolts,

on

be

installed

at

high speed without

1HE

MACHINE HEAD

the

back

of

the

of

the

table, then

on

bed

well-

+ Set the position so that the motor pulley and

balance wheel grooves are aligned straight as

shown in Fig. For proper operation when the

belt

is

inserted.

+ Then connect power supply cord and motor .

cord extened from switch.

4.

HOW TO

AND

+ The angle

important,

strength necessary

CONNECT

FOOT

THE MOTOR

PEDAL.

of

the slope

It

can make a difference in the

to

of

the

pedal can be

press the pedal.

lEVER

+ There might be a slight difference in operator' s

30°

-40°

posture,but generally

in Fig.(A) is considered best.

+ The treadle position shown in Fig. (B)

In

difficult.

connecting rod to suit the operator.

5.

HOW TO MOUNT

this case,adjust the length

1HE

angel as shown

will

of

BOBBIN WINDE

ASSEMBLY.

+ Set the position

provided

belt hole

operation position.

in

of

the bobbin winder assembly

accessory, to be

of

the table, with the lever pushed in

in

parallel with the

+ When bobbin winder pulley will come in contact

with the belt,

with two

fix

the assembly onto the table

screws

provided, as shown

in

Fig.

head

and

the

be

the

Hinge

0

x

plate

Motor

Balance wheel

(A)

Hinge

pulley

(B)~

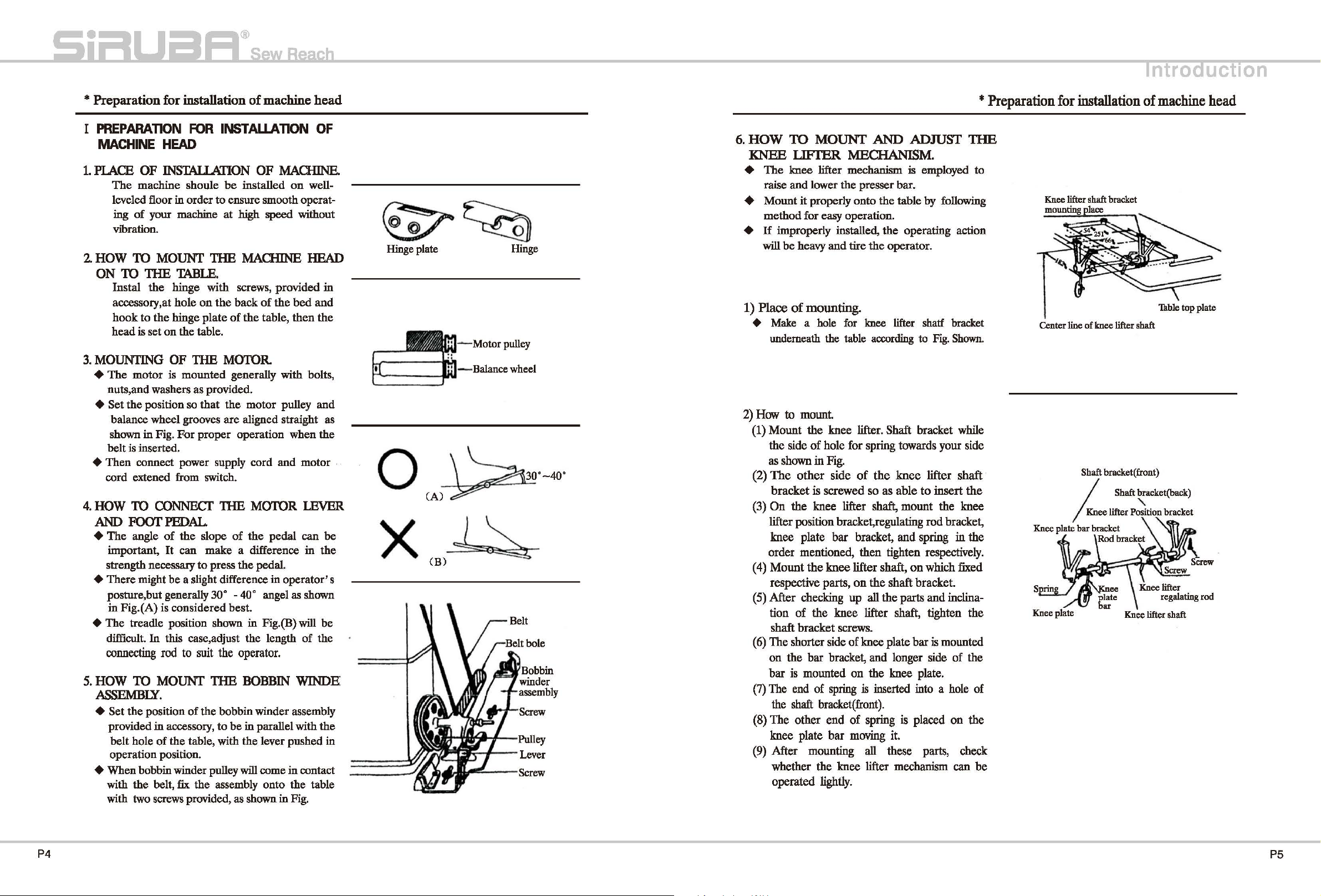

6.

HOW

KNEE

+

+ Mount it properly onto the table

+

1) Place

+

2)

(1) Mount the knee lifter. Shaft bracket while

(2)

(3)

( 4)

(5) After checking

(

(7)

(8) The other end

(9) After mounting

TO

MOUNf

LIFTER

The

knee lifter mechanism is employed

raise and lower the presser bar.

method for easy operation.

If

improperly installed, the operating action

will

be

heavy

and

of

mounting.

Make a hole

Wldemeath

How

to

the side

as

shown in Fig.

The

bracket

On

the knee lifter

lifter position bracket,regulating rod bracket,

knee plate bar bracket, and spring

order mentioned, then tighten respectively.

Mount

respective parts,

tion

shaft bracket screws.

6)

The shorter side of knee plate bar is mounted

on

the bar bracket, and longer side of the

bar

is

The end of spring

shaft

the

knee plate

whether the knee lifter mechanism can

operated lightly.

the

mount.

of

hole for spring towards your side

other

of

side

is screwed so as able

the knee lifter shaft,

the knee lifter shaft, tighten the

mounted on the knee plate.

bracket(front).

bar

AND

ADJUST

MECHANISM.

by

following

tire the operator.

for

knee lifter shatf bracket

table according to Fig.

of

the

knee

lifter shaft

to

insert

shaft,

mount the knee

on

which fixed

on

the shaft bracket.

up

all the parts and inclina-

is

inserted

of

spring

moving it.

all

into

a hole of

is

placed

these parts, check

* Preparation

1HE

to

Shown.

the

in

the

on

the

be

for

Center line

Knee plate

Knee plate

installation

of

knee lifter shaft

Shaft bracket(front)

of

machine

'Thble

I Shaft bracket(back)

I

Knee

lifter

P~tion

bar

bracket

Rod

bracket

Knee lifter shaft

top

bracket

UCtiOn

head

plate

P4

P5

Page 5

UCtiOn

* Preparation for installation of machine head

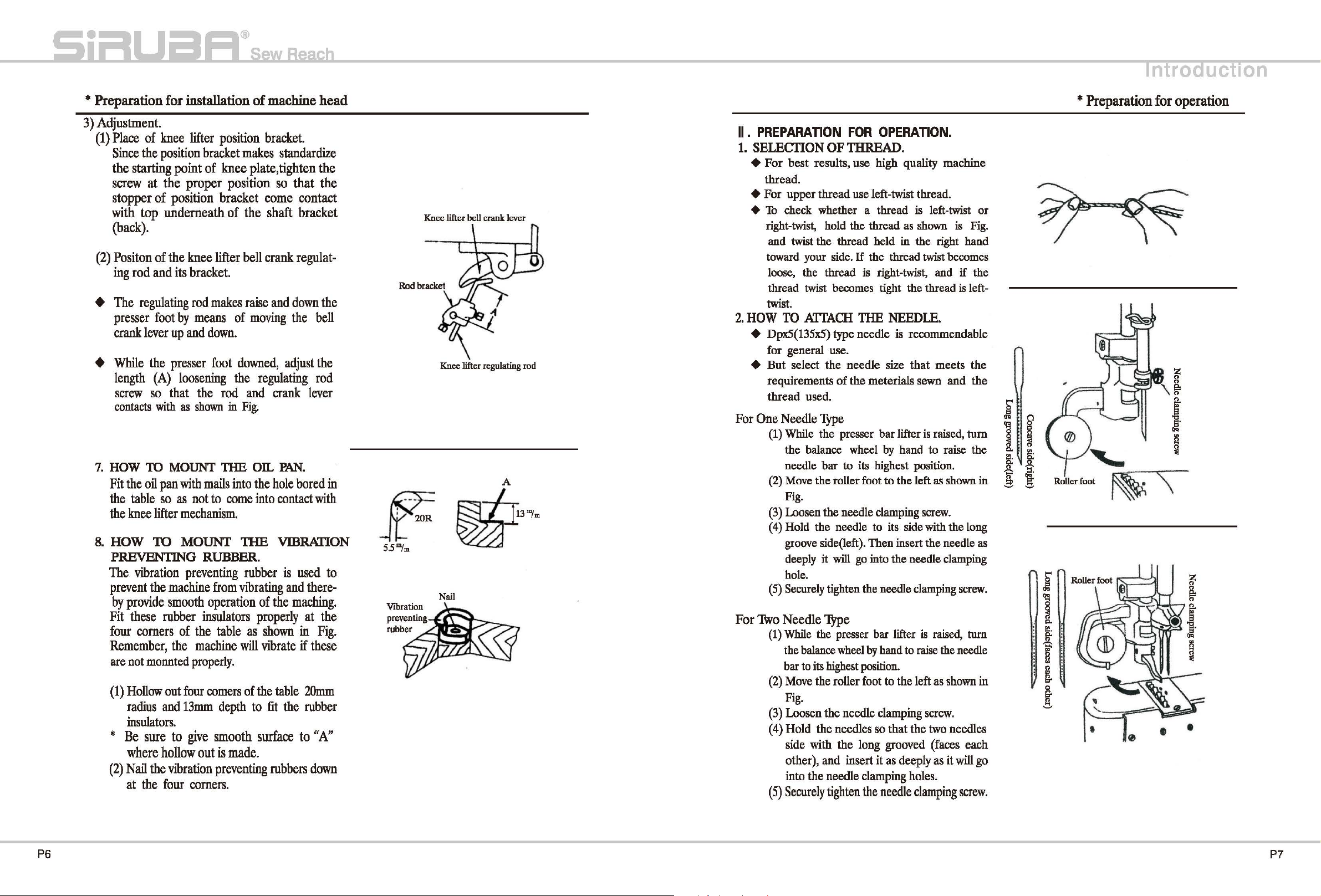

3)

Adjustment.

(1)

Place

of

knee

lifter

position

Since

the

position

the starting point of

screw

stopper

with

at

the proper

of

top

underneath

bracket

position

knee

bracket

(back).

(2)

Positon

ing

+

The

presser

crank

+

While

length

screw

contacts with as

7.

HOW TO MOUNT

Fit

the

the

8.

HOW

PREVENTING RUBBER.

The

prevent

by

Fit

four

Remember,

are

(1)

of

rod

and

regulating

foot

lever

the

(A)

so

the

oil

pan

table

so

knee

lifter

TO

vibration

the

provide

these

comers

not

monnted

Hollow

radius

the

knee

its

bracket.

rod

by

means

up

and

presser

loosening

that

the

shown

with

as

not

mechanism.

MOUNT

preventing

machine

smooth

rubber

of

the

the

machine

properly.

out

four

and

13mm

lifter

makes

down.

foot

rod

TilE

mails

to

from

operation

insulators

table

comers

depth

insulators.

*

Be

sure

to

give

smooth

(2)

where

Nail

at

the

the

hollow

out

VIbration

four

comers.

is

preventing

position

of

in

come

made.

bracket.

makes

plate,

come

the

shaft

bell

crank

raise

of

moving

downed,

the

regulating

and

Fig.

OIL

into

the

into

1HE

rubber

vibrating

of

properly

as

shown

will

vibrate

of

the

to

fit

surface

standardize

tighten

so

that

the

the

contact

bracket

regulat-

and

down

the

the

bell

adjust

the

rod

crank

hole

the

table

rubbers

lever

PAN.

bored

in

contact

VIBRATION

is

and

with

used

there-

to

maching.

at

the

in

Fig

if

these

20mm

the

rubber

to

".A:'

down

.

Knee lifter bell crank lever

Knee lifter regulating rod

Nail

II

.

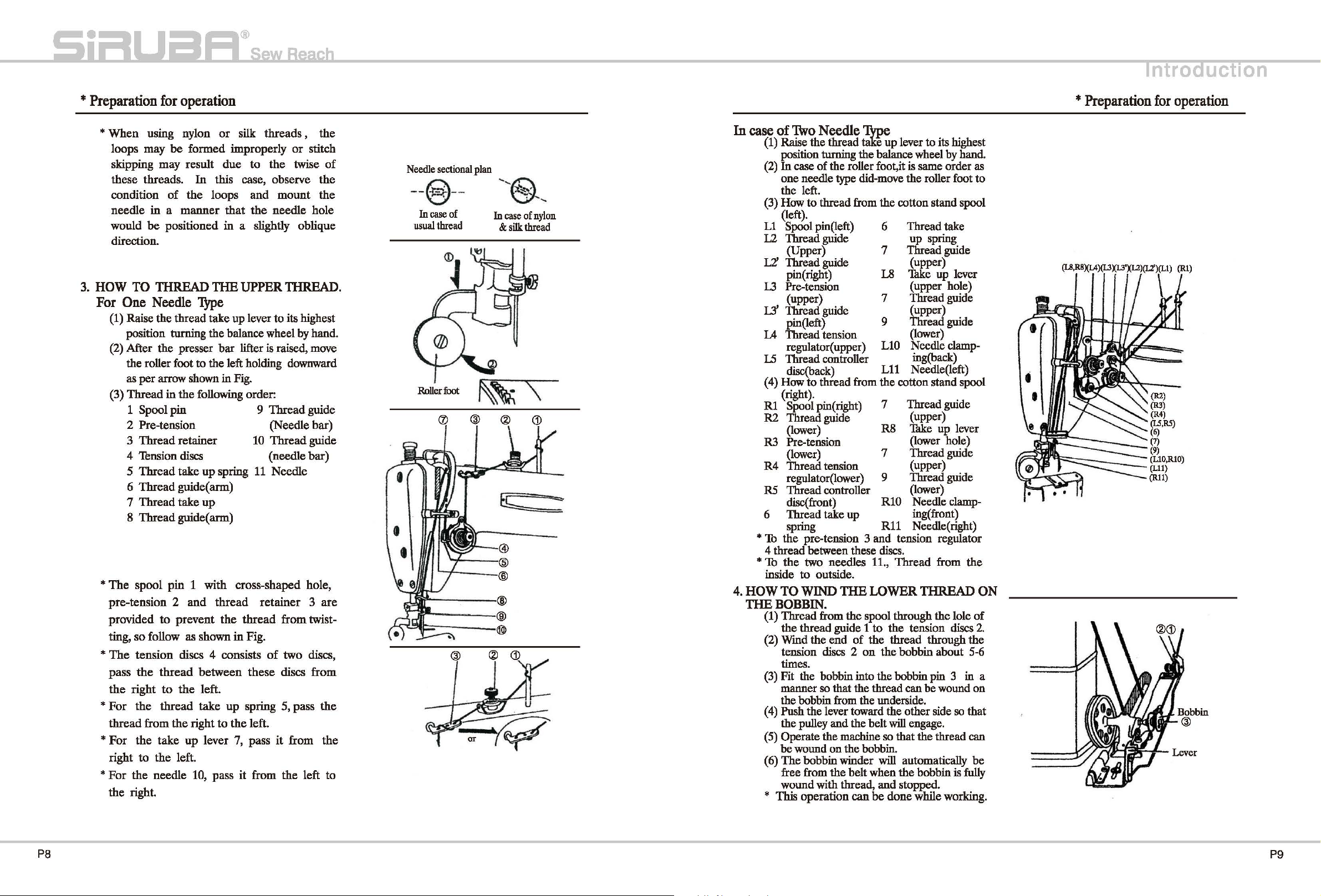

PREPARATION

1.

SELECTION

+

For

best

results,

thread.

+

For

upper

+

To

check whether a thread is left-twist

right-twist, hold the thread as shown is Fig.

and twist the thread held

toward your side.

loose, the thread is right-twist, and

thread twist becomes tight the thread is left-

twist.

2.

HOW

TO

ATTACH

FOR

OPERATION.

OF

THREAD.

use

high quality machine

thread use left-twist thread.

in

the

right hand

If

the thread twist becomes

THE

NEEDLE.

+ Dpx5(135x5) type needle is recommendable

for general use.

+

But

For

For

One

Two

select

requirements

thread

Needle

(1) While the presser bar lifter is raised,

the balance wheel by hand to raise the

needle

(2) Move the roller foot

Fig.

(3)

Loosen the needle clamping screw.

( 4) Hold

groove side(left). Then insert the needle as

deeply it will go into the needle clamping

hole.

(5)

Securely tighten the needle clamping screw.

Needle

(1)

While the presser bar lifter

the balance wheel

bar to its highest position.

(2)

Move the roller foot to

Fig.

(3) Loosen

Hold

( 4)

side

other),

into

(5)

Securely

the

used.

needle

of

the

size

that

meterials sewn

Type

bar

to its highest position.

to

the left as shown in

the

needle to its side with the long

Type

is

by

hand to raise the needle

the

left as shown in

the

needle clamping screw.

the

needles so

with

the

and

insert

the

needle clamping holes.

tighten

that

the

long grooved (faces each

it

as

deeply

the

needle

clamping

meets

and

raised, turn

two needles

as

it

or

if

the

the

the

turn

will

go

screw.

i

l

~

!

~

~

('>

"'

g:

~

c

* Preparation

"'-..

Roller foot

for

operation

~--=~

-

.---.\~

P6

P7

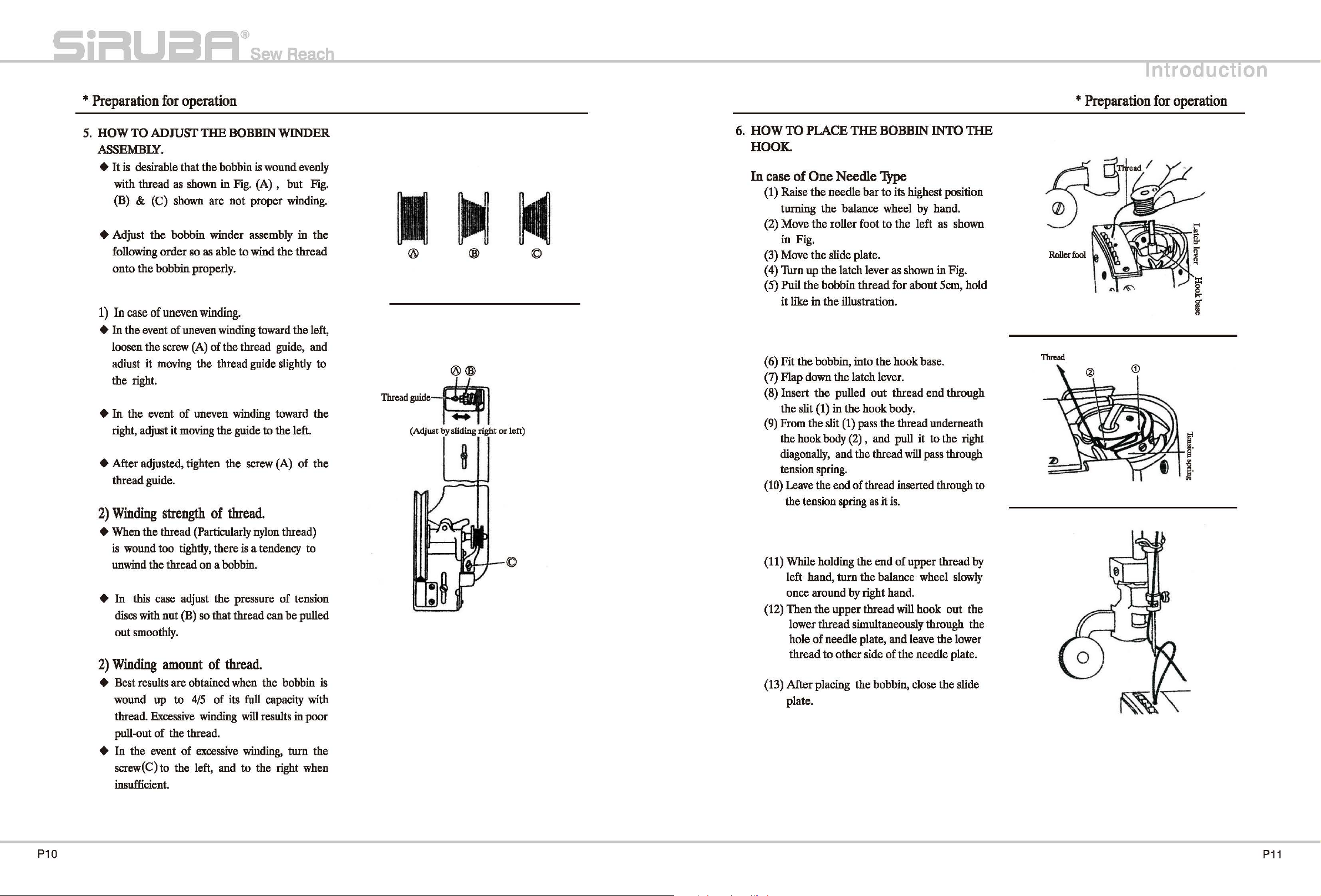

Page 6

UCtiOn

* Preparation

*

When

loops

skipping

these

condition

needle

would

direction.

3.

HOW TO THREAD

For

One

(1) Raise

position turning

(2) After

the

as

(3)

Thread

for

using nylon

may

may

threads.

in a manner

be

positioned

Needle

the

the

roller foot

per

arrow shown

in

1

Spool

be

of

thread

pin

2 Pre-tension (Needle

3

Thread

4 Tension discs

5

Thread

6

Thread

7

Thread

8

Thread

*The

*

*

*For

*

spool

pin 1 with

pre-tension 2 and

provided

ting,

The

pass

the

For

thread

right

For

the

so

follow

tension

the

right

the

from

the

to

the

the

needle

right.

to

thread

to

thread

the

take

operation

or

silk

formed

result

In

the

improperly

due

to

this case,

loops

TilE

and

that

in

a slightly

UPPER THREAD.

'!YPe

take

up lever

the

balance wheel by hand.

presser

the

retainer

take

guide( arm)

take

guide( arm)

prevent

as

discs 4 consists

the

up

left.

bar

lifter is raised, move

to

the

left holding downward

in

Fig.

following order:

up

spring

up

cross-shaped

thread

the

thread

shown

between

take

right

10, pass

left.

up

to

the

lever 7,

in

spring

it

Fig.

these

left.

pass

threads , the

or

stitch

the

twise

observe

mount

the

needle

to

9

Thread

10

Thread

(needle

11

Needle

retainer 3 are

of

it

from

hole

oblique

its highest

guide

bar)

guide

bar)

hole,

from

twist-

two

discs,

discs

from

5,

pass

from

the

left

of

the

the

the

the

to

Needle

sectional

-- --

§

Incase of

usual

thread

_plan

.

In

&

te===-=

!'ifi"-

--

-

-®

r

--

~~~:;:;-----@)

--®

case

silk

of

nylon

thread

In

case

of

1\vo

(1) Raise

position turning

In

(2)

one

the

(3) How

(left).

L1

Spool pin(left)

L2 Thread guide

L2'

Thread guide

L3

Pre-tension

L3'

Thread guide

u

Thread tension

Needle

the

thread e up lever

case

of

the

needle type did-move

left.

to

thread

(Upper) 7

pin( right)

(upper)

pin(left)

regulator( upper)

l.5 Thread controller

disc(back) L11 Needle(left)

( 4) How

Rl

R2 Thread guide

R3 Pre-tension

R4

R5 Thread controller

6 Thread take

*

1b

4 thread between these discs.

*

Th

inside

4.

HOW

THE

(1)

(2)

(3) Fit

(4) Push

(5) Operate

(6)

*

to

thread

(right).

Spool pin( right)

(lower)

(lower)

Thread tension

regulator(lower)

disc(

front)

spring

the

pre-tension 3

the

two needles 11.,

to

outside.

TO

WIND

BOBBIN.

Thread

the

Wmd

tension discs 2

times.

manner so that the thread can

the bobbin from

the

be

The

free from

wound with thread,

This

from

thread

the

pulley

wound

operation

guide 1

the

end

bobbin into

the

lever toward

and

the

on

bobbin winder will automatically

the

~e

the

balance wheel by hand.

roller foot,it is same order

from

the

6

L8 Thke

to

its highest

as

the

roller foot

cotton stand spool

Thread

up

spring

Thread

(upper)

up

(upper hole)

to

take

guide

lever

7 Thread guide

(upper)

9 Thread guide

(lower)

Needle clamp-

LlO

ing(back)

from

the

cotton stand spool

7

Thread

R8

(upper)

Thk.e

(lower hole)

guide

up

lever

7 Thread guide

(upper)

Thread guide

9

(lower)

R10 Needle clamp-

up

and

THE

WWER

the

spool through

to

of

the

on

the

the

underside.

the

belt

machine so that the thread can

the

bobbin.

belt

when

and

can be

ing(front)

R11 Needle(right)

tension regulator

Thread

from

the

THREAD

the

lole

the

tension discs

thread

the

the

will engage.

done

through

bobbin

bobbin pin 3 in a

be

other side so

the

bobbin is fully

stopped.

while working.

the

about

5-6

wound on

that

ON

of

2.

be

•

*

Preparation

for

(R2)

(R3)

(R4)

(LS,RS)

(6)

(7)

(9)

(LlO,RlO)

(Lll)

{Rll)

operation

P8

pg

Page 7

*

Preparation

5.

HOW

TO

ADJUST

for

operation

THE

BOBBIN

WINDER

ASSEMBLY.

+

It

is desirable that

with thread as shown in Fig. (A) ,

(B) & (C) shown are not proper winding.

+ Adjust the bobbin winder assembly in the

following

onto

1)

In

+

In

the event

loosen the screw (A) of the thread guide, and

adiust it moving the thread guide slightly to

the right.

+

In

right, adjust it moving the guide

+After

thread guide.

2)

Winding

+ When the thread (Particularly nylon thread)

is

wound too tightly, there

unwind the thread on a bobbin.

+ In this case adjust the pressure

discs with nut

out smoothly.

2)

Winding

order

the

bobbin properly.

case

of

uneven

the event

adjusted, tighten the screw (A)

strength

amount

the

bobbin

so as able to wind

is

wound evenly

but

the

winding.

of

uneven winding toward the left,

of

uneven winding toward

to

the left.

of

thread.

is

a tendency to

of

(B)

so

that

of

thread.

thread can

be

+ Best results are obtained when the bobbin is

wound up to

thread. Excessive winding

pull-out

+ In the event of excessive winding,

screw(C) to the

insufficient.

of

4/5

the thread.

left, and

of its

full

capacity with

will results in poor

to

the right when

tum

Fig.

thread

the

of

the

tension

pulled

the

® ©

®®

-Mphlo~

(Adjust

by

sliding right

or

left)

6.

HOW

TO

PLACE

THE

BOBBIN INTO

HOOK.

In

case of One Needle

(1) Raise the needle

the

turning

(2) Move

in

Fig.

(3) Move

( 4) Turn

5)

(

( 6) Fit

Puil

it

like in

up

the

the

(7) Flap down

(8) Insert the pulled out thread end through

the slit (1) in

(9) From the slit

the hook body (2) , and pull it to the right

diagonally, and the thread

tension spring.

(10) Leave the end of thread inserted through to

the tension spring

(11) While holding the end

left hand,

once around by right hand.

(12) Then the upper thread will hook

lower thread simultaneously through the

hole

thread to other side

(13) After placing the bobbin, close the slide

plate.

balance wheel

the

roller foot to the left as shown

the

slide plate.

the

latch lever as shown in Fig.

bobbin thread for about Scm, hold

the

illustration.

bobbin, into

the

the

(1)

tum

of

needle plate, and leave

JYpe

bar

to its highest position

by

the

hook base.

latch lever.

hook body.

pass the thread underneath

will pass through

as

it

is.

of

upper thread by

the balance wheel slowly

of

the needle plate.

hand.

out

the

lower

THE

the

Thread

*

Preparation

for

operation

UCtiOn

P10

P11

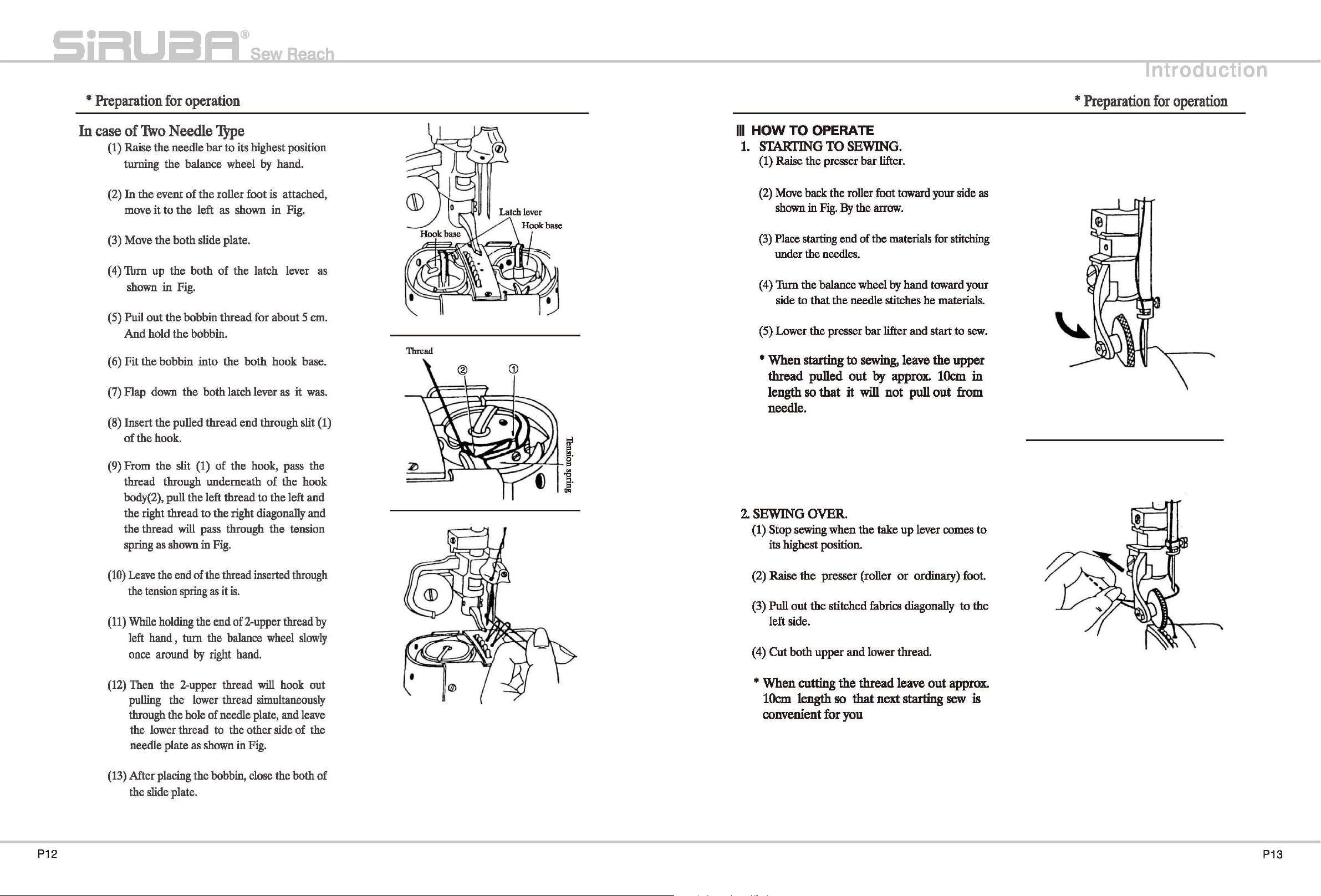

Page 8

*

Preparation

In

case

of

(1) Raise

turning the balance wheel

1\vo

the

for

operation

Needle

needle bar

'JYpe

to

its highest position

by

hand.

Ill

HOW

1.

TO

OPERATE

STARTING

(1) Raise the presser bar lifter.

TO SEWING.

*

Preparation

for

operation

UCtiOn

(2)

In

the event

move

(3) Move the

(

4)

Thrn

shown

( 5) Puil

(6) Fit

(7) Flap down

(8) Insert the pulled thread end through slit (1)

(9) From the slit (1) of the hook, pass the

out

And

hold

the

of

the hook.

thread through underneath

body(2), pull the left thread to the left and

the right thread

the thread

spring as shown in

of

the

roller foot is attached,

it

to

the

left as shown in Fig.

both

slide plate.

up

the both

in

Fig.

the

bobbin thread for about 5 em.

the

bobbin into

the

will

of

the latch lever

bobbin.

the

both hook base.

both latch lever

to

the right diagonally and

pass through the tension

Fig.

as

of

the hook

it

as

was.

Thread

(2) Move back the roller foot toward

shown

in

Fig.

By the

(3) Place starting end of the materials for stitching

under the needles.

Thm

the

( 4)

side

(5) Lower the presser

balance wheel

to that

the

* When starting to

thread pulled out

length

so

that it will not pull out

arrow.

by

needle stitches

bar

lifter and start

sewing,

by

approx.

your side

hand toward your

he

materials.

leave the upper

10cm

needle.

2.

SEWING OVER.

(1) Stop sewing when

its highest position.

the

take

up

lever comes

to

sew.

in

from

as

to

(10)

Leave the end of the thread inserted through

P1

2

the tension spring

(11)

While holding the end of 2-upper thread

left hand , turn the balance wheel

once around

(12)

Then the 2-upper thread will hook out

pulling the lower thread simultaneously

through the hole

the lower thread to the other side of the

needle plate as shown in Fig.

(13) After placing the bobbin, close the both

the slide plate.

as

it

is.

by

right hand.

of

needle plate, and leave

by

slowly

of

(2)

Raise

the

(3)

Pull

left side.

(4)

Cut

presser (roller

out

the stitched fabrics diagonally

both upper and lower thread.

or

ordinary) foot.

to

the

* When cutting the thread leave out approx.

10cm

convenient for you

length

so

that next starting

sew

is

P13

Page 9

*

Stitching

fV.

STITCHING ADJUSTMENT.

1.

ADJUSTMENT OF STITCH LENGTII.

+ Stitch length can

Adjustment

regulating

dial.

be

adjusted with the stitch

+ Figures on the stitch regulating dial indicates

mm.

the length in

set

on

the pin of the

desired stitch length.

2.

REVERSE STITCHING.

+

Reverse

pushing

lever

can

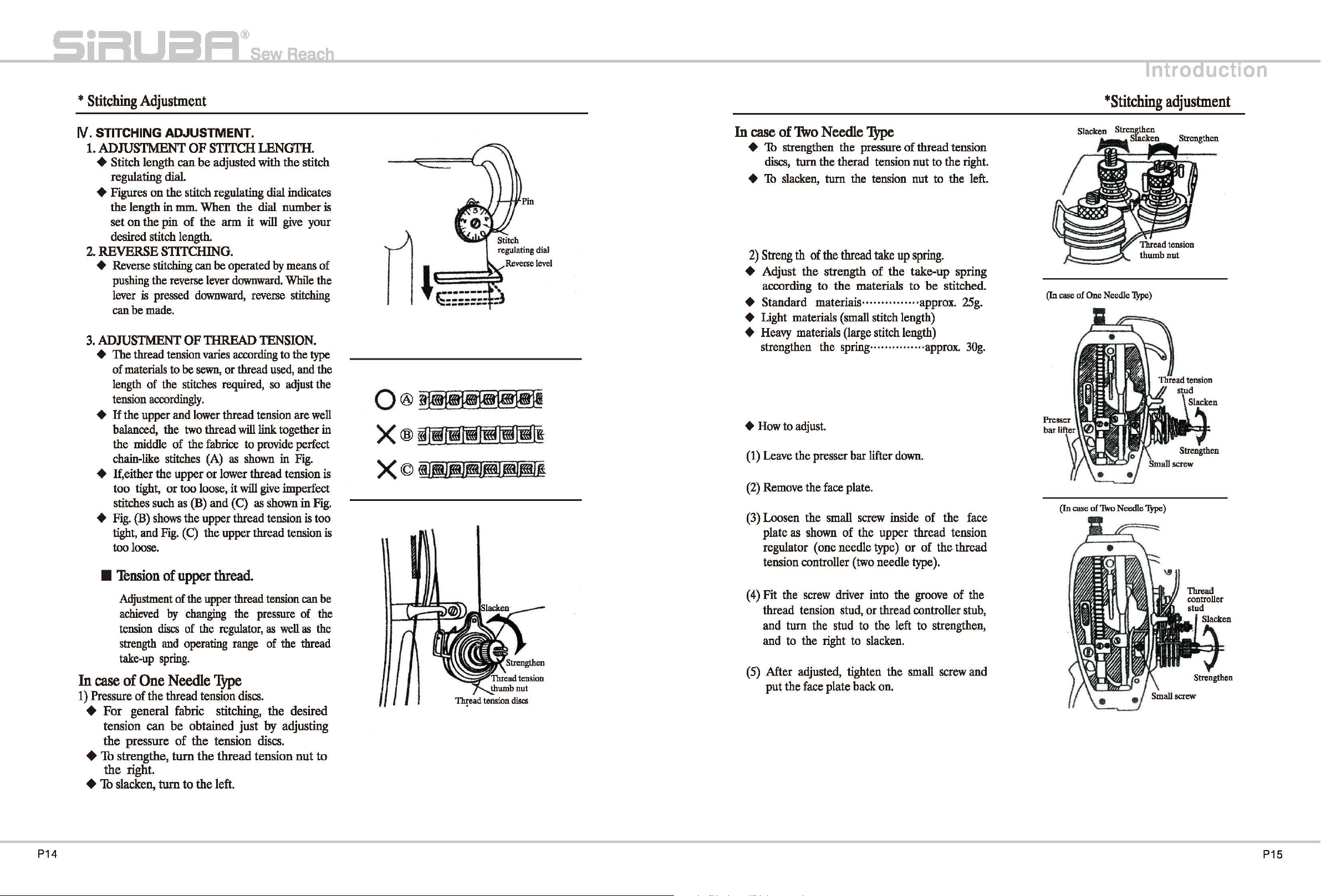

3.

ADJUSTMENT

+ The thread

of

length

tension

stitching

the

is

pressed

be

made.

materials

of

accordingly.

tension

the

+ If the upper and

balanced, the

the middle of the

chain-like

stitches

When the dial number

arm

it

can

be

operated

reverse

lever

downward.

downward,

reverse

OF THREAD

varies

according

to

be

sewn,

or thread

stitches

two

required,

lower

thread tension are

thread will link together

fabrice

(A)

as

to

shown

will

give

by

means

While

stitching

TENSION.

to

the

used,

and the

so

adjust

provide

in

perfect

Fig.

+ If,either the upper or lower thread tension

too tight,

stitches

+

Fig.

tight,

too

loose.

•

'Thnsion

Adjustment

achieved

tension

strength

take-up

In

case

of

1)

Pressure of the thread tension

+ For general fabric stitching, the desired

tension can

the pressure

+ Th strengthe,

the right.

+

Th

slacken, turn to the left.

such

(B)

shows

and

One

or

too loose, it

as

(B)

the upper thread tension

Fig.

(C)

the upper thread tension

of upper

of the

upper

by

changing

discs

of the

and

operating

spring.

Needle

will

and (C)

thread.

thread

the

regulator,

range

"IYPe

discs.

be

obtained just

of

the tension

turn

the thread tension

give

imperfect

as

shown

tension

pressure

as

well

of

the

by

adjusting

discs.

in

is

can

of

as

thread

nut

is

your

of

the

type

the

well

in

is

Fig.

too

is

be

the

the

to

0®~

X®

X©

~tmliftm419Im~

@J@l@l®!®®i®i

In

case

of

1\vo

Needle

'l.YPe

+ 1b strengthen the pressure of thread tension

discs,

turn

the therad tension nut to the right

+ 1b

+ Adjust the strength

slacken,

2)

Streng

according to the materials to be stitched.

th

of

turn

the

the tension nut to the

thread take

up

spring.

of

the take-up spring

+ Standard materiais ............... approx.

+ Light materials

+

Heavy

strengthen the

+

How

(1)

(2)

(3)

plate

(

4)

thread tension stud, or thread controller

and

and

(5)

materials (large stitch length)

to

adjust.

Leave

the presser bar lifter

Remove

Loosen the small

regulator (one needle

tension controller

Fit the

After adjusted, tighten the small

put the

the

as

shown

screw

turn the

to

the right

face

(small

stitch length)

spring

...............

face

plate.

screw

inside of the face

of the upper thread tension

type)

(two

needle type).

driver

stud

plate back

into the

to the left to strengthen,

to

slacken.

on.

approx.

down.

or of the thread

groove

screw

of the

left.

25g.

30g.

stub,

and

*Stitching

(In case of One Needle

(In case of

'1\vo

Needle

UCtiOn

adjustment

lYJ>e)

'JYpe)

P14

P15

Page 10

*

Stitching

Adjustment

*Stitching

UCtiOn

adjustment

3) Operating range of the thread take

+ In order to obtain proper

it

is

necessary

up

spring

range of the take-up

to adjust the strength of the take

as

well

working

as

change the operating

spring.

+ The operating range can be measured

take-up

when

tension spring

it

e In

....

e In

increase the operating range

..

e In

decrease the operating range

......

+How

(1)

Lower

(2)

Loosen the thread tension regulator set

(3)

Fit the

tension

right

(

4)

Thrn the stud to the left to large the operating

(5)

After adjusted, tighten the

+

How

(1)

Loosen the thread controller set

(2)

Fit the

thread controller

the

(3)

Turn

range.

(4)

After adjusted, tighten the

lever

is

the upper thread

moves

is

considered

case

of standand (general

ooapprox.

case

of

light

8mm(5/16

(small

at the

as

highest

within the

standard.

')

stitch

is

pulled, and the

winth

fabrics)

length) materials,

slightly

..

ooapprox.

case

of

heavy

8mm(5/16")

or

up

(large stitch length) materials.

slightly

approx,

8mm(5/16")

or

less

to adjustment (One Needle

the presser bar lifter.

screw

driver

regulator

to

small

the operating

rang.

to adjust

right

screw

to

small

('Ibw

driver

the stud to the left to rarge the operating

into

the

stud;

and

turn

range.

screw.

Needle

'!YPe)

into the

stud,

and

the operating

screw.

turn

up

spring.

condition,

when

the

position, and

of 8mm,

materials.

.. ·· .. ·· .. ··

........ .

'!YPe)

screw

groove

the stud to the

groove

rang.

of the

screw.

of the

the stud to

• Thnslon of

There

tension,

when

slighe

(1)

(2)

(3)

(

4)

4.

ADJUSTMENT

AND

RIALS .

The

feed

materials

the materials to

+ In

case

be

damaged

the pressure of presser on materials

+ In case of

uniforme stitching

.

properly

In

......

In

·..............

In

......

* The height

the feed dog

from

balance wheel

1)

Adjustment

(1)

Lay down the machine bed toward the

other side.

(2)

Remove

(3)

'Ibm the balance wheel

when

position from the surface of needle plate.

4)

Loosen the

(

crank.

(5)

Adjust the feed

moving

back and forth

Fig.

(6)

After adjusted, tighten the screw of feed

lifting rock shaft.

lower

is

virtually

except

adjustment

'Ibm

when

to

its

Move

thread

Fit

the

hook

tension

thread

Turn

thread tension.

PRESSURE

dog

must

of

if

or

case of light materials ... .

·........ approx.

case of general fabrics·

case of

·........ approx.

the

surface

the feed

thread.

no

need

to

adjust

for

special

kind

will

be

necessary

the

balance

the

thread

lowest

the

tension

screw

shaft

screw

tension.

the

screw

height and pressure of presser on

be properly adjusted according to

be

light

the

heavy

the pressure of presser

heavy

of

feet dog

is

raised to its highest position

by

of

the gear

the

wheel

take-up

position.

slide

plate

screw

of the

driver

into

bradket

screw

as

shown

to the

right

to the left to

OF

FEED

OF

PRESSER

sewn.

materials:

feed

dog

is

raised

materials: It will not make

if

the feed dog

0.8mm

approx.

of

hand.

feed

feed

l.Omm.

materials .................. · ..

1.2mm.

is

needle plate turning the

dog

box.

dog

is

raised to its highest

of feed lifting rock shaft

dog

to

lifting

as

per

an

the

lower

thread

of

fabrics

or

thresd,

by

hand,

and

lever

comes

down

so

that

you

find

hook

base.

the

hole

(A)

of

in

Fig.

Thm

to

strengthen

weaken

DOG

The material

excessively

is

is

................

........

measured when

the

HEIGHT

ON

MATE-

too

strong.

not raised

is

too

weak.

in height

· ............

in height

in height

height.

by

hand and stop

the desired

rock

arrow

height

shaft crank

shown

stop

the

the

the

the

may

or

.. ..

..

in

Thread tension spring

Thread

tension

screw

~~

~:

Feed lifting

Screw shaft crank

!o.smm

@I

1.2mm

21?

rock

P1

6

P17

Page 11

*

Stitching

Adjustment

*

Stitching

UCtiOn

adjustment

2)

Adjustment of pressure of presser

(1)

Thrn the presser regulating

(2)

5.

PROPER

AND

Place

scribed

in the

shock,

new a one.

1)

How

(1)

(2)

the right

presser

Turn

pressure of presser

E\NEEDLE.

and

below

hook,

or other

to

Turn

when

to

its

Remove

bobbin.

to

strengthen the pressure of

foot.

the screw to the left to loosen the

foot.

TIMING

adjust

in

or

when

causes,

remove

the balance

the thread take

lowest

the

BE1WEEN

the hook

case

of the thread

its

position

or

the

position.

slide

in

the

when

it

hook

wheel

up

plate, then take out the

thumb

THE

condition

gets

entangled

is

changed

is

replaced

by

hand and stop

lever

comes

foot.

screw

HOOK

de-

due

with

down

to

to

2) How

to

place

(1) Place the hook in backward order from

removing procedure.

(2)

When

place

taken out.

(3)

When

base

cap

Fig.

And

the hook

side.

(

4)

When placing the needle plate, place the

needle plate adjusting the hook base

the tip of hook base

finger of the needle plate

the

hook:

placing

it at the

inserting

the hook

same

the

hook

turning it to the left

fit

the hook

body

on

the inside of the other

body,

remember to

position

base

hold

base

brim

fits

into the hook

as

shown

as

the hook

as

shown

into

in Fig.

it

so

was

slot

that

in

of

Hook

base

brim

(3)

Remove

(4)

Remove

case

cover

(5)

Remove

remove

(

6)

Loosen

hook

shwon

(7)

Hold the latch lever up turning it

so

(8)

Remove

that it

the needle paate.

the hook

of

two

needle

plate(upper)both the front and

the hook opener

the opener.

the hook

gib

fixed

in

Fig.

that it can

the

can

be taken out.

cover

type,

gib

screw

in

front of the book

be

taken out.

hook

body

plate (front) (In

remove

center set

screw,

and

remove

the hook

back.)

and

then

the

body

as

slightly

screw

so

The

position

As

shown

2.0mm

the hook and

from

in

of

the

Fig.

its

lowest

needle

the

hook and needle:

When

the

needle raised

position of the

should

be

as

follows.

needle,

+ Upper part of the needle hole··················

... · ..

Lower

+

Tip

of hook ........ · ...... At center of needle.

+

Gap

face

of needle····· .... ····· .. ····· by

Adjustment

hook

* Move the roller foot to the left, remove the

needle plate for

by

1.6mm

between tip of hook

of the relative position of the

and

needle

from

can

easy

adjustment.

be

the

and

done

tip

of

lateral

0.05mm.

as

follows:

hook.

is

Lower part ...___,..___._

of

needle

~~~

needle 4

2.0mm.

Raise

by

o.osmm

}

Tip

of

book

(upper

view)

P18

P19

Page 12

*

Stitching

Adjustment

• Adjustment of needle bar position.

Adjust the needle

between

needle hole will

reised by 2.0mm from its lowest position.

(1) Raise the needle

(2) Loosen

(3) Adjust moving the needle

( 4) After adjusting the needle bar position, tighten

the

position turning the balance wheel by hand.

the

through a driver hole(lower)of

that

the tip

1.6mm from the upper

the needle bar connecting stud screw.

• Adjustment

+ Adjust so that the tip

of

needle.

(l)Remove

the needle palte

tip

of

be

needle

of

hook comes

of

tip

bar

timing so

hook and the upper part

1.6mm when

bar

by 2.0mm from its lowest

bar

connecting stud screw

part

of

hook

of

hook comes to the center

the

bar

up

at

the

of

needle hole.

and

slide plate.

that

the gap

the

needle is

face plate.

and

down so

position by

of

(In case

of

One

Needle JYpe)

+

Adjust

lateral

In

adjust it. However, in case

necessary

gauge sizes.

(1) Loosen

(2) Lay down the machine

(3) Remove

( 4) Loosen the hook shaft gear set screws.

(5) Loosen

( 6)Thrn the balance wheel

(7) Thm

(8) Move

(9) After adjusting, tighten the set screws

(10) Place the gear box.

that the

side

case

of

Plate(front and back).

side.

the needle is raised

position.

the

hook

to

the

left, so that the sap between the tip

and lateral side

shaft gear and bracket.

gap

between

of the needle to

1-needle,

to

adjust

the

the

the

hook by hand and bring

the center

there

it

when changing

screws

gear box.

set screws

of

hook shaft bracket

of

needle

the

come

is

virtually

of

of

the hook post cover

head

toward the other

of

hook shaft bracket.

by

hand, and stop when

by 2.0mm from its lowest

needle.

is

0.05mm.

tip

2-needle, it is

to

of hook and

to

0.05mm.

no

need

the

needle

the

tip

the right

of

hook

of

hook

to

of

and

(In case of

Two

*

Needle

_

Stitching

'!YPe)

.-:-~-~

_.-

Hook past cover

plate( upper)

UCtiOn

adjustment

Hook

past cover

set screw.

the

hook

needle.

the

the

(2) Lay down the machine head toward

Side.

(3) Remove the gear box.

( 4) Loosen the two set screws

gears.

Thrn the balance wheel by hand, and stop

( 5)

to

is

the

when the needle

lowest position.

( 6) Thm

(7) After adjusting, tighten

(8) Place

the

hook by hand enabling

hook

to

come

the hook shatf gears.

the

gear box.

of

raised 2.0mm from its

center

of

the

two set screws

other

shaft

tip

of

of

(In case of'IWo Needle

'!YPe)

~

~~of"

------::~-r

~~

~

g

:X:

!'i

0

...

~

I~

setscrew

6.

PROPER

TIMING

BE1WEEN

AND OPENER.

(1) Remove the slide plate.

(2) Turn

(3) Check whether the gap between

(1) In case the gap is too wide

(5)

the

balance wheel by hand, and stop at

the

position where the opener

plate are furthers point apart.

hook base(A)and the opener is approx. 0.2mm

as shown in Fig.

(There is a slight difference according

thread

it fitting the

of

opener adjustable

to the right or left.

to

be used)

screw

driver into a driver hole (B)

the hook shaft bracket, then loosen the

screw

After adjustment, tighten the opener adjustable

Screw.

and

and

or

narrow, adjust

moving

THE

HOOK

the

needle

the

part

the opener

to

of

the

,._..._,_

Opener adjustable

screw

P20

P21

Page 13

*

Stitching

7.

PROPER

DOG

The proper timing of the feed dog and needle

be when the material

tip reach

moment the feed dog begins to sink downward

through the needle plate surface

This adjustment

atl.Omm.

(1) Loosen the arm side cover thumb

(2) Move the side cover

upper side

Adjustment

TIMING

AND

NEEDLE.

to

the needle plate surface, just at the

is

as shown in

BETWEEN

is

fed through and he needle

based on the Feed dog height

to

the right, and open to

Fig.

TIIE

as shown in

screw.

FEED

will

Fig.

is

*

Cleaning

V.

CLEANING

1.

Cleaning.

The teeth

regulator

often covered

operation and uneven stitching. Therefore, clean

as

often

2.

lubrication.

Lubrication

the machine maintenance. With improper lubrication,

excess

shorten the life

lubricate in the order

1)

The

(1) Usual working

(2)

AND

of

feed

discs,

by

as

necessary.

is

one of the

abrasion

number

Continuous

LUBRICATION.

dog,

hook, upper thread tension

and thread controller

dust and lint causing improper

most

important phases of

of

machine paits

of

the machine, Therefore,

as

follows:

of

times for lubrication.

......

at

2-3 times per week.

working,

every

day·

will

.. once

discs

cause to

each

are

day

and

Lubrication

UCtiOn

(3) Loosen the set

( 4) While holding the feed lifting cam

tum

the balance wheel toward your side so

that feeding device

(5)

In

order to

balance wheel toward the other side.

(

6)

After adjustment, tighten the set

feed lifting cam.

2-screws

slow

of the feed lifting cam.

will

be faster.

the feeding device, tum the

screws

by

hand,

of

the

2) Volume

Places o

Place

mn

Place

3)

Places where

Lubricate the

(inside

of

of

lubrication:

""arked

' marked· .. approx. 5-6 drops

marked···approx. 1-2 drops

to

places

face

plate, arm bed)

.. ·approx.

lubricate.

where

arrow

is

Sec

shown

or

in

more

Fig.

P22

P23

Page 14

*

Cleaning

and

lubrication

*

Since

the

lifting crank

worked

working

oil,

it has

to

(if

oil

Dow

the

no

wick

for

the

oils,

oil

effect

connected

right

penetrate

wick

is

to

Dow

with

side

of

hook

oil

fully

not

penetrated with

oil),

Gear

the

shaft is

before

case

feed

(Hook shaft right)

Screw@

Feed Oil wick

liftin

cr:f

1.*1;$~

2.~00"Blf~~

s.WMIHl$~

6.¥1l.*tllfl!~

7

."""FtmJ:.

B.~B:ei*tl$~

9.~$1ll*tllfl!~

"""F~~$~

11.DC1*

ARM BED AND

ITS

ACCESSORIES

THREAD TENSION MECHANISM

NEEDLE BAR AND TAKE-UP LEVER MECHANISM

PARTS OF

UPPER SHAFT AND VERTICAL SHAFT

BACKSTITCH DEVICE

PRESSER FOOT MECHANISM

PARTS OF BOTTOM SHAFT

AND

TOP/BOTTOM

FEEDING

HOOK

MECHANISM

OIL LUBRICATION MECHANISM

GAUGE PARTS

ACCESSORIES

26

28

30

32

34

36

38

40

44

46

48

3. GREASE.

1)

Remove

gear

box

grease

2)

Remove the

shaft,

then

the

fixed

into

the

also

oil

to

holes

gear

grease

hole

screws(A)&(B),

arm and

periodically.

case

of

the left

into

the

hook

gears

of

shaft,

then

side

of

hook

sufficiently

the

1

2.~53UDCf**H

SPECIAL

PARTS

50

P24

P25

Page 15

Series

SiRUBFI

PARTS LIST P717K/P727K

ARM

Subject

BED

AND

ITS

ACCESSORIES

*HBB~

Page

1/2

Date

2013/6/28

SiRUBFI

PARTS LIST

Fig. Part No. Code No.

No.

.f-1:

P717K/P727K

••

Series

Mtt

$

Cl

AA

~

Subject

ARM

BED

AND

ITS

ACCESSORIES

*llffB~

Neme

of

Part

2013/6/28

-!Ita

Amt.rep

P717K

Page

2/2

Date

P727K

3

~

30

20

1 8100101-000 M91101 004

2 8100102-000 M9110B 002

21

8100103-000

3

8100103-001

4

81

001

04-000 MF

5 8100105-000

6

81

001

06-000

7

8100107-000

8

81

001

08-000

15 8100115-000 M9

16 8100116-000

17 8100117-000

18 8100118-000 MF

19 8100119-000

20 8100120-000 MV01AO

21

8100121-000

22 8100122-000 M95001 062

23 8100123-000

24 8100124-000

25 8100125-000

26 8100126-000

27 8100127-000

28 8100128-000

29 8100129-000

30

81

00130-000

31

8100131-000

MF 10AOB30

MF 10AOB30

60AO

326

M9 0915 003

M91107

MQ50A0584

M9 1108

M9 0908 015

MF

MF

M9 0904

M9150B

MQ50AO

M9 1110 002

MV

M9 1180

0901

10AO

60AO

10AO

11EO

002

001

035

186

880

180

011

001

-~

-~

iii~

iii~

jr}ji!9~(

Jj\)

-~

·-

~~-

-~

-~

·-

~-*"

jr}ji!9~(:;t)

~11.i§&l:+f

i§&l:+f

181

JIUJ

·-

~-

*•

m!!«JIC!

m!!«JIC!

-~

181

i§&l:+f(""P~)

-~

181

1§*1

080

i!BK

Screw(for Fig.3)

Screw(for Fig.3) 1 1

plate

Face

Plate For MS-551 0 1 1

Face

Side cover 1 1

Screw(for Fig.4)

Screw(for Fig.7) 1 1

Thread

Set screw(for Fig.19)

Screw(for Fig.1

Screw(for Fig.18)

Spool. pin 1 2

Arm side cover 1 1

3

Thread guide(arm) 1 1

Screw(for

Pin(for Fig.23) 1 4

Name

Arm and bed 1 1

Model plate 1

Model plade

Set screw(for Fig.902) 1

Thred guide(under arm) 1 1

Screw(for Fig.28)

Thread guide 1

Rubber cork 2 2

take-up

hole thread retainer 1

Fig.20)

plate 1 2

cover 1 1

B)

3 3

1 1

1 1

1

1 1

1 1

1 1

1 1

1

P26

P27

Page 16

Series

Sii=IUBFI

PARTS LIST P717K/P727K

UPPER

THREAD

Subject

TENSION

REGULATOR

MECHANISM

UJeUBB~

Page

1/2

l---=----1

Date

2013/6/28

Sii=IUBFI

PARTS LIST

Fig.

No.

Part No.

V#Mill

Series

P717K/P727K

Code

No.

MM

ms

UPPER

1::::1

AA

THREAD

~

Subject

TENSION

REGULATOR

MECHANISM

Page

2/2

Date

illifiilffR~

2013/6/28

mta

Amt.rep

P717K

Neme

of

Part

P7271<

903

t

27

P717K

~

11

~

8

25

\

~

i

7

16

45 44 43 42

t

26

---0

6

5

4

41

1tr

22

40 39

902

28

38

37

36

35

3

I

902 81003902-000 MV

903 81003903-

000

1

8100301-000

2

8100302-001

3

4

8100303-000

8100304-000

5

8100305-000

6

8100306-000

7

8100307-000

8

8100308-000

9

10 8100309-000

11

8100310-000

8100311-000

12

13

8100312-000

14

8100313-000

15

8100314-000

8100315-000

16

17

8100316-000

8100317-000

18

19

8100318-000

20 8100319-000

21

8100320-000

8100321-000

22

23

8100322-000

8100323-000

25

8100325-000

26

27

8100326-000

8100327-000

28

35 8100328-000

36 8100335-000 MF

37

8100336-000 MF

38 8100337-000

39 8100338-000

40 8100339-000 MF

41

8100340-000

42 8100341-000 MV

43

8100342-000 M9 0212 060

44

8100343-000

MV0230210

M91604

MV01A0802

MV01A0558

MV01A0553

MV01A0709

01EO

210

046

10A0245

10A0556

10A0555

01AO

187

~ttl!(¥jf)

~ttll(!fjf)

...

illAtMta

··~·

~·-·

•••

JliiWMf

...

...

~

ltMtl'f

ltfll#f

...

li

.*-&

••

·-

...

J:U1Jii

JUIU~

j8,it11.11

l8.M1LIIIII

liAt

••

j8,fil1(.j1;J.

...

fl$]!1

••

••

IIM#f

-~31:

...

·-

~ttJttiHIICI

~tt~•

~ttit

~tt-J:t

~tt~J:t

~ttit

~tt!lf.t

~ty:ttg••

~ttU

~ttmHJ:t

Thread tension regulator Assy

Thread tension regulator Assy 1

Nut 2 2

Spring Guide Assy 1

Tensin Spring 1

Thread Take-up Spring

Tension Disc 2 4

Thread Tension Stud 1 1

Screw 1 1

Thread Tension Regulator Bushing 1

Tension Releas Pin 1

Tension Releas Pin 1 1

Tension Releas Plate 1 1

Screw 2 2

Tension Release Spring 1 1

Nut 1

Upper Thread Tension Plate

Thread Tension Stud 1 2

Thread Guide Bracket 1 2

Thread Guida Disc 1 2

Thread Guide Spring 1

Thread Guide Cap

Screw 1 2

Tension disc Washer 1 2

Screw 1 1

Tension Ralaasihg Pin 1 1

Bushing 1

Screw

Screw 1

Thread tension regulating thumb 1

nut 1

Thread tension spring 1

Thread tension releasing disc 1

Tension regulator stop plate

Tension regulator bracket

Tension disc 1

Thread tension stud 1

Thread take-up spring 1

Thread tension releasing pin 1

1

1 1

1 1

1

1

1

2

2

2

1

1

1

2

2

1

1

P28

P29

Page 17

Series

SiRUBFI

PARTS LIST P717K/P727K

n-

•

87-

Q

r.,=

-90

109

108 107

106

NEEDLE

101

Subject

BAR

AND

TAKE-UP

tt•BB~

LEVER

MECHANISM

Page

1/2

Date

2013/6/28

SiRUBFI

PARTS LIST

Fig.

No.

75 8100575-000 MF

76

77

78

79 8100579-000

80

81

82

83 8100583-000 M9 0909 003

84 8100584-000

85

86

87

88

89

90 8100590-000

91

92 8100592-000 MN

93

94 8100594-000

95

96

97

98 8100598-000 M9

99

100 81005100--000 MF 60A2 740

101

102

103 81005103--000 MQ

104 81005104-000

105

106

107 81005107--000 MF

108 81005108--000 MF

109 81005109-000 M9 1110 002

Part

¥#!iii

81

00576--000 MF 10A2 740

8100577-000 M9 1102

8100578-000 MF 60AO

8100580-000

8100581-000 MN

8100582-000 MF

8100585-000

81

00586--000 MF

8100587-000 MF

8100588-000 M9 0802 003

8100589-000 MF 10A2

8100591-000 M9 1516

8100593-000

8100595-000

81

00596--000 MN

8100597-000

8100599-000 M9 1513

81005101--000 M9

81

0051

81

0051

81

0051

P717K/P727K

No.

Code

~-

60AO

MF 10E2 148

MN

10A1

10A1

10AO

MV

01AO

MV

02AO

10AO

10A1

10AO

MP

0080

MV

02AO

MN

10AO

10AO

MQ

50AO

1601

1606001

02--000 MF 20A2 352

50AO

MV

01AO

05--000

06--000 M9

MF 20A2 352

1801

10AO

10AO

Series

No.

742

001

663

500

740

665

660

660

664

181

181

001

587

582

582

588

387

661

001

001

232

383

002

662

325

Subject

NEEDLE

BAR

AND

TAKE-UP

ttttffBf9

c

$

lUI

~

Ull

$E@;~Jt

-~

ttft1Jf(fal)

flb,f_,

....

fib~

tt~a

-~

~~~~

~ttit*

ttft1l(l')

¥ttnld

ttft!U

-~

tt

Gal

¥tt~tl¥

~"·

~tt~tl¥

li*T~

~"-·

ttH:f&f

G*lill.

$E@;ft~J:t

fib~

G*&\M

am

UIJ.Ctr:)

~~~~~

G*l

G*l

08

tt~

Needie bar upper bushing cap 1 1

Needie bar upper bushing cap

Set screw(for Fig. 78) 2 2

Needle bar bushing( upper) 1 1

Oil wick 2 2

Plastic plug(for Fig. 84.85) 1 1

Felt 1 1

Needle bar connecting stud

Screw(for Fig. 82)

Needle bar 1

Needle bar 1

Needle bar bushing(under) 1 1

Thread guide 1

Needle clamp screw 1

Thread guide 1

Needle 1 2

Set screw(for Fig .92) 1 1

Take-up

Take-up

Takw-up

Take-up

Crank pin 1 1

Needel bar connecting crank rod

Set screw(for

Sat scraw(for

Fait 2 2

Set screw(for

Upper shaft collar 1 1

Upper shaft bushing(lett) 1 1

Crank 1 1

Sat scraw(for

Sat scraw(for

Needle bar connecting link guide

Square block(for Fig.82)

Screw(for Fig

-~

Neme

laver support stud

laver

lever

slide block

Fig.1

Fig.1

Fig.1

Fig.1

Fig.1

.1

LEVER

MECHANISM

of

Part

feH

04) 1 1

03) 3 3

02) 2 2

04) 1 1

04)

07)

P717K

Page

2/2

Date

2013/6/28

ill~

Amt.rep

P727K

1 1

1 1

1 1

1 1

1

1

1 1

1 1

1 1

1 1

1 1

2 2

P30

P31

Page 18

Series

Sii=IUBFI

PARTS LIST P717K/P727K

·~rn

.... QJ

PARTS

Subject

OF

UPPER

SHAFT

AND

VERTICAL

...tIll

lill!diiJ;t

904

~+-------------1~

'

\---------

1,..-------

-------142

SHAFT

2013/6/28

115

141

Page

1/2

Date

906

Series

Sii=IUBFI

PARTS LIST P717K/P727K

Fig. Part No. Code No.

No.

115

116

117

118

119

120-A 81007120-00A

120-B 81007120-008

121

122

123

124

125

126

904

127

127-1 81007127-001

128

129

130

131

132

133

134

135

136

905

137

138

139

140

141

142

143

!ilf.l:tiil

81007115-000

81007116--000

81007117-000

81007118-000

81007119--000

81007121-000

81007122-000

81007123--000

81007124-000

81007125-000

81007126--000

81007904-000

81007127-000

81007128-000

81007129--000

81007130-000

81007131-000

81007132-000

81007133-000

81007134-000

81007135-000

81007136--000

81007905-000

81007137-000

81007138-000

81007139-000

81007140-000

81007141-000

81007142-000

81007143--000

MM

M9

1606

MV

01AO

MF

10AO

MF

60A3 740

MQ

70AO

MF

6780 522

MF

6780 522

MQ

70AO

MF

10AO

M9

1508

MF

10AO

MF

10AO

MV

01AO

MV

01

M9

1508

MF

60A1

MF

60AO

M9

1516

MF

60AO

M9

1520 002

MF

6580 682

MN

6580 682

MV

01

M9

1203 002

MG

3080 740

MV

01AO

M9

1803 036

M9

1802 045

M9

2201

001

331

333

521

520

352

001

334

332

230

EO

280

001

740

700

001

233

EO

384

744

003 0

..

~ft(..t*b)

Oft

$J:§ft•J:t

n••c..c>

n•w<Jt:~>

o•~<l'>

D

UWfi

~U(R*b)21T

-

~ft(.*b)18T

U

!!!Uh

C!Htft

Cm!:ltlfi

U Set screw(for Rg.127)

ClbmfJI

idl.

JiiW(SitJ)

..

..t•WCt:i)

Blh

-

u

-~.an

idl~

-

:il~

1111)1]1~

il~JI'J·iti

...

PARTS

OF

...tidiWIIilbffB

(J:§J:§M)

Subject

UPPER

SHAFT

AND

VEimCAL

SHAFT

~

Neme of Part

Set screw(for Rg.116)

Bavelg~uppershaft)

Bevel

gear(vertical

Felt

Vertical

Vertical

Vertical

Vertical

Vertical

Setscrew(for

Bevel

Bevel

Upper

Feed

Feed

Ring

Feed

Felt

Spring(for

Set screw(for Rg.133)

Upper

Set screw(for Rg.135)

Balance

Screw(for

Crank

Screw(for

Felt

Crank

Feed

Crank

Fig.139)

Nut(for

Screw

shaft

shaft

shaft

shaft

shaft

gear(vertical

geat(hook

shaft

cam

Jw;y

cam

cam

rign

Fig.130)

shaft

wheel

Fig.135)

rod

Assy

Fig.139)

rod

for1<ed

rod taper screw(for

FIQ.141

shaft

upper)

bushing(upper)

bushing(upper)

bushing

collar

Fig.122)

shaft

under)

shaft)

bushing(right)

connection

)

2013/6/28

iilta

Amt.rep

P717K

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

2

1

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

Page

2/2

Date

P727K

1

1

2

1

2

1

1

1

1

1

1

1

1

1

1

2

1

2

2

1

1

2

1

1

1

1

1

1

1

1

1

1

P32

P33

Page 19

Series

Sii=IUBFI

PARTS LIST P717K/P727K

153

152

175 174 173 172

1?1

Subject

BACKSTITCH

ft!IIIIIMBB~

170-1

170 J 169 168 166 167

...

906

DEVICE

161

162

168 165

2013/6/28

163 164

Page

1/2

Date

Sii=IUBFI

PARTS LIST

Fig. Part No.

No.

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

906

170

171

172

173

174

175

¥f.l:;ftil

81009151--000

81009152--000

81009153--000

81009154--000 M91807

81009155--000 M91504002

81009156--000

81009157--000 M91513

81009158--000

81009159--000

81009160-000

81009161--000

81009162-002

81009163--000

81009164--000

81009165--000

81009166--000 M91003 653

81009167--000

81009168--000 M91501

81009169--000 MF60A0633

81

009906--000

81009170--000 MF60A0634

81009171--000

81009172--000

81009173--000

81009174--000

81009175--000

Series

P717K/P727K

Code

No.

M~

u

M9

0905063

MF

10AO

153

015

MV

01AO

152

001

MF

10AO

750

M90902063

MF

10A2

572

MV

01AO

640

MF

10AO

852

MF

1100

631

M91209002

M91207003

MF10AO

MF

M91501

MF60A0572

M91110002

MV

MV

1030

01AO

01AO

632

002

635

007

708

738

*'

itff

ilff*b

u

di!JJt

u

UIIJ·II~

,.

*'

tf"lii!#IJJlU

•m

tf"JH!JIJ)lftl

u

u

~··ii.l

itJalff

u

-

ftiJilliffll

itJ~ff

u

~-

u

~~-

!i!7tff

•

Subject

BACKSTITCH

DEVICE

i!IJitfltlftB~

Cl

RR

~

Screw 1 1

Set

Feed

SET

Set

Feed

Set

Feed

Set

Spring(for

Screw-bar for(Ms-551

Stopper pin(for

Stich

Screw(for

Screw(for

Spring washer(for

Reverse

Setsaew(for

Shaft(for

Reverse

Reverse

Set

Spning(for

Scraw(for

Bracket(for

Knee

Neme

pin(for

Fig.153)

connecting

PIN(FOR

screw(for

regulator

screw(for

Regulator

pin(for

Fig.156)

FIQ.162)

length

Fig.163)

Fig.167)

sewing lever 1 1

Fig.167)

sewing crank

sewing lever 1 1

screw(for

Fig.170)

Fig.174)

Fig.172)

lifter

rod

of

Part

link 1 1

Fig.153)

FIQ.156)

FIQ.158)

bushing

0,5520)

Fig.163)

regulator

Fig.167)

dial

Fig.167)

As&f

FIQ.170)

2013/6/28

.fl/8

Amt.rep

P717K

1 1

1 1

2 2