Page 1

Page 2

~R~~~Rm*m,

~~*m~~#~n~#Tfi,

~~~~•~.

RfflftMff~~~Rm~~~

~'!l:a:l~o

I.~~~ffl~~m*m,

2.~g~~~~·**~~Rm~~~o~*•~·••~~~o

J.Rm*moo.

4.

ftm*fJtOO!lX:Rm*fJL~.

*

•ti

fF

s.

1i1'¥Affl.~·®itQliM

6.~7~~A•~~.am•~~-~M~a•

~~*•~*m~*~~-~.fi~~~~~-~~mm

,

fk:~ftilfo

~7•~*~~~-~.

~

~'.JJtfiJII

.~ill

r.JT~~~~~~·3Y!Ne4lt1f~o

o

$S~~*AA·~~Rm*m·•·~~~~~'

~mm~M+~~

o

7.~~-~~·•*m~•**~•~~--~0

7.1

~Lft!.¥~

7.2

J!~;fJU-J-.

7. 3

:ill:ff$f~at

7.4

ti1'Jo!Ri!OC7GAR-.f

8.

;(£tJL:@1

1lf

Jil

rli

~

~IH:IL

irt!~'£1l'ViR

!lX:

:£;

BiJ1141.

0

•

t,

~

#ti.

o

~~'J'•L•itirt!~¥

~

1t

]t

**1-!f~

o

1J

U~!fM. JtJY(~n~rfJ1irt!!lX:ililm-MI,

•~.

o

tJL~jg~~,

~~~~~~

i¥f1rf!lll!f¥)'c

9.

~~

;fJ

L~m~

1

o.

*1L~

~

11.

miE~~:?l:iJ

12.

~·%i

1£~

$#-tQ~~~-.1I~w~m~m~o

13.

~mAAii31~/EAA~ruHWJEE~5tm~o

14.

:iE'Ittiif*fJLff.f·,

15.

IE

~~Ami?:l;t~~M~:fru~f.n:ff~M.l~M~

t6.

~-~i&:il~i&m:*m,

~;ijkff!.]J(1f

17,

**

JL

~Mmf~\.&~~31o

18.

~l'P~'*fJ!lf-1{1=

A

EJ~,

~u~.

II

~.&~:@Am!lX:~~.&-.Ji#Ama'.J:t~~~m:ff~*~:n$1tJ:~*"1'~·

o

ti w Am

F~~Li;tJ;fJL~~~~flf-;flliN~~~:m:.

~&m;frl

A.ol:iltff

ifni

m

~I

1'¥~·

@i

IE~~.&

-

f:N~$fl~;fn~!l&I

!IZ·%i:ill:fi1Jtm~,

iW*mlr5&:1'iJfi~~~mnflio

ii

Jt$

f~Am

-r1u±~

IfF~J.ft~m~!l~

tt*

1fo

o

Am

m:

ff

0

1£ffl~~

ti1J,

i?.,

:tl

l

liWJ~~~;fJL~o

*0-r.IJx.tm!ltrrur:~a'-11%~

&

*¥1.11J

it~-

~

- 1-

Page 3

IMPORTANT SAFETY INSTRUCTIONS

To get the most out

machine

for a long time.

2. Read

4.

5. This machine shall be operated by appropriately-trained operators.

6. For your personal protection. we recommend that you wear safety glasses.

7. For the

9. Tampering with the live parts and devices. regardless

correctly.

Please

Please remember to keep this manual in a safe place.

1.

3. Use the machine after it has been ascertained that it conforms with safety rules/standards

8.

10.

11. General maintenance and inspection works have to be done by appropriately trained personel.

12. Repair and maintenance works

13.

read this Instruction Manual carefully before

Observe the basic safety measures, including, but not limited to the following ones, whenever you use the

machine.

all the instructions. including, but

machine,

country.

All safety devices must be in position when the machine is redady for work

without the specified safety devices is not

7.1 For threading needle (s) and replacing bobbin.

7.2 For replacing part (s)

7.3 For repair work.

7.4 When leaving the working

If you should allow oil, grease, etc. used with the machine and devices to come

or skin

medical doctor.

Repair, remodeling and adjustment works must only

specially skilled personnel,

technicians

Whenever you find a failure

Periodically clean the machine throughout the period

In

following, turn off the power switch

or

swallow any

of

the many functions

addition, keep this instruction Manual so that you may read

of

needle, presser foot, throat plate,feed dog, cloth gude etc.

place

of

such liquid by mistake, immediately wash the contacted areas and consult a

of

or

under the audit and guidance

of

any

of

this machine and operate it in safety, it is necessary

use

. We hope you will enjoy the use

not

limited to this Instruction Manual before you use the

allowed.

of

disconnect the power plug

of

when the working place is unattended.

of

whether the machine is powered, is prohibited.

be

done by appropriately trained technicians

electrical components shall be conducted by qualified electric

of

specially skilled personne

of

electrical components, immediately stop the machine .

of

use.

of

your machine

it

at anytime when necessary.

valid in

or

in

operation. The operation

of

the machine from the receptacie.

in

contact with your eyes

l.

to

use this

you

r

or

14.

Grounding the machine is always necessary fot the normal operation

to be operated

15. An appropriate power plug has to be attached to the machine by electric technicians,

be connected to a grounded receptacle.

16. The machine is only

17. Remodel or modify the machine

safety measures. We assumes no responsibility for damage caused by remodeling

machine.

18. Warning hints are marked with the two shown symbols.

A Danger

in

an envivronment that is free from strong noise sources such as high-frequency welder

allowed to

of

injury to operator

be

used for the purpese intended. Other used are not allowed.

in

accordance with the safety rules/standards while taking all the effective

or

service staft

& Items requiring special attention

-ll-

of

the machine. The machine has

Power plug has to

or

modification

of

.

the

Page 4

t.~R~A~m•.8~~·~·

~~ffl•~~-·~·

•~¥*~mao

2.~~~oo•~m•~-~~

*flllt!fJLo

3.

~i!!i~A~f9ii!t,

4.

~·~A!tf~•

s.~#~~~-M.

il3f~o

6.~~~00-~A~m•.

1.

~~~n•~m•~~~~~~~~~••.m®m~•·~~-~~~•

rr.t

,

-

~

s.~-~

~!H:z~r.

§1~ff*1t~**!OCf*1'FtJLeat

,

~JL·~~at,

m~-=F-m:~t1:E~#~ili.

*

f-'i!

tJL

~

fJf.J

It

~

~m•~m~mttm.m•*~~~.

-~~~~~~••·

9.~R~Mtt.8~tt~-~~.•m~m•~~.

to

.

~n-~n•Stm!l!tt•tta!ll14=~1'.m.

~A~m•.

l:~.

&:1fHolt!.tJL.P.iJI'm~4ht:It13:frU!I11Jd'lt

-

~m¥-f-=F-:~t.A:ti~~~IAJ

§B~•m*m~~.

~•.~•~~m~~-~~

,

tJ

~*·•~#~.

m:m-•m:~tAma~AJM

•

ttm~~-o~•~m•~~

•*wme~tt~**o

::£E:tru.J.::_•W:r

:fru

o

Jm:m-

~:~t.f:EtJL-tt-r:n

0

•~w

~z

m.

t'R*Wtt~

*~·

.

~

0

matt

o

-iii-

Page 5

FOR SAFE OPERATION

~

&

1.To avoid electrical shock hazards, neither open the cover

motor nor touch the components mounted inside the

1.

To

avoid personal injury, never operate the machine with any of the belt cover, finger

guard

of

safety daevices removed.

2.

To

prevent possible personal injuries caused by being caught in the machine. keep

your fingers, head and clothes away from the handwheel, V belt and the motor while

the machine is operation.

3.

To

avoid personal injury, never put your hand under the needle when you turn "ON"

the power switch

4.

To

avoid personal injury, never put your fingers into the thread take-up cover while

the machine is in operation.

5. The

6.

7.

looper rotates at a high speed while the machine is

ible injury to hands, be sure to keep your hands away from the vicinity

during operation.

replacing the looper.

To

avoid possible personal injuries, be careful not to allow your fingers in the rna-

chine when

To

avoid possible accidents because

power to the machine when

or

In

tiling/raising the machine head.

In

addition, place nothing around them.

operate the machine.

addition, be sure to turn OFF the power to the machine when

of

abrupt start

tilting the machine head or removing the belt cover and

of

the electrical box for the

electrical box.

in

operation,

of

the machine, turn OFF the

To

prevent poss-

of

the looper

the V

belt.

8.

If

your machine is equipped with a servo-motor, the motor does not produce noise

while the machine is at rest.

machine, be sure to turn

·g.

To

avoid electrical shock hazards, never operate the sewing machine with the ground

wire for the power

10.

To

prevent possible accidents because of electric shock or damaged electrial camponent(s), turn

power

plug.

supply removed.

OFF the power switch in prior to the connectrion/disconnecti on

To

avoid possible accidents due to abrupt start

OFF the power to the machine.

of

of

the

the

-lV-

Page 6

~1'FMit~$!9i

·················

·······

·········

···

· · · · · · · · · ·

···

···

·····

···············

· · ·

·····

························

· · · · · · · ·

···············

··

·····

-1

- , 7f$Mit!.it.$J1i!

-=

'

ftJflit~$:rjji

~' ;f:JL~~~f~···

1!9,

m~tt-J~

Ji,

:tJnnf:J

1\

'

iii

til)

-t,

mr~l¥-1~7*

!\.,

}(E~I¥-1~1*

fL'

~~:l*-

-t'

ffi

~

-t-'

-t-=,

-t-

-t

#~Ei.I¥-Ji.ffll'il

;f:JL-ftl¥-1~~

,

ffi

[9

' :ili

~

......

........

irti

ii:

il~

................................

.......

..........

JJ!IJ

rWJ

1.l

*'~

?f

1¥-1

...........

.....

................................

······

············

......

....

················

..........................

....................................

=p-

.......

..............

............

.....

a'.J

i)!J

.......

....

.............

..................

..........

...........

.............

i.ml

=n-..............................

=p-

......

.................

..............................

.............

·········

··········

............................

.........

.........

..............

..............

........

.....

.........

........

....

......................

.......

............

.....................

.......

................

................

.......

.................

................................

...............................

.....................

......................

..........................

·····

···········

....................

·······

............................................

...........................

...........

........

....

.......

...

.....................

........

............

.......

...............

.................................

.......................................

.......

......

..........

.........

..........

............

..............

........

........................

······

.. ·········

..........

.................

..........

.......................................

............................................

................

.....

........

..........

....

.....................

...

..........................

........................

......

..............

......

.........

.................

.....

.....

............

................

.............

...

........

............

...

.....................

......

..............................

......

......................

...........

....

................

........

...

....................

................

..............

....

...

........

........

...............

.................

...

............

.....

......

.....

......

...........

.......

....

.....

......

......

. ]

..

-3

. 3

..

. 5

1

2

2

2

4

5

6

6

7

7

-tii,

-t

/'\

' # :ff

-t-!:;,

-tJ\.,

-t

iL ,

=

-t,

=-t- ,

= -t

-=

=-t-=:

=

-t

1!9,

=

-tii

=

-t/\

=

-t-t

= -t /\.'

:i!iM?f-!§#1¥-Jfil.l~

rlWJ

l.ll¥-1

i.ffl]

;fJL#:fO

~-ft

~t~-~¥-J'qn

~-ft:,fo;f:

,

,

,

,

,

~#i¥-Ji.ffll'iJ

;f:BX11JL#I¥-Jfi1.1~

it

JL#

l'

al

f*tt~a'.Jfil.l~

.f:*ti-~1¥-Jti'l::'i!i:

}(Eg&:tJg&[_)~

f:J~g&;f:fg&

r.f:llill~g&~

-ft;f&I¥-Ji.ffli~

~W;tJLa'.Jf!3f

:;t

i!&l$:f01t\'1if!!.

.

................

=p-

..........

.........

.........................

..............

......

a'.J

............

I

illi~

....

..........

..

...........................................

................................

.....................

..........................................................................................................................

i.m]'iJ;fli

....

................

............

1¥-Jf!L'I't

.....

....................................

......................

.......

.............

......

.....

.................

.......

..................

...

......................

..........

........

..........

......

..........

..............

......

.................................

· · · · · ·

...............

....

...................

.....................

.......

............................

......

..............

........

.......

.........

......

..........

...................

............................

............

....................

.....

.............................................................

...

................

..........

............

.......

............

. · · · · · · · · ·

..........

.....................................

........

............................................

...

.............

....

.........

......

.........

..............

......

.........

...............

......

.......................

...

....

........

....

.......................

........

.... · ...

............

.........

.....

................

........

.........

..................

................

.........................

.....

.......

........

· · · · · · · ·

..........

...................

..............

.......

......

......

.........

..........

.......

........

.........

.......

...............

............

............

....

........

..............

.............

......

.......

.........

......

.............

...... 9

.........

....

...

· · · ·

......

.......

...

....

..

...

..

7

8

8

. 9

. 9

10

10

10

11

]]

]J

12

12

*

ftf:-=f-

fj}]-

· · · · ........ · · · · · · · · · · · · · · ·

.....

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

- v -

..

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · - I 7

Page 7

Contents

Before operation ·········· ······················································ ························· ··············································-1

1.Pre-start checks ························································ ························ ················· ······································1

2.0pe

rating instructions-····················································· ········································································· I

3.Specification

4. Installation

5. Oiling ..................................................................................................................................................... 2

6. How to regulate oil amount by means

7. The threading

The

8.

9. Thread ten sion asm

12. Setting-up

13. Adjustment

15. The

16. Adjustment

threading

10.

Presser foot .................................... ....................................................................................................... 5

11.

To adjust stitch length .......................................................................................................................... _ 6

14.

Adjustment

timing

· ··················· ················· · · · · · · · · · ··························· ···· · · · · · · ·························· · · · · · · ························· 2

of

the machine .......................... · ..... ·················· ...................

of

manipulating elements on the face plate · · · · · · · · · · · · · · · · ·

of

needle thread · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 3

of

bobbin thread · · · ·

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

of

the needle ............................................... .......................................................................

of

the height

of

the heig ht

of

feed dog and needle ····························· ································································· ··········· 7

of tbe height

of

of

of need

..

· · · · · · · · · · · · · · · · · · · · · · · · ·· · · · · · · · · · · · · · · · · ····· · · · · · · · · · · · ········ · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ...

the presser bar·············· ···········--·····················

the feed dog········ ············ ············································································ 7

le bar ...................... ········· ................................... ······················· ········· 8

..

······· ......................... ·······

....

· · · · · · · · · · · · ·

..

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

..

·········································· 7

..

···

..

· · ·-4

..

· 2

··

..

...

3

5

6

17.

Adjustment

18.

The

timing

19. Thread-guiding amount

20.

The

clearance

21. The

22. Position

23. Loper thread take-up ca

24. The position

25. Frame thread eyel

26. Replacement

27. Maintenan

28. Common breakdowns and measures

PARTS

timing

BOOK

of

the needle and looper ..................................................................................................... 8

of

looper

of

of

needle guard ········ · · ··· · · · · · · · · · · · · · ········· ············

of

needle

of

of

ce

of

..

· · .. ·

in

reference to needle · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ... · · · · · · · · · · · · · ·

of

the loper·······································································································9

looper and needle ····································································· ··························· ········ 9

guard·

thread-amount adjusting plate

et

throat plate · · · · · · · · ·

the machine · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · .. · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

.. ·.

·························· ······························································ ···························-

m··

······················································ ·································· ···· ····················· I 0

· · · · · · · · · · · · · · · · · .... · · · · · · · · · · · · · · · · · · · · · · · · .. · · · · · · ·

..

· .................................................... · · · ........ · .............................................................

··

· ···· · · · · · · · · · · · ··· · .............. .... · · · · · · · · · ·

of

the thread take- up lever .............. ..............................

..

· · · · · · · · · · · · · · · · · · · ...... · · · · · · · · · · · · · · · · · · · · · · · · · · .. · · · · · · · · · · · · · · ·

· · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · ·

oftrouble shoo

ting ................................................... ................... 12

·· ··

· · ··········

··

· · · · · · · · · · · · · · · · · · · ·

..

··

9

10

10

11

11

..

II

· · · · · ·· 12

17

- V

I-

Page 8

:Jtfl:wH!lt$19l

71

~:

I Before operation

~-~··~-~~~•a.

·

~~~~~m*

•

liff

ri-A

It! ffi;!! N

·

~~

~~ -

•

TiffriA

It!

lJL~

·~m*•~

CAUTION:

To avoid malfunction and damage

• Before you put th e machine into operation for the first time after the set-up , clea

gathering during transportation and oil it well.

• Confirm that the voltage has been correctly se

power supply.

• Never use the machine in the sate where the voltage type is irrerent from the designated one.

• Confirm that the direction

• Operate your machine at the normal sewing speed or less for the flfst month after the set-up.

I,

llbft~*1Jil

2,mB~ft".M~m*~•ft~m~~~#:n~.~fi

3,

1£lfH

JJ~ffltf.J

4,~-~~mfim~~5~.

I. The machine shall not

2. The rotating direction

(View from

while

3. The machine sha

4.

Check, power source, voltage, and phase number to see wheth

plate

th

bal

ance wheel turning clockwise.

of

the motor to be use

•~·••••~.

iE

~~ , :fill~'~

~l'l!

ffi~*•••#~ffi~

J;1

1

1J

~

:1!

N

~-~n.m

l~Mf5~

~Jf

~ -

~

Ji

be

of

the balance wheel, when the machine is started running, shall be

e right side

ll

be under operation at less than 4

m~~~=

-~~•M•~~~-~~.

It!

VJlt~

~

:1!

N

lHiffJ

o

- •.•~~m*m

iE

1iffJ

o

•@~iE~~-riE~~~r~~

of

the machine, confirm the following:

t. Confirm that the power plug has bee n properly conn

of

rotation

$o

~, @1~

••

started running until the completion

of

the balance wheel.) A warning sha

d.

of

the mot

~:it

~~~4fi~

It!• .

~

or

pulley is correct.

it1

•4000

ffi&•m,~ffi;J!§iE•

,00

0 S.

P.M

#~~~~~~

.

.

.~~•ft

#i!H7~~H1~!&.

of

oilin

ll

be given

. for the first month.

er they

o

o

g.

in advance

are

in

accordance with the ratings on the

n it thoroughly. Remove all du

aga

.

st

ected to the

in

counter-clockwise one.

inst making the machine run

nam

e

=.

Bl!11li!~·JiJi

I,

tJLcB~~Brt,

2,m·~~~.

3,

fJLBrdu!Ef

4,*~

1'1!~«*

tJLBftUifiJ

5,

«B

~~H

iWi!

-~

•

ll:.FP.

*FP·

.

t.

-rn~

I Operating instructions

J:m-

=f-:J.&¥1

J#tf.J~$o

8 ~N

~Am~ff~-~

7t~t.l~~m

~r•tt~tr.J

a~t~,

o

•a

.

~~~;!tE:t:F-iN®

o

l'l!~m

~~•••~

:ili

~tfam~$~,

- ·~~

"V" m&#}. f

Efmt-t:ili.

6,

cm&m•

I.

Do

not put your hands under the low

2.

Do

not put your fingers into the thread take-

3.

Only when the machine stops can you turn the balance wheel by hand.

4. After the motor

have the machine tilted unless is stop

5. Keep away from the balan

6. Do not sta

&~m

rt

running the machine during mounting

a~

.-~JF~m•

sw

itch being turned off, due to inertia, the motor will continue to rotate for a while. Be careful not LO

ce

wheel,

V-b

o

er

part

of

up

s.

elt, winder and the mot

the needle when the machine is runnin

lever cover when the machine is running.

or.

or

replacing the

belt cover, finger guard, etc.

-1-

.~~

l!

g.

·~•·*~

l;1

Jm.

t!!~WrE*

ll:.

ft~~•

•

I!!i:tfx:~tE

Page 9

t1Li~1l»A~

~~~~

~

)~

~~*It

#fffi~

:«

tt

iitl

ie

~~~~J't

~

tj

i*

#WJ

~fN;ffi}l!ll

i

tt

~

ilflilt~

I!Y

..

1H

Ri

l.4~4m

3

1/8" 5/32

1t'HU

5/1

fi·H~t

-

~

i

1fi

J:::1Hi

ntJl

2%8

:lJLI~l'l{]~~(001)

jlf!fflll

Nearbodyside

I Specification

tJ~

tf-~

1Jj4Jj;Jtl1jl4500~

m

0mm

" 3/16" 7/

6" 3/8"

~

!l!:ftiJWi'i J:\~ 118"~1/

741~\

'

rei! ~ ):\

~

ilir

001

Fig. l

~UiJ:\!ii

32"

1/

4"

1/2"

2"jl!iffl

*

ffl

8~10m

m

/Installation

t~

\ii

l(l

Hinge si

de

"S

tit

ch

type

Speed

Stitch

leng

Stroke

of need

Gauges

of double-row

Thr

ead

take-up

Looper

Needle guar

Light

clearance

Oil suppl

y

Lubricating

of

the machine (Fig.l)

I .

th

le

bar

type

d

of

knee lifter

oil

M:at~~-=

ifi,

fflila:at~tr

Two-need

Max.4,500 s.p

1.4~4mm

30m

118" 5/32"

5/16" 3/8"

Needle bar

Separately adjutabl

Oscillating type and rig

8~

lmpeller-t

#2 while oil

·M·~-

Q)•:Jt

2.am~~-~~A••~~.

~. w•·~~~~fljfi~-~-

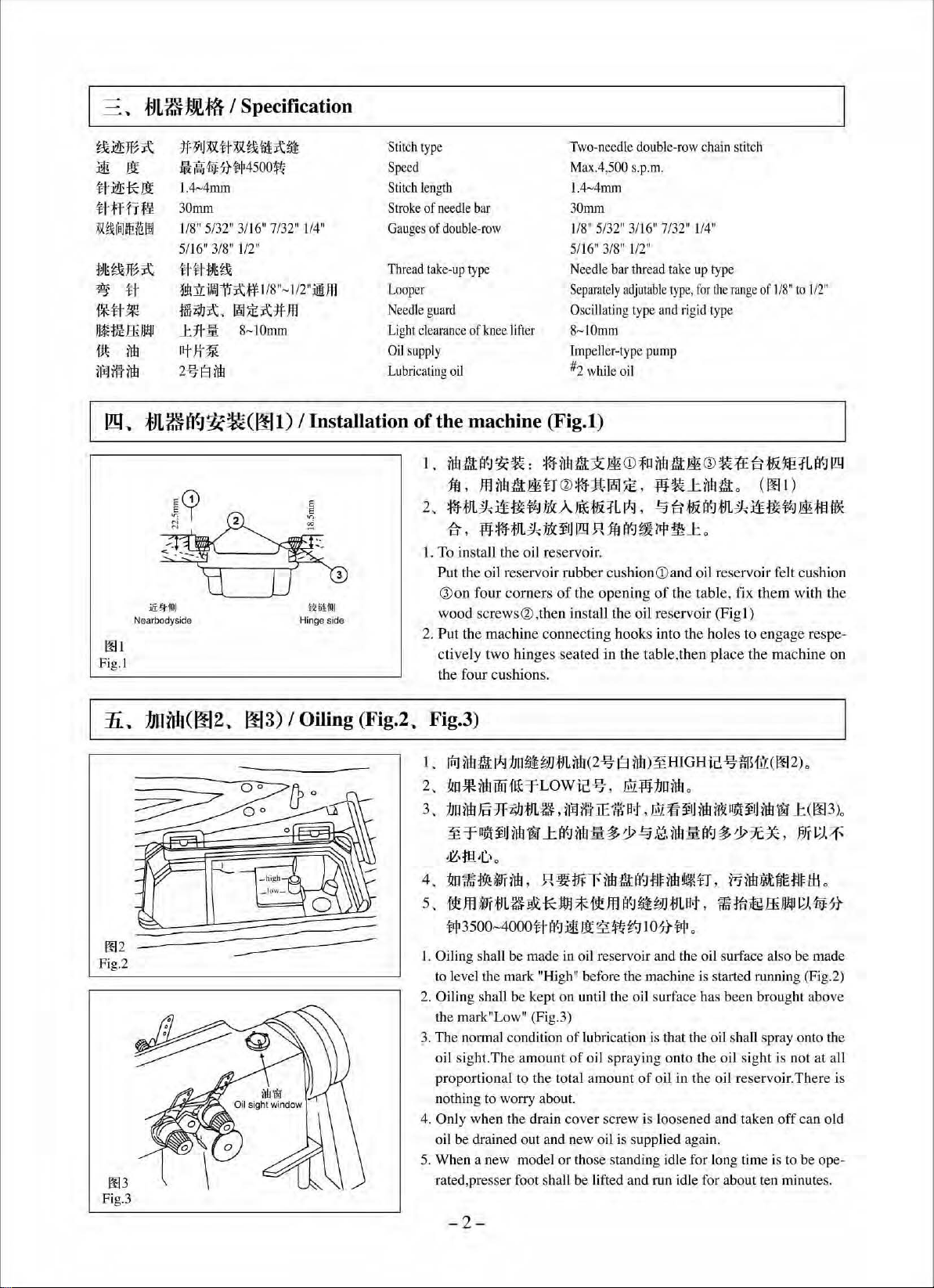

l.

To install the o

Put the o

Q)

oo

four

wood screws

2. Put the machine conn

ctively two hinges seated in

the four cushions.

il

reservoir.

il rese

rvoir rubber cushionOOand o

corners

of

the opening

<I>

,then install the oil reservoir (Fig I)

ec

le doubl

e-row chain sti

.m.

m

3/1

6"

7/32"

1/4"

112"

thr

ead take

l0mm

ype

pump

OO

~M:at•®

re!J/E,

up

type

e

type

,

for

the range

id

type

fi}~J:M:ato (~I)

~~•~m~~•~•m•

l:o

il

of

the tabl

ting hooks into the hol

the

table, then place the machine

tch

of

1/8

"

to

1/2"

·~~-m~~~

reservoir fe

e,

fix them with the

es

lt

cushion

to engage respe-

on

1i

..

JJnilfJ(002

002

Fig.2

003

Fig.3

..

003) I Oiling (Fig.2

..

Fig.3)

1.

lf:iJilb:at~1Jli

2.

-

~o

*

3,

)

JliM

~

~·~ilE

4.~---~.

s.Rmam•~*M*Rm~~mm~.

tJI•3

500-4000tl

l.

Oiling sha

to level the mark

Oiling shall be kept on until the o

2.

mark"Low" (Fig.3)

the

3.

The normal condition

oil sight. The amo

proportional to the total amount of o

nothing

4.

Only when the drain cover screw is loosened and taken

oi

l be drained out a

5. When a new

rated,presser foot shall be lifted and run idle

~~

JJmM

(2"%8 M)~lllGHic

nn

ffff

fl

.Ff

Low

ic

-~,

J§JF~tJm~,

wHJtlE'ffi"Ht

~l:

~MM

~~~

RWm~M:at~mM•tr.

·a'oJ:ia!Jt~f!<~

ll

be made

to

worry about.

in oil reservoir and the oil surface also be made

"I-Ugh

'1 befo

re

of

lubrication is that the oil sha

unt of

oil spraying onto the o

nd

new oil is supplied again.

mod

el or those standing

-%ffl

m w

»oilE

0

,

m~H~IJiltmlnY!¥1JM~

~MM~·~~*

•msffi•~•*

I 0

7H

ijl

0

the machine

il

is

started running (Fig.2)

surface has been brought above

il

in

the o

il

idl

e for long time is to be ope-

for about ten minutes.

H

!L(I¥J2

)o

J:

(003)

.

·~~~

~ilERftmllio

ll

spr

ay

onto the

il

sig

ht

is not

at

all

reservoir. There is

off can o

ld

-2-

Page 10

,\,

iiii~Sitkl:ifnlilCm4)

I

How

to

regulate

oil

amount

by

means

of

manipuJating

elements

on

the

face

plate

(Fig.4)

~~M~~~-.

~J~.

~ft(:t'~

t

mark

you desire. Otherwise, max.

wili~ff~fffi~a-t,

~-: ~~MA

.

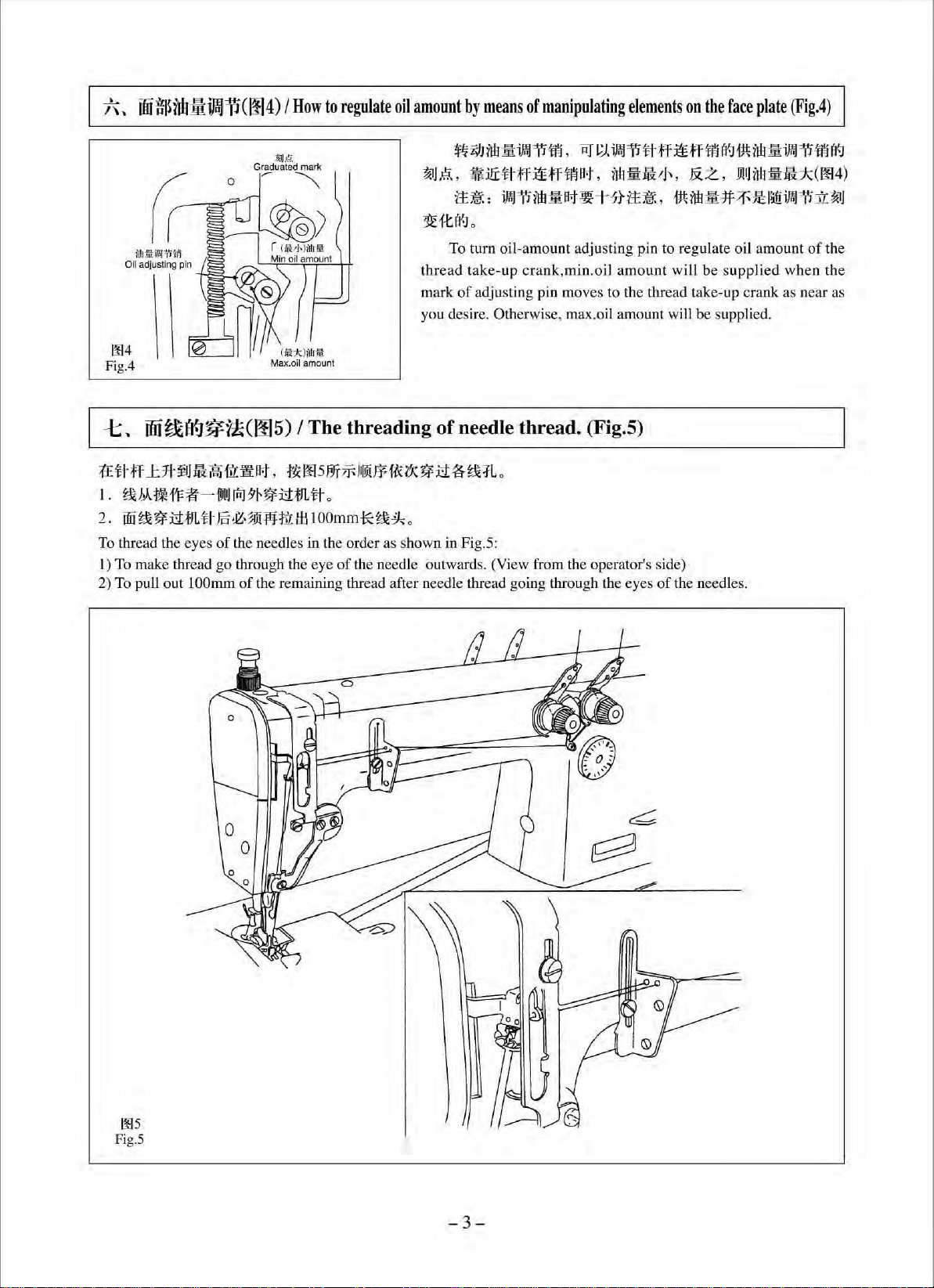

To

turn oil-amount adjusting pin to regulate oil amount

hread take-up cr

of

adjusting pin move s to the thread take-up crank as near as

illl

ti!W

n'i

Oil adjusting pin

'rn

Graduated mark

0

;-

Cltl]R,.

~

III4

Fig.4

--1:;,

Wt!f.J~~(005)

~~ff~*~•amft~.•oosm~•~•~•M3~R.

1.

r~

Mt*1'F:t--11Jl1JrfiJ9~~M;tJL~

2.

ilfi~~M:fJL#

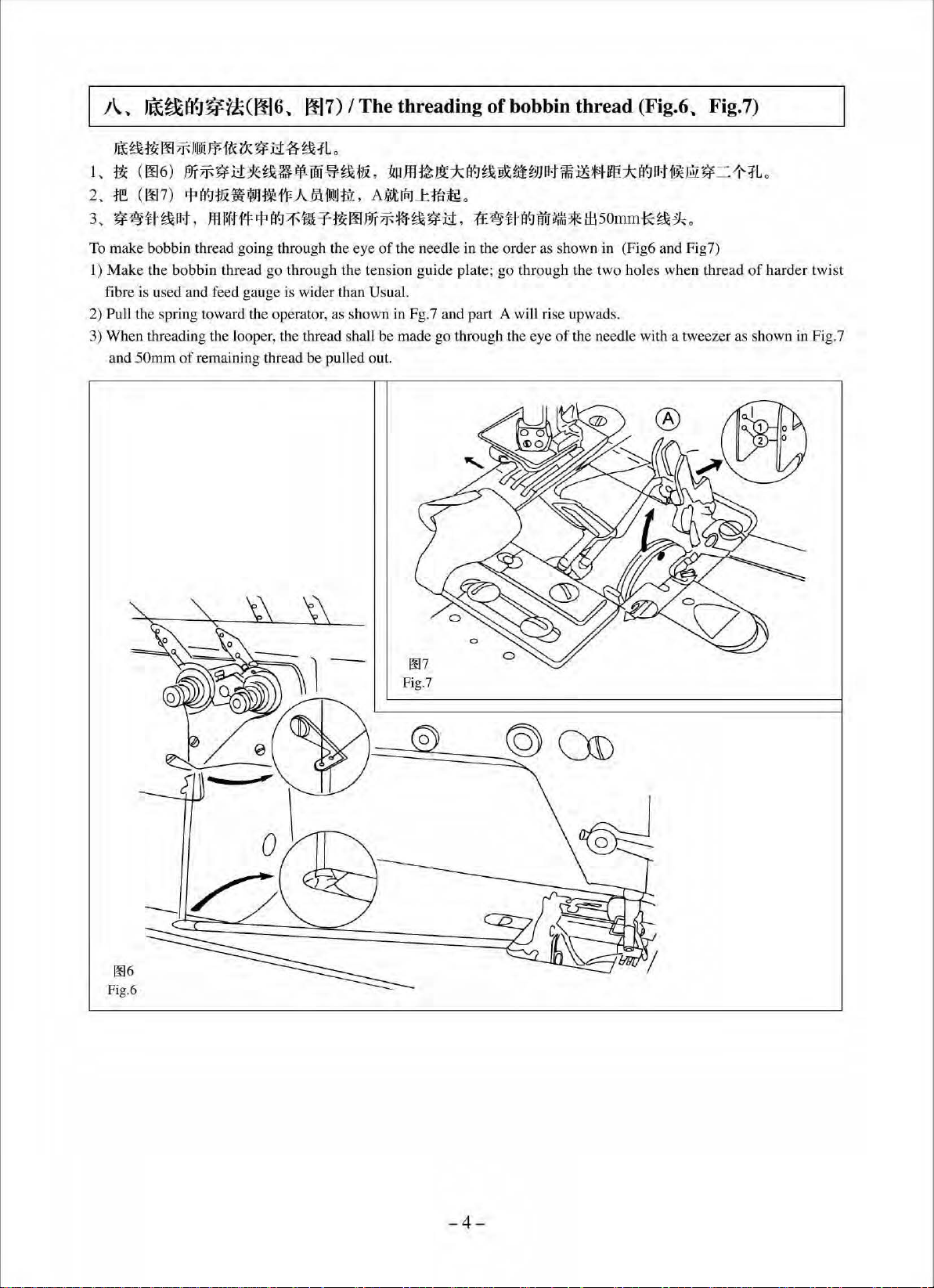

To

thread the eyes of the needles in the order as shown in Fig.

I) To make thread

2) To pull out 1

ni~·~flffl[l:f::llOOmm-!*~ik.

go

through the eye

OOmm

of

I The threading

.

of

the needle outwards. (View from the operator's side)

the remaining thread after needle thread going through the eyes

of

needle

thread.

S:

~~~~~ff~ff·~~M~~~-~

MflH

r!u

J~.

&z.

!J!IJM

!ift:k(i¥14)

a-t

W+#~

ank

,min .oil amo

• .

~M

·*~~

unt

will be suppli

oi

l amount will be supplie

-~~

ed

d.

(Fig.S)

of

the needles.

~~

of

the

when the

ms

Fig.5

- 3-

Page 11

J\.

~

fi.t~l'(.J~i!(006

~

007) I The threading

of

bobbin thread

(Fig.6~

Fig.7)

Ji.H!Ht<

I

.~(006)m7r-~:tt~~••oo~~~

2.

~e

3.

~~tt-~at,

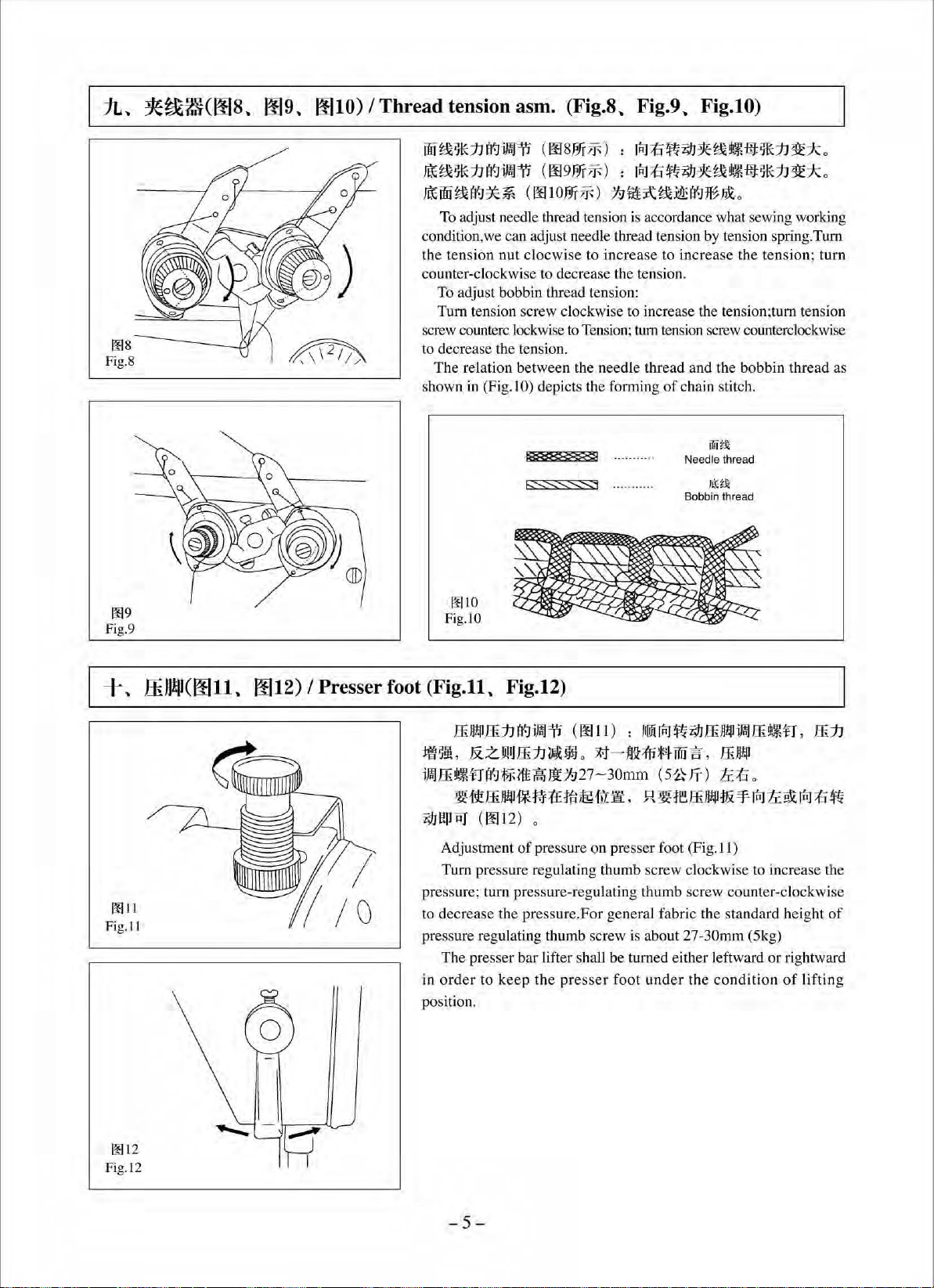

To make bobbin thread going through the eye

Make

I)

fibre is used and feed gau

2) Pull the spring towa

3) When threading the looper, the thread shall be made go through the eye

and

00

7f-

I1IDl

Fff"&

(X~

(

00

7)

r.p

~ ~&

.liYHlVd'F-

Jfll)f.tflj:r.j:I~/Fli-Tt?iOOJ-1JT

the bobbin thread go

rd

50mm

of

remaining thread

:i1

~~:fLo

.~m~~*~

A

1A

imtlm

, A

il.t ~ J:

iii

7f-

¥-f~~:tt.

of

the needle

thr

ough the tension guide plate;

ge

is wider than Us ual.

the operator, as shown in Fg.7 and part A will rise upwad

be

pulled o

ut.

lt9

~~-~

o

1:E~tl-

in

the ord

a~iW!tffil

er

as shown

go

through the two holes when thre

Mm

mMm*

=>IH

il50

of

the needle with a tweezer as shown in Fig_7

~MM@•=

mm*~#-

in

(Fig6 and Fig7)

s_

o

~R

ad

o

of har

der twist

-4-

Page 12

n~

~~~~(008~

008

Fig.&

009~

0010) I Thread tension asm.

(Fig.8~

ITif

g:

.B*

1J

l'f.J~

ag&*1JI¥J~~(0093f

a

oo

g&

ai:J

=rc ~ (

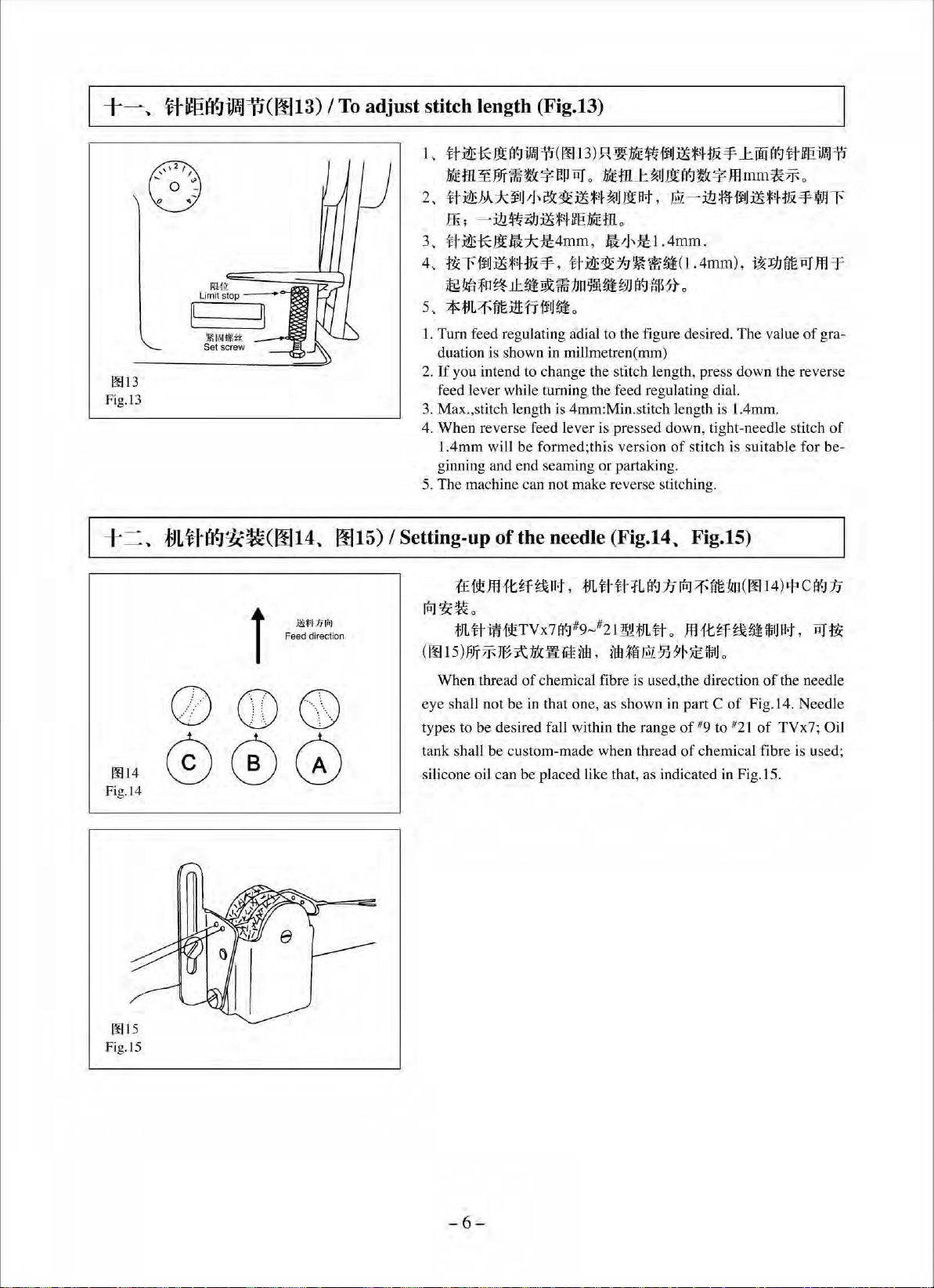

To adjust needle thread tension is accordance what sewi

condition,we can adjust needle thread tension by tension spring.

th

e tension

counte

r-

clockwise to decrease the tension.

To adjust bobbin thread tension:

Tum

tension screw clockwise to increase the tension;turn tension

screw counterc lock wise to Tension; tum tension screw counterclockwise

to

de

crease the tension.

The

relation between the needle thread and the bobbin thread as

shown

in

(Fig. I

(

00

8

3r

oo

1 o

1rr

nut

clocwise

O)

depicts the forming

7F) : rJiJ

7F): rJiJ

7ft )

to

Fig.9~

;(:]

tffl

;(:]ft

1:7

t4

j\;

g&

incr

ease

to increase the tension; turn

of

Fig.lO)

Z9J

*

g&

it'-

flt

~*

1J

1f

* o

Z9J

*M•~*:h1f*o

~

a~:J

*

nt

0

ng

working

Tum

chain stitch.

jTjjtl(

Needle thread

/If:~

Bobbin thread

009

Fig.9

+

~

ffiJJ!II(OOll.

0011

Fig.

II

0012) I Presser foot

1¥1

10

Fig.lO

(Fig.ll.

ffi

*~·

im!ffi!lt'-nfii:J;f'f><lf.ll

~~ffiJI!fJ§M~M~mft.

i;IJl'!PiiT ( 00

Adjustment

Tum

pressure; turn pressure-regulating thumb screw counter-clockwise

to decrease the pressure.For general fabric the standard height

pressure regulating thumb screw

The presser bar lifter shall be turned eith

in

order

position.

Fig.12)

J~

ffi

1J

a1:J

ifn]

i'J (

00

I I ) : )l

&Z~ffi:h-~o~-fi~MW~.

H£1:727-

12) o

of

pressure on presser foot (Fig. II)

pressure regulating thumb screw clockwise to increase the

to

keep

the

pres

ser

im

[Jij

~

i;IJ

ffi

Jl!fJ

~ ffi

!t'-

n , ffi

ffiJI!fJ

30mm

(

5~

JT)

ti.;(:]

0

R~WffiJI!flfi~~~~rJiJ;(:]ft

is

about 27-30mm (5kg)

er

leftward or rightward

foot

under

the

condition

of

lifting

1J

of

0012

Fig.l2

-5-

Page 13

+~~

1¥113

Fig. l3

-r

-

~

!ff~I

:

Ht{]WilCOOI3)

I

To

adjust stitch length (Fig.l3)

1 ,

tt~

•m~m••*•~·•m~•J3ti¥-1B*mmma~

2.

#~M*~'J'J'a~lti*I-~

lli

3,

#~¥:};{.ft:k~4mm

4,

~rfiiJJli~H~-¥.

,g

5,

**

I. Turn feed regulating adia l to the figure desired.

duation is shown

2.

If

you intend to change the stitch length, press down the reverse

feed lever while turning the feed regulating dial.

3.

Max.,stitch length is 4mm:Min.stitch length is l.4mm.

4.

Wh

1.4mm will be formed;this

ginning and end seaming

5.

The machine can not make reverse stitching.

f}L!ff(J{J~~(0014~

0015)

I Setting-up

*

J3t

1¥-1

oo

i1 (

;

-.ill~

#J

:ili*4

M:J

~n

~

_

u-J.ihx

JL::fnt

llH'Tfi

'J

in

en reverse feed l

of

the needle

oo

13)

.R

~

PJHHi

iJ

*

*4

f~

=¥-

1:

ffii

a%i· rm

_

~

.

J

/Jt

flit , mz-

.itl¥-ffj~**'-f~=¥-¥Al'

iE•tn .

,

IVJ,~I.4mm

#:i!Z£~79~*~(1.4mm),

1m

no

~liHi

&:9

J

(f.]

g-rs'lt

~.

millmetren(rnm)

ever

is pressed down, tight-needle stitch of

ver

sion

or

partaking.

(Fig.14~

.

i:r<~tm~J'!

•

The

value

of

stitch is suitable for be-

Fig.lS)

of

F

gra-

l'l

f

1¥1

14

Fig.l4

Feed direction

l

0®®

000

;(:£it

ffl

ft

~f

~at

,

*JL

ti-fi-:fL

rAJ~~.

*

JLth1HtTVx71'l'>J

(00

1

5)1ifrl'Ff~Jt.Jtx:]!fr£ftil

When thread

eye shall not be

types to

tank shall be custo m-made when thread

silicone oil can be placed like that, as indicated

be

desired fa

of

8

9

~82I~HJL#

'

chemical fibre is used,the direction

in

that one, as shown

ll

within the range

l'l''J

:17

lnJ

::f

fit

'!lo

(

.

JlHt~f~~iiJI

illl~L\!Z§J5'

~

)i::lli

l]

0

in

part C

of

8

of

of

8

9 to

21

chemical fibre is used;

in

Fig. IS.

00

14)

~

C

1'1''1

JJ

Jflit

,

~t:&:

of

the needle

Fig.14. Needle

of

TVx7 ; Oil

Fig.l5

-6-

Page 14

+ =

~

ffiJJ!Pf.lilll'miJJi1(0016) I Adjustment

of

the height

of

the presser bar: (Fig.16)

0016

Fig. l6

+lm~

~~...j-7f(t9iJW]l(0017.

0018)

~~-

00

17

Fig.17 A type B t

~

~

I

Adjustment

·:.

-

B'W

ype

~T-~ffi-~~~···

1,

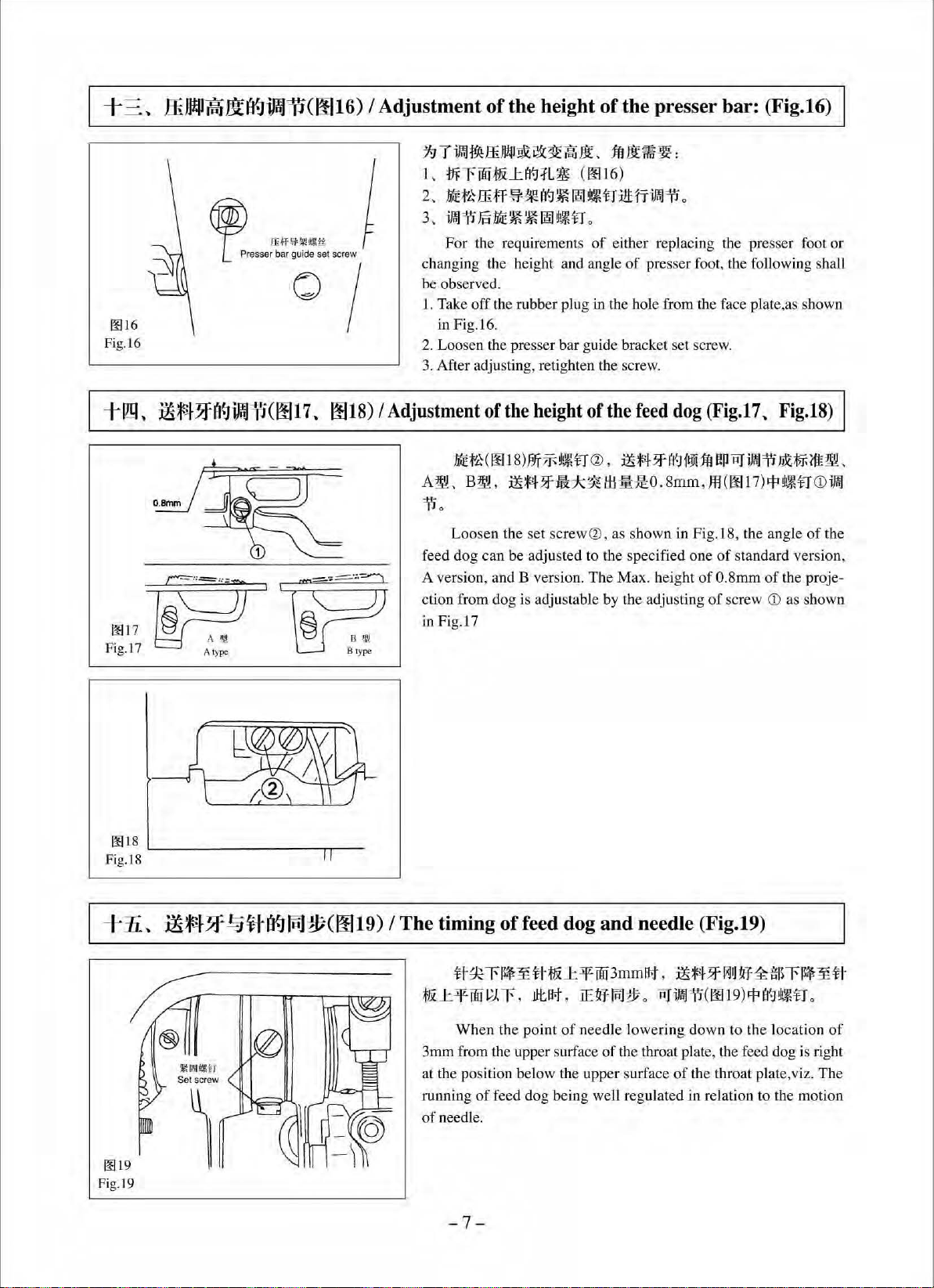

mrffii;f&J:a1:t

2,~~ffiff~~~~~~rt*fi~~

3.

ifol~m~~~ffiil~~n

For the requirements

th

changing

be

observed.

1. Take

in Fig.16.

2.

Loo

Af

3.

e height and angle

off

the rubber plug in the hole from the face plate ,as shown

sen the press

ter adjusting, retighten the screw.

of

MEt'~

(

00

A~.

B~ • .ili!¥47ffk*~'H

L

~

er

bar guide bracket set screw.

the

height

I8)P.Ji'7F~~rt

-~WW:

(OO

I6)

o

o

of

either replacing the presser foot or

of presser foot, the foll

of

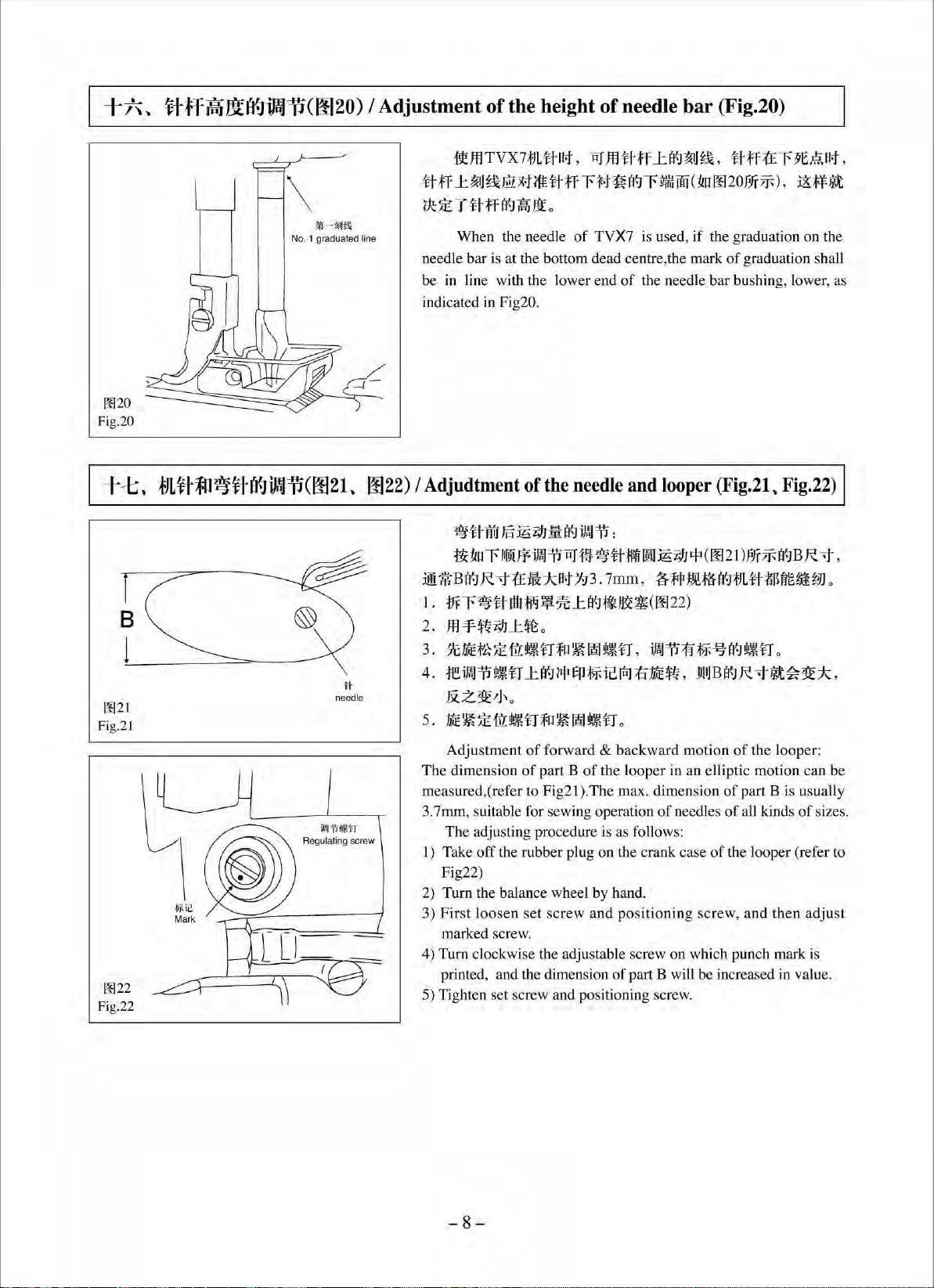

the

feed

dog

(Fig

CZl • .ili!¥4 ?fa1 ftJi

l

Lil:~0.8

1ft

I'.!

rnm,ffl(0017

i'io

Loosen

dog can be adjusted to the specified

feed

A version, and B versio

ction from

in Fig.

the set

screw

Q),

n.

The

do

g is adjustable by the adjusting

l7

as shown

Max. height

in

Fig.l8,

one

of

of

0.8mm

of

owing shall

.17.

Fig.18)

P

r.iJ

iml=il

JiX:$-Fl'ttm!L

)

rp~rtCDiml

the angle

standard versi

of the proje-

screw

(i)

of

the

on,

as shown

+

.Ii

~

00

19

Pig.l9

lli~-+~

~INIJI!'ff

Set

~ltl'l'!l15Jif;(0019)

scr

ew

I

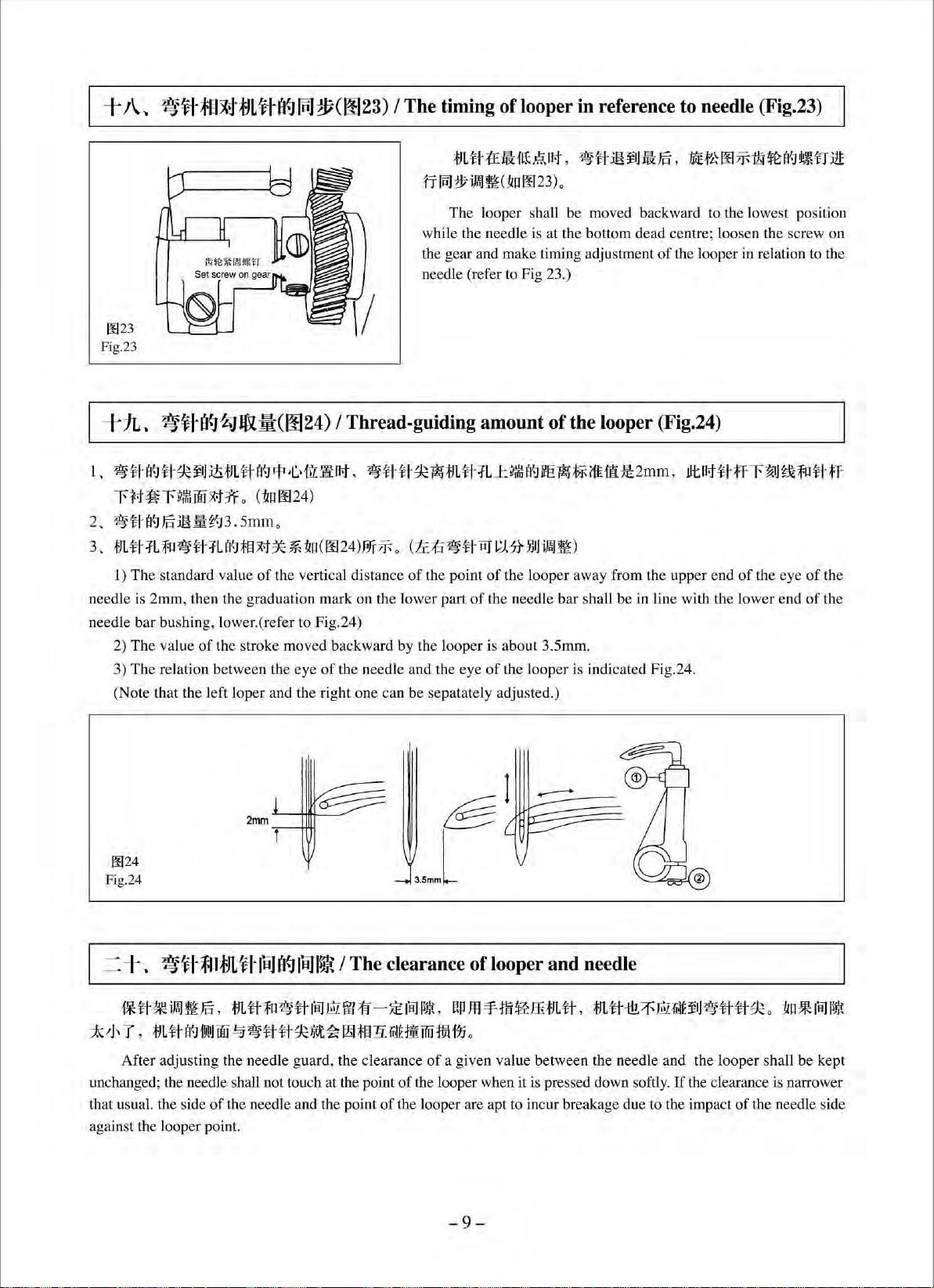

The

timing

·

t&

1:

if

3mm

at

the position bel

running

of

needle.

of

H~rlltf-~flt&J::ifffii3mm

w

t;J.

r ,

Wh

en the po

from the upper surface

of

feed d

feed

JJt

not

int

ow

og

dog

,

of need

the upp

being we

-7-

and

needle (Fig.19)

flit

,

iliff

IE~

1\lJ

t11

0

r.iJ

iffii

le l

owe

ring down to the l

of

the throat plate, the feed

er

surface

ll

regulated

of

?f~

IJ~

~ffl5rll$~-¥

11

(

oo

19)

rF

a'~

!1\.~U

ocation of

dog

is right

the thro

in

at

plate, viz.

relation to the motion

~

0

The

Page 15

-t

~\

~

**ff.liltD'>JiJJi1(0020) I Adjustment

of

the height

of

needle bar (Fig.20)

0020

Fig.20

-j---1::;.

~21

Fig.2l

0022

Fi

g.22

it!JflTVX71JLtf-Bt, ~ Jfl#ff

tt

ff

1:

~J

~fill

x.t

?1t

tt

tr

r

tk:

~

T -tl·ff

!i1-$<1

No

fJLftf;ll~ft(f.JiJW'PC0021.

Jt\l

. 1 graduated line

H

needle

0022)

I

needle bar is at the bottom dead centre,the mark

in

be

indicated

Adjudtment

>l};

11{

lin

1lt

B

I .

tlfT~Jtt-~rfll'iiii%J:ff.J~~~

2.

Jfl=f~i'JJJ:~

3.

%~~~~~fl~~~~fl.~11~~~ff.J~flo

4.ffi~l1-fll:ff.J~~~~~~-~.MBff.J,R.~U~~:k

JXZ~Ij'o

5.

-~~~t~nfn~~t~n

Adjustment

The

dimension

measur

3.7mm, suitable for sewing operation

The adjusting procedure is as follows:

1)

Take

Fig22)

2) Turn the balance wheel by hand.

3)

First loosen

marked screw.

4) Turn clockwise the adjustable screw on which punch mark is

printed, and the dimension

5) Tighten set screw and positioning sc rew.

ff.J

~

tft

o

When the needle

line with the lower end

in

Fig20.

of

-tl·

j'jiJ

!§

:iE

~n

r

''Pilr¥

A9

,R.

-t

tE

lil:kBt

of

of

ed,(

refer to

off

the rubber plug on the crank case

set screw a

of

the

needle

i;

b

iii

ff.J

~

ifnl

fi

PI

l~

1':1

o

forward

part B

of

Fig2l).The

J:ff.J~U~,

t-t

~

a9

r

~ffil

oo

(

~~~

TVX7 is used,

of

the needle bar bushing, lower, as

and

11

:

~ttwn

3 .

mn

7mm

, ~ #

0

& backward motion

the l

ooper

max. dimension

nd

positioning screw, a

of

part B will be increased

if

looper

:iEi;~i

!f1

~:Mi

(

0022)

in

an

of

needles

#ff1£r~.~ut,

oo

20

J1fr

:if\)

. ~

¥f

8,.t

the graduation on the

of

graduation shall

(Fig.21.

(

oo

21 )

A"J

fJL#

of

elliptic motion can

of

of all

of

the looper (refer to

Fig.22)

J1fr

:if\

ff.J

1-iB

fiMHJJ

the looper:

part

B is usually

kinds

nd

then

in

B R

-t

of

sizes.

adjust

value.

,

o

.

be

-8-

Page 16

i-

J\

0023

Fig.23

~

~fi·;f:H~f

fJLfti'J{J

lf.l1~(0023)

I

The

timing of looper

m#~•~~~. ~#m~aJE.•~m~cm~•nm

fff5J~imJ~(.t.IIJ0023)o

The looper shall be moved backward to the lowest position

while the need le is at the bottom dead centre; loosen the screw on

the gear and make timing adjustment

needle (refer to Fig 23.)

in

reference

to

needle (Fig.23)

of

the looper in relation to the

i-JL.

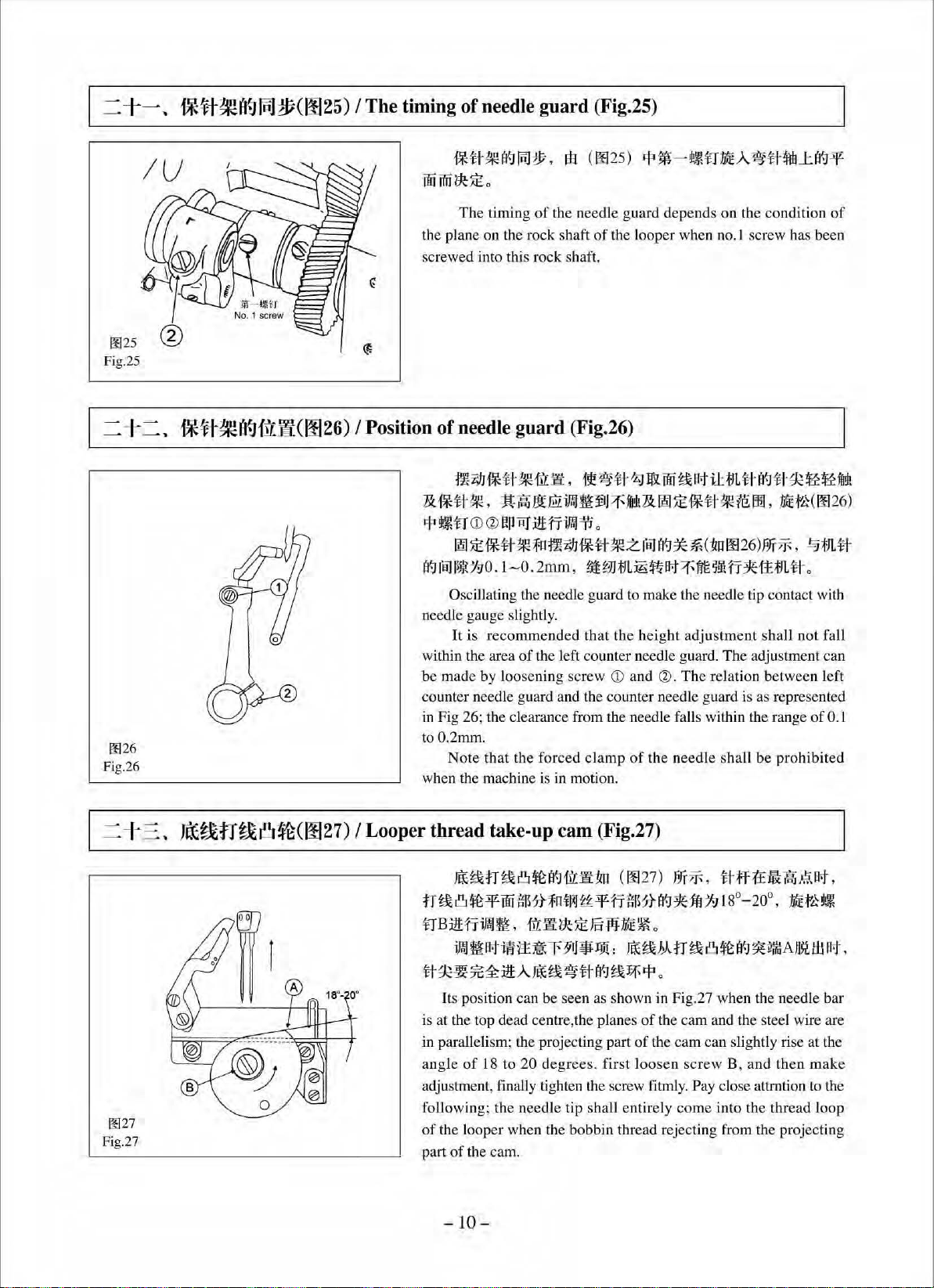

1.

~tta~uqc~IJit-tJL-tta~~

-rM-~r~lffiooM1f

2,

~ti"~JE

3, tJLtt:fL

1)

needle is 2mm, then the graduation mark on the lower part

needle bar bushing, lower.(ref

2)

3)

(Note that the left Ioper and the ri

0024

Fig.24

~fi-I¥J~~If(0024)

0 (

1.m0024

:itHII:r.J3.

fo

~~·1L~;f§M5c

The

standard value

The

value

The

relation between the eye

5mmo

of

the vertical distance

er

of

the stroke moved backward by the l

2mm

I Thread-guiding amount

.C

.'1!l::i!:A>t.

~tl·~-qc~m~-:fLJ:!Jffilfi::~ie~~i'f£it:ll2mm,

)

~

.t.to

(0024)W!"Jft

to Fig.24)

of

the needle and the eye

ght

one can be sepatately adjusted.)

o

(ti::tl~tl-

of

the point

ooper

of

the looper (Fig.24)

l'lJ

l;HHJIJimJ~

of

the looper away from the upper

of

the needle bar shall be

is about 3

of

the looper is indicated Fig.24.

)

.5mm

.

JltA>t

-tl·f-T-r~

end

of

the eye

in

line with the lower end

IJ

~fo~-.t:f

of

the

of

the

§t~-•~mJE,

*~T,mt~-~~w~~U#~a~~~~••ffiam

After adjusting the needle guard, the clearance

unchanged; the needle shall not touch at the point

that usual. the side

against the looper point.

mu~~t~-~@00~-~~•,

of

of

the needle and the point

of

the looper are apt to incur breakage due

~m¥m&ffim#,m#~~@·~~uuqco~•~•

o

of

a given value between the needle and the looper shall be kept

the looper when

it

is pressed down softly.

-9-

If

the clearance is narrower

to

the impact

of the needle side

Page 17

-

---t-

~, f*ft~B91iiJ~(0025)

I The timing

of

needle guard (Fig.25)

0025

Fig.25

=+=.

0026

Fig.26

f*ff·~l'f9{!L

it(0026)

/Position

i*tt~l'f.J[l'IJ~.

Ell

(0025)

r:p~-~~trmEA.~tt

!ftltl:fl~->f

ffi'iffiHJcJ:E.

The timing

the plane on the rock shaft

ewe

d into this rock shaft.

scr

of

needle guard(Fig.26)

•~•tt~m•.~-#~ailli~~~m~l'f.J#~&&M

2iH1!:tt~,

~

1,

u:n

CD~

11!1/E1*#~lt:Jm?9J1*fi

~~BJ~

J~Y!JO.l-0.2mm,

Oscillating the needle guard to make the needl

needle gauge s

It

is

recommended

within the area

be made by loosening screw

counter needle guard and the counter needle guard is as represented

in

Fig 26; the clearance from the needle falls within the range

to 0

.2mm.

Not

e t

when the machine is

of

the needle guard

of

the looper when no. I scr

~f.JJJJtfi!ZiffiJ~¥1

an

PI

Jn:

rrifn!Ti.

li

ghtly.

of

the left counter needle guard. The adjustment can

hat

the forced cl

in

J~.M

-

~Z.Iilll'f.J:}C~(:!m0026),P)f;if-,

~~:JJtJLi!i~IJot7f-~~Mff:9E1:HJLfi

that the height a

G) and

amp

motio

n.

dep

end s on the condition

&rnii5Ei*#~ffiEm,

e tip contact with

djustment

~.

The relat ion between left

of the needle shall be prohibit

ew

has been

mff'.{(0026

5JtJ

-

.

shall

not

of

of

)

L#

fall

0.1

ed

=-t-

:::::

.

J(E~fr~8~(0027)

I Looper thread take-up cam (Fig.27)

$;;

~

:J:T

~

8 ~

l'f.J

t'r:JI'J

tH~8~->JZWffiHtwmii->JZrrif~

trB*fi

ifnl~. ttm~!E

~-~~~-~~-~:

0027

Fig.27

tt~~~~

Its position can be seen as shown in Fig.27 when the needle

is at the top dead centre,the planes

ar

in p

ang

le

adjustment, finally tighten the scr

following; the nee

of

the looper when the bobbin thread rejecti ng from the projecting

of

part

*A.f

ij;~-#

allelism; the projecting part

of

18 to

20 degrees.

dle

tip shall entirely come into the thread l

the cam.

-10-

lll (

00

2

7)

lfr

jf-,

tHf

1£

-Ill

f.JJ

;!;i: ~ ,

7

tl'f.J:9EJHY!7

~w••·

t8°-

20°,

mff'.{t~

$;;~Mfi~8~1'f.J~-A~ill~,

B'-J

~J;:f\

9='

.

bar

of

the cam and the steel wire are

of

the cam can slightly rise at the

first l

oosen

screw

B,

and then

ew

fitrnly. Pay close attrntion to the

make

oop

Page 18

- -tn_

~

n.

:hll-~1';.£r:~-m.~m-+•~-~-~;;'*{~

11C~'f

I

~~

IJPJ

1117--"'P'J

~w

c~mzs)

M...EI..

13:

I

The

1

of

the

position

thread

of

the

take-up

tbread-am?unt

lever (Fig.28)

adjusting

plate

0028

Fig.28

~

-t1i.

t=f:tliiJ

~~:#;J(f!l29)

I Frame thread eyelet (Fig.29)

tt-fft£/!fij;,.:.\01",

ttW~.~#~-W~M.

~*

·

~fft£&~~~.~~~-oo~~~~~m.

«Rm•&~amM.

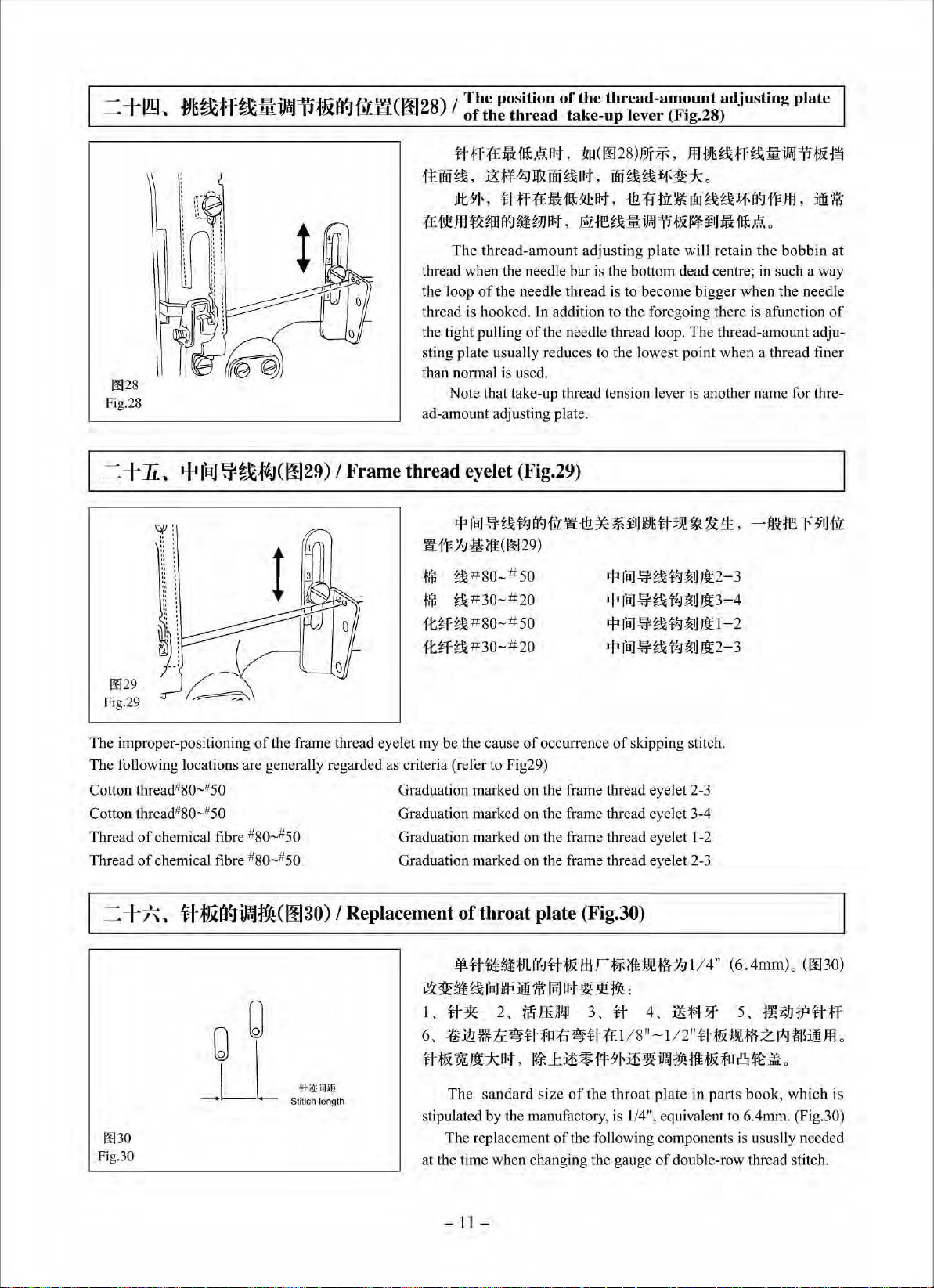

The thread-amount

thread when the needle bar is the bottom dead centre; in such a way

the loop

thread is hooked.

the tight pulling

sting plate usually reduce s to the lowest point when

than normal is used.

ad-amount adjusting plate.

m:

fill

tt

1-tJf~#80-

1{.;-f~#30-#20

of

the needle thread is to become bigger when the needle

of

Note

that take-up thread tension lever

1ft

fal

~~¥!1EI'.J{

1'F:Y9

~lft(0029)

~#80-#50

~#30-#20

#

50

~o(002

8),1Jr~.

00~~~~*0

Jfl1j~~ff~itiAI'TH.!it§

a~

~re~•~~-~~-~4

adjusting plate will retain the bobbin

In

addition to the foregoing there is afunction

the needle thread loop. The t!U'ead-amount adju-

is

another name for thre-

l'

tJ'f-tl!**~'Jll;j~tf-:EW.ftt~~.

~~=t

J

al~~~~'Jlt2-3

1ft

i

hT'il'~~~Jlt3

1ft

l

ill.'i)<~iiJ~

rp

IBJ.'i)<

J.rlt

1-2

~iiJ~Jll2-

o

a thread fin

-

M:reBIJ.fft

-

4

3

at

of

er

0029

Fig.29

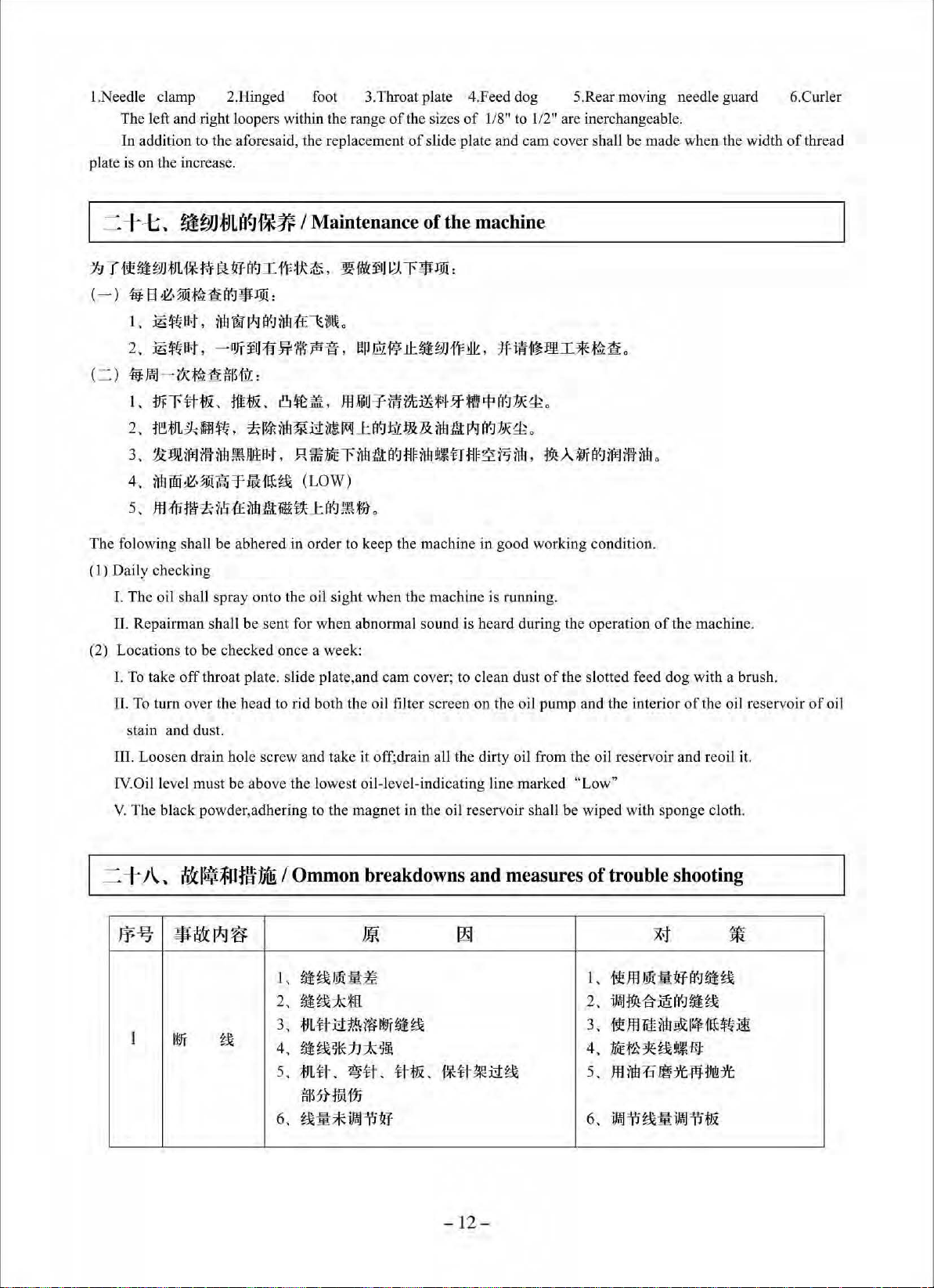

The improper-positioning

The following locations are generally regarded as criteria (refer to Fig29)

Cotton

Cotton thread#8Q-#

Thread

Thread

-

-t

0030

Fig.30

thread#

8Q---#5Q

of

chemical fibre #

of

chemical fibre #

,\,

t

l·:fit'f.J~~(f!l30)

5Q

of

the frame thread eyelet my be the cause

Graduation marked on the frame thread eyelet

Graduation marked on the frame thread eyelet 3-4

8080-

#50

#50

I Replacement

Graduation marked on the

Graduation marked on the frame thread eyelet 2-3

of

lft-tt-~~tJ

&~~.~lal~r:!lB!'~II'IJM!fiJ!~:

1.

tt-:'.IE

6,

Off

:iti

tt-fi m !Jt*

#~liill'f!

Stitich length

The sandard size

stipulated by the manufactory, is

The replacement of the fo

at the time when changing the gauge

of

throat plate (Fig.30)

La'.J

2.

tt.ffin~

fi

ft

Vf

t

~

Hot

,

r¥f-

occurrence

of

skipping stitch.

2-3

frame

thread eyelet 1-2

tUJi:±l

/:f>"FiftJ!i'.~:YiJl/

3.

# 4,

'_fll

:tJ

~tj-1:£

1:~ ~ f45'~:ili

of

l/

8

II

-1/2

!fi

V~H!MiHli

the throat plate

1/4", equivalent to 6.4mm. (Fig.30)

ll

owing components is ususlly needed

of

4" (6. 4mm)o (0030)

ili~Hf

II

tf-

in

double-row thread stitch.

s.

~i;IJ:fll#tr

fi

~

Ji!.~

Z

I*J

ljj):@}ij o

;fo

8 ~

iT£

o

parts book, which is

-11-

Page 19

l.Needle clamp 2.Hinged foot 3.Throat plate 4.Feed dog 5.Rear moving needle guard

The left and right loopers within the range

In addition to

plate is on the increase.

=

+-t:;.

~T~•mm•M~~~I~~~.WR~~~-~:

(-)

~B~·®l~~a"J¥J1if:

1.

:iE

the

aforesaid, the replacement

~~fJLB9f*ff

~~at

,

itl1

wr

rJg

I Maintenance of the machine

a'-1

nil

f£~ ~.

of

the sizes

of

slide plate and

of

1/8" to 1/2" are inerchangeable .

cam

cover shall be

made

when

the

width

6.Curler

of

thread

2.:iE~at.

(= )

~Jffj-{j(;f.~§$11l:

1.

m~~•.m•.

2.

mm~~-.

3.

~~~mMm•at.

4.

itllrm~·%i~rnlftt~

5 •

!lH

The

folowing shall

(I)

Daily

checking

f.

The oil shall spray onto the oil

U. Repairman shall be

(2) Locations to be checked once a week:

1.

To take

II. To turn over the head to rid both the oil filter screen on the o

stain and dust.

lll. Loosen

IV.Oil level must be

-

~~~~m~~. ~~w~•m~~. *••~I*~•

8~~.

~~M•M•~~a"J~a&itlla~a"J~~.

R••~itlla~mitll•nm~Ritll.•A~af.J~mitll

(LOW)

IH~~

i~

.:(£

itl1

a

fttH~

~

be

abhered in order to keep the machine in good working condition.

sent

for when

off

throat plate. slide plate,and

drain hole screw and

above

the lowest oil-level-indicating line mark

m~~•~mM~~~~~~.

a'-1

J\U5t

•

sight

when the machine is running .

abnormal sound is beard during the operation

cam

cover; to clean dust

tak

e it off;drain all the dirty

.

.

of

the

machine.

of

the slotted feed

il

pump and the interior

oil

from the oil reservoir and reoil it.

ed

"Low"

dog

with a brush.

of

the oil reservoir

of oil

V. The black powder,adhering to the magnet in the oil reservoir

~

+A.

FF-5

I

t&~Jiif;Utff1/t§

-~1"1~

~

tl

I

Ommon

breakdowns

)]{

I,

-~Jm:ji~

2,

-~::k.m

3,

fJL.ftM~iWitlf·~

4,

•tl*:h::k5!11

5,

,j:JL.ft.

$7t1J.

6,

~if-*iJW'n~

~#.

JHjj

#fli.

and

ffil

t~#~M~

-12-

sha

ll

be

wiped with sponge cloth.

measures of

I.

2,

3,

4.

5,

6,

trouble

~Jfl

ifn]~-€J:@:af.J·~

1:!1!

11iif'~~tlt~-ffJ:

ffl

i!Wi'i

shooting

X1

mi:il:~i't'>J·~

JfJ

1if

itl1

!!X:

ilH

1:i'

~

ft

~:ltl:

iffiJ

Wi

I~~~~

-

PHII/t7't

i'if&

Page 20

2

~t

~

ffij~Jmi#

I '

2.

~~liJEtl·

3,

1!1! m 1-t

J-f ~

4 •

1\f

m

~

!lXJf

o-t

l'l/;j

~~Eft

~~Bot

a{]

HJ6

t t

1,

if.l

~~H

2,

iJiiJ

~

3,

i

mltl:fJ

4,

tLH.Qi~

lffili'J

5,

iml

~

6,

~

1!E

7,

~1f-f*H~~fl!J!l!llmiV

~~IEr!ff!

8,

~:m:~~~~~

I,

;}t(J:~iii~liJ~#I,

2,

~1tti(E~

3,

Wifi&~5!ii~~~~~:n

4,

l&

1!1!

)fJ

1'

2,

llitfli~il

3,

1t

ffl1-t~f~

I ,

fl$f!i~il

2,

1tffliE

~lf5l

:li

'4f

f;f· !§

;fJL

tt

a~

fa]

~t

LH I

WhJ#i'f/;j

~a~

·

lmiV

rw

m:irn~ ~:it

;f}i

1ft

I

RJ

J.'lf

~

ti:J

~

ffi:

1l

;fJLtt'!i: ~ J!:

~

lE

T6H

:iEliffl

2~lt

8 $M%'0 ~

1tt~.iH~~f~

iE

ilH

;ll-N

IE

Ttfil

ffl

AI.J~1Lft

iili

5

3

4

~~~~

Wf

~

~

#

~

1 '

iii

~~g~jJ

:k$

2,

/i£g&5*:h

3,

!i~:k

4,

9='

5,

ffis

6,

#t&

1,

YL#>hJ

2,

lZi

3,

ffi

4,

-f*#~

5'

iii~'HE1JJ:J:5lii

6,

:tJLttJ.cm

l,

~~H~1J:i:J:5!ii

2,

~ ~

3 , ~ J:J:

4,

ffi~l

::l.c$

m

ftij

-'iHJW~

g&

:ff~Jiim!

*4

;fll;fJL

!W

~

:fr~8$~~[ff]

~iHb't

ffi1J

~

ft

~

'!i:

~

1f I

:fl

iEJ*M

115

:k

5!ii

ffi:

tl

~~IE

if~

1!l'1t

[tiJ

!V

EJ

1m

tlf

Jj(

1J

I

EJ

fW

1iffJ

~

lETifA

I,

ME~

1if

~~H~

2,

1tt~

~~

3,

lffil~:k

-15-

4,

iml

~

1ft

5,

iJiiJ

~

~ii.

6,

1!1!m#:rL

I ,

iffll~,fJL

-

H

2,

if.)

~

f

iJ

3,

ffi

n~?L

tJL#

9='

·C.·~-3&

4,

l&

1!t

f*#

5,

J.&:f'~

WI

~'HE

6,

1!1!

Jfl15-

:iW:

L

ll>tft£~~'*1J

~JHY.

H~::h

2,

ill

fiif~"TJ

3 ,

T!lf

~

~J:J:

4,

mEt~ifnlffit~n

~~

-et

~~

9\.~ffl:

;fJL

tt

I

RJ

Ji'f-

~ ~

j!J/;j

11L

'i!l

iJ3Ji11tH~

:k~trtoc

FnJ

ill

tJ·tocfLa~

.

~

1

¥-H

ffi:

rp;t:.

!L ~ ;fll

:'lt

1J

~

fJL

tt

~J}Ij~}ij;

,

,

ft

;f!:

lllJ

~

~;lHfi

Wt

•13

lffJ

:!9

-13-

Page 21

No.

Break own

Cause

Measures to be taken

2

Therad

br

ea

kage

Skipping

stitch

I Poor thread quality

2 Thread being too

3 Fusing thread due to high

at

temper

caused by machin

operation at high speed

4 Tension being too

Br

5

lo

needle gua

location

6 Failure to adjust thread

amount

!.Skipping stitch

thread (leaking

due to the loopers

hook the

ure

eakage

oper, throat plate, and

of

need1

thi

ck

of

needle

es

hi

gher

of

needle,

rd

at the

thread guide

of

needle

of

two stitches

fa

ilure to

e thread)

1.

Quality thread to be used.

2. Rep

lacement t.o be made

3.

Silicone oil to be used a

4. The tension nut to be loosen

5.

Fir

st grinding with oil stone and then polishing

6. Adjusting the thread amount adjusting plate

1.

Adjusting thread-hooking amount

2.

Adjusting clearance

3.

The

timing

of

needle

4. Adjusting the thread -amount adjusting

thr

ead

amount changing conditions.

5. Adjusting the frame thread eye let.

6.

Checking whether the mounting positon

needle is proper

7.

To

see if the locatio n

appropriate way and

regulated in relation to another.

8.

To see

way.

or

not.

if the needle thread threading is

by

an appropriate thread

nd

speed to be reduced

ed

of

bet

ween looper and needle.

in

reference to looper.

of

needle guard is

the timing

of

it is we U

looper.

pl

ate on

of

in

in

a proper

the

an

1) Reference to the above cases I and 2, as to skipping

stitch

of

2. skipping stitch

thread (leaking

needle failure to ent

looper eyelet)

Skipping stitch when thread

3.

of

chemical fribre being

4.Skipping stitch when thread

of

polyester fibre being in use

1. Needle thread tension being

too low.

2.

Bobb

in thread tension being

too low

Sewing thread being too

Twist

3

ed

stitches

3.

thi

ck

4. Improp

S.lmproper

6. Throat plate

er position

frame thread eyelt.

take-up tension plate

of

of

one stitch,

position

bobbin

er

the

in

of

the

of

thread

2) To see

we

3) Increasing tension

4) To see if the threading

correct way.

1)

Using sillicone oil

2) Reducing speed

use

3)

Using needle for threead

I Reducing speed

2 Silicone oil to be used

l. Tightening tension nut

2. Tightening tension nut

3.

Needle of large size to be used.

4. Read

5. Readjusting its position

6.

the eyelet

than norma l on

if

ll

reulated.

ju

sting

the needle

th

e timing

of

of

the needle thread.

of

bobbin thread cam has been

of

bobbin thread a bit highe

of

bobbin thread is

of

chemical fibre.

of

needle thread.

of

bobbin thread.

it

to a proper position.

in

an appropriate way.

throat plate to be used be

e.

r.

in

a

ing bigger

-14-

Page 22

Breakage

4

n

ee

dle

5 Puckering

I) Needle being bent.

2) The op

3) Setting-up

of

4) The problem

5) Needle thread tension being 6) Appropriate nee

6) Need le being too thi

L

2

3 The problem

4 The force on the presser

er

ation

of

feed d

og

being n

ot

well regulated in 1) Needle to

reference to the motion

needle.

of

the presser 3) To make both the centre

foot foot and the

of

the timing 4) The positioning & the timing

of

needle guard remainin g be taken into account.

un

solved 5) Relaxing needle thread

too high.

Thr

ead tension being too

high.

The problem

of

the bobbin thread cam

for thread guiding failing

to be solved.

finish arising from bobbin

thread going through the

parts on

foot being too great.

of

of

th

e thread guide.

of

ck

.

the timing

surface

2) Readjusting the timing to feed

needle.

l . Decreas

thread.

2.

Readjosting of the very cam sa

problem.

3. Surface finishing all the parts on

4. Thming

screw.

be rep

laced by another

of

ce

ntre of the eyel

dl

e to be used.

in

g thread tension, esp. tension

co

unter-clockwise the pressure-regulating

of

proper size.

dog

in res

the hole

of

the presser

et

of

the throat.

of

the needle gua

id

to solve the timing

th

e thread guide.

pect to the

of

bobbin

rd

to

-15-

Page 23

-th-

Page 24

*14~-JVI-

PARTS

BOOK

-17-

Page 25

42

8

6

41

'i

~

:

~

~

0

I

Q

0 0

40

4

--

@

®

~

0

0

0

0

Q

0

;3

3

\

40

-fJJj)/45

@{

@!;ji

~9

~~36

2

37

46

-18-

-

47

Page 26

1,

m-x'l}!liflf:

Arm bed components

%

~

Ref. No.

2

3

4

5

6

7

8

9

10

ll

12

13

14

15

16 GW288

17 GSOI28

18

19 GM242/9

20

21

22

23

24

25

26

27 GM245

28

29 GS045

30

31

32

33

34

35

36

37

38

39

40 GRI461

41

42

43

44

45

46

47

48 GSOI48

14

Part

GQ202/l3

GS0127

GRI823

GKI86

GRI812

GSIOO

GR1757/2

GRI758

GSIOO

GR1458

GRI813

GW287

GRJ814

GS069

GM241

GS012

GM243

GW289

GW290

GS045

GR1815

GS0129

GM244/6

GW291

GRI816

GSOJ29

GW292

GSOIO

GRI817

OS44

GRJ818

GSOIO

GRI819

OSOIO

GRI462

GR1463

GRI464

GRI465

GRI466

GRL916/5

GRI923

"5

No

15

~JL

:J'G

{f!Sftj:

ffii

J(El}i5(:7l(t'-H

J(EtJi:Xll(~

Jr.i

'@"

;fJi

Jr.iiHli~

lr.i

-oo-

t1i

~~

n

iii

l1i

{fl5

flj:

iii1'&'re:

ffr

;fJi

~~

tr

iii

l1i

iJWiHK{1L~

8~~ffi~

8~~ffiti~lJ1~

8~~ffil&~lJ1id~

8~_f:i[ffi~~t~n

~fHlf!J.(

~ ~

~ft

14

'!i

~

~

'¥(!

ff

~ft14!J.(

llff

8~i:Ji1i!Wt-

8~i:Ji

8~i:fif-c~

8$~_f:i['¥(!~

8~

8~1ir~~

8~_f:i[~~l'-H

1lH&ifBf~

~

l1i

~f!i

~

~~

n

14

!fi

~

~

:iE

1ll:

t"

n Screw

~sf!i~t~«n

:

tiU!i

#U!i

~

tftl&fi~'-tJ

tt*li-'il'~

#ft&~~~"n

ffU!iliJl~

tftllifiJl~!lt'-H

tftl&fH~-'F

tiU!i~:te-'F!Iti«H

-ll£*4

41il

r~~

1§

ill!

fli

J(E;ffi

rJ'I

ill!~

t'-

n

1a3ftHnm=~

m:lli

4:1b~

J:~b~

HHIHrtf~!lt'-t

~*'1-tt-il!ir.J:P~HL~

ta?f41il:tL~

r!Hbi~HL~

~ill

-lf:itl~~#c

~~imlli

t3

ill!~

!It'-

:iE

111:

t«

tL~

ill!

~tL~

L

r.J

fflHlf(l

I 4

n

~

11

)

"ffi:it13!lt'-tr

Description

Arm

bed complete

Bed screw stud

Bed support

Side plate

Gasket

Side plate screw

Face plate asm.

Face plate gasket

Screw

Rubber

Cam cover latch

Spring

Spring suspension

Screw

Attachment installing plate

Spring

Screw

Cam cover asm

Cam cover

Cam cover

Spring

Screw

Cam

Screw

Bed slide asm.

Bed

Spring

Screw

Bed

Screw

Bed

Screw

Latch

Screw

Bed

Screw

Bed oil shield

Screw

Rubber plug

Rubber plug

Rubber plug

Rubber plug

Rubber plug

Rubber plug

Folder

Gasket

Screw

plug

cover guide

slide

slide guide

slide lo

ck

oil shield

-19-

spring

1J!

~

--

Amt. Req .

t

2

l

I

8

I

3

2

I

l

L

2

1

(1)

L

4

1

I

(1)

I

l

2

I

2

2

I

2

4

2

1

I

1

L

l

2

Page 27

1s

15

1 13

14 "'\

@:D

26 25

/_

'

1

4

8 3

24

~~

2

\ I I

~--{j

39<::

38

27

29

---a

31

- 20 -

Page 28

2

..

1:

4111tt

ff7tm

14:

Main shaft & needle bar components

pt;

%

Ref. No.

2 OP132

3

4

5

6

7

8

9

10 OS05

II

12 OS04

13

14

15

16 OR1471

17

18 OS06

19

20

21

22

23

24 OH334

25

26

27

28 GS012

29 OR1479

30

3 1 OR1478-7

32

33

34

35

36 OS0130

37

38

39 OS766

ftj:

Part

OS02

OS03

OR!468

OZ303

00262/2

ORI824

OS33

00265-1

00303

OR1470

OX334

G0269

OH378

ORI472

OS07

OH379

OS48

OS041

00270

OS09

00271

00288

OS011

OU168-7

OZ304

OR

OV18

OR0341-7

No

I826

~

/2

/2

D

esc

~

1:

l:~

J:.~!l\.~tr

411!

'tr;

lfF

1::

t~n

J:J'dlMn

l:!AA

l:

~b

115"$1h

¥ -

lflWf:

l:41b:f'-='lml

J::$i

k

~~~~t~rr

J:.

411!

'P

411!

~{f

1H4-

~r~~t~rr

1:~mr~~mw~

!M~t~n

Jib

flJi

Mllll~

ftirJ

t9:

Jli1

;t-Wnb

it

~i'Hi1

!lb

;fW

M

ii:iJW'TH1~~

l1tl

;flJi

ni:J

:itiJW'THiW%

1m

#ff!lb:wi

t

~ffllb:wi

~

ffi:

t

~ffilil:wi~IIID~~

tt·ff~ff~

YHi

~ls¥&dliM~~tr

t

~ff~:f

#ff~ffm-ttlilllfx

tt· ff

~H-J::tt~

#ff

#ff

4tffrtt~

#ff~f*tt

#ff~f*ttl!(.;tr

t

~ff~f*ttffl-~

~ffi:~~tr

~~

tr

OJ~

I!!

rr

11tl1Vi

~

ffi:

~'-

tr

T

:iiff

ti:.Mi

~'-tf

1:

tt~t~n

l:t-J-~1L~

#ff

**

(114")

st#!l\.~tr

tJL#

t

~

fff*

::k

;1ft

tk-'il'tll.

m~~$Jtt~n

ription

End

screw

Hand wheel

Screw

Oil seal

Main shaft

Ma.in

shaft bush.ing,rear

Main shaft thrust collar

Screw

Main shaft bushing intermediate

Screw

Main shaft bushing,front

Scr

ew

Roller felt

Crank o

Rubber bushing

0-Rubber

COLmterweight as

Scr

ew

0-Rubb

Screw

Needle crank

Screw

Screw

Ne

edle bar crank rod

Needle roller bearing

Left

twi

Needle bar bushing upper

Screw

Rubber plug

Needle bar bushing, lower

Needle bar cormection asm

Screw

Crank slide block

Needle bar

Needle clamp( l/4

Scr

ew

Needle

Slide bleak bushing

Screw

il

adjusting pin

ring

er ring

st screw

m.

11

!I!

fl

--

Amt.

)

Req.

2

I

2

4

I

2

2

2

I

2

-21-

Page 29

10

34--~

36

@(

- 22 -

Page 30

3

..

ffi

~-+7tffi.

1lf

Presser bar components

%

ff

Ref.

No. Part

2

3

4

5

6 GR1827

7 GSOJ9

8

9 GR1525

10

11

12

13

14

15

16

17

18 GR1501/2

19

20 GR1504

21

22

23

24

25

26

27

28 GRL834

29

30

31

32

33

34

35

36

flj:

%

No

GS018

GLI8

GR1494

GW253

GZ305

G0273

GM246

GS020

GR1832

GRl833

GSOI29