Page 1

Page 2

- 1 -

Warning

against injuries and

material damages:

According to legislation, you as the user of an

electrical appliance are responsible for preventing

possible accidents through safety-conscious

behaviour:

• Keep your work space tidy. An untidy workplace

can lead to accidents.

• Provide adequate lighting when working!

• Do not wear loose clothing or jewellery, as these

can be caught in the moving parts. You should also

wear a hair net if you have long hair.

• Avoid abnormal posture. Remain steady and in a

well-balanced position at all times.

• Be alert! Pay attention to what you are doing.

Always take a rational approach to your work.

Never work with the sewing machine if you are

unable to concentrate or if you are feeling unwell!

If accidents occur as a result of handling the

machine with insufficient care, or failure to follow the

safety instructions in this manual, then the

manufacturer cannot accept liability.

Please use for your sewing machine the ZHEJIANG

FOUNDER presser foot, type FC-

9001.

Protection Class: II.

The sound pressure level under normal operating

conditions is 78dB (A).

If the supply cord that fixed with foot controller is

damaged, it must be replaced by the manufacturer

or its service agent or a similar qualified person in

order to avoid a hazard.

Do not dispose of electrical appliances as unsorted

municipal waste, use separate collection facilities.

Contact your local government for information

regarding the collection systems available.

If electrical appliances are disposed of in landfills or

dumps, hazardous substances can leak into the

groundwater and get into the food chain, damaging

your health and well-being.

When replacing old appliances with new once,

the retailer is legally obligated to take back

your old appliance for disposal at least for

free of charge.

Page 3

- 2 -

CONTENTS

Principal parts of the machine .............................................................................................................................3

Accessories ......................................................................................................................................................... 4

Power, switch ...................................................................................................................................................... 5

Removing extension table ................................................................................................................................... 5

Accessory box ..................................................................................................................................................... 5

Levelling the machine.......................................................................................................................................... 6

Replacing needle................................................................................................................................................. 6

How to remove and attach the shank.................................................................................................................. 7

Replacing presser foot ........................................................................................................................................ 7

Winding the bobbin........................................................................................................................................... 8-9

Inserting and remove the bobbin................................................................................................................... 10-11

Threading upper thread ...................................................................................................................................... 12

Automatic needle threader ................................................................................................................................. 13

Drawing up bobbin thread .................................................................................................................................. 14

Adjusting thread tension ..................................................................................................................................... 15

Bobbin thread adjustment ..................................................................................................................................16

Adjusting tension for zigzag and embroidery ..................................................................................................... 16

Fabric -Thread - Needle - Table ......................................................................................................................... 17

Sewing (pattern selector) and operation table .............................................................................................. 18-20

Operation buttons ............................................................................................................................................... 21

Reverse button ................................................................................................................................................... 22

Pattern operation instruction ..............................................................................................................................22

Twin needle operation instruction....................................................................................................................... 22

Zigzag non-section operation instruction ........................................................................................................... 23

Stitch length non-section operation instruction .................................................................................................. 24

Display the zigzag width operation instruction ................................................................................................... 25

Display the stitch length operation instruction.................................................................................................... 25

Start to sewing.................................................................................................................................................... 26

Error correction................................................................................................................................................... 26

Straight stitches .................................................................................................................................................. 27

Zig-zag stitch ...................................................................................................................................................... 27

Free arm sewing................................................................................................................................................. 27

Seam finishing .................................................................................................................................................... 27

Transfer sewing direction ................................................................................................................................... 28

Stitch balance dial .............................................................................................................................................. 28

Overcasting sewing ............................................................................................................................................ 29

Straight stretch stitch .......................................................................................................................................... 29

Three step zig-zag stitch .................................................................................................................................... 29

Blind stitch ...........................................................................................................................................................30

Buttonhole sewing ...............................................................................................................................................31

Zipper sewing ......................................................................................................................................................32

Hemming .............................................................................................................................................................33

Quilter guide ........................................................................................................................................................33

Button sewing ......................................................................................................................................................33

Cleaning and oiling ..............................................................................................................................................34

Oil inside of the face cover..................................................................................................................................35

Removing and replacing the bulb........................................................................................................................35

Fault finding chart ...........................................................................................................................................36-37

Page 4

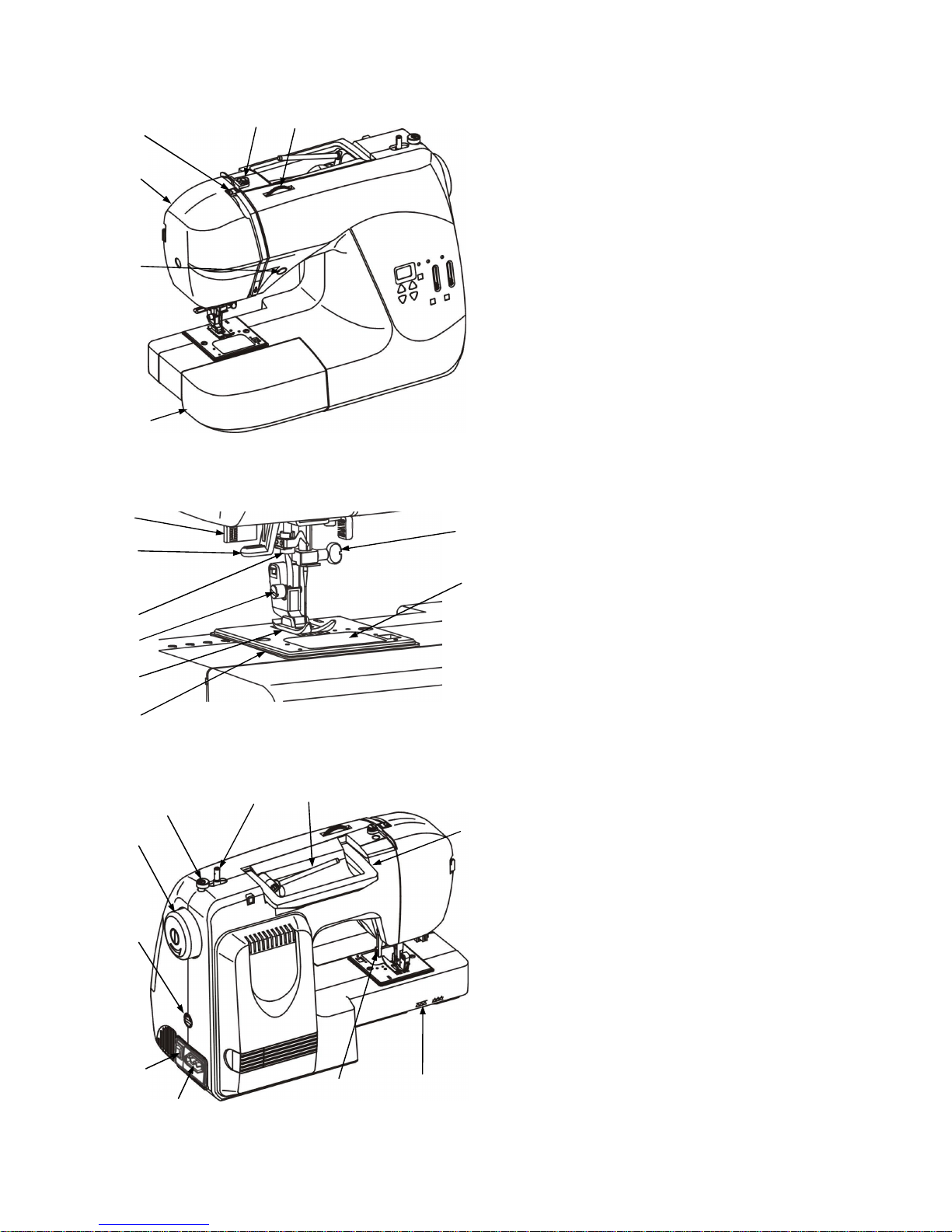

- 3 -

PRINCIPAL PARTS OF THE

MACHINE

1. Tension dial

2. Upper thread guide

3. Take up lever

4. Face cover

5. Reverse button

6. Extension table

7. Needle clamp screw

8. Bobbin & shuttle cover

9. Buttonhole lever

10. Threading lever

11. Needle threader

12. Presser foot holder screw

13. Presser foot

14. Needle plate

15. Bobbin winder stopper

16. Bobbin winder spindle

17. Horizontal spool pin

18. Handle

19. Hand wheel

20. Stitch balance dial

21. Power switch

22. Foot controller connector

23. Presser foot lever

24. Feed dog height lever

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

2

1

3

Page 5

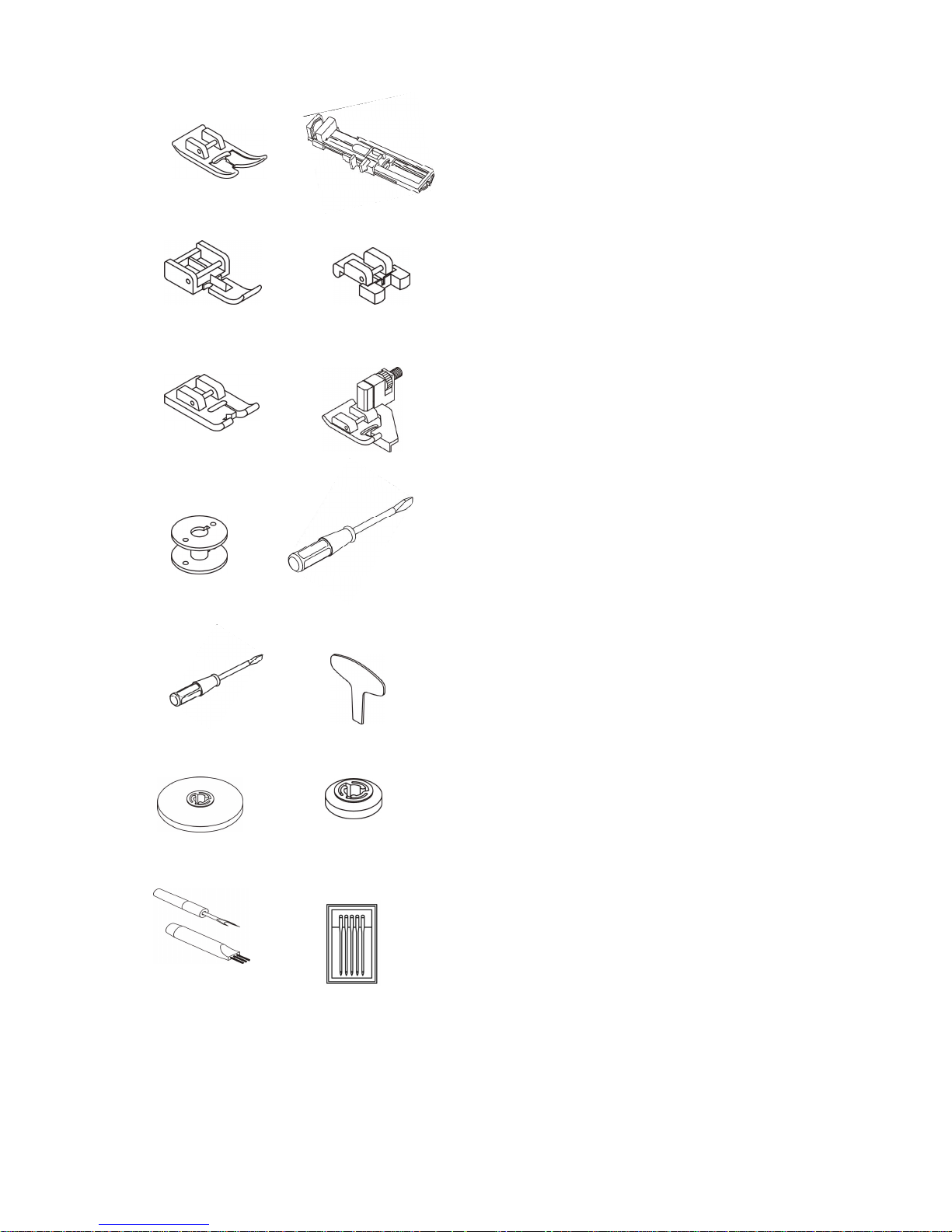

- 4 -

ACCESSORIES

1 2

3 4

5 6

7 8

9 10

11 12

13 14

A. All purpose foot (On machine)

B. Buttonhole foot

C. Zipper foot

D. Button foot

E. Gathering foot

F. Blind hem foot

G. Bobbin

H. Screw driver (Large)

I. Screw driver (Small)

J. Needle plate screw driver

K. Spool cap (Large)

L. Spool cap (Small)

M. Buttonhole cutter

N. Needles

Page 6

- 5 -

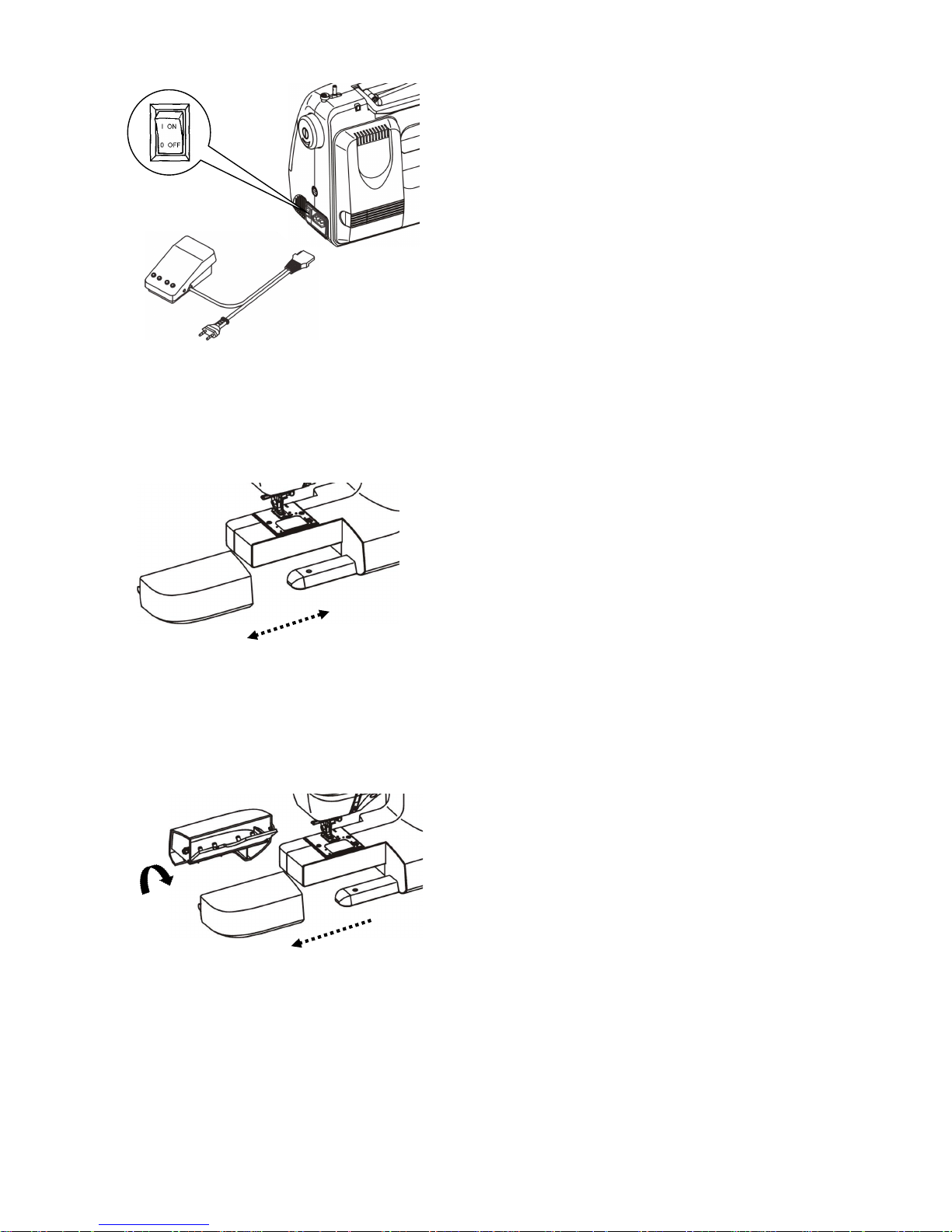

POWER, SWITCH

1. Input power : 220V, 60Hz.

2. Insert the foot control plug into the sewing

machine. Then plug the machine to the power

supply.

2. Turn switch to "ON" position.

3. Sewing speed can be varied by the speed

controller.

Separate the machine from the powersystem if you

leave it unsupervised.

Use only ZHEJIANG FOUNDER model FC-9001

foot controller with sewing machine.

REMOVING EXTENSION TABLE

Hold the left end of the table and pull it out in

direction of the arrow.

ACCESSORY BOX

1. The extension table can be open and accessories

taken out by following the arrow direction.

2. After taken accessories close by reverse side.

Page 7

- 6 -

Needle clamp screw

Needle clamp

Loose

Tight

REPLACING NEEDLE

1. Turn off power.

2. Raise needle to its highest position.

3. Loosen needle clamp screw, remove the old needle.

4. If any

needle is deformed, bent or damaged, replace

with a new needle.

5. With the flat side of the needle facing away from

you, insert needle as far up as it will go.

6. Tighten the needle clamp screw securely.

LEVELLING THE MACHINE

If the sewing machine is not level, remove the

sewing table and adjust the levelling by turning the

foot as illustrated.

Flat face side away

from you

To determine if the needle is bad, place the flat side of

the needle on something flat (a needle plate, piece of

glass, etc.). The gap between the needle and the flat

surface should be even.

Never use a bent or broken needle. It may cause

skipped stitches or thread breakage. Bad needles can

ruin the fabric.

Always purchase good quality needles. Change needle

often.

Down

Up

Page 8

- 7 -

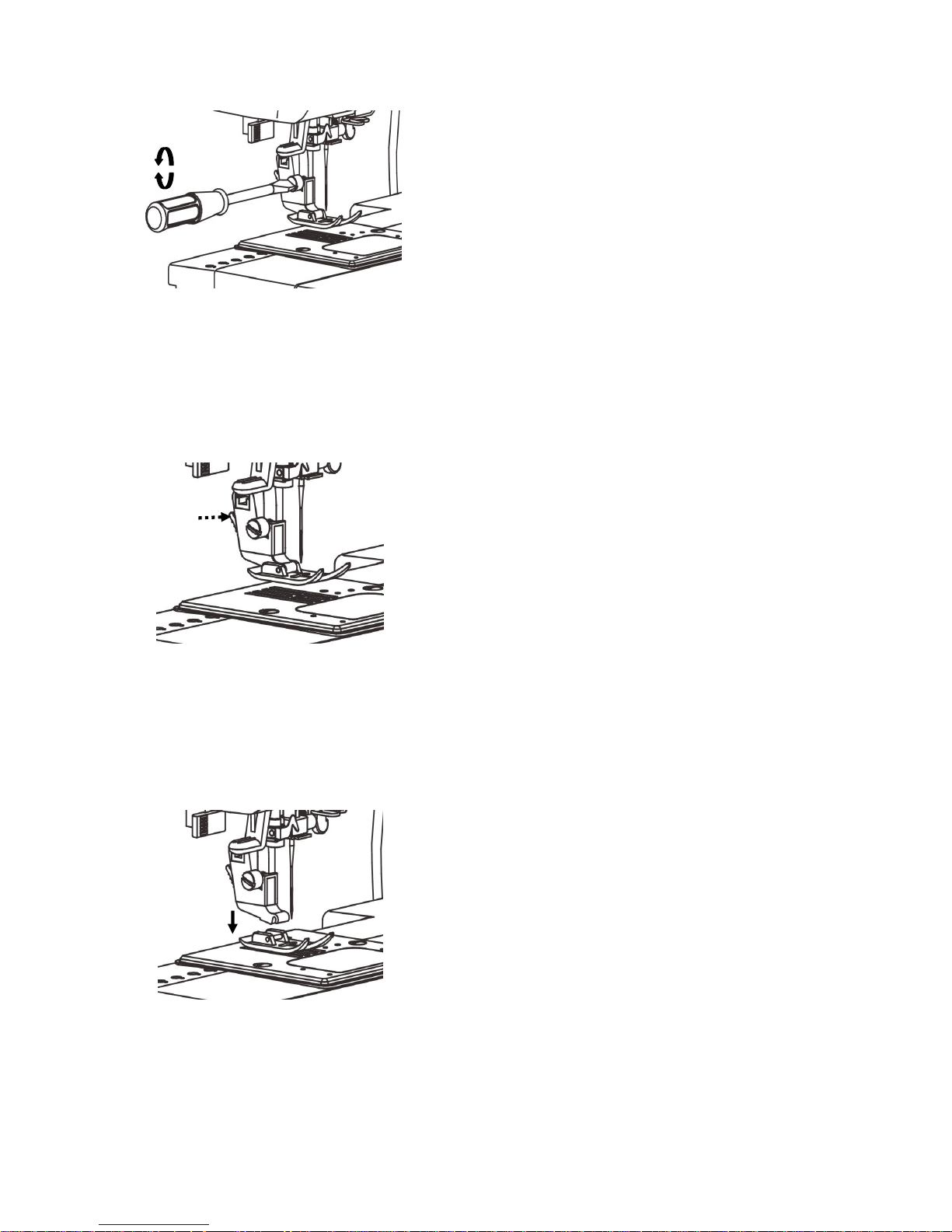

REPLACING PRESSER FOOT

1. Turn off power.

2. Raise needle bar to its highest position and raise

the presser foot.

3. Press release lever as shown, remove presser

foot.

1. Place the presser foot pin right under the groove

of the foot holder.

2. Lower the presser lever.

3. Press the presser lever, the lever bar will attach

the foot.

HOW TO REMOVE AND ATTACH

THE SHANK

Raise the presser foot.

Turn the screw counterclockwise with the screwdriver

to remove the shank.

When attaching, place shank on presser bar. Lower

the presser foot lever. Turn screw clockwise to tighten.

Page 9

- 8 -

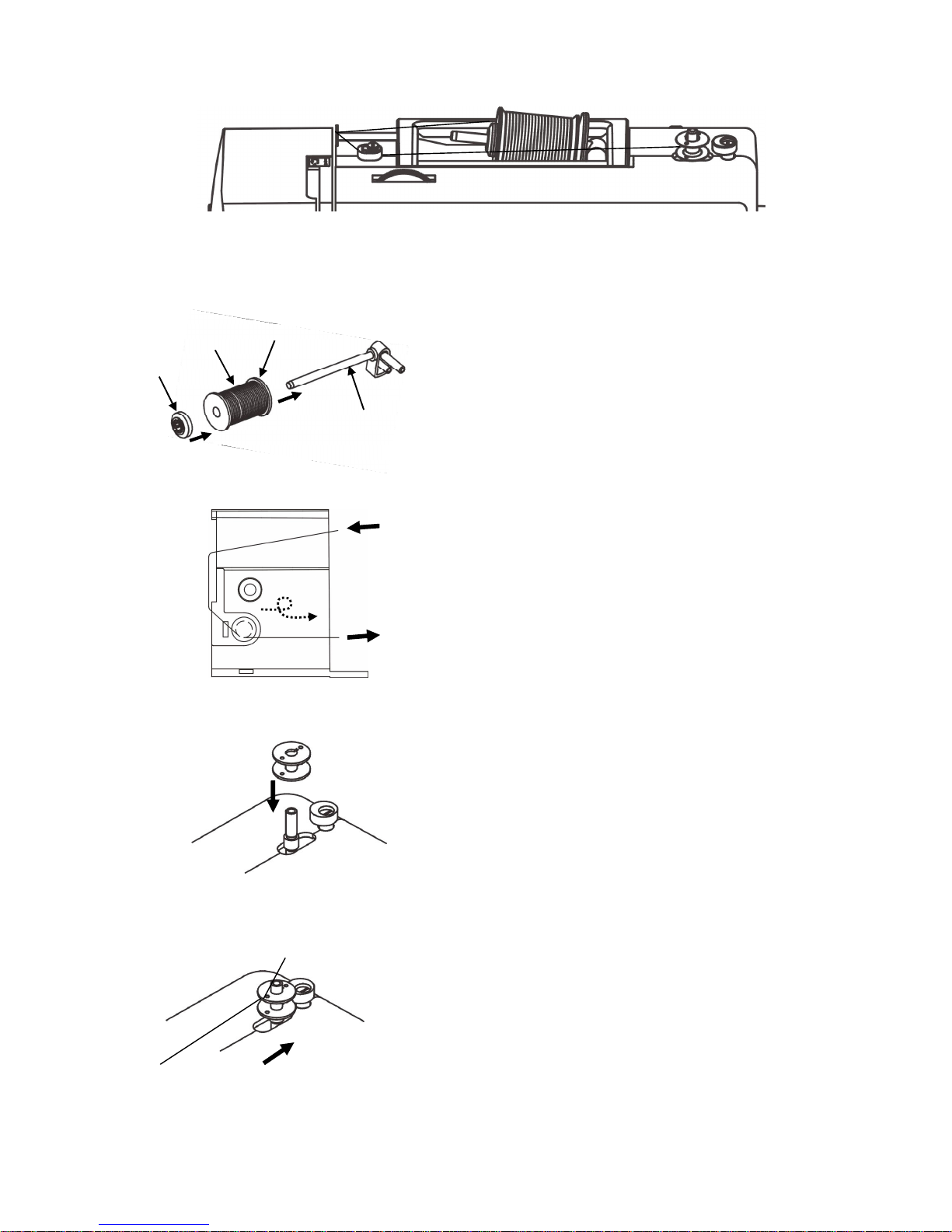

1﹒Place thread spool and spool cap onto spool

pin.(Make sure the cut at right side before

setup)

2﹒Follow the arrow direction, thread as diagram.

3﹒Thread through inside of the opening on the

bobbin edge, then place empty bobbin onto

spindle.

4﹒Push bobbin winder to the right, hold the end of

thread. Slowly press the foot control to start

winding.

WINDING THE BOBBIN

Spool

Gap

Spool pin

Spool cap

Page 10

- 9 -

5﹒When bobbin winder is completed, release the

foot control to stop machine then cut the thread.

6﹒

Return winder spindle to left and remove wound

bobbin.

If winding not even, make adjustments: Turn screw

colockwise: position down.

Turn screw counter clockwise: position up.

Until winding is even in bobbin.

Page 11

- 10 -

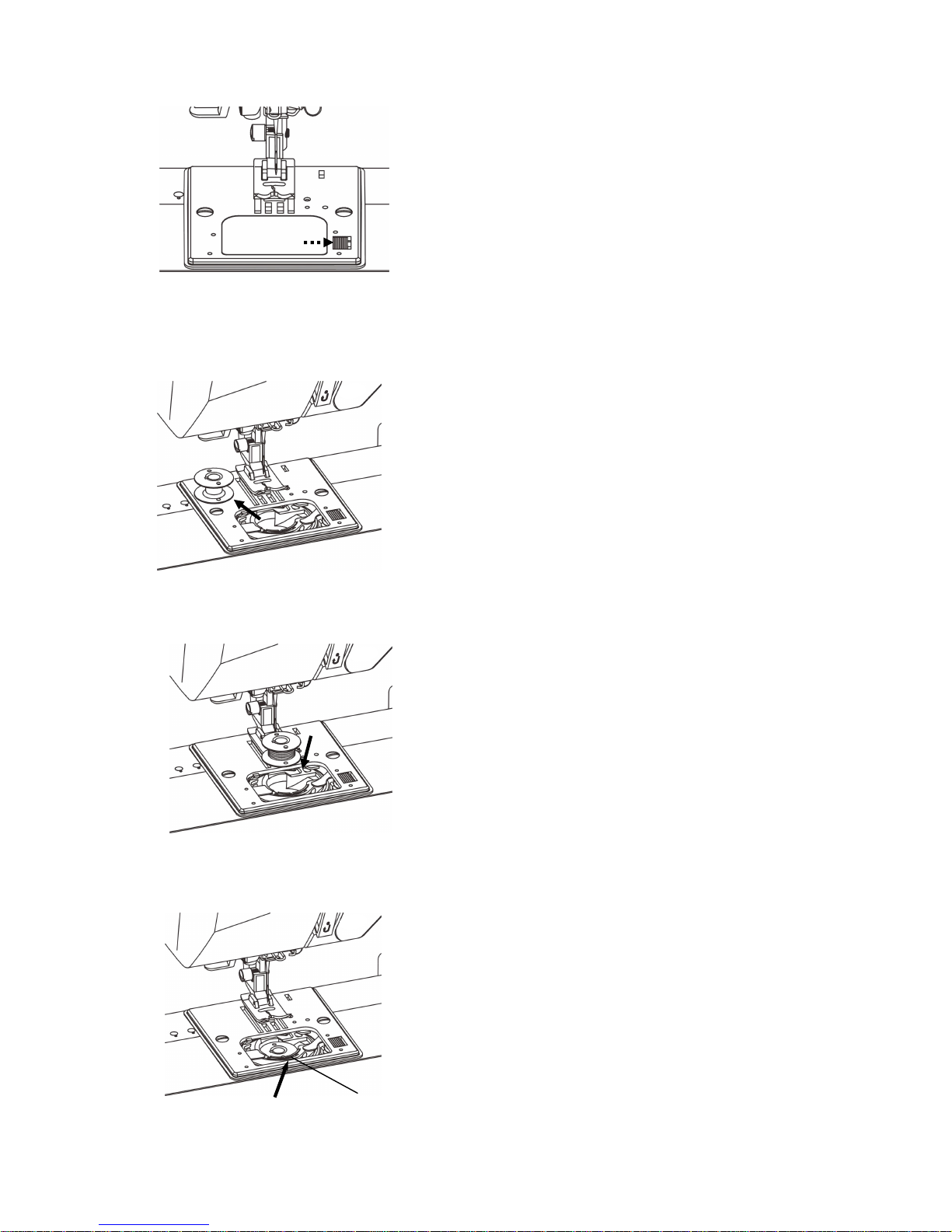

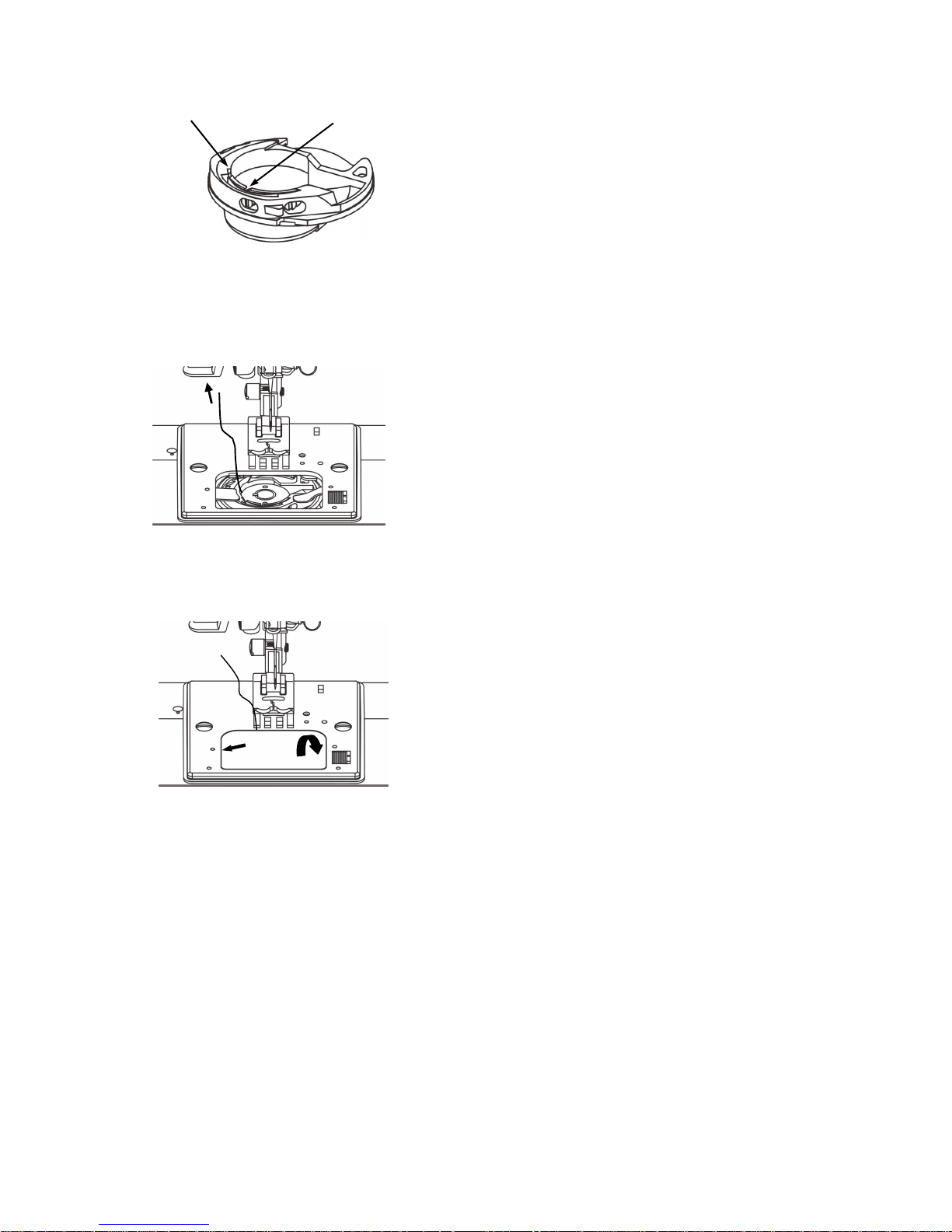

INSERTING AND REMOVE THE

BOBBIN

1. Release the lock of bobbin cover plate (push to

right) and remove the bobbin cover.

2. Remove the bobbin.

3. With newly wound bobbin draw thread on

bobbin out approx 10 cm, then put the bobbin

in bobbin case.

4. Whilst gently pulling the bobbin thread allow this

to pass into indentation on bobbin case (A), and

pull it towards to left.

(A)

Page 12

- 11 -

7. Attach bobbin cover, follow step A and B.

Note: Bobbin will rotate in anti-clockwise direction.

6. Pull the thread as arrow direction.

5. Next, pull thread into notch (B).

(A)

○

B

○

A

(B)

Page 13

- 12 -

THREADING UPPER THREAD

Turn the hand wheel toward you to raise the needle to its highest position.

Raise the presser foot.

1. Pull the thread under the thread guide and slide it up over the hook.

2. Puts in among two iron sheets.

3. Guide the thread down the right side slot and up the left side slot.

4. Firmly pull the thread from right to left, over the take-up lever and down into the take-up lever eye.

5. Puts in inside the wire.

6. Slide the thread to the left behind the needle bar thread guide.

7. Thread the needle from front to back.

Pass the thread from front to rear through needle and pull approx. 10 cm of thread through eye of needle.

(For Auto threaded system see page 13)

1

2

3

4

5

6

7

Page 14

- 13 -

AUTOMATIC NEEDLE THREADER

NOTE: * Needle must be in its highest position and

remove presser foot when using needle

threader.

*

Needle threader cannot be used with a twin

needle.

1. Raise the needle to its highest position.

Lower the needle threader lever as far as it will go.

2. Hook A will automatically insert itself into the

needle eye. Bring the thread around Guide B and

under Hook A.

3. Releas

e the lever and let the needle threader return

to its original position. Pull the thread loop to the

back to finish bringing the thread through the

needle eye.

Note: * Do not turn the hand wheel when using the

needle threader.

* Do not touch threader lever whilst sewing as

needle threader will be damaged. We advise

you to switch off power when using the

threader unit.

A

B

Page 15

- 14 -

DRAWING UP BOBBIN THREAD

1. Hold the upper thread with your left hand and turn

hand wheel slowly and towards you.

2. Gently pull the upper thread, and the lower thread

will come up in a loop.

3. Pull both threads together taking them backwards

and through presser foot to the rear of machine.

Page 16

- 15 -

4

ADJUSTING THREAD TENSION

In straight seams, the needle thread and the bobbin

thread should lock together in the center of the two

layers of fabric.

If you look at the top and bottom of the stitch, you will

notice that there are no gaps; each stitch is smooth

and even.

When adjusting needle thread tension, the higher the

number, the tighter the needle thread.

Here are some reasons you may change the thread

tension dial:

1. The fabric is stiff or heavy.

2. You are sewing more than two layers of fabric.

3. The stitch you are using needs the threads not to

lock together in the center of the fabric.

Tension is too tight.

The needle thread shows through on the topside of th

e

fabric and it will feel bumpy.

Turn the dial to a lower number to loosen the needle

thread tension.

Tension is too loose.

The needle thread shows through on the underside of

the fabric and it will feel bumpy.

Turn the dial to a higher number to tighten the needle

thread tension.

Weak

Strong

Weak

Strong

4

4

Page 17

- 16 -

Decrease

BOBBIN THREAD ADJUSTMENT

1.

Through the hole provided turn the screw to left to

decrease the tension.

2. The lower thread tension has already been

adjusted, do not adjust it if it is necessary.

ADJUSTING TENSION FOR ZIGZAG

AND EMBROIDERY

The upper thread tension should be slightly weaker

when sewing a zigzag or a satin stitch. The upper

thread should appear slightly on the underside of the

fabric.

Increase

Page 18

- 17 -

FABRIC–THREAD–NEEDLE –TABLE

Please pay attention to the following list as a guide for sewing different types of fabric.

There are many kinds of fabrics, threads and needles. It is important to use the correct ones together.

Always purchase good quality thread. It should be strong, smooth and even in thickness. Use the same thread for

needle and bobbin. Always test thread and needle size on a scrap piece of fabric.

In general, fine threads and needles are used for sewing lightweight fabrics and heavier threads and larger

needles are used for sewing heavyweight fabrics. There are many specialty needles available from your sewing

machine dealer.

A denim needle with a sharp tip is used to sew heavy fabrics such as denim and canvas. For topstitching, a special

topstitching needle with a larger eye must be used for heavier weight thread. Leather needles punch small holes in

leather and suede allowing the thread to follow through the hole. When sewing stretch, very fine or synthetic

fabrics, use a stretch needle. The stretch needle prevents skipped stitches.

Check your needles frequently for rough or blunt tips. Snags and runs in knits, fine silks and silk-like fabrics are

permanent and are often caused by damaged needles.

Fabric

Threads

Needles

Light Weight

Crepe de chine,

Voile, Lawn,

Georgette,

Organdy, Tricot

Fine Silk

Fine Cotton

or Polyester

Thread

10/70 or

11/75 or

12/80

Medium Weight

Linen, Cotton,

Woolens,

Double Knits

Medium Weight

Cotton

Polyester

Thread

11/75 or

12/80 or

14/90

Heavy Weight

Denim, Tweed,

Gabardine,

Coating, Drapery,

and Upholstery

Fabric

Heavier Cotton

or Polyester

Thread

12/80 or

14/90

Page 19

- 18 -

SEWING (PATTERN SELECTOR) AND OPERATION TABLE

Pattern list Zigzag width Stitch length

No. Pattern Stand Min Mix Stand Min Mix Presser foot Twin needle

00 3.5 0.5 6.5 2.5 0.5 4 A Y

01 6 0 6 2 0 3 A Y

02 3.5 0.5 6.5 2.5 1.5 3 A Y

03 3.5 0.5 6.5 2.5 1.5 3 E Y

04 3.5 2 6 1.5 1 3 D Y

05 6 4 7 1.5 1 3 A Y

06 3.5 2 6.5 1.5 1.0 3 E Y

07 6 3 6 2.5 1.5 3 E Y

08 6 3 6 2.5 1.5 3 E Y

09 6 3 7 2.5 1.5 3 E Y

10 5.5 4 6 0.4 0.3 0.7 B N

11 5.5 4 6 0.4 0.3 0.7 B N

12 5.5 4 6 0.4 0.3 0.7 B N

13 7 7 7 0.4 0.3 0.7 B N

14 7 7 7 0.4 0.3 0.7 B N

15 5.5 4 6 1.5 1 2 B N

16 5.5 4 6 1.5 1 2 B N

17 5.5 4 6 1.5 1.5 2 B N

18 6 3 7 0.5 0.3 1.5 E Y

19 6 3 7 0.5 0.3 1.5 E Y

20 6 3 7 0.5 0.3 1.5 E Y

21 6 3 7 0.5 0.3 1.5 E Y

22 6 3 7 0.5 0.3 1.5 E Y

23 6 3 7 0.5 0.3 1.5 E Y

24 6 3 7 0.5 0.3 1.5 E Y

25 6 3 7 0.5 0.3 1.5 E Y

26 6 3 7 0.5 0.3 1.5 E Y

27 6 3 7 0.5 0.3 1.5 E Y

28 6 3 7 0.5 0.3 1.5 E Y

29 6 3 7 0.5 0.3 1.5 E Y

30 6 2 6 1.5 1 3 E Y

31 3.5 2 6 1.5 1 3 E Y

32 3.5 2 6.5 1.5 1 3 E Y

33 6 3 7 2.5 1.5 3 E Y

34

6 3 6 2.5 1.5 3 E Y

Page 20

- 19 -

SEWING (PATTERN SELECTOR) AND OPERATION TABLE

Pattern list Zigzag width Stitch length

No. Pattern Stand Min Mix Stand Min Mix Presser foot Twin needle

35 6 3 6 2.5 1.5 3 E Y

36 6 3 6 2.5 1.5 3 E Y

37 6 3 6 2.5 1.5 3 E Y

38 6 3 7 2.5 1.5 3 E Y

39 6 5 7 2 1.5 2.5 E N

40 6 3 6 1.5 1.5 1.5 E Y

41 6 3 6 1.5 1.5 1.5 E Y

42 6 4 7 2.5 1.5 3 E Y

43 6 4 7 2.5 1.5 3 E Y

44 6 4 7 2.5 1.5 3 E Y

45 6 4 7 1.5 1.5 1.5 E N

46 6 4 7 1.5 1.5 1.5 E N

47 6 4 7 1.5 1.5 1.5 E N

48 6 4 7 1.5 1.5 1.5 E N

49 6 3 7 2.5 1.5 3 E Y

50 6 5 7 1.5 1.5 1.5 E N

51 6 5 7 1.5 1.5 1.5 E N

52 6 5 7 1.5 1.5 1.5 E N

53 6 5 7 1.5 1.5 1.5 E N

54 6 5 7 1.5 1.5 1.5 E N

55 6 5 7 1.5 1.5 1.5 E N

56 6 5 7 1.5 1.5 1.5 E N

57 6 5 7 1.5 1.5 1.5 E N

58 6 4 7 2.5 1.5 3 E Y

59 6 4 7 2 1.5 2.5 E Y

60 6 4 7 1.5 1.5 1.5 E N

61 6 4 7 1.5 1.5 1.5 E N

62 6 5 7 1.5 1.5 1.5 E N

63 6 5 7 1.5 1.5 1.5 E N

64 6 5 7 1.5 1.5 1.5 E N

65 6 5 7 1.5 1.5 1.5 E N

66 6 5 7 1.5 1.5 1.5 E N

67 6 5 7 1.5 1.5 1.5 E N

68 6 5 7 1.5 1.5 1.5 E N

69 6 5 7 1.5 1.5 1.5 E N

Page 21

- 20 -

SEWING (PATTERN SELECTOR) AND OPERATION TABLE

Pattern list Zigzag width Stitch length

No. Pattern Stand Min Mix Stand Min Mix Presser foot Twin needle

70 6 3 7 0.5 0.3 1.5 E Y

71 6 3 7 0.5 0.3 1.5 E Y

72 6 3 7 0.5 0.3 1.5 E Y

73 6 3 7 0.5 0.3 1.5 E Y

74 6 3 7 0.5 0.3 1.5 E Y

75 6 3 7 0.5 0.3 1.5 E Y

76 6 3 7 0.5 0.3 1.5 E Y

77 6 3 7 0.5 0.3 1.5 E Y

78 6 3 7 0.5 0.3 1.5 E Y

79 6 3 7 0.5 0.3 1.5 E Y

80 6 3 7 0.5 0.3 1.5 E Y

81 6 3 7 0.5 0.3 1.5 E Y

82 6 3 7 0.5 0.3 1.5 E Y

83 6 3 7 0.5 0.3 1.5 E Y

84 6 4 6 1.5 1.5 1.5 E Y

85 6 4 7 1.5 1.5 1.5 E Y

86 6 4 7 1.5 1.5 1.5 E Y

87 6 4 7 1.5 1.5 1.5 E Y

88 6 3 6 2.5 2.5 3 E Y

89 6 3 6 2.5 1.5 3 E Y

90 6 3 6 2.5 1.5 3 E Y

91 6 4 7 2.5 1.5 3 E Y

92 6 4 7 2.5 1.5 3 E Y

93 6 3 6 2.5 1.5 3 E Y

94 6 3 6 2.5 1.5 3 E Y

95 6 3 6 2.5 1.5 3 E Y

96 6 3 7 2.5 1.5 3 E Y

97 6 3 7 2.5 1.5 3 E Y

98 6 6 7 1.5 1.5 1.5 E N

99 6 6 7 1.5 1.5 1.5 E N

Page 22

- 21 -

OPERATION BUTTONS

1. LED screen

2. Twin needle light

3. Zigzag width light

4. Stitch length light

5. Twin needle set button

6. Stitch length VR button

7. Stitch length indication button

8. Zigzag width VR button

9. Zigzag width indication button

10. Single digit pattern button (+)

11. Single digit pattern button ( - )

12. Ten digit pattern button ( - )

13. Ten digit pattern button (+)

14. Reverse button

1

2

3

13

4

5

6

7

8

9

10

11

12

14

Page 23

- 22 -

REVERSE BUTTON

During sewing or before sewing. Machine will sew

reverse when press reverse button.

(Only for pattern 00~01)

○○○○

10

○○○○

11

○○○○

13

○○○○

12

○○○○

1

PATTERN OPERATION

INSTRUCTION

LED numbers display .

Press single digit pattern button , the digit is

from 0 to 9.

Press single digit pattern button , the digit is

from 9 to 0.

Press ten digit pattern button , the digit is from

0 to 9.

Press ten digit pattern button , the digit is from

9 to 0.

○○○○

1

○○○○

10

○○○○

11

○○○○

13

○○○○

12

○○○○

5

TWIN NEEDLE OPERATION

INSTRUCTION

Non-effective twin needle operation:

When press twin needle set button , and there

are three warning voices caused from buzzer, this is

shown no twin needle and when light is red, it could

not operate this pattern in order to avoid any danager

dued to broken twin needle.

Effective twin needle operation:

When press twin needle set button , without any

voice from buzzer and the twin needle light is green,

you can set twin needle for sewing.

PS: Effective twin needle operation indicate on

pattern list.

○○○○

5

○○○○

5

Page 24

- 23 -

○○○○

8

ZIGZAG NON-SECTION

OPERATION INSTRUCTION

The buzzer can make the sound, when you adjust the

button .

Zigzag width light-off:

When you move zigzag width VR

button

to the

bottom as

(Diagram 1).

Zigzag width light-red:

When you move zigzag width VR

button

to the min.

value as

(Diagram 2).

Zigzag width light-green:

The VR value can adjust between the min. value and max.

value, when you move zigzag width VR

button

as

(Diagram 3).

Zigzag width light-red:

When you move the zigzag width VR

button

to the

max. value as

(Diagram 4).

Exception: When the max. value is 7 and move to the max

value, the zigzag width light is green.

PS: Please refer the zigzag width value by the pattern list.

○○○○

8

○○○○

8

○○○○

8

○○○○

8

○○○○

8

(Diagram 1)

(Diagram 2)

(Diagram 4)

(Diagram 3)

Light off

Red light

Green light

Red light

Page 25

- 24 -

○○○○

6

STITCH LENGTH NON-SECTION

OPERATION INSTRUCTION

The buzzer can make the sound, when you adjust the

button

.

Zigzag width light-off:

When you move stitch length VR

button

to the

bottom as

(Diagram 1).

Stitch length light-red:

When you move stitch length VR

button

to the min.

value as

(Diagram 2).

Stitch length light-green:

The VR value can adjust between the min. value and

max. value, when you move stitch length VR

button

as

(Diagram 3).

Stitch length light-red:

hen you move the stitch length VR

button

to the

max. value as

(Diagram 4).

Exception: When the max. value is 4 and move to the

max value, the stitch length light is green.

PS: Please refer the stitch length value by the pattern list

○○○○

6

○○○○

6

○○○○

6

○○○○

6

○○○○

6

(Diagram 1)

(Diagram 2)

(Diagram 4)

(Diagram 3)

Light off

Red light

Green light

Red light

Page 26

- 25 -

DISPLAY THE ZIGZAG WIDTH

OPERATION INSTRUCTION

Press the zigzag width indication button until to

display the zigzag width value by number on LED

screen.

Release the zigzag width indication button , the

screen is restored previous display.

DISPLAY THE STITCH LENGTH

OPERATION INSTRUCTION

Press the stitch length indication button until to

display the stitch length value by number on LED

screen.

Release the stitch length indication button , the

screen is restored previous display.

○○○○

9

○○○○

9

○○○○

9

○○○○

7

○○○○

7

○○○○

7

Page 27

- 26 -

ERROR CORRECTION

During sewing, LED show out “ ” and stop. Turn

hand wheel to solve torque problem.

START TO SEWING (PREPARATION)

After has been familiar with sewing machine each regulator and the appendix function, and then may start sewing.

The following several points which are before stitch should pay attention, so it may cause sewing to be smoothly.

1. Inspects the needle to have straight, incisively and correctly installs.

2. Before start sewing and after completes sewing, raise the needle to the top.

3. Before sewing, first gently pull on the upper and down threads about approx 10 centimeters

(4 inches.) and pull both threads pass through under the presser foot.

4. Try to sewing on the some rags, to decide the suitable stitch length and the thread tension.

5. The seam cloth puts underneath presser foot.

6. Use foot speed controller. Slowly depress the foot controller to sewing.

7. Each suture line start and the ending must reverse sew a short distance to prevents off-line. (But reverse

sewing is only suitable in straight stitch)

8. Gently guide by the hand in front of the needle to deliver the cloth, do not hold on the cloth, otherwise can

affect sewing machine itself to deliver the cloth.

9. When turn the hand wheel, turn to front (counter-clockwise).

10. To avoid the sewing machine needle pulling curving or breaks off, after sew completes, before move away the

cloth, the needle-tip certainly must leave the cloth, rises to the top, and then move cloth by the needle back.

11. Separate the machine from the power system if you leave it unsupervised.

12. When turn on the machine and press the foot controller, the stepping motor & zigzag width motor will

functioning for “Neutralization the mechanism”, there will be some noise occurred, that’s a normal functioning

sound, don’t worry about such sound. After such “neutralizing” function, then you can start to enjoy the sewing.

Page 28

- 27 -

STRAIGHT STITCHES

1. This stitching is one of most commonly used

pattern.

2. The zigzag presser foot also can use in the

straight stitches and the zigzag stitches

3. To sewing thinner cloth may use smaller stitch

length.

ZIG-ZAG STITCH

Zig-zag stitch is a useful pattern. Setting the stitch

length to (0.3) the satin stitch (pattern 01) can be

used for embroidery, applique, etc. When you use

this kind of stitch to sew a thin fabric, please loosen

upper tension a little and place a piece of paper

under the fabric or lining cloth to avoid wrinkling.

(Use Zig-zag pattern, please turn the upper tension

dial in between 1-3).

Pattern selector position.

FREE ARM SEWING

1. Free arm sewing is useful for sewing sleeves,

trousers etc.

2. Your sewing machine can be used as a flat bed

machine but easily c

onvert to free arm machine by

removing the extension table.

SEAM FINISHING

When sewing to edge of cloth, push the reverse

button and sew in reverse for approx 2 centimeters.

Then raise needle to highest position, raise presser

foot and take the fabric to rear of machine. The

threads can be cut with thread cutter location in rear

face plate. (Arrow place)

Cutting thread slot

01

00

Page 29

- 28 -

TRANSFER SEWING DIRECTION

1.

Stop the sewing machine when you reach a corner.

Then lower the needle into fabric.

2. Raise presser foot and use the needle as a pivot.

Turn the fabric around the needle in the desired

direction.

3. Lower presser foot and resume sewing.

STITCH BALANCE DIAL

1﹒Arrow place is the pattern balance dial. “+”﹒“-”

2﹒Use L screwdriver to adjust.

3﹒

When you doing balance adjustment, please by

a spot adjustment, adjusts excessively many be

more and more.

1﹒When you sew out the pattern is overlaps (A).

Turn adjust dial “+” (Along clockwise).

2﹒

If sew out the pattern is separates (C). Turn adjust

dial to “-” (Counter clockwise).

Page 30

- 29 -

STRAIGHT STRETCH STITCH

Use this stitch with knitted, tricot or other stretchy

fabric. As general straight sewing, the machine will

feed forward and backward making a triple stitch not

easily broken offering strength on stretchy fabrics.

THREE STEP ZIG-ZAG STITCH

You can use this stitch for many sewing tasks.

Suitable for sewing toweling and patchwork.

OVERCASTING SEWING (Optional)

. Use these stitches for sewing an unfinished fabric

edges, seam and applique.

09 07 36

02

38 05

Page 31

- 30 -

BLIND STITCH

Set up position:

1. Fit blind stitch presser foot.

2. Pattern selection “04”.

3. Stitch length dial at between “1.5-2.5”

4. Needle width dial at “3-5”

5. Loosen upper tension slightly.

1. Fold the material as shown. Make the fold as wide

as you want the finished seam to be: the bottom

fold should be about 5 mm away.

2. Use the blind hem foot. While sewing, check the

seam width and needle setting, to ensure that the

seam remains uniform.

3. Sew the blind seam on the underside of the

material, so that only the peak of the zigzag stitch

pierces the out-side of the material. When you have

finished sewing, push the left of the

material over to

the right and smooth out. The seam is almost

invisible!

The table below shows the suggested settings for the

various values, depending on the material used.

04

Page 32

- 31 -

BUTTONHOLE SEWING

1. Exchange to buttonhole presser foot.

2. Pulls out upper and bobbin threads approx. 10cm,

and then lay aside under presser foot. (Diagram 1)

3. Set needle width dial at between 4-5. (Diagram 2)

4. Set stitch length dial at 0.3-0.5. (Diagram 3)

5. Make buttonhole locations on fabric. (Diagram 4)

6. Place fabric under presser foot.

As (Diagram 5) arrow place, put in the button.

7. Lower down presser foot.

8. Press the Buttonhole lever.

9. Set BH stitch pattern (10、11、12、13、14、15、16、

17), choose the pattern and raise the needle to

peak.

10. Start sewing slowly until it reaches bartacks of the

start line and then stop sewing.

11. Raise presser foot and take out fabric.

Buttonhole

locations

(Marks)

Bartacks

(Diagram 1)

(Diagram 2)

(Diagram 3)

(Diagram 4)

(Diagram 5)

Button adjuster

Button slot

Remake:

Buttonhole patterns are one time stitches.

Page 33

- 32 -

ZIPPER SEWING

Utilise the foot of closing zipper.

Select straight stitch.

1. Zipper foot is designed to sew close to a raised

edge, thus preventing sewing on zipper.

2. Place zipper foot in position and attach firmly.

3. Fold the fabric about 2 cm and place the fabric

under foot.

1. To sew the left side of the zipper, set the zipper on

the right side of the needle.

2. To sew the right side of the zipper, set it on the left

side of the needle.

Sew as illustrated.

Page 34

- 33 -

HEMMING (Optional)

1. Raise the presser foot and the needle to its highest

position.

2. Fold over the fabric edge about 3mm and place it

under the foot.

3. Insert the fabric fold into the spiral opening of

hemmer foot.

4. Lower the presser foot.

5. During the sewing, left hand holds on the fabric

edge and folds to the left a little. Right hand holds

on the fabric front end and leans to left about 10

degrees. Then start to sewing.

Only suitable materials can be used and some

practice may be necessary to achieve best result.

QUILTER GUIDE (Optional)

1. Slide quilter guide arm through hole on top of

presser foot holder.

2. Move the quilter guide to required stitch distance.

3. Sew one line to test the machine stitches, then

adjust the quilter position you wish to use.

Quilter guide is not included in the standard

accessories. It’s an option part.

BUTTON SEWING

1. Press the “feet dog height lever” to lower the feet

dog.

2. Use button sewing foot and attach firmly.

3. Place the button between presser foot and fabric

and lower presser foot.

4. Manually turn hand wheel toward you and test

carefully that the needle goes through the centre

of first one hole and then the other.

5. By median speed sew 5-6 stitches.

Match

01

Page 35

- 34 -

CLEANING AND OILING

Note: Pull stehts net-put for the machine if it out of

operation are, if the lamp replaced or if them

are cleaned.

Pull out power supply plug before clearing. In order to

maintain it’s to effective functions and pro-long

working life. This machine must be properly

maintained and cleaned and oiled after use.

1. Take off the needle plate by loosening the screws

on both sides.

2. Turn the hand wheel until the thread take-up lever

reaches the highest point.

3. Take out the bobbin case. Brush away fluff and lint

around feet dog, bobbin case and shuttle race.

4. Assembling the bobbin case. The “fixed point”

should be on the left side of “stop point”, as

illustrate.

Take up lever

Screw

Screw

Clean the feed dog

Clean shuttle race saddle

Clean the shuttle race

Fixed point

Stop point

Page 36

- 35 -

Oiling place

Oiling place

Oiling place

Anchor screw

OIL INSIDE OF THE FACE COVER

Note: Pull stehts net-put for the machine if it out of

operation are, if the lamp replaced or if them

are cleaned.

.

Open the face cover w

ith the screw driver and places

one drop of oil on moving points only.

REMOVING AND REPLACING THE

BULB

1. Remove the power supply plug and open the face

cover.

2. Wait bulb cools about 3~5 minutes.

3. Remove the bulb in downward directin as

illustrate. Fit a new one and push in upward

direction.

4. Use 12V ~ 5W bulb.

Note::::

When loads the bulb, the light bulb two side has

pillar must put in bulb holder.

Page 37

- 36 -

FAULT FINDING CHART

Suspected

problem

Probable cause Possible easy correction

Threads kink

together under

the fabric.

- Upper thread improper threading.

- Upper tension dial at O position.

- Re-thread. See page 12

- Increase upper thread tension. See page 15

Irregular

stitches

- Incorrect size needle.

- Improper threading.

- Loosen top thread tension

- Pulling fabric.

- Loose presser foot.

- Unevenly wound bobbin

- Nicks or burrs at needle plate.

- Needle plate broken

- Choose correct size needle.

- Re-thread. See page 12

- Tighten top tension. See page 15

- Gently pull the fabric.

- Re-set presser foot.

- Re-wind bobbin. See page 8、、、、9

- Cleaning bobbin case and base. See page 34

- Change needle plate.

Breaking needle

- Wrong needles size for the fabric.

- The needle has not installed. The needle

is curving.

- Pulling fabric.

- The needle clamp screw is loose.

- Rotate the pattern dial when needle

insert the fabric.

- Loose presser foot.

- Choose a needle to suit the thread and fabric.

- Re-set needle. See page 6

- Gently pull the fabric.

- Truly locks the needle clamp screw.

- When choice pattern, the needle must above

the fabric.

- Re-set presser foot.

Bunching of

thread

- Upper and lower threads not drawn back

under presser foot before starting seam.

- Pull both threads under and back of presser

foot, then rotates the hand wheel with right

hand.

Puckering

- Incorrect thread tension.

- Upper thread improper threading.

- Using two different sizes or type thread.

- Bent or blunt needle.

- Loosen presser foot

- Fabric too sheer or too soft.

- Re-set thread tension. See page 15

- Re-thread. See page 12

- Use same size and type threads.

- Insert new needle.

- Re-set presser foot.

- Use underlay or tissue paper.

Skipping

stitches

- Incorrect size needle.

- Bent or blunt needle.

- Incorrect setting of needle.

- Improper threading.

- Choose correct size needle for thread and

fabric. See page 17

- Insert new needle.

- Re-set needle. See page 6

- Re-thread. See page 12

Page 38

- 37 -

Breaking upper

thread

- Starting to stitch too fast.

- Improper threading.

- Top thread tension too high.

- Incorrect setting of needle.

- Wrong needles and thread for the fabric.

- Set thread pool and the position

indentation at left side.

- Incorrect setting of bobbin case.

- Needle eye is sharp.

- Burrs on bobbin.

- Burrs on needle hole.

- Start to stitch at a medium speed.

- Re-thread. See page 12

- Adjust top thread tension. See page 15

- Re-set needle. See page 6

- Choose correct needle and thread to suit the

fabric. See page 17

- Adjust position of the indentation to right side.

See page 8、、、、9

- Re-set bobbin case. See page 34

- Replace new needle.

- Sand or change bobbin case.

- Sand or change needle plate.

Breaking bobbin

thread

- Down thread improper threading.

- Down thread tension too high.

- Lint in bobbin or shuttle.

- Re-thread. See page 10、、、、11

- Adjust down thread tension. See page 15

- Clean bobbin case and shuttle. See page 34

Fabric not

moving

- Stitch length in “O” position.

- Scraps seize-up with feet-dog

- Sewing thread integral convexity

- Didn’t use the special-purpose bobbin.

- Adjust stitch length.

- Clean feed dog. See page 34

- Pull back upper and down threads under of

presser foot.

- Replace special-purpose bobbin.

Machine

jamming

knocking noise

- Thread caught in shuttle.

- Remove and clean shuttle. See page 34

Sewing machine

doesn’t operate

- The machine is not plugged in.

- Machine is not turned on.

- See page 5

- See page 5

Down thread is

pulled above the

cloth.

- Top thread tension too high.

- Upper thread improper threading.

- Down thread improper threading.

- Adjust top thread tension. See page 15

- Re-thread. See page 12

- Re-thread. See page 10、、、、11

Page 39

- 38 -

Page 40

Loading...

Loading...