Page 1

FA007

Page 2

Page 3

Page 4

CONTENTS

( FEATURES )

(

SPECIFICATIONS

........

..........

............

)·············

......

...

·························································································

( TABLE OF STANDARD GAUGE)

( INS:n :ALLING )

[I] Installing

12]

In

sta

~

Installing

~

Belt Tension adjustment · .... · ...... · .... ·

IS]

Installing

!§] Motor and

[2] Spool

lling

Stand

the

Machine

the

Treadle

the

Motor

the

Pulley Cover .. · ...... · · · .. · ...... · · · .. · · · · ·

Motor

· .... · .. · .. ·

( LUBRICATION

[I] Lubri

~

~

cat

ion

.. · ..

· .... · · · .... ·

Running In

........

CORRECT

......

...

.........................................................................................................

Head

and Chain · · · · · · · · · .. · · · ·

Pulley·········

Pulley

..

· ...... · .... · · · .... · · ·

AND

· .. · .. · .. · .. · · ...... · ...... · .. · .. · · .... · .. · .. · · .. · .... .. · ...... · ........ · .. · .. · .. · .... · · .. · · · · · · ...... · · .... · ·

· · · · · · · · · · · · · · · · · · · · · ·

······· ···

.........

.....

................

..

..

·..................................................................................

·.

· .....

·· ..........................

· · · · .. ·

........

...

..........

· .. · · .... ·

..

· .. · · · · ...... · .... ·

RUNNING IN)

..

· ........ · .. · .. · .... · · .. · · ...... · · · .. · .... · ...... · · · .. · · .... · ·: .... · · · · .......... · .......... · ...... · .... · .... 4

OPERATION) ..........................................................................................

..........

.......

......................

...

....

...

.............................

.......................................................................

..........

· · ........ ·

........

........ · · · ·

..

· · · .. · .. · · · · .... · ·

.....

........

......

.........

· · ·

............

............

..

· .. · .. ·

..................

· · · ·

............

....................

· · · .. · .. · .. · · · · · · · ........ · · .. ·

..

· · .. · .... ·

··· ........

..

.............

· .. · .... .. ........ · · · ·

.......................

· · · · · · · · · ... · · · · · · · · · · · · · · · · · · 3

......

..

· ..... ·

..

· .. · .. ·

..................

..........

.........................

........

.........

..

· · · .. · · .... ·

..

· .. · · · · ........ · .. · 4

· · .. ·

..

. 2

··· 4

..

· 4

.........

· .. · .. · ·.. 4

..........

· 5

1

2

3

3

4

4

5

[I] Needl

[2]

131

~

IS]

!2]

[2]

IS)

~

~

( STANDARD

IIl Needle and Looper

12]

131

~

[5]

!2]

[2] Installing

IS)

~

ng

IUl

II2J

Ill Puller Device Timing Adjustment (Model 928-SP,-PL) ..

es

and

Thread

Installing

Upper

Lower

Installing

Sewing · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · · 7

Thread

Pr

esser

Stitc

Puller Feed Adjustment (Model

Needle

Looper Timing for Avoiding Cont

Needle Guard Adjustment · · · ......

Feed Dog Heig

Puller

Upper

Thread

Thread

Upper

Lower

the

Threading

Thread

the

Ten

sion .... · · · .. · .. · · · .. · · · · .. · ...... · .... · .. · .. · .. · .. · · .. · .... · .. ·

Foot

Pressure Adjustment

h Length Adjustment · · · .. · · .. · · · .. · · · · · .... · .. · · · · .. · · · ·

Bar

Height Adjustment .. · · · .... · · · .. · ...... · .... · ...... · · · .. · · · · .. · .... · · · .. · · · .. ·

Height Adjustme

the Spacer

Thread

Release Lever Adjustment .. · .... · · .. · · · · · .. · .. · .. · .... · · .. · .... · ........ · · .. · · .. .... · ...... · · · ...... · · · ........ · ·

Release Sha

Thread

Thread

s .. · .. · .. · ........ ·

Needles .. · · · · .. · · · · .. · ...... · · · .. ·

........................................................................................................

ing

.........................................

Lapper ...........

ADJUSTMENTS

Timing

ht

Adjustment ..... · .. ·

nt

(Model928

(For

the

Take-up

Nipper Adjustment

Take

Thread Guide Adjustment ........

ft

Adjustment .... ..

-up Timing Adjustment · ...... ...... · ...... · ........... ·

..........

................

928-SP,-PL)

Adjustment ......

act

..............

denim specifications)· .......

·· ...... · .... ·· .. · .... · .... ·· .... · .. ·· .. ···· .. ·

..

· .. · · · · · · · .. · · .. · · · .. · · · · · .... · · · · .. · · · · .. · · · ........ · · .. · · · ·

......................

...

.......................................

.........

...........

with Needles ........

........

· .. · .. · · · · ... ·: · ...... ......... ..... ·

-SP

,-PL)

.....................

.................................

........

....................................................................................

)

...........

...........

· ...... · .... · ........... · ..... ........ · · ..... · ........ ·

.......

..

·· .... ···· .. · .. ·

.............................................

..............

..........

...........

........

· ...... · .... · .. · .. · .. · .. · .. · .. · ...... · .. · .... · .. · .. · .. · 7

........

· · · · · .... · · .... · · .. · · .......... · ........ · .. · · .. · .... ·

..........

..........

...............

.......................................................

.......... · .................................. · ..........................

..

· .... · · ...... ·

............

..........

................

............................................................

...

..............................

...................................................................

.....

.......................................

..

· · .. · .... · ...... · .... ...... · .... · ...... · ........ ·12

....

................

.......................

...

........................

..................... · ..........

.. ..

............................... ...... 12

...

..

·· .... · .. ·······

..

· .. · · · ·

........

...

.............

...........

...........................

........

.............

.....

........

· · · .. · ...... .. · · ·

... ........ n

............................. ·11

....

.......................

...........................

.........

...........

................

· ...... ·

........

..

· .. · 5

· · .... · 5

..

· · · · .. · 8

.....

.......

..

· · · .. ·13

.........

· ..

. 6

..

. IQ

·10

. 13

6

7

8

8

10

13

14

14

14

14

(

TROUBLESHOOTING , ....................................................................................

...

.........

15

Page 5

( FEATURES)

*Model

materials, such

* Machines

prevent sewing irregularity

*M

heavy materials.

* Machines made

*Machines

for a wide

FA007 Double Chain Stitch Feed-off-the-arm Machine is most suitable for sewing tubes of medium and heavy

as

those

made

to

the

achines made

made

ran

to

the puller and the denim specifications employ a movable needle guard which

to

the puller

to

the

ge

of

materials

of

jackets, denim trousers, fatigue clothes and

puller and denim specifications employ a presser foot , a needle p

and

assure

easy

sewing

and

the denim specificatio

puller specificati ons employ a proximity puller system which assures outst anding feeding performance

from medium heavy to heavy.

of

materials

ns

have independent loopers for ease

which

work

may

trou

sers

.

be different

lat

e,

and feed dogs

in

thickness.

of

that

makes

them ideal for sewing

adjustment.

have steps

to

~1~

Page 6

C

SPECIFICATIONS

)

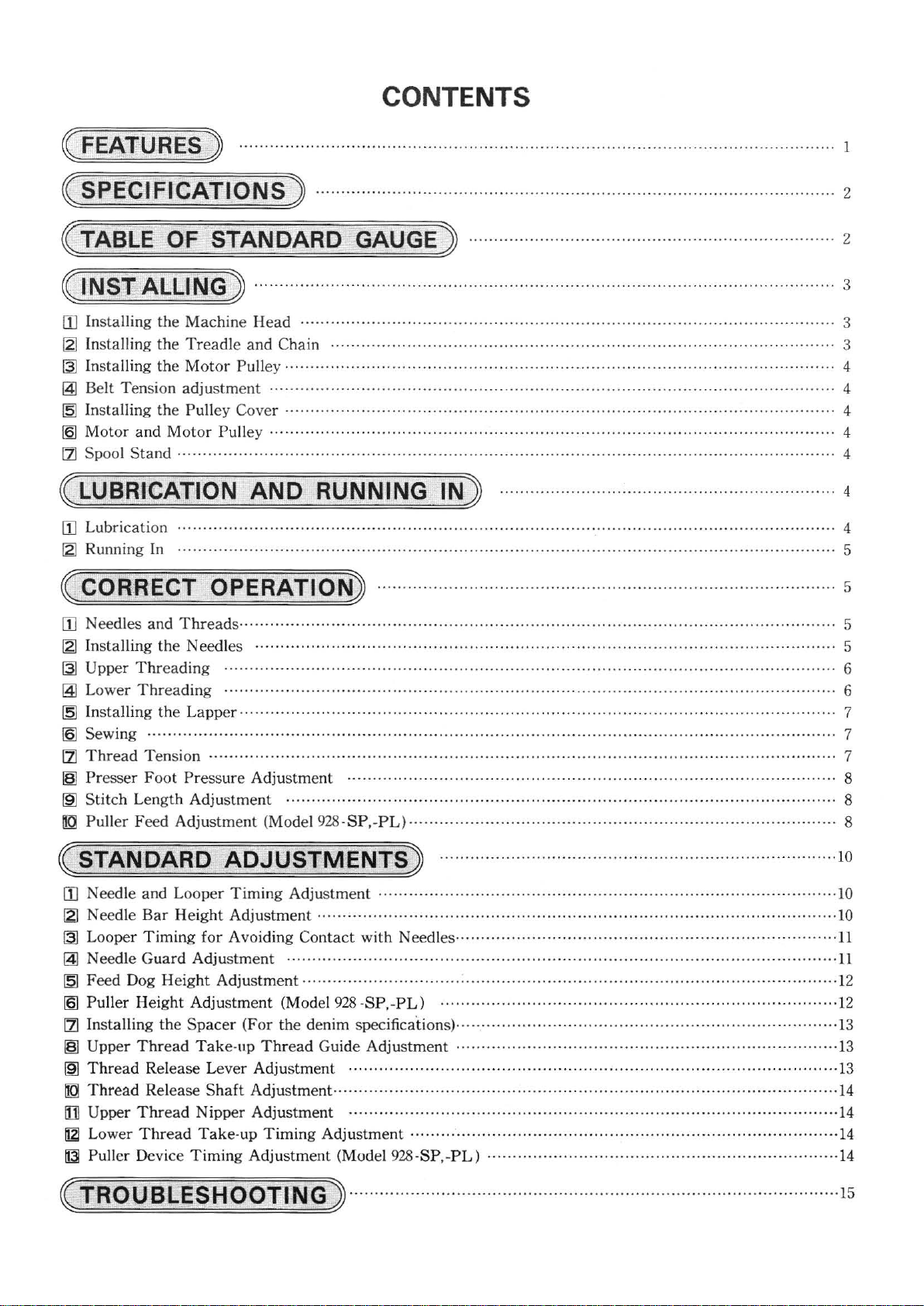

Model

Stitch

St i tch

No.

Need

Min

Puller

pattern

sewing speed 3,600

I ength

of Needle 3

Need

I e gauge

le bar

imum

str

tube

device

oke

size

FA007-364 M

3

-li

ne

paralle

.Y64Yf>~(5.6

:Y.'12/J2(

l sewing

1 . 4

"-'

4.

2mm

nrn)

·

Y11

8.0nrn) • }'i6)'\G(9.6nrn)

33.4mm

YR

None

(6.4nrn)

2-11ne

allel

par

}'i6(4

Y4

Equipped

FA007-

sewing

2

.81!1n)

c6.4nrn>

364

XL/SP

3-

line

paral

lel

sewing

spm

2"-'4. 2mm

3

Vs

Vs

(6.4nrn)

~2%:!(

8.0nm)

~6~

6(9.611111)

190mm

Equ

ippe

d Equipped

FA007

2-11ne 3-11ne

parallel sewing

2

1;4

(6.

35mm

4nrn)

-364

XLIDP

parallel

1

/s

Ys

(6.4nrn)

%%:!

(8.0nn)

Equipped

sewing

3

( TABLE OF STANDARD GAUGEJ

Specificat

Standard

Specification

Denim

Spec

if I cat

ion

ion

FA007-364 M

FA007-364

/S

P ,

DP

Needle Needle

gauge

'V64 'V64

YsYs

%2 %2

%%

%%

XL

%2%2

%%

Clalq)

'V64 'V64

Ys% Ys%

%%

%%

Ys%

%2%

716%

Needle

Plate

'V64

'V64 'V64 'V64

%%

%%

Ys%

%%

%%

Presser

foot

YsYs

%2%2

%%

%%

%z

%2

%%

Feed

YsYs

%%

54 5

~2%

YsYs

%%

%%

dog

tl2

LOOPer

&ssenOiy

'V64 'V64

YsYs

%%

~6%

%%

%z

%2

%%

Lapper

'Y:12

MH

'Y:12

H

114

MH

114

H

¥t&

MH

o/16

H

¥s

MH

¥sH

1

14

XL

o/i&XL

%XL

~2~

Page 7

( INST

[I]

Insta

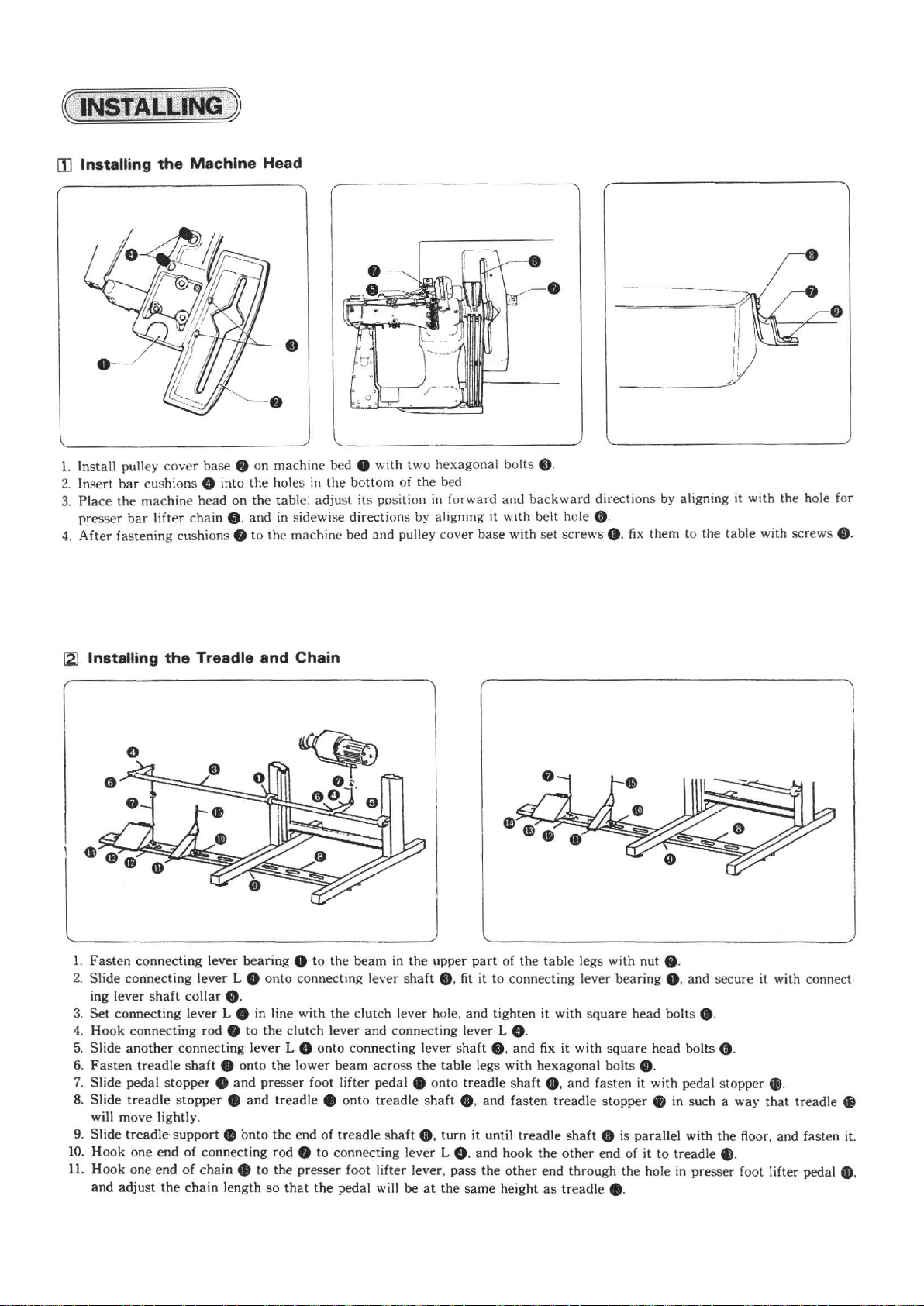

1.

Install pulley

2.

Insert

3.

Place

presser

4.

After

ALLING

lling

the Machi

cove

bar

cushions 0 into the holes

the machine head on the table: adjust

bar

lifter chain C). and

fastening cushions 0

)

ne

Head

r base 8 on machine bed 0 with two hexagonal bolts $ .

in

the

in

sidewise directions by aligning it with belt hole e.

to

the machine bed and pulley cov

bottom of the bed.

its

position

in

forward

er

and

base wi

backward

th

set

screws G.

-

-

·

-

-

--

-

~

'

I

__j)

directions by aligning it with the hole for

fix

them to the table with screws

k

.

e.

[2]

Installing

l

~---------------

1.

Fasten

2.

Slide connecting lever L 8 onto connecting lever s

ing lever

3.

Set

connecting lever L 8 in line with the clutch lever hole, and tighten it with

4.

Hook

5.

Slide another connecting lever L 8 onto connecting lever

6.

Fasten

7.

Slide pedal stopper e

8.

Slide

will

9. Slide treadle-

10

. Hook one end of connecting rod e

11.

Hook one end

and adjust

the

connecting l

shaft

connecting

treadle

treadle

move

lightly.

the

Treadle and Chain

----------

ever

bearing e

collar e.

(Od e to

shaft

stopper

support

of

chaine

chain length

the

• onto the l

and

presser foot lifter pedal e onto

e and treadle • onto

e onto the end

to

the presser foot lifter lever , pass the

so

------

clutch lever

ower

that

--------~

to

the beam in the upper

and

beam

of

treadle

to

connecting lever L 8 . and hook the

the pedal will be

across

tread

shaft

part

of the table legs with nut • .

haft

e.

fit

it

to

connecting lever bearing 8 . and secure it with connect-

connecting lever L 0 .

shaft

e. and fix

the

table legs wi

tread

le

shaft

e. and fasten

O. turn

at

the same height

it

th

le

shaft

until treadle

other

square

head bolts e.

it

with

square

hexagonal bo

e. and fasten

treadle

shaft

other

end through the hole

as

tr

eadle e.

lt

s e.

it

with pedal stopper

stopper e in such a way

e is parallel with the floor, and fasten it .

end of

it

head bolts

to treadle e.

(t

.

in

presser foot lifter pedal

e.

that

treadle

411

G),

~3~

Page 8

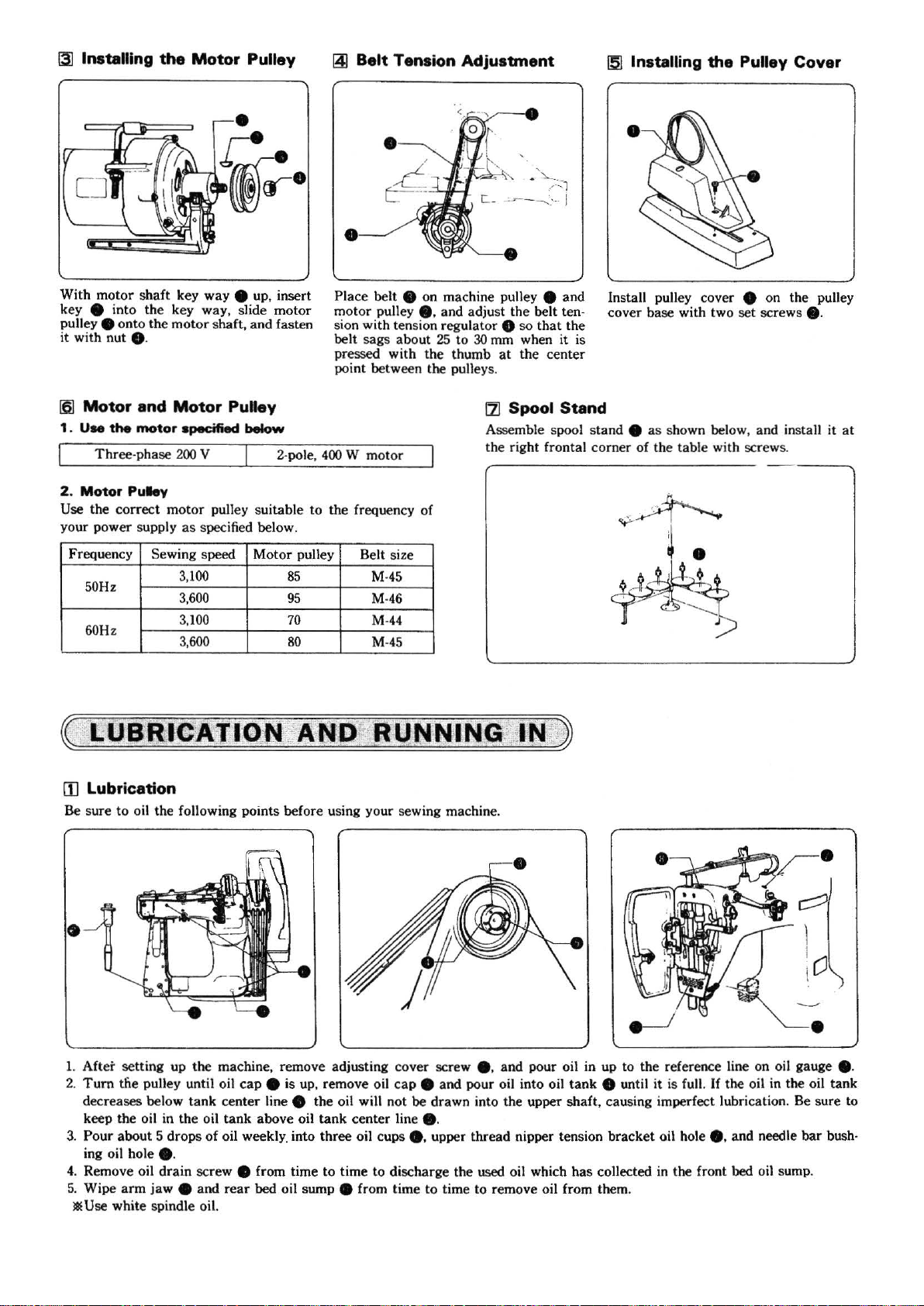

13]

Installing

With

motor shaft

k

ey

8 into the key way, slide

pulley 8 onto

it with

nut 8 .

[6]

Motor

1 . Use

2.

Use

your power supply

the

Three-phase 2

Motor

the correct

the

and

motor

Puley

the

Motor

key

motor

Motor

specified

00

mot

or pulley suitable to the frequency of

as

Pulley

way

8 up, insert

and

motor

fasten

shaft,

Puley

below

V

specified below.

2-pole,

141

Belt Tension Adjustment

•

Place belt 8

mo

tor

sion with tension regulator

belt

sags

pr

essed with

point between the pulleys.

400 W motor

on machine pulley 8 and

pulley 8 . and adjust the belt

about

25

to

the

30

thumb

!5J

lnstaiUng the Pulley Cover

Install pulley cover 8 on

-

cover

base

the

tand 8 as

with two

shown below, and install it

so

the

ten

that

center

8

mm when it is

at

121

Spool Stand

Assemble spool s

the

right frontal corner of the table with screws.

set

scre

the

ws

pulley

8-

at

Frequen

[j]

Be sure to o

cy

50Hz

60Hz

lubrication

•

Sewing speed

3,100

3,60

0

.100

3

3

,600

il

the following points before using

Motor

pulley

85

95

70

80

Belt size

M-

45

M-

46

M-44

M

-45

your

sewing machine.

•

c:::::'

1

I

[

CJ

1.

After setting up

2.

Tum

the pulley until oil

decreases below

keep

th

e oil in

3.

Pour

about

oi

l hole 8 .

ing

4. Rem

ove

oil

5. Wipe

Jl

arm

U

se

white spindle oil.

the

machine, remove adjusting cover screw

tank

the

oil

5 drops

drain

jaw

of

screw e from time

8 and

cap 8 is

center line 8

tank

above

oil

weekly_

rear

into three oil cups

bed

oil sump e from time to time to remove oil from them.

up, remove oil

the

oil will not be drawn into

oil

tank

center

cap

line 8 .

8.

to

time to discharge the

8 .

and

pour oil in up

8 and pour oil into oil

the

upper shaft, causing imperfect lubrication. Be sure to

upper thread nipper

used

oil which

ten

~4~

to

the

ref

eren

ce

line on oil gauge 8 -

tank

8 until it is full. If the oil in the oil

sion

has

bracket

collected

oil hole

in

8.

and needle

the front bed oil sump.

•

bar

tan

bush-

k

Page 9

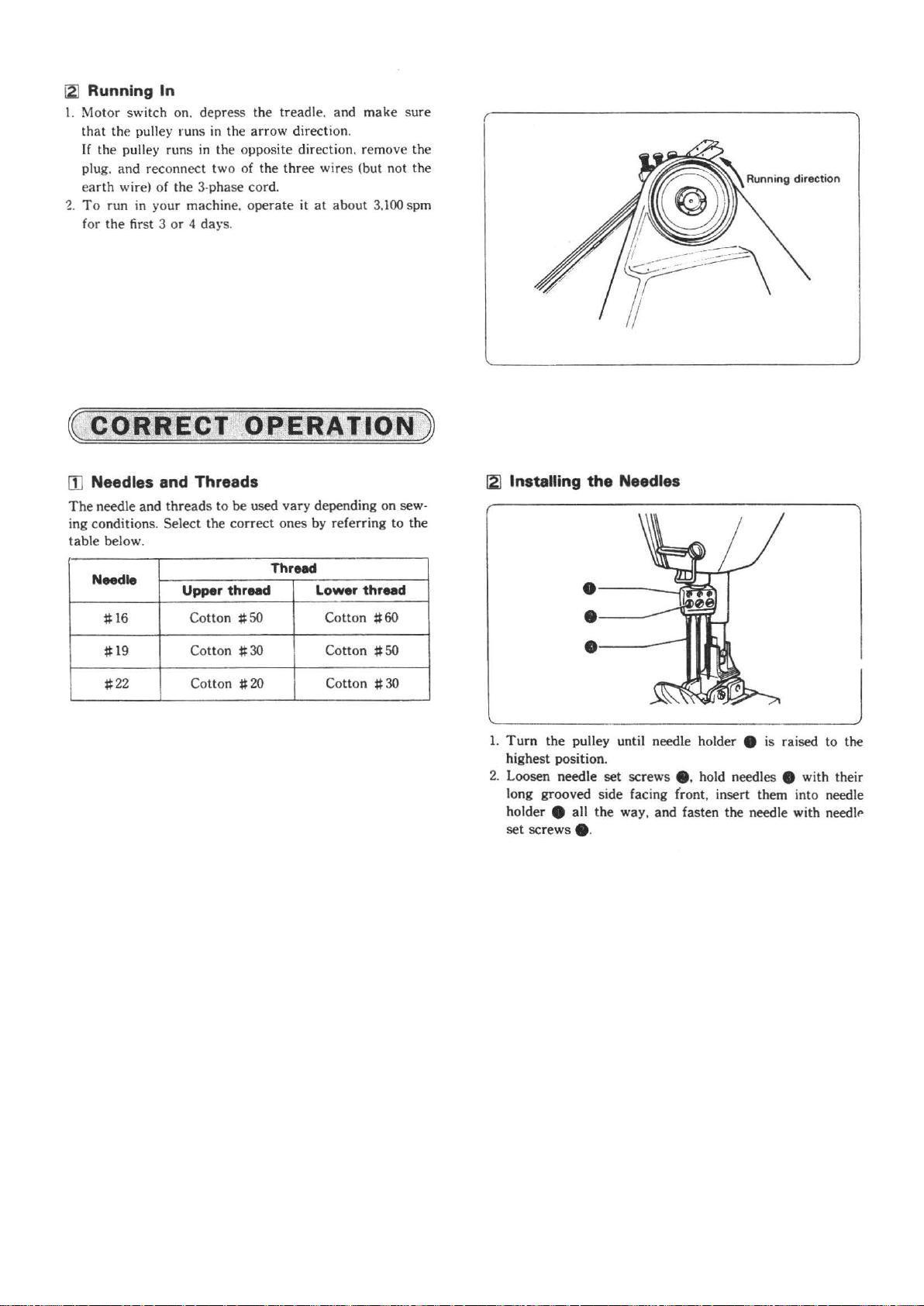

iZJ

Running In

l.

Motor switch o

that the pu

If

the pulley runs

plug. and reconnect two of the three wires (but not the

e

arth

wire) of the 3·phase cord.

'2. To

run in your machine. operate it

for the

(

[]]

The

ing conditions. Sele

table below.

fir

CORRECT

Needles and Threads

needle and

n. depr

ll

ey runs

st 3 or 4

thread

ess the treadle. and

in

the arrow directi on.

in

the opposite direction. remove the

at about 3

day

s.

o.

PERATION

s to be used vary depending on sew·

ct

the

correct

ones by referring to the

make

.100

sure

spm

)

[21

Installing

the

Needles

Needle

~16

~19

~

22

Thread

Upper threed Lower

Cotton

Cotton

Co

tton

~50

~

30

~20

Cotton

Cotton

Cotton

thr

..

~60

~50

~30

d

·--

·-

·--

1.

Tum

the pulley until needle holder 8 is raised to the

highest position.

ed

2. Loosen ne

long grooved side facing

holder

set

screws e.

le set screws e. hold needles e with their

e all the way, and fasten the needle with needll'

--

----

--

(r

ont, insert them into needle

~5~

Page 10

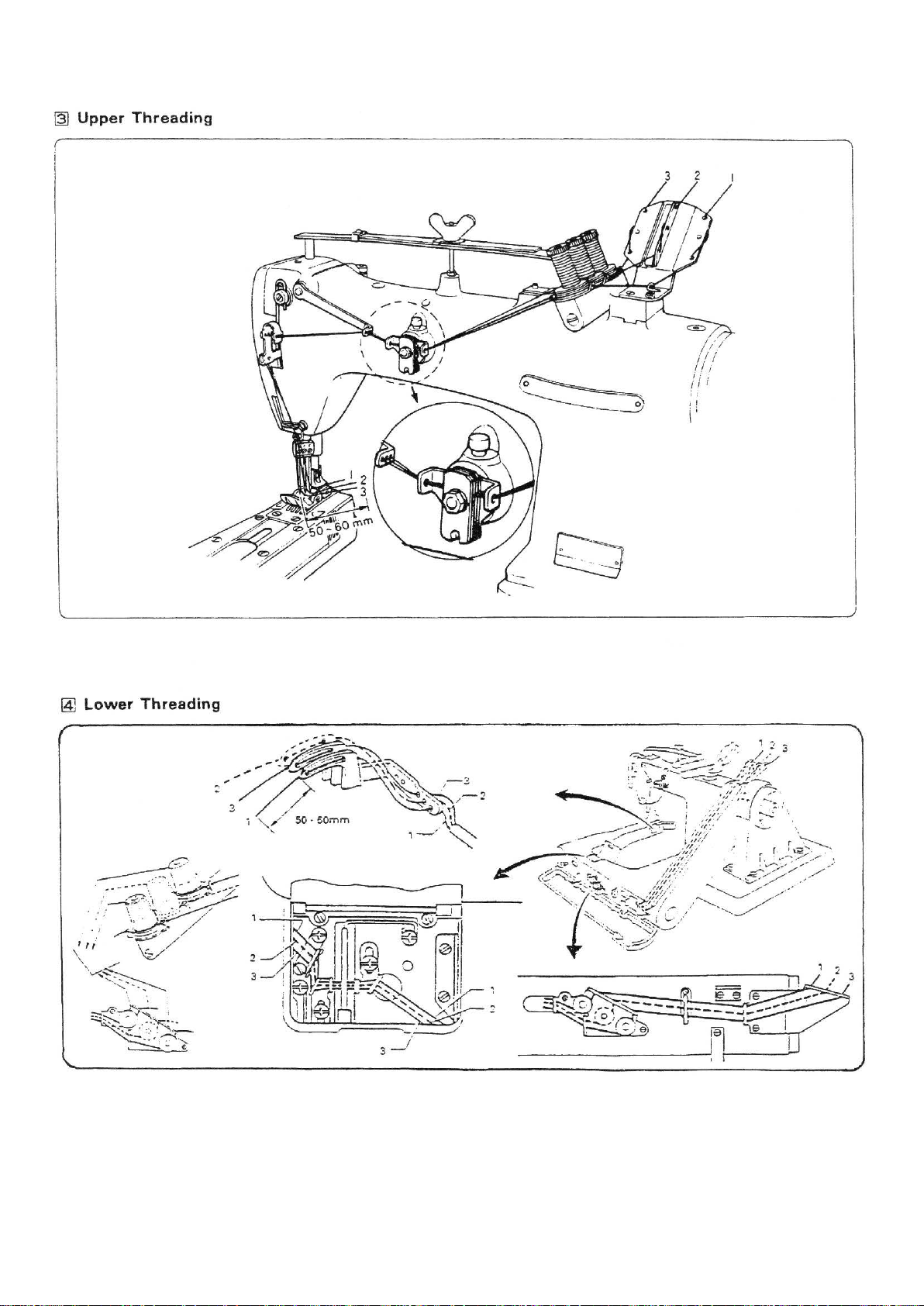

~

Upper

Threading

~

Lower

Threading

~6~

Page 11

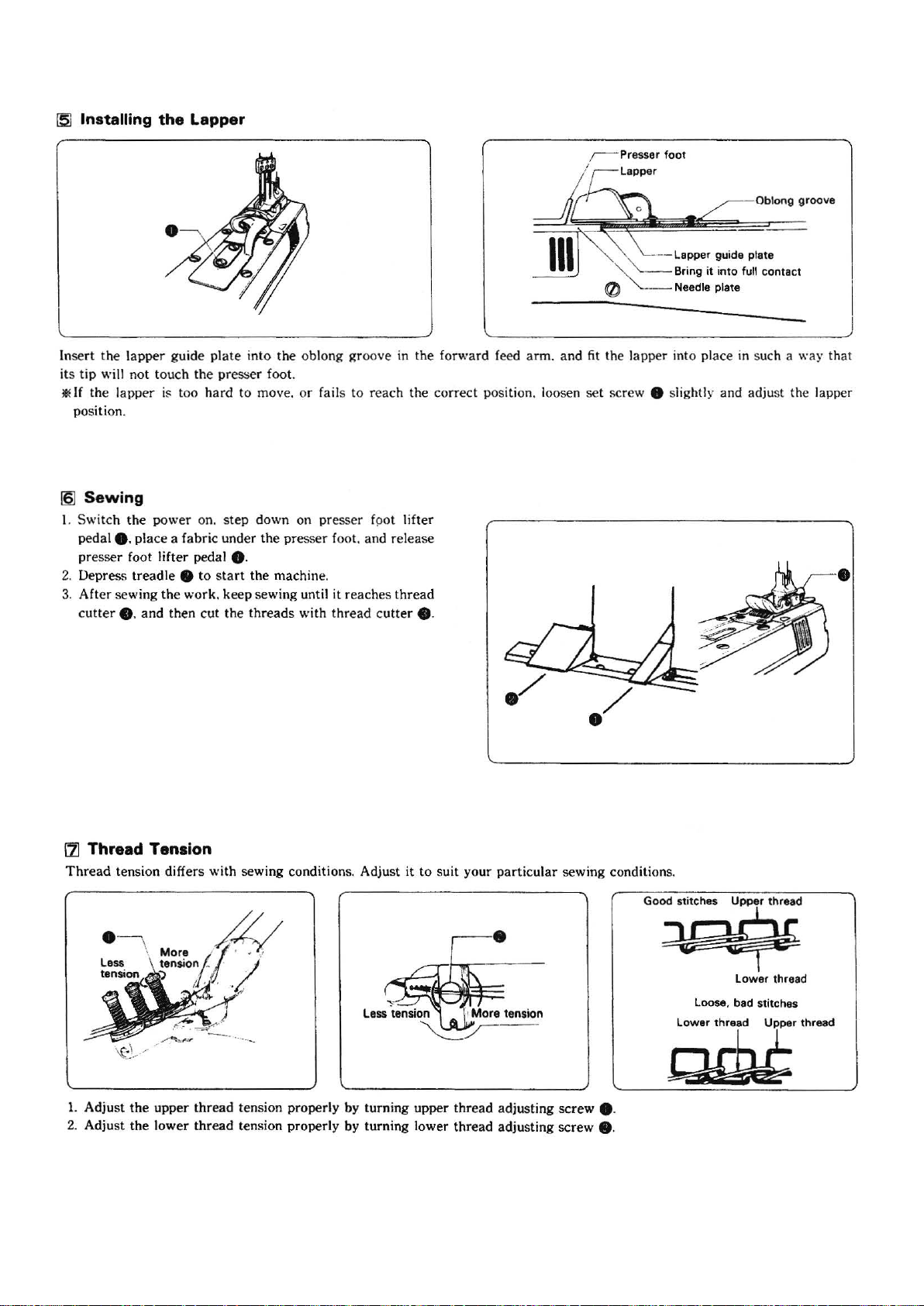

[5]

Installing

the

Lapper

/

,r--

Presser f

lapper

oot

In

sert

the

lapper guide

it

s tip will

ll

lf

position.

16)

1.

Switch the

pedal8.

presser foot lifter pedal

2.

Depress treadle 8

3.

After sewing the work. keep sewing until

cutter

not

touch the presser foot.

the la pper is too ha rd to move.

Sewing

power

place a fabric under the pre

e.

and

plate

on.

step

8-

to start the

then cut the

into the oblong groove in the forward feed arm. and

down on

machine.

threads

or

fails

to rea

pre

sser fpot lifter

sser

foot. and release

it

reaches

with

thread cutter

ch

the correct position. loosen

thread

e.

~

~

~

"-"-._"'-·-

0

fit

the lapper into place in such a way that

set

screw 8 slightly and adju

:---Lapper

Br

"'-.____

Needle plate

.

C

guide plate

ing

it

into full

o~'""'

••w

••

contact

st

the lapper

•

171

Thread Tension

Thread

tension differs with sewing condition

s.

Adjust

it

to

suit your

particular

sewing condition

· - \

1. Adjust the upper

2. Adjust the lower

thread

tension properly by turning upper thread adjusting

thread

tension properly by turning lower thread adjusting screw e.

~7~

screw

s.

G~

~

8 -

Lower thread

Loose. bad stitch

es

....

~

Page 12

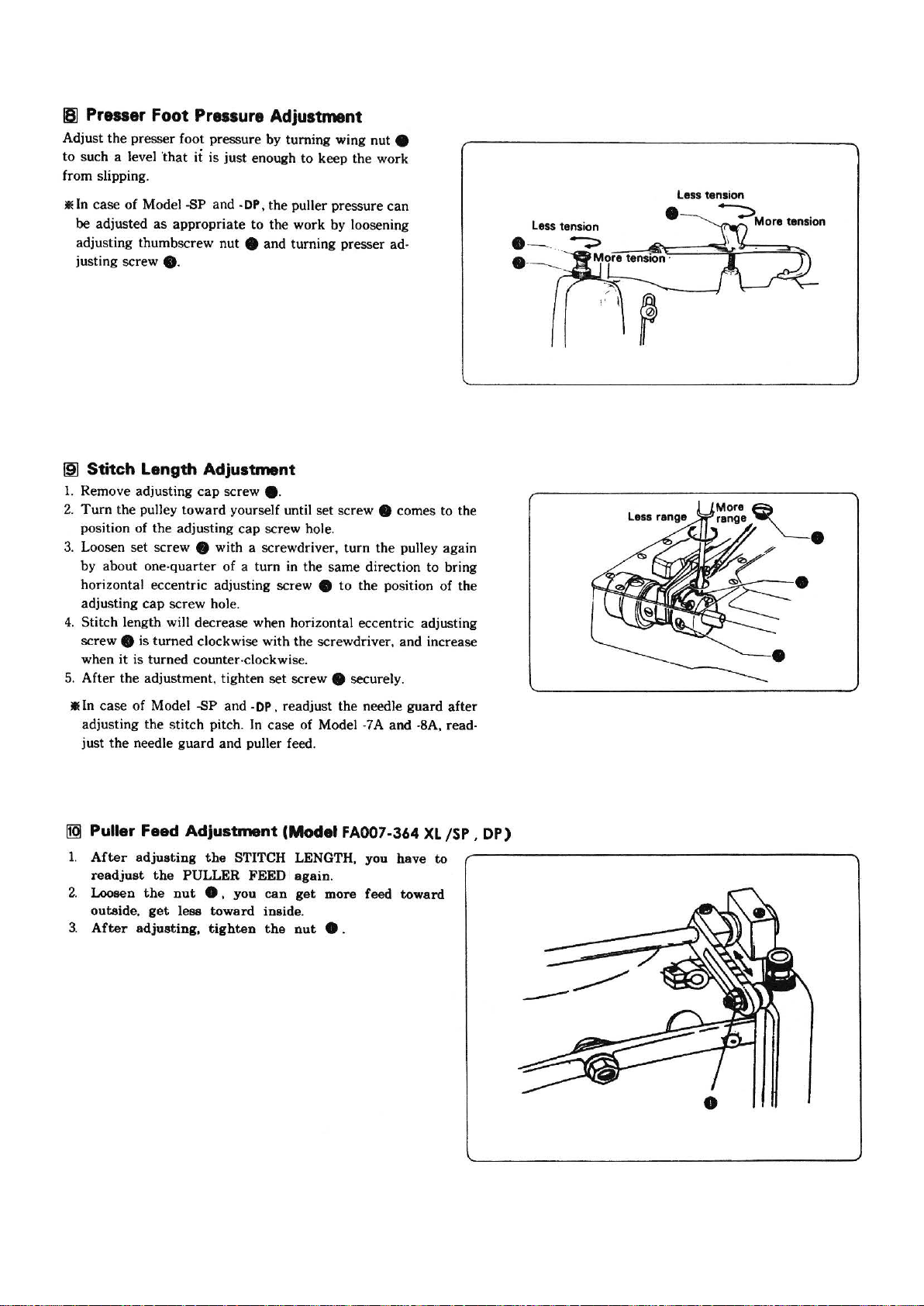

IS]

Presser

Adjust

to such a level 'that

from slipping.

liE

In

case

be

adjusted

adjusting thumbscrew nut

justing screw

19]

Stitch Length Adjustment

1. Remove adjusting

2.

Turn

position of the adjusting

3.

Loosen set screw e with a screwdriver,

by about one·

horizontal eccentric adjusting screw

adjusting

4.

Stitch length will decrease when hori zontal eccentric adjusting

screw

when

5.

After the adjustment, tighten

Foot

Pressure

the

presser foot pressure by turning wing nut e

it

is just enough to keep the work

of

Model -SP and -OP, the puller pressure

as

appropriate

Adjustment

to

the work by loosening

can

e and turning presser ad-

e.

cap

screw e.

the pulley toward yourself until

cap

screw hole.

quarter

cap

screw hole.

of a

turn

set

screw e comes to the

turn

the pulley again

in the same direction

e

to

the position of the

to

e is turned clockwise with the screwdriver, and increase

it

is turned counter-clockwise.

set

screw e securely.

bring

Less tension

•

--::>More

tension

liE

In case of Model -SP

adjusting the stitch pitch. In case of Model ·7 A and ·8A, read·

just

the

needle guard and puller feed.

1!9J

Puller Feed Adjustment (Model FA007-364

1.

After

adjusting

readjust

2. Loosen

outside,

3.

After

the

the

nut

get

adjusting,

the

PULLER

e,

less

toward

tighten

and

-OP,

readjust the needle guard after

STITCH LENGTH, you

FEED

again.

you

can

get

more

inside

.

the

nut

e .

feed

XL

have

toward

to

/SP,

DP)

•

~8~

Page 13

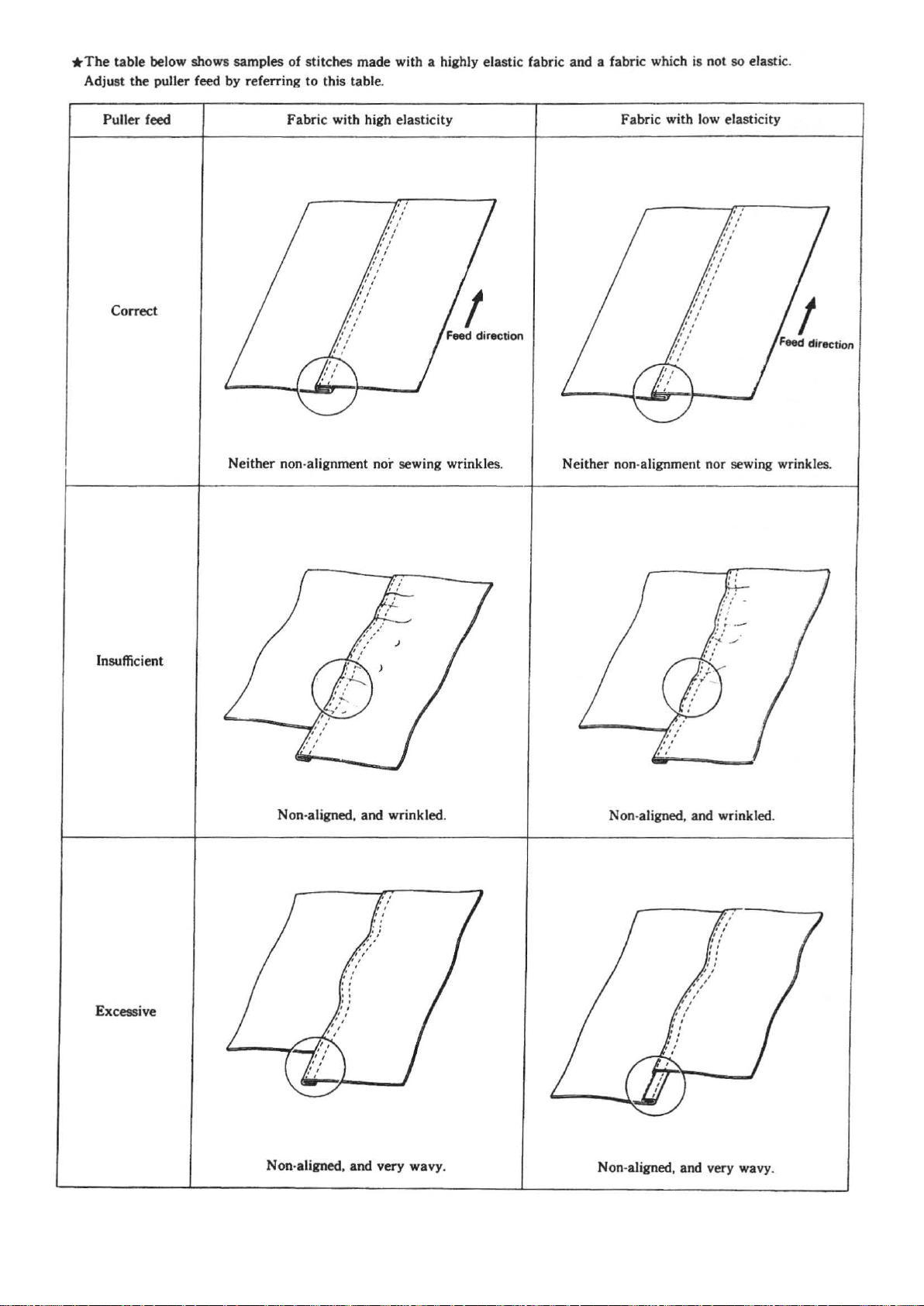

*The

table below shows samples of stitches made with a highly elastic fabric and a fabric which

Adjust the puller

feed by referring to this table.

is

not so elastic .

Puller feed Fabric with high elasticity

Correct

Neither non-alignment nor sewing wrinkles.

Fabric with low elasticity

Neither non-alignment nor sewing wrinkles.

Insufficient

Excessive

Non-aligned, and wrinkled.

Non-aligned, and wrinkled .

Non-aligned, and very wavy.

~9~

Non-aligned, and very wavy.

Page 14

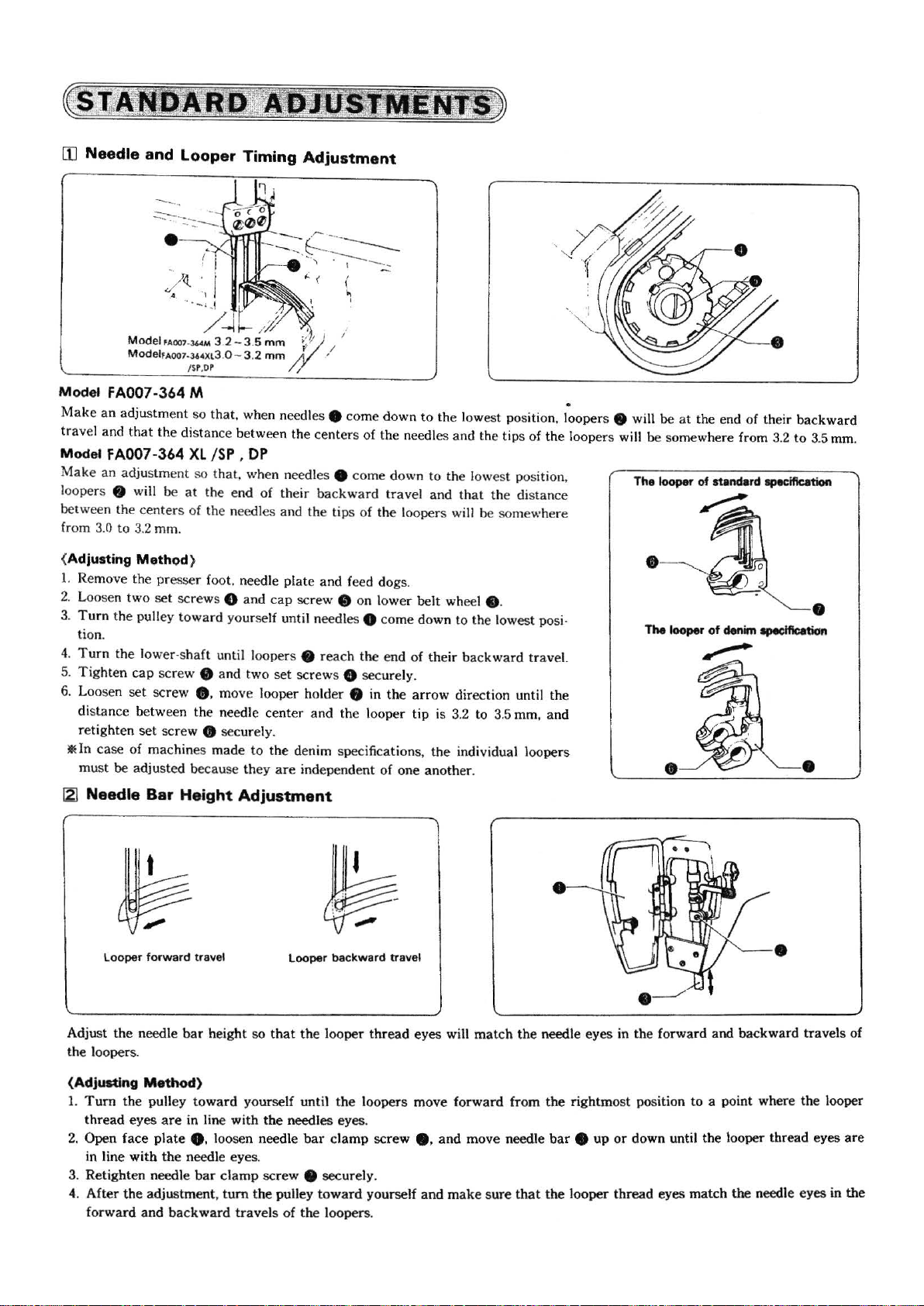

[1] Needle and Looper Timing

Adjustment

Model

FA007-364 M

an

Make

travel and

Model FA007

Mak

loopers

between the cent

from 3.0 to

{Adjusting

1.

2. Loosen two

3.

4.

5.

6. Loosen set screw e. move looper holder 8 in the

IE

[2)

adjustment so that, when needles 8 come down

that

the distance

-364

XL

e an adjustment so that, when needles 8 come down to the lowest position,

8 will

Remove the

Turn

the pulley tow ard yourself until n

tion.

Turn

the lower -s

Tighten

distan

ce

ht

retig

In

case

mu

st

be

Needle Bar

be

at the end

er

s of the needles and the tips of the loopers will be somewhere

3.2

mm.

Method

cap

between the needle center and the looper

en

set

of machines made

adjusted because they

}

pre

sser foot. needle pl

set

screws 8

haft

screw e and two

scre

w e securel

Height

between the centers of the needles and the

/SP ,

OP

of

their b

ackwa

rd

ate

and feed dogs.

and

cap

screw e on lower belt wheel 0 .

eed

les 0 come down to the lowest posi·

until loopers e reach the end of the

set

screws 0 securel

y.

to

the denim specifications, the individual loopers

are

independent of one another.

Adjustment

travel

y.

arrow

tip

to th

e lowest position,

and

that

the distance

ir

backward trave

direction until the

is 3.2 to 3.5 mm, and

tip

s of the loop

l~oper

s

8 wi

ll

ers

will be somewhere from 3.2

l.

be

at

the end of their backward

to

3.5

•

mm.

•

Looper

forward

Adjust the needle

the loopers.

{Adjusting

1.

Tum

thread

2.

Open face

in line

3. Retighten needle

4.

After the adjustment,

forward

Method)

the pull

eyes

with

an

travel

bar

height

ey

toward

are

in line with

plate

e. loosen needle

the

needle eyes.

bar

d backward

Looper bac

so

that the looper

yourself until the loopers move forward from the rightmost position to a point where the looper

the

needles eyes.

bar

clamp

scre

w 8

tum

the pulley toward yourself

trave

ls of the loopers.

kward

thread

clamp

securely.

travel

eyes will

screw

8 . and move needle

and

make sure

mat

ch the needle eyes in the forward and backward travels

bar

that the looper

~10~

•

8 up

or

down until the looper thr

thread eyes match the needle eyes in the

ead

of

eyes are

Page 15

13]

Looper Timing

0 - 0 .

Model FA007-364

05mm

for

Avoiding

0.2mm

Push

needle

M Model FA007-364

Contact

0.2-

Xl/SP,

with

0.3

Needles

•

mm

DP

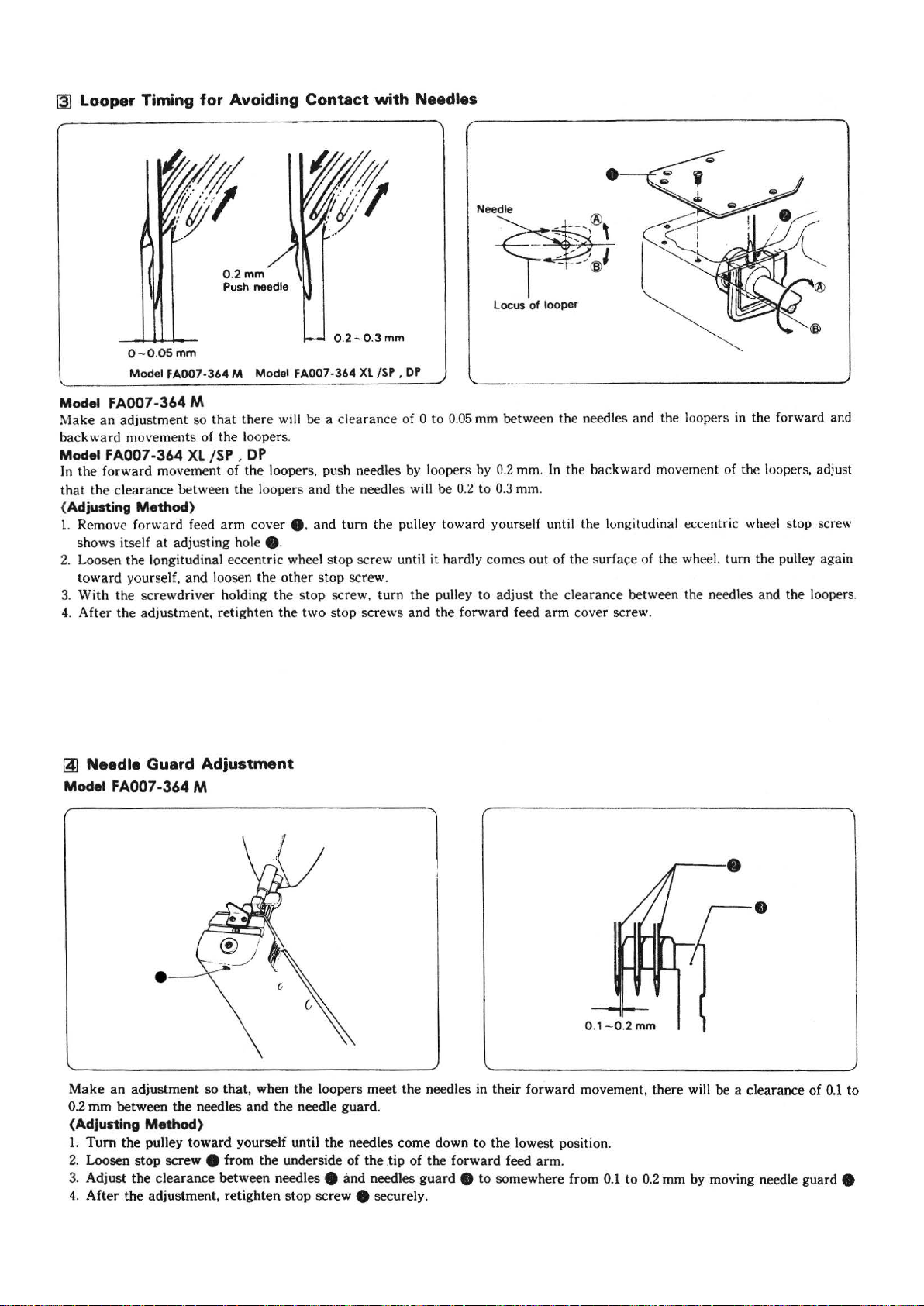

Model FA007

Make

an

backward movements of the loopers.

Model FA007-364

In

the forward movement of the loopers. push needles by loope

that

the clearance between the loopers and the needles will be 0

(Adjusting Method)

1.

Remove forward feed

shows itself

2.

Loosen the longitudinal eccentric wheel stop screw until it hardly comes out of the surface of the wheel. turn the pulley again

toward yoursel

3.

With the screwdriv

4. After the adjustment, retighten the two stop screws and the forwa rd feed

~

Needle Guard Adjustment

Model FA007-364 M

-364

adjustment so th

M

XL

/SP.

at

adjusting hole • ·

f,

and loosen the other stop screw.

er

at

there will be a clearance of 0 to

DP

arm

cover 8 . and turn the pulley toward yourself until the longitudinal eccentr

holding the stop screw. turn the pulley to adjust the clearance between the needles and the loopers.

0.05

mm between the needles and the loopers

rs

by

0.2

mm.

In

the backward movement of the loopers, adjust

.2

to 0.3

mm.

ar

m cover screw.

in

the forward and

ic

wheel stop screw

•

Make

an adjustme

0.2 mm between the needles

{Adjusting Method)

1.

Tum

the pulley toward yourself until the needles come down to the lowest position.

2.

Loosen

3.

Adjust the clearance between needles e and needles

4.

stop

After the adjustment, retighten stop screw e securel

nt

so

that, when the loopers meet the needles in their forward movement, there w

and

the needle guard.

screw e from the unde

rs

ide of the .tip of the forward feed arm.

guar

d e

to

somewh

y.

~11~

ere

0.

1-0.2

from 0.1 to

•

mm

ill

be a clearance of

0.

2 mm by moving needle guard e

0.1

to

Page 16

Model FA007-364

The

clearance between the needles

lo

opers will be 0.

guard

8 .

XL

/SP,

05

mm, pushing

DP

the

and

the tips of

needles

by

the

needle

(Adjusting Method)

1.

Turn

the

pulley toward yourself until

come down to the lowest position.

2.

Lo

osen stop screw e. and raise

8 so

that

the bottom ends of the needle eyes will be

about 0.5 mm above the bottom of needle

3. T urn the pulley toward yourself again until

of the loopers come to the c

4. Loosen stop screw

left or to the right,

between the needles

be 0.

05

mm, pushing needle points by needle guard

At

this time, please

between the loopers

in the

backward

151

Feed Dog Height Adjustment

Model FA007-364 M

Make

an

adjustment so that. when feed dog e is

pos

ition. the feed

needle

plate

.

Model FA007-364

Make

an ad

justme

be

1.2 mm above

(Adjusting Method)

Adjusting the feed

e.

and

and

make

and

move

ment

dog

will be 0.8 mm above

XL

/SP,

nt

so

that

the

top surface of the needle

dog

height by turning feed

or

enters

move needle

adju

st so

the tips

sure

the needles is 0

of

the

DP

the

highest

the

lower needle

of

the

needles.

guard 8 to

that

the

of

the

loopers will

that

the clearance

.2-

loopers.

the

part

needles

guard

guard

e.

the

tips

the

clearance

8.

0.3 mm

at

top

surface

of

the

feed

plate

.

base

eccentric

the

highest

of

dog

shaft

--

··

-

-·

~1-2mm

0.

05

mm-++---o

the

will

.2 - 0.3

•

mm

••

16)

Puller Height Adjustment (Model FA007-364

Adjust

the

height of puller e so

the top of

{Adjuatlng Method)

Loosen

puller

the

needle plate.

set

screw e. and move puller

e is

0.1

to

0.2

mm

above

that

the

it is

support

top

of

0.1

the

to

0.2

e up

needle

mm

htgh from

or

down until

plate

XL

.

/SP,

DP)

~12~

Page 17

lZJ

Installing

(For

If

stitch irregularities develop in sewing very heavy materi-

al

s, adjust the sub-feed dog

(Adjusting

1. Remove

2.

Placer spac

scre

w e.

!lEThe s

the

the

Method)

set screw

pacer

Spacer

denim

specifications}

to

e and sub-f

er e under sub-feed dog e

is in the

parts

the correct

eed

box.

height by spacer.

dog e.

and

retighten

set

eJ

Upper

Thread

Adjustment

\

I

\

I

\

Model FA007-364 M

Make

an

the lowest position, the

thread hole meets

Model

Please adjust

thread

7-Smm.

FA007-364

take-up and

••· .••

•

Upper thread W

take-up

adjustment so

the

the

distance between the center

Take-up

~

Thread

-..{

-l·ll. guide

Model

FA007-364M

that,

when

top

bottom

XL

/SP ,

the top

Thread

of

the upper thread

of

the

Guide

the

needle

thread guide.

Model

bar

DP

of

the thread guide wi

FA007-

is down

take-up

of

the uppe r

36.X

/SP.OP

at

ll

be

l

19]

Thread

Release

Lever

Adjustment

(Adjusting

1.

Turn

the

down

at

2.

Loosen

th

rea

d guide e

top of

liE

The

higher

greater

Method)

pulley toward yourself until the needle bar is

the

lowe

st

positio

n.

set

screw e. and move upper thread take-up

up

or

down until its bottom meets the

the upper

will be

thread t

th

e upper thread take-up thread guide 8. t

the

ake

-up thread hole.

upper thread loops.

ht

Make

an

the th

re

ad

(Adjusting

1.

Tum

the

2.

Loosen set

tension

liE

Th

e higher

adjustment so

hole in upper

Method}

pulley until

screw

bracket

the

e.

e.

thread

that,

when

thread

tension

the

needle

and

raise

or

release lever,

the nee

dle

bar

is down

bra

cke

t e.

bar

is down

lower thread release lever e until its

the

at the lowest position.

tighter

will

be

at

the

the

lowest position,

stitches.

thread hole meets the thread hole in upp

~13~

the

thread release l

ever

thread hole meets

er

thread

Page 18

I!QI

Thread Release

Make

an

adjustment so

loosen when

presser foot

the

is

Shaft

presser foot is raised , and tighten when the

lowered.

that

the

Adjustment

thread tension discs will

[j] Upper Thread Nipper Adjustment

Adjust the clearance between the upper thread nipper ten-

bracket

sion

0.8 mm and

and tension plates to somewhere between

1.0

mm.

(Adjuating

1.

Loosen stop screw 8 .

2.

Make

so

the presser

the needle

3. After the adjustment, retighten

jgj Lower Thread

Make

move

to 7

(Adjusting

1.

Insert a screwdriver into the adjusting hole in the bed,

and loosen two stop screws

2. Raise lower

take-up

3. After

Method)

an

adjustment by turning thread release s

that

the

thread tension discs will begin

foot

is raised 4 mm above

plate

.

stop

Take-up

an adjustment so that, when the loopers begin to

backward

mm

, lower thread take-up e will rise about 5

above lower

Method)

thread

Timing Adjustment

take-up

to

loosen when

the

top surface of

screw 8 securely.

bracket

• ·

e.

thread

take-up 0 5 to 7 mm above thread

bracket

the

• ·

adjustment, retighten

two

stop screw e.

haft

(Adjusting

1.

Loosen

•

sion

and tension plates

*Stitch

ance between upper thread nipper tension bracket

the

Method)

stop

bracket

tightness

arm.

screw

8.

and move upper thread nipper ten-

• in

or

out until the clearance between it

e is somewhere from 0.8 to

can

be improved by

narr

owing the clear-

7mm

1.0

mm.

8 and

~

Puller Device Timing Adjustment (Model FA007-364

1.

With

3mm

2.

The timing

needle

6mm.

3.

After

• &

wrench

of

is

away

and

stoping

adjusting the

•.

the

from

to

loosen

feed

the

at

lOmm.

timing.

will

needle

the

screw

be

stsrting

plate

retighten

8 & e

when

about 5 or

the

screw

the

XL

/SP

, DP)

~14~

•

Page 19

(TROUBLESHOOTING)

Trouble

Thread breaks.

Needles break.

I

I

Needles installed

improperly_

Upper thread tension too

great.

Lower thread tension too

Thread

Needle eyes too sma

threads.

Loopers

'---------

!lieedles damaged.

'------------

Needles hit loopers.

Needles in

improperly.

Needl

Needle

threads.

Cause

relea

damaged

es

hit

eyes

sta

se

lever

out

ll

for

.

---

--

--------'

lled

needles guard.

too small for

I

of

t---

-'

I----

L

Inspection

Direction of long groove.

Upper thread tension.

Lower thread tension.

Threa

d release lever

and

Needle size

---------

----

Direction of long groove.

rciearance

and needles guard.

Needle size and thread

thread

------11

--

-------1JRep

between

n~edles

I

I

L

Refer to-

'--

ne __

J

Ref~r_t_o_t_h_e

.__"

smooth

~d__e~per

~n

Adjust looper timing to

avoid contact with needles.

Ad' t. ell d

Remedy

;;;-

s-t-ru_c_t-

e_d_l_e_i_ns_t_a~l_ir_tR

_

N_e_ed_l_e_s_an_d_T_h_r~ds"'

loopers with

or_?~.!!

lace needles with

__

e_s_.

________________ ~ __

--

---------··----

JUS

nee

------------

I Refe; to the -sec

"l'<eedles

and

io_n_s_f_o;-l·

:

_ _

____ , __

-se-.c-ti_o_n_

o_

n_ --r---

1

_

___j

_::~_

-r~

-

·

_

____1:-::::

~ood

I

--

-EJ

- -

e~

guar . !

--t-:Threads"

~--;!

i-on

__

o_n

__

--,

-

--=-~

:J

__

j

-

l

J

_ J

j

5

_ j

1

11

_j

-----'

1

___

~

Stitches

Upper

skip.

threads loose.

Needles installed

improperly.

Looper

points

are

'------

Needle

wrong.

Clearance between needles

and loopers too

Lower

timing wrong.

Upper

small.

Lower thread tension too

great.

Upper

guide

Upper

not tighten upper threads.

-

and

thread

thread

thread

out

of position.

thread

dull. r---

--

-----'

looper timing

great.

take-up

tension too

take-up

thread

nipper does

Direction of long groove.

--

------

Needle and looper timing.

r:C~

I-ea-r-an

_c_e 7be_t_w-ee_n_n_ee_d_l

and looper

Lower

timing.

Upper

Lower thread tension.

t-----------------------

Tension

s.

thread

thread

plate

------t

~s

take

-up

tension.

~Ie

arance

.

Refer to instructions for

needle installing.

Replace loopers with good I

Adjust needle and looper

timing.

Adjust clearance

needles and loopers. __

~djust

lower thread

·

ttmtng. ,

~

~

th~ea-

I I Adjust

---

upJX'r

d

guide position. .

u)!lper

~

~___.1

__ ._l_l

betw~-~

____

take·u~

~--

thread take-up

thr

ead

n~pper

c

10

10

-1-l

j_

-

~

14

7

ll

13

~

14 !

.

_

__

1

j

_j

1

l

j

~15~

Page 20

Tr

ouble

I

I

Cause

I I

Inspection

I I

Remedy

I Pag

el

Feed dog too low.

Presser foot pressure too

small.

not

Machine does

work.

Non-lllignment lind

wrink

...

(Model · FA007·364M )

Non-alignment lind

wrinkles

(Modei·FADD7·364XL/~f.Df]

feed

Feed dog worn out.

Presser foot floats and does

not fully press work.

Feed dog and presser foot

work on one side only.

Sub feed dog height

incorrect.

Presser foot pressure

incorrect.

Feed dog height incorrect.

Pu

ll

er

Puller feed incorrect.

Presser foot pressure

incorrect.

timing wrong.

Feed dog height. Adjust feed dog height.

Presser foot pressure.

Adjust presser foot

pressure.

I Have serviceman check it.

I Have serviceman check it.

Have serviceman check

them.

Sub feed dog height. Adjust sub feed

Presser foot pressure.

Feed dog height. Ajust feed dog height.

Puller timing. Adjust puller device timing.,

Puller feed.

Presser foot pressure.

Adjust presser foot

pressure.

Adjust puller feed.

Adjust presser foot

pressure.

dog

height.

L/1

L/1

14

Feed dog height incorrect.

Feed

dog

height. Adjust feed dog height.

~16~

Page 21

CONTENTS 目錄

CO-MACHINE BODY

............................................................................1

機體下拉布輪

C1-UPPER SHAFT MACHANISM

......................................................3

上軸結構

C2-NEEDLE BAR MECHANISM-FEED MECHANISM

針柱與送布傳動結構

C3-PULLY MECHANISM

......................................................................7

皮帶傳動結構

C4- PRESSER BAR MECHANISM

....................................................9

壓腳柱結構

C5-LOOPER MECHANISM

................................................................11

彎針傳動結構

C6-UPPER THREADING MECHANISM

.........................................13

上導線張力結構

................5

C7-LOWER THREADING MECHANISM

........................................15

下導線張力結構

C8-LOWER SHAFT MECHANISM-GAUGE PARTS

....................17

下軸結構與針位組

C9-GAUGE PARTS(SP) SP

..............................................................19

針位組

C10-GAUGE PARTS (DP) DP

..........................................................21

針位組

C11-PULLER DEVICE MECHANISM DP、SP

............................23

上拉布輪結構

C12-ACCESSORIES

...........................................................................25

配件

~17~

Page 22

4

1

C2

CO~1~

Page 23

MACHINE BODY

REF. NO.部件編號

C0-01

C0-C2

C0-04

C0-05

C0-05-1

C0-06

C0-07

C0-08

C0-09

C0-11

C0-11-1

C0-12-1

C0-12A

C0-B17-1

C0-A17-3

C0-17-3

C0-18

C0-X28-1

C0-X31

C0-X67

C0-X67-2

C0-X77

MACHINE HEAD 機體(上)

MACHINE REST BOARD 機體(下)

OIL PLUG 油塞

LOWER WHEEL 拉布輪

LOWER WHEEL 拉布輪

LOWER WHEEL CONNECTION 拉布輪軸

ONE WAY TRIANGULAR AXLE 單向三向軸片

ONE WAY STILL SPRING 單向彈簧

ONE WAY STILL BALL 單向滾珠

ONE WAY PUSHING PLATE 單向推輪

PIN 銷

FEED DOG PUSHING PLATE LINK 推輪連桿

SCREW 合葉螺釘

PULLER COVER 導蓋(右)

PULLER TOP COVER 護輪蓋

PACKING 導蓋

PLASTIC COVER 橡膠塞

SCREW 11/64×40 螺釘

SCREW 9/64×40 L8 螺釘

SCREW 3/32×56 螺釘

SCREW 3/32×56 L6 螺釘

SCREW 11/64×40 L9 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

2

6

6

1

1

1

1

1

1

1

2

2

3

3

3

2

~2~

Page 24

Y2

4

4-1

PL,PL-M,SP

X9

X38-1

X38-1

SM

9-1

6-1(PL,SP,PL-M)

PL,PL-M,SP

7-1

6(SM)

31

16

C1~3~

Page 25

UPPER SHAFT MACHANISM

REF. NO.部件編號

C1-01

C1-02

C1-03

C1-04

C1-04-1

C1-Y2

C1-06

C1-06-1

C1-07

C1-08

C1-09

C1-7-1

C1-9-1

C1-10

C1-11

C1-12

C1-13

C1-14

C1-15

C1-16

C1-17

C1-18

C1-18-1

C1-18-2

C1-18-3

C1-19

C1-21

C1-22

C1-22A

C1-23

C1-24

C1-25

C1-26

C1-27

C1-29

C1-30

C1-31

C1-102

C1-102-1

C1-X3

C1-X4

C1-X5

C1-x6

C1-X7

C1-X9

C1-X38-1

PULL BAR ENDING SCREW 合葉螺釘

VERTICAL PULL BAR 傳動連桿

PULL BAR BEARING 滾柱軸承

VERTICAL PULL BAR FIXING SCREW 合葉螺釘

WASER 墊圈

PULL BAR SCREW NUT 止動螺母

UPPER SHAFT 上主軸

UPPER SHAFT 上主軸

BALL BEARING 6202 軸承

BEARING SUPPORT 軸承圈

OIL STOPPER 油封

FIXING BUSHUNG 上軸套(前)

CHOCK RING 定位圈

BEARING CASE ASSEMBLY 軸套筒

BEARING 6302 軸承

OIL TANK 儲油器

OILGAUGE WINDOW 油鏡

PACKING 油封墊圈

OIL GAUGE FLANGE 儲油器蓋

OIL TANK PACKING 止油銅墊圈

PACKING 橡膠墊圈

UPPER WHEEL ECCENTRIC WHEEL 偏心凸輪

ECCENTRIC WHEEL WASHER 凸輪蓋

BEARING 滾柱軸承

SCREW 9/64×40 螺釘

UPPER WHEEL MOVING PULL BAR 凸輪傳動連桿

PULL BAR SCREW NUT 合葉螺釘

FIXING PULL BAR SCREW WASHER 止滑墊圈

WASHER 墊圈(厚PL,PL-M,SP)(薄PL,PL-M)

PULL BARSCREW NUT 螺母

THICKNESS ADJUSTING PULL BAR 擺動傳桿

PULL BAR FIXING PULL BAR 螺釘

UPPER WHEEL CONNECTION 傳動軸

MOVABLE LEFT-RIGHT CHOCK RING 定位圈

CONNECTION COPPER TUBE 銅套筒

VERTICAL PULL BAR 雙頭合葉螺釘

WASHER 墊圈

BEARING FIXING SCREW 外牙螺母

BEARING FIXING BUSHING 緊壓套筒

SCREW 15/64×28 螺釘

SCREW 15/64×28 螺釘

SCREW 9/64×40 螺釘

CAP SCREW 覆蓋螺釘

SCREW 1/4×28 螺釘

SCREW 15/64×28 螺釘

SCREW 11/64×40 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

2

2

2

2

1

1

2

1

1

1

1

1

1

4

1

2

2

2

~4~

Page 26

10(PL-M,SM)

10-1(PL,SP)

12-1(PL-M,SM)

12(PL,SP)

9(PL-M,SM)

9-1(PL,SP)

11(PL-M,SM)

11-1(PL,SP)

(PL,SP,#22)

(PL-M,SM,#18)

X9

3(PL-M,SM)

3-1(PL,SP)

(PL,SP) 66

(PL-M,SM) 7

×

×

X7

C2~5~

Page 27

NEEDLE BAR MECHANISM-FEED MECHANISM

REF. NO.部件編號

C2-01

C2-02

C2-03

C2-03-1

C2-04

C2-05

C2-C6

C2-07

C2-08

C2-09

C2-09-1

C2-10

C2-10-1

C2-11

C2-11-1

C2-12

C2-12-1

C2-14

C2-15

C2-16

C2-17

C2-18

C2-C19

C2-20

C2-C21-1

C2-22

C2-23

C2-24

C2-C25

C2-26

C2-X7

C2-X8

C2-X9

C2-X10

C2-X14

C2-X31-1

C2-X49

C2-X66

NEEDLE BAR CRANK 固定軸

NEEDLE BAR CRANK BOD 提升連桿

NEEDLE BAR BRACKET 針柱夾

NEEDLE BAR BRACKET 針柱夾

WICK 油蕊

OIL LEAK PROOF CAP 防油蓋

WICK 油蕊

NEEDLE BAR GUIDE SLIDE BLOCK 四方滑塊

NEEDLE BAR GUIDE 導軌

NEEDLE BAR 針柱

NEEDLE BAR 針柱

NEEDLE BAR BUSHING (UPPER) 針柱套筒(上)

NEEDLE BAR BUSHING (UPPER) 針柱套筒(上)

NEEDLE BAR BUSHING (LOWER)針柱套筒(下)

NEEDLE BAR BUSHING (LOWER)針柱套筒(下)

THREAD TAKE-UP CRANK 平衡凸塊

THREAD TAKE-UP CRANK 平衡凸塊

OIL CAP 橡膠塞

NEEDLE 針(PL,SP#22)(PL-M,SM#18)

FEED DOG ECCENTRIC AXLE 調節凸輪

WASHER 墊圈

ECCENTRIC WHEEL SLEEVE 銅滑塊

ECCENTRIC WHEEL WITH SCREW 上下凸輪

ECCENTRIC WHEEL SLEEVE 銅滑塊

FEED BAR SLIDE BLOCK ASSEMBLY 送布傳動曲柄

PACKING 油封墊圈

FEED LIFTING FORK 叉動柄

FEED BAR SLIDE BLOCK ASSEMBLY 四方滑塊

FEED BAR ECCENTRIC SHAFT 偏心軸

FEED DOG ECCENTRIC SET 固定座

SCREW1/4×40 螺釘

SCREW11/64×40 L12 螺釘

SCREW 15/64×28 螺釘

SCREW 15/64×28 螺釘

FEED ECCENTRIC ADJUSTING SCREW 倒位螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 L5 螺釘

THREAD TAKE-UP CRANK 平衡凸塊

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

5

4

5

2

1

1

1

1

~6~

Page 28

X7

C3~7~

X7

Page 29

PULLY MECHANISM

REF. NO.部件編號

C3-01

C3-02

C3-03

C3-04

C3-05

C3-06

C3-07

C3-08

C3-09

C3-10

C3-20

C3-X01

C3-X07

X3-X09

C3-X18

C3-X22

C3-X79

PULLEY 皮帶輪

TIMING BELT WHEEL ASSEMBLY (SUPPER) 同步皮帶輪(上)

TIMING BELT WHEEL ASSEMBLY (LOWER) 同步皮帶輪(下)

TIMING BELT 同步時規皮帶

BELT COVER 皮帶座

BELT COVER PLATE 皮帶座蓋板

PACKING 防油墊片

PULLEY COVER BASE 配重固定塊

PULLEY COVER 皮帶輪護蓋

WASHER 墊圈

SPRING COIL O型彈圈

SCREW1/4×28 螺釘

SCREW1/4×28 螺釘

SCREW1/4×28 螺釘

SCREW 15/64×28 螺釘

SCREW 7/16×14 螺釘

SCREW 3/16×32 L8 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

2

3

2

5

2

2

2

2

~8~

Page 30

(SP,SM)

D2-27

SP

X95

1A

5-1

C4~9~

1B(PL)

1(PL-M,SM )

5(PL,PL-M,SM)

Page 31

PRESSER BAR MECHANISM

REF. NO.部件編號

C4-01

C4-1A

C4-1B

C4-02

C4-03

C4-04

C4-05

C4-5-1

C4-06

C4-07

C4-08

C4-09

C4-10

C4-11

C4-12

C4-13

C4-14

C4-15

C4-16

C4-17

C4-B18

C4-19

C4-20

C4-24

C4-X8

C4-X9

C4-X25

C4-X26

C4-X27

C4-X31

C4-X44

C4-X60

C4-X95

C4-Y02

C4-D2-27

PRESSR BAR 壓腳柱

PRESSR BAR 壓腳柱

PRESSR BAR 壓腳柱

FACE PLATE UPPER HINGE ASSEMBLY 蝶型後鈕

STEEL BALL 鋼珠

PRESSER BAR BUSHING (UPPER) 壓腳柱軸套(上)

PRESSER BAR BUSHING (LOWER) 壓腳柱軸套(下)

PRESSER BAR BUSHING (LOWER) 壓腳柱軸套(下)

FACE PLATE (LOWER) 前蓋板(下)

PACKING 防油墊片

PRESSER BAR CLAMP ASSEMBLY 壓腳柱夾

PRESSER BAR CLAMP SPRING 壓力板

PRESSER BAR CLAMP SPRING PIN 定位銷

PRESSER BAR CLAMP SPRING ASSEMBLY 上壓力彈片

GUIDE WASHER 定向墊片

WING NUT 蝶型螺母

PRESSER BAR LIFTER 壓腳提放勾

KNEE LIFTER LEVER 壓腳提放柄

KNEE LIFTER SPRING 壓腳提放彈簧

PRESSER FOOT LIFTER CHAIN ASSEMBLY 傳動鏈條

FACE PLATE (UPPER) 前上蓋

STOPPER SPRING PLATE (L) 彈片勾(外)

STOPPER SPRING PLATE (S) 彈片勾(內)

OIP CAP 油塞

SCREW11/64×40 螺釘

SCREW 15/64×28 螺釘

PRESSER ADJUSTING SCREW 全牙螺釘

STUD SCREW 15/64×28 螺釘

STUD SCREW 5/16×28 螺釘

SCREW 9/64×40 L10 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 3/16×32 螺母

RUBBER PLUR 橡膠塞

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

3

4

1

1

1

1

~10~

Page 32

2

C29

X35

C5~11~

21

Page 33

LOOPER MECHANISM

REF. NO.部件編號

C5-02

C5-C3

C5-C4

C5-C5

C5-06

C5-C7

C5-C8

C5-09

C5-10

C5-C11

C5-12

C5-C13

C5-A14

C5-C15

C5-16

C5-17

C5-C18

C5-C19

C5-20

C5-21

C5-22

C5-23

C5-25

C5-26

C5-27

C5-C28

C5-C29

C5-C30

C5-C31

C5-32

C5-33

C5-702

C5-X9

C5-X28

C5-X28-1

C5-X31

C5-X32

C5-X34

C5-X35

C5-X36-1

C5-X37

C5-X38-1

C5-X42

C5-X50

C5-X56

C5-Y01

ECCENTRIC WHEEL SLEEVE 銅滑塊

LOOPER FEEDING FORK 滑動叉

LOOPER FEEDING SHAFT 滑動叉(軸)

LOPPER FEEDING SHAFT BRACKET 滑動叉基座

PIN 叉銷

LOOPER FRONT-REAR TRANSMISSION 前後驅動連桿

SLIDE BROCK SHAFT 固定軸牙

LOOPER LEVER SHAFT ?節固定軸

PACKING 墊圈

CONNECTING ROD GUIDE PLATE 上下驅動連桿

WASHER 墊圈

LOOPER SHAFT CLAMP 傳動軸夾

LOOPER SHAFT 傳動軸

LOOPER SHAFT BUSHING (F) 傳動軸套筒(後)

LOOPER SHAFT BUSHING (B) 傳動軸套筒(前)

SET COLLAR 定位夾

FORWARD ARM CONER ASSY 平面蓋板

PACKING 防油墊片

OIL GAUGE 探油棒

PACKING 橡膠墊圈

CAP PLATE 下軸蓋

PACKING 防油墊片

"8"TYPE TRANSMISSION DEVICE 8字銅連桿

ECCENTRIC WITH SCREW 小凸輪

EYEPIECE H型連桿

STEEL BALL 萬向滾珠

LOOPER SLIDE BASE 連桿固定片

WASHER 波浪彈片

LOOPER FEEDING FORK 叉動柄

---

--SQUARE BALL 四方滑塊

SCREW 15/64×28 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 3/32×56 螺釘

SCREW M3.5 L=10 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 1/2×28 螺釘

SCREW 9/64×40 L=5 螺釘

SCREW 15/64×28 螺釘

NUT 15/64×28 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

16

2

1

2

4

1

2

3

4

2

1

~12~

Page 34

i

X65

1

7-1

n

X44

PL ' SP • PL

X51

T~

X

-M -

26

SM -826

~~1-1

30

~

e

~lU1

r

XB

~

I i

ij

w

~-..j

X34

-1

~-~

~

34(PL-M,SM)

34-1(PL,SP)

C6~13~

Page 35

UPPER THREADING MECHANISM

REF. NO.部件編號

C6-01

C6-03

C6-06

C6-07

C6-7-1

C6-08

C6-09

C6-10

C6-11

C6-12

C6-13

C6-14

C6-15

C6-16

C6-17

C6-18

C6-23

C6-24

C6-25

C6-26

C6-27

C6-28

C6-29

C6-30

C6-31

C6-32

C6-33

C6-34

C6-34-1

C6-35

C6-36

C6-37

C6-38

C6-39

C6-A40

C6-41

C6-43

C6-44

C6-X8

C6-X9

C6-X31-1

C6-X34-1

C6-X44

C6-X47

C6-X48

C6-X49

C6-X50

C6-X51

C6-X53

C6-X54

C6-X56

C6-X58

C6-X59

C6-X65

C6-B26

C6-C22

C6-Y04

UPPER THREAD GUIDE RETAINER 上導線座

BRACKET 過線片

THREAD HANGER 導線圈

LINE GUIDE DEVICE 倒位基座

PIN 銷

TENSION SPRING WASHER 彈簧墊圈

TENSION SPRING WASHER 彈簧墊圈

NUT 螺母

TENSION DISC 沙拉片

TENSION DISE PRESSER 張力墊圈

UPPER THREAD TENSION SPRONG 張力彈簧

UPPER THREAD RELEASE PIN 銷

THREAD RELEASER SHAFT 轉軸

--

-UPPER THREAD TENSION SUTD SCREW 過線固定片

LOWER THREAD TENSION PLATE 張力夾線片

PIN 銷

TENSION RELEASE CRANK 連桿

TENSION RELEASE CONNECTING BAR 上線鬆放提柄

THREAD RELEASER LEVER 撥線片

THREAD RELEASER LEVER SAFT 撥線軸

TENSION RELEASE CONNECTING ROD 連桿

TENSION RELEASE LINK 小連柄

TENSION RELEASE SUTD 壓腳柱夾

THREAD GUIDE 導線勾

WASHER 墊圈

UPPER THREAD TAKE-UP LEEVER ASSEMLY 天秤

UPPER THREAD TAKE-UP LEEVER ASSEMLY 天秤

THREAD CHECKER 天秤夾線片

SPRING 彈簧

LOWER THREAD GUIDE 導線勾(D)

WASHER 墊圈

UPPER THREAD TENSION REGULATOR ASSEMBLY ?通導線片

UPPER THREAD TENSION SUTD ASSEMBLY 張力調節軸

UPPER THREAD TENSION SPRING 彈簧

WASHER 墊圈

UPPER THREAD FASTENING CAM WITH SCREW 上線張力凸輪

SCREW 9/64×40 螺釘

SCREW 15/64×28 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 L=5 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 L=6 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 3/32×56 螺釘

SCREW 15/64×28 螺釘

UPPER THREAD TENSION STUD SCREW 叉口合葉螺釘

SCREW 11/64×40 螺釘

SCREW 3/32×56 L=4 螺釘

TENSION RELEASE CONNECTING BAR 上線鬆放提柄

THREAD TAKE-UP COVER 天秤護蓋

NUT 11/64×40 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

3

3

3

6

3

3

1

1

3

4

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

1

1

2

1

1

1

1

1

2

3

1

2

2

1

1

~14~

Page 36

X31-1

X92

X44

X9

X31-1

C7~15~

X31-1

Page 37

LOWER THREADING MECHANISM

REF. NO.部件編號

C7-01

C7-02N

C7-03

C7-03N

C7-06

C7-12

C7-12-1

C7-17

C7-A10

C7-A11

E7-A12

C7-A14

C7-A14-1

C7-A17

C7-A18

C7-A50

C7-A51

C7-A55

C7-C20-B

C7-C21-B

C7-C22-B

C7-C23-B

C7-C25-B

C7-27

C7-28

C7-29

C7-30

C7-31

C7-32

C7-33

C7-34

C7-35

C7-36

C7-37

C7-39

C7-40

C7-41

C7-44

C7-45

C7-47-1

C7-48

C7-49

C7-A50-2

C7-A50-3

C7-A50-4

C7-A51-4

C7-C68

C7-X9

C7-X31電

C7-X31-1

C7-X31-2

C7-X44

C7-X45

C7-X50

C7-X60

C7-X64

C7-X65

C7-X66

C7-X67-1

C7-X92

C7-X95

C7-Y05

LOERT THREAD GUIDE RETAINER 導線架(上)

THREE PIPE-LINE THREAD TUBE 三線過線管

BRACKET 過線片

THREAD TUBE CLAMP 導線圈

LOWER THREAD GUIDE SUPPORTER 支架輔助

LOWER THREAD GUIDE HINGE ASSEMBLY 活動鈕(上)

LOWER THREAD GUIDE HINGE ASSEMBLY 活動鈕插銷

LOWER THREAD COVER 橡膠墊

LOWER THREAD COVER 下前蓋

PLATE SPRING 彈簧勾

FIXING PLATE 活動鈕(下)

LOWER THREAD TENSION BRACKET 三通過線片

THREAD GUIDE 穩線片

LOWER THREAD GUIDE RETAINER ?通過線片

PLATE SPRING 彈片勾

LOOPER SIDE COVER (R) ASSY 彎針護蓋

LOOPER SIDE COVER (L) ASSY 彎針護蓋

LOWER THREAD GUIDE 過線片

THREAD TENSION ROD 沙拉螺柱

LOWER TEREAD TENSION BRACKET 沙拉托架

LOWER TEREAD TENSION NUT 沙拉螺母

LOWER TEREAD TENSION PLATE 沙拉片

LOWER TEREAD TENSION SPRING 沙拉彈簧

THREAD TAKE-UP LEVER COVER 護線蓋

SPRING 彈簧勾

LOWER THREAD TAKE-UP LEVER FRAME 過線輔助架

LOWER THREAD TAKE-UP LEVER COVER SHAFT 銷

LOWER THREAD TAKE-UP LEVER BASE 過線支架

GUIDE PLATE 過線輔助架

WASHER 墊圈

LOERT THREAD GUIDE PLATE 固定片

SCREW 彈簧

WASHER 墊圈

LOWER THREAD GUIDE(LEFT) 彈片扣

LOWER THREAD GUIDE(LEFTRIGHT) 導線勾

LOWER THREAD GUIDE(LEFT) 導線勾

LOWER THREAD GUIDE PLATE 固定片

LOWER THREAD TAKE-UP DISC ASSEMBLY 配線凸輪

LOWER THREAD FEED TUBE 過線管

LOOPER THREAD GUIDE BRACKET 針受座

THREAD CUTTER GUIDE PLATE 切線刀

THREAD CUTTER 切線刀

STOPPER SPRING PLATE 彈片勾

PIN 銷

FACE PLATE UPPER HINGE ASSEMBLY(R) 蝴蝶後扭(右)

FACE PLATE UPPER HINGE ASSEMBLY(L) 蝴蝶後扭(左)

PIN 銷

SCREW 15/64×28 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 L10 螺釘

SCREW 9/64×40 L5 螺釘

SCREW 9/64 螺釘

SCREW 9/64 螺釘

SCREW 9/64×40 L4 螺釘

SCREW 3/32×56 螺釘

SCREW 3/32×56 L4 螺釘

SCREW 1/4×40 螺釘

SCREW 3/32×56 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

NUT 9/64×40 螺母

NAME OF PARTS 說明

Amt req需求量

1

1

1

6

1

2

2

2

1

2

2

1

1

1

2

1

1

1

3

3

3

6

3

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

2

4

1

1

1

1

3

12

2

7

2

2

1

3

2

2

6

1

1

2

~16~

Page 38

PL-M,SM

L1

L2

X3

18

14H

X44

X50

A20

A19

A21

C10-11

C8~17~

Page 39

LOWER SHAFT MECHANISM-GAUGE PARTS

REF. NO.部件編號

C8-C1

C8-02

C8-03

C8-04

C8-05

C8-06

C8-07

C8-08

C8-09

C8-10

C8-C10-11

C8-11

C8-14H

C8-15

C8-18

C8-A19

C8-A20

C8-A21

C8-102

C8-L1

C8-L2

C8-X3

C8-X31

C8-X32

C8-X44

C8-X50

C8-X74-1

C8-X75

C8-X77

C8-X79

C8-X81

C8-X82

LOVER SHAFT 下主軸

BEARING 6200 Z 軸承

BEARING 6201 Z 軸承

BALL BEARING BUSHING 內套筒

BEARING CASE ASSEMBLY 軸套筒(下)

BEARING FIXING BUSHING 緊壓套筒

NEEDLE CLAMP WITH SCREW 針夾

NEEDLE PLATE 針板

PRESSER FOOT ASSEMBLY 壓腳組

FEED DOG 送布齒

NEEDLE GUARD 針受

BEARING 6302 軸承

LAPPER ASSEMBLY 導布架喇叭

SPRING 彈簧

LOOPER LONG 彎針(長)

LOOPER HOLDER (SHORT) 彎針台(短)

LOOPER HOLDER (MIDDLE) 彎針台(中)

LOOPER HOLDER (LONG) 彎針台(長)

BEARING FIXING SCREW 外牙螺母

LOOPER SHORT 彎針(短)

LOOPER MEDIUM 彎針(中)

SCREW 5/16×28 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 L10 螺釘

SCREW1/4×28 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

3

1

1

3

1

1

2

~18~

Page 40

SP

D8-13K

A17

A16

14XL

A18

C9~19~

Page 41

GAUGE PARTS(SP) SP

REF. NO.部件編號

C9-01

C9-02

C9-03

C9-05

C9-06

C9-07

C9-09

C9-11

C9-14XL

C9-15

C9-A16

C9-A17

C9-A18

C9-A19

C9-A20

C9-A21

C9-X9

C9-X44

C9-X50

C9-X77

C9-X79

C9-X82

C9-X83

C9-X86

C9-X91

C9-X93

C9-Y05

C9-D8-13K

NEEDLE CLAMP ASSEMBLY 針夾

NEEDLE PLATE 針板

PRESSER FOOT ASSEMBLY 壓腳頭

PRESSER FOOT (F) SPRING 彈簧

PRESSER FOOT ASSEMBLY 壓腳底

SUB FEED DOG 導布齒

FEED DOG 送布齒

NEEDLE GUARD 針受

LAPPER ASSEMBLY 導布架喇叭

NEEDLE GUARD BRACKET 針受連結

LOOPER (SHORT) 彎針(短)

LOOPER (MIDDLE) 彎針(中)

LOOPER (LONG) 彎針(長)

LOOPER HOLDER (SHORT) 彎針台(短)

LOOPER HOLDER (MIDDLE) 彎針台(中)

LOOPER HOLDER (LONG) 彎針台(長)

SCREW 15/64×28 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 9/64×40 螺釘

STUD SCREW 螺釘銷

SCREW 3/32×56 合葉螺釘

SCREW 5/64×60 螺釘

SCREW1/8×44 螺釘

NUT 9/64×40 螺釘

SCREW 9/64×40 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

4

3

1

1

2

1

2

3

1

1

~20~

Page 42

PL

X65

A17

A16

14XL

A18

C10~21~

Page 43

GAUGE PARTS (DP) DP

REF. NO.部件編號

C10-01

C10-02

C10-03

C10-04

C10-05

C10-06

C10-07

C10-08H

C10-09

C10-10

C10-11

C10-14XL

C10-A16

C10-A17

C10-A18

C10-A19

C10-A20

C10-A21

C10-X31

C10-X32

C10-X44

C10-X50

C10-X65

C10-X77

C10-X79

C10-X82

C10-X83

C10-X86

C10-X87

C10-X88

C10-X89

C10-X91

C10-X93

NEEDLE CLAMP ASSEMBLY 針夾

NEEDLE PLATE 針板

SPRING M 彈簧

SPRING F 彈簧

SPRING BL 彈簧

PRESSER FOOT ASSEMBLY 前壓腳底

SUB FEED DOG 導布齒

NUT 1/8×44 螺母

FEED DOG 送布齒

SPRING BS 彈簧

NEEDLE GUARD 針受

LAPPER ASSEMBLY 導布架喇叭

LOOPER (SHORT) 彎針(短)

LOOPER (MIDDLE) 彎針(中)

LOOPER (LONG) 彎針(長)

LOOPER HOLDER (SHORT) 彎針台(短)

LOOPER HOLDER (MIDDLE) 彎針台(中)

LOOPER HOLDER (LONG) 彎針台(長)

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 3/32×56 螺釘

SCREW 11/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 9/64×40 螺釘

STUD SCREW 螺釘銷

SCREW 3/32×56 螺釘

SCREW 1/8×44 L5 螺釘

SCREW 1/8×44 螺釘

SCREW 3/32×56 螺釘

SCREW 5/64×56 螺釘

SCREW 1/8×44 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

3

1

3

1

1

3

1

1

1

1

2

3

~22~

Page 44

PL,PL-M

9A

D1-9

X9

10

X19

SP

11

14

X67-1

13

15

12

X67-2

9

X47

X31

X82

X67-1

21A

22A

20A

X82

19A

C11~23~

X67

17A

Page 45

PULLER DEVICE MECHANISM DP、SP

REF. NO.部件編號

C11-01

C11-02

C11-03

C11-05

C11-06

C11-07

C11-08

C11-09

C11-10

C11-11

C11-12

C11-13

C11-14

C11-15

C11-17

C11-A18-1

C11-D1-9

C11-X09

C11-X19

C11-X31

C11-X47

C11-X47

C11-X67

C11-X67-1

C11-X67-2

C11-X82

C11-01A

C11-02A

C11-03A

C11-04A

C11-05A

C11-06A

C11-08A

C11-09A

C11-10A

C11-12A

C11-14A

C11-16A

C11-17A

C11-18A

C11-19A

C11-20A

C11-21A

C11-22A

PRESSURE ADJUSTING SCREW 外牙螺母

UPPER WHEEL PRESSER BAR 立軸

SPRING 張力彈簧

WHEEL DIRECTION FIXING DEVICE 拉布輪壓力提柄

FRESSER ROD BUSHING 軸套

UPPER WHEEL SEAT 拉布輪架

UPPER WHEEL CONNECTON 固定軸

ONE WAY PULL HOLDER 拉柄

PACKING 防油墊片

LOWER WHEEL 拉布輪

ONE WAY TRIANGULAR WHEEL 單向三角軸片

UPPER WHEEL 拉布輪

ONE WAY STILL BALL 單向滾珠

ONE WAY STILL SPRING 單向彈簧

CHOCK RING E型扣環

FACE PLATE (UPPER) DP上前蓋座

RUBBER PLUG 橡膠塞

SCREW 15/64×28 螺釘

SCREW 螺釘

SCREW 9/64×40 螺釘

PRESSER FOOT LIFTER 螺釘

SCREW 螺釘

SCREW 3/32×56 螺釘

SCREW 3/32×56 螺釘

SCREW 3/32×56 螺釘

SCREW 9/64×40 螺釘

PRESSURE ADJUSTING SCREEW 外牙螺母

NUT 螺母

PRESSER FOOT LIFTER 手提柄

STUD SCREW 固定銷

SPRING 張力彈簧

PRESSER BAR GUIDE ASSEMBLY 拉布輪壓力提柄

ROLLER PRESSER BAR LIFTER 舌片

SCREW PRESSER ROD BUSHING 螺釘

PRESSER ROD BUSHING 軸套

UPPER WHEEL PRESSER BAR 立軸

PULLER SUPPORTER ASSEMBLY 拉布輪架

ONE WAY PULL HOLDER 拉柄

UPPER WHEEL CONNECTON 固定軸

FACE PLATE 拉布輪基座

ONE WAY TRIANGULAR WHEEL 單向三角軸片

UPPER WHEEL 拉布輪

ONE WAY STILL BALL 單向滾珠

ONE WAY STILL SPRING 單向彈簧

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

2

1

6

6

1

1

4

1

2

1

1

1

3

6

3

3

2

1

1

1

1

1

1

5

1

1

1

1

1

1

2

1

6

6

~24~

Page 46

16

2-1

C12~25~

Page 47

ACCESSORIES

REF. NO.部件編號

C12-01

C12-02

C12-2-1

C12-03

C12-04

C12-05

C12-06

C12-07

C12-08

C12-09

C12-10

C12-11

C12-12

C12-13

C12-14

C12-16

C12-X1

C12-X2

THREAD STAND 六葉線架

CUSHION ASSEMBLY 固定座

WASHER 墊圈

BASE CUSHION 橡膠墊塊

HEAD COVER 防塵套

OIL TANK 大油壺

OILER ASSEMBLY 小油瓶

NEEDLE 針

TWEEZERS 線夾

SPANNER 固定板手(#7)

SPANNER 固定板手(#8)

SCREW DRIVER 大起子

SCREW DRIVER 小起子

SCREW DRIVER 中起子

THREADLE 腳踏板

SPANNER 固定板手(#10)

SCREW1/4×28 螺釘

SCREW 6.2×26 木螺釘

NAME OF PARTS 說明

Amt req需求量

1

2

2

2

1

1

1

5

1

1

1

1

1

1

2

1

2

2

~26~

Page 48

Sir:tUaA

TABLE

CUT-OUT

750

725

Series

Item Code

FA007 FA007-T1

I

!

\

:

~

---------

0

0

co

..-i

om

com

(\J(\J

r

Subclass I Remark

• FOR FA007 Series

L()

co

(Y)

012

L()

(Y)

L()

Mounting

Fully-submerged

Date

2014 I 7 I 18

f+1>

~

~

-jmg

~

~

~!CF

~

~

;;;o""'

~

lt

"@

n

0

4~

\:':

'-

I--<

/'--j

Am3

""'3

~

- =

~

~

~ln~

§j

D~

~

~

~

fQ

I+

[\)

~

-¥=

680

210 4-R10

.~b------+-~~v---t--t-

g -

-------

-----

--

520

026

~

..

lrl

..

08.5

A-A

:§iJtm

017

-f=-r--

85

o--~~----~--------------------------~r---~-~---0

L()

co

0

Loading...

Loading...