Page 1

FA007

1im~a~W*f!:FII

·

INSTRUCTION AND PARTS LIST

·

Sir:.UaFr

·

CE

ml

GE

~

®

ai~fti1S3f5i~~fla]

KAULIN

MFG~CO

..

LTD

.

Page 2

Page 3

Page 4

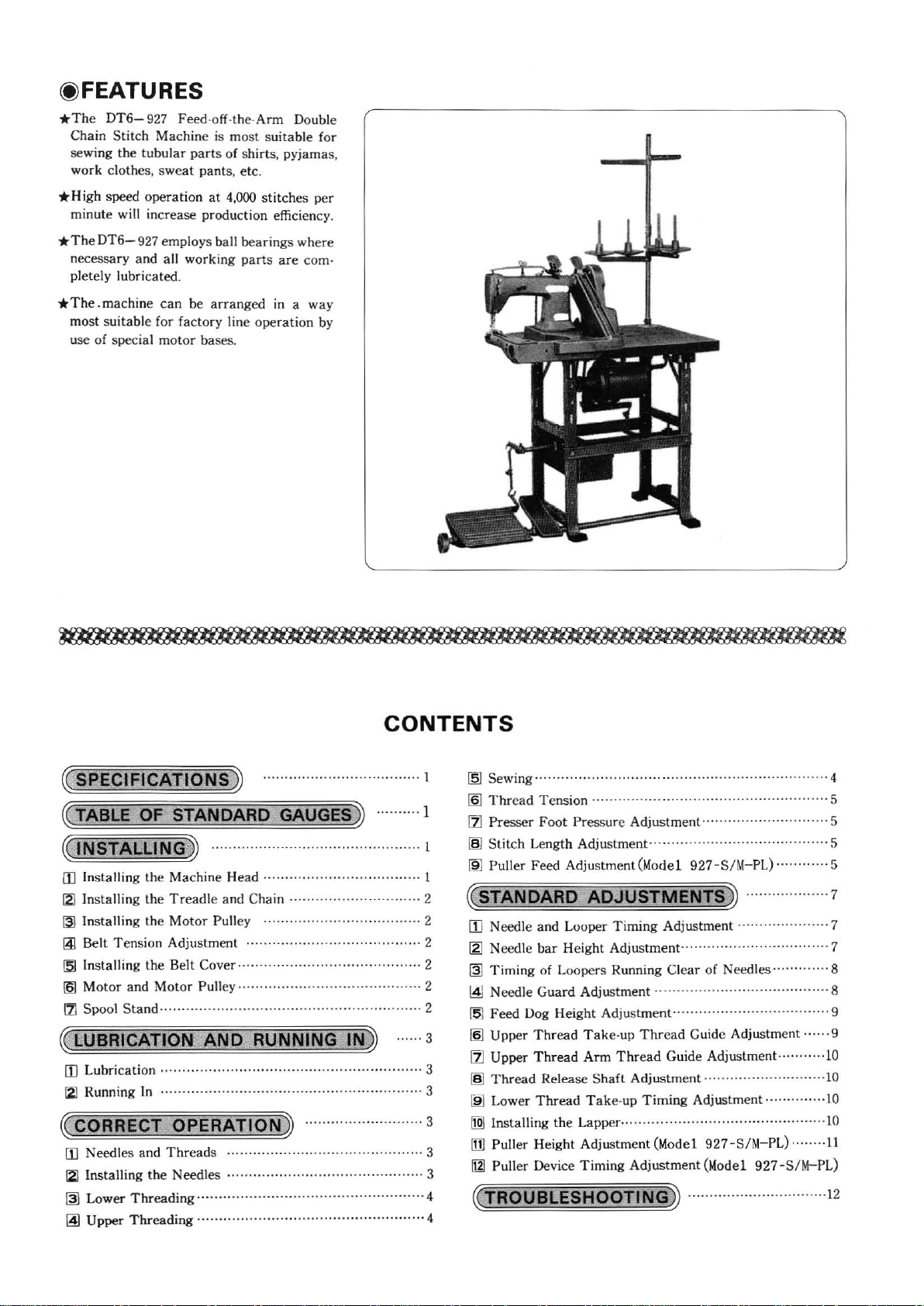

(f) FEATURES

*The

DT6-927 Feed

S

Chain

sewing

work

tit

the tu

clothes,

ch Machine is

bular par

swe

at

-off-th

e-Arm

most

ts of shirts, pyjamas,

pant

s, etc.

Double

suitable for

*High

*TheDT6-

*The.machine

speed

operat

minute

necessary

pletely lubricated.

most

u

se

will in cr

927 employs ball

and

suitable

of

special

ion

at

4,000 stitches

ease

production efficiency.

all

working parts

can

be

arranged

for

factory

motor

line

bases.

bearings

are

in a

operation

per

where

com-

way

by

~

SPECIFICATIONS

~

TAB

LE

OF

STANDARD

~JN

STALLING

[I]

Ins

talling

the Machine Head

121

Installing the

(3]

In

sta

lling

~

Belt

Tension

[5)

Installing the

161

Motor

111

Spool

~

LUBRICAT

[I]

Lubrication

121

Running In ....

~

CORRECT

[I]

Needl

es

(2]

Installing

@]

Lower

~

Upper

Treadl

the

Motor

Adjustme

Belt

and

Motor

Sta

nd

.... ·

ION

···

.....

OPERATION

and

Threads .....

the

Needles

Threading··

Threading

....

.............

~

~

................................................

e and Chain ....

Pulley

nt

.. ......

Cover .... ·

Pulley

.......................... · ........

.

AND. RUNNING

· ..

......... · .................

·········

· · · · · .. · · · · · · · · · · · .. · · · .. · · · · · · · · .. · .. · · · · · · · · · .. · · · 4

..............

..........................................

............

..............

...... ·

........

················

CONTENTS

............

....................................

....................................

........................

GAUGES» ..........

...............

...................

· .. · .. · .. ·

....................

~

...........................

..........................

··

...

· · ·

·························

....

....

........

........

··

....

..........

IN

~

· .. · ·

.................

....

......

...................

.... · 2

· .... 2

......

.. . 2

· 3

·· · 3

1

1

l

l

2

2

2

3

3

3

3

4

~

Sewing

[§]

Thr

1Zl

Presser

~

Stit

~

Puller

~

STANDARD

[I] Needle

~

@]

~

[5]

[§]

11J

1§1

~

[I2J

[1]

~

~

TROUBLESHOO

........

ead

Tension

Foot

ch Le

ngth

Feed

and Looper

Need le

Timing

Needle

Feed

Upper

Thread

Low

In

bar

Height Adjustment

of Loopers Running

Guard

Dog

Height

Thread

Upper

Thread

Release

er

Thread

sta

lling the Lapper· .. ·

Puller

Height Adjustme

Puller Devi

ce

...

.................

...............

Pressure Adjustment

Adjustment .........................................

Adju

stment(Mo

ADJUSTMENTS»

Timing

Adjustment

Adj

Take

Arm

Sha

Take-up

Timing

.....

...

del

Adju

............

ustment"

-up

Thread

Thr

ead

ft

Adjustment

Timing

...

. ·

........................

nt (Model 92

Adjustment (

TI

NG

................

........

.............. · ........

927-S/M-PL

stment

....

............

Clear

...............

Guide Adjustment

Guide Adjustment

Adjustment .....

»

......

.......

................

) ........ .... 5

....

.........

...

........

.............

of

Needles

.......

...........

....

...............

... ....

.....................

............. ·lO

7-

S/M

-PL)

Mod

el 927 -S/ M- PL)

...............

......

.... . 4

............

· .. · .. 5

......

.........

.....

.........

..........

......

...........

.........

........

...........

5

5

7

· 7

7

.... 8

8

9

9

10

10

1Q

11

12

Page 5

(SPECIFICATIONS)

Model

Use

Stitch

pattern

Max. se

Stitch lengt

Needle

Needle

Needle

Min. arm

Puller

wing

speed

h

gauge

bar stroke

size

device

(TABLE

Ga

uge

set

Needle holder Needle

Y.MH

!J<s

MH

Y.

MH

OF

Ya

!J<s

Y.

Thin

materials

Twin

-needle,

3,600

spm

1.2

-2.5

mm

)(5

inch

(4.8

mm)

27

mm

_j___

Equipped _

STANDARD

plate

Ya

!J<s

Y.

H

_

GAUGES)

Presser

Ya Ya

!J<s

Y.H

foot

FA007

I

twin-thread

I

Ys

inch

Medium-thick

double

(3.2

mm)

TVxl

I

178mm

Feed

dog

Looper

!J<s !J<s

Y.

H

chain

4,000 spm

1

.2-3.2

I%

inch

materials

stitch, parallel sewing

mm

(4

mm) I

~

inch

27mm

None

assemblY

.

Looper

oruide .....,

Ya

Y.

H

(4.8

thread

Ya

Ya

Y.H

I Thick materials

mrn)

I U

inch

30

I

(6.4

mm

Lapper

Ya

MH

~~

MH

Y.MH

mrn)

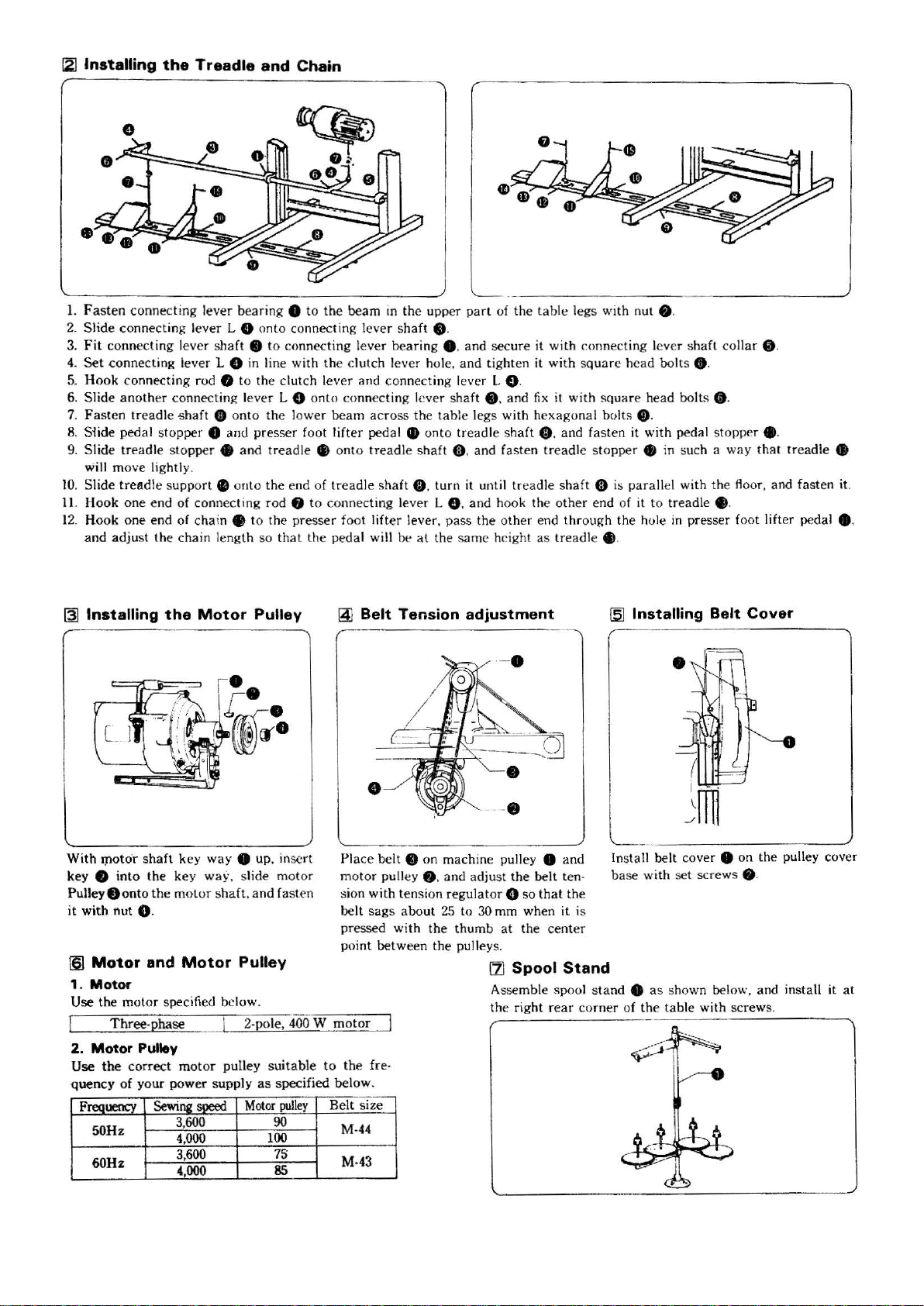

(INSTALLING)

[]]

Installing

1.

Install pulley

2. Insert

3.

Place

presser

4. After

the

Machine

cover base 8 on

bar

cushions 0 into the

the mac

fastening

bar

lifter chain

hine head on

cushions 8 to

0 .

Head

the

and

machine

holes in the

table, adjust

in sidewise

the machine

bed

0 wi

th

two hex

bottom

directions

bed

of the bed .

its position in

and

pulley

by

aligning it

cover base

l"g

onal

forward

bolt

s

@).

and bac

with belt

with

set

kward

hole e.

screws

directions

e. fix them

by ali

gning it with the hole for.

to

the

table

with screws 0

~1~

Page 6

121

Installing

1. Fasten

2. Slide

3.

Fit connecting lever s

4.

Set conne

5.

Ho

ok conn

6. Slide

7.

Fast

en

8.

Siide pedal stopper 8 and

9. Slide

will move lightly .

10

. Slide t

11.

Ho

ok

1

2.

H

ook

and

adj

the

Treadle

connecting

connecting le

cting lev

ect

ing rod 0 to

anoth

er connec ting le

treadl

e shaft 0

treadl

e stopp

re

edle

support e

one

end of connecting rod 8

one

end

of

chain e to

ust

the

chai

and

Chain

lever

bearing 8 to

ver

L 0 onto

haft

er

L 0 in

onto

er e and treadle •

on

n len

gth

connecting lever shaft

• to connecting lever bearing

li

ne

with

the

clut

ch lev

ver

L 0 on

the low

presser

to the end

the

so

that the

pre

foo t lifter peda

the

beam

the

clutch lever

er

and connecting l

to connecting l

er

beam across

onto

tread

of

tre

adle shaft 0 . turn

to

connec

ting

sser foot

lift

pedal will be

in the u

pper

8 .

e.

and

hole.

and

ever

eve

r s

haft

the

tab

le l

l e

onto treadl

le

shaft

G. and f

it

lever L 8 .

er

lever. pass the oth

at

the same height

L _ _

part

of

the

tab

le legs

with

nut • ·

sec

ure

it with connecti

tighten it with s

L

G.

e. and

egs

unt

and

fix

with hexagonal bol

e shaft 0 .

asten tread

il treadle shaft G is parallel with the floor.

hook the

er

end

as

quare head

it with square

and

le s

other

through

tread

ng

lever sh

bol

ts

head bol

ts

Cl)

.

fasten it wi

topper

end of it

le e.

th

pedal stopp

e in such a

to

tre

adle • .

the hole in presser foot lift

af

t coll ar e.

• .

ts

• .

way

er

e.

that

and

treadle

fasten it.

er

peda

•

l • .

[3]

Installing

With

!pOto·r

key e

Pulley

f)

it

with

161

Motor

1.

Motor

Use

the m

2.

Motor

Use the

q

uen

cy

F

50Hz

60Hz

the

shaft

ke

into

the key way, slide

onto

the

motor shaft.

nut 8 .

and

Motor

otor

spec

Thr

ee-phase

Pulley

correct

of

your

Sewing

mot

power

3,

4,000

3,

4,000

Motor

y way 8 up. in

Pulley

and

Pulley

ifi

ed

below.

2-

pole, 400 W motor:]

or pull

ey suit

sup

ply

as

speed

600

600

Motor

~

sert

motor

fasten

able

specified below.

pull

90

100

75

85

to the fre·

ey

Belt

Pl

motor pull

sion with

belt

pr

poi

M-44

M-4

Belt

•

ace

belt e

sags about

essed

with

nt

between

size

3

Tension

on

machin

ey

• . and adju

tension

regulat

25

the thu

the

adjustment

/

·-·

·

-·

e pulley 8 and

st

the belt ten·

or 8 so that

to 30 mm wh

mb

at the

pulleys.

LlJ

Spool

Assemble spool

the right

the

en

it is

center

Stand

rear corn

15.1

Installing Belt

In

sta

ll

base

with

stand 8 as

er of the

Cover

belt c

over

8 on the pulley cover

set

screws

e.

shown below. and install

tab

le with screws.

it

at

~2~

Page 7

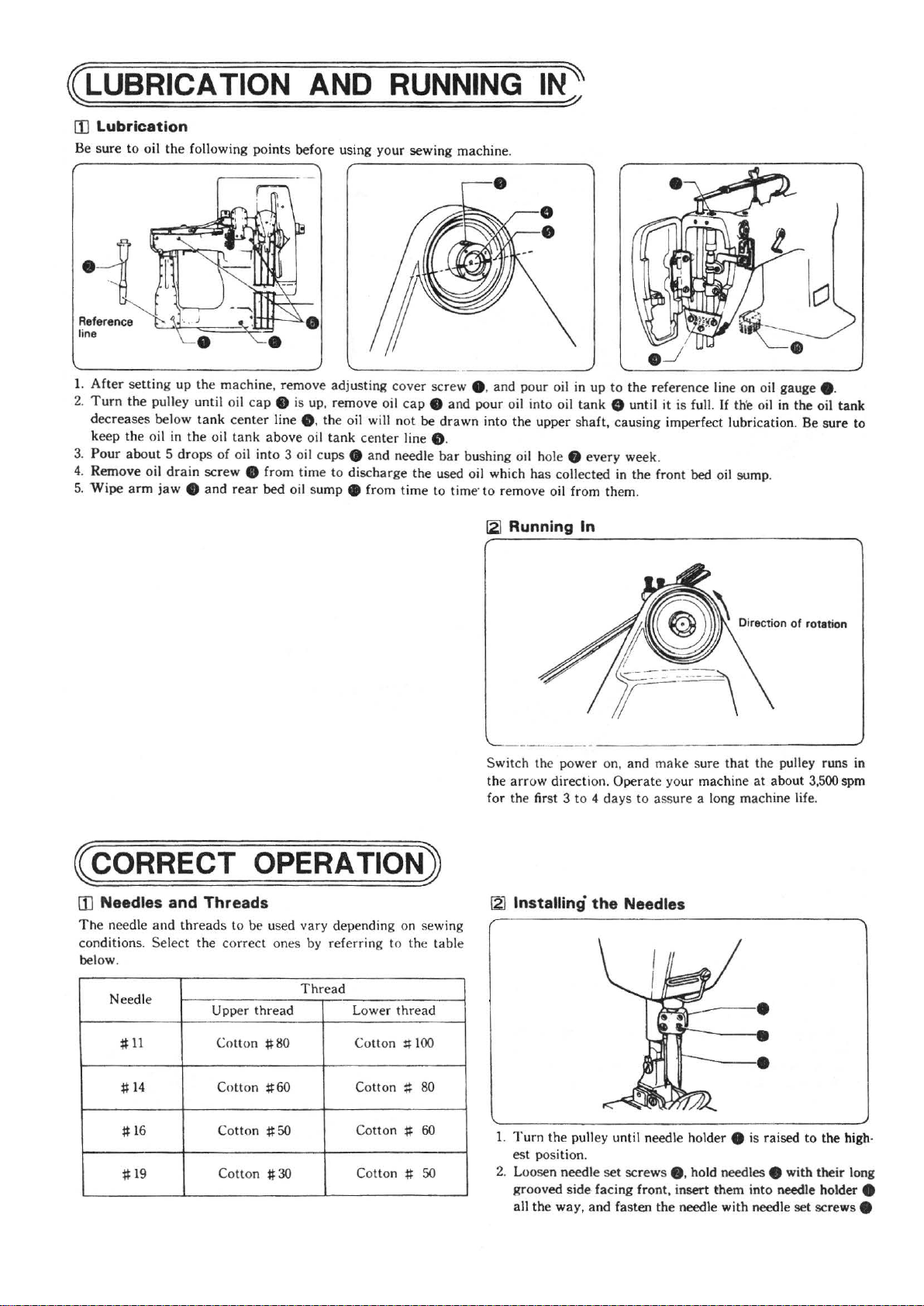

~LUBRICATION

ill

lubrication

Be

sure

to

oil

the

1.

After

2.

Turn

decreases

keep

3.

Pour

Remove

4.

5.

Wipe

following

setting

the

the oil in

about 5 drops

arm

up

the

pulley until oil

below

tank

the

oil

drain

jaw e and

screw

machine

center

oil

tank

of

oil

rear

points

ca

into

e from

AND

before using

, remove adjusting

p e is

up

, remove oil

line e. the oil will

above

oil

tank

center

3 oil

cups e and

time

to

discharge

bed

oil

sump

e from

RUNNING

your

sewing machine.

cover

screw

e.

cap e and

not

be

line e.

needle

the

time

pour

drawn

into

bar

bushing oil hole e

used oil which

to time· to remove oil from them.

and

[21

IN~

pour

oil in

up

oil into oil

the

has

Running

tank

upper

shaft,

collected in

In

every

to

the

reference

0 until it is full.

causing imperfect lubrication. Be

week

.

the

front bed oil

line on oil gauge e.

If

th'e o

il

in

the

sump

.

oil

sure

tank

to

~CORRECT

!I]

Needles and Threads

The need

conditions.

below.

le

and

threads to

Select

the

Needle

~11

~

14

~

16 Cotton

~

19

OPERATION)

be

used vary depending on sewing

correct

Upper

Cotton

Cotton

Cotton # 30

ones

thread

~80

~60

~50

by

referring

Thread

Lower

Cotton

Cotton

Cotton ~ 60

Cotton ~ 50

to

the

thread

#

~

100

80

table

- -·-··

··--·-

Switch

the

for

the

arrow

the first 3 to 4

~

Installing

1.

Turn

the

es

t position.

2. Loosen needle

grooved side facing front, insert them i

all

the

---

power

on,

direction.

days

the

pulley until needle holder e is raised

set

way,

and

---·

and

make

Operate

your machine

to assure a long machine life .

Needles

scre

ws

e.

fasten

the

needle

---

sure

that

hold needles e with

with

-

----'

the

pulley runs in

at

about 3,500 spm

nto

needle holder e

needle

set

to

the

their

screws

high·

long

e

~3~

Page 8

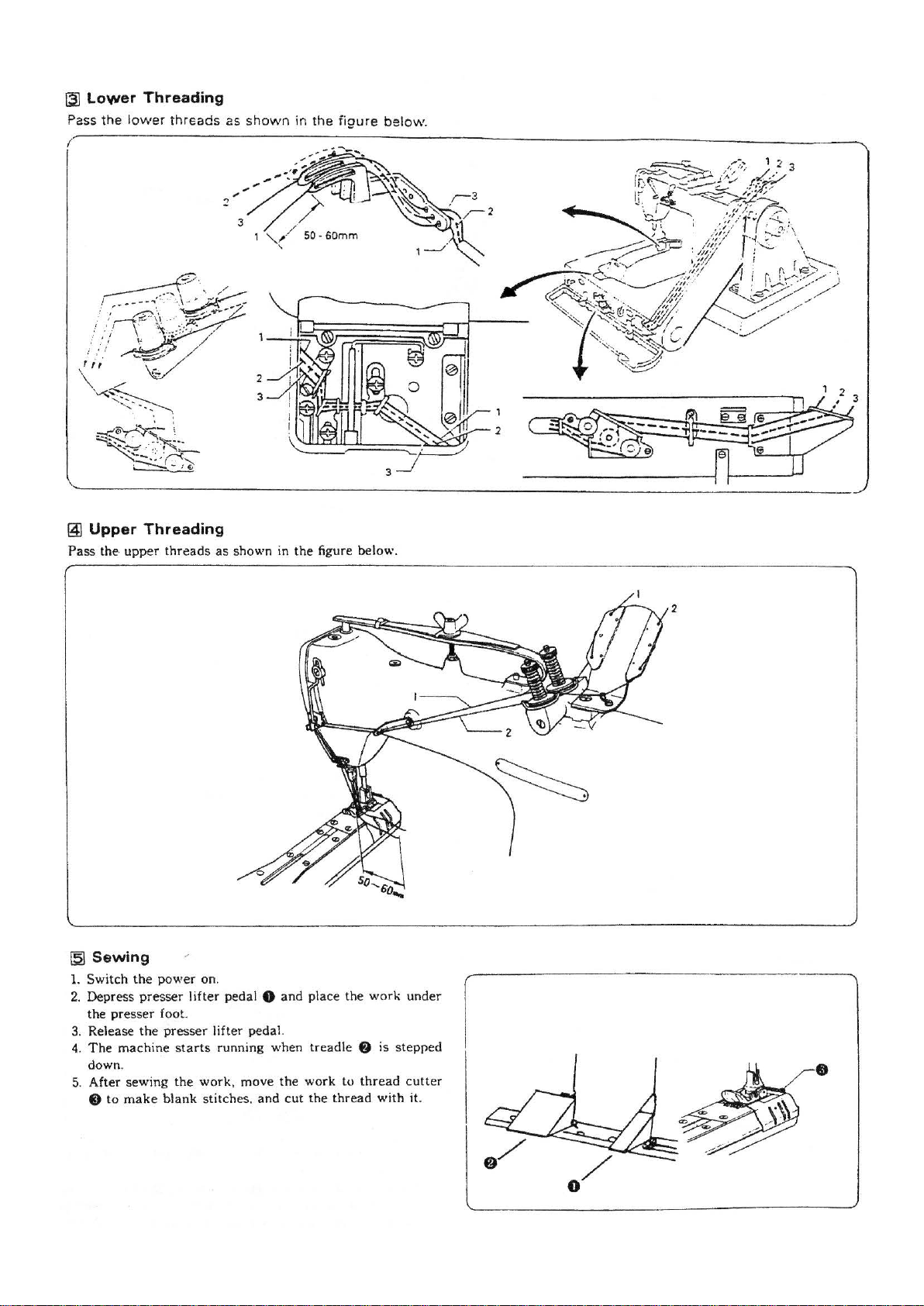

~

Pass

~

Pass

Lower

the lower

Upper

the· upper

Threading

threads

Threading

threads

as

as

shown

shown in

in

the

figure

the

figure below.

below.

~Sewing

1. Switch

2.

Depress

the presser foot.

3. Rele

4.

The

down.

5. After

the

presser

ase

the

machine starts

sewing the

fi)

to

make

power

lifter pedal 8

presser

work

blank

on.

and

place the

lifter pedal.

running when treadl e 8 is stepped

. move the

stitches.

and

work

cut the

to

thread

thread

work

with

under

cutter

it.

2

•

~4~

Page 9

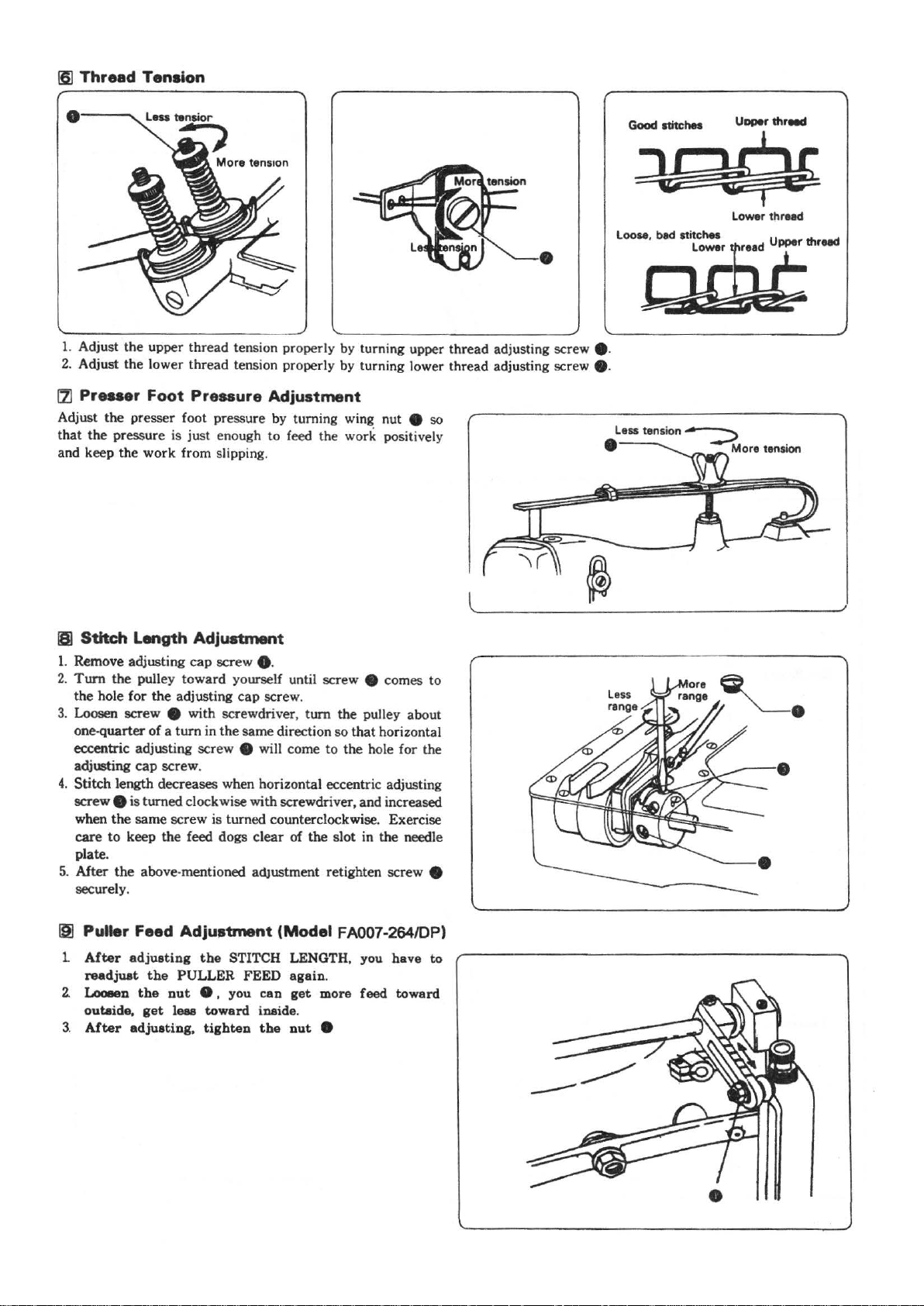

16]

Thread

Tension

Good

ltltchel

Uoper threed

1. Adjust

2.

121

Adjust the presser foot pressure by turning wing

that

and keep the work from slipping.

the

upper

thread

tension properly by turning upper thread adjusting screw e.

Adjust the lower

Pr

...

er

the pressure is just enough

Foot

thread

Pressure

tension properly by turning lower thread adjusting screw e.

Adjustment

to

feed the work positively

nut

e so

•

;y:

loose,

bad stitchel Upper thread

!&:~

lower

~

thread

181

Stitch

1.

Remove adjusting

2.

Turn

the hole

3.

Loosen screw e with screwdriver, turn the pulley about

one-quarter

eccentric adjusting screw

adjusting cap screw.

4.

Stitch length decreases when horizontal eccentric adjusting

screw

when

care

plate.

5.

After

securely.

IS]

Puller

1

After

readjuat

2.

Looeen

outaide,

3.

After

Length

the

for

pulJey

cap

toward

the

adjusting

of a turn

Adjustment

screw e.

yourself until screw e comes to

cap

screw.

in

the

same

direction

e wilJ come to

so

that

th

horizontal

e hole

for

e is turned clockwise with screwdriver, and increased

the

same

screw

is turned counterclockwise. Exercise

to

keep the feed dogs clear

the

above-mentioned adJustment retighten screw e

Feed

Adjustment

adjusting

the

the

get

adjusting,

the

STITCH LENGTH, you have to

PULLER FEED

out

8,

you cao

leas

toward

tighten

of

(Model

again

inaide.

the

out

the

slot

FA007-264/DP)

.

get

more

e

in the needle

feed

toward

the

~5~

Page 10

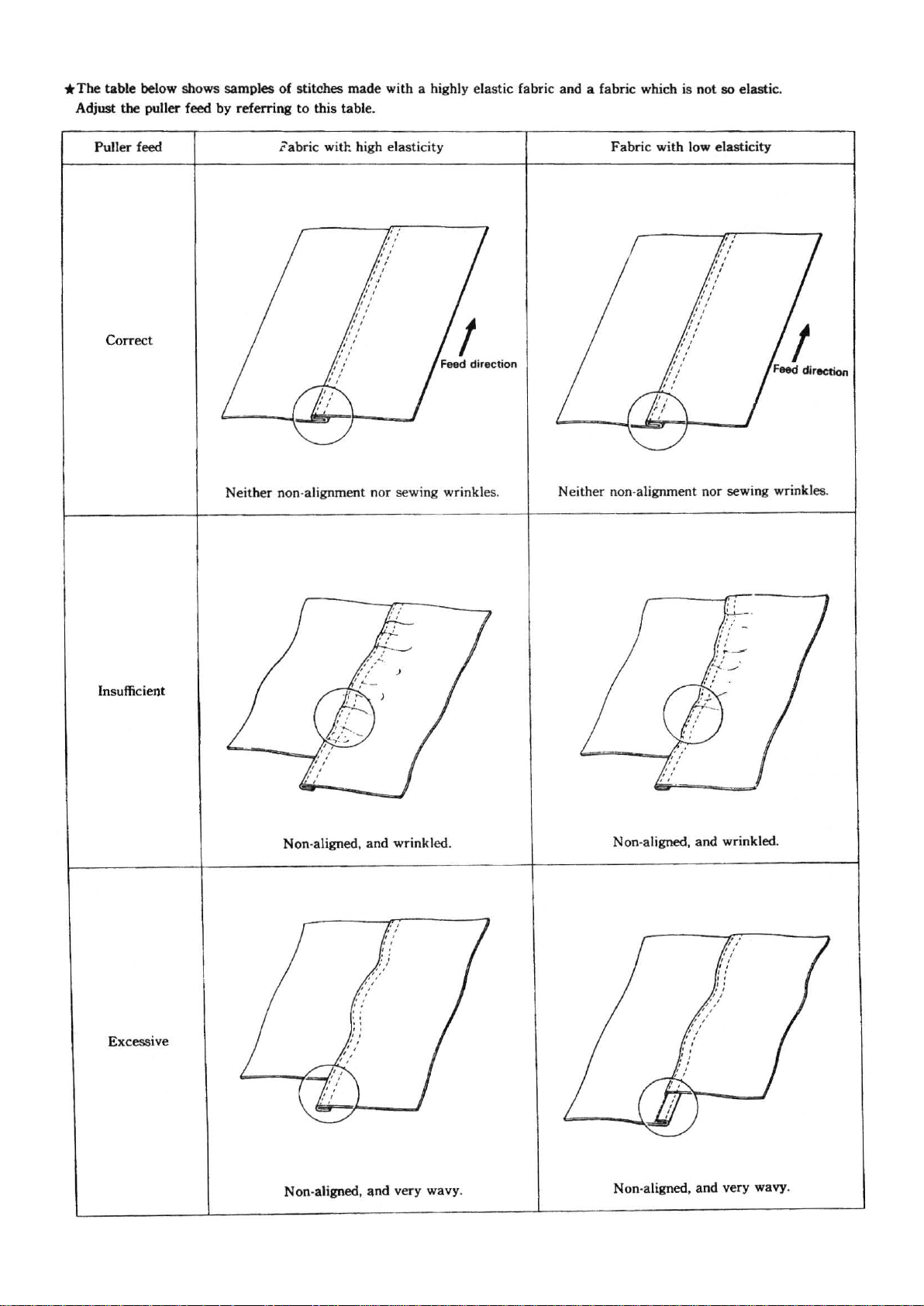

*The

Adjust

table

below shows samples

the

puller feed

Puller

feed

Correct

by

referring

of

stitches

to this table.

labric

made

with a highly elastic fabric and a fabric which

with high elasticity Fabric with low elasticity

is

not

so

elastic.

Insufficient

Neither non-alignment

Non

-aligned, and wrinkled.

nor

sewing wrinkles.

Neither non-alignment nor sewing wrinkles.

Non-aligned, and wrinkled .

Excessive

Non

-aligned,

and

very wavy.

~6~

Non-aligned, and very wavy.

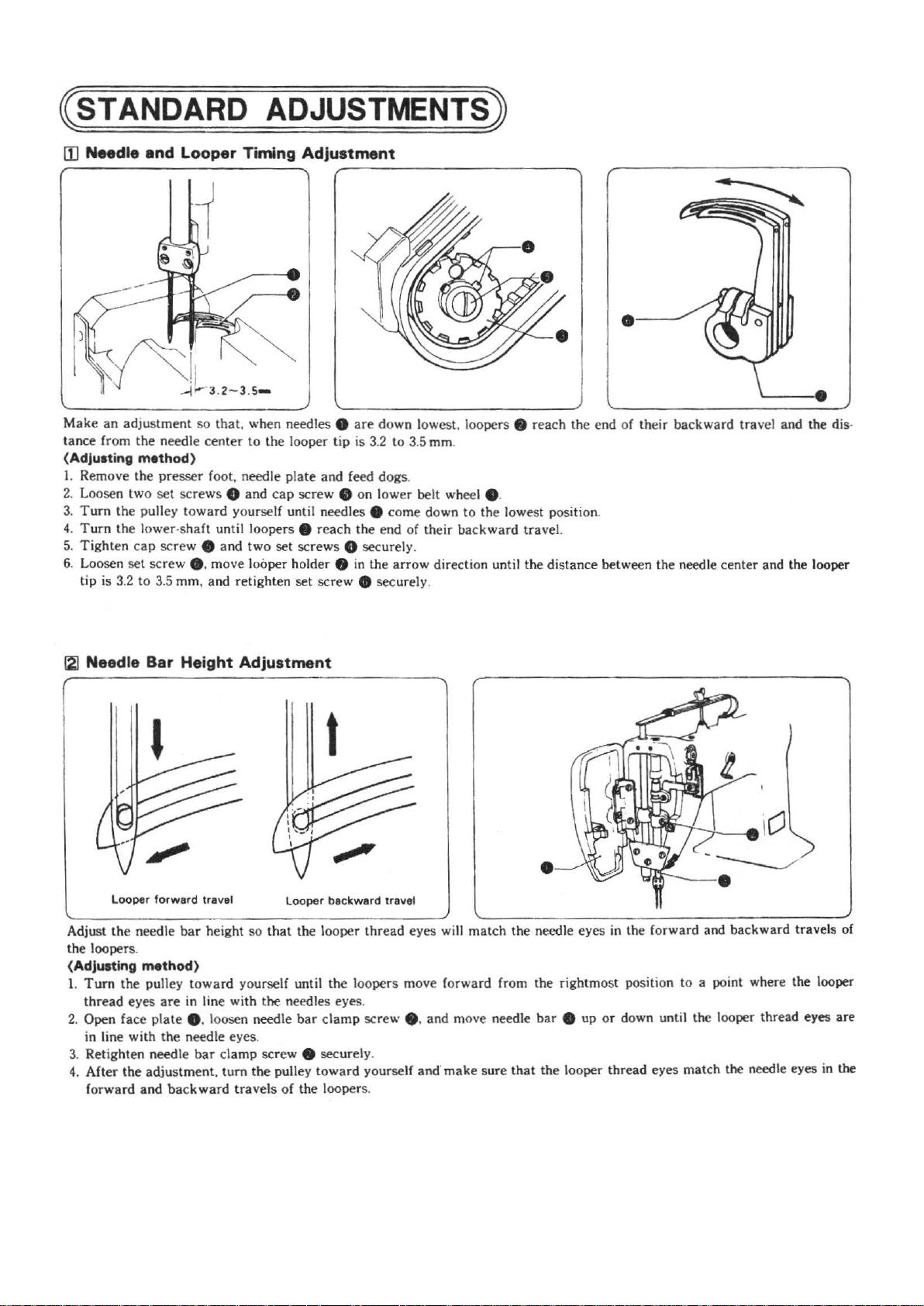

Page 11

~STANDARD

Make

an

adjustment so

tance

fr

om

the nee

(Adjusting

I.

Remove the presser foot, needle pl

2. Loosen

3.

Turn

Turn

4.

5.

Tight

6. Loosen

tip

m•thod)

two

set screws 8

the

pulley toward yourself until needles e come down

the lower-sh

en cap screw

set

screw

is 3.2

to

3.5 mm, and

that.

dle center

aft

until loopers 8 reach the end of their

e and

•.

move looper holder 8

ADJUSTMENTS)

when needles e

to

the

looper

ate

and

cap

screw e on lower belt wheel e.

two

set

screws 8 securely .

ret

ighten set screw • securely.

are

down lowest, loopers . reach the end of their backward

tip

is 3.2 to 3.5 mm.

and

feed d

in

the

ogs

arr

·---'

.

to

the lowest position.

bac

kward

travel.

ow direction until the distance between the needle cen

trav

el and the dis·

ter

and the looper

f2]

Needle Bar Height Adjustment

Looper

forward

Adju

st

the

needle bar height so

the

loopers.

(Adjusting

1.

Turn

thread

2.

Open face

in line with

3. Retighten needle

4.

After

forward and

m•thod)

the pulley

eyes

plate

the adjus

travel

that

toward your

are

in line with the needles eyes.

self until the loopers move forward from the rightmost position to a point where the looper

e. loosen needle

the nee

dle eyes.

bar clamp

tment, tum

backward

screw e sec urely.

the

pulley t

travels

of

Looper

backward

the looper thread eyes will

bar

clamp

owa

the loopers.

travel

screw e. and move need

rd yourself and·

mak

match

e sure

•

the needle

le

that

eyes

in the forward and backward travels of

bar

e up

or

the looper thread eyes

down until the looper thread eyes

mat

ch the needle eyes in the

are

~7~

Page 12

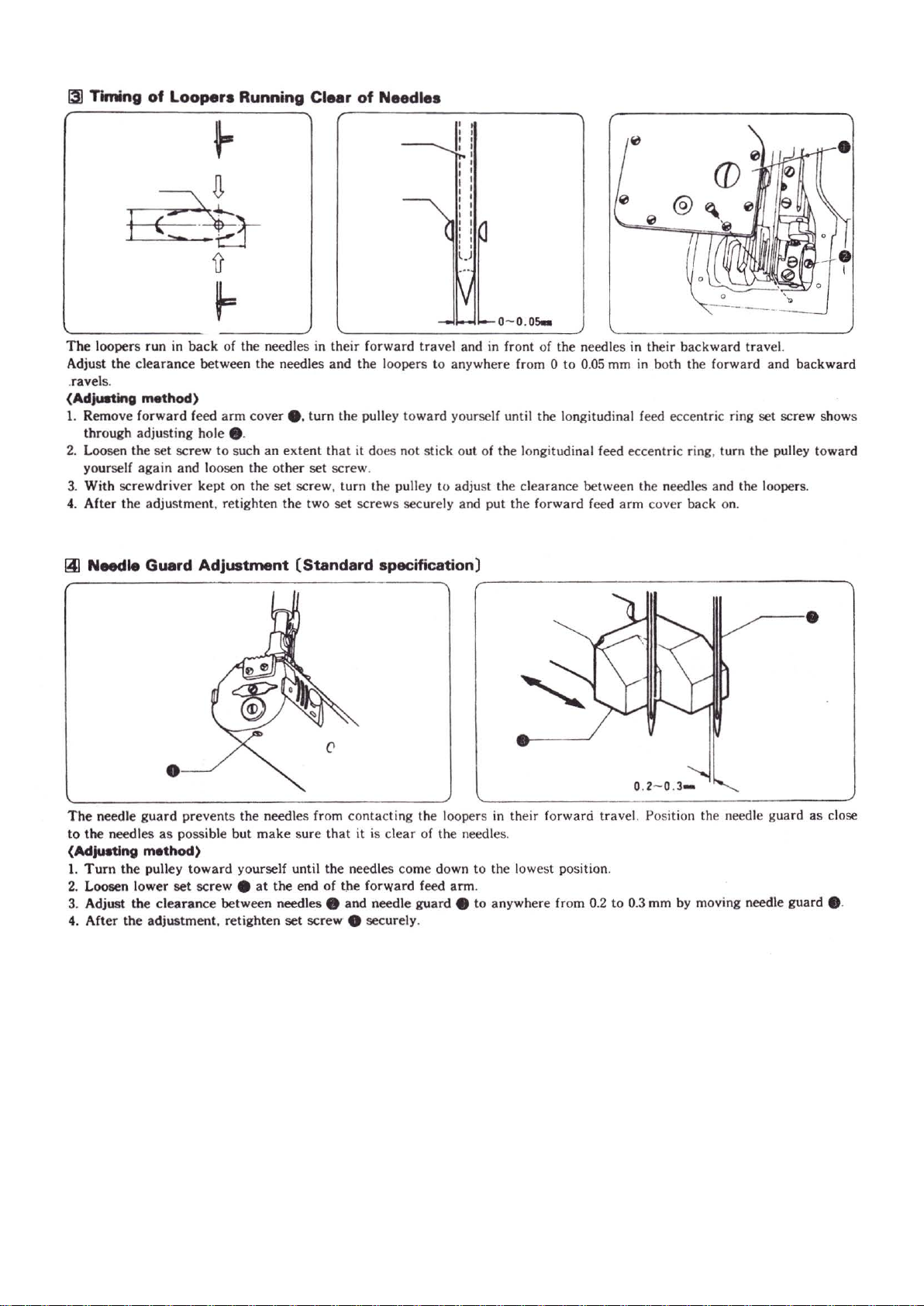

131

Timing

of

Loopers Running Clear

of

Needles

The

loopers run in

Adjust the

.ravel

(Adjusting

1.

Remove forward feed

thr

2.

Loosen the set screw to such

yourself

3. With scr

4.

After the adjustment. reti

~

Needle Guard Adjustment (Standard specification)

clearance

s.

method)

ough adjusting hole e.

again

ewdriver

back

of the needles in

between the needles

arm

cover e.

an

and loosen the

kept on the

ghten the

their

forward travel and in front of the needles in their

and

the

tum the pulley

extent

that

it does not stick out of the longitudinal feed eccentric ring, turn the pulley toward

other

set

screw

.

set

screw, turn the pulley

two

set

screws securely a

loopers to anywhere fr om 0 to

toward

0

,.,

-----

backward

0.05

mm

in

both the forward and

yourself until the longitudinal feed eccentric ring set screw shows

to

adjust the cl

nd

put

earance

the

forward feed

between the needl

arm

cover back on.

es

trave

l.

backward

and the loopers.

-----

·

The

needle gu

to

the

(Adjuatlng

1.

Turn

2. Loosen lower

3. Adjust the

4.

After

ard

needles

as

method)

the

pulley

clearance

the

adjustment, retighten

•

prevents

possible but

toward yourself until

set

the

needles from contacting the loopers

make

screw e at

between needles e and needle

sure

the end

set

screw

that

it

is

clear

the

needles come down

of

the forward feed

e securely.

of the needles.

to

arm

.

guard

e to anywhere

in

their forward travel. Position the needle guard as close

the lowest position.

fr

om 0.2

to

0.3 mm by moving needle guard 8 .

~8~

Page 13

(Puler ..,.cificetion)

The

clearance between the needles and the tips of the

be

0.05

mm,

loopers will

guard

•.

pushing the needles by needle

(Adju8ting

L

Turn

come down to the lowest position.

2.

Loosen

0 so

about

3.

Tum

of

4.

Loosen

left

between the needles

be

At

between the

in

l5J

Feed Dog Height Adjustment

Adjust the height of feed dog e so it

of

the

(Adjusting

Adjust the height of feed dog 8 by turning feed bar eccentric

shaft

Method)

the pulley toward yourself until the needles

stop

screw

e. and raise

that

the

bottom en

0.5

mm

above the bottom of needle guard e.

the

pulley toward yourself again until the tips

the

loopers come

stop

screw

or

to

the right, and adjust so

0.05

mm, pushing needle points by needle guard 8 .

this

time, please

the

backward

needle plate when feed dog 8

method)

loopers

movement

to

the centers of the needles.

e.

move needle guard 8 to the

and

make

and the needles is

or

lower needle guard

ds

of the needle eyes will be

that

the clearance

the tips of the loopers will

sure

that

the clearance

0.2-0.3

of

the loopers.

is

0.8 mm above the top

is

at

the highest position.

8

mm

--....:_.,

---...

..

O.OS..--1#-~0.2-0.J.

16)

Upper Thread

Adjust the height of the upper thread take·up thread guide

that, the upper

reaches the lowest point after the loopers run out

method)

the

upper

set

thread

s.

pulley

thread

screw e. and raise

guide e until

thread loop

(Adju.t

1.

Tum

of

2.

Loosen

up

Take-up

thread

will not be loose when the needle

toward

loops.

Thread Guide Adjustment

yourself until the loopers run

or

lower upper thread

it contact

s the upper

of

thread

upper

take

.

so

bar

out

·

~9~

Page 14

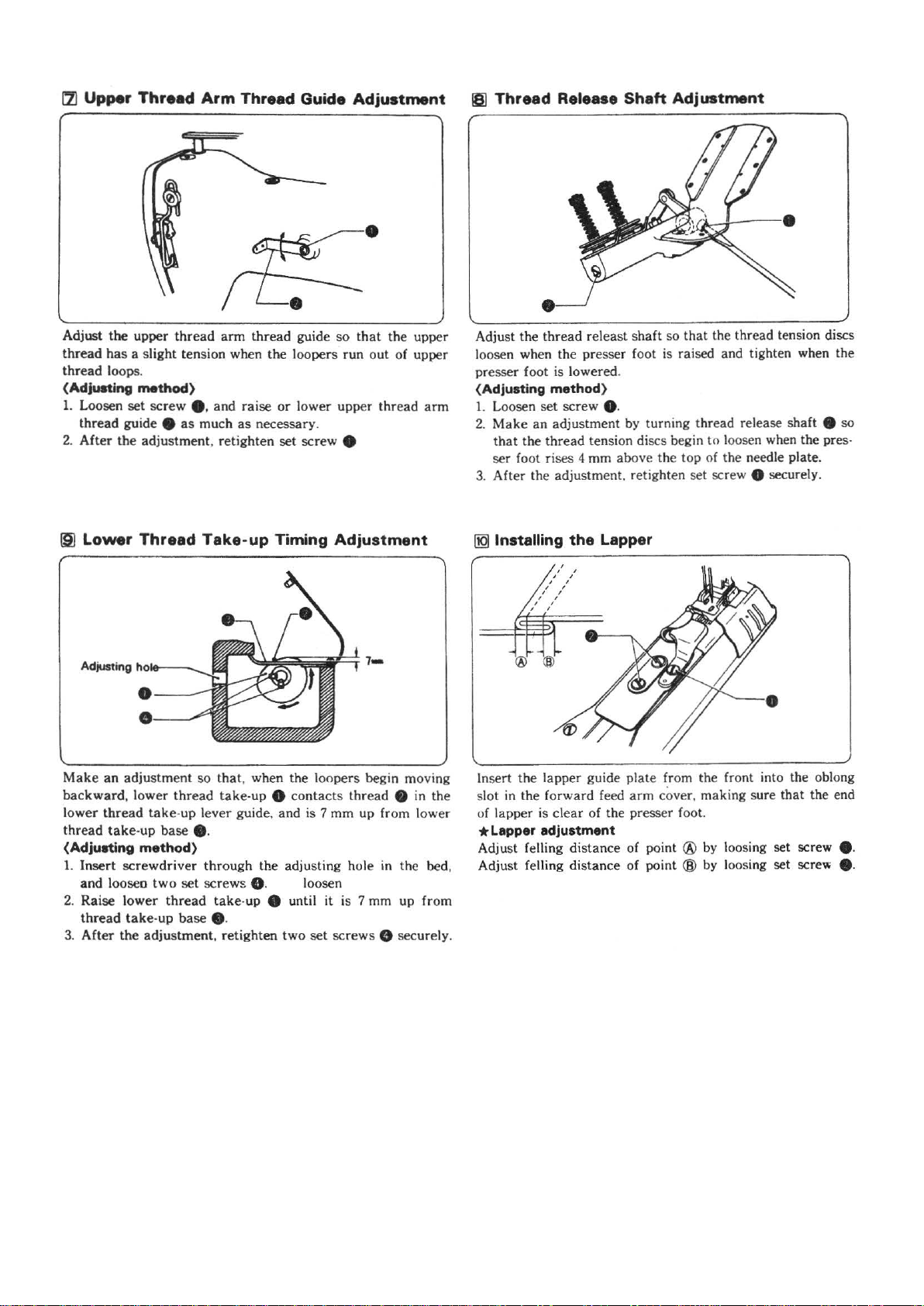

!7l

Upper

Adjust the upper

thread

thread

(Adjusting

1.

Loosen set screw e. and raise or lower upper thread

thread guide e

After

2.

19]

Lower

Thread

has

a slight tension when the loopers

loops.

method)

the

adjustment, retighten set screw e

Thread

Arm

thread

as

much

Take-up

Thread Guide

arm

thread guide

as

necessary.

Timing

Adjustment

so

that

run

out

Adjustment

the upper

of upper

arm

181

Thread

Adjust

loosen when the presser foot is raised and tighten when the

presser foot is lowered.

(Adjusting

1.

Loosen set screw e.

2.

Make

that

ser foot rises 4 mm above the top of the needle plate.

3.

After the adjustment, retighten set screw 8 securely.

[jQJ

Installing

Release

the

thread releast shaft so

method)

an adjustment by turning thread release shaft e so

the thread tension discs begin to loosen when the pres-

the

Shaft

Lepper

Adj

uatment

that

the thread tension discs

Make

an

adjustment so

backward,

lower

thread take-up

(Adjusting

1.

Insert

and

2. Raise

thread

3.

After

lower

thread

method)

screwdriver

looseo

lower

take

the

adjustment, retighten

that

, when

thread

take-up 8

take

-up lever guide, and is 7

base

e.

through

two

set screws Q. loosen

thread

-up

take-up 8 until it is 7 mm up from

base

e.

the

the

loopers begin moving

contact

s thread e in the

mm

up from lower

adjusting hole in the bed ,

two

set

screws 8 securely.

In

sert the tapper guide plate from the front into the oblong

slot in the forward feed

of lapper is clear of the presser foot.

arm

cover, making sure that the end

* Lapper adjustment

Adjust felling distance of point ®

Adjust felling distance of point ®

by

loosing set screw

by

loosing set screw e.

e.

~10~

Page 15

[llJ

Puller Height Adjustment (Model

Adjust the height

the

top

of

of

puller 0 so

the needle plate.

that

it is

927-S/M·PL)

0.1

to

0.2

mm high from

(AdjU8ting

Loosen

puller

~

Puller Device Timing Adjustment (Model FA007-264/DP)

1.

With

2.

The

needle ia

6mm,

3.

After

Method)

set

screw

8 is

0.1

3mm wrench

timing

and

adjusting

e.

and move puller support 8

to 0.2

mm

above the top

to

loosen

of

the

feed will be

away

from

the

needle

etoping

the

at

lOmm.

timing,

of

the needle plate.

the

screw

starting

plate

retighten

up

or

down until

8 & •

when

about 5 or

the

screw

the

0 • • .

0

~11~

Page 16

\(TROUBLESHOOTING)

J

ThrMd

Tro~

breHa.

I I CeuH

Needles installed improperly.

Upper

thread

ten

great.

Lower

thread

great.

thread

Upper

guide out of position.

Needle eyes too small for

threads.

Loopers damaged .

Needle groove

Needles hit loopers.

Wrong

timing of needles

and

loopers.

Needle hit loopers.

sion too

tension too

arm

damaged

thread

I

.__I

_IMpect_ion

Direction

Upper thread tension.

Lower thread tension.

Needle size

Damaged

.

Burrs in long groove.

Clearance between needles

and loopers.

Timing

loopers.

Clearance between needles

and needles guard.

of

long groove.

and

thread

of needles and

thread

way.

____,I

IL____~_Y

to

instructions for

Refer

needle installing.

Adjust upper thread

tension.

Adjust lower thread

tensio

n.

Adjust upper thread arm

thread guide.

Refer

to

the section on

'N

eedl

es

'

Replace loopers.

Replace needle.

Adjust timing of loopers

running clear of needles.

Adjust timing of Need les and

loopers.

Adjust needles guard.

and Threads"

_

_,__I

Page----...JI

Stnc:n.

lklp.

Needle eyes too small for

threads.

Needles installed improperly.

Looper points

Clearance between needles

and

loopers

Needle and looper timing

wrong.

Lower

timing wrong.

Upper

small.

Lower

great

.

Upper

2Uide

Feed dog

Presser

small.

are

too

thread

take·up

thread

tension

thread

tension too

thread

take

out

of

position.

too

low.

foot pressure

dull.

great.

·up

too

thread

too

Needle size and thread

Direction

Lower

timing.

Upper thread tension .

Lower thread tension.

Feed

Presser foot pressure.

thread

dog

of

long groove.

take·up

height.

Refer to the section

"Needles and Threads".

to

instructions for

Refer

needle installing.

Adjust timing of loopers

running clear of needles.

Adjust needle and looper

timing.

Adjust lower

timing.

Adjust upper thread tension.

Adjust lower thread tension .

Adjust upper thread take-up

thread guide position.

Adjust feed dog height.

Adjust presser foot pressu

thr

ead take·

on

UP

re

.

Mechlne

!Ia.

not fMd work.

Feed dog worn out.

Presser foot floats

not fully press work.

Feed dog and presser foot

work

on

one

and

side only.

f---

does

1------------------l

- - -

--

--------i

~12~

Have serviceman check it.

Have

serviceman check it.

Have seNiceman check them.

Page 17

Trouble

I

I

Puller timing

Puller feed incorrect. Puller feed.

Presser

incorrect.

Feed dog height incorrect. Feed dog height.

Cauee

wrong

foot

press~ae

I I

. Puller timing.

Preseer

IMpection

foot

press~ae

.

I I

Adilllt

puller device

A<liust

A<liust

pressure.

A<ljust

R...-cly

timq

puller feed.

preseer

foot

feed dog height.

I

.

Pea-

l

~13~

Page 18

Page 19

CONTENTS目錄

CO-MACHINE BODY

..................................................................1

機體下拉布輪

C1-UPPER SHAFT MACHANISM

...................................................3

上軸結構

C2-NEEDLE BAR MECHANISM-FEED MECHANISM

針柱與送布傳動結構

C3-PULLY MECHANISM

................................................................7

皮帶傳動結構

C4-PRESSER BAR MECHANISM

..................................................9

壓腳柱結構

C5-LOOPER MECHANISM

............................................................11

彎針傳動結構

.....................5

C6-UPPER THREADING MECHANISM

..........................................13

上導線張力結構

C7-LOWER THREADING MECHANISM

.........................................15

下導線張力結構

C8-LOWER SHAFT MECHANISM-GAUGE PARTS(SM1/4)

............17

下軸結構與針位組

C8-LOWER SHAFT MECHANISM-GAUGE PARTS(SM3/16)

下軸結構與針位組

C10-GAUGE PARTS (DP) DP

........................................................21

針位組

C11-PULLER DEVICE MECHANISM DP

.......................................23

上拉布輪結構

..........19

C12-ACCESSORIES

......................................................................25

配件

Page 20

B17

-1

()

[)_18

C 2

C0~1~

Page 21

MACHINE BODY

REF. NO.部件編號

C0-01

C0-C2

C0-5-1

C0-06

C0-07

C0-08

C0-09

C0-11

C0-11-1

C0-12-1

C0-12A

C0-B17-1

C0-A17-3

C0-17-3

C0-18

C0-X28-1

C0-X31

C0-X67

C0-X67-2

C0-X77

MACHINE HEAD 機體(上)

MACHINE REST BOARD 機體(下)

LOWER WHEEL 拉布輪

LOWER WHEEL CONNECTION 拉布輪軸

ONE WAY TRIANGULAR AXLE 單向三向軸片

ONE WAY STILL SPRING 單向彈簧

ONE WAY STILL BALL 單向滾珠

ONE WAY PUSHING PLATE 單向推輪

PIN 銷

FEED DOG PUSHING PLATE LINK 推輪連桿

SCREW 合葉螺釘

PULLER COVER 導蓋(右)

PULLER TOP COVER 護輪蓋

PACKING 導蓋

PLASTIC COVER 橡膠塞

SCREW 11/64×40 螺釘

SCREW 9/64×40 L8 螺釘

SCREW 3/32×56 螺釘

SCREW 3/32×56 L6 螺釘

SCREW 11/64×40 L9 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

2

6

6

1

1

1

1

1

1

1

2

2

3

3

3

2

~2~

Page 22

Y2

4

4-1

X38-1

X38-1

31

C1~3~

Page 23

UPPER SHAFT MACHANISM

REF. NO.部件編號

C1-01

C1-02

C1-03

C1-04

C1-04-1

C1-Y2

C1-C6

C1-07

C1-08

C1-09

C1-10

C1-11

C1-12

C1-13

C1-14

C1-15

C1-16

C1-17

C1-18

C1-18-1

C1-18-2

C1-18-3

C1-19

C1-21

C1-22

C1-22A

C1-23

C1-24

C1-25

C1-26

C1-27

C1-29

C1-30

C1-31

C1-102

C1-102-1

C1-X3

C1-X4

C1-X5

C1-X6

C1-X7

C1-X38-1

PULL BAR ENDING SCREW 合葉螺釘

VERTICAL PULL BAR 傳動連桿

PULL BAR BEARING 滾柱軸承

VERTICAL PULL BAR FIXING SCREW 合葉螺釘

WASHER 墊圈

PULL BAR SCREW NUT 止動螺母

UPPER SHAFT 上主軸

BALL BEARING 6202 軸承

BEARING SUPPORT 軸墊圈

OIL STOPPER 油封

BEARING CASE ASSEMBLY 軸套筒

BEARING 6302 軸承

OIL TANK 儲油器

OILGAUGE WINDOW 油鏡

PACKING 油封墊圈

OIL GAUGE FLANGE 儲油器蓋

OIL TANK PACKING 止油銅墊圈

PACKING 橡膠墊圈

UPPER WHEEL ECCENTRIC WHEEL 偏心凸輪

ECCENTRIC WHEEL WASHER 凸輪蓋

BEARING 滾柱軸承

SCREW 9/64×40 螺釘

UPPER WHEEL MOVING PULL BAR 凸輪傳動連桿

PULL BAR SCREW NUT 合葉螺釘

FIXING PULL BAR SCREW WASHER 止滑墊圈

WASHER 墊圈(薄)

PULL BARSCREW NUT 螺母

THICKNESS ADJUSTING PULL BAR 擺動傳桿

PULL BAR FIXING PULL BAR 螺釘

UPPER WHEEL CONNECTION 傳動軸

MOVABLE LEFT-RIGHT CHOCK RING 定位圈

CONNECTION COPPER TUBE 銅套筒

VERTICAL PULL BAR 雙頭合葉螺釘

WASHER 墊圈

BEARING FIXING SCREW 外牙螺母

BEARING FIXING BUSHING 緊壓套筒

SCREW 15/64×28 螺釘

SCREW 15/64×28 螺釘

SCREW 9/64×40 螺釘

CAP SCREW 覆蓋螺釘

SCREW 1/4×28 螺釘

SCREW 11/64×40 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

2

3

2

2

2

1

1

2

1

1

1

1

1

1

4

1

2

2

~4~

Page 24

X9

X7

X49

X8

C2~5~

X9

Page 25

NEEDLE BAR MECHANISM-FEED MECHANISM

REF. NO.部件編號

C2-01

C2-02

C2-03

C2-04

C2-05

C2-C6

C2-07

C2-08

C2-09

C2-10

C2-11

C2-C12

C2-14

C2-C15

C2-16

C2-17

C2-18

C2-C19

C2-20

C2-C21-1

C2-22

C2-23

C2-24

C2-C25

C2-26

C2-X7

C2-X8

C2-X9

C2-X10

C2-X14

C2-X31-1

C2-X49

NEEDLE BAR CRANK 固定軸

NEEDLE BAR CRANK BOD 提升連桿

NEEDLE BAR BRACKET 針柱夾

WICK 油蕊

OIL LEAK PROOF CAP 防油蓋

WICK 油蕊

NEEDLE BAR GUIDE SLIDE BLOCK 四方滑塊

NEEDLE BAR GUIDE 導軌

NEEDLE BAR 針柱

NEEDLE BAR BUSHING (U) 針柱套筒(上)

NEEDLE BAR BUSHING (D)針柱套筒(下)

THREAD TAKE-UP CRANK 平衡凸塊

OIL CAP 橡膠塞

NEEDLE 針

FEED DOG ECCENTRIC AXLE 調節凸輪

WASHER 墊圈

ECCENTRIC WHEEL SLEEVE 銅滑塊

ECCENTRIC WHEEL WITH SCREW 上下凸輪

ECCENTRIC WHEEL SLEEVE 銅滑塊

FEED BAR SLIDE BLOCK ASSEMBLY 送布傳動曲柄

PACKING 油封墊圈

FEED LIFTING FORK 叉動柄

FEED BAR SLIDE BLOCK ASSEMBLY 四方滑塊

FEED BAR ECCENTRIC SHAFT 偏心軸

FEED DOG ECCENTRIC SET 固定座

SCREW1/4×40 螺釘

SCREW11/64×40 L12 螺釘

SCREW 15/64×28 螺釘

SCREW 15/64×28 螺釘

FEED ECCENTRIC ADJUSTING SCREW 導位螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 L5 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

1

1

4

4

5

2

1

1

1

1

~6~

Page 26

X7

C

X9

X1

X7

C

C3~7~

Page 27

PULLY MECHANISM

REF. NO.部件編號

C3-01

C3-02

C3-03

C3-C4

C3-C5

C3-06

C3-07

C3-08

C3-09

C3-10

C3-20

C3-X01

C3-X07

X3-X09

C3-X18

C3-X22

C3-X79

PULLEY 皮帶輪

TIMING BELT WHEEL ASSEMBLY (SUPPER) 同步皮帶輪(上)

TIMING BELT WHEEL ASSEMBLY (LOWER) 同步皮帶輪(下)

TIMING BELT 同步時規皮帶

BELT COVER 皮帶座

BELT COVER PLATE 皮帶座蓋板

PACKING 防油墊片

PULLEY COVER BASE 配重固定塊

PULLEY COVER 皮帶輪護蓋

WASHER 墊圈

SPRING COIL O型彈圈

SCREW1/4×28 螺釘

SCREW1/4×28 螺釘

SCREW1/4×28 螺釘

SCREW 15/64×28 螺釘

SCREW 7/16×14 螺釘

SCREW 3/16×32 L8 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

2

3

2

5

2

2

2

2

~8~

Page 28

(SM)

D2-27

C

X8

X95

X44

C4~9~

Page 29

PRESSER BAR MECHANISM

REF. NO.部件編號

C4-C1

C4-02

C4-03

C4-04

C4-05

C4-06

C4-07

C4-08

C4-09

C4-10

C4-11

C4-12

C4-13

C4-14

C4-15

C4-16

C4-17

C4-B18

C4-19

C4-20

C4-24

C4-X8

C4-X9

C4-X25

C4-X26

C4-X27

C4-X31

C4-X44

C4-X60

C4-X95

C4-Y02

C4-D2-27

PRESSR BAR 壓腳柱

FACE PLATE UPPER HINGE ASSEMBLY 蝶型後鈕

STEEL BALL 鋼珠

PRESSER BAR BUSHING (UPPER) 壓腳柱軸套(上)

PRESSER BAR BUSHING (LOWER) 壓腳柱軸套(下)

FACE PLATE (LOWER) 前蓋板(下)

PACKING 防油墊片

PRESSER BAR CLAMP ASSEMBLY 壓腳柱夾

PRESSER BAR CLAMP SPRING 壓力板

PRESSER BAR CLAMP SPRING PIN 定位銷

PRESSER BAR CLAMP SPRING ASSEMBLY 上壓力彈片

GUIDE WASHER 定向墊片

WING NUT 蝶型螺母

PRESSER BAR LIFTER 壓腳提放勾

KNEE LIFTER LEVER 壓腳提放柄

KNEE LIFTER SPRING 壓腳提放彈簧

PRESSER FOOT LIFTER CHAIN ASSEMBLY 傳動鏈條

FACE PLATE (UPPER) 前上蓋

STOPPER SPRING PLATE (L) 彈片勾(外)

STOPPER SPRING PLATE (S) 彈片勾(內)

OIP CAP 油塞

SCREW11/64×40 螺釘

SCREW 15/64×28 螺釘

PRESSER ADJUSTING SCREW 全牙螺釘

STUD SCREW 15/64×28 螺釘

STUD SCREW 5/16×28 螺釘

SCREW 9/64×40 L10 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

NUT 3/16×32 螺母

RUBBER PLUR 橡膠塞

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

3

4

1

1

1

1

~10~

Page 30

2

C29

X35

C14

C

C5~11~

21

Page 31

LOOPER MECHANISM

REF. NO.部件編號

C5-02

C5-C3

C5-C4

C5-C5

C5-06

C5-C7

C5-C8

C5-09

C5-10

C5-C11

C5-12

C5-C13

C5-A14

C5-C15

C5-16

C5-17

C5-C18

C5-C19

C5-20

C5-21

C5-22

C5-23

C5-25

C5-C26

C5-27

C5-C28

C5-C29

C5-C30

C5-C31

C5-32

C5-33

C5-702

C5-X9

C5-X28

C5-X28-1

C5-X31

C5-X32

C5-X34

C5-X35

C5-X36-1

C5-X37

C5-X38-1

C5-X42

C5-X50

C5-X56

C5-Y01

ECCENTRIC WHEEL SLEEVE 銅滑塊

LOOPER FEEDING FORK 滑動叉

LOOPER FEEDING SHAFT 滑動叉(軸)

LOPPER FEEDING SHAFT BRACKET 滑動叉基座

PIN 插銷

LOOPER FRONT-REAR TRANSMISSION 前後驅動連桿

SLIDE BROCK SHAFT 固定軸牙

LOOPER LEVER SHAFT 雙節固定軸

PACKING 墊圈

CONNECTING ROD GUIDE PLATE 上下驅動連桿

WASHER 墊圈

LOOPER SHAFT CLAMP 傳動軸夾

LOOPER SHAFT 傳動軸

LOOPER SHAFT BUSHING (F) 傳動軸套筒(後)

LOOPER SHAFT BUSHING (B) 傳動軸套筒(前)

SET COLLAR 定位夾

FORWARD ARM CONER ASSY 平面蓋板

PACKING 防油墊片

OIL GAUGE 探油棒

PACKING 橡膠墊圈

CAP PLATE 下軸蓋

PACKING 防油墊片

"8"TYPE TRANSMISSION DEVICE 8字銅連桿

ECCENTRIC WITH SCREW 小凸輪

EYEPIECE H型連桿

STEEL BALL 萬向滾珠

LOOPER SLIDE BASE 連桿固定片

WASHER 波浪彈片

LOOPER FEEDING FORK 叉動柄

--

-SQUARE BALL 四方滑塊

SCREW 15/64×28 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

電

SCREW 11/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 3/32×56 螺釘

SCREW N3.5 L10 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 1/2×28 螺釘

SCREW 9/64×40 L5 螺釘

SCREW 15/64×28 螺釘

NUT 15/64×28 螺母

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

3

1

1

1

1

1

1

1

1

1

1

1

1

2

1

1

16

2

1

2

4

1

2

3

4

2

1

~12~

Page 32

(SM)B26

(PL)

7-1

X34-1

C

X9

X31-1

X50

B40

C6~13 ~

Page 33

UPPER THREADING MECHANISM

REF. NO.部件編號

C6-01

C6-06

C6-C7

C6-7-1

C6-08

C6-09

C6-10

C6-11

C6-12

C6-C13

C6-14

C6-C15

C6-18

C6-C19

C6-C21

C6-C22

C6-25

C6-26

C6-B26

C6-C32

C6-33

C6-C34

C6-37

C6-38

C6-B39

C6-B40

C6-X08

C6-X09

C6-X31-1

C6-X34-1

C6-X44

C6-X47

C6-X48

C6-X50

C6-X53

C6-X58

C6-X59

C6-X65

C6-Y04

UPPER THREAD GUIDE RETAINER 上導線座

THREAD HANGER 導線圈

LINE GUIDE DEVICE 導位基座

PIN 銷

TENSION SPRING WASHER 彈簧墊圈

TENSION SPRING WASHER 彈簧墊圈

NUT 螺母

TENSION DISC 沙拉片

TENSION DISE PRESSER 張力墊圈

UPPER THREAD TENSION SPRONG 張力彈簧

UPPER THREAD RELEASE PIN 銷

THREAD RELEASER SHAFT 轉軸

UPPER THREAD TENSION SUTD SCREW 過線固定片

UPPER THREAD TAKE-UP GUIDE 天秤過線

UPPER THREAD ARM GUIDE 鬆放過線

THREAD TAKE-UP COVER 天秤護蓋

TENSION RELEASE CRANK 連桿

TENSION RELEASE CONNECTING ROD 上線鬆放提柄

TENSION RELEASE CONNECTING ROD 上線鬆放提柄

THREAD GUIDE TAKE-UP GUIDE 導線鉤

WASHER 墊圈

UPPER THREAD TAKE-UP ASSY 天秤

LOWER THREAD GUIDE 導線勾(D)

WASHER 墊圈

LOOPER THREAD GUIDE BAACKET 固定圈

RUBBER PLUG 橡膠塞

SCREW 9/64×40 螺釘

SCREW 15/64×28 螺釘

SCREW 11/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

UPPER THREAD TENSION STUD SCREW 叉口合葉螺釘

SCREW 3/16×32 螺釘

SCREW 3/32×56 L4 螺釘

NUT 11/64×40 螺母

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

2

2

2

4

2

2

1

1

2

1

2

1

1

1

1

1

1

1

1

2

1

1

1

1

1

2

1

1

2

1

1

2

1

1

3

~14~

Page 34

C2N

X92

X67-1

X44

X9

PL

X31-1

47-1

X31-1

A55

X9 5

X31-1

2

X31-2

C7~15 ~

Page 35

LOWER THREADING MECHANISM

REF. NO.部件編號

C7-01

C7-C2N

C7-3N

C7-06

C7-12

C7-12-1

C7-17

C7-A10

C7-A11

C7-A12

C7-A14

C7-A14-1

C7-A17

C7-A18

C7-A55

C7-C20-B

C7-C22-B

C7-C23-B

C7-C25-B

C7-27

C7-28

C7-29

C7-30

C7-31

C7-32

C7-33

C7-34

C7-35

C7-36

C7-37

C7-39

C7-40

C7-41

C7-44

C7-45

C7-46

C7-47-1

C7-48

C7-49

C7-53

C7-A50-2

C7-A50-3

C7-A50-4

C7-A51-4

C7-B50

C7-B51

C7-C68

C7-X5

C7-X9

C7-X31電

C7-X31-1

C7-X31-2

C7-X44

C7-X45

C7-X50

C7-X60

C7-X64

C7-X65

C7-X66

C7-X67-1

C7-X92

C7-X95

C7-Y05

LOERT THREAD GUIDE RETAINER 導線架(上)

THREE PIPE-LINE THREAD TUBE 過線管

THREAD TUBE CLAMP 導線圈

LOWER THREAD GUIDE SUPPORTER 支架輔助

LOWER THREAD GUIDE HINGE ASSEMBLY 活動鈕(上)

LOWER THREAD GUIDE HINGE ASSEMBLY 活動鈕插銷

LOWER THREAD COVER 橡膠墊

LOWER THREAD COVER 下前蓋

PLATE SPRING 彈片勾

FIXING PLATE 活動鈕(下)

LOWER THREAD TENSION BRACKET 三通過線片

THREAD GUIDE 穩線片

LOWER THREAD GUIDE RETAINER ?通過線片

PLATE SPRING 彈片勾

LOWER THREAD GUIDE 過線片

THREAD TENSION ROD 沙拉螺柱

LOWER TEREAD TENSION NUT 沙拉螺母

LOWER TEREAD TENSION PLATE 沙拉片

LOWER TEREAD TENSION SPRING 沙拉彈簧

THREAD TAKE-UP LEVER COVER 護線蓋

SPRING 彈簧勾

LOWER THREAD TAKE-UP LEVER FRAME 過線輔助架

LOWER THREAD TAKE-UP LEVER COVER SHAFT 銷

LOWER THREAD TAKE-UP LEVER BASE 過線支架

GUIDE PLATE 過線輔助架

WASHER 墊圈

LOERT THREAD GUIDE PLATE 固定片

SCREW 彈簧

WASHER 墊圈

LOWER THREAD GUIDE(LEFT) 彈片扣

LOWER THREAD GUIDE(LEFTRIGHT) 導線勾

LOWER THREAD GUIDE(LEFT) 導線勾

LOWER THREAD GUIDE PLATE 固定片

LOWER THREAD TAKE-UP DISC ASSEMBLY 配線凸輪

LOWER THREAD FEED TUBE 過線管

LOOPER THREAD GUIDE RACKET 針受座

LOOPER THREAD GUIDE BRACKET 針受座

THREAD CUTTER GUIDE PLATE 切線刀

THREAD CUTTER 切線刀

LOOPER GUIDE 過線片

STOPPER SPRING PLATE 彈片勾

PIN 銷

FACE PLATE UPPER HINGE ASSEMBLY(R) 蝴蝶後扭(右)

FACE PLATE UPPER HINGE ASSEMBLY(L) 蝴蝶後扭(左)

LOOPER SIDE COVER (R) ASSY 彎針護蓋

LOOPER SIDE COVER (L) ASSY 彎針護蓋

PIN 銷

SCREW 9/64×40 螺釘

SCREW 15/64×28 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 L10 螺釘

SCREW 9/64×40 L5 螺釘

SCREW 9/64 螺釘

SCREW 9/64 螺釘

SCREW 9/64×40 L4 螺釘

SCREW 3/32×56 螺釘

SCREW 3/32×56 L4 螺釘

SCREW 1/4×40 螺釘

SCREW 3/32×56 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

NUT 9/64×40 螺母

NAME OF PARTS 說明

Amt req需求量

1

1

4

1

1

2

2

2

2

1

2

2

1

1

1

2

1

2

2

4

2

1

1

1

1

1

1

2

1

1

2

1

1

1

1

1

1

1

1

1

2

4

1

1

1

1

1

1

1

3

12

2

7

2

2

1

3

2

2

6

1

1

2

~16~

Page 36

SM1/4

X3

X93

C10-1B

X31

C14-1B

X49

C8~17 ~

Page 37

LOWER SHAFT MECHANISM-GAUGE PARTS

REF. NO.部件編號

C8-C1

C8-02

C8-03

C8-04

C8-05

C8-06

C8-C7-1B

C8-C8-1B

C8-C9-1B

C8-C10-1B

C8-11

C8-C13-1B-1

C8-C13-1B-2

C8-C13-1B-3

C8-C13-1B-4

C8-C14-1B

C8-C16-1B

C8-C17-1B

C8-C18

C8-C19

C8-102

C8-X3

C8-X8

C8-X31

C8-X32

C8-X49

C8-X50

C8-X74-1

C8-X75

C8-X77

C8-X78

C8-X79

C8-X82

C8-X83

C8-X93

LOVER SHAFT 下主軸

BEARING 6200 Z 軸承

BEARING 6201 Z 軸承

BALL BEARING BUSHING 內套筒

BEARING CASE ASSEMBLY 軸套筒(下)

BEARING FIXING BUSHING 緊壓套筒

NEEDLE CLAMP WITH SCREW 1/4 針夾

NEEDLE PLATE 1/4 針板

PRESSER FOOT ASSEMBLY 1/4 壓腳組

FEED DOG 1/4 送布齒

BEARING 6302 軸承

NEEDLE GUARD 針受座

NEEDLE GUARD 針受座(右)

NEEDLE GUARD 針受座(左)

NEEDLE GUARD 針受座(中)

LAPPER ASSY 1/4 導布架

LOOPER 1/4 彎針

LOOPER 1/4 彎針

LOOPER HOLDER 彎針座

LOOPER HOLDER 彎針座

BEARING FIXING SCREW 外牙螺母

SCREW 5/16×28 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 1/4×28 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

2

3

1

1

2

2

~18~

Page 38

SM3/16

X3

X93

C10-2B

C7-2B

C14-2B

C8-2B

X31

C17-2B

C16-2B

C9-2B

X49

C8~19 ~

Page 39

LOWER SHAFT MECHANISM-GAUGE PARTS

REF. NO.部件編號

C8-C1

C8-02

C8-03

C8-04

C8-05

C8-06

C8-C7-2B

C8-C8-2B

C8-C9-2B

C8-C10-2B

C8-11

C8-C13-1B-1

C8-C13-1B-2

C8-C13-1B-3

C8-C13-1B-4

C8-C14-2B

C8-C16-2B

C8-C17-2B

C8-C18

C8-C19

C8-102

C8-X3

C8-X8

C8-X31

C8-X32

C8-X49

C8-X50

C8-X74-1

C8-X75

C8-X77

C8-X78

C8-X79

C8-X82

C8-X83

C8-X93

LOVER SHAFT 下主軸

BEARING 6200 Z 軸承

BEARING 6201 Z 軸承

BALL BEARING BUSHING 內套筒

BEARING CASE ASSEMBLY 軸套筒(下)

BEARING FIXING BUSHING 緊壓套筒

NEEDLE CLAMP WITH SCREW 3/16 針夾

NEEDLE PLATE 3/16 針板

PRESSER FOOT ASSEMBLY 3/16 壓腳組

FEED DOG 3/16 送布齒

BEARING 6302 軸承

NEEDLE GUARD 針受座

NEEDLE GUARD 針受座(右)

NEEDLE GUARD 針受座(左)

NEEDLE GUARD 針受座(中)

LAPPER ASSY 3/16 導布架

LOOPER 3/16 彎針

LOOPER 3/16 彎針

LOOPER HOLDER 彎針座

LOOPER HOLDER 彎針座

BEARING FIXING SCREW 外牙螺母

SCREW 5/16×28 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 1/4×28 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 11/64×40 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

1

1

1

1

2

3

1

1

2

2

~20~

Page 40

PL

X32

X31

X8

C14-2B

C14-3

C14MH

X8

C10~21~

Page 41

GAUGE PARTS(DP)

REF. NO.部件編號

C10-C7-1

C10-C7-2

C10-C7-3

C10-C8-1

C10-C8-2

C10-C8-3

C10-C9-1

C10-C9-2

C10-C9-3

C10-C10-1

C10-C10-2

C10-C10-3

C10-C12

C10-C13

C10-C14MH

C10-C14-2B

C10-C14-3

C10-C16-1

C10-C16-2

C10-C16-3

C10-C17-1

C10-C17-2

C10-C17-3

C10-C18

C10-C19

C10-X8

C10-X31

C10-X32

C10-X77

C10-X79

C10-X82

C10-X83

NEEDLE CLAMP EITH SCREW 1/4 針夾

NEEDLE CLAMP EITH SCREW 3-16 針夾

NEEDLE CLAMP EITH SCREW 1/8 針夾

NEEDLE PLATE 1/4 針板

NEEDLE PLATE 3/16 針板

NEEDLE PLATE 1/8 針板

PRESSER FOOT ASSY 1/4 壓腳組

PRESSER FOOT ASSY 3/16 壓腳組

PRESSER FOOT ASSY 1/8 壓腳組

FEED DOG 1/4 送布齒

FEED DOG 3/16 送布齒

FEED DOG 1/8 送布齒

FINGER GUARD 針受

NEEDLE GUARD 針受

LAPPER ASSY 導布架喇叭

LAPPER ASSY 導布架喇叭

LAPPER ASSY 導布架喇叭

LOOPER 1/4 彎針

LOOPER 3/16 彎針

LOOPER 1/8 彎針

LOOPER 1/4 彎針

LOOPER 3/16 彎針

LOOPER 1/8 彎針

LOOPER HOLDER 彎針台

LOOPER HOLDER 彎針台

SCREW 11/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 9/64×40 螺釘

SCREW 11/64×40 螺釘

SCREW 3/16×32 螺釘

SCREW 9/64×40 螺釘

STUD SCREW 螺釘

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

1

2

3

1

1

2

~22~

Page 42

PL

9A

D1-9

X9

10

X67-1

14

C20

15

12

X67-2

9

C11~23~

Page 43

PULLER DEVICE MECHANISM

REF. NO.部件編號

C11-01

C11-02

C11-03

C11-05

C11-06

C11-07

C11-08

C11-09

C11-9A

C11-10

C11-12

C11-14

C11-15

C11-17

C11-A18-1

C11-C20

C11-X9

C11-X19

C11-X67-1

C11-X67-2

C11-D1-9

PRESSURE ADJUSTING SCREW 外牙螺母

UPPER WHEEL PRESSER BAR 立軸

SPRING 張力彈簧

WHEEL DIRECTION FIXING DEVICE 拉布輪壓力提柄

FRESSER ROD BUSHING 軸套

UPPER WHEEL SEAT 拉布輪架

UPPER WHEEL CONNECTON 固定軸

ONE WAY PULL HOLDER 拉柄

SCREW 螺釘

PACKING 防油墊片

ONE WAY TRIANGULAR WHEEL 單向三角軸片

ONE WAY STILL BALL 單向滾珠

ONE WAY STILL SPRING 單向彈簧

CHOCK RING E型扣環

FACE PLATE (UPPER) DP上前蓋座

UPPER WHEEL 拉布輪(上)

SCREW 15/64×40 螺釘

SCREW 15/64×40 螺釘

SCREW 3/32×56 螺釘

SCREW 3/32×56 螺釘

BUBBER 橡膠塞

NAME OF PARTS 說明

Amt req需求量

1

1

1

1

1

1

1

1

4

1

2

6

6

1

1

1

1

1

3

3

4

~24~

Page 44

16

8

2-1

C1

C12~25~

Page 45

ACCESSORIES

REF. NO.部件編號

C12-C1

C12-02

C12-2-1

C12-03

C12-04

C12-05

C12-06

C12-07

C12-08

C12-09

C12-10

C12-11

C12-12

C12-13

C12-14

C12-16

C12-X1

C12-X2

THREAD STAND 四葉線架

CUSHION ASSEMBLY 固定座

WASHER 墊圈

BASE CUSHION 橡膠墊塊

HEAD COVER 防塵套

OIL TANK 大油壺

OILER ASSEMBLY 小油瓶

NEEDLE 針

TWEEZERS 線夾

SPANNER 固定板手(#7)

SPANNER 固定板手(#8)

SCREW DRIVER 大起子

SCREW DRIVER 小起子

SCREW DRIVER 中起子

THREADLE 腳踏板

SPANNER 固定板手(#10)

SCREW1/4×28 螺釘

SCREW 6.2×26 木螺釘

NAME OF PARTS 說明

Amt req需求量

1

2

2

2

1

1

1

5

1

1

1

1

1

1

2

1

2

2

~26~

Page 46

Sir:tUaA

TABLE

CUT-OUT

750

725

Series

Item Code

FA007 FA007-T1

I

!

\

:

~

---------

0

0

co

..-i

om

com

(\J(\J

r

Subclass I Remark

• FOR FA007 Series

L()

co

(Y)

012

L()

(Y)

L()

Mounting

Fully-submerged

Date

2014 I 7 I 18

f+1>

~

~

-jmg

~

~

~!CF

~

~

;;;o""'

~

lt

"@

n

0

4~

\:':

'-

I--<

/'--j

Am3

""'3

~

- =

~

~

~ln~

§j

D~

~

~

~

fQ

I+

[\)

~

-¥=

680

210 4-R10

.~b------+-~~v---t--t-

g -

-------

-----

--

520

026

~

..

lrl

..

08.5

A-A

:§iJtm

017

-f=-r--

85

o--~~----~--------------------------~r---~-~---0

L()

co

0

Loading...

Loading...