Page 1

® '

J

•

15f!ffl

INSTRUCTION

IDt~

i!i

&

~

~

®

~

**

KAULIN

]

~

151

MFG.

&~ftf~

PARTS

~

~N

~

CO., L TO

BOOK

PJ

.

Page 2

~I

I N D E X

J!{

/PAGE

{!Jij~IJJ

.

:t(.

..

~

• •

. II

tl

.Rti~2J!tl

·

·~112J!tl

.at.&t2~1J-IItl

.at2J!

.!J

ji

.

at~

·

~···

.J:J(

.jq~Az

.!1~-flJl;ZJilt

.ji¥ARI1J~Jl2

·~

·

fi-~IJJ

..

at

••

.at-~at;Z~ift·~

.~at~••z••

. ill

JJ{

.

fi

JJ{

.~f5JAiflJliilt

.

~

f5J

.J:Jt

.J:J(

.jq~Af17t2illl

.at

-~atillfifJIJ~ruJ

Jt

m

tl

1Jl!

• ·

tt

2

••

~-t!Jiilt

il~t

~

·

rlll

Jlil.

at

J=l

•

ll

at

J=l

• •

AM

.fiiiiW

fjflJill

j!f

illt

2

illl

it.2iill

. ~

at

ft1J

• •

.~at-W

JJJ

fi2iilt

OPERATION

GUIDE

.INSTALLATION

.MOTOR

AND

BELT

.LUBRICATION

.HOW

.HOW

.LUBRICATING

.HOW

TO

CHANGE

TO

REPLACE

TO

REPLACE

THE

.THREADING

.ADJUSTING

.ADJSUTING

.ADJUSTING

.ADJUSTING

.

ADJUSTING

.ADJUSTING

.ADJUSTING

MAINTENANCE

.THE

HEIGHT

.TIMING

.ADJUSTING

.ADJUSTING

.ADJUSTING

.

ADJUSTING

.ADJUSTING

.SETTING

THREAD

.

ADJUSTING

.ADJUSTING

THREAD

NEEDLE

SPREADER

PRESSER

STITCH

DIFFERENTIAL

THE

GUIDE

OF

OF

NEEDLE

THE

THE

THE

THE

THE

THE

POSITION

GUIDE

THE

PRESSER

.ADJUSTMENTING

AND

LOOPER

.ADJUSTING

.ADJUSTING

THE

THE

OIL

THE

THE

OIL

FILTER

NEEDLES

NEEDLES

AND

TENSION

THREAD

TAKE-UP

THREAD

FOOT

LENGTH

RATIO

PRESSURE

NEEDLE

AND

LOOPER

FRONT

REAR

NEEDLE

HEIGHT

FEEDING

OF

BAR

LOOPER

THREAD

NEEDLE

OF

FEED

TILT

OF

SPREADER

SPREADER'S

FOOT

THE

TIMING

LOOPER'S

LOOPER

LIFT

MOTION

THREAD

THREADS

TAKE-UP

PRESSER

TAKE-UP

GUARD

GUARD

DOG

STROKE

OF

NEEDLE

GUIDES

FOOT

1

2

2

3

3

3

3

4

4

5

5

6

6

7

7

8

8

11

11

12

12

13

15

15

16

17

17

17

SPARE

PARTS

LIST

-~·

•m~

•~t•

SPARE

TABLE

PARTS

CONVERSION

CUT-OUT

CHART

18-33

34

35-37

Page 3

OPERATION

GUIDE

INSTALLATION

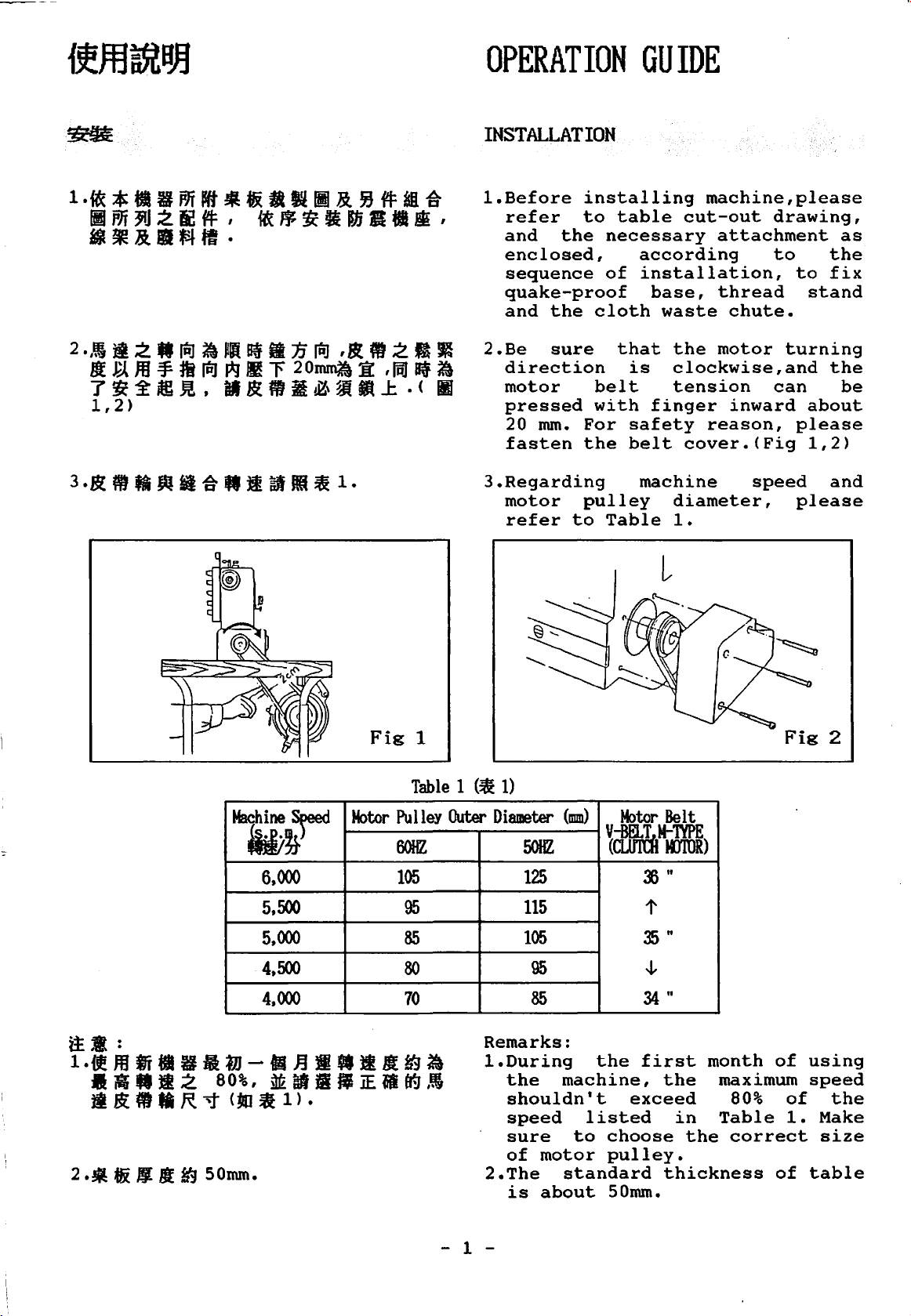

!.Before

refer

and

enclosed,

sequence

quake-proof

and

2.Be

direction

motor

pressed

20

fasten

3.Regarding

motor

refer

the

the

sure

mm.

to

installing

to

table

necessary

according

of

installation,

base,

cloth

that

is

belt

with

For

the

pulley

finger

safety

belt

machine

Table

machine,please

cut-out

attachment

thread

waste

the

clockwise,and

tension

diameter,

1.

chute.

motor

inward

reason,

cover.(Fig

speed

drawing,

to

can

the

to

fix

stand

turning

the

about

please

1,2)

and

please

as

be

2

·*

li

/!1./Jf

r3

Machine~

~~

6,000

5,500

5,000

4,500

4,000

50mm.

Fig

Motor

1

Table

Pulley

60HZ

105

95

85

80

70

1

(~

Outer

Remarks:

!.During

2.The

1)

Diameter

50HZ

125

115

105

95

85

the

shouldn't

speed

sure

of

motor

is

about

(mm)

Motor

Belt

~~N-,tg)

l)"

t

35"

~

34"

the

machine,

exceed

listed

to

choose

pulley.

standard

50mm.

first

month

the

thickness

in

the

maximum

80%

Table

correct

Fig

of

of

1.

of

2

using

speed

the

Make

size

table

- 1 -

Page 4

tcroR

~BELT

1

••

~.

'".

3*6

2.,15

i1

2fi

i2.

2.

1/2,'1

M.

tc

jJ

VI!Blfl•

&It:'

il

(gl

II.

400£

,\lti&:MtateJt:roaa.z·•-••

II

Bl

) ,

M

ft

..

Ill

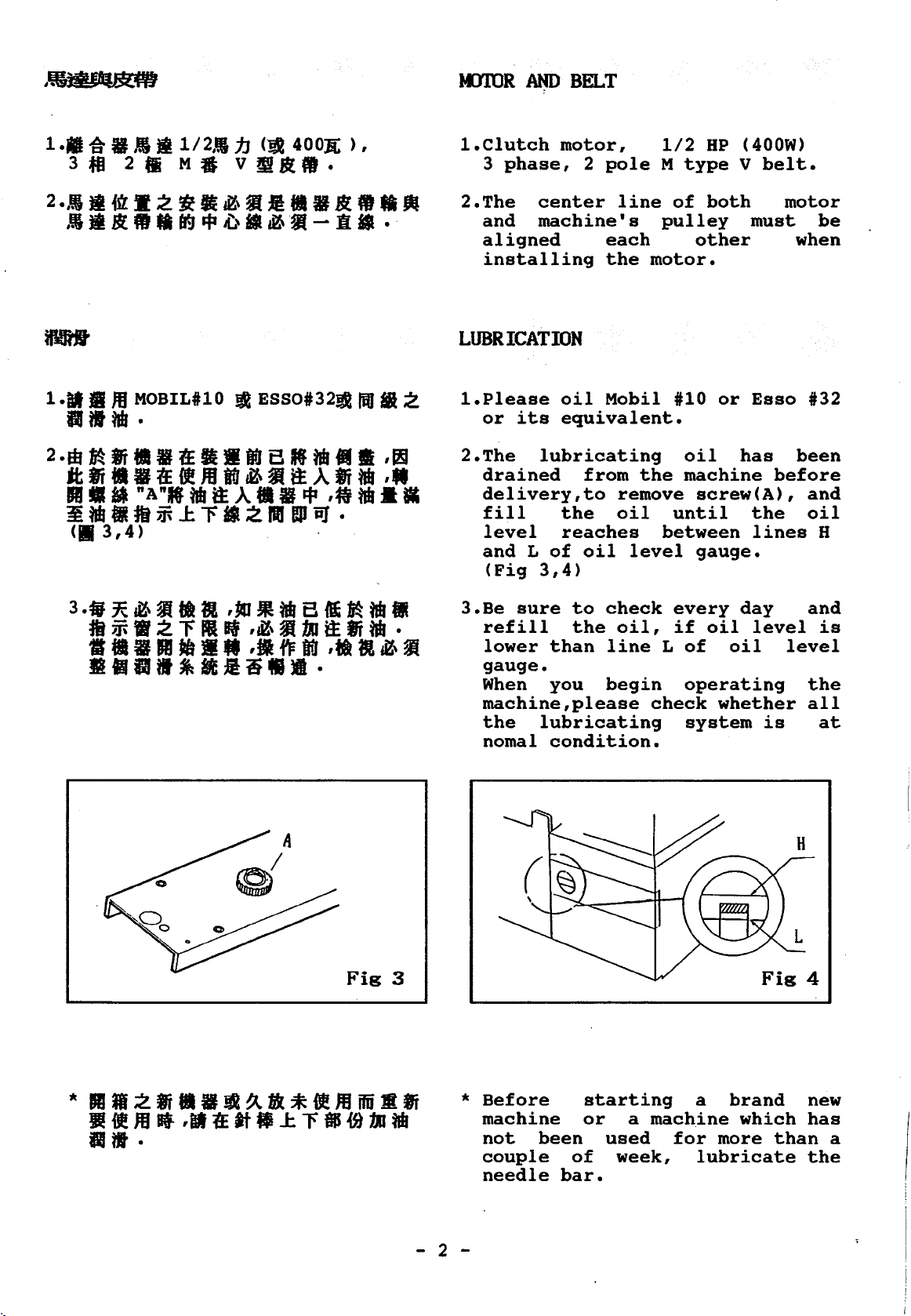

!.Clutch

2.The

LUBRICATION

l.ftl.

JU

MOBIL#lO

!'2

ESS0#32!1fiU ifl

2.

iltlbll·

2.Eif

~

ii

8 U

1£

It

II

ftiJ

B If

Nl

••

tt

li

• •

1£

fJ!

m

tf1

~

it

it

.A

f1i

ll.t.l

~t~~~llttti.J\J:raaznaepiiJ.

(.

"A"Ifbllit.AfiiiJt:l

3,

4)

~-~··

,mJ

~

'"

!.Please

2.The

motor,

3

phase,

center

and

aligned

installing

or

drained

delivery,to

fill

level

and L of

(Fig

machine's

oil

its

equivalent.

lubricating

the

reaches

3,4)

2

pole

each

the

Mobil

from

oil

1/2

M

line

remove

oil

of

pulley

motor.

the

until

between

level

HP

type

both

other

#10

or

oil

machine

screw(A),

gauge.

(400W)

V

belt.

motor

must

Esso

has

before

the

lines

be

when

#32

been

and

oil

H

Fig

3

3.Be

sure

refill

lower

gauge.

When

machine,please

the

noma!

than

you

lubricating

condition.

to

the

check

oil,

line

begin

every

if

L

of

operating

check

system

day

oil

level

oil

whether

is

Fig

and

is

level

the

all

at

4

*

Before

machine

not

couple

needle

- 2 -

been

bar.

starting

or

used

of

a

machine

week,

a

for

more

lubricate

brand

which

than

new

has

a

the

Page 5

HOW

1U

CHANGE

OIL

1.31.

M < 1

ltillliJitll

2 .a

g-ut*

II

M

ti

J! •

--~.

)Jill

,~

.(llf5)

~

M

a • a ilt ,ftl

li

tdl

I

Jll

It

2.

ti

~

Bn

&'3

• (lg ill

:ffi

~

~

~

j~

m w

_ij

J!

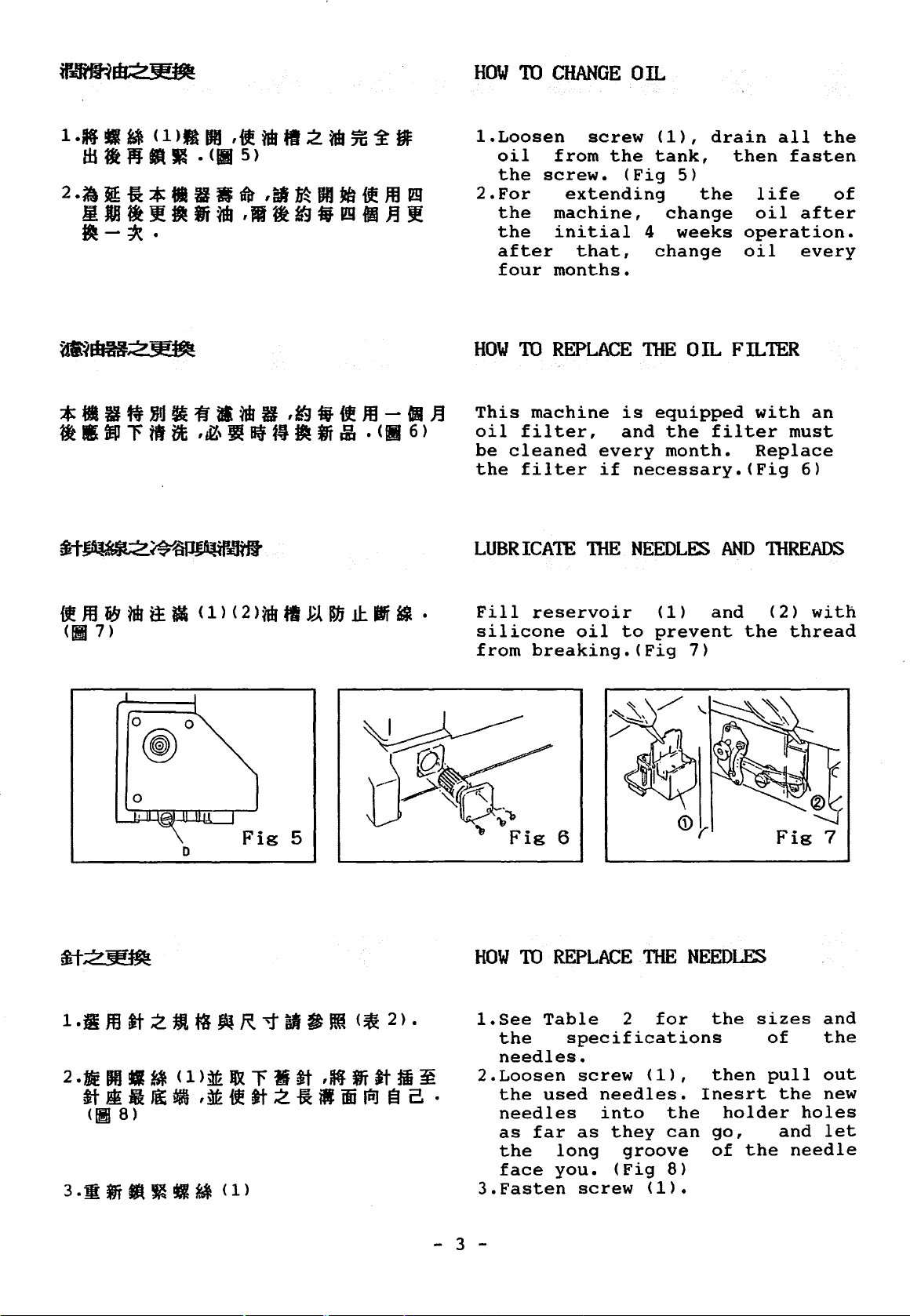

!.Loosen

oil

the

2.For

the

the

after

four

HOW

This

oil

be

the

from

screw.

extending

machine,

initial

months.

TO

REPLACE

machine

filter,

cleaned

filter

LUBRICATE

screw

that,

every

if

'mE

the

(Fig

(1),

tank,

4

change

drain

5)

the

change

weeks

TilE 0 IL FILTER

is

equipped

and

the

filter

month.

necessary.(Fig

NEEDL~

AND

all

then

fasten

life

oil

after

operation.

oil

every

with

must

Replace

6)

111READS

the

of

an

D

Fill

silicone

from

HOW

!.See

2.Loosen

3.Fasten

reservoir

breaking.(Fig

1U

the

needles.

the

needles

as

far

the

face

oil

to

REPLACE

Table

specifications

used

long

you.

screw

needles.

into

as

they

(Fig

screw

2

groove

(1)

prevent

niE

for

(1),

the

can

8)

<1>.

and

the

7)

NEEDLES

the

sizes

then

Inesrt

holder

go,

of

the

<2>

thread

Fig

of

pull

the

and

needle

with

7

and

the

out

new

holes

let

- 3 -

Page 6

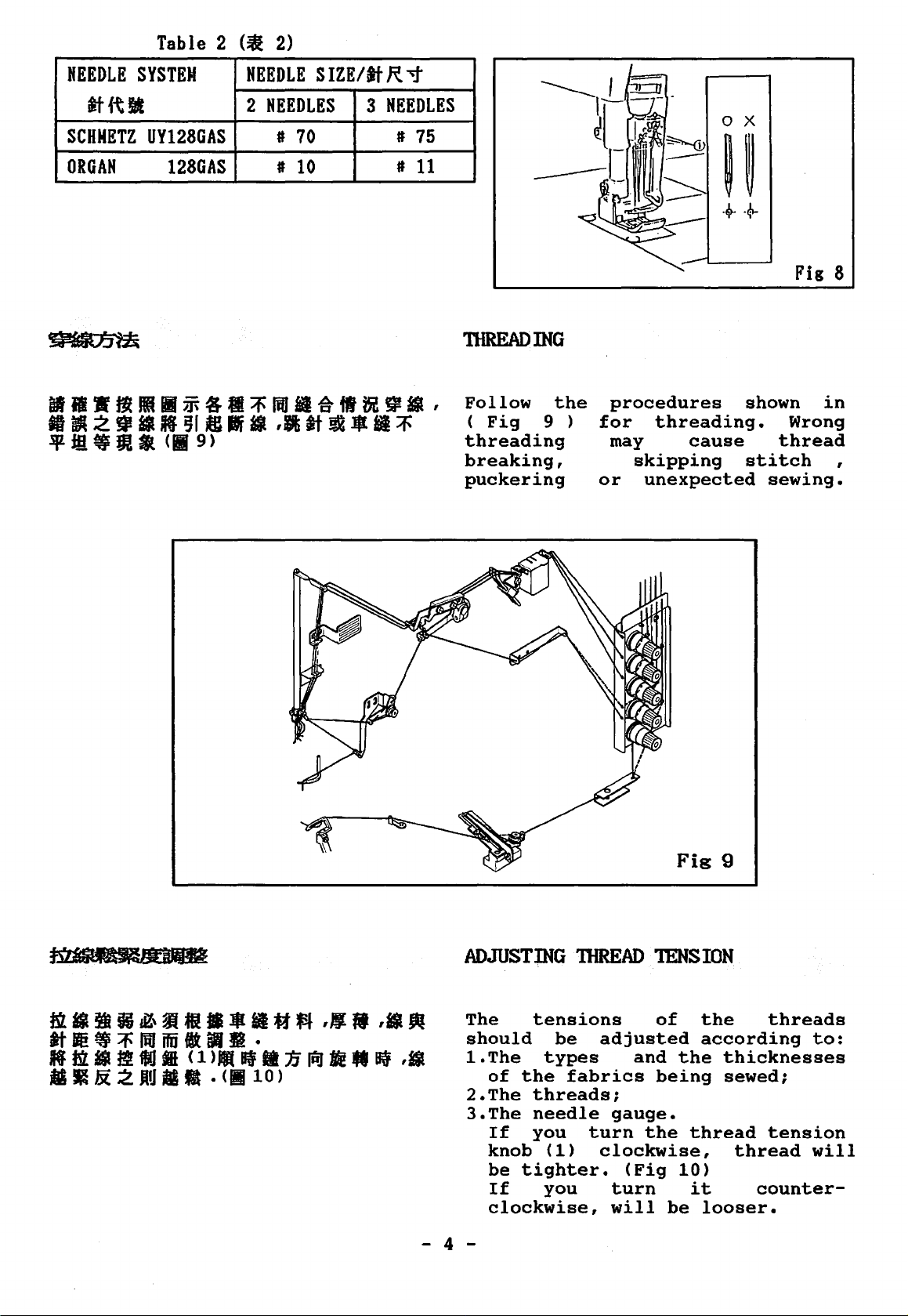

Table 2

(~

2)

NEEDLE

SYSTEM

at{t!J!

SCHNETZ

UY128GAS

ORGAN

128GAS

NEEDLE

2

NEEDLES 3 NEEDLES

I

70

I

10

SIZE/at

R.

# 75

#

'1'

11

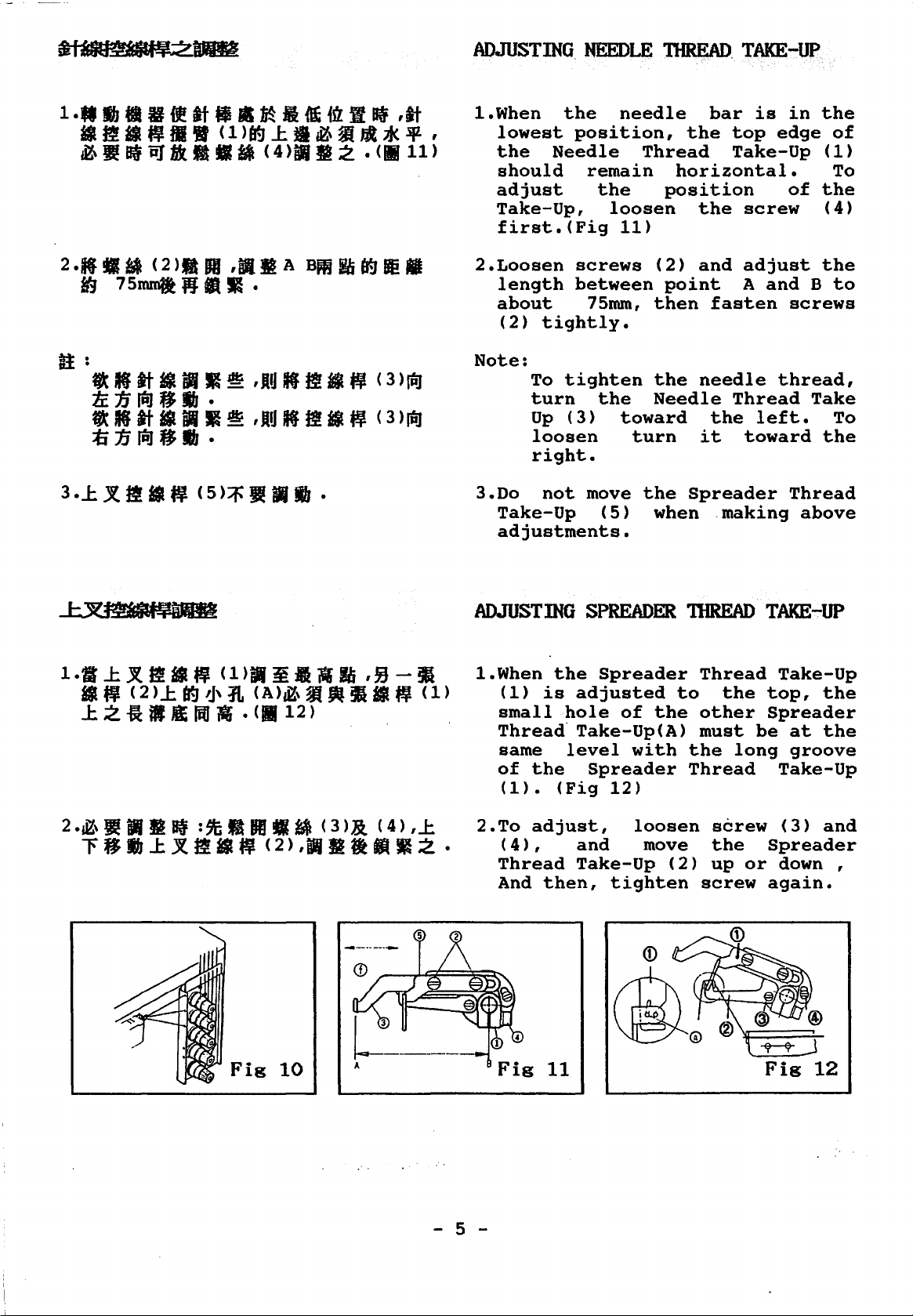

niREADING

Follow

(

Fig

threading

breaking,

puckering

the

9 )

procedures

for

or

threading.

may

skipping

unexpected

cause

shown

Wrong

thread

stitch

sewing.

Fig 8

in

,

ADJUSTING

-

The

should

1.The

2.The

3.The

- 4 -

tensions

be

types

of

the

fabrics

threads;

needle

If

you

knob

be

If

clockwise,

(1)

tighter.

you

TIIREAD

adjusted

and

gauge.

turn

clockwise,

(Fig

turn

will

1ENS

of

being

the

be

Fig

9

ION

the

according

the

thicknesses

sewed;

thread

10)

it

looser.

threads

tension

thread

counter-

to:

will

Page 7

ADJUSTING.

NEEDLE

~-

TAKE-UP

1.When

lowest

the

should

adjust

Take-Up,

first.(Fig

2.Loosen

length

about

(2)

tightly.

Note:

To

turn

Up

loosen

right.

3.Do

not

Take-Up

adjustments.

the

position,

Needle

remain

the

screws

between

75mm,

tighten

the

(3)

move

(5)

needle

Thread

loosen

11)

(2)

then

the

Needle

toward

turn

the

when

bar

the

top

Take-Up

horizontal.

position

the

and

point

fasten

needle

Thread

the

it

Spreader

.making

is

in

edge

of

screw

adjust

A

and B to

screws

thread,

left.

toward

Thread

the

of

(1)

To

the

(4)

the

Take

To

the

above

ADJUSTING

1.When

(1)

small

Thread·

same

of

(1).

2.To

(4),

Thread

And

the

is

hole

level

the

(Fig

adjust,

then,

SPREADER

Spreader

adjusted

of

the

Take-Up(A)

with

Spreader

12)

loosen

and

Take-Up

move

(2)

tighten

niREAD

Thread

to

the

other

must

the

Thread

screw

the

up

screw

TAKE-UP

top,

Spreader

be

long

Spreader

or

again.

Take-Up

the

at

the

groove

Take-Up

(3)

and

down ,

Fig

10

Fig

- 5 -

11

Page 8

ADJUSTING

PRESSER

FOOT

B

~

~at

-Jt

dJ

6-18ft

1 •

2£

•

4 •

OIDinfll

IV

II

i'! •

!I

ll

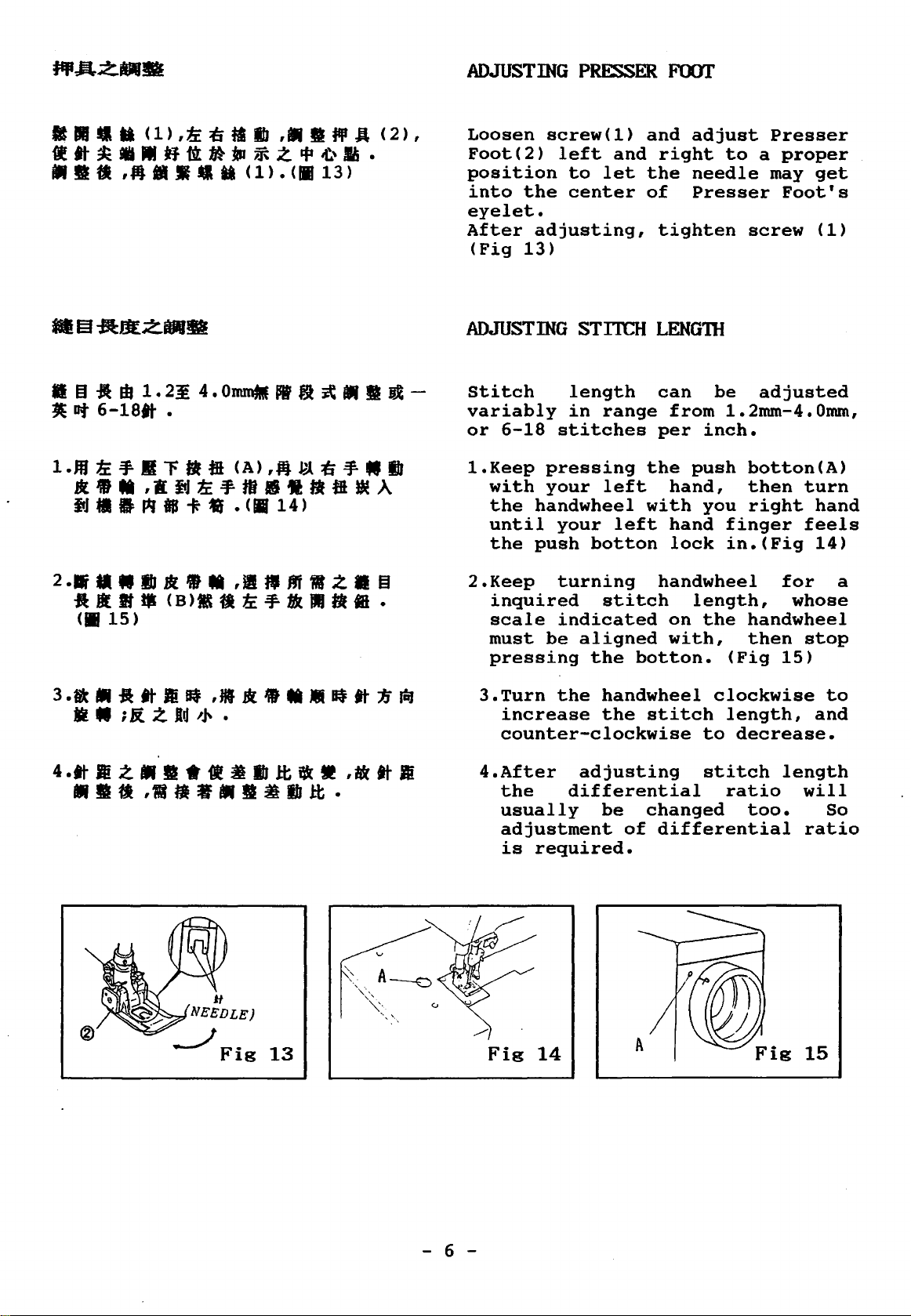

Loosen

Foot(2)

position

into

eyelet.

After

(Fig

ADJUSTING

-

Stitch

variably

or

!.Keep

with

the

until

the

2.Keep

inquired

scale

must

pressing

screw(!)

the

adjusting,

13)

6-18

pressing

your

handwheel

push

be

and

left

to

let

center

and

right

the

of

tighten

STITCH LENGnl

length

in

range

stitches

left

your

botton

turning

stitch

indicated

aligned

the

the

with

left

botton.

can

from

per

hand,

hand

lock

handwheel

on

with,

adjust

needle

Presser

be

inch.

push

you

length,

the

Presser

to

a

may

screw

adjusted

1.2mm-4.0mm,

botton(A)

then

right

finger

in.(Fig

handwheel

then

(Fig

proper

get

Foot's

(1)

turn

hand

feels

14)

for

whose

stop

15)

a

3 .a •

-a

• • ; li. z

tt

m

Bf

ld

NEEDLE)

J

,JI * • • •

,.~

•

It

Fig

13

If

tt

1i

lfiJ

3.Turn

increase

counter-clockwise

4.After

the

usually

adjustment

is

Fig

the

handwheel

the

adjusting

differential

be

required.

14

stitch

changed

of

differential

clockwise

length,

to

decrease.

stitch

ratio

too.

to

and

length

will

So

ratio

- 6 -

Page 9

*••zmiJtbiiJfl

1:2.9

* •• i11J

••••

tb • ((1116)

1:0.3

••~

<1>,J:rt¥1JJIMt¥

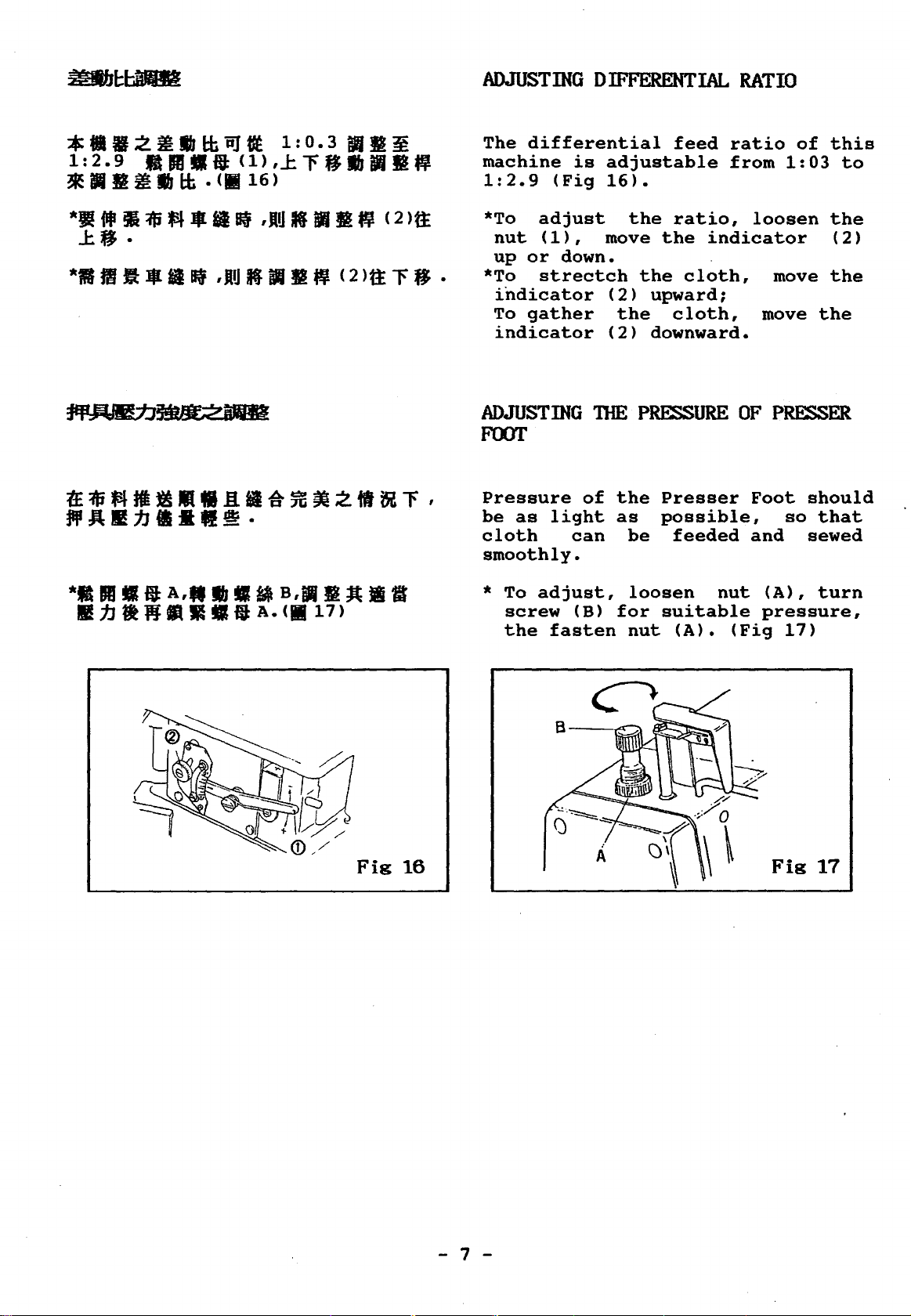

ADJUSTING

The

differential

machine

1:2.9

is

(Fig

DIFFERENTIAL

feed

adjustable

16).

RATIO

ratio

from

of

1:03

this

to

*J!

J:f¥.

*II

fi1Jii

m

Jllllll

:$

ft

lll

Sf

iii

Sf

,JlU

,JlU

If

K Jl II

B1

t¥

M

< 2

'-it

>tt

< 2

r

>tt

fJ

*To

nut

up

*To

•

indicator

To

indicator

ADJUSTING

FOOT

Pressure

be

cloth

smoothly.

*To

adjust

(1),

or

strectch

gather

as

adjust,

screw

the

down.

Tim

of

light

can

(B)

fasten

the

move

the

(2)

the

(2)

P~URE

the

as

be

loosen

for

nut

ratio,

the

indicator

cloth,

upward;

cloth,

downward.

Presser

possible,

feeded

nut

suitable

(A).

(Fig

loosen

move

move

OF

P~ER

Foot

and

(A),

pressure,

17)

should

so

sewed

the

(2)

the

the

that

turn

Fig

16

- 7 -

Fig

17

Page 10

MAINTENANCE

niE

HEIGHT

OF

GUIDE

NEEDLE

BAR

2-

NEEDLE

TABLE

3 (¥i

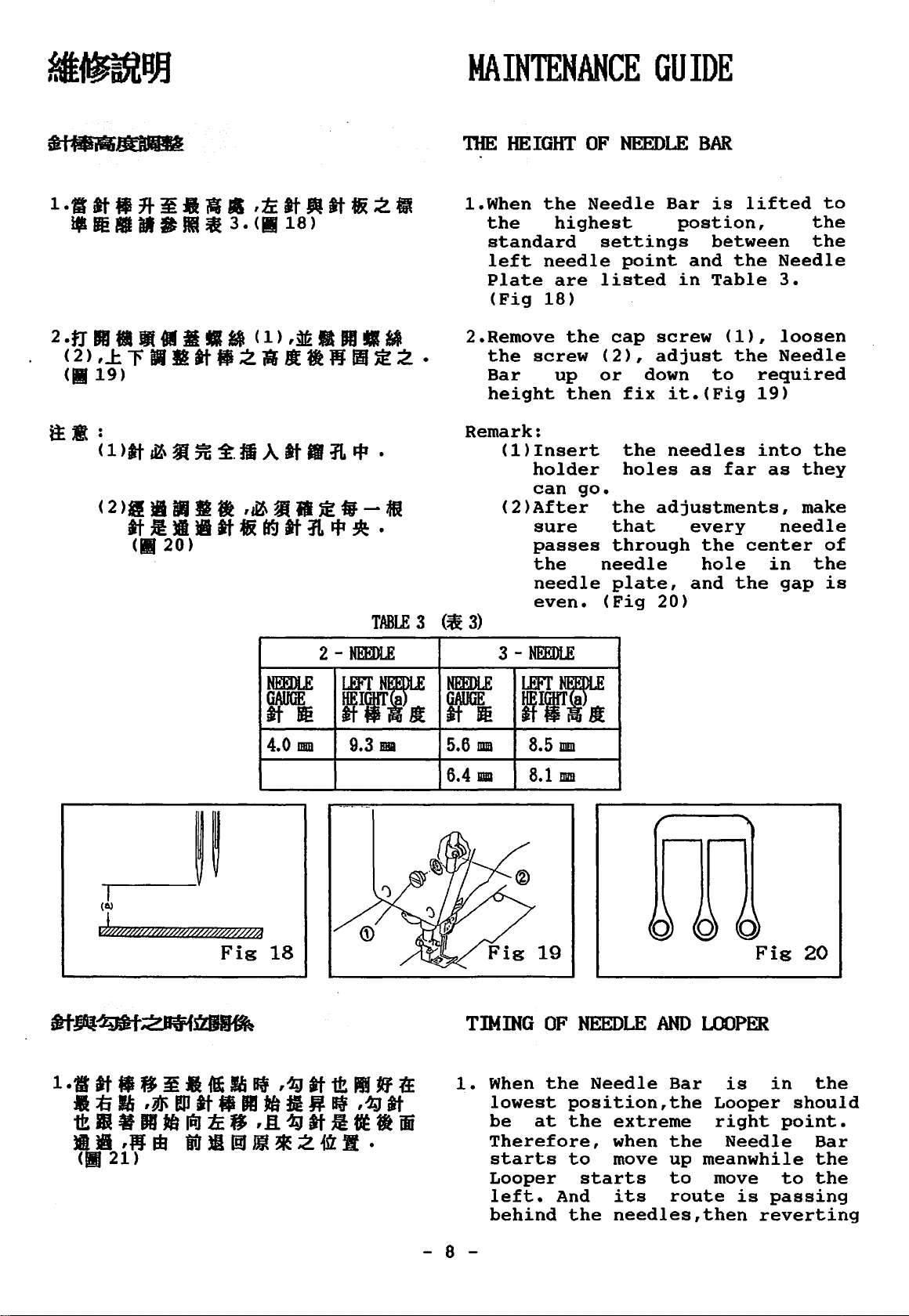

1.When

the

standard

left

Plate

(Fig

2.Remove

the

screw

Bar

height

Remark:

(1)Insert

holder

can

(2)After

sure

passes

the

needle

even.

3)

3

-NEEDLE

the

Needle

highest

needle

are

18)

the

up

then

go.

settings

point

listed

cap

screw

(2),

or

needle

(Fig

adjust

down

fix

the

holes

the

adjustments,

that

through

plate,

20)

Bar

is

postion,

between

and

in

Table

to

it.(Fig

needles

as

every

the

hole

and

lifted

the

(1),

the

far

center

the

the

the

Needle

3.

loosen

Needle

required

19)

into

as

they

make

needle

in

gap

the

the

to

of

is

(a)

J,////ff@'///M////$///////4

Fig

NEEDLE

GAUGE

atm

4.0

mm

18

ftrT.

9.3

BBI

NEEDLE

GAUGE

atm

5.6

mm

6.4

IDIIl

TIMING.

1.

When

lowest

be

Therefore,

starts

Looper

left.

behind

ftr1::

8.5

mm

8.1

mm

OF

NEEDLE

the

Needle

position,the

at

the

extreme

when

to

move

starts

And

its

the

needles,then

AND

Bar

the

up

to

route

Fig

LOOPER

is

in

Looper

right

Needle

meanwhile

move

point.

to

is

passing

reverting

20

the

should

Bar

the

the

- 8 -

Page 11

••

Elf

:

<•

22)

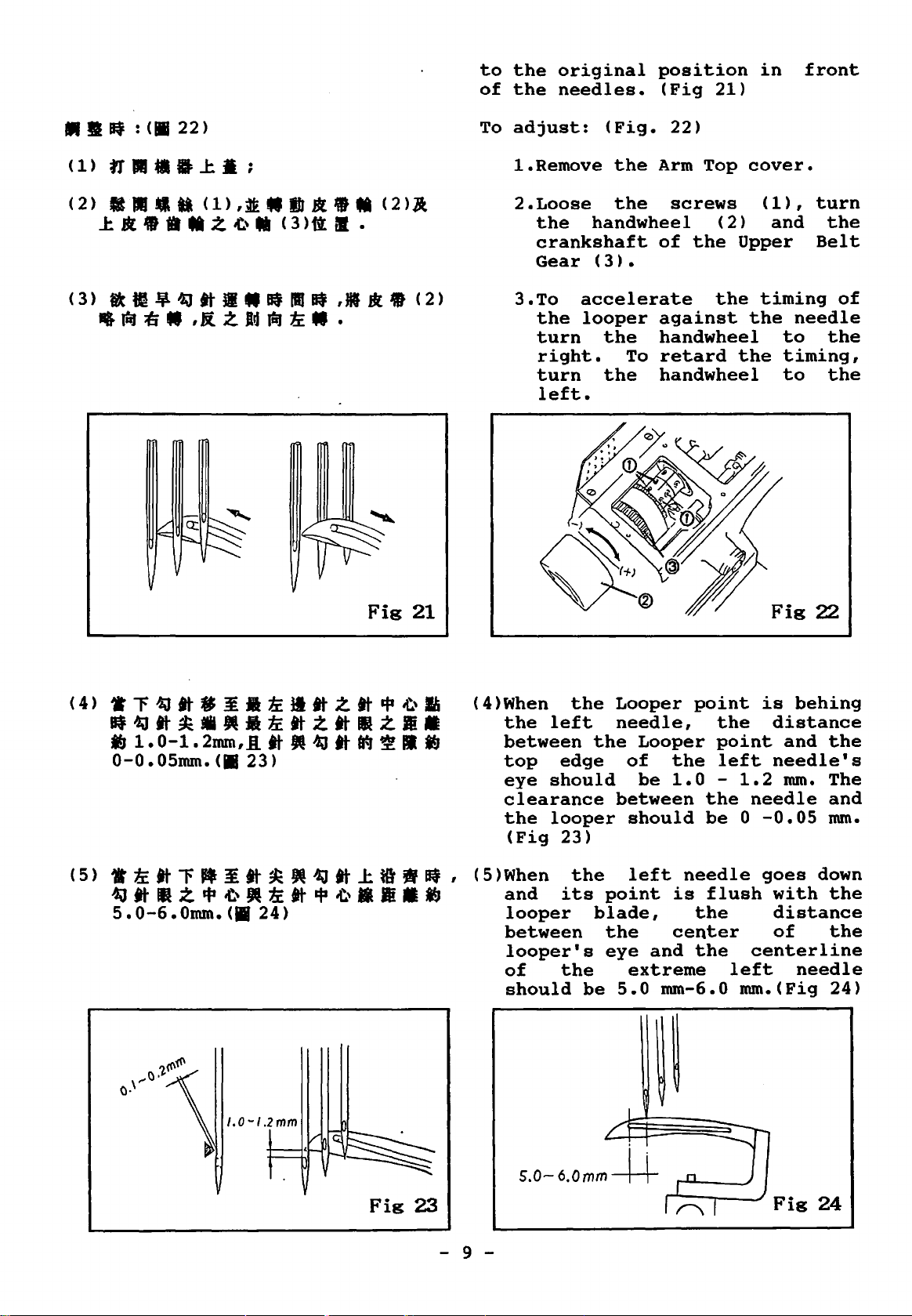

to

of

To

the

original

the

needles.

adjust:

(Fig.

position

(Fig

21)

22)

in

front

(1)1J···J:.·;

<2>

ltiiJ•ta

J:lll•••z..r.

<1>,tt.IJI1l.M

...

(3)ftll.

<2>A

Fig

21

1.Remove

2.Loose

the

crankshaft

Gear

3.To

the

turn

right.

turn

left.

accelerate

looper

the

Arm

the

handwheel

(3).

the

the

screws

of

against

handwheel

To

retard

handwheel

Top

the

(2)

the

cover.

(1),

and

Upper

timing

the

the

Fig

turn

the

Belt

needle

to

the

timing,

to

the

22

of

1.0

-I.Z

mm

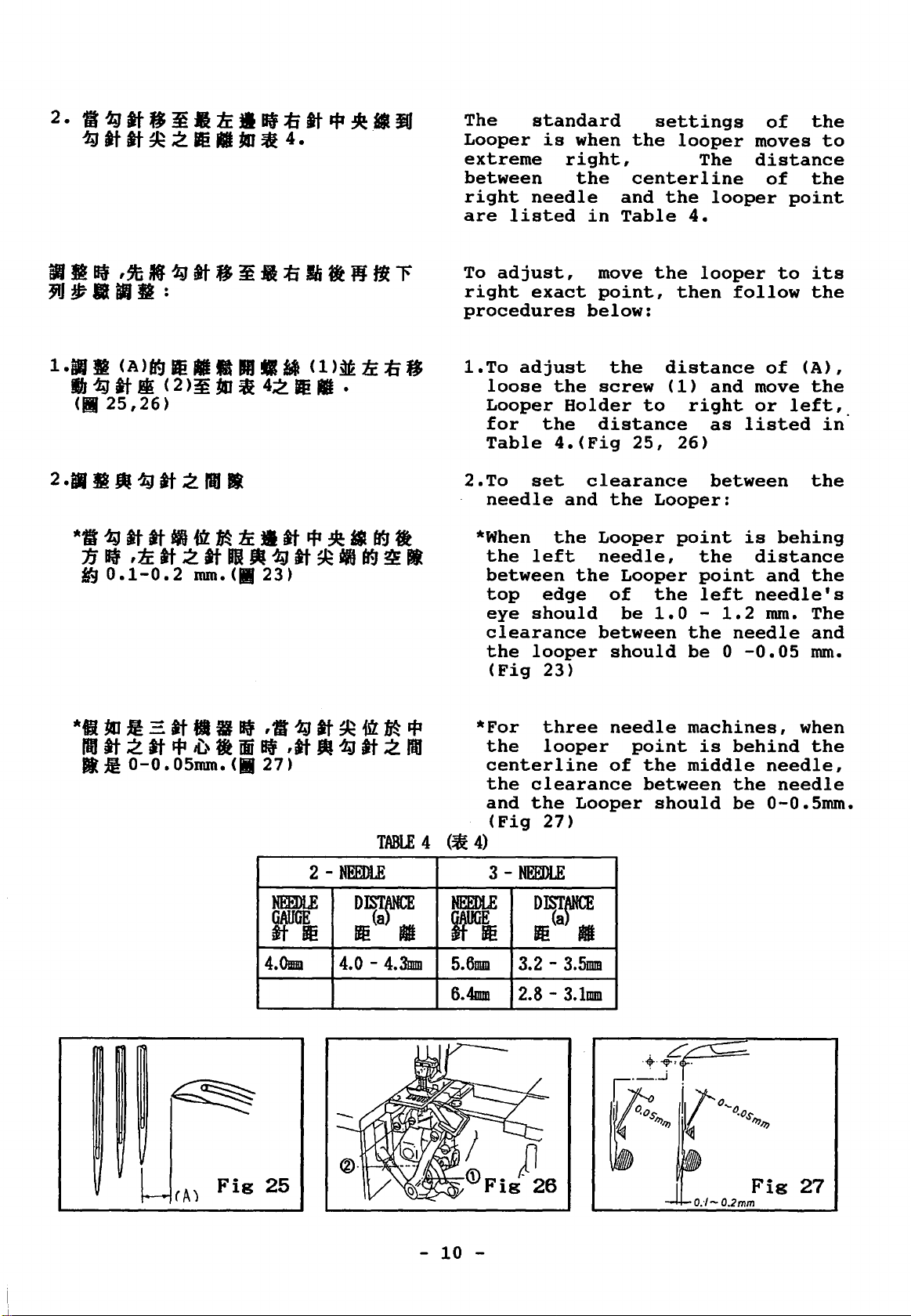

(4)When

the

between

top

eye

clearance

the

(Fig

(5)When

and

looper

between

looper's

of

should

the

left

the

edge

should

looper

23)

the

its

blade,

the

be

Looper

needle,

Looper

of

be

between

should

left

point

the

eye

and

extreme

5.0

point

the

point

the

1.0

mm-6.0

left

the

be 0 -0.05

needle

is

flush

the

center

the

is

distance

and

needle's

1.2

mm.

needle

goes

with

distance

of

centerline

left

mm.(Fig

behing

the

The

and

mm.

down

the

the

needle

24)

S.0-6.0mm~

Fig

23

- 9 -

Fig

24

Page 12

The

Looper

extreme

between

right

are

To

right

procedures

standard

is

needle

listed

adjust,

exact

when

right,

the

in

move

point,

below:

settings

the

looper

centerline

and

the

Table

the

then

The

looper

4.

looper

of

moves

distance

of

to

follow

the

to

the

point

its

the

TABLE

4

1.To

2.To

(¥&

*When

*For

4)

adjust

loose

Looper

for

Table

needle

the

between

top

eye

clearance

the

(Fig

the

centerline

the

and

(Fig

the

the

4.(Fig

set

the

left

edge

should

looper

23)

three

looper

clearance

the

27)

the

screw

Holder

distance

clearance

and

the

Looper

needle,

the

of

between

should

needle

of

Looper

distance

(1)

to

25,

Looper:

Looper

the

be

1.0

point

the

between

should

and

right

as

26)

between

point

the

point

left

-

1.2

the

needle

be

0

machines,

is

behind

middle

the

be

of

move

or

left,

listed

is

behing

distance

and

needle's

mm.

-0.05

needle,

needle

0-0.5mm.

(A),

the

in·

the

the

The

and

mm.

when

the

2

rA)

Fig

NEEDLE

GAUGE

ltfti

4.0mm

25

-NEEDLE

DIST~

Be(a

8

4.0 -4.3mm

-

10

3-

NEEDLE

ifUGjg

5.6mm

6.4mm

-

NEEDLE

~~~

3.2 -3.5mm

2.8 -3.1mm

O:I-0.2mm

Fig

27

Page 13

-~---------

----------

2/3

ADJUSTING

The

Looper

release

when

is

!.For

2.For

To

in

the

2/3

(Fig

of

to

the

(Fig.

adjust:

the

the

the

end

position

28)

the

the

29)

LOOPER

the

thread

point

following

2-needle

of

the

3-needle

left

lower

loosen

then

Thread

niREAD

Thread

of

the

left

of

the

machine,the

needle

edge

the

turn

Cam

TAKE-UP

Cam

of

the

left

position:

machine,

needle

Looper.

is

vertical

of

the

screw

the

(2).(Fig

should

Looper

needle

while

is

in

end

Looper.

(1),

Looper

30)

Fig

28

Fig

29

ADJUSTING

!.When

the

right

.· . exact

the

needles

Needle

of

the

2.The

needles

Guard

that

pass

3.To

and

(1)

only

through.

adjust,

move

back

THE

FRONT

Looper

..

exact_

_point

:point·,.

Guard

needles.(Fig

clearance

and

the

should

the

needle

loosen

the

Front

or

forth.

NEEDLE

goes

to

it:

..

passes

and

(1)

the

is

31)

between

Front

rema~n

threads

the

Needle

30

GUARD

from

the

the

left

behind

Front

in

front

the

Needle

so

close

can

screw(2),

Guard

-

11-

Page 14

ADJUSTING.!

THE

REAR

NEEDLE

GUARD

1.8

1

«f

iJ

~II

0-0.5MM,If

(1),~JifJf.ltllblltt.f*Ji

(.

33)

fJIJit.l

(2).

M

When

the

of

clearance

the

needle.

clearance

middle

point

in

the

1.In

2.When

the

right

the

looper

the

middle

order

about

screw

guard

top

line

located

the

right

needle

of

And

of

needle

when

rear

0

(1),

(2)

the

of

its

(A)

looper

needle,

guard

about

point

it

is

0 - 0.5mm

and

the

needle.(Fig

to

back

needle

of

1/3

needle

looper

of

the

gain

0.05mm,

then

or

lowest

the

be

point

the

0-0.5mm

and

move

forth.(Fig33)

is

needle

low

eye.(Fig.

is

centerline

should

between

the

also

centerline

position,

the

between

the

point

32)

a

clearance

loosen

the

in

below

guard

the

behind

have

right

same

the

looper

is

of

the

needle

the

the

is

top

of

34)

a

••.

If

8

rt~IJJ.

·+·¥'~

r·--"

r

1.3:

MM.

r

,,

'J.'rlo

A

i5

:tfi

a J:

<II

·.,

35)

II

tJ M < 1 >

....

O.os

0.1-0.2mm

11-

"''~~

Fig

I M

,~

nt

32

i8i

ft

tt » < 2

II

It

0.8-1.2

>iaJ

.1:

*To

ADJUSTING

1.The

.

adjust,

then

upwards

is

0.8

highest

move

or

THE

height

position.

loosen

the

Rear

downwards.

HEIGHT

of

1.2mm

when

the

Needle

OF

Main

it

(Fig

screw

Fig

FEED

Feed

is

35)

(1)

Guard

34

DOG

dog

in

the

-

2.Adjust

12

-

so

same

of

that

the

the

level

Main

Differential

the

point

height

Feed

Dog.

as

B

the

Feed

is

point

at

Dog

the

A

Page 15

ill

~

Mlf

t1

•

Mil.

<II

36

>

tat

< 4 > < 5 >

,~

J:

r fJ

Fig

1J

35

~

To

adjust,

(4)(5),

upwards

loosen

and

or

move

downwards.

the

the

feed

(Fig

screws

dog

36)

••

Iff:

l.IIJ-r••

<II

37>

(l)&_J:ii

(2)(3).

ADJUSTING

The

the

parallel

when

highest

To

!.Remove

2.Loosen

straight

whole

the

Feed

position.

adjust:

cover ( 2) ( 3)

the

feeding

screw·

niE

feed

with

(Fig

the

the

tilt.

FEEDING

line

dog

tooth

the

Dog

is

37)

screws

•

screw

(5)

to

TR.T

(a),

Needle

raised

(1)

(4)

adjust

crossing

tips,

Plate

to

the

and

the

and

turn

the··

is

-

13

SE1TING

l.The

be

the

Plate.(Fig

-

11IE

height

kept

top·

Fig

:g

POSITION

at

surface

OF

of

the

Spreader

ar.ound 8 •.

of

38)

SPREADER

3-8.

7mm

the

Needle

must

from.

Page 16

Blfillf:

2.There

between

point

the

needle.

clearance

the

left

in

(Fig

To

adjust:

is

and

Spreader

hooking

needle

its

extreme

39,40)

a

clearance

the

Spareader's

the

about

point

when

left

passes

And

4.5-5.mm

left

the

about

needle

there

(B)

Spreader

point.

hooking

the

between

and

0.5mm

when

left

is

a

the

is

Cl>.f&lltl~

UfJ

It

tJ

!tl

t;

( 2 ) •1:

;tj

tJ

~8.5MM,~filtll!tiM

C4>,MIJJ:Jl.filt¥

IJ

(

1)

,~fill~~.

C

4)

• Cfl •

JJJ

1:

J(

41)

( 1 ) I

I! ~ ,.

r-

~

~6.1mrn

W~/M

.\.

A

at

C3>.

I\

I

Fig38

<5>,&

,

••

fi

;2

~

!.Loosen

move

forth,

Spreader

finishing

the

2.Move

downwards

the

fasten

the

the

screw

the

needle

the

screws

Spreader

while

Lever

the

(4).

spreader

to

set

plate

screw

turning

(5),

setting,

(Fig.41)

(1)

its

to

8.5mm ,

(3).

(4)

,

(1)

back

tighten

upwards

height

Fig

and

or

the

after

or

from

then

39

Fig

8.3-B.7mm

40

-

14

-

Fig

41

Page 17

SE'ITING

'DIREAD

11IE

GUIDE

f(EITION

OF

SPREADER

l.When

lowest

(2)

eye

clearance

and

set

2.When

lowest

should

Spreader

Needle

concavity

the

other.

,--·

••

.#"

__

_

__,

the

position,the

should

of

the

the

to

the

position,

Thread

thread

(Fig

)

Needle

be

set

guide

between

Spreader

O.Smm.

Needle

be

l.Omm

Thread

Guide

of

the

eye

42)

Bar

Thread

just

(3).

Thread

(1)

(Fig

Bar

42)

moves

the

between

Guide(2)

(3).

Spreader

should

is

in

Guide

below

And

Guide(2)

should

to

its

clearance

the

and

the

The

and

face

each

its

the

the

be

.(.

8.3-

B.7mm

~/

ADJUSTING

The

Spreader's

(Fig

!.Remove

2.Loosen

39)

screw

(1).

Connecting

downwards.

*In

order

Spreader's

Connecting

Fis

niE

the

the

42

SPREADER

stroke

Arm

(Fig

nut

Rod

stroke,

Rod

Cover

43)

(2)

(3)

to

(3)

.STROKE

is

17-17.5mm

and

and

move

upwards

decrease

move

upwards.

the

the

or

the

the

*In

order

Spreader's

Connecting

-

15

-

to

stroke,

Rod

(3)

increase

move

downwards.

the

the

Page 18

3

••••

,JIJ:ll

......

3.After

fasten

adjustments,

the

above

Fig

43

said

remember

screws.

to

2.••••

<l>,~•••aa

4.tW.fli!PJ:fl-tJM

~112i1M

<1>.

<2>rtrt.

<2>ffllflJift

<3>,

ADJUSTING

Presser

distance

and

Presser

position.

!.Rotate

2.Loose

3.Lower

4.After

the

the

position;

screw

Presser

height

screw

(3)

lock

Feed

the

the

and

the

(.2);

(2)

P~ER

Foot

between

Needle

Foot

(Fig

the

adjustments,

is

44)

handwheel

Dogs

nut

lever(3)

Foot

up

to

tighten

position.

FOOT

Lift

the

Plate

at

to

(1)

to

touch

LIFi'

Presser

its

the

and

and

the

the

means

when

highest

to

lower

raise

raise

the

nut

the

Foot

the

lower

lowest

the

the

proper

the

lever

(1)

to

-

16

-

Fig

44

Page 19

ADJUSTING

NEEDLE

MOVEMENT

AND

niE

niE

OF

LOOPER

TIMING

BACK

BETWEEN·

AND

FORni

11m

Loosen

the

of

the

ADJUSTING

1.The

behind

left

orginal

the

2.The

according

needle,

(4),

clockwise

looper's

contrary,

counter-clockwise

the

the

eccentric

crankshaft

11m

Looper's

the

end,

position

needles.

adjustment

by

turn

motion.

screw

LOOPER

needles

then

to

loosening

to

motion.

turn

(Fig

(1),

(2)

and

(3).(Fig

'S

motion

reverts

in

can

the

the

decrease

45)

and

the

t«JTION

is

to

front

be

size

the

screw

On

the

to

increase

align

groove

45)

passes

the

to

done,

of

screw

screw

far

the

of

the

(5)

the

the

ADJUSTING

When

exact

between

slightly

According

the

Thread

level

thread

the

point,

bracket

Guides

which

guides

11m

LOOPER

Looper

the

the

tensioned

to

two

the

(3),

the

are

is

looper

guides

(Fig.

alinging

adjust

(3)

and

eyes

parallel.

1liREAD

at

the

should

46)

(4)

of

GUID~

left

thread

be

mark

the

the

to

on

two

the

two

Fig

45

-

17

-

Fig

46

Page 20

PARTS LIST FOR MA GROUP

MA04D

_...........SM132

K 7

MA02D

'

~

MA1:.:3

SM461

-

18

-

MAll-2

MAll-1

MAOl

MAll

SM

432

Page 21

/

/

/

/

Page 22

MCB:'f

SM433-9T

MBOl

SM446

SM436

,v

I

0

SM496

MB04

MB05

WMBOO

-

20

-

Page 23

~502

I

- 21 -

Page 24

HC/2

r

MC/3

-

22

-

Page 25

f1010

SHS02

HD~

MDII

\

604

r

PM/II

HD/7

(MDJ!-2

r8ody\

1/

l,·

MD31-I S/1602

CBeot;ng)

-

23

-

Page 26

st.'•

~04

--~~HE/6

MH7~

...

,

V'f£85

4~

I I

SK441

1

SK27D

""

'~

""'ME14 \

M£11

SH/38

ME28

tb

91135

SM~

431

~~

/~

HEB2

/

HE71

r-tb4

·-;._,.

~1'1401

-~,

sMSIO

Page 27

MFOI-1

SM502

~

\

\

MF30

-

25

-

SMS34

HFV

Page 28

4

SM430

HG56

-

26

-

Page 29

MV24

EN0601

~14D

. . -MH78

~

~

~137

SMSII

MH41

-

27

-

Page 30

MJt/5

SK-2/6

-

28

Pxxxx

-

Page 31

S/1432

'\ri

WN400

v~K~

-

29

-

HKI'l

-~

r

SN301

~,K21

Page 32

SM461

/

K2q

MK28

SM482

G..'-,

11K23

-

30

-

Page 33

------

-----

··----

ML13

NH4.10

SM43~

~

'

HLSQ

-

31

-

HL/7

A'Jr.

tf'MLJ9

SN430

Page 34

1(

KXOS

KX04

i.i

~;.-··-"forf7-

FR

··au

L

YT

-·------·

--·---

----·

KX/0

-···-

--·

··--

-

32

-

Page 35

PARTS LIST

FOR

MY

GROUP

MY14

MYOl

KY05

...............

MY02

KY0

7

I

I

KYOB

https://manualmachine.com/

,K\Oq

~

Ky04

--KY21-

(FOR FR

KY2

KR3

l

1

5

ONLY)

-

33

K T

14

-

Page 36

SPARE

PARTS

OONVERSION

CHART

MODEL

F007-V122

F007-U122

F007-U122

/FP

F007-V123

F007-V222

/FQ

F007-U222

/FQ

GAUGE

240

248

3S6

364

240

248

3S6

364

232

240

248

3S6

364

240

248

356

364

240

248

356

364

NEEDLE

HOLDER

M4240

M4248

M4356

M4364

M4240

M4248

M4356

M4364

M4232

M4240

M4248

M4356

M4364

M4240

M4248

M4356

M4364

M4240

M4248

M4356

M4364

NEEDLE

PLATE

E1524

E1S25

E1826

E1827

E1524

E1S2S

E1826

E1827

E1623

E1534

E153S

E1836

E1837

E3024

E302S

E3326

E3327

E3024

E3025

E3326

E3327

MAIN

FEED

D1206

D1206

D1207

D1207

01206

D1206

D1207

D1207

D1206

D1206

D1206

D1207

01207

D121S

D121S

D1216

D1216

D1215

D121S

D1216

D1216

DOG

DIFF.

FEED

DOG

812S8

812S8

812S9

812S9

81258

812S8

81259

812S9

812S7

81258

81258

81259

812S9

81261

81261

81262

81262

81261

81261

81262

81262

PRESSER

FOOT

P0014

POOlS

P0116

P0117

P0214

P021S

P0316

P0317

P4011

P0014

POOlS

P0116

P0117

P1814

P181S

P2116

P2117

P2314

P231S

P2616

P2617

SPREADER

MH41

----

----

MH41

MH41

----

NEEDLE

UY128GAS

110

110

Ill

Ill

110

110

Ill

Ill

114

110

110

Ill

Ill

110

110

Ill

Ill

110

110

Ill

Ill

F007-V223

F007-VS22

/FE(FFC)

/FR

F007-US22

/FE(FFC)

/FR

F007-VS22

/FE

/FFC

F007-US22

/FE

/FFC

F007-U612

/FBQ

240

3S6

364

240

248

356

364

240

248

356

364

240

248

356

364

240

248

356

364

2S6

264

M4240

M4356

M4364

M4240

M4248

M4356

M4364

M4240

M4248

M43S6

M4364

M4240

M4248

M4356

M4364

M4240

M4248

M4356

M4364

M4356

M4364

E3034

E3336

E3337

E6024

E602S

E6326

E6327

E6024

E602S

E6326

E6327

E1S24

E152S

E1826

·E1827

E1S24

E1S2S

E1826

E1827

E1826

E4001

E1827

E4001

D121S

D1216

D1216

02221

D2221

D2222

D2222

D2221

D2221

D2222

D2222

D1206

01206

D1207

D1207

01206

01206

D1207

D1207

D5001

D5001

81261

81262

81262

82267

82267

82268

82268

82267

82267

82268

82268

812S8

81258

812S9

812S9

812S8

81258

812S9

81259

85001

85001

P1814

P2116

P2117

P2814

P281S

P3116

P3117

P3314

P331S

P3616

P3617

P2914

P2915

P3216

P3217

P3414

P341S

P3716

P3717

P4000

P4002

P4001

P4002

N841

M841

----

MH41

----

----

----

110

Ill

Ill

110

110

Ill

Ill

110

110

Ill

Ill

110

110

Ill

Ill

110

110

Ill

Ill

114

(116)

114

(116)

F007-U612

/FBP

256

264

M4356

M4364

E1826

E1827

-

D1207

D1207

34

812S9

81259

-

P4000

P4001

----

----

114

116

Page 37

TABLE

=~tSJZ.Jfll'~:&t-t&IM

TABLE

~.fil:

UNIT:

NO.

CUT-OUT

M M

MM

F007

SEMI-SUBMERGED

0 N

o o

.q-

r"J

L() L()

co..q-

N N

0

¢17

15

8-B

B-B SECfiON

HIJ

fm

445--

345--1--

310

119

~-

0

------

,---3

-~:-f/J-9--,

---~

~

t

7-RlO

...___---;---------:-+-----··-

__

J:_~

J

____

___:15_9_.

1¢30

R23

234

4_-~13~---;------L----

-~~---~--.IL~--.--

540

465

H--:r7f---

-~

412

392

383

B

----!--

.

..

- - . -

55

0

("....

L()

l.()

0

0

r")

0

--

N

0

Page 38

TABLE

NO.

F007-1

=~.SJL.$""l'~~*t&IIB

TABLE

ft!{\1::

UNIT:

CUT-OUT

MM

MM

SEMI-SUBMERGED

445

--r---

345

--t----

310-+--

15

B-B

B-B

HIJ

oo

SECTION

119

--t---

.---,

1-----------------:----~-----7"------y-

3-~¢9

~

~ 1 -_l__~

I

I I

7-RlO

I

R23

234

159

1¢30

~-

I

I B

I

0

---t-"""

-===::t=.

¢17

540

465

412

3 9 2

383

60

---.1~---

0-----

0

<D

LC>

4-~13~-

--+---__.____

0

0

t'")

---t-

0

0

55

0

Page 39

TABLE

=

jf

.sp.

TABLE

NO.

•

I'

F007-2

~

CUT-OUT

:it

. *

*&

llil

SEMI-SUBMERGED

l.C)

r---.

0

!t!-lll:

UNIT:

MM

MM

8-8

B-B

SECTION

15

HIJ

iii

445

---

345--f---

310

--1--

119

--~--

60

--1---

0------

I

1.

l i 0

r---.

L()

Ln

l.()

N

l.()

I

0

0

n

0

_)

0

Page 40

IN

S. NO. 05-FS

01

MAR. 19

93

•

suBJE

CT TO C

HAN

GE

WITHOUT

NOTICE.

Loading...

Loading...