Page 1

DL7200

1f ffl

~

a~

~

INSTRUCTION BOOK

OL1200-aa11

(€

f/41

~

$

iAi~Jliif.l~~OEJ

KAULIN

MFG.CO

..

LTD.

Page 2

*

ii

ffl

ii~•~

3

ii

ffl

nt

.I-~

""FM~

:

The

DL7200-BM1-XX/DL7200-BH1-XX

~.

Explanation of Dangerous Level

content

*.

~

A

fe:llt

Dangerous

of

this instruction book

ffl

~

!4l

~

m.iffl.

11:t~

!a

ffii

ii

fi

7 H ~

~

ffl"

.=.

~

J...

ff

ffl:

11

a2

~

t:

Don't ignore the warning sign and

Or

it

will cause the person or the third party seriously injured or dead

during maintenance.

M

~~mi

11:~

•

ac

mn.w-rr

7

~a2m=~J...fl~~~~•a•a•

A

51~ the person involved

Caut ion

Ignoring this warning sign and proceed incorrect operation will cause

or

dur

damaged

ing maintenance.

ir.J

ii~

a<J

the th i

is

for

the

models:

ti

tJUI

11c,

1i

II

lfi

~

)E

*

i3

I ffi

don'

t proceed incorrect operation.

a f4i11f,

rd

party wounded and equipment

-1i

• lfj

lriD"

~

•

;,

1

~

•

iffl

• •

=If

■

iS"lll~fi;J\&fi;J\8~~ml~

Explanation of Warning Signs and Labels

illbg5'fir,

Moving part, beware

~~I

il!JI~

of

L8

~■

!~'fit

ii

IJ1j

J\lliil

~i5-II~~~

Warning Si

gn

A

High voltage, beware of electric shock

i1l

51

R~

uL

, ~ lttHi 1' $

High temperature, beware of burns

•

A

it

(S)

ffi~tt•

Instruction Label

@

l.t Prohibited

tti!da<JIUI~~

Indication

of

ground wiring

industrial accident

~

Ml:

Page 3

I

I

1----------------------------------

! •sl INDEX

----------------------------------

------------------

ft/PAGE

~-----------------------------------------------------------------------------------------------:

--~~$1'iN~

GENERAL SAFETY INSTRUCTIONS

1

•li:£½•:iji~~

ffi~tl$Jl

lltt~½IIN

Mil

-~•jjjtsa<J~il'fiiii

~iHt~tili

fflt&

-~*ffllaTI•~~½

>i11$Ti

IMPORTANT SAFETY INSTRUCTIONS

WARNING

WARNING

SAFETY ILLUSTRATION OF NEEDLE GUARD

MOVING THE SEWING MACHINE

THE INSTALLATION POSITION OF THE SEWING

MACHINE

NAMES OF MAJOR

SPECIFICATIONS

IMPORTANT SAFETY INSTRUCTIONS OF THIS

MACHINE

TAG

PAR

TS

3

7

7

8

9

9

10

11

14

~ti

)djll~~

ti!'.19~&

ftrz~•

-~~~

SlliahHlr~MftZ~K

tlffl!1.

atlePJUI

ll~~AmTt-Bz~~

INSTALLATION

OIL

PAN

INSTALLATION

INSTALLING THE NEEDLE

SETTING THE BOBBIN

THREAD

THE

MOUNTING

THREADING THE MACHINE

ST

ITCH LENGTH ADJUSTMENT

ADJUSTMENT OF KNEE-CONTROL PRESSER

FOOT

STAND

BELT

COVER AND THE BOBBIN WINDER 20

LI

FTER

ASSEMBLY 20

15

16

17

18

21

21

22

LE

NEED

ADJUSTMENT

THREAD/BOBBIN THREAD TENSION

23

Page 4

,----------------------------------------------------------------------------------------------- ~

t I

:

I I

------------------------

•sl

f.,

tt-m:•

sni

-

------------

INDEX J

GENERAL SAFETY

INSTRUCTIONS

~-----------------------------------------------------------------------------------------------~

.ti:.

-g

'

Warning!

-~fflM~~-'~*~~ffi~-ffi~~ When

~.~~ff*~·••-~~~A~~~

.II.~ 0

ff~~m~~-Z~

.EL~

1.

ii~

•atro~ilw•-=r•m

2.

~.

'Bi"a".l-1

t2.

M

,u

I

fl:

I

fl=

""F~--~

0

fl

ffi~

IC

tlffi

fl

ii

0

•

-002~fl~~~

;,1

0 Cluttered areas

tB

~

1.

2.

~•••~Mm*z~-~tt•E~~$

x

J1i

0

~~I~

~

M

0

1:'F

fB

~=

~

3.

~~--~~~OOffl~MMA

t;

JiJr

Ji

R1

!'&

lffl , ~-ffJDt~IA

3.

$l1itC■1it•

ff

O

'i

fl

i3

I

~

0

~~•n•M~~~~-m~oo

... ' ffit~4tJtl

'

J.,j_~~,--)

using

precautions

reduce

persona

Read all these i

operating

instruct

Keep work

injuries.

Consider work area environment

Do not expose

machine

Keep

Do not

to

Avoid

grounded

work

cause

Guard against electric shock

body

this

should alw

the risk

l injury,

this

ions.

area

too

ls in

area well lit.

use

power

any

fire or explosion.

contact

surfaces

machine, basic

ays

of

fire, electric

including the following

nstructions

product

clean

and

power

damp

and

benches

to

rain.

or

wet

tools

where there is ri

with earthed

(e.g. Pipes, radiators,

safety

be

followed

shock

before

save th

invite

Do

not

locations.

or

to

and

s .

ese

use

sk

ranges refrigerators.)

Keep children away

4.

~iirt•mm

4't!ill~*D1MIA~:m:l!H$'1tli

5.

ilSe~n,•

4.

Do not l

extension

5. Dress properly

Do not

et

visitors

code.

wear

4'-~---~~~~-~-·~~~~

mD•~~Af~WB~M0~-~-B~

~~1±~

6.

~~-ffiltutJttM

M4'~m••~~~•H•~~~M~~

...

~-~*~~-~ooo••~--~-~

-~~~1Ui¥

7.

■

11~••11

-~-ffi-~~~m~~~~~~#o~

~~~IAffl~•~••m~~·•~m

ta

ffi

tro

'1UJH A 3IHIJ~

·

0

can

be

caught

protecting

hair.

Do

not

6.

Never

to

cord

e

dges

abuse

carry

disconnect

away

from

.

7. Maintain machine with care

Follow

changing

periodically

instructions for

accessories. Inspect

touch

loose

hair cover i

the

. If

clothing

in

moving

the

cord

machine

it from

heat, oil,

damaged,

the

tool

or

parts. Wear

ng

to

conta

by

cord

the

socket

and

lubrication

have

or

jewel

ry,

in

long

or yank

. Keep the

sharp

and

tool

cord

it

repair

they

it

ed

by

an authorized service f

-1-

acility

.

Page 6

a.

~IHHIB

-~~ffl~H~·-~tt-~&~~~#

ft~

0

9. lti.llBllfJ

~-~~m•M~~~

~BffiAt~~IA

• ill

Im

1111

~

Ill

10.

~----~

tf

il-~-oom

M

l'(.J

HJ:tz

■

LZ~•-~

•

~~~m•zffi,

•

trr

,

mui,1,,t>ffl:~M

w~3•~~~~~w•~~•A*ffl~

*

1i

_.

iE

fil

31

fl~.§.~

!Jtlll

fp1Jfm

0

8. Disconnect machine

When not in use, before servicing

when changing accessories.

9.

Avoid unintentional starting

Do n

ot

carry a plug-in

the switch . Ensure the power switch is off

when plugging in.

10.

Check damaged parts

Before further use

other part that is damaged should be

carefully checked

too

l with a finger on

of

the tool, a guard or

to

determine that it will

and

11

.

■

fi

~7ttm*oom~~~M~ea~~~z

9~

.

1r

fiiI

~f-f

~

:m

~

1i

((.J

{5e

m ,

trRJ

•

fl

1'1

A

ii

w

891B

12.

EB~tlAA*•JIBA

ffi~89-~I~-~~~ffi~Aft00ffl~

fmffl

)JU*

f.f:

*

ft:.

1.

R "iij

00:fi

"

CE"~ifftY.Hi~~ib~-ilil

~!tllff•

2.

~~~oomm~~~•w~~~~•·

~

!I

0

G

w-e

operate properly and perform i

function.

11

. Warning

The use

otherthan those recommended in this

instruction manual, may prese nt a risk

personal injury.

12.

Have

person

Repairs should only be carried out

qua

parts.

SPECIAL WARNING FOR ELECTRIC

CONNECTION!

1.

Incorporate

certificate hold-

2. Follow the ins

of

any accessory

your tool repaired

lified persons using original spare

this

machine only with "CE"

to

-run control device.

tr

uction manual device

ts

intended

or

attachment,

by

a qualified

by

to

of

3.

~~~~§*•~~-~-H~~~~

i:I!!

G

4.

r±RM·~~W#·~~-~~-ZM•

~ffi~~~ffi~WM~mili,~ffi~ff~

ffll

fi

a~

.:z

9~

89

~lb

mHi

~

m;

~

0

install control device.

3. Always earth machine appropriately

during operation.

4.

Before adjustment , parts change or

servicing must be sure to pull out the plug

from socket to prevent the hazard

unintentionally start

-2-

of

machine.

of

Page 7

I

1----------------------------------------------------------------------------------------------- ,

: £jf;~~1llllfflBI.I IMPORTANT SAFETY :

:

~-----------------------------------------------------------------------------------------------·

•a~afl$•a~700~8~M~

ff~~~~~~&~~~~~.~~

~-~~ffim~■H•~ffiflmff~M

~~m~~-·~~~ffi~~~ffl~o

if~

ffl

Hf;

J1t

~

a'A.

~

1±

~

~

RJl

ffl

((.j

ii!?

"jjo

INSTRUCTIONS :

For

0

operating

best

functions

must

operate

and foll

manua

references. We

will

enjoy

1.

ow

l,

enjoy

manufacturing it.

Instead

when

the

and

this

of

you

sa1ely

of

it

instructions

keep it

machine

the

use

and

this

machine, you

correctly.

at

are

confident

following

this

machine,

getting

Please

of

this

hand

for

as

much

instructions,

the

read

future

that

as

please

you

we

2.~m•n~•~7~~~mm~~

0

3. ~~~--~~s•~~:i:M~&

0

(S)

5.

06.

~

7.

..

9~

, iiff~M5ilt1t!tff

llll~~-

I!t5'~' ffl~t\1iff~*ffffi~ajl

c ,

.1-1

oo

~~•

!I~~

,

11J~m•a

RI

.1.~u1

ittlll~J;x~fl=~ilat

ffi!

11

~

11

ic

It

fvUit

, tt

:i: li!

fflf"F

~

11=

~

'.:f'

•:ft~~

EB

~

ft-O"J

0

~

iI

it

~

a/II

ii

W~.A.R~il

Jtttl ill

tifl=

~ 7 ~

/JI

O

½ ,

nt

0

,

&"i

M ;z

fftHI~

mz

ne

Jilrl!f

~:i:

1)

Jifi

ifil

,

j.j

ji

11=

Ii~½

0

Mo

~~ffi~•ffi~HM~~d~~~

Jm:

(1)

vtta , ilWJ=t , ~:qr~.1.1&

J! •

._-r~•

0

~

~

.i.

Ii

pay atte

measures.

02

03

Before

.

read

instructions.

keep

Before

.

ascertain

standards

country

& 4. When

operation,

must

without

is

not

(S)

06.

&1.

This

5.

properly

your

For

wearing

Please

disconnect

circumstances

(1) When

adjusting

thread

ntion

using this

this

manual

this

manual

using this

that

and

.

the

machine

all

be

ready.

the

specified

allowed.

machine

trained

own

goggles.

turn

off

it

threading

guide(s),

to

the

basic

machine,

and

all

related

In

addition, please

for

future needs.

machine, please

it

conforms

regulations

is

ready for

the

safety

Operate this

must

opera

safety,

the

for

any

of

the

thread

equipments

safety

be

operated

tor.

we

suggest

power

switch

one

of

fo

llow

needle(s)

Take-up(s),

and/

safety

please

with

safety

of

your

machine

devices

the

ings :

,

or

by

you

or

a

replacing

(2)

J!ittt

tt

'ft!!

,

~A

l:t ,

PJ!Pll

1W

~~it~

, ttt& ·

'

-~?#ffi

O

igA

•

~&it

, ffi

-3-

(2) When

feet, needle

needle

guides

accessories,

replacing

guards, horns,

and

bobbin(s),

need

plates,

other

parts

les,

feed

cloth

or

presser

dogs,

Page 8

{S)

&

(3)

M~I

11:fey

•

~)GRI~~M~I~~MfflAW

0

IUf

~)~~m•~-~~~~~-~~

fitill 1°'tl

8.

5dlJE,

ii

xat

3'.l:

,

~~~~il~~~.u:

illl a ~Jfr.14

fifli

~Jffl6=

il

J.1

* jft

,

$$Ul

flffl

Bl

Mel!~*Ri ·

111

~!Hrr

&

;z

fii.t

$m

~

0

~

0

(3) When repairing,

(4) When the operator leaves the

ng

worki

machine unattended.

(5) If clutch motors without brake

pads are used, must wait until

the motor stops completely.

If grease, oil, or any fluid contacts

your skin

please wash the

complete ly with clean water and

ult

cons

place

or

eyes

a doctor.

or

leaves the

by

any chance,

co

ntacted area

Or,

swallow any

& 9.

10.

0

I::\

'Y

12.

~~me

&51a11a•~:1:~alffl11t

fflftlrtt1itiz•t-1:9!~cf-l:

,

J.i~

~ir.A.~~11·

MIJ,

~••anriliY-Jf!Sifi~M~liz

• at H

flei&Jl!'lWift,

~

ff

ffl

fli

~

z *

f-1:

ii

EB~

O

at

0

11-=f*f-l:fflJ&ii•Itt~~lEB:il

~1¥-Jtl-=ffiBililiz

~

A

ii~

=tf

&

:tli

flat , a

:rr

~11'

,

~El3~~~JAa

8 ,

~

il

11:

m

•ii,,

11

*

ff:

0

ffl

&_

9. Do not touch any functioning parts

o 1

{S)

{S)

11

12. Maintain and check the electronic

fluid mistakenly, consult a

immediatel

and devices. Always attend to

whether power switch is on or off

before operating in order

anyone from

O.

Qualified technicians are required

for adjustment, modification, and

repair. Only use assigned parts for

replacement.

. Routine maintenance and service

must be performed

persons ,

parts must be

electrician

any electronic part damaged

y.

gett

ing hurts.

by

or

qualified technicians.

done

by

or

well-trained persons. If

doctor

to

prevent

well trained

qua

lified

or

malfunctioned,

immediatel

I::\

\Y

13.

{'ffi•fla!b~~~(@J~&lIHI

ff((.JfllilJ.15i~·If1:Wi, IIWilfi

~-~

fflJ

J.15~

w

~

~

~

~ ~

&

,

II

,

jej

■

~

M

i:p

91

t(:;9~~

1nm

•

-~ffl-J-

ff~

~&~fi~15=

a<1

tt

IUi

(ijj

a12

J..;JJII

II

••it

!lo~~

M&

fl

fi

I::\

'Y

;z 0

14.

1n1-oo.m-natrm

0

JI

0

,

&-m)Ewn•

0

-4-

13. The air hose has

from the machine and the

compressor

of

f before repairing and servicing

cut

the mach ine equipped with

pneumatic parts such as

cylinder. Qualified technicians

well-trained persons are required for

adjustment and repairs.

14. To ensure the best performance,

periodically clean the machine

necessary.

stop

y.

to

or

air supply has

the machine

be detached

to

be

an

air

or

is

Page 9

0

0

15.

lif!•fftm1Emjlf1=.&•Plli~

ti

i:t 5

~

IfI

ni:11!!

..I:.

• •

MA

fl=

ti

ft

J:.

J:.

0

Bfl

I

0

16.

,.~

Ill

if

IIJ:tHI

ll1i

~1t

ti~

ti

ir.J

JI

'iUt-1

~.

ti!!

M ;z

±Ji~

~~

tt

fl

ti~

.

HB

~

tt

~

, ~EB~ -r

1l.

mi~.

ti

o 15. In order

reduce the no ise, please place the

machine flat and level on the ground.

Avoid operating the sewing machine

at

a noisy surrounding.

16

. Select a proper power plug and

0

IC\

install it

connect the power

grounded receptacle.

17

. This machine can only be used

by

to

operate

an electrician. Please

prope

plug

to

rly

a

and

to

for

~

\;:>I

1

a.

~

~

d

fl

J1-~

1,1!i

, ~lli~IIRfi°~(l{J~:i:ffl

,

~

21

dWJ!IIHP/rsl

(

1)

fHl{1=

i!t

•-IB~7il~Mtlzfe:1!1l , ~

~HM~it'aiff~Z9~1i

~Alflt1H~~imz*f1:

JI

ti

Fi.Pf

It~

ff

!.!a-~

jJ:

II

~•-z•

J.IIUi

1:E

1RJ

.A.

1/i

ffl ~

,Ld3

Et

;z

~

ltiHJ

O

11

It~

ffl

~

·

-tl?.:if

0

'.IE

\:::I the designed purpose. Othe r uses

this machine are not allowed.

IC'\ 18. Any

\::,,

made

conformed with the safety standards

and regulations. Precaution is

necessary. No responsibility will

company take for damages caused

by

this machine without permission .

19

.

applied

mod

ification

on this machine

any

mod

ification

Two

safety warning signs are

as

warni

ng

(1) For

the

safety

service

open

control boxes of

devices and

pe

rsons, please

the

cover

don't

or

conversion

must

or

conversion

signs:

of

operators

of

any electronic

mo

tor or other

touch

be

don

any

our

and

't

of

of

(2) ~~~~U>iiUJJ14

a. M

~

=f

i:iJ

tt

3

lffl

ffi1iit~d~½~f-F~

fi.

ff~

fl=

'

j.j

~1'io

b.

~

7

li!aflHIHilfi

Bi1'91fi ,

~lli •

}lf;it ;

jij

tit_. t£

.A.A~11

1m

89.=J: , BIU.Jl

-~-~ti&•Jsl•}1

lft9~~@${iLffjj

fRJ

4tl

£ ,

°

Bl

fli a ,

,

~.ft.A.

,

1'1\1

Iii

J.j

!~)I

=J:

31

i!

=f

ft

components inside

e

le

ctrical sh

(2) Always

a. Please never

machine w

finger guard

device

injury.

b. Please keep your hair, fingers

and

hand wheel, V belt and

while

op

eration,

put

to

prevent the ri

by

tangled

ock

keep

in mind :

it

to

avoid physical

clot

hs away from the

the

machine is in

as

anything near these parts,

into

to

avoid

hazards.

operate

hout belt

or

any safety

well as never

them.

sk

of injuri

cove

this

r,

motor

es

-5-

Page 10

~

c. •

1t1UJ

lffl

11

EH'±

rt

ffl

i:f:I

-=¥-

nt

t£

tt

B9

~9~mi:f:I

,

1! 0

d.

Wliffilifi~

lb,

~7ii!~f.t.:J:AJfls

;z e

~

,

!!!HR

~m•tt~a11t-HLE

I!

ti~

T

~

81i11M

• 0

· J.1~9Jft.A..R~

~

Im

Ill

fl~

ti~

,

~

1"

AJ

JM

iflHrtl

"""F

n

:ex

tt

•~al

J-i~•BA.I.~

, tfmii!iilM

l®

ii

:i'.1fa

a<J

.:f

ii

•

11t9~

, a

,

ii

:i'.

~jjt

lffl

IHI

a\

c. Please never

under

thread

prevent physical injuries when

you turn on

or operate

d. While

operation,

a hi

your

area

po

In addition, please

to

the needle(s)

take-up

the

gh

speed

hands away

of

hook

tential injury to

turn

off

put

your fingers

or

cover to

the

power swit

the

machine.

machine is in

the

hook rotat

. Please

to

prevent any

the

power

keep

from

your

make

of

in the

the

hands .

the

ch

es

at

sure

a\

a\

A

e.

S!Rm:aJtHU!Hlejitlf

~Hll

=¥-

II

M

ti

ft

i:f:I

B.A.A~11

t.

~

7

31!t~ltH~~Ail1Jffii

~lmlt9~ ,

im

m

~a~

tlfttlll

11

0

g.

~

m

1&H1<.i

..

Sflimfti~~S

mm~

, J-j~9Jft.A.ff.~

ffl!

w

~

a~x

it,ljff~Dll:~8~·~

jj;m:f•~~Plftir-.J ,

m~•w~~iilb

~-9~

jJj 0

,

1t•11~f1Bt

' lj\,i:)

•

J.j

,

~

fn.l

rm i3I

~

9J

~I

11

ti

Iii~

li

7

®AJ

ffi

a\

a\

A

machine whi

bobbins

e. Be careful and

your

fingers inside

machine

lifting

avoid

injuries.

f.

Please turn

be

head

cover

possible

abrupt

g. For machines

motors, the m

produce

machines are at rest.

Therefore, please turn

power of

the

possible

fore tilting the

or

and

le

changing

.

do not place

when placing

machine head

phys

off

the

removing

the V be

accidents

start

of

this

equipped

otors

noise while the

this

machine

the

or

to

ical

powe

r

machine

the

belt

lt

to

avoid

due

to

machine

servo

do

not

off

to

.

the

avoid

to abr

h.

~

7

A

lf~MtizffiJft , •M

1"

~tt

3 1Uli%Hlttf!IHl

fl

A

{1:tlff O

-6-

h. Never

machine after the

is removed

shock

possible

upt

start of

ope

rate the

to

hazards.

accidents

the

machine.

sew

ground

avoid

electrica

due

ing

wire

l

Page 11

A

i.

~ 7 M:t.11ill~llr*1f

mi

~

I g

;z

"iij

fffi

1l

9~

,

~jljjt

'

:jij•J:.!2fRtf•ai

~

5t

fafi

+JJ

llf

Q

i.

Please turn t

before connecting

disconnecting the power plug to

pr

event possible

to

electric

el

ectronic components.

he

pow

acc

shoc

k or damaged

er switch off

or

idents

due

------------------------------------------------------------------------------------------------

WARNING

r - - - - - ---- - - - - - - - - - -

~7B~MB~s~•~•-$t•~~

~*lfi

1

0

02

.

.

03.

:

-~~~~Sftffl,~ffl-~

~11:frl , illtJg$i;i*M

~litili!~~-~2.PJ!ll»m:±L:z.

0

5feHli

il'.itS

~iEil

---

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ---- - - - - - - - - - - - - ~ - - - - - - - - - -

Pl

ease confirm the followings to avoid

malfuncti

■

H

0

o

1.

After installing the machine, and

be

clean

o 2. Clean all

during transportation.

■

~milffil&(Itiffi~-=ffi)~

O

03

@4·

Confirm that the voltag e and the

.

phase (single

are

Confirm that the power

correc

supply.

Never

-'-~-

- - - - - - - - - - - - - •

on

or damage to this machine.

fore the first operation, please

it

completely.

dust

and overflowed oil

or

3 phase)

set

correctly.

tly

connected to the power

use the machine when the

of

plug

motor

is

1

I

local voltage type is different from

the marked voltage on the nametag

attached on the mach ine.

06. -~•HMDn~~a~~

0

0

A

•s

.-.a

■

*ti

r-----------------------------------------------------------------------------------------------

-~~ffl-~M~

~---~~~-N~-.~~--ff~

JflB

·

•

r±

ti

11=

ex

a111

m *

~

q:,

1n

m

111

z

a-$

llfrl ,

tilH~~fflllhii,,;xzM11~

■ WARNING TAG :

o

~St~fljjrHI~

•

ffl•~--J:.~~M

·

J.j_~~l\

0

.-

"-"

0

A Warning:

• The following warning t

• When using

6. Confirm that the rotating

the mach

Be

fore

adjustment described later in this

manual, please turn the power off

prevent accidents caused by abrupt

start

on

the sewing machine. {Fig. 1, Fig. 2)

ol

low the instructions of the tags. Please

f

contact the

ine pu

doing

of

the sewing machine .

the

sewing machine, please

dea

ler if any

lley is correct.

any

ope

ration or any

ags

will be attached

of

the

tags

direct

is fallen

ion of

,-

to

.--

I

I

•

off

or

fuzzy.

-7-

Page 12

®

LDJ~~

........

aaa5.»lltMm!IH

T

cu:hi'9

presart

T

U'Tl

befae

@@

@~

~½1~ilf&X(lil3)

(A)

~ffi

~D~-~~~.~~~--~~D~~

/jj{~

0

~~ftlbnfi:il

ilffiH

aeas

ca,

off rra,

q:l81~

1l

tfl!

DANGER

~.ff

wt-a'e

resut

switch

'this

lil1/Fig. 1

hig1 vdta]es

i'I

severe injuy.

ax:.!

a:MK.

wait

&

ae

5 mirules

~!!!

CAUTION

•t1-fflli!S{~•~••.1:

&

A

-1¥t1••

l!jl.tlil'.WIJ!f.lill

Of,

at

~

a Ill

Mov

i~

Operate

T l.ffl aff

1tYeocirg

neede.

perts

dea,ioo

112/Fig

with

rrrin

~

. 2

"1

rray

safety

switch

@@ Must have ground wire.

A loosen

wire is

shock

®~ Indicates rotating

Safety Protecti

(A)

Finger Pro

or a did

the

reason causing electronic

or

malfunction.

on

tecto

not

connect

di

rection.

Device {Fig. 3)

r

•

ii

ca.ise

bctbh

well

.

•

i"IJu-y

devices.

befae

CJ1d

ground

.

;

-------------

!

:

____________

■

~-~•z~R~~R•M

~~~2~~~½·M»M~~-m~

--------

tt;;:i:

__

---

--------------

■

mt

____________________________________________________________________

-----

■~~.~~~

0

-8-

SAFETY ILLUSTRATION

NEEDLE

The presser

shown

operators, this device is restricted

disassemb

as

the figure 4. For safety

GUARD

foot

protection

le.

dev

113/Fig

OF

ice is

of

all

to

. 3

_

as

Page 13

114/Fig.

4

---------------------------------------------------------------------------------

r

-------

-

-----------

-

-------------------------

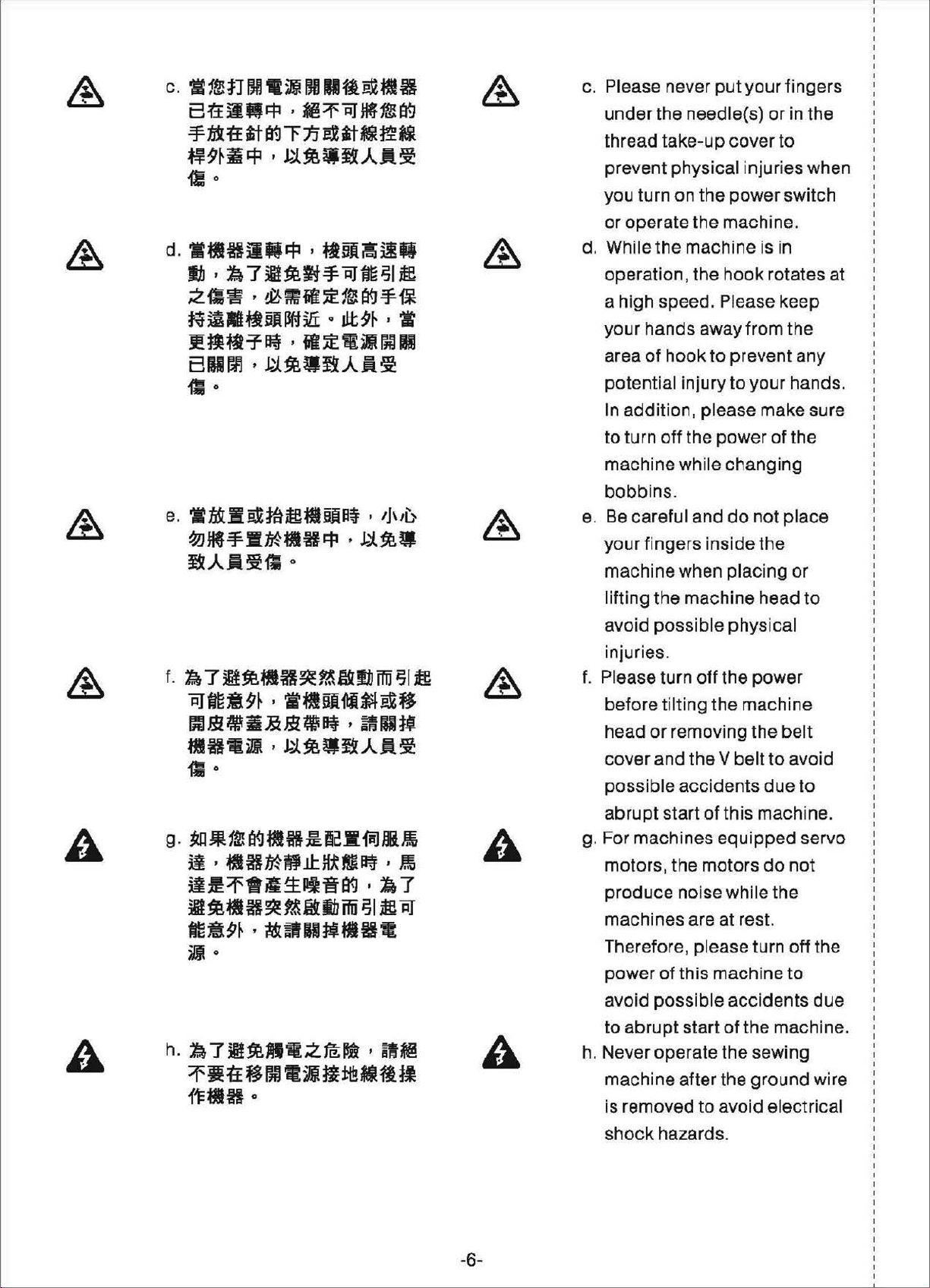

MOVING THE SEWING MACHINE

----

----------------

1. The machine should be carried

people

2.

Hold

pulley will not rotate.

3. Please wear a

moving the sewing machine. (Fig.

the

as

shown in the figure.

motor

-

----------------

cover A

pair

of

by

sk i

dproof

by

hand,

shoes whi le

so

two

that

5)

---- -------

the

I

- - •

------

L-----------------------------------------------------------------------------------------------1

:,:

1 THE SEWING MACHINE

~•••~ii:•m•

11

1.

-~~-~-~M~-~fi•~-~--

~fi•~-~~~~•~m~@~-cJ~

--~■ir.Jtlf-=ffl.ln~·

2.

hl~M~tlAffHmAACtiiitl~

{fffl

~~ii I cJfm.iftJiil:111:i!&lll

0

(116)

,

rul.

0

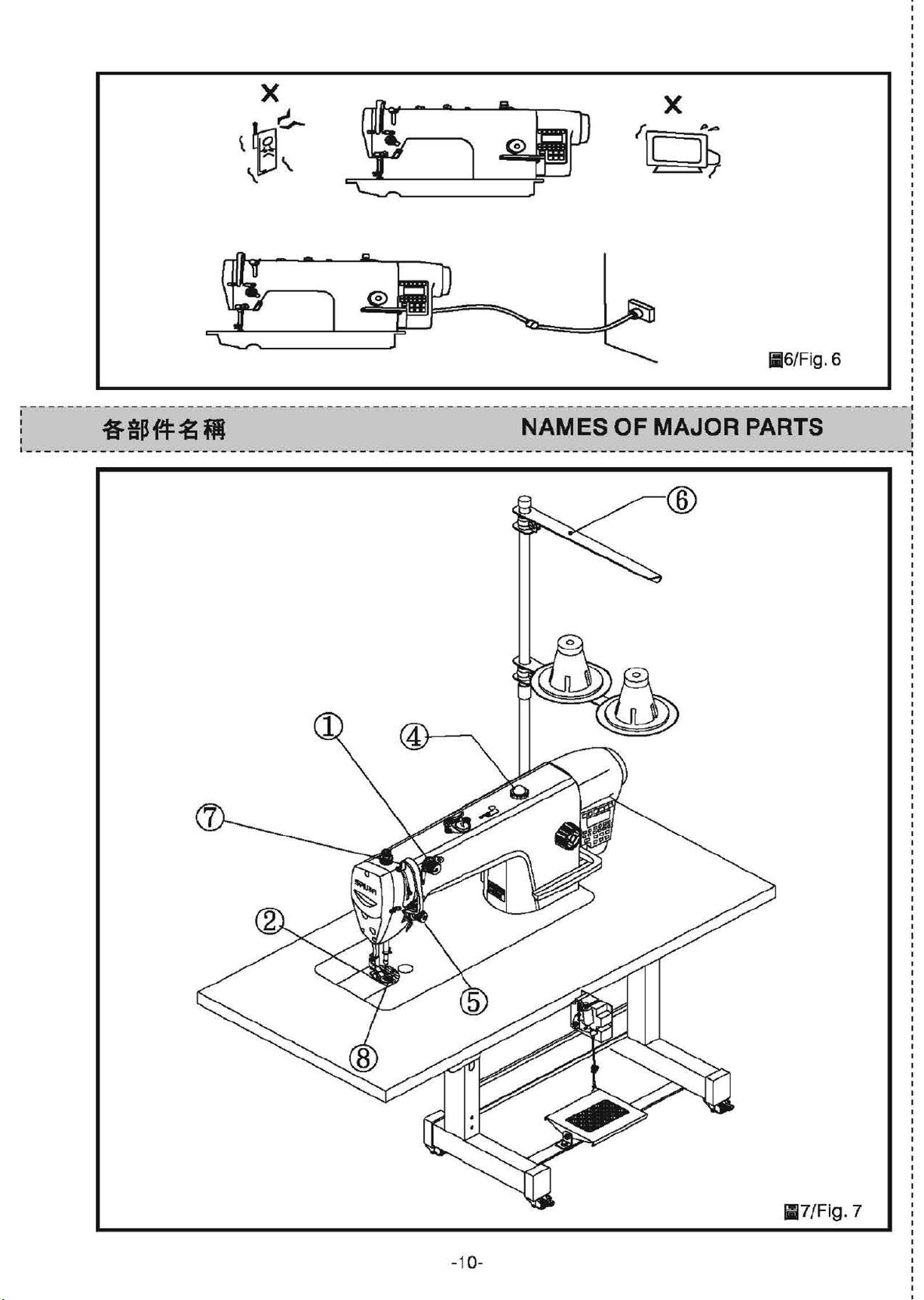

THE 1NsTALLAT10N Pos1T10N

1. Please

near

Radio,

equipments will experience electronic

interferen

2. The wire should insert

socket

this

-9-

do

not install the sewing machine

the equipments, such as Television,

or

Wireless Telephone. Or these

ce

. (Fig. 6}

directly.

might

cause malfunction.

115/Fig.

to

the

If using the extension wire,

5

AC

power

oF

I

Page 14

X

l::J~

116/Fig. 6

I

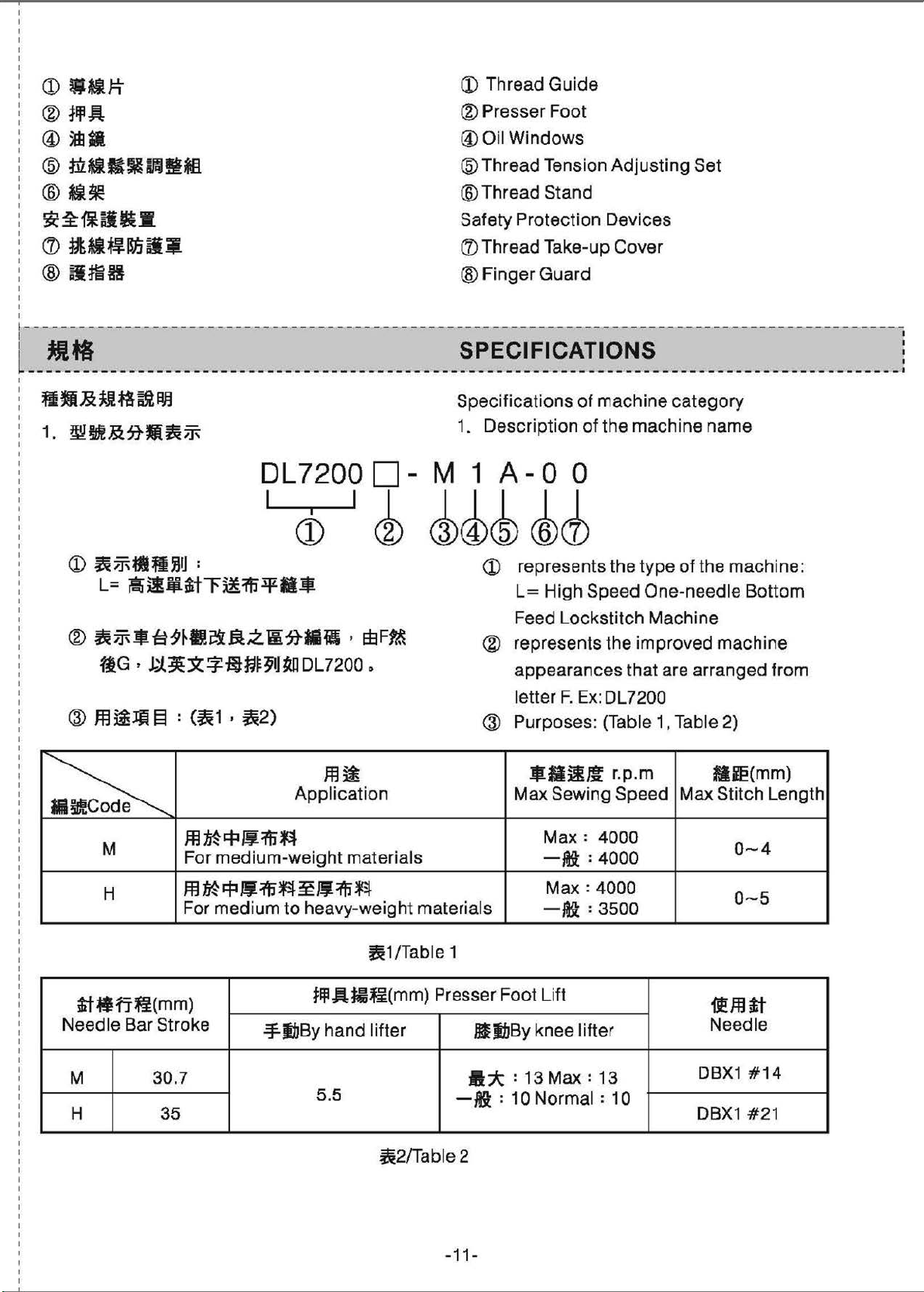

: 4fl~f-l:~ M NAMES

I I

------------------------------------------------------------------------------

OF

MAJOR PARTS :

•-----------------------------------------------------------------------------------------------,

@

1

I

-10-

117/Fig.

7

Page 15

CD

®

@

W'1M-

llll:R

5dla

Q)

Thread

® Presser

@Oil

Windows

Guide

Foot

@

tll•

M

@ll~

:ti:

:i: 1i ~

(7)

ll!i~IJ1.iil•

@ ~ffiH

••

~

1M

!!f

~

Threa

@

® Thread St

Safety

(J)

Thread Take-up

®

Finger

d Tension

and

Protection

Guard

Adjusting

Devices

Cover

Set

----------------------------------------------------------------------------------------------- ,

M.M

SPECIFICATIONS :

l-----------------------------------------------------------------------------------------------·

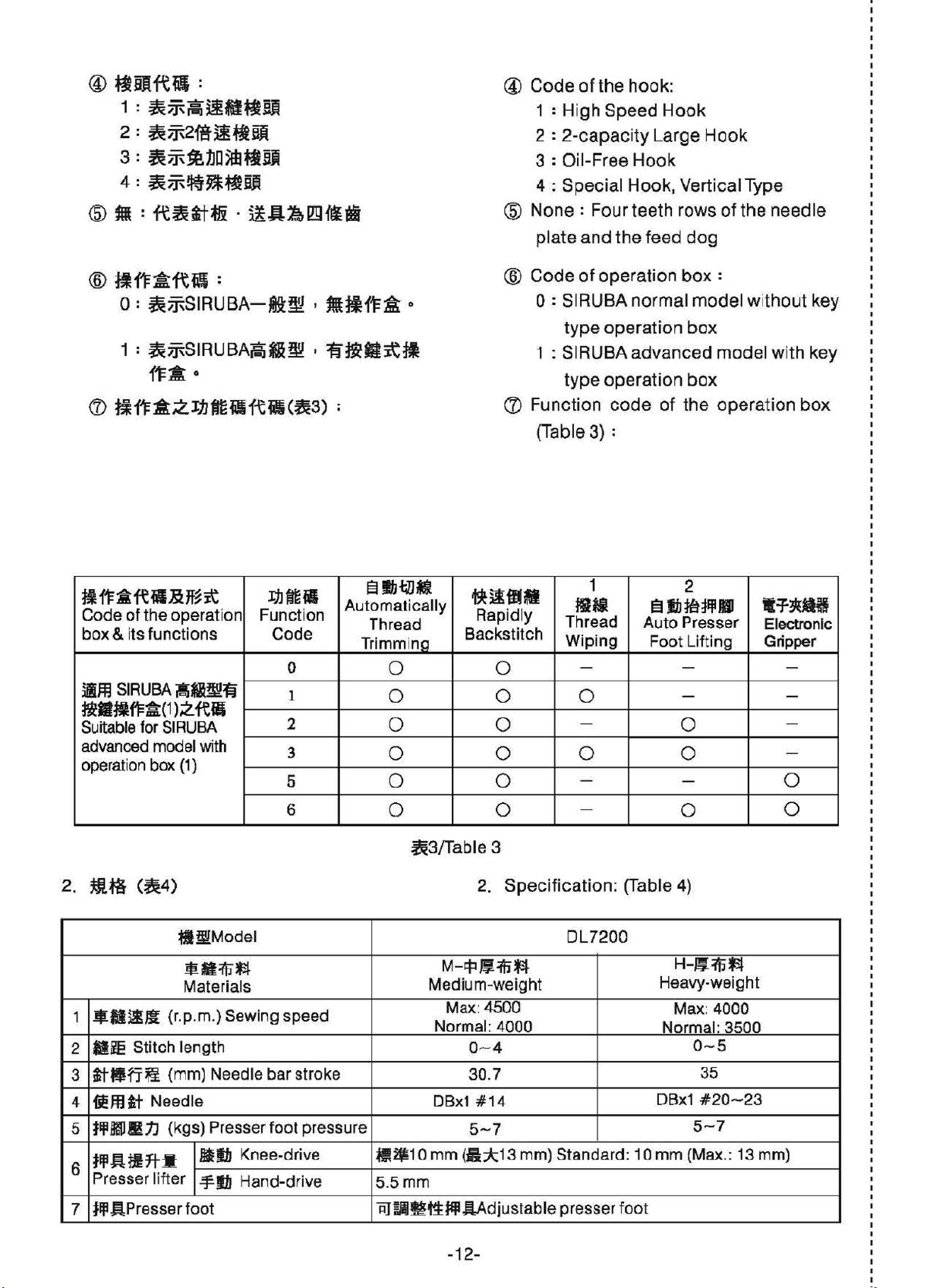

'-i B &

1.

:tJU!

~

aJJ

~~&~Mfi,j\

DL7200

1

1

CD

Specifications

1.

□

-M 1

~

~4ck

Description

A-

0 0

4~

<D

represents

L=

High

of

machine

of

the

the

Speed

mach

type

One

category

ine

name

of

the

mach

-needle

ine:

Bottom

CID

~~-~9~1leillZWdtliHI

flG •

J..j_~)t~-fin~91JR!l

~

M

H

ti~fi~(mm)

Needle

Bar Stroke

,

EBF~

DL7200 o

m~

Applica

m

~

qi

i,:

=Ai~

For

medium-weight

ffi'M~~ffi~~~1'i'~

For

medium

to

heavy-weight materials

.:¥,IIJBy

tion

materials

flJIAm~(mm) Presser Foot Lift

hand

~1

/Table 1

lifter

Feed

® represents

appearances

letter

@ Purposes: (Table 1, Table 2)

Max Sewing

Lockstitch

F.

$Sil~

Max:

-Ji: :

Max:

-~:

Machine

the

improved

that

Ex: DL72O0

r.

p.m

Speed

4000

4000

4000

3500

are

arranged

Mie(mm)

Max Stitch Length

ifffltt

DIIIJBy

knee

lifter

Needle

machine

from

0-4

0-5

M

H 35 DBX1

30.7

5.5

-~:

~2/Table2

-11-

A* :

10

13

Max

Norma

: 13

l : 10

DBX1

#14

#21

Page 16

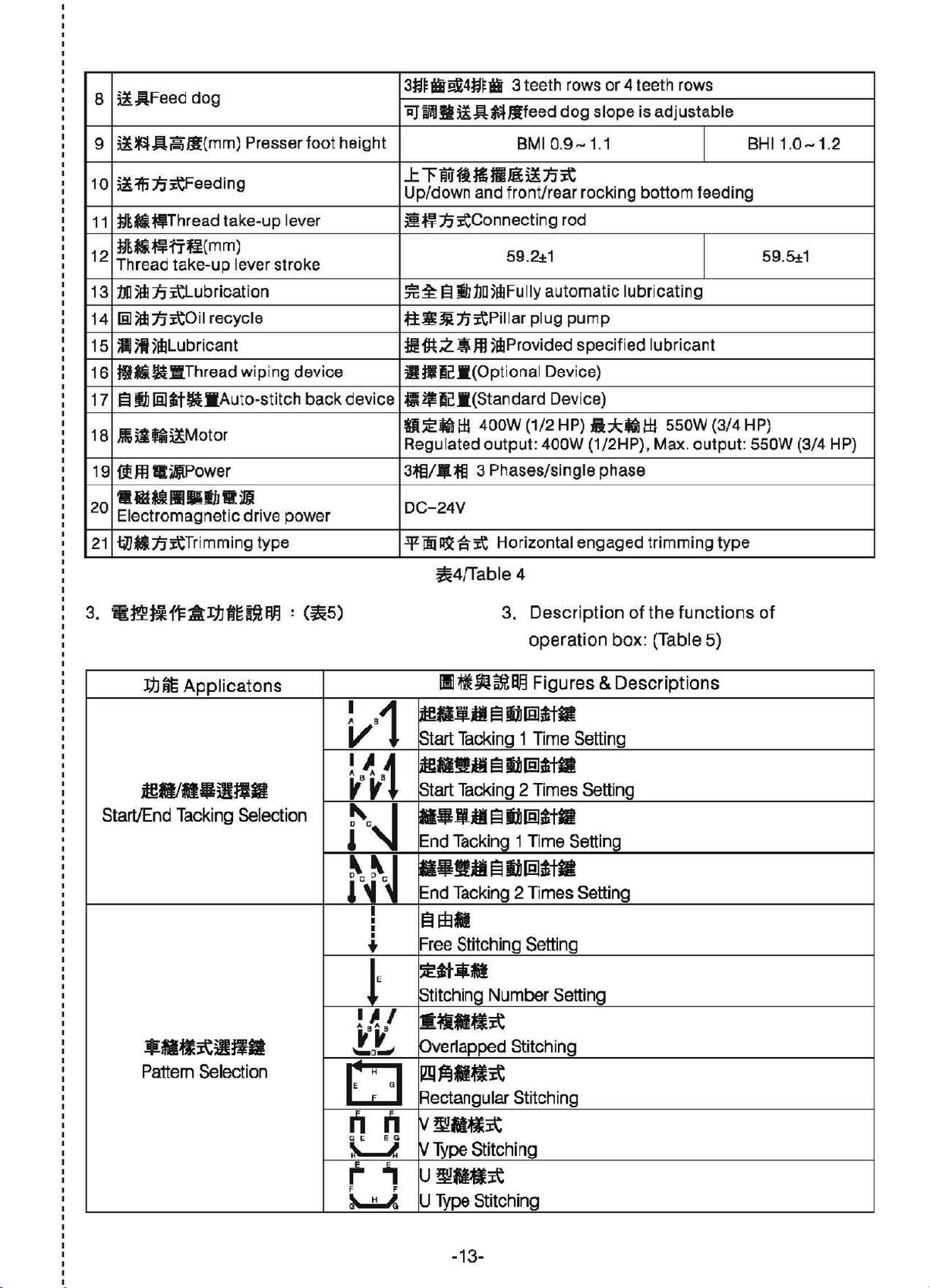

©

~Dfciil:

1 :

~;J\~~-f:t~

2 : ~;J\2,fA-iiftBli

3:

~;J\

4 :

<ID

M :

®

~fF~ftfl:

O:

1 :

~1.J□5fb

~;]\!jt~~~

fc~tt

~;J\SIRUBA-6:~

~;J\S

IRUBAF-iM~ ,

ttBJi

ffi · i!A~

{'¥* 0

(7)

fifF*~li1ftll{tii(~3)

lrn{ld

, ffltjl{

~:li-~r,I

:

'f

A

©

Code

@

None

@

Code

0

({) Function code of the operation

of t

he

hook:

1 : Hi

gh

Speed

2 :

2-capaci

3 : Oil-Free

4:

Special Hook, Ver

: Four

plate

and

of

0 : SIRUBA n

t

ype

1 : SIRUBA

t

ype

(Table 3) :

ty

Hook

teeth

the

ope

ration

operation box

advanced

operation

Hook

Large

feed dog

ormal model without key

Hook

tical Ty

rows

of

box

:

model with

box

the

pe

need

le

key

box

fl

fl::&-re

Code

box & i

•m

tR■ll

Suitable for SI

advanced model with

operation box

2.

ffl~

1 •ll~m {

lllie Stitch

2

3

it•n

4

I!

t

ljl

5

tlfl.atlft-I

6

Presse r lifter

ii

& Jf~it

of the operation Function

ts func

SIRUBA

f1=a

(1

(~4)

jljff

)Z

RUBA

(1)

WiW.Model

r.

lengt

~ (mm) Needle

.lfl

tt

Needle

Bl!IJl!t.l

(kgs) Presser foot pressure

11.J~-

tions

~

f\!

tl

•·*~

Materials

p.m.) Sewing speed

h 0~ 4

Code

0

1

2

3

5

6

bar

stroke

ellbtJlMl

Automatically

Thread

Tr

immina

0

0

0

0

0

0

~3/Table3

llilb Knee-drive l!UJ10 mm (

.:f

111

Hand-drive 5.

5mm

~ilfflM

Rapidly

Backstitch

0

0 0

0

0 0 0

0

0

2. Specification : (Table 4)

M-q:i~i1J'3J

Medium-weight

Max: 4500

Normal: 4000

30.7

0Bx1 #14

5~7

fi*1

3 mm) Standard: 10

1

ff

Hi

Thr

ea

d

Wiping

2

El

lb

1a ~Ill

1111

Auto Presser

Foot Lifting

- - -

- -

-

-

-

DL7200

0

- 0

0

H-~1\j"f:I

0~5

35

#20

5~7

ght

- 23

Heavy-wei

Max: 4000

Normal: 3500

DBx1

mm

(Max.: 13 mm)

t=f~

Electronic

G

ri

pper

-

-

0

tlflAPressar

7

foot

AJ~~tt

~

AA

djustable presser fo

-12-

ot

Page 17

~AFeed

8

dog

3i~ii~4~~ii 3

'iij~gi!A~Jlfeed

teeth

rows or 4

dog

slope

teet

h rows

is

adjustable

~~AjijJ'B(

9

10

~1'11.fitFeeding

11

~-

•Thread

~-~fi~{

12

Thread

1Jl

5111

13

14

15

16

17

18

19

20

21

jj

IBl

,din

•

;I

5dlLubri

ffltlllilll.Thread wiping

~

jJJ

la)

ffiitffi~Motor

{flfl

.i,!{Power

•&Uilll■lb•~

El

ectromagnetic

t}Jflnit

m

m) Presser

take-up

m

m)

take-up lever

~Lubrication

itO

il recycle

cant

atl!t•Auto-stitch

Tri

mming

foot height

lever

stroke

device

back

drive power

type

device

BMI

0.9~ 1.1

..I:

"""F

mi

ff

i&

tl'Ul

~

:rr

it

Up/down and

jffi~:fj~Connect

~~

~

lb1JD511lFully

tt.lUitnitPillar

~#tZW..lfl 5dlProvided

111112I(Optional Device)

11~12I(S

o~•uu

Regulated

3ffl/•ffi

DC-24V

!flffii~~rC

~4/Table4

fro

nt/rear rocking

ing

rod

59.2±1 59.5±1

automatic

plug

pump

specified

tandard Device)

400W (1/2 HP)

outpu

t: 400W (1/2HP),

3 Phases/single

Hor

izont

•*•lli

al

engaged

bott

lubricating

phase

om

feeding

lubricant

550W (3/4 HP)

Max. output:

trimming

type

BHI

1.0~1.2

550W (3/4 HP)

~~

~M/8.iljtll

St

art/End

•••

Pattern

Applicatons

Tacking Selection

;:tjl~-

Selection

lll~W~Bi.l

iffllU1UI 811!1Eiltttl

1,,,

91

Start

Tackin

ifflMWtl

~B

,~91

Start Tacking 2

~•¥a

tc~

~~

1 Ci C'

I

•

•

•

♦

E

!

~

ta

t'

'-o-...,,

□

Ii

Ii

E G

GE

~

.,

f

F F

~ H ~

nd

Tacking

···-~l:IJ

E

nd

Tacking 2 Times Setting

EI

EEM

Fr

ee

Stitching

~ti

-•

Stitching

/

••••

Over1apped St itching

~

~--it

Rectangu

V ffl!M•it

V T

ype

U~Hit

U T

ype

3. Descripti

operation box: (Table 5)

Figures & Descriptions

g 1

Time

El

11J

lel

tt11

Times Setting

El

i1Jlelttil

1 T

ime

(g]

ffll

Sett

ing

Number Setting

it

lar Stitching

Sti

tching

Sti

tching

on

Setting

Setti

ng

of the functions

of

-13-

Page 18

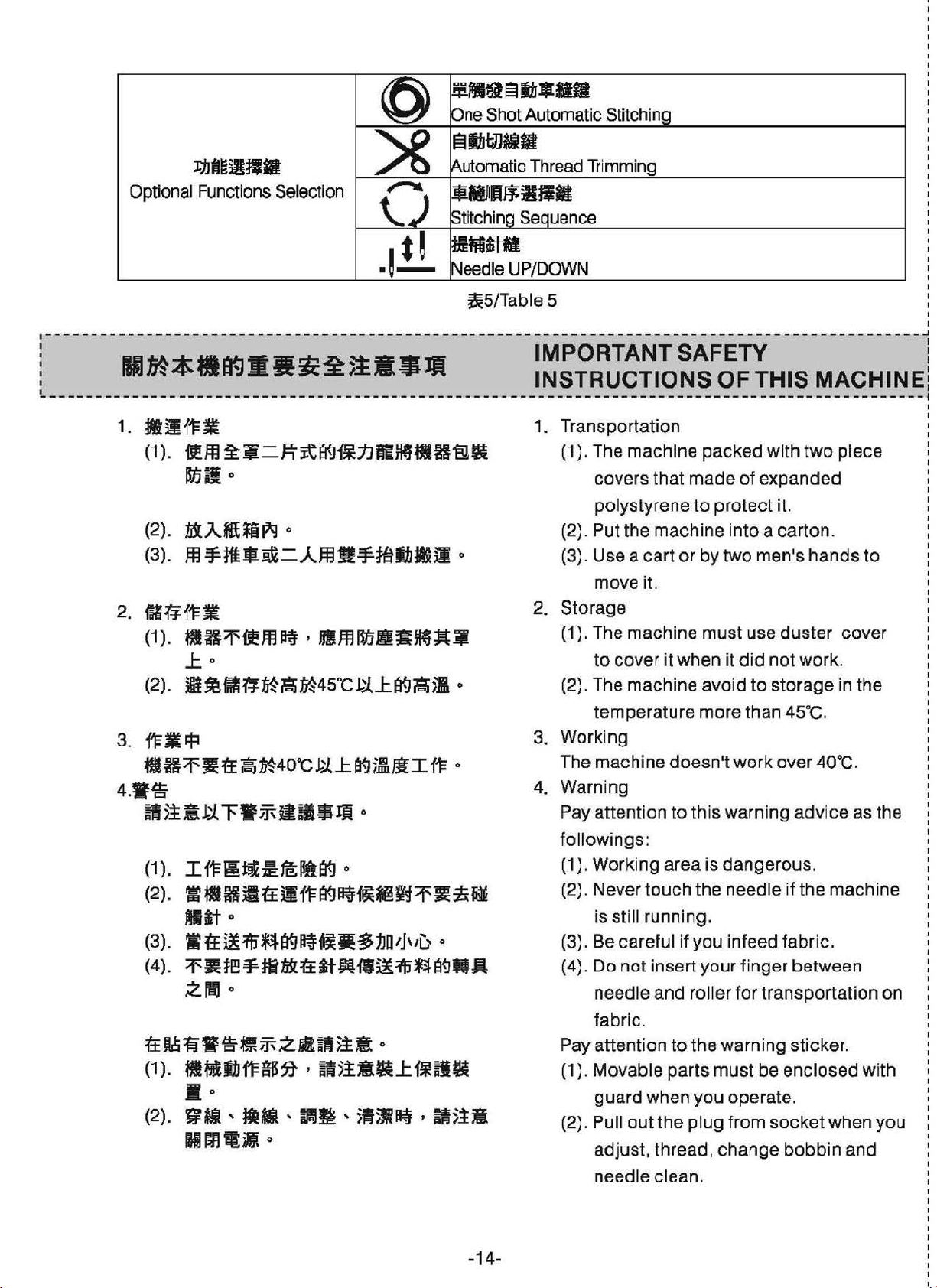

ne

Shot Automatic Stitchin

ljJlf~m~•

Optional Functions Selection

utomat

Needle UP/DOWN

~5/Table

ic Thread Trim

5

ming

,-----------------------------------------------------------------------------------------------~

: IMPORTANT SAFETY !

,

I -----------------------------------------

llll~*

1.

lli111=¥

( 1 ) .

(2). iii.A~~

(3). ffl

2.

ffilff{1=~

(1). MH1'iffflfey, Rlffll31ill~~Jt!J

(2).

■

B9•1!~:i:5±aSJ1t

if

ffl ~:a=~

~ii

0

"'1

it

ir-.J

ii

J'J

Ii

ll@II $ ffl R

0

~tt•~=.A.ffl!f~ffiltJIUI

..I:

0

IUt!iftffM~M45°C.l-~.t.l:.a(J~j&

INSTRUCTIONS

--

----------------------------------------------------1

1.

T

ranspo

(1). The

(2).

0

0

(3).

2.

Storage

(1

}. The machine must use duster cove r

(2). The

rtation

machine

covers

polystyrene

Put

Use a cart

move

to

that

the

machine

it.

cover

machine

it when

packed

made

to

or

by

avo

OF

THIS

with two

of

expanded

protect

into a carton.

two

it

did

id

it.

men's

not

to

storage

MACHINE!

piece

hands

work

.

in

to

the

3.

fl:.~

SH1'~~~~40°C.l-~L.l:.ir-.JjAJiI

4

.•

~

:a

$i

~

J.1

"f •

;J\

m :1 s

( 1 ) . I

~-

(3). Wt±~1'lr~99~ji-~1Jo,J,,D-

{1=

11

~

:m:

ffl;

!It!

=•nffl~~~~~~~~~~~~

■

ti

D

l1i

ir-.J

0

o

~-~-~¥ffi.QtiW~~-•~MA

;ZIIJ

0

r±

ffi!i

li

( 1 ) .

W 'a-tt

fl

fJi1

lb~

~

z

tf6

'3-

14

,

!ft

~

$1

$1

it

ii

.0

~-

V~·••·=~-~~~.a~•

Iii

m • jJi

0

0

R

{1=

..l:.1i

0

0

at~

temperature

3.

Working

The

machine

4.

Warni

Pay

followings:

(1

(2).

(3}. Be careful

(4).

Pay

(1

(2). Pull

ng

attention

).

Wor

Never

is still

Do

needle

fabric.

attention

).

Movable

guard

adjust, thread,

king

touch

running

not

when

out

more

doesn't

to this warning

area

if

insert

and

to

parts

the plug

work over

is

dangerous

the

needle

.

you

infeed

your

finger

roller for

the

warning

must

you

operate

from

change

than

45

°C.

40°C.

advice

.

if

the

machine

fabric.

between

transportation

sticker.

be

enclosed wit

.

socket

when

bobbin

as

and

the

on

h

you

needle

-14-

clean.

Page 19

INSTALLATION

r------------------------------------------------------------------------------------------ ---

--l

~-~~-~~~ffiAfl•~~-~-

Machine installation

~~~Sflfi~-~-~A~~fi•~~M

Contact

done.

M

i1J

M

The sewing machine weighs 36kg . The installati

mo

•

A Use both

~

re

ttic~~~iliI

Do

not

if

the

Mi1J■~ffl~Hffl~.amw~~ff~~

!i~-fl

original

heavy

your

dealer

•3

621

fi

people

connect the

treadle

to hold,

0

hands

pos

.

is

ition. If

should only

or a qualified

,

~

il

I

ft&-~

,

~~iU!fiCj]j,

power

depressed

to hold

only

and

may caus

cord

by

the

machine head when tilting

using

0

be

carried

electrician f

Eb

~ A

J.;1

J:.

tal:~~flt~Jblffl

until installation

mistake,

one hand,

e human

which

the

phy

out

by a

qua

lified

technic

0

or

any

3R

electrical

0

:it;

Pl

on

should be carried

work

Ill, M~fflllbfl=•W~~il

is

comple

could

0

-~~~~~-~-~ffi•K-~~~

weight

sical injuries.

res

of

te. The machine

ult

in injury.

it

back

or

the

machine

ian.

that

may

out

returning

head

by

two

may

it

to

may

need

0

operate

its

be

or

too

to

be

1.

~~ffllBM~-~ffiR

~~~~.~~~K~--~•M•o

)it:

(1)

ilffl

lfillH , AM-MF.I a<JilQ~Ji

■

&~~ffi~~M

~~~~-~8<]00%,ff~-~-~

.

~ii~-R'1"

(2)

:!lfi~m~40

0

(~~6)

mm

fi:

m~R~•~~•m~~~~~-•~~

~fffiliJYf~Ji O

1. Please ref

parts lists

a

nd

the thread stand.

ATTENTION:

(1)

(2)

Note:

The bel t size is different

choosing

er

to

table

to install the

The operati

the

max

. speed

d

uring

the

max. speeds

li

sted

The

about40

the first month. Ple

correc

standa

t size

on Table 6.

mm.

motor and

cut-out

anti-shock

ng

speed

and

rd thickness

is

for

a newly machine

of

the

motor

the

belt sizes

based

the

brand.

drawing

base

about

of

80

ase choose

belt. The

are

the

table

on

the

and

%

of

is

-15-

Page 20

------------------------------------------------------------------------------------------------,

I I

: 5mllii:C

I I

OIL

PAN INSTALLATION :

•-----------------------------------------------------------------------------------------------,

I

I

CD

1. The corners

placed

groove

on

of

the

the

of

the oil reservo ir has

four

corners

machine

at

table. (Fig. 9)

CD

to

the

cut

out

1119/Fig.

be

9

2.

ffl~■M~Z~T®•~~-•mm©~

'.AEM

A

~(~-f1=fl1.iltiJ)

~--~~M~~~@~~MB~~~

8~1ili:iJ), ~ffl.iliHf~M@'1tJ:.

, Mfff

lttllli~DI

0

(lil10)

2. Use nails ®

seats

Use

rubber

cushion seats ® on

B).

Place oil

seats. (Fig. 1

4

Q)

as

on

side

based

reservoir@

O)

19.5

mm

illustrated

A(the

operator

adhesive

the

hinge

to

fix

two

rubber

's side).

to

fix

two

side (side

on the fixed

-------

---

A

-16-

s-----11~

■

10/Fig.

10

Page 21

3.

~~-~-~~MA~-~~@~M•~

~~-©~~-~~ffi~~R~•~KW

~-~-Mffiffi~---g~®~=MH

□

i:f=1

°

(11111

' 1

2)

3. Place the

holes before

onto

Then, install the machine head

the

hinge

four

<D

into

placing

cushions

the

(ID

the

two

machine

of

the desk.

fixi

ng

head

onto

the

machine

rubber

cush

bed

ion®

that

has

two

openings

of

each. (Fig. 11, 12)

11111/Fig.

with

11

lil12/Fig.

·------------------------------------------------------------------------------------------------.

I I

:

I 1

1------------------------------------------------------------------------------------------------

tf-Qgic&

~~-~$~ffifl~ffi~ft~M~~

~iiJJt,

~WJRQ~Rtt

O

{11113)

0

~R

INSTALLING THE NEEDLE :

Choose a right

type

of

used. Turn

needle. (Fig. 13)

-17-

the

needle size

thread and

the

powe

r off

according

the

type

befo

of

the material

re

placing

to

12

the

the

Page 22

~~-fflffi~~~Mffl~-~~~ti

~-~

, 1ilffl~~-ti

O

(1113)

0

~g

Choose a

type

of

the

right

needle si

thread

and

ze

the

type

according

of

the

to

the

materia

l

used. Turn the

needle. {Fig. 13)

1.

Turn

1.

-~~-~tt•~~fl~--~o

2.

~--~®~~~ti©•OOXtim~~~

2. Loosen

ffiA~~OO~~nB0~~~tiZ~~C

il'Jriili:iJli:

D

0

the

bar

to

with

its

right in

long

groove c

exactly

power

hand

its

highest

screw®, and

indented

direction

to

the left in

off

wheel

position.

side A facing

B,

of

the needle

before

to

hold

and

direction

placing

raise the needle

the

needl

exactly

make

sure

is

facing

D.

the

e(!)

to

that

-· - o

:t

I

I

--A

B

11113/Fig

. 13

-18-

Page 23

I

I

I

I

L-----------------------------------------------------------------------------------------------1

I I

:

"l~Zii:li

SETTING

THE

BOBBIN :

1----------------------------------------------------------------------------------------------- I

1.

~~~r~~-~•~M•n~~M~~

0

1.i

[ci]

(Ii

14)

2.

~ti·9~M~A••~~C1.i~~-•

~~•ti~~~~-~ffla©•tt~B~

tfi.1!

□

91±10

3.

~~c~•~•~r~-•~~~ffi1.i~

MiJJ

0

/J

1. Set the

way that

clockw

2. Pass the thread

pull the thread in direction

will

and

3. Be sure the

as

toward c.

bobbin

the thread

ise. (Fig. 14}

be

pulled

will be pulled

the arrow shows when thread is pulled

in the

through

under

out

bobbin

bobb

in case in the

wound direction is

thread slit

C.

the

tension spring Q)

from

notch

rotates in the direction

A,

and

The thread

B.

C

1114/Fig.

14

-19-

Page 24

.---

- - -

-------------------------------------------------------------------------

-

---------------~

I

:

--~-

THREAD STAND ASSEMBLY I

'------ ---------------------- ---------- -------------------------------------------

1.

Assemble the thread stand

inst..a.U.ing

the

hole on

. Place the thread stand set onto

the

tab

le

top

2. Fix the thread stand with a nut

top

under the table

.

set

. (Fig. 16)

CD

---~

before

loc

--------

ked

-;

-2

0-

11

16/Fig. 16

Page 25

I

I

I

I

I

,-------------------------------------------------------- -

1 I

l

11&9111

\ I

r

------------------------

~

---~-------------

THREADING THE MACHINE :

-

------------------

---

-----------------------------

-

---------------------------------

----

---

•

li

18/Fig.

l ttffilll.ll! STITCH LENGTH ADJUSTMENT

I

~---

--------------------------------------------------------------------------------------------·

1.

~~~~~~~-~-~~~B

W

•tt~

m~•*w~•~ A O c1119)

2. JHl&H..clUII¥iiZ:!:iHI

3.

~~~~-~~·-~-~~~&©·~

Pl}ffj&ff

®tt"""F

■

0

~

1. Turn stitch length

indicates

align with mark A on the machine.

(Fi

g.19)

2.

The calibration on the

3. Press the feed lever ®

stitch length a

stitch length.

to

dia

l ill as the arrow

have the desired

dial

is millimeters.

down

dj

ustment dial

number

and turn the

(D

to

change

18

-21-

Page 26

1119/Fig

. 19

,-----------------------------------------------------------------------------------------------1

:

: z · PRESSER

IJl~~AaftllZD.UI

ADJUSTMENT

FOOT

OF

KNEE-CONTROL

LIFTER

I-----------------------------------------------------------------------------------------------

1.

~m•~~am*H•~~~~Amff~

)Jr~10mm

2.

~~~m•a~~~*•~~•~ID•M

~JU.1~~13mm

3.

i?~A&IJ~•llffl~10mm~

O

(1120, 1121)

0

• iifil~tf-

•u:~aB®~altfll!H,A@J:.$

The standard lifting height is

1.

using knee-control presser foot lifter.

(Fig.20, Fig. 21)

By

2.

3.

0

adjusting the screw

control ler, the presser foot can be lifted

to 13mm.

When the presser foot is adjusted to

lifted over 10mm, assure the

of the needle bar

does not hit the presser foot.

<ID

<D

in

its

lower position@

1 0 mm by

at the knee

bot

tom end

up

be

-22-

lii20

/Fig. 20

Page 27

11121/Fig.

21

----------------------------------------------------------------------------------------------·

NEEDLE THREAD/BOBBIN THREAD

TENSION ADJUSTMENT

--------------------------------------------------------------------------~--------------------l

1.

ttallli.ll!'il!a(lii22)

(1) ~J~~at151Rl(A 1.ifFil)tilhtiliBII

~~&Q.),~M~SUti~~---

~o

~;m!tiil151RJ(B

(2)

~tUl!Q.),

(3) ~1~~&15ra:J(C

~:t;HH®, &tMB!RJlW!R

(

4)

~~~&11.i!Rl(D

~$UM®

2.

~M<~•)R!Rll~~

( 1 )

it<

Iii

Iii

ii

15

(2)

-~@

~i!lffil

■

M@

,

~lllBIUll!M

1.ilRJ( F 1.iraJ)QlbllR~:tU

, Jlllll111Jll!U

,

15raJ)ttlbtifiUM

1t•W:Ei

0

nfi:iJ)fflbit-MllM

15

fRJ)fflhti~IIM

ttlili!lllWft

ftiJ

( E 1i

faJ)

ff

ltJ

0

0

0

0

8

IU!

ffiU

1. Needle thread tension adjustment (Fig.

22)

(1) The

(2) The left thread tail will be longer, as

(3) Increase the tension on needle thread

(4) Reduce the tension on needle thread

Bobbin thread tension adjustment

2.

(1) The

(2) The

lef

t thread tail on the needle will

be

sho

rter after thread trimmed as you

turn thread tension nut Q)clockwise.

(in A

thread tension nut

clockwise (in B direction).

by

clockwise (in C direction).

by

counter clockwise (in D direction).

increased as tension

is turned clockwise (in E direction).

reduced as screw

direct

turning thread tension

turning thread tension

bobbin

bobbin

ion)

Q)

is turned counter

thread tension will be

adjust

th read tension will be

Q)

is turn

nut®

nut®

screw@

ed

counter-

1

I

I

I

clockwise (in F direction).

-23-

Page 28

11122/Fig.

22

I---------------------------------------------------------------------------------------------

:

: ADJUSTMENT

ifti-tn

■

illJf!

NEEDLE STOP POSITION

•-----------------------------------------------------------------------------------------------

(1)

~~jEMfllll:

-~~~~~A~~-~~M~B~

Jf

(2)

i.Jtt~r~~~ = fffJltiff;{±:uili~

0

HPi:iJ

MrJ!M~CD

·

Hfll~tt

tiffl2'~11:mll.,

, tE«mllL~ ~~-iY

C

:nftil•!JJJ

,

•tf-~1.1:~

lffl~iw O

•

~•~tto:nJtiJtiiti,

•atw1.1:iey

IHI~~ 0

~

,

0

1. Needle "UPPER"

trimming. (Fig. 23)

(1) Standard

needle

mark A on

mark B on

(2) Timing

Stop

point,

and

hole.

· Move

·

stop

Adjustment

the

and

adjust

the

advance

Move

delay

the

the

stop

position

Stop

Position : the

point

is

simply

the

machine

the

hand

wheel.

of

Needle Stop :

needle

then loosen the screw

at

the

screw

screw

the

needle

screw

needle

its

upper

in

in

direction C

in

direc

stop timing.

head

the

stop

tion D

after

standard

to

dead

elliptic

timing.

align

with

the

the

CD)

to

to

j

-24-

Page 29

□□□□□□

I I

□□□□□□

□□□□□□

□□□□

□□□

2.

•atT~1'u(ll24)

WBffi~~R~•~@~~~•·•~~

T~~~•~•ti®~~-~~•~B8

M®t±fflil:JL~lt'IIUIM

(1)

HfilMtt A nraJfflb

tl1iiJ

0

(2) Hf!llfftt B

}jE~o

nraJtilJJ , •tt-~.1.1:ltilll

0

,

•tt~ll:lllfffl

2. Needle "DOWN"

When treading the pedal forward

returned

needle DOWN

adjusted as

needle

loosen the

in the elliptic hole.

(1) Move the screw in direction A

(2)

to

CD

at its

screw®

advance the needle stop timing .

Move

the needle

the

stop

position (Fig. 24)

the neutral position,

stop

position

the

followings. Stop

lower

screw

stop

dead

and adjust the screw

in

direction B to

timing.

1123/Fig.

the

can

point, and then

23

and

be

the

to

delay

-25-

1124/Fig.

24

Page 30

5ili

! l-1.J:.~fi :

(1) 8~:t&llfl , ~~~11=8.lff

(2) RlliB!blM ,

ffl~~Jf"fdl

..

Attention !

0

0

{1) Do

(2) Do

About

not

operate

screws are

not

remove screw;

screw.

above

the

loose

adjustments:

machine

ned.

only

after

loosen

the

1-----------------------------------------------------------------------------------------------

THE

THREAD TAKE

UP

SPRING

ADJUSTMENT

I-----------------------------------------------------------------------------------------------

1.

Adjusting the stroke

of

thread take

up

(1)

Mrft!f!I

(2) 'ftilm~S1i

2@

(3)

~m~&anlaJ(B

ill® ,

(1) 1Jtflflltl\® ,

..

® D

[ciJ

(A

1i

[ciJ)

Qlbll!R~~

, ~Mffliillfi@tff111JD

nraJ)QlbRIH!Ui

l!~illlllfifffft~2'

lal~~~-~jikiJ.

0

0

'

(5)

m"fo

(2)

tt••~®

(3)

~m~itn

8 ® , j!iJMIUl~f.Hffif:t.m

(4) ~m~S1ifi:iJ(B 1ifi:iJ)QIJJ£.j!lll

2@

, ~IQM5'1f~1Jfff

D

IRJ

(A

JJ

[R])Qlbllli~-

)£1)

0

0

spring

(1) Loosen

(2) T

(3) The stroke will be

2. Adjusting the pressure

spring

(1) Loosen

{2) Loosen

(3) The pressure will

(4) The pressure will

Cl).

(Fig. 25)

screw®.

he

stroke

spring will

nob

k

direction}.

the

knob@is

clockwise

Q)

tension

tension

(in A direction).

tension

clockwise

of

the

be

inc

(ID

is turned

turned counter-

(in B direction).

.

screw

disks@.

screw@.

knob

knob@

(ID,

(ID

(in B direction).

thread take-up

reased

clockwise

decreased

and remove thread

be

is turned

be

is turned

as

the tension

of

thread

increased

clockwise

reduced

counter

(in A

as

the

take

as

as

up

-26-

11125/Fig.

25

Page 31

-----------------------------------------------------------------------------------------------1

¥fl

A~fl-~

r

------------------------------------------------------------------------------------------------

MANUAL PRESSER FOOT :

LIFTING LEVER :

1.

~-H~~•--A~~Qti~A-ffff

O

CD

(lil26)

2.

flllJ!!Uf

J:tlft-'9

5.5

mm,

MimllEZ

m~Bn~@~Mti~A~ftffOO~·~

a~•m1~1m1iL•

0

1. Stop

O

I:

2. The presser foot will

the

machine and turn

l

foot lifting

keep it up. (Fig. 26)

5. 5 mm and wil I remain

Turn hand lifter lever

direction)

original position.

ever(!)

to

release presser foot

up

(in A direction)

be

Q)

the

presser

lifted up

at

that

down (in B

to

position.

to

to

about

its

1126/Fig. 26

----------------------------------------------------------------------------------------------

MIA■t.Ja•

r

-----------------------------------------------------------------------------------------------'

1.

1n1:11•-al®.

flflAlt:t.J

2.

#i~aian

jH

(DJey

3.

~~~-•fflRam®

' 111.J)i~ 0

1.J=i!iall2UJM1!1Jl'.5

~iffil!filn~<An~>nJJJ

jdf&O(j)~

[i:i]

< s

15

,

fi:il)

■

1Jif1JD

ttlb~

0

-fi~~~--

kg,

O

a,51

tJ

S~fll\7

(lil27)

fill~

ADJUSTING PRESSER FOOT :

PRESSURE

Loosen nut

1.

regul

ator

increase the presser foot pressure. (Fig.

27)

Turn presser spring regulator (j) counter

2.

clockwise (in B direction) to reduce

presser

3. Lock

nut®

regular fabric, the normal pressure

presser foot should be set at 5kg,

®,

Turn

presser spring

CD

clockwise (in A direction) to

foot

pressure.

after adjustment

is

done

for

the

. For

of

the

I

:

~o~--z~•·••~-~-z•

1.J

, :;t

ft~

ffl

~1

&-fi ;Z • M

~

JD

heavy fabric is 7kg. (

sewing result, please adjust

To

have the best

the

proper

presser

material.)

-27-

foot

pressure according

to

the

Page 32

[127/Fig. 27

:-----------------------------------------------

i

tiNiaAlitw&I.I

■

ADJUST THE

TIMING

NEEDLE AND FEED DOG

I-----------------------------------------------------------------------------

1.

aa•68•CD~z®~®•~·~ffl•

fflD~~d&ffl~~~ffti-~8•CD•

iil~hi~fil:X~ , MffllUII~

a/b/c)

2.

-~-~-m~•=•tiR~MT~~ti

0

(1128-

fioo~,~~A-•L-~tizti~L-

~~W;t~J:-.SX-Ala

3.

•M~ff~m~m=~~~7~~~flC

M•Mfi~~•©•fi~~~ff~ftm,

J~i!AllifiZtl

iF.i

O

(1128-b)

O

(11128-a)

Loosen

1.

eccentric cam (D, move the feed

eccentric cam (D in the direction of th e

arrow

arrow, and lock the screws firmly. (Fig. 28-

a/b/c)

Standard timing adjustment: when the

2.

upper side

to the needle plate surface, adjust the

upper sides

needle hole

needle plate

Antedated timing adjustment:

3.

the

eccentric cam

screws®

or

the opposite direction

of

of

to

upper

fab

ric deflected from feeding, turn the

and ® on the feed

the

needle hole travels down

the feed

be

at the same level

surface. (Fig. 28-a}

CD

by

the arrow direction

BETWEEN 1

of

the

dog

teeth and the

of

the

to

prevent

to

antedate the feed timing. (Fig. 28-b)

4.

~~~-~~~~=~~~~•••m•

ffl~~6~-CD-&ffi~~~-~~~·

fE~A~urg•

$!It:

1"AJJfllfi,i:n~M(D~Jb~* ,

imlr&t

O

0

(11128-c)

11~

Alfffii31

-28-

Delayed timing adjustment:

4.

the stitch tension , extend the feed timing

by

turning the feed eccentric cam

opposite direction of the arro

Attention:

Please

cam Q)

do

too

to

increase

CD

in the

w. (Fig. 28-c)

not move the feed eccentric

far to avoid needle breakage.

Page 33

♦

1128/Fig.

28

-----------------------------------------------------------------------------------------------,

ADJUSTING

OF

THE

FEED

THE

DOG

ANGLE

OF

TILT

--------------------------~--------------------------------~--------------------------------~---

1.

•

1±

~

A

fi

IL}

lb®

J:.

a9

a:,~

Bil~ I i!flZ

29-a)

2.

~7•~~•~••m■Mfflr~••u

CD

,

Hf

iz. A 11

MMJiJjJJJc!J!Jtt!~

,u

fib®~

i6

S~aa9

9~,RJ~-~-~-•~MM~~

(1129-b)

3.

~7•~~~~~~~•m•ff&r~&

ilM<D

iliilb90Jll

~

, Jffi!Affii,ufel®#(~filib((.JJ'jjRJ

,

RJ

1!i!A

0

(S:~f:J~~at)

imiiffiiS , ~fl1'ftltt

(11129-c)

tlilBA!2

O (II

n

raJ

ti

-

lb

0

1 . When

shaft®

the

gradient becomes

a)

2.

To

prevent the fabric puckering, loosen

the

screw

feed

dog

the

arrow

gradient

til

ting-front

To

3.

prevent uneven fabric feeding, please

turn

the

degree

This

could

angle

mark A on

is

aligned

(D

by

a

eccentric

direction

of

the feed

status. (Fig.

feed d

opposite

of

the feed

og

decrease

the

feed

dog

with

the

horizontal. (Fig.

screw

shaft

to

reduce

dog

driver

® 90 · toward

and to

29-b)

eccentric

to

the arrow

the

backward

dog

and to

eccentric

crest line B,

and turn the

the

front

form

a

shaft®

direction

form a tilting

90

tilt

29-

.

-

I

I

I

I

back

status. {F

materials). (Fig. 29-c)

After adjusting

4.

~~1'ft~M~~~~.~~~m~•~

W•ffi~~A~~m~~~~A~~--

Jl

0

4.

dog, this

dog

. Therefore, please recheck

after adjusting

dog

.

-29-

wi

II

or

adjusting

the

change

the

tilt

tilt

angle

the

height

angle

the thick

of

the

feed

of

the

its

height

of

the

feed

feed

Page 34

fl~

Backside

https://manualmachine.com/

jlfl=_aM

Front side/

Operator

a

side

fV\lvvv,.A

►•

)

b

C

A

I I

I

I

ADJUSTING THE HEIGHT

FEED DOG

1129/Fig. 29

OF

THE

'------------------------------------------------------------------------------------------------

1 .

i!

A

?ai

Ji

(j!

A ffl lfi

tt

ffi

ii

lf.J

'Sj Ji) «

at~!i(1'ifl~31Wl~trrF = (11130-a/b/c)

~~~fl

}JJ

1fJ' ~ : 1.0 - 1.2

2.

~JH~A~~~lli

:

0.85-0.95

mm

((i30a)

mm

(11130

, !tU&Ul:,in~~~~iJI

~m•o

3.

~A~Jliltl

(1) ttflllllffiCDilM®

~)~~3ti~ffi

*1JDJ.:JJJUf

=

0

(D

~~-~ff~~~~

"

b}

ti:\

Jii

1 . The feed

dog

surface) is

the followings: (Fig. 30-a/b/c)

Normal

Heavy

2. If the feed

very easily

sewing thin fa

3.

To

adjust

(1) Loosen screw

(2) Move the crank

dog heig

emerged from the needle plate

set

fabric:

fabric : 1.0 - 1.2 mm (Fig. 30b)

dog

to

the feed

move the

ht

{the height the feed

by

the

fab

ric thickness

0.85~0

is emerged

form the puckers when

br

ics.

feed

.95 mm (Fig. 30a)

too

dog

height

(ID

on

(D

up

bracket

:

crank

and

down

up

and down to

much, it is

(i).

as

to

adjust.

(3)

Lock

adjustments.

4.

4.

~~@~~~---~~~OO•HBA•

~

·~

~llaffi

~

~~□~ffiff~~~

mo

-30-

There should

plain surface

(l). Also, avoid the situation

loosening happening. Otherwise, the

opening part

easily

the

screw® secure

be

no

space

of

the

roller®

of

the

crank

ly

after

between the

and the crank

of

parts

00

will

get

worn

the

Page 35

a

?ZZZJ~

0.85 ~ 0.95 mm

1

.0~1.2mm

I

:

~m~aa:tH:llm

:

ill

~9.ilRJl;J'llL

1m

CORRELATION

AND

HOOK

1130/Fi

BETWEEN

g.

30

NEEDLE

r-----------------------------------------------------------------------------------------------·

1.

The

1.

tiW~~~m~~Mr=•~~•~ti•

Pl~Ait~(r~~)

31)

(1)

muttt•

·

(DBti)Hfti.®J:;ZtUi

~

Ji

•r&•®ll~

, Mtt<!ll~d)

=

, ~tlffl!Rllil:€8

~Q)o

·

(DAitt)

~tt-®J:zfflti

•r1'1W@~BB , ~flffllillil:iffl

ffQ) 0

0

(Ill

A ~J!fti

C fij!ttf-

timing

and

hook

the

needle

point

. (Fig. 31)

(1)

Adjusting

· (DB

· (DA

adjustment

is:

turn

bar

down

of

its stroke, and

the

needle)

need

le

bar

of

needle

then

needle)

needle

of

needle

bar

tighten

bar®

bar

between

the

hand

wheel to

to

the

lower

loosen

height

Align

<ID

the

Align

of

needle

the

with

the

lower

with

lower bushing

bushing®,

setscrelN(D .

the

the

needle

lower

dead

the

screw

bar:

mark line A on

bottom

mark

line

bottom

edge

and

Con

edge

@,

Q)

and

:

:

then

tighten

(2)

(2)

~IUtBJtzw:x =

· (DBtt)tiiliUilllZ3ffl~~!llff , M

11.J

=¥

lfUft&tff®

•r&a@.li$

LZC

0

a B fO!f

tt

Adjusting

· (DB

setsc

hand

the

needle)

rews on the hook,

wheel

on ascending needle

bottom

bushing@.

edge

-31-

the

setscrew

position

Loosen

to align

of

need

of

the

the

the

bar®

le

(1).

hook

three

and

mark

bar

:

turn

the

line B

with the

lower

Page 36

·

(□Ati)1iillfftBftZ3ti~~!DIM

lb

.:J=

fa~

tHf

®

J:.

L ffl

Ii

D tO!t

, Q

tt

Mi"'Fll•®i&i3°

- When a

the

turn

DA

three setscrews

the

hand wheel, and

needle is

used loosen

on

the

hook

align

,

(3)

ffJ:.~•l!tpllfi

,

~~~~®"ti

~6@fift•H•ttN~9~z~~

&Ji