Page 1

BH780

1~FF.J

~

SJ3

-~~1~

(;)

INSTRUCTION AND PARTS LIST

[/411®

C€

~

~~JK119~Jl~f]a]

KAULIN

MFG.CO

.•

LTD.

Page 2

TO ENSURE SAFE USE

For the sewing machine, automatic machine and ancillary devices (hereinafter collective ly referred

"machine"), it is inevitable to conduct sewing work near moving parts of the machine. This means that there

of

is always a possibility

operate the machine and maintenance personn

machine are strongly recommended

before using/maintaining the machine. The content

contained in the specifications of your product.

sk

The ri

of

indications are classified into the following three different categori

the labels. Be sure to fully understand the following description and strictly observe the instructions.

unintentionally coming in contact with the moving parts. Operators who actually

to

carefully read

OF

YOUR SEWING MACHINE

el

who are involved in maintenance and re air of the

to full

y understand the following Sa

of

the I

Safet

y precaut

io

ns I includes items which are not

es

to help understand the meaning

fety prec

to

auti

as

ons

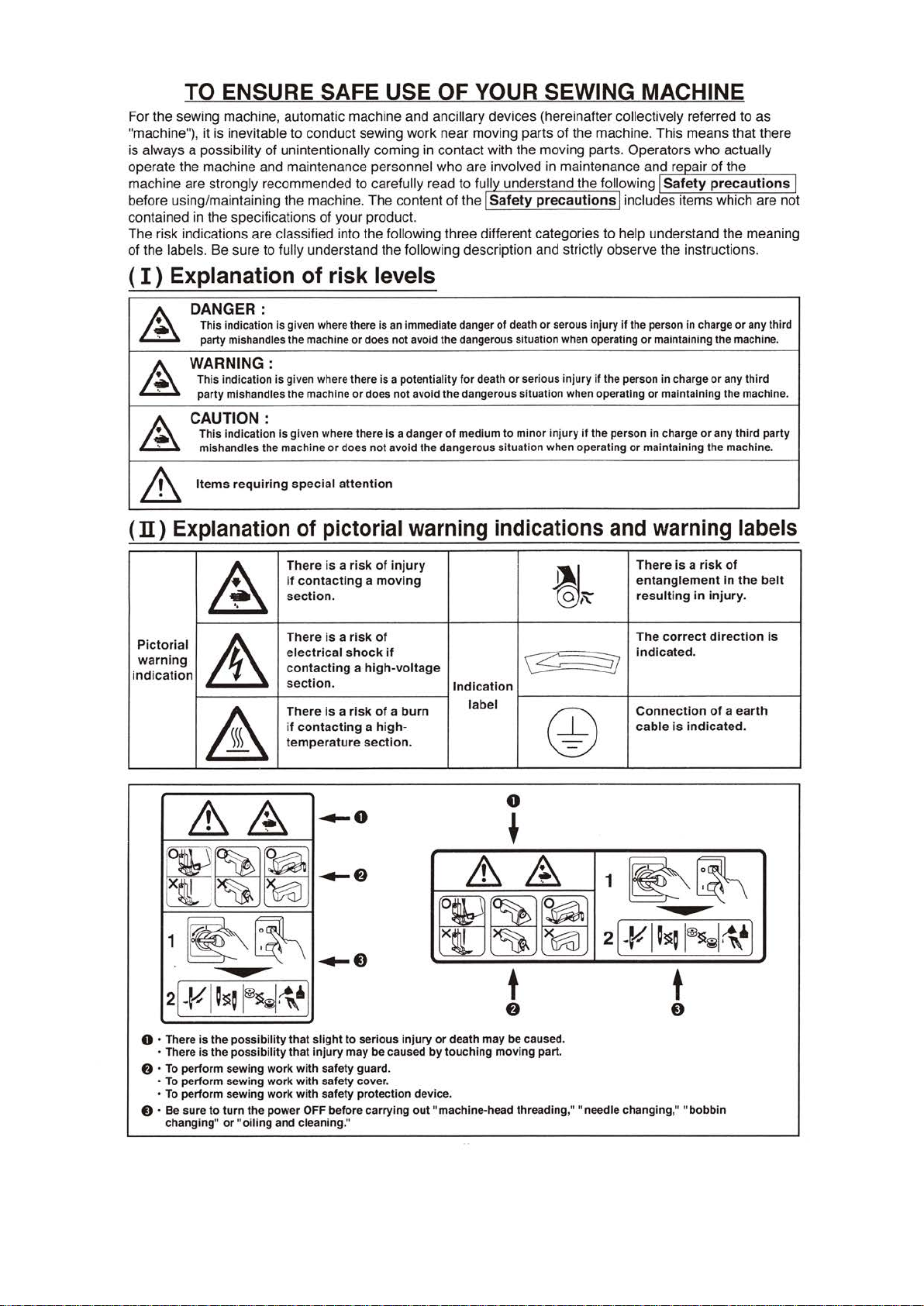

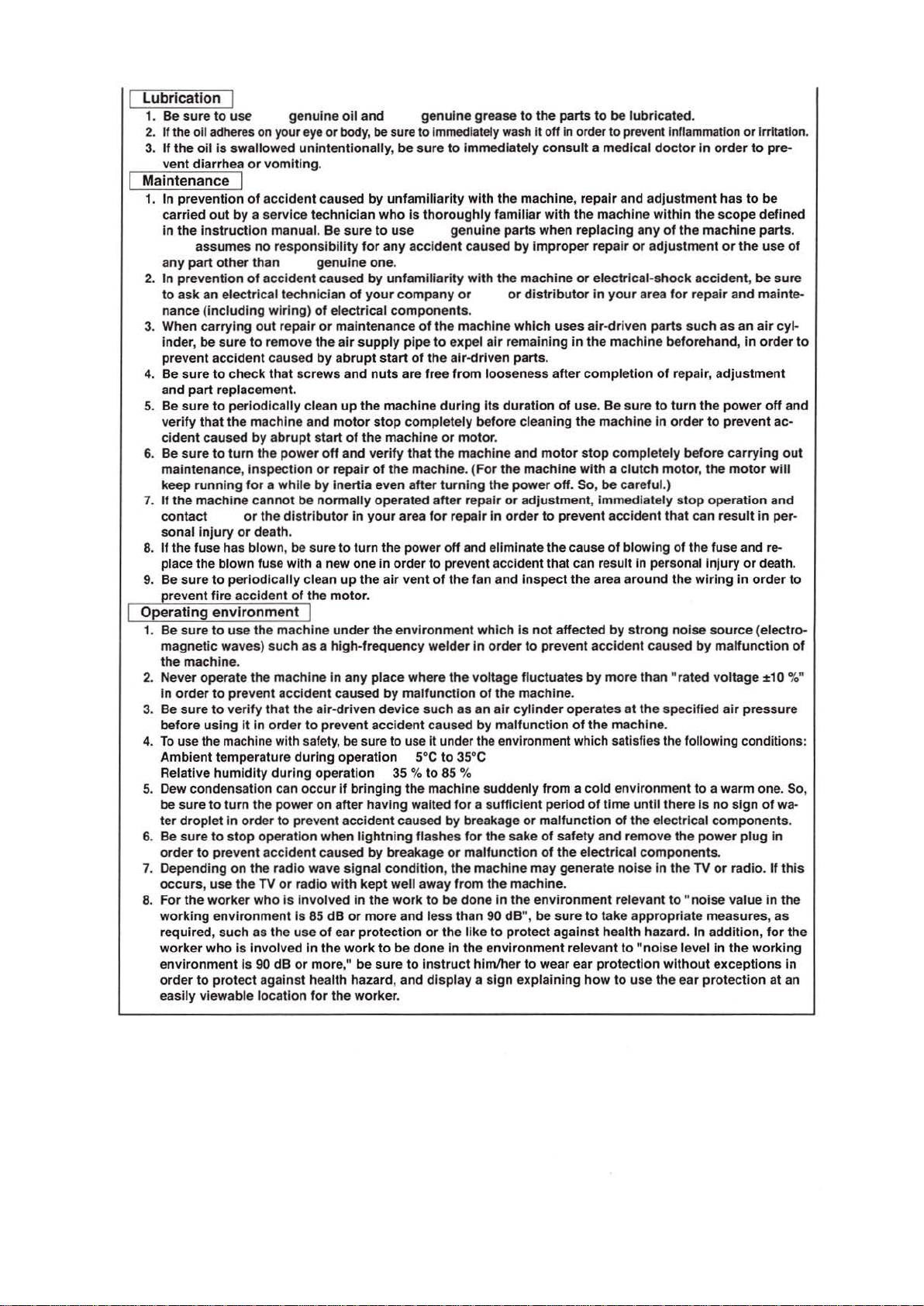

( I ) Explanati

DANGER:

~

~

~

This indication is given where there is

party mishandles the machi

WARNING:

Th

is indication is given where there is a potentiality for death

party mishandles the machine

CAUTION:

This indication Is given where there Is a danger

mishandles the machine

Items

requ

&

(II)

Expl

anation

~

Pictoria

indication

warni

l

ng

it

&

on

of risk levels

ne

or

does not avoid the dangerous situation when operating

iri

ng

speci

al

att

of pictorial

There is a

if

contacting a mov

section

.

There

is a risk

elect

rical shock

contacti

secti

There

if

tempera

ng a high-voltage

on.

is

a ri

contacting a high-

ture sectio

an

or

or

ention

immediate danger of death

does not avoid the dangerous situation when operating

does not avoid the dangerous situati

of

medium to minor injury

warning

risk

of

injury

ing

of

if

or

serous injury

or

serious injury

if

on

when operating

if

the person in charge

indications

~

~

~

In

di

cat

ion

sk

of a burn

n.

label

@

if

the person

the person in charge

or

and

T

e

r

The corr

ind

Connecti

cable

in

or

maintaining the machine.

or maintaining the machine.

maintaining the machine.

warning

here

is a r

ntanglement

esultin

g in

ect directi

icated.

on

is indica

charge

or

any third

or

any third

or

any third party

labels

isk

of

in

the

injur

y.

on

of a eart

ted.

belt

is

h

0

&

~

~·

*

~f)

~~~

LL~~

1

~~

....

2

[·¥1~~

0 · There is the

• There is

f)

·

To

perform sewing work with safety guard.

To

perform sewing work with safety cover.

•

• To perform sewing work with safety protection device.

0 · Be

sure

changing"

~N~~

possibility

the

possibility

to

turn

the

power OFF before carrying

or "oiling

~o

I

that

slight

that

injury

and cleaning."

to

serious

may be caused

injury

out

&

~

1

~~

2

[

·¥

~

~~

t

f)

or death may be caused.

by

touching

"machine-head threading," "needle changing," "

movi

ng part.

I~~

-

~

I@~~~~

t

0

bobbin

~

J

Page 3

SAFETY PRECAUTIONS

A DANGER

1. When

wait

for

shock.

it

is necessary

five minutes

to

open

the

or

more before opening

control box containing electrical parts, be sure

the

A

Basic

precaution

1. Be sure

the machine before using the machine. Carefully keep

ments at

2.

The content

3.

Be

4.

Those

Safety

1. Be sure

works

2.

If any

prevent accident

3. Be sure

that can result in personal injury

change

Application

1. Never use the machine for any application other than

prescribed in the instruction manual in order

machine

2.

Never modify and alter

which

Education

1. In

only

tion and

ensure

cate/train them beforehand.

Items

~

Turnin

L

----

1. Be

failure in

2.

To protect against

ing operations after

be

stops

3. Be sure

vent

4. Be sure

5.

Be sure

age

to

read the instruction manual and

hand

for

quick

of

this

sure

to

wear safety goggles

who

use a

devices

assumes

assumes

order

by

for

-

g

the

------

sure

sure

2-1. For example, threading

threaded,

2-2. For example, changing

2-3. For example, when inspecting, repairing

electrical-shock, earth-leakage

of

and

to

operate

normally in

of

the safety

to

keep the warning labels adhered on

it

with

a new one.

and

modification

no

for

any application other than the intended one.

has been modified

completely.

electrical components.

no

and

training

to

prevent accident resulting

the

operator who has been trained/educated

how

to

the

which

-po..;er off:

to

operate the machine with safety

above,

the

-------

to

immediately turn the power

order

to

carry

out

or

to

remove

to

turn

the

to

turn

the

reference.

section

heart

warning

the

order

devices

that

includes items

pacer have

machine after verifying

can result in personal

to

labels

to

prevent accident caused

is removed, be

or

I

responsibility

the

responsibility

for

machine in order

for

or

altered.

I

the

employer has

power

to

the

machine

-

T~rning

applies

protect

accident

clhanging the

the

power

power

the

po~er-sw~c

to

the

------------

against accident that can result In personal

resulting

turning

the

the

power plug

power off. For

following

the

bobbin

or

adjusting

off

whenever the machine is left unattended between works.

off

in

the

protect against accident caused

to

following.

operations after

parts

by

case

other

which

use

the

I

sure

injury

death.

If

any

damages

damages

to

or

to

to

from

unfamiliarity with

establish an education/training plan

has

-h

-

off

if

any abnormality

from

abrupt

such as the needle,

.

all

holding

fire accident.

of

power failure

machine after consultation with a medical specialist.

or

or

off,then

component

the

~

cover

in order

Accident

1 personal

1 damage

~--------

to

prevent accident leading to electrical

to

means

to

turn

injury

or

property."

------

the

power

;to

CAUTION-------------,

explanatory documents supplied with accessories

the

instruction

are

not

contained in

that

safety device(s)

by

lack

to

replace

or

the

machine clearly

of

the labels

prevent accident that can result in personal injury

personal

prevent accident that can result in personal injury

personal

to

acquire adequate knowledge and operation skill.

to

be

-----

start

the

machine incorporating a

turning

or

cleaning

plug section instead

of

it

and verify that

death.

has

its

intended one and in any manner other than that

injury

injury

by

the

the

employer with respect

turned

~emo,;in

------------------------~

or

of

the machine,

the

power

looper

parts

the

in

order

manual and the explanatory

the

specifications

by

needle breakage.

is

correctly installed

the

device(s).

vis

stained

or

death resulting

or

death resulting

machine,

off

I

g

-the-po~er

failure

, spreader

of

the

machine

to

it

works

ible in order

or

come unstuck,

the

machine

for

the operators and edu-

plug

from

is

found

injury

be

off

machine.

of

prevent accident resulting

or

or

death.

sure

to

clutch

and verifying that

etc. which

or

leaving

the

cord

of

your

in

place and

normally in

to

prevent accident

be

from

the

use

from

the

machine

has

to

in

carry

motor

the

section in

to

the

machine opera-

the

outlet-This

the

case

out

the

, in particular,

the

have

to

machine.

order

of

cause-

death

or

off

and

of

docu-

product.

order

sure

to

or

death.

of

the

or

death.

be used

To

- - ,

power

follow

-

machine

be

to

pre-

of

break-

- ,

--~

to

I

PRECAUTIONS

Transportation

1. Be sure

to

the

text

to

lift

of

I

and

the

TO

move

the

instruction

BE

TAKEN

machine in a safe manner taking

manual

for

the

IN

mass

of

VARIOUS

the

machine.

OPERATION

the

machine weight in consideration. Refer

STAGES

I

Page 4

2.

Be

sure

to

take

suff

icient safety measures

machine in

3. Once

breaka~e

order

to

the

machine has been unpacked, never re-pack

resulting

protect

from

Unpackin_ I

1. Be

sure

to

unpack

the

personal

The

2.

Be

careful!

nails

sure

injury

have

to

check

in

order

or

to

death.

be

removed.

the

machine

to

prevent

machine in

Installation

( I ) Table and table stand

1.

Be

sure

to

use

sonal

injury

select

operation.

2. If casters are fitted

them

accident that can result in personal

(

n)

Cable and

1. Be

sure

electrical-shock, earth-leakage

section

and

the

2. Be

sure

3. Be sure

cident.

(

m)

Grounding

1.

Be

sure

caused

plug

Be

sure

2.

or

the

table and table stand

to

secure

wiring

to

prevent an extra

such

cable.

to

avoid

to

securely connect

In

addition

to

have

by

earth-leakage

to

the

grounded

to

ground

genuine

death. If

to

the

the

machine

as

the

V·belt,

star

burst

, be

sure

an

electrical expert install an appropriate

outlet

the

earth cable in

(IV) Motor

to

prevent falling

against

unexpected

In

the

it

is

inevitable

table stand,

force

be

connection

to

or

dielectric strength voltage fault. In addition , be

without

accident

accident

the

case

the

for

the

accident

table and table stand

which

during

the

injury

from

or

fire

sure

to

the

connectors

remove

exceptions.

order

that

or

prescribed

machine

position

that

to

be

accident

provide a space

the

of

can

result

use

a table and table stand which are

are able

operation, maintenance,

being applied

in

to

sure

to

or

death.

. In addition,

order

to

in

order

connector while

to

prevent accident caused

genuine

can

dropping

order

Is

crated,

Its

center

in

in

support

use

prevent electrical-shock, earth-leakage

to

or

dropping

result

in

it

order

the casters

to

of

personal

for

transportation

.

In

order

to

In

particular,

of

gravity

personal

the

prevent electrical-

product)

injury

to

prevent accident

the

machine weight and reaction

with a locking

inspection

cable

if it

Is

30

mm

or

holding

power

plug in

in

before

injury

or

to

protect

prevent accident

be

sure

and take

during

necessary

more

Its

connector

order

It

or

death.

that

not

mechanism and

and repair

the

use in

to

cable

between

shock

order

to

sure

by

earth leakage.

to

prevent accident caused

lifting

or

moving

death.

the

machine against

that

can

to

carefully

out

from

can result

order

the

, earth-leakage

section.

prevent accident

to

connect

result

check

the

package

genuine

force

In

order

to

prevent

near

the

or

fire

the

operating

operating section

the

In

nails.

in

perones

during

lock

to

prevent

accident.

or

fire

power

,

ac-

by

1. Be

sure

to

make

sure

that

the

fore

turning

2.

Never

put

in

personal I

In addition, check

If

the

3.

table stand

ad usters,

the

your

njury

if

connectors

power on

hand Into

or

to

with

rovided,

in

order

the

moving

death.

be sure that the direction of rotation

casters

In

order

is

to

used,

protect

and cables are free

to

prevent accident resulting

sections

of

the

machine in

be

sure

to

against accident caused

of

secure

from

damage,

in

personal

order

the pulley agrees with the arrow shown on pulley.

the

table stand

by

dropout

Injury

to

prevent accident that can result

by

locking

abrupt

start

of

Durin o eration

1.

Be

sure

not

to

put

your

hand pulley and

to

prevent accident caused

sure

not

to

2. Be

cover

when

can result

3. The machine

spreader, needle bar,

against Injury.

ly

stops

4. Be careful

and table when removing

can result

5. Be sure

ing the belt cover and V-belt in order to prevent accident caused by abrupt start of the machine

6. If a servomotor

Be sure

7. Never

use

accident

place

turning

In

personal

runs

In

before changing

not

to

In

personal

to

turn the power

Is

not

to

forget

the

machine with

by

overheat.

fingers,

motor

or

your

the

power on

Injury

at a

high

hook

addition, be

allow

your

Injury

used with

to

turn

hair

or

or

while

death.

cloth

trimming

to

turn

or

death.

to

machine,

off

cooling

clothing

the

surround

the

bring

the

any

other

from

be

sure that the machine and motor completely stop before remov-

the

in

opening

place something near

by

entanglement

fingers near

or

speed. Never

and

sure

the

thread.

fingers

the

machine

or

off

and check

the

the power

the

close

those

that

can

area

mach

ine is In operation

your

hands near

knife

during

power

off

parts

or

replacing

motor

does not

order

to

prevent accident caused by abrupt start of

of

the

to

the

moving

sections

result

of

motor

while

In personal I

of

the

needle

the

operation in

and

check

to

your

body

it

on

the

table

produce noise while

power box shielded in

sections

the

moving

be

to

such

machine Is

njury

or

death.

or

inside

in

order

be

in

the

order

to

prevent accident that

sections

to

protect

sure

that

the

caught between the machine

order

to

the

and looseness be-

or

death.

the

casters

or

with

the

machine.

as

the

handwheel,

In

operation in

thread take-up lever

such as

machine complete-

prevent

machine Is at rest.

order

looper

your

hands

accident

or

motor.

to

prevent

the

motor.

order

,

that

fire

Page 5

Lubrication

1. Be

sure

to

2.

If the oil adheres

3.

If

the

oil

vent diarrhea

use

is

swallowed unintentionally,

on

or

vomiting

genuine

your

eye

or

.

Maintenance I

1. In

prevention

carried

in

the

Instruction

assumes

any

part

2.

In

prevention

to

ask

nance (including

3. When

4. Be

5.

6. Be

7.

8.

9.

carrying

inder, be

prevent accident caused

sure

and

part

Be

sure

verify

that

cident

sure

maintenance,

keep

running

If

the

machine

contact

sonal

injury

If

the fuse has blown, be sure

place the blown fuse with a new one

Be

sure

revent

of

accident caused

out

by

a service

manual.

no

responsibility

other

than genuine one.

of

acci

dent

an

electrical technician

wiring)

out

repair

sure

to

remove

to

check

that

screws

replacement.

to

periodically

the

machine

caused

by

to

turn

the

inspection

for a while

cannot

or

or

death.

to

periodically

fire

accident

abrupt

power

the

distributor

of

be

technician

Be

caused

of

or

the

by

clean

and

start

off

or

by

normally

clean

the

Operating environment

1.

Be

sure

to

use

the

machine

magnetic waves)

the

machine

2. Never operate

in

order

to

3. Be

sure

to

before

using

4.

To

use the machine with safety,

Ambient

Relative

5. Dew condensation can

be

ter

6.

Be

order

7.

Depending

occu

8.

For

working

required, su

worker

environment

order

easily viewable

sure

to

droplet

sure

to

to

rs,

use

the

worker

who

to

prevent

protect

temperature

humidity

environment

such

as a high-frequency

.

the

machine

prevent acci

verify

It

In order

turn the

in

order

stop

on

the

the

who

ch

as

is

Involved In

Is

90

dent

that

the

air-driven

to

prevent

during

during

operation 35

occur

power

on after having waited

to

prevent accident caused

operation

accident caused

radio

TV

the

dB

against health hazard, and

location

or

radio

is

Involved

Is

use

or

when

wave

85

dB

of

the

more

for

oil

and

body,

by

sure

for

by

of

your

electrical

maintenance

air

supply

abrupt

and

nuts

up

the

motor

stop

of

the

and

verify

repair

of

inertia

In

your

to

turn the power

up

the

motor.

under

the

in

any place

caused

accident

be

sure to use It under the environment which satisfies the following conditions :

operation soc

if

bringing

lightning

by

signal condition, the

with

kept

in

the

or

more

ear protection

work

," be

the

worker.

genuine

grease

be sure to immediately

be

sure

to

Immediately

unfamiliarity with

who

Is

thoroughly

to

use

any

unfamiliarity

company

components

start

are free

machine

machine

the

even

operated

area

in

order

air

vent

environment

by

malfunction

device

breakage

well away

work

and

to

be

sure

genuine

accident

of

pipe

of

completely

that

machine

after

where

%to

the

flashes

done

to

caused

with

or

.

the

machine

to

expel

air

the

air-driven parts.

from

loo

during

Its

before

or

motor

the

machine

. (

For

turning

after

for

to

of

welder

such

caused

to

85

machine suddenly from a cold environment

to

less

or

the

instruct

display a sign

the

repair

repair In

off

and eliminate the cause

prevent accident that can result In personal

the

fan

which

In

order

the

voltage

of

as

an

by

35°C

%

for

a sufficient period

by

breakage

for

the

or

malfunction

machine

from

the

be

done

than 90 dB",

like

to

In

the

environment

him/her

to

the

parts

wash

it

off

in

order to prevent inflammation

consult

the

machine, repair and

familiar

the

.

and

the

air

malfunction

In

with

the

parts

when replacing any

by

Improper

machine

or

distributor

which

uses

remaining

seness

duration

cleaning

and

the

machine

power

or

adjustment

order

Inspect

is

fluctuates

machine

cyli

or

sake

machine

the

protect

to

explaining

in

after

of

use.

the

motor

off. So, be

to

prevent

the

not

affected

to

prevent

.

nder

operates

of

malfuncti

of

safety and

of

the

may

generate noise

.

environment

be

sure

against

relevant

wear ear

or

with a clutch

electrical

to

be lubricated.

a medical

machine

repair

electrical-shock

in

air-driven

the

completion

Be sure

machine

stop

, immediately

area

accident

by

more

the

of

time until there Is

on

to

take

health hazard. In addition,

protection

how

doctor

adjustment

within

or

adjustment

your

area

parts

machine

of

to

in

completely

motor, the

careful.)

accident

of

blowing

around

by

strong

caused

than

at

the

specified

machine

of

the

electrical

remove

components

in

relevant

appropriate

to

"noise

without

to

use

the

in

the

of

the

machine

accident, be

for

repair

such

beforehand,

repair,

turn

the

order

to

before

stop

operatio

that

can

of

the fuse and re-

injury

the

wiring

noise source

by

"rated

.

to a warm

the

power

the

TV

to "noise

measures,

level

ear

protection

order

has

scope

or

and

as

adjustment

power

prevent

carrying

motor

result

malfunction

voltage

air

no

sign

components

.

or

radio.

value

in

the

exceptions

or

irritation.

to

pre-

to

be

defined

parts.

the

use

sure

mainte-

an

air cyl-

in

order

off

ac-

will

n and

in

per-

or

death.

in

order

(electro-

±1

0 %"

pressure

one. So,

of

wa-

plug

in

If

in

the

as

for

working

at

of

to

and

out

to

of

.

this

the

In

an

Page 6

--------FOR

~

&

2.

3.

4.

5.

6.

7.

8.

9.

10. Be careful

SAFE

1.

Don't

put

your

hand

under

"on"

the

power

switch

put

your

Don't

Never

bring

handwhe~l,

If

your

machine

operate

When

caught

To

supply

Before inserting/removing the

in

In time

from

If

condensation

after

ping, and

your

tilting

under

ensure safety,

removed.

advance.

of

the

the

machine

you

hand

your

V-belt, bobbin

machine with

the

the machine head.

thunder

reeceeptacle

may

have confirmed

of

handling

the

like

or

into

fingers;

is

provided with a

machine

never

and

lightening,

so

is

sudden

be observed. In

this

since

OPERATION--------

the

cloth

cutting

operate

the

winder

head, exercise care

operate

as

that

this

the

machine.

thread take-up cover while

hair

or

clothing

wheel

or

motor

belt

cover,

any

of

them removed.

the

machine with the

power

plug, the power switch has

stop

your

to

ensure safety.

ly

moved

there

product

product

from

a ·

this

case,

is

no danger

so

as

not

is

a precision instrument.

knife and

close

to,

during operation.

finger

guard

not

to

allow

ground

work

and

disconnect

cold

place

turn

ON

the

of

water

to

pour

water

the

needle when

the

machine

or

place

and

your

to a warm

power

drops

or

oil,

you

is

running.

anything

safety plate,

fingers

wire

to

in

for

be

turned

the

power

place,

to

the

the

machine.

shock

etc.

the

machine

by

turn

on

the

never

to

be

power

OFF

plug

dew

drop-

Page 7

l£rtiliMi'F~(J<J~

tFVLD(J<J~tFm~••*~(J<J••Am.

~tF

.

.11t

1

fi~~~~~~-IYi

DM~Jfli3VlJl~i2.t&FJ'bfi~~H

i*t

i!fOI,

1!fut:r-1!J.7f'~:iliVLff~'i;I

J

(J<J~:g:~f4it!fr~i'Fmi1!1DJfigt~fM!i

0m~••ff•~•l

1

"Picj£(J<J~~fi(J<J7f'~.fflf'w:J~fl~im&M!~m(J<Jr:J:J~

1

H-~~.

~*t~:f1V&~?t.1-J:!IOT¥P~

fi~~~~~~-~

.

ii'tJE?tTMiS@r*J~.

1

J~'i;IJ*:g:~f!f,

1 .

~*••~wz§~it!ff

.

~9~.

.1-JT~itJtlf'Jt:?t

1f~'\1'tli

IZ5!Jit~j!,~~

!1!!

~

(J<J~;J(

.

&

&

&

w

if=.

1=1

A

1!1

~

~

*

&

ff-

fB~~

§gl±::.

1=1

1==1

~

!~

I

~

~~•••~*m~~

~9Er~@.otliiJi~tcz~

~~~••§*m~"·

~9E"C~@.nt:l:iJia<Jjft1fii]"~g

~~•••~*m~~

..

JOC

"P

$i

fJj

fi

ti

tUH

tcz~

.

fititt~l't!JI$.

a<J

tcz

~.

fi

ti~

!Poii~ff~.

~

.

~•~•A.

.

~-~•A.

~•~•A.

~

iiJ

~g

.

@.otffdJi~

IJ

ff~

.

@.ot~tl't!

@.nt~iJi~fcZ

~

.

1~

~

ff-

~

•3•~~-~~~fi~~~-~.

•3•~~-~~~fi~~~-~. fi~

•3•~~-~-~fi·~~-~.

@

fi~J\Bl:'lfi

IJ.&

o

.

.ot

ffl

iJi

fi~

fi@

aq

1iZ

~A

1~ff-iE~~~M:nr'cJ

1~ff-ii!!~~iiti

.

.

@

&

~~~

1

~~

~

~1%J

•

2

[

·~1~~~

0 .

lil~1:.1'jl$£Jlf~~-

-~m7~~-~a9~.

f)

·

Ei~~~~l!1it

·

Eil~~~~t

·

Eil~~i*t?~fl

0 ·

~'~

~t)Jrtfi~V!.ZFR.

r nc

im.

~~

~1~

?H. ~FR-ilii1H'T~iM

?.a. ~FR-MiiHT&liM

.

~FR-iliiiH'T~lM

iiH.;J

1

a9HH1=

~o

~·

~-

]

Afi:f9i.

9E"Ca9fli:

lil~1:.mffla9fli:~

-Mi1H'T

r

~li

.

.

.

J. r

~.

.

~lt

0

&

*

A 1

~~~

t

f)

.

J. r

:if~~;tt

J

tt~

~~

2[

.Jtl

-

~

~~

~

~~~~~]

t

0

Page 8

N3S3t~a9i1

$¥

Iffi

....---------

r--------------------

I

¥*1!~~n:oo

1.

~mzwr. t~1a:-~~~~{fJfJi~PJl·1H:.t~ll#~agJifffiit~aJl~n

~*·

2*~-~~~fi8~~-~-~£2AAM~agmH•mag~3

3.

~7i!Jjlt.r!fiHJ.~.fOCaglJ1C(

4.

{fffllL'.Ill1Jt£twHag.A

I

~:i:~ii-

1.~7i!Jjlt.~~mfii~~~:i:~ii~-.10Cag~1C(

~f!t~zm~ilH'T~i1=

2.~7i!Jjlt..AA*1C(

3.~7i!Jjlt..AA*1C(·

fln£~10C~ag~~

I

ml£.

&~

1.

~71l!ilt..AA*1C(·

~~{fm~•~m•~*"·

2.~7i!Jjlt..AA*1C(·

I

~llf±tSiJII

1.~7mlt.~~~-•~•.f0Cag•1C(.

ft~W. ~fiRUA:fii1f~~m~~~~-ag~~AM{fm*mH

i'I=.AMag~W

I

&::,

~

m*ffl!t!iJJag•~ I ~

I I

~-~~-~*~mm~~. ~•M

,

tifiXJ:~:i:I!JjfpPIHli1H'Tt~H~

,

~ -

~~1ff1~j::~~zm~{fJfJ

V

E-~~

I

.

·

~~7~:i:~~~

~~-15-~~HM~MMB~~~~~~agmHJ:.~~MMd~j::~m. ~~

.

I

~~~~*mH{fJfJ~**agJfJi£~1l{fffli.~

*~~-~~mawma

-~~~~mH.~~~~~~~j::ag.1C(

I

±

giJIIi.t~~J

.

*tJJ~~~~

&

Lll

~m•m&alii**mHag~~~~:i:~••~

.

*i~fltiai

I I

I

fB~t

A

~

~

~

3EE3

H~~~~~oo

.

~~*mHH. ~~~~:i:~fi£~~~~~~B-

~ -

~~~~B-*agmii.

-~-

~J:·~-.~~m~

----------,

.::e::.

------------------~

~

~~

.

.

.

.

.

P

J}~-~ag{fffl1Ji!tB~ag}fJ~

.

,

*~~--~lffWmff

.

~~

t~*~it!-i7F*.£i

*~~~--~~-

.

~m•m-~•wr~~m

.-

#13.

-

~liff!tiiJ.J.~iili

o

.

.

.

~m~.Amm

~

I

1.

~7i!Jjlt..AA*1C(

2.~7i!Jjlt.~mH•MJt£M8.fOCag*$

•&~~~

2-

1.

f§IJ~. iaJ~Jltt.

2-2.

f§IJ~. J!~dil!lflffl.IOC~JtHagJifflii*81!1=H

2-

3.

f91J~. ~~-

3.~7i!Jjlt.~lt!-~lt!-

4.

~{fm~tJJmf*l:tNH

s.

~

71l!i

lt.~

I

tm

m I

1.

~7i!Jjlt.AA~$

fi*mH:m•

2~7mlt..AA*1C(

3.~71l!ilt.~~ffi~ag~•-

,

~~i-.A.

7

~-,

1C(I!lmtUH~It!H.

, -~~

*~lt!;w.~

i~JI.

lt!~~Bi!fagt.ro~•.f0Cag*1C(·

.

.

•~~{fmm~~agm~

·

-~~~7~~m~:i:~lt.ftMzm~mft~~

~H.

~~H~~~~~JHF-J~f!I=M~

il!Jt3tJLHH

*~····It!·~~~

.

-~~*ffilt!•

1±

1aJt£~~~JL~MH.

~-~~m~MH. ~*~~1¥~:i:agm~mlt.~•-

~MlJ1C(.

. a•7HJLHH.

.

~~~ffl

mHm~.

-~H.

.

-~~~ffl~~-lt!~

~lt!mll-~*

~it~

ilt-~~lHI8mHag:mii*JfJ~1¥~:i:ag1J;!m~;:Hmili

.

a{])!~

•~~~~s~B~*magmHmftHNili

I * m I

1.

~7mlt.AA•1C(.

.:r-tL~

·

.

•~n.:r-

2.

~71l!ilt..AAlJ1C(,

*m"~~!ffiJ..A.J:n*~ag

J..A.**RJ:•~•

~I±HJlHH. ~-~1l5t~i..A.tJlHag:m~L.,m:A:Mm'J'lL'~~:±l

·

J

®l.~¥m~;:*m.

~~fln*ffllt!iJJ

·-~*ffilt!iJJzm~mft~~

'T

~H~dJ!~~;t;H

ffilt!iJJ

.

.

MM£{fJfJ

.

.

.

~~-~~It!~·

·

.

f;IY!

.

~9~.

~•

-

.

*ms~H.

tw-~~'J'

.

1

L'~~~rr

Page 9

~

I

~

( I

( n l

I

)fJl~.

~JWJ

1.

117IDJ

R~~~mH~•-~•a-t~t-J&nm~~t-Jm~

2.

1J7M.ltA.~-$:

••••·

-

ft!~lt

1!lti

1.

jJ7IDJ.ltM~ft!

~-M~il~11fll#ilf1!li~ft!~Ata1.

2.

jJ7IDJ.lt~ft!.

3.

jJ7IDJ.lt~ft!

tlB.ti

(mltlit!!

1.

jJ7IDJ.lt~iiift!.

·-:iE1Eft!iiml~~tl~tlit!!lt-J~iitf.ll.

2.

jJ7IDJ.lt~~~@•~•13!:.

(N)~~

1.

jJ7IDJ.lt~~~~ii'ii@dlt-J$$:

2.

ifJflm~ili~ag~~~~~

~li£$~P~It-Ji§i~

t~

i'F

I

I

I

M'

1.

2.

3.

t~

1.

2.

3. !it

4.

5.

6.

7.

j]Q

1.

2.

3.

I

jJ7IDJ

.ltA.~-13!:

jJ7IDJ

.ltA.~$$:

if}fj$

JWJ~~t-Jm~JWJ~

~JWJjE

JWJ~~~

1-F

~

I

jJ7IDJ

.lt~Aii'ii@dag$~.

•MooisL.

~~~

jJ7IDJ

ltA.~=~. tl~ft!•~•mB~n~.

~m.

.

!9:1

~Jl

~~~~mftftM.jJ7IDJ.lt~ffl~

~iiiMOOi!

1!JtJJ

JJ

~

l1H=r£

jJ7IDJ

ltA.~*~·

jJ7IDJ

.lt~~~ag~M@dlt-1$~

±1.1~:i:w;.lt~m~m~n~e

*OQ,~

ifJfliiil~

~ffJ~l

jJ7IDJ

iitiifffl

jJ7IDJ

jJ7IDJ

~~~It-t

••

.lt~J:I~@d~t-J.:k.;t:•~·

)Ill

I

UK

J

.11:~&~-M. ~M. ~-~~11#7~~

.11:~~-~M.

.lt

A.~¥13!:.

m-:iEifffl~iE~t-J~Jt~.

.

~~JWJ~~~JI1JJ~~~iffflAfiR~~-It-Jm~:iE~~It-JJWJ~

•~-•~a-tmft~:iE::r-~mH~M

.

i.lmft! . .:k.;k:$13!:.

~ft!

.

.:K.;t:•13!:

.

i.lmft! . .:k.;A;:*$:,

iffflft!~Atlt-tiW:f~ioJft!~At»l§JJOJ:I:*:It-J~

B~iJ:ft!~Atllei§i'E:il'1

.

~::r-~mft~ft1!lti

.

~tfiftitffii'ii@fiX~$$:,

M-:iEreit!!titlit!!.

,

~-:iEifJfl~:iEIY-J~:iE~~(~iE~l

.

~~~AV*li£mii'ii~fiXag·~

Q,~

.

.

tl~ft!ii~-

. •

:f~1E~~~mM~OO~

.

jJ7IDJ.lt~~~t-J~M@diY-1*~·

.

i!!.:f~re4m~1iU

.

~9~. J!~fu'UJJ~JltJltilt-t

.

Mm~~memmm~.

.

mH~.lt~Q,~:f~ili-B

I

~iEIY-JtJliltlfO

J UK I

~-~~7m~. •ft~i.t~~mfi.

~-:iE~~-tlH.ft!B~~~~fi~ffl-~M-~M

~nmB~.

I

J~im

.

meli£m~~~&v*li£*~·

.

ifJfl~•::r-~CttQ,~ft!iim~t-J~~c

~iEIY-J)ji]jfUijioJ~.!i!:iE00isLm~T1JO)ltlfO~i*iiiJift

~JWJ. ::r-~t.!ifJfl~~~iE~t-J~i*a-t

.

~JWJ

.

.

ii.

~9~.

30mm

t.!~

.

.

~-:iE$~it!!~:iE~tlB

-:iE-Afift!~~ll~iR~A.~~ft!iitf.ll~

~

.

. ~*·

=~~::r-~iJ:~m-~~

.

~n~~~:f~iJ:~

. •

••~~~~~••lt-1~~~.

.

·~~li£m~lt-JftM~ioJA~~~~-~

~::r-~re~mftilfmH

;.'lCf.ijf@.li.

jJ7IDJ.lt~~~ag~M@dag·~·

.

~~

-~tlBit-t.

.

· ·-

~~Jfl~~fiiDJ.lt~A~~

~-:iE~:iEJWJ~.

-

a

ilf•H-~tiB

~i.A

7!il~9J~JlfOQ,~±1.J~:i:~.lt~m~

•-:iE~f.ijft!ii.

mfi~~H~. •~~

~~ailfli£m~.~M~~

.

i!!.:r-~re~m~~mti"~

•~~:r-~~~~m

.

ftlii.

·ft~mft~~

.

·

~-:iEifffliiTt.!

.

~nmHa-t.

~ v 1f

~li£m

·-:iE~M~

.

~9~

.

.

-a.

.

H"····

.

~~7~!9Jm

·~-;:r-~~~

Page 10

I

!ttf!J~W

1.~7~ttm~~~~@~~•$.

2.~7~ttm~••~~~~-$~&~tt~••$.

3.~7mttm•M~EM~~~$$,

~~7mttA.•••· •~~~~~~••#~

~mH~~fflM~·· ~-~~M~mft~a.~M.

6.

7.~7mttA.•••·

8.

~~7~tt~~~*~••· ~~M~mft••~~c~~a~~~~~~-~

I

~ml.1'm

1.

2.

1~7mttm~Mn•~~••·

4.

~~7~ttm•~*B#~E~~~Mn~~~••· M8~~I.1'±~a~~-~~~~~:nm&~F~

6.~7~ttm•~*B#~-~~~Mnm~~••·

I

~~~~-~g. ~-~u~~mH~m~~w~*A.~~~~m

-~~~m~mft~~~~~-~~

~-~~~~~&~m*~~••#~~~•$.

tt~r.s~~*A.~iZH-r~~-~~f~I.no~tf~

i#~~Rf.Wi.:r.

f;jj•llJ..

m~i'!tf~~W.

~~i6M. ~~-~f;fl-llJ.m~i6~~fflttmM@~mftM-~M~

~ft~~ft*A.~irJIJil

~7~ttA.A$M.

~i.fi~ll.&M

tn:th

t1:1

1.t

oo

~~~zmJ}m~-r•~~mf~~w

~lA

7~WJtJL~~~~7t:i:~ttzmJ}mft

~if.

f!J~M. ~-

&tta~~~.

.

~~~~mrmm.

.

~~*B#M. ~-~·ffl*~~~~~*B#.~~~~~

*~~-~~ma~~a

m-~u•~•~•n•~~A.-~ft*~~

(

1£m:tflfat

-~~m&~W~ffl~MW~ffi~~~-H~

m-~~~~M~••~~~M

~~f,fl-llJ.

mH~~~~mnM.

J.R-~mrm•D.

.

~}A

l.

.

~7mttm•M~EM~~~~···

;ffa

.

7~~JJtJL~~i6~~:i:~ttZ.mJ}iZHi'~ff

~~~~tt~n.

t~~~7~~M:tf§Wf~mtmz.m.

.

.

~-~~~~~

.

l

~*~~•tt~r.s~~.

.

I

~7~ttlli1i~Mffm~~••

~7~ttm~Mff~~~••·

~m

.

~7~:i:ii!!~m~WJtJL.

MffM~~!H.A!J.l

MffM~ttl~il.ll

~3~~. ~-~*~7t:i:T~Z.mJ}~~-D

5"c-35

35

·

~.ff;~~~~-~m•~£11/,rtrD

.ff~ttiJi~•ffi

~~~m~ue

i~-~.ff~91JJ.1\il~m~-rifm

±

1o%~ii!!:n.

affi~~~•m.

.

1

•lii:ti&:

ill~JJ~m~WJm

•~~7ffi~M~~~zmJ}mft

·c

% -85%

.

n~M~7~~

m~tt~n. *~~-Rf.~~

l

~P(a)~J.i\il~~ffl!:iUJJtJL

.

~-~~

.

I~

£~ttl~~~

.

-

~~~-;&:~-~

m•wtn.

8.

~~.(£ r {f~J.i\ii~PJBfi.ff

~mw.

~~-~A.~. ~7~~~Jj~~m~.

~~~m:n~•~~~~A.~·~~-~~:n

~~w~nA.~~mmwm~m~.~~.ffrn~I.1'il~~•mi69~s~~J~J.1\il~~n

~~~~~fflfi~-·-·

~i\fm

.

85dB

~.:Lt.~

90d

•-~u~nA.~~mmwm~m~.

~--*·~--~"·

B

~.:.t~

J

~J.i\ii~HHf~WltJl~A.~.

.

~.ffffiffi~*~Wltll~ii!!:n•

*~~*m•~~m

~7~~fit}j~

Page 11

A!

~

H-.::>X

II

A

1.

;t)TilJj.lt),.~-$:1¥1~~.

tHfltlJJR1~:LN,#jU9JtJl~~~.

N.tllHI¥lllfH!i.

2.~71lJj.lt~MI¥1~~-~A~$$,

t~ltlJJ

.

3.

~71lJj.lt~.&:~.AtllHI¥JA~$$,

~-·-

~~-mn•~~-~.

$~~~M~

~~JJM~~~ii!f:if'~:m.':ft!!i,

····~~v~Jtmfl1.

~:if'~1e!*~$BMH~W

i'R:if'~1e!Eftl!i$~!JB~J1141,

3k~-

~RU'iili&:m$t,

t.J]JJ~:L

·-~~

v

.

~~TilJj.tt.A~*$:1¥1~~

~;JJtJl

.

a.~TilJj.tt~~•#m~l¥1•$:.

9.;t)71lJj.lt·~-#8~~·$.

*mij¥;~=f

11

.

~;t)*rr~li-T*l'.ttllH

tllH~iit~

m~tHf~tlJJ

~tJlHIIftm.

•:if'~a•~••m~~-~~llJj~H•~~·~I¥1~~~~~

n~a1•~.tt~~.

M8~1¥1~~---·~-~~I¥1-~R1.

.

.

.PJTW~iffl1

ii!i3t~l!~

.

*•~~t-~3k~~~~~.

~~~~~.

:if'~te*,

iWiJ!l~ilfJlH~W.

~:if'~iJ:

M

Page 12

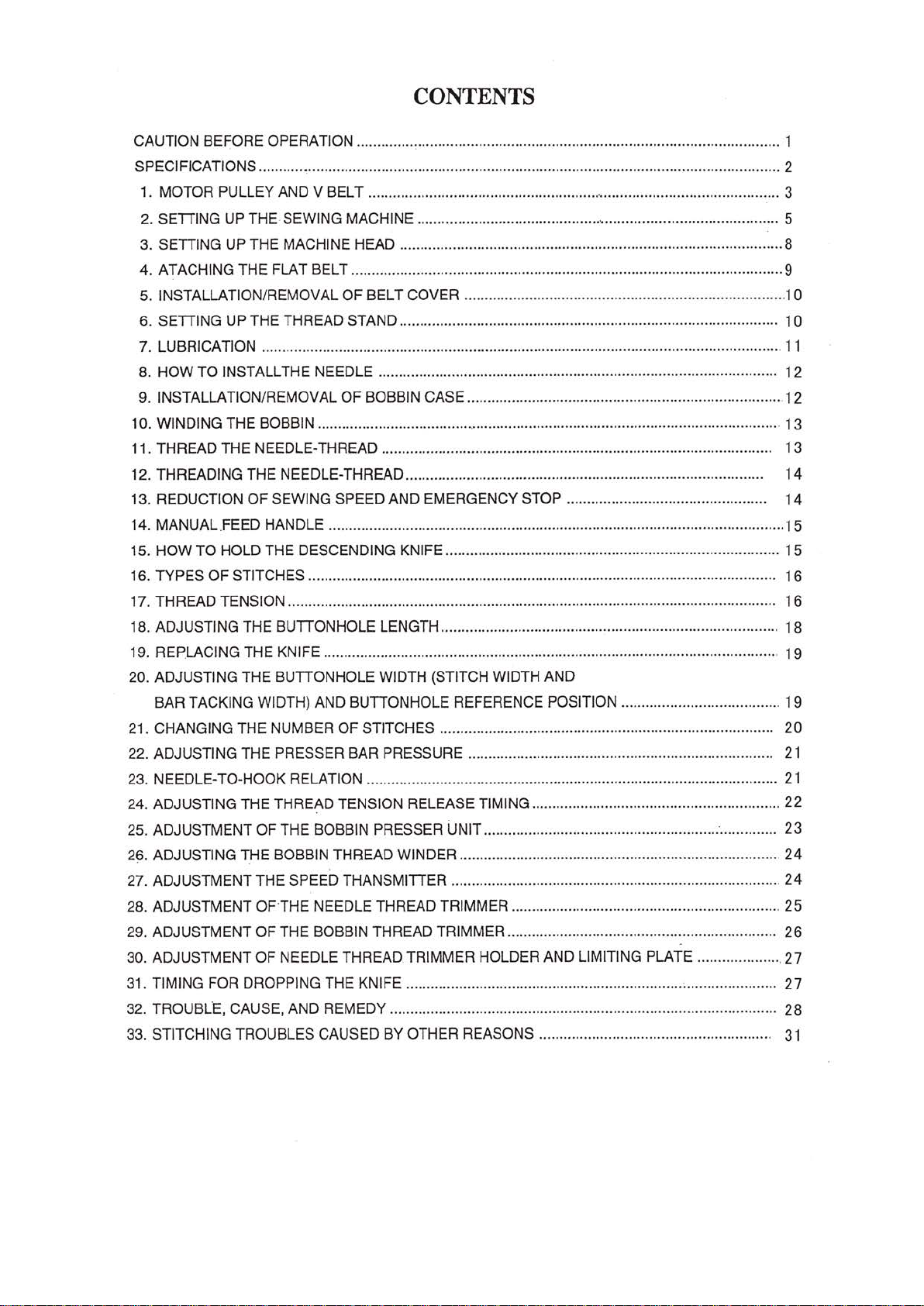

CONTENTS

CAUTION BEFORE OPERATION··············

:··

······················································································· 1

SPECIFICATIONS············.···················································································································· 2

1.

MOTOR PULLEY AND V BELT .......................................................................................

2.

SETIING

3.

SETIING

UP

THE SEWING MACHINE ......................................................................................... 5

UP THE MACHINE HEAD .............................................................................................. 8

...

............ 3

4. ATACHING THE FLAT BELT .......................................................................................................... 9

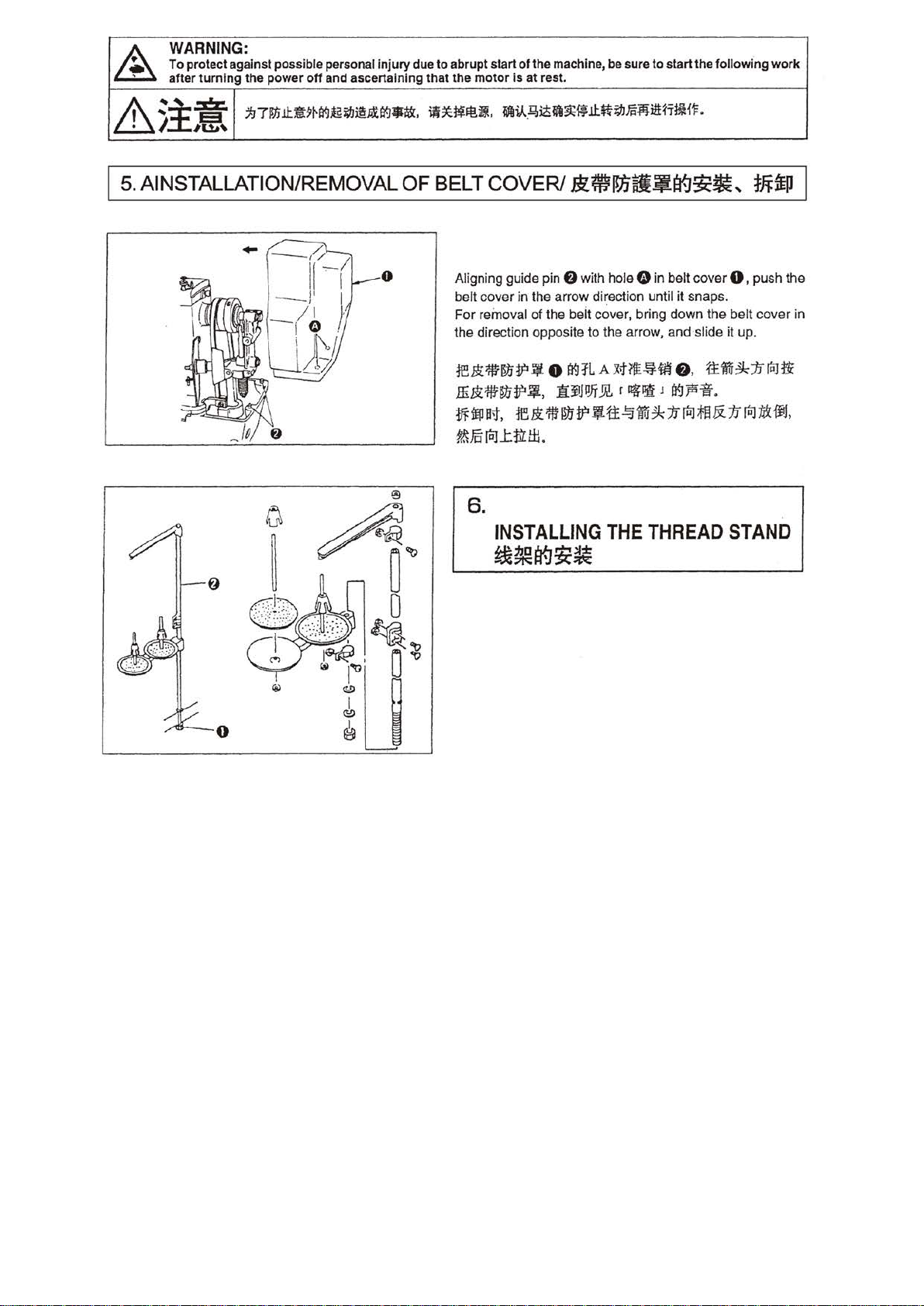

5. INSTALLATION/REMOVAL OF BELT COVER ............................................................................... 1 0

SETIING

6.

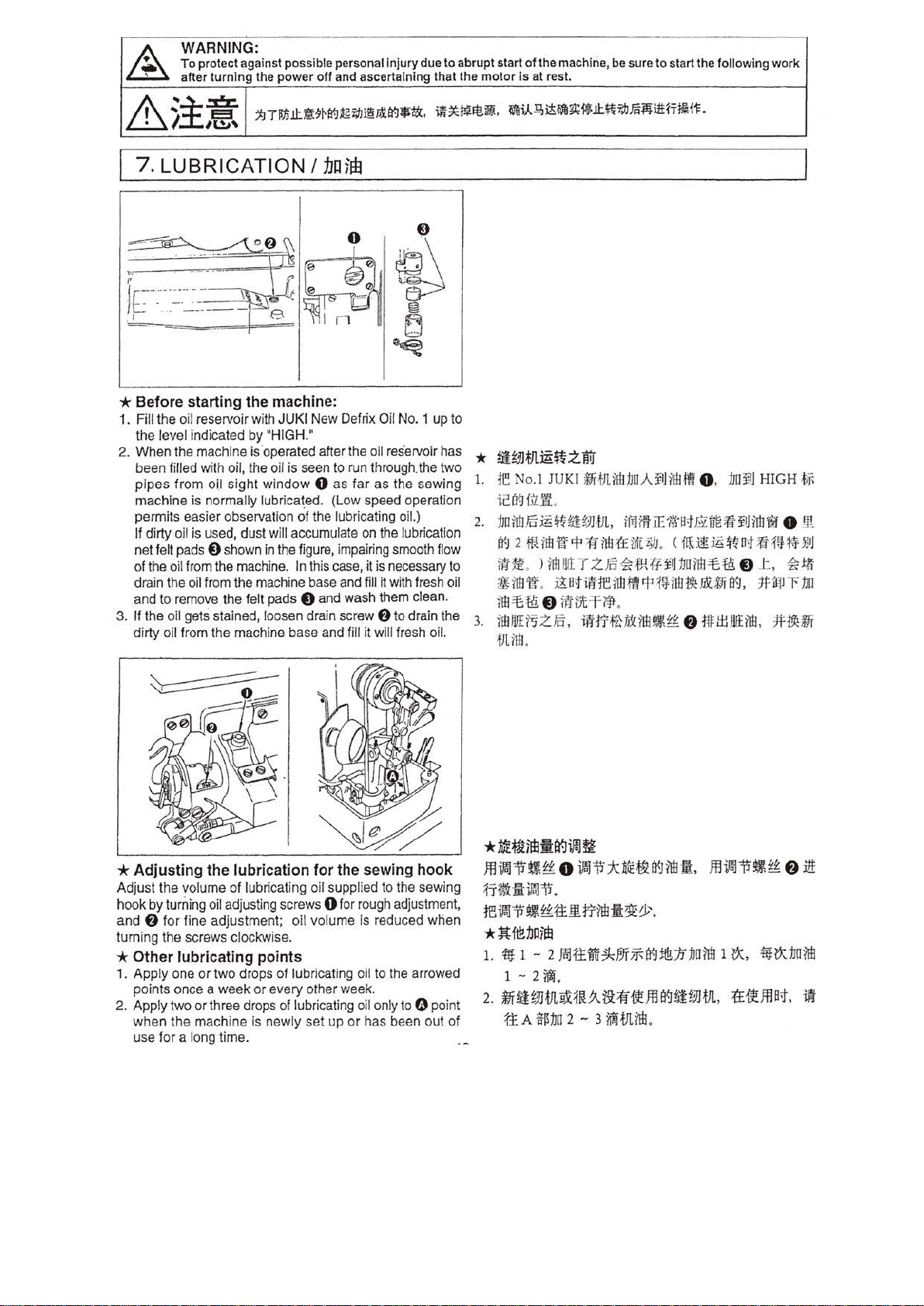

7. LUBRICATION ........................................................................................................ ......................

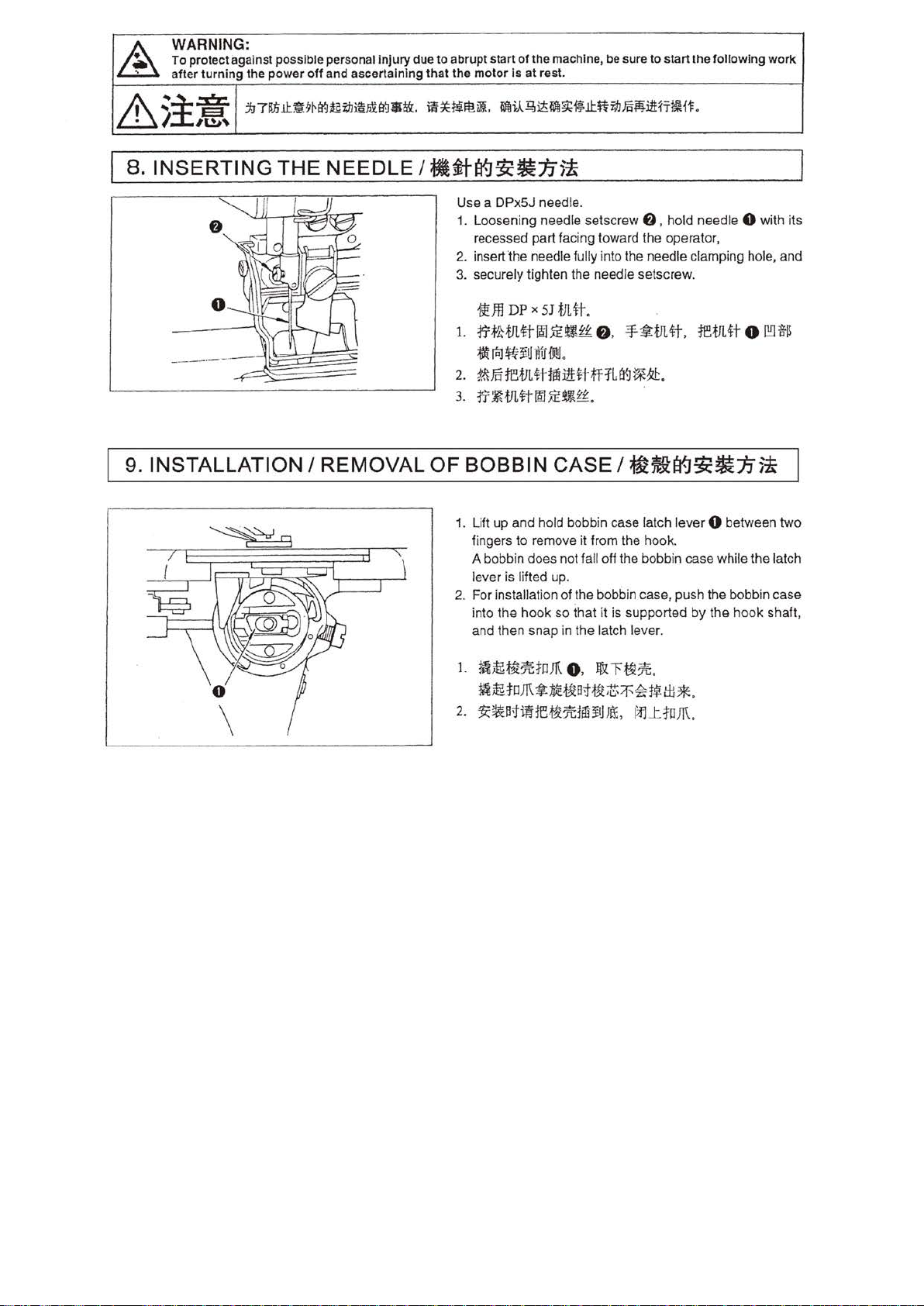

8. HOW TO INSTALL THE NEEDLE ..................................................................................................

9. INSTALLATION/REMOVAL OF BOBBIN CASE ............................................................................

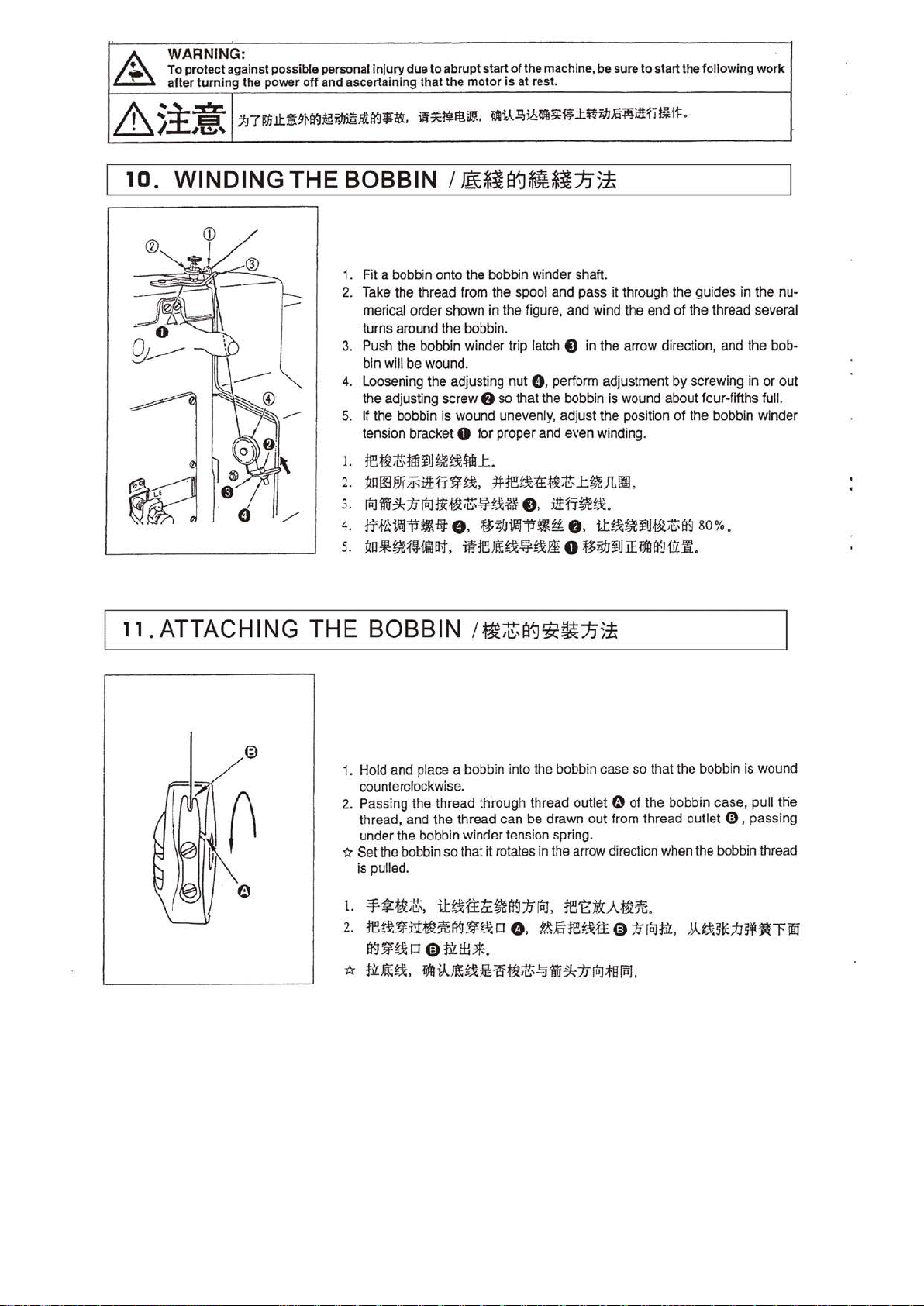

10. WINDING THE BOBBIN ..................................... y

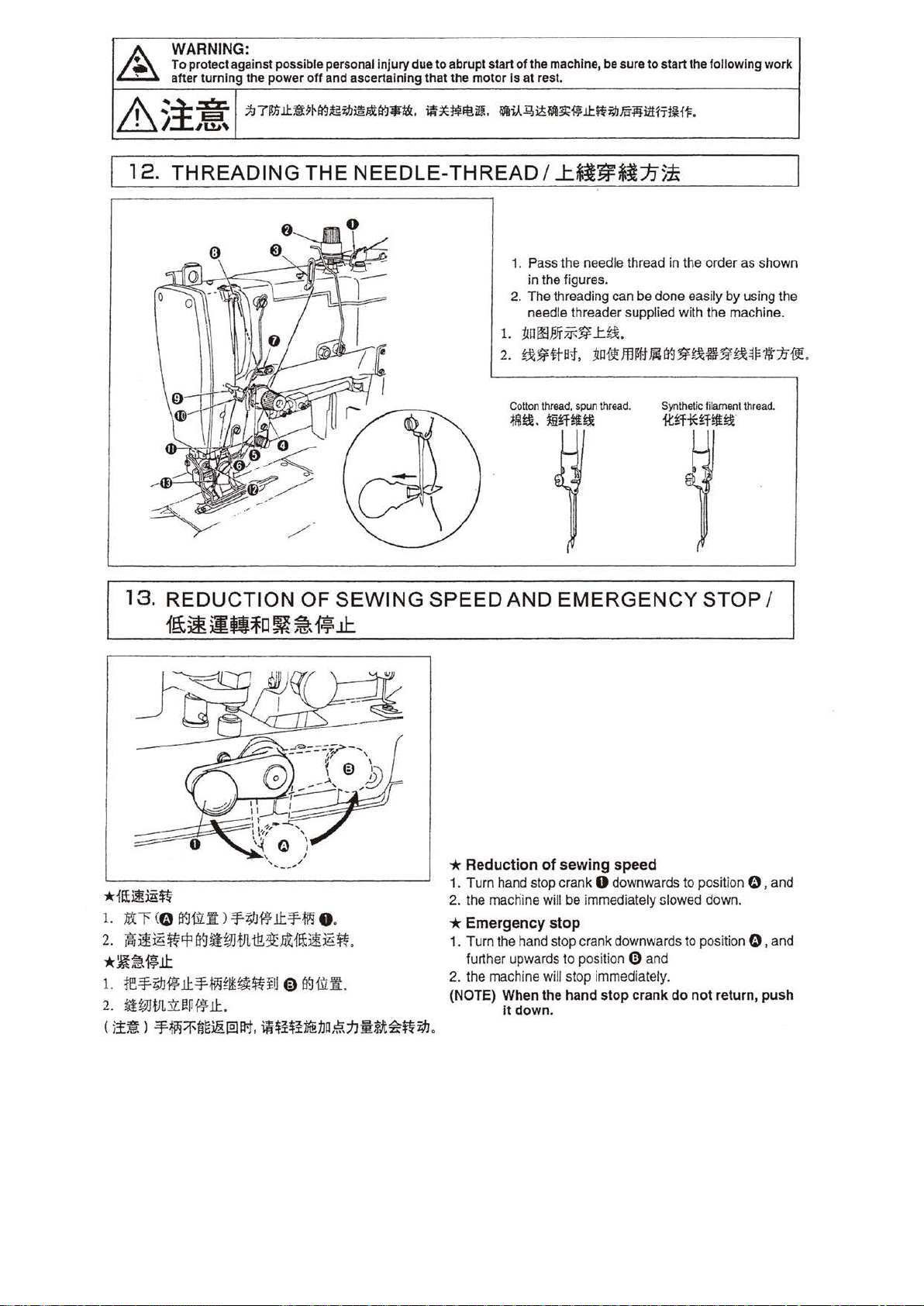

11. THREAD THE NEEDLE-THREAD................................................................................................

12. THREADING THE NEEDLE-THREAD........................................................................................

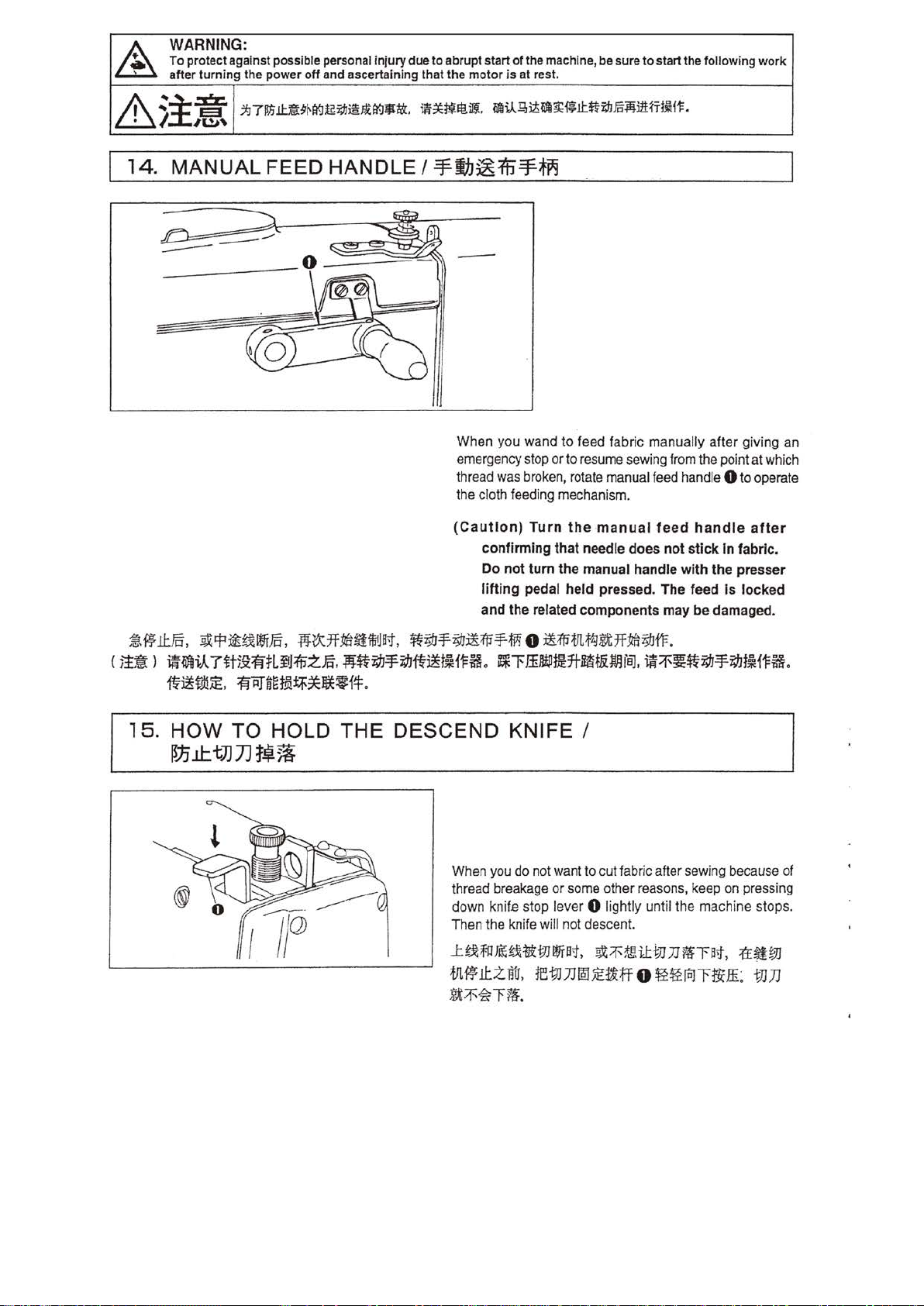

13. REDUCTION OF SEWING SPEED AND EMERGENCY STOP.................................................

14. MANUAL .FEED HANDLE ................................................................................................................

UP THE THREAD STAND ............................................................................................. 1 0

..

11

12

..

12

.....................

.......

..............................................

.

13

13

14

14

15

15. HOW TO HOLD THE DESCENDING KNIFE .................................................................................. 1 5

16. TYPES OF STITCHES

17. THREAD TENSION ........................................................................................................................

..

....................................................................... ...... ...................... ...... ........ 1 6

16

18. ADJUSTING THE BUTIONHOLE LENGTH ................................................................................... 1 8

19. REPLACING THE KNIFE ................................................................................................................

19

20. ADJUSTING THE BUTIONHOLE WIDTH (STITCH WIDTH AND

BAR TACKING WIDTH) AND

21. CHANGING THE NUMBER OF STITCHES ..................................................................................

22. ADJUSTING THE PRESSER BAR PRESSURE ...........................................................................

23. NEEDLE-TO-HOOK RELATION .....................................................................................................

24. ADJUSTING THE THREAD TENSION RELEASE TIMING .............................................................

25. ADJUSTMENT OF THE BOBBIN PRESSER UNIT ........................................................ . : ..............

26. ADJUSTING THE BOBBIN THREAD WINDER ..............................................................................

27. ADJUSTMENT THE SPEED THANSMITIER .................................................................................

28. ADJUSTMENT OF·THE NEEDLE THREAD TRIMMER ................................................................

BUTIONHOLE

REFERENCE POSITION .......................................

19

20

21

21

22

23

24

24

..

25

29. ADJUSTMENT OF THE BOBBIN THREAD TRIMMER .................................................................. 2 6

30. ADJUSTMENT OF NEEDLE THREAD. TRIMMER HOLDER AND LIMITING PLATE ..................... 2 7

31. TIMING FOR DROPPING THE KNIFE .................................................................... : ......................

32. TROUBLE, CAUSE, AND REMEDY ............................................ ...................................................

33. STITCHING TROUBLES CAUSED BY OTHER REASONS .........................................................

27

28

31

Page 13

)E~WJtr..J)t~-J]i

m;f:3..........

1.

2.

3.

4 .

5.

6.

7.

8.

9.

10.Ji:i;~tr..J~~1J):Jr............

11.;Mi;lttr..J~~1J):Jr

12

13.

.................................

~itw.:m:~;fo

~~iJJVl.tr.J~~'jj):£:

~~iJJtfl~tr-J~~.

.3¥

It

iWtr..J

W.iWiJ1ifP.!Jtr..l~~-

~~tr..J~~

1JDiiE

................................................

tflittr..J~~'fj):Jr..............

W?'etr..J~~1Ji:Jr.............

.

..t~~~1J):Jr

fl£i!)E~jfQ~~-~.lt

14 . .'f.i;l)i!:f!i

1

5.1!J).lttJJJJt

16.

~~1f~it

17

.

~~*11

...........................................

18.

i9liii*Ii ( i!:f!i:ii: ) tr..Jirn:P

19. tJJ:f!i

20

21.

]Jtr..JJ!t!J:!............................................

.i9lU

!t~

Jl ( !ti;IJ~Al;fll1m~~~Ji

it~tr..J:A:t!J:!1J):Jr

22. ffi.IIWtr..Jffij)ifflfl..........

23.

tl.itjfQMf;Mitr-J;c~

24.

tfl~t'~~IJ1lmtr..liJ!Jfl

25.

W~ffi):\"tr-JiJ!Jfl........................

26.

ra;~~~~fitr-Ji,I!Jfl

27.

;Jtj!i§tr-Ji,I!Jfl.....................

28

.

..t~tJJ~tr..lifflfl

29.

Ji:i;~tJJJJtr..liJ!Jfl

30

.

...t~tJJ~i;I.Jf'

31. tJJJJliJJIJ1Wltr..Ji,I!Jfl

32.

fl';c~~Mtr-Ji!&~,

33.~iM

~.:L9~tr..li!&l!a,

...............

..........................

.......................

v

1f~Jtm

.....................

.....

......................

........

......................

1ii

:Jr

................................

tfiiff.l..............

........................

..........................

.'f.ti!i............................

~)i

......................

.....................

I=IHI*tll~rl~RiM~&tf.Jif..l~

.................................................................................................

.....

.........

......

.

. .. . ..

.... ....

. .....

.

...............

..

.......

......

.....

......................

..................

........

........................

..............................................................

..............

..............

..........

... ...

.........

.

........

........................................................

..............

......

....

.................

............

...............

................................................

........................

....

..........

.......

..........

.....

............

..........

.....

......

...

.............................................................................

......

...

........................

....

.........................

......

.........

.. .. ....................

................

......

...........

..... . .

............

....

............

.....

....................

......

..................................

......

..............

...

...............

................................................

...............

..........

...

.

....

.

....

.

.............

......

..........

............

......

.....

.........

...

..............

.......

....

...

................

.....

...............

..............

....................

..................

....................................

................

.......

...........

.............

........

..........................

........................................

.

.............................

.............................

l

~.:tR~tJ!l~iiUifitr..JiJ!lfl

......

.....................................

........

...........

.....

...........

...............

..

..............

......

................

...

............

....................

.......

........

.........

...........

....

.............

............

..........

..........

....................................

.......

...............

..

. .

..............

.....

...................................................

...

............................

..........

.......

......................

...................

.

......

. .

...

................

...

.............................

.

...

....................................

............................................

.......................................................................

JiRr!I~~.H.l1Ji:Jr

ERr!l~~!.l1Ji:Jr

..

.......................................

...................

...

.............

..........

...

......

...................

...........

.......

.............

...................

...............

.............................

................

.................

.......

...........

.

..................

........

..........

......

.........................

.................

........

..............

......

...

........

.....

........................

....................

..........

.....

...................

....

......

....

.........

......................................

.....................................

..............................

......

....................

.......

.................

.....

................

.............

.....................

.. .

....

......................

.....

..............

.............

..............

..............

.....

....

.....................

...................

..............

....

.. ..

......

..............

........................................

....

...........

...........

....

...

...........

............

.....

......

.............

............

............

....

............

....

...........

....

.............

...

....

...............................

...................................

......

...

.........................................

........

..........

....................................................................

.......

.....

..................

..........................................

..................................

.............

....

......................................

...

........................

.

. ..

......

...............

....

.....

.........................................

......

.......

........................

..........

......................................

..........................................

.

........

.

.........

...

...................

......

.

.........

....

. .

................

..

...............

......

..............

.............

..

...

..................

......

.........

..............

......

...............

........

..........

............

..................................

...........

...................................

............

................................

.................................

...............

. . .

...

............

........

...........

............

......

..............

..............

...................

........

.......

...

...............................

.........

....

........

....

........

...

...........

..........

..

. .

...

.......

...

...........

.................

.................................................................................

........

....

................

......

....................

........

.......

...........

......

.......

.....

.............

..

.......

.............

.....

.....................

.......................

.

...

.....................

. 5

..

..............................

........

....................................

....

.......................

..........

........

.........

.

......

.........

........

...........

. .

...

.. ....

....

...... ..

..

.......

.....

..............

........

...

......

........

.....

....................

...

....

..........

.............

....

............

......

.................

.............

.......

............

........

.........................

....

..............................

....

.................................

.....

................................

.............

......

...................................

.......

...................

...

..............

..............

.

...

.....

.............

............

....

... 14

..................

......................

....

. 14

......

' 1 8

..............................................

...........

...........

.......

...........

..

.....

.......................

........... ...........

.............................

.................................

....

.................

..........

......

.......

................

.

....

...............

......

.

...............................

..

.......

.

..................

....

..........

.

...................................................

.......

..................................

.....

..........

....

...........................................

1

2

3

8

9

1 o

. 1 0

11

12

1 2

13

13

1 5

15

1 6

16

1 9

19

20

21

21

22

23

24

24

2 5

26

27

27

28

31

Page 14

BEFORE OPERATION

_

if\

~

WARNING:

To avoid malfunction and damage of the machine, confirm the following.

.

'-=----------'

• The normal rotating direction of the sewing machine

side. Be sure

• Never operate the machine unless the sewing machine head base has been properly l

• Be sure

• Be sure

and check the amount

• Be

su

re to return the activating pedal to the home position after the machine has started

pedal

is

sewing at

• Confirm that

Confirm that the power plug has been properly connect.ed

not

• Do

The feed Is locked and the related components may be damaged.

turn the manual handle

not

to

let

it

rotate

in

a clockwise direction.

to

remove the bobbin case and needle thread from the machine when doing trial sewing.

to

remove any dust from the hook or bobbin thread cutting knife section at the end

of

oil remaining.

held depressed, the sewing machine may doubie the seam

high

speed.

the

voltage has been correctly set.

wit

h the presser lifting pedal held depressed.

is

counterclockwise, as observed

or

cause a

to

the power supply.

from

the pulley

ubr

icated.

of

to

run.

stop-motion

t-

the day,

If

the

during

r-

&1f:~

•

•

·

•

•

•

•

~

E3

I

M.$:'iW$t19JIJ~~!!JJtrl~Mt~:tflo:J£J$1f.:tlt1ilol.

~1U!JJtrtiftltt~)9:~:tJoimlf.:t.

iitm~lf.:t.

{1=~~:sRZ~.

if.lfl;g~~t&lf.:t,

mWfli.Ail!.ffii9:;E£slEWfl.

Rl'ff~m*~t&~~.

j:J71!1ill:Vtvt~m~~i'l=ii1j9im,

,1.!1~

~~m~~m~~!!JJtrt.

~ftPl'~~*ll.t~.

mfflf31irt~.

~!!JJtfl;g~~i1Ue!~t&ll&liD~'JmBfttt-JUL:Jt.

WJJ$~1JZ~.

~Wfli.Ail!iJJfftii~£slEWfli!1l.

~~~~~~~~~a.ft~a;g,

11t~i.A.ja]"f~

~)!~~~.&:~.

1H1fli.Aiftl:ii:£~3t.rE..

~

.

s

9!1J~~~-~~~~~lli~!fli;.l.t~*~.

~~nm~~~v#

.

Page 15

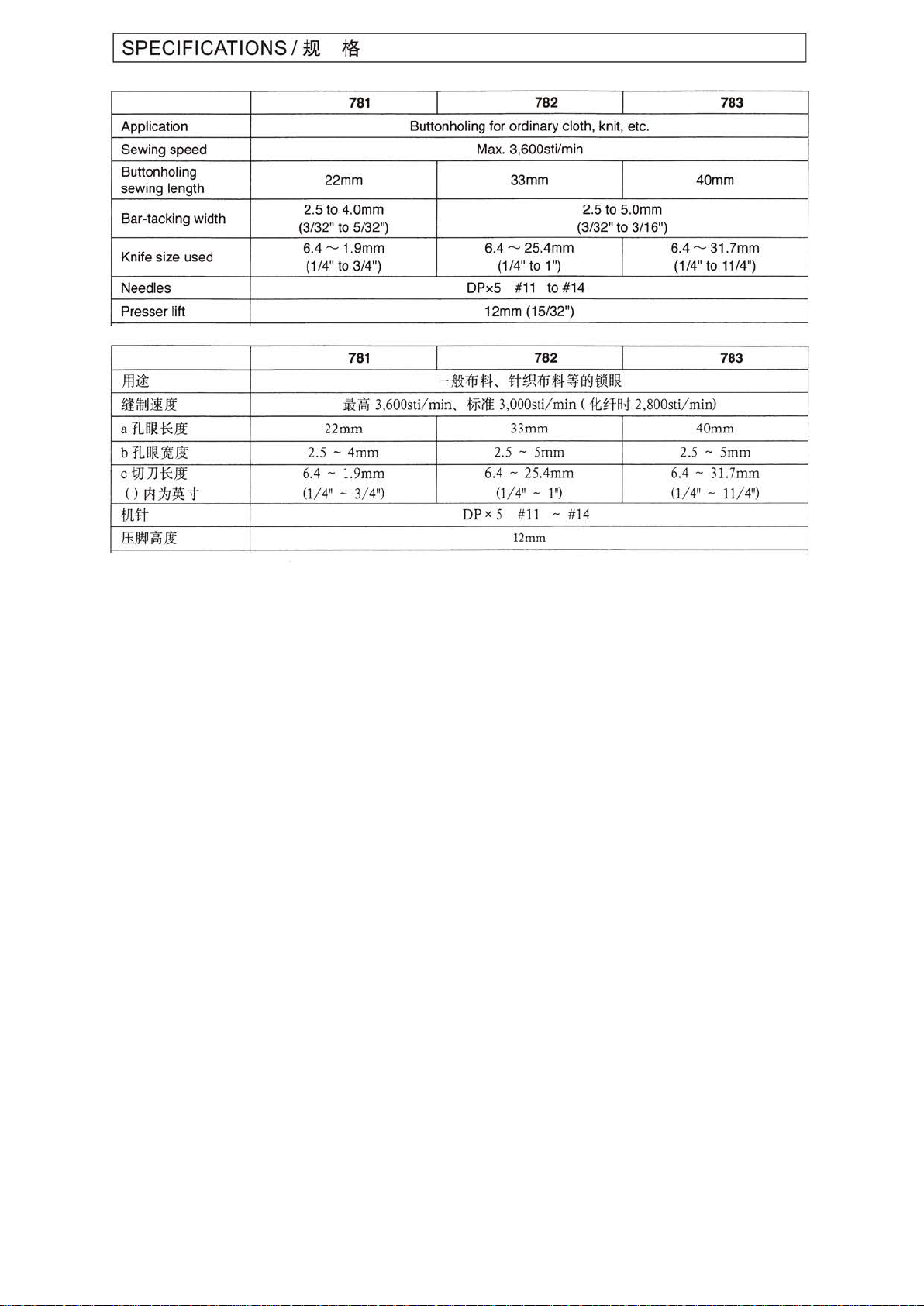

I SPEC

IF

ICATIONS I

~.m

~

781

Application Buttonholing for ordinary cloth, knit, etc.

Sewing speed Max. 3,600sti/min

Buttonholing

sewing length

Bar-tacking width

ze

Knife si

Needles DPx5 #

Presser lift 12mm (15/32")

used

22mm 33mm

2.5 to 4.0mm 2.5 to 5.0mm

(3/32" to 5/32")

6.4 - 1.9mm

to

(1/4"

3/4")

6.4 - 25.4mm

781

J'llii

tJfffirJJ3!lt

a

tLH~*.!t

b

tLH~~lt

cVlJJ*ll

()

1*1

1-J~'t

t!Ut

ffiJJ!P~Jj

ii~

3,600sti/min,

22mm

2.5 - 4mm

6.4

- 1.9mm

(1/

4" - 3/4") (1/4" - 1

-

mt;{jj*4-

.f

;j;

DPx

lfE

6

782

I

I

(3

/32" to 3/16")

(1

/4" to 1")

11

to

#14

782

<tH,q;{ji

.t4

~

3,000st

i/m

in

33m

m 40mm

2.5

- 5mm

.4

- 25.4mm

")

5 #

11

- #

12mm

I

B'HJI!D~

( 1tHat 2,800

14

783

40mm

6.4 -31.7mm

(1

/4" to 11/4")

783

sti/min

)

2.5-

5mm

6.4

- 31.7mm

(1/

4" - 11/4")

Page 16

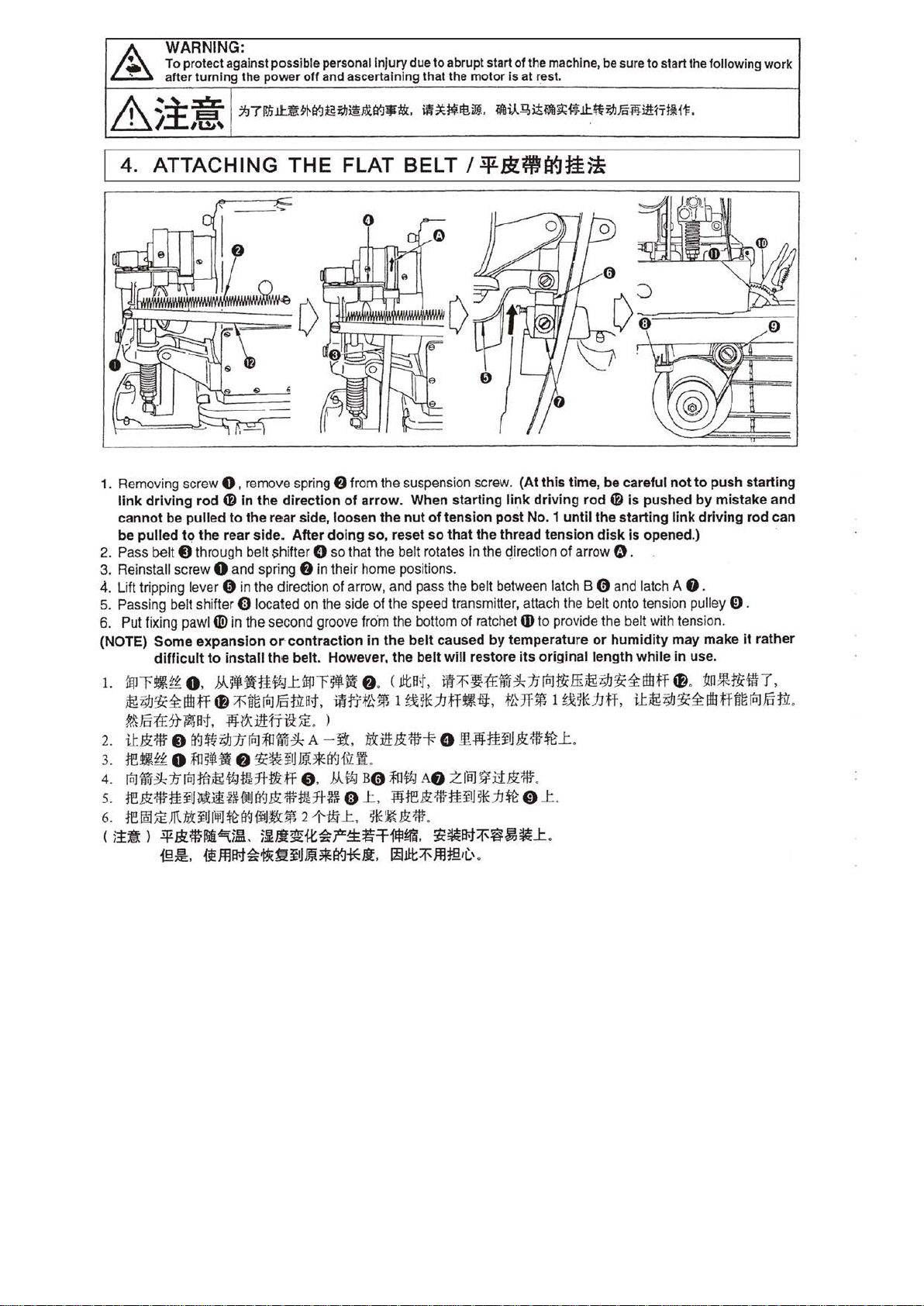

WARNIN

~

To protect against possible personal injury due to abrupt start

after turning

G:

th

e power off and ascertaining that the

motor

of

the machine, be su

is

at rest.

re

to sta

rt

the following work

&

~~:.0:.

/.

l&

~71!Ji.i.l:.iHHt-J~i;:tJ@.6.t((.J.$:,

~

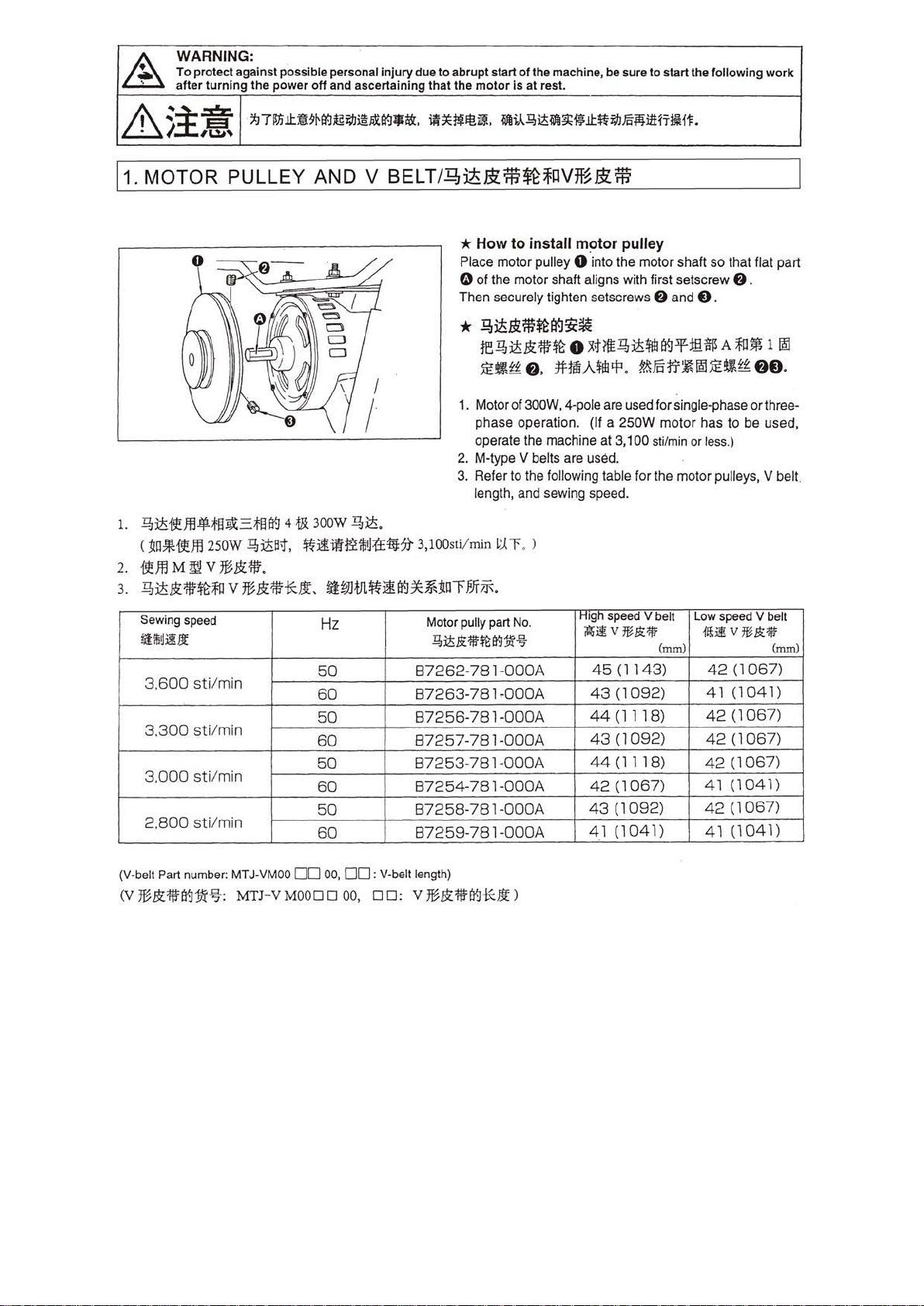

11. MOTOR PULLEY AND V

1.

~~-r!Jfl·;f§~:=;f§B3

( 1to*-r!

ffl25

0W

4lbt

300W

~:itB;f.

~lfil~~tl:(f4ij:?}

~~.

iR~J~It!~.

BELT

/Qdii

* How

Place

0 of the motor shaft aligns with first setscrew

Then securely tighten setscrews

*

1. Motor of 300W, 4-pole are used

2. M-type

3. Refer to the following table

3,100sti/min

~iA.lH~~~~.i.l:.~il!Jm-MnH'Tl~Hf.

&:iW~

~

IlVm&:

to

install motor pulley

motor

pulley 0 ·into the

iW

motor

f)

and

shaft

0 .

so

that flat part

f)

.

.!?!lti&:m~tr.J~~

re~~-•~•~~~~-~~mBA~•~~

):E~zt

f)

, 1HlfiA.rf1.

phase

opera

tio n. (If a

operate the machine

V belts are used.

length, and sewing speed.

~r

.

)

?.&Fotr~!SIJE~H~

for

single-phase

250W

motor has

at

3,100 sti/min or less.)

for

the

motor

f)f)

or

three-

to

be used,

pulleys, V belt.

.

2.

19!Jfl

M

~

V

*••

·

3.

~~--~~v*•**•·

Sewing speed

tiiilitliU£

3.600

3.300

3.000

2.800

(V·belt Part number:

(V

%.1!fi¥J:!Jt%:

sti/mi

sti/min

sti/min

sti/min

n

MT

J-VMOO

MTJ-V

~wm~lf~*••rm~

Hz

50

60

50

60

50

60

50

60

0 0

00,

MOOD

0 00, 0 0 : V

00

Motor pully part

~~Jt1tmtlj~%

87262-781-000A

87263

87256-781-000A

87257-781-000A

87253-781-000A

87254-781-000A

87258-78

87259-781-000A

: V-belt

le

ngth)

*•11fi¥J¥:!Jt)

-781

.

No.

~OOOA

1-0

00A

H1gh

speed v belt

~]!V*.!t'llf

45 (11

43

44 (1118)

43

44

42

43

41

(1

(1

(1

(l

(1

(1

43)

092)

092)

1 18)

067)

092)

041)

Low spee

~ifV%Jt'lif

(nun) (nun)

42

41

42

42

42

41

42

41

d V belt

(1

(1

041)

(1

067)

(1

067)

(1

067)

(1

041)

(1

067)

(1

041)

067)

Page 17

0

*

How

to

install V

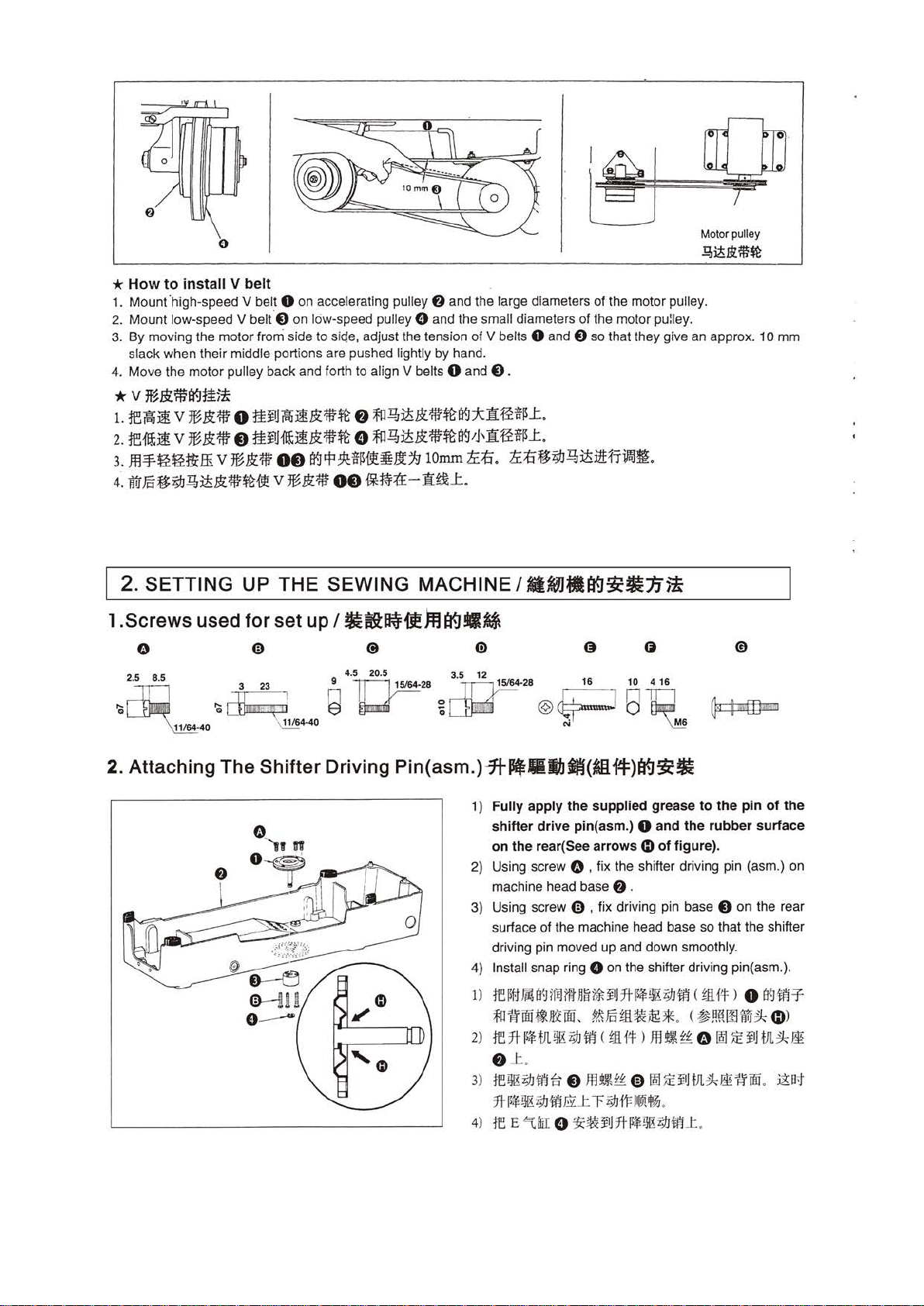

1. Mount ·high-speed V belt 0 on accelerating pulley 0 and the large diameters

2.

Mount low-speed V belt.O

3. By moving the

sl

ack

when their middle portions are pushed lightly

4.

Move

the

motor

* v

~.ftfji

ag

1.

ffl~ji

2.

re-m;j! v %&:111

3.

ffl~

4.

li1IFcf$;1JQ,J;5Jt1!1~~

v

M&:1!1

~ ~.

£rtffi

belt

on

low-speed pull

motor

from side to siqe, adjust the tension

pulley back and forth to align V belts 0

}ti!

0

tti!Jitfij!Jt1f1~

e

ttiJJ{ij;j!Jt1f1~

v %

&:

*

00

89

!fl

:9i!:

v

%&:7W

00

ey

f)

~l?JJ;5&:1!1~89:X1I~~~J:.

o

~l?JJ;5&:1!1~89'J'1I~~~_t.

~~~~It

~M=:(E-1I~L..

9 and the sma

of

by

hand.

and

1iJ

1

Omm

tr:

ll

diameters of the motor pu:ley.

V belts 0 and 0 so th

0 .

1:i

.

tr:

1:i

f$

;1J

l?7J;5iiHrifol~.

of

the motor pulley.

at

they give

Motor pulley

l?!i!.rtm$t

an

approx. 10

mm

2. SETTING UP THE SEWING MACHINE I

l.Screws

0

2 5 8 5 4.5 20.5

. . 3 2.3 9

'a

2. Attaching The Shifter Driving

used

'&

~

-40

for

set up I

~4-

Q

40

~fti~{t)@ag•ij\

3.5

lfl

~28

~

Pin(asm.)-7t~lllbM(iiH4:)H9$:•

12

~

i

[}}D

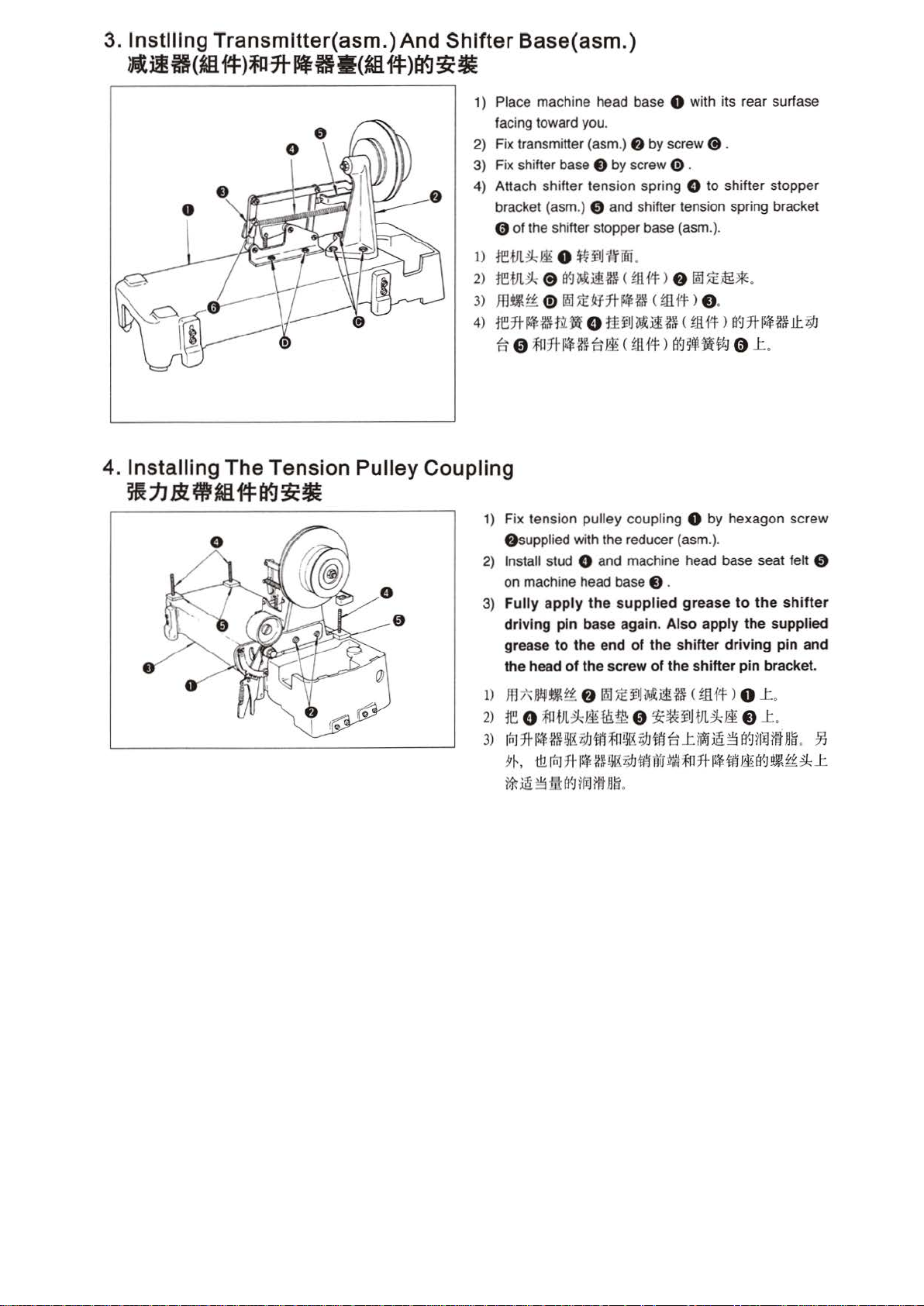

1)

2)

3)

4) Install snap ring

1>

2)

3)

4)

8~MH9$:Jtn~

28

Fully apply the supplied grea

shifter drive

on

the rear( See arrows C)

Using screw 0 , fix the shifter d

machine head base

Using screw 0 , fix driving pin base 8

surface

driving pin moved

16 10

@~Bid

N -

pin

(asm.) 0 and

416

~

se

to

the

of

figure).

ri

ving pin (asm.) on

the

rubber surface

0 .

of

the machine head base so that the shifter

up

and down smoothly.

0 on the shifter driving p

re~u~a9t

~'Itoo~~wL

re

f)

rerJIK;tJlf!~

7t

~

re

f

ilntn~~~IJ:Jt~!MK;IJiJ

?1.\Fo!ll.~~*

::1t

!!*

tllll!Uro

.1:

.

o

rJtK

Z9J

m

EY:

E ~

flii o :t<~~

WI < !11.1!f:

mt~£-£ CDIM~~~Jtll;'k~~oo

_t

r

)Jfl

Z9JtFJ®i 4%.

J7t

~rJIKZ9Jli!JL.

(

!JHt:

· ( ~~~OOTilT~

~

1-£

0

1M

.

pin

on

the rear

in

(asm.).

> o

09iiT-

dD

~

~HJl

.

of

the

>

;'k

mt

)!at

Page 18

3. lnstlllng

Transmitter(asm.)And

Shifter Base(asm.)

l.fl~ft(~f-1:)~71-~ft·(~f-F)tf.J:it.

1)

Place machine head base 0 with its rear surfase

you

facing toward

2)

Fix transmitter (asm.) 8 by screw

3)

Fix shifter base 0 by screw (!) .

4)

Attach shifter tension spring 0 to shifter stopper

bracket (

asm

.

(j

.

.) 0 and shifter tension spring bracket

0 of the shifter stopper base (asm.).

1)

te-tJl~~

2)

rem~

3)

mmx-f:

4)

re7t~t.~tJL~

~ 0 ~lJH~2Hi~

0

$UIJ·IfUfi

Ci

B<J~.!.ilU~

0

m=~~M7t~~

o

.

< ffi.{lt)

c

mft

tt~J~JI~

<

gJH4

>

8

121~it!BIC

> o.

c

mftt

a9~f-~~

.

>

B<J7t

llil!~.IL

0 ..t.

4. Installing The Tension Pulley Coupling

~jJBl.~~f-Ftf.J:it.

1)

Fix tension pulley coupling 0 by hexagon screw

& supplied with the reducer (asm.).

2)

Install stud 0 and machine head base seat felt 0

on

e

0

machine head base 0 .

3)

Fully

apply

dr

ivi

ng

pin base again .

grease to

the head

of

the

the

the

end

screw

supplied

Also

of

the

of

the

grease

apply

shifter

shifter

to

the

the

driving

pin

supplied

pin

bracket.

~

shifter

and

1)

Jtlt\jj!p~£-f:

2>

re

o

3)

inJ

7ti~Mi00:iY

*·

&inl7t~U~~M00.~7t·M~B<JS~~..t

tt-

if!~

f)

~~~J~ilR~

;trHJt~ii

ill:

En.~ 0 :tc~~Jm~~

J

.mffi~HK

;

Mil!

(

i<J

71IJ

rtHI!

.

<

tJHt:

i!..t?iti

> 0 ..t.

o ..t.

~§

B'~tfiJffl

nli

.

;'i'j

Page 19

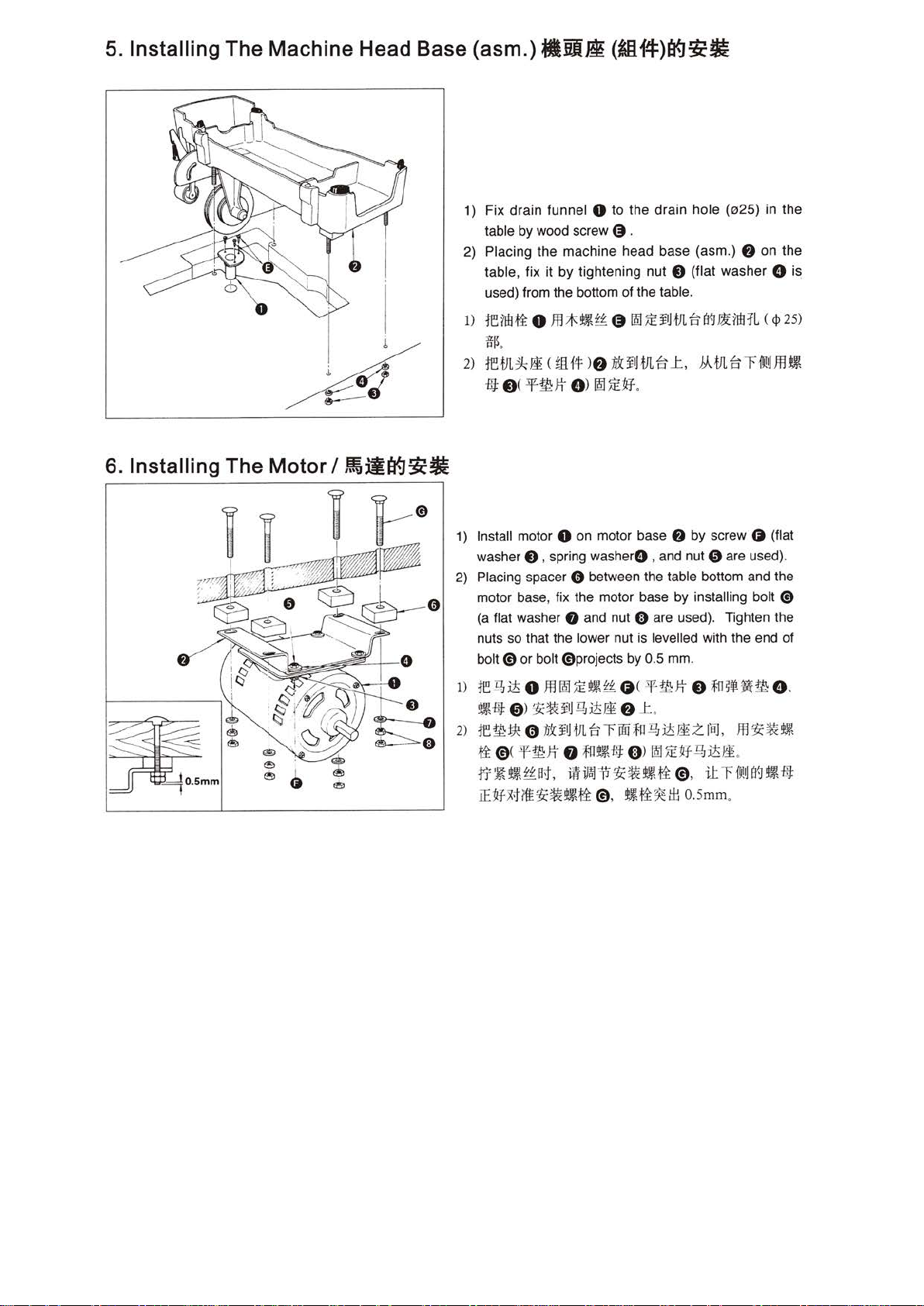

5. Installing The Machine Head Base (asm.) 8DlRl

(llf-I:)B(]gc~

6. Installing The Motor I

1) Fix dr

table by wood screw

2) Placi ng the machine head base (asm.)

table , fix it by tightening nut

used) from the bottom of the table.

1)

rerm.fi

}}~.

2)

retJL~~

-BJ:

e<

,~)lB(]gc~

1) Install motor 0 on motor base

washer

2) Placing spacer

motor base, fix the motor base by installing bolt

(a flat washer 0 and nut 0 are used). Tighten the

nuts so that the lower nut is levelled with the end

bolt 0

ain

funnel 0

o

m*t~z-f:

U.H.f!f:

-'¥-mJt

8 , spr

to

the

~

.

@

f9:1J:E¥1HJL

)

f)

$:¥1JtJL

G)

f9:J

J:E~.

in

g washerO , and nut 0 are used).

0 between the ta

or

bolt 0 projects by 0.5 mm.

dra

in hole

(0

25)

f)

8 (flat washer 0 is

8-tr-.JJl:M:r

~

J:

,

J.AVL

f)

by screw 0 (flat

bl

e bottom and the

L <

ftrfJ!

in

the

on the

<P

25)

IJ

Jfl~

0

of

~

fl+

mm

1)

rei& ito m

~ff]:

0 )

2)

rem*

ti

@(

~-~#~, -~~~··.fi@.

.iEM-Miff~~~.fi

IQI

Ji:!Jlllt-t-

o<

SJZ-mJt

~~¥1JI!.J;)t~

0

nj

¥U

tJL

-'¥-fl!:Jt

0

f)

.t

..

ft r mnn

."f11~-I±J:

@,

.!JJ

(f))

!U!Ji:M-Q,it~

!Jlllti~tl:l

it

e

to~!f!~~

Ji

z

raJ,

m ~ ~

.

ftTOOIY-.J

O.

Smm

.

e,

t~

••

Page 20

3. SETTING UP THE MACHINE HEAD

WARNING:

To

preve

nt

mo

re when the

possible accidents caused by the fail

machin

e is moved.

of

the sewing machine, perform the

/ilktnltifHf.J~-

work

by

two

persons or

i.

Attach oil-drain funnel 0 to the oil-drain section

2. Attach studs

3. Put machine base felt pads (4 pes.)

4. Put the machine base

5. Hang S-shaped metal fitting 0 on starting link 0 attached in the rea r of the mac