Page 1

Page 2

iiEFEJ~8~~~i~~

INSTRUCTION

P1-11

P12-13

P14-15

P16-17

P18

-----

-----

-----

-----

-----

3i~li~~:g~~

~~~~

J.J~~~~~~

~J.J15~~~

tifF~OmtBF.I

MANUAL

&

PARTS

-----

-----

-----

-----The

-----

Parts I i

Assemble

changing

Instruction

LIST

st

of

the

the

adjustment

table

cutting table

of

the

grinding

system

P19

P2o

P21

P22-24

-----

-----

-----

-----

sm111

tt~~m

~)ii*•fm~f.l~

~~~Oi~i~i~~

-----Circuit

-----Caution

-----

c I

-----

diageam

ean i ng & rna i ntenance

Inverter

error

code

Page 3

12

1

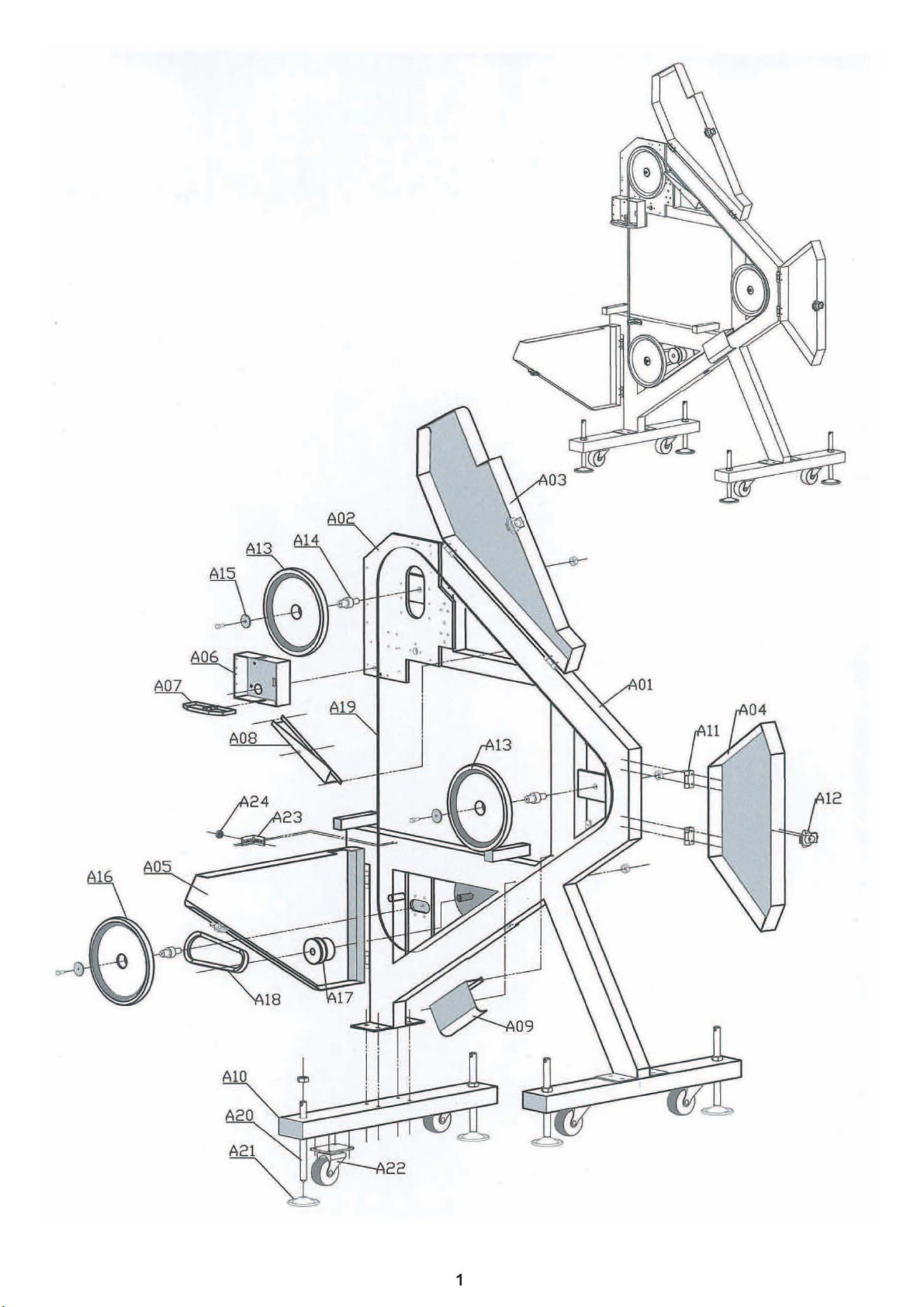

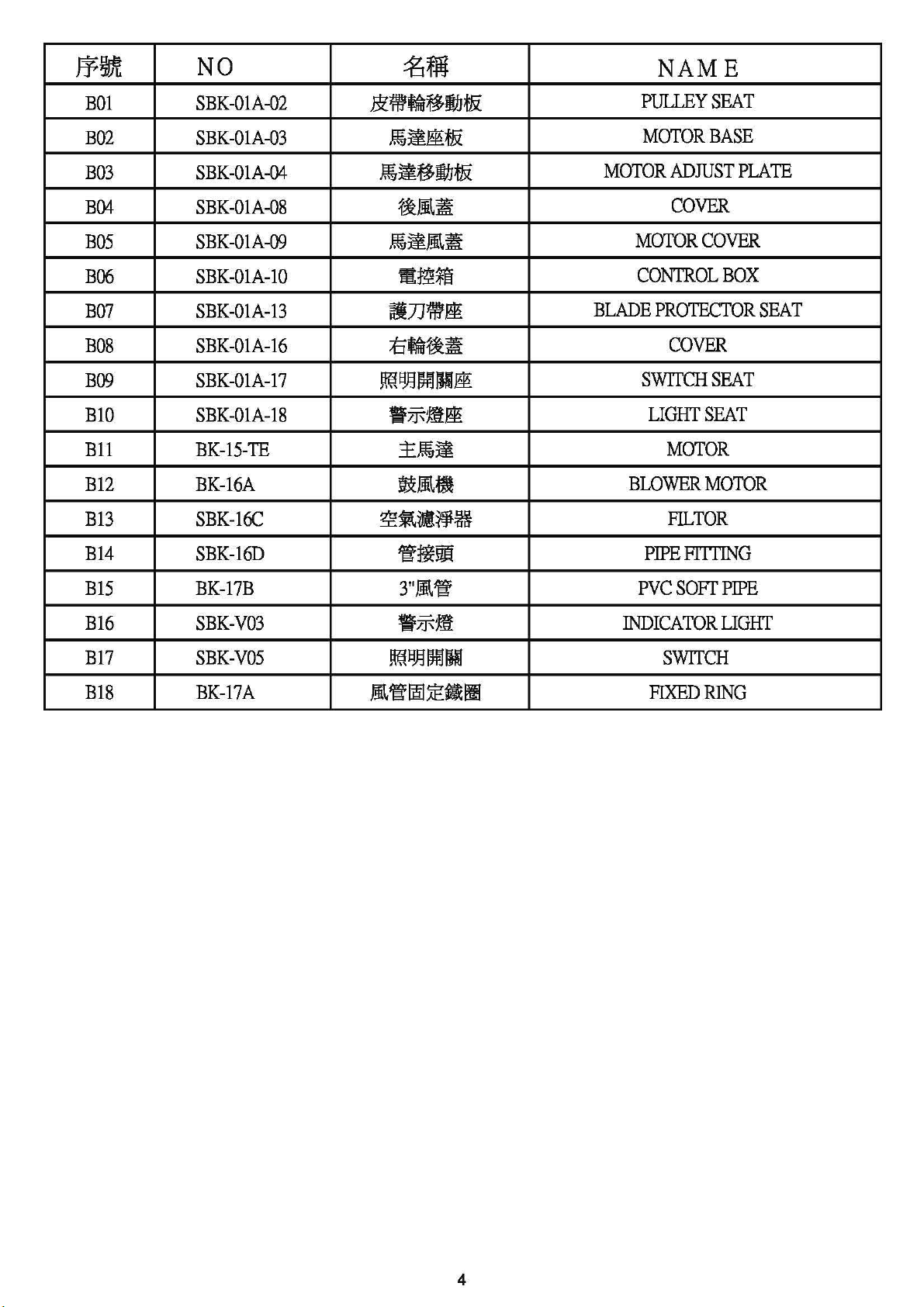

Page 4

P¥~

NO

i]fi

NAME

A01

A02

A03

A04

A05

A06

A07

A08

AOO

AlO

All

A12

A13

SBK-OlA

SBK-OlA-01

SBK-OlA-05

SBK-OlA-06

SBK-OlA-07

SBK-OlA-11

SBK-OlA-12

SBK-OlA-14

SBK-OlA-15

SBK-OlA-19

SBK-OlA-20

SBK-OlA-21

SBK-20

1t~

l:ltt&

1:&~

till.~

~&~

IJ7J5~

-~;fi

7J~l:~;f&

7J~~~tM

JJ§P~

~-

m1o

7]~-

FRAME

UPPER

COVER(DOWN)

GRINDING

SAFETY

SAFETY

FOOT

DRAW

FRAME

COVER

COVER(R)

GRIT

(UP)

BOX

TRAY

PLATE

PLATE

STAND

HINGE

LATCH

PillLEY

A14

A15

A16

A17

A18

A19

A19A

A20

A21

A22

A23

A24

SBK-20-1

SBK-20-2

SBK-21

SBK-22

SBK-25

BK-04-3500

BK-04-3960

BK-32L

BK-33

BK-34

BK-23

BR-11

-fltf

-~ml~

.Rif17J~-

&:tR'f-

&:~

7]~

7]~

Jmll~:m•c~)

m••~

:f$1f1.

rnn~f:~lfifc~

608!ffifif\

WHEEL

BEAR

BELT

LONG

SOLEPLATE

MOVING

BEAR

AXLE

CAP

PillLEY

WHEEL

BELT

BLADE

BLADE

SCREW

WHEEL

SEAT

BEAR

2

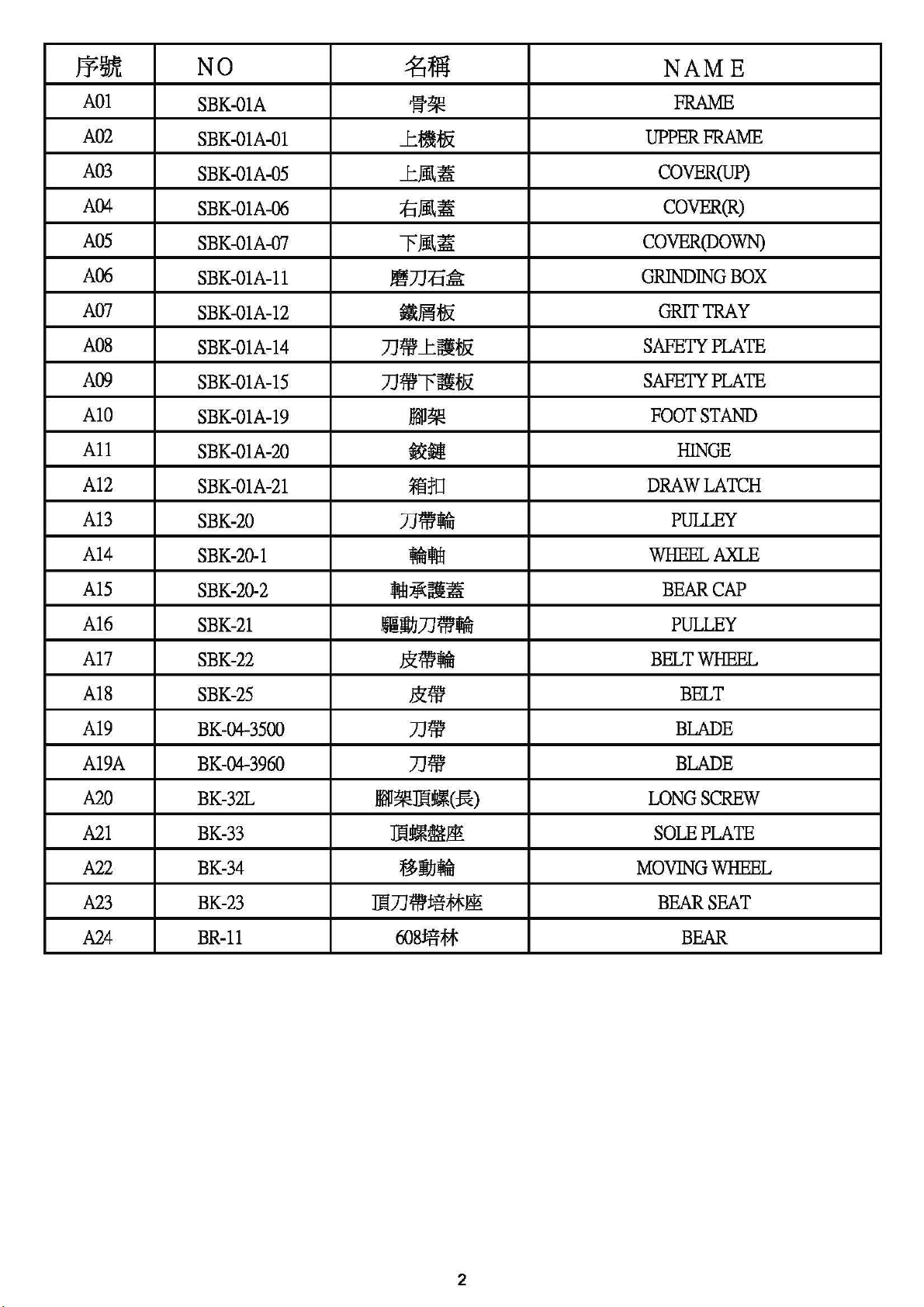

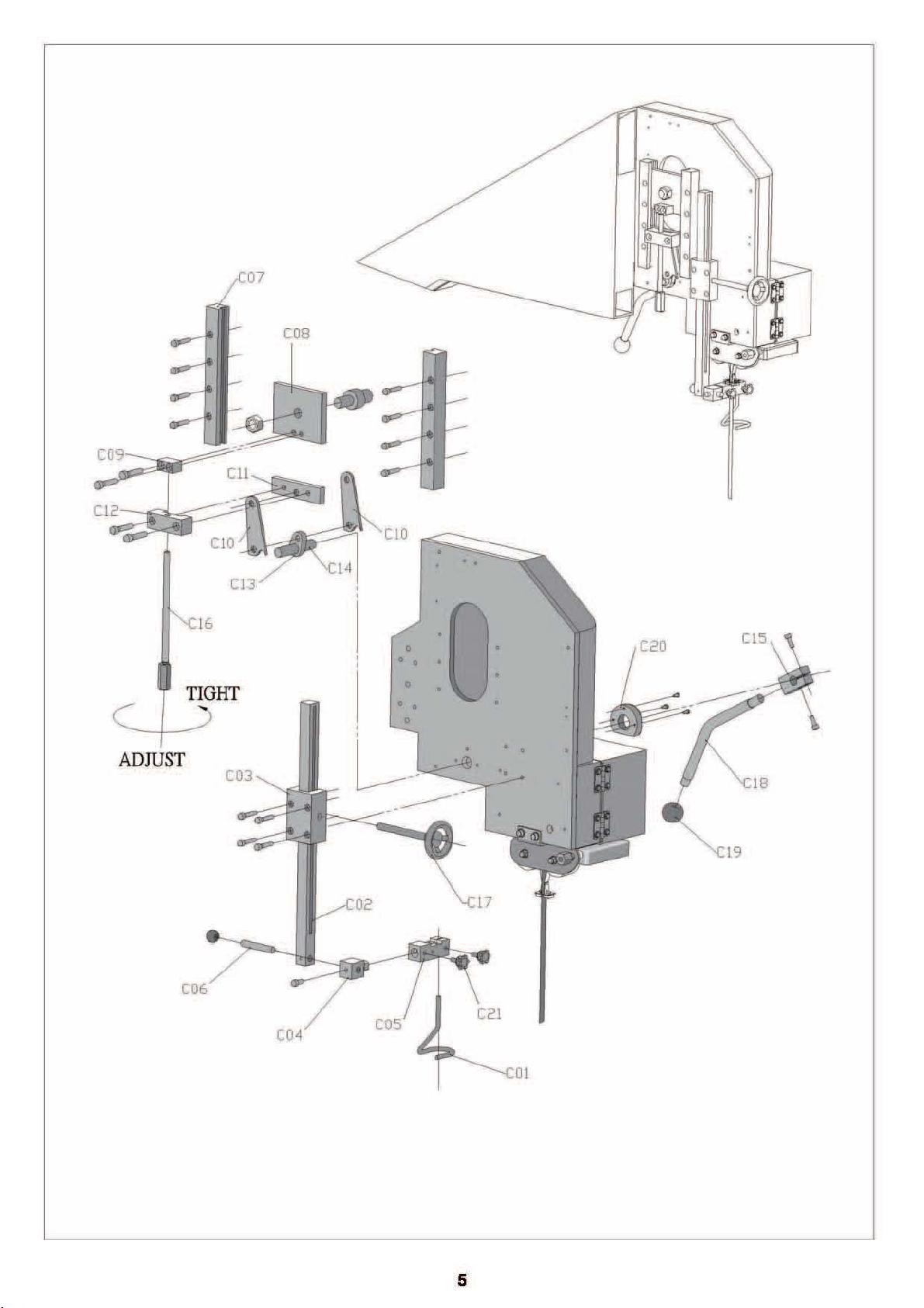

Page 5

3

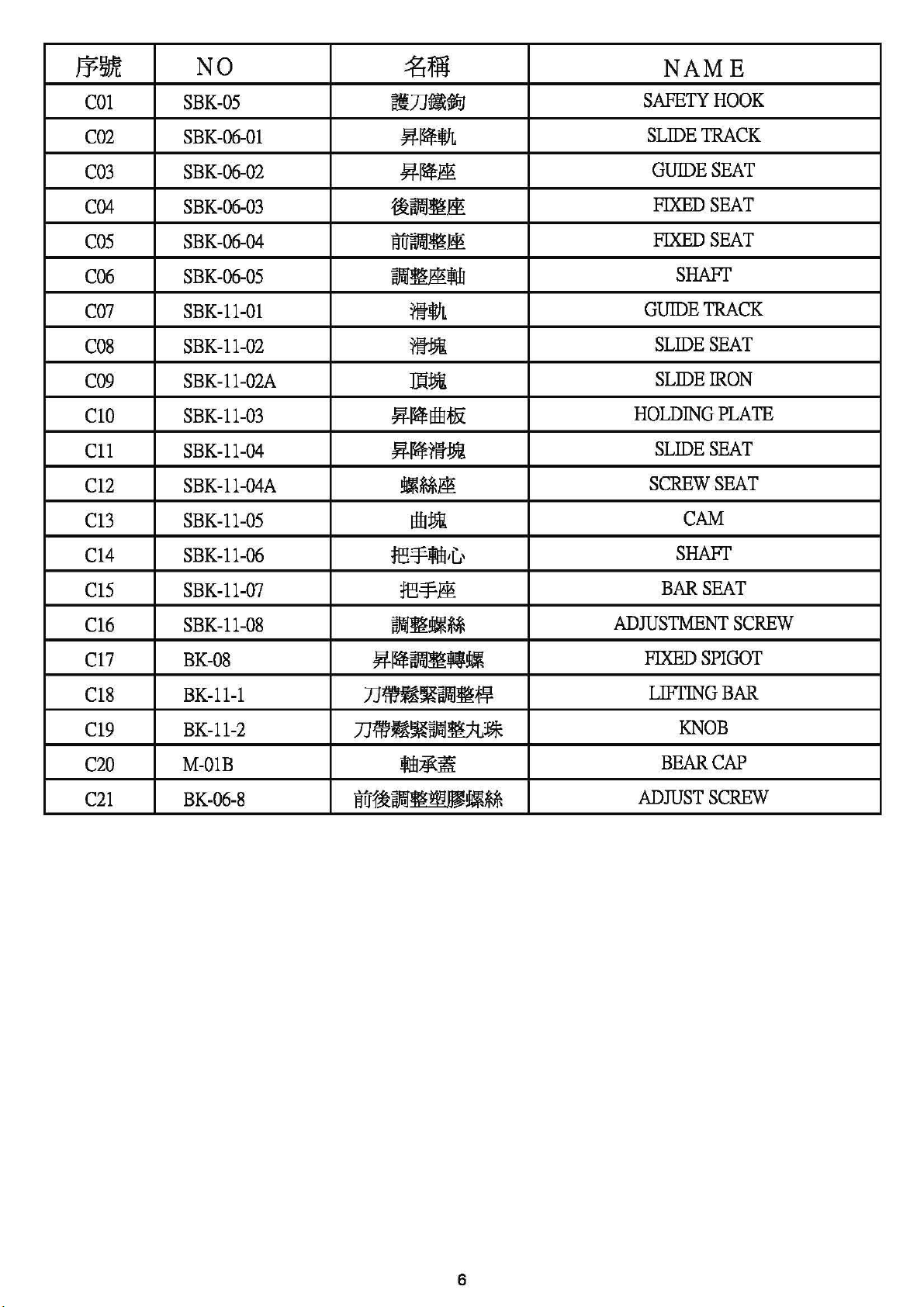

Page 6

P¥~

NO

ijflij

NAME

BOl

B02

B03

B04

B05

B06

B07

B08

B09

BlO

Ell

B12

B13

SBK-01A-02

SBK-01A-03

SBK-01A-04

SBK-01A-08

SBK-01A-09

SBK-01A-10

SBK-01A-13

SBK-01A-16

SBK-01A-17

SBK-01A-18

BK-15-TE

BK-16A

SBK-16C

El~~f$!1flif&

~~J~Ji

~~f$!1bt&

1&/lt~

~~Mt~

-~~

~n~m

:ti~1&~

~~~IHJ*

BLADE

e7]\mm

~~~

~Mt-

gg~-~~

PUlLEY

MOTOR

MOTOR

MOTOR

CONTROL

PROTECTOR

SWITCH

LIGIITSEAT

BLOWER

SEAT

BASE

ADIDST

COVER

COVER

BOX

COVER

SEAT

MOTOR

MOTOR

FILTOR

PLATE

SEAT

B14

B15

B16

B17

B18

SBK-16D

BK-17B

SBK-V03

SBK-V05

BK-17A

~~~

3"/lt~

e7]\m

~f!J31m!HJ

lt~lril~-~~

PIPE

FTITING

PVC

SOFf

INDICATOR

SWITCH

FIXED

RING

PIPE

LIGIIT

4

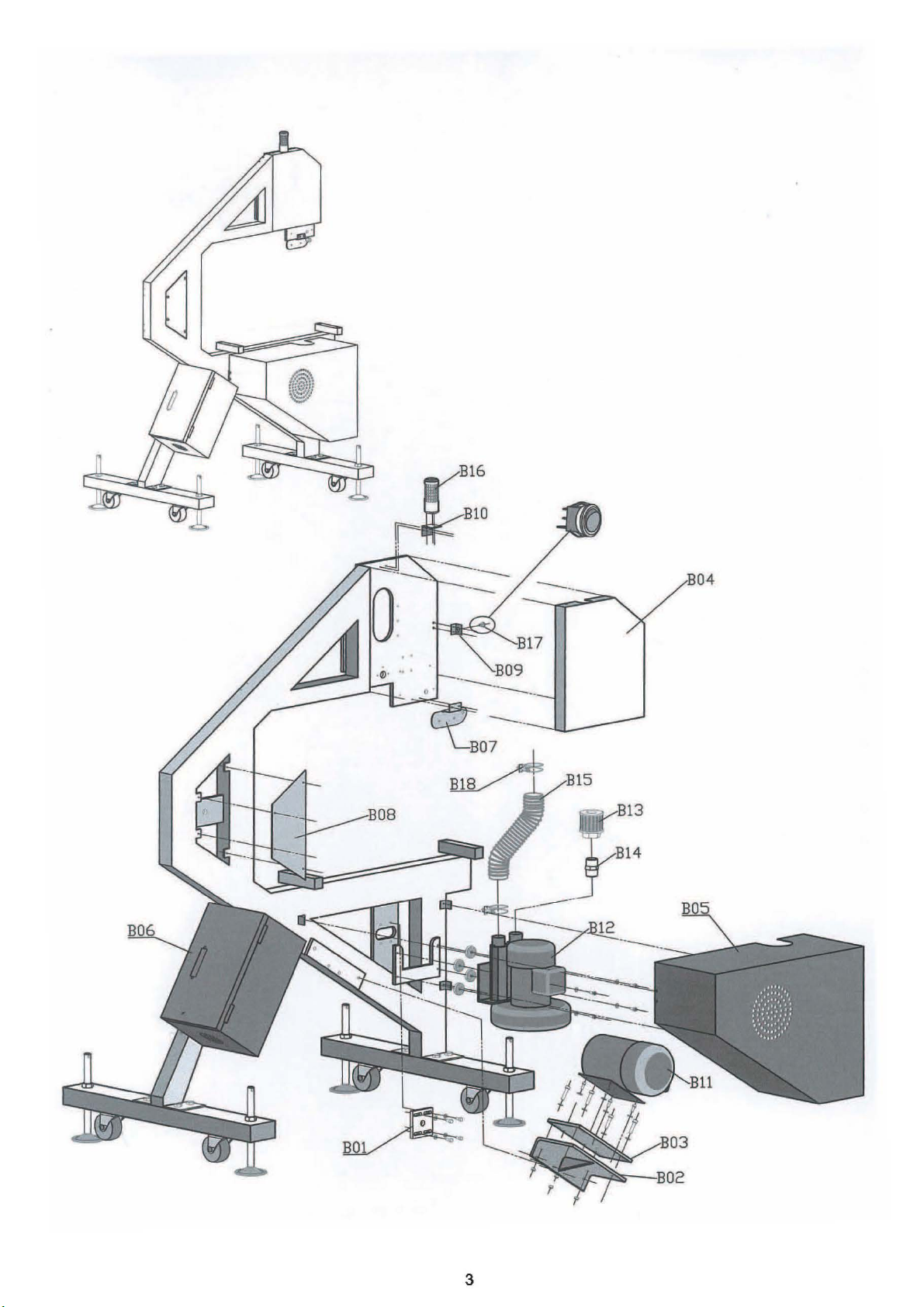

Page 7

ADJUST

C06

TIGHT

[04

01

5

Page 8

F¥~

NO

ijM

NAME

COl

C02

C03

C04

C05

C06

C07

C08

C09

ClO

Cll

C12

C13

SBK-05

SBK-06-01

SBK-06-02

SBK-06-03

SBK-06-04

SBK-06-05

SBK-11-01

SBK-11-02

SBK-ll-02A

SBK-11-03

SBK-11-04

SBK-11-04A

SBK-11-05

~JJitJY

n~fli.

n~~

~13~m

~u~~m

13~J*$11J

mfli.

~

:rnWi

:n~a±Jt&

:n~~

•**~

I±HWi

SAFETY

SLIDE

GUIDE

FIXED

FIXED

HOOK

TRACK

SEAT

SEAT

SEAT

SHAFf

GUIDE

SLIDE

SLIDE

TRACK

SEAT

IRON

HOLDING

SLIDE

SCREW

SEAT

SEAT

CAM

PLATE

C14

C15

C16

C17

C18

C19

C20

C21

SBK-11-06

SBK-11-07

SBK-11-08

BK-08

BK-11-1

BK-11-2

M-OlB

BK-06-8

~-'¥$liJILJ'

te

-'¥

~

13~91**

ADWSTMENT

n~Wl3~"•

JJ~~~Wt3~W

JJ1r!f¥~~wm~:tt~

qiffi*~

fri~~~~-**'

SHAFf

BAR

SEAT

SCREW

FIXED

LIFTING

SPIGOT

BAR

KNOB

BEAR

CAP

ADWSTSCREW

6

Page 9

7

Page 10

rr;~

NO

i5W

NAME

DOl

D02

D03

D04

D05

D06

D07

D08

D09

DlO

Dll

D12

D13

BK-28-1

BK-28-2

BK-28-3

BK-28-4

BK-28-5

BK-28-6

BK-28-7

BK-28-8

BK-28-9

BK-28-10

BK-28-llA

BK-28-12

BK-28-13A

P!JJE~

-(j/~\7\:fEJ!II-@

®/~\~

{ij}J~\~~¥-j!

~~~,~~¥-l!:tL~

tr:~~(~)

tl~~(~)

tr:~/~\(1£!f)

tl~~~'(IE!f)

B~608f€H%

~~-*'*

IDm¥-l!!ll*i

iNIDm~!m5E:W

ADJUSTMENT

GRINDING

SHAFf

GRINDING

CAP

SHAFf

GRINDING

BAR

KNOB

ALUMINUM

ALUMINUM

FIXER(L)

FIXER(R)

SHAFf(L)

SHAFf(R)

BALL

BEARING

ADruSTMENT

FIXED

SCREW

IRON

SET

BAR

BOLT

SEAT

D14

D15

D16

D17

D18

D19

D20

D21

D22

D23

D24

D25

D26

BK-28-13B

BK-28-14

BK-28-15

BK-28-16

BK-28-17

BK-28-18

BK-28-19

BK-28-105-GE

BK-06-8

NUT-M8-13

NUT-M8-13L

lli-M6-30

K-27

~IDm~!m5E:W

iN~~~-**

~~•m

~Wffl~

~~~

~~M~

~~~HI!

:ll(

-

ADJUSTMENT

r:rmnE

~~:m~•**

M8!flm

M8!flm

M6!11*-*

M7JE~J3.x¥-l!

IRON

ADmSTMANT

ADJUSTMENT

SPRING

SPRING

STEEL

RUBBER

BALL

RING

GRINDSTONE

GRINDING

SPIGOT

COUNTERSUNK

COUNTERSUNK

SCREW

HOLDING

BOLT

SEAT

SCREW

NUT

D27

D28

D29

D30

D31

D32

D3

3

BK-07

SBK-V06

SBK-48

BK-37

SBK-10

BK-lOA

BK-lOB

~7J~ii

LED~~~jf

=Bftm

=BJ€

lti£:11~

m.~

~-

~-

8

BLADE

PR01ECfOR

LEDUGHf

FELT

FELT

GRINDING

MAGNET

HIN

SEAT

BOX

GE

Page 11

EOS

E.lB

~

T

02

9

Page 12

ff~

NO

::g.w

NAME

EOl

E02

E03

E04

E05

E06

E07

E08

E09

E10

Ell

E12

El3

BK-01A-403

BK-02A

BK-02-1

BK-02-5

BK-03

BK-03-1

BK-12

BK-13

BK-14

BK-17B

BK-17C

BK-18A

BK-24

ll!ti5Efrj~

~t&

ll!ti5E~f&

~H~~

~Ml~

~H'ellll!ti5E~

~ti!il~~

3(~~~1'*

~1'*~*'*

3''~~

~~ll!ti5E~~

A_~U~

~f&ll!ti5E~

SCROW

SCREW

TABLE S

RUBBER

TABLE

LEG PLAT

ROUND

TABLE PLAT

FOR

P

VC

FIXED

BLO

WING

FOR

ETTI

NG

IRON

TABLE

PLATE

PAD

LEG

E

PLATE

E

TABLE

SOFT

PLATE

PIPE

RING

MOUTHPIECE

TABLE

HOLDING

E14

E15

E16

El7

E18

E19

E20

E2

1

E22

E23

BK-30

BK-30A

BK-31B

BK-31Y

BK-32S

BK-25A-1

IH-M8-65-F

NUT-3/4

BK-33

BK

-25-

2

m~~

~:3~

:±.m~moo~

~i~~oo~

HflP~JJ!~<~lD

~~~~1'ff&

ll!ti5E~**

7}7\frj~$§1

JJ!t"fi~

m•~t~*JR

SWITCH

N

AMEPLATE

KNIFE POWER

AIR

SWITCH

LEG SCREW

CONTROL

SCRE

WOOD

SCREW

SOLEPLATE

TRANS

MISSION

BOX

SWITCH

PANEL

W

CABLE

10

Page 13

Jr;~

NO

~f.lij

NAME

FOl

F02

F03

F04

F05

F06

Fa7

F08

F09

FlO

FDI

BK-19

BK-25-2

BK-25A

BK-26

BK-38

P-71A

V-03

V-03A

V-03D

SBK-V04

-A

L__j

7H§~'maNiJJE:SiKSS

'm-~~~CAT-5E

~!m~~

~U$'m~Jl~±TK80W120

lnJ)E~ilffij-Tfi6P

CrJ?ll~~

~~f*lfh*>*J*.

~~f*lfb*>*.t.~mm

f*~if*'

±INV

125-250VAC

TFB-10110A

lOA

FVR1.5E1S-2J

x1~TB25-6

AG-20(~

2*

10A(220V)

lP

TFB-ImiOA

@.)

8*8CMJ$1JjAC220V

TRANSMISSION

INVERTER

RESISTER

TERMINAL

EMI

FILTER

COMBINATION

FUSEBWCK

FUSE

BLOCK

FUSE

FAN

CABLE

BLOCK

COVER

lOA

FOI

F04

F05

II

~

f-------

~

I

-

F02

l

I

F03

-

1--

-P

;

FAN

~

oo-

+FlO

F06

KEY BOARD

I c:=:J

000

~

r

000

I \

ooo

\

El9

F07 F09

~

~~

I

DO

L

___

~E-1

FOB

~

~

_ j

9

F-

02

E-

16

11

Page 14

12

Page 15

j.

~&

~ * #

~~~

-t}t

E}i

1

2

Table

#~~t~(E02ff}JE!"J~tEz]~J)£~(E03)9=J~~\fL{lziJ~~~~~JE~~

ti::H'!f2f4~Ps~~**(E20)~~~

Mount

the

table

#~~!JW(E05)~~~~!JW~5EJ*(E06)

Mount

screws

asc::em

the

cutting

with

bolts

two

table

legs

(E18)

into

table

(E20).

(E05)

sole

bly

by

aligning

fixed

plate

(E22).

procedure

a

the

tapped

,

~#~~P~Jj~~(E

beneath

the

holes

table

of t

he

table

18)1DCAJJ

by

screws. Then

**(

E13)

line

rs

(E03).

U~MJ*(E

put frame

'

illUf:2

Fasten

22)

hold

ing

a

3

4

5

#~~

rg(E 1

(Ell) a

Slip the

hose

clamp

{R~~?JTW:

Adjust

#~OO~~(E14)~5E:tE~~t!T*~Tift#~~~~~t~*

Attach the swit

cable(E23)

O)~t~f~~~~~f~(B

blower

long

hose

(E1

0)

onto

(Ell).

~

Jj]JWJ~~P~Jj~~(A201StE

and short scr

ch

box

into

control

ew

(E

14)

panel

(A20&E

to

12)1St~ti

the

the

cutt

(E19).

air

mouthpi

18){£

18)

to

ing

J\~O~(E

ece

~t&ZfS~

prop

er

table, and plug

(E

12)

tight.

12)

)7

TIE~~~~

and

fasten the hose with

a

~(E23)t

the

connector

rg~)£~

~

_t

a

of

contro

l

a

13

Page 16

Al9

Cl7

Al.3

.

Cl6

A07

C16

ADJUST

D22

~

-

_CCil

14

Page 17

Installment

l

1m

:tc~~~~(

or

adjustment

E08

)lUl"-f

for

new

o

knife

Remove

lm~7JEif.lm~!l!!«~:l&~(

the

table

plate ( E08

).

D22

) •

:MLimM7JE

2

Unscrew

Jmn~~~f$!11!«(

the

plastics

screw(D22)

C17

):!&~ • lm'ifi7Jt.f*ll7T¥Ufi~t&~M~Im~

and

take

off

3

Unscrew

im-~~(

the

bolt ( C17 ) and

A07

)&7Jt.fifiS1J(

rise

up

the

COl

knife

)lf5ltB

4

Take

out

the

grit

tray ( A07 ) and

safety

wire ( COl

the

grinder

guide

if.(FOl)lCil"-f

assembly(FOl).

to

highest

o

).

o

o

position.

im7JtffiJ~~~m:fll!(C18)ftlf

f

)E • fj!7JtffiJ.(Al3)~"-f

5

Press

down

the

Jm~

7J

1/W(

A19~A19A

adjustable

driver

of

knife

tension

):t&:tE=~nlflfljj~IJ$00

(Cl8) to

6

Mount a new

f!:lt7J1/W(

knife ( A19

A19g\GA19A

or

)~~ • :ML~g1J1Ef$7Jtrf~m!i!!«**(

A19A ) ride

on

three

pulleys

7

Test

the

f&!{ijm

knife ( A19

1-4~tv.w~m~JJ.i

or

A19A)

tension.

~

#t&n~F¥~§1

..

8

Install

by

step

1 -

step

4.

o

lower

•

:MLJm

7J

and

pull

the

knife

wheel

tfW~~~(

up

the

C18

driver ( C18

C16) o

(A13).

)rtiJl:iii

o

).

15

Page 18

* * *

* * *

16

Page 19

X

X

0

1

2

3

~]]~

l!f7J~Ilfli!~(D22)t&Ji

Mount

~=ilrr&ruW~n~l«~<Dtt> , ~JJE<D2t)

~gfm~~¥TJ7Jf/1(A19~19A)

Adjust

grinder

1E~lf7Jf/1(A19~19A)}J~Jmtl~il

See

the

grinder

the

screws

stone

attached

(D21)

for

adjusting

system

of

touch

-~·1J!l~!Y~1>t~

Grinder

t

holding

grinder

(D11)

the

the

knife

knife.

:i&A.J!!7J~If.~(D26)~~

(D26)

o

to

correct

(A19

Wheel

and

screw

position

or

A19A).

it tight

to

let

o

the

0

17

Page 20

#h

1-'F

ffi-

~lftl

~

aJl

Instruction

~5felil;xE*$t~f.£AC220V

1

Make

sure

the

voltage

~J.E:$;t&{IDJjfi¥J

rr-RUN

2

KNIFE

RUN

STOP

~~J!~~~1'Fmrt&_ti¥J

~m

3

A

V

~1'F00t&..t.

4

FUNC/DATA

key:

key:

w v

key:

key:

.n

l'iJ-at!7J1f{¥im$$

key:

Connect

Start

Stop

.n

m~1J£7J~~gr

Increase

Lower

the

IT"RJNC/DATA.n

key:

is

rr-KNIFE.n

the

the

knife.

the

knife.

the

speed,

speed,

Select

•

ML~m$t*~H~¥U~m*-*'lmiBI

AC220V,

•

connect

~il:(E-16)

~}E

w

STOP

the

•

.n

power.

w A

.n

ll!mffl1Jonm~gr

,

ftfWJ{$

maximun

minimun

ampere,

to

60HZ.

to

OHZ.

J1Jfj~-1U11J~7J\~

power,

or

power

fj!;tt:'M$t~A.~~B

l'iJ-at!7J1ff¥W

o

HZ

voltage.

0

wire

to

Jtim$$ o

•

ft~~$

§ •

•

fJ§~,~~~~_t

NFB

and

'WJJtlD

: 3(!tf

connect

•

¥J~IE~B~1'Pttl.l¥1

6oHZ

~

:W$

the

0

o

ground

~

~

wire.

...

~

o

LED~~!ij~,~JHt~m

s

~umJ~C

Press

~m:$;t&{IDJil®

6

AIR

fabric

~fT'mlml:trJ*4~

7

Put

0

KNIFE(E-16)

key

(E-17):

can

be

moved

the

knife

guide

Turn

rr-

KNIFE.n

first,

and

press

w

AIR.n

lightly

•

m!~~nm*Mmr~m~m~woo..t.

on

~<E-17)

on

the

blower

on

the

the

fabric

when

~(E-16)-at!;tt:'ClJj~

LED

lighting

m~nm~~.

and

air

layer

control

is

formed

switch

,

¥J~mLED~I!I3~fliU

(B-17)

~*t~~:n~-at!:trJ*4~tJJR

between

to

control

fabric

and

table

table.

0

cutting.

kEY BO

AR

D

I I 8

@ @ 8 E

-1

® MS

the

9

!m

!IIJ(B-17)~

light.

0

~

~

surface

so

that

the

E- 16 E- 17

I<NIFT

18

AI

R

Page 21

~~~lll

.....

co

p

OwER

NFB 5

?+

220VAC

10

N

L

Gl

'+-

CIRCUIT

~

DB

l 1

Pl

r--------~

FUJI

RJ4

DB1

lfG

DB

~

L1

L2

30220VAC1

KN

IFE

F

USE

10A

~~~±=====Lll

L

lP

h

Pl

L2

FV

R-EllS

1.

5KV/ - 2HP I I

CONNED

l

P<+ N<-

L3

N

:~V

H Ml G n

MOT

OR

TOR

u vi

v;

JGl

v;

p S

~

____

DIAGRAM

KEY BOARD

- _

KNI

L2

""'

_I.LT-'1

~========J_Jl~--_j~

CICCI

0 0 0

000

FE AIR

wl

1--

L1

~

......._,..r--

N Q

Sw 2

~

......

o-

~~

L3

t-...tJ-+-~

Sl,/3

1r~~~

"t--

L4

..

o

\:

L3 N _

~

NF

r

Lll

L...---

___

l N

L.

I N I

l

0.----J

_____A,'---'0-

~

L.

1 I T N AIR M

I

T

['-----1

2 N lu

......

l-;;1

1022o

vAc

OTO

R N,,_._

l M 2 F A N

L2 G

·~~

-

l?.:-.--~

~~

~

Page 22

Specification of

Band

Knife

Cutter

~~~Model

BC-700 BC-900

I 1'Ffiiiilifit Table Size ( rnn) 1800x1500 2100x1500

Ifl:fli'&Hl(1iJ~)

Table Height (Adjustable)

W~ArmSize

BJH~~

8ft~-

~-R.

'f

§~R.

JJ

Minimum Width

Machine

Machine Gross Weight

Complete Set Dimensions (

'f"Packing

1JRi

R.

'f

Knife Size ( rnn) 3500xlOx0.45

JJ1Nlif!Jf.l~/j\J[}i

fli!Jf.li'&JI

~~Voltage

!m$

ii:;ktJJ!!!itl/¥HfMax.

~~~~fM

Speed Control

11!1Jf.!M£

Drive Motor

The

applicable restriction

(Frequency

~M.~ii

BitJJ:ffi~

~Jl:ffiflBitJJ~RtiJ

(rnn)

(rnn)

Net

Weight 240kg 260kg

700 900

381kg 428kg

rnn

Dimensions (

of

the

Knife (

rrrn)

Available Height

rnn

)

)

2210(L)x1500~x1720(HO

1670QL)x970~x20800H)

¥m

Frequency

cutting thickness ( rnn) 180

< 1iii'!l)

(Variable)

(tiM)

Conversion)

Blower

Motor

Available Fabric

of

the

special fabrics

CD

fi!1'14-ff:ffi2"

® fii1'11J1Bl4'itl1'il2"

@

fi!miJIBll"

@

IDVCBll"

®

fi!~

PX.Bll"

H :

j..j,J:.filf~fi!WflitJ

j..).

j..).

j..).

"'F

0

.......

=m

-~

-ltittt6,lX1i!JZii:ffifl

General Knitted, Woven Fabrics

j..).

"'F

o Rigid Jean below

j..).

"'F

"'F

o Rigid Plastic leather below

o Rigid PVC leather below 1" .

"'F

o Rigid synthetic leather below 1" .

o Note: All

850--950

2490(L)x1500~x1720(HO

2270QL)x970~

3960x10x0.45

2.5

8"

Single Phase 220V AC± 10%

50Hz

.......

60Hz

1060 m/min (

Q.-..60

Hz)

Three Phases 220V I 750W

Single Phase 220V I 180W

2"

.

o Rigid rubberized non-woven fabric below 2" .

I"

.

of

the above has turning restriction.

x 19400H)

~11=1Jlt

Bc-1oo1

• o

31b.&ti1lM

9oo~

~u

t~fl:elt~:MMBtJJ

MtJJ:ffi~"'F:n~~t•-~m

o

1'1l~

.-fJe~n:~AAtJJ!!!iu

JJ11MiiJ..;i.BitJJ~HI1Pfl

The major operation mode

of

all,

move

the fabric along the template shape

Operation Mode

cutting pieces. First

desk

after air flotation motor

locate

it

and

then

trimming for small fabric; moreover, it

fabrics.

"f=

~

lf:Ultlft'tffiJ ·

1

Lower

the

knife

~tey~~lf:Ultlf~·~~-~~-·

2

Disconnect

~ffl~~~W~·li'R~-~~H~m~M·

3

Press

I~A~~ffl~IT~ffiJ·~~~m•w~~~·

4

It

is

the

reco

mmended

the

power

power

Ji'ROO:lii7Jtmmt.&¥U®~H~:!ii:!;OO

guide

down

to

the

table

supply

to

put

supply

button

on

cable

from

off

if

stainless

the

stee

surface

power

the

outlet

l mesh

for

if

supply

gloves

safety

the

cutter

is

interrupted

for

,

i¥3E.A~~7Jtm~h

.

is

safety.

!!!itl,Ml!!iD

I

.mihll$!¥.~ilm

J:.n~aJ..;I.•Jt~fil!lte~:AE'lllfli!ltJJ

o

JJ:ta~{g,1iJf«MB'J'1'il~•:iE((.JflfttJJ!!!itl

o

of

BC-700/ 900 series,

put

a paper

under

started.

By

the way, a

can

~

Caufun

attaching

the

fabric to

mo

adjust tbe knife rotation s

F'i

~

LED ligb.t in cutting

make

the fabric move

ld

or rigid template

by

hands to

.±

• M

PM~•

I

uetJJ!U:ffifl~:ON±~iiDJ:

•

is

needed

cut

This

peed

to fit

J!J

Iii

mn¥~

~

fijj..j,

~lb31h1'il~

I

JJ:t9~~1iJ&fj•

area,

is to fine cut smal

and

on

model

tum easily

the fabric

can

for

on

to

also do mien

cutting

varioUJ

thl

we

•

not

being

during

operated

operation.

for a long

period

of

time.

20

Page 23

~mm~~~oo~~~~~~~~~~~·~•~BI~%-~m~o

1

Remove

cloth

waste

on

the

table

at

regular

intervals.

~mm~•~~<A-07)~~~-~~~oo . ~•

2

Remove

JEm~1!t+e~<D-3o),

Clean

3

Change

5Emm~~~-1J~<B-13)<~P9M,

4

Clean

Change

jtlfUl7Jttf~?*~lf.f

1

If

l.:ft1!t·~~S~AC220V

Check

the

grit

the

felt

it

if

the

air

it

if

knife

the

from

the

(D-

30)

extremely

filter

and

extremely

is

damaged,

voltage.

grit

tray

once a week.

m~r5t5&~1Jn~na.

and

fill

silicon

dirty.

cloth

waste

dirty.

~,

,

~ft<Wfff1U~JJH.~JJ!:ft1!t

check

b)

by

o

oil

once a week.

inside

Mt

steps:

~~-1J~M:m:¥5~1f.f~J!~,

the

case

-ti

~~Jmm~~~

llm¥5t51f.f~£~,

which

is

under

the

table

once a month.

Maintenance

o

0

~~~~m~~~

••~ffl!I.FJ~~~~

0

0

2.:ft~~*-*'~slflm

Check

3.:ft1ftl!I~~(F-06)~N~Jl

Check

4.:ft1!t~tm~(F-03){g-2iii1'FWt&CE-19)~st&~

Check

5.:ft~tt~:H~s~t&~ft~

Check

6.:ft1!tKNIFEf1iil:lm!BICE-16)~Nt&~

Check

7

.:ft1!t7JtR'fJ.t;~(B-11)~St&~

Check

amt~~~?*lb1'Fif.f

2

If

the

l.t9l~~~~:S:~AC220V

Check

2Atitf~df~*-*~slflm

Check

3.~~AIRtiemlmiBICE-17)~st&~

Check

4.:ft

Check

the

fuse.

the

wave

filter.

the

inverter

the

error

code

the

switch

the

knife

blower

the

voltage.

the

fuse.

the

switch

i!t

5WitJ.t;~(B-12)~

the

blowing

for

motor.

motor

for

o

o

o

and

control

of

inverter.

knife

·

~ft<~""f1U~lJi~lJi~~

is

not

working,

blowing.

motor.

power.

o

0

:S:

t&~

panel.

·

:fifu~ft<~~ttff!ML~F~

o

o

o

check

by

steps:

0

o

o

21

Page 24

;!t.Jlf~

Error

code

Description

-f*"il3/J~6

~~3!1'1/l

Detail

OCl

OC2

C3

QUI

OU2

OU3

~-~1*~

Overcurrent

protection

~~

Short

-circuit

protection

!:tit!!~~

Ground

fault

protection

~U-f*lii • WJtU~ o tzD5F!:Mim~Df!J3ia~j(I¥.JU!flf

Overvoltage

protection

~ZSJ~~ffifij

Stop

the

IZSI!Iitl:BUI¥.J~ij

Stop

the

short-circuiting

-R:tE~I1J~~•te~I¥.JW~i3

~f~!rffftlmm~

Stop

the

the

output

tum

ON

~tll:BW:mttf:11YJUI¥.J~::k-mJM

Stop

the

phase

protection

rm~•~-1*~1/Jfr

inverter

inverter

inverter

the

inverter

200

is

in

circuit.

inverter

V,

800

not

output

output

output

to

protect

f~~-~-f*mlbf'F

to

protect

the

output

•

-srn~~~rr-1*~

to

protect

This

protection

without

output

assured

VDC

upon

for

three-phase

if

extremely

•

the

the

circuit.

the

is

removing

detection

~

Jt~!111~

inverter

inverter

0

inverter

effective

the

ground

( 3

~EI200V

of

an

400 V class

large

AC

0

from

an

overcurrent

•

1¥

_rtg~

from

overcurrent

rm~¥.J~mmt

from

overcurrent

only

during

fault,

:

• w

startup

this

DC400V

•

overvoltage

line

condition ( 400

series)

in

voltage

is

due

o

due

to

Jt~~~ 0 :tEW:till~

due

to a ground

of

the

protection

•

3~EI400V

J!U::f11~1*lff

the

DC

applied

to

overload.

a

fault

inverter.

may

If

not

work.

:

DC800V)

o

VDC

for

three-

link

bus.

This

inadvertently.

in

you

LU

Lin

OPL

~1!tl:BW:mttf:11YJU~~fl£

'WJtU~ o {B~ • ~~

j;:_MJE-f*~

Undervoltage

protection

!litA.~~EI-1*~

Input

phase

protection

Ml:B~fEI-1*~

Output

loss

phase

protection

~~l:f1-~o

Stop

the

inverter

level

(200

VDC

for

However,

voltage

~tl¥UMA.~~EI

ttr

NP{j!t£!1itA.mR:~EII¥.J'Ift?5?.~

~-~~l:BQiRfEI

loss

Detect

from

voltage

reactor

~1!fl:f1~11J~~~tpi¥J•te~~I¥J~~·{¥Jt~~o

Detect

the

if

data 114

drops.

•

i3

rmu~J::tiWJ~!lffffi¥.Jff!:JJi3

input

phase

undergoing

unbalance

is

connected

breaks

inverter

in

inverter

output.

( 3

~EI200V

1

F14=4

output

when

the

three-phase

11

or

5

is

selected

• W

Jt~~~ o ~Jjj1J~-aJPJ1$jjJtffi~m~~~EI:®G~EizFd1::fZJS

•

~~ffti¥1~-~~~PJNfftW:~-mm~~

DC

200V,

for

J!,IG5J

link

400

Fl4,

ffi!i

bus

voltage

VDC

no

rmm•

:

DC200V

•

NP{j!W:1fittf:1Fd1~11Jiff~

for

alarm

0

• 3

~EI400V

drops

below

three-phase

is

output

:

DC400V)

the

undervoltage

400 V class

even

if

the

series).

DC

link

•

•

•

-tl1.

bus

-tl1.

o

loss,

and

stop

the

heavy

and

to

stress

may

the

output

that

damage

inverter,

wiring

inverter

may

the

this

output.

be

caused

inverter.

function

at

the

start

This

by

input

If

connected

will

not

of

running

function

phase

load

preven

loss

is

detect input

and

during

ts

the

or

inter-phase

light

or a DC

phase

loss

running,

inverter

if

any.

stop

22

Page 25

OHL

dbH

~H~

Overheat

protection

J-Jm-~~~J.tma~Jltt~;fO~~

Stop

the

inverter

fan

failure

~D5fH'f·$ff#Jmtr~~llU~~

*~'aJ!f~®iMtJJtl~llU

Discharging

braking

*

resistor.

Function

or

overload.

and

codes

output

inverter

must

be

upon

operation

·

tti!fte~~Jl®U

detecting

•

~

•

are

set

corresponding

• w

excess

JtJvr~IIJ{'F;fO~~UmtJ{'F

~)E)jjfjge§

stopped

to

heat

due

the

sink

temperature

o

to

overheating

braking

resistor.

in

0

case

of

Jt~~u

o

of

an

external

cooling

OLU

OH2

OLl

OL2

~i®fful:B1!7frt;f0]7q$Utt1t

~~-f*iM

Overload

protection

~MJi~

Stop

temperature

over

51--$tf~~

flu

A.

External

alarm

~i®~lftiffuA.Fs~

Place

input

~i&tm.:r~m3mijg~~JE:WJ£:~~3.

·:ff~~$fBIIIP"1-f*Hffl~~o

1!-T~Il-3

Electronic

thermal

overload

·:ff~~$~~pi\J-f*~~Wffl~~o

*1liP.J.~1'FW.J..&~Jf,ffm'M~

In

the

accordance

-

Protect

-

Protect

The

operation

0

the

inverter

calculated

the

preset

value.

the

inverter

following

with

general-purpose

inverter

level

output

( THR)

in

alarm-stop

cases,

the

electronic

motors

and

if

the

from

the

the

inverter

motors

over

thermal

•

~ll!GBT

Insulated

output

·WJt.M~I¥J-¥llo

state

Gate

current and

upon

ll\Jff

Bipo

lar

receiving

~it~~

B®~liir.)j{

Transistor

temperature

•

(IGBT) int

of

digital input

0

o

stops

thermal

over

the

entire

time

running

overload

the

entire

frequency

constant

the

motor

protection

frequency

range

can

be

set

to

protect

setting.

range

(FlO = 2.)

by Fll

mte~itft!~

•

1¥

Jt

ernal

inside

the

signal

(FlO

and

THR.

the

= 1.)

Fl2.

inverter

motor

is

in

OH4

Er1

Er2

Er3

PTCY11m

PTC

thermistor

~a·r:~

tt~m

Memory

error

detection

Nkf'FOO;f.&

~rn~m

Keypad

communications

error

detection

CPU~'M

CPU

error

detection

1lJ~~c~m·WJt~~3·~~~~

il#ff-

[ c1 l - [

11

l

zrm~~PTc

~~~ll • ~5Em1firr£t&..t®miHI.&mijg

0

e§o

A

PTC

thermistor

Connect a PTC

and

slide

switch

U-m$tmJ;fO~A.UJeytt1!t~!!l

WJtl!~3o

The

inverter

memory

~~~

~U~1'FOO;f.&Wt!~U*IIFm$J~rn~'M

The

keypad

~~te~~~51Jte$JCPU

If

this

inverter

the

inverter

function

error

OO;f.&C*R

during

input

stops

thermistor

on

the

interface

checks

stops

is

detected,

by

memory

~

detecting a communications

operation

detects a CPU

stops

the inverter

the

inverter

between

PCB

data

after

the

inverter

~)~~Jj]fj~~OO;f.&C

using

the

standard

~'M

error

or

output

for

motor

protection.

terminals

[C1]

and

[11]

and

set

accordingly.

•

tt1!ttB~c·f:IMI¥J~'M

power-on

and

when

the

data

stops.

~~~)~~~

• W

Jtt!

~U

o

error

• W

ll::~~

LSI

error caused

keypad

3

between

or multi

o

by

noise or

the inverter

-fun

ction keypad

.

the

•

is

written.

some

function

other

codes

If

a

·

and

the

(optional).

factors,

23

Page 26

Er4

~ft:JR

~w:fi.-m

Option

communications

error

detection

U~Wff:~fmfliJey

Upon

card,

detection

stop

the

of

inverter

an

•

~ff~~!fiJh~~*lll¥1~rn:fi.-m

error

in

the

communication

output.

between

•

Wll:~~~

the

inverter

and

an

optional

Er5

Er6

Er7

Er8

~DaR~

Option

detection

~IV1'P~1ft

Operation

protection

1ft

error

U~~ff:~fmfiiJey

When

llPU~flffifril'Uffi~tfHDJf~~~

-~ • ~fMtt~~Wll:

Pressing

if

the

communications

~~:fi.-m

Tuning

error

detection

Rs-48s~w~m

RS-485

communications

error

detection

~~~mm~$ · ~rr~~ruc

Wll:g~o

During

abnormal

~1'POO~I¥Jil!~a~~s-485

~·ml/J\~mo

When

designed

displays

an

option

the

inverter

tuning

condition

the

inverter

for

an

error

key

is

of

the

card

has

on

the

running

Oink

operation).

motor

has

is

connected

keypad,

code

er8

•

dft:WFOOJfti!U~m

detected

o

keypad

by

parameters,

been

an

error,

this

C~ll:U/f\Er6

forces

any

detected

the

inverter

run

commands

After

the

motor

,

$BT

if

the

tuning

in

the

~rn~~JTJmt1~

to a communications

detecting a communicatio

• w

ll:~~~

function

•

~tfF~1'Ptmt&I¥JSTOP

stops

o)

to

decelerate

given

via

the

terminalsor

stops,

the

inverter

,

~~*B*I¥1~-mffif

has

failed

or

tuning

result,

the

•

~~rr~w~-mffif

network

ns

error

via

stops

.

o

the

inverter

and

stop

issues

has

aborted,

inverter

the

the

inverter

output.

the

alarm

•

or

stops

• w

RS-485

motor

even

er6.

an

its

output.

ll:~~

port

output

and

ErF

ErP

ErH

Err

!Xm&ffif

~-~:fi.m

Data

save

error

during

undervoltage

RS-485

~m~'m

(~ft:l{tf:)

RS-485

communications

error

detection

(optional)

iij!fll

~-m

Hardware

m•t&~

Mock

error

alarm

.XmE-f*~lb1'Pffif

If

the

data

could

the

inverter

U~llli{tf:RS-485

•ml/J\~mo

When

the

displays

inverter

communications

displays

~iMEIJiiJU~!n-1Jj£;t&QJGWOO--FI¥J~~::f

OOI¥J~ffif·wll:~~~·•/f\~mo

The

(control

board

detected

.m~t&~m~ · ffiJU~tBV¥~

Simulated

an

inverter

PCB)

(interface

.

alarm

error

is

stopped

and

•

tlD*~ff~f*ffU

not

be

saved

during

the

alarm

~ffi-F-~KM~I¥J'r1ir5l'F

is

connected

card,

detecting a communications

code

erp

.

when

poor

power

printed

PCB)

or

option

is

output

to

check

activation

code.

to a communications

connection

circuit

card,

or

the

•

~Uml/l\~-m

of

between

board

(power

short-circuit

o

fault

sequence.

o

the

undervoltage

•

ft~IT~ffi~'ntffif

network

error

stops

~ • ~Jl:BliffifT

the

control

PCB),

between

protection

via

an

optional

the

inverter

printed

interface

terminals

printed

function,

• W

ll:~~~

RS-485

output

[

13

circuit

l - [

and

11

board

circuit

[13]

and

[11]

l

is

24

Loading...

Loading...