Page 1

ASV-ATS100

使用說明書與零件圖

ORIGINAL INSTRUCTIONS BOOK

Page 2

重要安全聲明

SAFETY INSTRUCTIONS

•

感謝客戶您購買本公司產品

為安全且正確地使用本產品 ASV-ATS100,請

詳細閱讀以下注意事項後再實施操作。

1. 在使用本機器前,請先詳讀說明書內容,必

須遵守說明書的指示與規定。

2. 此設備的使用,由經過適當訓練的操作人員

實行。

3. 在使用本機器時,若發現異常或故障,應立

即停止使用,並切除電源,以進行妥善修理。

4. 嚴格禁止對本機器進行改造和變更。本公司

對改造或變更過的機器不予保固,若因此造

成危害,本公司將不負任何賠償責任。

•

危險

為杜絕觸電事故必須遵守以下安全措施。

1. 安裝本機器時,必須確實做好接地動作。

2. 對本機器的電氣做定檢與維修,都必須由具

有資格的電氣技術人員執行,或專家的監督

指導下進行。

•

警告

為了杜絕觸電、火災、燒損或對人的傷害,必

須遵守以下安全措施。

1. 本機器在有電壓的狀態下,絕對禁止人員接

觸通電之機件。

2. 本機器若需要做零件更換或進行維修時,應

將電源切換至 OFF

狀態。

•

Thank you for purchasing our company’s

products.

For your safety and using our product ASPEBJ100 properly, please read the instructions

below deliberately, then start operating the

machine.

1.Before using the machine, you must follow

the instructions and rules.

2.The operators must been well trained.

3.If you found some abnormal phenomena

or the machine malfunction, you should

stop using the machine at the moment and

cut the power off, in order to do the proper

repair.

4.Strictly forbid to do the extra transformation

or alteration. We do not have the warranty

to the machine which had been transformed

or altered. Therefore, our company will be

irresponsible for any compensation if the

machine has caused any danger.

•

Hazards

In order to prevent from the electric shock, you

must to obey the safety measure below.

1. While install the machine, make sure you

have do the grounding.

2. The electric routine inspection and

maintenance of the machine have to be

done by the electric technical personnel who

qualied or under the expert’s supervision.

•

Alert

You must to obey the safety measure below,

in order to prevent from the electric shock, fire

accident, burning loss, or human body injured.

1. Absolute forbid workers to touch the

machine

’s

parts while the machine is in a

voltage state.

2. If the machine

’s

parts need to be changed

or do the maintenance, you should switch

the power off.

Page 3

3. 當本機器不能正確工作時,應立即停止操作

機器。該機器有必要進行修理、電氣或機器

方面的調整時,需要和本公司的代理商或直

接與本公司聯繫商談,採取合適的解決措

施。

4. 本機器的的維修、調整須經由適當訓練的技

術員或專業人員進行。維修時,需使用本公

司所指定的更換零件。

5. 一般的保修檢查,要由經過適當訓練的人來

進行。

6. 在維修或保養各式氣缸或氣壓相關連動機構

時,務必將供應氣源的接頭拔下,在氣壓完

全切斷的狀態方可進行。不過,只限於受過

適當訓練的技術人員或專業人員進行調整和

運行確認時例外。

7. 該機器準備啟動前,所有的保護蓋必須安裝

定位至機器上。

8. 本機器的內部裝置和控制箱裡不能殘積金屬

粉末和灰塵,要定期打掃。

9. 本機器在運行當中,所有可動部分都絕對不

可用手觸碰,或身體(包括頭髮、衣服類)

靠近。

3. While the machine cannot operate properly,

you should

stop operating it immediately. If

the machine has the necessity to repair, or

do the electric and machine adjustment, you

should contact with our factors, or contact

us directly, then take the proper resolution.

4.The machine’s maintenance and adjustment

need to be done by well- trained technician

or professional. You need to use the specific

parts from our company while under

maintenance.

5. The

repair within the warranty need to be

repair by the worker who well trained.

6. While doing the repair or maintain variety

of cylinders and pneumatic actuator

associated, you must unplug the supply air

source connector before you do the repair

and maintenance. However, it could be

only done by the well- trained technician or

professional.

7. Before ready to start the machine, all of the

protective

covers need to be on the position

of the machine.

8. The inner device and the control box of the

machine need to be regularly cleaned, in

case of any dust or metal filings remains in

the machine.

9. While operating the machine, do not use

your hands to touch or let your body to close

(including hair or clothes) all of the movable

parts.

10.Do not use the wet hands to operate the

machine, it mig

ht cause electric shock or

other major injured.

11.Please be sure to follow the alert pictorial

markings by next page.

10. 絕對不可用濕手操作,可能造成觸電等重

大傷害發生。

11. 警告提示如次頁圖案,請務必遵守。

Introduction

Page 4

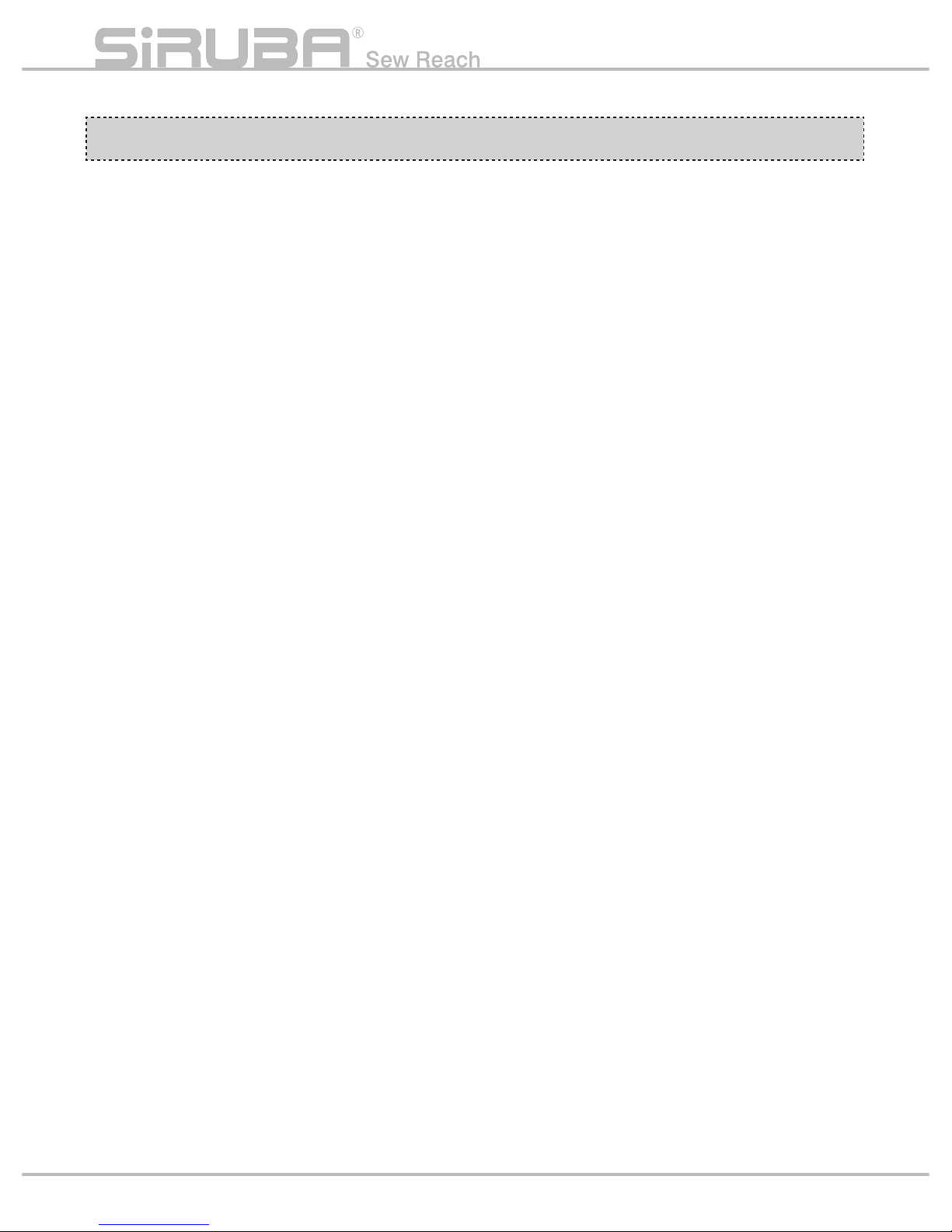

警告圖案表示

INDICATED THE ALERT

PICTORIAL MARKINGS

高壓部位

HIGH-VOLTAGE POSITION

務必關閉電源 10 分鐘後始打開電控

箱蓋子

Be sure to turn off the power and wait

till 10 minutes before opening the

control box’s cover.

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

CAUTION

機械作動部份請注意裝上

保護裝置

穿線、換線、 調整、清潔

時請注意關閉電源.

Moving parts may cause in jury.

Operate with safety devices.

Turn off main switch before

threading, changing bobbin and

needle, cleaning etc.

Page 5

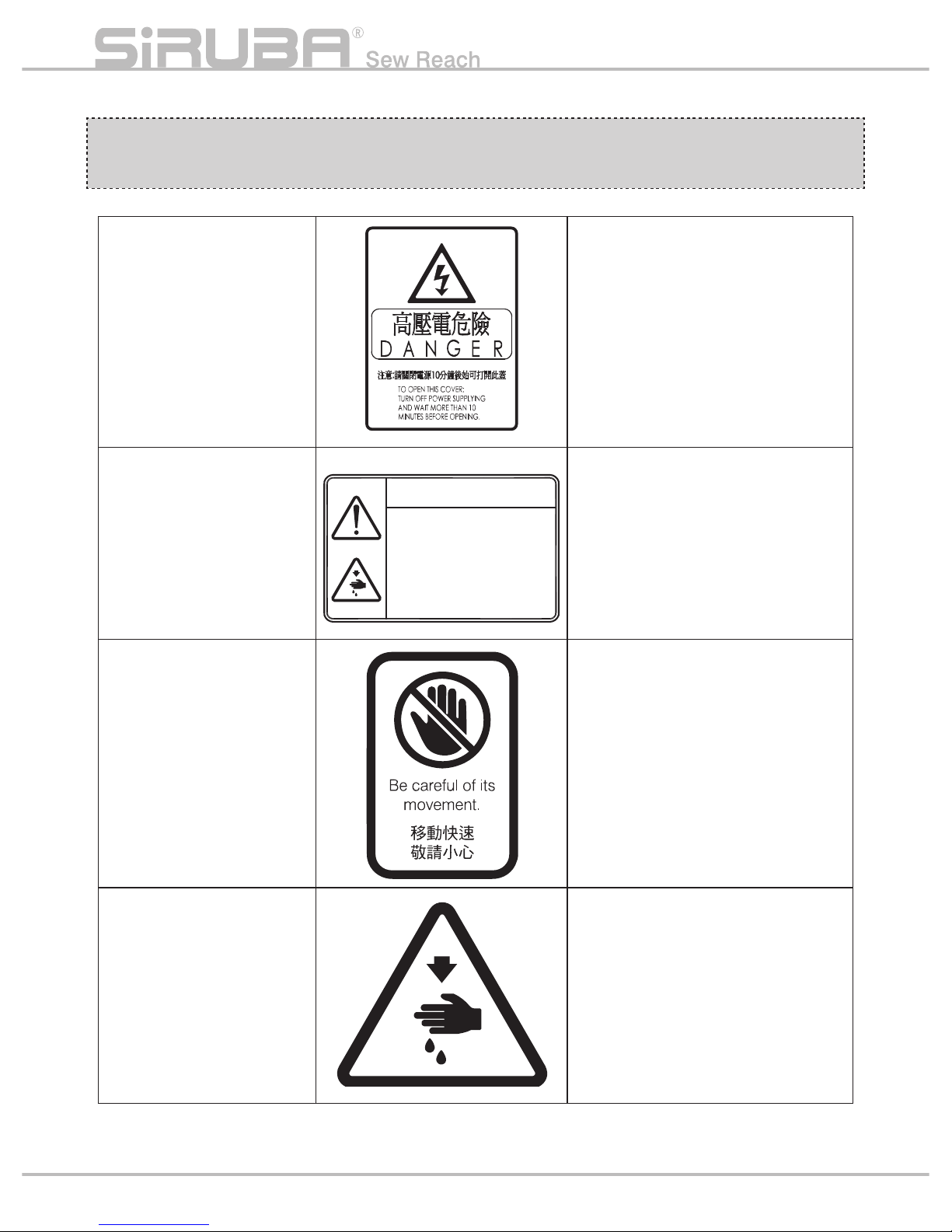

安全注意事項

SAFETY INSTRUCTIONS

機器動作範圍 ( 區域 )

Area with moving parts

1. 機器在運轉時,不可將手指等放入該區域

內。

2. 為了保修、檢修卸掉罩蓋時,必須將電源切

到 OFF。

1. Do not put your fingers into the area while

machine is operating.

2. Must switch off the power before take down

the cover for repair and maintenance.

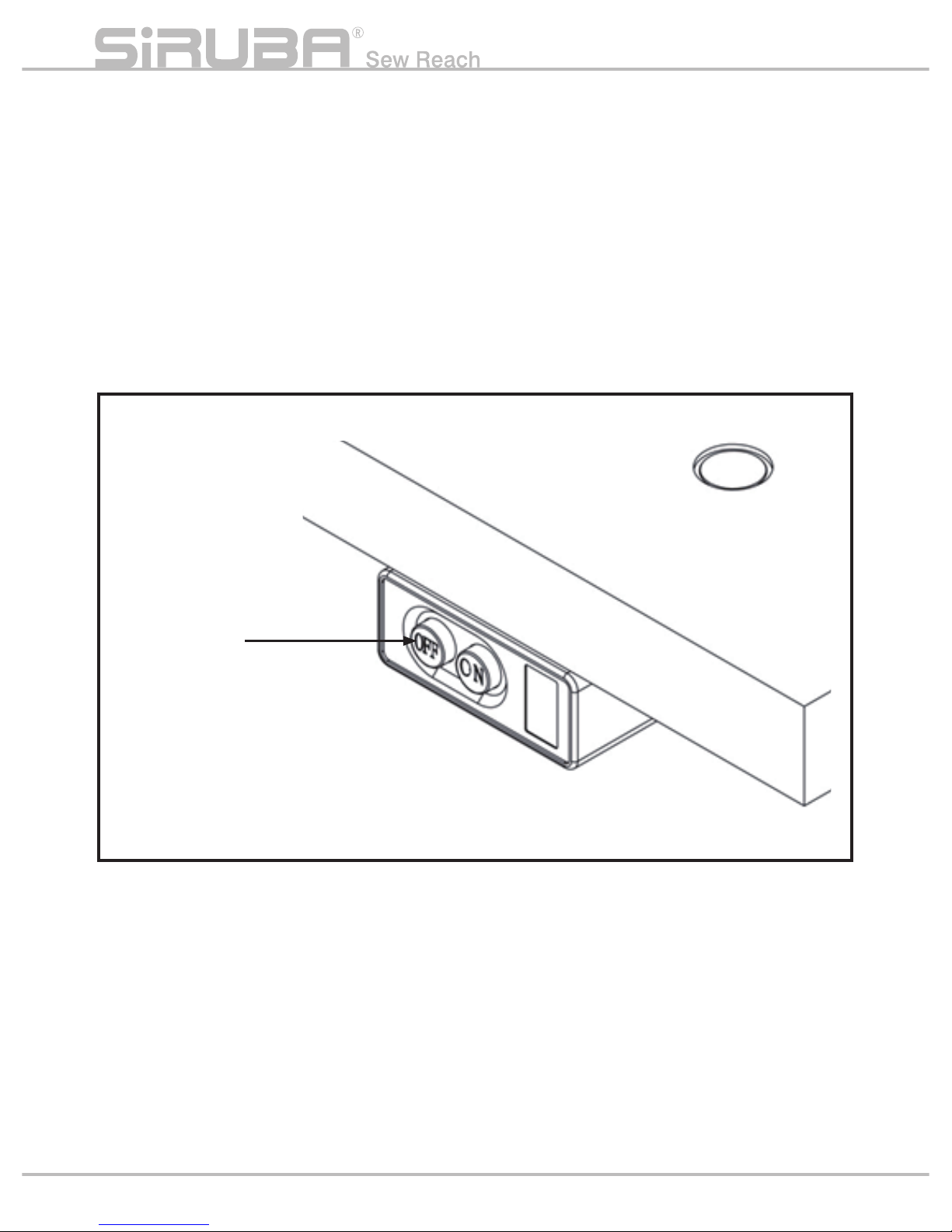

電源開關

Power switch

Introduction

Page 6

3. 在有危及人體的高壓電處,貼有觸電危險警

告標記。在貼有本警告的電器控制部位而需

要保修、檢修時,打開罩蓋僅能由專業的電

氣技術人員進行。

3. Stick the electric shock alert pictorial marking

at high voltage place which may cause human

danger. Therefore, only the professional and

electric technician could open the cover, while

the electric place which have sticked on the

alert pictorial marking need to be repair and

maintenance.

4. 機器運轉時,有必要馬上停止機器的時候,

可以按下斷電開關。

4. If there’s a necessity to stop the machine right

away while machine operating, you could

press the machine halt switch to switch the

power off.

5. 電源線、氣壓管線需確實固定安置,不可散

落在地面,以免人員絆倒而發生危險。

6. 為了生命安全,在任何情況下,不可將電源

地線拔掉運轉機器。

7. 打雷時,為了安全要停止作業, 切斷電源。

8. 離開機器工作地點時或工作結束後一定要將

電源開關轉到 OFF。

9. 機器運轉下,不可卸下罩蓋類。

5. Power cord and pneumatic line pipe need to

make sure being fixed and settle do

wn. Do

not put them disordered on the ground in

case of people stumble and cause danger.

6.No matter under any circumstances, for your

life safety, do not pull out the power ground

wire while operating the machine.

7.For your safety, you need to stop your work

and cut off the power, if it starts thundering.

8.Must switch off the power before you leave

your work or work ending.

9.Do not take down a

ny cover while operating

the machine.

斷電開關

Power Off

Page 7

索引

INDEX

頁 /PAGE

規格 SPECIFICATION 1

安裝 INSTALLATION 2

操作說明 OPERATION PREPARATION 3

(1)電源及氣壓確認 (1) POWER AND AIR PRESSURE CHECK

(2)電源開啟

(2) POWER ON

(3)腳踏板控制 (3) PEDAL CONTROL

(4)切刀微動開關

(4) FINE TUNING SWITCH OF CUTTER

設定及調整

SET UP AND ADJUSTMENT

(1)調整

(1) ADJUSTMENTS

(2)參數設定 (2) PARAMETER SETTINGS

Introduction

Page 8

規格

SPECIFICATION

型式 Model ASV-ATS100

車縫型式 Sewing way

多針機、上帶車縫 Multineedle, 3-stripe

attaching machine

車縫速度 Sewing speed 最高 2000 rpm. Max to 2000rpm

使用針 Type of needle UOX113GS#11

車縫平台寬度 Width of sewing space 440mm

針距 Needle gauge 6.4mm

電源電壓 Voltage 單相 Single-phase AC220-240V 50/60Hz

氣壓 Air Pressure 0.5 Mpa(5Kg/c ㎡)

氣體消耗量 Air consumption 40L/ 分 . 40L/minute

生產樣式 Sewing pattern

P1

Page 9

縫紉機腳架①與收料架②固定鎖緊。 Fixed and fastened the table stand① and

collection rack②.

安裝

INSTALLATION

線架

Thread rack

②

①

P2

Introduction

Page 10

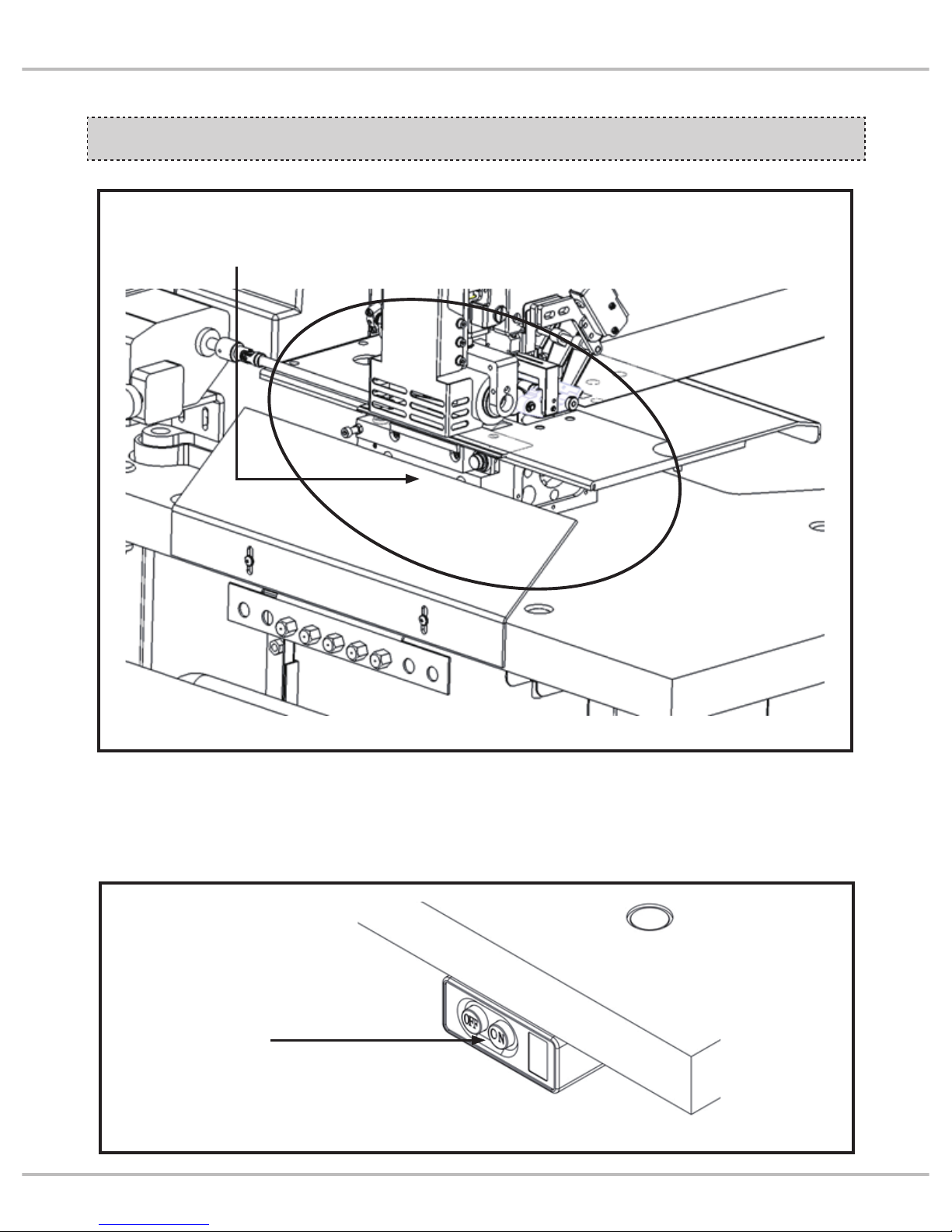

(1) 電源與氣壓

A . 電壓

使用定額電壓 220V±10%。

接地線一定要接地。

B. 氣壓

使用 0.5Mpa(5kg/c ㎡)。

(2) 電源開啟

按壓電源 ON 後開啟三貼條輔助裝置電源。

(3) 腳踏板控制

往①方向踩踏控制車縫速度。

往②方向踩踏壓腳抬起。

(4) 切刀微動開關

按下開關,切刀執行一次裁切。

操作說明

INSTRUCTIONS

② ①

※ 注意請勿將手放置切刀區域。

※

Do not pu t hands o n the

cutter area.

(1) Power and air pressure

A. Voltage

Rated voltage 220V±10 % .The earth wire

must be grounded.

B. Air pressure

Use 0.5Mpa(5kg/c ㎡).

(2) Power on

Press the power on button then turn on the

power of the 3-stripe attaching device.

(3) Pedal control

Step forward ① direction to control the sewing

speed.

Step forward ② direction to lift the presser.

(4) Press

the switch of ne-tuning cutter, the

cutter will execute one cutting operation.

P3

Page 11

設定及調整

SET UP AND ADJUSTMENT

(1) 調整

Ⓐ

後帶布輪調整;Ⓑ送距調整;Ⓒ送貼條速度

調整

(1) Adjustments

Ⓐ

Rear roller adjustment;Ⓑstitch length

adjustment knob;Ⓒ3-stripe feeding speed

adjustment

(2) 參數設定

按壓操作面板

A 切換;B 百位數;C 十位數;D 個位數

(2) Parameter setting

Press on the operation panel

A:shift; B:hundreds digit; C:tens

digit; D:units digit.

參數: Parameter:

面板顯示

Display on panel

調整內容。Contents

P5 前切針數。Count stitches before cloth.

P6 後切針數。Count stitches after cloth.

T7 撥布出力、延遲動作。Cloth allocation, delay time.

T8 撥布出力、動作時間。Cloth allocation, action time

T9 吹布出力、延遲動作。Cloth blowing, delay time.

TA 吹布出力、動作時間。Cloth blowing, action time.

TB 翻布輸出、延遲動作。Cloth turnover, delay time.

Ⓐ

Ⓑ

Ⓒ

P4

Introduction

Page 12

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

SK8A1*4

ASP-0210-A

ATS-0001

KX09*4

SW07*4

NK45*8

SK392*2

ATS-0015

ATS-0014*5

ATS-0053

SK392*2

ASV-ATS100

2017/12/07

/

1 1

ATS-0001-A

P5

Page 13

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

SM616

SM810

SM510

ATS-0047

ATS-0021

ATS-0022

SM5107N

ATS-0025

SM5107N

SM502*2

ATS-0052*2

SM614N*2

SM6104N*2

ATS-0024

ATS-0043

JA042*2

AC069

ATS-0023

EM040

ATS-0019

ASV-ATS100

2017/12/07

/

1 3

ATS-0019-A

P6

Page 14

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

NM516*4

NM516

ATS-0018

ATS-0016

ATS-0017

SM5055*4

SM5055*4

NM516*4

SM611N

SM5055

ATS-0019

ASV-ATS100

2017/12/07

/

2 3

ATS-0019-A

P7

Page 15

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ATS-0017

ATS-0019

SM616N*2

WM601*2

ATS-0045

ATS-0020

ATS-0044*3

ASV-ATS100

2017/12/07

/

3 3

ATS-0019-A

P8

Page 16

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ATS-0035

ATS-0030

ATS-0029

EM020*2

ATS-0031

ATS-0037*2

SM303*4

ATS-0026

SM5200*2

ATS-0036

ATS-0032*2

BR5050*2

ATS-0033

ATS-0046*3

ATS-0028

ATS-0042

ATS-0027

ATS-0039*6

ATS-0034*2SM303*4

SM2056*2

ATS-0038

SM401*2

EM040

BR5050*2

ATS-0032*2

SM303*2

BR5050

ASV-ATS100

2017/12/06

/

1 1

ATS-0026-A

P9

Page 17

Page 18

由於對產品的改良及更新,本產品使用說明書中與零件圖之產品及外觀的修改恕不事先通知 !

The specification and/or appearances of the equipment described in this instruction

book & parts list are subject to change because of modification which will without

previous notice.

ASV-ATS100.MAR.2018

Loading...

Loading...