Page 1

ASP-PTA100

使用說明書與零件圖

ORIGINAL INSTRUCTIONS BOOK & PARTS LIST

Page 2

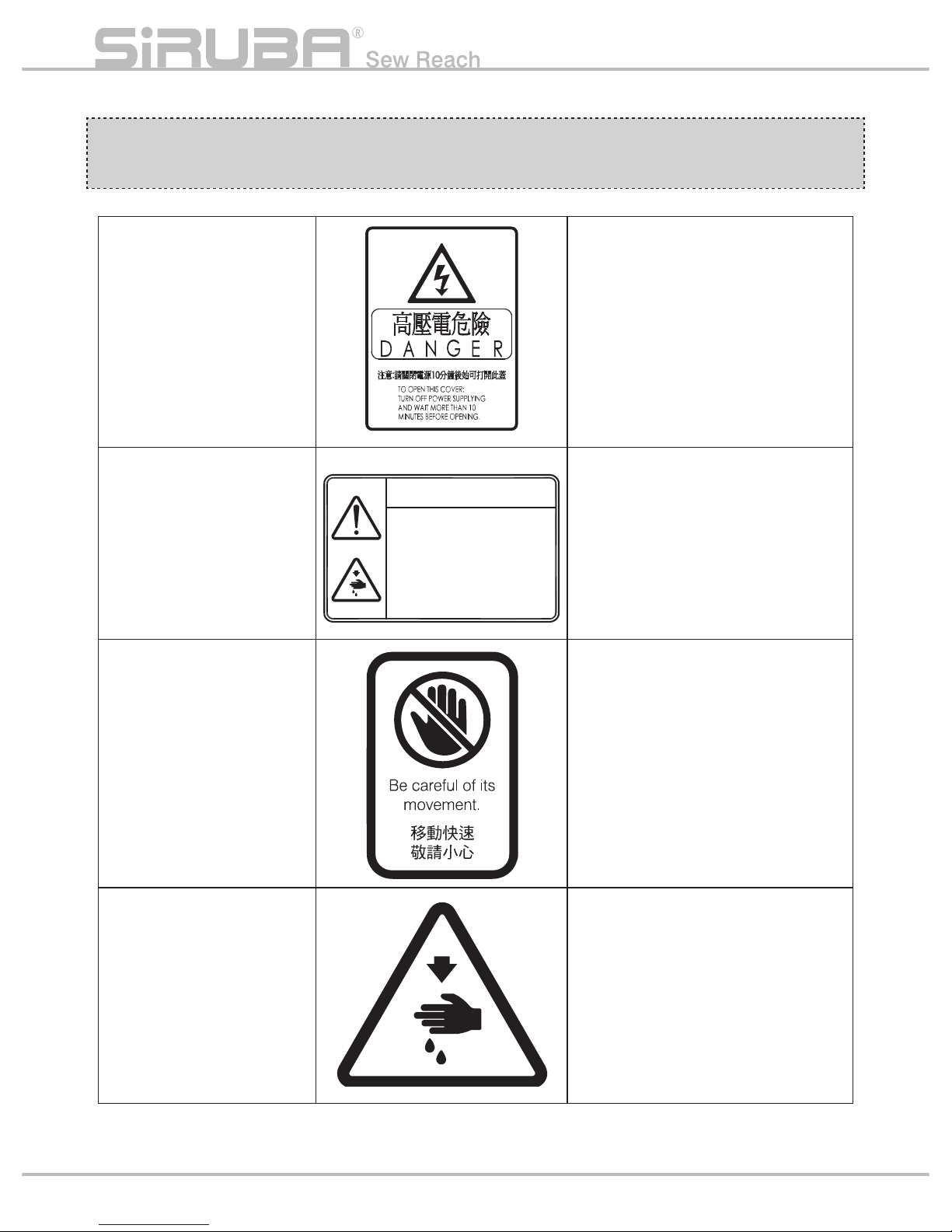

警告圖案表示

INDICATED THE ALERT

PICTORIAL MARKINGS

高壓部位

HIGH-VOLTAGE POSITION

務必關閉電源 10 分鐘後始打開電控

箱蓋子

Be sure to turn off the power and wait

till 10 minutes before opening the

control box´s cover.

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

CAUTION

機械作動部份請注意裝上

保護裝置

穿線、換線、 調整、清潔

時請注意關閉電源.

Moving parts may cause in jury.

Operate with safety devices.

Turn off main switch before

threading, changing bobbin and

needle, cleaning etc.

ii

Page 3

安全注意事項

SAFETY PRECAUTION

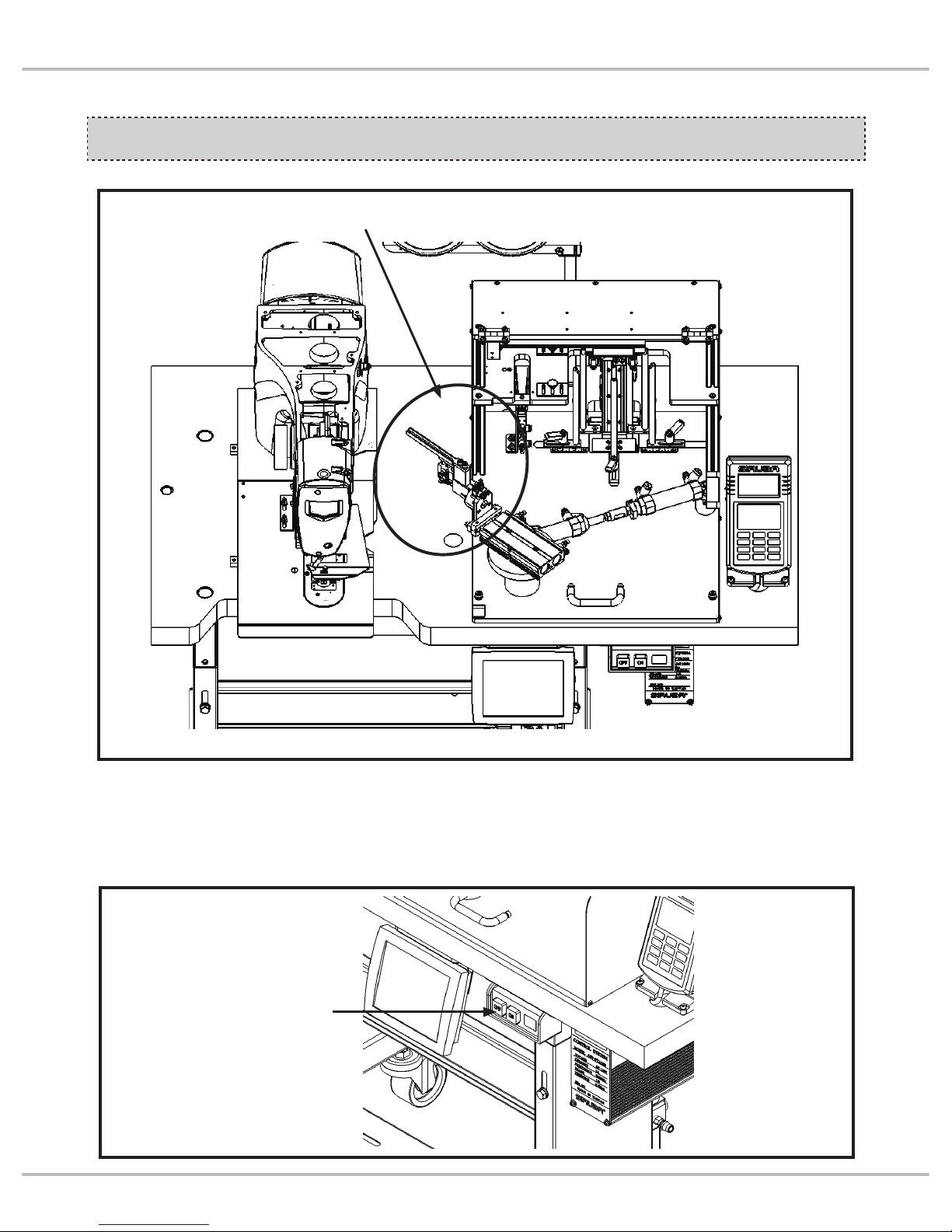

1. 機器在運轉與開關機時,請勿進入該區域

內。

2. 為了保修,檢修卸掉罩蓋時,必須將電源切

到 OFF。

1. When machine is in process, do not enter

working space.

2. When in maintenance, make sure turn off the

power before inspecting and removing the

cover.

電源開關

Power switch

機器動作範圍 ( 區域 ) Machine working space (region)

iii

Introduction

Page 4

3. 在有危及人體的高壓電處,貼有觸電危險警

告標記。在貼有本警告的電器控制部位而需

要保修、檢修時,打開罩蓋僅能由專業的電

氣技術人員進行。

3.In working place with high voltage power,

there is warning sign. When maintaining

machine control part with this warning, open

the cover and only process by professional

electrical engineer.

4. 機器運轉時,有必要馬上停止機器的時候,

可以按下緊急停止開關。

4. When we need to stop machine in process,

we can press emergent stop button.

5. 電源線、氣壓管線需確實固定安置,不可散

落在地面,以免人

員絆倒而發生危險。

6. 為了生命安全,在任何情況下,不可將電源

地線拔掉運轉機器。

7. 打雷時,為了安全要停止作業, 切斷電源。

8. 離開機器工作地點時或工作結束後一定要將

電源開關轉到 OFF。

9. 機器運轉下,不可卸下罩蓋類。

5. Settle down power line and air line certainly.

Tools should not spread on the floor or

stumble workers in danger.

6. For the safety of life, do not disconnect

ground wire in any situation when

processing machine.

7. When in thunder, cut off power to stop the

process for safety.

8. Must t

urn OFF the power when leaving

working place or finishing working.

9. When processing machine, do not remove

the cover.

緊急停止開關

( 電源 OFF)

Emergent stop button

(power OFF)

iv

Page 5

索引

INDEX

頁 /PAGE

規格 SPECIFICATIONS 1

安裝 INSTALLATION 2

運轉準備 OPERATION PREPARATION 3

操作面板與啟動開關 OPERATION SWITCH 4

車頭參數設定 MACHINE HEAD CONFIGURATION SETTING 5

紙卡安裝與對位 LABEL INSTALLATION AND ALIGNMENT 6

錯誤代碼 ERROR CODE 11

異常排除 TROUBLE SHOOTING 12

動作模式 MODE SELECT 20

按鍵說明 BUTTON INSTRUCTIONS 23

操作說明 OPERATION INSTRUCTION 24

參數說明 PARAMETER INSTRUCTION 27

故障排除 TROUBLE SHOOTING 31

控制板 ( 一 ) CONTROL BOARD (I) 32

控制板 ( 二 ) CONTROL BOARD (II) 33

I/O 板 I/O BOARD 34

出現錯誤代

碼 E01:

通訊故障

ERROR CODE E01: COMMUNICATION ERROR 36

簡易維修流程圖 SIMPLE MAINTENANCE 36

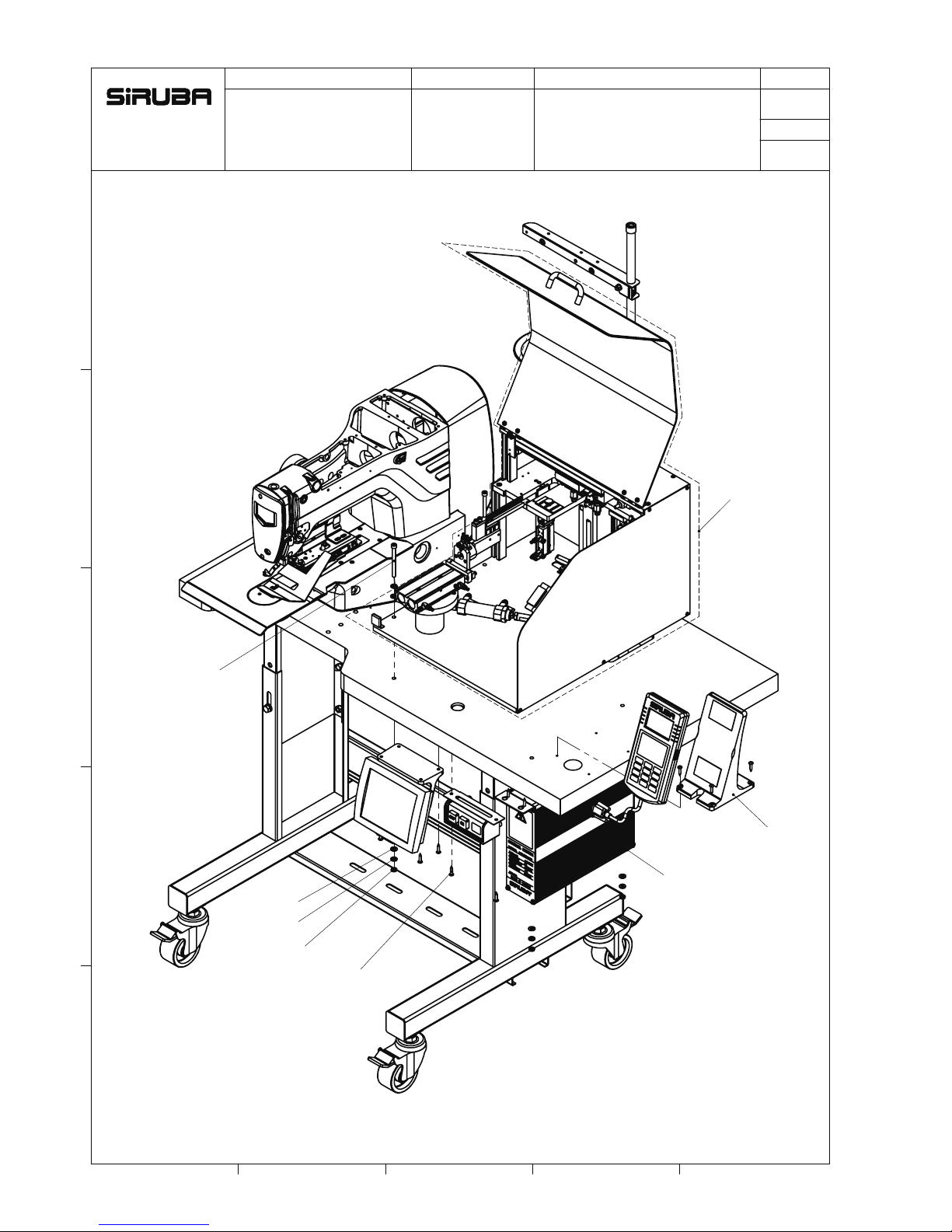

零件圖 PART LIST 38

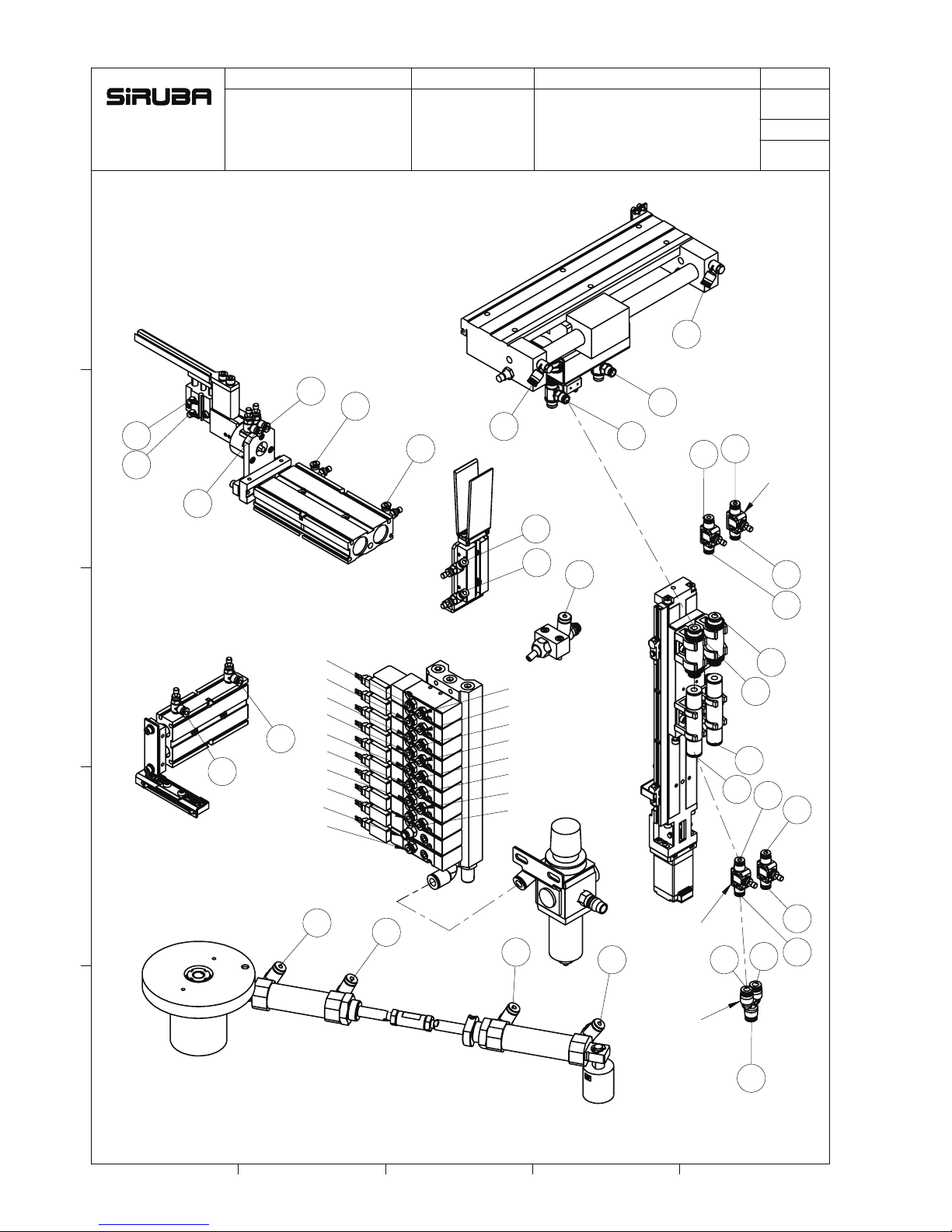

氣壓流程圖 AIR PRESSURE DIAGRAM 52

氣壓裝配圖 AIR PRESSURE ASSEMBLY DIAGRAM 53

路線總圖 CIRCUIT DIAGRAM 54

v

Introduction

Page 6

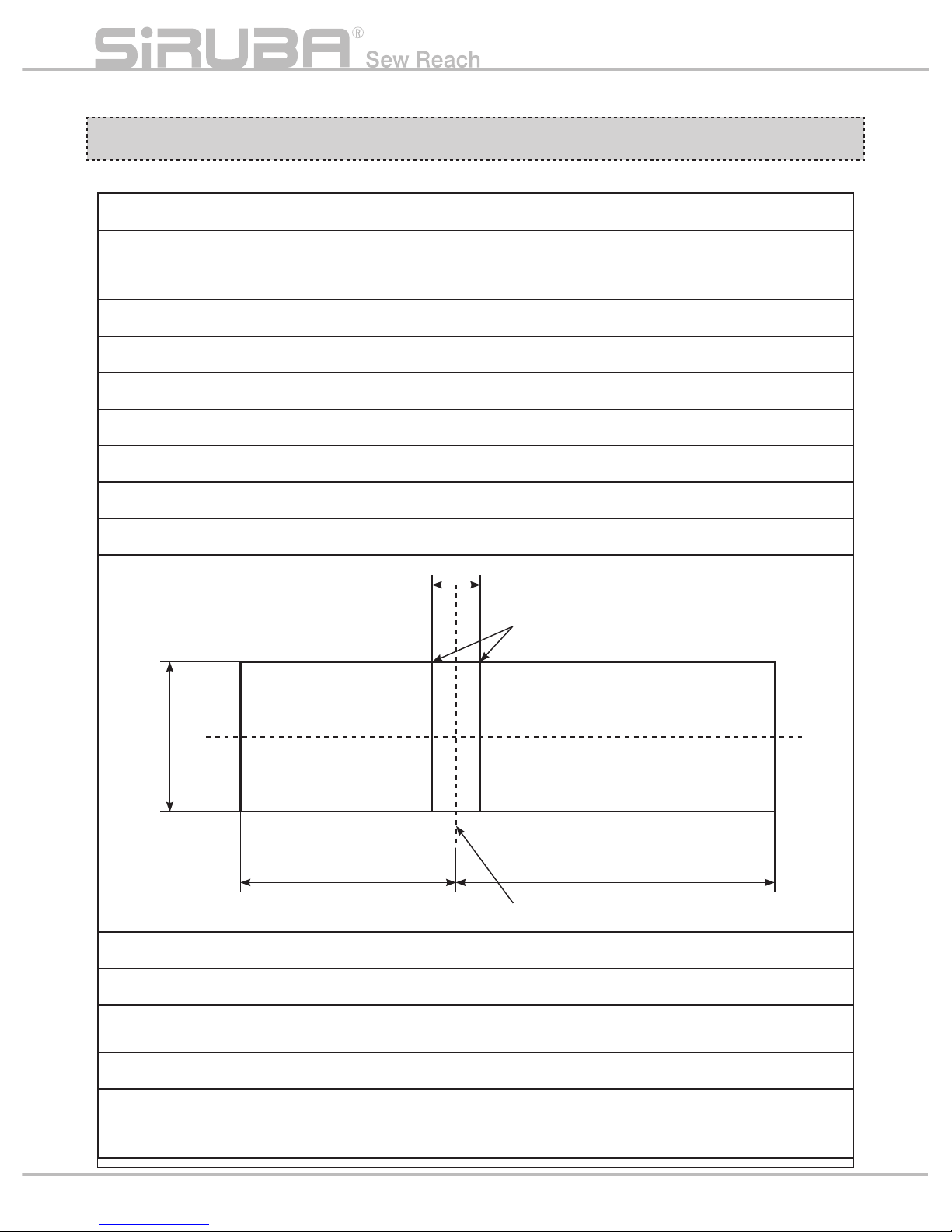

規格

SPECIFICATIONS

型號 Model ASP-PTA100

搭配縫紉機機頭

Collocation Machine Head

平縫(高速電子套結機)

lockstitch (high speed electrical bartacking

machine)

車縫速度 Sewing speed 最高 Max 2000 SPM

使用針型 Needle Type DP×17 #11

紙卡單邊長 Label Length 35~65mm

紙卡寬度 Label Width 35~65mm

摺痕寬度 Crease Width 5~6mm

紙卡厚度 Label Thickness 0.4~0.6mm

車縫範圍 Sewing range 水平 3~6mm ( 最大 ) X axis 3~6mm

氣體消耗量 Air consumption 2L/min

氣壓 Air Pressure 0.5 Mpa

電源電壓 Voltage

單相 AC200~240V 50/60Hz

Single Phase

AC200~240V 50/60Hz

消費電力 Voltage consumption 1150VA(最大 Max)

機器尺寸 Dimensions

寬 1050× 深 750× 高 1530mm ( 含桌板、線架 )

(W)1050×(D)750×(H)1530mm ( With table

and thread stand )

適用紙卡規格

Applicable label dimension

P1

摺痕寬 Crease width

摺縫中心線

Label crease center

5~6mm

35~65mm

35~65mm 35~65mm

Page 7

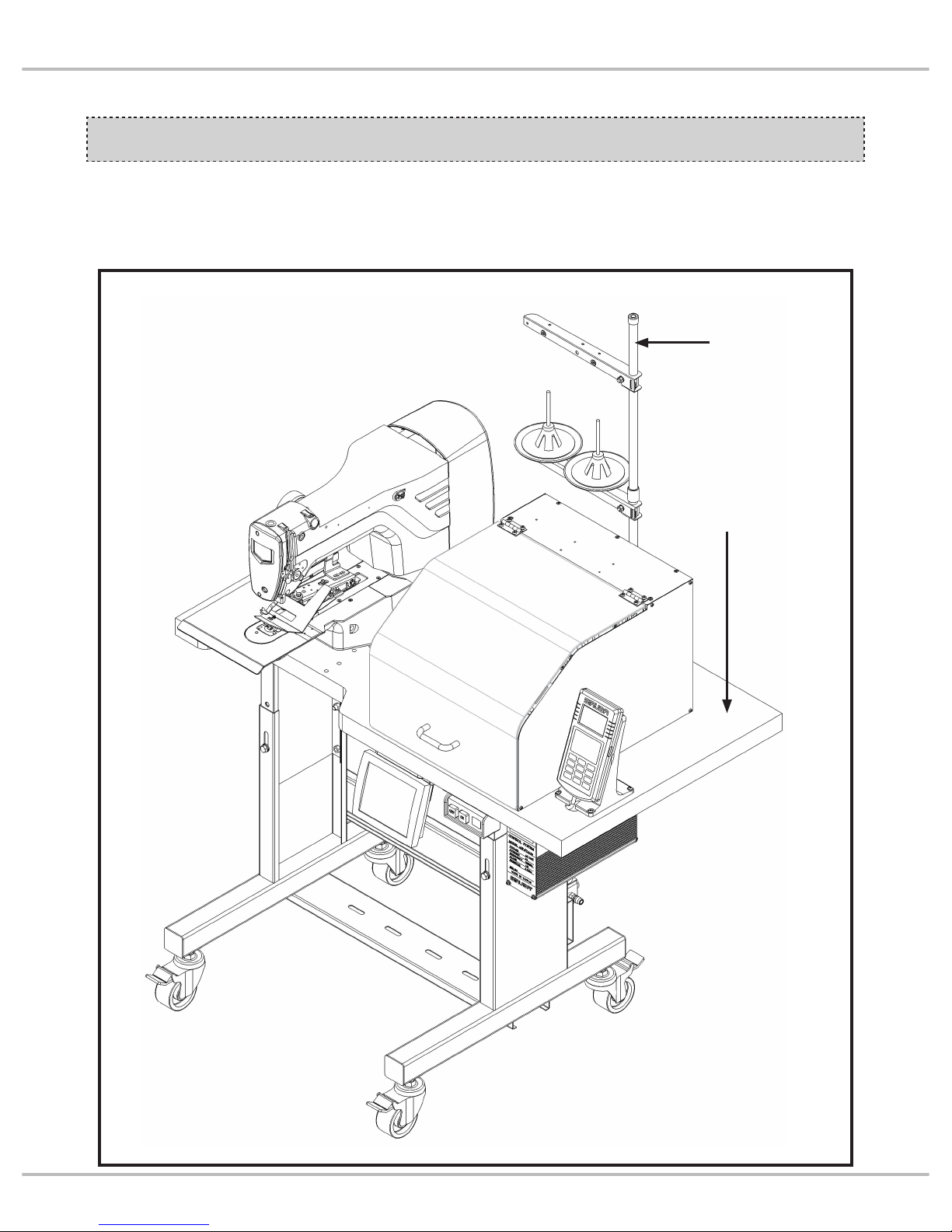

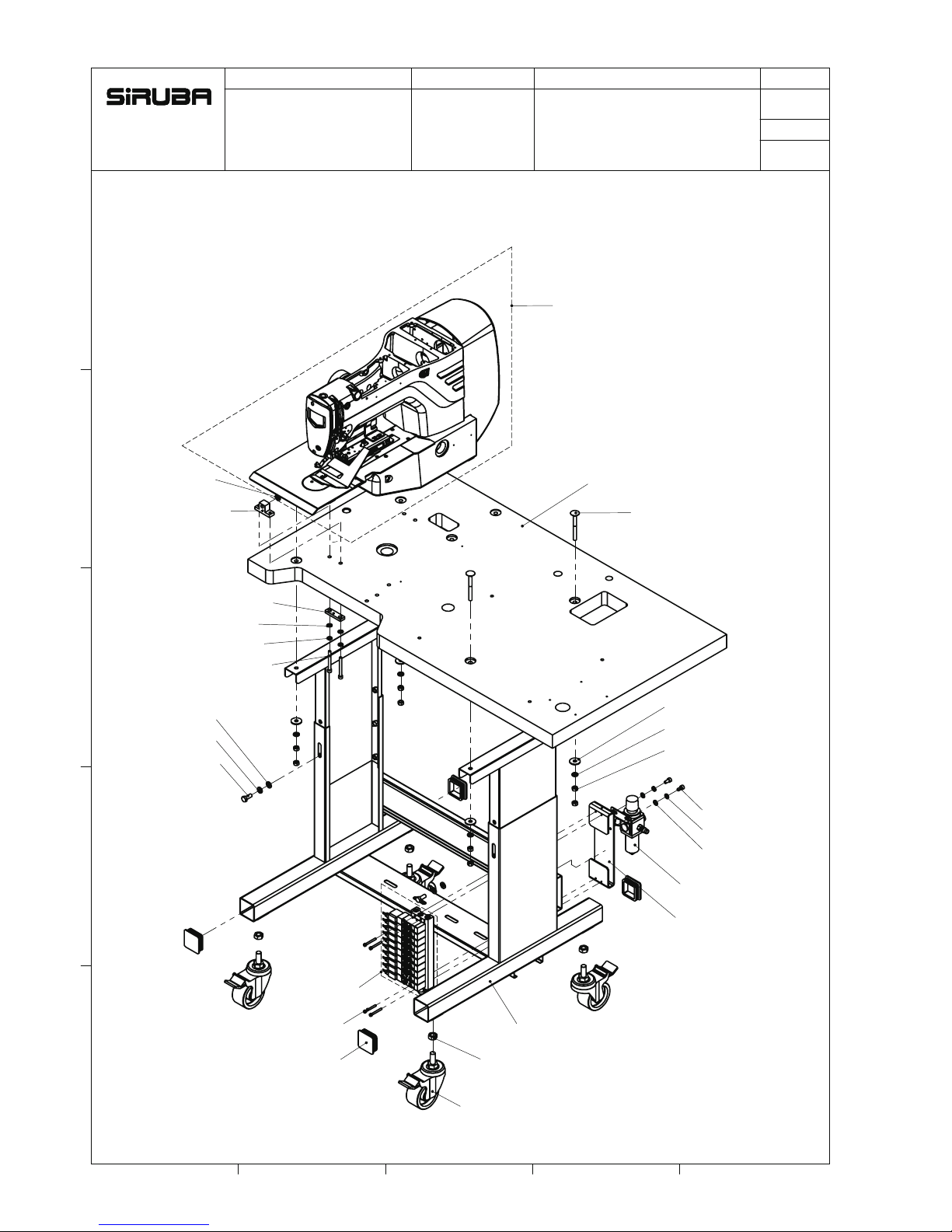

桌板①上,鎖付線架②。

( 線架組裝組請參照 LKS-1903AN 使用說明書 。)

Install thread rack ② on the table ①.

(Ref LKS-1903AN user manual.)

安裝

INSTALLATION

②

①

線架

Thread rack

P2

Introduction

Page 8

1. 電源電壓

A. 單相 AC200~240V 50/60Hz ±10%。

B. 接地線一定要接地。

2. 氣壓

A. 使用 0.5 Mpa(5kg/c㎡ )。

3. 供油

A. 縫紉機頭部

請參照 LKS-1903AN 使用說明書。

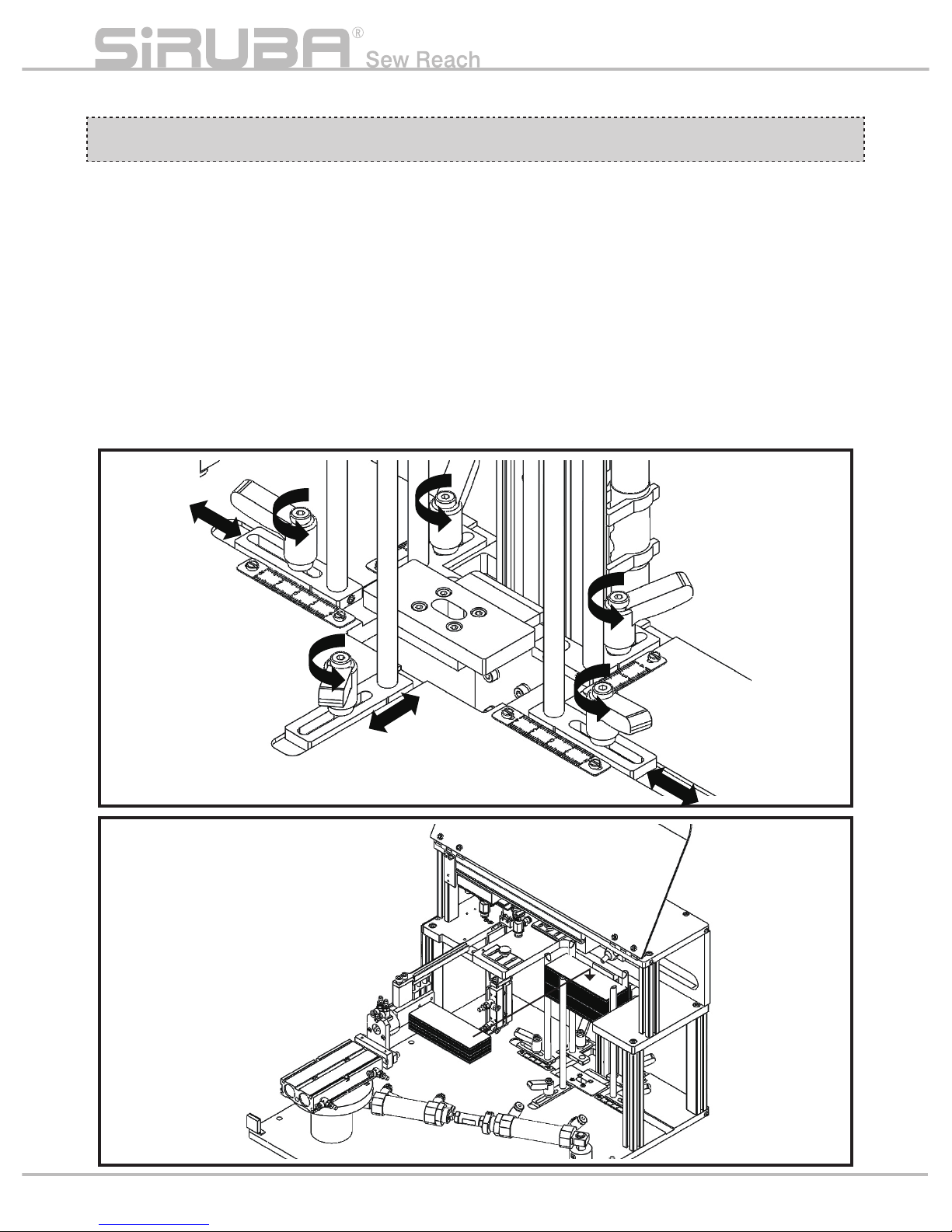

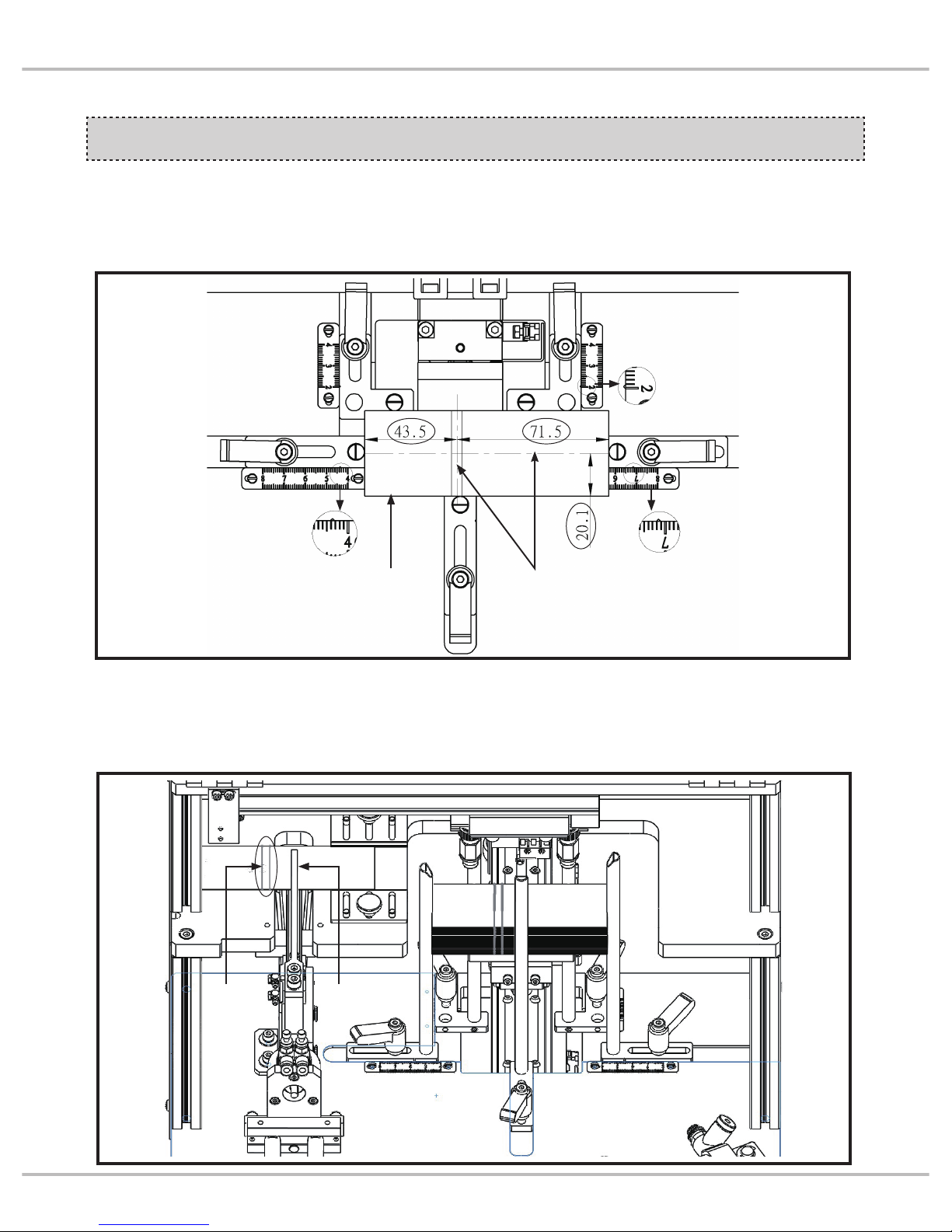

4. 設定紙卡尺寸及補料

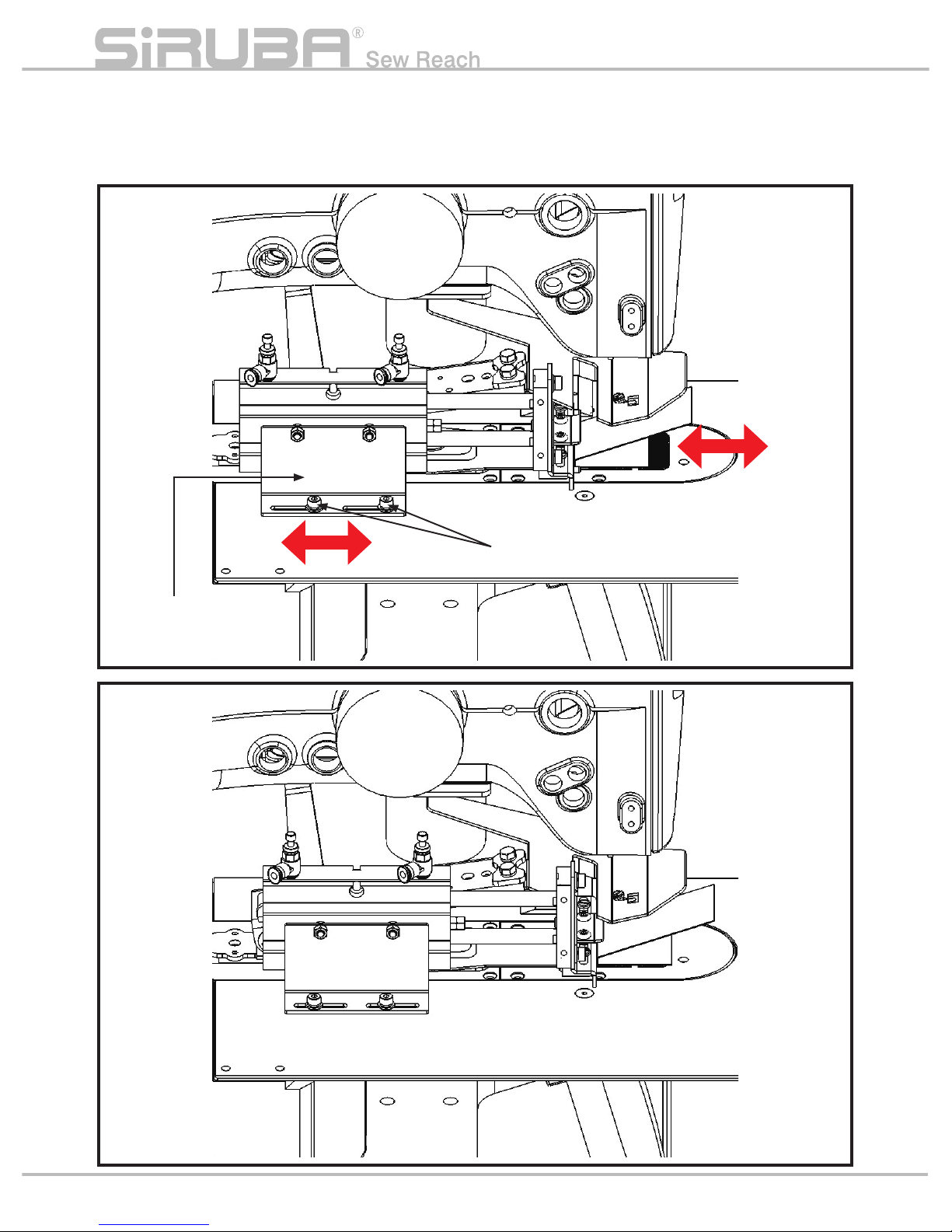

鬆開快速把手①後調整滑塊②至紙卡規格對

應尺寸,再將料卡放置於載料平台。

1.Voltage

A. Single Phase AC200~240V 50/60Hz ±10%

B. Ground wire must connect.

2.Air pressure

A. Use 0.5 Mpa(5kg/c㎡ )。

3.Feed oil

A. Machine head

Ref LKS-1903AN user manual.

4. Set label dimension and fill the material

After loosing quick spancer

① , adjust sliding

block ② to satisfy label dimension and then

put label material on material platform.

運轉準備

OPERATION PREPARATION

P3

Page 9

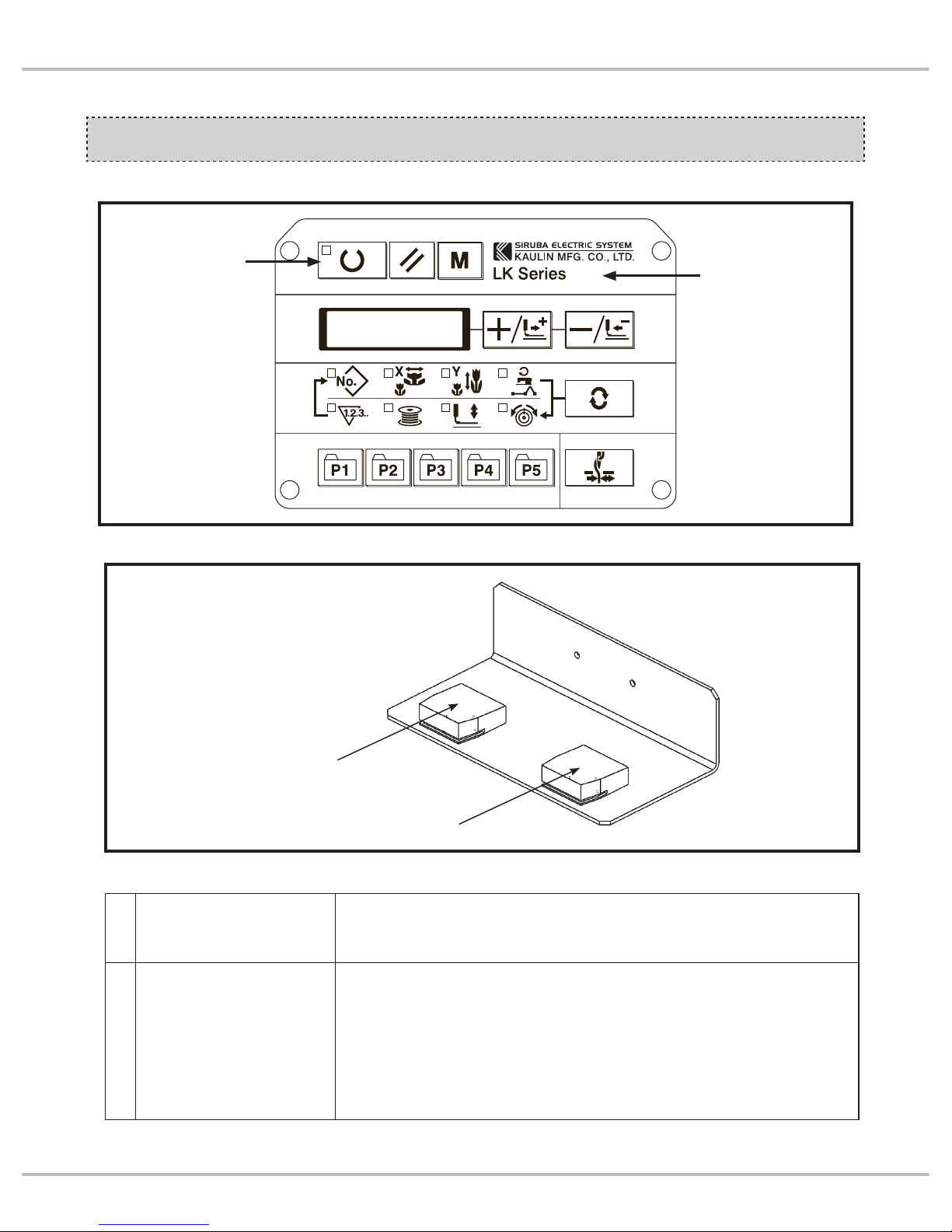

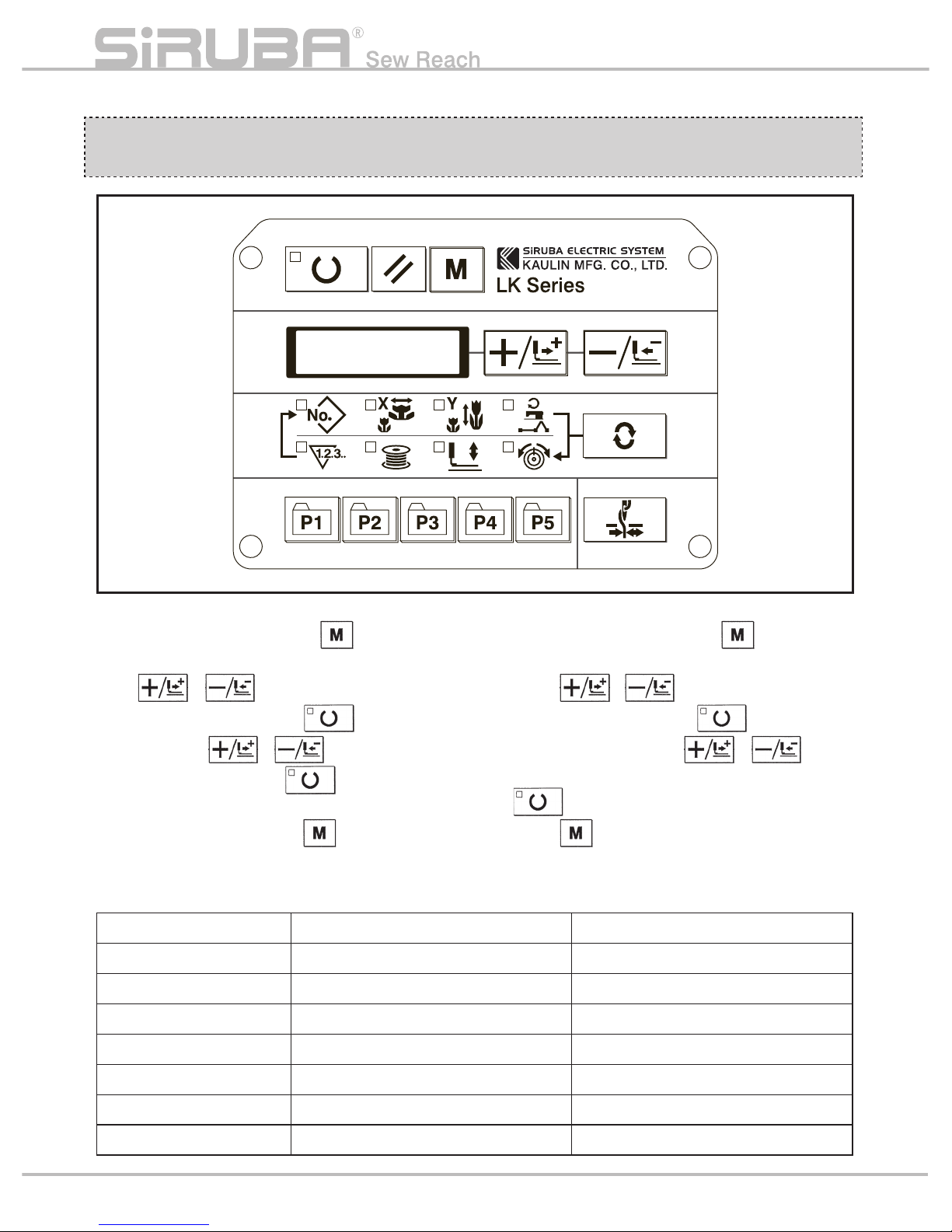

1. 操作面板 1. Operation panel

操作面板與啟動開關

OPERATION SWITCH

準備鍵

Ready button

SIRUBA

LKS-1903AN

操作面板

Operation panel

P4

Introduction

啟動開關

Activation switch

壓腳開關

Switch for presser foot

1

直接啟動車縫模式

Directly sewing mode

踩踏啟動開關時,壓腳自動下壓就直接車縫

When activation switch, lowering presser foot automatically, then

directly start sewing

2

兩段式車縫模式

2-step sewing mode

單踩壓腳開關時,可使壓腳下壓或抬升用於車縫對位,壓腳必須處

於下壓狀態,踩踏啟動開關才有作用,壓腳未下壓則無法啟動車縫

動作

We could merely tread switch for presser foot to lower or to raise

presser foot to align sewing position. Users should lower presser

foot and then activation switch will work. If

not, users could not

start sewing.

啟動車縫有兩種模式: Two modes to enable sewing:

※ 模式選擇請參閱人機介面使用說明 ※Please refer to instruction book of human

machine interface for mode selection

2. 腳踏開關 2. Knee pedal switches

Page 10

車頭參數設定

MACHINE HEAD

CONFIGURATION SETTING

1. 按下 電源 ON 開關,按 住 鍵約 6 秒進

入設定模式。

2. 按

、 鍵選擇參數。

3. 找到要變更的參 數,按

鍵,進入修

改模式,按

、 鍵來變更內容,

更改完 後,再 按一次

鍵跳出修 改模

式。

4. 所有參數都修改完後按

鍵跳出設定模

式。

5. 修改的參數內容如下

1.Press power on switch hold

about 6

seconds to enter setting mode.

2.Press

、 button to select figures.

3.Select the figures. Press

button enter

adjusting mode. Press

、 to

change content. After adjustment, press

to exit adjusting mode setting value.

4.Press

button to exit setting mode.

5.Refer below for configuration figurces.

順序 Sequence 參數編號 Configuration No. 設定值 Setting value

1 241 9

2 19 2

3 20 1

4 24 0

5 37 1

6 51 1

7 62 1

P5

Page 11

紙卡安裝與對位

LABEL INSTALLATION AND ALIGNMENT

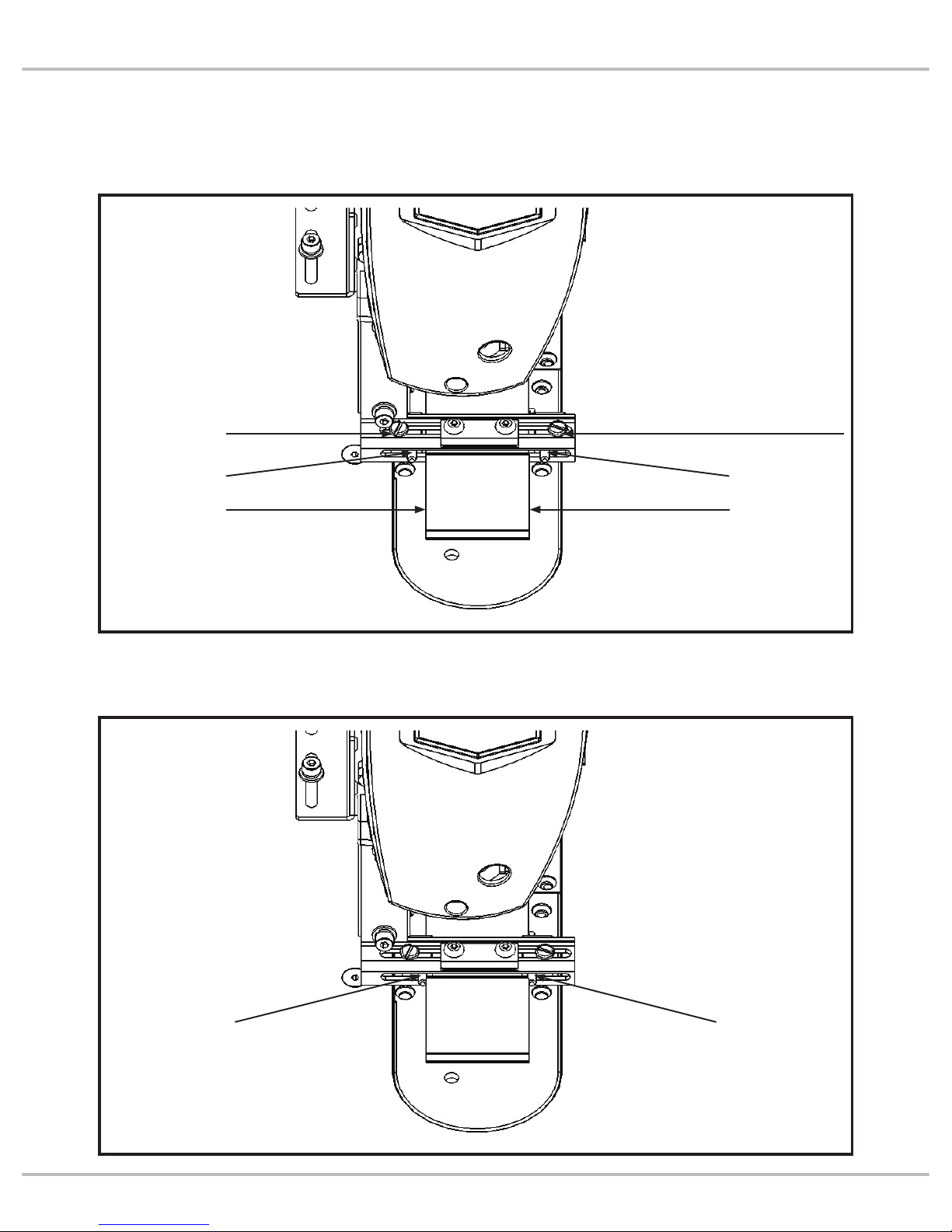

1. 紙卡尺寸變更時

依紙卡摺痕中心至左及右邊的長度來調整

滑塊對應的刻度,寬度亦是如此。

2. 紙卡摺痕偏移調整

若紙卡摺痕偏離夾具位置時,需微量調整紙

卡安裝位置以符合夾持位置。

1.When label dimension changes

According to label crease center, adjust

length between left border and right border

and then adjust width by the same way.

2.Adjust the deviation of label crease

If label crease deviates from the clamp

position, fine tune the installation posit

ion of

label to fit clamp position.

P6

Introduction

紙卡

Label

摺痕

Crease

紙卡摺痕中心

Label crease center

夾具

Clamp

Page 12

微調紙卡長度位置即可將摺痕偏移至夾具位

置。

Fine-tune label length position to move the

crease deviation to the clamp position

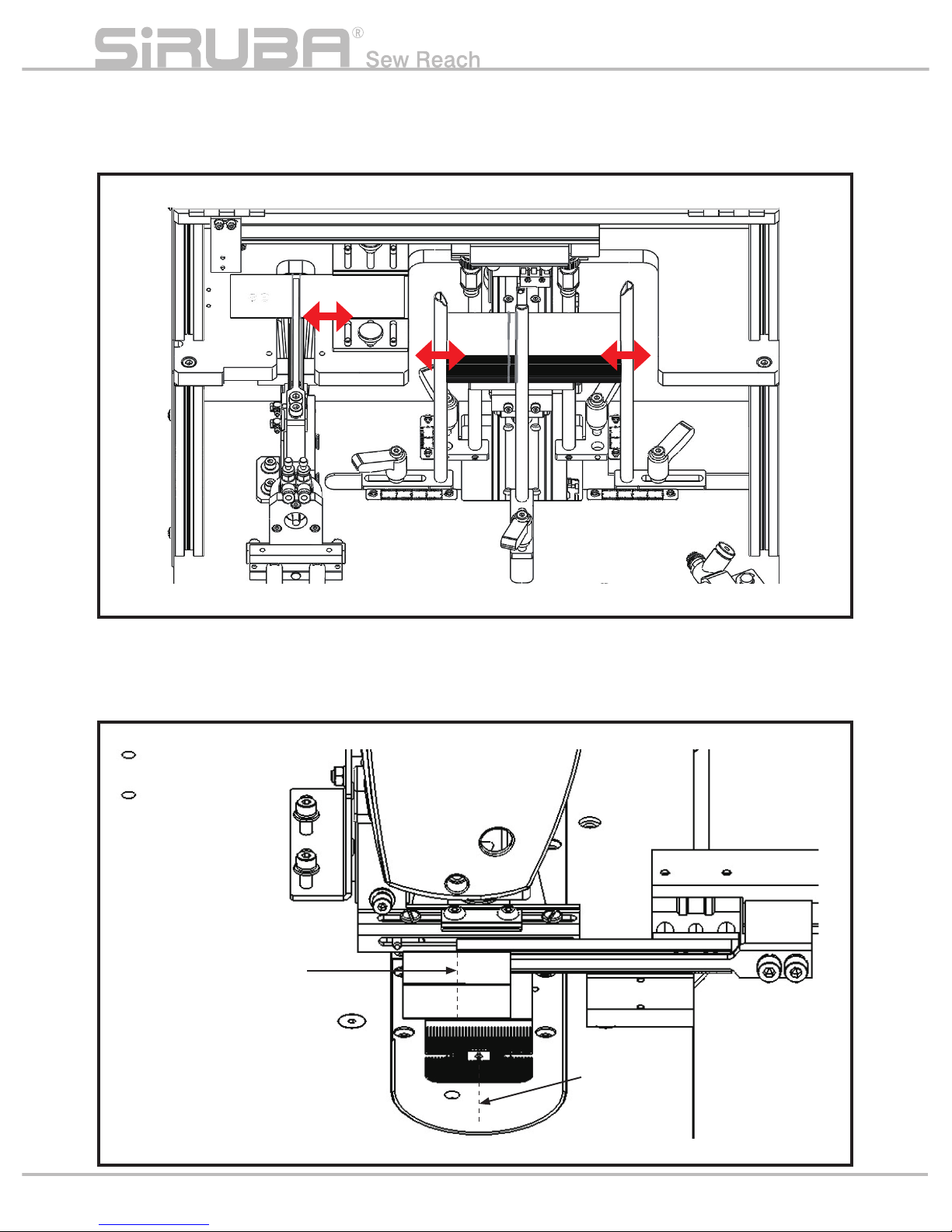

3. 縫線位置調整

紙卡中心偏左或偏右時,將造成縫線不在卡

片正中心位置上。

3. Adjust sewing position

When label deviate left or right from center,

sewing line will not be in the middle of label.

P7

卡片中心線

Label center

縫紉中心

Sewing center

Page 13

微調卡片寬度位置與限位塊即可改變縫線偏

左或偏右的問題。

Fine-tune label width position and limiting

block to solve the problem that sewing line

deviates left or right.

P8

Introduction

中心線對準

Align center line

限位塊

Limiting block

Page 14

調整擋邊氣缸固定座可決定紙卡縫線前後的

位置。

Adjust guide block cylinder seat to set label

sewing line position.

P9

擋邊氣缸固定座

Guide block cylinder seat

螺絲鬆開後調整

Adjust after loosing screws

Page 15

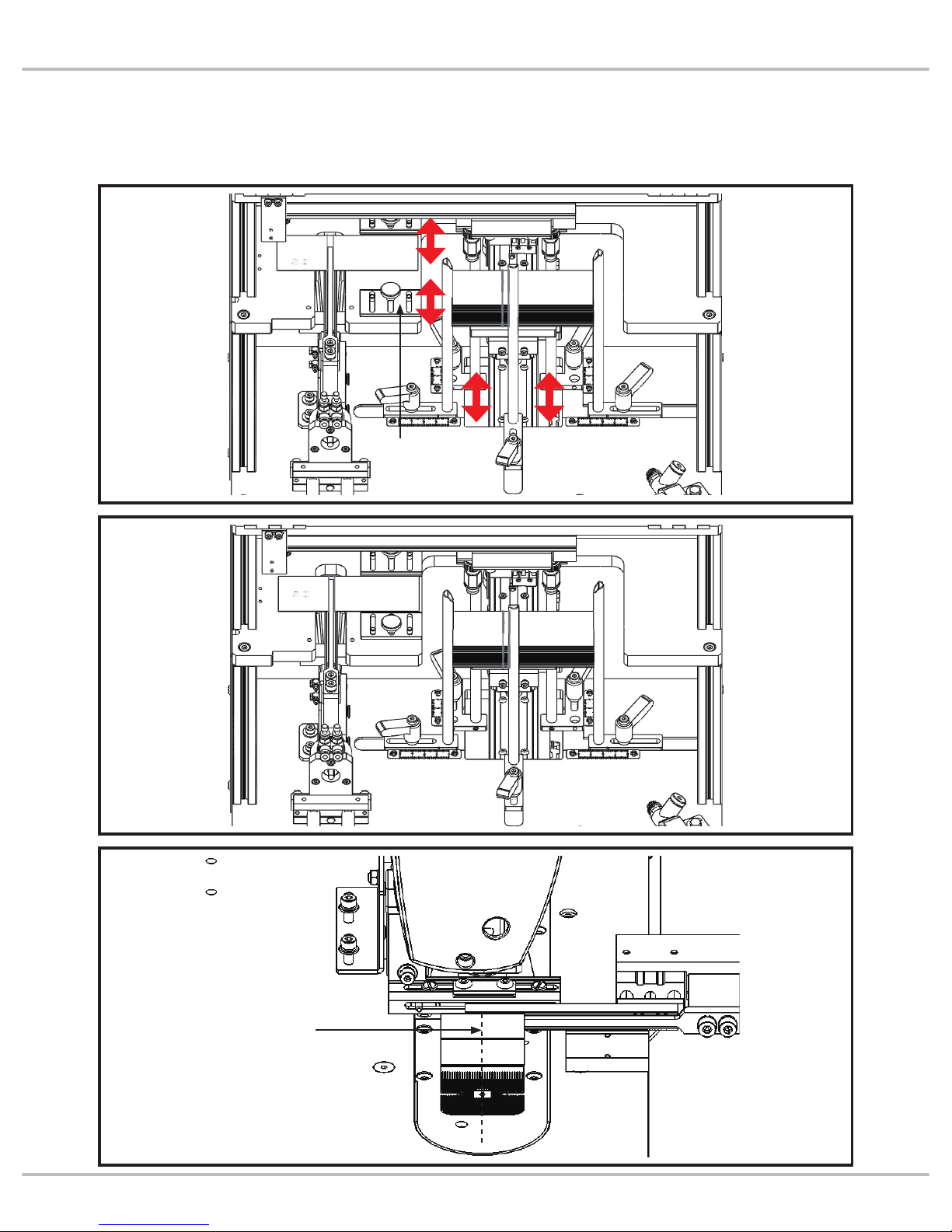

限位銷可限制紙卡左右些許的偏差範圍,當

卡片寬度變更時需調整至紙卡邊界。

Limited pin could limit the deviation of the

label. When label width changes, limited pin

needs to adjust to the label boundary.

限位銷與紙卡邊界需留間隙約 0.5 ~ 1mm,

如此紙卡才不會被撞歪。

Need to keep 0.5~1 mm space for limited pin

and label. Then label will not crash.

P10

Introduction

螺絲鬆開可調整位置

Loose screw to adjust

the position

螺絲鬆開可調整位置

Loose screw to adjust the position

限位銷

Limited pin

保留間隙

Keep space

限位銷

Limited pin

保留間隙

Keep space

紙卡邊界

Label boundary

紙卡邊界

Label boundary

Page 16

錯誤代碼 ERROR CODE

代碼

Code

說明

Description

備註

Memo

E01

通訊異常

Network error

見 4. 故障排除 章節

Ref. by paragraph 4.Trouble shooting

E02

缺料顯示

Show lack of material

待載料平台下降,進行補料後,按下重置鍵

Lower material platform, fill material and press

reset button

E11

運料氣缸未確實處於

準備點 / 原點位置

Cylinder for material transmission

does not stay in standby/original

position well

1 號氣缸 / 準備點微動開關 / 原點磁簧開關異常

No. 1 cylinder/standby point micro switch or

original point re

ed switch error

E12

前伸氣缸未確實縮回

Forward cylinder does not retract well

2 號氣缸 / 磁簧開關異常

No. 2 cylinder/reed switch error

E14

塑形氣缸未確實下降

Forming cylinder does not lower well

4 號氣缸 / 磁簧開關異常

No. 4 cylinder/reed switch error

E16

夾料臂未確實到待命令位置

Clamp does not arrive standby point

well

6 號氣缸 / 磁簧開關異常

No. 6 cylinder/reed switch error

E18

擋邊氣缸未確實退回

Guide block cylinder does not return

well

8 號氣缸 / 磁簧開關異常

No. 8 cylinder/reed swi

tch error

-

若於運料時,運料失敗,導致成型區

感應器未判讀有料,夾爪不會執行前

伸動作

If transmitting material is not well,

sensor on forming part does not detect

material. Clamp will not forward and

catch material

按下 重置鍵 再次進行運料動作

Press reset and feed material again

P11

Page 17

異常排除

TROUBLE SHOOTING

現象

Description

原因

Reason

對策

Solution

參考頁數

Ref. page

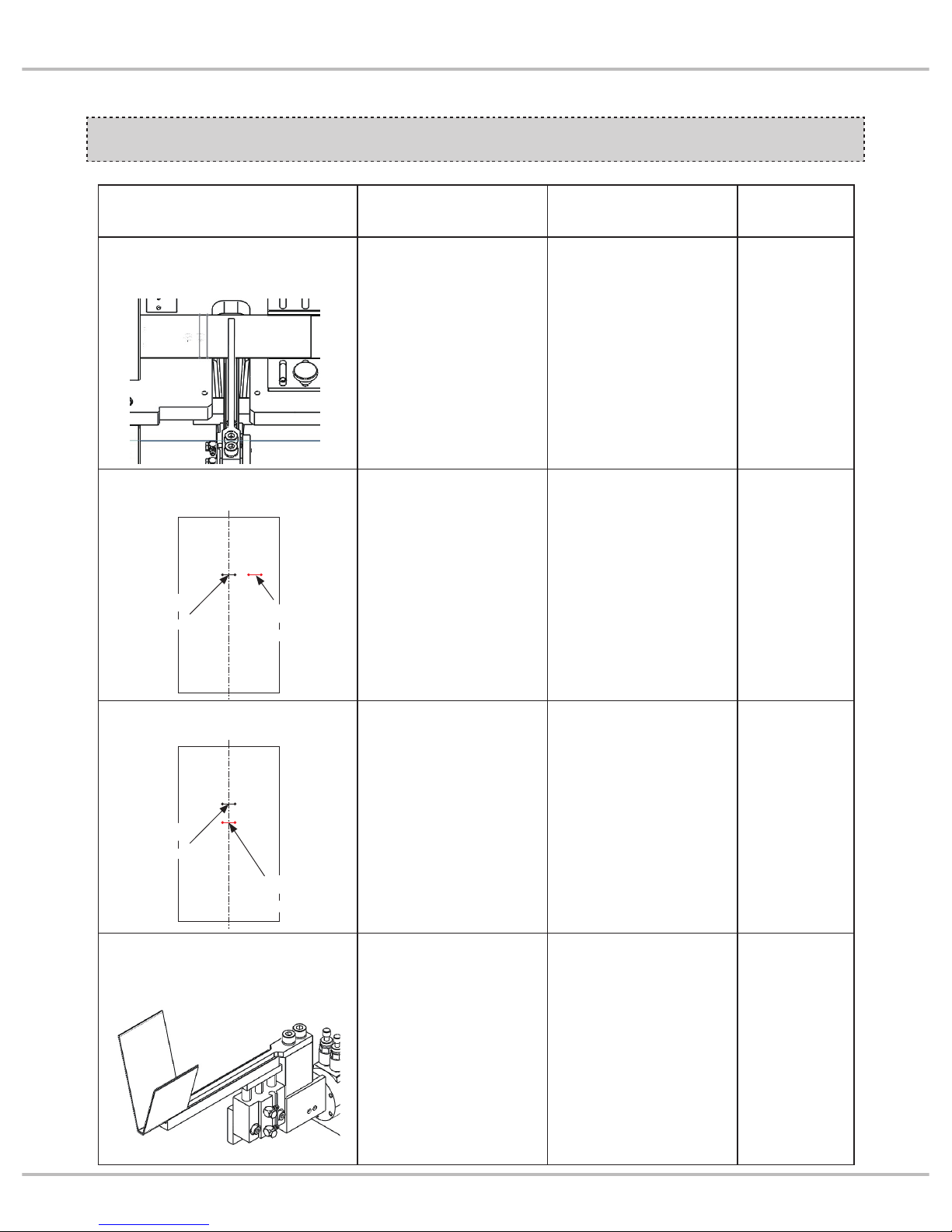

摺痕未對夾具中心

Crease is not in the clamp

middle

1. 紙卡安裝位置偏移。

2. 夾具機構位置錯誤。

1.Label position

deviates

2.Clamp position error

1. 微調料槽長度滑塊位

置。

2. 調整氣缸束環位置。

1.Fine tune length

sliding block position

of material platform

2.Adjust the position of

cylinder limiting ring

P.00~P.00

P.00

縫線未在紙卡正中心

Sewing line is not on the label

middle.

1. 紙卡安裝位置偏移

1.Label position

deviates

微調料槽寬度滑塊位

置及限位塊。

Fine tune position of

width sliding block

and limiting block

P.00~P.00

縫線未在指定位置

Sewing line is not on assigned

location

1. 擋邊氣缸位置錯誤

1.Wrong position of

guide block cylinder

微調擋邊氣缸固定座的

鎖固位置。

Fine tune fixed position

of guide block cylinder

seat

P.00

夾槽無法開啟

Unable to open clamp

slotlocation

1. 疊料造成

1.Materials overlap.

吸盤分料時,調整吹嘴

角度與風量使疊料分

離。

When suction cup

catches material,

adjust the angle of air

nozzle and the strength

of air to separate

material stack.

P.00

P12

Introduction

實際位置

Actual location

實際位置

Actual location

預定位置

Assigned

location

預定位置

Assigned

location

Page 18

現象

Description

原因

Reason

對策

Solution

參考頁數

Ref. page

成形角度不足

Forming angle is not enough 1. 夾槽選用錯誤。

1. Select wrong clamp

slot

更換適用該紙卡摺痕

寬度的夾槽。

Replace clamp slot

which is suitable for

label crease width.

P.00~P.00

吸盤取料失敗

Failure to catch material by

suction cup

1. 載料平台上升停止

位置過低。

1.Material platform

raises not enough.

微調入料檢知位置。

Fine-tune filling

detection position.

P.00

夾具撞擊夾料區紙卡

Clamp crashes label on forming

part

1. 料卡不平整拱起而

被進

入的夾棒撞歪。

1.Material label is not

flat and arch so it is

crashed by clamping

rod when rod is

entering

料卡拱起程度不可超

過 3mm,需人工整

平。

Material label can not

arch more than 3 mm

or need to smoothen

it by users.

P.00

P13

Page 19

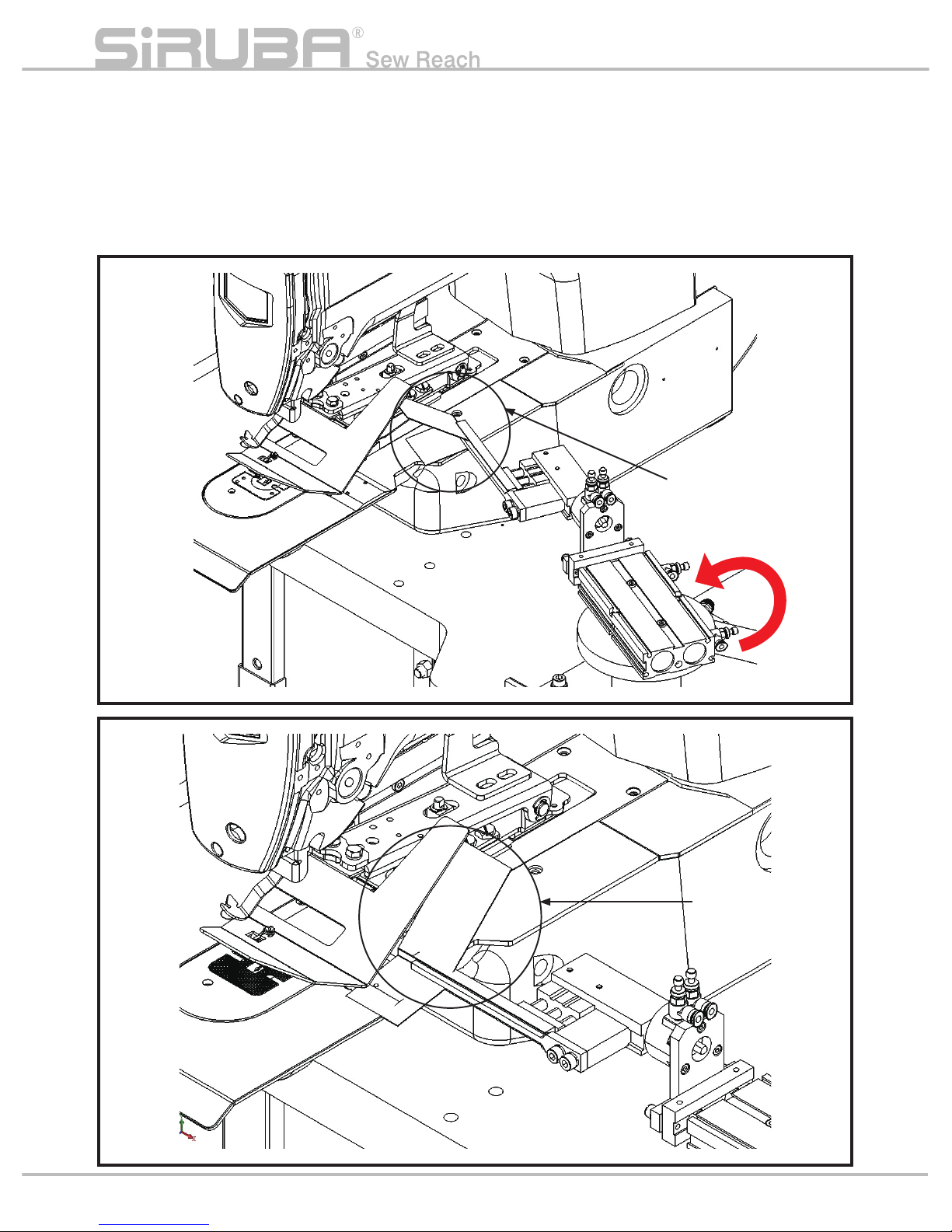

1. 紙卡疊料

吸盤吸附紙卡兩張以上時,將造成夾具無法

開夾而異常,此時可以調整吹氣嘴的角度與

吹氣量大小來進行疊料排除。(註: 紙卡若

因印刷油墨沾黏則需人工排除)

1. Labels overlap

When suction cup catches more than 2 labels,

clamp will not open and error. In this situation,

we can adjust the angle of air nozzle and the

strength of air blow to remove material stack

(note: users will need to remove by hand if

labels stick together by ink or else)

旋轉螺桿可調整吹氣量大小

Able to adjust blowing strength

by rotatory screw rod

需使用 3mm 六角板手伸入氣孔調整吹氣角度

Need to use 3 m m hex wrench to enter air

inlet to adjust the angle of blowing air

氣嘴調整方式

Air nozzle adjustment

氣嘴

Air nozzle

P14

Introduction

Page 20

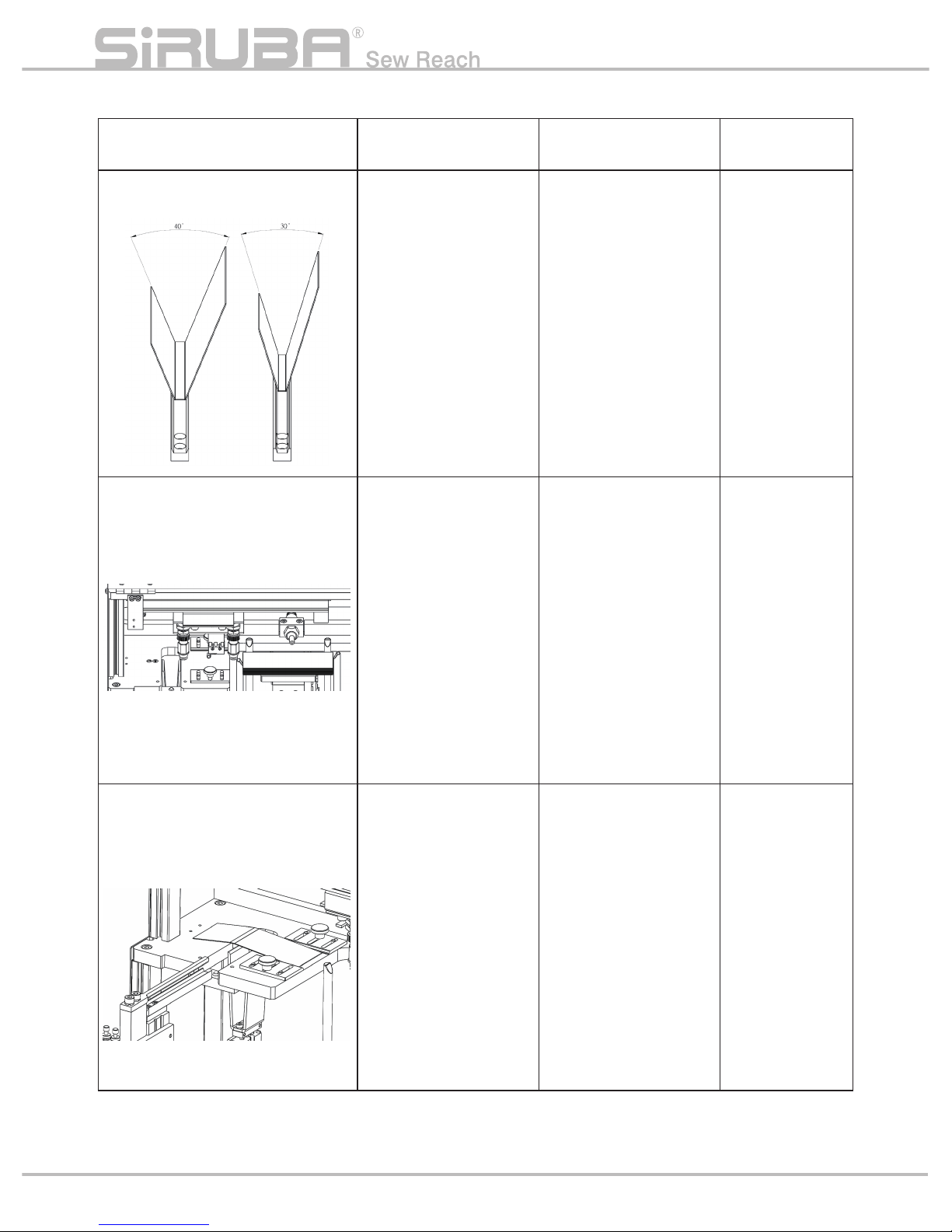

2. 成型角度不足

夾具有對應摺痕5mm或6mm寬的夾槽,

當成型角度不足時,會發生進料失敗的情形,

此時需更換正確的夾槽才能順利成形。

2.Incorrect forming angle

Clamp need to match 5mm or 6mm width

clamp slot. When the forming angle is not

enough, feeding process will be error. In such

situation, we need to replace correct clamp

slot to form it correct.

P15

夾角過大

Too large angle

進料失敗

Failure to

feed material

Page 21

夾槽選用錯誤時將產生成形角度不足的問題

If choosing wrong clamp slot, it will result in

the problem of not enough forming angle.

夾槽更換方式

Exchange of clamp slot

P16

Introduction

摺痕 5mm 寬的紙卡

5

mm

width Label

crease

摺痕 6mm 寬的紙卡

6

mm

width Label

crease

5mm 寬的夾槽

5

mm

width clamp slot

6mm 寬的夾槽

6

mm

width clamp slot

夾棒

Clamp rod

鬆開螺絲將夾棒拆下後,可拆除夾槽

內鎖固螺絲再進行更換夾槽作業

After loosing screws and remove

clamp rod, we could remove locking

screws in clamp slot and then start

to change clamp slot

夾槽

Clamp slot

Page 22

3. 機構位置錯誤

夾 具 歪 斜 可 鬆 開 汽 缸 束 環 的 位 置 來 進 行 微

調。

3. Incorrect mechanism position

If clamp skews, we can loose cylinder limiting

ring for fine tuning the position.

限位束環是鎖在氣缸軸上,鬆開螺絲後微調

位置再鎖固即可改變夾具歪斜角度。

Limiting ring is locked on the cylinder shaft.

Loose, fine-tune position and then lock the

screw to adjust the clamp skew angle.

P17

夾具歪斜

Clamp skews

限位束環

Limiting ring

限位束環

Limiting ring

Page 23

4. 吸盤取料失敗

台移載時未將料卡吸住則為取料失敗

4. Failure for suction cup to catch material

When suction cup platform moves to next

step but does not catch material label well,

suction cup fails to catch material.

調整入料檢知位置可決定載料平台的上升高

度。

To adjust filling detection position could

control the raise height of material platform.

P18

Introduction

鬆開螺絲後可

調整檢知位置

After loosing

screws, we

could adjust

detection

position

Page 24

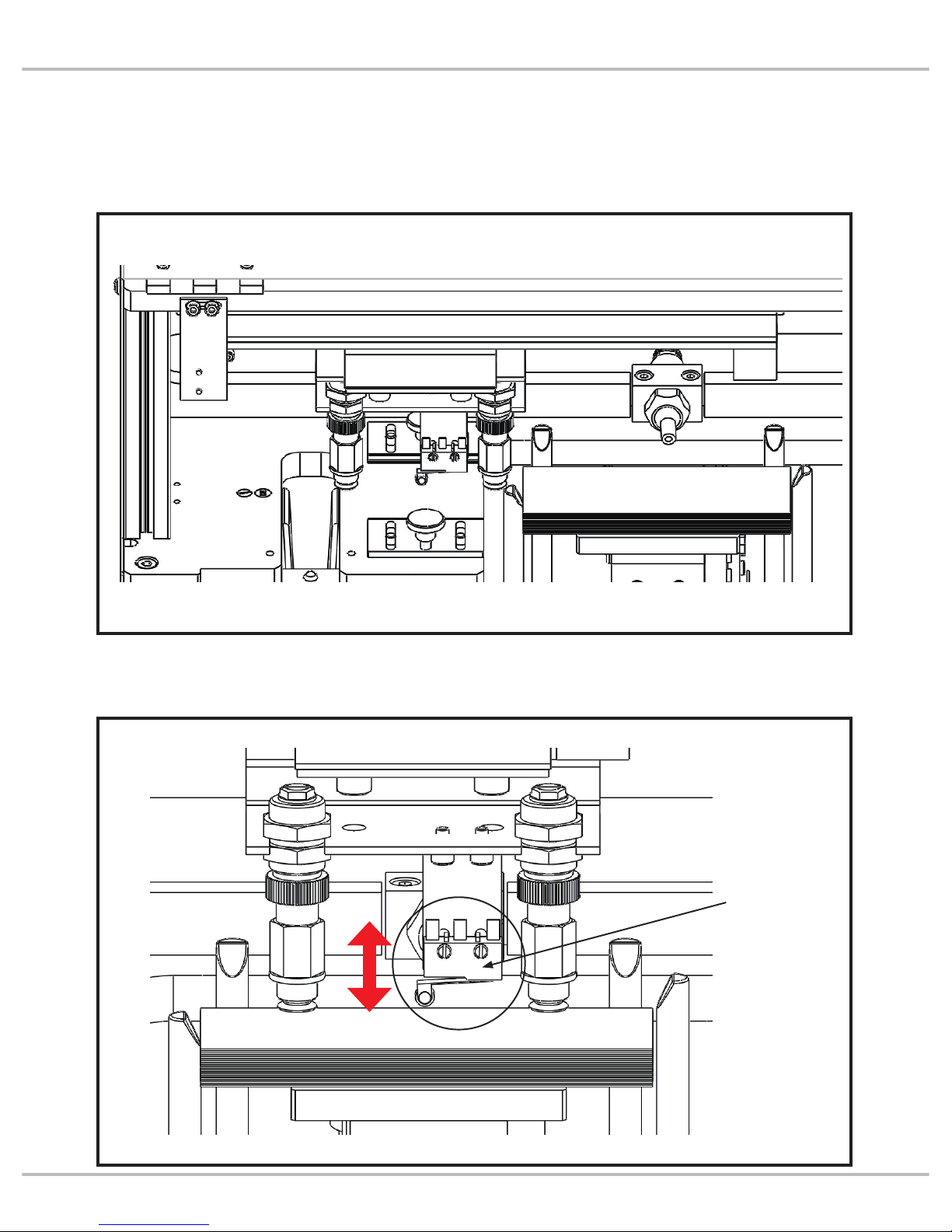

真空吸氣量亦是取料因素之一,可單獨調整

氣壓調速閥控制吸力大小。若發現過濾器已

髒汙嚴重時請進行更換,未更換則吸力會因

阻塞逐漸變弱。

Vacuum suction strength is also a factor to

catch material label. We can only adjust flow

control valve to adjust suction strength. If

users find air filters seriously polluted, please

replace it, or suction strength will become

lesser because of blocks.

P19

過濾器

Filter

真空產生器

Vacuum generator

氣壓調速閥

Adjustable valve of air

pressure

Page 25

動作模式

MODE SELECT

(1)單動模式 ( 1 ) Single-step mode

手動狀態 Manual mode

選擇手動模式 OK,車頭 READY,機構回

原點

Select manual mode -> OK, machine

head READY, machine back to original

point

載料平台下降至下極限點,放入料卡

Lower material platform to lower limit and

fill material labels

吸盤平台 ON -移動向後

Suction cup platform ON - move forward

載料平台上升至吸料高度

Raise material platform to the level to catch

material

吸盤 ON -吸附

吹嘴 ON

載料平台下降至待命點

Suction cup ON - attach

Blow ON

Lower material platform until ready

吸盤平台 ON -移動向前

Suction cup platform ON - move forward

吸盤 OFF -紙卡落下

吹嘴 OFF

Suction cup OFF - label fall down

Air nozzle OFF

吸盤平台 OFF -移動向後

Suction cup platform OFF - move

backward

前伸氣缸 ON -進入夾料區

Forward cylinder ON - enter material

region

夾具氣缸 ON -夾持

Clamp cylinder ON - clamp

整形氣缸 ON -上升整形

Forming cylinder ON - raise to form

前伸氣缸 OFF -後退

Forward cylinder OFF - backward

整形氣缸 OFF -下降

Forming cylinder OFF - lower

待轉氣缸 ON -待轉區

Standby cylinder ON - standby region

旋轉缸 ON -旋轉

Rotatory cylinder ON - rotate

進料氣缸 ON -進料

Feeding cylinder ON - feed material

前伸氣缸 ON -進入車縫區

Forward cylinder ON - enter sewing

region

壓腳下壓

Lower presser foot

夾具氣缸 OFF -開夾

Clamp cylinder OFF - open clamp

前伸氣缸 OFF -後退

Forward cylinder OFF - backward

擋邊氣缸 ON -推至縫紉區

Guide block cylinder ON - move to

sewing region

壓腳抬起

Raise presser foot

壓腳下壓,車縫開始-結束

Lower presser foot, sewing start-finish

P20

Introduction

Page 26

(2)自動模式 (2)Automatic mode

手動狀態 Manual mode

自動狀態 Automatic mode

吸盤平台 ON -移動向後

Suction cup platform ON - move forward

載料平台上升至吸料高度

Raise material platform to the level to catch

material

檢查夾料區訊號

Check the signal

from forming region

吸盤 ON -吸附

吹嘴 ON

載料平台下降至待命點

Suction cup ON - attach,

Blow ON (2 secs),

Llower material platform to standby point

吸盤平台 ON -移動向前

Suction cup platform ON - move forward

吸盤 OFF -紙卡落下

Suction cup OFF - label fall down

吸盤平台 OFF -移動向後

Suction cup platform OFF - move

backward

檢查夾料區訊號

Check the signal

from forming region

前伸氣缸 ON -進入夾料區

Forward cylinder ON - enter material

region

夾具氣缸 ON -夾持

Clamp cylinder ON - clamp

整形氣缸 ON -上升整形

Forming cylinder ON - raise to form

前伸氣缸 OFF -後退

整形氣缸 OFF -下降

Forward cylinder OFF - backward

Forming cylinder OFF - lower

開機第一次 FEED

First FEED after

turning on

進料氣缸 OFF

待轉氣缸 OFF

旋轉缸 OFF

Feed cylinder OFF

待轉氣缸 OFF

Rotatory cylinder OFF

選擇手動模式 OK,車頭 READY,機構回原點

Select manual mode -> OK, machine head READY,

machine back to original point

載料平台下降至下極限點,放入料卡

Lower material platform to lower limit and fill material labels

待轉氣缸 ON -待轉區

Standby cylinder ON - standby

region

旋轉缸 ON -旋轉

Rotatory cylinder ON - rotate

檢查車縫結束訊號

Check sewing

finish signal

進料氣缸 ON -進料

Feeding cylinder ON - feed

material

前伸氣缸 ON -進入車縫區

Forward cylinder ON - enter

sewing region

壓腳下壓

Lower presser foot

夾具氣缸 OFF -開夾

Clamp cylinder OFF - open clamp

前伸氣缸 OFF -後退

Forward cylinder OFF - backward

擋邊氣缸 ON -推至縫紉區

Guide block cylinder ON - move

to sewing region

壓腳抬起

Raise presser foot

壓腳下壓,車縫開始

Lower presser foot and start

sewing

車縫結束

Finish sewing

P21

Page 27

(3)單縫模式(補縫模式)

開啟電源後,在單動模式下按下人機介面數

字鍵8即進入單縫模式,此時自動送料機構

停止動作。主要用於人工摺紙卡再進行車縫

或補縫用。

(4)單捲線模式

此模式下可單獨捲線

注意!!啟動此模式前請將車針拆下避免撞

斷車針

依照下列順序進行。

A. 將 " 電源開關① " 切至OFF。

B. 將 " 電源開關① " 切至O N。

D. 按下 " 準備鍵② " 變成O N。

E. 按下 " 準備鍵② " 變成OFF。

G. 按下 " 運轉鍵③ ",使其燈號在 " 捲線圖案

" 上亮起。

H. 按下 " 準備鍵② " 變成O N。

I. 按下 " 起動鍵④ " 即可運轉。

J. 捲完線,按下 " 起動鍵④ " 即可停止。

(3)Only sewing mode (re-sew mode)

After turning on the power, press number "8"

on the panel in s

tep mode to enter only sewing

mode. Then, automatic feeder stop working.

This mode is mainly designed for users to fold

label by hand and then to sew or to re-sew it.

(4)Only winding mode

We could only wind in this mode.

Notice !! Please remove sewing needle to

prevent crushing the needle before activating

this mode.

Follow below sequences:

A. Turn OFF "Power switch ① ".

B. Turn ON "Power switch ① ".

D. Press "Ready ② " to become ON.

E. Press "Ready ② " to become OFF.

G. Press "Operarion ③ " to turn on "Winding

symbol" light.

H. Press "Ready ② " to become ON.

I. Press "Activation switch ④ " to run.

J. After winding, press "Activation switch ④ " to

stop.

P22

Introduction

捲線圖案 Winding symbol

①

②

③

④

Page 28

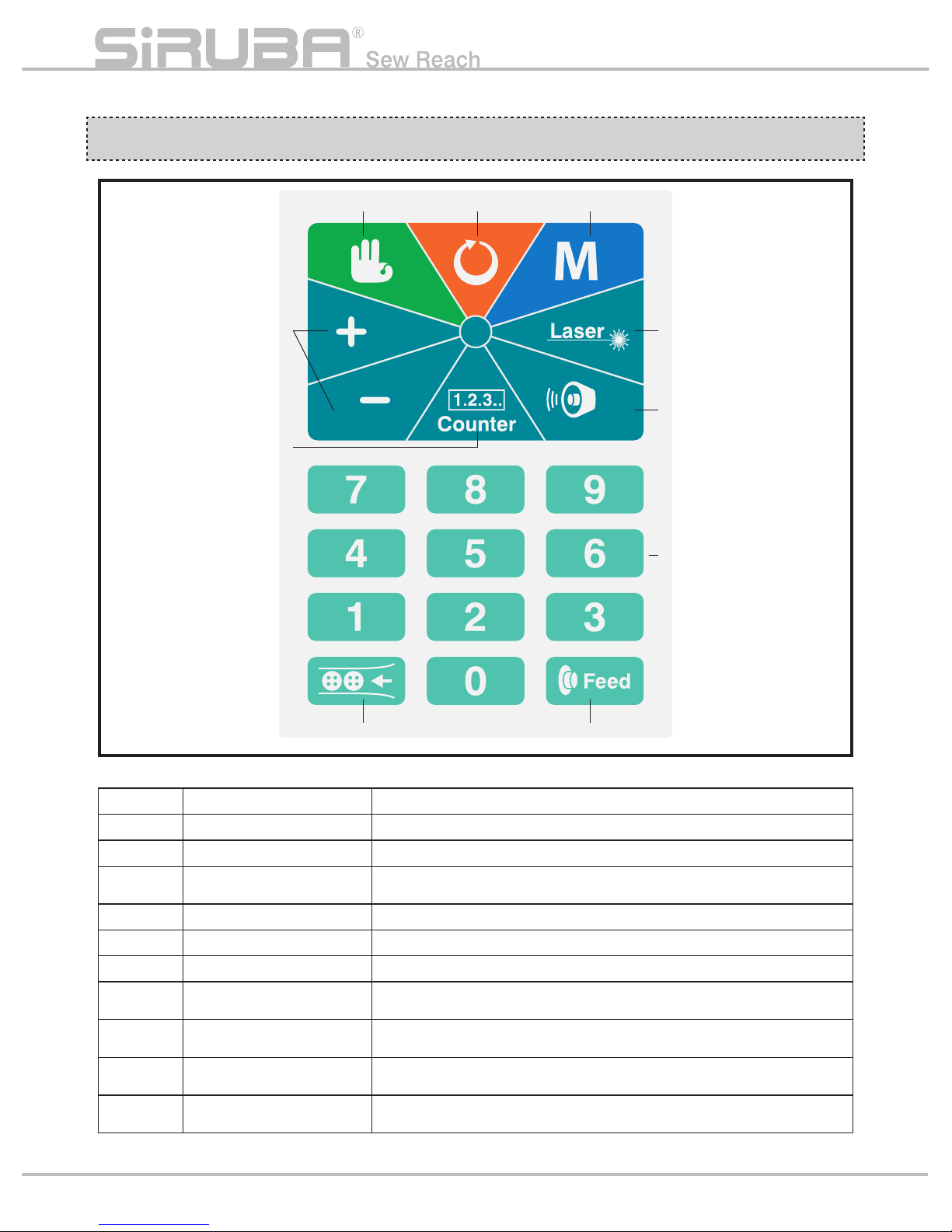

按鍵說明 BUTTON INSTRUCTIONS

代號 Code 名稱 Description 備註 Memo

1 確認 ( 準備 ) Enter

2 重置 Reset

3 參數 Parameter

在主頁面時按下可進入 A 參數頁面。

Press this key to enter "A" parameter page under main menu.

4 備用 Spare 無使用。No function

5 備用 Spare 無使用。No function

6 備用 Spare 無使用。No function

7 選擇 ( 調整 ) Select

進入參數調整與馬達測試時使用

Use for parameter adjustment or motor test

8 數字鍵 Digit Key

氣缸測試模式時使用

Use for test mode of an air cylinder

9 送料鍵 Feed Material

送紙卡至待車縫區

Send label to sewing region

10 補料鍵 Fill Material

自動模式時,讓載料平台下降,進行補料動作

In automatic mode, lower material platform and then fill materials

P23

① ② ③

④

⑤

⑥

⑦

⑧

⑨⑩

Page 29

操作說明 OPERATION INSTRUCTION

Auto Run 操作說明 < 單踏板 > Auto Run operation instruction<single pedal>

按確認鍵進入模式

Press enter button

to enter the mode

主畫面顯示

Auto 模式

Home screen

shows Auto mode

按送料鍵進行送料動作 ( 第一步

動作須先送一紙卡至待車縫區 )

Press this button to feed material

(first step is to send one label to

sewing region )

進入 Auto Run

模式

Enter Auto Run

mode

踩車縫踏板 (L)

進行車縫與送料動作

Tread on activation pedal (L)

to process sewing

按補料鍵進行補

料動作

Press this button

to fill material

按送料鍵進行送料動作

Press this button to feed material

補料完成後按下重

置鍵

After

filling material,

press reset button

按確認鍵 離開 Auto Run 模式

Press enter button to leave Auto

Run mode

經人工判斷發現夾到兩張紙卡時,先按一次重置鍵,

手動將紙卡取出,再按一次重置鍵,進行再次夾料

動作

If users find more than two labels on the clamp,

press reset button first and then take labels out.

Press reset button again and then let machine

clamps material again

夾料臂於待命令

位置 , 等待命令

Clamp stays in

original and wait

for order

Au to

Mode

:

STAR T

Fu nction

Auto Run

P24

Introduction

Page 30

Auto Run 操作說明 < 雙踏板 > Auto Run operation instruction <2-step pedals>

踩壓腳踏板 (R) 將壓腳下壓

Tread on this pedal (R)

to lower presser foot

踩車縫踏板 (L) 進行車縫與送料動作

Tread on activation pedal (L)

to process sewing and feeding

按補料鍵進行補料動作

Press this button to fill

material

按送料鍵進行送料動作

Press this button to send material

(must raise presser foot in advance)

補料完成後按下重置鍵

After filling material,

press reset button

按確認鍵 離開 Auto Run 模式

Press enter button to leave Auto Run mode

經人工判斷發現夾到兩張紙卡時,先按一次 重置鍵,手

動將

紙卡取出,再按一次 重置鍵,進行再次夾料動作

If users find more than two labels on the clamp, press reset

button first and then take labels out. Press reset button again

and then let machine clamps material again

夾料臂於待

命令位置 , 等

待命令

Clamp stays

in original

and wait for

order

按確認鍵進入模式

Press enter button

to enter the mode

主畫面顯示

Auto 模式

Home screen

shows Auto mode

按送料鍵進行送料動作 ( 第一步

動作須先送一紙卡至待車縫區 )

Press this button to feed material

(first step is to send one label to

sewing region )

進入 Auto Run

模式

Enter Auto Run

mode

Au to

Mode

:

STAR T

Fu nction

Auto Run

P25

Page 31

Manual 模式 < 單踏板 > Manual mode <One pedal>

Manual 模式 < 雙踏板 > Manual mode <2-step pedals>

進入 Manual 模式

Enter Manual mode

進入 Manual 模式

Enter Manual mode

踩車縫踏板 (L) 執行車縫動作

Tread on activation pedal (L)

to process sewing

踩壓腳踏板 (R) 將壓腳下壓

Tread pedal for presser foot (R) to lower presser foot

踩車縫踏板 (L) 執行車縫動作

Tread activation pedal (L) to process sewing

按 選擇鍵 + 進行下一步動作

Press select button “+" to process next step

按數字鍵 8 將擋邊伸出 / 退回

Press number “8" to stretch guide block out/back

按確認鍵離開 Manual 模式

Press enter to leave

Manual mode

Manual

Manual

按確認鍵進入模式

Press enter button

to enter the mode

按確認鍵進入模式

Press enter button

to enter the mode

主畫面顯示 Auto 模式

Home screen shows Auto mode

主畫面顯示 Auto 模式

Home screen shows Auto mode

Au to

Mode

:

STAR T

Fu nction

Au to

Mode

:

STAR T

Fu nction

按 選擇鍵 + 進行下一步動作

Press select button “+" to process next step

按數字鍵 8 將擋邊伸出 / 退回

Press number “8" to stretch guide block out/back

按確認鍵離開 Manual 模式

Press enter to leave Manual mode

P26

Introduction

Page 32

模式選擇方式 Mode selection

按確認鍵進入

Press enter button

to enter system

主畫面顯示當前模式

Home screen shows

present mode

按選擇鍵選擇模式

Press select button

to select mode

Au to

Mode

:

STAR T

Fu nction

Mode

:

STAR T

Fu nction

Manual

M

Au to

Mode

:

STAR T

Fu nction

參數說明 PARAMETER INSTRUCTION

Item

參數編號

Code

參數名稱 Description 備註 Memo

1 A01

電磁閥 / 壓腳測試 Solenoid valve / presser foot test

0~9 , 補料鍵

0~9 , button to fill material

電磁閥

編號

Solenoid

valve

No.

1 運料電磁閥 Transmission solenoid valve

2 前伸電磁閥 Forward solenoid valve

3 夾爪電磁閥 Clamp solenoid valve

4 塑型電磁閥 Forming solenoid valve

5 翻轉電磁閥 Rotation solenoid valve

6 定位電磁閥 Position solenoid valve

7 到位電磁閥 Arrival solenoid valve

8 擋邊電磁閥 Guide block solenoid valve

9 壓腳 Pre

sser foot

0 吸嘴電磁閥 air nozzle solenoid valve

補料鍵

Fill material

吹氣電磁閥 Blowing solenoid valve

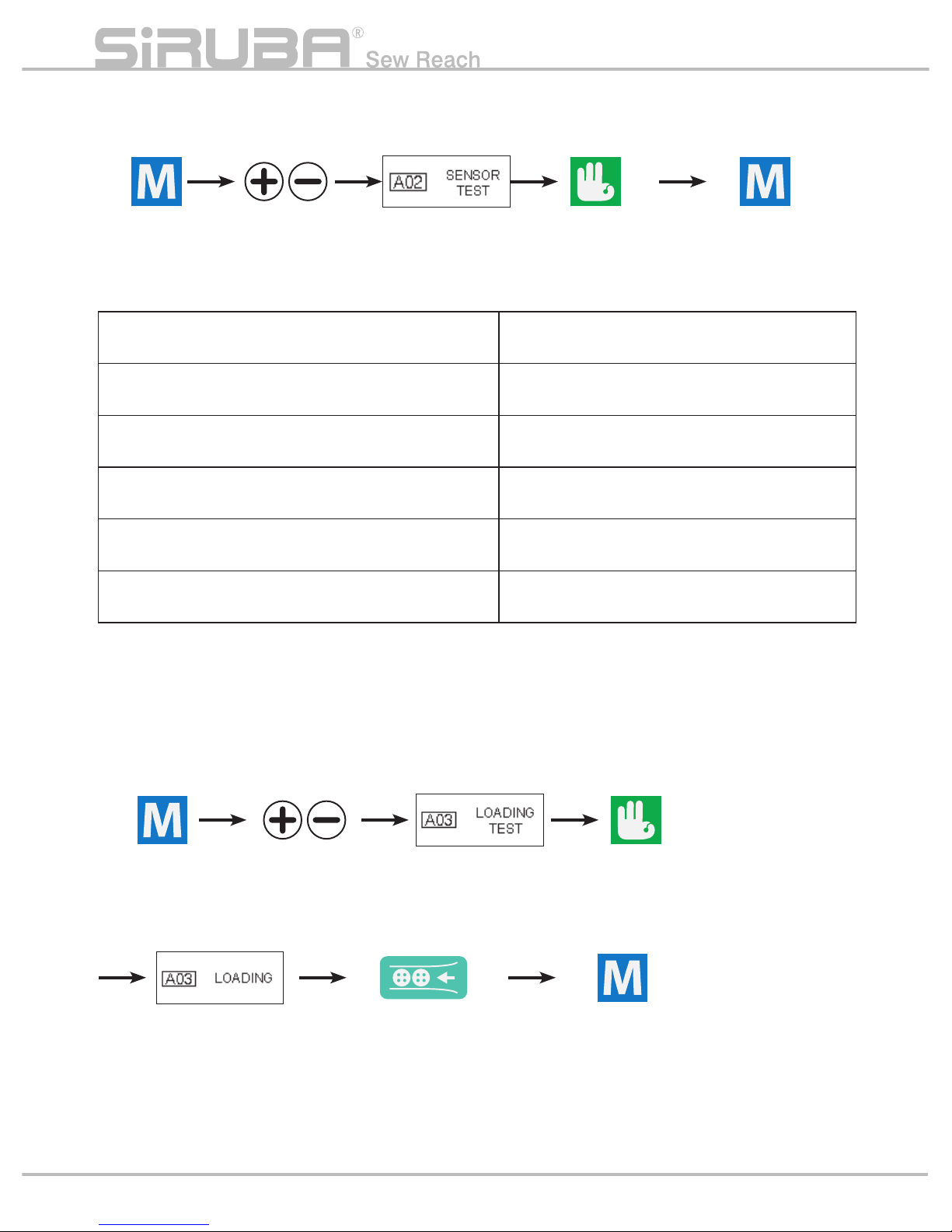

2 A02 SENSOR / 訊號 測試 SENSOR / signal test IN1~IN9 , INA~INC

SENSOR

編號

SENSOR

No.

IN1 前伸氣缸磁簧開關 Forward cylinder reed switch

IN2 塑型氣缸磁簧開關 Forming cylinder reed switch

IN3 定位氣缸磁簧開關 Position cylinder reed switch

IN4

擋邊氣缸磁簧開關 Guide block cylinder reed switch

IN5 車縫踏板訊號 Sewing activation pedal signal

IN6

準備點位置微動開關

Micro switch on stan

dby point of suction cup

IN7 成型區感應器 Sensor on forming part

IN8

原點位置磁簧開關

Reed switch on original point of suction cup

IN9 上極限開關 Upper limit switch

INA 下極限開關 Lower limit switch

INB 有料判別開關 Storage material detect sensor

INC 壓腳踏板訊號 Presser foot pedal signal

3 A03 入料動作測試 Filling material test

4 A04 步進馬達動作測試 Stepping motor action test

5 A05

單 / 雙 踏板動作方式選擇

Select one/two-step pedals

1 : 單踏板方式 .2 : 雙踏板方式

1:one pedal/ 2:2-step pedals

7 版本顯示 Version display

P27

Page 33

A01 各電磁閥測試 A01 test each solenoid valve

進入後以下列選擇數字鍵 / 補料鍵測試 After entering parameter menu, press following

numeric key/ filling button to test

附註 :

●

運料氣缸需馬達於下極限與前伸氣缸於縮回狀態才

能做動

●

前伸氣缸需運料氣缸於原點位置才能做動

●

翻轉氣缸需前伸氣缸於縮回狀態與夾料臂於待命令

位置點才能做動

●

定位氣缸需前伸氣缸於縮回狀態與翻轉氣缸未翻轉

狀態下才能做動

●

到位氣缸需前伸氣缸於縮回狀態與夾料臂於待命令

位置點才能做動

●

壓腳動作需 JUKI 車頭為 Ready 狀態下才能做動

Memo:

●

Transmission cylinder only works when motor is on

lower limit and forward cylinder moves back

●

Forward cylinder only works when transmission

cylinder on the original point

●

Rotation cylinder only works when forward cylinder

moves back and clamp is at standby point

●

Position cylinder only works when forward cylinder

moves back and rotation cylinder does not rotate.

●

Arrival cylinder only works when forward cylinder

moves back and clamp is at standby point

●

Presser foot only works when JUKI machine head

is on ready status

A 參數 - 需在主頁面按才有動作 A parameter - only activate on home screen

數字鍵

Number key

電磁閥

Valve

說明

Description

1

電磁閥 1

Valve 1

運料電磁閥

Transmission solenoid valve

2

電磁閥 2

Valve 2

前伸電磁閥

Forward solenoid valve

3

電磁閥 3

Valve 3

夾爪電磁閥

Clamp solenoid valve

4

電磁閥 4

Valve 4

塑型電磁閥

Forming solenoid valve

5

電磁閥 5

Valve 5

翻轉電磁閥

Rotation solenoid valve

6

電磁閥 6

Valve 6

定位電磁閥

Position solenoid valve

7

電磁閥 7

Valve 7

到位電磁閥

Position solenoid valve

8

電磁閥 8

Valve 8

擋邊電磁閥

Guide block solenoid valve

9

壓腳

Presser foot

壓腳動作

Move presser foot

0

電磁閥 9

Valve 9

吸嘴電磁閥

Air nozzle Solenoid valve

補料鍵

Button to fill material

電磁閥 10

Valve 10

吹氣電磁閥

Blowing solenoid valve

按數字鍵 / 補料鍵

Press numeric key/

fill-material button

按項目選擇鍵

press select

button

按參數設定鍵

Press parameter

setting button

按參數鍵 2 次回主畫面

Press parameter button

twice to move back

home screen

選擇 A01

Select A01

P28

Introduction

Page 34

A02 SENSOR / 訊號檢測 A02 SENSOR / SIGNAL DETECTION

A03 入料動作測試 A03 test the action of filling material

※ 手動操作氣缸, sensor 有亮滅,且螢幕有 ON/OFF 切換表示正常;上 / 下極限開關用一金屬物靠近

以輔助判別 sensor 是否正常

※Users operate cylinder, sensor LED on/off well and screen shows ON/OFF switch -> machine is well;

use a metal rod to approach upper/lower limit switches to check if sensors are well.

按參數設定鍵

Press parameter

setting button

按項目選擇鍵

press select

button

選擇 A03

Select A03

進入測試模式

Enter test mode

按參數鍵 2 次回主畫面

Press parameter

button twice to move

back to home screen

按補料鍵執行入料動作

Press this button to

process filling material

按確認鍵進入設定

Press enter button to

enter the setting

IN1:前伸氣缸磁簧開關

IN1:Forward cylinder reed switch

IN7:成型區感應器

IN7:Sensor on forming part

IN2:塑型氣缸磁簧開關

IN2:Forming cylinder reed switch

IN8:原點位置磁簧開關

IN8:Reed switch on original point of suction cup

IN3:定位磁簧開關

IN3:Position reed switch

IN9:上極限開關

IN9:Upper limit switch

IN4:擋邊磁簧開關

IN4:Guide block reed switch

INA:下極限開關

INA:Lower limit switch

IN5:車縫踏板訊號

IN5:Sewing activation pedal signal

INB:有料判別開關

INB:Storage material detect

sensor

IN6:準備點位置微動開關

IN6:Micro switch on standby point of suction cup

INC:壓腳踏板訊號

INC:Presser foot pedal signal

按確認鍵進入設定

Press enter button

to enter the setting

按項目選擇鍵

press select

button

按參數設定鍵

Press parameter

setting button

按參數鍵 2 次回主畫面

Press parameter button

twice to move back

home screen

選擇 A02

Select A02

P29

Page 35

A04 步進馬達測試

A05 單 / 雙踏板方式選擇 A05 choose single/double pedals

版本顯示 Version display

按參數設定鍵

Press parameter

setting button

按參數設定鍵

Press parameter

setting button

按參數設定鍵

Press parameter

setting button

按項目選擇鍵

press select

button

按項目選擇鍵

press select

button

按項目選擇鍵

press select

button

按選擇鍵選擇

單 (1)/ 雙 (2) 踏板

Press select buttons to select

one(1)/ 2-step(2) pedals

選擇 A04

Select A04

選擇 A05

Select A05

顯示版本代號。

D_VER: 控制板版本

M_VER: 操作盒版本

Display version code

D_VER: control board version

M_VER: control box version

由選擇鍵

+ / - 選擇

馬達運轉方向

(+) 載料平台向上

( - ) 載料平台向下

Press select button

+ / - to choose

rotatory direction

of motor

Motor direction

(+) raise material

platform

( - ) lower material

platform

按參數鍵 2 次回主畫面

Press parameter

button twice to move

back to home screen

按參數鍵 1 次回主畫面

Press parameter

button once to move

back to home screen

按參數鍵 1 次回主畫面

Press parameter

button once to move

back to home screen

按確認鍵進入設定

Press enter button

to enter the setting

按確認鍵進入設定

Press enter button

to enter setting

按確認鍵確認方向

Press enter button

to decide direction

按確認鍵確認方向

Press enter

button to select

踩車縫踏板 (L), 馬達運轉

Tread activation pedal (L),

motor starts running

※ 選擇方向後須再次按下 確認鍵 ※Need to press enter button after choosing

direction

xx.xx.xx

xx.xx.xx

P30

Introduction

Page 36

故障排除 TROUBLE SHOOTING

•DC24V 電源供應器 •DC24V power supply

AC110/220V 電源輸入

AC110/220V

INPUT

PIN 符號 Symbol 說 明 Description

1 L AC220V 輸入 Input

2 N AC220V 輸入 Input

3 PE 接地 Ground

4 -V 0V

5 -V 0V

6 +V +24V

7 +V +24V

P31

Page 37

CN1 I/O 板連接埠 ( 排線連接 IO 板 CN1)

CN1 Control board port ( Flexile flat cable

connect with CN1 on control board )

CN1000 I/O 板連接埠 ( 排線連接 IO 板 CN2)

CN1000 Control board port ( Flexile flat cable

connect with CN2 on control board )

控制板 ( 一 ) CONTROL BOARD (I)

CN11 輸入控制

CN11 INPUT CONTROL

CN10 輸出控制

CN10 OUTPUT CONTROL

PIN 符號 Symbol 說明 Description PIN 符號 Symbol 說明 Description

1 VCC

外部輸入電壓

Input power

1 PC12

校正成型區感應器

Correcting sensor on forming part

2 VCC 備用 Spare 2 PC13 備用 Spare

3 PA11 車頭訊號 Machine head signal 3 PC14 車縫 Sewing

4 PA12 備用 Spare 4 PC15 壓腳 Presser foot

5-8 24V DC24V

J3 VCC2 跳帽電壓選擇埠

J3 VCC2 voltage select port for

jumper cap

J2 VCC1 跳帽電壓選擇埠

J2 VCC1 voltage select port for

jumper cap

J4 VCC 跳帽電壓選擇埠

J4 VCC voltage select port for

jumper cap

PI

符號

Symbol

說 明

Description

PI

符號

Symbol

說 明

Description

PI

符號

Symbol

說 明

Description

1 24V

DC24V 電源輸入

DC24V Power Input

1 24V

DC24V 電源輸入

DC24V Power Input

1 24V

DC3.3V 電源輸入

DC3.3V Power Input

2 VCC2 2 VCC1 2 MS2

馬達全 / 半步選擇

Full/half step motor select

3 5V

DC5V 電源輸入

DC5V Power Input

3 5V

DC5V 電源輸入

DC5V Power Input

3 GND GND

跳帽選擇 5V&COM

Jumper selects 5V&COM

跳帽選擇 24V&COM

Jumper selects 24V&COM

跳帽選擇 MS2&GND

Jumper selects MS2&GND

P32

Introduction

J3 J2 J4

CN11 CN10

CN1 CN1000

Page 38

CN9 ADC 信號輸入

CN9 ADC Signal Input

CN6 DC24V 輸入

CN6 DC24V Input

CN7 DC24V 風扇輸出

CN7 DC24V Fan Output

PIN

符號

Symbol

說 明

Description

線色 PIN

符號

Symbol

說 明

Description

PIN

符號

Symbol

說 明

Description

1 3.3V

3.3V 電源輸出

3.3V Power Input

紅 Red 1 24V

DC24V 電源輸入

DC24V Power Input

1 24V

2 GND GND 黑 Black 2 0V 2 0V

3 IN

ADC 信號輸入

ADC Signal Input

藍 Blue 3 FG 外殼接地 GND

4 NC

CN12 IIC 信號 ( 備用 I/O)

Spare for Signal I/O

CN8 操作盒通信接口

Communication Connector

CN4 步進馬達

CN4 Stepper Motor

PIN

符號

Symbol

說 明

Description

PIN

符號

Symbol

說 明

Description

PIN

符號

Symbol

說 明

Description

線色

1 GND GND 1 5V

5V 電源輸出

5V Power Output

1 CA

A 相中心點

A Phase center

白 White

2 PA8

壓腳踏板

Presser foot pedal

2 BOOT0 2 CB

B 相中心點

B Phase center

黃 Yellow

3 PB9

有料判別開關

Storage material

detect sensor

3 GND GND 3 A A 相 A Phas

e 紅 Red

4 PD2 備用 Spare 4 4 /A /A 相 /A Phase 藍 Blue

5 PB15

準備點位置微動開關

Reed switch on standby point

5 5 B B 相 B Phase 綠 Green

6 TX 6 /B /B 相 /B Phase 黑 Black

7 RX

信號輸入

Signal Input

8 GND GND

控制板 ( 二 ) CONTROL BOARD (II)

P33

CN9 CN4

CN12

CN8

CN7

CN6

Page 39

I/O 板 I/O BOARD

PIN 符號 Symbol 說明 Description

IN(X)_Pin1 P24 X=1~7 此接點為輸出 24V Output 24V on X=1~7

IN(X)_Pin3 GND 此接點為輸出 GND, GND output

IN(X)_Pin1 VCC

X=8~10 此接點可由 J1 跳帽選擇輸出 24V or 5V

Output 24V or 5V switched by jumper cap J1 on X=8~10

IN1~IN10 輸入信號 IN1~IN10 Input signal

IN 1_Pin2 IN1 前伸氣缸磁簧開關 Forward cylinder reed switch

IN 2_Pin2 IN2 塑型氣缸磁簧開關 Forming cylinder reed switch

IN 3_Pin2 IN3 定位氣缸磁簧開關 Position cylind

er reed switch

IN 4_Pin2 IN4 擋邊氣缸磁簧開關 Guide block cylinder reed switch

IN 5_Pin2 IN5 下極限開關 Lower limit switch

IN 6_Pin2 IN6 車縫踏板 Sewing activation pedal

IN 7_Pin2 IN7 上極限開關 Upper limit switch

IN 8_Pin2 IN8 成型區感應器 Sensor on forming part

IN 10_Pin2 IN10 原點位置磁簧開關 Reed switch on original point of suction cup

CN1 控制板連接埠 CN1 control port

( 排線連接控制板 CN1) (connector control board CN1)

CN2 控制板連接埠

CN2 control port

( 排線連接控制板 CN1000)

(connector control board CN1000)

P34

Introduction

IN10 IN7 IN4 IN1

IN8 IN5 IN2

IN9 IN6 IN3

CN2

CN1

Page 40

J1 VCC 跳帽電壓選擇埠 Jumper voltage select port

腳位

PIN

符號

Symbol

說明

Description

1 24V DC24V 電源輸入 DC24V Power Input

2 VCC

3 5V DC5V 電源輸入 DC5V Power Input

跳帽選擇 5V&COM Jumper select 5V&COM

J2 VCC2 跳帽電壓選擇埠 Jumper voltage select port

腳位

PIN

符號

Symbol

說明

Description

1 24V DC24V 電源輸入 DC24V Power Input

2 VCC2

3 5V DC5V 電源輸入 DC5V Power Input

跳帽選擇 24V&COM Jumper select 24V&COM

CN4 I/O 板輸出連接埠 CN4 I/O board output port

腳位 PIN 符號 Symbol 說明 Description

1 OUT 7 到位氣缸電磁閥 Arrival cylinder solenoid valve

2 OUT 8 擋邊氣缸電磁閥 Guide block cylinder solenoid valve

3 OUT A 備用 Spare

4 OUT 9 吸嘴氣缸電磁閥 Suction nozzle cylinder solenoid valve

5 OUT 10 吹氣氣缸電磁閥 Blowing cylinder solenoid valve

6 OUT B 備用 Spare

7~9 24V DC24V 電源輸入 DC24V power input

10~12 VCC2 J2 跳帽選擇 24V&COM J2 jumper cap selects 24

V&COM

CN3 I/O 板電磁閥連接埠 CN3 I/O board solenoid connection port

腳位 PIN 符號 Symbol 說明 Description

1 OUT 1 運料氣缸電磁閥 Transmission cylinder solenoid valve

2 OUT 2 前伸氣缸電磁閥 Forward cylinder solenoid valve

3 OUT 3 夾料氣缸電磁閥 Clamp cylinder solenoid valve

4 OUT 4 塑型氣缸電磁閥 Forming cylinder solenoid valve

5 OUT 5 翻轉氣缸電磁閥 Rotation cylinder solenoid valve

6 OUT 6 定位氣缸電磁閥 Position cylinder solenoid valve

7~12 24V DC24V 電源輸入 DC2

4V Power Input

J1

J2

CN3

CN4

P35

Page 41

檢查控制板和操作盒連接

的訊號線接頭是否鬆脫 ?

Check if signal cable

between control board

and control box is loose

or not

檢查訊號線外觀

是否有破損 ?

Visually check if

outlook of signal

damages or not

電表量測訊號線

兩端對應訊號

Use meter to

detect relative

cable signals

from both end

sides

重新接妥再測一次

Re-connect and check again

重新開機後再測試一次

Re-boot and test again

更換線材再測一次

Exchange cable and

check again

更換線材再測一次

Exchange cable and

check again

更新程式時重開

機 ?

Check if re-boot

when renewing

program ?

簡易維修流程圖 SIMPLE MAINTENANCE

U3 電路圖

U3 circuit diagram

CN6 電路圖

CN6 circuit diagram

P36

Introduction

YES

YESYES

NO

NO NO

出現錯誤代碼 E01:

通訊故障

ERROR CODE E01:

COMMUNICATION ERROR

U3

F1

CN6

Page 42

A. 無電源

Step 1. 檢查電源插頭是否完整插入 ?

Step 2. 檢查電源開關是否開啟 ?

Step 3. 檢查控制基板

a. 檢查控制板 LED 是否正常亮起 ?

b. 電表量測 CN6 是否為 DC24V?

c. 檢查 F1 ( 3.15A FUES) 是否燒斷 ?

d. 電錶量測 U3 是否為 5V 與 3.3V?

5V 量測 U3 Pin3 與 Pin1

3.3V 量測 U3 Pin2 與 Pin1

B. 步進馬達轉動異常

目測 U11 (SLA7073MRT ) IC 外觀塑膠部份是

否有裂痕 ?

A. No Power

Step 1.check if power connector fully plugs

in.

Step 2.check if power switch is on.

Step 3.check control board.

a.check LED of control board is on.

b.use meter to check

if CN6 is DC24V.

c.check if F1 ( 3.15A FUSE) burn out.

d.use meter to check if U3 is 5V or 3.3V.

5V check U3 between Pin3 and Pin1

3.3V check U3 between Pin2 and Pin1

B. stepping motor runs error

Visually inspect U11 (SLA7073MRT ) IC if

there is damage on plastic outlook.

U11

P37

LED

Page 43

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

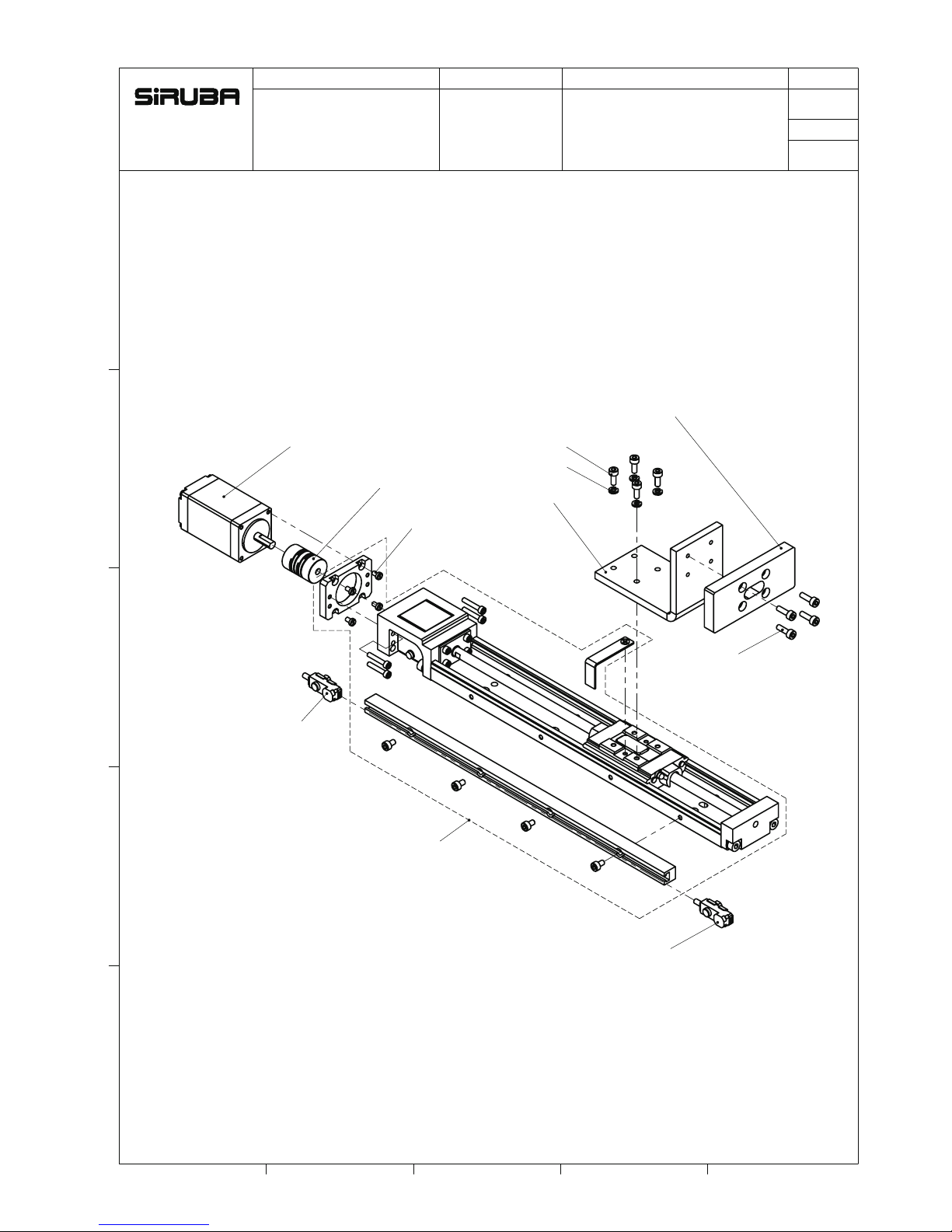

PTA-0034

4-SM031

4-SM313N

4-WM310

PTA-0006

PTA-0007

4-SM311N

PTA-0321

PTA-0314

PTA-0315

PTA-0035

/

1 16

ASP-PTA100

PTA-0035-A

P38

Page 44

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

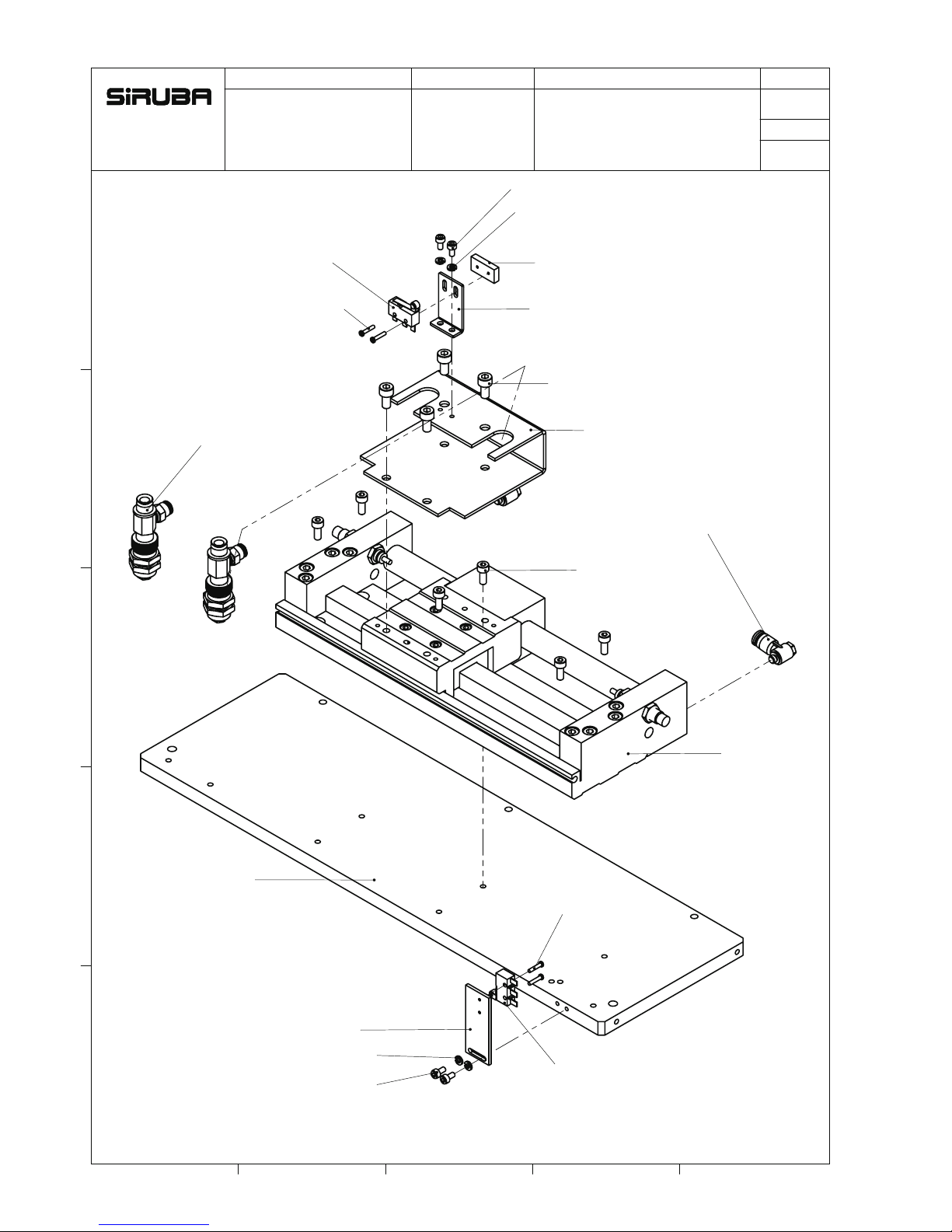

UWB-0018

PTA-0011

2-SM310N

2-WM310

PTA-0320

2-SM233

4-SM510N

PTA-0010

2-PTA-0024

6-SM411N

2-JA291

PTA-0033

2-SM310N

PTA-0318

AC914

PTA-0003

2-WM310

2-SM233

/

2 16

PTA-0003-A

ASP-PTA100

P39

Page 45

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

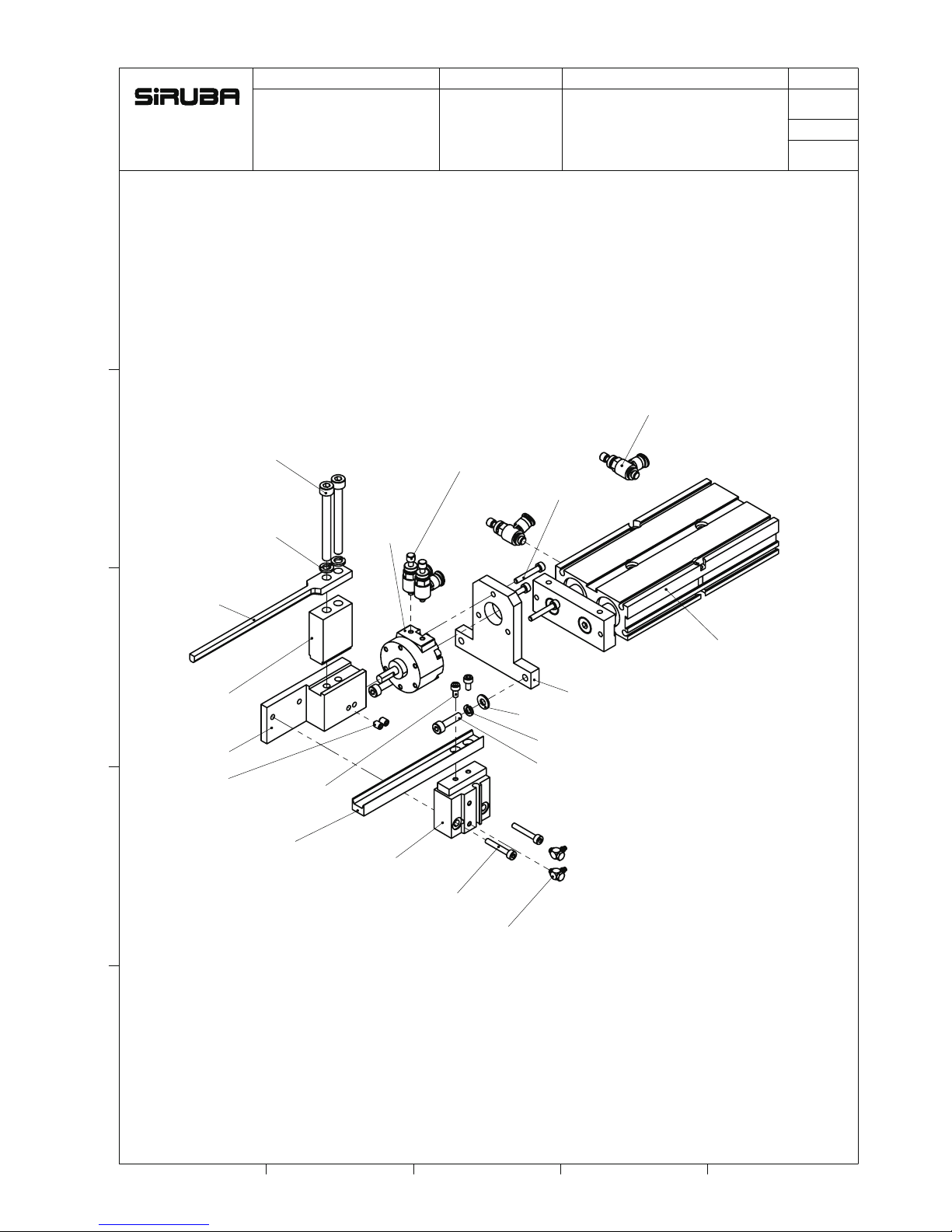

PTA-0004

2-SM4107N

JA045

2-PTA-0025

2-PTA-0023

2-SM516N

3-SM411N

2-SM411N

PTA-0012

PTA-0062

E449-E

2-SM310N

PTA-0036

2-PTA-0013

PTA-0032

PTA-0031

4-PM406

SM357

PTA-0002

/

3 16

PTA-0002-A

ASP-PTA100

P40

Page 46

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

PTA-0035-A

4-PTA-0022

4-SM510N

SM418N

WM410

PTA-0020

PTA-0028

PTA-0005

2-PTA-0029

8-SM418N

2-PTA-0030

4-SM313N

PTA-0021

2-SM313N

2-WM310

5-PTA-0026

3-PTA-0008

5-SM404

2-JA0403

2-SM411N

2-WM410

2-WM4001

AC702

2-SM311N

2-PTA-0009

4-PTA-0015

PTA-0016

2-ASP-4088

8-SM031

2-PTA-0060

PTA-0001

/

4 16

ASP-PTA100

PTA-0005-A

P41

Page 47

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

PTA-0003-A

PTA-0002-A

8-SM410N

4-WM410

3-SM411N

6-SM510N

2-ASP-0191

4-NM413

PTA-0018

9-SM4050

PTA-0017

ASP-0205

PTA-0019

PTA-0005-A

PTA-0027

/

5 16

ASP-PTA100

PTA-0019-A

P42

Page 48

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

PTA-0043

2-PTA-0042

2-EM070

PTA-0041

PTA-0039

AC332

AC331

PTA-0040

PTA-0037

2-BR1122

BR7200

PTA-0038

4-JA045

2-SM404

/

6 16

PTA-0038-A

ASP-PTA100

P43

Page 49

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

PTA-0045

PTA-0048

AC718

2-SM3100N

2-JA213

2-SM4106N

2-WM410

2-WM407

2-SM310N

2-SM404

2-SM517

2-WM510

AC717

2-JA042

3-SM3100N

2-JA0403

AC606

PTA-0044

PTA-0072

PTA-0046

/

7 16

PTA-0045-A

ASP-PTA100

P44

Page 50

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

SM814N

2-SM6104N

2-SM4108N

PTA-0019-A

PTA-0045-A

PTA-0038-A

/

8 16

PTA-0001-A

ASP-PTA100

P45

Page 51

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

2-NM413

2-WM410

PTA-0051

2-JA042

2-SM4108NAC714

2-SM502

2-PTA-0055

2-PTA-0053

2-PTA-0054

PTA-0052

2-NM413

2-SM446

2-SM4074

PTA-0061

2-SM411N

2-WM410

2-WM407

/

9 16

PTA-0051-A

ASP-PTA100

P46

Page 52

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

PTA-0067

SM337

WM310

PTA-0059

PTA-0058

SK4202

WM502

2-NM511

2-SM520

2-WM510

/

10 16

PTA-0058-A

ASP-PTA100

P47

Page 53

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

PTA-0063

PTA-0058-A

2-ABF513

2-SM556N

2-SM310N

PTA-0057

PTA-0056

2-SM411N

2-WM407

2-WM410

PTA-0051-A

2-SM411N

LKS-1903ANSS

/

11 16

PTA-0100-A

ASP-PTA100

P48

Page 54

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

4-SK8A1

4-KX09

4-SW07

8-NK45

2-WM601

2-WM610

2-SM6104N

PTA-0099-A

PTA-0050

4-SM4113N

PTA-0064-A

2-ASP-1243

2-WM8000

PTA-0100-A

2-ASP-4161

4-WM601

4-WM610

4-SM6108N

PTA-0049

ASP-0210-A

4-ASP-0211

4-ASP-0212

4-NK72

4-SM821N

4-WM810

4-WM8000

/

12 16

PTA-0049-A

ASP-PTA100

P49

Page 55

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

AMT-0011

DKT301ADE-1

BQ19

23-SM4837

PTA-0065

3-CP106

ASK-0074

AMT-0015

EPS001104

PTA-0323-E

PTA-0324-E

PTA-0069

4-SK392

FU102

/

13 16

PTA-0069-A

ASP-PTA100

P50

Page 56

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

8-WM601

8-WM610

4-NM615

14-SK392

4-SM6109N

BN707

PTA-0069-A

PTA-0001-A

/

14 16

ASP-PTA100

ASP-PTA100

P51

Page 57

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

黑

白

SV-1

2

氣源

1

4

夾具進給

3

夾具

整形

5

翻轉

6

黑

白

黑

黑

黑

白

黑

白

白

待進

Setting pressure:0.5Mpa

移載

SV-2

SV-3

SV-5

SV-6

#1A

#1B

1F

1

#2A

#2B

#3A

#3B

#5A

#6A

#6B 6F

6

5

2F

3F

3

2

inletoutlet

PTA-0099-A

AC914

AC702

AC331

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(11)

(14)

(13)

(8)

JA225*2

AC718

AC717

SV-4

4F

4

#4A

#4B

白

(9)

(10)

黑

B

A

#5B

白 (12)

5F

AC606

(15)

(16)

AC332

7

7F#7B

#7A

SV-7

進料

白

黑

7

擋邊

8

AC714

8

8F

(18)

黑白(17)

#8A

#8B

SV-8

SV-9

SV-10

JA222*2

9

吸嘴

10

吹嘴

#9A

白

#10A

黑

(19)

(20)

(21)

(22)

(23)

(24)

(25)

(26)

(27)

(28)

#9

#9

#10

ASP-PTA100

/

15 16

氣壓流程圖

P52

Page 58

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

#6A

#6B

#7B

#7A

#8B

#8A

#9

10

10

10

10

#4A

#4B

10

10

1B

1A

#2B

#2A

#5A

#5B

#3A

#3B

1B

1A

10

10

10

10

10

10

JA225*2

JA222*2

JA072

#1B

#1A

#1A

#2A

#3A

#5A

#4A

#6A

#7A

#8A

#9

#10

#1B

#2B

#3B

#4B

#5B

#6B

#7B

#8B

#10

/

16 16

ASP-PTA100

氣壓裝配圖

P53

Page 59

P54

Page 60

由於對產品的改良及更新 , 本產品使用說明書中與零件圖之產品及外觀的修改恕不事先通知 !

The specification and/or the equipment described in the instruction book and parts list

are subject to change because of modification with out previous notice

ASP-PTA100.JUN.2018

Loading...

Loading...