Page 1

ASP-BST100

使用說明書與零件圖

INSTRUCTION BOOK & PARTS LIST

Page 2

Page 3

重要安全聲明

SAFETY INSTRUCTIONS

•

感謝客戶您購買本公司產品

為安全且正確地使用本產品 ASP-BST100,請

詳細閱讀以下注意事項後再實施操作。

1. 在使用本機器前,請先詳讀說明書內容,必

須遵守說明書的指示與規定。

2. 此設備的使用,由經過適當訓練的操作人員

實行。

3. 在使用本機器時,若發現異常或故障,應立

即停止使用,並切除電源,以進行妥善修理。

4. 嚴格禁止對本機器進行改造和變更。本公司

對改造或變更過的機器不予保固,若因此造

成危害,本公司將不負任何賠償責任。

•

危險

為杜絕觸電事故必須遵守以下安全措施。

1. 安裝本機器時,必須確實做好接地動作。

2. 對本機器的電氣做定檢與維修,都必須由具

有資格的電氣技術人員執行,或專家的監督

指導下進行。

•

警告

為了杜絕觸電、火災、燒損或對人的傷害,必

須遵守以下安全措施。

1. 本機器在有電壓的狀態下,絕對禁止人員接

觸通電之機件。

2. 本機器若需要做零件更換或進行維修時,應

將電源切換至 OFF

狀態。

•

Thank you for purchasing our company’s

products.

For your safety and using our product ASPBST100 properly, please read the instructions

below deliberately, then start operating the

machine.

1.Before using the machine, you must follow

the instructions and rules.

2.The operators must been well trained.

3.If you found some abnormal phenomena

or the machine malfunction, you should

stop using the machine at the moment and

cut the power off, in order to do the proper

repair.

4.Strictly forbid to do the extra transformation

or alteration. We do not have the warranty

to the machine which had been transformed

or altered. Therefore, our company will be

irresponsible for any compensation if the

machine has caused any danger.

•

Hazards

In order to prevent from the electric shock, you

must to obey the safety measure below.

1. While install the machine, make sure you

have do the grounding.

2. The electric routine inspection and

maintenance of the machine have to be

done by the electric technical personnel who

qualied or under the expert’s supervision.

•

Alert

You must to obey the safety measure below,

in order to prevent from the electric shock, fire

accident, burning loss, or human body injured.

1. Absolute forbid workers to touch the

machine

’s

parts while the machine is in a

voltage state.

2. If the machine

’s

parts need to be changed

or do the maintenance, you should switch

the power off.

i

Introduction

Page 4

3. 當本機器不能正確工作時,應立即停止操作

機器。該機器有必要進行修理、電氣或機器

方面的調整時,需要和本公司的代理商或直

接與本公司聯繫商談,採取合適的解決措

施。

4. 本機器的的維修、調整須經由適當訓練的技

術員或專業人員進行。維修時,需使用本公

司所指定的更換零件。

5. 一般的保修檢查,要由經過適當訓練的人來

進行。

6. 在維修或保養各式氣缸或氣壓相關連動機構

時,務必將供應氣源的接頭拔下,在氣壓完

全切斷的狀態方可進行。不過,只限於受過

適當訓練的技術人員或專業人員進行調整和

運行確認時例外。

7. 該機器準備啟動前,所有的保護蓋必須安裝

定位至機器上。

8. 本機器的內部裝置和控制箱裡不能殘積金屬

粉末和灰塵,要定期打掃。

9. 本機器在運行當中,所有可動部分都絕對不

可用手觸碰,或身體(包括頭髮、衣服類)

靠近。

3. While the machine cannot operate properly,

you should

stop operating it immediately. If

the machine has the necessity to repair, or

do the electric and machine adjustment, you

should contact with our factors, or contact

us directly, then take the proper resolution.

4.The machine’s maintenance and adjustment

need to be done by well- trained technician

or professional. You need to use the specific

parts from our company while under

maintenance.

5. The

repair within the warranty need to be

repair by the worker who well trained.

6. While doing the repair or maintain variety

of cylinders and pneumatic actuator

associated, you must unplug the supply air

source connector before you do the repair

and maintenance. However, it could be

only done by the well- trained technician or

professional.

7. Before ready to start the machine, all of the

protective

covers need to be on the position

of the machine.

8. The inner device and the control box of the

machine need to be regularly cleaned, in

case of any dust or metal filings remains in

the machine.

9. While operating the machine, do not use

your hands to touch or let your body to close

(including hair or clothes) all of the movable

parts.

10.Do not use the wet hands to operate the

machine, it mig

ht cause electric shock or

other major injured.

11.Please be sure to follow the alert pictorial

markings by next page.

10. 絕對不可用濕手操作,可能造成觸電等重

大傷害發生。

11. 警告提示如次頁圖案,請務必遵守。

ii

Page 5

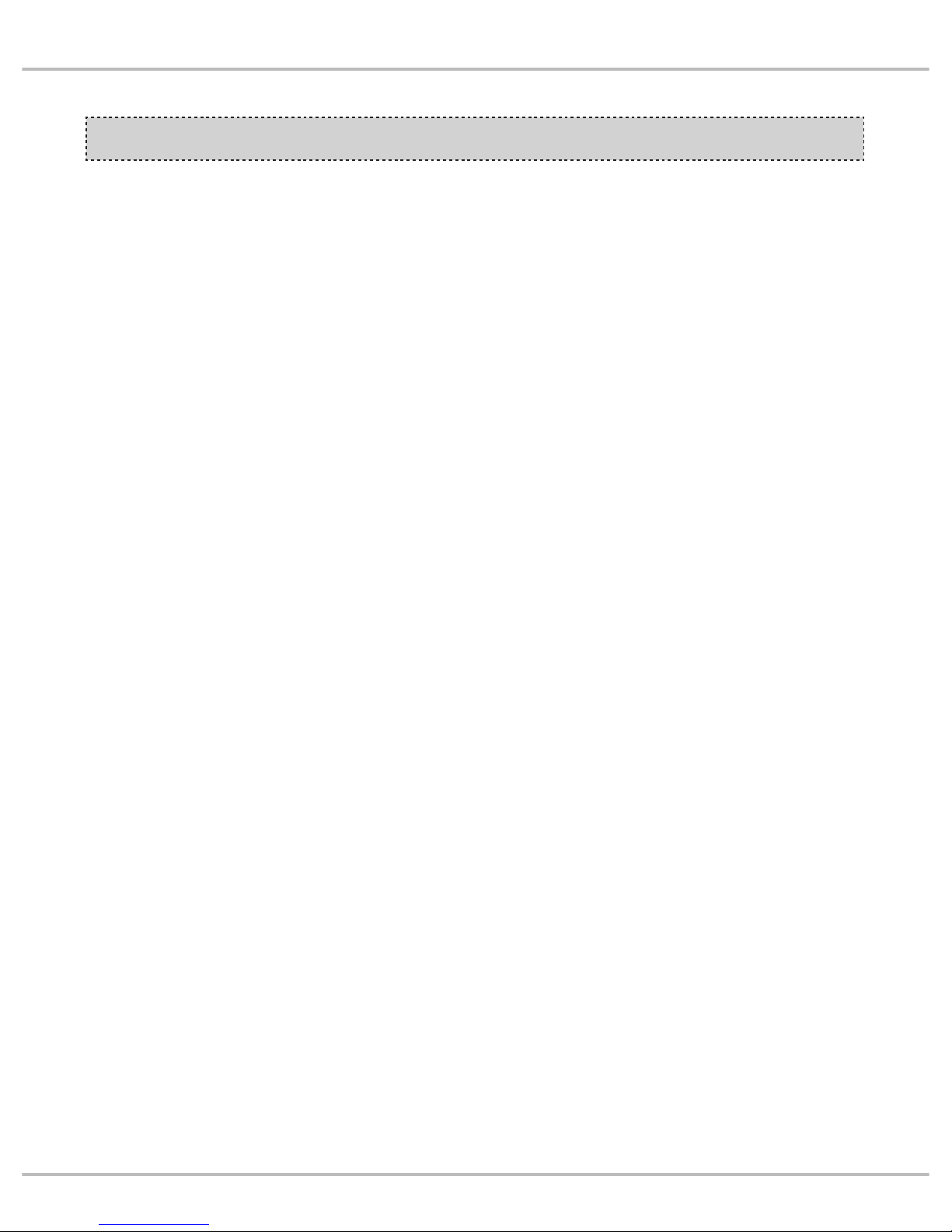

警告圖案表示

INDICATED THE ALERT

PICTORIAL MARKINGS

高壓部位

HIGH-VOLTAGE POSITION

務必關閉電源 10 分鐘後始打開電控

箱蓋子

Be sure to turn off the power and wait

till 10 minutes before opening the

control box’s cover.

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

高速運動部位

HIGH SPEED MOTION

POSITION

謹防工傷事故

In case of industrial accident

CAUTION

機械作動部份請注意裝上

保護裝置

穿線、換線、 調整、清潔

時請注意關閉電源.

Moving parts may cause in jury.

Operate with safety devices.

Turn off main switch before

threading, changing bobbin and

needle, cleaning etc.

iii

Introduction

Page 6

安全注意事項

SAFETY INSTRUCTIONS

2. 為了保修檢修卸掉罩蓋時,必須將電源切到

OFF。

1. 當機器運作中時,請勿將手指等放入機器動

作範圍內。

2.Be sure to turn off the power switch when

the cover is removed for an inspection.

1. Do not put a finger or any other object in the

area where there are moving parts while the

machine is working.

電源開關

Power switch

機器動作範圍 ( 區域 )

Area with moving parts

iv

Page 7

3. 對危及人體的高壓電處,貼有觸電危險警告

標記。在貼有本警告的電器控制部位而需要

保修、檢修時,打開罩蓋僅能由專業的電氣

技術人員進行。

4. 機器運轉時,有必要馬上停止機器的時候,

請將緊急停止開關轉到 OFF。

3.An electric shock warning label is affixed

where there is high voltage electric terminal

which is dangerous to the human body.

Nobody except a special electrician should

open the cover to inspect a control box with

a warning label.

4.If there’s a necessity to stop the machine

right away while mach

ine operating, you

could press the urgent machine halt switch

to switch the power off.

觸電危險警告標記

Electric shock warning label

緊急停止開關 ( 電源開關 )

Urgent machine halt switch

(Power switch)

v

Introduction

Page 8

5. 電源線、氣壓管線需確實固定安置,不可散

落在地面,以免人員絆倒而發生危險。

6. 為了生命安全,在任何情況下,不可將電源

地線拔掉運轉機器。

7. 打雷時,為了安全要停止作業, 切斷電源。

8. 離開機器工作地點時或工作結束後一定要將

電源開關轉到 OFF。

9. 機器運轉下,不可卸下罩蓋類。

5.Power cord and pneumatic cord should

be settled, in order to prevent people from

stumbling.

6.For safety do not operate the machine when

it is not earthed.

7.When there is lightning, stop the machine

and pull out the plug for safety.

8.Turn off the power sw

itch when you are not

near the machine or after the operation is

finished.

9.Do not operate the machine with the covers

off.

vi

Page 9

索引

INDEX

頁 /PAGE

規格 SPECIFICATION 1

安裝 INSTALLATION 2

( 一 ) 八字扣保持器 8-SHAPED BUCKLE FEEDING STAND 2

( 二 ) 圓扣保持器 CIRCLED-BUCKLE FEEDING STAND 2

運轉準備 PREPARATION FOR OPERATING 3

( 一 ) 電源電壓 POWER VOLTAGE 3

( 二 ) 氣壓 AIR PRESSURE 3

( 三 ) 加油 LUBRICATION 3

( 四 ) 穿線 THREADING 3

肩帶裝置方法 STRAP INSTALL METHOD 4

操作 OPERATION 5

( 一 ) 操作面板 OPERATION PANEL 5

( 二 ) 自動運轉的啟動與停止 AUTO-OPERATION START & STOP 7

( 三 ) 自動停止燈燈號、燈滅時復原操作 AUTO-STOP LAMP'S LAMP SIGNAL, OPERATION AGAIN AS LIGHT OFF 7

( 四 ) 縫

製樣式 NO. 的變更方法 METHOD OF CHANGING SEWING PATTERN NO. 10

( 五 ) 縫製尺寸的放大、縮小方法 METHOD OF SEWING SIZE MAGNIFY AND MINIFY 11

( 六 ) 單步操作的運轉 ONE SHOT OPERATION 11

( 七 ) MANUAL 操作 MANUAL OPERATION 12

裝置的標準位置 PRECISE POSITION OF DEVICE 13

( 一 ) 切刀 TRIMMER 13

( 二 ) 八字扣的標準尺 STANDARD RULER OF 8-SHAPED BUCKLE 13

( 三 ) 扣環供給底板及扣環供給端頭 BUCKLE FEEDING BED AND UPPER END 14

( 四 ) 裝置台 DEVICE BED 15

測量器的交換與調整 MEASURER'S CHANGING AND ADJUSTMENT 16

( 一 ) 夾帶盒與上彈簧板的交換 CHANGE OF ST

RAP-FIXED DEVICE AND SPRING PLATE 17

( 二 ) 調節式八字扣固定器的調整 ADJUSTMENT OF ADJUSTABLE 8-SHAPED FEEDING HOLDER 18

( 三 ) 扣環供給底板的交換及調整 CHANGE AND ADJUSTMENT OF BUCKLE FEEDING BED 19

( 四 ) 八字扣保持器的交換 CHANGE OF 8-SHAPED BUCKLE FEEDING STAND 20

( 五 ) 穿板及導帶的交換 CHANGE OF STRAP THREAD PLATE AND STRAP GUIDE 20

( 六 ) 圓扣供給端頭的交換 CHANGE OF CIRCLED-BUCKLE FEEDING UPPER END 21

( 七 ) 圓扣保持器的交換 CHANGE OF CIRCLED-BUCKLE FEEDING STAND 21

( 八 ) 八字扣標準尺的調整 ADJUSTMENT

OF 8-SHAPED BUCKLE STANDARD RULER 22

( 九 ) 反摺導帶的調整 ADJUSTMENT OF COUNTER-FOLDED STRAP GUIDE 22

配線圖 WIRING PICTURE 23

配管圖 PIPING PICTURE 25

不良現象,其原因以及解決方法 DEFECTIVE PHENOMENA'S REASON AND SOLUTIONS 29

零件圖 PARTS LIST 33

vii

Introduction

Page 10

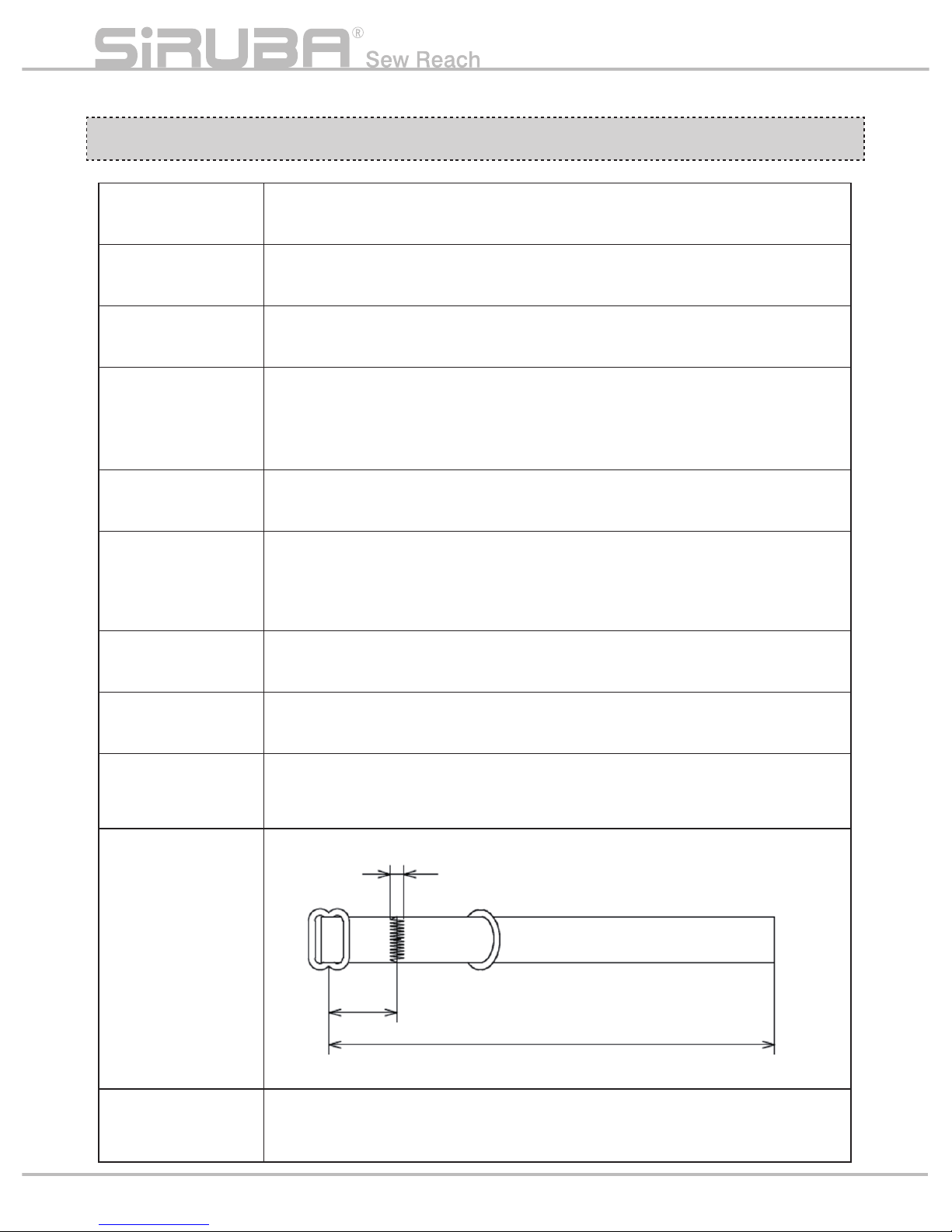

規格 SPECIFICATION

型 號

Model

A S P- B S T 1 0 0

使用針型

Needle Type

DP x 5 SERV7 75 (藍獅)

DP x 5 SERV7 75 (Schmetz)

縫製速度

Sewing speed

2000 RPM(最高 /Maximum)

生產能力

Productive capability

五秒 / 約肩帶一條 ( 當肩帶製作尺寸為 400 mm 時)

Approximately 5 sec. / 1 product (As product sewing size is 400 mm)

寬 度

Width

7mm ~ 18mm

電 源

Power source

單相/3相200~240V 50/60Hz 3. 5A(最大)( 視客戶需求 )

Single-phase/3-phase 200~240V 50/60Hz 3.5A(Maximum)(Depend

on customer’s need)

氣

壓

Air pressure

0. 5MPa

空氣消耗量

Air consumption

30L/ 分

30L/min

機器尺寸

Machine size

寬 1200× 深度 1050× 高 1900 mm

Width 1200×Depth 1050×Height 1900 mm

縫紉尺寸

Sewing size

完成尺寸

Finish product size

150 ~ 1200 mm

3

15

肩帶長度 150~1200mm

Length of strap 150~1200mm

P1

Page 11

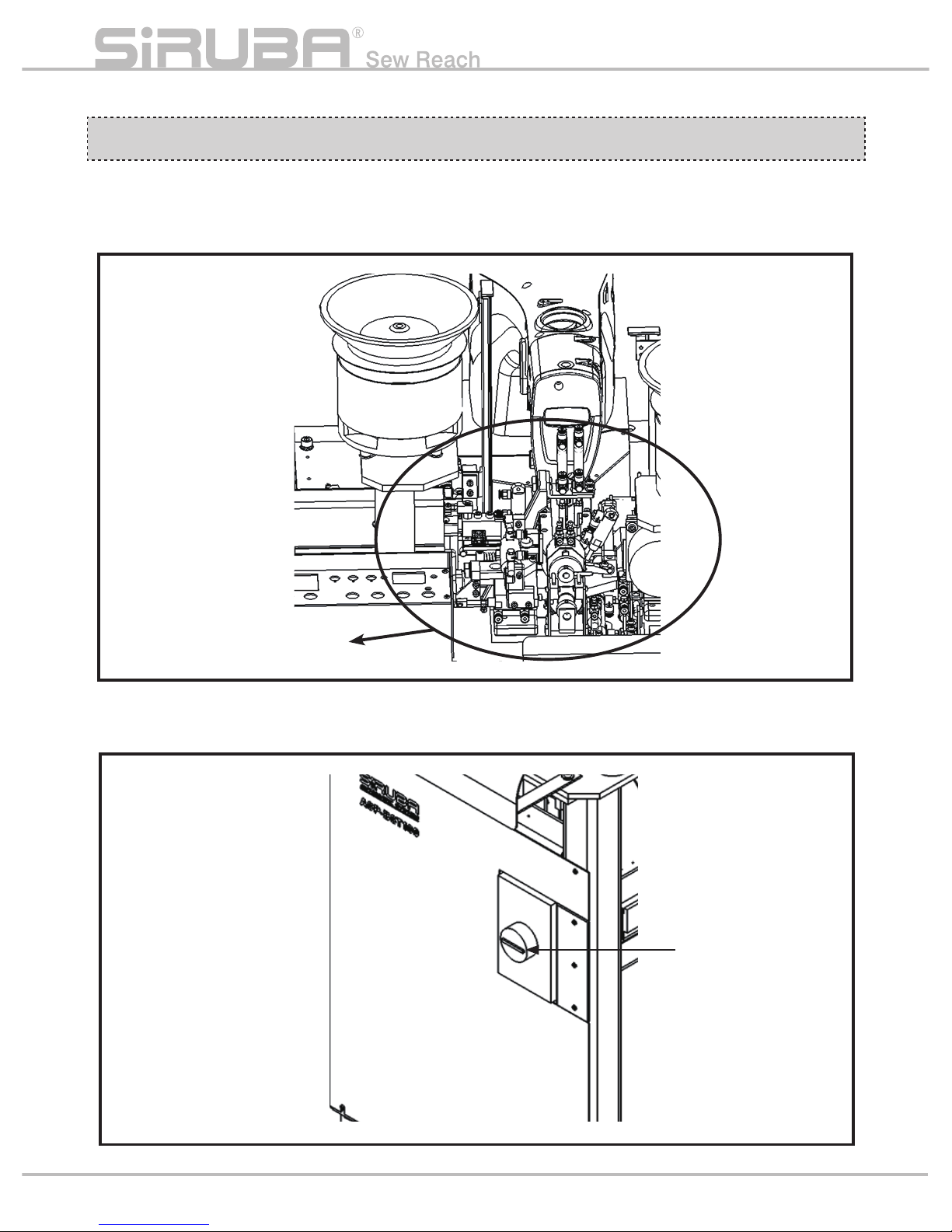

安裝 INSTALLATION

※ 注意:安裝作業需兩人以上執行。

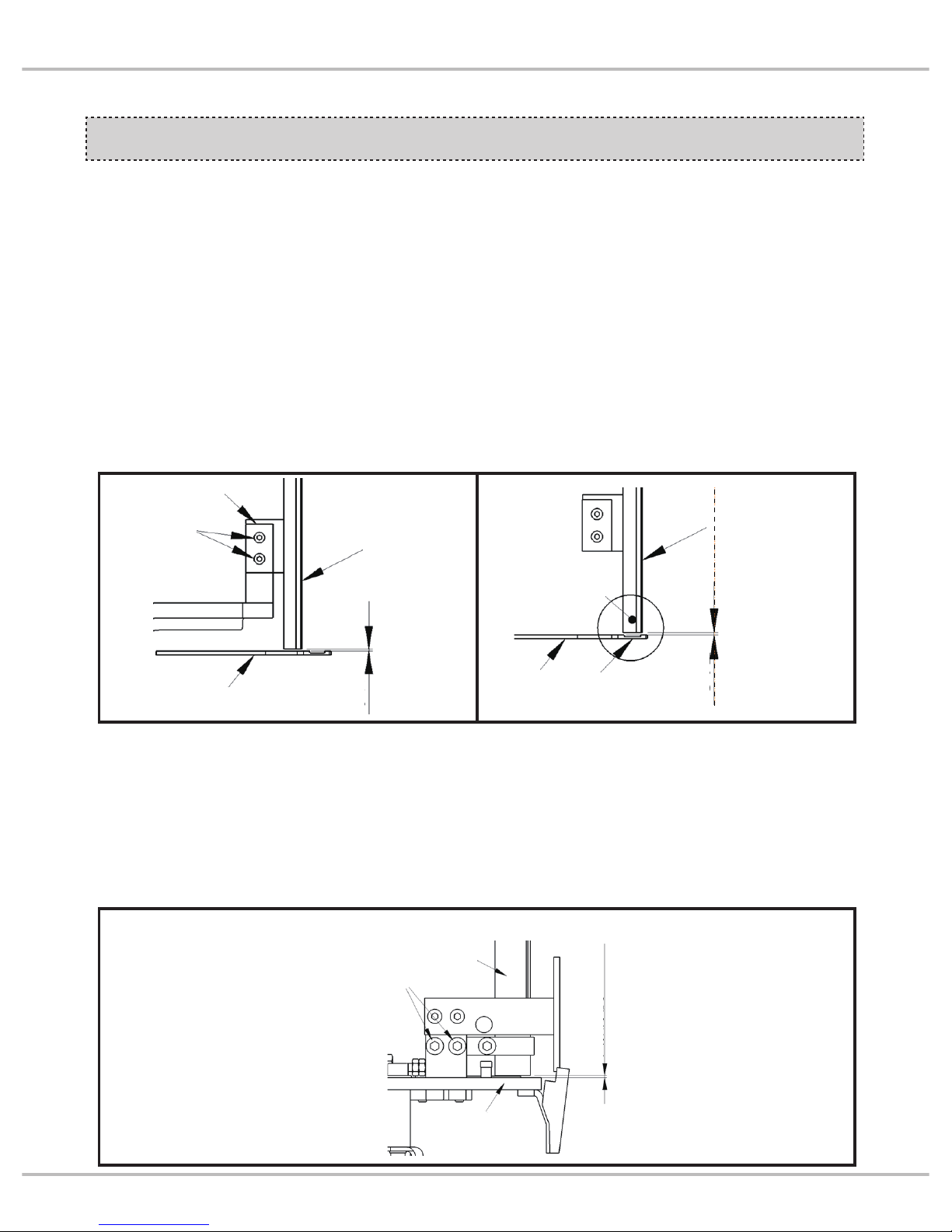

1. 八字扣保持器①

⑴將座板②用螺絲③ (2 顆 ) 固定。

⑵安裝標準

八字扣保持器①與扣環供給底板④的縫隙

為 0.2mm。

扣環供給底板④倒退到最後時,讓八字扣

保持器①底部⑤的內側面和扣環供給下④

的槽一致。

2. 圓扣保持器⑦

⑴將圓扣保持器⑦用螺絲⑧ (2 顆 ) 固定。

⑵安裝標準

圓扣保持器⑦與圓扣供給底板⑨的縫隙為

圓扣厚度的 +0.2mm。

※Caution※ The installation work need two or

more people to proceed.

1.8-shaped buckle feeding stand ①

⑴Use two screws③ to fix plate② .

⑵Install standard

The gap of 8-shaped buckle feeding

stand ①and buckle feeding bed④ are

0.2mm.

As buckle feeding bed④ go backward

at the end, let the inner side of 8-shaped

buckle feeding stand①’s bottom⑤ and

the notch④under the buckle feeding

stand at the same position.

2.Circled-buckle feeding stand ⑦

⑴Use two screws⑧ to fix circled-buckle

feeding stand ⑦.

⑵Install stan

dard

The gap between circled-buckle feeding

stand⑦ and circled-buckle feeding

bed⑨ are the thickness of circledbuckle +0.2mm.

①

③

⑤

⑥

④

①

0.2

0.2

②

④

⑦

圓扣厚度 + 0.2mm

Circ led-bu ckle thickn ess + 0.2mm

⑧

⑨

P2

Introduction

Page 12

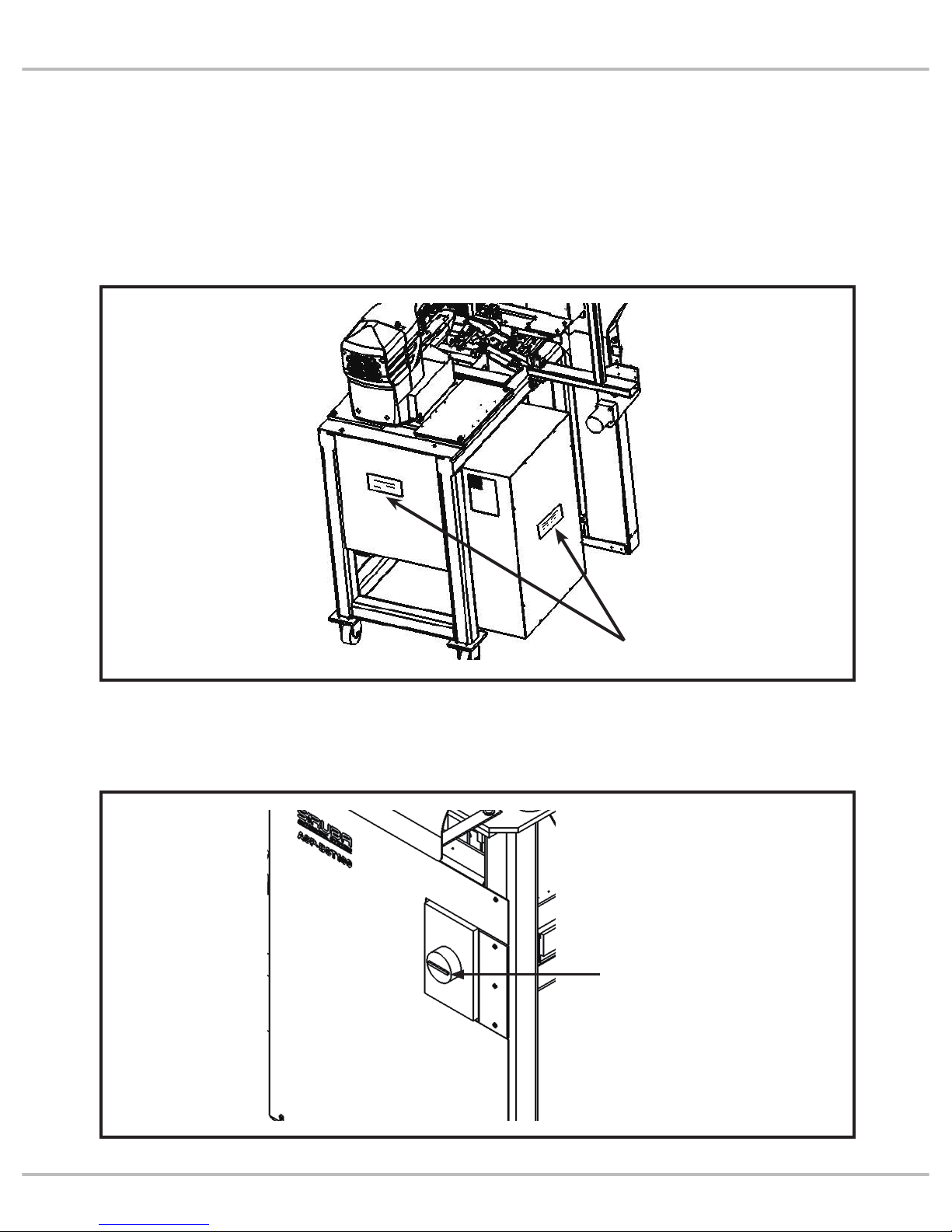

運轉準備 PREPARATION FOR OPERATING

1. 電源電壓

⑴在限定電壓的 ±10% 以內使用。

⑵必須接地線。

2. 氣壓

⑴設定為 0.5MPa

3. 加油

⑴縫紉機頭部依照 LK-1900A 的使用指南加

油。

⑵定期在紅漆標記的給油處為裝置加油。

4. 穿線

⑴在斷線檢測器①穿線。

⑵依照 LK-1900A 的使用指南穿線。

1.Power voltage

⑴Limited voltage uses within ±10%.

⑵Need to be earthed.

2.Air pressure

⑴Set at 0.5MPa

3.Lubrication

⑴Lubricate to sewing head according to LK-

1900A instruction manual.

⑵Regularly lubricate to the device on the

red marking places.

4.T

hreading

⑴Thread at disconnecting detector①.

⑵Thread according to LK-1900A instruction

manual.

①

P3

Page 13

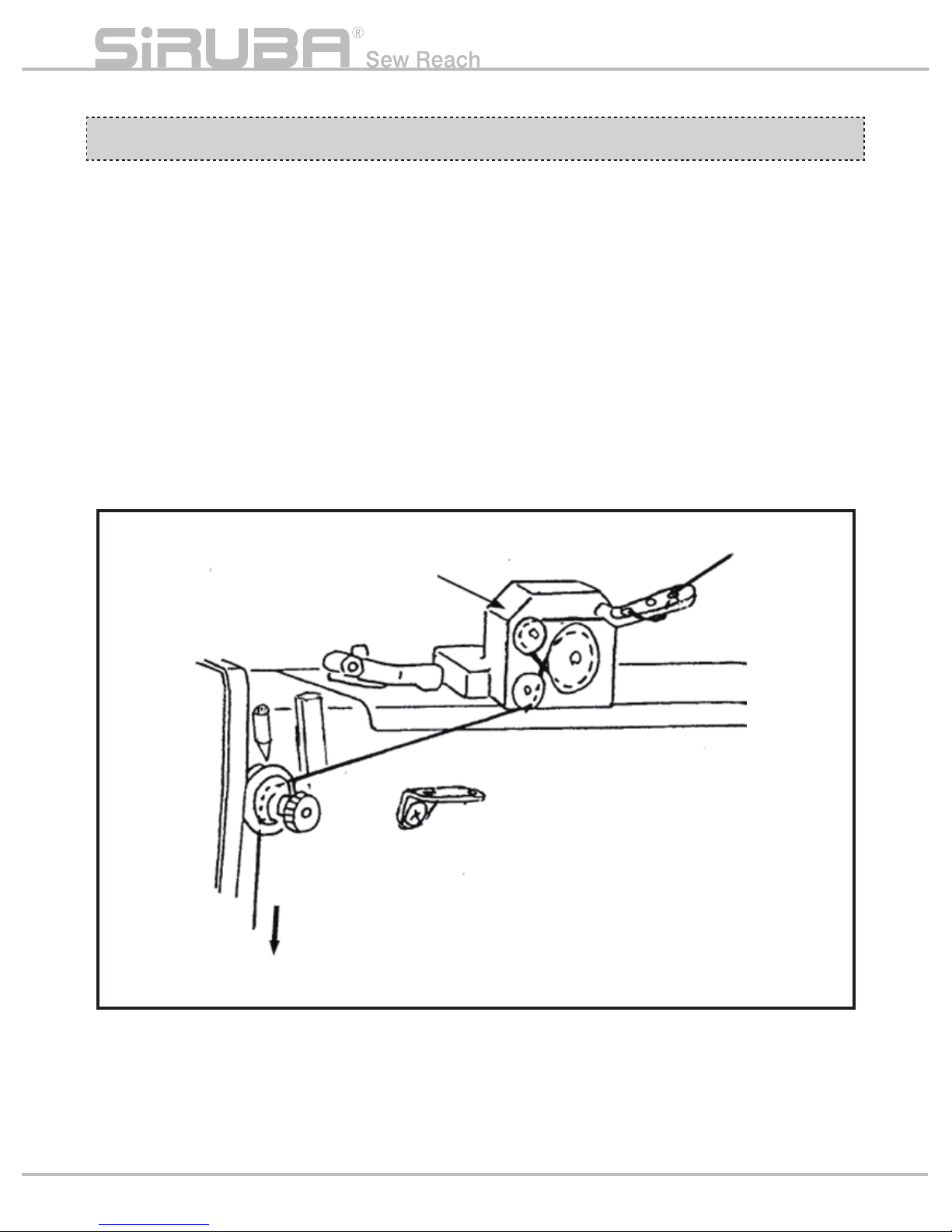

肩帶裝置方向 STRAP INSTALL METHOD

⑴通過送帶導柱①。

⑵通過肩帶結束開關②的中間。

⑶提起肩帶接縫開關③柄桿通過。

⑷通過送帶導柱④。

⑸提起送帶滾輪⑤的柄桿通過。

⑹從導帶線⑥的圈中通過。

⑺通過帶墜⑦。

⑻通過送帶導柱⑧。

⑼按夾帶開關⑨,將帶子放入夾帶盒⑩的槽

部,從夾帶盒

露出約 3~5mm。

⑴ Through tape feeding guide part①.

⑵ Through the middle of strap sensor②.

⑶ Lift the shaft of seam strap sensor③ and

make through.

⑷ Through tape feeding guide part④.

⑸ Lift shaft of tape feeding roller⑤ to make

through.

⑹ Through the antistatic coil⑥.

⑺ Through the counterweight⑦.

⑻ Through tape feeding guide part⑧.

⑼ Press strap-fixed switch⑨, put the strap

in the notch⑩ of strap-fixed

device

and reveal 3~5mm from the strap-fixed

device

.

⑩

①

⑤

⑥

⑦

⑨

⑧

③

④

3~5mm

②

P4

Introduction

Page 14

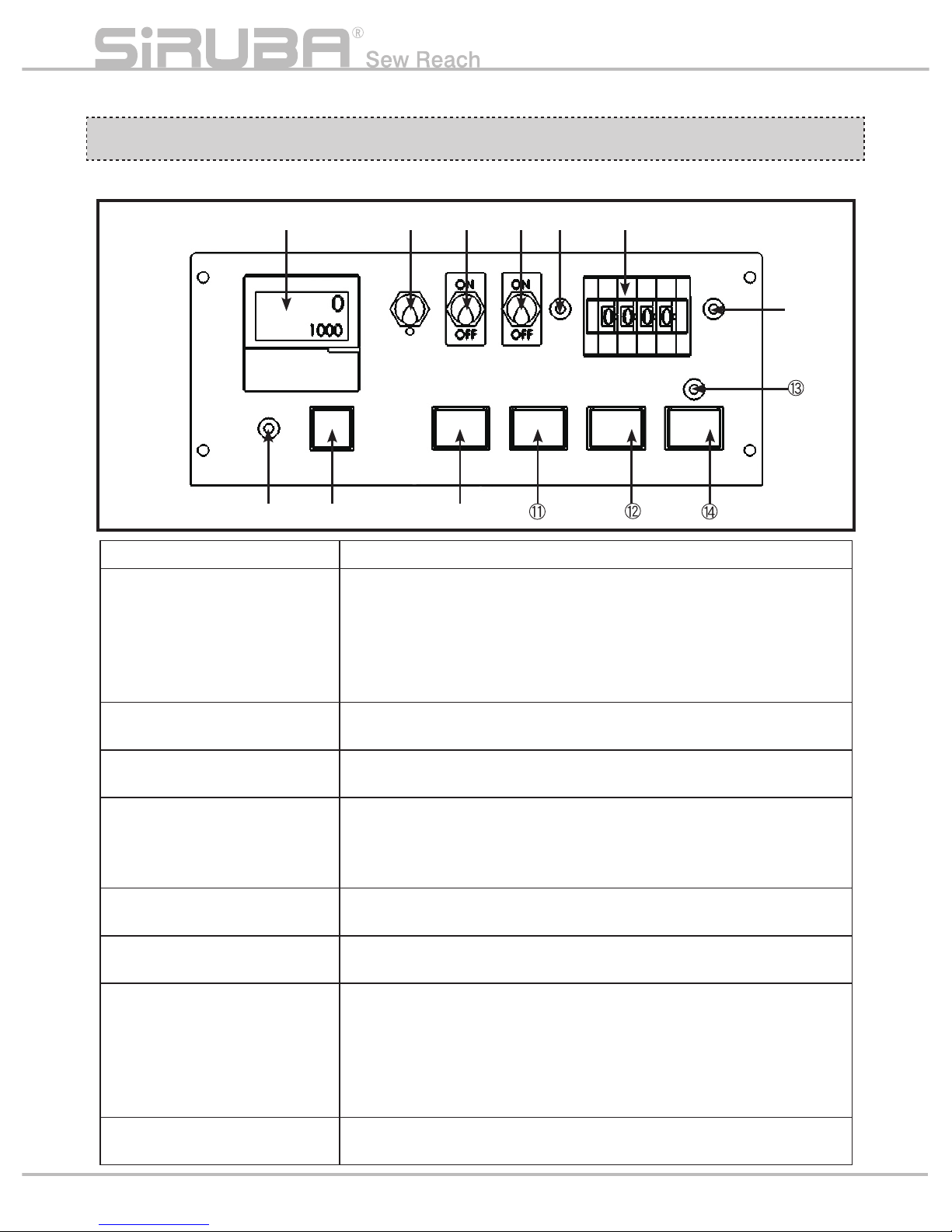

操作 OPERATION

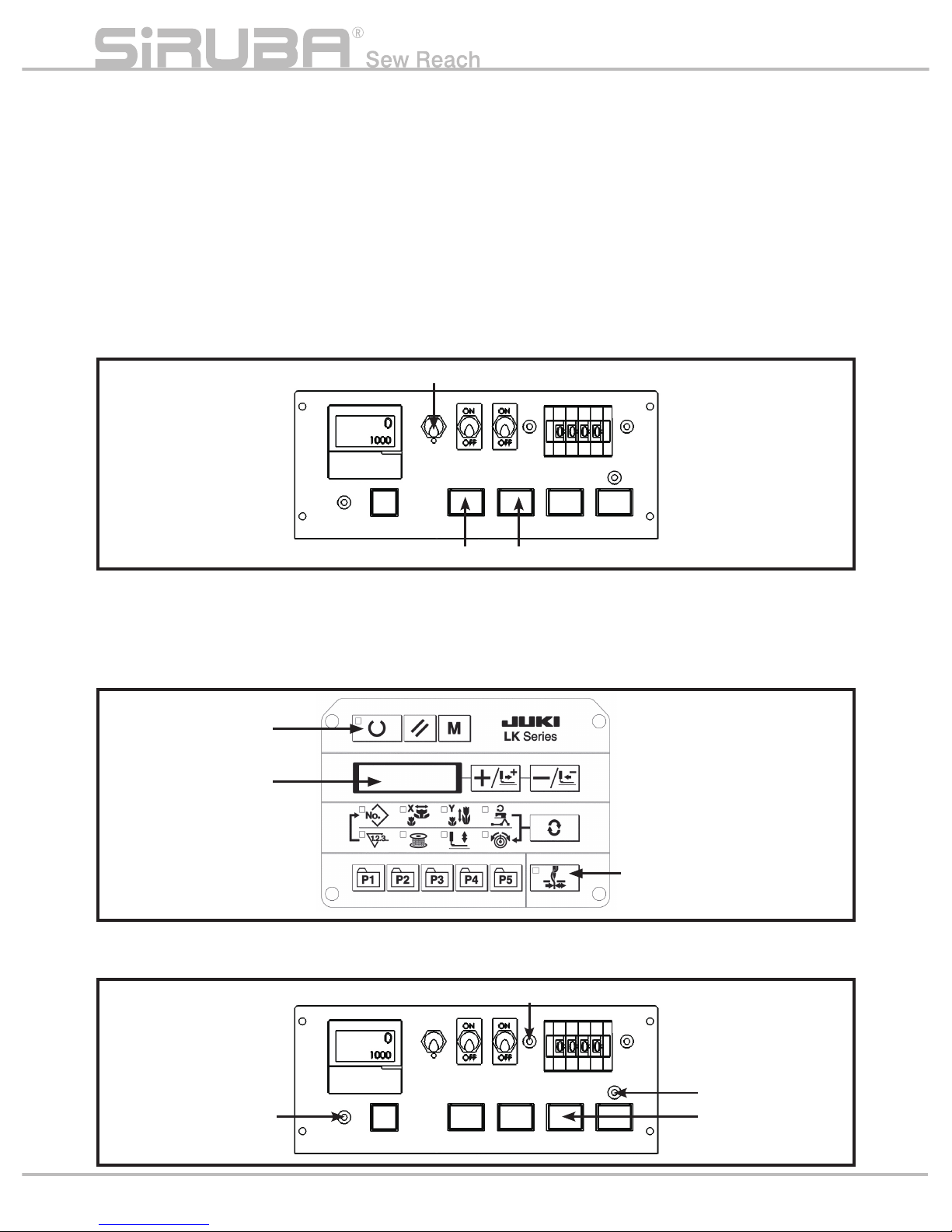

1. 操作面版 1.Operation panel

手動

MANUAL

自動

AUTO

電源

POWER

單動

ONE SHOT

斷線檢知

THREAD

DETECTOR

長度調整

TAPE FEED LENGTH

緊急停止

EMERGENCY STOP

開始

START

循環開始

CYCLE START

循環停止

CYCLE STOP

計數復歸

COUNT RESET

計數器/COUNT

開關名稱 Name 功能 Function

①計量下線

Count

下線消費量用量計算的設定。( 以 1 鎖針 1 計算 )

當其計算與設定值一致時將自動停止。(MANUAL 時則不進行計算 )

Setting of counting lower thread consumption. (one stitch one

count)

Automatically stop as the counting is the same as setting value.

(Will not counting as MANUAL.)

②累計器燈

Counter Lamp

下線消費自動停止燈。(P9)

Lower thread consuming automatically stop lamp. (P9)

③下線累計重新設定開關

Count Reset

將下線計算重新設為「0」。(P9)

Reset lower thread counting as「0」(P9)

④ AUTO/MANUAL 切換開關

AUTO/MANUAL Switch

自動:切換成自動運轉模式。(P7)

手動:切換成縫紉機單獨運轉模式。(P12)

Auto:Change to auto-operation mode. (P7)

Manual:Change to sewing machine isolated operate mode. (P12)

⑤單步操作切換開關

One Shot Operation Switch

切換成單步操作模式。(P11)

Change to one shot operation mode. (P11)

⑥斷線切換開關

Thread Detector

將斷線自動停止狀態調至 ON/OFF 狀態。

Adjust the thread break auto-stop status to ON/OFF.

⑦斷線燈

Thread Detector Lamp

斷線自動停止燈(燈亮)→恢復操作順序為 (P9)

斷線不良自動停止燈 ( 燈滅 ) →復歸操作順序為 (P9)

Thread break auto-stop lamp(Light up)→ Sequence of return to

operation (P9)

Defective thread break auto-stop lamp (Light off) → Sequence of

return to operation (P9)

⑧送量設定開關

Tape Feed Length Switch

帶子長度的設定。(單位:約1mm)

Setting of tape

’

s

length(Unit:About 1mm)

① ④ ⑤ ⑥ ⑦ ⑧

⑩③②

⑨

P5

Page 15

開關名稱 Name 功能 Function

⑨電源燈

Power Lamp

電源開關ON時燈亮。

Light up when power switch ON .

⑩單次循環停止開關

Cycle Stop Switch

1. 自動運轉的停止。

2. 單次循環運轉。(只想製作一個作品時)

3. 定時運轉的最初啟動。(只想制作一個作品時)

1. Auto-operation stop.

2. One cycle operation.(Make one product only.)

3. The initial start of time operation.(Make one product only.)

循環啟動開關

Cycle Start Switch

1. 自動運轉的啟動。

2. 單次循環運轉的最初動作啟動。

1. Start of auto-operation.

2. Initial start of single-cycle operation.

啟動開關

START Switch

1. 扣環用完,帶子用完以及檢測出接頭而自動停止後的再啟動。

2. 八字扣固定器中重新設定扣環。

3. 緊急停止後的再啟動。

4. 斷線不良自動停止後的再啟動。

5. 下線計算後的再啟動。

6. 單步操作之後的動作啟動。

7. MANUAL 模式時的縫紉機啟動。

8.(任選)圓扣裝置不良時,圓扣重新設定。

1. Auto-stop when run out of buckles, tape, and detected piecing

then start all over.

2. Reset buckles in 8-shaped buckle holder.

3. Start again after emergency stop.

4. Start again after defective thread break auto-stop.

5. Start again after

counting lower thread.

6. Motion start after single-operation.

7. Sewing machine start in MANUAL mode.

8.(Optional)Reset circled-buckle as circled-buckle device

defective.

停止燈

Stop Lamp

1. 扣環用完後自動停止燈。(燈亮)(P8)

2. 肩帶用完時自動停止燈。(燈亮)(P8)

3. 檢測出接頭時自動停止燈。(燈亮)(P8)

4. 八字扣固定器中的裝置不良燈。(燈亮)(P8)

5. 緊急停止燈。(燈亮)

6.(任選)圓扣裝置不良燈(燈滅)→恢復操作順序為(P8)

1. Auto-stop lamp after run out of buckle.(Lights up)(P8)

2. Auto-stop lamp after run out of strap.(Lights up)(P8)

3. Auto-stop lamp while detecting strap.(Lights up)(P8)

4. 8-shaped buckle holder defective lamp(Lights up)(P8)

5. Emergency stop lamp(Lights u

p)

6.(Optional)Circled-buckle device defective lamp(Lights off)

→ Sequence of return to operation(P8)

緊急停止開關

Emergency Stop Lamp

全部動作停止。

Whole motions stop.

P6

Introduction

Page 16

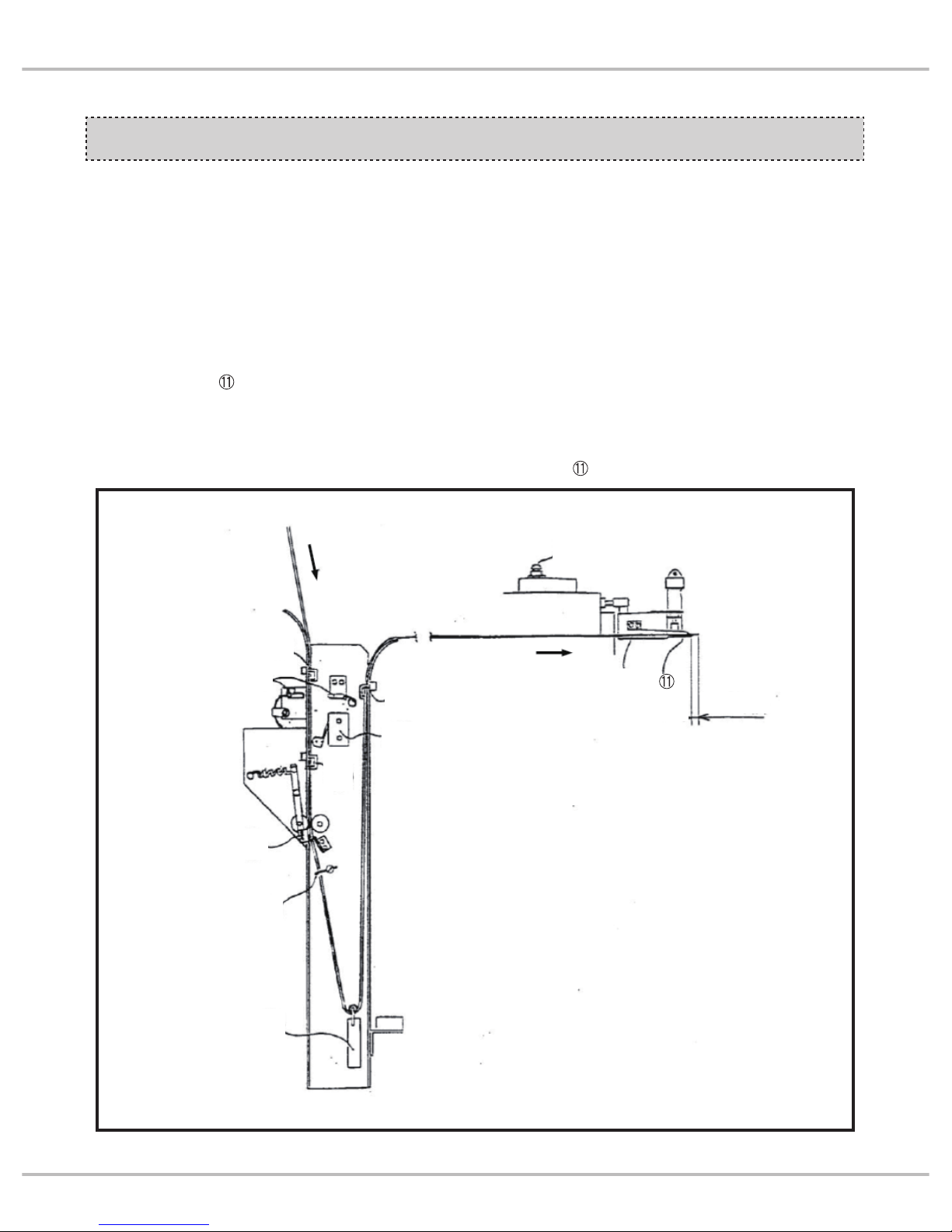

2. 自動運轉的啟動以及停止

將 AUTO/MANUAL 切換開關①轉換成

AUTO。

⑴連續運轉

•啟動:按開關②「循環啟動(白)」。

•停止:按開關③「單次循環停止(黃)」。

⑵ 1 循環運轉

• 啟動:按開關③「單次循環停止(黃)」。

(只製作一個作品後,停止)

※ 當電源開關調至 ON 時,LK-1900A 操作面

版表示。(有關 LK-1900A 操作板的詳細程

序,請參照 LK-1900A 使用指南)

2.Auto-operation Start & Stop

AUTO/MANUAL switch① turn on AUTO.

⑴Continuous operation

•Start:Press switch②「Cycle-Start(

White)」.

• Stop:Press switch③「Single-cycle stop

(Yellow)」.

⑵Cycle operation

• Start:Press sw

itch③「Single-cycle stop

(Yellow)」.(Make one product only then

stop.)

※LK-1900A operation panel will show, when

power switch ON.

(Please refer to LK-1900A instruction

manual for LK-1900A operation panel

detailed procedure.)

3. 自動停止燈燈亮、燈滅時的復原操作。 3.Auto-stop lamp’s lamp signal, operation

again as light off.

手動

MANUAL

自動

AUTO

電源

POWER

單動

ONE SHOT

斷線檢知

THREAD

DETECTOR

長度調整

TAPE FEED LENGTH

緊急停止

EMERGENCY STOP

開始

START

循環開始

CYCLE START

循環停止

CYCLE STOP

計數復歸

COUNT RESET

計數器/COUNT

手動

MANUAL

自動

AUTO

電源

POWER

單動

ONE SHOT

斷線檢知

THREAD

DETECTOR

長度調整

TAPE FEED LENGTH

緊急停止

EMERGENCY STOP

開始

START

循環開始

CYCLE START

循環停止

CYCLE STOP

計數復歸

COUNT RESET

計數器/COUNT

②

③

①

③ ②

④

亮燈

Light up

線夾 on

( 參考 LK-1900A 使用手冊 )

Cable clamp on

(Refer to LK-1900A

instruction manual)

縫紉樣式

( 參考 P10)

Sewing pattern

(Refer to P10)

①

P7

Page 17

(1) 當停止燈①燈亮時

a. 八字扣保持器裡的八字扣剩下一點時

補充八字扣,按開關④「啟動(綠)」後

重新啟動。

b. 圓扣保持器裡的圓扣剩下一點時

補充圓扣,按開關④「啟動(綠)」後重

新啟動。

c. 肩帶用完時

重新裝置肩帶,按開關④「啟動(綠)」

後重新啟動。

d. 檢測出肩帶接口

除去接口後,重新裝置肩帶,按開關④

「啟動(綠)」後重新啟動。

e. 八字扣固定器裡的八字扣沒裝置完整

按開關④「啟動(綠)」→八字扣重新設

置後繼續進行作業。

(2) 停止燈①燈滅時「當附有圓扣檢測裝置

(任選)時」※1

a. 圓扣沒補給足夠

(a) 檢查圓扣供給裝置,確認圓扣裝置沒

被阻塞。 (如有阻塞物請將阻塞物除去)

(b) 按開關④「啟動(綠)」→圓扣重新

設置後繼續進行作業。

【注】就算電源開關為 ON 狀態,停止燈①為

燈滅時仍可按開關④「啟動(綠)」→圓扣

重新被設置,等待啟動(待機狀態)。

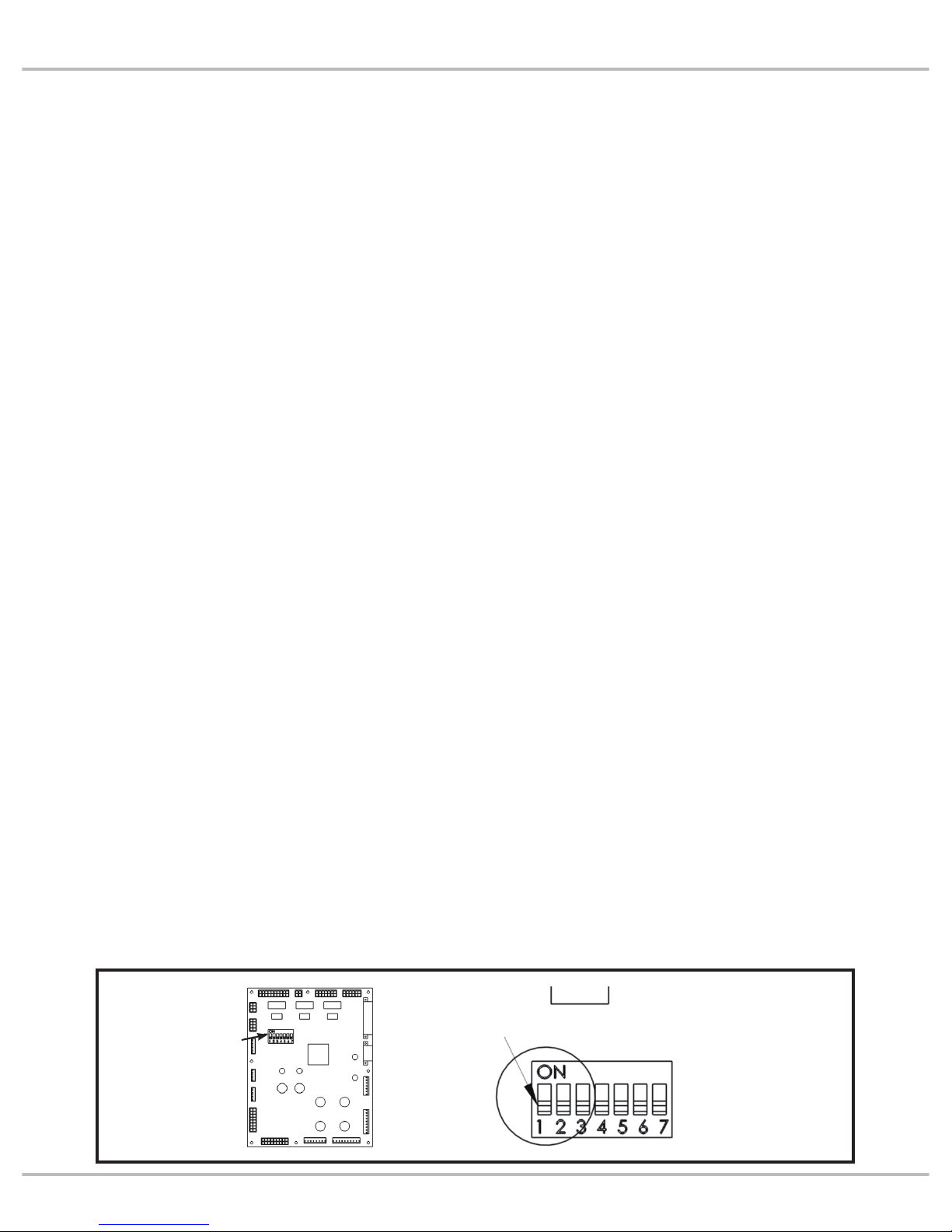

※1:當圓扣檢測器為無效狀態時,制卸基

板 ⑤雙列開關 D

S1 的 NO.1(⑥)為

ON。

(1)When Stop lamp① lights up.

a.8-shaped buckle remains a little in the

8-shaped buckle feeding stand. Resupply

8-shaped buckles, press switch④「

START(green)」then restart.

b.Circled-buckle remains a little in the

circled-buckle feeding stand. Resupply

circled-buckles, press switch④「START

(green)」then restart.

c.Run out of strap.

Reset strap, press switch④「START(

green)」then restart.

d.Detect the seam of strap.

After detach the seam, reset the strap,

then press switch④「START(green)」

then restart.

e.The 8-shaped buckles in the 8-shaped

buckle holder do not set completely.

Press switch④「START(green)」

→ Redo operation after reset 8-shaped

buckles.

(2)Stop lamp① lights off「With circled-buckle

detecting device(Optional)」

a.Circled-buckle insufficient.

(a)Check circled-buckle feed

ing device,

make sure that circled-buckle device

do not be jammed.(Remove the jam if

there have any.)

(b)Press switch④「START(green)

」→Redo operation after reset circledbuckles.

【Note.】You still could press witch④「

START(green)」 even power on and

the stop lamp① lights off.→ Reset circledbuckle and wait for starting(Standby status

).

※1:When circled-buckle detecting device

is invalid, switch board⑤dual

lines

DS1’s NO.1(⑥)is ON.

⑤

⑥

P8

Introduction

Page 18

(3) 斷線燈②燈亮時(當斷線開關⑦)為 ON 狀

態時。

a. 切斷上線

(a) 將電源開關調至 OFF。

(b) 邊按肩帶固定器開關「參照 P4 的(肩

帶裝置方法)」,將下個肩帶的先端

以手動方式調回開始的位置。

(c) 穿線。

(d) 將電源開關調至 ON。

(e) 將縫紉機下殘餘的肩帶除去後,按開

關⑧「循環啟動(白)」重新啟動。

•想要重新縫製發生斷線的肩帶時,可依下列

步驟重新啟動。

1. 在不變動縫紉機下肩帶的狀態下穿線。

2. 同時按下「單次循環停止(黃)」⑨、「循

環啟動(白)」⑧、「啟動(綠)」④三

個開關。→當肩帶被重新縫製後,繼續進

行作業。

(4) 斷線燈②燈滅時(就算斷線切換開關⑦為

OFF 狀態也可進行動作)。

a. 斷線不良

(a) 用剪刀等工具剪去剩餘的線。

(b) 按開關④「啟動(綠)」。→將堆垛

機歸回縫紉機旁,繼續進行作業。

(5) 計算燈③燈亮

a. 下線計算計算完畢

(a) 按開關⑩「下線計算重新設定

(藍)」。

(b)(連續運轉中狀態時)按下

「啟動

(綠)」開關。→繼續進行動作(循

環停止時)按開關⑧「循環啟動

(白)」→再次啟動

(3) When thread break lamp② lights up, the

thread detector⑦ is ON.

a.Cut off upper thread

(a) Switch OFF power switch

(b) Press strap-fixed device switch 「

Refer to P4(Installation of strap)

」, and adjust the front end of the

next strap to the beginning position in

manual way.

(c) Threading.

(d) Turn power switch ON.

(e) After detached the remaining strap

under the sewing machine, press the

switch⑧「Cycle Start(white)」and

restart.

•If you want to re-sew the strap which thread

break, you could restart according to the

procedure below.

1.Thread strap without moving the sewing

machine.

2.Press three switches 「Single-cycle Stop(

yellow)」⑨,「Cycle Start(white)」⑧,「

Start(green)」④ simultaneously. → After

re-sew the strap, proceed operation.

(4) Thread break lamp②

lights off.(Even the

thread break switch⑦ is OFF, it could be

operated.)

a.Thread break defective.

(a) Cut off remaining thread with scissors

or other tools.

(b) Press switch④「START(green)」→

let the unloading part back to sewing

machine and keep the operation.

(5) Counting lamp③ lights up

a.Lower thread counting finish

(a) Press switch⑩「Reset lower thread

counting(blue)」

(b)(Continuous operation)Press

「START(green)」switch.

→Continuous operation(Cycle Stop

)Press switch⑧「Cycle Start(white

)」→Restart

手動

MANUAL

自動

AUTO

電源

POWER

單動

ONE SHOT

斷線檢知

THREAD

DETECTOR

長度調整

TAPE FEED LENGTH

緊急停止

EMERGENCY STOP

開始

START

循環開始

CYCLE START

循環停止

CYCLE STOP

計數復歸

COUNT RESET

計數器/COUNT

②⑦

③

⑩

⑨ ⑧

④

①

P9

Page 19

L 尺寸

L Size

標準樣式 NO.

Standard Pattern NO.針數Stitches

縱向縫製位置修正用樣式

Vertical sewing position correctional pattern

A:縫線偏離位置在前側時

A:Sewing deviate position

forward side

B:縫線偏離位置在後側時

B:Sewing deviate position

backwaard side

7mm 2 30 1 3

8mm 12 31 11 13

10mm 22 39 21 23

13mm 32 45 31 33

16mm 42 56 41 43

18mm 52 64 51 53

4. 縫製樣式 NO. 的變更方法

(1) 按準備鍵①,使縫製②燈滅。

(2) 利用+按鍵③或是-按鍵④來選擇 NO.5

(參照下表)。

(3) 按準備鍵①,使縫製 LED ②燈亮。

•標準縫製樣式

1. 縫製尺寸為擴大縮小率 100% 的尺寸。

2. 以標準樣式 NO. 縫製,當縫線位置如下圖

偏離

時,可使用縫線位置修正用樣式進行修

正。修正量為 0.4mm。

4.Method of changing sewing pattern NO.

(1)Press Ready switch① to let the sewing

switch② lights off.

(2)Use +switch③ or -switch④ to choose

NO.5(Reference table below).

(3)Press Ready switch① to let the sewing

switch LED② lights up.

•Stantard Sewing Pattern

1. Sewing size is to expand the size of the

reduction ratio of 100%.

2. Use standard pattern NO. to sew, as the

sewing

position deviate like below, use

sewing position correctional pattern to

correct. Correction size are 0.4mm.

② ① ③

④

⑤

縫線偏離位置在前側時

Sewing deviate position

forward side

縫線偏離位置在後側時

Sewing deviate position

backwaard side

A B

L

3

P10

Introduction

Page 20

5. 縫製尺寸的放大、縮小方法

(1) 按準備鍵①,使縫製 LED 燈②熄滅。

(2) 按選擇鍵③,使 X 放大縮小率燈④或是 Y

放大縮小率燈⑤點亮。

(3) 利用+鍵⑥或是-鍵⑦來設定放大縮小率

⑧。

(4) 按準備鍵①,使縫製 LED 燈②燈亮。

6. 單步操作的運轉

將機械一連貫動作的主要部份一時停止,確

認機械動作時機以及裝置位置。

(1) 將 AUTO / MANUAL 切換開關⑨調至

AUTO,單步操作切換開關⑩調至 ON。

(2) 按開關

「單次循環停止(黃)」→停止肩

帶被拉出。

(3) 按開關

「啟動(綠)」,進行接下來的動

作。之後按開關

「啟動(綠)」,進行動

作。

(4) 肩帶的縫製及排出結束後,動作完成。

「欲再次重複動作,重新返回 (2)」。

5. Method of sewing size magnify and minify

(1)Press Ready switch①to let sewing LED

lamp② lights off.

(2)Press Selection switch③ to let X scale

rate lamp④ or Y scale rate lamp light up.

(3)Use + switch⑥ or - switch⑦to set the

scale rate ⑧.

(4)Press Ready switch① to let sewing LED

lamp② lights up.

6. One shot operation

Let the main parts of the

machine which

the connecting action temporary stop, to

check the timing of the machine action and

position of the device.

(1)AUTO/MANUAL switch⑨turn to AUTO,

and ONE SHOT operation switch⑩turn ON.

(2)Press switch

「Single-cycle stop(yellow

)」→Stop the strap to be pull out.

(3)Press switch

「START(green)」, and

proceed to the next action. After, press the

switch

「START(green)」to proceed

action.

(4)After strap sewing end and strap out the

machine, the action finish.「Redo the same

action, back to (2)」.

②

①

⑥⑤④⑦

⑧

③

手動

MANUAL

自動

AUTO

電源

POWER

單動

ONE SHOT

斷線檢知

THREAD

DETECTOR

長度調整

TAPE FEED LENGTH

緊急停止

EMERGENCY STOP

開始

START

循環開始

CYCLE START

循環停止

CYCLE STOP

計數復歸

COUNT RESET

計數器/COUNT

⑩

⑨

①

P11

Page 21

7.MANUAL 操作

不更動裝置,只有縫紉機單動作。

(1) 縫紉機單獨運轉

a. 將 AUTO / MANUAL 切換開關①調至 \

MANUAL。

b. 將欲試縫的布料放入縫紉機壓板下,按

開關②「啟動(綠)」。

(2) 下線卷

在筒管中下線尚未準備時進行動作。

a. 將 AUTO / MANUAL 切換開關①調至

MANUAL。

b. 按準備鍵③,使縫制 LED 燈④熄滅。

c. 按選擇鍵⑤,選擇線圈⑥。

d. 按準備鍵③,使縫製 LED 燈④點亮。

e. 按下開關②「啟動(綠)」後下線圈開始動

作。(注意針棒此時也會動作,請先將上線

從針頭上拔除)

f. 再次按下「啟動(綠)」開關②後停止動作。

(緊急停止開關也可使其停止動作)

7.MANUAL operation

Do not move the device, only the sewing

machine single action.

(1)Sewing machine isolated operati

on

a.AUTO/MANUAL switch① turn to

MANUAL.

b.Put the sewing fabric under the presser

bar of sewing machine, press switch②「

START(green)」

(2)Lower thread reel

Proceed action while the reel of lower

thread unready.

a.AUTO/MANUAL switch① turn to MANUAL.

b.Press Ready switch③, to light off sewing

LED lamp④.

c.Press Selection switch⑤, choose the reel⑥.

d.Press Ready switch③, to light up sewing

LED lamp④.

e

. After press switch②「START(green)

」, reel of lower thread start action. (

Be careful the needle will be action, too.

Please pull out the upper thread from

needle first.)

f. Press 「START(green)」 switch② again

then stop action.(The Emergency stop

switch could stop the action, too.)

手動

MANUAL

自動

AUTO

電源

POWER

單動

ONE SHOT

斷線檢知

THREAD

DETECTOR

長度調整

TAPE FEED LENGTH

緊急停止

EMERGENCY STOP

開始

START

循環開始

CYCLE START

循環停止

CYCLE STOP

計數復歸

COUNT RESET

計數器/COUNT

①

②

③

⑥

⑤

④

P12

Introduction

Page 22

裝置的標準位置 PRECISE POSITION OF DEVICES

1. 切刀

⑴切刀的咬合為 0.5mm。

【調整】將螺絲①轉鬆調整。

⑵切刀壓板:尺寸 1 ~ 2mm。(如將 S 尺

寸調整至必要以上的大小,將會加快切刀

的消耗速度)

【調整】將螺絲

轉鬆調整。

⑶可動式切刀

降下時,將其就空隙與固定

刀具

的前端部份保持 K = 0.2 ~ 0.3mm

的距離。(如將 K 尺寸調整至必要以上的

大小,將會加快切刀的消耗速度)

【調整】將螺絲

轉鬆調整。

2. 八字扣的標準尺

當八字扣固定器②移動到縫紉機旁時,八

字扣固定器②與八字扣標準尺③的縫隙為

0.3mm。

【調整】將螺絲④轉鬆調整。

1.Trimmer

⑴The occlusion of the trimmer is 0.5mm.

【Adjustment】Loosen the screw① to

adjust.

⑵Trimmer presser bar:size1~2mm.(

If adjust the S size larger for necessity, it

would accelerate the consumption speed

of the trimmer.)

【Adjustment】Loosen the screw

to

adjust.

⑶Keep the distance K=0.2~0.3mm

between movable trimmer

and the

front end of the fixed trimmer

as the

movable trimmer

lower down.(If adjust

the k size larger for necessity, it would

accelerate the consumption speed of the

trimmer.)

【Adjustment】

Loosen the screw to

adjust.

2.Standard ruler of 8-shaped buckle

When 8-shaped buckle holder② move aside

to the sewing machine, the gap between

8-shaped buckle holder②and 8-shaped

buckle standard ruler③are 0.3mm.

【Adjustment】Loosen screw④ for

adjustment.

①

0.5mm

肩帶 Strap

K=0.2~0.3mm

S=1~2mm

④

③

②

0.3mm

P13

Page 23

3. 扣環供給底板及扣環供給端頭

⑴供給底板⑤的先端與八字扣固定器②之間

的縫隙為 0.5mm。

【調整】將螺絲⑥轉鬆,以調整螺絲⑦來

調整。

⑵從扣環供給端頭⑧到扣環供給底板⑤的先

端距離為 0.2mm。

【調整】將螺絲⑨轉鬆調整。

3.Buckle feeding bed and upper end

⑴The gap between the front end of feeding

bed⑤ and 8-shaped buckle holder② are

0.5mm.

【Adjustment】Loosen screw⑥ in order

to use screw ⑦to adjust.

⑵The distance between the buckle feeding

front end⑧ with buckle feeding bed front

end ⑤ are 0.2mm.

【Adjustme

nt】Loosen screw⑨ to adjust.

⑧

⑤

0.5mm

0.2mm

⑦

⑥

⑨

②

P14

Introduction

Page 24

4. 裝置台

當肩帶⑦放入縫紉機壓板⑧的下方時,針頭

⑨的中心與縫紉機壓板⑧的記號⑩,肩帶⑦

的中心線

成為一致狀態。

【調整】將螺絲

(3 處)轉鬆,並將裝置

台

以前後方向(箭頭 )移動進行調整。

【注】螺絲

為決定裝置台 位置的螺絲。

當裝置台

在縫紉機旁動作時,轉鬆自鎖螺

帽

,將螺絲 以逆時針方向轉動後進行動

作。欲前後調整裝置台

時,將螺絲 以順

時針方向轉動,用自鎖螺帽

固定其停止位

置。

4. Device bed

While putting strap ⑦ under the presser

bar⑧ of sewing machine, the marking of

the center of the needle end⑨ and the

presser bar ⑧ of sewing machine would

align with the center line

of strap⑦.

【Adjustment】Loosen screw

(three

of them), and move the device desk

backward and forward to adjust(Arrow

).

【

Note】Screw is the screw which

decide the position of the device desk

. When device desk has action

aside to sewing machine, loosen selflocking nut , and do action after turn the

screw counterclockwise. To adjust the

deice desk back and forward, turn the

screw clockwise, then use self-locking

nut to fix it on the position.

⑩

⑩

⑧ ⑧

⑨

⑦

P15

Page 25

①

②

( 一 ) 測量器的種類

⑴肩帶寬度變更時

①夾帶盒

②穿板

③導帶

⑵八字扣變更時

①八字扣保持器

⑶圓扣變更時

②圓扣保持器(組)

(一)Type of measurers

⑴Change the width of strap

①Strap-fixed device

②Strap thread plate

③Strap guide

⑵Change of 8-shaped buckles

①8-shaped buckle feeding stand

⑶Change the circled-buckle

②Circled-buckle feeding stand(set)

測量器的交換與調整

MEASURER'S CHANGING AND

ADJUSTMENT

①

②

③

7mm ASP-1254 ASP-1259 ASP-1264 ASP-1269 ASP-1274 ASP-1279

8mm ASP-1255 ASP-1260 ASP-1265 ASP-1270 ASP-1275 ASP-1279

10mm ASP-1133 ASP-1135 ASP-1096 ASP-1076 ASP-1199 ASP-1198

13mm ASP-1256 ASP-1261 ASP-1266 ASP-1271 ASP-1276 ASP-1280

16mm ASP-1257 ASP-1262 ASP-1267 ASP-1272 ASP-1277 ASP-1281

18mm ASP-1258 ASP-1263 ASP-1268 ASP-1273 ASP-1278 ASP-1281

參數值

Value

更換零件

P16

Introduction

Page 26

( 二 ) 測量器的交換與調整

1. 夾帶盒①與上彈簧板②的交換

⑴ 將螺絲③轉開,並將包括上彈簧板②的彈

簧板組④拆開。

⑵ 將螺絲⑤轉鬆,交換夾帶盒①這時,⑥與

⑦的部份為緊密狀態。

⑶ 上彈簧板②拆除更換,以螺絲③組裝固定

彈簧板組④。

⑷ 用手將夾帶盒①移動側最右側,確認夾

帶盒①的先端⑧是否通過了滾軸⑨中槽的

中心線。如果位置有偏差的話,其原因為

⑥、⑦部份中產生的間隙需修正。

(二)Measurer’s changing and adjustment

1.Change of strap-fixed device① and upper

spring plate②.

(1)Loosen screw③, and take apart the set

of spring plate④ including upper spring

plate②.

(2)Loosen screw⑤, parts ⑥ and ⑦ are

tightly close when change the strap-fixed

device①.

(3)Take apart the upper spring plate② and

use screw③to assemble and fix the set

of spring plate④.

(4)Use hands to move the strap-fixed

device① to the most right side, and

make sure the front end of the strap-fixed

device① has make through the center

line of the middle notch of the roller⑨.

If the position has deviation, the reason

would be the gap

between parts ⑥ and

⑦ which needs correction.

⑥

① ③

④

⑦

⑧

⑨

②

③

⑤ ①

P17

Page 27

2. 調整式八字扣固定器③、④的調整

⑴ 將 2 顆螺絲①與 2 顆螺絲②轉鬆。

⑵ 將八字扣放入調整式八字扣固定器③、④

中,以 2 顆螺絲①與 2 顆螺絲②暫時固定。

⑶ 用手移動帶夾帶盒⑤,將其先端移至八字

扣中心附近。

⑷ 將 2 顆螺絲⑥轉鬆,並把氣缸⑦往箭頭⑧

的方向移動,當從箭頭

的方向推入八字

扣時,讓夾帶盒⑤的先端從八字扣的正中

央通過。

⑸ 將 2 顆螺絲①與 2 顆螺絲②轉鬆,軸⑨

的中心線與八字扣固定器③、④之間保留

0.2mm 左右的空隙。

2.Adjustment of adjustable 8-shape feeding

holder ③,④

(1)Loosen two screws① and two screws②.

(2)Put 8-shaped buckles into adjustable

8-shaped buckle feeding stand③,④ and

use two screws① and two screws② to

fix it temporary.

(3)Move the strap-fixed device⑤with hands,

and moves its front end around the

8-shaped buckle center

.

⑷Loosen two screws⑥, and move the

cylinder⑦ toward arrow⑧ direction. When

push the 8-shaped buckle to the direction

as arrow

, let the front end of the strap-

fixed device⑤ make through the center of

8-shaped buckle.

⑸Loosen two screws① and two screws②,

align the the center line of shaft⑨ and

center line of 8-shaped buckle. Keep

around 0.2mm gap between 8-shaped

buckle holder③,④ .

⑤

③ ②

①

② ④

⑥

⑦ ⑧

③

⑨

④

⑩

相等

Equal

⑤

相等

Equal

P18

Introduction

Page 28

3. 扣環供給底板①的交換及調整

⑴將螺絲②轉開,交換扣環供給底板①。

⑵當扣環供給底板①移至最右邊時,溝③的

中心線④與八字扣固定器的中心線⑥保持

一致。

【調整】轉鬆自鎖螺帽⑦,以轉動氣壓缸

桿⑧來調整。

⑶當扣環供給底板①移動至最右邊時,扣環

供給底板①與八字扣固定器⑤之間的縫隙

為 0.5mm。

【調整】將螺絲⑨轉鬆,以轉動調整螺絲

⑩來調整。

⑷扣環供給端頭

出來時,使其先端比供給

底板②多 0.2mm。

【調整】轉鬆

來調整。

②

①

①

④

③

⑥

⑤

①

⑤

0.5mm

0.2mm

①

⑤

⑧

⑦

①

⑨

⑩

3. Change and adjustment of buckle feeding

bed①

(1)Loosen screw②, and change the buckle

feeding bed①.

(2)When the buckle feeding bed① move to

the right most, align the center line④ of

the notch③and center line⑥ of 8-shaped

buckle holder.

【Adjustment】Loosen self-locking nut⑦

in order to turn the cylinder shaft for

adjustment.

(3)When the buckle feeding bed① move to

the right most, the gap between buckle

feeding bed① and 8-shaped buckle

holder⑤ are 0.5mm.

【Adjustment】Loosen screw⑨ in order

to turn the adjustable screw⑩ for

adjustment.

(4)While the buckle feeding front end

out,

make it more 0.2mm than the feeding

bed②.

【Adjustment】Loosen

for adjustment.

P19

Page 29

4. 八字扣保持器①的交換

⑴將座板②與螺絲③轉開,交換八字扣保持

器①。

⑵八字扣保持器①與扣環供給底板④的縫隙

為 0.2mm。

【調整】以轉鬆螺絲③來調整。

⑶當扣環供給底板退後到最後側時,使八字

扣保持器①的底部⑤的內側面與扣環供給

底板④的溝⑥成一致。

【調整】以轉鬆螺絲③來調整。

5. 穿板⑦及導帶⑨的交換

⑴ 將 2 顆螺絲⑧轉開,交換穿板⑦。安裝時,

要使穿板⑦往箭頭

的方向均勻的進入八

字扣長孔

中。

⑵ 將 2 顆螺絲⑩轉開,交換導帶⑨。

4.Change of 8-shape buckle feeding stand①

(1)Loosen screw③ and bed② to change

8-shape buckle feeding stand①.

(2)The gap between 8-shape buckle feeding

stand① and buckle feeding bed④ are

0.2mm.

【Adjustment】Loosen screw③ for

adjustment.

(3)While buckle feeding bed back to the

most, make the bed inner side⑤ of the

8-shape buckle feeding stand① and the

notch⑥ of the buckle feeding

bed④ at

the same position.

【Adjustment】Loosen screw③ for

adjustment.

5.Change of strap thread plate⑦ and strap

guide⑨

(1)Loosen two screws⑧, and change strap

thread plate⑦. While installing, make

sure to let strap thread plate⑦ through

the 8-shaped buckle hole

toward arrow

direction even.

(2)Loosen two screws⑩to change the strap

guide⑨.

①

②

③

④

0.2

0.2

①

⑥

⑤

④

⑦

⑧

⑦

⑨

⑩

P20

Introduction

Page 30

6. 圓扣供給端頭 的交換

⑴ 轉鬆螺絲

,交換圓扣供給端頭 。轉開

螺絲時,將螺絲

轉鬆把圓扣供給端頭

從上方撥開。組裝時將圓扣供給端頭 由

上方插入,並以螺絲

固定于其停止位

置。

7. 圓扣保持器①的交換

⑴ 將螺絲②轉開,交換圓扣盒①。

⑵ 圓扣保持器①與圓扣投放盤③的縫隙為圓

扣厚度的+ 0.2mm。

【調整】以轉鬆螺絲④來調整。

6. Change of circled-buckle feeding upper

end

(1)Loosen screw , change circled-buckle

feeding upper end

. Loosen screw

, and push circled-buckle feeding upper

end

aside. Assemble circled-buckle

feeding upper end

from up, and fixed it

in the position by screw

.

7.Change of circled-buckle feeding stand①

(1)Loosen screw② and change the circled-

buckle feeding stand①.

(2)The gap between circled-buckle feeding

stand① and circled-buckle putting plate

are the circled-buckle thickness+0.2mm.

【Adjustment】Loosen screw④for

adjustment.

①

②

③

④

圓扣厚度 +0.2mm

Circled-buckle

thickness

+0.2mm

P21

Page 31

8. 八字扣標準尺⑤的調整

⑴ 當八字扣固定器⑥往縫紉機旁側移動時,

八字扣固定器⑥的先端與八字扣標準尺⑤

之間的縫隙為 0.3mm。

【調整】以轉鬆螺絲⑦來調整。

9. 反摺導帶的調整

⑴ 當肩帶①進入於縫紉機壓板②的下方時,

讓前擋板③與後擋板④的各自先端碰到肩

帶①的側面。

【調整】將前擋板③的螺絲⑤轉鬆,移動

量桿⑥進行調整。轉鬆螺絲⑦調整後擋板

④。

8.Adjustment of 8-shaped buckle standard

ruler⑤

(1)While 8-shaped buckle holder⑥ move

to the sewing machine side, the gap

between 8-shaped buckle holder⑥ front

end and 8-shaped buckle standard

ruler⑤ are 0.3mm.

【Adjustment】Loose

n screw⑦ for

adjustment.

9. Adjustment of counter-folded strap guide

(1)When strap① get under sewing machine

presser bar②, let each front end of

the front strap holder③ and rear strap

holder④ touch the side of strap①.

【Adjustment】Loosen t he screw⑤ of the

front strap holder③, move the shaft of

the front strap holder⑥ for adjustment.

Loosen screw⑦ to adjust rear strap

holder④.

⑦

⑤

⑥

0.3mm

④

②

②

①

③

⑥

⑤

P22

Introduction

Page 32

配線圖 WIRING PICTURE

配線圖 Wiring picture 1/2

P23

Page 33

配線圖 Wiring picture 2/2

P24

Introduction

Page 34

配管圖 PIPING PICTURE

Piping picture 1/4

P25

Page 35

Piping picture 2/4

P26

Introduction

Page 36

Piping picture 3/4

P27

Page 37

Piping picture 4/4

P28

Introduction

Page 38

不良現象,其原因以及解決方法

DEFECTIVE PHENOMENA'S

REASON AND SOLUTIONS

現象 Phenomenon 原因 Reasons 對策 Strategies

1. 切刀刀刃不良

1.

Blade of the trimmer

defective

a. 固定切刀的裝置不良 P13「1. 切刀」

的項目中,S 與 K 的尺寸過小

b. 切刀彈簧壓力不足

c. 刀刃耗損

a. Device which fixed trimmer

defective. P13 In item「1.Trimmer」,

size of S and K too small.

b. Pressure of trimmer’s spring not

enough.

c. Blade consumes.

a. 參照 P13 中「1. 切刀」的

S 項目,調整固定刀具,

將 K 的尺寸調整適當

b. 參照 P13 中「1. 切刀」的

b 項目,將刀具的束環調

整適當

c. 研磨切刀,或是更換新品

a. Refer to P13 item S

「1.Trimmer」, adjust the

fixed knife, adjust the size

of K properly.

b. Refer to P13 item b

「1.Trimmer」,adjust the

ring of knife properly.

c. Grind the trimmer or

replace the new one.

2. 斷線檢測不良

(1) 線沒被切斷機械卻停止 ( 控

制板表示燈燈亮 )

(2) 線斷了卻不停機 ( 操作面

板表示燈燈滅 )

2.Thread detector defective

(1)Machine stops without

cutting the thread. (Control

board indicator lamp lights

up. )

(2)Machine wouldn’t stop

even thread break.

(Control board indicat

or

lamp lights off.)

( 用手慢慢的轉動斷線檢測器中的編碼

器的皮帶輪,當基板一的確認燈 LD3

燈滅時 )

a. 線的穿線方法錯誤

b. 縫製時發生斷線

( 用手慢慢的轉動斷線檢測器中編

碼器的皮帶輪,當基板上的確認燈

LD3 燈滅時 )

c. 編碼器不良

( 縫紉機動作中,基板上的確認燈

LD4 燈滅時 )LK-1900A 的感線線斷

線 ( 參照 P23 配線圖 )

(Use hands to roll the belt roller of the

encoder in the thread device slowly

while the checking lamp LD3 of the

board 1 lights off.)

a. Wrong threading method.

b. Thread break while sewing.

(Use hands to roll the belt roller of

the encoder in the thread device

slowly while the checking lamp

LD3 of the board 1 lights off.)

c. Encoder defective.

(The checking lamp LD4 of the

board lights off while sewing

machine operating.)

Thread detector of LK-1900A

thread break. (Refer to P23 Wiring

picture.)

a. 參照 P3 「4. 穿線」

b. 調整縫紉機穿線

c. 交換編碼器

a. Refer to P3

「4.Threading」

b. Adjust the sewing

machine threading

c. Change the enco

der

斷線檢測確認燈

Thread break detect

checking lamp

針下信號確認燈

Under needle

checking lamp

控制基板 ( 主基板 )

Control Board

(Main Board)

P29

Page 39

現象 Phenomenon 原因 Reasons 對策 Strategies

3. 製品的不良

(1) 肩帶縫製不良

(2) 肩帶完成時長度脫落

(3) 帶端不能縫入

3. Product defective

(1) Strap sewing defective

(2) Strap falls off

(3) Strap can not sew

properly

(4) 縫合部份錯開

a. 向上錯開

(4)Stitched part stagger

a.Stagger up

b. 向下錯開

b. Stagger down

•導帶滾輪的壓力力道過強

•導帶滾輪的壓力力道過弱

•肩帶反摺部份長度不足

•導帶板位置錯開

•Feeding strap roller force

of pressure too strong.

•Feeding strap roller force

of pressure too

weak.

•Length of strap counter

folded part insufficient.

•Feeding strap plate

position different.

•壓力力道轉弱 ( 將螺絲往左轉,箭頭 A

方向 )

•壓力力道轉強 ( 將螺絲往右轉,箭頭

B 方向 )

•Make the force weak. (Left turn the

screw, arrow A direction.)

•Make the force strong. (Right turn the

screw, arrow B direction.)

•將肩帶反摺長度放長。

【調整】

1. 轉鬆螺絲①,將刀具調整沿②向著

使氣缸③行程減短 (a 尺寸增長 ) 方

向移動

2. 轉鬆螺絲④,將極限開關安裝板⑤,

向←方向移動。

3. 轉鬆輸帶滾筒調整沿停止螺絲⑥,

將刀具到夾帶盒夾子⑦前端設定為

3 ~ 5mm

•Lengthen the strap folded part.

【Adjustment】

1.Loosen screw ① adjust knife

toward direction ② to make

cylinder ③ stroke shorter (size a

longer.)

2.Loosen screw ④ , to let limited

switch install plate ⑤ move toward

← direction.

3.Loosen feeding strap roller and

adjust stop screw ⑥ , to make the

distance between knife and front

end of strap-fixed device clamp ⑦

3-5mm.

⑤

④

⑥

②

①

③

⑦

3~5mm

A

B

P30

Introduction

Page 40

現象 Phenomenon

原因 Reasons

對策 Strategies

4. 肩帶接縫檢測不良

(1) 到了肩帶接縫口不停

(2) 肩帶從肩帶接縫開關滾輪

上脫落

4. Strap seam detect

defective.

(1)Wouldn’t stop even till

the strap seam end.

(2)Strap fall off from strap

seam sensor roller.

•肩帶接縫檢測調整不良

•肩帶輸送引導針的調整不

良

•Strap seam detect adjust

defective.

•Strap feeding guide

needle adjust defective.

a. 導帶板往 A 的方向移動

b. 導帶板往 B 的方向移動

【調整】

將螺絲⑧轉鬆後進行

a.Feeding strap plate move toward A

direction.

b.Feeding strap plate move toward B

direction.

【Adjustment】

Proceed after loosen screw ⑧

•調整到接縫處,將肩帶接縫開關調至

ON,通過後調至 OFF。

【調整】

將螺絲①轉鬆後進行。

•Adjust to the seam part, turn ON

strap seam sensor, turn OFF after

getting through.

【Adjustment】

Proceed after loosen screw ① .

•將肩帶輸送引導針往箭頭方向移動,

使其和肩帶寬度對齊。

【調整】

將螺絲②、③轉鬆後進行。

•Move the strap feeding guide needle

toward arrow direction in order to

align with the strap’s width.

【Adjustment】Proceed after loosen

screw ②、③ .

①

A

B

⑧

肩帶寬度

肩帶接縫

開關滾輪

②

③

肩帶接縫

Strap seam

開關滾輪

switch roller

肩帶寬度

Width of strap

P31

Page 41

現象 Phenomenon 原因 Reasons 對策 Strategies

5. 按了啟動開關機械沒有開始

動作。( 停止燈燈亮 )

5. Machine without action after

turn ON. (Stop lamp lights

up.)

a. 八字扣、圓扣用完

b. 肩帶有接縫

c. 肩帶用完

d. 肩帶接縫開關在打開狀態

e. 肩帶確認燈燈亮 ( 當使用

薄肩帶的時侯 )

a. Run out of 8-shaped

buckle and circled-

buckle.

b. Strap has seam.

c. Run out of strap.

d. Strap seam sensor ON.

e. Strap checking lamp

lights up. (When use thin

strap.)

a. 補充八字扣、圓扣。( 不要忘記墜子 )

b. 去掉接縫。

c. 安裝上新的肩帶。

d. 參照「(4)肩帶接縫檢

測不良」的

解決方法。到燈滅為止感應器往→方

向移動。

【調整】

將螺絲①轉鬆進行

a. Supply 8-shaped buckle and

circled-buckle. (Don’t forget

counterweight.)

b. Take off seam.

c. Install new strap.

d. Refer「(4)Strap seam detect

defective」solution until lamp lights

off, the sensor move toward →

direction.

【Adjustment】

Proceed after loosen screw ① .

6. 八字扣被安裝至八字扣固定

器後機械沒有反應。( 燈滅 )

6. Machine didn’t react after

install 8-shaped buckle at

8-sha

ped buckle holder.

(Lights off)

•八字扣穿棒沿調整不良

•The shaft which push

8-shaped buckle adjust

defective.

•從燈亮處到沿邊調整到 1mm

【調整】

將螺絲②轉鬆後進行

•Adjust from the light about1mm.

【Adjustment】

Proceed after loosen screw ② .

電燈

燈亮位置

①

②

燈亮位置

Position of lights

電燈

Lamp

1mm

電燈 Lamp

P32

Introduction

Page 42

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ASP-1223

ASP-0159

M5x0.8x15L*2

EEC001201

ASP-0202*2

ASP-1231

ASP-0158

ASP-1232

AC323

SM510N

JA291*2

SM418N*2

KN43*2

KN42*4

LA43

SM504

ASP-1239

ASP-1238

ASP-1241

ASP-1242

ASP-1228

ASP-1230

SM418N*2

SM418N*2

SM418N*2

ASP-1226

ASP-1229

ASP-1236

ASP-1237

ASP-1224

AC073

JA291

BST100

2014/07/15

/

1 1

車頭組

P33

Page 43

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ASP-1011

ASP-1014

ASP-1018

ASP-1021

ASP-1008

ASP-1007

ASP-1012

ASP-1009

機體組

SM4052*8

ASP-1017

WM4001*14

SM418N*14

BA730*14

NM413*14

SM4052*4

ASP-1083

ASP-1215

ASP-1001

ASP-1010

ASP-1023

WM5000*2

SM5105N*2

ASP-1219*2

SM814N*8

EPT050001

SM4052*5

WM601*2

WM610*2

SM6104N*2

SM4052*4

SM4052*4

SM510N*4

NM413*4

ASP-1006

ASP-1005*2

ASP-1004

ASP-1002

WM810*4

SM812N*4

WM8000*4

SM4052

CP102

SM812N*2

WM810*2

WM8000*2

SM6204N

NM615

CP102

SM4052

ASP-1003

SM812N

SM6203N

SM4052*4

SM814N*4

WM8000*5

WM810

NM615

ASP-1013

WM601*2

WM610*2

SM614N*3

NM615

ASP-1029

PM404

SM5104N*3

ASP-1026

ASP-1024

SM812N*2

WM8000*2

WM810*2

SM5104N*2

ASP-1028

SM812N*2

ASP-1025

SM319N*4

SM412N*2

ASP-1027

ESH001101*2

ASP-1216*2

ASP-1220*2

電磁閥聯座

BST100

2014/07/15

/

1 1

P34

Page 44

ASP-1078

ASP-1075

EM030*2

ASP-1069

ASP-1073

ASP-1072

ASP-1071

ASP-1068

ASP-1074

ASP-1061

ASP-1065

ASP-1058

ASP-1060

ASP-1089

AC062

ASP-1067

ASP-1057

ASP-1062

ASP-1079

ASP-1059

ASP-1063

ASP-1077

ASP-1076

SM418N*2

ASP-1070

AC063

SM411N*2

PM306

SM411N*2

ASP-1064

SM411N*2

M4x0.7x25L*2

ASP-1214

SM611N*2

WM8000*2

SM814N*2

SM6104N*2

WM601*2

EM050

SM611N*2

EM040

SM4106N*2

SM411N*8

SM454*2

SM412N

M2.5x0.45x15L*2

ESH001101

SM6104N*2

WM601*2

SM331*2

SM619N*2

WM601*2

SM412N*2

WM411*2

CP102

SM4052

JA0401*2

JA0401*2

SM510N

ASP-1217

ASP-1240*2

2014/07/15

/3 12

8字扣組

BST100

P35

Page 45

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ASP-1128

ASP-1118

ASP-1116

ASP-1112

ASP-1113

ASP-1114

ASP-1111

ASP-1115

ASP-1109

ASP-1110

ASP-1119

ASP-1120

AC064

ASP-1121

ASP-1070

ASP-1123

ASP-1124

ASP-1125

ASP-1117

AC067

ASP-1127

ASP-1126

SM602

SM412N

SM411N

SM454*2

SM812N*2

WM810*2

WM8000*2

SM418N*2

EM030

WM411*2

SM411N*2

SM411N

EM040

EM040

SM614N*2

WM601*2

WM610*2

EM030

SM411N

SM410N

SM516N*2

SM4107N*2

JA291*2

JA291*2

BST100

2014/07/15

/

1 1

切刀組

P36

Page 46

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

SM418N*2

SM516N*2

ASP-1097

ASP-1099

ASP-1101

ASP-1098

ASP-1108

ASP-1100

ASP-1091

ASP-1084

ASP-1086

ASP-1103

ASP-1102

AC060

ASP-1106

ASP-1087

ASP-1088

SM510N*4

SM319N*2

ESH001101

SM4052

CP102

SM5104N

PM306

SM510N*2

WM8000*2

WM810*2

SM812N*2

SM331*4

PM113

SM310N*3

SM410N*2

ASP-1096

ASP-1092

ASP-1094

ASP-1093

ASP-1095

SM4052*2

AC072

ASP-1090

SM515N*2

SM418N*2

ASP-1216

ASP-1104

SM410N

M2.5x0.45x15L*2

WM510*2

WM5000*2

SM5104N*2

ASP-1089

EM050

SM331

ASP-1107

ASP-1105

SM4052

CP102

ESH001101

ASP-1085

JA113*2

JA251*2

ASP-1218

JA291*3

ASP-1221

EM050*2

WM306

BST100

2014/07/15

/

1 1

送帶穿扣組

P37

Page 47

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

AC066*2

ASP-1131

ASP-1130

ASP-1132

ASP-1134

ASP-1135

ASP-1133

ASP-1129

SM418N*4

SM410N*2

WM4001*2

穿線組

SM5105N*2

JA291*4

BST100

2014/07/15

/

1 1

P38

Page 48

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ASP-1198

ASP-1195

ASP-1197

ASP-1201 ASP-1194

ASP-1200

ASP-1188

ASP-1211

ASP-1193

ASP-1192

AC070

ASP-1189

ASP-1191

AC070

ASP-1190

ASP-1186

ASP-1184

ASP-1185

ASP-1202

ASP-1187

AC071

ASP-1204

ASP-1205

ASP-1206

ASP-1203

SM618

BR1052*2

ASP-1207

ASP-1208

WM604

ASP-1210

SM310N*2

SM5105N*2

BF886JK

WM601*2

SM6104N*2

WM601*2

SM611N*2

SM418N*2

ASP-1078

ASP-1199

WM4001*2

SM412N*2

SM418N*2

SM5106N

SM5105N*2

ASP-1196

SM411N*2

WM402*2

SM418N*2

SM410N*2

SM311N*2

SM412N*2

SM6104N*2

WM601*2

WM8000*3

WM5000*3

SM5105N*3

SM501*2

NM514

SM5104N*2

SM410N*2

JA291

JA291*2

JA291

JA0401

NM615

BST100

2014/07/15

/

1 1

送扣退帶組

P39

Page 49

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ASP-1033

ASP-1030

送料組

LF289-E

ASP-1032

BF331

ASP-1031*2

SM6104N*2

WM610*2

WM601*2

SM516N*3

SM4052

CP102

SM4110N*4

WM402*4

EMT014002

EMT010001

EMT010001

EMT014001

SM4110N*4

CP102

SM4052

ASP-1055

SM5107N

BR1050*2

ASP-1039

ASP-1040

SM410N*2

ASP-1042

ASP-1038

SM318N*2

ESE000501

SM4052

CP102

SM418N*4

ASP-1053

ASP-1054

SM410N

ASP-1051

ASP-1050

SM3102N*2

WM306*2

ESH000301

ASP-1047

ASP-0128

SM2050*2

ESE000601

BF331*3

ASP-1045*3

SM418N*2

ASP-1043

ASP-1034

SM602

SM418N*2

SM2050*2

ESE000601

ASP-1036

SM313N*2

SM418N*2

ASP-1046

SM616N*2

SM616N*2

ASP-1037

ASP-1035

SM510N*2

ASP-1044

SM602

SM4052

CP102

ASP-1041

ASP-1049

ASP-1048

ASP-1052*2

ASP-1056

WM402*4

BST100

2014/07/15

/

1 1

P40

Page 50

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ASP-1141

ASP-1066

ASP-1122

ASP-1145

ASP-1137ASP-1139

ASP-1136

ASP-1140

AC068

ASP-1142

ASP-1121

ASP-1143

ASP-1138

ASP-1144

SM418N*2

SM418N*2

SM4108N*2

SM504*2

EM030

SM410N*2

SM4106N

WM4001

SM410N*2

SM411N

ASP-1222

EM030

SM410N

EM030

JA291*2

BST100

2014/07/15

/

1 1

送圓扣組

P41

Page 51

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ASP-1168

ASP-1164

ASP-1163

ASP-1148

AC064

ASP-1162

ASP-1165

ASP-1176

ASP-1173

ASP-1153

ASP-1150*2

ASP-1151

ASP-1152

ASP-1149

ASP-1154

ASP-1167

ASP-1169

ASP-1067

ASP-1089

SM410N

ASP-1174

ASP-1178

AC069

ASP-1177

AC061

ASP-1170

SM5105N*2

ASP-1147

ASP-1160

ASP-1159

ASP-1157

ASP-1158

ASP-1156

ASP-1146

ASP-1155

ASP-1172

AC603

SM412N*4

EM190

SM418N*2

SM412N*2

SM411N

EM030

EM050

EM040

SM410N*2

SM410N

SM319N*2

ESH001101

SM6104N*2

SM410N*2

ASP-1172

ASP-1216

ASP-1161*2

SM313N*4

BR3220*2

PM306

SM602*4

SM501

SM411N*4

SM520*3

SM411N*2

SM410N

SM410N*2

SM4052

CP102

VX-012-1A3

SM319N*2

ASP-1216

SM410N*2

ASP-1166

SM408*2

ASP-1175

SM418N*2

JA0401

JA291

JA0401

JA291*2

JA0401*2

SM411N

SM335*2

AC058

ESH001101

BST100

2014/07/15

/

1 1

送縫組

P42

Page 52

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

ASP-1182

ASP-1183

AC065

ASP-1180

ASP-1181

AC602

NM413

SM412N*2

SM4106N*2

SM411N

CP102

SM4052

JA0404*2

JA0401

JA291

BST100

2014/07/15

/

1 1

退料組

P43

Page 53

PARTS LIST

Series

Parts Group

Subclass Remark

Page

Date

1 2 3 4 5

E

D

B

C

A

切刀組

送縫組

JUKI機體

穿線組

送扣退帶組

退料組

ASP-1213

送圓扣組

送料組

BST100

SM4106N*2

WM601*5

WM610*5

SM614N

WM601*2

WM610*2

SM619N*2

WM8000*2

WM810*2

SM812N*2

SM614N*2

WM610*2

WM601*2

WM8000*2

WM810*2

SM812N*2

機體組

SM619N*2

WM610*2

WM601*2

ASP-1171*2

SM5106N*4

SM812N*2

WM810*2

WM8000*2

SM812N*2

WM810*2

WM8000*2

SM4108N*4

ASP-1082*2

SM4106N*2

ASP-1212

ASP-1080

ASP-1081

8字扣組

ASP-1019

SM4106N*2

ASP-1020

WM8000*2

WM810*2

SM812N*2

送帶穿扣組

ASP-1227*2

WM8000*2

ASP-1243*2

ASP-1227*2

ASP-1252

ASP-1016*2

ASP-1015*2

SM553N*4

SM614N*8

NM610*8

WM809*2

WM601*2

SM619N

ASP-1251

BST100

2014/07/15

/

1 1

P44

Page 54

P45

Page 55

Page 56

由於對產品的改良及更新 , 本產品使用說明書中與零件圖之產品及外觀的修改恕不事先通知 !

The specification and/or the equipment described in the instruction book are subject to

change because of modification with out previous notice

ASP-BST100.JUN.2015

Loading...

Loading...