Page 1

700L

使用說明書與零件圖

ORIGINAL INSTRUCTIONS BOOK & PARTS LIST

Page 2

運動 部 位, 謹 防工 傷 事故

Moving part, beware of industrial accident

高壓 部 位, 謹 防觸 電 事故

High voltage, beware of electric shock

高溫 部 位, 謹 防燙 傷 事故

High temperature, beware of burns

禁止

Prohibited

地線 的 接線 表 示

Indication of ground wiring

如果忽視 此 標記而運行了 錯誤的機械操 作 ,保養時肯 定 會引起當事者

或第三者人 員重傷或死亡。

如果忽視 此 標記而運行了 錯誤的機械操 作 ,保養時有 可 能會引起當事

者或第三者 人員受傷及造成 設備損壞。

Page 3

索引

INDEX

頁 /PAGE

一般安全事項說明 GENERAL SAFETY INSTRUCTIONS 1

重要安全事項說明 IMPORTANT SAFETY INSTRUCTIONS 3

特別事項 WARNING 7

警告標籤 WARNING TAG 8

護針安全圖說 SAFETY ILLUSTRATION OF THE NEEDLE GUARD 9

搬運縫紉機 MOVING THE SEWING MACHINE 9

縫紉機的安裝位置 THE INSTALLATION POSITION OF THE SEWING MACHINE 10

規格 SPECIFICATIONS 11

各部件名稱 NAMES OF MAJOR PARTS 13

安裝 INSTALLATION 14

照明設備 LIGHTENING EQUIPMENT 16

新機器使用規定 HOW TO OPERATE THE NEW MACHINE 17

潤滑

油之注入與更換 LUBRICATION AND DRAINAGE 17

穿線方式 THREADING THE MACHINE 19

控線調整 ADJUST THREAD TENSION 20

換針方式 REPLACE THE NEEDLE 23

針距調整 ADJUST THE STITCH LENGTH 23

差動比調整 ADJUST THE DIFFERENTIAL FEED RATIO 24

更換切刀 REPLACE THE TRIMMERS 25

包邊寬度調整 ADJUST THE HEM WIDTH 26

針高度之調整 ADJUST THE NEEDLE HEIGHT 27

押具調整 ADJUST THE PRESSER FOOT 27

送具調整 ADJUST THE FEED DOG 29

針與勾針之關係 THE RELATIONSHIP BETWEEN NEEDLE AND LOOPER 31

環勾針運動之調整 ADJUST THE CHAINSTITCH LOOPER MOVEMENT AMOUNT 33

ii

Introduction

Page 4

索引

INDEX

頁 /PAGE

保養 MAINTENANCE 34

報廢流程 DEMOLITION PROCEDURE 35

MODEL 700L

Net Weight(Kg) 27 Noise Level, dB(A) 82dB(A)

Serial No. Vibration (m/sec2)

Dimension

Length Width Height

35cm 22cm 31cm

iii

Page 5

一般安全事項說明

GENERAL SAFETY

INSTRUCTIONS

警告!

當使用這台機器,基本安全預防應恆被遵守

,以減輕火災、電擊、或是個人傷害的風險

。包含以下注意事項。

在操作這台機器之前,請閱讀所有說明並且

緊記於心。

1. 保持工作場所清潔

雜亂的環境與椅子會招引危害。

2. 考量工作場所環境

勿暴露電源於雨水之中、勿在溼氣重的地方

或潮濕的場所使用機械器具。保持工作場所

良好整齊。當有引發火災或爆炸危險時,勿

使用電源工具。

3. 免於電擊危害

避免身體接觸地線或是接地表面。( 即:

管線,發熱物體,以及冷凍庫 )

4. 勿使孩童接近

不要讓訪客接觸工具或是延伸管線。

5. 適當的穿著

不要穿著寬鬆衣物或是穿戴珠寶,這可能被

活動零件拉扯而導致危險。穿戴護髮套可包

住長髮。

6. 不要任意拉扯電線

絕不要用電源端拉扯機器,或是從插座猛拉

電線來拔掉電線。使電線遠離熱源、油類或

是尖銳邊緣。

7

. 謹慎保養機器

遵從指示來添加潤滑油或是更換附件。定期

檢測工具用線,如果有所損害,請使用合格

的維修器具來修復。

Warning!

When using this machine, basic safety

Precautions should always be followed to

reduce the risk of re, electric shock and

personal injury, including the followings.

Read all these instructions before

operating this product and save these

instructions.

1. Keep work area clean

Cluttered areas and benches invite

injuries.

2. Consider work area environment

Do not expose power to rain. Do not use

machine tools in damp or wet locations.

Keep work area well lit.

Do not use power tools where there is risk

to cause any re or explosion.

3. Guard against electric shock

Avoid body contact with earthed or

grounded surfaces (e.g. Pipes, radiators,

ranges refrigerators.)

4. Keep children away

Do not let visitors touch the tool or

extension code.

5. Dress properly

Do not wear loose clothing or jewelry,

they can be caugh in moving parts. Wear

protecting hair covering to contain long

hair.

6. Do not abuse the cord

Never carry the machine by cord or yank

it to disconnect it from the socket. Keep

the cord away from heat, oil, and sharp

edges..

7. Maintain machine with care

Follow instructions for lubrication and

changing accessories. Inspect tool cord

periodically. If damaged, have it repaired

by an authorized service facility.

P1

Introduction

Page 6

8. 中斷機器電源

當不使用機器時、維修前、以及更換配件

時。

9. 避免誤啟動

不要以手指置於啟動開關上之後,搬運一個

已插入電源的工具。確定在插電之前,電源

開關是關閉的。

10. 檢查損害零件

在進一步使用器具之前,應該小心檢查並

確認損傷的零件或是穿戴保護器具來確認

零件會正確運轉並且呈現應有功能。

11. 警告

除了在這本使用說明手冊中建議的功能之

外,任何附件或是配件的使用,都可能會

導致個人傷害的危險。

12. 由合格人員來修理器具

所以修理工作應由合格的人員使用原始個

別零件來作修理。

連接電源的特別警示 !

1. 只可與有 "CE" 認證的按壓啟動裝置連接這

台機器。

2. 遵守此使用說明手冊來安裝控制裝置。

3. 在操作過程中,永遠保持機器適當的接地。

4. 在調整、更換零件、或是維修保養之前,必

須確定將插頭由插座拔出,以預防任何機器

意料之外的啟動而造成危害。

8. Disconnect machine

When not in use, before servicing and

when changing accessories.

9. Avoid unintentional starting

Do not carry a plug-in tool with a nger on

the switch. Ensure the power switch is off

when plugging in.

10. Check damaged parts

Before further use of the tool, a guard or

other part that is damaged should be

carefully checked to determine that it will

operate properly and perform its intended

function.

11. Warning

The use of any accessory or attachment,

other than those recommended in this

instruction manual, may present a risk of

personal injury.

12. Have your tool repaired by a

qualified person

Repairs should only be carried out by

qualied persons using original spare

parts.

SPECIAL WARNING FOR ELECTRIC

CONNECTION!

1. Incorporate this machine only with "CE"

certicate hold-to-run control device.

2. Follow the instruction manual device to

install control device.

3. Always earth machine appropriately

during operation.

4. Before adjustment, parts change or

servicing must be sure to pull out the plug

from socket to prevent the hazard of

unintentionally start of machine.

P2

Page 7

重要安全事項說明

IMPORTANT SAFETY

INSTRUCTION

恭喜您購買本機器,為了使這台機器能獲

得最佳功能以及安全的操作,務必請正確

的使用這台機器,使用前請仔細閱讀使用

說明書,希望您能長期使用它。請記得將

此說明書放在容易取得的地方。

1. 當您使用機器時,除了以下事項外,請

注意其他基本安全措施。

2. 使用機器前,除了本使用說明書外,

請詳細閱讀其他相關說明書。此外,

請妥善保存此說明書,以便需要時可

以隨時取閱。

3. 先確認機器是符合貴國安全規定及標

準後,再使用機器。

4. 當機器完成操作時,所有安全配備必

須安裝就緒,在缺少所述安全配備下

操作是不被允許的,以免導致人員受

傷。

5. 此機器應由受過適當訓練之操作員操

作。

6. 為了安全,我們建議您配戴安全眼

鏡。

7. 以下情形,請先關閉電源或拔掉插頭 :

(1) 穿針線、導線片、天平等以及更換

梭子時。

(2) 更換針、壓具、針板、送具、頂針

片、車布導板,以

及其他附屬配件

時。

(3) 維修工作時。

(4) 離開工作場所或工作場所無人看

顧時。

For operating safely and getting the

best functions of this machine, you must

operate it correctly. Please read and

follow the instructions of this manual,

and keep it at hand for future references.

We are condent that you will enjoy this

machine as much as we enjoy

manufacturing it.

1. Instead of the following instructions,

when you use this machine, please pay

attention to the basic safety measures.

2. Before using this machine, please read

this manual and all related instructions.

In addition, please keep this manual

for future needs.

3. Before using this machine, please

ascertain that it conforms with safety

standards and regulations of your

country.

4. When the machine is ready for

operation, all the safety equipments

must be ready. Operate this machine

without the specied safety devices is

not allowed.

5. This machine must be operated by a

properly trained operator.

6. For your own safety, we suggest you

wearing goggles.

7. Please turn off the power switch

or disconnect it for any one of the

circumstances of the followings:

(1) When threading needle(s), adjusting

thread Take-up(s), thread guide(s),

and/or replacing bobbin(s).

(2) When replacing needles, presser

feet, needle plates, feed dogs,

needle guards, cloth guides and

other parts or accessories.

(3) When repairing.

(4) When the operator leaves the

working place or leaves the

machine unattended.

P3

Introduction

Page 8

8. 假如不慎讓機器及配件使用之油或油

脂,接觸到眼睛、皮膚或誤食時,請立

刻以水清洗接觸部位及就診。

9. 請勿擅自碰觸運轉中之零件或配件及注

意機器電源是否已開啟,以免導致人員

受傷。

10. 維修、修改及調整等工作,須由受過

適當訓練的技師或熟手為之。維修時

只許使用指定之零件。

11. 一般維修及檢查工作必須由受過適當

訓練的人員為之。

12. 電子零件維修及保養工作必須由資深

的電子技師為之,或由非常熟練的人

員檢查及指導,當發現零件損壞時,

請立刻停止機器運轉。

13. 在做裝有氣動式零件 ( 例如氣缸 ) 機器

的維修及保養工作前,機器連接空壓

機及高壓空氣必須予以關閉及卸除,

機器中殘存高壓氣體必須予以消除,

此外調整及性能檢查只能由受過適當

訓練的技師或熟手為之。

14. 機器使用一段時間,必須定期清理。

8. If grease, oil, or any uid contacts your

skin or eyes by any chance, please

wash the contacted area completely

with clean water and consult a doctor.

Or, swallow any uid mistakenly,consult

a doctor immediately.

9. Do not touch any functioning parts

and devices. Always attend to whether

power switch is on or off before

operating in order to prevent anyone

from getting hurts.

10. Qualied technicians are required

for adjustment, modication, and

repair. Only use assigned parts for

replacement.

11. Routine maintenance and service

must be performed by well trained

persons, or qualied technicians.

12. Maintain and check the electronic

parts must be done by qualied

electrician or well-trained persons.

If any electronic part damaged or

malfunctioned, stop the machine

immediately.

13. The air house has to be detached

from the machine and the compressor

or air supply has to be cut off before

repairing and servicing the machine

equipped with pneumatic parts such

as an air cylinder. Qualied technicians

or well-trained persons are required

for adjustment and repairs.

14. To ensure the best performance,

periodically clean the machine is

necessary.

P4

Page 9

15. 為使機器能正常操作以及減少噪音,

機台務必平放地上,機器避免在強烈

噪音的環境下操作。

16. 選用適當的電源插頭,並由電子技師

將其安裝在機器上,且插頭必須插在

接地線之插座上。

17. 機器只允許被使用於指定用途上,其

他用途是不允許的。

18. 修改或變更機器必須依照安全規定及

標準,同時採取有效的安全措施或變

更機器所引起損壞之責。

19. 警告提示以兩種符號標示:

(1) 對操作員或服務人員之傷害危險,也

為了避免觸電之危險,請勿打開馬達

電器箱之外蓋,也不要觸摸電器箱裡

面之零件。

(2) 必須特別注意事項

a. 絕對不可在移動外蓋,手指保護蓋或

安全配件後,進行機器操作,以免

導致人員受傷。

b. 為了避免被機器纏住,當機器運轉

中,您的手、頭髮及衣服,需遠離

手輪;此外這些部位周圍不可放置

任何物品,以免導致人員受傷。

15. In order to operate properly and to

reduce the noise, please place the

machine at and level on the ground.

Avoid operating the sewing machine

at a noisy surrounding.

16. Select a proper power plug and install

it by an electrician. Please connect the

power plug to a grounded receptacle.

17. This machine can only be used for

the designed purpose. Other uses of

this machine are not allowed.

18. Any modication or conversion made

on this machine must be conformed

with the safety standards and

regulations. Precaution is necessary.

No responsibility will our company

take for damages caused by any

modication or conversion of this

machine without permission.

19. Two safety warning signs are applied

as warning signs:

(1) For the safety of operators and

service persons, please don't open the

cover of any electronic control boxes

of motor or other devices and don't

touch any components inside to avoid

electrical shock hazards.

(2) Always keep in mind:

a. Please never operate this machine

without outer cover, nger guard or

any safety device to avoid physical

injury.

b. Please keep your hair, ngers and

clothes away from the hand wheel

while the machine is in operation,

as well as never put anything near

these parts, to prevent the risk of

injuries by tangled into them.

P5

Introduction

Page 10

c. 當您打開電源開關後或機器已 在運轉

中,絕不可將您的手放在針的下方或針

線控線桿外蓋中,以免導致人員受傷。

d. 當機器運轉中,梭頭高速轉動,為了避

免對手可能引起之 傷害,必須確定您的

手保持遠離梭頭附近。此外,當更換梭

子時,確定電源開關已關閉,以免導致

人員受傷。

e. 當放置或抬起機器時,小心勿將手置於

機器中,以免導致人員受傷。

f. 為了避免機器突然啟動而引起可能意

外,當機頭傾斜時,請關掉機器電源,

以免導致人員受傷。

g. 如果您的機器是配置伺服馬達,機器於

靜止狀態時,馬達是不會產生噪音的,

為了避免機器突然啟動而引起可能意

外,故請關掉機器電源。

h. 為了避免觸電之危險,請絕不要在移開

電源接地線後操作機器。

i. 為了避免觸電或電子零件損壞而引起之

可能意外,請先切斷電源,再插上或拔

掉插頭。

c. Please never put your ngers under the

needle(s) or in the thread take-up cover

to prevent physical injuries when you

turn on the power switch or operate the

machine.

d. While the machine is in operation, the

hook rotates at a high speed. Please

keep your hands away from the area

of hook to prevent any potential injury

to your hands. In addition, please

make sure to turn off the power of the

machine while changing bobbins.

e. Be careful and do not place your

ngers inside the machine when placing

or lifting the machine head to avoid

possible physical injuries.

f. Please turn off the power before tilting

the machine head to avoid possible

accidents due to abrupt start of this

machine.

g. For machine equipped servo motors,

the motors do not produce noise while

the machines are at rest. Therefore,

please turn off the power of this

accidents due to abrupt start of the

machine.

h. Never operate the sewing machine after

the ground wire is removed to avoid

electrical shock hazards.

i. Please turn the power switch off before

connecting or disconnecting the power

plug to prevent possible accidents due

to electric shock or damaged electronic

components.

P6

Page 11

特別事項 WARNING

為了避免機器故障及損壞,請先確定以下

事項:

1. 當您安裝好機器後,做第一次機器操作

前,請徹底清潔機器。

2. 清除運送途中累積之灰塵及溢出之油

脂。

3. 確定電壓及馬達相數 ( 單相或三相 ) 安

裝正確。

4. 確定電源插頭正確地接上電源。

5. 當使用電壓與標示電壓不同時,請勿使

用機器。

6. 確定機器轉動方向是否正確。

警告:

在操作或調整本書中所提到之各步驟

前,請先將電源關掉,以免因為機器突

然啟動造成之意外。

Please conrm the followings to avoid

malfunction or damage to this machine.

1. After installing the machine, and before

the rst operation, please clean it

completely.

2. Clean all dust and overowed oil during

transportation.

3. Conrm that the voltage and the phase

(single or 3 phase) of motor are set

correctly.

4. Conrm that the power plug is correctly

connected to the power supply.

5. Never use the machine when the

local voltage type is different from

the marked voltage on the nametag

attached on the machine.

6. Conrm that the rotating direction of

the machine pulley is correct.

Warning:

Before doing any operation or any

adjustment described later in this

manual, please turn the power off to

prevent accidents caused by abrupt

start of the sewing machine.

P7

Introduction

Page 12

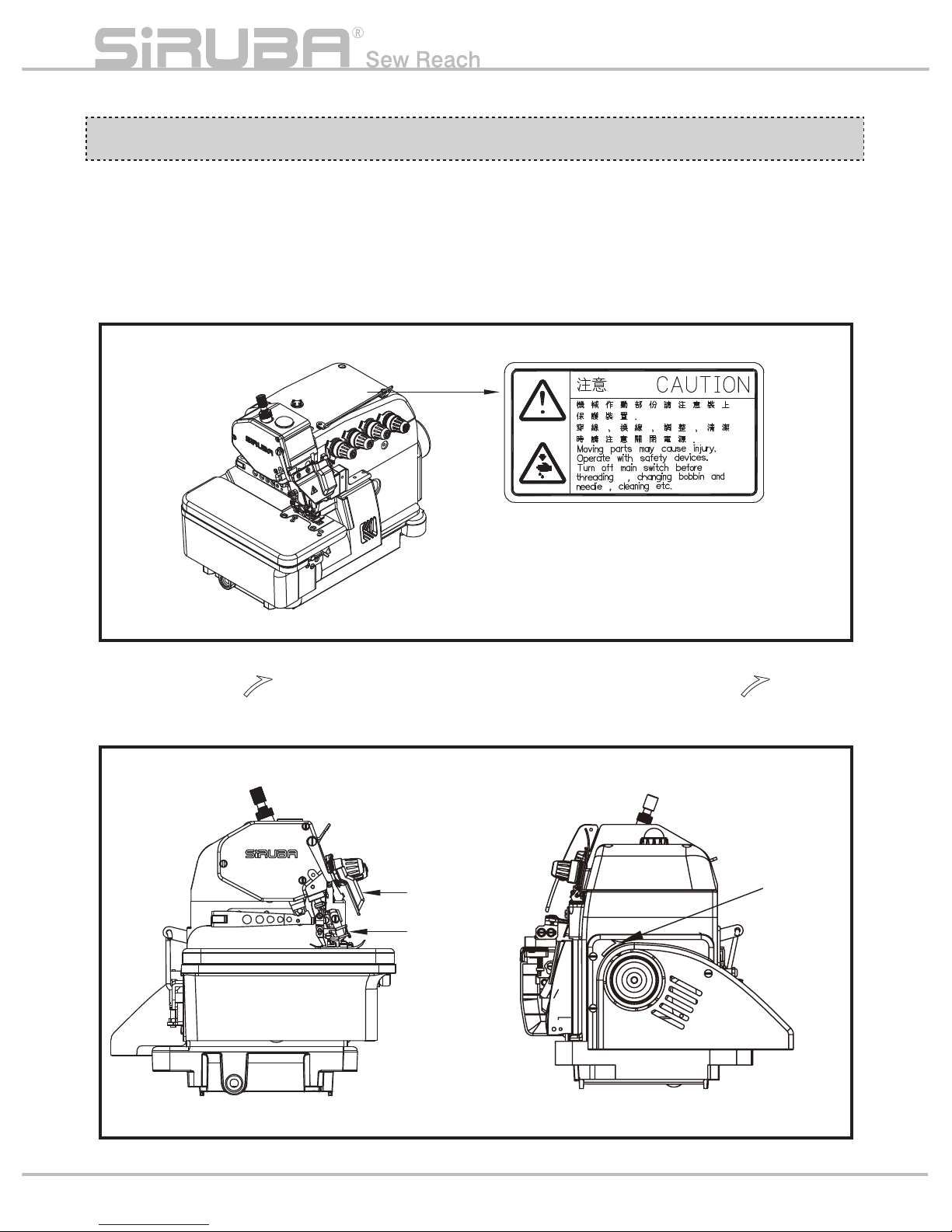

警告標籤 WARNING TAG

1. 縫紉機上有警告標籤 ( 圖 1)。

2. 當使用縫紉機時,請遵守標籤上的說明。

如果標籤脫落或模糊不清,請和購買商店聯

繫。

1. The following warning tags will be attached

on the sewing machine.(Fig. 1)

2. When using the sewing machine,please

follow the instructions of the tags. please

contact the dealer if any of the tags is fallen

off or fuzzy.

圖 2 / Fig. 2

警告標籤

Warning Tag

護目鏡

Spectacles

護指器

Finger guard

轉動方向

Rotary direction

3. 安全防護裝置及

轉動方向。( 圖 2)

3. Safety protection device and

rotary

direction. (Fig.2)

圖 1 / Fig. 1

P8

Page 13

搬運縫紉機 MOVING THE SEWING MACHINE

• 應按圖適用左手托住前機殼本體,右手撐扶

住機頭底部進行搬運,搬運時需穿著安全鞋。

( 圖 4)

• To move the sewing machine, please follow

the gure shows. Using left hand to hold the

front machine cover body, and right hand to

hold the bottom plate to move. Please wear

safety shoes while moving.(Fig.4)

護針安全圖說

SAFETY ILLUSTRATION OF

THE NEEDLE GUARD

• 本縫紉機之押具防護裝置如圖所示,為保護

操作者之操作安全,嚴禁將此裝置拆卸。

( 圖 3)

• The presser foot protection device is as

shown as the fugure 3.

For safety of all operators,this device is

restriced to disassemble.(Fig.3)

圖 3 / Fig. 3

圖 4/ Fig. 4

P9

Introduction

Page 14

縫紉機的安裝位置

THE INSTALLATION POSITION

OF THE SEWING MACHINE

圖 5 / Fig. 5

1. 勿將該縫紉機置於設備附近,如電視機、收

音機或無線電話等,否則這些設備可能會對

縫紉機的電子干擾所影響。( 圖 5)

2. 應將縫紉機直接插入 AC 電源插座,如果使

用延長線,可能會造成操作故障 。

1. Please do not install the sewing machine

near the equipments,such as Television,

Radio,or Wireless Telephone.Or these

equipments will experience electronic

interference.(Fig.5)

2. The wire should insert the AC power socket

directly.If using the extension wire,this might

cause malfunction.

P10

Page 15

規格 SPECIFICATIONS

1. 型號分類表示 :

(1) 表示線數分 737、747、757、767

(2) 機種別

(3) 縫合方式 ( 圖表 1)

(4) 車縫布料

F: 輕薄布料

L: 薄布料

M: 中厚布料

H: 厚布料

X: 特厚布料

(5) 送具型式

(6) 針寬

(7) 包邊寬度

3: 3mm, 4: 4mm, 5: 5mm, 6: 6mm

(8) 配件

1.Description:

(1)Thread numbers / Four types:

as 737、747、757、767

(2)Machine type

(3)Sewing type(Chart1)

(4)Sewing materials

F: Fine weight material

L: Light weight material

M: Medium weight material

H: Heavy we

ight material

X: Extra heavyweight materia

(5)Feed dog type

(6)Needle width

(7)Seam width

3: 3mm, 4: 4mm, 5: 5mm, 6: 6mm

(8)Attachment

圖表 1 / Chart1

747 514 M 2 2 4L CT

(1) (2) (3) (4) (5) (6) (7) (8)

型式 Type 504 512 514 516 644

圖形

Pattern

P11

Introduction

Page 16

2. 規格說明 ( 表 1)

2. Specication(Tab.1)

機型 Model 700L

最高縫速 Max Stitch Speed 7500rpm / 7500rpm

噪音值 Noise Level 82 分貝以下 under 82 dB

縫距 Stitch Length 4 / 5 / 6 mm

針棒行程 Stroke of the needle bar 24.3 ±0.2 mm

押具揚程 Presser Foot Lift 5.5mm

押具壓力 Presser Foot Pressure 5kg

送具高度(凸出針板面)

Feed Dog Height (over the plate)

0.7~0.9mm

使用針 Needle for Use DCX27

送具傳動方式 Feed Dog Transmission 偏心輪、連桿 Eccentric, Connecting Rod

送具齒寬度

Teeth Width of the Feed Dog

1.6mm

縫目調整裝置 Stitch Adjusting D

evice 按鈕調整 Button Adjustment

押具裝置 Presser Foot Device

彈簧式、旋紐調整式

Spring Type, Knob Adjustment Type

加油方式 Oil Filling

儲油槽儲存方式,毛氈、棉線毛細管自動供油

Oil ank storage type. Automatic oil supply by Oil felt,

otton thread capillary action.

回油方式 Oil Return Solution 偏心泵浦 Eccentric Pump

使用油 Oil for Use

提供專用油 (MOBIL #10)

Provide Specific Oil (MOBIL #10)

表 1 / Tab. 1

P12

Page 17

各部件名稱 NAMES OF MAJOR PARTS

(1) 押具扳手 ( 圖 6)

(2) 押具

(3) 線架

(4) 油窗

(5) 手輪

(1)Lifting lever (Fig. 6)

(2)Presser foot

(3)Thread stand

(4)Oil gauge window

(5)Pulley (Hand Wheel)

圖 6 / Fig. 6

①

③

⑤

②

④

P13

Introduction

Page 18

圖 7 / Fig. 7

1. 縫紉機拆箱搬運過程中,不可扶持布板蓋

①。( 圖 7)

1. While moving the sewing machine, please

do not hold the below side of the cloth

cover

①

.(Fig. 7)

安裝 INSTALLATION

P14

Page 19

3. 裝置導布屑及線架。( 圖 9)

3. Assemble the waste disposal set and the

thread stand. ( Fig.9)

2. 依本機所附桌板裁製圖及零件組合圖所列之

配件,依序安裝防震機座鋁板①。 ( 圖 8)

2. Please refer to the attached table cut-out

diagram and the parts list to assemble the

anti-chock machine aluminum plate ① in

order. (Fig.8)

圖 9 / Fig. 9

圖 8 / Fig. 8

①

P15

Introduction

Page 20

圖 10 / Fig. 10

本體與桌板不得干涉

The machine cannot

touch the table.

4. 馬達啟動踏板①裝於左邊, 押具腳踏板②則

裝於右邊。( 圖 10)

4.Install the motor activating plate ① to the

left, and the presser pedal ② to the right.

(Fig.10)

①

②

貼心使用者設計的照明機構,其採用不發熱、

壽命長之發光二極體 LED 燈具,讓使用者能方

便於穿線。( 圖 11)

Thoughtful lightening equipment is deigned for

the operators. Non-heating and long life LED

lamps are adopted so that the operators can

thread easily.(Fig.11)

照明設備 LIGHTENING EQUIPMENT

圖 11 / Fig. 11

P16

Page 21

新機器使用規定

HOW TO OPERATE THE

NEW MACHINE

1. 新機器在最初啟用磨合期的四個星期內,請

用低於最高速度 20% 的速度運轉,之後換上

新潤滑油,才運轉至最高速度。

2. 定期 之清 潔 保 養,確 保延 長 機器 之使 用壽

命。

1. Please operate this machine in 80% of the

maximum speed in the first four weeks for

engagement. After four weeks, please do

not operate under the maximum speed until

replacing the new lubrication oil.

2. Periodically maintain and clean the machine

to ensure and extend the usage term of the

machine.

潤滑油之注入與更換

LUBRICATION AND DRAINAGE

圖 12 / Fig. 12

1. 潤滑油之注入 ( 圖 12 )

(1) 將油鏡Ⓐ旋開,以包裝箱內所附之超高速潤

滑 油 或 選 用 ESSO#32( 或 MOBIL#10) 等

相當之機油加入,使油量指示桿位於油標上

下之間即可,然後再鎖緊油鏡Ⓐ。

(2) 開箱 新 機 器或久置未 使 用 要重新用時,請

在上勾針台等加油潤滑。

1.Fill the lubrication oil (Fig.12)

(1)Remove the oil level inspection leng Ⓐ

and ll it with the attached ultra high speed

lubricating oil, or choose ESSO#32 (or

MOBIL #10)or equivalent. Tighten the oil

level inspection leng

Ⓐ after the oil livel

indicator locates between the two marking

lines.

(2)Please lubricate the needle bar and

the upper looper shaft before starting

ooperating a new machine or a long idling

machine.

上限

下限

Upper limit

Lower limit

P17

Introduction

Page 22

圖 13 / Fig. 13

2. 潤滑油之更換 ( 圖 13)

(1) 將螺絲Ⓑ放鬆旋開,使油槽內的油完全排出

後再將螺絲Ⓑ鎖緊。

(2) 為延長本機器之壽命,請於開始使用後四個

星期更換新油,爾後約每四個月更換一次。

(3) 為延長本機器之壽命,特別裝有濾油器之機

構,請在每使用一個月後卸下清洗乾淨,必

要時得換新品。

2.Drainage and rell the oil :(Fig. 13 )

(1)Loosen the screw Ⓑ and drain all the oil

inside the oil tank. Then, tighten the screw

Ⓑ

again.

(2)In order to extend the term of usage, please

replace the oil after the rst four week, and

then replace it every

four months.

(3)To extend the usage term, this machine has

equipped an oil lter. Please disassemble

and clean it every month, as well as change

it if needed.

圖 14 / Fig. 14

3. 針之冷卻油

使用油 : 矽油 (SILICON OIL)。( 圖 14)

3. Needle cooling lubrication oil:

SILICON OIL. (Fig. 14 )

P18

Page 23

穿線方式 THREADING THE MACHINE

• 請確實按照圖示穿 線,錯誤 之 穿線將引起斷

線、跳針或車縫不平…‥等現象。

• Follow the procedures for threading. Wrong

threading may cause thread breaking, stitch

skipping, puckering or unexpected sewing.

1.737 用穿線圖 ( 圖 15)

2.747 用穿線圖 ( 圖 16)

1. For three thread only 737(Fig. 15)

2. For four thread only 747(Fig. 16)

圖 16 / Fig. 16

圖 15 / Fig. 15

圖 17 / Fig. 17

3.757 用穿線圖 ( 圖 17)

3. For ve thread only 757(Fig. 17)

P19

Introduction

Page 24

控線調整 ADJUST THREAD TENSION

線張力必須根據縫合布料種類,布料厚薄,線

及包邊寬度等之差異而做不同的調整。順時針

旋轉張力控制螺帽,縫線張力加大,反之減弱。

1. 調整鈕之控線關係。 ( 圖 19)

(1) 調整鈕①控制雙環針線或左邊拷克線。

(2) 調整鈕②控制包邊針線。

(3) 調整鈕③控制上勾針線。

(4) 調整鈕④控制下勾針線。

(5) 調整鈕⑤控制雙環勾針線。

The thread tension should be adjusted

properly according to the kinds and the

thickness of the materials, stitch length,

and seam width, etc. In addition, adjust

the nuts case by case individually. Turn the

nuts clock

wisely will increase the thread

tension. Otherwise, the thread tension will be

decreased.

1. Thread tension adjusting nuts. (Fig.19)

(1)The rst adjusting knob ① controls double

chain stitch threads or the left over-lock

needle thread.

(2)The second adjusting knob ② controls the

seam lock needle thread.

(3)The third adjusting knob ③ controls the

seam lock needle thread.

(4)The fourth adjusting knob ④

controls the

lower looper thread.

(5)The fth adjusting knob ⑤ controls the

lower looper thread.

3.767 用穿線圖 ( 圖 18)

3. For ve thread only 757(Fig. 18)

圖 18 / Fig. 18

P20

Page 25

圖 19 / Fig. 19

2. 針線控線關係 ( 圖 20 )

(1) 縫合方式 504、512、514 時,將過線組件

⑥ 移至最下端,縫合方式 516 時,則將過

線組件 ⑦ 、⑧ 移至最上端。

(2) + 表示增加針線放線量。

(3) - 表示減少針線放線量。

2.Needle thread control. (Fig. 20)

(1)When the sewing type is set to 504, 512

or 514 , move the threading part ⑥ to

the lowest part. When the sewing type is

516,move the threading part ⑦ and ⑧ to

the highest point.

(2) The + direction indicates to increase the

length.

(3) - means to decrease the needle thread

length.

弱 Weak

強 Sreong

圖 20 / Fig. 20

P21

Introduction

Page 26

4. 環縫線凸輪控線關係 ( 圖 22)

(1) 調整底線導致線環不穩定 ( 鬆塌或成形不足 )

時。

(2) + 表示增加針線放線量。

(3) - 表示減少針線放線量。

4. Chainstitch thread cam control .( Fig.22)

(1)Adjusting the lower thread causes the

thread ring unstable (too loose or didn't

form a thread ring).

(2) + means to have more thread amount

while sewing.

(3) - means to have less thread amount

while sewing.

圖 21 / Fig. 21

圖 22 / Fig.22

3.Looper thread control.( Fig. 21)

(1) When the sewing type is 504 and the upper

looper is on the lowest point, adjust

⑨ and

⑩ at the position of + .

(2) Adjust xed thread guide plate and

as the following: The direction + is for more

thread in sewing seam, and the - direction

is for less thread in sewing seam.

11 12

3. 勾針控線關係 ( 圖 21)

(1) 若縫合方式 504,上勾針移至最低時,將

⑨ 及 ⑩ 調至 + 位置。

(2) 固定線導板 、 如下 :

+ 方向為縫合線較多,- 反之較少。

11 12

P22

Page 27

換針方式 REPLACE THE NEEDLE

1. 使用 DCX27 或同規格之針。

2. 旋開螺絲 ① 並取下針。

3. 將新針插至針孔最底端,並使針之溝面向自

己,固定螺絲 ①。( 圖 23)

1.Please use the needle DCX27 or the

equivalents.

2.Loosen the screw ① and take off the needle.

3.Insert the new needle till reaching the end,

as well as the long groove faces your side.

Tighten the screw ①. (Fig.23)

圖 23 / Fig.23

圖 24 / Fig.24

針距調整 ADJUST THE STITCH LENGTH

• 通常依據車縫布料,差動比等之不同而調整。

持續壓下按鈕 ① 並轉動手輪使按鈕卡住,再

轉動手輪至所需之針距後放開此按鈕。 ( 圖

24)( 表 2)

• The stitch length is adjusted according to the

fabrics, the differential ratio or other factors.

Keep pressing the button ① and turn the

pulley till the button is locked. Then, release

the button after reaching the desired stitch

length.( Fig.24)(Tab.2)

表 2 / Tab.2

最大差動比

Maxi Diff ratio

機種

Machine type

皮帶輪刻度 Pulley scale

1 2 3 4 5 6 7

1:2 接縫 Seaming 0.6 1.13 1.66 2.19 2.72 3.25 3.8

1:3 摺縫 Shirring 0.6 1.03 1.46 1.89 2.32 2.71 3.2

1:1.3 包邊 Serging 0.8 1.5 2.2 2.9 3.6 4.3 5

1:4 特規 Special 0.6 1.02 1.44 1.66 2.28 2.7 -

粗 Thickness

細 Thin

P23

Introduction

Page 28

差動比調整

ADJUST THE DIFFERENTIAL

FEED RATIO

若主送具之運動行程大於差動送具運動行程

時,布料車縫時會伸張,反之則會收縮。

1. 調整方法一:

為放鬆調整鈕 ①,當調整桿 ② 向下調整時

使布料收縮,反之則伸張,調整後再鎖調整

鈕 ① 。( 圖 25)( 表 3)

If the stroke of the main feed dog is larger

than the stroke of the differential feed dog,

the fabric will be extended while sewing.

Otherwise, it will be shrunk.

1.Adjust solution 1:

Loosen the adjusting nut ①. Adjust the

adjusting rod ② downward will shrink the

fabric, whereas move it upward will extend

the fabric. Tighten the adjusting nut ① after

the adjustment nishes. (Fig.25)(Tab.3)

表 3/ Tab.3

刻度 Scale 1 2 3 4 5

差動傳送比

Differential feed ratio

1:1.3 - 1:0.7 1:0.9 1:1.1 1:1.3

1:2 1:0.7 1:1 1:1.14 1:1.17 1:2

1:3 1:1 1:1.5 1:2 1:2.5 1:3

1:4 1:1.1 1:1.6 1:2.3 1:2.3 1:3.3

2. 調整方法二 :

(1) 鬆開螺絲 ③ 並從機台後方移開外蓋 ④。

(2) 鬆開螺帽 ⑤ ,上下移動連桿 ⑥

欲增加差動比,把連桿⑥往 ( + ) 方向移動

欲減少差動比,把連桿⑥往 ( - ) 方向移動。

(3) 在調整過後,把外蓋 ④ 放回機台後方並鎖

回螺絲③。( 圖 26)

2.Adjust solution 2:

(1)Loosen the s

crew ③ and remove the cover

④ from the rear side of the machine bed.

(2)Loosen the nut ⑤ , and move the

connecting rod ⑥ upward and downward.

To increase the differential feed ratio, move

the connecting rod ⑥ to (+) direction. To

decrease it, move the connecting rod ⑥ to

(-).

(3)After adjusting, put the cover ④ back to

the rear of the machine bed and tighten the

screw ③.(Fig.26)

圖 25 / Fig. 25

伸張 Stretch

收縮 Shrink

圖 26 / Fig. 26

P24

Page 29

圖 27 / Fig. 27

更換切刀 REPLACE THE TRIMMERS

1. 更換上切刀

(1) 放鬆螺絲①將下刀座②向左邊推,輕鎖螺絲

① 。

(2) 取下螺絲③換上新刀片後,輕輕鎖緊螺絲③

。

(3) 轉動皮帶輪使上刀移至下死點,調整上刀高

低使上刀與下刀相交約 0.5~1.0mm,鎖緊

螺絲。

(4) 放鬆螺絲①使下刀座還原位置,並試驗上下

刀能確實剪斷車縫線,鎖緊螺絲 ①。

2. 更換下切刀

(1) 放鬆螺絲①將下刀座②向左邊推,輕鎖螺

絲。( 圖 27)

(2) 放鬆螺絲④取下舊刀換上新刀。

(3) 調整下刀之刀口與針板面平齊後,鎖緊螺絲

④。

(4) 放鬆螺絲①使下刀座還原位置並試驗上下刀

能確實剪斷車縫線,鎖緊螺絲①。( 圖 27)

1.Replace the upper trimmer:

(1)Loosen the screw ① and move the lower

trimmer hold

er ② to the left. Then, tighten

the screw ① a little.

(2)Remove the screw ③ and put the new

trimmer. Then, tighten the screw ③ a little.

(3)Turn the pulley to move the upper trimmer to

the lower dead point. Adjust the height of

the upper trimmer so that the upper trimmer

can cross the lower trimmer about 0.5 ~

1.0 mm. After that, tighten the screw .

(4)Loosen the screw ① and return the lower

tr

immer to its original position. Test if the

upper and the lower trimmer can cut the

thread exactly, and then tighten the screw

①.

2.Replace the lower trimmer:

(1)Loosen the screw ① and move the lower

trimmer holder ② to the left. Then,tighten

the screw ① a little.(Fig. 27)

(2)Loosen the screw ④ . Take off the trimmer

and replace a new one.

(3)Adjust the edge of the lower trimmer to be

alight with

the surface of the needle plate.

Then, tighten the screw ④ .

(4)Loosen the screw ① to return the lower

trimmer holder to its original position and

test if the upper and the lower trimmer can

cut the thread exactly. Then, tighten the

screw ① .(Fig. 27)

P25

Introduction

Page 30

圖 28 / Fig. 28

包邊寬度調整 ADJUST THE HEM WIDTH

1. 轉動手輪,將上刀移至下死點。( 圖 28)

2. 放鬆螺絲①,向左移動下刀座疊②後,暫時

輕鎖螺絲①。

3. 放鬆螺絲③,移動上刀座向左或向右,直到

達到所要的包邊寬度後再鎖緊螺絲 ③。

4. 放鬆螺絲①,使下刀座② 位置還原,並測試

能切斷車縫線後,鎖緊螺絲①。

1. Turn the pulley to move the upper trimmer to

the lower dead point. (Fig.28)

2. Loosen the screw ①and move the lower

trimmer holder ② to the left, and then

tighten the screw ① a little.

3. Loosen the screw ③ and move the upper

trimmer holder left or right till reaching the

desired width. Then, tighten the screw

③.

4. Loosen the screw ① to return the lower

trimmer holder ② left or right till reaching

the Test if the trimmers can cut the thread,

and then tighten the screw ① .

P26

Page 31

針高度之調整 ADJUST THE NEEDLE HEIGHT

1. 轉動手輪使針上昇至最高點時,針尖至針板

面之距離為 (a)。( 圖 29)

2. 調整 :

(1) 打開上蓋①。

(2) 放鬆螺絲②,移動針棒至所需高度鎖緊螺絲

②。

(3) 放回上蓋①須密合鎖緊。

1.The (a) is the distance from the needle tip

to the surface of the needle plate when the

needle is rised to the highest point after

turning the pulley.(Fig.29)

2.Adjustments:

(1)Open and remove the upper cover ① .

(2)Loosen the screw ②, and move the needle

bar to the desired height.

Then, tighten the

screw ② .

(3)Put the upper cover ① back, and seal it.

圖 29 / Fig. 29

押具調整 ADJUST THE PRESSER FOOT

1. 押具位置調整

(1) 放鬆押具壓力①及押具螺絲⑦。

(2) 移動押具⑥使其押具槽與針板之針槽一致

押具底平壓於針板上,鎖緊螺絲⑦。

(3) 放鬆螺絲⑤左右移動④,使③與②吻合,且

②能上下活動輕順,鎖緊螺絲⑤。

(4) 調整適當壓力,螺絲①順時針方向旋轉,壓

力加大,反之減弱。( 圖 30)

1.Adjust the presser foot position.(Fig.30)

(1)Release the pressure spring ① of the

presser foot and the screw ⑦ of the presser

foot.

(2)Move the presser foot ⑥ so that the groove

of the presser foot can align with the groove

of the needle plate. Also, the bottom of the

presser foot can stand on the needle plate

atly, and then tighten the screw ⑦ .

(3)Loosen the screw ⑤ , and move ④ left and

righ

t so that ③ can match ② and ② can

move upward and downward smoothly.

Then, tighten the screw ⑤ .

(4)To adjust to a proper pressure: turn the

screw ① clockwise will increase the

pressure, where as turn it counter clockwise

will decrease the pressure.

standar stroke 10.4~10.6mm

high strok 11.8~12mm

標準行程 10.4~10.6mm

高行程 11.8~12mm

①

②

③

P27

Introduction

Page 32

圖 30 / Fig. 30

圖 31 / Fig. 31

弱 Weak

強 Sreong

2. Adjust the lift amount of the presser foot.

(1)Rotate the pulley to move the feed dog

downward until the feed dog is under the

needle plate, as well as the bottom of the

presser foot touches the needle plate atly.

(2)Loosen the nut ④ , push down the lever

⑥ to arise the presser to the appropriate

position, around 5.0 ~5.5mm. Adjust the

screw ⑤ and x the nut ④.

(3)There should be a cl

earance of 1mm

between the pull rod ① and the xed

bracket ②, which can be adjusted by

loosening the screw ③ slightly.

(4)After all the adjustments above pleasea

tighten the screw ③.(Fig.31)

2. 押具提升量調整

(1) 轉動手輪使送具降至針板下,押具底平貼針

板。

(2) 放鬆螺帽④,壓下拉桿⑥使押具上昇至適當

位置約 5.0~5.5mm,調整螺絲⑤及固定螺

帽④。

(3) 拉桿①與固定座②須保持有 1mm 的間隙

可輕輕放鬆螺絲③調整。

(4) 要確實鎖緊螺絲③。( 圖 31)

P28

Page 33

送具調整 ADJUST THE FEED DOG

1. 送具高度調整

(1) 轉動手輪使送具上升至針板上最高點。

(2) 放鬆螺絲①,上下移動主送具②,使其齒面

高出針板面約 0.9~1.1mm,鎖緊螺絲①。

(3) 放鬆螺絲③,上下移動差動送具④,使其齒

面高出針板面約 0.9~1.1mm 鎖緊螺絲③。

( 圖 32)

1.Adjust the feed dog height.

(1)Rotate the pulley to rise the feed dog the

highest point of the needle plate.

(2)Loosen the screw ① , and move the main

feed dog ② up and down in order to keep

the teeth side over the needle plate about

0.9~1.1mm. Then ti

ghten the screw ①.

(3)Loosen the screw ③ , and move the

differential feed dog ④ up and down in

order to keep the teeth side over the needle

plate about 0.9~1.1mm. Then, tighten the

screw ③. (Fig.32)

圖 32 / Fig. 32

0.9~1.1mm

P29

Introduction

Page 34

圖 33 / Fig. 33

2. 送具水平調整

(1) 送具齒的齒面在運轉的循環中,必須保持針

板面成水平。

(2) 調整時放鬆螺絲⑤,旋轉後支軸 ⑥,齒面

呈水平後固定螺絲⑤。( 圖 33)

2. Adjust the feed dog horizontally.

(1)During operation, the teeth side of the feed

dog should keep parallel with the surface of

the needle plate.

(2)For adjustment, loosen the screw ⑤ , and

rotate the rear support shaft ⑥. Do not

tighten the screw ⑤ until the teeth side of

the feed dog is horizontal. (Fig. 33)

3

. 輔助送布齒高度

輔助送具 ⑦ ,其齒面比送布齒齒面低

0.3~0.5mm,可放鬆螺絲 ⑧ 來調整。

( 圖 34)

3. Adjust the auxiliary feed dog height.

The teeth side of the auxiliary feed dog ⑦

is 0.3~0.5mm lower than the feed dog.

The height can be adjusted by loosening

the screw ⑧.(Fig.34)

圖 34 / Fig. 34

⑤

⑥

⑦

⑧

P30

Page 35

圖 36 / Fig. 36

針與勾針之關係

THE RELATIONSHIP BETWEEN

NEEDLE AND LOOPER

1. 針與上勾針之關係

當上勾針移至最左時,勾針尖端與針中心距

約 4.4 ~ 4.7mm ,雙針時其左針中心與勾

針尖端距約 5.4~5.7mm 。( 圖 35)

1.The relationship between the needle and the

When the upper looper moves to the leftest

point, the distance from the looper tip to the

middle line of the needle is 4.4 ~ 4.7mm.

For double needles model, the distance from

the looper tip to the middle line of the left

needle

is 5.4~5.7mm.(Fig.35)

2. 針與下勾針之關係

(1) 當下勾針移至最左時,勾針尖端與針中心

距約 3.7~3.9mm( 雙針時以左針為主 )。

( 圖 36)

2.The relationship between the needle and the

lower looper.

(1)When the lower looper moves to the leftest

point, the distance between the looper tip

and the middle line of the needle should

be about 3.7~3.9mm. For double needles

model, the distance is from the lower looper

tip to the m

iddle li ne of the left needle.

( Fig.36)

圖 35 / Fig. 35

1~1.3mm

P31

Introduction

Page 36

4. 針與環縫勾針之關係

當環縫勾針移至最左時,勾針尖端與針之中

心距離為 1.6~2.3mm。( 圖 39)

3. 上勾針與下勾針之關係 ( 圖 38)

當上下勾針相交時,兩勾針盡量接近,但不

可磨擦或碰撞,其間隙 ① 點為 0.1~0.3mm

② 點為 0.35~0.65mm。

4. The relationship between the needle and the

chainstitch looper.

When the chainstitch looper moves to

the leftest point, the distance from the

chainstitch looper pin to the middle

line of

the needle is 1.6~2.3mm. ( Fig.39)

3. The relationship between the upper looper

and the lower looper. ( Fig.38)

When the upper and the lower looper cross,

keep them as close as possible. Somehow,

the loopers shall not either touch or collide to

each other. The clearance ① is 0.1~0.3mm,

as well as the clearance ② is 0.35~0.65mm.

(2) 當下勾針向右移至針中心時 ( 雙針以左針

為主 ) 針

與勾針之間隙為 0~0.05mm。

( 圖 37)

(2)The relationship between the needle and

the middle line of the needle (use the left

needle as standard when it's double needle

model), the clearance between them should

be 0 ~ 0.05mm.( Fig.37)

圖 39 / Fig. 39

1.6~2.3mm

圖 37 / Fig. 37

圖 38 / Fig. 38

②

①

0~0.05mm

0.1~0.3mm

0.35~0.65mm

P32

Page 37

環勾針運動量之調整

ADJUST THE CHAINSTITCH

LOOPER MOVEMENT AMOUNT

圖 41 / Fig. 41

The movement of the chainstitch looper is

oblong shape. When the difference of the

changed needle number is too large, or if

necessary to adjust the front/rear movement

amount a of the chainstitch looper, please

follow the steps below to adjust.

1.

Open the sealed cover ① in the back side of

the machine.

2.Loosen the screw ③ slightly.

3.

Turn the screw ② to adjust. To increase the

move

ment amount, turn to + direction. To

decrease the movement amount, turn to -

direction.

4.Tighten the screw ③ after the adjustment.

5.Then, seal the cover ① .( Fig.41)

環勾針之運動呈橢圓形,當針號數變動過大時

或有必要調整環勾針之前後運轉量 a 時,請依

照以下步驟調整。

1. 打開縫紉機背面的封蓋 ① 。

2. 輕輕放鬆螺絲 ③。

3. 旋轉調整螺絲 ②,

向 + 方向加大前後運動量。

向 - 方向減少前後運動量。

4. 調整後鎖緊螺絲 ③ 。

5. 封蓋 ① 。( 圖 41)

圖 40 / Fig. 40

5. 針與檔針片之關係

(1) 當下勾針由左向右至針中心時 ( 雙針以左針

為主 ) 針與後檔針片之間隙為 0~0.05mm。

(2) 當針在下死點時針與前檔針片之間隙為

0.1~0.2mm。( 圖 40)

5.The relationship between the needle and the

needle guard.

(1)When the lower looper moves from left to

right to the central line of the needle (when

it's double needle model, it means the left

needle), the clearance from the needle to

the rear needle guard is 0 ~ 0.05 mm.

(2)When the lower loope

r moves from left to

right to the central line of the needle and

the front needle guard is 0.1~0.2mm.

( Fig.40)

高行程 0.05~0.1mm

high strok 0.05~0.1mm

0~0.05mm

0.1~0.2mm

P33

Introduction

Page 38

保養 MAINTENANCE

P34

Page 39

報廢流程 DEMOLITION PROCEDURE

1. 當機器需要被淘汰與報廢時,有一些基本規

則必須採納、遵守以保護環境及公眾健康。

2. 所有的機器零組件必須依照下列分類來區分

開:

(1) 所有護套、可伸縮軟管及塑膠或非金屬零

件。

(2) 電器零件:開關、照明器具等。

(3) 絕緣材料:石棉、彈性/可伸縮橡膠片。

(4) 金屬:含鐵金屬、銅、青銅與黃銅、其他各

種金屬。

3. 以此方法,所有材質可以正確的淘汰,回收

再利用或鎔解為可再使用或再處理而不至於

危害環境。

1.When the machine needs to be eliminated

and demolished, certain basic rules must

be observed to protect the environment and

public health.

2.All machine componenets

must be divided

according to categories as the followings:

(1)All sheathes, exible hosing and plastic or

non-metal components.

(2)Electricity components: switches, or lighting

components.

(3)Insulation materials: rock wool, and exible

rubber strips.

(4)Metals: ferrous metals, copper, bronze and

brass, various.

3.In this way, all materials can be eliminated

correctly, recycled, or melted down fo

r reuse

or disposed of so that they do not harm the

environment.

P35

Introduction

Page 40

由於對產品的改良及更新 , 本產品使用說明書中與零件圖之產品及外觀的修改恕不事先通知 !

The specification and/or appearances of the equipment described in this instruction

book & parts list are subject to change because of modification which will without

previous notice.

KZ08L.JUN.2017

Loading...

Loading...