Page 1

flm~a~w

INSTRUCTION BOOK

700F

·1~

CE

F41®

~

iR~Jii1Bf5iPSDaJ

KAULIN MFG.CO

..

LTD.

Page 2

Page 3

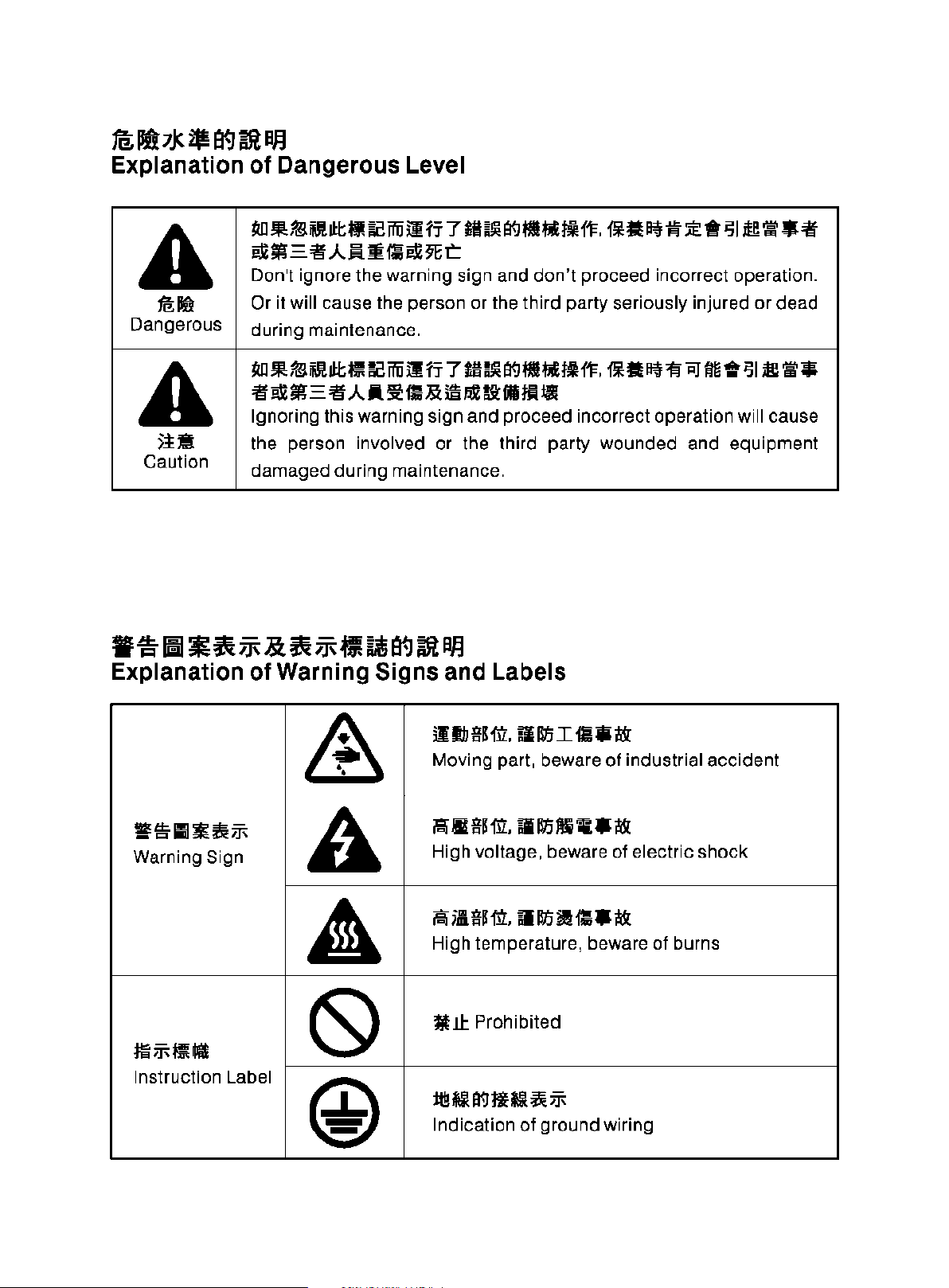

ta;

llff7Jc

Explanation

2IH19

A

~Jijk

Dangerous

A

).!!l

Caution

~

PF.1

of

Dangerous Level

~IL~

$ill!

ill:;

81

~

iffi

i1 rr 7 til

..

;(l='i!'.A..!l.J!~

Don't ignore the warning sign and

Or

it

will

cause the person or the third party seriously injured or dead

during maintenance.

~mm~Jll:;~~iffi~rr7~~a<JI!IIl'~~il!•~•~~•~I~\O!*

'~~'"";r!-'I!'.A.A~m~~~~-~~

Ignoring this warning sign and proceed incorrect operation will cause

the person involved or the third party wounded and equipment

damaged during maintenance.

..

9Et:

~

a<J

1!111'

1¥

don't

11',

ill

lit

~ ~

:;E

*

~

I

i!e

\0!

!II

'II'

proceed incorrect operation.

-~~~~1.1'&~1.1'-l!i.&atJ~PF.I

Explanation

of

Warning Signs and Labels

lllb

f!l'fil.

Moving part, beware

ill

lt'i

I

filii

I&

of

industrial accident

&

1fiS-III*~ff;

Warning Sign

A

i'UU!'fil. lllt'iMi 'ill

High voltage, beware of electric shock

F-\

iUI'fil.

High temperature, beware of burns

lllt'i

.I&

l!

m•l&

A

:lll;J<I~Ull

(S)

Instruction Label

@

¥!1: Prohibited

il!!~a<Jli~

Indication

...

;j;

of

ground wiring

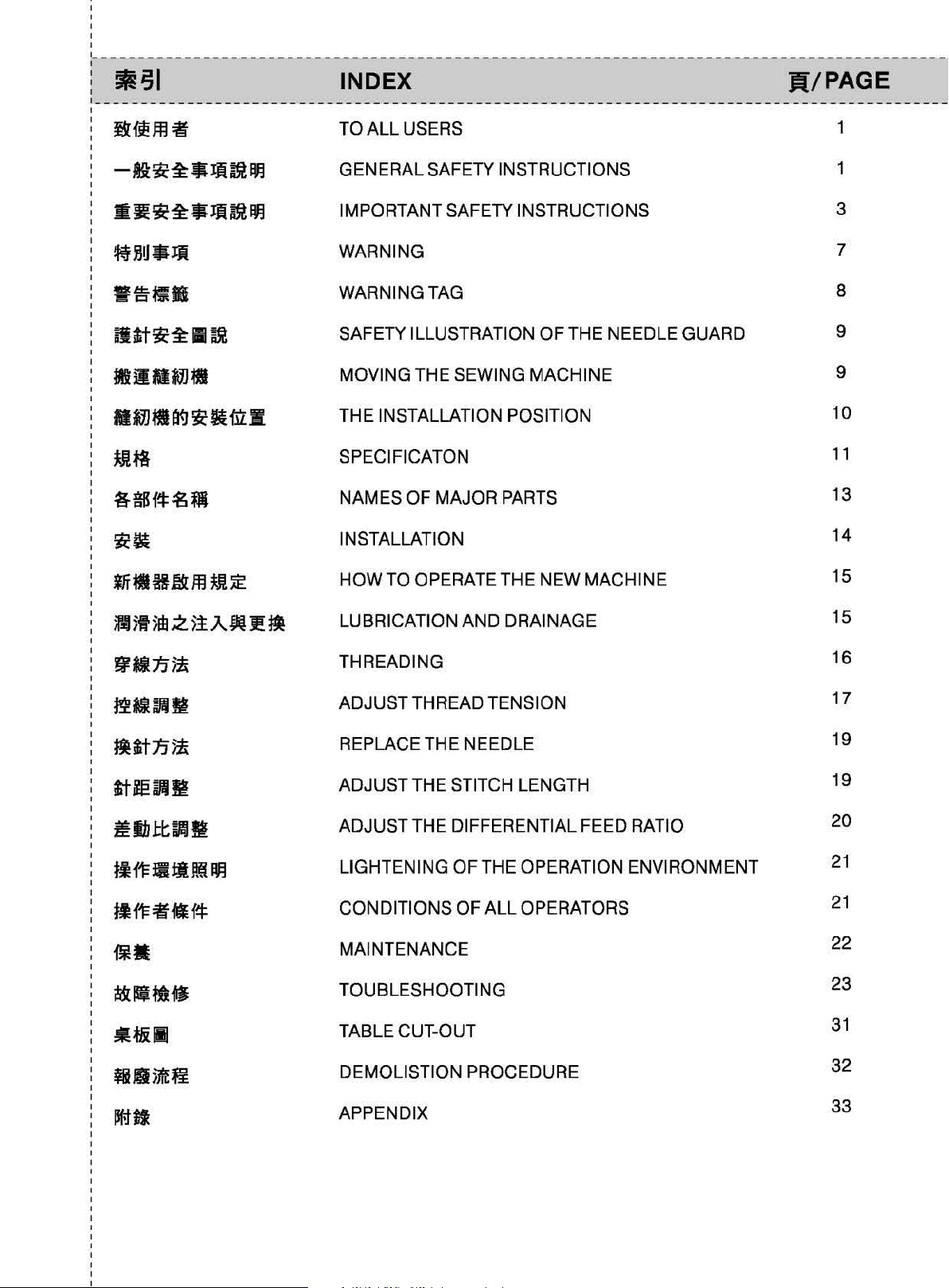

Page 4

Page 5

I

I

,---

----------------------

i

-~~

---

------------------

INDEX

- --

---------------------------------------

---·

J{/PAGE

TO

Jf{ilf.l=!f

-6:~~-Jji~!Jl

·-~~*JRN!Jl

~HU*li

iltt~~·~

ltiiMjjj.a

MM.J.a!J9~ltfl!ll

m~

§BSf~:Sfll

ffiWHmmmj£

ALL

GENERAL SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

WARNING

WARNING

SAFETY ILLUSTRATION

MOVING THE SEWING MACHINE

THE INSTALLATION POSITION

SPECIFICATON

NAMES OF MAJOR PARTS

INSTALLATION

HOW TO OPERATE

USERS

TAG

OF

THE NEEDLE GUARD

THE NEW MACHINE

1

1

3

7

8

9

9

10

11

13

14

15

f4

51

5IB Z $1

A.

JB!!

}t

v•1i$

l!.JV.

fttiJJ$

tf-BEi-1.

~lbl:l::~-

tl

11=

Jl

t.i

IH~

jl

11=

=if

·1~

fia

i!&lllftl.

-~·

fi.flljM~

LUBRICATION

THREADING

ADJUST

REPLACE

ADJUST THE STITCH LENGTH

ADJUST THE DIFFERENTIAL FEED RATIO

LIGHTENING

CONDITIONS OF

MAINTENANCE

TOUB

TABLE CUT-OUT

DEMOLISTION PROCEDURE

THREAD TENSION

LESHOOTING

AND

DRAINAGE

THE NEEDLE

OF

THE OPERATION ENVIRONMENT

ALL

OPERATORS

15

16

17

19

19

20

21

21

22

23

31

32

llf;fjl

APPEND IX

33

Page 6

Page 7

I

'--------------------------

I

,

&flm

=r

---

------------------

- --

---------------------------------------

To

ALL

usERs

---·

'------------------------- -------------------------------------------------------------------

•

a.-,~t:~li~ffJHlm*~aJW~zmiii"

ii:Rtf"IHIM~IIC~~-)

·n~EM~~~~-~~~~~7M*II

w•~z~~~~w~~mn~·~w~

..-1SHI·~~-~~~~

o

o

·~~~-~~·=·~~A~~~~-~

~~z•~~•~•n~·~~~~~*

ltfto

• Thank you very much for using our Ultra

High Speed Straight Needle

Overlock/Safety Stitch Machine.

• Before operating this machine, please

book

read this instruction

understand the functions and features of

this machine. This will help you

increase the sewing efficiency and quality.

•

Attention: Because this is an ultra high

speed machine, please fill the lubrication

oil and confirm that the motor turning

direction is clockwise before turn the

power on.

amply to

to

,

--~~·111ft~

'----------------------------------------------------------------------------------

=~mm~•w·&*~~m~afi~~

·~'

~~~~ft*~,--,~~-A~-~

Jl.llt o

tt~~~~•wzM·=•~~fim~~

Hii~M,D-

1.

ii~Ifl:tiffi~-

Mila<J

2.

~Aifl:tlffiltliJ

~···~Mm*Z~'~tt···~~

n~*·a<J~~~ffl*~ftAo~~I~

~PJT!iRJ!II.

a~ , ~fiffl

3. !!1it

it~!tllfi1li1Ui~~fiii!!~im

••

~

~

J.~

""F

51

Ji

!JUfi

o

o

lllil W fit

••

1t.

'

g~~-' j.~~~Jl·)

-T

e

tB

i31

ffl;

W o

0

'Xfi51&*~~-tFm;~

•~Ill

o

o

CRP

:

GENERAL SAFETY INSTRUCTIONS

Warning!

When using this machine, basic safety

precautions should always be followed

reduce the risk of fire, electric shock and

personal injury, including the followings.

Read all these instructions before

operating this product and save these

instructions.

1.

Keep

Cluttered areas and bencges invite

injuries.

2.

Consider

Do

machine tools in damp or wet locations.

Keep work area well lit.

Do

to

3.

Guard against

Avoid body contact with earthed or

grounded surfaces

work

area clean

work

not expose power to rain.

not use power

cause any fire or explosion.

area environment

Do

not use

tools

where there is risk

electric

shock

(e

.g. Pipes, radiators,

-

---------

to

ranges refrigerators.)

4.

Keep children away

Do

extension code.

-1-

not let visitors touch the tool or

Page 8

5. ll1itll9!1'fl

~~~~-~~~~~u~•·~~~~

~D~~m•~•ft•~·~•~•~a

~~1't~!H·

a.

~JHfj:fJHJt

~~~m~~~mhlmft·~£~~~~

m••*~~••·~-~~-~~,~

llli~£~illil*f·

1

:ltl1Uillft

•~m~*~•~m~~£~~ffl#·~

~~~I~m~·~*wmm~·~~m

t;~t-JM~ft~*~1!1·

B.

5HIJI!ft

z~~mmw~,M~M,••~~re#

H1;

•

9.

lH

!!

iili<

it

~~-~m·~~~OO~LZ~·-~

MB~A~~t-JI~·~~ff~~zM•

3.

«~~~~~·*~~~••m•~~

t«!o

4.

H~-,~~-~,~~--~·~M·

~~ft~~~~w~~~lli·~m~~~

taaa~.:z~~a<J~IhmH~~~il

o

2. Foll

3.

4.

ow

the instruction manual device to

install control device.

Always earth machine appropriately

during operation.

Before adjustment, parts change or

servicing must be sure to pull out the plug

from socket to prevent the hazard

unintentionally start of machine.

of

·~:J;:~·llli~

, _____

---------

~-~·~*~~R~7fim8t~W~

---- - ----

----

- - - - - - ---- - - -

-~--~~~~~~~-~·5~~

~Ra<Joomm~••·~m~BHEM

moom~~-·~Z~~-~~m~o

II

!2ft

Mf

Ilt

~

aJJ

Cth.

H

'48.

~

lfi

1Jo

•tm~m•w~,

~~ , =5.±.aJtf~•*~~mMfi

2.~ffl*MM·~7~*00ffl~~

0

0

& 4,

A

a&

~~ • ~!¥EllUl

Ilt~~

'

il~~iirfil*fiffl~IJ.J

• •

J.j_1fS~t~RJJ.1allimzMJ

3.

~~~t~H~~~-~~~m~~

8*fi•M1fffli!Bo

-~ftjCJtllfF~·~

~-~~~~RitM·tt~~PJi~~

~ftC.

WB.A.A~'fl

IlttiBillw

flf'F

1\7

&;o

7.

~"'F-~·-~IIIM·~~~~M

ill:

"'F

ll

f'F

~il~•~n•z~~Ji.

0

~it ' ~ir,ttiifmftel2~itllll

;Jt

:m

1'

o

ll*7

f~

fi

~

:ft

J.j_""f*li

Ill~

I

~

----

---------

fl

a<J

tl!!

o 1. Instead

o

aJJ. o

o

PJifi~~

a<J

'

j.j_

~

L8

IMPORTANT SAFETY

INSTRUCTIONS

- - ------------- - -

For operating

best functions of this machine, you

must operate it

and follow the instructions

manual, and keep

references.

will enjoy this machine as much as we

enjoy manufacturing it.

when you use this machine,

pay attention to the basic safety

measures.

Before using this machine,

read this manual and all related

instructions.

keep this manual for future needs.

Before using this machine,

ascertain that

standards and

country.

4.

When the machine is ready for

operation,

must be ready. Operate this machine

without the specified safety dev ices

is not

This machine must be operated by a

properly trained operator.

For your own safety, we suggest you

wearing

Please

disconnect

circumstances of the

safely and getting the

We

of

the following instructions,

all the safety equ ipments

allowed.

goggles .

turn

----

----

correctly. Please read

of

it

at hand for future

are confident that you

In

addition, please

it

conforms with safety

regulations

off

the power sw itch or

it

for any one of the

followings :

------------

this

please

please

please

of

your

-3-

Page 10

fC'\

\;>I

(1)

!UtM,

ll!m~tH~

(2)

l!!mtt,

tt

}'\"

ffllllf;J

(3)

MIIJI

< 4 l

llllllll

.lllleyo

(

5)

~if!

'iitey

1l.l

~D

1'

11Hil

Jilin~.

n!I4UrJilltilt,

011

:il:

ltrJ

P..(

Oi!i

~II

&

J.UUl!l!lli~

M)jjf\"'

I'!IA,

'

!Ill

Pi\

!II

~21'f

feiey

I

fe~

lllllll

€;

, ~

iiiH<H!O

liB & D21'f

7};

irl

JS<

IS!iliM

!i

,

'

a!;

o

m

iUIO

n!

ft

:!Hi

!Jill\l!.A.R"itflo

12.

iiH'

*

i**lllJ & iUU

JJI11l(J

II!:

-T

J-t

~~

lo z •

fl9

.A.

i!.

«ufE

& Jill# •

151ey

•

~

:il:~t~Jwli:lli!Bilili

~'I'~J.:.l&

M~,

J!i>i'li

o

.u

I

ii

it""

Siiiii.Ui!i\:SI:i~

1!G

l!IHi'i:

~A,

!J ~ •

1'F~

ilil

if!

J.:.l

!i'f

l!ltA.

11!1

;.&

Jli

~~11:

Ill

z

J~

& lit

ot

JJi

& :It

tr

F\"

1lii

o

.U

•

o

(98.

&

<P

z

*it

.U

D21'f

B lllll& •

J.:.t

~

(1) When threading needle(s),

(2) When replacing needles, presser

(3) When repairing,

(4) When the

(5)

If

your

please wash the

completely

consult

fluid mistakenly,

immediately.

Do

and devices. Always

whether power switch is on

before operating

anyone from

o 10. Qualified technicians are required

for adjustment, modification, and

repair.

replacement.

(S}

11. Routine maintenance and service

must be performed by

persons,

1'F

~>lHE

e!t

Ell

'iF

~

~UJ!~

:!1:

Ill

1'f

o

i!f

a

m

1\:\ 12. Maintain and

\;)I

parts

electrician

any

malfunctioned, stop the machine

immediately.

adjusting

thread guide(s), and

replacing

feet,

needle guards, horns,

guides

accessories,

working

machine

If clutch motors

pads

the

motor

grease, oil,

skin or eyes by any chance,

not

touch

Only use

must

electronic

thread Take-up(s),

I

bobbin(s),

needle plates, feed

and other

operator

place or leaves the

unattended.

are used, must wait until

stops

or

with clean water and

a doctor.

any functioning parts

getting

or

qualified technicians.

check

be done by qualified

or

well-trained persons. If

part

parts

leaves the

without

completely.

any

fluid

contacted

Or,

swallow any

consult a doctor

attend

in

order

hurts.

assigned

well trained

the

damaged

or

dogs,

cloth

or

brake

contacts

area

to

or

o1f

to prevent

parts for

electronic

or

-4-

Page 11

tt::'\ 13.

\.Y

1±

i!l:IIHi"

MIY:l*IIJJ.I.iH~·I

~~lllitr..I!~JI!l&,jll'f>.l;J.Illlr.!Jlit

fin

1t1<

J.:.l)J!l

1!:1<

S'l

'i!t

i&l

li!\!!1J

• m l!l

•

Jtt

lUI

"'

l\1

9f

Ollli!<

i/11

81Y:l

"i\

i'¥

'*

f!fo

f'FilU

r..

lfl!!

lit

tt

tU!i

(

i§tJ

liilllft

lllliil'i!t R llll

i'.1i

;Zo

15. :ii\uei!I!MfllliE mlif'F litjlj!1-'Pi'lif •

0

0

ll

i!

~

&,

'I'

liJl

ii!L.I::

• Ill H

Wi

lit

IY:llii

Ill

T llf'F "

16. lX/llli!l

am

~

!lllttllJi!!*I!Z!IIi~J:o

\O!IY:llltili!lilliili

:11:

11<

!l<

1±

m l!l

..1::

• .!lJI iili

'

iilllUDll

• lllllllll

!I!>

""

7

~ .f.

:1;,

lit~

tt

'l!li

Mi

S'I'II'Tli

!I!>

iWl

tt::'\ 13. The air hose has

'-.)I

0

0

0

from the

compressor

cut

the machine

pneumatic parts such

cylinder. Qualified technicians

well-trained persons are required for

adjustment

14,

To

periodically clean the machine is

necessary.

15.

In

reduce the noise, please place the

machine

Avoid operating the sewing machine

at a noisy surrounding.

16. Select a proper power plug and

install it by an electrician. Please

connect

machine

off

before repairing and servicing

and repairs.

ensure the best performance,

order

to

operate properly and

flat and level on the ground.

the power plug to a

to

be

and the

or air

supply

equipped

detached

has to be

with

as

an

air

or

to

tt::'\ 1

\.Y

grounded

receptacle.

IC'\ 17. This machine can only

~

B.

1iJ

OJ!

i'.li

Iii!

l!!

ll

H &,

!lll-fll"

!Ill

'iii:

:i:

~

lE

lit

i1ll

i1!

' [li]

!ey

l*

Ill!"'

~

IY:l

'iii:

:i:

Ill

ii

• *

~

jjj

'!'

jl\

llff

foJ

~Hl

l1l

(lJ

OJ!

i'.lil!l!!lll!lffi~lil!ltll!llzl!f"

(1)

tlll1'Ffti'.li6~~.A.ft;Z1!1~M:

~·~:I;,7J!I~'Billtzf;;;!*•Oil

o/.1

mliH!i

Jl!

1!11

llllt

lU~

H

*li

H*li z 9f

i'l

iii

z *

li

f-F

•

"

~'I'

I\:\

\::::1

the designed purpose. Other uses

this machine are not allowed.

18. Any modification

made on this machine must be

conformed with the safety standards

and

regulations. Precaution is

necessary. No

company

by any modification

this machine without permission.

19.

Two

safety warning signs are

applied

(1)

as warning signs:

For the safety

service persons, please don't

open the

control

devices and

responsibility will our

take

for

cover

boxes of

don't

be

used for

or

conversion

damages

or

of

operators and

of any electronic

motor

touch

caused

conversion of

or other

any

of

-5-

components

electrical

shock

inside

hazards.

to

avoid

Page 12

(2) !0

a . M Jt'f'

b .

c .

Always

ilii

!IUJ

11

a llillll

OJ

1±

3

!;

Jlll.\li

li1!

•

~

<~

~

iUii;;,!!

rrl!l!3!lit

~flo

ll> 7 i!!

l!8

i1 Q

il<Jfi•1JillAIIII~~·Jlll;\\'i.&

.110

li

;

OJ!illllfffol~oll.·J;I,~!!J~

.A.

JB'l'

'!ir

~

n

B

tt

l&

~lilltt:&ti'(,J"f}J;;,I!&t~l'l'~

~9fil<P

~

:!£

fti!

i'i'

fl

•

jfg

•

J.:J.~llii~Jdo.

~'Ill

I!!!

31111

tt

' lil'

1!11

<!>

•

~

1'(,1 ~ ,

I1t

:9

f

i!

J!!;

1'!

•

llll

~iii!

r.nll

M

<!>

•

li!!

•

PJ~!S~.A..Il.~

Ill!

'f'

iiUUi

ili:

~

tl

;;,ii

OJ

~

Ill

'f'

1!11

3

1flll'(,l

(2)

a.

b.

c.

ill·

keep

Please

machine

finger

device

injury.

Please keep your hair,

and

hand

while

operation,

put anything near these parts,

to

by

Please never

under

thread

prevent physical injuries when

you turn on the

never

guard

to avoid physical

cloths

wheel, V

the

prevent

tangled

the needle(s) or in the

take-up

in

mind:

operate

without

or

any

away

belt

machine

as

well as never

the

risk

into

them.

put

cover to

power

this

belt cover,

safety

fingers

from

the

and

motor

is in

of injuries

your

fingers

switch

or operate the machine.

While the machine is in

d.

ZI!Bllili<P

ill

•

ll>7i!!~Ji~OJfMiit!l

;Z

ill

W • !0 ~

ffllAIII!!IIiiltl!t;tl!I 0 tt9f

l!!l*i!I-Ttey•lifllE!Iil£iil~Jiill

BIIIIM·J;J,~W~.A..Il.~

• !lliili;l!;l!Q

lil!:iE:

~

(I{J

~

'

~

'!ir

II•

e.

lil'

till

'II

;;,!!

:til

;t!l

II

iili

'"

•

'J

"c,

~

Mn

JrMI!I!

a'*' • J.:J.

~

•

~..~.-~m·

f.

1.o

7l!i

~

1!11

3

~

?&

lli:

!!11

ilil

~I

it!l

OJ

~

;;:

9f

•

1ir

1!11

iili M til

Ill]

Jlll,llii

il.&

Jlll,llii

tey

I!I!M~il£i

'

PJ~W~.A..Il.~

1'*·

'

~

;;,!!

3

1111

j"

d.

operation, the

a high

your

area

potential injury

In

to

machine

bobbins.

e.

Be careful and

your

machine

lifting

avoid

injuries.

f.

Please turn

before tilting the

head or removing the

cover and the V belt

possible

abrupt

speed.

hands

of

hook

addition, please make sure

turn

off

while

fingers inside the

when

the

machine

possible

accidents

start of this machine.

hook

rotates at

Please

away from the

to

prevent

to

your hands.

the power

off

the

of

changing

do

not place

placing

head

physical

power

machine

to

due to

keep

any

the

or

to

belt

avoid

-6-

Page 13

G.

~

.19!

l'f.J

II

ft

:m:

~I

fiiJ

niH~

ii•IIBMB.L!:~D~·~

il!!:1'1t&~lllfil'f.J•1:i7

it~ti~~~~JNihffii

tlit9~

j}o

h.

1:6

1'•tt~~m•~•ma~fltt

'

i!&illltjtlft.

71¥~111-.:Zfe;rt

iJI

ieRJ

' All!

fFflfto

g. For machines

motors, the motors

produce noise while

machines are at rest.

Therefore,

power

avoid

to

h. Never operate the sewi

machine after

is removed

of

possible

abrupt

equipped

do

the

please turn

this machine

accidents

start

of

the

the

ground

to

avoid electrical

servo

not

off

the

to

due

machine.

ng

wire

I

i

M~.mall

i.

1:6

7

~~~Mtl:eX.T-W.f.FHUI

ffii

iJI

JW.:Z

RJtma9~

11~ • ~HIL.I:sxt~~tiBJi

,

tt9t+J.Jif

o

i.

WARNING

shock

Please turn the

off

disconnecting

to

due

damaged

components

hazards.

before

prevent

to

electric

power

connecting

the

power plug

possible

electronic

.

accidents

shock

switch

or

or

1--------------------------------------------------------------------------------------------

~7~~~~•i!&•~M•·a9t•~~

~-Jft:

'l'ftl!it&iltlfttl•

~11=M • ilflUl5l~ltH

j.

~

il

il

it

'fl 5

5m

n6

o

lt~--~~il~ll(Jl~:eX-

MM-i~tlll

o

tl

.:Z

1!k

II&~

ttl

;Z

~)~

&:iEmo

Please confirm the followings

malfunction

or

damage

to

o 1. After installing the machine,

before the first operation, please

clean it completely.

Clean all

during transportation.

Confirm that

phase

are set

Confirm that

dust

the

(single

cor

rectl

the

and overflowed oil

voltage

or

3 phase)

y.

power

to

avoid

this machine.

and

and

the

of

motor

plug

is

{S)

5.

-7-

correctly

supply.

Never

local

the

attached on the mach ine.

Confirm that the rotating direction

the

connected

use

the machine when the

voltage

marked voltage

machine

type is different

pulley

to

the

power

on

the nametag

is correct.

from

of

Page 14

·ti::.·

~

-~~~~~~*•~~m~z*~

am;

I

~5tHf115J.[iH~

flft~f&~i1J3if.iX.:Zlt9~

·---

---

----

---

--

~~

------ -- -

••••

------------------------------------------------~-------------~-~---------------------------A

2.

~~mM~fl~·••~••~~m~o

~•••~~~~-~~~-~a•Bm

••

0

I

J,).~~~

0

~-

----

---·---

---

A Warning:

6.A

--- -- ----

WARNING TAG

1. There is a warning tag attached on the

2.

Before doing any operation

adjustment desc ribed later in this

manual, please turn the power

prevent accidents caused by abrupt

start of the sewing machine.

--------------

sewing machine.

When using the sewing machine, please

follow the instructions

contact the dealer

fuzzy.

- -------

{F

ig.

if

the tag is fallen

-·--·--

1)

of

the tag. Please

or

~

-·--

any

off

- --

off

to

or

---

~

I

I

I

3. Safety protection device (Fig. 2)

Finger protector

-8-

~§ll

~~~H

111/Fig. 1

Goggles

.2/Fig.

2

Page 15

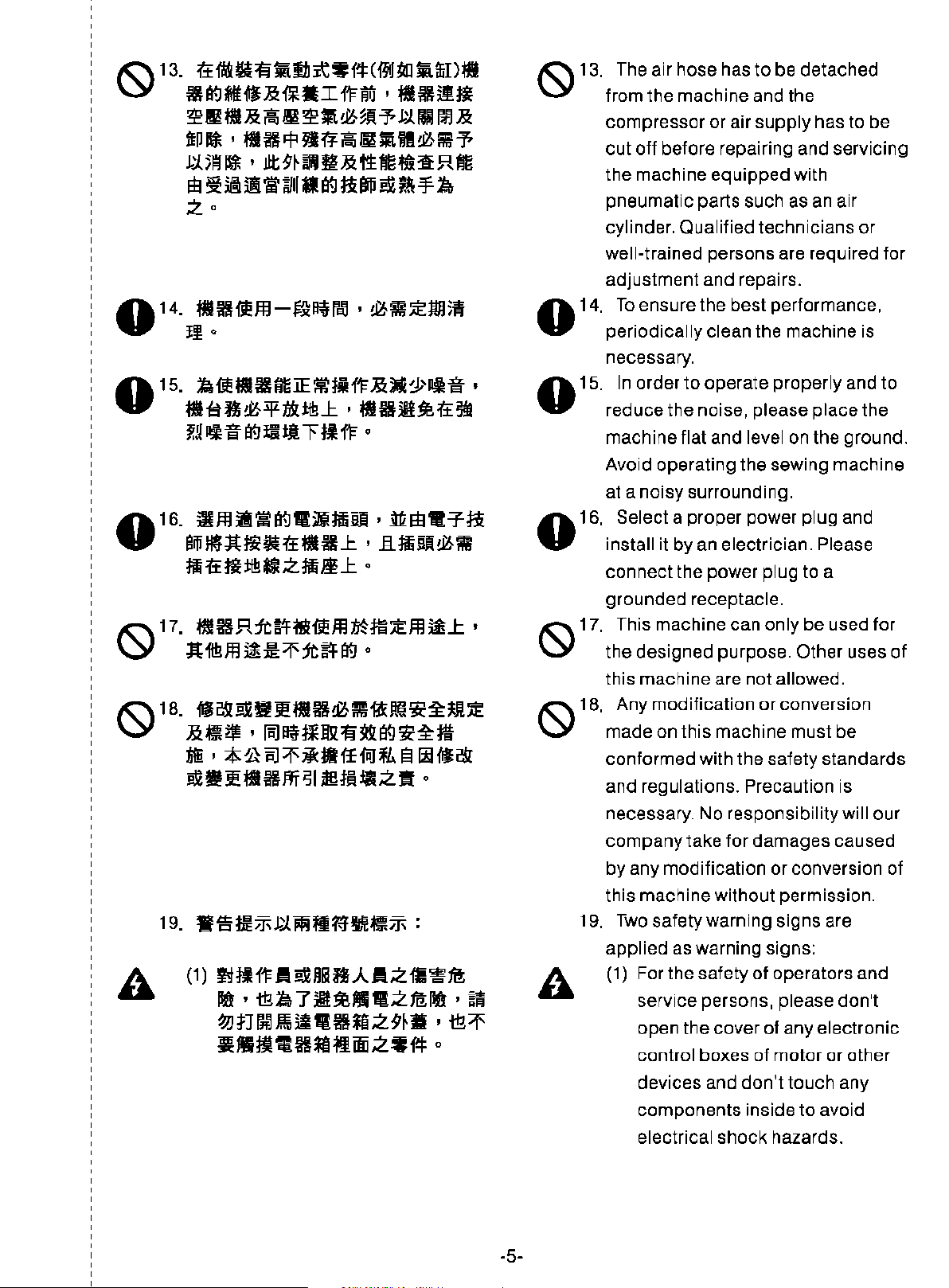

4.~

~7.J'f1Jh1JIRJ

0

(113)

4~

Indicates rotating direction.(Fig.

3)

SAFETY ILLUSTRATION

I

1--------------------------------------------------------------------------------------------

*•~•z~A~~-·~•m~,~§~

jl{1==lf(l9{1=!t~i£

4)

'

-~~JtR.K#iffP

o <II

NEEDLE GUARD

This presser foot protection device is as

10.

shown as the Fig.

operators, this device shall not be

disassembled. (Fig.

For safety of all

4)

~3/Fig

OF

THE

.

3

-----

--------

I

---------

----

-

----

----..-

----

-----------------------------------

! ltjJJIIJM MOVING

'

~~~------~-~~

M*JHI

1.

-~·~m~~~~M-B*R·~~

jj;~J&MilfiiUI

z

ltil

--------

~~~

<1115)

o

-----------~------

-~~

----------

Moving the sewing machine (Fig.5)

1.

To

follow

hold the fromt machine cover body, and

right hand to

move.

2.

Please wear safety shoes while moving.

-9-

114/Fig. 4

..-

---

---

------------

THE

---

move the sewing machine, please

the figure shows. Using left hand

SEWING

----

-----

hold the bottom plate to

MACHINE

--------

--~

---------

---

--

--.

---------

to

Page 16

1115/Fig.

5

·-----------------------------

---

-----------------------------------------------------------~

MIJ.a<Jii:&fil• THE INSTALLATION POSITION I

-------------------------------------------------------------------------------------------- l

1.

~~~-~~-M~~~~,~-~~'

®SM~---~~'~ru~®~-~~

*M~.Hia<J.-TT-tiJiJT~W

o

<1116)

1. Please

near

Radio,

equipments

interference. (Fig. 6)

do

not

install

the

equ

ipments, such as Television,

or

Wireless Telephone .

will experience electronic

the

sewing

Or

machine

these

X

2.

BIHfM~IIl!Ui~.MC.~M~

fiffl~~-• ~fl*iitiXtlfFZ&.

7)

•

tto*

o

<II

2. The wire

socket

this mi

shou

directly

ght

cause malfunction. (Fig. 7)

X

-10-

1116/Fig

ld

insert

. If using

lii7/Fig.

. 6

to

the AC power

the

extension wire,

7

Page 17

Page 18

II

Model

Jill

2. Specification

fl!\!1!!

Standard

700F

IOJfjf.!i!.

High

Stroke

Jiitr'OJIIi!Ji

Max

Stitch

Speed

l!li"rlf:

Noise

Level

~

l1e

Stitch

Length

jlfmf;jjj1

Stroke

11!1J'!Hiifl

Presser

11!1J'!~.:IJ

Presser

~!<.

Feed

{tllJjlf

of

the

needle

Foot

Lift

Foot

Pressure

i'iliffl'

(r'JI±\jlffRjlij)

Dog

Height

plate)

Needle

bar

(over

for

Use

the

needle

7500

spm

80?tft.DXf

under

80dB

3mm 4mm

24.7mm

5mm

5kg

under

l.Omm

DCX27

7500spm

82M'rf

82

26.6mm

5.5mm

dB

~J'l,{$t'J/)~

Feed

Dog

Transmission

~J'!~1i:ffl'

Teeth

Width

of

the

Feed

Dog

~§w.l~ll€l!i

Stitch

Adjusting

11!1Jl.~jli[

Presser

:tJUi!lr:IJ~

Oil

@)~/)~

Oil

!till

Oil

Foot

Filling

Return

ill!

for

Use

Device

Device

Solution

iii{,·~

Eccentric,

Button

'lfll~~-limw.J~~

Spring

~~m~~11~-~ft-~~~~~~t'J~~

Oil

tank

storage

Type,

type.

Automatic

.

J!!!f!j!

Connecting

1.8mm

~Ww.l~

Adjustment

Knob

Adjuslment

oil

capillary

Rod

supply

action.

by

Type

felt,

cotton

thread

iiiiMll'ii

<!<2/Table

jJE-fMJ!ll

Provide

2

Specific

Ecoentric

Pump

ill!(MOBIL#

Oil

(MOBIL

10)

#10)

-12-

Page 19

I

'--------------------------

---

------------------

- --

---------------------------------------

NAMES

OF

MAJOR PARTS

---·

'------------------------- -------------------------------------------------------------------

G)

G)

~'~tli~

Lifting lever

<2)

1,~

@~tUft

@ji~

@ )W'I'

@~·

® Presser

@ Control

@Thread

@Oil

@Pulley

gauge window

(Hand Wheel

(j)

foot

box

stand

-13-

118/Fig . 8

Page 20

--------------------------------------------------------------------------------------------~

I

INSTALLATION

0

A

~-CAUTION

~-~~-~~&~A··~~-~-o

Machine installati

on

should only be carried out by a qualified technician.

~~R·-~B•aw•A~~fi··~·o

Contact your dealer

to be done.

llj}JM.4821JT.

The sewing machine weighs 48kg. The installation should be carried out by two

more people.

~~-~~~,"~-~~-~~~-~~tiOO

Do

not connect the power cord until installation is complete. The machine may

operate if the

•~•Bm~wg~~m•~~ft~~o·~~~~~~~~•~•••-m~

JhWif~{lo

Use both hands to hold the machine head when tilting it back

treadle

or

a qualifi

~Vii1'F~~B:IRiiAJ.1J:*~.SX

is

depressed by mistake, which could result

ed

electrici

an

for any electrical work that may need

o

•.

M~Wti~*WB~~o

in

injury.

or

returning it to its

or

original position. If only using one hand, the weight

too heavy to

1.

•*•m~•~•••&•~M~•m~

hold, and may cause human physical injuries.

1. Install the rubber cushion and the rest

~~~··8~-~--~~~0~~

~~m~q,M~ti~oooo•oo~~-~

100

mm'

2.

•~w~•~~-~~~~~·~Aam

~,RIJ·~~-

4.

~-~~~-~~~~-~~·m~~•

SIJIJ.:J.m~li~~-~M10

ii: o

~~5.7eit.RIJR~5

o

m11MWII~·ilil·ft«~3

mm

o

mm~SIIJ.~

o

2.

3.

4.

of

the machine head may be

board in sequence as the attached

cut-out drawing and the part lists.

of the semi-submerged type

the distance from the surface of the

needle plate to the surface of the table is

installation,

table

In

case

100 mm, whereas the fully-submerged

installation is only 5 mm.

type

Install the pedal of clutch motor on the left

side, and the pedal

the right side .

Install the waste chute and the thread

stand as the part

The turning direction

clockwise . In addition, the best tension

that the belt can be pressed inward about

10

mm by a finger. Please refer to Table 3

of

presser foot lift on

lists show.

of

the motor is

is

to see the interaction of the

the sewing speed.

-14 -

belt pulley and

Page 21

-~

Machine

..

~

(S.P.M)

60Hz

~itff$if;fmr~

Motor

pulley Diameter(rnrn)

50Hz

6,000

6,500

7,000

7,500

! - - ----

I

I

i

I

1

-------------

----

-----

-----

----

---

- - - ---------

-----

fJHIIIItJOM.:ii:

-~-

~-~-~

--

--------

tJHIBttii:VJJNJf.laJ~Wla91mii£WJ~

Jf.liEEM:II:iSil./120%a9il!.l•tt'

ffi~715dl

' ::tii • .¥Aitiil11 o engagement. After four weeks, please

------

--~-

'it

zfljtJ:. maximum speed

95

105

110 135

120 145

~3/Table

-------

3

- - - -

HOW

---

---------

-----

TO OPERATE

MACHINE

----------~~--~ ~

Pleaseoperatethismachinein80%ofthe

operate under the maximum speed

~-------------------------

1

i

BHiaZ~AiilJ!.

'----------------------

-

----

---

------------------

- --

--------------

replacing

---

------------------------------------------

LUBRICATION AND DRAINAGE

----------------------

the new lubrication oil.

115

125

- - - -

------

----

-------

THE

-------------

in

the first tour weeks for

-

------------

NEW

-

~-

until

-----

------------

do

not

-------------

- - .

1. JJ)i5W.:Z.$1A.(II9)

(1)

~•**<D~~m

~il~jf5dla2i1Jf.IMOBIL#10~

AGIP#32W~'I'.:Z.tl5di1JDA.,

m~~m•~~J:.~z~~~~~•

iii.SUIM<D

1. Fill the lubrication oil (Fig.

,

J.j~t&$6~1ifirwzm

(1)

fl@$dl.

o

9)

Remove the screw

the attached

lubricating

oil,

G),

and fill it with

ultra high speed

or

choose MOBIL#1 0

or AGIP#32 or equivalent. Tighten the

screw

CD

after the

oillivel

indicator

locates between the two marking

lines.

-15-

1119/Fig.

9

Page 22

(2)

r»UlUIHIMf!~I*fiffl

• ,

J:.liltiitW1Jil5m~;~

2.

Jljf)W;ZJ!lt(ll1

(1)

HfiiMCDtitRMEM

~HHiiflMIHR

(2)

1\i!E~*tiB.:ZW$

fllm£1J)J!1t1Ff5W···~-Imii~

)!~-;~

a~

'

Mt±ti

o

0)

•

'fil!5WM~a<J5m~

o

• tiMMMHiffl

0

(2) Please lubricate the needle bar and

the upper

operating a new machi

idling

2. Drainage and refill the oil (Fig. 1

(1) Loosen the screw

oil inside the oil tank. Then, tighten the

screw

(2)

In

order to extend the term of usage,

please replace the oil after the first

four week, and then

four months.

looper shaft before starting

ne

or a long

machine.

0)

CD

and drain all the

CD

again.

replace it every

~

111

0/Fi

g.

10

3.

3.

ttz~w>m

ff!m5m

:

~5m

Needle cooling lubrication oil: SILICON

OIL.

THREADING

------------------------------ ------------- --------- --------------- ---------------- --------

~~-~M~~~~~~-~~~9-·U

~.:Z!I.w.Ji31lelli.,

0

lift

(11111)

~tt&$8~3Jli!l~

Follow the procedures shown in (Fig

threading. Wrong threading may cause

thread breaking,

unexpected sewing. (Fig.

§89*111

st

itch skipping, puckering or

11)

For seam type 516 only

9)

for

I

-1

-16-

Page 23

I

'--------------------------

---

------------------

- --

---------------------------------------

---·

ADJUST THREAD TENSION

'------------------------- -------------------------------------------------------------------

~-~~~~m••~~~••,••,•

~~&§~KM~z~~~-~~z~M

1.

~~ez~••~<•12)

(1)

M--lt&

<D

~tGWJi~MEXtrJI~

o

£ji

The thread tension

properly according to the kinds and the

thickness of the materials, stitch length , and

seam width , etc.

case by case individually.

1.

Thread tension adjusting nuts (Fig. 12)

{1)

The first adjusting nut

double chain stitch threads

aver-lock needle thread.

(2)

The second adjusting nut

the seam lock needle thread.

(3)

The third adjusting

upper looper thread.

(4)

The fourth adjusting

the lower

(5)

The fifth adjusting

double chain looper thread.

should be adjusted

In addition, adjust the nuts

<D

controls

or

the left

(2)

controls

nut@

looper thread.

nut@

controls the

nut@

controls

controls the

2.

2.

at•~••~<ll13)

(1)

HM-8"1J:ft504'

~:ft "'F~ ' MSJJ~503&505Ht

G)'(2)3~ftJ:~o

(2) ( +

)~~11110~·1&··

-~~M1JiM•o

514Hi '

Mf<D'

'

(-

)~~

®3

' ~

-17-

Needle thread control (Fig. 13)

(1)

(2)

IJi12/Fig. 12

When the sewing type

514, move the nut

lowest point. When the sewing type is

503 or 505, move the nut

the highest point.

The (

+)

direction indicates

the needle thread length,

to decrease the needle thread

<D

and

is

set to 504 or

(2)

to the

<D

and®

to

increase

(-)

means

length.

to

Page 24

3.

tt:

I

1;J

tt!!!'*illliMI14)

c1J

:ttli~nl'\11.512.

··~®M~~~~~~mi·~Ii

~n'i\:11.503,

ftm:•

(2)

~:;E~!If;j&@~~:

All

81\:#l~lll

CJ.';:M~n'i\:512

(3)

~:;Eill!lf;!&@~~:

DJ.';

Ell;:

C +

l:1JiOJ11.1i~iiUli~

•

114®M~Illi!!~'JUim'l'

:

JB

n flllllllll

:

1B

ftO

fllllilil

#I~

lll

!ILI::1;Jtt~~r.tc

504,

*i

505MJ:1;Jtt~~

•

JiLZftl)ilid>

•

•

I!!J13/Fig.13

3'

Looper thread control (Fig. 14)

(1) When the sewing type is 512, and

upper

adjust d)

dotted line.

503,504,

the

and®

continuous line.

(2) Adjust fixed thread

followings:

Point

Point

Point

(3) Adjust fixed thread

followings:

Point

PointE: for blind hemming

NOTE:

The

direction(+)

sewing seam, and

less thread

looper

lowest position,

at the position as the

A:

8:

C:

D:

is

on

the

left

and®

or

for

for blind hemming.

for sewing type 512.

for

in

sewing seam.

at the position as the

When

505,

nylon

stretchy thread.

the sewing type

and upper looper

set

the

guide@

stretchy thread.

guide@

is

for

more

thread

the(-}

direction

est

side,

take-up

as the

as the

in

is

is

is

CD

for

at

-18-

lii14/Fig. 14

Page 25

I

'--------------------------

I

---

------------------

- --

---------------------------------------

---·

· llatn5t REPLACE THE NEEDLE

'------------------------- -------------------------------------------------------------------

fflf!DCX27eila];i~;Zti

1.

2.

tifi!ml!II**CD~Im'"fMo

3.

~~tiM¥tiRa~•·~~tiz~~oo

JRJ~2o

4.

iJ)E!IIMCD

0

o

(.15)

Please use the needle DCX27 or the

1.

equivalents. (Fig. 15)

CD

Loosen the screw

2.

needle.

Insert the new needle till reaching the end,

3.

as well as the long groove faces your side.

4.

Tighten the screw

and take off the

CD

.

1

1115/Fig. 15

~-------------------------------------------------------------------------------------------·

I ttBelll! ADJUST

l_----

-------------

~mMM~~M·~ti~z~la.I~R~oM

•m'"'F~BCD~Mtim~MffO*~'M.

111m

1f¥nt

~

Pfi

16 ' fi4)

m z

----

tt

~ -~ -~-~

BE

fi

nt

-----

rm

Jlt

tt&

-------

o c •

--~ ~

~--------- ---

The stitch

fabrics , the differential rat io, or other factors .

Keep pressing the button

pulley till the button is locked. Then, release

the button after reaching the desired stitch

length. (Fig. 16, Table

THE

length is adjusted according to the

STITCH LENGTH

-------

~-----

CD

4)

----

and turn the

~ ~

~-

------

-19-

(116/Fig. 16

Page 26

Max

Dif

ratio

Machine

type

Pulley scale

1 2 3 4 5 6 7

Seaming

Shirring

Serging

Special

- - - - - -----

1:1.3

----

1:2

1:3

1:4

-----

-- -- - - - - - - -------

•11Jttll•

~~~~tt±~A~~~~~~AzM~n

tr.J

J:t~J

0

1.

~±~~Az~b~*~~~~~A-~

~~·M•fl••~~~·&zM~fi

2.

•~n$~~--~~•ti•~®m~•

n~~~-fl~fi·&zM~~··~~

MlillE!I!I'*CD o

(.17)

1

0.7

1.6

0.6

~4/Table4

-·-

-·-- - - - - - - - -

o

1.

5 2

1

2.3

0.9

-----

1.4

3

.1

1.2

-------

ADJUST THE DIFFERENTIAL

2.5

1.7

3.9

1.5 1.8

--

- - - - -

----

3

2

4.7

3.5 3.8

2.3

5.4

2.1

·--·--

- - - - - -- - - - - - ---l

2.5

5.9

-

FEED

RATIO :

The

differential

movements

di

fferent

1. When

2. Loosen

ial

the

bi

gger

fabric

to

clockwise for

reverse

is

the

contrary.

feed

between

feed

dog.

movement

than di

direction

fferential

stretched

screw

stretching

ratio is

<D

and

for

main

feed

of

main

feed

in

sewing

turn

shrinking

the

the

the

rat

io

of

dog

and

feed

dog,

the

and

shirked

screw®

fabric,

the

dog

is

in

and

fabric,

in

i

~:

-~-~®2~~~~tt~~~·~~

IIJJ:t~1:

R1"0011J~~~~1:

1 f

~~~ISilEtt~JIJ2j.~J:Pi

o. 1 o

<e::~Jfi5)

and

then tighten

NOTE:

When

I

set

ratio

it

1:0. 7. (see Table 5)

at

can

the

the

is

1 :1,

make

surface

scale

and

the

the

of

2 ,

the

if it is

fabric

screw

adjusting

<D

differential

set

over

stretch

. (Fig. 17)

level@

feed

the

scale

to

the

ratio

be

2,

-20-

II17/Fig.17

Page 27

Scale

1:1.3

1

-

2

1:0.7

1:

3

0.9

4

1:1.1

5

1:1.3

Diff

ere

ntial

Feed

ratio

1:3

1:2

1:

4

I - - - - - - - - - - - - - - - - - - - - - - - - - - -

,,

: afFIIiJftlaij LIGHTENING

I ENVIRONMENT

~

~ ~ ~ ~

-~

-- -- ---

--~ ~ ~ ~--

...-

- - - - - - - -

--

mm-••~•~·~~~m~=I•m•

~~~~-~~a~mtt~-~~~*~ti

~M-·M·MttM·~~-;~~--~

ft*·A~--~~~ft~M·'·M~-

····~~~~~···~-~~-~

ft~~~-M~~~~~~

18(fi~

o

·~-~~-

1:0.7

1:1

1:1.1

~5/Table5

---

~

-

--

- --- - ------ - - - - ---- --- - - - - - - - - - - - - - - - - - - - - - - - ------- - - - - -

1:1

1:

1.5

1:1.6

1:1.4 1:1.7

1:2 1:2 1:3

1:2.3

OF

-- ----

~

---~

---------

Provide a warning

unit or sewing system must always be

unplugged from the local

sewing area before relamping, the marking

maximum rated

discernible while the lamp

indicated on

shown on Fig. 18.

---

input

or

near the

-

~~

that

1:2

1:2.3

1

:3.3

THE OPERATION

~

~ --~ ------~-~

an industrial sewing

lighting

of a lamp shall be easily

Is being replaced

lamp

of

the

socket as

of

~

,------

~:k51rt~·

Maximum····

~

'J'

51rt

Minimum·····

--~

---------------------------------------------------------------------------------

····51

~-

• • · · 430

·

51

430 Lum

ii18/Fig

i flfF:f.f-j: CONDITIONS

1.

MS~71W1fffl~~-~~

2.

~illfH-3$rJ.Jft~~>1M*ll

3.

7M3W~*IMZMJ.Io

4.

71WM~MH;Zji{1=1J~

5.

tl{1=~~1i~*lfliAA8.tlH

o

o

o

o

Read and understand well the content

1.

this instruct ion book.

Know the functions

2.

understand the notices.

Truely realize the meanings

3.

tags

.

Realize and be familiar with

4.

operate this machine.

Operators have to keep well menta l

5.

status.

o

mta~

0 Lum

)iff

a~

. 18

OF

ALL OPERATORS

of

major parts and

of

all warning

how

to

·

of

-21-

Page 28

6. Operators shall wear appropiate and

proper working suits.

7.

Develop the familiarity of how to operate

the machine if needed.

ii.

____________________________________________________________________________________________

MAINTENANCE :

I

j

~

)I~JH'l=~iW

"'/......_1!-\_.Turn

!:::\

\Ysliea~

!:::\

\Y

off

the power switch before carrying out cleaning. The machi

treadle is pressed incautiousl

1J[]•5t)m~Jt5fblli

o

Be sure to wear protective

grease so that they

be resulted.

J'J5tt5m~j()dJ1"~ftm

Furthermore,

diarrhea. Keep the oil away of the reach

M~tl~~~~•m~·a~W-=Filfi~f'Fo

Use both hands

&position.

I

fi+JJifj

do

not

to

A

0

••

I

~t!IZ-12~1i!IIUI2~-¥~

do

drink

hold the machine head when tilting

-~Mielb~lllfti

y,

which could result

gogg

les and gloves when handling the lubricating oil and

not get into your eyes or onto your skin, otherwise inflammation can

,

aftrJ~ftslmlftn±~Diil,

or

eat the oil nor the grease for they can cause vomiting and

s±acAuTION

I

fljj]tlltJf'F~·BA.A~11

in

injury.

I

J.)Jn~715mil.AIUI~~5o«szaJ:

~5dLfiitt'J\~*1'¥1Ja9iii!n

of

children.

or

°

ne

may operate if the

returning it to its original

, ~

o

~

-~-~Jii~~-~-a9··~-~--~-~-fi~~o

If

only using one hand

pping

sli

and you may get hurt.

to

«1i•»

1.

~liH'A

2.

~~~•M®m~·~•m~~~®

move the machine, the weight of the machine head may cause

For keeping the machine quality and

lengthening the usage term of this sewing

In

and lints on

o

machine, please maintain it everyday.

addition, before first use after a long idling

ow

time, please foll

maintain.

(CLEANING)

1. Raise the presser foot.

2.

Remove the two

remove the needle

3.

Use a soft brush

the feed

4.

Install the need Ia

dog

the following steps to

screws®.

plate®.

to

teeth@

plate®

clean

. (Fig. 19)

and then

dust

after cleaning.

-22-

Page 29

1119/Fig. 19

-f*llfi!J~

Maintenance Cycle

1.

~~~JJt

1. Clean the lint

2.

mx.

Daily

~

Weekly 2. Keep the operational panel clean

4!=.

00}3

Quarterly

1i~

Annually

ttit~-~

2. Check

should

3.

~-3rui1'F

3. Keep the machine and the operation table clean.

1.

~

-

Keep

l.

2.

~1J

3.

*:E:11${

3. Check

1.

J!~ftj?g;Z_~Jm~

1.

Change the liquid oil inside the oil

1.

*

~

1. Check the transmission belt to see

.r.

z.~~

on

the feed dog.

~l[

~~zlfltmrm

if

there has enough liquid oil inside the oil pan. (The amount

be

between

~;;.·

the

power cords looking clean and neat.

1'F

OO~~

~

{lf:~:S~JM!J!G;frlEif{

if

the power parts

ltl&:~

the

t:i'

~~

:a!f

(Periodical Maintenance Items))

Maintenance

red

up

and

M~

is

loosening

z.~~m

f*.

JJ!

o

<~

down paint

ii

~

or

pan

if

it

§

Items

:lt

:ff~flz

mark

still

at

the right position

is

weariful

or

(Tab

.r.

..

-r~~~~c!1f

of

the oil level gauge.)

damaged

le

6)

OO

)

~6/Table6

TROUBLESHOOTING

A

A r±ilrrt&llt!HJilP.JzJFJ ,

~

tl*lbfF

Before processing the troubleshooting, please turn

the electronic cord. Otherwise, if touching the start switch incautiously, the sewing

machine

,

~-B.A.&1i\ti

will function and will probably cause injuries happened o operators.

D$tiiiJJ•J:t~tiw•ili

o

~-CAUTION

-23-

,

6ftiJ~lHlM~NI1JJmlll

off

the power switch and

unp

,

aM.J

lug

Page 30

No.

ffi.~

Problem

~~.&ilffl!'il1!

Exam and Adjustment

The

Skipping

Stitch

ofNeedle Thread

·!lt~~.:IJ

The

:lfoi"fll!*)j!G~/

tension

of

the

needle

J

\?

thread

is

too

loose

or

to

tight?

@ilfflJJ!!!f!ltU.:!Jo

Adjust

Choose

@~J!l!C-El';;'JJ:lEII¥J:$!ltlJ!!*il~ljl1li!ijo

Select

••

Bad

@~~l!i!lfo

Change a new

el!i!ltlJ!!tr./;;JW*iiffiZillH11lll~~?

Any clearance between

the

needle

the wrong needle?

the

needle and thread number match the fabrics

!it

1'

Jl!.?

needle?

thread

needle

tension

the

needle

and

the

top

of

the

left looper?

@IDIJ'I'Iftr.1;JW*!lffii~lli!ltZilll±O

Adjust

needle

e~.:IJIDI!'!I!f/J~'liHmfJ'Ill?

The

the

to

small

distance

be

±0

spring

from

of

tension

the

top

adjustment

of

the

left

does

looper

not

to

the

function?

@(1)/Ni!!l~Hmf'F!lJ~

tl'A:I"<J!~~;Jitg:~~

(I)

If

the

small

spring

more

tightened.

happen

(2)~ilffl!'ll!:fi;J!t~~Wi

(2)

If

adjusting

e!lt~i¥1~.1J:ot~?

The

@(l)tf'l!lt~~.:IJ

(l)Loose

there

tension

the

if

pull

the

is

any

groove

plate.

of

the

~ltilffll~

tension

does

(Note)

spring

please

needle

of

the

·

~'l1¥!Jl'tL~~!!\'i

0

not

function,

The

brokeo

too

tight.

'

Jl~:11i~~IDI!'II!:fi

existing

change a new

thread

on

is

0

needle

thread

the

one.

too

tight?

thread

pull

tension

o

(~:@:)

it

to

be

will

properly.

0

-24-

Page 31

No.

:fl!il<

Problem

*

Exam

1!!:.&

iiliiJ~

and Ad'ustment

2.

3.

M~ll9l'J'Wo:fl!~

The Skipping Stitch

;b1;)!1f~ll9l'iWo

The Skipping Stitch

Looper

Thread

of

Needle Thread

of

the

Right

(2)11'l!it~ll9W!I(A)ii'iiJ>IIHEJii!:i'iiif:!L~

~m'(B)fl9!it~l!ll:t±:l:i:~:P

(2)Adjust

position,

thread

(3)1!'l~(C)ti:@H!'b

(3)Lean

amount

eki

The space between the

wide?

@;b1;)MfE.Jkii.!!!.l&lf!i

l!l::flllE:\l!Jl<JtT1;JM

fl

When

distance

the

line

(A)

of

the

so

that

the

release

from

thread

hooking

•

the

line

(C)

to

left a little

of

the

1;1~

r

W:!l<

looper

~

r

1191111

thread.

'jjl::.t::*:?

right

'

:ID.!IL!itil91111~&:·~.lmm

• <ffol!:fl.!it •

fll1'H~1!1!>ilil'~ll9:fi

the

tight

to

the

looper

needle

tum

has

•

needle

amount

will

Wti.1.J01;JMil9tll!t.61t±:l:l:

to

looper and needle is too

1;)~

l

tight

and

to

be

0.1

•

l!l::lilt~ll91;)

thread

of

to

the

decrease.

increase

~M

backward,

mm,

which

the

highest

needle

the

release

•

J!i!fl

the

is

•

•

15

using

J'J

4

ti:1;JM~Il9l'J'Wo

The

Skipping

Stitch

of

Left Looper

the

correct

each

thin

fabrics,

e!ll'liltlf!i

The

distance

when

©>rn~ki1;J~~~il9ti:ki&~~.&ki1;J!ifmLT~

~&~z~~~~·r~ii'iil~tr1;JliltJ¥J~~~·

1'Eki1;Jlilt

Because

right

position

of

the

the

descending

e;~e:t11;Jliltxxlf!i

The

right looper dido'!

while they

right

looper.

type,

such

as

are

included)

·

:t11;JM-W:6:liltll9r.ll!il:7<:?

is

too

using 2 needles?

T~lf!i

the

correlationship

looper

while

of

the

looper.

right

When

amount

(The

single

need, 2 needles,

wide

between

•r-f:6:liltllUkililtll9TMHJ~:P

of

assembling

looper

the

seat,

right

from

•

:t11;Jlilt

hook

are

crossing

each

appropriate

the

right

tight

looper

materials,

and

left

for

and

needle

•

the

left/right

and

the

adjust

looper

left

::flt1;J¥Uti:1;J!if~?

other?

descends,

needle

the

left looper thread

position

up/down

the

movement

to

right

of

moving

d=ase

needle.

the

path

@~¥1f:6:1;Jlilt

lil'ililllltf:\~7

Change

is

looper

the

new

worn. When fix and replace, the protrusion

top

shall not be

-25-

•

(;6:1;)lilf'cRftffilltffjl

j;Jft(}!jlf)

left

looper.

worn.

•

(The

·

'!!~IEII;f

top

of

the

•

::ft<lolt'l

left looper

fo

the

Page 32

No.

l3i\11<

Problem

~'!'t:&iil!l~

Exam and Adjustment

5

The Skipping Stitch

!tit

Needle

Broken

l

I I

j

/ /

-

.

.

.

/I

of

Left Looper The wear

@~1'1f1;)~!liG!IIilll:O~<Rf!ffiii'.ilVoR

·-~1¥:1~~=1'~?

@:tE:ffl:lSfNt~~:fLI¥Jliilii>!II"J

e.JI!!""I¥l""l!H

@';(~~~~~ffl:iji'j}f-~~.jlj!~~~~$*o

.

e¥&:ffl®l¥1'9:~lili1li.T~?

@illf~j!g:fflJ!iil'Jr!lJ!l<~

of

the right looper top?

Change a new

Choose the wrong needle?

Use

thick

pinhole

looper

needle

occurred

or

within

on

the

use

the

fabric.

.lit?

Bad

assembling

During

central

Wrong

.JI!!~ItiJ

assembly,

point

assembling

of

the

presser

make

sure

of

the

presser

height

0.8mm-lmm'

o

the

range

the

foot.

of

the

0

oil

stone

to

wear

the

top.

·

{]I!#Jf.l.!~~I¥J:iji'J}f-

that

there

will

be

foot?

needle

feeding

can

insert

teeth?

[OJ~~~il'J

no

to

o

the

The

Top

of

the Needle Damaged

~

\ i

Adjust

to 1 mm.

pressure.

the

height

Meanwhile,

of

the

keep

feeding

the

teeth

to

be

appropriate

around

presser

0.8

foot

mn

-~~"''ll<?

Bad

threading?

@~~:fUJ!iiii'i~ll'>%:/JofJ~lll!f&

If

there

is

any

connecting

dealt

first.

Then,

rethreading.

The

right

looper

position?

©J:iji'j}f-:t£~~~~~~·m~m~~-~~oo~

~·~~<Rf!ffii~"''~~~~~j}f-·~~iil!l~-~~

1l1!liG:t11;)J}f-I¥Jlli!IIJ0:~·

When

the

push

the

needle

the

top of

and

needle

the

moves

forwards a little

needle

part

the

needle

close

touches

of

to

the

•

ii-l'li~*&

the

thread,

have

wrong

the

upper

by

finger.

right

looper

it

height

dead

See

or

•

needs

point,

whether

not.

Then

to

be

adjust

position

-26-

the

height

of

the

of

right

the

looper.

needle

position

or

the

moving

Page 33

No.

J31.~

Problem

jt~J;liif;J~

Exam

an<f

Adjustment

6.

7

-~J-ij<iiffii~tll

The

Top

of

the Needle Damaged

•m~

©tll\

·~t!li'ti.'~li!PI'W?

©re~t!liNWi'ti.'~~A$*(1(}1lll~::k~~.

-~~il'J~.fLl9.:flft?

Broken

Stitch

Tbread

and

Rough/Uneven

©!llli'J>~.fL/!flliiM7'6

Jt:t:~lif'?

The

ejector

]lij(I(JJ<i~

lli'f

•

lltJ!ttlli~l1iftllll

@lll'i'::k~

The

ejector

the

top

needle.

needle

Incorrect

When

so

that

The

thread

plate

!t

£'{(i:(Etc

0.2mm

plate

of

the

left

The

distance

is

about

0.2

needle

assembling

the

space

hole

plate

of

is

too

close?

•

inside

looper

between

mm.

assembling

the

needle

of

part A can

the

thread

1;)~(1(J~Jlffi!¥1J~l!L~

·

mroom~

must

leave

reaches

Jtllifl!l~(I(Jill.l'j£,

from

the

the

right

side

the

front

ejector

position?

plate.

pull

it

forwards

be

larger.

stand

did

not

polish?

·

Use

emery

cloth

to

polish

the

surroundings

needle

of

plate

of

the

:.bii!Ullff

before

the

to

the

a little

thread

,,

hole.

//

·~(I(J~~r,;r~?

'F

/

Choose

©:11!~(1(]~

Change a better

·~(I(J~:!:Jml!'i'!!f?

Cannot

©~~ft:.b1;J~(I(J~T-~~·~~~~~~~ili

'Jl.'l±:lil:¥1J:flllil(I(J*'l!'i!!ft

Please

should

needle,

noticed.

A.N~~*'l!~ft1;J~*'l!~~:.b1;J~*'l!~~·

A.

B.N~ft~~~~:.b~~*'l!~~~~*'llili~~·

B.

the

wrong

thread?

'

~-W:'3EJ

thread

adjust

to

the

be

noted

that

not

be

too

loose.

the

related

Pull

the

needle

loose~the

Poll

the

left

changes

thread

right

looper

to

balance

best

thread

•

the

threads

When

tightly--+the

looper is

thread

.

the

tension?

of

the

adjust

of

the

threads

tighter

tightly-+the

threads.

left/right

the

position

are

left

looper

right

looper

of

needed

is

looper

one

to

is

be

looser--+the

C.

N~:.b1;)~f~~ft1;J~f*'lld~~l*'lld

C.

Poll

the

right

thread

-27-

is

looser-+the

needle

looper

thread

thread

needle

is

looser,

too.

tightly--+the

thread

is

left

looser

•

looper

Page 34

No.

m~

Problem

~J'fliUJll~

Exam and Adjustment

7

lfi*&W!iillil"

Broken

Stitch

8

The Thread

Doing Chainstitch

"Hll

Thread

does

and

Rough/Uneven

not

Come

Out

When

e1f!IJJ.~'i!il'illl~T

Incorrect

@im!~1f!IJ'-5!i'l'i'E!leil"ffi'Z!ffll¥.rf!f:!SI

Adjust

adjustment

the

presser

.l.i!.?

of

foot

flexibility

the

presser

to

foot

fit

spring?

the

fabric.

eW7JMtll?

The

knife

is

worn?

@l!ftU7JD~:l!!lfl1~61t

Sharpening

the

knife

o

or

changing a new

one.

e£1!1tt*I!Bil"?

The

differential

ratio

not

match?

@iiiJJfi!Bi\":ffl:jSfi¥.J£11JJ21ifJfo

Adjust

The

@W!J~'I!I"R<J~lilili/Hir

Adjust

the

cam

the

dillerential

of

the

chainstitch

cam

to

feeding

looper

o

an

appropriate

to

match

is

position.

the

feeding

not

appropriate?

fabric.

9.

Cannot Separate

Thread

the

Thin

and

Thick

·t.'l!~l*T

Thread

@(I

)1\IIJ'!I!f~~5ilil3!'

(1

)adjust

(2)!JmJ\';~~

(2)polishing

•1fll*1&5!11~3('i.H

The

©JmJi1iiml~l!i!~~lfl1~

J.i!.?

tension

the

presser

device

spring

or

changing a new

does

strength

J.i!.?

foot

rear

spring

not

work

well?

one

did

not

assemble

•

ll!'1fll*mlli§~o

well?

·

il!zlill:;~t~

:fJo

Readjust

presser

The

@il'fi!.:F~~ll!I:B-il!'ii!Jl!ll3lU~llfiL.t

Clean

eJ!ii.G,~lilili1'1!$U5!11'A'li!'il~T'M?

the

foot

can

eccentric

the

stuck

spring

act

is

rusty?

part

or

change a new

smoothly

so

the

and

the

oil

test

o

can

one

to

its

pressure.

reach

make

the

cam.

sure

the

Inappropriate

adjustment

spring?

@W!J~'!Oiz~i31'

Adjust

-28-

to

the

•

proper

{BTllJ~

tension,

of

the

eccentric

but

o

should

cam

not

control

be

too

loose.

Page 35

No.

m:l!<

Problem

~

'l't

liUIIJ'!i!:

Exam and Adjustment

9.

10.

f.llRIE~Offl~:fr

Cannot

Separate

the

Thin

and

Thick

Thread

fr!'fl '

Loud

ill~'

Noise,

Strange

Noise

·~ltifilll!ilflll'iGt'iZ.71!-J}lll'iGt'i"F'i'?

Inappropriate match with

stopper

@(l)!l<JE

(!)Correct

(2)]!!jjr!

cam?

KP09DJ[)l't~ii'J'KP06FJ[)l't

the

width ofKP09D

KP06F

short.

KP09D/KP06F •

the

slide block of the

or

polish

•

the

width of

(2)ChangeKF09D/KP06F

.,

i:.'lill!!!l!l!Jtl:\'l'?

The

main

shaft

is

loose

and

has

noise?

@ll'l:k'C.'J::fi<J~Jt'Z.Jill!ii~1l!f~

Clean

lhe

shaft

and

copper

readjust.

glue

from

lhe

•

mmii\111'11!:

copper

cover

of

•

lhe

main

eJJian:tci1>11>JI'l?

Noise

of

lhe

pump

(scratchy?)

@!lim~:JJoll!iJJii!ll®4iill

Use

lhe

and

fixture

keep

lhe

to

pump

add

pressure

running

•

~

on

3-5

minutes.

3-5

:B-Bll~llJ

lhe

gear

of

lhe

•

pump,

-~~~~!liP.

The

needle

@ l!!!fUr

Change a new

so

that

ei!.!!~

J::ti)i1MIIll!Wlz

The

fixed hook of

clearance

@(l)~**:IJD~

(!)Add glue onto

)lllf

11:11

( 2

(2)Polish

(3)]!!jjr!~fo

(3)Change a

bar

is

loosening?

r11.

~llliS

the

clearance is smaller.

is

*

the

;!tl:~tfll

one

or

to

lill

!E

the

connecting

loosening

the

screw

l,liG

{llj fil

goove

new

width

one.

e_L:r7JmftHW?

Incoorect position

@i\111

'!IH7J

r 7J

Adjust the angles of

%J

!t

of

the

·

the

1!ii

~z

llll!Wl!!!!

polish

or

upper

the

contacting

1;1~111

•

OOt~?

rod

controlling the

clashing?

wider

upper

or

chamfer

and

the lower knife?

and

the

'J' .

surf

lower knife.

act

-29-

Page 36

No.

II.

:Of'

fjgft

The

Oil Does

"-ll.~

Problem

Not

Splash

~

i!f

liUill'l!£

Exam and Adjustment

e'lltnHl±iilll?

The

oil

docs

not

come

out

from

the

pump?

@(l).!li;~li{l!{i'I~

12. JJ!t:'f''flj

The

Knife

Is

Not

\

Sharp

\\

. "

\

\\

(2)Change a new

(3)m~~B9*~~~1\Ii

(3)Clean

(4)/ll~t.l!mJmillll!ll

(4)Use

the

the

dirt

iron

filter

or

change a new

wire

to

clean

one

thmugh

the

oil

path.

ew;J:'f''fiJ?

The

knife

is

not

sharp?

@(I

:JI'flj~]!!~1\fi

(l)Polishtior

(2){i(1EJ:

(2)Correct

knife

(3l!I!1\111Elifl!~~(~;l;l;jj';Wlf!/!~~)

TJJ!t~fii.l@'

the

set

(3)Reassemble it correctly

and

adjust

ill!<2/Chart 2

&'o

change a new

angle

based

of

on

the

the

one

upper

(to

assemble

norm)

and

lower

-30-

Page 37

I

~--------------------------

I

:

••.

'--------------------------------------------------------------------------------------------

---

------------------------------------------------------------

TABLE CUT-OUT

---·

1

A

I

·-

1

~I

crrrmr:::

Bg_

~~

._____--------~~~

I I

I. I.

~§

II

I.IJ.II..

~

~~~~

II

I I

1 m

l..l·

~

j L

~

~~

~

ft!l

1Q2Q

~~

~

A-AHli

.20/Fig

. 20

-31-

Page 38

-------------------------------------------

-

------------------------------------------------1

DEMOLITION PROCEDURE

I

I

I

1.

•~w•••~~w~•~,fi-®&*

m~Q~~~,~q~•••~~~~•

.0

2.

~~~~--~#Q~~m~~~•*•

~M:

(1)

Ji.lf~IIJf'

JIW,#o

•wwf¢:

(2)

(3)

Ma*ffl

}:to

~)~~:··~·'·'·~~-~'

ltf~~Hi~JI

3.

~~n~~~~~•RI~~-~~~~~

~~~m~MM~RI~oom~~•~~~

~MfB1f.!jo

RJfltl*ie'IJ~HlHIIP.lG~F~

m111,

:

:S~

!!fa,ijftAtf

'~ff/RJfEPtifiDI

o

o

When the machine needs to

1.

and

demolished, certain

be observed

and

public

ALL machine componenets must

2.

divided

followings:

(1) All sheathes, flexible hosing and

plastic

(2) Electricity components: switches, or

lighting components.

(3) Insulation materials: rock wool,

flexible rubber strips.

(4) Metals: ferrous metals, copper,

bronze and brass, various.

In

this

3.

correctly, recycled,

use or

health.

according

or

way, all materials

disposed

be

eliminated

basic

to

protect the environment

to

categor

non-metal

of

components

can

or

melted down for re-

so that they

rules must

ies as the

be

eliminated

do

be

.

and

not

harm

the

environment.

-32-

Page 39

I

~--------------------------

I

:

!~Hal

---

------------------------------------------------------------

---·

APPENDIX

'------------------------- -------------------------------------------------------------------

MAX

MODEL

SPEED

(S.P.M)

737F-504M2-04 7000

737F-504M3-05

737F-505Fl-04 7000 80.0

737F-504Ml-15 7000

737F-504M2-04/LFC-2 6000

737F-504M2-04/TR 6000

737F-504M5-04nBFC

737FIWRILF-B 6000

747F-512M2-25 6000

747F-514M2-24 6000

747F-514M2-24/LF-C

747F-514M5-23nBFC 7000

747F-514H4-24/GA

7000

6000

6000

7000

NOISE

LEVEL

dB(A)

79.0

76.0

80

.0

75.0

79.0

82.0

83.0

80.0

80.0

77.0

82.0

82.0

AVAILABLE

p

..

EC

...

LF-A

LF-A

LF-A

VT,

VT,

LF-A

PffiC

VT

VT

ES

VT

..

...

...

..

...

P$G

CT

CT

DEVICE

EC

EC

EC

EC

...

P$GffiC

747F-514M2-24trG 7000

747F-514M7-24 7000

747EFT-514M2-24

7000

747ERT-514M2-24 7000

757F-516Ll-24

757F-516Ll-35

757F-516M2-35

757F-516M2-55

7000 82.0 CT

7000

7000

7000

82.0

79.0

80.0

80.0

82

.0 CT

82.0

82.0

CT

CT

757F-516H2-56 7000 82.0 CT

757F-515X2-56

757F-401M2-50/TA

757F-516H4-35/GA

757F-516H4-55/GA

757EFT-516M2-35

757EFT-516M2-56

757EFT-516H4-35/GB

7000

7000

7000

6000

6000

6000

6000

84.0

82.0

82.0

82.0

82.0

82.0

82.0

p

..

EC,PffiC

p

..

EC,PffiC

PB,

EC

CT

DT

VT,

CT

..

PS

..

PSffiC

, PS

..

PSffiC

CT

EC

..

P$G,P$GffiC

..

P$G,P$GffiC

DT

DT

PB/EC

757EFT-516H4-56/GB

757ERT-516M2-35

757ERT-516M2-56

767F-516M2-324

767F-516M2-524

6000 82.0

6000

83.0

6000 83.0

7000

7000

82.0

82.0

-33-

PB

...

PB/EC

DT

DT

CT

CT

Page 40

Page 41

Page 42

The specificati

change

on

because

and/

or

appearances

of

modification wi

of

thout

the

equipment deacrlbed In

previous

notice

.

thlalnatructlon

book

are

subject

to

KZ64. SEP.

2006

Loading...

Loading...