Page 1

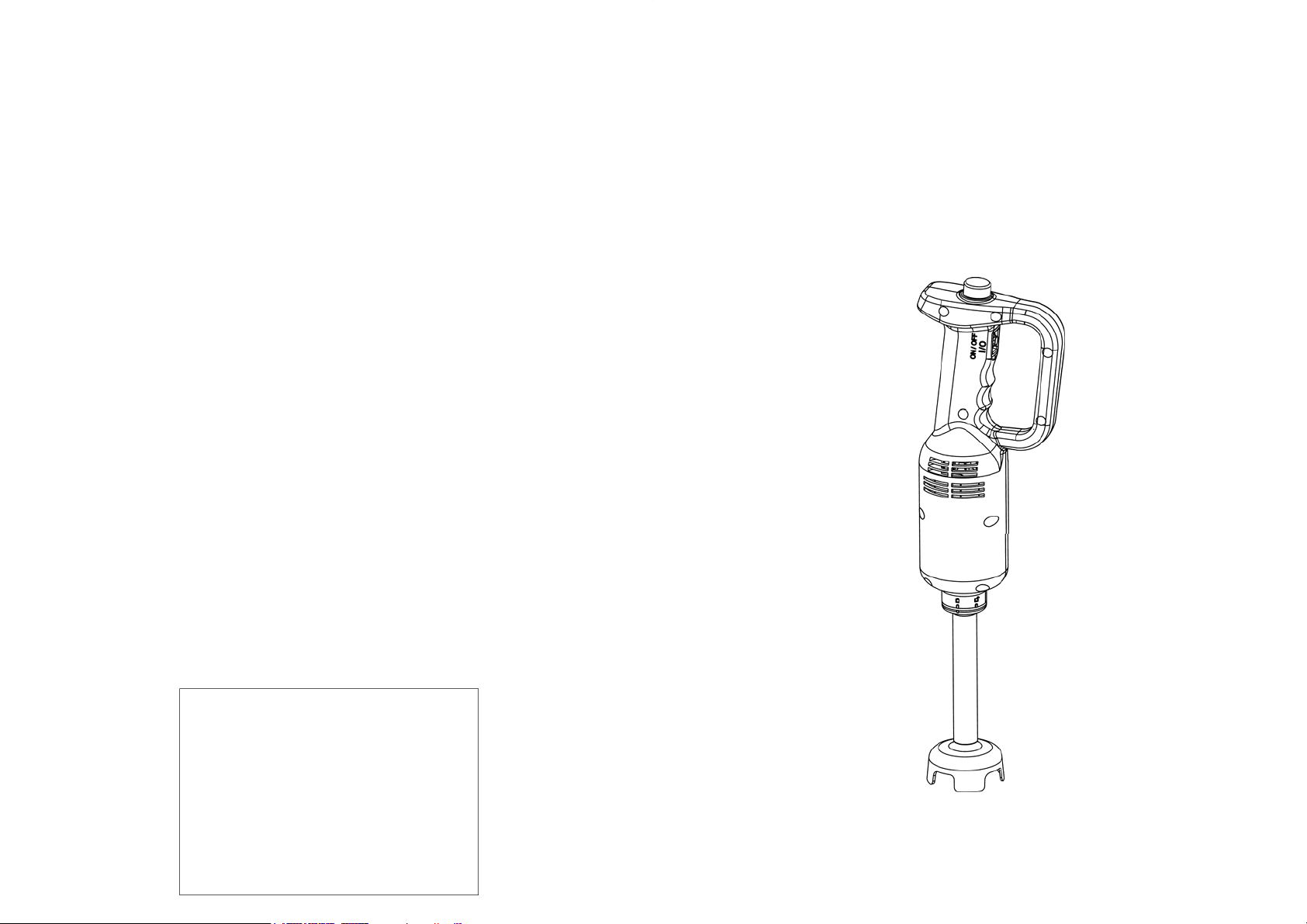

Professional Hand-Held Mixer

S 20

Regular,

Speed variator,

SERVICE CENTRE

AUTHORISED DEALER

24

Ed. 11/2015

Instructions for use and maintenance

1

Page 2

CHAP. 8 - DISPOSAL OF THE MACHINE

8.1 - DISINSTALLATION

If it has been decided to disinstall the machine for some reason, ensure that the

machine is unusable by anyone: detach and cut electrical connections.

8.2 - WEEE Waste of Electric and Electronic Equipment

Directive 2002/95/EC, 2002/96/EC and 2003/108/EC on the restriction of the

use of certain hazardous substances in electrical and electronic

equipment, and waste electrical and electronic equipment.

This symbol, crossed out wheelie bin, on the product or on its packaging indicates that

this product must not be disposed of with your other ho use hold waste.

Separate waste collection of this appliance is organised and managed by the

manufacturer. It is the user’s responsibility to contact the manufacturer and follow the

waste treatment system the manufacturer has adopted for separate waste collection.

The separate collection and recycling of your waste equipment at the time of disposal

will help to conserve natural resources and ensure that it is recycled in a manner that

protects human health and the environment.

2 23

Page 3

CHAP. 7 - MAINTENANCE

7.1 - GENERAL INFORMATION

Before carrying out any maintenance task, it is recommended to:

unplug the feeding cable from the net to insulate the machine from the rest of the

plant completely.

7.2 - DIPPING OF ACCIDENTAL FALL OF THE MACHINE

In case of immersion or accidental fall of any accessory or the machine itself, do

not use it and contact CUSTOMER SERVICE.

7.3 - SHAFT

Check that the shaft is firmly and solidly fixed to the engine’s body. If this is not

the case, please contact CUSTOMER SERVICE.

7.4 - FEEDING CABLE

Periodically, check the state of wear of the feeding cable and in case, contact

CUSTOMER SERVICE.

7.5 - COMMANDS LINING

Periodically, check the state of wear of the rubber commands lining and in case

of wear contact CUSTOMER SERVICE.

7.6 - BLADE

Check the sharpness of the shaft’s blades to replace them, please contact

CUSTOMER SERVICE.

7.7 - GASKETS - SEALING RINGS

Periodically check the sealing gaskets, once the knife-holding base is

disassembled (Fig. n°51).

If these show wear, contact CUSTOMER SERVICE.

INTRODUCTION

This manual has been written to supply the Customer with all the information on the

machine and the related safety rules, as well as the instructions for the receipt of the

machine itself, cleaning, maintenance and disposal that allow to use and maintain the

means keeping its efficiency intact throughout the time.

This manual it to be kept till the disposal of the machine.

This manual is to be kept at disposal of members of staff that have been appointed to

operate the machine and to carry out maintenance tasks.

TABLE OF CONTENTS

CHAP. 1 - RECEIPT OF THE MACHINE page 5

1.1 - PACKAGING

1.2 - BOX CHECK UPON RECEIPT

CHAP. 2 - INSTALLATION page 6

2.1 - UNWRAPPING

2.2 - PLACEMENT

2.3 - ELECTRICAL CONNECTION

2.4 - ELECTRICAL DIAGRAM

CHAP. 3 - MACHINE’S INFORMATION page 8

3.1 - GENERAL PRECAUTIONS

CHAP. 4 - GETTING ACQUAINTED WITH THE MACHINE page 11

4.1 - IN-BUILT FEATURES

4.2 - IN-BUILT SAFETY DEVICES

4.2.1 - Mechanical safety devices

4.2.2 - Electrical safety devices

4.3 - MACHINE’S DESCRIPTION

4.4 - OVERALL DIMENSIONS, WEIGHT, FEATURES

CHAP. 5 - USE OF THE MACHINE page 15

5.1 - ACCESSORIES ASSEMBLY

5.2 - PREPARATORY CHECK

5.3 - USE’S FIELDS

5.4 - MACHINE’S USE

CHAP. 6 - REGULAR CLEANING page 19

6.1 - GENERAL INFORMATION

6.2 - EXTRA CLEANING

6.2.1 - GENERAL INFORMATION

22

3

Page 4

CHAP. 7 - MAINTENANCE page 22

7.1 - GENERAL INFORMATION

7.2 - DIPPING OF ACCIDENTAL FALL OF THE MACHINE

7.3 - SHAFT

7.4 - FEEDING CABLE

7.5 - COMMANDS LINING

7.6 - BLADE

7.7 - GASKETS – SEALING RINGS

CHAP. 8 - DISPOSING OF THE MACHINE page 23

8.1 - DISINSTALLATION

8.2 - WEEE Waste of Electric and Electronic Equipment

(Fig. n°50)

Such operation is an exclusive re-

quirement of this machine.

This operation is to be carried out

only in case of poor cleaning tasks

executed by previous operators or in

case unpleasant smells, internal encrustations, etc. can be perceived.

This operation is quite delicate and

particular even if simple and could

compromise the functioning of the

machine. Therefore, it is recommended to have it carried out only by

responsible and expert members of

Fig. n°50

staff.

ATTENTION: this operation exposes

the operator to risks due to the manipulation of knives and sharp parts. Hence, it

is recommended to use protective gloves and to be extremely careful all the

time.

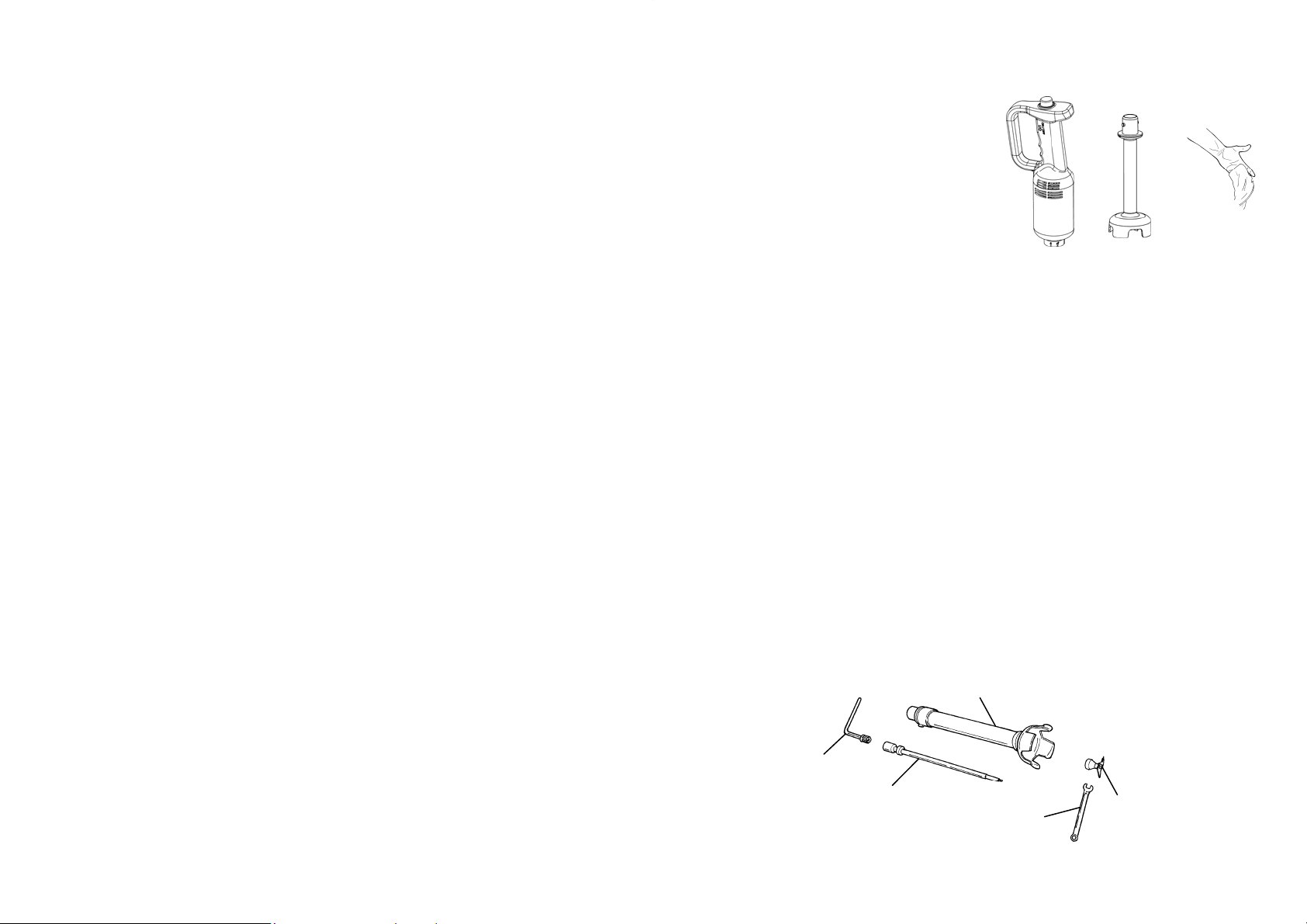

Disassembly of the shaft (Fig. n°51)

1. Detach the shaft from the engine’s body and position it on a surface with the

knives on the right side.

2. Predispose the tools (a-b), grip the tool (b) with the left hand and insert it in the

dragging device inside the shaft

3. ATTENTION: Using a key (a), unscrew clockwise till the blade group is re-

moved.

4. Remove the inner shaft from the main shaft pushing it towards the tool (b).

5. Proceed to clean the single pieces with a dump cloth and some dish detergent,

keeping in mind that the bearings must not come into contact with liquids.

6. In case of encrustation, insist with the cloth. Do not use abrasives, pointy or

sharp tools.

7. Disassemble everything the opposite way. ATTENTION: fix firmly the knife or

this could detach itself during the operating stage.

2

(b)

3

1

(a)

4

21

Fig. n°51

Page 5

5) Empty the container, rinse it and fill

it with warm water. Let the machine

operate again for some more 10-15

seconds, if necessary repeat the operation till a complete and thorough

rinse is guarantied.

6) Check the result of the operation

and if necessary repeat from point

(2) or intervene manually on the

parts that are still dirty.

ATTENTION: At this stage it may be

instinctive to approach the blades

with your hands.

could provoke wounds to the hands

(Fig. n°46). Always disconnect the

machine from the power supply and

always pay maximum attention.

7) Reuse the tool for another operation

or:

8) Dry the tool with a cloth and position

it vertically for 1 or 2 hours to ease

the drainage of residual liquid (Fig.

n°47).

ENGINE’S BODY:

1. unplug the feeding cable from the

net to insulate the machine from the

electrical feeding completely (Fig.

n°48).

2. Remove possible product splashes

that deposited on the machine’s

body with a wet sponge and dry immediately with a cloth.

3. Check that no residual from the

work nor liquid did not enter the

cone fixing the tools and in such

case remove them with a cloth.

6.2 - EXTRA CLEANING

6.2.1 - GENERAL INFORMATION

The knives area

ATTENTION!

Fig. n°46

Fig. n°47

Fig. n°48

CHAP. 1 - RECEIPT OF THE MACHINE

1.1 - PACKAGING

The package includes:

engine’s body

operating shafts

manual

(Fig. 1): cartoon box, polystyrene

inserts, nylon, etc. will have to be

disposed of separately as per the

enforcing norms of the country of

installation.

ATTENTION!

Superimpose up to a maximum of

five boxes of the same type (Fig. 2).

It is recommended to keep the box at

least throughout the time of warranty to

facilitate transportation in case of repairs, etc.

Do not leave the box exposed to humidity and rain (Fig. 3).

Fig. n°1

Fig. n°2

Fig. n°3

20

Fig. n°49

Do not overturn the box (Fig. 4).

Fig. n°4

5

Page 6

Please ensure that the box is held

firmly at the far ends of its longest

sides, while carrying it and keep the

box itself parallel to the floor (Fig. 5).

1.2 - BOX CHECK UPON RECEIPT

Once the item has been received, proceed to the opening and check that all the

material is inside if the box does not show

external damages. While if the box or the

contents show signs of misusing (Fig. 6),

knocks, fall or ruptures, it is necessary to

inform the freight forwarder of the damage by writing a detailed report about the

possible damages suffered within three

days of the delivery date. Generally, complaints that are not communicated immediately are not taken into consideration by

the freight forwarder.

CHAP. 2 - INSTALLATION

ATTENTION!

All the tasks must be carried out by

trained members of staff (Fig. 7).

2.1 - UNWRAPPING

Ensure that the box is not upturned by

checking the direction of the external

writings (Fig. 8)

The contents include:

a) cartoon wrapping

b) inserts

c) the machine’s body

d) operating shaft

e) the instructions manual

Remove the adhesive tape fixing the

upper flaps of the box and lift the

machine’s body.

CHAP. 6 - REGULAR CLEANING

6.1 - GENERAL INFORMATION

The cleaning of the machine is an

operation to be done absolutely at

the end of every working cycle.

Immediate cleaning, can save a lot of

time, guaranties hygiene and mainte-

Fig. n°5

nance of the machine.

The cleaning must be scrupulously

detailed in all the parts that come

into direct or indirect contact with

food.

The dipping blender must not be

cleaned with water cleaners or water

jets (Fig. n°43), and/or with acid or

corrosive detergents that can ruin the

surface (Fig. n°44).

Tools and brushes or else must not

be used as they might damage the

Fig. n°6

machine (Fig. n°44).

Check that the vent’s opening are

not obstructed by dust, dirt or else

periodically. In case these are obstructed call the CUSTOMER CENTRE.

ATTENTION: do not use air jets or

else that could provoke dirt’s infiltra-

tions inside the machine (Fig. n°43).

For a correct cleaning, it is necessary:

SHAFT (Fig. n°45)

1) Get a container sufficiently high to

Fig. n°7

immerge the shaft to the maximum

level allowed

2) Fill it with hot water 50-60º C and

a-b)

c)

add dish detergent according to the

need

3) Let the machine operate for 20 seconds simulating the normal productive process.

d)

4)

When the motor is off, using a non-

abrasive damp sponge, clean the

e)

Fig. n°8

6

outside of the shaft with the deter-

gent previously used (Fig. no. 47).

Fig. n°42

Fig. n°43

Fig. n°44

Let the dipping

blender work for 20

seconds during the

cleaning stage.

19

Fig. n°45

Page 7

Alternate the revolution even in the

movements from the top to the bottom

to ease the entry of the products to be

cut in the operating bell (Fig. n°39).

Work till the desired consistency is

obtained, once finished using it,

switch the machine off.

ATTENTION: Do not use the machine in free air and to avoid any

risk of physical or mechanical

damage, never extract the tool

from the product while still rotating

(Fig. n°40).

ATTENTION: as a result of the centri-

fuge effect, the liquid tends to rotate

and to higher its level closer to the

border of the container, when the

blender is functioning, hence never fill

the container over 2/3 of its capacity

(Fig. n°39-40).

Never carry out work cycles for over

10 minutes and keep the blender

switched off anyway for at least 10

minutes between a work cycle and

the next (Fig. n°41).

At the end of the working cycle, remove the machine from the working

container and proceed immediately to

the cleaning of the tool (see chapter

6 Regular cleaning).

Never leave the machine unattended inside the container.

Cicli di lavorazione:

10 minuti ON - 10 min. OFF

Fig. n°39

Fig. n°40

Fig. n°41

2.2 - PLACEMENT

The machine and its related accessories must be kept in a dry environment, far away from heat, humidity,

splashes, dust and anything else that

might damage the dipping blender

and its accessories (Fig. 9).

In case the accessories are unused

for a long time, they might be stored

in other places as long as these latter

respect the above-mentioned requirements and that they guarantee good

conservation of the accessories themselves (for instance, drawers that can

bump the components one against

the other or cause them to fall must

be avoided).

2.3 - ELECTRICAL CONNECTION

Check that the data reported on the

register-technical plate (Fig. 10) of the

delivery documents match the

delivery documents, if not please

contact the supplier to have an

explanation.

At this point, make sure that

the

electric plant of the building is

according to law.

The dipping blender is supplied with a

feeding cable with section 2x1 mm

2

,

length > 1,6m and a SHUKO plug

(Fig. 11).

The machine is not foreseen to be

ground mass as it is supplied with

double isolation. This means that all

the external components that might

be handled by the operator cannot be

subjected to tension not even in case

of failure.

Link the dipping blender 230 V. – 50

Hz, interposing a differential (safety

device, Fig. 12) - 10A ∆Ι = 0.03Amagnetothermic switch.

Fig. n° 9

Fig. n°10

Fig. n°11

Fig. n°12

18

7

Page 8

2.4 - ELECTRICAL DIAGRAM 115V. – SINGLE-PHASE 230V. (Fig. 13)

Normal version

VV version

Fig. n°13

CHAP. 3 - MACHINE’S INFORMATION

3.1 - GENERAL PRECAUTIONS

Even if these general precautions seem obvious, they are of paramount importance for the installation, the use, the maintenance and possible inconveniences

and related remedies.

The producer has no responsibility

in the following cases:

The machine has been tampered

by non-authorised members of

staff.

Some components have been

replaced with non-original ones.

The instructions of this manual

have not been followed carefully.

Keep this manual with care for fu-

ATTENTION!

Fig. n°14

5.4 - MACHINE’S USE

ATTENTION:

- Check that the machine is perfectly

dry and that there is no dirt or humidity from previous uses or washes

(Fig. n°35).

- Check that the shaft or the whip

have not residual encrustations from

previous uses.

- Before using it, ensure that the shaft

and the whip are fixed to the en-

gine’s body properly (Fig. n°36).

- Check that in the previous uses the

components or protections have not

been removed.

- Check the state of the feeding cable

that could have been worn out by

the different knives and tools in the

kitchen. In this case, please contact

CUSTOMER SERVICE immediately.

Grip the dipping blender by the handle

with one hand and grip the lowest part

with the other one. Never grip the engine’s body in a way to obstruct the

vent’s opening (Fig. n°37).

Posture correctly and comfortably in order to work safely and easily. It is not

recommended to use the dipping

blender on kettles positioned above

fires or work surfaces that are too high

(Fig. n°38).

Immerse the immersion blender with

the utensil slightly tilted, making sure

that the blade unit does not touch the

bottom of the container. For optimal operation, the shaft must be submerged

up to ⅔ of its length.

Switch the machine (please see paragraph 5.1) and move the shaft towards

the inner part of the container with slow

but regular revolving movements.

Fig. n°35

Fig. n°36

Fig. n°37

⅔

Fig. n°38

8

17

Page 9

starts at maximum speed. Be aware of

the counterblow that the engine’s

power can provoke in the hand and in

the wrist when gripping the machine

tightly.

- If the machine has a speed variator,

after the engine has started, work on

the speed variator’s handle (4) with

the other hand and check the correct

its functioning

- Check if the machine starts even

without pressing the button (1). In

this case, give up the test and call

the producer immediately.

5.3 - USE’S FIELDS

The dipping blender has been designed

to blend, fruit, vegetables, meat, foodstuffs in general not frozen and in any

case soft.

The dipping blender has not been designed to work chemicals, sewages,

glues and anything that is not strictly

food.

Even if designed to blend also hot products, it is recommended to operate with

products at a temperature below 70 degrees C. always for a short lapse of

time (maximum 10 minutes).

Blending:

Use of the shaft (Fig. n°34).

Fruit, vegetables, meat, food in general

as long as mixed in some liquid solution.

Food pieces must have maximum dimensions of a nut (3x3x3 cm cubes as

long as without bones or stones and as

long as they are not too hard and consistent).

2-Speed variator’s handle

1-Switch on

Fig. n°33

Fig. n°34

ture reference (Fig. 14).

The dipping blender must be used

only by trained members of staff,

who must know the safety rules contained in this manual perfectly.

In case of staff turn-over, please

proceed to train the new members

of staff in timely fashion.

Do not allow children, incompetents

or untrained members of staff to use

the blender (Fig. 15).

Before carrying out any cleaning or

maintenance task, unplug the machine from the electrical feeding network (Fig. 16).

Before replacing accessories, un-

plug the machine from the electrical

feeding network (Fig. 16).

When intervening for ordinary main-

tenance or cleaning, carefully evaluate risks.

Focus your attention on the opera-

tions in course during the use, maintenance and cleaning.

To clean the machine, follow care-

fully the instructions of the chapter

“Ordinary cleaning”.

Do not wash the blender by means

of the dishwasher or water jets (Fig.

17-18).

The dipping blender has been de-

signed to blend fruit, vegetables and

meat (unfrozen and without bones

or stones) (Fig. 19), and anyhow

food that is not particularly hard or

resistant to be processed. Any other

use is to be considered improper

and therefore dangerous.

Dry the machine’s body and the

used accessories after having

cleaned them.

Do not expose the blender to nox-

ious agents such as the sun, the

rain, splashes, humidity, frost (Fig.

20).

Fig. n°15

Fig. n°16

Fig. n°17

Fig. n°18

Fig. n°19

Fig. n°20

16

9

Page 10

Do not pull the feeding cable to un-

plug (Fig. 21).

Check the status of the feeding ca-

ble on regular basis as a worn out

cable or imperfect presents serious

electrical dangers.

If the machine remains unutilised for

a long time, have it checked by an

Customer Service Centre before using it.

If the machine shows signs of mal-

functioning, it is recommended to

switch it off, not to use it and not to

intervene directly.

to repair it and call the Customer

Service Centre whose details can

be seen at the back of this manual.

In case of fall or immersion of the

blender, do not use it and contact

CUSTOMER SERVICE immediately

to have a detailed check.

Do not leave the dipping blender

plugged in pointlessly. Unplug it

when not using the machine. (Fig.

22).

Do not hang f handle the dipping

blender by means of the feeding cable (Fig. 23).

Even if the machine is built accord-

ing to the enforcing laws, there are

some dangerous zones. Therefore,

it is recommended to avoid to approach the hands to the blades or

other parts in movement (Fig. 24).

Do not posture in such a way that

might lead parts of the body in

direct contact with the blades.

10

Fig. n°21

Fig. n°22

Fig. n°23

Fig. n°24

CHAP. 5 - USE OF THE MACHINE

5.1 - ACCESSORIES ASSEMBLY:

The tools must be installed on the engine’s body when the machine is unplugged.

All the dipping blender’s tools are perfectly interchangeable. However, they

might differ according to the model,

date of production, producer. Hence, it

is recommended to keep separate the

various accessories of other dipping

blenders.

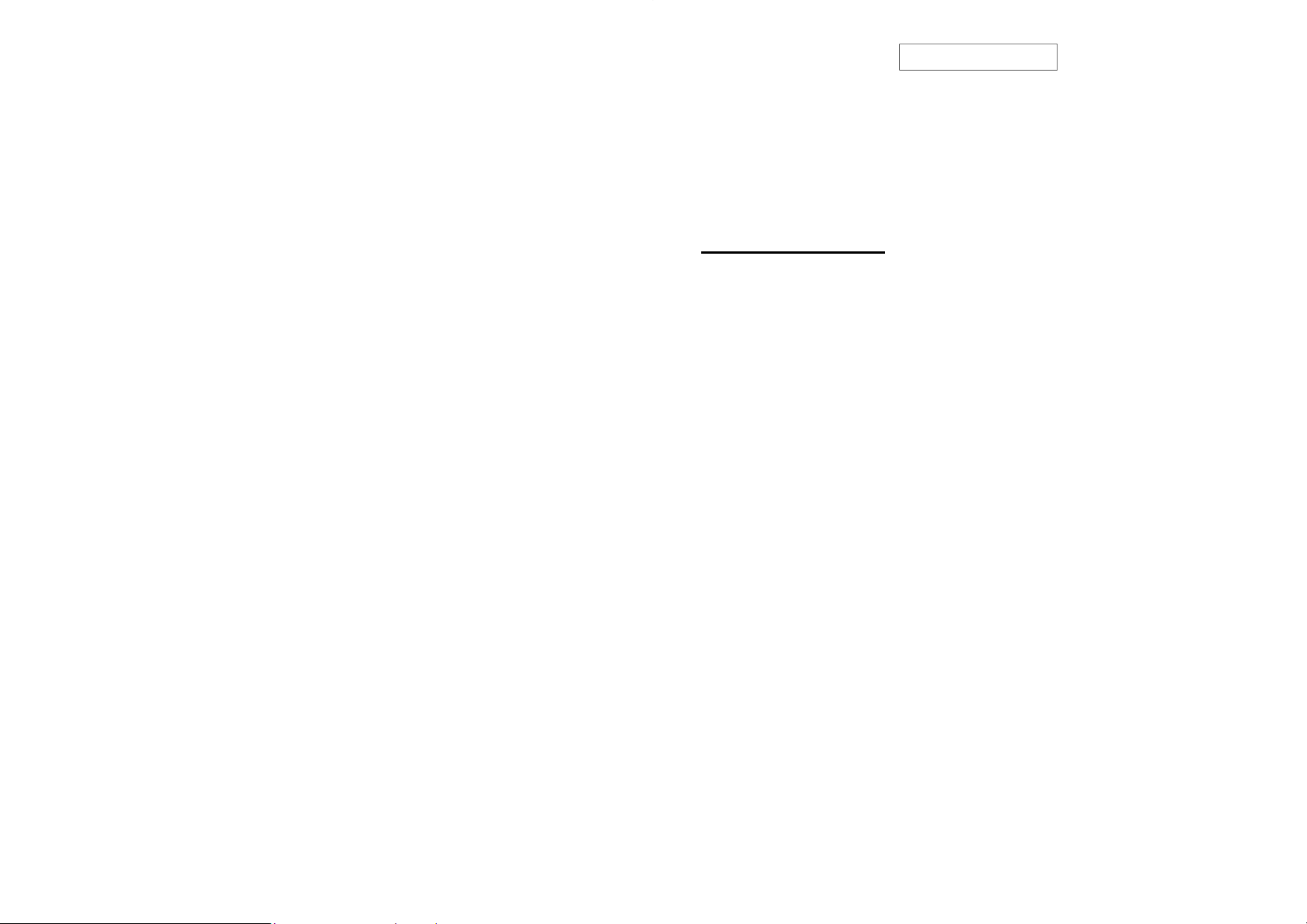

ENGINE’S BODY - SHAFT (Fig. n°31)

Grip the engine’s body by the handle,

grip the shaft with the other hand. Align

the shaft’s rung to the clutch of the machine’s body (1). Insert the shaft deeply

(2) and rotate it of about 45° degrees

anticlockwise till the shaft is firmly

blocked to the machine (3). The catch

will fit the engine’s body reference.

5.2 - PREPARATORY CHECK

Check that the tools are perfectly as-

sembled as per chapter 5.

Check that the electrical connections

has been done correctly as per para-

graph 2.3.

Hold the machine with a hand and after

that check its functioning with the fol-

lowing procedure (Fig. n°32-33):

- Ensure that the switch (1) is not

pushed

- Insert the machine’s plug into the

socket

- Hold the blade unit near the table, in

any case away from utensils, garments and parts of the body.

- Press the power button (1). The ma-

chine will start to work.

- If the machine is normal the engine

15

(1) (2)

(3)

Fig. n°31

Fig. n°32

Page 11

by this manual under the titles ATTENTION

. They concern the danger of cut,

contusion and else that is provoked by the blade and the dragging device, by

the whip and by other components of the machine or by electrocutions.

4.3 - MACHINE’S DESCRIPTION

Hand-Held Mixer (body only) Shaft

C

C

CHAP. 4 - GETTING ACQUAINTED WITH THE MACHINE

The dipping blender is made up by more elements than the ones that in this

manual are named:

- Engine’s body

- Operating shaft.

4.1 - IN-BUILT FEATURES

The engine’s body is built in highly-resistant ABS with stainless steel details.

These materials guarantee hygiene when there is contact with food and good resistance to the agents contained by food. Moreover, high mechanical resistance

is guaranteed due to their formation.

The operating shaft is made up almost completely by stainless steel, aluminium

and coated in highly-resistant ABS.

A

Fig. n°30

A B

4.4 - OVERALL DIMENSIONS, WEIGHT, FEATURES

ATTENTION:

The electrical features of the machine are indicated by a plate placed by the grip

(Fig. n°10).

TABLE 1 - OVERALL DIMENSIONS A ND TECHNICAL FEATURES (Fig. n°30)

Power Power source Knives

watt r.p.m. lt mm Kg

S 20 200 230V/50Hz 12.500 20 74X145X290 1,1

S 20 VV 200 230V/50Hz 2000÷12.500 20 74X145X290 1,1

A Net weight

mm mm kg

Shaft 16 ø 65 160 0,2

revolution

C

14

Working

Capacity

AxBxC Net

weight

KEY (see Fig.25):

01

variator with stabilizator

02

upper-grip handle

03

air-exhaust grill

04

dragging device (female)

05

air-aspiration grill

06

switch

07

dragging device (male)

08

hooking cone

09

hooking rung

10

tube

11

bell

12

blade

11

Page 12

Hand-Held Mixer Engine’s body

4.2 - IN-BUILT SAFETY DEVICES

01

06

02

05

04

Operating shaft

09

07

08

10

11

12

03

Fig. n°25

4.2.1 - Mechanical safety devices

As far as mechanical-nature safety, the

dipping blender described by this manual complies to:

- the EC 2006/42 machine’s directives

The dipping blender is provided with:

- Shaft-protecting bell (Fig. 27)

- Anti-accidental switching handle

(Fig. 29)

- Respect of the minimum space to

grip the machine as per what is prescribed by law

4.2.2 - Electrical safety devices

As far as electrical-nature safety, the

dipping blender described by this man-

ual complies to:

- the EC 2006/95 low tension directive

- the EC 2004/108 electro-magnetic

compatibility directive

Therefore the dipping blender is provided with:

- Double-insulating system to guaran-

tee that all the details that might

come in contact with the operator

are not subject to tension not even

in case of breakdown.

- Ergonomic positioning of the start

button to prevent accidentally pow-

ering (Fig. no.29).

- Internal components protection from

liquid splashes

- Although the dipping blender is pro-

vided with the electrical and mechanical measures (operating during

the working phase and during cleaning and maintenance) as per the en-

forcing laws, there are some RESID-

UAL RISKS that cannot be elimi-

nated completed. These are recalled

Aspiration

grill air

Escape grill

air

Fig. n°26

Fig. n°27

Fig. n°28

Fig. n°29

12

13

Loading...

Loading...