Page 1

20

INFORMAZIONE AGLI UTENTI

In compliance with art.13 of the Legislative Decree n. 151 dated 25 July 2005,

”Implementation of the 2002/95/CE,2002/96/CE and 2003/108/CE

Directives, relative to the reduction of the use of dangerous substances in

electric and electronic appliances, as well as the disposal of waste”

The barred wheeley-bin symbol on the appliance or

the package indicates that at the end of the products useful life

span, it must be collected separately from other waste.

The recycling of this product at the end of its service life, is arranged for and carried

out by the manufacturer. The user who wishes to dispose of this product must

therefore contact the manufacturer and adhere to the system that he has adopted for

the correct disposal of this product at the end of its service life

The correct disposal of the old product for the processes of recycling, treatment and

compatible waste disposal will help prevent potential negative consequences for the

environment and human health, and will result in the reuse and recycling of the

materials and components which make up the appliance.

Abusive disposal of the appliance leads to the application of administrative

sanctions envisioned by the Standards in force.

7.2 WEEE Waste Electric and Electronic Equipment

AUTHORISED DEALER

1

English

VACUUM PACKAGING MACHINE

USE AND M AINTENANCE MANUAL

25

30

40

Ver. 002 03.2017

Page 2

2

19

English

6

Obligations in the e vent of m alfun ct io ni ng and/ or pot ent i al

dangers

The operators must inform their direct seniors of any deficiency and/or potential

dangerous situation that should occur.

6.1 - User obligations

The user must inform the manuf act ur er imm ediately if any defects and/or m alfunctioning of

the accident-preventio n syst em ar e det ect ed, as wel l as any presumed dangerous situati on

of which he becomes aware. It is pr ohibited for t he user and/ or third parties (excluding duly

authorised manufacturer ’s st af f ) t o m ake any t ype or ent ity of modifications to the machine

and its functions, as well as to this t echnica l document. In the event of malfunct ioning and/or

dangers, owing to failure t o respect the afore-said, the manufacturer is not liable for any

consequences. We recom mend you r equest any modification s f r om the Manuf act ur er .

7 Troubleshooting

7.1 - Troubleshooting

1 After having connected the master switch, the machine does not start:

a) Check that the plug is well inserted into the socket and, if necessary, control the

contacts inside the plug itself.

b) Check that on lowering the lid, the micro switch positioned on the rear below

the right fixing hin g e, is exc ited.

2 The machine operates regularly, but the package is not sealed when the

lid is opened

a) Lift the Teflon and check that the resistance is not interrupted and it is blocked

on the lateral clamps.

3 If the machine does not achieve an excellent vacuum

a) Close the lid and disconnect the line when a negative pressure of about 90%

has been reached. Check whether the vacuum percentage indicated on the

display remains fixed or decreases.

- In the first case, there are no leaks, therefore the problem has another source

(pump van es, oil replac ement) .

- In the second case, there is the presence of air infiltration into the tank:

• Check the membrane below the sealing bar, checking that it has no holes or

is ripped

• Check the integrity of the sealing gasket positioned under the lid; if the

afore-mentioned pieces must be replaced, request them directly from the

authorised dealer.

WARNING!

In case the machine is turned off or there is a power outage during the

vacuum cycle, it may happen that the lid does not open due to the vacuum

reached at the time of switching off.

To open the lid is necessary to bring the pressure in the tank. Then turn on

the machine with the side button, after one second the drain valve opens and

you can re-open the lid.

Page 3

18

5.2- Maintenance

1. Clean the sealing bars and the silicon counter-bar more or less every 15 days

using alcohol.

2. Change the oil every 400 hours of working (data variable depending on the type

of product packed).

After 2000 cycles the machine envisions an automatic oil control, the display

shows the “oil change” message. The user must call the dealer, who will

check the efficiency of the oil and will repla c e it, if n ecess ary .

3. Rep lacement of electric resistances, Tef lon sea ling bar, lid sealing gaskets

about every 200 working hours.

4. Replacement of the silicon counter-bar

5. Check pump vanes, filters, pneumatic solenoid valve seals every 35,000

work cycles.

5.2.1 - Vacuum pump

For the safeguarding and the duration of the vacuum pump, follow the indications

given below scrupulously:

- Do not suck up steam, liquids and flours of any type.

This compromises the viscosity of the pump oil and damages the pump itself.

- Periodically check the pump oil level through the visual inspection window

A level below minimum can damage the pump

A level above maximum can damage the pump filter and the pump itself

- Periodically check the colour of the pump oil. I f the oi l appears

cloudy, dark or emulsioned, it must be replaced immediately.

- Replace the pump oil every 2 / 4 / 6 or 12 months, depending on use and location

of the eq uipment, or appearing the notice "change oil" on the display.

The pump oil may have to be repla ced ever y month .

- Replace the pump oil before prolonged machine shutdown.

ATTENTION!!:

Cons idering that the vac uum packagin g m achin e is nearly always loc ated in t he

kitchen, an environment full of steam and humidity, the level and quality of the

pump oil must be checked constantly and replaced frequently and periodically.

AGIP ARNICA 32 Q8 HAENDEL 32

SHELL TELLUST 32 ESSP INVAROL EP46

Types oil

3

English

INDEX

1. Delivery and warranty 5

1.1 Foreword.

1.2 Preservation and use of this manual

1.3 Warranty

1.4 G eneral recommendations and limits of liability of the Manufacturer

1.5 Description of the machine

1.6 Declared use

1.7 Use not allowed

1.7.1 Safety prescriptions

1.7.2 Lighting

1.8 Company information

1.8.1 Warning and Danger signs

2. Technical features 9

2.1 Main parts

2.2 Technical features

2.3 Dimensions and weight of the machine

2.4 Wiring diagram

3. Inspection, transport, delivery and installation 12

3.1 Inspection

3.2 Delivery and handling of the machine

3.3 Installation

3.3.1 Disposal of packaging

3.4 Connections

3.4.1 Ch eck oil level

3.4.2 Ch eck pla te data

4. Using the machine 14

4.1 Control board key

4.2 Cavity vacuum packing cycle

4.3 External vacuum packing cycle

4.4 Packaging of liquid or semi-liquid products

4.4.1 Packaging of liquid or semi-liquid products with the use of the

standard inclined surface

4.4.2 Pa ckagi ng of thi n products wit h use of optional rai sed surface

4.5 Cleaning the machine

4.6 Vacuum pump heating

Page 4

4

5. Controls and maintenance 17

5.1 Controls and maintenance

5.2 Maintenance

5.2.1 Va cuum pum p

6. Obligations in case of malfunctioning and/or potential dangers 19

6.1 User obligations

7. Troubleshooting 19

7.1 Troubleshooting

7.2 WEEE Waste Electric and Electronic Equipment

17

English

4.5 - Cleaning the machine

ATTENTION!

Disconnect the machine from the mains electricity before cleaning.

Do not clean the machine using a jet of water.

Use non-toxic detergents only, expressly intended for clearing components coming

into contact with foodstuffs. DO NOT use ch lorin e-based detergents.

DO NOT use ethyl alcohol to clean the Plexiglas dome.

The Plexiglas lid be cleaned regularly with a soft, damp cloth, using cold or warm

water, with a small amount of neutral detergent.

It is recommended to avoid:

- the use of products containing: denatured ethyl alcohol, solvents in general,

Benzen e, Trichloroethy lene

- the use of abrasive materials and contact with sharp objects

Drying

When the lid has been cleaned, it can be dried using a slightly damp chamois

cloth, without rubbing hard.

4.6 - Vacuum pump heating

During the winter period, in the morning it is recommended to briefly

pre-heat the pump in order to fluidify the oil before it goes into

circulation:

- Posi tion the master swit ch (ref. 1 fig. 4.6.1) at ON.

- Turn the suc t ion cock to close (ref. 5 fig. 4.6.1)

- Press the UP key 3 times (ref . 3 fig 4. 6.1)

The machine will perform an oil heating cycle.

The duration of the cycle is 15 minutes.

If the operator wants to interrupt the cycle before it ends,

he must press the switch-on key ref. 2 fig 4.1.1.

N.B. This operation must only be performed with the

int ake cock closed.

5 Contro ls and maintenance

5.1 - Controls and maintenance

Acces s to the inter nal part of the m achin e i s reserved exclusively to our

specialised technician.

If the machine is accessed voluntarily, the manufacturer declines all civil and penal

liability regarding any accidents or damage caused to persons or objects.

All electric components are protected within the machine body and the relative

guard must be removed in order to gain access. Whenever access must be made,

remo ve the plug from the electric control boar d curren t sock et .

1

Fig. 4.6.1

1

2

3

4

5

Page 5

16

4.4 - Packaging liquids or semi-liquids

With t he d ome vacuum pa ck i ng m ac hi n es we pr o d uce, i t i s pos s i bl e t o va cu um pa ck

liquids and semi-liquids (soups, juices, sauces, etc…) lengthening their duration and

maintaining flavour and hygiene unaltered.

In th ese cas es, rem ember th at the b ags must n ever be f illed up to ma ximum lim it,

but up to 50% of the capacity, making sure that the edge is at a higher level with

respect to the sealing bar.

1. The vacuum cycle remains progr ammed as described in the USI N G THE

PACKAGING MACHINE chapter. (4.2)

2. As liquids are incompressible, they do not require

packaging in modified environments, i.e. with the addition

of inert gases.

3. All of the packet s can be stored in a cold room and

stacked normally.

4.4.1 - Packaging liquids or semi-liquids with the

use of standard bracket

When liquid products must be packed,

the use of the inclined bracket is

recomme n d ed, in o rd er to fac i litate the

operation.

4.3.2 - Packaging of thin products with the use of the

optional raised surfac e

When thin products such as sliced cured

meats must be packed, the use of the

raised surface is recommended, in order

to facilitate the operation

Fig. 4.4.1

Fig. 4.4.2

FRESH MEATS

BEEF 30/40 days

VEAL 30/40 days

PORK 20/25 days

WHITE MEATS 20/25 days

RABBIT AND GAME ON THE BONE 20 days

LAMB/GOAT 30 days

SAUSAGES 30 days

OFFAL 10/12 days

PRESERVATION TIME OF VACUUM PACKE DPRODUCTS

KEPT AT A TEMPERATURE OF +0°/+3° C.

FISH: Average duration 7/8 days with extremely fresh product

CURED COLD CUTS: Maintenance time to perfection over 3 months

MATURED CHEESES: Grana, pecorino, etc. 120 days

FRESH CHEESES: Mozzarella, brie, etc 30/60 days

VEGETABLES: In general 15/20 days

5

English

1 Delivery and warranty

1.1 - Foreword

ATTENTION!

The symbols used in this manual intend to call the reader’s attention to points and

operations that put the operator’s personal safety at risk or which can cause

damage to the machine itself.

Do not operate with the machine if you are not certain to have correctly understood

that highlighted in these notes.

ATTENTION!

Some illustrations in this manual represent the machine or parts of the same with

panels or guards removed. This is in order to make things clearer.

Do not use the machine in these conditions, but only with all protections mounted

correctly and in perfect working order.

The Manufacturer prohibits reproduction, even partial, of this manual and its

content cannot be used for purposes not permitted by the same.

Any breach thereof will be dealt with under the pr ovisions of said Law.

1.2 - Preservation and use of the manual

The purpose of this manual is to make the users of the machine aware of the

prescriptions and essential criteria relative to transport, handling, use and

maintenance of the machine itself, via texts and figures.

Therefore, this manual must be read thoroughly before the machine is used.

Keep it in a safe place near to the machine, which is easy and quick to access for

future consultation.

If the manual is lost or deteriorated, request a copy from your dealer or the

Manufacturer directly.

If the machine is transferred, inform the Manufacturer of the name and address of

the new owner.

This manual reflects the state of the art at the time of marketing and cannot be

considered inadequate merely because it is updated successively on the basis of

new developments. The manufacturer also reserves the right to update production

and relative manuals without the obligation to updating earlier issues, except in

exceptional cases.

If in doubt, consult the nea rest after-s ales c entre or the Manufacturer directly.

The manufacturer is intent on continuous optimisation of its product.

For this reason it is pleased to receive any signals or proposals for improvement of

the machine and/or manual.

The machine has been delivered t o the user with v alid warranty condi t ions at the

time of purchase.

Contact your own supplier for all clarifications.

Page 6

6

1.3 - Warranty

The Manufacturer is committed for 12 (twelve) months, from the date of shipping

and direct delivery of the goods, to guaranteeing the customer or authorised dealer

the integrity and good operation of the components relative to the machinery in

question.

The warranty excludes all parts of the machinery subject to normal wear, i.e

components in which use generates unstoppable constant wear:

A. Electric resistances – Teflon - Sealing gaskets – Dome opening pistons –

Sealing membrane– Air filters – Oil filters – Oil change – Pump vanes.

B. Whenever a vacuum pump relative to a machine under warranty is returned to

the Manufacturer due to problems regarding suction and malfunctioning, the

Manufacturer reserves the right to control whether foreign bodies have been

sucked up: (liqui ds, solids, juic es, sauces etc.). If thi s situation is verifi ed, the

repair materials and labour will be charged regularly, as the problem is not

linked to manufacturing defects but Customer negligence during use.

C. Any problems linked to the electronic circuit boards of the circuit must be

examined by the Manufacturer before the piece to be replaced is sent under

warr anty. A volt age ch ange, elec tric o ver-f eedi ng, i nter fer ence i n the ext erna l

mains, could cause damage that is not the manufacturer’s fault or which can

be blamed on the manufacture of the piece.

D. Any problems linked to pneumatic, structural, mechanical parts, will be solved

normally under warranty without charge.

E. During the warranty period, for interventions covered by the same, there will

be no charge for the materials replaced, while labour costs will be calculated.

For any interventions performed during the warranty period that are not

covered by the warranty itsel f, the materials replaced and the l abour will be

charged regularly.

F. If external interventions by our technicians are requested during the warranty

period, travel expenses (return) will be charged in full, independent of the

cause of the intervention.

1.4 - General recommendations and li mits of li abi li ty of the

Manufacturer

Every operator-m achin e interaction, within the declar ed use am bit and the entire

life cycle of the same, has been car efully and thoroughly analysed by t he

Manufacturer during the design and construction phases and when drawing up the

instruction manual. In spite of this, it is intended that nothing can r eplace the

experience, suitable training and especially the “good common sense” of those

int eracti ng with t he machi ne. The last requisit es are therefo re deem ed

indispensible in every operational phase inherent the machine and when reading

this manual.

Failure to comply with the precautions or specific recommendations present in this

manual, use of the machine by unsuitable staff, violate all Safety Standards

concerning the design, manufacture and decl ar ed use of the supply and relieve the

Manufacturer from all liability in the event of damage/injury to obj ects/persons.

15

English

4.2 Chamber Vacuum Packing Cycl e

1 - Press the gener al switch (right side of machine)

Ref. 1 Fig. 4.2.1 in the ON position. The display li ghts up

and the word OFF appears

2 - Press the 2 but ton and put the machine in an O N mode.

The machine is ready for the cavity vacuum packing cycle.

Check that the ti ming of vacuum packi ng and sealingti me s

are optimal (the machine is sold with preset vacuum packing

and sealing val ues).

3 - Place the bag i nside the cavity (fig. 4.2.2), resting the open end

on the seali ng bar in a perfectly flat manner.

4 - Low er the lid to start a wor k cycle.

5 -

Check that the vacuum packaging percentage has reached 100%

6 -

Finish the cycle, open the lid and extra ct the se ale d vacu u m

packedproduct.

Start again from phase 3 for a new cycle.

Note: Every work step may be stopped by pressing the 2 but ton

Pressing the 1 button once = stop the vacuum packing and start the sealing cycle

Pressing the 1 button twice = cancel the cycle without sealing

4.3 External Vacuum Packing Cycle

1 - Place the switch (right side of the machine) Ref. 1 f ig. 4.3.1 in the ON position.

The display will read OFF.

2 - Press the 2 but ton and put the machine in the ON mode

(vacuum packing cavity).

3 - Simultaneously press buttons 3 and 4 for 1 sec.

The display will show the message EXT. VACUUM

4 - Check th at the set time is su fficient.

5 - If necessary, i ncr ease or decrease the time with

keys 3 and 4 fig. 4.3.1.

6 - Insert the tube for external suction optional)

in the suction hole, being careful to

remove the adjustable cap 5 fig. 4.3.1.

7 - Press the 2 b utton to start the cycle.

The cycle will stop automatically when it

reaches the set time.

Please note: Pressing buttons 2 and 3

at the same time will return it to th e

vacuum chamber packing mode.

1

Fig. 4.3.1

1

2

Fig. 4.2.1

1

2

3

4

SURPLUS BAG

SEALING BAR

Fig. 4.2.2

5

Page 7

14

4B Use of the machine

4.1 - Control Pa nel Legend

1. ON-OFF

- Turning the machine on and off:

briefly pressthe ON button

pressthe OFF button for 3 sec.

- Interruption of work phase:

During the work phases, if pressed, it st ops t he pr ocessin g and passes to the next one.

- Vac Time or Seal Time Selection:

when in the ON mode, if pressed,it allows you to move the arrow in order to select

Between VacTime and Seal Time (for their modification use keys 2 and 3 to

increase or decreasetheirvalues)

Note: the software always saves the latest change.

2. Increase the Selected Values

- Press to increase the values previously selected:

Adjustable values: vacuum packing time; seal time or external vacuumpacking time

- When in the OF F m ode, if pressed for 3 times in a row,th e pre-hea ting cycle or

expulsion of water residues from the oil pump will be started

To be performed after vacuum cycles with liquid products, or ever y 15 days.

The duration of the cycle is 15 minutes and can be interrupted by pressing the 1 button

NB This should be always performed with the suction cap closed (turn the

cap to cl ose the slots)

3. Decrease the Selected Values

- Press to decrease the values previously selected:

Adjustable values: vacuum packing time; sealing time or external vacuum pa ckingtime

Pressing buttons 2 and 3 simultaneously switching from vacuum packing cavity

mode to external vacuum packing mode in a cyclic modality.

4. Analog Display

- It allows the worki ng modalities to be viewed:

OFF

cavity vacuum packing

external vacuum packing

pre-heating or expulsi on of water residuals

Vacuum percentage

1 4 3 2

Fig. 4.1.1

7

English

The Manufacturer is not deemed liable for the consequences caused by the

user’s failure to comply with the safety precautions given in this manual.

1.5 - Description of the machine

The va cuum packa ging ma chin e with d ome is c ontrol led el ect ric ally a nd ther efo re

not subject to wear. The electronically-governed sealing system, is composed of a

flat resistance (5mm) bakelite bar which, thanks t o an excellent pneumatic system

installed, guarantees balanced and even sealing on any type of bag to be used

(nylon, polyethylene, Cryovac).

The va cuum pumps us ed are ver y moder n and g uara ntee sur pri sin g silen ce even

though operating with uninterrupted cycles along with a very high level of final

vacuum.

The models represented in this manual have been created in compliance with the

2006/42 EEC Directive and successive amendments.

In the event of an accident, the manufacturer cannot be held responsible if the

machine ha s been modified , tamp ered with, the safety protect ions h ave been

removed or used in ways not declared by the manufacturer.

1.6 - Declared use

The machine has been designed and manufactured to vacuum pack products

according to the instructions in this manual and must be intended for this use onl y.

Any other use must be considered improper and therefore dangerous. The

Manufacturer cannot be considered responsible for any damage deriving from

improper, incorrect or unreasonable use.

It must be used in professional environments and any st aff using the machine must

have experience in the sector and have read and understood this manual.

1.7– Uses not allowed

1.7.1 - Safety prescriptions

The following points must be respected:

1 never touch the metal parts of the machine with wet or damp hands;

2 do not pull the power supply cable or the appliance itself, to disconnect the plug

from the current;

3 do not allow the packaging machine to be used by chi ldr en or untrained staff;.

4 the el ectr ic safet y of thi s machi ne is onl y assur ed when t he same i s corr ectly

connected to an efficient earth plant, as envisioned by the electric Safety

Standards in force; this fundamental requirement must be verified. If in doubt,

request an accurate control of the system by professionally qualified staff; the

Manufacturer cannot be considered responsible for any damage caused by

the failure to earth the system;

5 in th e event o f possi ble damage to th e earth p r otection, t he machine must be put

out of service, in order to prevent undesired and/or involuntary activation;

Page 8

8

6 always use protection fuses that are in compliance with the Safety Standards in

force, with the correct value and suitable mechanical features;

7 avoid the us e of repa ired fuses and the crea tion of short circuits betw een the

terminals on the fuse holders;

8 the packaging machine power supply cable must never be replaced by t he user;

contact the machine manufacturer exclu sively in the event of damage t o the

cable, or for its replacement;

9 keep the cable away from hot parts;

10 always switch the machine off and disconnect it from the mains electricity

before starting any global clearing procedure or washing operation;

11 clean the machine coverings, panels and commands using soft, dry cloths

dampened i n a weak solution of detergent or alcohol;

1.7.2 - Lighting

The place of installation of the machine must have sufficient natural and artificial

lighting i n compliance with the Standards in force in the co untry of installation of

the packagi ng machine.

In all cases, the lighting must be uniform and guarantee good visibility in all parts

of the packaging machine and must not create dangerous reflections.

The lighting must allow the control panels to be read correctly and clearly identify

the emergen cy butt ons.

1.8 - Company details

An exact description of the "Model", the "Serial number" and the "Year of

Manufacture" of the m achine will facilitate quick and effective response by our after

-sal es assi stanc e. I t is advised to indica te the model of t he machine and the serial

number every time the after-sales service is contacted.

Identify the plate data r epresen ted in fig. 1.8.1.

We suggest you write the data of your machine in the box below as a

reminder.

Machine Model………………………..

Serial number……………………………………

Year of constr uction ………………………… …...

Type………………………………………………..

Fig. 1.8.1

E

A = Machine model

B = Power supply

C = Motor power

D = Motor frequency Hz

E = Weight

F = Amperage

G = Year of construction

H = Serial N°

I = Manufacturer

L = Bar code

A

B C

D E

F G

H

I

L

13

English

Before carrying out any check that leads to the removal of some item s, the plug

must be removed from the mains electricity.

3.3.1 - Disposal of the packaging

The packaging materials such as cardboard, nylon and wood ar e products similar

to solid urban waste. They can therefore be disposed of freely.

Nylon is a pollutant, which produces toxic fumes if burned.

Do not burn and disperse in the environm ent , but di spose accordi ng to th e Laws in

force.

If the machine is in a countr y where t here ar e parti cular regula tions, dispose of th e

packaging in compliance with that described by the Standards in force.

3.4 - Connections

Before start-up, check the oil level

via the control window present

on the pump.

Before connecting the packaging machine, make sure that the plate data

correspond with that of the mains electricity.

The plate is on the rea r of th e m achin e.

When the level has been checked and everything closed, connect the plug to the

230V socket.

In the event of incompatibility between the socket and plug, have the socket

replaced with a suitable one by professional ly qualified staff.

In particular, the latter must check that the section of the cables is suitable for the

input power of the machine. In general, the use of adapters, multiple socket outlets

and/or extensions is not recommended.

Whenever their use is indispensible, only simple or multiple adapters and

extensions must be used that are in compliance with Safety Standards in force;

however p a y i n g at t ent i o n not t o exc e ed t he c a p aci t y li m it i n ter m s of c ur r ent value,

and the maximum power value marked on the multiple outlet.

MIN

MAX

Fig. 3.4.1

OIL FILLING

OIL DISCHARGE

Page 9

12

3 Inspection, transport, delivery and installation

3.1 - Inspection

The machine you own h as been i nspected at ou r establishment in order to c er tify

correct operation and ad justment.

3.2 - Delivery and handling the machine

All material delivered has been accurately controlled before consignment to the

carrier.

Unless agreed differently with the Custom er or for pa r ticul arly onerous t ransport,

the machine is wrapped i n nylon and cardboard.

The packaging dimensi ons are given in fig. 3.2.1

On rec eipt of the machine, check t he integ rity of the packaging .

If the packaging is damaged, sign the documents for receipt with the following

note:

"Accepted subject to checking..." and the reason.

Open t he packaging, and in t he pres ence of machine comp onents t hat are r eally

damaged, make a claim to the carrier within three days from the date indicated on

the documents.

3.3 - Installation

After having removed the packaging, check t he integrity of the machine.

In particular, check that the machine is integral and without visible damage, which

could have been caused during transport.

If in doubt, do not use the machine and contact the Manufacturer.

Place

Position the packaging machine place with a low percentage of humidity and away

from heat sources.

A B C

Gross

weight

mm mm mm Kg

25 420 660 310 32

30 600 740 610 46

40

600 740 610 51,5

Fig. 3.2.1

9

English

1.8.1 - Warning and danger plates (Fig. 1.8.2)

2 Technical features

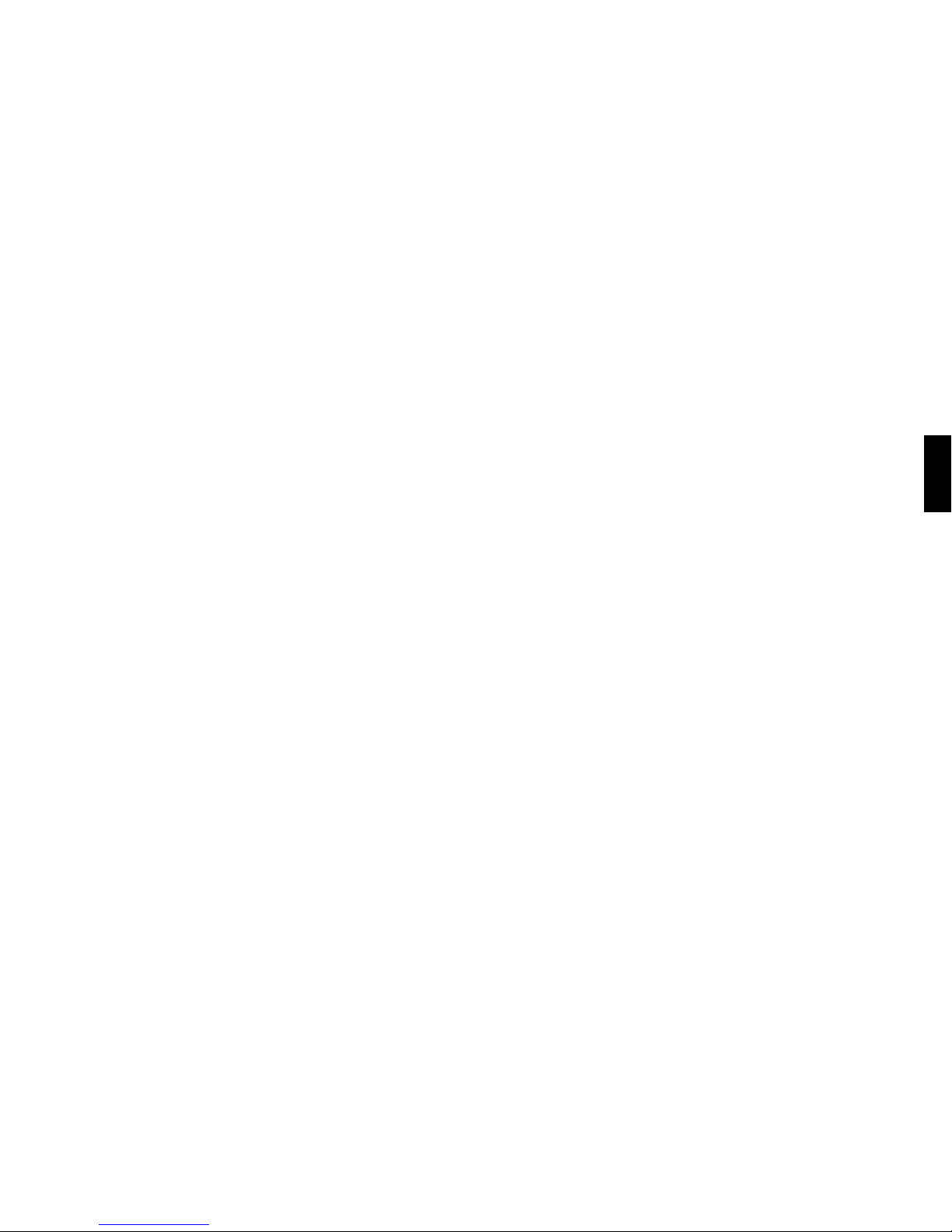

2.1 - Main parts

To facilitate comprehension of the manual, the main mach ine components are

listed below and represented in fig.

2.1.1.

A

B

C

Fig. 1.8.2

Fig. 2.1.1

1. Control panel

2. Cavity

3. Power supply cable

4. Master switch

5. Transparent Plexiglas cover

6. Silicon counter-bar

7. Sealing gasket

8. Suction pipe for vacuum

9. Sealing bar

A

B

C

1

2

3

4

5

6

7

8

9

Page 10

10

2.2 - Technical features

2.3 - Dimensions and weight of the machine

Power

Kw

Vacuum

pump

Sealing

bar

Cavity

dimensions

Power supply Oil tank capacity

0,1 Kw 4 mc/h 260 mm 270x350 h75 mm 230V/50Hz ml 60

25

30

0,1 Kw 4 mc/h 310 mm 336x378 h75 mm 230V/50Hz ml 60

40

0,35 Kw 8 mc/h 410 mm 426x438 h75 mm 230V/50Hz ml 250

A B C D E1 E2 F G Net weight

mm mm mm mm mm mm mm mm Kg

25 320 560 685 257 340 263 264 708 30

30 406 565 685 315 335 246 336 731 37

40

494 637 755 315 395 308 426 810 42,5

Fig. 2.3.1

11

English

Wire map legend

1 = Black

2 = Red

3 = White

4 = Orange

5 = Gray

6 = Blue

Fig. 2.4.1

2.4 - Wiring diagram

Loading...

Loading...