Page 1

1 February 2011 / Change 4

Aircraft Serial No: ________

Author: Ing. M. Zahálka, TL-Ultralight, s.r.o.

This Pilot Operating Handbook must remain in the aircraft and be accessible to the pilot all times.

Page 2

(THIS PAGE BLANK)

Page 3

Pilot Operating Handbook Section 0

TL3000 Sirius Introduction

Dear Sirius Owner:

Congratulations on the purchase of your TL-3000 Sirius which is the result

of many years of development by our company. We strive to be the leading

designer of quality aircraft worldwide. You will find your new Sirius aircraft very

enjoyable, extremely economical, and easy to maintain.

The Sirius is the ideal Light Sport Airplane. It is fast, economical, pleasing to the

eye, and user friendly. We at TL Aircraft are certain that your Sirius will give you

hours and hours of leisure flying and enjoyment. With this Pilot Operating

Handbook (POH), we hope to help inform you about the design and operation of

your aircraft.

This Pilot Operating Handbook is to be used as a guide to assist the pilot to safely

use the Sirius aircraft. The contents are not intended to be a final authority and

although proofed extensively they are still not considered error free. Therefore, the

pilot in command is the final authority for the safe operation of the aircraft. Should

there be any questions or errors found in reading this handbook please contact us

immediately and we will issue a clarification.

I believe that your airplane will be very satisfying and provide you with years of

pure enjoyment. Please study and become familiar with this POH manual and the

respective manuals for the propeller and rescue system.

Thank you again for your business. We look forward to a continuing satisfied

customer relationship. Feel free to contact us if you have any questions or

comments regarding your Sirius aircraft.

I wish you a lot of joy flying your new TL-3000 Sirius.

In Hradec Králové 1st January 2010.

TL Ultralight L.T.D.

(sig)

Jiri Tlusty

1 Feb 11 – Chg 4 i

Copyright © 2011 Reproduction of this document or any of its parts is forbidden

Page 4

Pilot Operating Handbook Section 0

TL3000 Sirius Introduction

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

TL-ULTRALIGHT s.r.o.

Airport, building 84

503 41 Hradec Kralove

tel/fax 495213378

tel 495.218.910.521.1753

info@tl-ultralight.cz

www.tl-ultralight.cz

1 Feb 11 – Chg 4 ii

Copyright © 2011 Reproduction of this document or any of its parts is forbidden

Page 5

Pilot Operating Handbook Section 0

TL3000 Sirius Introduction

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

SECTION INDEX

GENERAL INFORMATION .............................................. 1

OPERATING LIMITATIONS ............................................ 2

EMERGENCY PROCEDURES ........................................ 3

NORMAL PROCEDURES ............................................... 4

PERFORMANCE ............................................................. 5

WEIGHT & BALANCE INFORMATION ........................... 6

AIRPLANE and SYSTEMS DESCRIPTION ..................... 7

REQUIRED PLACARDS & MARKINGS .......................... 8

AIRCRAFT HANDLING, SERVICE & MAINTENANCE ... 9

SUPPLEMENTARY INFORMATION & APPENDIX A ..... 10

1 Feb 11 – Chg 4 iii

Copyright © 2011 Reproduction of this document or any of its parts is forbidden

Page 6

Pilot Operating Handbook Section 0

NOTE

CAUTION

WARNING

TL3000 Sirius Introduction

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

NOTES, CAUTIONS, AND WARNINGS

Throughout this manual, small boxes are inserted referencing a Note, Caution,

or Warning. These are items which require particularly close attention for

special conditions or procedures.

This text box emphasizes specific operating conditions, steps in a

procedure, helpful hints or useful advice.

This text box represents danger to equipment or operation. By not

observing the cautions, the result could be the destruction of

equipment and possibly personal danger and injury.

This text box represents a hazardous situation. Warnings are

used to call attention to operating procedures or conditions

which, if not strictly observed, may result in personal injury or

death.

Every owner, pilot, operator, or user of the Sirius should become familiar with the

entire contents of this Pilot Operating Handbook (POH). The text consists of

flight and maintenance information combined with training instruction, Section 10,

in accordance with ASTM 2245 and is required to be on board the plane and

available to the pilot during all flights. It also incorporates only partial information

about related systems from Rotax®, the engine manufacturer, Woodcomp® or

DUC® ,the propeller suppliers, and Galaxy

system. Please refer to the latest edition of those manufacturer manuals for

specific and complete detailed operation of each aircraft system.

®,

the installed aircraft parachute

1 Feb 11 – Chg 4 iv

Copyright © 2011 Reproduction of this document or any of its parts is forbidden

Page 7

Pilot Operating Handbook Section 0

CAUTION

TL3000 Sirius Introduction

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

This flight and operational manual produced by TL Ultralight is designed to

introduce TL -3000 SIRIUS aircraft to its operator. It provides the basic usage

information and operational procedures ensuring the most effective aircraft

utilization by the operator.

Each holder of this flight and operational manual and/or its parts is obliged to

maintain it in updated state by implementation of amendments, revisions

and changes as published in the bulletin through the following web-page:

http:/sirius.aero/owners/downloads

Owners are encouraged to keep their address and contact information

current in order to receive the latest continued airworthiness program

information. See the contact information below to email, fax, call or mail

your contact data so that you can be informed and kept current on the safe

operation of your aircraft.

This flight and operational manual is divided by topics into several sections

that are split into paragraphs according to the significance and importance of

their subject matter. Page replacement, amendment or handwriting revision,

must all be recorded on the ‗List of Changes‘ log page by recording the

change or amendment serial number, number of the published change or

page changed or amended, new page or change publishing date, and

implementation date and signature.

This operational manual is established in such a way that any revision or

amendment execution is only possible by replacing or adding the

appropriate pages and discarding the obsolete pages. Therefore, it is

necessary that all manual holders pay increased attention to recording all

changes and amendments and their implementing instructions.

1 Feb 11 – Chg 4 v

Copyright © 2011 Reproduction of this document or any of its parts is forbidden

The Sirius meets the standard specification Design and Performance

(D&P) established by ASTM International, Inc, (ASTM) Document F

2245, and it is therefore restricted by that guideline. The aircraft does

not comply with any FAA Part 22, or 23 certification processes.

Compliance with regulations placed upon the airplane category

should be strictly adhered to by the pilot in command (PIC)

Page 8

Pilot Operating Handbook Section 0

CAUTION

NOTE

TL3000 Sirius Introduction

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

The items discussed in each of the amplified procedures are

intended to comply with ASTM airplane Flight Training Supplement

(FTS) in lieu of a separate manual. Additional flight training

information is available in Section 10 of this manual. None of these

items or procedures is intended to replace properly qualified ground

or in-flight instruction by an FAA certified flight instructor (CFI).

This POH manual is valid only if the PIC complies with any changes

that may be issued at a later date. Any pages affected by a change

should be removed and replaced with the current effective pages

immediately.

The aircraft manufacturer issues notices of information and mandatory

bulletins to ensure continued airworthiness in accordance with ASTM

2295 for the TL-3000 Sirius Special Light Sport Aircraft (SLSA). The

notices are provided to all known owners of the Sirius aircraft.

All bulletins may be downloaded from:

http://www.sirius.aero/owners/downloads

To receive updates and bulletins on the safe continued operation of

your aircraft please contact us at the address below. If this manual

is found not to be current, revisions missing, or pages removed

contact our USA location in accordance with the ASTM / TL

Continued Airworthiness Service program for replacements.

TL Ultralight, s.r.o.

Continued Airworthiness Service

8222 Remount Road

KORK Municipal Airport

North Little Rock, AR 72118

Info1@sportair.aero

www.sirius.aero

Phone: 501.228.7777

Fax: 501.227.8888

1 Feb 11 – Chg 4 vi

Copyright © 2011 Reproduction of this document or any of its parts is forbidden

Page 9

Pilot Operating Handbook Section 0

TL3000 Sirius Introduction

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

LIST OF EFFECTIVE PAGES

Page ...................... Date

Cover .............. 02-01-11

i ....................... 02-01-11

ii ...................... 02-01-11

iii ..................... 02-01-11

iv ..................... 02-01-11

v ...................... 02-01-11

vi ..................... 02-01-11

vii .................... 02-01-11

viii .................... 02-01-11

1-1 ................... 02-01-11

1-2(blank) ........ 02-01-11

1-3 ................... 02-01-11

1-4 ................... 02-01-11

1-5 ................... 09-31-10

1-6 ................... 02-01-11

1-7 ................... 02-01-11

1-8 ................... 02-01-11

1-9 ................... 02-01-11

1-10 ................. 02-01-11

1-11 ................. 02-01-11

1-12 ................. 02-01-11

1-13 ................. 02-01-11

1-14 ................. 02-01-11

1-15 ................. 02-01-11

1-16 ................. 02-01-11

1-17 ................. 02-01-11

1-18 ................. 02-01-11

1-19 ................. 02-01-11

1-20 ................. 02-01-11

2-1 ................... 02-01-11

2-2 (blank) ....... 02-01-11

2-3 ................... 02-01-11

2-4 ................... 02-01-11

2-5 ................... 02-01-11

2-6 ................... 02-01-11

2-7 ................... 02-01-11

2-8 ................... 02-01-11

2-9 ................... 02-01-11

2-10 ................. 02-01-11

2-11 ................. 02-01-11

2-12 ................. 02-01-11

3-1 ................... 02-01-11

3-2 (blank) ....... 02-01-11

3-3 ................... 02-01-11

3-4 ................... 02-01-11

3-5 ................... 02-01-11

3-6 ................... 02-01-11

3-7 ................... 02-01-11

3-8 ................... 02-01-11

3-9 ................... 02-01-11

3-10 ................. 02-01-11

3-11 ................. 02-01-11

3-12 ................. 02-01-11

Page ...................... Date

3-13 ................. 02-01-11

3-14 ................. 02-01-11

3-15 ................. 02-01-11

3-16 ................. 02-01-11

3-17 ................. 02-01-11

3-18 ................. 02-01-11

3-19 ................. 02-01-11

3-20 ................. 02-01-11

3-21 ................. 02-01-11

3-22 ................. 02-01-11

4-1 ................... 02-01-11

4-2 (blank) ....... 02-01-11

4-3 ................... 02-01-11

4-4 ................... 02-01-11

4-5 ................... 02-01-11

4-6 ................... 02-01-11

4-7 ................... 02-01-11

4-8 ................... 02-01-11

4-9 ................... 02-01-11

4-10 ................. 02-01-11

4-11 ................. 02-01-11

4-12 ................. 02-01-11

4-13 ................. 02-01-11

4-14 ................. 02-01-11

4-15 ................. 02-01-11

4-16 ................. 02-01-11

4-17 ................. 02-01-11

4-18 ................. 02-01-11

4-19 ................. 02-01-11

4-20 ................. 02-01-11

4-21 ................. 02-01-11

4-22 ................. 02-01-11

4-23 ................. 02-01-11

4-24 ................. 02-01-11

4-25 ................. 02-01-11

4-26 ................. 02-01-11

4-27 ................ 02-01-11

4-28 ................. 02-01-11

4-29 ................ 02-01-11

4-30 (blank) ..... 02-01-11

5-1 ................... 02-01-11

5-2 (blank) ....... 02-01-11

5-3 ................... 02-01-11

5-4 ................... 02-01-11

5-5 ................... 02-01-11

5-6 ................... 02-01-11

5-7 ................... 02-01-11

5-8 ................... 02-01-11

5-9 ................... 02-01-11

5-10 ................. 02-01-11

5-11 ................. 02-01-11

5-12 (blank) ..... 02-01-11

6-1 ................... 02-01-11

Page .................... Date

6-2 (blank) ....... 02-01-11

6-3 ................... 02-01-11

6-4 ................... 02-01-11

6-5 ................... 02-01-11

6-6 ................... 02-01-11

6-7 ................... 02-01-11

6-8 ................... 02-01-11

6-9 ................... 02-01-11

6-10 ................. 02-01-11

6-11 ................. 02-01-11

6-12 ................. 02-01-11

6-13 ................. 02-01-11

6-14 ................. 02-01-11

6-15 ................. 02-01-11

6-16 ................. 02-01-11

7-1 ................... 02-01-11

7-2 (blank) ....... 02-01-11

7-3 ................... 02-01-11

7-4 ................... 02-01-11

7-5 ................... 02-01-11

7-6 ................... 02-01-11

7-7 ................... 02-01-11

7-8 ................... 02-01-11

7-9 ................... 02-01-11

7-10 ................. 02-01-11

7-11 ................. 02-01-11

7-12 ................. 02-01-11

7-13 ................. 02-01-11

7-14 ................. 02-01-11

7-15 ................. 02-01-11

7-16 ................. 02-01-11

7-17 ................. 02-01-11

7-18 ................. 02-01-11

7-19 ................. 02-01-11

7-20 ................. 02-01-11

8-1 ................... 02-01-11

8-2 (blank) ....... 02-01-11

8-3 ................... 02-01-11

8-4 ................... 02-01-11

8-5 ................... 02-01-11

8-6 ................... 02-01-11

8-7 ................... 02-01-11

8-8 ................... 02-01-11

8-9 ................... 02-01-11

8-10 ................. 02-01-11

9-1 ................... 02-01-11

9-2 (blank) ....... 02-01-11

9-3 ................... 02-01-11

9-4 ................... 02-01-11

9-5 ................... 02-01-11

9-6 ................... 02-01-11

9-7 ................... 02-01-11

1 Feb 11 – Chg 4 vii

Copyright © 2011 Reproduction of this document or any of its parts is forbidden

Page 10

Pilot Operating Handbook Section 0

Nr.

Date

Revised

Pages

Type of Revision

Posted

By

0

1 May 2009

None

Original Issue

N/A

1

31 Mar 2010

All

Re-issue

N/A

2

31 Aug 2010

All

Re-issue

N/A

3

31 Oct 2010

All

Re-issue

N/A

4

1 Feb 2011

All

Re-issue

TL3000 Sirius Introduction

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

Page ...................... Date

9-8 ................... 02-01-11

9-9 ................... 02-01-11

9-10 ................. 02-01-11

9-11 ................. 02-01-11

9-12 ................. 02-01-11

9-13 ................. 02-01-11

9-14 ................. 02-01-11

9-15 ................. 02-01-11

9-16 ................. 02-01-11

9-17 ................. 02-01-11

9-18 ................. 02-01-11

9-19 ................. 02-01-11

9-20 ................. 02-01-11

9-21 ................. 02-01-11

9-22 ................. 02-01-11

9-23 ................. 02-01-11

9-24 ................. 02-01-11

9-25 ................. 02-01-11

9-26 ................. 02-01-11

9-27 ................. 02-01-11

Page ...................... Date

9-28 ................. 02-01-11

9-29 ................. 02-01-11

9-30 ................. 02-01-11

9-31 ................. 02-01-11

9-32 ................. 02-01-11

9-33 ................. 02-01-11

9-34 ................. 02-01-11

10-1 ................. 02-01-11

10-2 (blank) ..... 02-01-11

10-3 ................. 02-01-11

10-4 ................. 02-01-11

10-5 ................. 09-31-10

10-6 ................. 02-01-11

10-7 ................. 02-01-11

10-8 ................. 02-01-11

10-9 ................. 02-01-11

10-10 ............... 02-01-11

10-11 ............... 02-01-11

10-12 (blank) ... 02-01-11

Page ............... Date

APPENDIX A

10-13 ............... 02-01-11

10-14 ............... 02-01-11

10-15 ............... 02-01-11

10-16 ............... 02-01-11

10-17 ............... 02-01-11

10-18 ............... 02-01-11

10-19 ............... 02-01-

10-20 ............... 02-01-11

10-21 ............... 02-01-11

10-22 ............... 02-01-11

10-23 ............... 02-01-11

10-24 .............. 02-01-11

List of changes

1 Feb 11 – Chg 4 viii

Copyright © 2011 Reproduction of this document or any of its parts is forbidden

Page 11

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

SECTION 1

GENERAL INFORMATION

TABLE OF CONTENTS PAGE

INTRODUCTION ............................................................................................... 1-3

AIRCRAFT ......................................................................................................... 1-4

3D TRANSPARENT DRAWING ........................................................................ 1-3

TOP VIEW DRAWING ....................................................................................... 1-5

SIDE VIEW DRAWING ...................................................................................... 1-6

FRONT / REAR VIEW DRAWING ..................................................................... 1-5

BASIC DIMENSIONS ........................................................................................ 1-7

AIRPLANE WEIGHTS ....................................................................................... 1-8

CABIN / ENTRY DIMENSIONS ......................................................................... 1-8

BAGGAGE SPACE AND ENTRY DIMENSIONS .............................................. 1-8

PROPELLEORS ................................................................................................ 1-8

ENGINE ............................................................................................................. 1-8

PARACHUTE SYSTEM ..................................................................................... 1-9

FUEL .................................................................................................................. 1-9

OIL ................................................................................................................... 1-10

BAGGAGE ....................................................................................................... 1-10

SYMBOLS, ABBREVIATIONS, AND TERMINOLOGY .................................... 1-11

GENERAL AIRSPEED TERMINOLOGY ......................................................... 1-11

METEOROLOGICAL TERMINOLOGY ............................................................ 1-12

AIRPLANE PERFORMANCE AND WEIGHT TERMINOLOGY ....................... 1-12

ABBREVIATIONS ............................................................................................ 1-16

V SPEED DEFINITIONS .................................................................................. 1-20

1 Feb 11 – Ch 4 1-1

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 12

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

(THIS PAGE BLANK)

1 Feb 11 – Ch 4 1-2

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 13

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

INTRODUCTION

This manual is organized to conform to the ASTM F2746 Standard Specification for

Pilot‘s Operating Handbook (POH). A copy of this POH is issued with each

aircraft and must remain in the aircraft and available to the pilot during flight.

All pilots of this aircraft must read and understand the operation and limitations of

this aircraft design. As such, many items are added as narrative information to

assist them in clearly understanding what is required and in most cases help in

achieving the necessary performance. The POH does not intend to and cannot

replace properly qualified ground or in-flight instruction by an FAA certified flight

instructor. (CFI)

Maintenance and operation of major components, engine, and aircraft parachute

system, propeller, avionics or other installed equipment is provided in the

appropriate manufacturer manuals which are included with the aircraft. The

appropriate manufacturer‘s manual takes precedence over any conflict in this POH.

The Sirius has a high cruising speed and may traverse very different weather

conditions during a single flight. The pilot is responsible for the safe flight of the

aircraft and should be prepared to avoid any meteorological conditions which will

endanger the occupants, the aircraft or both.

Section 1 provides general information and descriptive figures relevant to the aircraft

and the engine. It also contains certain definitions of aeronautical terms, ASTM

Design and Performance standards and commonly used abbreviations.

1 Feb 11 – Ch 4 1-3

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 14

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

AIRCRAFT

The TL3000 Sirius is a full three axis, high wing, two place, side-by-side seating, tricycle

landing gear aircraft with a toe brake steerable nose wheel. The primary aircraft structure

is carbon fiber and fiberglass UV resistant reinforced laminate with an inner foam core

creating a ‗sandwich‘ layered construction between each ply.

Various options may also be installed; therefore your aircraft may vary from the

descriptions in this manual. Please check with the TL Continuing Airworthiness Center if

you have any specific questions not addressed here.

Front View

Fig. 1-1

1 Feb 11 – Ch 4 1-4

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 15

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

Side View & Top View

Fig. 1-2

1 Feb 11 – Ch 4 1-5

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 16

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

3D View

Fig. 1-3

1 Feb 11 – Ch 4 1-6

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 17

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

BASIC DIMENSIONS

Length .......................................................................... 22.15 ft.

Height .......................................................................... 7.38 ft. (at tail)

Cabin width .................................................................. 45 in.

Nose to Main wheel base……………………………… .. 5.02 ft.

Main wheel spacing…………………………… .............. 7.12 ft.

Wings

Area ............................................................................. 121.23 ft

2,

Span……………………………….................................. 30.84 ft.

Aspect Ratio……………………………………………… 7.92

Root Chord……………………………………………… .. 4.27 ft.

Tip Chord………………………………………………… . 2.95 ft.

Loading…………………………………………………… . 10.89 lb/sf.

Ailerons

Area ............................................................................. 10.98 ft2

Span…………………………………………………… ..... 12.28 ft.

Deflection up…………………………………………… ... 11.50 deg.

Deflection down………………………………………… .. 7.60 deg.

Flaps

Area ............................................................................. 14.22 ft

2

Span……………………………………………… ............ 13.60 ft.

Deflection takeoff……………………………………… .... 10.00 deg.

Deflection half…………………………………………… . 28.00 deg.

Deflection landing……………………………………… ... 45.00 deg.

Elevators

Area….………………………………………………… ..... 21.64 ft2

Span……………………………………………………… . 9.84 ft.

Deflection up………………………………………… ....... 16.70 deg.

Deflection down……………………………………… ...... 8.50 deg.

Rudder

Area…………………………………………………… ...... 12.81 ft2

Deflection left-right…………………………………… ..... 20-20 deg.

General

Glide ratio .................................................................... 13:1

Tire pressure…………………………………………… ... 30 psi

Brakes, left-right-park………………………………… .... Hydraulic disk, DOT 3 or 4

1 Feb 11 – Ch 4 1-7

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 18

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

AIRPLANE WEIGHTS

Maximum Ramp Weight: 1326 Lbs

Standard Empty Weight: 760 Lbs

Maximum Useful Load: 540 Lbs

Maximum Takeoff or Landing Weight: 1320 Lbs (1430 seaplane)

Maximum Baggage Weight: 75 Lbs. (see limitations)

Maximum Calculated Structural Weight: 1320/1430 Lbs

CABIN / ENTRY DIMENSIONS

Door width: 37―

Door height: 30‖

Head room (from seat bottom to ceiling): 38.5‖

Leg room (from seat back to rudder pedals): 49.5‖

Cabin width: 45‖

Seat width: 19-22‖

Note: Cabin doors are trapezoid not rectangles and are measured at entry.

BAGGAGE SPACE AND ENTRY DIMENSIONS

Maximum Compartment Width: 41‖

Maximum Compartment Height: 32‖

Maximum Compartment Length: 20.5‖

Minimum Compartment Width: 36‖

Minimum Compartment Height: 21.5‖

Entry Width: 37.5‖

Entry Height: 18‖

Note: Baggage area narrows aft from a cube shape to above sizes. Aft baggage shelf is

sloped, and not included in the above area or dimensions.

PROPELLER

Propeller Manufacturer: Woodcomp®, DUC, Sensenich.

(See Master Equipment List (MEL) latest date)

Number of Blades: 2/3

Propeller Type: Fixed-pitch, ground-adjustable

ENGINE

Number of Engines: 1

Engine Manufacturer: Rotax® G.m.b.H. Aircraft Engines

Engine Model Number: 900 Series, Standard Equipment

(See Master Equipment List (MEL) latest date)

Engine Type: Normally-aspirated, liquid/air-cooled, dry sump, gear-reduced

drive, dual carburetor-equipped, four-cylinder, four-stroke,

electronic dual ignition, horizontally-opposed engine.

1 Feb 11 – Ch 4 1-8

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 19

Pilot Operating Handbook Section 1

NOTE

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

GALAXY ROCKET PARACHUTE SYSTEM (GRS)

The rocket deployed aircraft parachute system is standard equipment. It is activated

inside the cockpit by pulling a red ―T‖ handle located on the lower right pilot side position.

The system is secured by a brass safety pin attached to an embroidered red safety tag.

Refer to the Galaxy operational manual included with the aircraft for detailed information.

FUEL

The use of Premium Grade automobile fuel is approved for Rotax 900 series

engines. See the Rotax Operator‘s manual section 10 for more data.

An Antiknock Index (AKI) is the usual octane rating for the US. Rotax specifies a

minimum AKI of 91 for the 912ULS engine. AKI is an average of the RON and the

MON rating method where: AKI = (RON+MON) / 2.

RON is common in Europe and sometimes causes confusion for owners who

operate European engines. 91 RON is approximately 87 AKI (US Regular auto fuel)

and 95 RON is approximately 91 AK (US Premium auto fuel).

Rotax Service Instruction SI-912-016 (or revised latest revised edition) details all

specifications for Rotax engine fluids. A current copy is available at the

airworthiness center web site:

www.sirius.aero/owners/downloads.

Approved Fuel Grade:

91 AKI Unleaded Automobile Fuel, ―Auto gas‖ (Amber color).

Approved Alternate Fuel Grade:

100LL Aviation Fuel, ―Avgas‖ (Blue color).

Total Fuel Capacity:

34.2 US Gallons, in two wing tanks.

Total Unusable Fuel:

2 US Gallons, total fuel system

100LL Avgas is an acceptable alternate fuel if 91 octane unleaded

auto fuel is not available. Due to the high lead content, the use of

100LL Avgas should be less than 30% of engine time without

increased engine maintenance. See the latest Rotax engine

operational supplement for more detailed fuel specifications and

information.

1 Feb 11 – Ch 4 1-9

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 20

Pilot Operating Handbook Section 1

NOTE

CAUTION

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

Total unusable fuel is the minimum amount of fuel an aircraft may

have in its gas tanks before engine fuel starvation. Unusable fuel, as

its name implies, cannot be consumed by the engine for power and

thus cannot be relied upon for flight, but is included in the aircraft

empty weight.

During refueling of the wing tanks, a fuel spill may cause crazing of

the aircraft windows. Flush immediately with clear water but do not rub

the surface to remove the fuel. If the tank is full to the brim it will

eliminate all fuel expansion area. As fuel warms it expands and will

be forced out of the fuel vent line, spill on to the parking area and

cause a fire hazard.

OIL

Oil Capacity: 3.7 Quarts (Empty system)

Oil Filter: Rotax part number 825 701, (or latest Rotax part number).

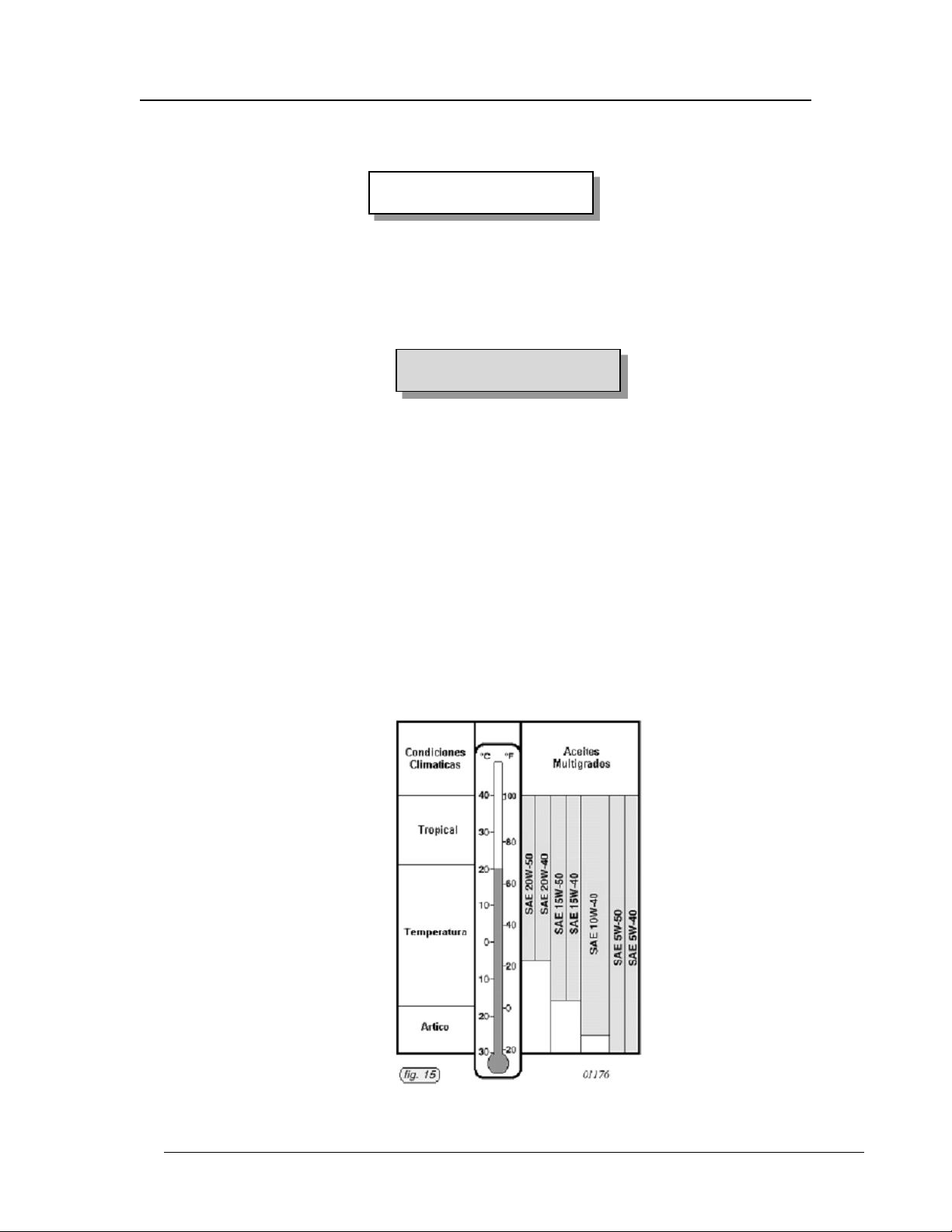

Oil Specifications: Vary depending on the engine operation and may vary from one

aircraft to another depending on the operation, environment and fuel type. Refer to

Figure 1-5 below and the latest Rotax engine oil service, fluid specification and

instructions.

Oil Grade and Temperature Conditions

1 Feb 11 – Ch 4 1-10

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 21

Pilot Operating Handbook Section 1

CAUTION

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

Fig. 1-5

Oil level is checked immediately after engine shutdown for best indication. An oil

change will not require 3.7 quarts as some oil remains in the system for pre oiling and

is not drained. Do not over fill.

No substitutions allowed!

Normal Rotax 900 series engine oil pressure may force the

oil to bypass the filter of non-OEM filters. Rotax Oil Filter:

part number 825 701, or latest version must be used,

BAGGAGE

Baggage is stored behind the seats .The baggage compartment can hold

a maximum of 75 Lbs and is further limited by the maximum aft CG and

structural loading for the aircraft. No concentrated loads are allowed. A

weight and balance calculation should be completed by the PIC prior to

each flight.

SYMBOLS, ABBREVIATIONS, AND TERMINOLOGY

GENERAL AIRSPEED TERMINOLOGY

Best Angle-of-Climb Speed (VX): The speed which results in the greatest gain of

altitude in a given horizontal distance.

Best Rate-of-Climb Speed (VY): The speed which results in the greatest gain in

altitude in a given time.

Best Glide Speed (VG): The speed that will result in maximum glide distance.

Design Cruise Speed (VC): The optimal cruise speed.

Knots Calibrated Airspeed (KCAS): Indicated airspeed corrected for position and

instrument error and expressed in knots. KCAS is equal to KTAS in standard

conditions at sea level.

Knots Indicated Airspeed (KIAS): The speed shown on the airspeed indicator

and is expressed in knots. (Decreases approximately 2kt/1000‘ of ALT.)

Knots True Airspeed (KTAS): KCAS corrected for non-standard temperature and

pressure and is expressed in knots.

1 Feb 11 – Ch 4 1-11

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 22

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

Maneuvering Speed (VA): The maximum speed at which you may use abrupt full

control travel without exceeding structural limitations of the aircraft or control

systems.

Maximum Flap Extended Speed (VFE): The highest speed permissible with wing

flaps in a prescribed extended position.

Maximum Structural Cruising Speed (VNO): The speed that should not be

exceeded except in smooth air, and then only with caution.

Maximum Sustained Speed in Level Flight (VH): The highest speed that can be

attained in level flight at sea level under standard conditions while the engine is

operating at the manufacturer designated maximum continuous power setting.

Never Exceed Speed (VNE): The speed limit that may never be exceeded under

any conditions at any time due to structural limitations of the airframe or control

systems.

Stalling Speed (VS): The minimum steady flight speed at which the airplane is

controllable without flaps.

Stalling Speed (VS0): The minimum steady flight speed with power off and full

flaps.

METEOROLOGICAL TERMINOLOGY

Indicated Altitude: The altitude displayed on the altimeter.

Mean Sea Level (MSL): The average level of the ocean‘s surface – the level

halfway between mean high and low tides, used as a standard reference for

expressing altitude.

Outside Air Temperature (OAT): The free air static temperature, expressed in

either degrees Celsius (C) or degrees Fahrenheit (F).

Pressure Altitude: The altitude displayed on the altimeter on a standard day when

the altimeter's barometric scale has been set to 29.92 inches of mercury (1013 mb).

Standard Temperature: 15°C (59°F) at sea level pressure altitude. (Decreases

approximately 2°C (3.5°F) for each 1000 feet increase of altitude.)

True Altitude: The true height above mean sea level (MSL). True altitude is

indicated altitude corrected for nonstandard atmospheric pressure.

1 Feb 11 – Ch 4 1-12

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 23

Pilot Operating Handbook Section 1

NOTE

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

AIRPLANE PERFORMANCE AND WEIGHT TERMINOLOGY

Arm: The horizontal distance expressed in inches from the reference datum plane

to the center of gravity (CG) of an item or location.

Units of measurements and weights must be consistent for each set

of calculations and in the same system of units, i.e., pounds and

inches, or kilograms and centimeters.

Ballast: A specific amount of weight attached in a specific location, which can be

temporarily or permanently installed in an aircraft, to help bring its CG within the

required limits. If temporary ballast must be used for certain operations, the exact

amount and its location must be placarded on the instrument panel within clear view

of the pilot. The use of Ballast increases Empty Weight and reduces Useful Load.

Basic Empty Weight: The standard empty weight plus the weight of any

additionally installed or optional equipment.

Empty Weight Center of Gravity: The CG of an aircraft in its basic empty weight

condition, and is an essential part of the weight and balance record.

Brake Horsepower: The power developed by the engine expressed in

horsepower and measured by an instrument resistant (brake) device.

Center of Gravity (CG): A point along an aircraft‘s longitudinal axis at which all the

loads and forces are perfectly concentrated and balanced. It is computed by

dividing the total moment by the total weight of the airplane. Its distance from the

reference datum is found by dividing the total moment by the total weight of the

airplane.

(Total Moment / Total Weight = Center of Gravity)

Center of Gravity Arm: The arm (distance) from data plane obtained by adding

the airplane's individual moments and dividing the sum by the total weight.

Center of Gravity Limits are the extreme forward and aft CG locations (limits)

within which the airplane must be operated at any given weight.

1 Feb 11 – Ch 4 1-13

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 24

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

Center of Gravity Range: The horizontal distance, along an aircraft‘s longitudinal

axis, within which an aircraft has been found to be fully maneuverable at all

specified design speeds, weights and loading configurations.

Datum: (datum plane) A convenient vertical reference plane along the longitudinal

axis of an aircraft from which all horizontal measurements are taken, the forward tip

of the propeller spinner is the datum for the Sirius.

Demonstrated Crosswind Velocity: The velocity of the crosswind component at

which adequate control of the airplane was demonstrated during takeoff and

landing tests. The value is not considered to be a maximum limit.

Empty Weight Center of Gravity: The CG of an aircraft in its current empty

weight condition, an essential part of the weight and balance record.

Gallons Per Hour: The amount of fuel (in US gallons) consumed in one hour.

Gear Box: The gears forward of the engine and aft of the propeller used to change

(reduce) the propeller RPM by a factor of 2.43 of the engine RPM.

Installed Equipment: All accessories and equipment permanently installed on an

airframe or engine at the time of weighing included in the ―Installed Equipment List‖

resulting in the Basic aircraft weight. Additions and deletions must be noted in the

list and new Weight and Balance calculations performed to determine the

magnitude and effect of weight change

Manifold Pressure: The atmospheric pressure measured in the engine's induction

system and is expressed in inches of mercury (Hg).

Maximum and Minimum Weights: Due to balance, structural, and aerodynamic

considerations, maximum or minimum weights for certain locations on the aircraft

are specified. For example, the pilot‘s minimum (100Lbs) and maximum (250Lbs)

weight are specified for some CG calculations. The same is true for baggage,

cargo, fuel, and any other disposable or variable load.

Maximum Forward and Maximum Aft CG Locations: A specified forward most

and rear most CG location along the aircraft longitudinal axis. These CG location

limits are expressed in inches from a convenient reference datum, the forward face

of the engine propeller flange.

Maximum Design Weight: The maximum total weight, for which the aircraft‘s

structure has been tested by the manufacturer for normal or seaplane operations.

1 Feb 11 – Ch 4 1-14

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 25

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

Maximum Gross Weight: The maximum total weight, for which the aircraft‘s

structure and performance have been tested by the manufacturer for normal

operations.

Maximum Landing Weight: The maximum weight for the landing touchdown.

Maximum Ramp Weight: The maximum weight approved for ground maneuvers.

(It includes the weight of start, taxi and run-up fuel.)

Maximum Takeoff Weight: The maximum weight at which an airplane is approved

for the start of its takeoff roll.

Mean Aerodynamic Chord: (MAC) The chord of a rectangular wing which has the

same area, aerodynamic force and position of the center of pressure at a given

angle of attack as a given wing. Simply stated, MAC is the width of an equivalent

rectangular wing in given conditions. For simplification of the CG calculations the

Sirius uses the length of arm limits and so does not require MAC calculations.

Moment: The product of the weight of an item multiplied by its arm (distance from

datum plane). (Moment = Weight x Arm)

Nautical Miles per Gallon: The no-wind travel distance (in nautical miles) which

can be expected per gallon of fuel consumed at a specific engine power setting

and/or flight configuration.

Reference or Datum Plane: An imaginary vertical plane located on the forward

face of the engine propeller hub from which all horizontal distances are measured

for weight and balance purposes.

Revolutions per Minute: Expressed as engine ―speed‖, is the number of 360

degree rotations that the engine crankshaft completes in each minute of time. (The

propeller, driven by the gear box, completes one revolution for each 2.43 engine

revolutions.)

Standard Empty Weight: The weight of a standard airplane, including unusable

fuel and full engine operating fluids.

Station: A vertical location along the airplane fuselage horizontal axis given in

terms of the distance from the reference datum plane.

Tare: The weight of items used when weighing an airplane included in the scale

readings. Tare is deducted from the readings to obtain the actual airplane weight.

Useful Load: The total amount of weight available for pilot, passengers, baggage,

cargo and usable fuel. The difference between the maximum ramp weight and the

1 Feb 11 – Ch 4 1-15

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 26

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

basic empty weight. The useful load will be reduced by the installation of additional

equipment.

Usable Fuel: The amount of fuel available for engine use in flight.

Unusable Fuel: The quantity of fuel that cannot be safely used in flight.

Weight: Actual individual weight of each item such as airframe, crew, fuel,

baggage, cargo, expressed in pounds or kilograms

ABBREVIATIONS

100LL – 100 Octane Low Lead Aviation Fuel (Avgas)

A – Amps, Electrical Amperage

ADI _ attitude reference – Solid state gyro; Attitude Directional Indicator

AGL – Above ground level (in feet)

AMP – Amps, Electrical Amperage

AHARS – Attitude Heading and Reference System

ALTN – Alternator (switch)

AOI – Aircraft Operating Instructions (No longer used in LSA, AOI=POH)

AOA – Angle of Attack, relative angle of the wind to an airfoil

APPH, Approach, (Intermediate flap deflection) – 2nd extended flap Setting (28 degrees)

ARTCC – Air Route Traffic Control Center (FAA)

ASAP – As Soon As Possible

ASTM – ASTM International (Previously -American Society of Testing & Materials)

ATC – Air Traffic Control (Center) (FAA)

AUX – Auxiliary (pump)

Auto Gas – Automobile fuel, 91 Octane is min auto gas rating for Rotax engines

Avgas – 100 Octane Low Lead Aviation Fuel (100LL)

Big Angle – Large AOA of the Propeller blade in relation to the air stream

BHP – Brake Horse Power

CAS—Calibrated airspeed

CB – Circuit Breaker

CBLT – Cabin Light (switch)

CBS – Circuit Breaker Switch

CFIT – Controlled Flight Into Terrain

Ch, Chg – Change

CK – Check, Checked

CM – Centimeter

Code – Transponder Setting (Squawk Code)

Com, Com1 – VHF radio

CSP – Constant speed propeller, (not used in LSA)

1 Feb 11 – Ch 4 1-16

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 27

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

CG – Center of Gravity

CI – Cubic Inch(s)

D&P – Design and Performance (ASTM) Standards

Datum – Location plane for base for measurement(s) along aircraft length

DC – Direct Current

DOT – (US) Department of Transportation

EIS – Engine Information System

EFIS – Electronic Flight Information System

EMS – Engine Monitoring System

EMSB – Engine Monitoring System + Backup Instruments

ETA – Estimated time of arrival

EWCG – Empty weight center of gravity

EXTRA – Extra, spare

FAA – (US) Federal Aviation Agency

FLAP – (settings): Stage0/UP; Stage1/Takeoff; Stage2/Approach; Stage3/Landing

FLSG - Fuel Level Sight Gauge (left or right wing root)

FSDO – Flight Standards Service District Office (FAA)

FPM – Feet per Minute

Ft – (FT) Foot (Feet)

FTS – Flight Training Supplement

Full – (Landing flap deflection) – Stage 3; Max extended Flap Setting (45 degrees)

G – Acceleration due to gravity

GAL– (US) Gallon(s)

GEN – Generator

GPH – (US) Gallons per hour

GPS – Global Positioning System

GMT – form of 24 hour time display, commonly known as ―Greenwich Mean Time‖

GRS – Galaxy Rescue System (aircraft rocket parachute system)

Half (Intermediate flap deflection) – Stage 2; 2nd extended Flap Setting (28 degrees)

HOBBS – Engine hour meter

Hp – Horse Power

IAW – In Accordance With

IFR – Instrument Flight Rules (does not infer IMC)

IGN1-2 – Ignition (switch)

IMC – Instrument Meteorological Conditions (infers IFR)

In – Inch(s) (IN)

INST – Instrument, Avionics (switch)

Kg – Kilogram

1 Feb 11 – Ch 4 1-17

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 28

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

KM – Kilometer

KPH – Knots per hour

Kt(s) (K) – Knot(s), nautical mile(s),

LAND, Landing – (Full flap deflection) – 3rd extended flap Setting (45 degrees)

Lb(s) – Pound(s) (#)

LL – Low Lead, as in 100LL avgas

LSA – Light Sport Aircraft

LSP – Light Sport Plane

Ltr – Liter

M – Meter

MAC – Mean Aerodynamic Chord

MAG – Magnetic (slang=engine ignition system)

MAIN – Master (switch)

Max – Maximum

MB – Milibar

MC – Magnetic course

MEL – Master Equipment List

MIDO – Manufacturing Inspection District Office (FAA)

Min – Minimum

MODE C – Altitude data transmitted to ATC by the XPDR

MODE S –Data transmitted to ATC by the XPDR, then rebroadcast by ATC to the XPDR

MoGas – Low octane ‗motor gas‘, not approved for Rotax engine operation

MPH – Miles per hour

MPG – Miles per gallon

MSL – Mean Sea Level (in feet)

NE – Never Exceed (as Vne)

NM – Nautical Mile(s)

NTSB – National Transportation Safety Board

OEM – Original equipment manufacturer

OP – Oil Pressure

OT – Oil Temperature

POH – Pilot Operating Handbook

PIM – Pilot Information Manual (No longer used in LSA, PIM=POH)

PITO – Pitot, heat (switch)

PSI – Pounds per Square Inch

RPM – Revolutions per Minute

Small Angle – Small AOA of a Propeller blade in relation to the air stream

Stage0 – (No flap deflection) – Flaps fully retracted, Flaps UP

1 Feb 11 – Ch 4 1-18

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 29

Pilot Operating Handbook Section 1

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

Stage1 – (Intermediate flap deflection) – 1st extended flap Setting (10 degrees)

Stage2 – (Intermediate flap deflection) – 2nd extended flap Setting (28 degrees)

Stage3 – (Full flap deflection) – 3rd, Full extended flap Setting (45 degrees)

STRB – Strobe (switch)

STRT – Start (switch)

T&B – Turn and bank indicator

Tach – Tachometer

Takeoff – (Intermediate flap deflection) – 1st extended Flap Setting (10 degrees)

TC – Turn Coordinator

TDC – Top Dead Center, the highest position of the engine piston in the cylinder.

UP – (Minimum flap setting, Stage 0) – Retracted Flap Setting (0. Degrees)

UBER – The ultimate, above all, the best, top, nothing is better, a superlative example of

its kind or class, Sirius, (included because there is only one abbreviation in U)

V – Volt(s) DC

V(_) – Speeds, with subscript (see descriptions next page)

VDC – Volts Direct Current

VFR – Visual Flight Rules (infers VMC)

VHF – Very High Frequency

VMC – Visual Meteorological Conditions (may infer VFR or IFR)

VSI – Vertical Speed Indicator

VVI – Vertical Velocity Indicator

WgWg – Wig Wag recognition light flashing system

XPDR – Transponder

XTRA – Extra, Spare (switch)

Z (Zulu) – form of 24 hour time display; an absolute time reference which is the

same time around the world and doesn't change with the seasons. It is the

same as Greenwich Mean Time (GMT). GMT was established in 1884 and placed

the Prime Meridian at Greenwich, England. Zulu time is also known as Universal

Time Co- ordinated (UT or UTC).

1 Feb 11 – Ch 4 1-19

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 30

Pilot Operating Handbook Section 1

V-speed

designator

Description

V1

Maximum speed during takeoff at which a pilot can safely stop the aircraft without

leaving the runway.

VA

Design maneuvering speed, also known as the ―Speed for maximum control

deflection.‖ This is the speed above which full application of any single flight control

may generate a force greater than the aircraft‘s structural limitations.

VC

Design cruising speed, also known as the optimum cruise speed, is the most

efficient speed in terms of distance, speed and fuel usage.

VD

Design diving speed.

VDF

Demonstrated flight diving speed.

VFE

Maximum flap extended speed.

VH

Maximum speed in level flight at maximum continuous power.

V

LOF

Lift-off speed.

VNE

Never exceed speed.

VNO

Maximum structural cruising speed or speed for normal operations

V

Ref

Landing reference speed or threshold crossing speed.

VS

Stall or minimum steady flight speed for which the aircraft is still controllable.

VS0

Stall speed or minimum flight speed in landing configuration.

VX

Speed that will allow for best angle of climb.

VY

Speed that will allow for the best rate of climb.

VBE

Best endurance speed – the speed that gives the greatest airborne time for fuel

consumed.

Vg

Best glide speed maximum lift-to-drag ratio thus the greatest gliding distance

available.

Vme

Max endurance

Vmp

Minimum power

Vmr

Max range

VPD

Maximum speed at which aircraft parachute deployment has been demonstrated

V

tmax

Max threshold speed

TL3000 Sirius General Information

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible authority for the safe operation of this aircraft.

“V” Speeds

V-speeds or Velocity-speeds are standard terms used to define airspeeds useful to the

operation of aircraft The actual speeds represented by these designators are expressed in

terms of the aircraft‘s indicated airspeed, so that they can be read without having to apply

correction factors.

1 Feb 11 – Ch 4 1-20

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 31

Pilot Operating Handbook Section 2

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

SECTION 2

OPERATING LIMITATIONS

TABLE OF CONTENTS Page

INTRODUCTION ............................................................................................... 2-3

AIRSPEED LIMITATIONS ................................................................................. 2-3

AIRSPEED INDICATOR MARKINGS ................................................................ 2-4

FLAP AIRSPEED LIMITATIONS ....................................................................... 2-4

MAXIMUM DEMONSTRATED CROSSWIND VELOCITY ................................. 2-5

AIRSPEED CONVERSION IAS TO CAS ........................................................... 2-4

SERVICE CEILING ............................................................................................ 2-6

ENGINE LIMITATIONS ...................................................................................... 2-7

ENGINE OPERATION LIMITS........................................................................... 2-7

ENGINE MONITOR SYSTEM ........................................................................... 2-7

ENGINE MONITOR COLOR INDICATIONS ..................................................... 2-7

ENGINE FUEL GRADE ..................................................................................... 2-7

ENGINE OIL SPECIFICATIONS........................................................................ 2-7

PROPELLER ................................................................................................... 2-11

OPERATIONAL WEIGHT LIMITS .................................................................... 2-11

CENTER OF GRAVITY LIMITS ....................................................................... 2-11

MANEUVER LIMITS ........................................................................................ 2-11

FLIGHT LOAD FACTOR LIMITS ..................................................................... 2-12

FLIGHT OPERATION LIMITATIONS ............................................................... 2-12

1 Feb 11 – Ch 4 2-1

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 32

Pilot Operating Handbook Section 2

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

(THIS PAGE BLANK)

.

1 Feb 11 – Ch 4 2-2

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 33

Pilot Operating Handbook Section 2

V

SPEED

KIAS

KCAS

REMARKS

VNE

Never Exceed Speed

138

135

Do not exceed this speed in any operation.

VH

Maximum Sustained Speed in

Level Flight

119

116

Maximum speed with maximum continuous rated

engine power in horizontal flight at sea level in

standard conditions at full gross weight.

VNO

Maximum Structural Cruising

Speed

115

114

Do not exceed this speed except with caution

and in smooth air.

VA

Maneuvering Speed

86

85

Do not make full control defection or abrupt

control movements above this speed.

VFE

Maximum Flap Extended Speeds:

Takeoff (Stage 1) Flaps

Approach (Stage 2) Flaps

Landing(Stage 3)(Full) Flaps:

75

65

55

74

64

56

Do not exceed these speeds with the given flap

settings. Damage to the flap mechanism may

occur due to excessive air loads.

VS

Stall Speed (No Flaps)

40

42

Do not attempt to fly slower than this speed at full

gross weight when operating without flaps.

VS0

Stall Speed (Full Flaps)

32

35

Do not attempt to fly slower than this speed when

operating with full (Landing) flaps.

WARNING

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

INTRODUCTION

Section 2 includes specific operating limitations and airspeed instrument

markings. The limitations provided in this section should be adhered to for safe

operation of the airplane.

AIRSPEED LIMITATIONS

Speeds shown are for full gross weight at sea level, standard conditions.

VFR/VMC night operation is acceptable only when equipped with

operational VFR/VMC night minimum equipment in accordance

with the Aircraft Operating Limits (airworthiness certification) and

FAA FAR 14 CFR 91.205.

IFR/VMC operation is acceptable only when equipped with

operational IFR/VMC instrument minimum equipment in

accordance with the Aircraft Operating Limits (airworthiness

certification) and FAA FAR 14 CFR 91.205.

1 Feb 11 – Ch 4 2-3

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Fig. 2-1

Page 34

Pilot Operating Handbook Section 2

MARKING

RANGE

KIAS

SIGNIFICANCE

White Arc

31 – 75

Flap Operating Range

Lower limit is maximum weight VS0 in landing configuration.

Upper limit is maximum speed permissible with flaps extended

to first stage 1. (Takeoff)

Green Arc

40 - 115

Normal Operating Range

Lower limit is maximum weight VS at most forward CG

with flaps retracted.

Upper limit is maximum structural cruising speed. Vno

Yellow Arc

116 - 137

Caution Range

Operations must be conducted with caution

and only in smooth air

Red Line

138

Never Exceed Speed. Maximum speed for all operations.

CAUTION

CAUTION

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

IFR/IMC operation must be approved by the manufacturer, included

in the Aircraft Operating Limits (airworthiness certification). Flight in

IMC conditions will contain aircraft serial number specific IFR/IMC

restrictions on operations. These restrictions will be noted in the

POH and referenced in a required placard on the instrument panel.

AIRSPEED INDICATOR MARKINGS

Speed indicator markings and colour code significance are shown in the table:

Fig. 2-2

Maximum speed for aircraft parachute deployment at gross weight: 138 Kts.

FLAP AIRSPEED LIMITATIONS

Flap speed limits do not contain additional load factors for higher

than specified speeds. Adhere to the following maximum limits to

prevent damage to the flap attachment hinges or drive system.

75 KIAS Maximum = Takeoff Flaps (Stage 1), 10 degrees

65 KIAS Maximum = Approach Flaps, (Stage 2), (Half), 28 degrees

55 KIAS Maximum = Landing Flaps, (Stage 3), (Full) 45 degrees

1 Feb 11 – Ch 4 2-4

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 35

Pilot Operating Handbook Section 2

CAUTION

CAUTION

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

Landing is acceptable with any or no extended flaps. Extreme side

slips with full flaps may develop high sink rates. The disturbed

airflow may impose negative loads on the inboard portion of the flap

panels as well as create turbulence at the horizontal tail.

MAXIMUM DEMONSTRATED CROSSWIND VELOCITY: 17 Knots

1 Feb 11 – Ch 4 2-5

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Crosswind Component Chart

Fig. 2-3

Flight operations should be stopped during gusty

wind conditions in excess of 17Kts.

Page 36

Pilot Operating Handbook Section 2

Indicated Airspeed conversion to Calibrated Airspeed Chart

Speed in

IAS (kts)

Flaps 0,

Retracted

Speed in

CAS (kts)

Flaps 0,

Retracted

Speed in

IAS (kts)

Flaps 10,

Takeoff

Speed in

CAS (kts)

Flaps 10,

Takeoff

Speed in

IAS (kts)

Flaps 45,

Landing

Speed in

CAS (kts)

Flaps 45,

Landing

27

29

29

31

28

30

34

35

35

36

35

36

38

39

40

41

40

41

43

44

43

46

44

47

49

50

49

51

50

52

54

55

56

57

55

58

59

59

64

62

64

63

65

64

68

67 70

69

74

72 76

74

80

78

81

79

86

84

92

89

97

94

103

99

108

104

113

110

119

115

124

121

130

126

135

132

140

137

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

IAS TO CAS CONVERSION:

Fig. 2-4

Notes: Standard conditions; Shaded area in table 2-4 is outside aircraft limits

SERVICE CEILING:

Standard conditions, standard day: 16,500 Ft

LSA altitude limits: 10,000 Ft MSL or 2,000 Ft AGL (above terrain)

1 Feb 11 – Ch 4 2-6

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 37

Pilot Operating Handbook Section 2

CAUTION

NOTE

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

ENGINE LIMITATIONS

Engine Manufacturer: Rotax® G.m.b.H. Aircraft Engines

Engine Model Number: 912ULS or 914UL

Maximum Power: 100 BHP or 115 BHP

See the latest engine manufacturer‘s manual supplied with the

aircraft for more detailed 900 series Rotax engine data.

Engine Operating Limits:

Maximum Engine RPM: 5501-5800 RPM (5 Minutes Maximum)

Maximum Continuous Engine RPM: 5500 RPM or less (No time limit)

Minimum Engine Idle RPM: 1850 RPM (visually about 2000 rpm)

Maximum Cylinder Head Temperature: 256°F (radiator cap marked ‗1.2 bar‘)

Maximum Exhaust Gas Temperature: 1616°F (1742°F 914UL)

Oil Temperature, Maximum: 266°F

Normal: 180 – 230°F

Minimum: 120°F

Oil Pressure, Maximum: 102 psi

Normal: 29 – 73 psi

Minimum: 12 psi

Fuel Pressure, Maximum: 5.8 psi (914UL, Airbox pressure+5.08psi,)

Minimum: 2.2 psi (914UL, Airbox pressure+2.18psi.)

Exceeding the maximum fuel pressure may override the float

valves of the carburetors and cause erratic engine operation. The

912ULS fuel pressure including the operation with the additional

electrical aux pump must not exceed 5.8 psi. Therefore, takeoff with

the electric aux pump ON is not recommended.

Operate both 914UL electric fuel pumps ON for takeoff and landing.

Engine Monitor System (EMS)

Various models of EMS equipment are installed. Generally these

electronic monitors will provide the pilot with an increased awareness for

the engine conditions that surpasses analog gauges. The following

summaries of limit settings for the installed systems show the alert

conditions and the situation significance for the alert color.

1 Feb 11 – Ch 4 2-7

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 38

Pilot Operating Handbook Section 2

MARKING

RANGE

PSI

SIGNIFICANCE

Red Arc

0 - 1

Immediate action required to correct or land .

Yellow Arc

1 - 2

Too low for safe engine operation

Green Arc

2 - 5

Normal Operating Range – 2.2–5.8

Yellow Arc

5 - 6

Caution – Carburetor pressure limit.

Red Arc

7+

Immediate action required to correct or land .

MARKING

RANGE

PSI

SIGNIFICANCE

Red Arc

0 - 12

Immediate action required to correct or land .

Yellow Arc

13 - 28

Too low for safe engine operation

Green Arc

29 - 73

Normal Operating Range – 29-73

Yellow Arc

74 - 92

Caution – cold start ops only.

Red Arc

93 - 102+

Immediate action required to correct or land .

MARKING

RANGE

˚F

SIGNIFICANCE

Red Arc

0 - 99

Immediate action required to correct or land .

Yellow Arc

100 - 119

Warm-up prior to high engine RPM

Green Arc

120 - 230

Normal Operating Range – +/- 180-230

Yellow Arc

231 - 248

Caution – Take action to correct.

Red Arc

249 - 266+

Immediate action required to correct or land .

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

Engine Monitor Color Indication Settings

Fuel Pressure

Indicator markings and colour code significance are displayed in the EMS screen:

Fig. 2-5

Oil Pressure

Indicator markings and colour code significance are displayed in the EMS screen:

Fig. 2-6

Oil Temperature

Indicator markings and colour code significance are displayed in the EMS screen:

Fig. 2-7

1 Feb 11 – Ch 4 2-8

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 39

Pilot Operating Handbook Section 2

MARKING

RANGE

˚F

SIGNIFICANCE

Red Arc

0 - 99

Immediate action required to correct or land .

Yellow Arc

100 - 119

Warm-up prior to high engine RPM

Green Arc

120 - 230

Normal Operating Range – +/- 180-230

Yellow Arc

231 - 248

Caution – Take action to correct.

Red Arc

249 - 256+

Immediate action required to correct or land .

MARKING

RANGE

˚F

SIGNIFICANCE

Red Arc

0 - 499

Immediate action required to correct or land .

Yellow Arc

500 - 999

Low limit for minimum operation

Green Arc

1000 - 1550

Normal Operating Range – +/- 1300-1550

Yellow Arc

1551 - 1616

Upper limit for maximum operation.

Red Arc

1617 - 1717+

Immediate action required to correct or land .

MARKING

RANGE

RPM

SIGNIFICANCE

Red Arc

0 - 1399

Action required to protect gearbox. .

Yellow Arc

1400 - 1849

Idle operation above 1850 recommended.

Green Arc

1850- 5500

Normal Operating Range – +/- 4800-5500

Yellow Arc

5501 - 5700

5 minute limit for RPM above 5500.

Red Arc

5701 - 5800+

Attention required to prevent RPM overrun.

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

Cylinder Head Temperature

Indicator markings and colour code significance are displayed in the EMS screen:

Fig. 2-8

EGT Temperature

Indicator markings and colour code significance are displayed in the EMS screen:

Fig. 2-9

Engine RPM

Indicator markings and colour code significance are displayed in the EMS screen:

Fig. 2-10

1 Feb 11 – Ch 4 2-9

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 40

Pilot Operating Handbook Section 2

NOTE

NOTE

NOTE

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

Fuel Grade: 91 Octane Unleaded Auto Gas, maximum Ethanol limit of 10%;

100LL Avgas (alternate grade)

100LL Avgas is to be used as an alternate fuel type if 91 octane

auto fuel is not available. Use of 100LL Avgas over 30% of engine

operation time requires additional maintenance as recommended

by the engine manufacturer. If 91 Octane Unleaded is not available

during travel, adding 100LL Avgas in any proportion to partial tanks

of 91 Unleaded is acceptable.

The aircraft manufacturer does not recommend the use of fuel

additives such as TCP for leaded fuel (Avgas) operations. Ethanol

maximum limit content of 10% is an acceptable additive.

Oil Specifications: Oil type is dependent on engine operating conditions IAW

latest Rotax Service Instructions. Confirm the latest Rotax engine oil

recommendations prior to selection. In general, the use of a semi-synthetic

motor-cycle oil with gear additives is recommended.

Aviation type ‗ashless‘ detergent oils are not recommended with

Rotax 900 series engines.

PROPELLER

Several propellers have been approved for operation with this airframe and

engine combination. See the latest TL Master Equipment List (MEL) for details.

See Section 10 for more information. The current MEL version is posted on line

at: http://www.sirius.aero/owners/

Limitations

Each propeller manufacturer will provide the operation, limitations and

maintenance requirements for their propellers and associated equipment. See

the propeller operation manual and log book furnished with the aircraft.

1 Feb 11 – Ch 4 2-10

Copyright © 2011 Reproduction of this document or any of its parts is forbidden.

Page 41

Pilot Operating Handbook Section 2

WARNING

TL3000 Sirius Operating Limitations

Notice! The information contained in this document is for reference and information only.

The pilot is the final and only responsible party for the safe operation of this aircraft.

Adjusting the propeller blades to high pitch (high propeller

„angle of attack‟ AOA or „big angle‟) static blade setting, in an

attempt to obtain a high cruise speed, may cause one of

more of the following problems:

1. Low engine RPM ―bog-down‖ at full throttle

2. Inability to obtain a sufficient ground RPM,

3. May not allow a safe takeoff or climb out.

4. Detonation, engine damage, or failure,

5. Extended takeoff rolls and low climb rates.

6. High engine CHT & oil temperatures during climb

7. Vibration due to minor differences in the blade pitch.