Page 1

Congratulations on your purchase!

Thank you for choosing a Sirius product.

SL906 series & SL907 700

UNDERMOUNT RANGEHOOD INSTALLATION INSTRUCTIONS

SL906 L 520 EAN #9351116000677

SL906 L 850 EAN #9351116000745

SL906L EXCEL 850 EAN #9351116000806

SL906L EXCEL1000 EAN #9351116000899

SL906L EXCEL 1200 EAN #9351116002015

SL907 700 EAN #9351116000714

www.siriusbrand.com

1

Page 2

CAUTION

BEFORE YOU INSTALL – please read

Sirius warranty covers only Sirius product. If you choose to install a non-Sirius

branded accessory such as flexible ducting, Sirius will only warrant the hood

and motor. If installation is found to be the cause of failure or issue then charges

will apply for service and parts.

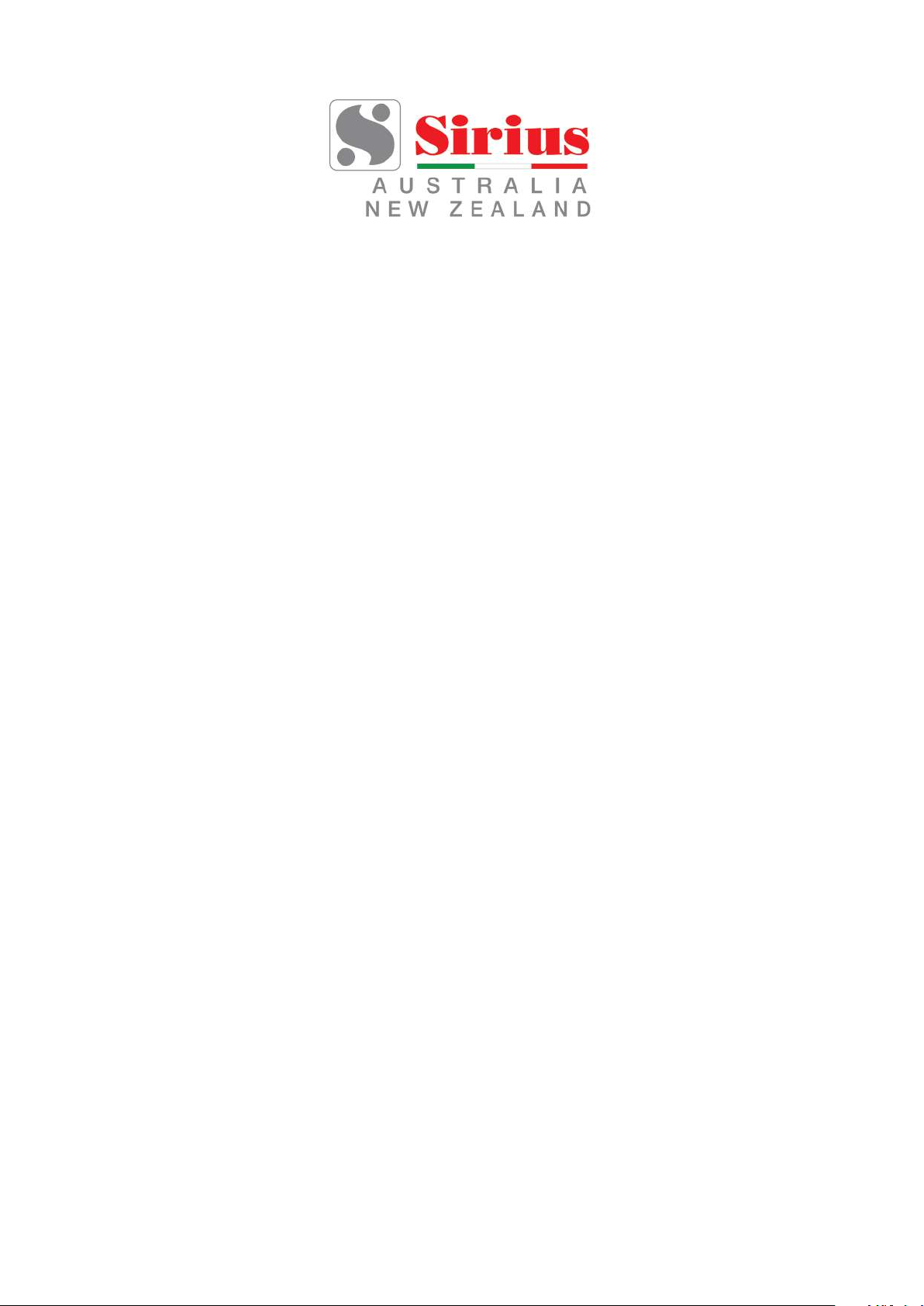

Flexible ducting is not permitted under any circumstances. Flexible ducting has

been found to increase noise levels, increase vibration and reduce airflow.

Sirius Semi-rigid or solid ducting can be used in lieu. There is a range available

to suit any application.

Ducting available at www.siriusbrand.com

A reduction in the duct diameter from stated ducting size will void warranty.

If you are in doubt about the ducting, please contact Sirius on 1300 762 219 prior to installation

The symbol on the product or on its packaging indicates that this product

may not be treated as house-hold waste. Instead it shall be handed

over to the applicable collection point for the recycling of electrical and

electronic equipment. By ensuring this product is disposed of correctly,

you will help prevent potential negative consequences for the environment

and human health, which could otherwise be caused by inappropriate

waste handling of this product. For more detailed information about

recycling of this product, please contact your local city office, your

household waste disposal service or the shop where you purchased the

product. This appliance is marked according to the European directive

2002/96/EC on waste electrical and electronic equipment (WEEE).

2

Page 3

WARNING

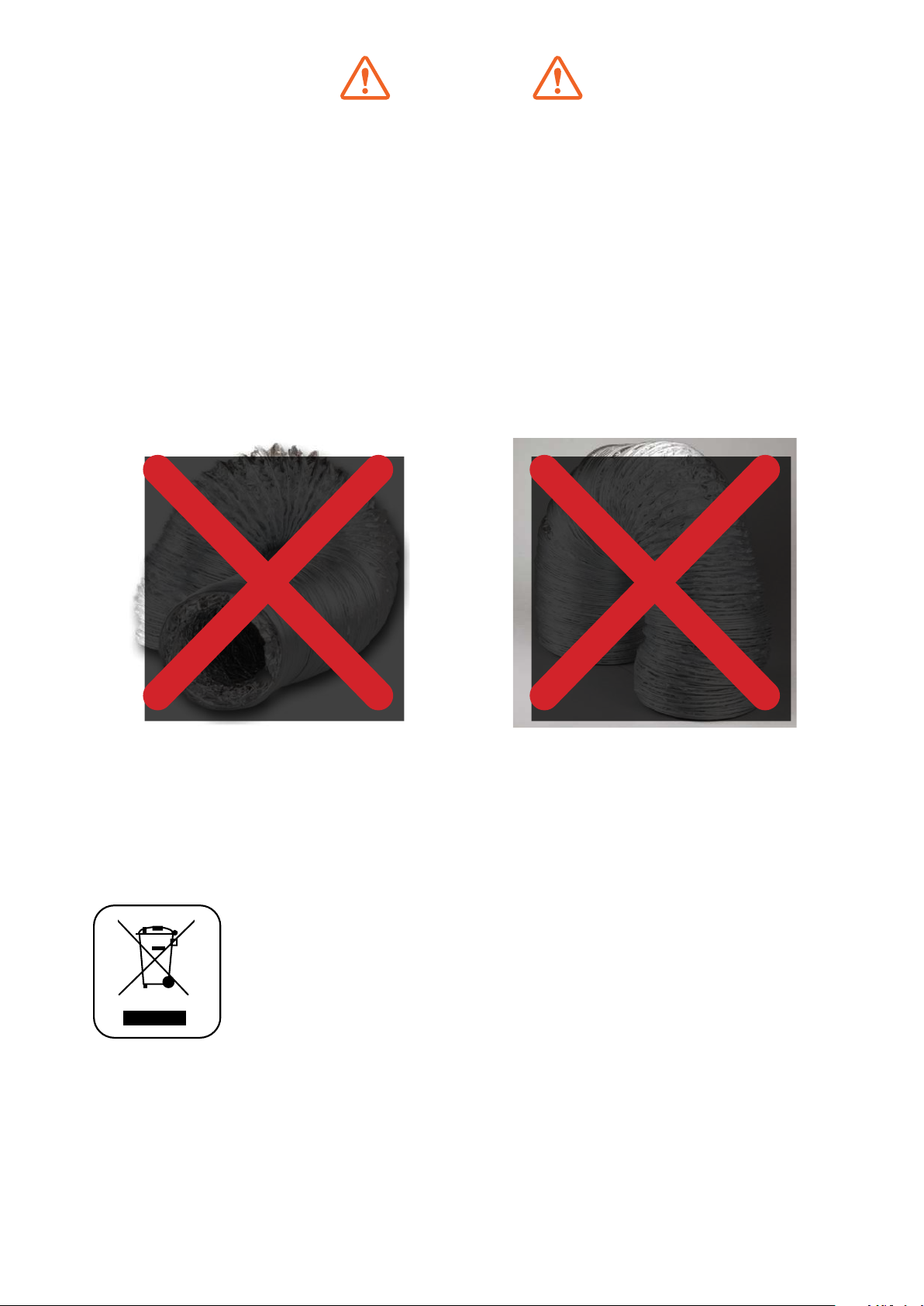

Min. 600mm - Max. 650mm for induction cooktops.

Min. 600mm - Max. 750mm gas cooktops.

If the rangehood is positioned above the max height

recommended, warranty may be compromised

as performance of the rangehood will be affected.

Measurement is taken from the top of the trivets to

the underside of the hood. (Fig.1)

600 - 650mm (induction)

600 - 750mm (gas)

600 - 650mm (induction)

600 - 750mm (gas)

flexible cable and plug, or with another device

ensuring omnipolar disconnections from the grid,

with an opening distance between the contacts of at

least 3mm, then such disconnecting devices must be

supplied within the fixed installation.

If the fixed appliance is endowed with a supply cord

and a plug, the appliance has to be put in a place

where the plug can be reached easily.

The use of materials which can burst into flames

should be avoided in close proximity of the appliance.

When frying, please pay particular attention to fire

risk due to oil grease. Being highly flammable, fried

oil is especially dangerous. Do not use uncovered

electric grills. In order to avoid possible fire risk, all

instructions for grease-filter cleaning and for removing

eventual grease deposits should be strictly followed.

SIDE VIEW FRONT VIEW

(Fig. 1)

• The air being drawn can’t be conveyed through

or into a duct used to let out fumes from

appliances fed by energy other than electric

power (eg. centralized heating, radiators, water

heaters, etc.).

• Attention: remove any possible PVC film from the

stainless steel, including the filters.

• To externally vent, please comply with the

pertaining rules given by competent authorities.

• Provide the room with an adequate ventilation

when a rangehood and appliances fed by energy

other than electric power (gas, oil, or coal stoves,

etc.) are used simultaneously. The rangehood,

when evacuating the air, could generate a

negative pressure in the room which can’t exceed

the limit of 0.04 mbar, in order to avoid the

suck of exhausts deriving from the heat source.

Therefore the room should be provided with air

intakes to allow a constant flow of fresh air.

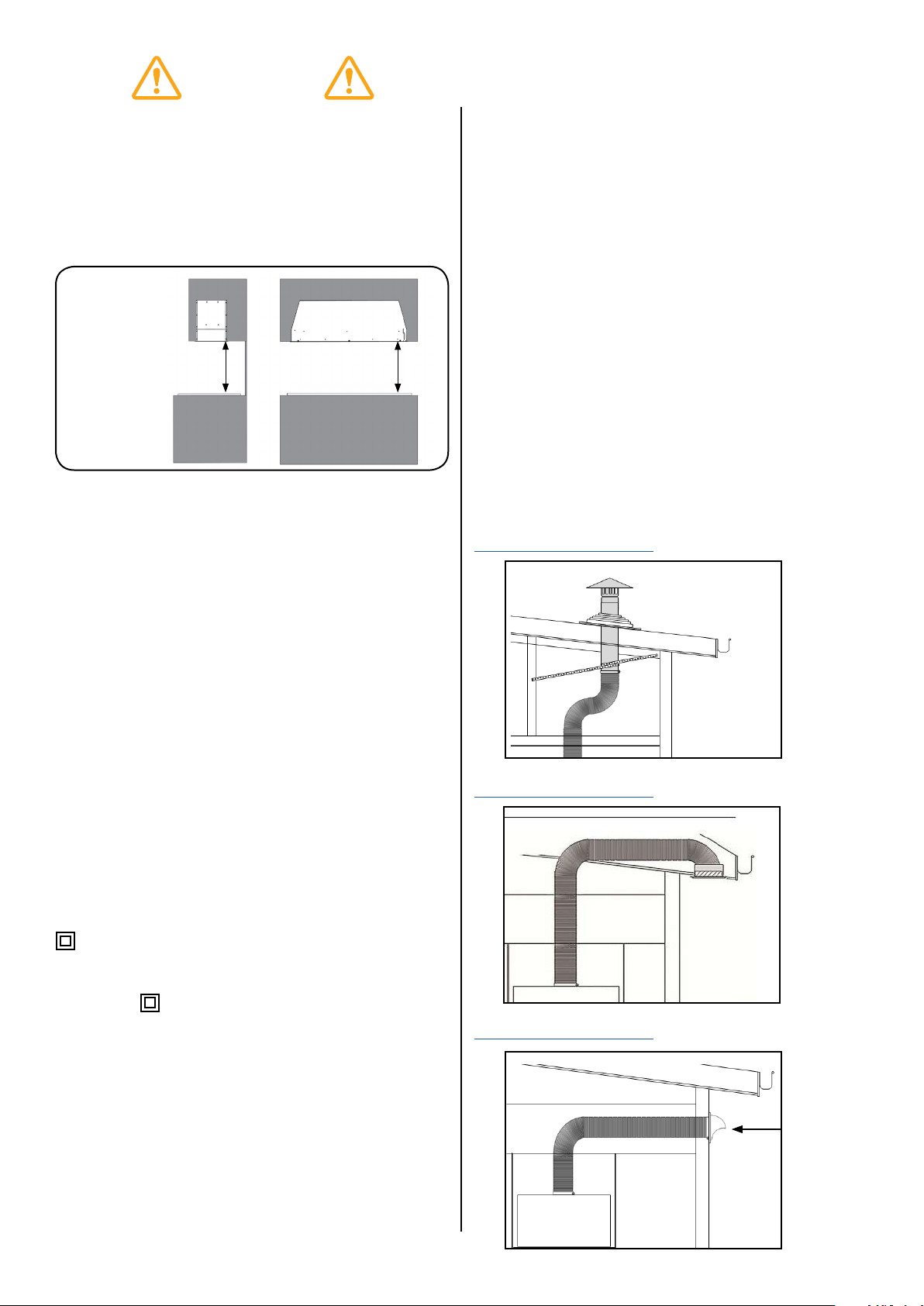

When ducting rangehood, options are as follows:

Roof vent - EASYROOF 150T/M

EASYROOF 200T/M

*Kit includes roof flashing

Download installation guide

(Fig. 2a)

Eave vent - EASYEAVE 150/200

Download installation guide

If the rating label in the rangehood shows the symbol

, the appliance is built in class II° and it does not

need any earth connection.

If the rating label in the rangehood does not show

the symbol , the appliance is built in class I° and it

needs the earth connection.

When performing the electrical connections on the

appliance, please make sure that the current-tap

is provided with earth connection and that voltage

values correspond to those indicated on the label

placed inside the appliance itself.

Before carrying out any cleaning or maintaining

operations, the appliance needs to be switched off.

If the appliance is not provided with a non-separable

(Fig. 2b)

Wall vent - EASYWALL 150/200

Download installation guide

Dome

featured on

200mm kit

only

(Fig. 2c)

3

Page 4

SL906-L series INSTALLATION ONBOARD

NOTE

Before installing the appliance, make sure that

none of the parts are damaged in any way. In

case of damaged parts, contact your retailer

and do not proceed with installation. Read all

of the following instructions with care before

installing the appliance.

• Use ducting within the min/max specifications

• Limit the number of ducting bends.

• Do not make any changes in ducting diameter

(recommended constant diameter: Ø 150 mm /

Ø 200 mm or equal surface area).

Before installing the appliance - in order not to

damage the appliance itself - the metal grease filter

should be removed. These filters could be removed

by pushing the handles towards the back side of the

rangehood and pulling it downwards to unfasten it

from its slot. (Fig.3).

To install the appliance please respect the follow

instructions:

• The appliance must be installed by qualified

technicians, or where possible use a Sirius

recommended installer. See siriusbrand.com. In

order to avoid damage to the electronic parts

of the appliance, please do not use additional

screws.

• Essential precautions to respect before installing

the appliance are the following:

To have made a cutout on the bottom of the

cabinet which is suitable to hold the appliance in

position (fig. 4):

SL906 L520 - 501 x 265mm

SL906 L850 - 835 x 265mm

SL906 L EXCEL 850 - 835 x 265mm

SL906 L EXCEL 1000 - 985 x 265mm

SL906 L EXCEL 1200 - 1100 x 265mm

(Fig.3a)

(Fig.4)

1. Prepare the power supply - 240 volts.

2. Prepare a hole for the exhaust - 160mm diameter

for single motor & 210mm for for twin motor

versions.

• Maximum length of ducting should not exceed 7

metres to motor.

• (SEM 1 or SEM 8) Additional 5 metres from motor

to atmosphere.

• Do not use screws to fix the ducting to the

rangehoods as they will prevent the movement of

non-return valves.

• Limit the number of elbows in the ducting, since

each elbow reduces the duct efficiency by 1

metre. (i.e. if you use two 90° elbows, the length

of ducting must not exceed 5 metres.)

• Avoid abrupt direction changes.

• Use 150mm constant diameter ducting for the

whole length for the single motor, 200mm ducting

for the twin motor model.

• The use of Sirius ducting will increase the

warranty of the unit to 4 years.

(Fig.3b)

4

Page 5

WARNING

CAUTION

The rangehood is quite heavy, so two people

will be needed for installation.

1. To install the appliance, adjust the position of the

adjustable side-springs using the supplied screws

(fig.5), according to the thickness of the board, in

which the appliance will be fixed.

27mm

(Fig.5)

2. Insert the rangehood into the cutout in the

cabinet until the stop click of the side-springs is

heard and the rangehood is supported.

3. Insert the screws provided into the holes inside

the rangehood (Fig.6) to fix it to cabinetry.

Before connecting any ducting to the motor,

make sure the non-return valves - which are on

the air outlet of the motor - can swing open.

External venting

• Connect the flange to the exhaust hole with the

appropriate ducting. Connect the rangehood with

the electrical mains through the supply cord.

Rear vented version

• All the models with one motor can be rear

vented; if the customer wants to use this option,

it is necessary to remove the 18 screws from

the motor group support. Then take the metal

support with motor included out (fig.7a). Turn

the motor to have the air outlet on the rear side

(fig.7b) and fix the scews previously removed.

4. Insert the grease channel.

5. Insert the grease filter (Fig.3b)

(Fig.7a) (Fig.7b)

(Fig.6)

5

Page 6

SL907 700 INSTALLATION

NOTE

Before installing the appliance, make sure that

none of the parts is damaged in any way. In

case of damaged parts, contact your retailer

and do not proceed with installation. Read all

of the following instructions with care before

installing the appliance.

• Use an air outlet ducting within min/max

specifications.

• Limit the number of pipe bends. Use a material

approved by standards and regulations.

• Avoid any sudden changes in pipe section

(recommended constant diameter: Ø 150 mm.

(Fig.10)

Insert the grease filter again and close the perimeter

panel.

• The use of Sirius ducting will increase the

warranty of the unit to 4 years.

1. Before carrying out installation, please remove the

grease filter in order to avoid possible damages

to the appliance. Please follow the following steps

to remove the metal grease filter: open the light

panel first, by turning it downwards (fig.8), then

remove the grease filter.

(Fig.8)

2. Make a hole on the surface of the following

dimensions (fig.9):

SL907 700 - 270 x 680mm

(Fig.9)

3. Insert the SL907 unit, making sure the control

panel is on the right, looking at the product from

the front of the cabinetry.

4. Connect the electrical lead and connect the air

outlet flange from the unit to a suitable exhausting

duct.

5. Fix the unit by using the four screws provided and

tighten them as shown in (fig.10).

OPERATION

SL906-L series - S907 700 (fig. 11)

A: Light switch on/off

B: Motor switch on speed 1/off - (low/simmer)

C: Motor switch on speed 2 - (general cooking)

D: Motor switch on speed 3 - (high power)

E: Motor switch on speed 4 - (booster)

F: 10 minute shut-off timer

(Fig.11)

MAINTENANCE

• Accurate maintenance guarantees good

functioning and long-lasting performance.

• Particular care is due to the grease filter panel. It

can be removed by pushing its handle toward the

back side of the rangehood and pulling the filter

downwards so to unfasten it from its slot (Fig.3).

To insert the filter just perform the opposite

operation.

• After 30 hours of operation, the push button

control panel will flash, signaling the filters are due

for cleaning. Press the timer button to reset.

The grease filter needs cleaning by regular

handwashing or in dishwashers every two

months at least, depending on its use.

• To clean the appliance itself, water and detergent

are recommended, while abrasive products

should be avoided. For steel appliances

specialized detergents are recommended (please

follow the instructions indicated on the product

itself to obtain the desired results).

6

Page 7

NOTE

To remove the rangehood from the cabinet,

remove the fixing screws (fig. 6) using a

screwdriver, and remove the grease filters

(fig.3).

• Push down on the small handle of the springs,

which are inside the rangehood, with the

necessary strength to unhook the hood from the

cabinet.

WARNING

If the supply cord is damaged, it must be

replaced by the manufacturer or its service

agent or a similarly qualified person in order to

avoid a hazard.

REPLACING THE SL 907 700

FLUORESCENT LAMP

1. To replace the fluorescent lamps of SL907 model,

you need to open the perimeter panel, by rotating

it as shown in (fig.7).

2. Remove the panel fixing screws (fig.10), paying

special care in holding it during this step, then

remove the lamps and replace the damaged one

(fig. 13).

REPLACING THE LED LIGHT ON THE

SL 906-L

1. Before replacing the LED light, switch off the

rangehood, then - by using appropriate tools remove the LED light from its slot (fig.12).

2. Take out the LED light from its connector and

replace.

• To find the correct LED light, please contact Sirius

directly on our toll-free number: 1300 762 216.

(Fig.13)

3. Insert the panel again.

• If the supply cord is damaged, it must be

replaced by the manufacturer or its service agent

or a similarly qualified person in order to avoid a

hazard.

(Fig.12)

• NB: light is easier to remove from centre of

LED globe. Use a small, flathead screwdriver

(pictured), pallette knife or blunt butter knife.

7

Page 8

WIRING DIAGRAM SL906-L (1 motor)

8

Page 9

WIRING DIAGRAM SL906-L (2 motor)

9

Page 10

WIRING DIAGRAM SL907 700

10

Loading...

Loading...