Sirge KFR-25GW,KFR-25GVWa Service Manual

I

Split Wall-Mounted Type

Air-Conditioners

Service Manual

KFR-25GW/VWa

CONTENTS

I. Photo of the Production ··············································································· 2

II. Operating Principle ······················································································ 3

III. Exploded Views of the Production ······························································ 5

IV. List of common wearable parts···································································· 8

V.

Main Technical Data and Cooling and Heating Characteristic

Curver ··············

8

VI. Dismantling Procedure ················································································· 11

VII.

Fault Analysis of the Product Available and Typical

Examples ························································

14

1

I Photo of the production

Feature:

1. Stylish and deluxe design

2. Compact size, easy to install and operate

3. Sends out air in gentle stream for physical comfort

4. Use multi-fold evaporator to create the area of heat exchange

5. Intelligent blur defrost

6. Remote control

2

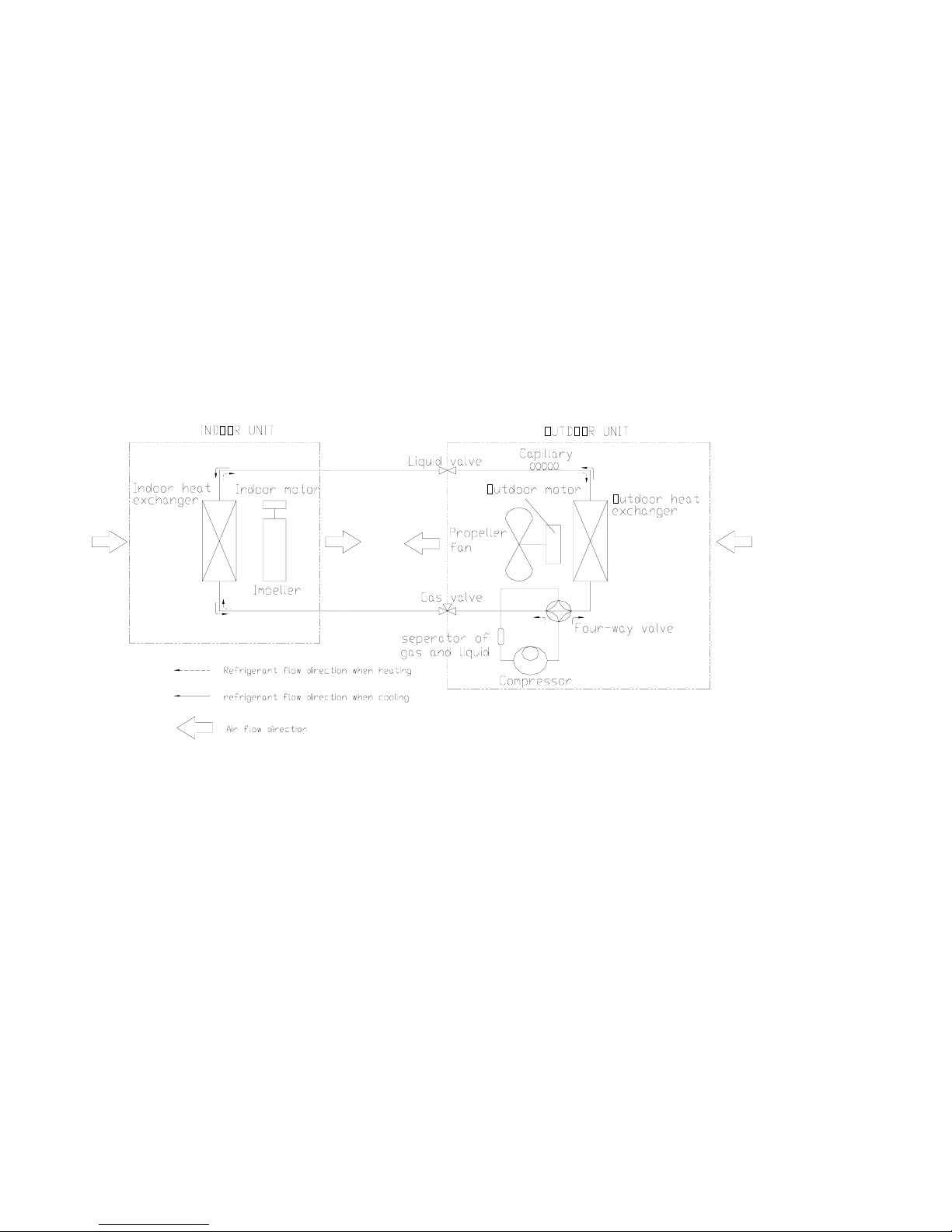

II Operating P rinciple

A. Cooling

After the power suppl y is switched on, the m achine is set to COO L mode. With the

compressor being operated, the low-temperature and low-pressure refrigerant vapor is

sucked into the compressor where it is turned into high-temperature and high-pressure

gas. Then it is cooled down in the outdoor heat ex changer b y the air a nd becomes

liquid. Af ter be ing thr ottled b y th e capillary, th e r efrigerant liquid c omes into the

indoor unit and then it e vaporates in th e indoor heat, exchanger, absorbing h eat an d

reducing t he room t emperature. The evapo rated refri gerant vapor ret urns t o t he

outdoor unit and is a gain sucked into the compressor, completing the c ycle. With the

refrigerant cycling bein g kept on, the obj ective o f lowering th e room tem perature is

fulfilled.

B. Heating

After the power supply is switched on, the machine is set to HEAT mode and the coil

of the e lectromagnetic four -way v alve is e nergized. Af ter the c ompressor sta rts to

operate, t he hi gh-temperature and hi gh-pressure refri gerant gas fi rst com es i nto t he

heat exchanger of th e in door unit, wher e it is co oled, rele ases h eat and increases the

room te mperature. The c ooled hi gh-pressure re frigerant is the n thr ottle1d in the

outdoor unit and returns to the compressor af ter evaporation. With such c ycles being

maintained, the objective of increasing the room temperature is fulfilled.

C. System Schematic Diagram

Please see the following Diagram

3

4

III Exploded Views of the Production

Detailed part list of KFR-25GW/VWa indoor unit

S/N Part Name Drawing No. Part No.

1 Front panel assy KFR-25G/V.010.00 KFR-25G/VWa 01

2 Air strainer KFR-25G/V.050.00WX KFR-25G/VWa 02

3 Upper frame assy KFR-25G/V.020.00 KFR-25G/VWa 03

4 Right locating cover KFR-23G/T.000.06 KFR-25G/VWa 04

5 Electric box cover KFR-23G/T.000.09 KFR-25G/VWa 05

6 Indoor control board KFR-23W/T101.041.00 KFR-25G/VWa 06

7 Electric box KFR-23W/T.100.01 KFR-25G/VWa 07

8 Step motor KFR-23G/T.061.00WX KFR-25G/VWa 08

9 Transformer KFR-23G/T.100.03WX KFR-25G/VWa 09

10 Indoor motor KFR-25G/V.070.00WX KFR-25G/VWa 10

11 Lower frame assy KFR-25G/V.040.00 KFR-25G/VWa 11

12 Impeller fan KFR-25G/V.080.00WX KFR-25G/VWa 12

13 Water-collecting plate assy KFR-25G/V.030.00 KFR-25G/VWa 13

14 Left locating cover KFR-23G/T.041.04 KFR-25G/VWa 14

15 Fixing clip KFR-23G/T.000.05 KFR-25G/VWa 15

16 Screw ST4*12FT SJ 2823-87 KFR-25G/VWa 16

17 Eavaporator assy KFR-25G/V.060.00 KFR-25G/VWa 17

5

Loading...

Loading...