SIPOS Seven Aktorik Ecotron Series, Seven Aktorik Ecotron 2SQ7, Seven Aktorik Ecotron 2SA7, Seven Aktorik Ecotron 2SG7 Operation Instructions Manual

Operation instructions

Electric actuators

2SA7, 2SG7, 2SQ7

ECOTRON

Issue: 11.18 Y070.301/EN

Subject to changes without notice!

Operation instructions

Table of contents

SIPOS SEVEN ECOTRON

Contents

1 General information ������������������������� 3

1.1 Safety information .................................. 3

1.2 Transport and storage ............................ 4

1.3 Disposal and recycling ........................... 4

1.4 Notes to the operation instructions ......... 4

1.4.1 Safety instructions:

Used symbols and their meanings ......... 4

1.4.2 Scope ..................................................... 5

1.5 Supplementary operation instructions .... 5

2 General information ������������������������� 6

2.1 Functional principle ................................ 6

2.2 Sub-assemblies ...................................... 7

2.3 Block diagram (electrical connections) ... 8

3 Assembly and connection �������������� 9

3.1 Mount to valve/gear ................................ 9

3.1.1 General assembly instructions for

all output shaft types .............................. 9

3.1.2 Output shaft type A ................................. 9

3.1.3 Mount stem protection tube ................... 10

3.2 Electrical connection ............................ 11

3.2.1 Connection with round plug .................. 11

3.2.2 Fieldbus connection ............................. 12

3.2.3 External potential

conductor connection ........................... 12

3.3 Separate mounting ............................... 13

4 Instructions on operator

control and operation �������������������� 14

4.1 Crank handle, hand wheel .................... 14

4.2 Light emitting diodes

(status and fault signals) ...................... 15

4.2.1 Overview of light emitting diodes .......... 15

4.2.2 Indication of control,

operation direction, end position ......... 16

4.2.3 Status and fault signals ........................ 17

4.3 Display .................................................. 19

4.4 Navigation in the display ...................... 20

4.4.1 Operation of the ”Drive Controller“

rotary push button. ............................... 20

4.4.2 Navigation through the menus ............. 20

4.5 Menu structure ..................................... 20

4.6 Menu overview ..................................... 21

4.6.1 Local operation menu

4.6.2 End position menu

4.6.3 Parameter menu

................. 21

...................... 22

......................... 22

4.7 ‘Local' actuator operation ..................... 22

4.8 COM-SIPOS

PC programming software .................... 24

5 Commissioning ������������������������������� 25

5.1 General information .............................. 25

5.1.1 Observe the following notes ................. 25

5.1.2 Ensuring prerequisites

for commissioning ................................ 25

5.2 Procedure for commissioning ............... 25

5.3 Check/set parameters .......................... 28

5.3.1 Access to the Parameter menu ............ 28

5.3.2 Adjust tripping torques .......................... 28

5.3.3 Adjust speeds/positioning times ........... 30

5.3.4 Select output signal set ........................ 31

5.3.5 Set control mode .................................. 32

5.4 Further settings via COM-SIPOS ......... 32

5.5 Adjust end positions ............................ 35

5.5.1 Position recording with

signaling gear - functional principle ...... 35

5.5.2 Sequence during

end position adjustment: ...................... 36

5.5.3 Adjust signaling gear ratio

(version with signaling gear) ................. 36

5.5.4 Adjust end positions ............................. 37

5.5.5 Adjust mechanical position indicator .... 40

6 REMOTE mode (Remote control) 41

6.1 REMOTE control .................................. 41

6.2 Display and LED indications

in REMOTE mode ................................ 41

6.3 View parameter settings

in REMOTE mode ................................ 42

7 Maintenance, inspection, service 43

7.1 General information .............................. 43

7.2 Lubrication intervals and lubricants ...... 44

7.2.1 Lubrication intervals ............................. 44

7.2.2 Lubricant assignment and quantity: ...... 44

8 Spare parts ��������������������������������������� 45

8.1 General information .............................. 45

8.2 Spare parts list ..................................... 45

8.3 Exploded views .................................... 46

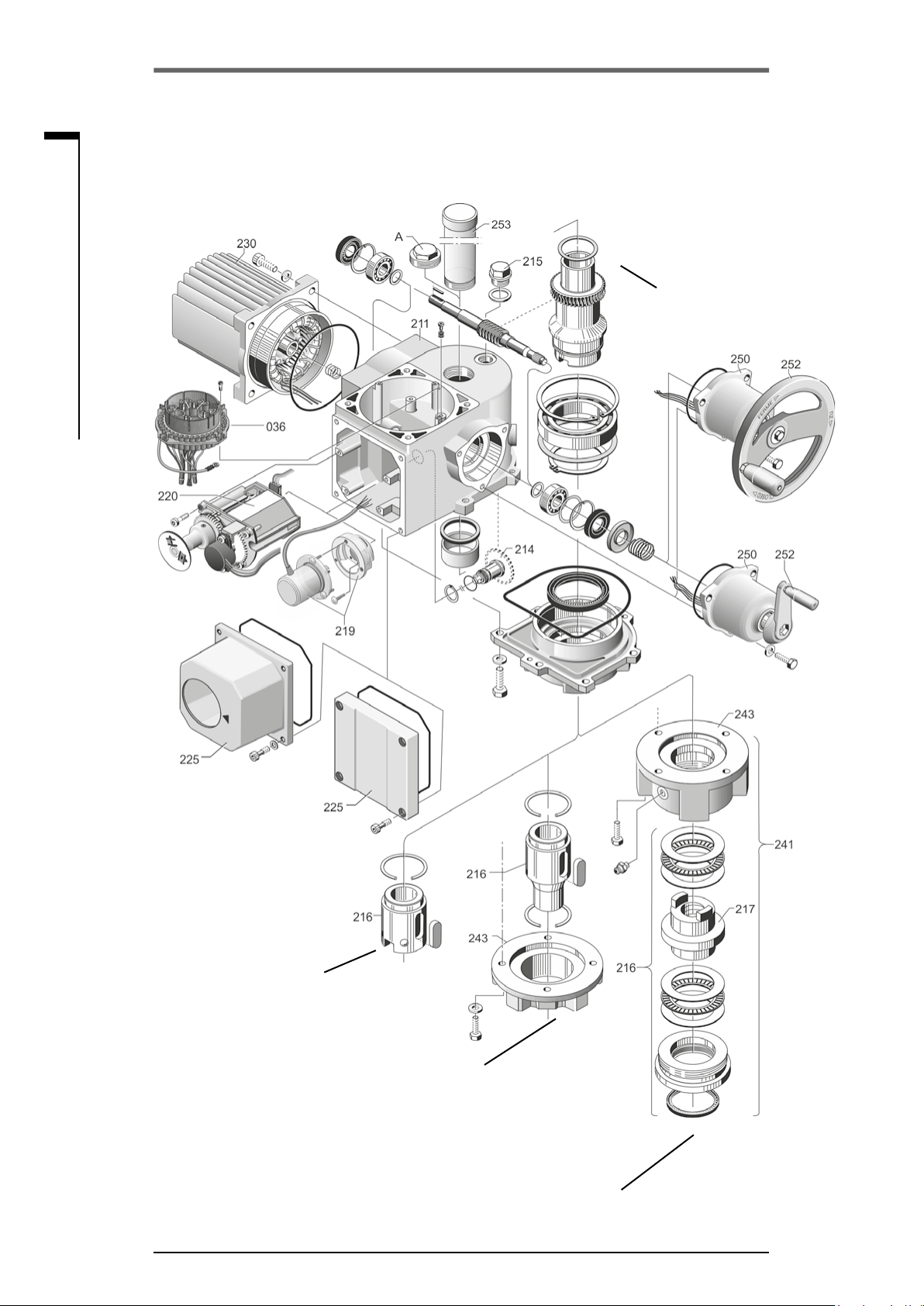

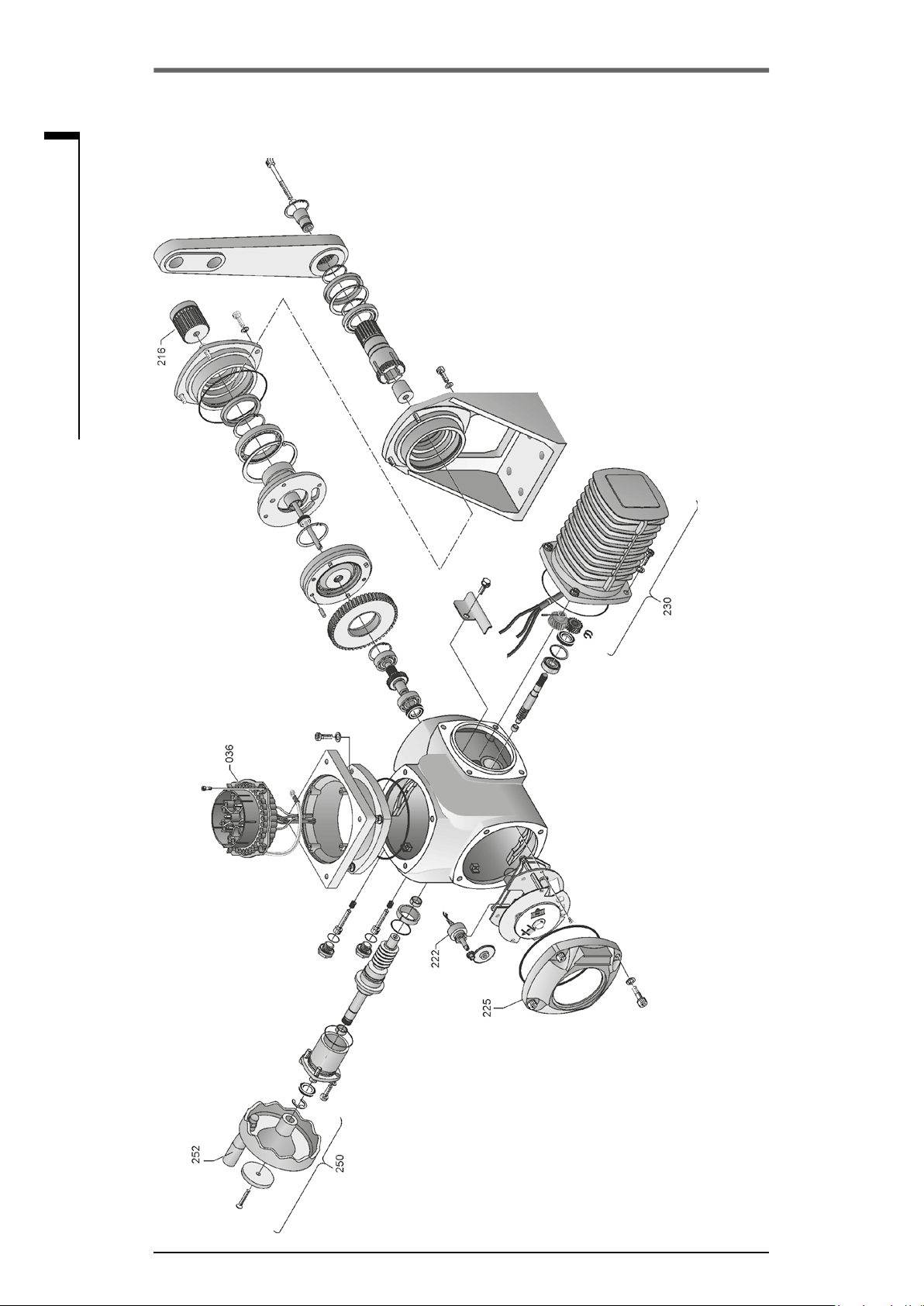

8.3.1 Gear unit 2SA7.1 1/2/3/4.- ................... 46

8.3.2 Gear unit 2SA7.5 5/6/7/8.- .................... 47

8.3.3 Small part-turn gear unit 2SG7...- ........ 48

8.3.4 Small part-turn gear unit 2SQ7...- ........ 49

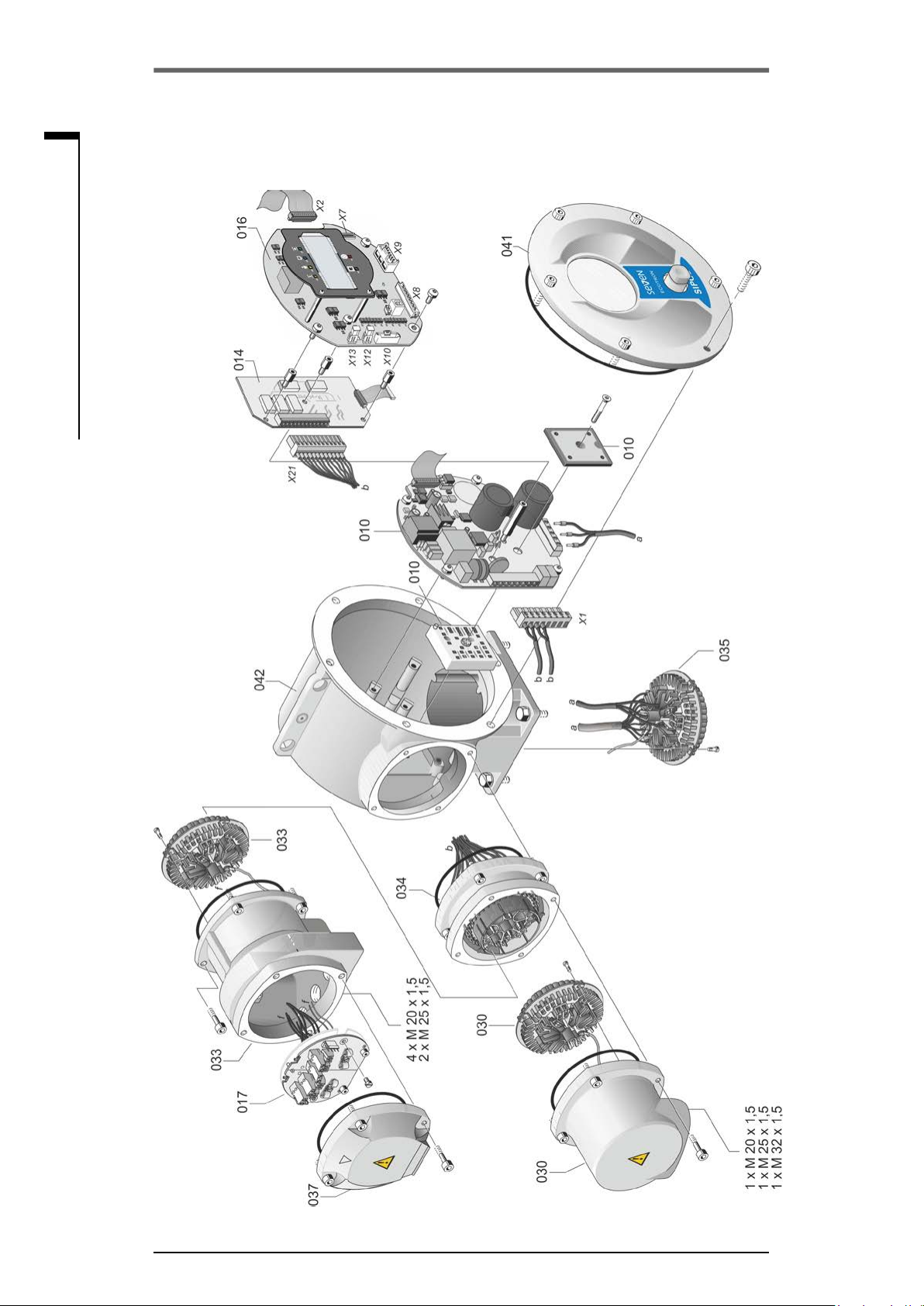

8.3.5 Electronics unit (motor up to 1.5 kW) .. 50

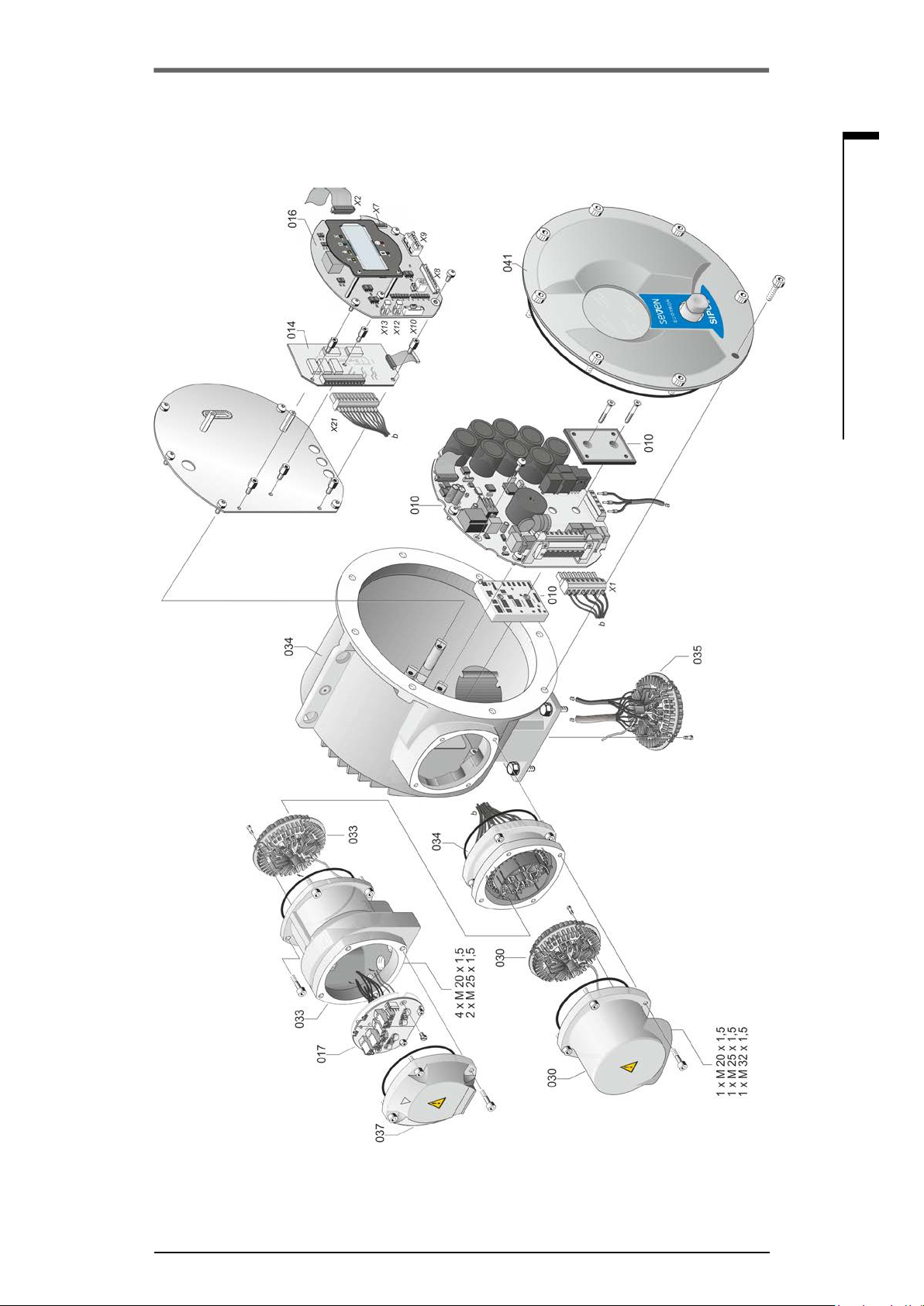

8.3.6 Electronics unit (motor from 3 kW) ....... 51

EU Declaration of conformity/Declara-

tion of incorporation

in accordance with

Machinery Directive ������������������������ 55

Page 2 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

1 General information

1�1 Safety information

General information

The devices referred to in this document are components of installations conceived for industrial

applications. They are designed in accordance with the recognized engineering rules.

All work involved in transport, assembly, installation, commissioning, maintenance and repair has to

be performed by qualied personnel.

Qualied personnel within the meaning of the relevant safety instructions of this documentation are

all persons authorized to perform the required tasks according to the standards of safety technology and who may recognize and avoid potential hazards. They must be thoroughly familiar with the

warnings at the device and the safety instructions of these operation instructions.

For work on power installations, the prohibition of the use of non-qualied persons or similar is stipulated in EN 50110-1 (formerly DIN VDE 0105) or IEC 60364-4-47 (VDE 0100 part 470).

■

Leakage currents

As standard, the leakage current of the actuators exceeds 3.5 mA. Therefore, xed installation

in accordance with IEC 61800-5-1 is required.

■

Residual current circuit breaker or monitoring devices

The integral frequency converter can be used to generate a direct current within the protective

grounding conductor.

Should a residual current-operated protective (RCD) or monitoring (RCM) device be used upstream the network, it must be of type B.

Correct transport, proper storage, mounting and installation, as well as careful commissioning are

essential to ensure trouble-free and safe operation.

1 General information

1

General information

The distribution of this product is restricted according to IEC 61800-3

and may cause radio interferences in domestic environments. In this case it may be necessary to

take additional measures.

The following is of particular importance:

■

The technical data and information concerning the permissible use (installation, connection, am-

bient and operating conditions) provided in the catalog, order documents, operation instructions,

rating plate data and in the other product documentation;

■

The general installation and safety guidelines;

■

The local, plant-specic regulations and requirements;

■

The local ambient conditions, in particular the vibration load, which can be caused when mounting an actuator to a vibrating valve

■

The proper use of tools and lifting and transport equipment;

■

The use of personal protective equipment, especially in high ambient temperatures and with

potential high actuator surface temperatures.

Warnings on the device

Danger of crushing. When pressing in the crank handle or the hand wheel ensure that neither the hand nor

the ngers are crushed, refer to gure.

Applicable for devices of the 2SA7.5/6/7/8 series:

Indicates the lubricant used. Refer also to chapter „7.2

Lubrication intervals and lubricants“ on page 44

Hot surface. Risk of hot surface temperatures (caused

by high ambient temperatures and frequent operation

as well as long activation times).

Y070.301/EN Page 3

Fig�: Danger of crushing

1

Operation instructions

1 General information

SIPOS SEVEN ECOTRON

General information

1�2 Transport and storage

■

The device must be supplied in sturdy packaging.

■

For transport, loop the rope around the hand wheel housing,

refer to illustration. Only use the eyes provided on the elec-

tronics unit (g. item 1) to lift the actuator's own weight.

■

Do not attach the ropes and hooks at the crank handle or

hand wheel for the purpose of lifting.

■

Store in well-ventilated, dry room

at -30 °C – +80 °C.

■

Protect against damp oors by storing on a shelf or pallet.

■

Keep connection hood/cover and cable glands as well as the

cover of the electronics unit closed.

1�3 Disposal and recycling

Packaging

The packaging of our products consists of environmentally friendly materials which can easily be

separated and recycled. We use the following packaging materials: Wood-based panels (MSB/

OSB), cardboard, paper, PE foil. For the disposal of the packaging material, we recommend recycling and collection centers.

Actuator

Fig�: Transport

SEVEN actuators have a modular design and may therefore be easily disassembled, separated

and sorted according to materials, i.e.: electronic parts, different metals, plastics, greases and oils.

The following generally applies:

■

Collect greases and oils during disassembly. As a rule, these are substances hazardous to water

and must not be released into the environment.

■

Arrange for controlled waste disposal of the disassembled material or for separate recycling

according to materials.

■

Observe the national/local regulations for waste disposal.

1�4 Notes to the operation instructions

1�4�1 Safety instructions: Used symbols and their meanings

The following symbols, which have different meanings, are used in the operation instructions.

Non-observance of safety instructions may lead to serious injuries or damage.

Warning marks activities which, if not carried out correctly, can affect the safety of persons or

property.

Notice marks activities which have major inuence on the correct operation. Non-observance of

these notes may lead to consequential damage.

Electrostatically endangered parts are located on circuit boards which may be damaged or destroyed by electrostatic discharges. If the boards need to be touched during setting, measurement

or for exchange, it must be assured that immediately before touching an electrostatic discharge

through contact with an earthed metallic surface (e.g. the housing) has taken place.

Procedure may have been performed by valve manufacturer:

If actuators are delivered mounted to a valve, this step has been done in the valve manufacturer’s

factory. The setting has to be checked during commissioning.

Page 4 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

1�4�2 Scope

For the sake of clarity, not all details of all versions of the product are described in these operation

instructions, nor can they cover all conceivable cases regarding installation, operation and mainte-

nance. For this reason, the operation instructions only contain instructions for qualied personnel

(refer to section 1.1) that are necessary when the equipment is used for the purpose for which it is

intended or in industrial applications.

If the devices are used in non-industrial applications with increased safety requirements, they have

to be ensured by additional safety measures during assembly.

In case of any questions, and especially where detailed product information is not available, contact

the SEVEN sales representative in charge. Always state the type designation and the works number of the respective actuator (see name plate).

It is recommended that the services and support of the factory service are utilized for all planning,

installation, commissioning and service tasks.

The contents of these operation instructions and product documentation shall not become part of or

modify any prior or existing agreement, commitment or legal relationship. The Purchase Agreement

contains the complete and exclusive regulation on material defect liability of SIPOS Aktorik. These

contractual regulations are neither amended nor limited by the descriptions contained in these operation instructions and documentation.

1 General information

1

General information

1�5 Supplementary operation instructions

2SG7 small part-turn actuator

2SQ7 small part-turn actuator

COM-SIPOS PC parameterization software

PROFIBUS operation instructions

MODBUS operation instructions

Enclosure protection IP68-8 m “K51“

Increased vibration resistance “K57“, “K58“

Increased vibration resistance according to seismic class S2A “K59“

Very high corrosion protection

corrosivity category C5 with long protection duration “L38

SIPOS SEVEN actuator with USP

Binary and analog inputs freely available via bus

and other

Any special installation and operation instructions furnished by the suppliers of subcontracted com-

ponents, attachments or xtures are attached to the set of instructions and have to be observed.

Y070.301/EN Page 5

2

Operation instructions

2 General information

SIPOS SEVEN ECOTRON

General information

2 General information

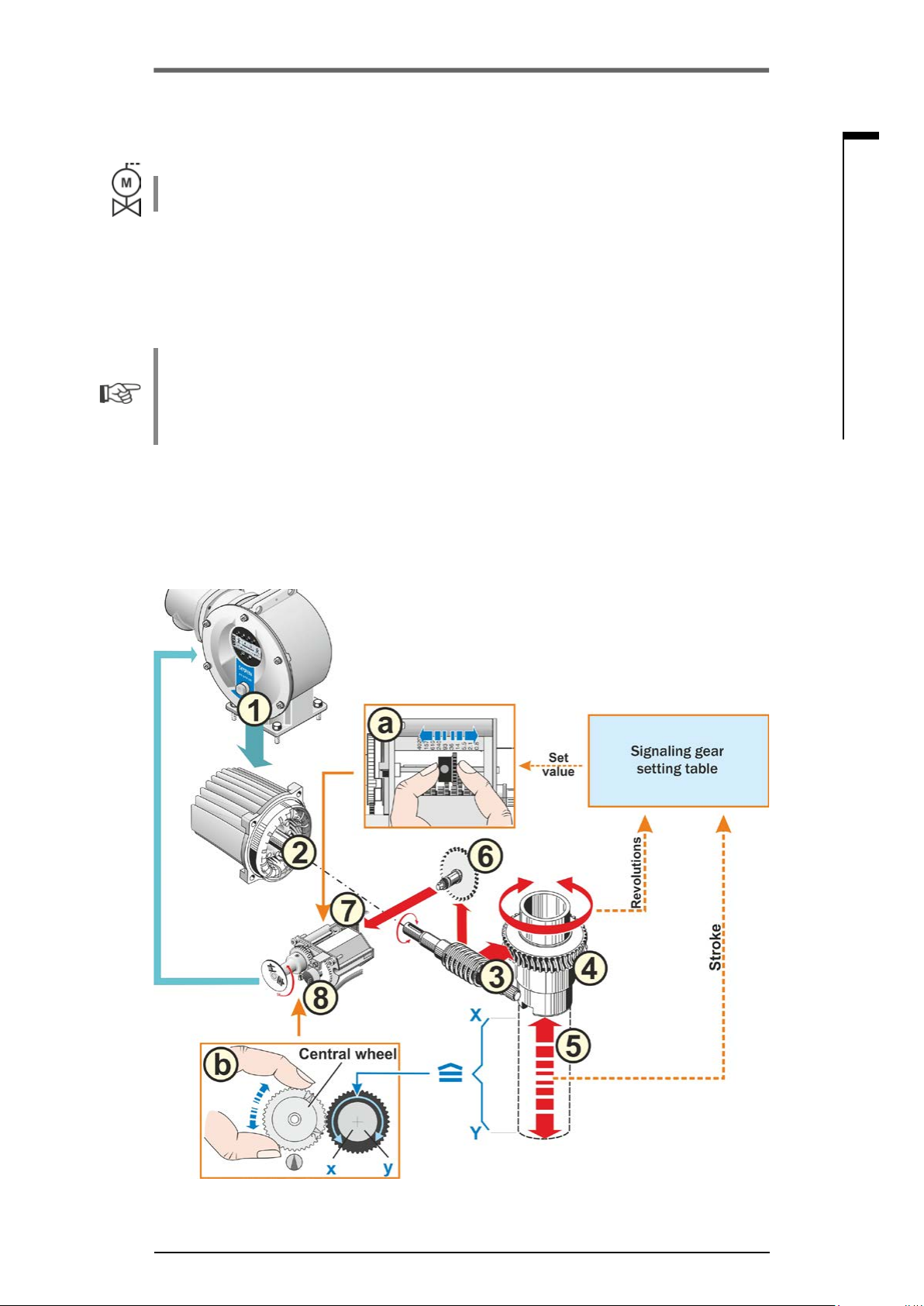

2�1 Functional principle

Description

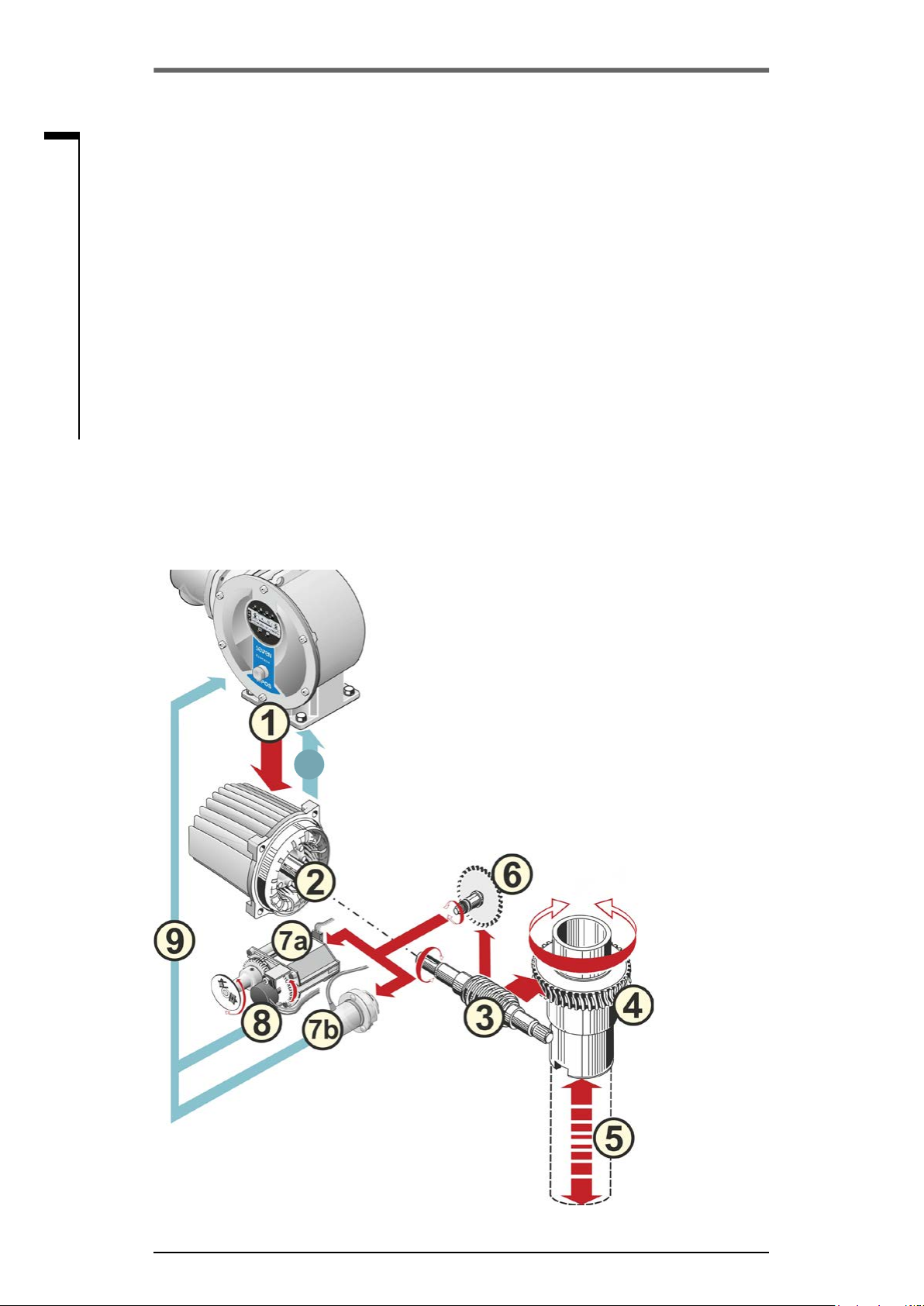

The electronics with integral frequency converter (1) controls the motor (2). The motor turns the

output drive shaft (4) via the worm shaft (3). The output drive shaft (4) drives a gear or a valve stem

(5) via a stem nut.

The motion of the worm shaft (3) is transferred via the signaling shaft (6) to

■

The signaling gear (7a). The signaling gear reduces the movement and turns the potentiometer

(8)�

or:

■

The non-intrusive position encoder (niP) (7b) for "non intrusive“ version. The non-intrusive position encoder counts the number of rotations and records the position within one rotation. The

position recording is also performed without external power supply.

From the position of the potentiometer or the non-intrusive position encoder, the electronics recognizes the position of the output shaft (9) and therefore the position of the operated valve. The motor

is controlled according to the process requirements.

The torque detection (TD) is performed electronically.

TD

Fig�: Functional principle

Page 6 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

2�2 Sub-assemblies

The actuators of the SIPOS SEVEN series

comprise two main assemblies: gear unit and

electronics unit.

For details, refer to chapter „Spare parts“.

The main sub-assembly gear consists

of the sub-assemblies:

1 Plug element electronic connection,

2 Motor

3 Gear unit

2 General information

2

4 Signaling gear or non-intrusive position en-

coder (not for 2SG7) with cover

5 Manual drive (with crank or hand wheel),

6 Possible mechanical extensions, depending

on the version

For the small 2SG7 and 2SQ7 part-turn

actuator, the signaling gear is omitted; the gear

unit has a different shape.

The main sub-assembly electronics unit

consists of the sub-assemblies:

1 Electrical connection (two versions available),

2 Plug element gear connection,

3 Electronic housing with cover

4 Power control PCB, including power module

5 Relay board (option)

6 Control PCB with display and eldbus con-

nection (as an option),

General information

Fig�: Gear unit sub-assemblies

Fig�: Electronics unit sub-assemblies

Y070.301/EN Page 7

2

Operation instructions

2 General information

SIPOS SEVEN ECOTRON

General information

2�3 Block diagram (electrical connections)

The block diagram shows the electronic sub-assemblies and the inputs and outputs for possible

customer-specic connections.

Fig�: Block diagram

Page 8 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

3 Assembly and connection

3�1 Mount to valve/gear

If actuators are delivered mounted to a valve, this step has been done in the valve manufacturer’s

factory. However, the setting has to be checked during commissioning.

■

Heed safety information (refer to chapter 1.1)!

■

Prior to starting the assembly

– Make sure that the intended measures (possible operation of the valve, etc.) are not likely to

cause any injuries to persons or to interfere with the equipment.

– Heed the local ambient conditions, in particular the vibration load, which can be caused

when mounting an actuator to a vibrating valve

■

During assembly, the output shaft insert may fall out of the output drive shaft.

■

When disassembling the electronics cover, make sure the insert does not fall down.

3 Assembly and connection

3

It is recommended that the services and support of the responsible SIPOS Aktorik service centers

are utilized for all planning, installation, commissioning and service tasks.

3�1�1 General assembly instructions for all output shaft types

■

Mounting and operation is possible in any position. Heed the local ambient conditions, in particular the vibration load, which can be caused when mounting an actuator to a vibrating valve.

■

Do not apply force and avoid shocks!

■

Check that the end connection ange and the output shaft type match the valve/gear.

■

Thoroughly clean mounting faces of output mounting anges at actuator and valve/gear.

■

Slightly grease the connection points.

■

Place the actuator on the valve/gear, making sure it is properly centered.

■

Use bolts with at least 8.8 quality. If similar stainless steel bolts are used, they should be greased

slightly using petroleum jelly.

The depth of engagement should be at least 1.25 x the thread diameter.

■

Position the actuator on the valve/gear and tighten the bolts evenly in diagonally opposite sequence.

■

The housing of the actuator consists of an aluminum alloy which is corrosion resistant under

normal environmental conditions. If the paint was damaged during assembly, it can be touched

up with original paint supplied in small quantity units by SIPOS Aktorik.

3�1�2 Output shaft type A

Assembly and connection

Assembly instruction

The stem nut is screwed onto the valve stem by turning the crank handle or the hand wheel.

Spring-loaded A end shafts are subject to high pre-tension. Fitting and removal of the stem nut for

thread cutting must be performed in accordance with assembly instructions!

Fitting and removing the stem nut

If the stem nut was not ordered with a trapezoidal thread (sufx "Y18" to ordering number), or if the

stem nut is worn and has to be replaced, proceed as follows:

Y070.301/EN Page 9

Operation instructions

3 Assembly and connection

SIPOS SEVEN ECOTRON

3

Assembly and connection

Output ange (g. item 1) does not have to

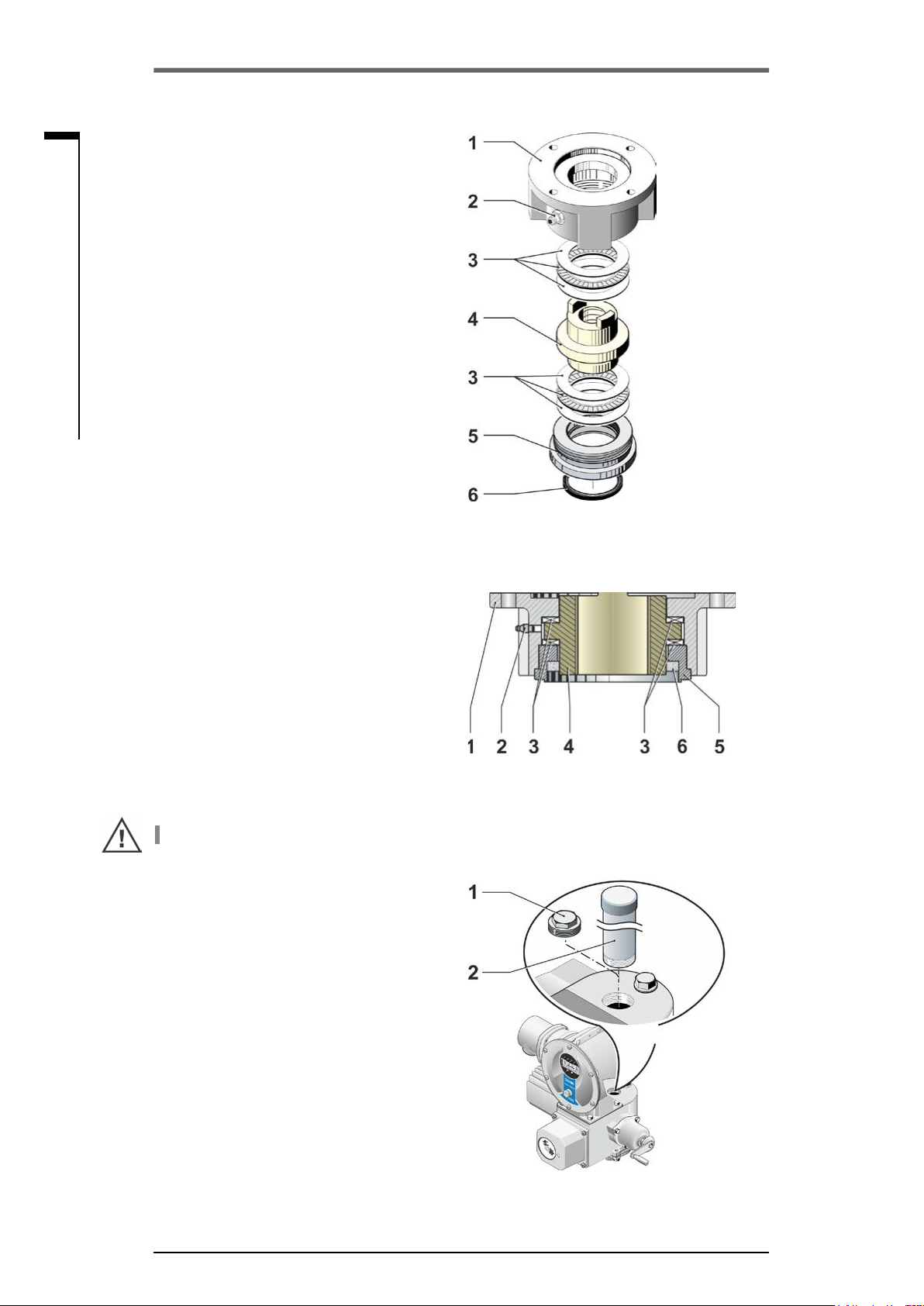

be removed from the rotary actuator!

1. Unscrew centering ring (g. item 5) from

output ange.

2. Take off stem nut (4) together with axial

needle-roller assembly and axial bearing

washers (3).

3. Remove the axial needle-roller assembly and

the axial bearing washers (3) from the stem

nut.

4. Only if the stem nut was delivered without

thread: Cut a thread in the stem nut (4)

(check the concentricity and the axial run-out

when clamping the stem nut) and clean it.

5. Lubricate axial needle-roller assembly and

axial bearing washers (3) with ball bearing

grease and t them on the new or machined

stem nut (4).

6. Insert stem nut (4) with axial needle-roller

assembly into output ange (claws have to

engage properly into the groove of the output

shaft of the actuator).

7. Screw in the centering ring (5) and tighten it

to the stop. Make sure that the radial shaft

seal (6) is inserted correctly.

8. Using a grease gun, press ball bearing

grease into the nipple until lubricant is discharged between the centering ring (5) and

the stem nut (4).

For output shaft form A, ensure that the valve stem is greased separately!

3�1�3 Mount stem protection tube

1. Remove fastener (g. item 1).

Fig�: Output shaft type A

assembly

Fig�: Output shaft type A

installed

2. Check that the extended stem does not exceed the length of the protective tube.

3. Apply sealing compound to the thread and

the sealing faces (e.g. 732 RTV from Dow

Corning, Munich, Germany).

4. Screw in the stem protection tube (2).

Fig�: Mounting the stem protection

tube

Page 10 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

3�2 Electrical connection

The components are designed as to ensure that once connected correctly, uninsulated, live parts

cannot be touched directly; i.e. protection against electric shock is provided in accordance with

IP2X or IPXXB.

Dangerous voltages are also applied when the motor is at standstill. Before opening the terminal

cover or the connection hood, disconnect the supply voltage from the actuator.

Allow at least 1 minute for the capacitors to discharge and do not touch any contacts.

■

The supply voltage must always lie within the voltage range specied on the name plate.

■

For short-circuit protection and for disconnecting the actuator from the mains, fuses and

disconnect switches have to be provided by the customer.

■

Mains cable: Use metal cable glands for mains connection.

■

Signal cable: Use metal cable glands with cable shielding for the connection of the signal cable

to avoid the occurrence of electronic faults. The signal cable must be shielded and the shield

must be xed or grounded on both sides. Ensure careful connection of the screen within the

cable gland!

■

It must be ensured that the cable glands and seals (O-rings) are tted carefully and correctly in order to guarantee the enclosure protection. For details of the permissible conductor

cross-sections, see wiring diagram.

■

Cable glands and cables are not included in the scope of delivery.

3 Assembly and connection

3

Assembly and connection

3�2�1 Connection with round plug

1. Unscrew connection hood (g. item 2) with

plug element (1).

2. Unscrew screw plugs from the required cable

entries in the connection hood.

3. Unscrew plug element (1) from connection

hood (2).

4. Screw in the cable gland (3) only slightly and

insert the connecting cables (4).

5. Connect the connecting cables in accordance

with the circuit diagram enclosed in the connection hood, connecting the earth lead to the

provided terminal in the connection box.

6. Screw plug element (1) into the connection

hood (2) and then x connection hood.

7. Tighten cable glands (3).

Fig�: Connection with round plug

Y070.301/EN Page 11

Operation instructions

3 Assembly and connection

SIPOS SEVEN ECOTRON

3

Assembly and connection

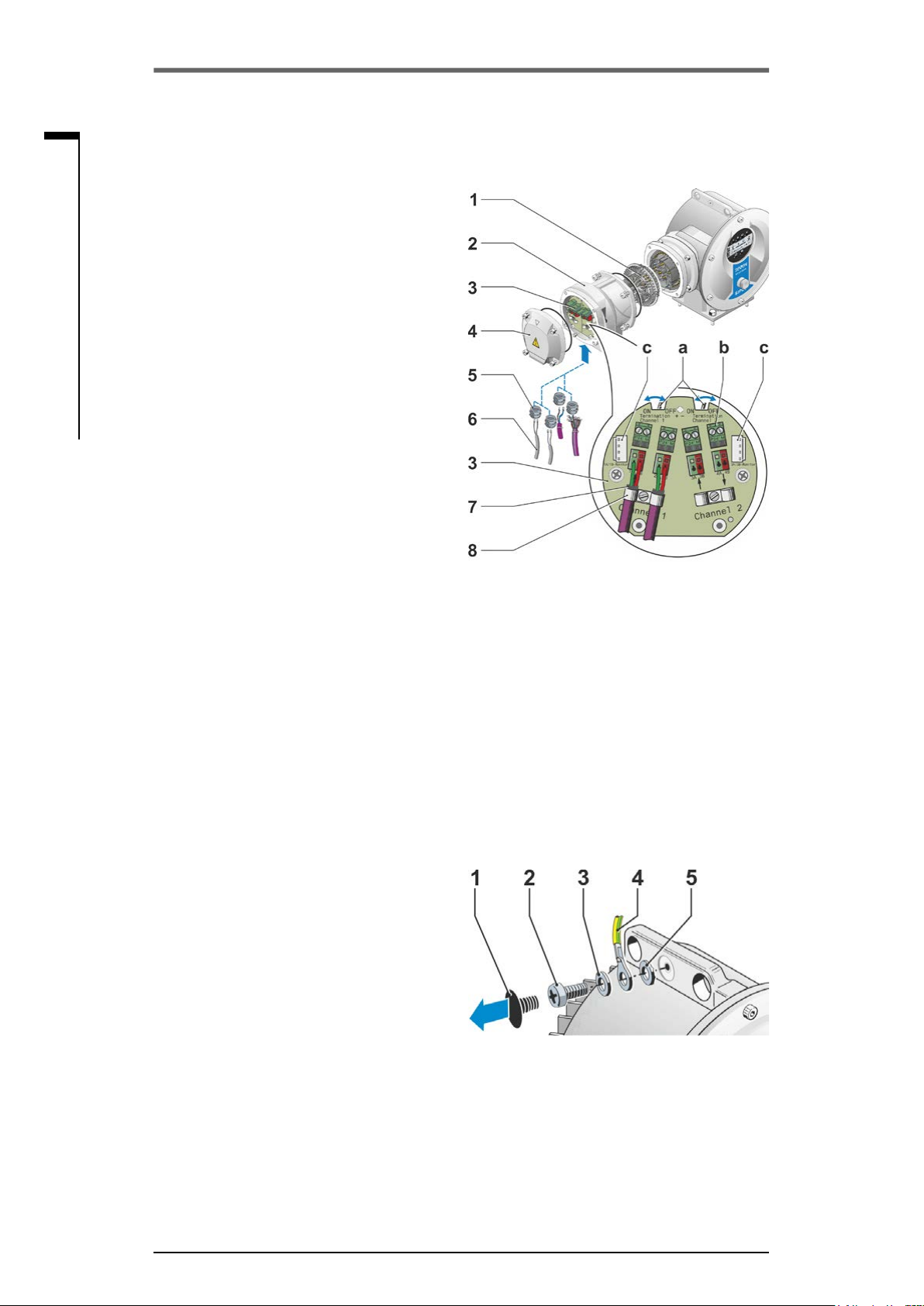

3�2�2 Fieldbus connection

1. Dismantle eldbus connection housing

(g. item 2) and connection cover (4).

2. Unscrew plug element (1) from eldbus con-

nection housing (2).

3. Unscrew screw plugs from the required cable

glands in the eldbus connection housing.

4. Screw in the cable glands (5) only slightly and

insert the connecting cables (6).

For eldbus cables, cable glands without

shield are sufcient, refer to point 7 below.

5. Connect the mains cables and, if required,

signal cables in accordance with the circuit

diagram enclosed in the connection housing,

connecting the earth lead conductor to the

provided terminal in the connection box.

6. Fit plug element (1) into eldbus connection

housing (2) again.

7. Connect eldbus connecting cables to the

bus termination PCB (3). Lead shielding (7)

under metal clamp (8).

8. Fit connection cover (4) and eldbus connec-

tion housing (2) again.

9. Tighten cable glands (5).

Fig�: Fieldbus connection

a = If the actuator is the last device of the bus

b = Connection for external 24 V power supply.

c = Connection for PROFIBUS DP bus monitor

3�2�3 External potential conductor connection

The external potential conductor connection

can be used for functional grounding and not for

protective grounding.

1. Remove plastic fastener (1) from the electronics housing.

2. Fit potential conductor (4) and gripping disc

(5) (shims point in direction of the housing!)

with M5 screw (2) and washer (3).

Fig�: Fit potential conductor

segment, the termination resistor must be

set to ON or a termination must be done

externally.

Enables communication even if the mains

are disconnected.

(Protocol Analyzer).

Page 12 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

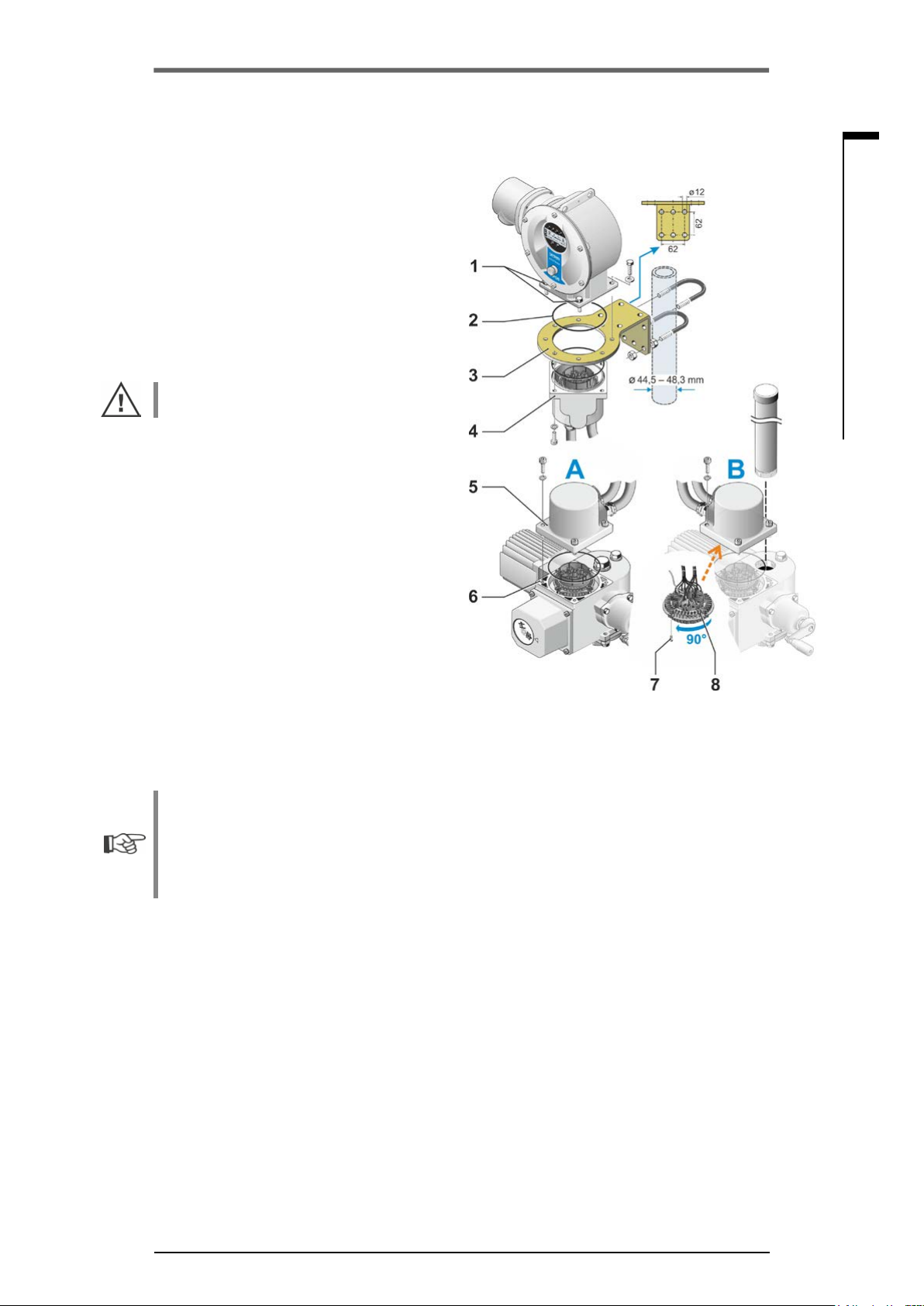

3�3 Separate mounting

If the ambient conditions such as extreme

vibration, high temperature and/or if access is

difcult, the electronics unit is to be mounted

separately from the gear unit.

The assembly kit for mounting the gear unit

and electronics unit separately can be ordered

directly with the actuator or separately as an

accessory (2SX7300-. . .). The assembly kit is

pre-assembled. If the assembly kit is ordered

directly with the actuator, it is included separately with the actuator.

Before starting the work, disconnect actuator

from the mains!

Procedure

1. Install mounting bracket (g. item 3) at the

mounting location of the electronics unit.

2. Remove electronics housing (1) from the gear

unit (6) and mount it on the mounting bracket

(3) with the O-ring (2).

3. Standard assembly, refer to A

Fit "Separate mounting“ assembly kit: Plug

cover with contact pins (4) on lower side of

wall bracket (3) and plug cover with contact

sockets (5) on the gear unit (6).

4. Assembly with stem protection tube, refer

to B

Turn connection hood by 90° or 180° to ensure that cables are not impaired by the stem

protection tube:

Remove screws (7) from round plug, turn

round plug by 90° to 180° and x screws

again. Continue as described in section 3.

3 Assembly and connection

3

Assembly and connection

Fig�: Separate mounting

A = Standard,

B = with stem protection tube

■

During installation, it is important to ensure that the O-rings are tted correctly in order to

guarantee the degree of protection.

■

Generally, it has to be ensured that movable parts, e.g those of the swing lever of the part-turn

actuator, are not impaired by the cables.

■

In exceptional cases, the motor might become very hot. Therefore the cables should not touch

the motor.

Specication of the connecting cable between the electronics unit and the gear unit

Mains connection: shielded and UV resistant, e.g. TOPFLEX®-611-C-PUR-4G1,5/11,3 cable.

TOPFLEX® is a trademark of HELUKABEL.

Control connection: Shielded and UV resistant, e.g. L IY11Y-7x2x0,5/11,4-S.

The connecting cables are available in different lengths:

■

Standard lengths: 3 m; 5 m; 10 m,

■

With additional equipment (lter) up to 150 m.

For separate mounting exceeding 10 m including lter, the value "Cable length exceeding 10 m

and connection via LC lter“ has to be activated for the "Separate mounting" parameter. Refer to

COM-SIPOS tab “Other"

Y070.301/EN Page 13

4

Operation instructions

4 Instructions on operator control and operation

SIPOS SEVEN ECOTRON

Instructions on operator control and operation

4 Instructions on operator control and operation

The COM-SIPOS PC programming software provides for comfortable programming and reading

of the actuator data, refer to „4.8 COM-SIPOS PC programming software“ on page 24.

4�1 Crank handle, hand wheel

■

Motor driven operation of the crank handle/hand wheel is not permitted.

■

After commissioning, the actuator must not be operated beyond the parameterized end positions using the crank handle/hand wheel.

■

When pressing in the crank handle/the hand wheel, make sure that the hand is removed between crank handle/ hand wheel and housing: Danger of crushing! See the following operation

step 3.

The crank handle/handwheel does not rotate during motor operation

Operation

Operation of all actuators except for 2SG7

and 2SQ7:

1. The actuator must be at standstill (1).

2. Remove the clamp (option) (2). The clamp

is used as protection against accidental

engaging of the crank handle/hand wheel, if

the actuator is exposed to heavy vibration or

water pressure (enclosure protection IP68-8).

3. Press crank handle/hand wheel in direction of

the gear housing against spring force (3) and

turn (4). (Caution: Danger of crushing when

engaging!)

If crank handle/hand wheel is pressed in, the motor stops. The actuator can only be operated electrically once the crank handle/hand wheel is released.

Fig�: Operate crank handle

If the actuator is operated manually in "REMOTE“ state and an operation command is present, the

actuator is immediately operated after releasing the crank handle/hand wheel.

For 2SG7 only:

Turn hand wheel without pressing it in. Manual operation interferes with motor operation: If the hand

wheel is turned during motor operation, the positioning time is either extended or reduced, depending on the direction of rotation.

For 2SQ7 only:

Only engage manual drive while motor is at

standstill. Manual operation is automatically

disengaged when switching on the motor.

Direction of rotation

Clockwise turning of crank handle/hand wheel

leads to

■

2SA7 rotary actuator: Clockwise rotation of the output drive shaft (exception: 2SA7.7. and

2SA7.8.)

■

2SG7, 2SQ7 part-turn actuator: With view on the mechanical position indicator: clockwise rotation

at the coupling or at the swing lever.

Depending on the potentially installed gear unit, the direction of rotation may vary.

Fig�: Engage manual operation for 2SQ7

Page 14 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

4 Instructions on operator control and operation

4�2 Light emitting diodes (status and fault signals)

The actuator informs the user via

■

Light emitting diodes (LEDs)

■

Display (refer to chapter „4.3 Display“ on page 19).

This chapter contains an overview of light emitting diodes and the information they provide for the

user.

4�2�1 Overview of light emitting diodes

The LEDs indicate the state of the actuator:

4

1. Light emitting diode

The CLOSE LED is ashing if the actuator

moves in CLOSE direction and is continuously illuminated if the actuator is in end

position CLOSED.

2. Light emitting diode

The LOCAL LED is illuminated if "local operation” is selected.

3. Light emitting diode

The LOCAL LED is illuminated if "REMOTE

mode” is selected.

4. Light emitting diode

The OPEN LED is ashing if the actuator

moves in CLOSE direction and is continuously illuminated if the actuator is in end

position OPEN.

5. LED

operation, refer to “Status and fault signals“

overview below. During end position adjustment, it will be illuminated until the end

position adjustment is OK.

6. LED

is ready for operation. During end position

adjustment and when the crank handle/hand

wheel is operated as well as during faults of

the change over from REMOTE to LOCAL,

the green LED will be ashing. Refer also to

“Status and fault signals“ overview below.

(red) indicates a fault signal during

(green) is illuminated if the actuator

(CLOSE, yellow).

(LOCAL, yellow).

(REMOTE, blue).

(OPEN, green).

Instructions on operator control and operation

Fig�: LEDs

Y070.301/EN Page 15

Operation instructions

4 Instructions on operator control and operation

SIPOS SEVEN ECOTRON

4

Instructions on operator control and operation

4�2�2 Indication of control, operation direction, end position

When illuminated or by ashing, the light emitting diodes (LEDs) indicate

■

the control type: LOCAL mode or REMOTE mode,

■

the direction (OPEN or CLOSE) during operation,

■

the end position if the actuator is in one of the end positions (OPEN or CLOSED).

The states of the LEDs (off – illuminated – ashing) are represented in the operation instructions as

follows:

LED is not illuminated (off)

LED is illuminated

LED is ashing

Arrangement of the LEDs State of the LEDs Explanation

(yellow) (green)

(yellow)

(green)

(blue)

(red)

Both LEDs are not illuminated:

Actuator is at standstill and in mid-travel.

The CLOSE LED is ashing:

The actuator operates in CLOSE direction.

The OPEN LED is ashing:

The actuator operates in OPEN direction.

The CLOSE LED is illuminated:

The actuator is in end position CLOSED.

The OPEN LED is illuminated:

The actuator is in end position OPEN.

The actuator is in “LOCAL mode”.

The actuator is in “REMOTE mode”.

The LEDs indicate: "Ready" or "Fault" and

the states during commissioning. Refer to

"Status and fault signals" chapter below.

Page 16 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

4�2�3 Status and fault signals

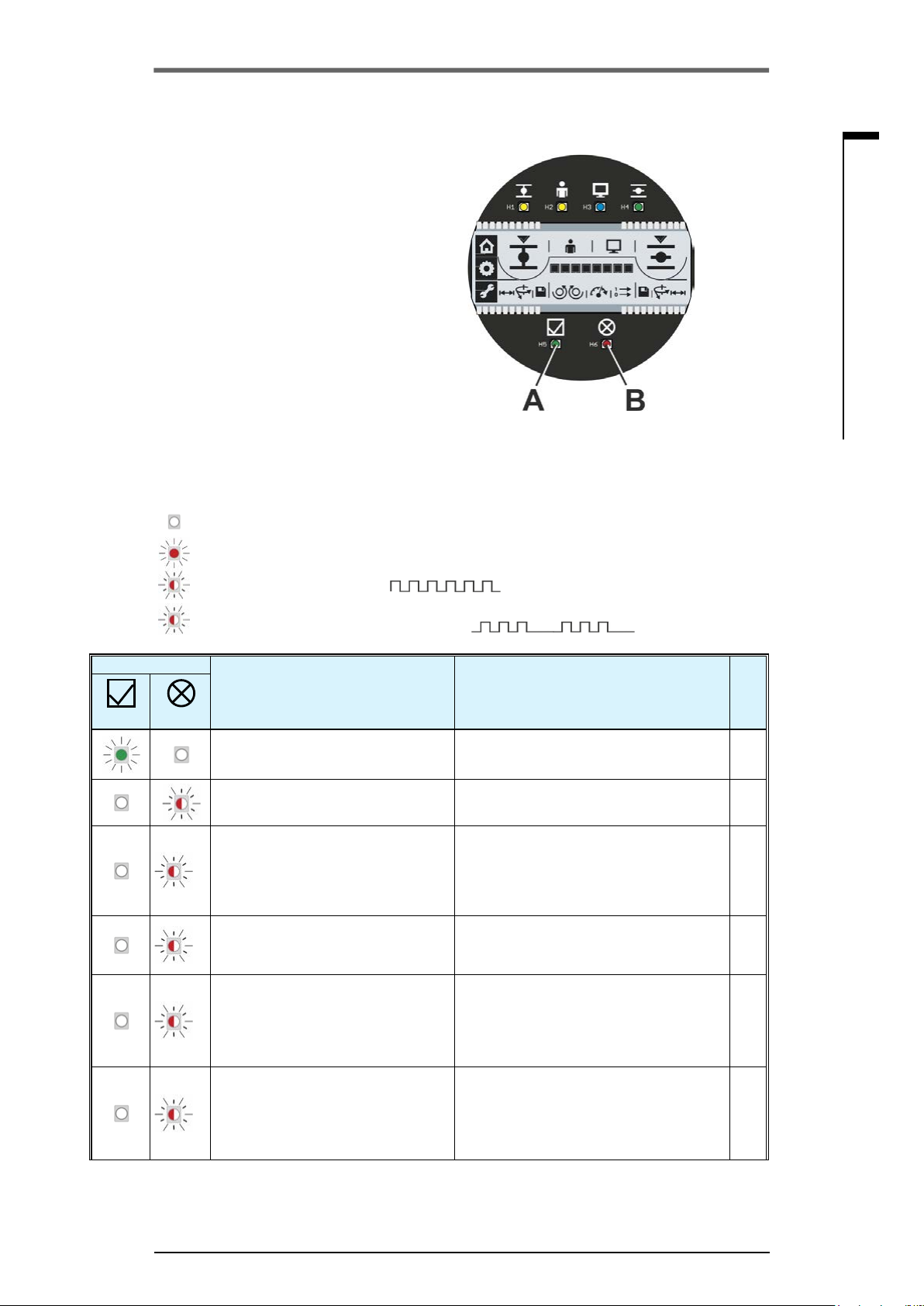

LEDs ”Ready“ (g. item A) and the ”Fault“

(Pos. B) indicate the device state and the

signals during faults. This enables an analysis

of the faults. Some of the "Fault signals” can be

reset, refer to right column "Fault type" in the

following table.

The symbols have the following meaning:

■

S – automatically resetting fault signals

Once the cause of the fault is eliminated, the

fault signal is automatically reset.

■

N – Non-resettable fault signals.

The cause of the fault must be eliminated.

The table below lists possible states of the

“Ready” and “Fault” LEDs and the respective

signications as well as corrective actions. The

states of the LEDs (off – illuminated – ashing)

are represented in the operation instructions as

follows:

4 Instructions on operator control and operation

4

Fig�: A = LED ”Ready“ and

B = LED ”Fault“

(green)

LED

= LED is not illuminated (off)

= LED is illuminated

= LED is continuously ashing

= LED is ashing periodically. The ashing, here 3 times, is repeated after a pause

3 x

of 1 s: 3 x ashing + pause = 1 period

Signication Corrective actions

(red)

The actuator is ready for operation.

Fault: commissioning is invalid

Fault:

2x

Motor temperature too high

Fault:

3x

Mains failure or excessive mains

voltage uctuations.

Fault: Open-circuit behavior of

■

Travel potentiometer/non-intrusive

4x

position encoder or temperature

sensor;

■

feed cables from REMOTE.

Fault:

Travel is blocked, i.e. tripping torque

5x

reached within travel.

Actuator can still be operated into the

opposite direction (leaving the block)

Fault

type

Perform commissioning.

Refer to „5 Commissioning“ on page 25.

■

Check valve for sluggishness.

■

Reduce number of starts.

■

Ambient temperature impermissibly high

■

Check "Separate mounting“ parameter

using COM-SIPOS.

Check supply voltages. S

■

Check cables for separate installation.

■

Check cables (eldbus, if applicable)

■

Check valve for sluggishness.

■

Increase torque values.

■

Check "Separate mounting“ parameter

using COM-SIPOS.

Instructions on operator control and operation

N

S

S

S

Y070.301/EN Page 17

4

Operation instructions

4 Instructions on operator control and operation

SIPOS SEVEN ECOTRON

Instructions on operator control and operation

(green)

LED

(red)

6x

1x

1x

1x 2x

2x

2x

3x

4x

Fault:

■

End positions were passed

■

Fault during runtime monitoring

Fault: Device failure. Service, repair necessary.

Actuator does neither respond

to remote control nor to Drive

Controller.

Commissioning (IBS) active:

End position adjustment OK

Commissioning active:

End position adjustment not OK

Commissioning active:

Commissioning not possible.

Crank handle/hand wheel operated.

Commissioning active:

Crank handle/hand wheel operated

during commissioning.

Commissioning active:

Commissioning via USB or eldbus

active, i.e. on-site commissioning

and operation via local control unit

not possible.,

Change-over from REMOTE to

LOCAL blocked.

Signication Corrective actions

■

Recommissioning.

■

Check signaling gear and travel potentiometer.

■

Check valve for sluggishness.

■

Increase torque values.

■

Check "Separate mounting“ parameter

using COM-SIPOS.

Slide BOOT switch (1) on control PCB

and press RESET (2).

--- ---

Perform commissioning. N

Abort commissioning and evaluate ash

pattern.

■

Release crank handle/hand wheel.

■

Check cables for separate installation.

Release crank handle/hand wheel. S

--- ---

Enable via eldbus. S

Fault

type

N

N

S

Page 18 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

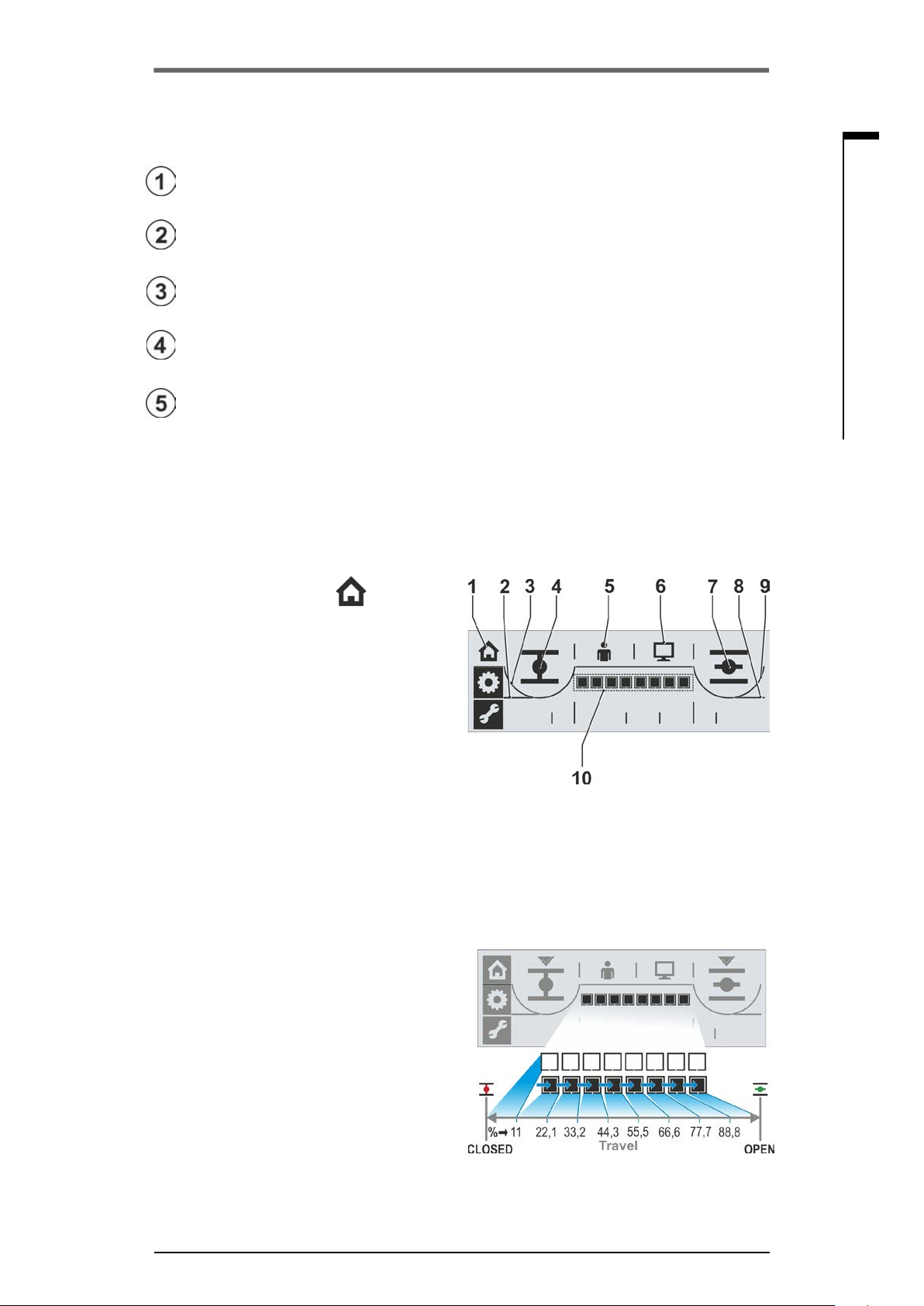

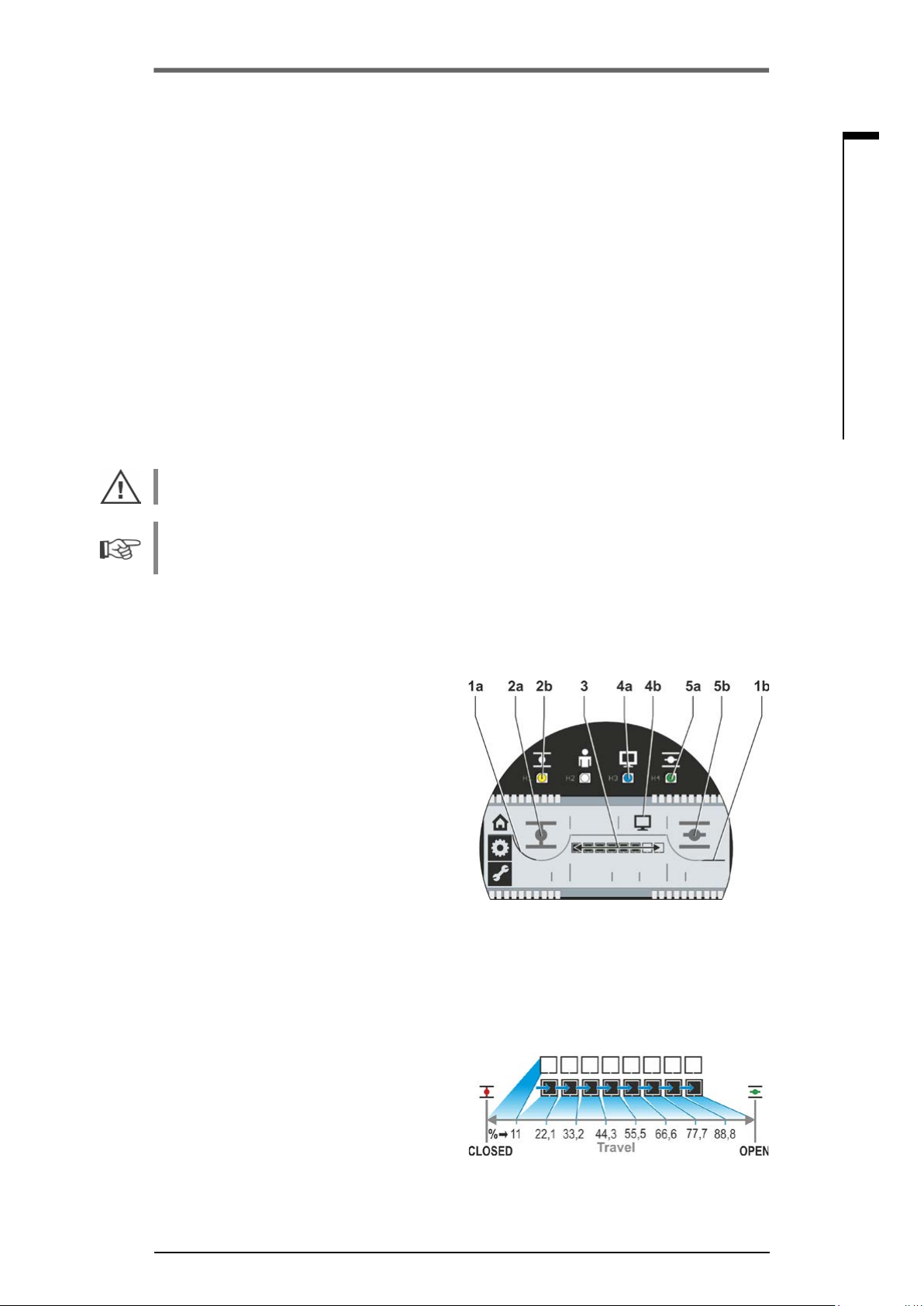

4�3 Display

The graphic segment display utilizes different symbols to indicate the actuator state during

operation, commissioning and parameterization. Clear representation and unambiguous symbols

enable simple operation. The Drive Controller (rotary push button) enables operation directly at the

actuator.

This chapter provides an overview of symbols in the display and the information they provide for the

user. Once acquainted with the signication of the symbols, actuator operation is quick and easy.

4 Instructions on operator control and operation

4

Fig�: Segment display

Item Description on page ▼

1

2

3

4

5

6

7

8

9

10

11

12

13

Parameterization menu 28

End position adjustment menu 37

Local operation menu 22

Indicates the cut-off mode in CLOSE

direction:

Travel dependent or

Torque dependent 38

Indicates that end position

CLOSED is selected

Tick conrms correct end position adjustment

Symbol for end position

CLOSED

LOCAL mode 22

REMOTE mode 22

Symbol for end position OPEN 37

Indicates that end position

OPEN is selected

Tick conrms correct end position adjustment

Indicates the cut-off mode in OPEN

direction:

Torque dependent or

38

37

37

37

37

37

37

Item Description on page ▼

Setting of the cut-off mode in end posi-

14

tion OPEN:

Travel dependent cut-off mode

or

Torque dependent cut-off mode 37

15

16

17

18

19

20

21

Save settings for end position

OPEN

Output signal set for binary

outputs and control mode

Speed 30

Scale shows

■

depending on the preselected

function; the setting for

– tripping torque

– output speed

– output signal set

– control mode

■

the position during travel

Closing direction adjustment:

clockwise or 37

counterclockwise 37

Save settings for end position

CLOSED

Setting of the cut-off mode in end

position CLOSED:

Torque dependent cut-off mode 28

37

37

37

31

28

30

31

32

21

37

Instructions on operator control and operation

Travel dependent 37

Y070.301/EN Page 19

Travel dependent cut-off mode 37

4

1

2

5

3

4

Operation instructions

4 Instructions on operator control and operation

SIPOS SEVEN ECOTRON

Instructions on operator control and operation

4�4 Navigation in the display

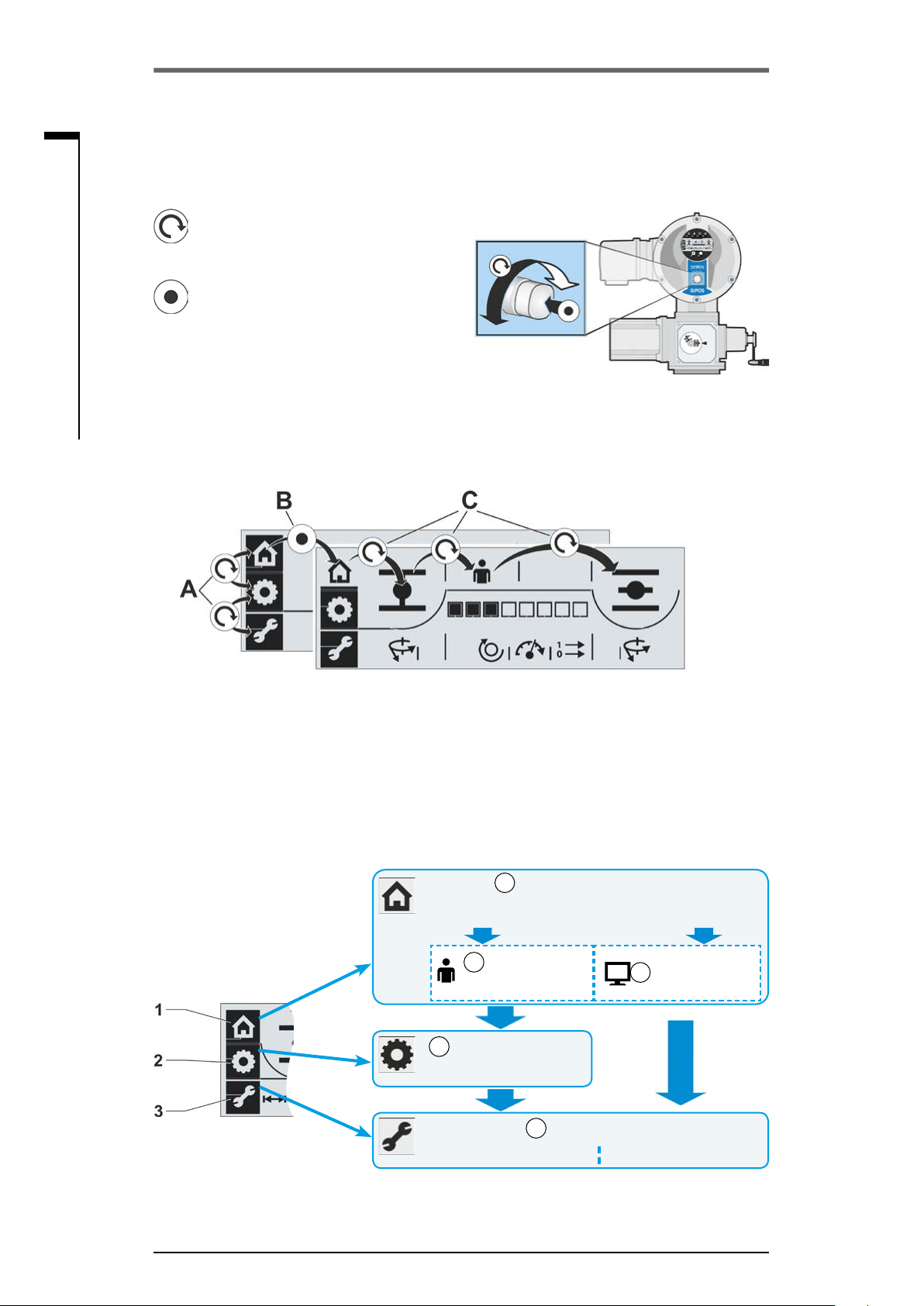

4�4�1 Operation of the ”Drive Controller“ rotary push button�

= Turn Drive Controller:

Select menu item,

end position, setting

= Press Drive Controller:

Conrm selection.

If the Drive Controller is not operated for

more than 10 minutes, the display illumination

changes to standby mode. Hold down Drive

Controller for 2 s or turn by 3 latching positions

to reactivate display.

Fig�: Operate the Drive Controller

4�4�2 Navigation through the menus

Fig�: Navigation in the display

A = Turn Drive Controller:

Selection between menus.

Selected menu is ashing.

4�5 Menu structure

The display proves three menus:

1 Local operation

2 End positions

3 Parameter

Fig�: Menus

B = Press Drive Controller:

Conrm selected menu. Actuator

changes to selected menu and

the menu symbol is no longer

presented inversely.

Localoperation menu

Change over between

LOCAL mode and Remote mode

LOCAL mode

Operate actuator

End position menu

End position adjustment

Change parameter View parameters

Page 22

Page 22

Page 35, 37

Page 28

C = Turn Drive Controller:

Change between menu

items within a menu.

Page 22

REMOTE mode

Parameters menu:

Page 21

Page 41

Page 22

Page 42

The overview shows the menu structure. The encircled digits refer to the explanation below, the

page numbers to the detailed description.

Page 20 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

Explanation

Use the ’Local operation‘ menu to change over between ’LOCAL mode‘ and ’REMOTE mode‘.

The actuator can be operated manually in local operation.

The ’End position‘ menu is used to set the closing direction, end positions OPEN and

CLOSED and the respective cut-off mode.

If the ‘Parameter’ menu is selected in ‘LOCAL mode’, the parameter values can be modied.

If the ‘Parameter’ menu is selected in ‘REMOTE mode’, the set parameter values may be

viewed but cannot be modied.

4�6 Menu overview

4 Instructions on operator control and operation

4

The following descriptions show the display indications and functions available for the individual

menus.

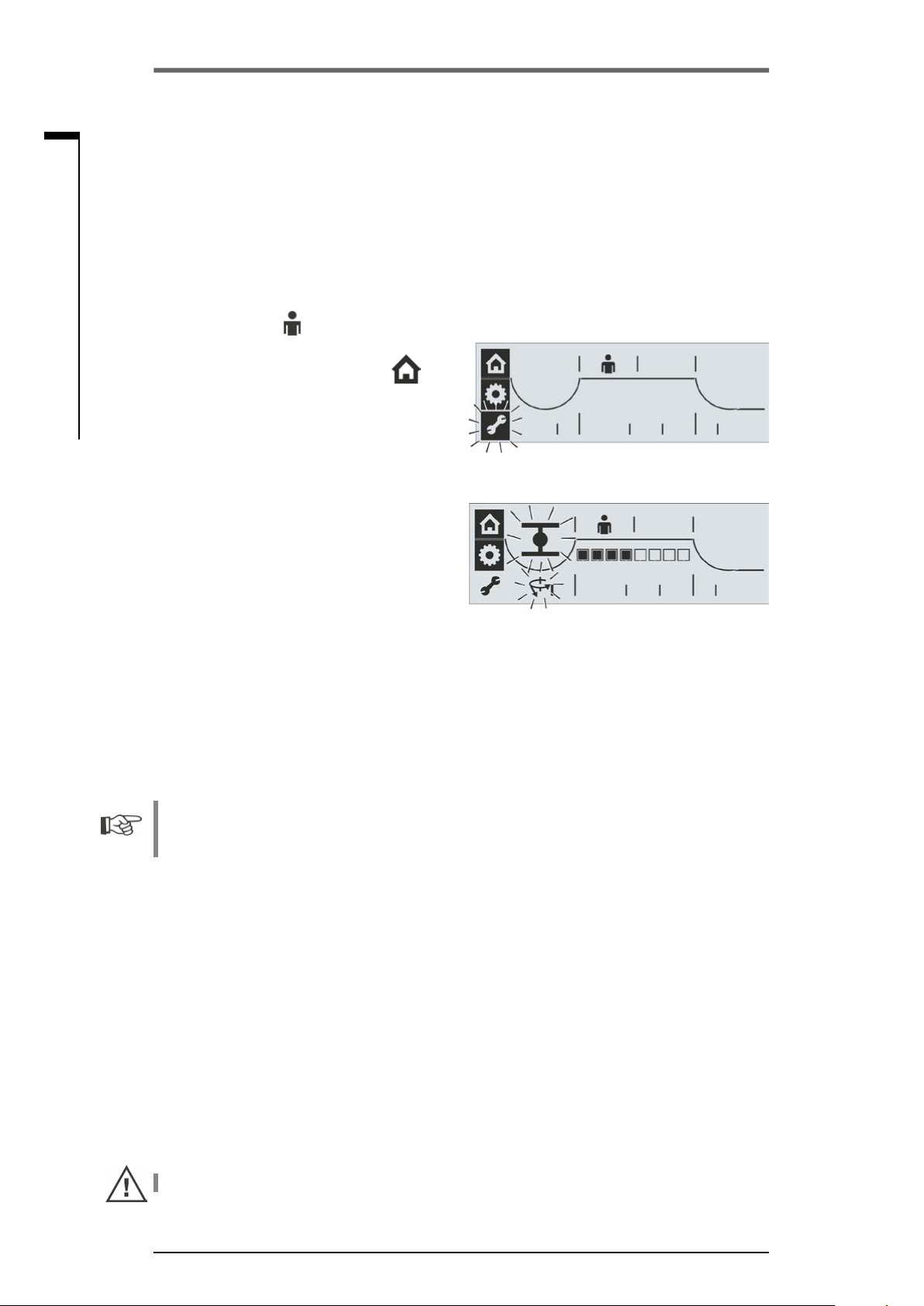

4�6�1 Local operation menu

1 ‘Local operation’ menu is active.

2 Cut-off mode in end position CLOSED is

travel dependent (straight line),

or

3 Cut-off mode in end position CLOSED is

torque dependent (bent line),

4 CLOSE symbol for selection of CLOSE direc-

tion into which the actuator is operated.

5 Control performed locally (LOCAL mode),

or

6 Control performed by DCS/control room (RE-

MOTE mode).

7 OPEN symbol for selection of OPEN direction

into which the actuator is operated.

8 Cut-off mode in end position OPEN is travel

dependent (straight line),

or

9 Cut-off mode in end position OPEN is torque

dependent (bent line),

10 Position indicator; the black rectangles

(segments) indicate how far the actuator has

moved in position OPEN. Each segment corresponds to approx. 11 % of the entire travel.

Refer to gure 2 on the right

Example:

■■■■□□□□ = position OPEN 44.3 – 55.5 %.

If there is no segment active, the actuator is

between CLOSED and 11 % OPEN.

Instructions on operator control and operation

Fig� 1: Local operation menu overview

Fig� 2: Position indicator

Y070.301/EN Page 21

Operation instructions

4 Instructions on operator control and operation

SIPOS SEVEN ECOTRON

4

Instructions on operator control and operation

4�6�2 End position menu

1 ‘End position‘ menu is active.

2 Indicates that end position CLOSED is

selected.

3 Cut-off mode in end position CLOSED:

a = travel dependent;

b = torque dependent

4 Save position for end position CLOSED.

5 Tick indicates that end position CLOSED

has been correctly saved.

6 Closing direction

a = counterclockwise;

b = clockwise.

7 Tick indicates that end position OPEN has

been correctly saved.

8 Save position for end position OPEN.

9 Cut-off mode in end position OPEN:

a = torque dependent;

b = travel dependent

10 Indicates that end position OPEN is

selected.

Fig�: End position menu overview

4�6�3 Parameter menu

1 ‘Parameter‘ menu is active.

2 Tripping torque in CLOSE direction,

3 Scale; indicates the setting of the respective

parameters.

4 Speed.

5 Output signal set selection for signaling

outputs and control modes.

6 Tripping torque in OPEN direction.

If the ‘Parameter’ menu is accessed in

´’REMOTE’ mode, the parameter values may

only be viewed.

4�7 ‘Local' actuator operation

The actuator can only be operated for valid end position setting! For local actuator operation,

‘LOCAL mode’ must be active and the ‘Local operation’ menu selected. The menu can be accessed

from “REMOTE mode” or one of the two other menus.

Change from ’REMOTE mode‘ to

’LOCAL mode‘ and operate the actuator�

The actuator is in the "REMOTE mode" state.

REMOTE LED is illuminated and the symbol for

REMOTE mode

is indicated (g. 1).

Fig�: Parameter menu overview

Fig� 1: Display indicates REMOTE

mode active

Page 22 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

1. Select LOCAL mode: Turn Drive Controller

counterclockwise.

’LOCAL mode‘ symbol

ashing (g. 2).

appears and is

4 Instructions on operator control and operation

4

2. Conrm selection: Press Drive Controller.

LOCAL mode is active, the symbol for

LOCAL mode is continuously displayed

and the yellow Local LED is illuminated.

The symbol for REMOTE mode and the

REMOTE LED are not illuminated (g. 3).

3. Select operation direction:

– CLOSE > Turn Drive Controller coun-

terclockwise, until CLOSED symbol is

displayed.

– OPEN > Turn Drive Controller clockwise

until OPEN symbol is displayed.

4. Operate actuator: Press Drive Controller.

The actuator is operated in direction of

the selected end position

indicator is changing accordingly, see also

previous chapter 4.6.1.

If you hold down the Drive Controller for more than 3 sec., self-retaining starts.

Pressing the Drive Controller once again will stop the actuator.

1

and the position

Fig� 2: Change over to local operation

mode is selected

Fig� 3: Local operation mode is active

Changing from one of the menus to the

’Local operation‘ menu�

1. Complete end position adjustment or

parameterization and select ‘Local operation‘

(house symbol).

The house symbol is ashing inversely

(g. 4).

2. Conrm selection. Press Drive Controller.

The symbol is ashing normally (g. 5) and

the local operation menu is active.

3. Continue as described above from step 4.

Instructions on operator control and operation

Fig� 4: Local operation menu selected

Fig� 5: Local operation menu active

1

If the actuator has switched off automatically before reaching the end position, two causes are possible:

■

Sluggish nal closing element or unfavorable torque curve. In this case, cancel procedure or

■

Valve has reached mechanical stop, in this case readjust end positions (chapter 5)

Y070.301/EN Page 23

4

Operation instructions

4 Instructions on operator control and operation

SIPOS SEVEN ECOTRON

Instructions on operator control and operation

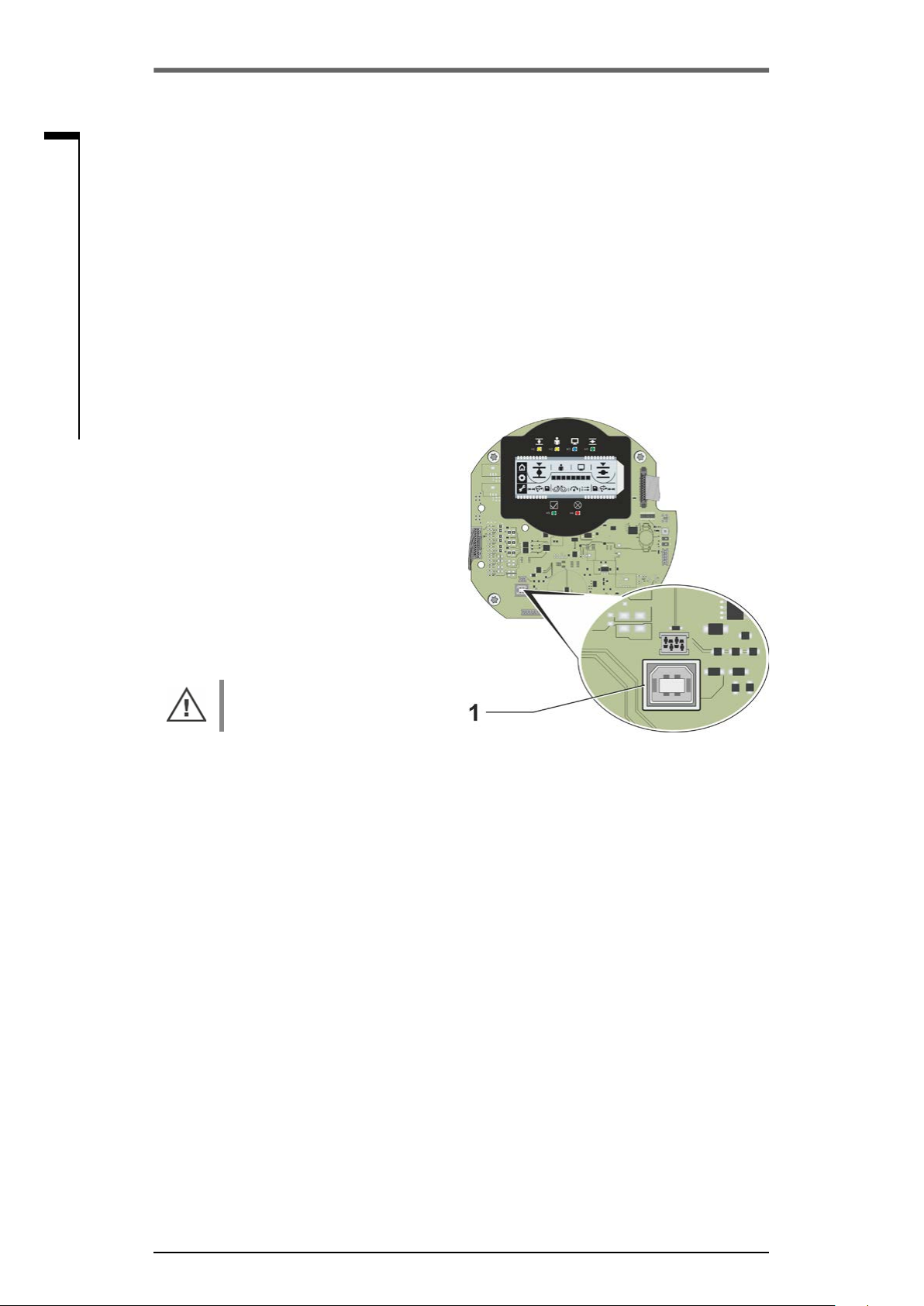

4�8 COM-SIPOS PC programming software

The COM-SIPOS PC parameterization program is a software tool for

■

Observe: Reading the actuator parameters and the device state;

■

Diagnosis: Trouble shooting;

■

Loading new rmware: Software update to the state-of-the-art;

■

Archiving: Saving of the actuator parameters on a PC/laptop;

■

Operation: Operation of the actuator in LOCAL mode;

■

Parameterization: Settings which can be changed in LOCAL mode in the display can

also be changed using COM-SIPOS. Furthermore, the following control types can be

set for REMOTE mode:

– Binary: Pulse contact

– Fieldbus: Permanent contact

– Binary: Permanent contact

■

For further settings via

COM-SIPOS, refer to chapter

„5.4 Further settings via

COM-SIPOS“ on page 32.

The connection between computer

and actuator is established via a USB

cable A/B. The USB port is located on

the control PCB, refer to g. item 1.

COM-SIPOS is available incl. USB

cable and user manual (on ash

drive); order number:

2SX7100-3PC02.

When disassembling the electronics

cover, make sure the insert does

not fall down.

Fig�: USB connnection on control PCB

Page 24 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

5 Commissioning

5�1 General information

5�1�1 Observe the following notes

■

Before performing any work on the installed actuator, check with the plant personnel in charge

that the commissioning may not cause any fault of the plant or hazards to persons.

■

If a cut-off mode is selected that is not appropriate for the valve, the valve may be damaged!

■

There are hazardous voltage levels within the actuator.

■

When changing to 'REMOTE' mode, the actuator moves once an operation command from the

DCS is present!

It is recommended that the services and support of the responsible SIPOS Aktorik service centers

are utilized for all planning, installation, commissioning and service tasks.

5�1�2 Ensuring prerequisites for commissioning

5 Commissioning

5

Commissioning

Check and ensure the following points after assembly or during revision and inspection:

■

The actuator is correctly assembled.

■

All xing screws and connecting elements are rmly tightened.

■

The grounding and equipotential bonding has been correctly implemented.

■

The electrical connections have been correctly implemented.

■

All protection against accidental contact has been implemented for moving or live parts.

■

Neither the actuator nor the valve is damaged.

■

The permitted temperature range for the actuator is maintained and heat dissipation from the nal

control element is also taken into account.

Further checks are also necessary in accordance with the plant-specic conditions.

5�2 Procedure for commissioning

Commissioning is divided into 4 main steps:

1. Change actuator to LOCAL mode

2. Check/set parameters

3. For version with signaling gear: Check/adjust signaling gear ratio.

4. Adjust end positions including closing direction and cut-off mode

Y070.301/EN Page 25

Operation instructions

5 Commissioning

SIPOS SEVEN ECOTRON

5

Commissioning

The following overview shows the individual steps of commissioning�

The numbering of the pages indicate the detailed description.

local operation.

tripping torque

Action Explanation

Switch actuator to LOCAL mode

Change to ‘Local operation’ menu

and

select

Check/set valve parameters

Program

Select local operation Page 22

Change to ‘Parameter’ menu Page 28

■

Program in end position

CLOSED and end position

OPEN.

■

For 2SQ7, set at torque switch

mechanism

For a

description,

refer to:

Page 28

Supp. instr.

Page 5

Program speed or

positioning time

Select output signal set

and control mode

For version with signaling gear: Adjust signaling gear ratio

Adjust

signaling gear

Check/program speed or

positioning time.

■

Select one of the 4 output signal

sets and determine the assignment at the 5 signal outputs.

(Determine predened signals).

■

Select control mode:

–

binary: pulse contact

–

binary: permanent contact

–

eldbus: permanent contact

Check/adjust signaling gear ratio. Page 36

Adjust end positions including closing direction and cut-off mode

Change to ‘End position’ menu Page 37

Select closing

direction

Select rst

end position

/

/

Check/adjust closing direction:

counterclockwise or clockwise

Cannot be selected for 2SQ7.

Select symbol for end position

OPEN or CLOSED. (In our

example end position OPEN. It is

not relevant which end position is

set rst.)

Page 30

Page 31

Page 32

Page 38

Page 38

Cut-off mode 1. Program

Page 26 Y070.301/EN

end position

/

Check/program cut-off mode in the

rst end position; travel-dependent

or torque dependent.

Page 38

Operation instructions

SIPOS SEVEN ECOTRON

Action Explanation

Turn

central wheel

to mid position

5 Commissioning

5

For a

description,

refer to:

Signaling gear only:

1

1

2

2

2

1

Turn central wheel so that arrows 1

and 2 point in upward direction.

Page 38

Approach position

of rst end position

Adjust

central wheel

Save position

of rst end position

Adjust position

indicator

Cut-off mode 2. Program

end position

Approach position of

second end position.

Approach position of rst end

position (here end position OPEN).

Commissioning

1

2

2

2

1

1

Signaling gear only:

Turn central wheel until arrow

points downward and the save

symbol appears in the display.

Turn Drive Controller until Save

symbol starts to ash. Press Drive

Controller.

If mechanical position indicator is

available, check/adjust position

OPEN.

Check/program cut-off mode in the

second end position; travel-

/

dependent or torque dependent.

Move actuator to second end

position (Here end position

CLOSED).

Page 39

Page 40

Page 39

of second end position

Save position

Select Save symbol and

acknowledge.

If mechanical position indicator is

Page 40

available, check/adjust position

Adjust position

CLOSED.

indicator

Change over to

REMOTE control

Change to REMOTE mode in the

‘Local operation’ menu.

Page 22

You do no have to perform all settings. Depending on whether settings have already been

specied when ordering the actuator or whether the actuator was delivered mounted to the valve,

checking the settings will be sufcient.

Y070.301/EN Page 27

5

Operation instructions

5 Commissioning

SIPOS SEVEN ECOTRON

Commissioning

5�3 Check/set parameters

Parameters ‘Cut-off torque CLOSE‘, ’Cut-off torque OPEN‘ ’Speed‘, and ’Signal set‘ are set/programmed via the ’Parameter‘ menu. The sequence of the programming steps is not binding. In the

following descriptions, the sequence complies with the indication in the display.

5�3�1 Access to the Parameter menu

1. Change to the ’LOCAL mode‘ state:

a. Select symbol

b. Conrm selection: Press Drive Controller.

2. Select symbol for ‘Local operation‘ Turn

Drive Controller.

The symbol is blinking.

3. Conrm selection: Press Drive Controller.

The ’Local operation‘ symbol is blinking

inversely.

4. Select ‘Parameter’ menu:

Turn Drive Controller until wrench symbols

starts to ash inversely (g. 1).

5. Conrm selection: Press Drive Controller.

The actuator is in the ‘Parameter‘ menu,

the wrench symbol is continuously illuminated and the symbol for the rst parameter is blinking, here torque in end position

CLOSED (g. 2).

Now the individual parameters can be selected

(turn Drive Controller).

: Turn Drive Controller.

Fig� 1: Select Parameter menu

Fig� 2: Parameter menu active

Select and conrm wrench symbol to quit the

‘Parameter’ menu.

5�3�2 Adjust tripping torques

■

For 2SQ7 actuators, the tripping torque can be set at the torque switching mechanism, refer to

supplement to operations instructions Y070.449

■

For 2SG7 actuators, the tripping torque cannot be changed.

Tripping torque

The setting determines the torque to be achieved in relation to the load, to cause the motor to trip.

This applies to torque-dependent tripping in the end position as well as to a block. Therefore, the

tripping torque also has to be adjusted for travel-dependent cut-off mode.

The tripping torque of an actuator is based on the sizing, dened by the application. The tripping

torque range of the actuator is listed on the name plate.

For

■

actuators of duty classes A (OPEN-CLOSE duty) and B (inching/positioning duty) between

30 – 100 % and for

■

actuators of duty class C (modulation duty) between 50 – 100 %,

the tripping torque can be set in steps of 10% of the max. torque. Default setting is the lowest

possible value (typically 30 % of the maximum value for classes A and B, and 50 % of the maximum

value for class C).

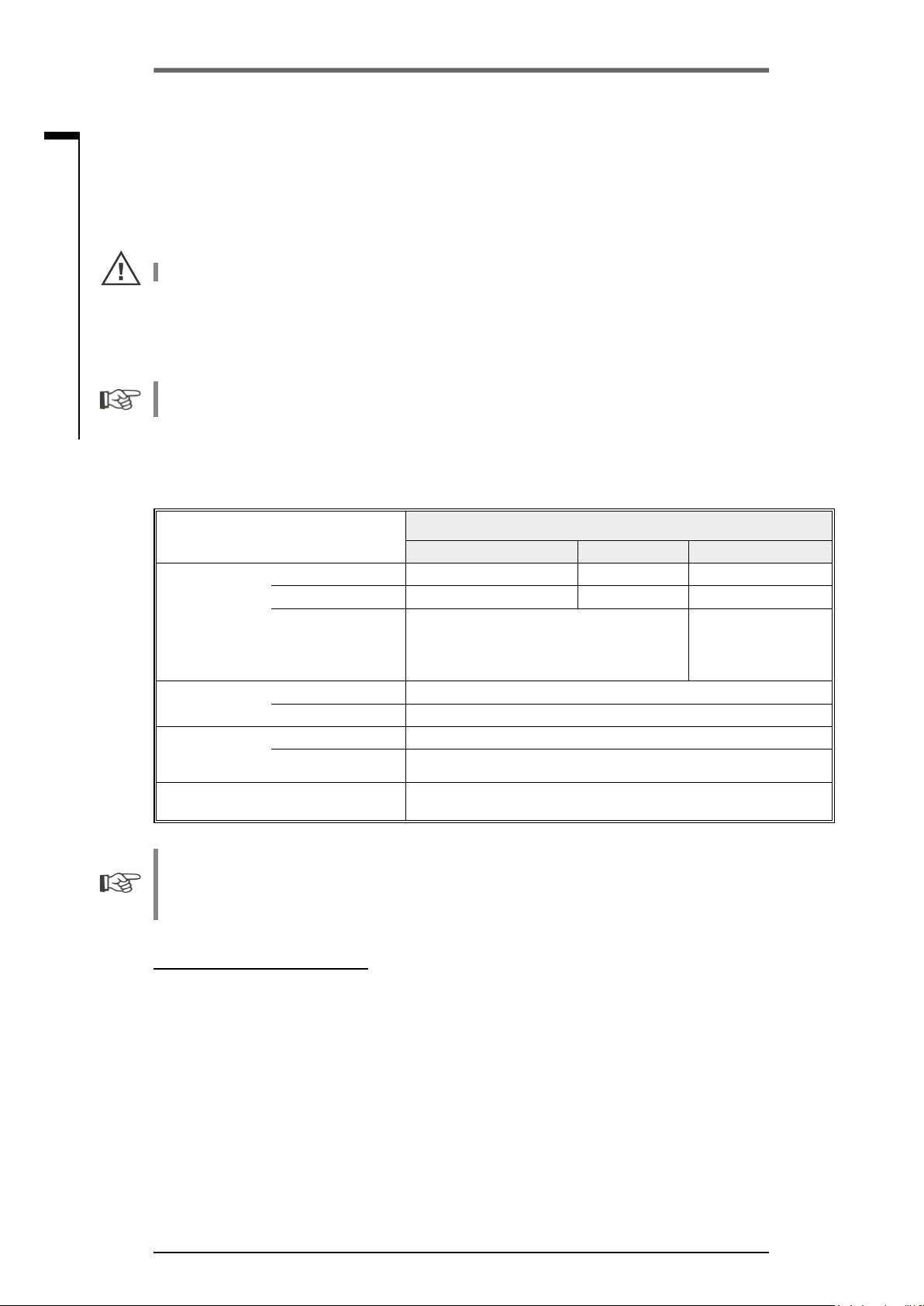

The following table shows the possible setting values.

If a cut-off mode is selected that is not appropriate for the valve, the valve may be damaged!

Page 28 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

5 Commissioning

Tripping torques

Tripping range

[Nm]

Indication in the

display ►

Classes A and B (type of duty in compliance with EN 15714-2) – 2SA70���/2SA73���

9 – 30 9 12 15 18 21 24 27 30

18 – 60 18 24 30 36 42 48 54 60

37 – 125 37 50 62 75 87 100 112 125

75 – 250 75 100 125 150 175 200 225 250

150 – 500 150 200 250 300 350 400 450 500

300 – 1,000 300 400 500 600 700 800 900 1,000

600 – 2,000 600 800 1,000 1200 1400 1600 1800 2000

1200 – 4,000 1200 1600 2000 2400 2800 3200 3600 4000

Class C (type of duty in compliance with European Standard EN 15714-2) – 2SA75���

10 – 20 10 12 14 16 18 20

20 – 40 20 24 28 32 36 40

40 – 80 40 48 56 64 72 80

87 – 175 87 105 122 140 157 175

175 – 350 175 210 245 280 315 350

350 – 700 350 420 490 560 630 700

700 – 1,400 700 840 980 1120 1260 1400

1400 – 2,800 1400 1680 1960 2240 2520 2800

30 % 40 % 50 % 60 % 70 % 80 % 90 % 100 %

■□□□□□□□ ■■□□□□□□ ■■■□□□□□ ■■■■□□□□ ■■■■■□□□ ■■■■■■□□ ■■■■■■■□ ■■■■■■■■

▲30 % are set as standard

Possible values for setting in Nm of Md

▲50 % are set as standard

max

5

Commissioning

Operation sequence

1. Call up ’Parameter‘ menu; the wrench

symbol

„5.3.1 Access to the Parameter menu“

on page 28.

2. Conrm; press Drive Controller.

The symbol for tripping torque (1) in end

position CLOSED (2), both blinking, as

well as the scale (4) with the setting range

between 30 % and 100 % will be displayed.

The segments (black triangles) (3) indicate

the current setting, one segment represents

a step of 10 %. The illustration on the right

indicates that the adjusted tripping torque

amounts to 60 % of the maximum torque.

3. To change the indicated setting, press the

Drive Controller.

The symbols for tripping torque and

end position CLOSED are continuously

illuminated and the black segments of the

scale are blinking.

4. Turn Drive Controller, to change the setting

(for actuator classes A and B: 30 % – 100 %;

for actuator class C: 50 % – 100 %).

For the setting values per level, refer to the

table above.

The scale (g. 2, item 1) indicates the modication.

5. Press Drive Controller; the changed setting

is accepted and the symbols for end position

CLOSED and tripping torque will be ashing

again.

Proceed accordingly to set tripping torque in end

position OPEN. Select the symbol for tripping

torque in end position OPEN (g. 3, item 1) and

continue from step 3 as described above.

is blinking. Refer also to

Fig� 1: Set tripping torque in end position

CLOSED

Fig� 2: Tripping torque scale

Fig� 3: Tripping torque in end position

OPEN

Y070.301/EN Page 29

Operation instructions

5 Commissioning

SIPOS SEVEN ECOTRON

5

Commissioning

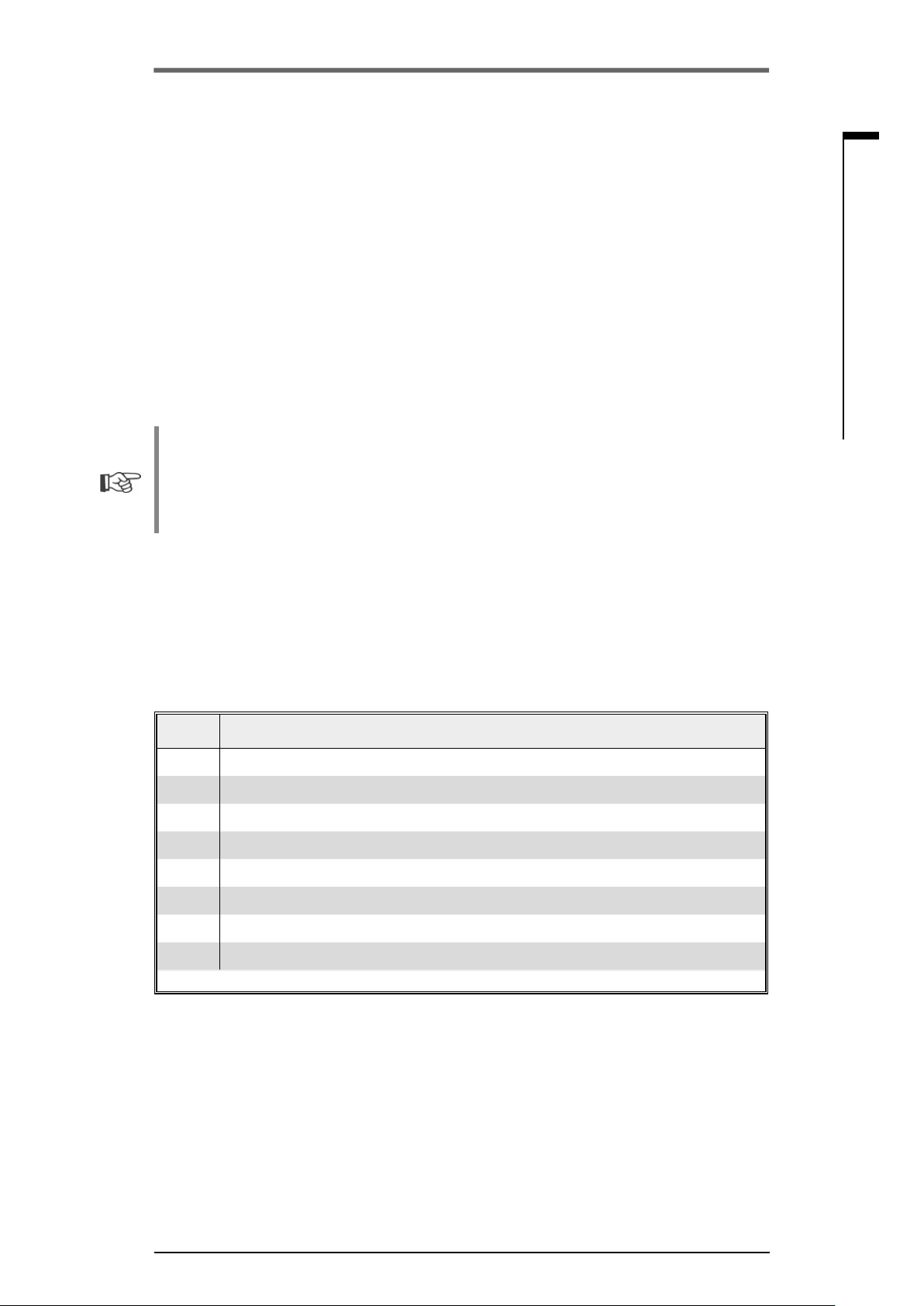

5�3�3 Adjust speeds/positioning times

Adjust the speed/positioning time to dene the speed at which the actuator is operated. Depending

on the actuator type, different values can be set for speed/positioning time, refer to table below (actuator type and the adjustable speed range is also indicated on the name plate). New actuators are

set in the factory. Unless requested otherwise by the customer, the default parameter for CLOSE

and OPEN directions is level 4 of the 7-level setting range (step-up factor: 1.4).

If the current values are to be retained, continue with chapter „5.3.4 Select output signal set“ on

page 31.

Speed

ranges

Indication in the

display ►

1,25 – 10 1.25 1.75 2.5 3�5 5 7 10

2,5 – 20 2.5 3.5 5 7 10 14 20

5 – 28 5 7 10 14 20 28 --5 – 40 5 7 10 14 20 28 40

10 – 80 10 14 20 28 40 56 80

20 – 112 20 28 40 56 80 11 2 ---

20 – 160 20 28 40 56 80 112 160

Positioning time

range

80 – 10 80 56 40 28 20 14 10

■□□□□□□□ ■■□□□□□□ ■■■□□□□□ ■■■■□□□□ ■■■■■□□□ ■■■■■■□□ ■■■■■■■□

Positioning time for part-turn actuator 2SG7 and 2SQ7

Possible values for speed [rpm]

Possible values for positioning time [s/90°]

Operation sequence

The actuator is in the ‘Parameter‘ menu.

1. Turn Drive Controller until symbol for speed

is blinking (g. 1, item 2).

The black segment in the scale, g. 1,

item 1, indicates the currently set speed/positioning time level, see also table above.

2. Press Drive Controller.

The black segments in the scale are

blinking (g. 2).

3. Turn Drive Controller and selected desired

speed/positioning time level.

The scale indicates the selected level (g. 2,

item 1).

4. Press Drive Controller.

The parameter value of the selected level is

accepted and the speed symbol is blinking.

Now, one of the 4 output signal sets can be

selected. Turn Drive Controller until the symbol

for signal set is indicated.

▲

Level 4 is set as standard.

Fig� 1: Speed/positioning time level

Fig� 2: Change speed/positioning time level

Page 30 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

5�3�4 Select output signal set

You may dene which output signals are present at the 5 signal outputs. You may choose between

4 output signal sets (consisting of predened output signals for each of the 5 signaling outputs).

Output signal

sets

Indications on

display

Set 1

(defaut setting)

■□□□□□□□

Set 2

□■□□□□□□

Set 3

□□■□□□□□

Set 4

□□□■□□□□

* H = active high: supply voltage binary output,

L = active low: 0 V).

Level active high or active low is set when reaching the status.

** for 2SG7... “Fault motor temperature”

Level*

outputs

Signaling

H a Travel OPEN

1

H b Travel CLOSE

2

L c Torque OPEN/CLOSE reached

3

H d Ready + REMOTE

4

L e Warning motor temperature**

5

H f End position OPEN

1

H g End position CLOSED

2

H h Blinker

3

H d Ready + REMOTE

4

L i Warning motor temperature**

5

H f End position OPEN

1

H g End position CLOSED

2

L j Fault

3

H k Local

4

L i Warning motor temperature**

5

H a Travel OPEN

1

H b Travel CLOSE

2

H d Ready + REMOTE

3

L l Torque OPEN reached

4

L m Torque CLOSE reached

5

Signal Explanation

5 Commissioning

a Travel OPEN:

For travel-dependent cut-off in position 100 % OPEN;

for torque-dependent cut-off in position >= 98 % OPEN.

b Travel CLOSE:

For travel-dependent cut-off in position 0 % ;

for torque-dependent cut-off in position >= 2 % OPEN.

c Torque OPEN/CLOSED reached:

For torque-dependent cut-off within end position range OPEN

or CLOSED.

Ready + REMOTE

d

If the actuator can be operated from REMOTE.

e Warning motor temp�:

If the set motor warning temperature (default: 135 °C) has

been reached.

f, g End position OPEN, end position CLOSED:

For travel-dependent cut-off in position 100 % OPEN/ 0 %

OPEN.

For torque-dependent cut-off,

if tripping torque within end position range (>= 98 % OPEN/

<= 2 % OPEN) is reached.

h Blinker:

0.5 Hz-change between high/low level if the actuator is

operated (low at standstill).

j Fault:

If a fault has occurred.

k Local:

Actuator is in position Local.

Torque OPEN reached:

l

If tripping torque in OPEN direction is reached.

m Torque CLOSE reached:

If tripping torque in CLOSE direction is reached.

5

Commissioning

Operation sequence

1. Turn Drive Controller in the ‘Parameter’

menu until symbol for speed is blinking

(g. 1, item 2).

A black segment indicates the current

set within the rst four digits of the scale

(item 1); in g.1, set 4 is selected (see also

table above).

2. Press Drive Controller.

The black segment, which indicates the ad-

justed output signal set, is ashing (g. 2).

3. Turn Drive Controller and select desired

signaling set (g. 2, item 1).

The segment in the scale indicates the se-

lected output signal set; the rst position on

the left stands for output signal set 1.

4. Press Drive Controller.

The parameter values of the selected output

signal set are accepted and the black

segment for the selected output signal set

is continuously illuminated and the control

mode options are available.

Refer to following section.

Y070.301/EN Page 31

Fig� 1: Indication of output signal sets

Fig� 2: Output signal set selection

Operation instructions

5 Commissioning

SIPOS SEVEN ECOTRON

5

Commissioning

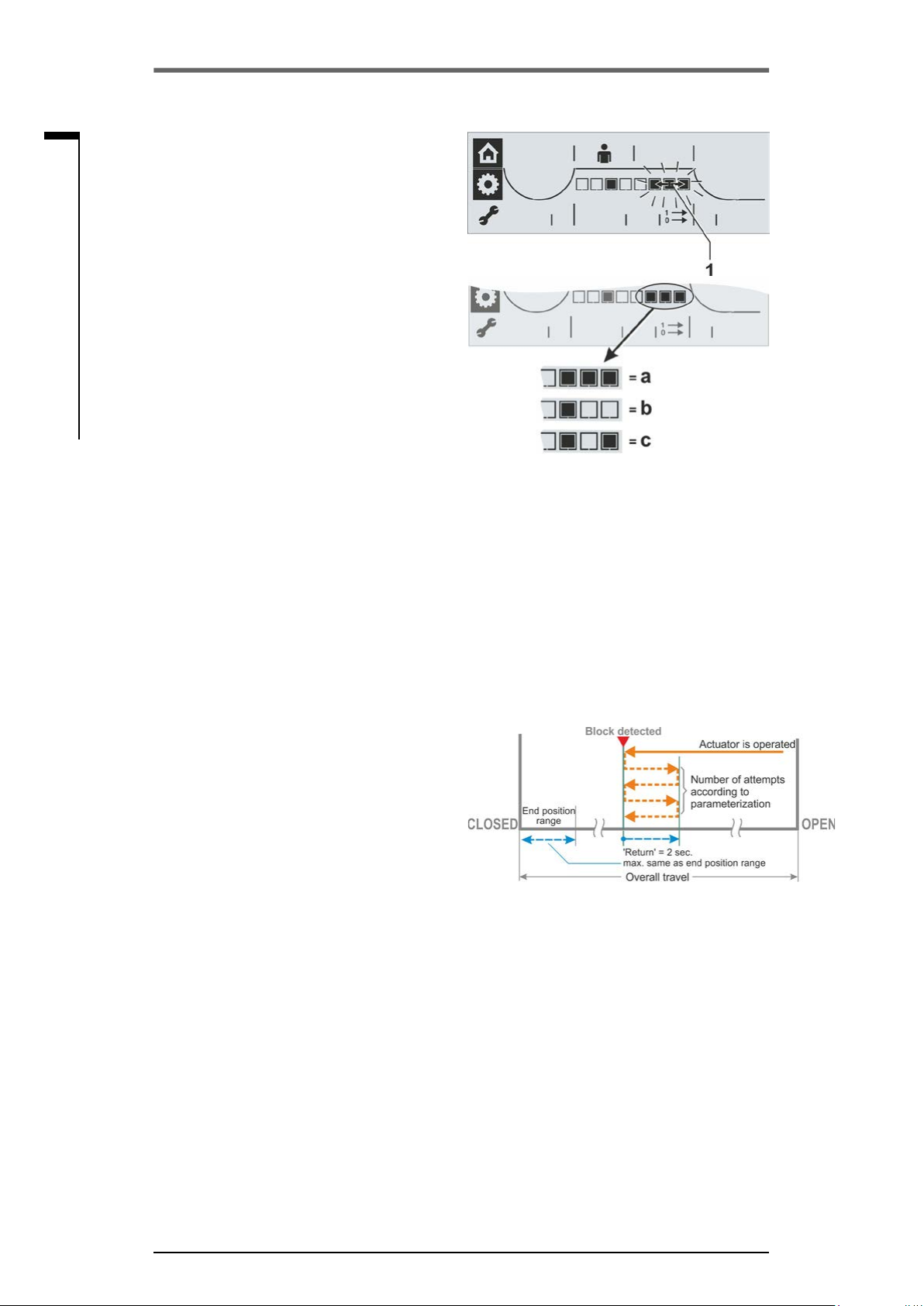

5�3�5 Set control mode

After an output signal set has been selected,

as a next step the setting of the control mode

is enabled; in the display one, two or three

segments will be ashing (see g. 1, item 1).

Operation sequence

1. Turn Drive Controller until the segment(s)

for desired control mode is/are ashing

(see g. 2):

a = Binary: Permanent contact (default

setting)

b = Binary: Pulse contact,

c = Fieldbus: Permanent contact

(only available with eldbus hardware).

2. Press Drive Controller.

The selected control mode is accepted and

the segment(s) for the selected control mode

is/are continuously illuminated.

Fig� 1: Control mode indication

Fig� 2: Control mode selection

5�4 Further settings via COM-SIPOS

Other parameters can be set using the COM-SIPOS PC parameterization program. Some are

described in the following. For further information refer to „4.8 COM-SIPOS PC programming software“ on page 24.

Retry torque block

If the actuator is blocked in move (block outside the end position range), the actuator is tripped and

the red LED ashes periodically 5 times. The actuator is still "ready" since it can still be operated

into the opposite direction.

If the value for the "retry torq.block" parameter

is not equal to zero, the actuator is automatically operated into the opposite direction once

a block has been detected and then again in

the direction of the block. The partial stroke for

this opposite movement will be corresponding

to the setting of the end position range it was

moving to, but not longer than 2 seconds. Then

the movement reverses automatically back. This

happens until the block has been overcome

or the programmed number of tries has been

reached.

Default setting is 0.

Fig�: Retry torque block

Motor temperature warning

A warning is issued once the motor temperature has reached a preset value.

A value between 0 and 155 °C can be set.

The warning signal can be provided via binary signal and eldbus protocol.

Default value is 135 °C.

This parameter is not available for the part-turn actuator 2SG7.

Motor heating

The motor heating can be switched on to prevent condensation. When the heater is activated, the

motor can be heated with DC current. The heating up depends on the difference between motor

temperature and ambient temperature.

The heater is switched off as standard.

If exposed to strong climatic uctuations, the actuator should be operated with the motor heater

switched on.

Page 32 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

Motor protection

The motor is equipped with full electronic motor protection against thermal damage. The motor

protection is activated in the factory.

5 Commissioning

End position range

Within the end position range, travel is at a low

speed (positioning speed or long positioning

time). In the event of torque dependent actuator

tripping outside this range, a fault is detected

(„Status and fault signals“ on page 17).

5

5�4�1 DC link voltage limitation

During actuator standstill, high connection voltages (operating voltage above the voltage tolerance

of up to +15 %) will increase the DC link voltage, which will be electronically limited to a permissible

value.

Deactivating this function is only useful for very specic plant conditions and should only be performed after consulting SIPOS!

5�4�2 Runtime monitoring

As standard, SEVEN actuators are equipped with runtime monitoring. When running the actuator

for the rst time over a distance of at least 3 % of the entire travel after setting the end positions, the

runtime is measured and stored in a non-volatile memory. The actual motor frequency or speed is

taken into account during the measurements.

During future operation, it will be checked whether the position reached after the runtime is plausible. Tolerances due to different loads and measurement inaccuracies during position measurement

are taken into account. If the expected position is not reached in time, the actuator changes over to

the “fault” state and signals “runtime error”.

This internal monitoring can be deactivated, i.e. exceeding the runtime will not cause a fault signal.

This can prove useful for special applications.

Commissioning

Fig�: End position ranges

Runtime monitoring is activated on delivery.

5�4�3 End position speed

Within the end position ranges, the actuator operates at an end position speed dened for each

device to change to the dened speed when leaving the end positions.

For extremely long total runtimes, it may be desired that the actuator changes as quickly as

possible, even before leaving the end position range to the adjusted, typically high speed. It may,

however, also be required that the actuator operates as long as possible at the dened speed when

approaching the end position to be able to quickly stop in the end position.

Refer also to “End position range“ on the previous page and chapter „Adjust speeds/positioning

times“ on page 30.

Y070.301/EN Page 33

Operation instructions

5 Commissioning

SIPOS SEVEN ECOTRON

5

Commissioning

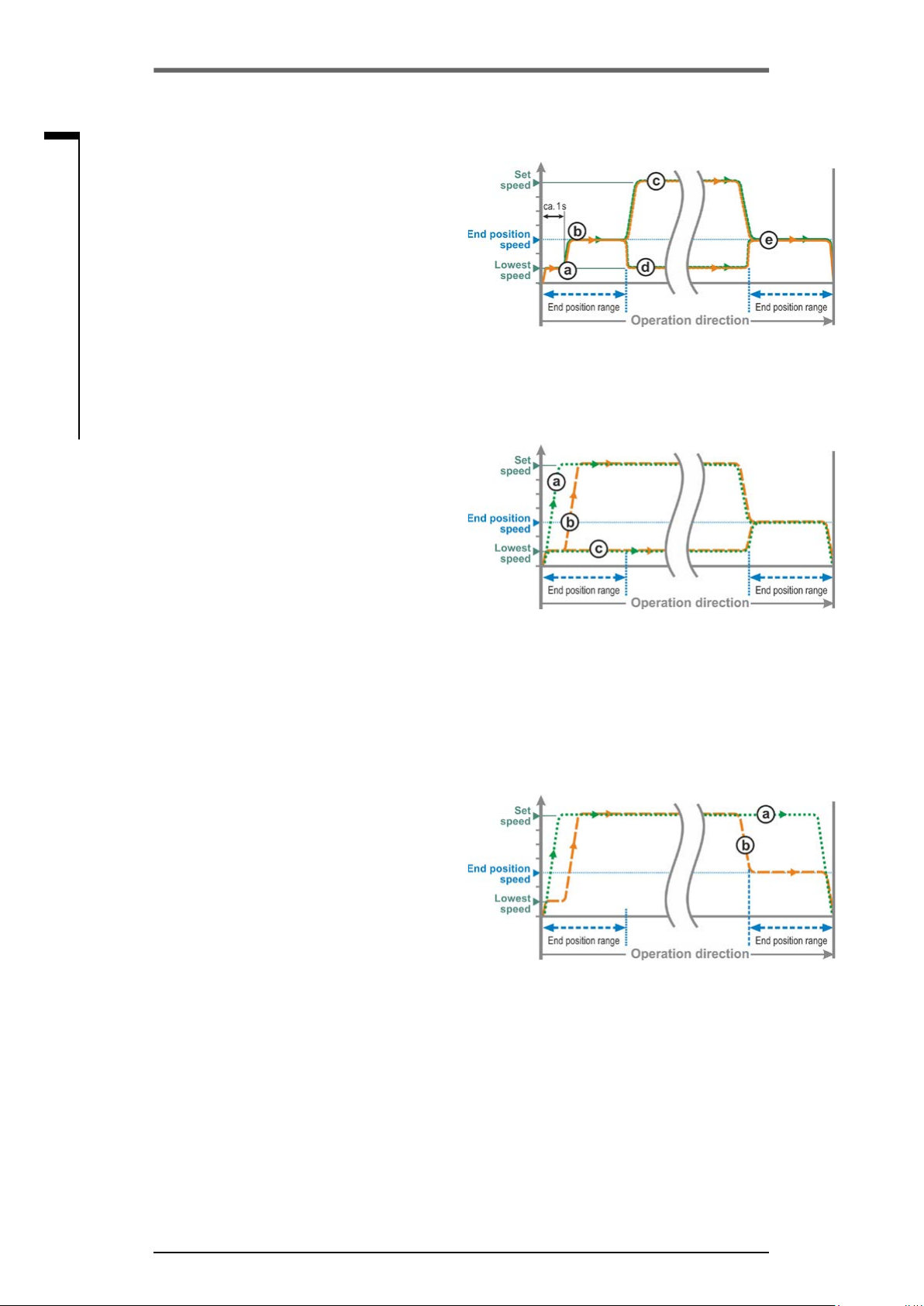

Normal

for travel and torque-dependent cut-off mode,

the actuator runs

■

from the end position at the lowest speed,

approx .1 sec. (g. 1: curve a), to change to

the end position speed, refer to b;

■

after the end position range with the set

speed. This speed is usually higher than the

end position speed (curve c). It can also be

set lower, refer to curve d.

■

to the end position with the “normal“ end position speed (e).

Quick start

Leaving the end position:

■

For travel-dependent cut-off, it will be immediately changed to the set speed to keep the

runtime as short as possible. Refer to g. 2,

curve a.

■

For torque-dependent cut-off, the end

position is left at the lowest possible speed

for approx. 1 sec. prior to changing to the set

speed; refer to curve b.

Fig� 1: End position speed ’Normal‘

The speed can however be lower than the end

position speed, refer to curve c.

Approaching the end position:

Shortly before reaching the end position range

(independent of the cut-off mode), the speed will

be reduced to the end position speed as for the

“Normal” setting.

Quick start/stop

Leaving the end position is identical to ’Quick

start‘ setting.

Approaching the end position:

■

For travel-dependent cut-off, the speed will

be reduced shortly before reaching the end

position so that the actuator is at standstill;

refer to g. 3, curve a.

■

For torque-dependent cut-off, the speed will

still be changed to the end position speed

before actually reaching the end position

range to avoid excessive torque and potential

damage to the valve, refer to curve b.

End position speed “Normal” is set in the factory.

Fig� 2: End position speed ’Quick start‘

Fig� 3: End position speed ’Quick start/stop‘

Page 34 Y070.301/EN

Operation instructions

SIPOS SEVEN ECOTRON

5�5 Adjust end positions

If actuators are delivered mounted to a valve, this step has been done in the valve manufacturer’s

factory. The setting has to be checked during commissioning.